MCS-64

(Multi Channel System for Process Industry)

Manual MCS-6 with Modbus on Ethernet

FUSE

5X20

0

Y

5

V+

1

9

6

5

PWR

PGM 86.1

Com

6

5

4

3

2

1

PB Adresse

0

Act

Profibus Connector

FLINTEC

www.flintec.com

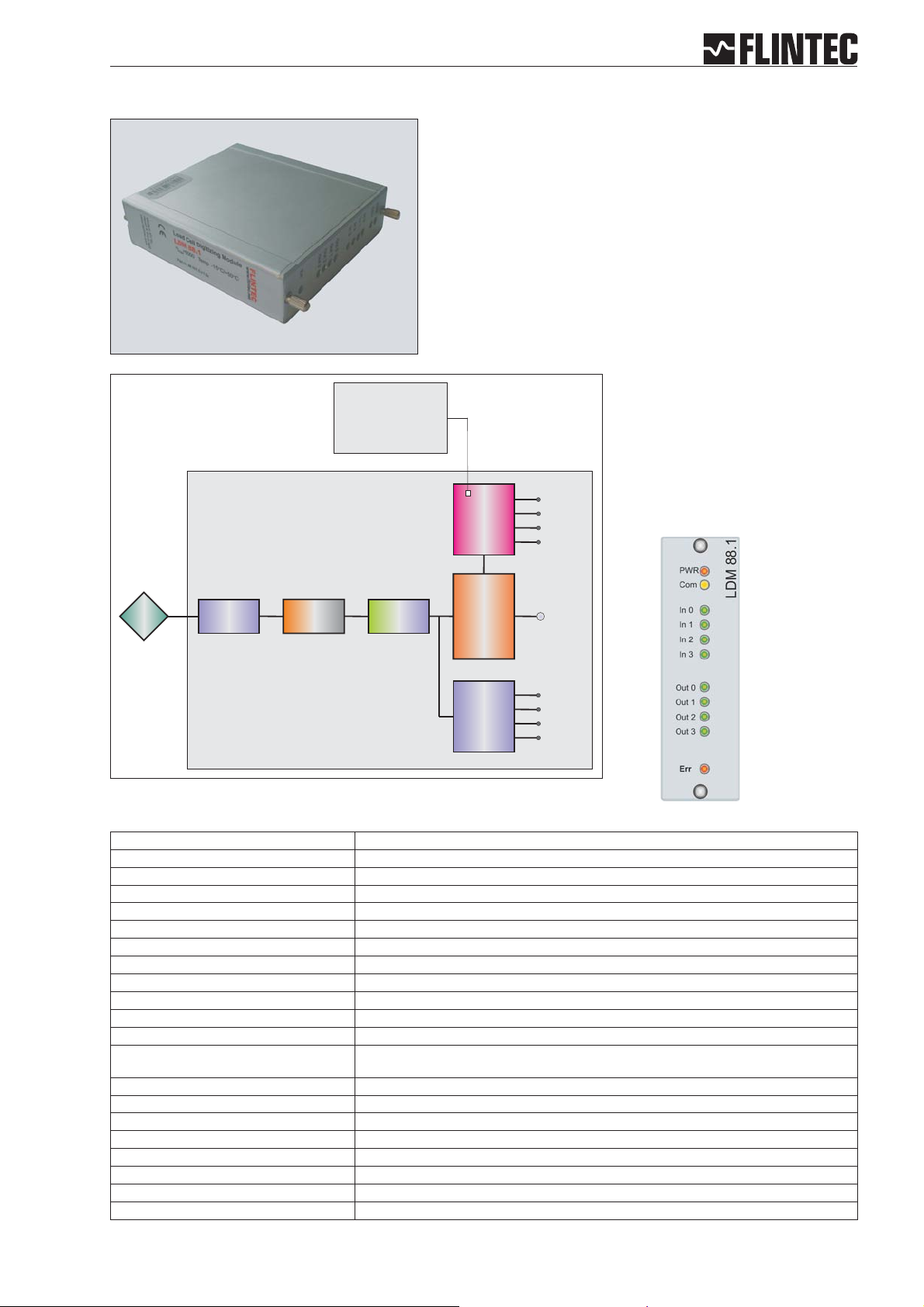

Example of MCS-64 with 5 channels and Profibus-Gateway

C0123C C0123C

PWR

Com

In 0

In 1

In 2

In 3

Out 0

Out 1

Out 2

Out 3

Err

Sig+

Sen+

Exc+

PWR

Com

LDM 88.1

Exc-

Sen-

Sig-

LDM 88.1

In 0

In 1

In 2

In 3

Out 0

Out 1

Out 2

Out 3

Err

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Logic out

Logic in

BC

470uF

+HP

Load

Cells

FLINTEC Fl112081 B16

Mt1

ON DIP

1234

FLINTECFl112081 B16

FLINTEC

www.flintec.com

Exc+

Mt27

PWR

Com

In 0

In 1

In 2

In 3

Out 0

Out 1

Out 2

Out 3

Err

Sen+

