Flintec 52-18SS User Manual

Doc. No: 4-9131 Rev3

Date: 2008-12-10

Sign.: KN

Application Guidelines

for Weigh Modules type

52-18RS and 52-18SS

1

Content

Page No

Brief product description 3

Principle of Rocking System 4

Principle of Sliding System 5

Pre assembled weigh modules/Function of aligning plate 6

Jacking device 6

Lift off protection 7

Overload protection 7

Dimensions 8

Data 8

2D CAD files 9

3D CAD files 9

Installation 10-11

Enclosures:

Drawing No 2-9023. Assembly drawing of Weigh Module 52-18RS-50kN (Rocking System)

Drawing No 2-9026. Assembly drawing of Weigh Module 52-18SS-50kN (Sliding System)

Drawing No 3-8758. Procedure for installation without use of welding fixtures.

2

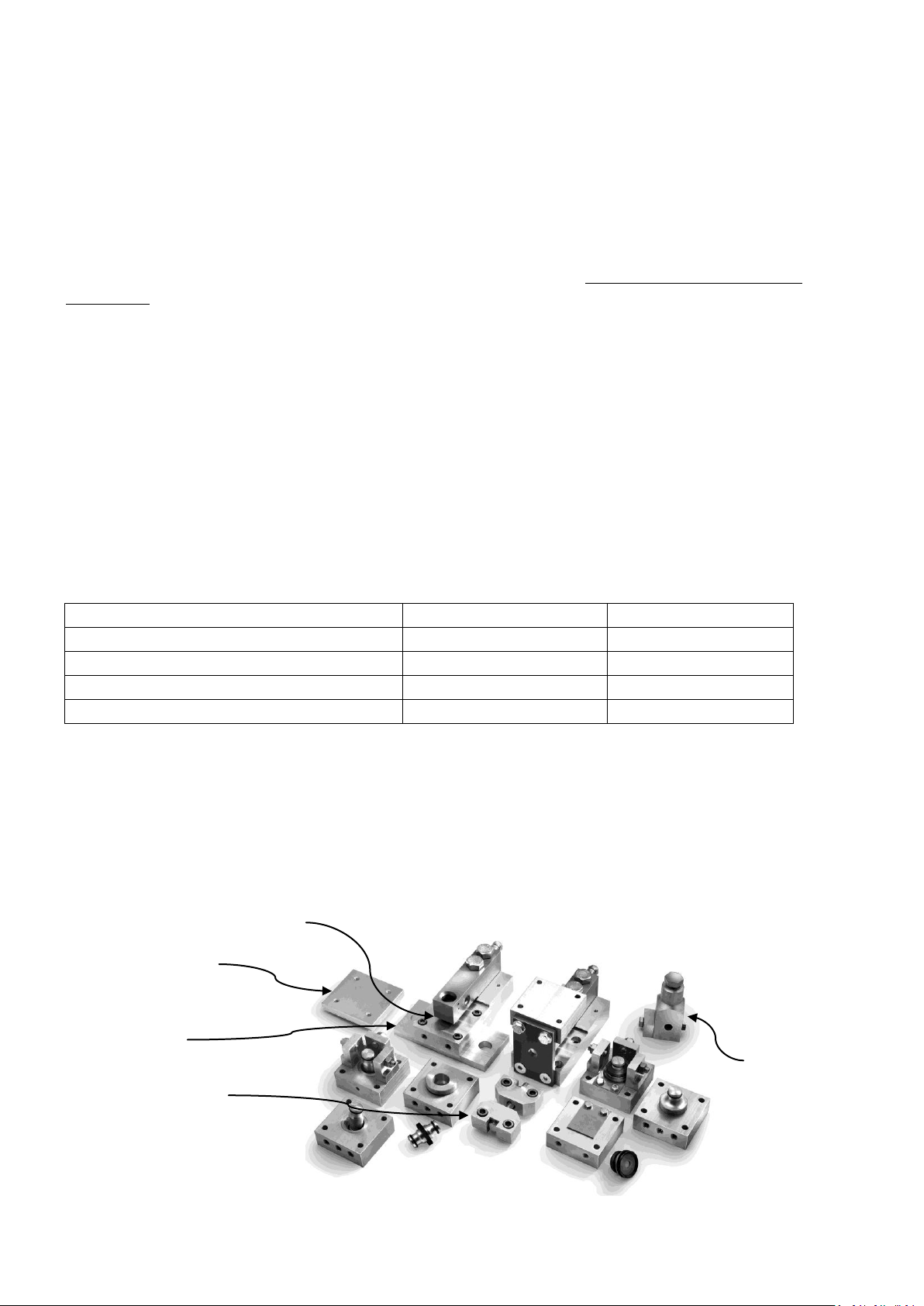

Brief Product Description

Type of application

52-18RS (Rocking System)

52-18SS (Sliding System)

Static load applications

X

X

Scales with agitator

1)

X

Scales with large temperature expansions

X

High resolution applications

X

1) Possible with close adjusted bumpers and special orientation.

Type 52-18 weigh modules are designed for load cells type SB4, SB5, SB14 and SLB and are available in 2 basic

versions, 52-18RS employing the Rocking System and 52-18SS employing the Sliding System.

The weigh modules are being delivered preassembled and centered with an Aligning Plate for easy installation.

Both versions have identical outer dimensions and utilize same mounting principles, but have somewhat different

features. Some features are overlapping and which version is the optimal choice depends on the actual

application.

The 52-18RS-C with its Rocking Load Introduction and Internal Bumping, is the first choice for static load

applications, because:

-It is easiest to install.

-All weigh modules in a scale are identical.

-Modules can be oriented freely in any direction.

-It is the most cost effective version.

However, this module is not suitable for tanks with agitators, which rotating movement might cause the scale to

oscillate, as it is standing on rockers.

For agitator applications, the 52-18SS, with Sliding Load Introduction and external bumping shall be used.

This module is also the choice when very large expansions due to temperature or other reasons are expected.

This module can tolerate side forces up to as much as 100% of rated load, whereas the 52-18RS-C is limited to

50%.

The selection guide below further illustrates when to use which module.

The 52-18 is a modularized weigh module which means that it is comes in a basic version, which can be fitted with

a number of options as required for the actual application:

Overload protection

Welding plates

Bolting plates

Jacking device

Lift off protection

3

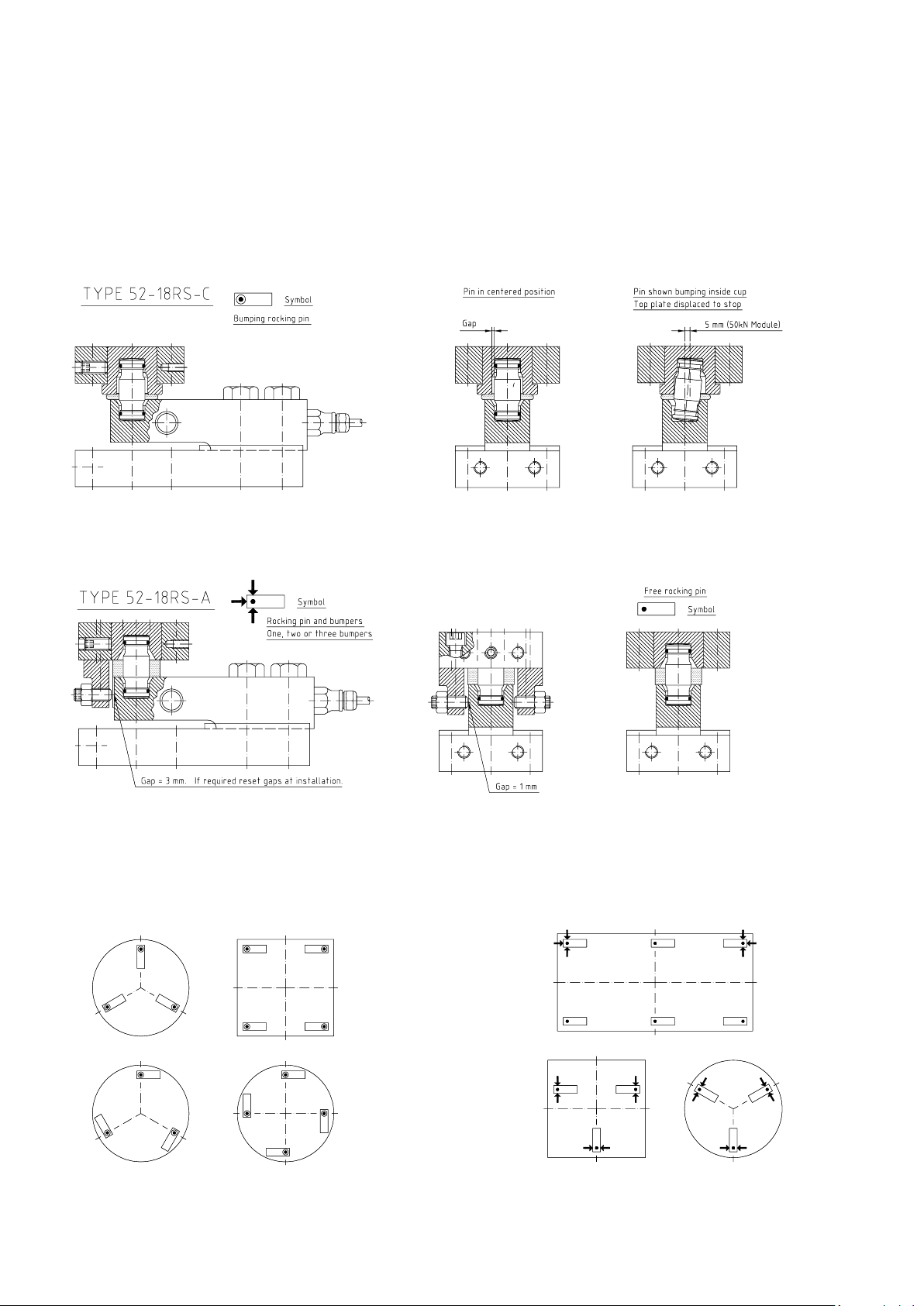

Principle of Rocking System

The rocking pin is “self centering”. The pin has relatively large radiuses (larger than ½ the pin height) and

therefore the rocker strives to stand straight up. With pins in vertical position, or near to vertical position,

possible horizontal forces between the load cells are zero, or very close to zero, which enhances repeatability and

thus the accuracy of the scale. The Rocking System is the most accurate load introduction system there is for

multi load cell scales.

The Rocking System comes in 2 versions. With rocking pin bumping internally in the loading cup (figure 1),

respectively with regular rocking pins and external bumpers (figure 2).

Figure1. Type 52-18RS-C. Module with pin bumping internally in loading cup.

Figure 2. Type 52-18RS-A. Module with external bumpers.

Figures 3 and 4 below show a few examples of how to orient the Rocking System weigh modules.

Figure 3. Orientation with internally bumping pins. Figure 4. Orientation with external bumpers.