C0123CC0123CC0123C C0123C

Mt2

Logic out

Logic in

T6

J14

R1

R2

BC

470uF

+HP

LDM 88.1

PWR

Com

In 0

In 1

In 2

In 3

Out 0

Out 1

Out 2

Out 3

Err

LDM 88.1

PWR

Com

In 0

In 1

In 2

In 3

Out 0

Out 1

Out 2

Out 3

Err

LDM 88.1

T26

Load

Cells

Mt28

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Sen+

Exc+

Exc-

Sen-

Sig-

Sig+

Document no. G165-Rev1-GB

www.flintec.com

Manual MCS-64 Page 1

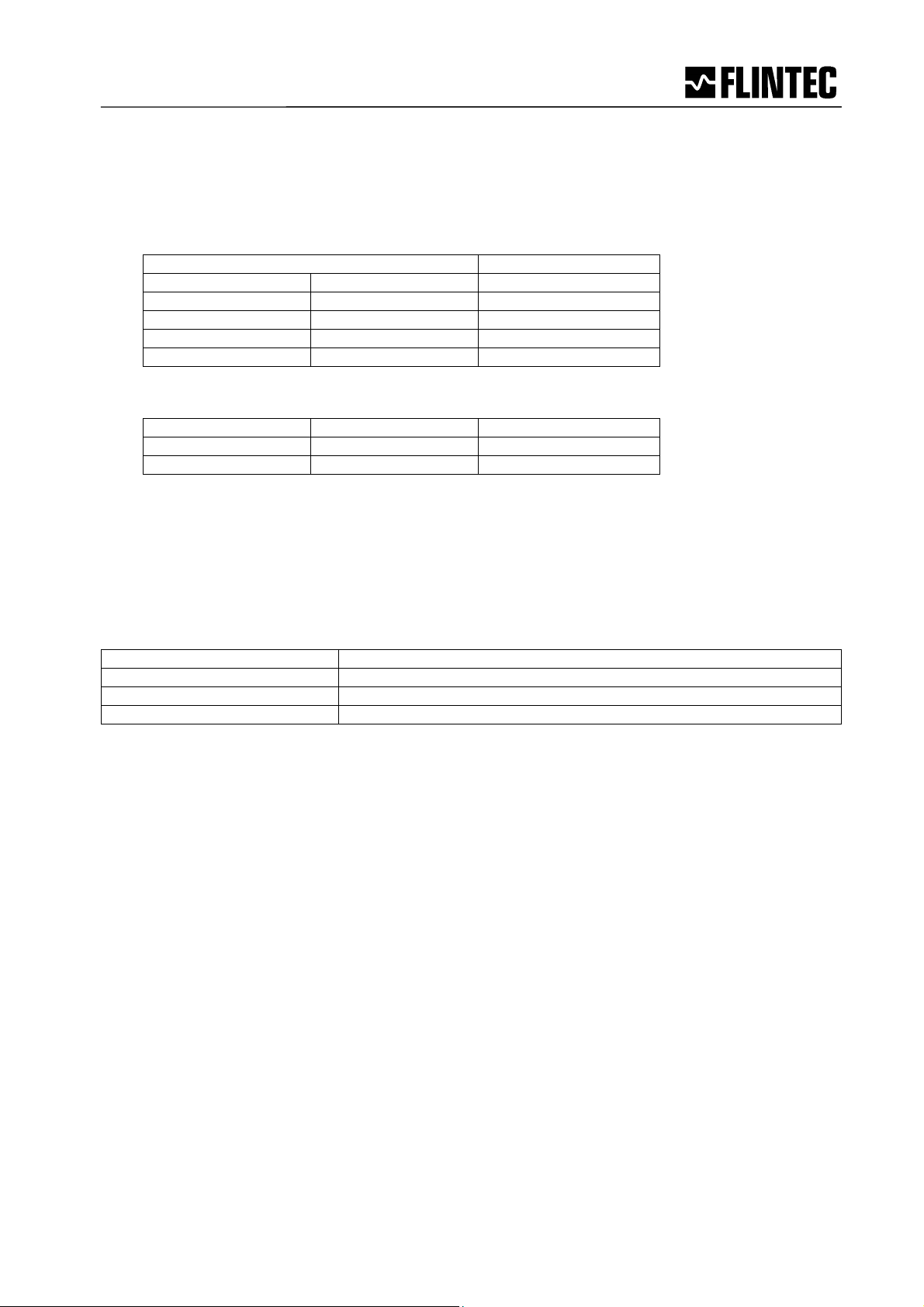

Components of MCS-64 in overview

Base Board

MB 89.1

LDM 88.1

CGM 85,1

Load Cell

#1

Load Cell

#2

Load Cell

#64

LDM 88.1

#1

LDM 88.1

#2

RS485 - Bus

LDM 88.1

#64

RS 232

Service-Port

Gateway

- Profibus (PGM 68.1)

- CANopen (CGM 85.1)

- Ethernet (EGM 87.1)

Components of MCS-64

All boards have the same technical features:

Spring clips for load cell terminals in 6-wire-technique

•

• 4 DI’s via spring clip terminal blocks

•

4 DO’s via spring clip terminal blocks

Fieldbus

Extension Boards

MB 89.2

MB 89.3

MB 89.4

PGM 86.1

MB 89.1

EGM 87,1

•

Slot for one Gateway CGM 85.1 / PGM 86.1 / EGM 87.1

•

2 Slots for weighing processor LDM 88.1

•

RS 232 Service port

Extension Boards MB 89.2/.3/.4

•

2/4/8 Slots for weighing processor LDM 88.1

MB 89.2

MB 89.3

Base Board MB 89.1

Dim 104 x 135 mm

MB 89.4

Dim 79 x 135 mm

Dim 129 x 135 mm

Dimensions 229 x 135 mm

Page 2 Manual MCS-64 Ethernet

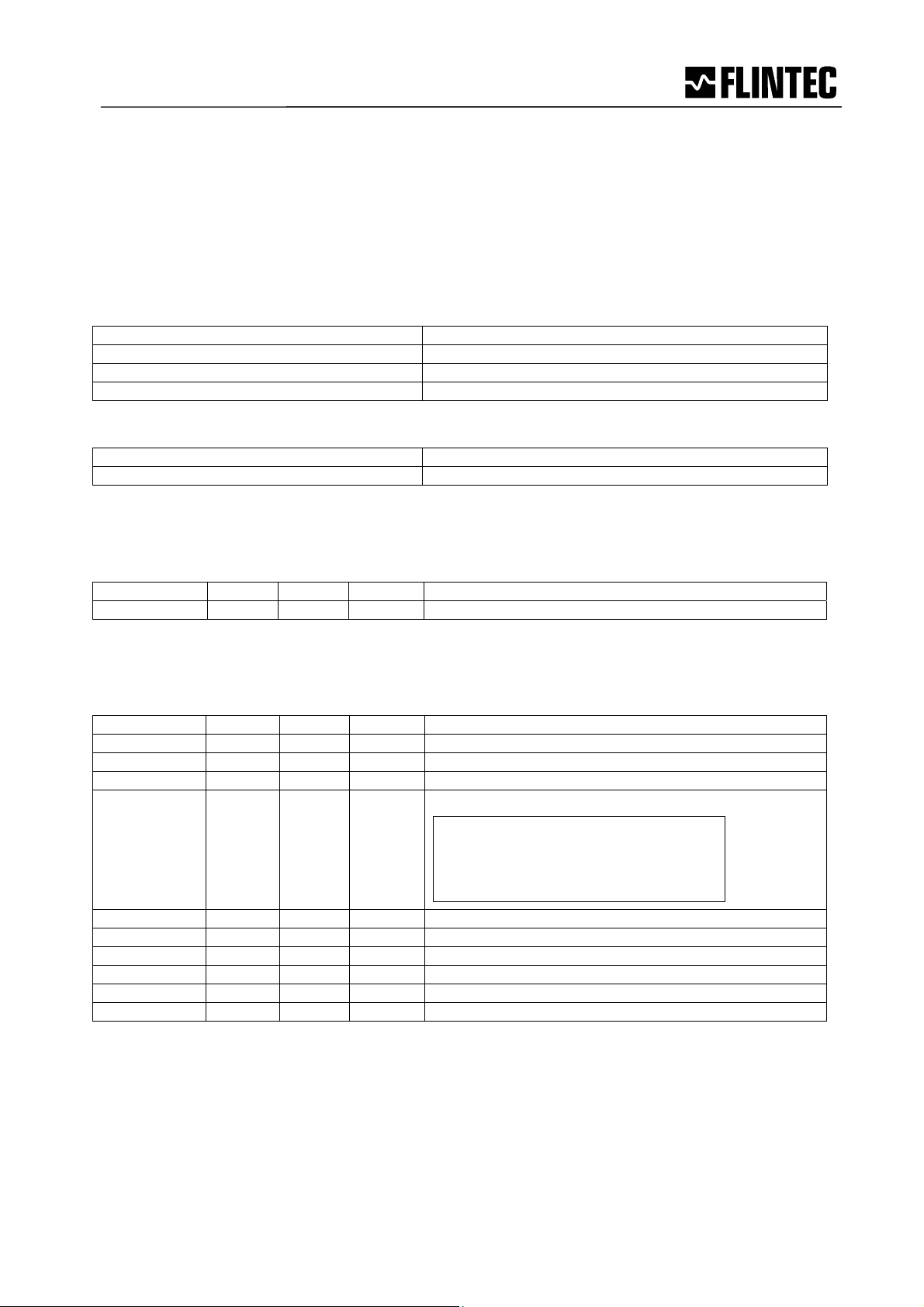

Weighing Processor LDM 88.1

Remote Control Output

Start Filling Cycle

Trigger Signal

The digital weighing processor LDM 88.1 is a load cell

digitizing unit for precise measuring of loads in motion.