4

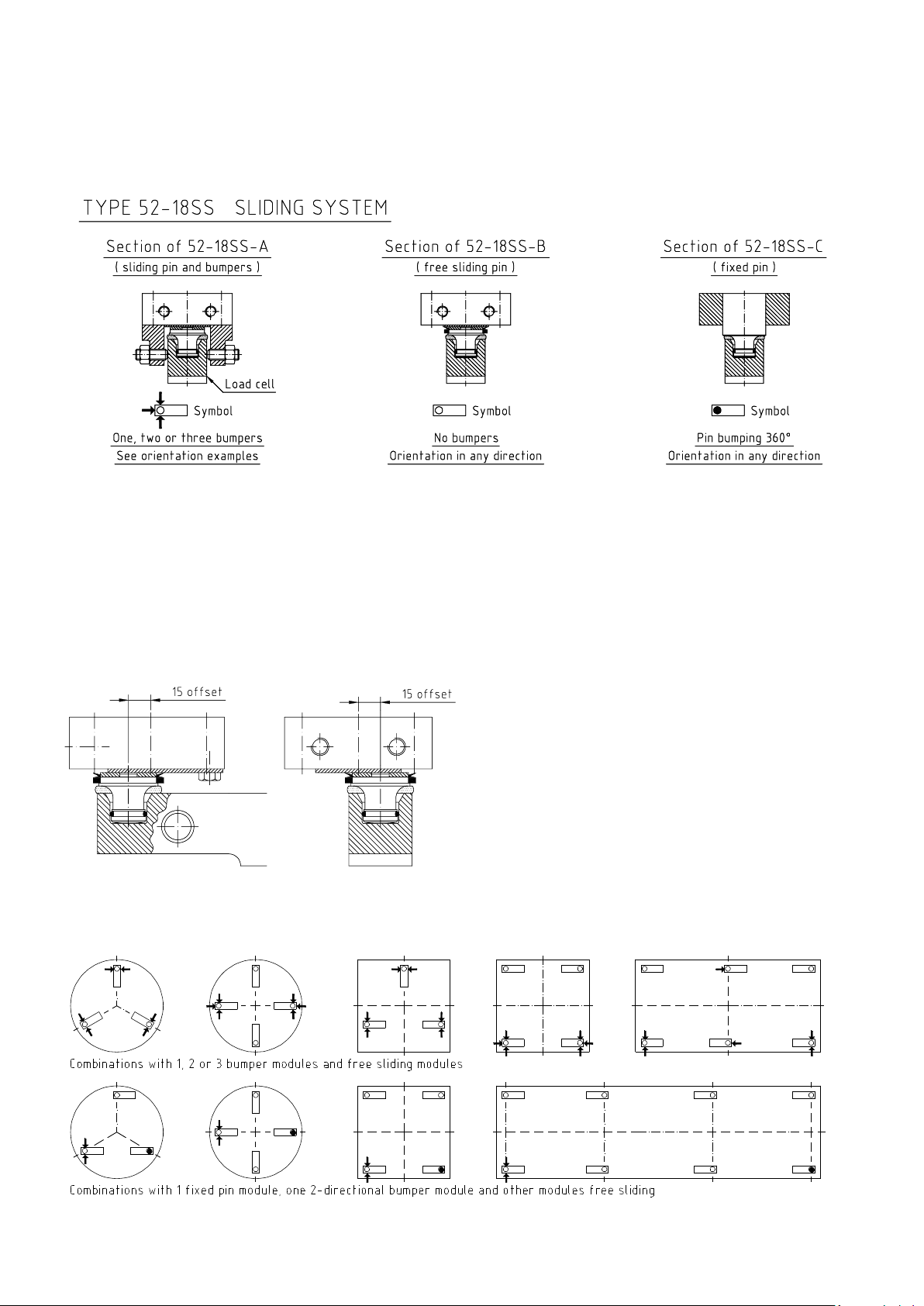

Principle of Sliding System

The Sliding System is based on loading pins fitted with Teflon (PTFE) sliding plates sliding against Stainless Steel

Sheets with very smooth surface (Surface finish 2B). This surface combination gives a very low friction coefficient

(typ < 5-6%). It allows length changes of the load carrier to take place, without causing any considerable

horizontal forces between the load cells.

Figure 5. Type 52-18SS Variants with bumpers, without bumpers, resp. with fixed pin.

Movement of the load carrier is restricted by bumpers acting against the loading end of the load cell.

A module can have 1, 2 or 3 bumpers, or no bumpers at all. It can also have a “fixed loading pin” which acts as a

360˚ bumper.

These variants make possible a large number of bumper combinations. Which variant is the optimal choice

depends on the actual application. One combination which works well for most types of load carriers is: “one

fixed pin module, one module with 2 bumpers and all other weigh modules free sliding”.

The Sliding System is perfect for applications which

exhibit very large temperature expansions.

Figure 6 illustrates that that the top plate of a 50kN

module can be positioned offset, by as much as

15 mm and still function. This also means that the

centering of the sliding modules during installation is

not very critical.

Figure 6. Top plate of -50kN module, shown offset by 15 mm.

Figure 7. This figure shows some typical examples on how to orient the Sliding System weigh modules.

5

Loading...

Loading...