± 18 bit resolution (±260 000 d)

•

Excitation5VDC/50mA

•

2 400 Measurements/s internal,

•

600 Measurements/s external

mV/V calibration

•

4 DI’s

•

4DO’s

•

RS 485 bus, 115.2 kBaud

•

Digital Filter (FIR and IIR)

•

for static or dynamic weighing

•

processes

3 Firmware versions

•

LDM 88.1

Digital

Load Cell

Low-Pass

Filter

ADC

Digital Filter

IIR- / FIR

Input

1 ... 4

- Net

- Gros

- Average

- Dose

Digital

Output /

Setpoint

1 ... 4

binary format

RS 485 / 230 kBaud

LDM 88.1

LDM 88.1 Specifications

Linearity < 0.002 % FS

Excitation 5 V DC, load cells 100-2 000 Ohm, 6 wire technique

Analogue input range ±2.2 mV/V (bipolar)

Minimum input per vsi 0.05 μV per interval non approved

Resolution ±260 000 counts , ±18-Bit-A/D convertor

Conversion rate 2400 measurements per second intern

Digital Filter FIR Filter 2.5 ... 19.7 Hz or IIR Filter 0.25 ... 18 Hz; programmable in 8 steps each

Calibration software calibration and set up

Computer interface intern RS485/RS422, full duplex, 115 200 Baud, bus capability up to 64 devices

Weighing functions zero, gross, tare, net, filter etc.

Inputs 4 opto-isolated inputs, 10 ... 30 V DC max. 3 mA

Outputs 4 OC outputs, < 35 V DC, 500 mA

Temperature effects on zero 5 ppm/°K typ.; max. < 10 ppm/°K

Temperature range –10 °C to +50 °C (operating); –30 °C to +80 °C (storage)

Enclosure Aluminium, protection IP40

Dimensions 80 x 23 x 100 mm, with two M3 fixing screws for mounting on boards MB89.1/2/3/4

Power supply 12 ... 24 V DC ±10 %, < 60 mA,(reversed voltage, burst and ESD protected)

Power consumption 1,5 W max.

EMC CE 73/23/EEC; 93/98/EEC and 89/336/EEC

Computer interface via Service Port MB 89.1 RS232C, 115 200 Baud

Vibration withstands 1.0 G operational; 2.5 G non-operational

on span 4 ppm/°K typ.; max. < 8 ppm/°K

Manual MCS-64 Ethernet Page 3

Contents

Part A: Modbus on Ethernet.........................................................................................pages 6 - 13

Part B: Commands......................................................................................................pages 14 - 35

Part C: MCS-64 Components and Configuration........................................................pages 36 - 45

Introduction...........................................................................................................................6

1.

1.1. Identification and Scope ................................................................................................6

1.2. Purpose .........................................................................................................................6

2. System Design......................................................................................................................6

2.1 General..........................................................................................................................6

2.2 Backplane handling.......................................................................................................6

2.3 Ethernet Gateway..........................................................................................................7

2.3.1 IP Settings.................................................................................................................7

2.3.2 The Modbus port .......................................................................................................7

2.3.3 The ASCII entry port..................................................................................................7

3 Ethernet Gateway Profile.....................................................................................................8

3.1 The Modbus Objects .....................................................................................................8

3.2 Communication Profile ..................................................................................................8

4 Modbus Mapping..................................................................................................................9

4.1 Modbus Register Map Overview ...................................................................................9

4.1.1 Gateway Register Map..............................................................................................9

4.1.2 LDM Register Map...................................................................................................10

5 COMMANDS........................................................................................................................14

5.1 System diagnosis – ID, IV, IS......................................................................................15

5.2 Calibration Commands – CE, CM, CI, DS, DP, CZ, CG AZ, AG, ZT, FD, CS.............16

5.3 Motion detection Commands – NR, NT.......................................................................20

5.4 Filter setting Commands – FM, FL, UR.......................................................................21

5.5 Set Zero/Tare and Reset Zero/Tare Commands – SZ, RZ, ST, RT............................23

5.6 Output Commands – GG, GN, GT, GS.......................................................................25

5.7 Setpoint Commands - Sn, Hn, An ...............................................................................26

5.8 Trigger Commands – SD, MT, GA, TE, TR, TL...........................................................28

5.9 Trigger Special Commands– RW, TT, TS, DT, TW, TI, HT.........................................31

5.10 Save calibration, setup and setpoint parameters Commands – CS, WP, SS .............34

5.11 Filling Commands – PD1 to PD21, DI, SC, AC, GD, DT, SD......................................35

5.12 Loss in Weight Commands – PL1 to PL5, LC, LI, GF, GR, GM, SL...........................35

5.13 Speed Estimation Multi-Channel System MCS-64......................................................35

Page 4 Manual MSC-64: Modbus on Ethernet

6 MCS-64 Components and Configuration..........................................................................36

6.1 Base Board MB 89.1 for 1 Gateway and 2 LDM 88.x..................................................36

6.2 Extension Board MB 89.2 for 2 LDM 88.x...................................................................37

6.3 Extension Board MB 89.3 for 4 LDM 88.x...................................................................38

6.4 Extension Board MB 89.4 for 8 LDM 88.x...................................................................39

6.5 Address setup guide extension boards for 1 – 16 channels........................................40

6.6 Address setup guide extension boards for up to 32 channels.....................................41

6.7 Example Check Weigher Wiring ..................................................................................42

6.8 Example Liquid Filling Wiring ......................................................................................43

6.9 LDM 88.1 – Digital Input / Digital Output -...................................................................44

6.10 Firmware Versions.......................................................................................................45

6.11 DOP software for Windows 2000/XP...........................................................................45

Manual MCS-64: Modbus on Ethernet

Page 5

1. INTRODUCTION

1.1. Identification and Scope

This document describes the system design for the Modbus on Ethernet (EGM 87.1) and up to

64 Load Cell Digitizing Modules (LDM88.x) using the Flintec backplane system. It describes the

functionality of the backplane, the protocol used on the backplane and the Modbus mapping used

to access the LDM88 modules via the EGM87 Gateway.

1.2. Purpose

The purpose of this document is to specify functionality and performance of the Gateway and the

Load Cell Digitizing Modules (LDM88) with the available firmware versions (standard 88.183,

filling 88.184, loss in weight 88.185).

2. SYSTEM DESIGN

2.1 General

This software connects an Ethernet network to the local backplane modules. The Gateway

transports commands and responses from and to the Ethernet.

Ethernet

Ethernet

Ethernet

ADAPTOR

ADAPTOR

LDM an d other IO

Up to 64 modules per backplane

BACKPLANE

Figure 1- ETHERNET Gateway in context

2.2 Backplane handling

The Gateway translates Modbus requests to local backplane requests and local backplane

responses to Modbus responses. The Modbus is currently fixed to port 502 using an UDP/IP

connection. Multiple register access through the Ethernet will produce multiple accesses on the

local backplane. The PLC response timeout must allow 3.125 ms for each register access

required.

However reading registers 2000 or 2004 will cache register 2060 also allowing the PLC to

acquire the corresponding qualifier to the weight values.

Page 6 Manual MSC-64: Modbus on Ethernet

2.3 Ethernet Gateway

The Ethernet Gateway is using a 10/100baseT on RJ45 connection (IEEE 802.3u standard).

The Gateway is essentially a server waiting for a node to connect to one of its services.

Application stacks:

Modbus Application Layer Setup

Port 502 Port 502 Port 23

MBAP MBAP TCP UDP TCP

IP IP IP

802.3 802.3 802.3

System stacks:

(echo / ping) (Dynamic IP addr.) (Address Resolution)

ICMP DHCP IP IP ARP

802.3 802.3 802.3

2.3.1 IP Settings

The IP address is set by connecting a terminal program (e.g. HyperTerm) to the DB9 service port

on the MB 89.1 Base board. After the system is powered up it is possible to communicate with

the Ethernet Gateway Module (EGM). After openening the gateway with command "OP 64" it is

possible to set and/or examine the gateway settings with the address command:

Command

op64 opens serial communication to the gateway

ai 192.168.1.29 sets the gateway’s IP address to “192.168.1.29”

ai selects a dynamic IP address (DHCP) for the gateway

a reads current MAC address and IP address of the gateway

Example:

op64

OK

a

mac=00:50:C2:70:50:62

ip= DHCP

2.3.2 The Modbus port

[Port 502, TCP/IP (Modbus) or UDP/IP (Modbus)]

The Modbus is a simple Master-Slave connection; the master asks and the slave answers.

Modbus over TCP or UDP is just another way of transporting Modbus communication. One of the

registers will be used to define a streaming port. When a client connects to this user-defined port

the gateway will scan the backplane and transmit the LDM data on a regular basis.

See Chapter 3 “Ethernet Gateway Profile” below.

2.3.3 The ASCII entry port

[Port 23, TCP/IP (Telnet)]

This entry is for simple setup and diagnostic use. It works as if you were connected to the service

port except it goes through the Ethernet. The HyperTerm program in Windows can access the

gateway in this manner. Refer to LDM 88.1 commands, see chapter 5.

Manual MCS-64: Modbus on Ethernet

Page 7

3 ETHERNET GATEWAY PROFILE

3.1 The Modbus Objects

All parameters and result data can be accessed in this way. Please note that many of the

registers in the 2000 – 20FF range require a local backplane access cycle per register. Reading

multiple registers in this range may produce a very long response time.

Below is the preliminary Modbus Map.

3.2 Communication Profile

The parameters which are critical for communication are determined in the communication

profile. This includes the data for manufacturer's product nomenclature, for identification, or the

parameters for object mapping.

Abbreviations used in the tables:

R = read only

R/W = read / write

W = write only (read will not be regarded as an error, but returns undefined results)

UI16 = Unsigned16 (single register)

UI32 = Unsigned32 (register pair)

Int16 = Signed16 (single register)

Int32 = Signed32 (register pair)

Float = 32 bit IEEE754 floating point (register pair)

Page 8 Manual MSC-64: Modbus on Ethernet

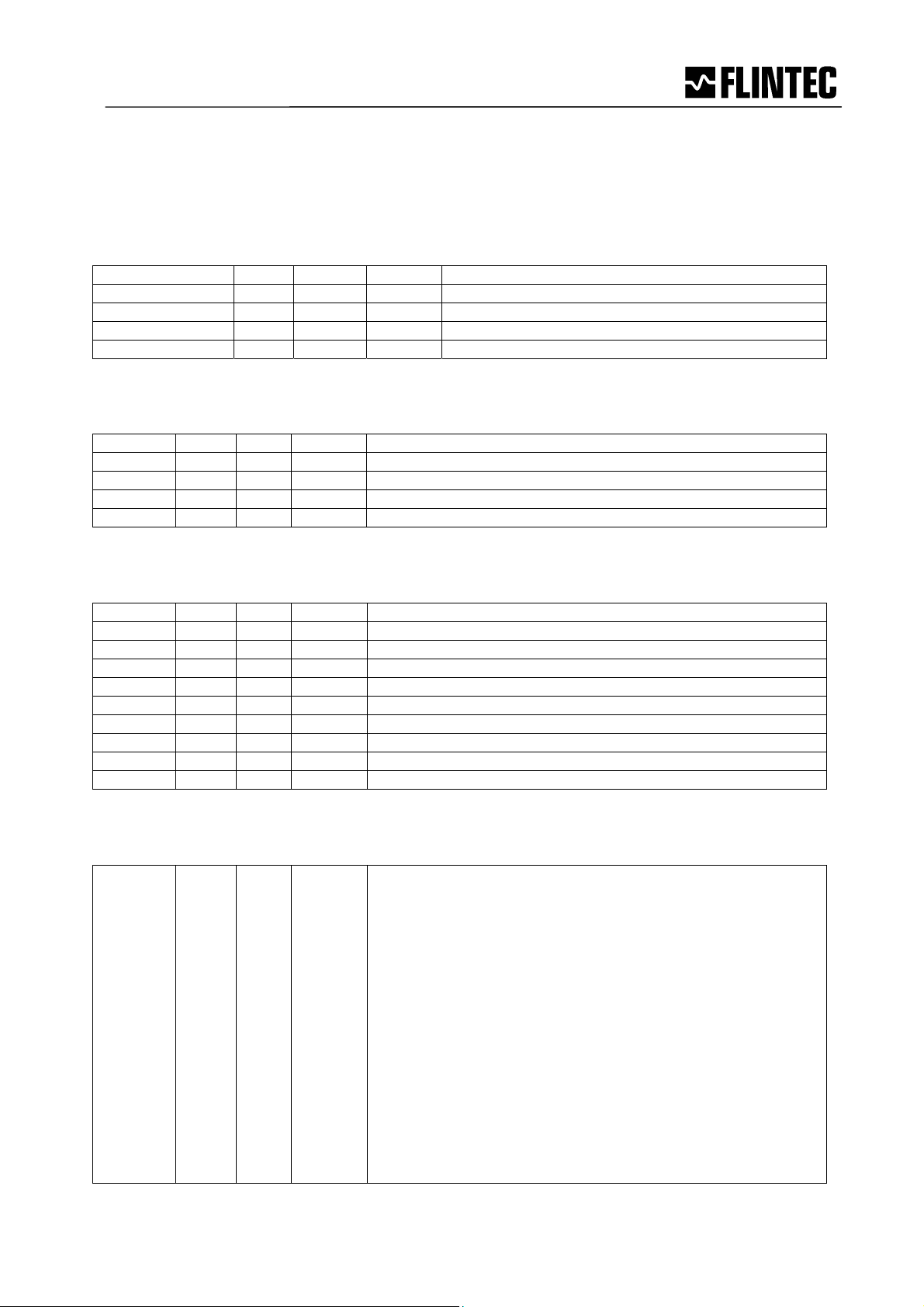

4 MODBUS MAPPING

The MBAP header “Unit Identifier” field is used to select a module in the backplane. Address 0

(zero) is reserved for broadcast. Address 1 to 64 is then used for direct communication with any

LDM in the backplane using registers in the range 2000-2FFF (hex). Access to the gateway

should use address 0xFF (255 dec) and registers in the range 3000-3FFF(hex).

Currently implemented function codes are: Access

03 Read Holding Registers

04 Read Input Registers

06 Write Single Register

16 Write Multiple Registers

Used exception codes are: Meaning

01 Illegal or unkown function code

02 Illegal data address or no response from LDM

4.1 Modbus Register Map Overview

Register Type Size Access Function

2000 – 2FFF Selected LDM

3000 – 30FF Gateway

4.1.1 Gateway Register Map

Register Type Size Access Function

3000 Int16 1 R/W LDM selector [0..63]

3001 Int16 1 R/W LDM multiple register selector.

3002 Int16 1 R/W LDM multiple register mode

3003 – 300F - - (reserved)

3005 Int16 1 R/W Auto-Scan Control/Status

3006 Int16 1 R/W Auto-Scan Port (IP port no.)

3007 Int32 2 R/W Auto-Scan Interval (ms)

3009 – 30FF (reserved)

3100 – 31FF R/W Multiple register access across multiple LDM modules.

3200 – 32FF Float 2+2+1 R Multiple read of LDM packets

3300 – 33FF Integer 2+2+1 R Multiple read of LDM packets

Bit:

15 10 9 2 1

+------------+--------+-----+

| Last scan | unused | R/S |

+------------+--------+-----+

Manual MCS-64: Modbus on Ethernet

Page 9

4.1.2 LDM Register Map

The register map for each LDM.

LDM overview

Register Type Size Access Function

2000 – 201F Float 08 * 2 R/W Data in Float Format

2020 – 205F Int32 16 * 2 R/W Data in Integer Format

2060 – 207F Int16 08 * 1 RW Control/Status functions

2080 – 20FF (reserved)

2100 – 2FFF - - R/W Parameter pages

Data in Float Format

Register Type Size Access Data in Float Format

2000 Float 2 R Gross weight

2002 Float 2 R Net Weight

2004 Float 2 R/W Tare

2006 Float 2 R Dosed weight

2008 Float 2 R Average weight

Data in Integer Format

Register Type Size Access Data in Integer Format

2020 Int32 2 R Gross weight

2022 Int32 2 R Net Weight

2024 Int32 2 R/W Tare

2026 Int32 2 R Dosed weight

2028 Int32 2 R Average weight

202A Int32 2 R A/D sample

202C Int32 2 R Device ID

202E Int32 2 R FW Version

2030 Int32 2 R Device Status

2032 Int32 2 R ADC Reference

Control/Status Functions

Register Type Size Access Control/Status functions

2060 Int16 1 R Measurement Qualifier Values:

$0001 - Under range

$0002 - Over range

$0004 - Not within Zero range (not yet implemented, zero)

$0008 - Exactly zero

$0010 - No motion, still stand, steady state

$0020 - Tare set

$0040 - Preset tare (0=tare is measured, 1=tare is set by user)

$0080 - Invalid weighing (wire-break, A/D ref. out of range)

$0100 - Set-point 0 (source>limit)

$0200 - Set-point 1

$0400 - Set-point 2

$0800 - Set-point 3

$1000 - Filling in progress

$2000 - Filling has completed

$4000 - Average ready

$8000 - Cold start

Page 10 Manual MSC-64: Modbus on Ethernet

2061 Int16 1 R/W Bit commands. Functions regardless of the setting of the LDM

selector register.

Bit 1: Reset Zero (RZ)

Bit 2: Set Zero (SZ)

Bit 3: Reset Tare (RT)

Bit 4: Set Tare (ST)

Bit 5 – 7: unused

Bit 8 –15: LDM#

Write a “1” to activate function, reads as “1” until command done

2062 Int16 1 R/W Trigger: Functions regardless of the setting of the LDM selector

register.

Write the LDM number to trig LDM;

Write the LDM number + 80h(128 dec) to cancel measurements

(LDM 88.183 only)

2063 Int16 1 R/W Parameter page select. Valid values= [0..4].

General parameter values

Calibration parameter values

Filling parameter values

Check weigher parameter values

Mass flow parameter values

2064 Int16 1 R/W TAC access, see calibration page.

2065 Int16 1 R/W START / ABORT filling process.

Writing a Non-zero value starts filling process.

Writing a zero ABORTS filling process.

2066 Int16 1 R/W EEPROM functions:

Bit 1: Save analogue parameters (AS)

Bit 2: Save calibration (CS); TAC protected

Bit 3: Save general setup parameters (WP)

Bit 4: Save dosing parameters (SD)

Bit 5: Save setpoint parameters (SS)

Bit 6 –14: unused

Bit 15: Factory default; TAC protected

2067 Int16 1 R/W Set-point select [0..3]

2068 Int32 2 R/W Set-point source

206A Int32 2 R/W Set-point hysteresis

206C Int32 2 R/W Set-point Value

206E Int16 1 R Read the dose info:

Bit value Meaning

$0001 Coarse valve open

$0002 Fine valve open

$0004 Dose program running

$0008 Not used

$0010 Not used

$0020 Not used

$0040 Tare out of range – no filling in this cycle

$0080 Zero out of range

$FF00 The High byte has the following interpretation:

00= Idle

01= Waiting for trigger(2

nd

trigger)

02= Bottle on, calculating tare

03= Pre-fill

04= Main Filling

05= Fine Filling

06= In-flight delay

07= Post fill calculations

08= Post Filling

Manual MCS-64: Modbus on Ethernet

Page 11

Page 0 – General Parameter Values

Register Type Size Access General parameter values

2100 Int32 2 R/W Analog action

2102 Int32 2 R/W Analog high

2104 Int32 2 R/W Analog low

2106 Int32 2 R/W Filter setting

2108 Int32 2 R/W Filter Factor

210A Int32 2 R/W Output status

210C Int32 2 R/W Input mask

210E Int32 2 R/W Measuring Time

2110 Int32 2 R/W Filter mode

2112 Int32 2 R/W No-motion range

2114 Int32 2 R/W No-motion time

2116 Int32 2 R/W Output mask

2118 Int32 2 R/W Tare

211A Int32 2 R/W Start Delay

211C Int32 2 R/W Trigger Edge

211E Int32 2 R/W Trigger Level

2120 Int32 2 R/W Update rate

2122 Int32 2 R/W Zerotrack (TAC protected)

2124 Int32 2 R/W dtime

Page 1 – Calibration Parameter Values

Register Type Size Access Calibration parameter values

2200 Int32 2 R/W Absolute gain calibrate (32 bit Integer)

2202 Int32 2 R/W Absolute zero calibrate (TAC protected)

2204 Int32 2 R/W Calibrate enable

2206 Int32 2 R/W Calibrate gain (TAC protected)

2208 Int32 2 R/W Set calibration point B

220A Int32 2 R/W Set calibration point A

220C Int32 2 R/W Calibrate max (TAC protected)

220E Int32 2 R/W Calibrate min (TAC protected)

2210 Int32 2 R/W Calibrate save (TAC protected)

2212 Int32 2 R/W Calibrate zero (TAC protected)

2214 Int32 2 R/W Decimal point (TAC protected)

2216 Int32 2 R/W Display step size (TAC protect)

Page 2 - Filing Parameter Values

Register Type Size Access Filling parameter values

2300 Int32 2 R/W Pre-fill mode

2302 Int32 2 R/W Correction factor for in-flight value

2304 Int32 2 R/W Zero Check Time

2306 Int32 2 R/W Tare delay

2308 Int32 2 R/W Tare Average Time

230A Int32 2 R/W Delay after pre-fill

230C Int32 2 R/W Blanking time

230E Int32 2 R/W In-flight delay time

2310 Int32 2 R/W Filling Weight Average Time

2312 Int32 2 R/W Zero tolerance

2314 Int32 2 R/W Tare reference

2316 Int32 2 R/W Tare tolerance

2318 Int32 2 R/W Pre-fill level

231A Int32 2 R/W Fine-fill weight

231C Int32 2 R/W Filling weight

231E Int32 2 R/W In-flight value

Page 12 Manual MSC-64: Modbus on Ethernet

Register Type Size Access Filling parameter values

2320 Int32 2 R/W Secondary pre-fill level

2322 Int32 2 R/W Timeout value in milliseconds

2324 Int32 2 R/W Underweight post-fill time

2326 Int32 2 R/W Tare interval

2328 Int32 2 R/W Bag Rupture Blanking

Page 3 – Check Weigher Parameter Values

Register Type Size Access Checkweigher parameter values

2400 Int32 2 R/W Trigger Level

2402 Int32 2 R/W Trigger Edge

2404 Int32 2 R/W ReTrigWindow

2406 Int32 2 R/W ReTrigTime

2408 Int32 2 R/W HoldTime

240A Int32 2 R/W TareWindow

240C Int32 2 R/W TareTime

240E Int32 2 R/W ReTrigStop

2410 Int32 2 R/W Measuring time

2412 Int32 2 R/W Start delay

2414 Int32 2 R/W dTime

Page 4 - Mass Flow Parameter Values

Register Type Size Access Mass Flow parameter values

2500 Int32 2 R/W Decimal Point

2502 Int32 2 R/W Scale values

d/sec d/min d/hour

x1 0 1 2

x1.000 3 4 5

x1.000.000 6 7 8

2504 Int32 2 R/W dTime

2506 Int32 2 R/W dWeight

2508 Int32 2 R/W Delay after Refill

Page 5 - Mass Flow Control Values

Register Type Size Access Mass Flow parameter values

2600 Int16 2 R/W Flow Control

2601 Int16 2 R/W Flow Status

Page 6 - Mass Flow Results

Register Type Size Access Mass Flow parameter values

2700 Float 2 R Mass Flow Value

2702 Float 2 R Mass Flow Trend

2704 Float 2 R Total Mass

Manual MCS-64: Modbus on Ethernet

Page 13

Part B

5 COMMANDS

These pages describe the ASCII commands as they must be used by the DOP software. For

each command the corresponding Modbus register and data types are shown in brackets [ ]

for reference.

5.1

System diagnosis – ID, IV, IS......................................................................................15

5.2 Calibration Commands – CE, CM, CI, DS, DP, CZ, CG AZ, AG, ZT, FD, CS.............16

5.3 Motion detection Commands – NR, NT.......................................................................20

5.4 Filter setting Commands – FM, FL, UR.......................................................................21

5.5 Set Zero/Tare and Reset Zero/Tare Commands – SZ, RZ, ST, RT............................23

5.6 Output Commands – GG, GN, GT, GS.......................................................................25

5.7 Setpoint Commands - Sn, Hn, An ...............................................................................26

5.8 Trigger Commands – SD, MT, GA, TE, TR, TL...........................................................28

5.9 Trigger Special Commands– RW, TT, TS, DT, TW, TI, HT.........................................31

5.10 Save calibration, setup and setpoint parameters Commands – CS, WP, SS .............34

5.11 Filling Commands – PD1 to PD21, DI, SC, AC, GD, DT, SD......................................35

5.12 Loss in Weight Commands – PL1 to PL5, LC, LI, GF, GR, GM, SL...........................35

5.13 Speed Estimation Multi-Channel System MCS-64......................................................35

Page 14 Manual MSC-64: Modbus on Ethernet

Loading...

Loading...