Page 1

GE Fanuc Automation

Computer Numerical Control Products

Symbolic CAP T

Basic Module V1

Operator’s Manual

GFZ-62824EN/02 November 1998

Page 2

Warnings, Cautions, and Notes

as Used in this Publication

Warning notices are used in this publication to emphasize that hazardous voltages, currents,

temperatures, or other conditions that could cause personal injury exist in this equipment or

may be associated with its use.

In situations where inattention could cause either personal injury or damage to equipment, a

Warning notice is used.

Caution notices are used where equipment might be damaged if care is not taken.

GFL-001

Warning

Caution

Note

Notes merely call attention to information that is especially significant to understanding and

operating the equipment.

This document is based on information available at the time of its publication. While efforts

have been made to be accurate, the information contained herein does not purport to cover all

details or variations in hardware or software, nor to provide for every possible contingency in

connection with installation, operation, or maintenance. Features may be described herein

which are not present in all hardware and software systems. GE Fanuc Automation assumes

no obligation of notice to holders of this document with respect to changes subsequently made.

GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of the information contained herein. No warranties of merchantability or fitness for

purpose shall apply.

©Copyright 1998 GE Fanuc Automation North America, Inc.

All Rights Reserved.

Page 3

B-62824EN/02 SAFETY PRECAUTIONS

s-1

SAFETY PRECAUTIONS

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into Warnings

and Cautions according to their bearing on safety. Also, supplementary

information is described as Notes. Read the Warnings, Cautions, and Notes

thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there

is a danger of both the user being injured and the equipment being

damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the

approved procedure is not observed.

NOTE

Notes is used to indicate supplementary information other than

Warnings and Cautions.

¡ Read this manual carefully, and store it in a safe place.

NOTE

In this manual, a program used to specify operations of the CNC

machine tool is referred to as "NC data." In CNC machine tool

manuals, such a program may be referred to as a "machining

program," "part program," or "program," in place of "NC data." The

above precautions must also be applied to those programs in a CNC

machine tool manual, assuming that the programs have the same

usage and purpose as those of the NC data as described in this

manual.

Page 4

SAFETY PRECAUTIONS B-62824EN/02

s-2

GENERAL WARNINGS AND CAUTIONS RELATING TO USE WITH A CNC

This chapter presents the safety precautions which must be observed when

the conversational automatic programming function, described in this

manual, is used with the CNC machine tool.

WARNING

(1) Before starting any operation related to the conversational function

(such as preparing NC data or running an NC data program),

thoroughly check the work area to ensure safety. For example, close

the door of the machine, if it is open. Failure to ensure safety may

result in death or serious injury. Operating the machine with

incorrect NC data may result in the tool colliding with the workpiece

and/or machine, possibly causing damage to the machine,

workpiece, and/or the tool itself, or injury to the user.

(2) When the tool offset function is used, before activating the machine,

check the direction and value of the offset to ensure that the tool will

not collide with the workpiece or machine. Any collision may cause

damage to the tool, machine, and/or workpiece, or injury to the user.

(3) Before starting the NC data program prepared using the

conversational function, thoroughly check the NC data to ensure that

the tool path and machining processes are set correctly, and that the

tool will not collide with the workpiece or machine (including the

chuck and tailstock). Before starting a production run, perform a dry

run to ensure that the tool will not collide with the workpiece or

machine (including the chuck and tailstock). For example, start the

NC data program without mounting a workpiece on the machine.

Any collision may cause damage to the tool, machine, and/or

workpiece, or injury to the user.

(4) Before using the conversational function to perform programming,

ensure that all the data required for the conversational function,

including tool data and cutting condition data, is set correctly. If

these data values are not set appropriately, the cutting conditions

required for machining may not be set correctly, possibly causing

damage to the tool, machine, and/or workpiece, or injury to the user.

(5) After pressing the power-on button, do not touch any keys on the

keyboard until the window is displayed. Some keys are specifically

designed for maintenance or other special operations; if any of these

keys is pressed before the window is displayed, the machine may

behave unexpectedly.

Page 5

B-62824EN/02 SAFETY PRECAUTIONS

s-3

GENERAL WARNINGS AND CAUTIONS RELATING TO USE WITH A

PERSONAL COMPUTER

This chapter presents the safety precautions which must be observed when

the software, described in this manual, is used with a personal computer,

and when the prepared NC data(Note) is used with a CNC machine tool.

WARNING

(1) Before using NC data with a CNC machine tool to perform a

production run, ensure that the machine and tool under the control of

the NC data commands will operate safely. If incorrect NC data is

used carelessly, or if correct NC data is handled improperly, the

machine or tool may behave unexpectedly, possibly causing damage

to the machine, tool, and/or workpiece, or injury to the user.

(2) In this software, once NC data has been automatically created,

whether the NC data program runs appropriately for the CNC

machine tool is not checked. When using the NC data with a CNC

machine tool to perform a production run, follow the instructions in

(1) above.

(3) In this software, whether other software for drawing or checking NC

data runs appropriately for the CNC machine tool is not checked.

When using the NC data with a CNC machine tool to perform a

production run, follow the instructions in (1) above.

(4) When even proven NC data is used repeatedly, the contents of the

NC data may have changed when it is input to the CNC machine tool,

due to degradation in the NC data storage, or changes in the

communication facilities for data transfer. When using the NC data

with a CNC machine tool to perform a production run, follow the

instructions in (1) above.

Page 6

B-62824EN/02 PREFACE

p-1

PREFACE

Thank you for purchasing FANUC Symbolic CAP T.

The FANUC Symbolic CAP T software provides total support of all lathing

phases from blank figure creation and parts figure creation through to NC

data creation. To take full advantage of the functions and features of

FANUC symbolic CAP T, users are advised to read and become familiar

with the entire contents of this manual.

FANUC Symbolic CAP T is compatible with Microsoft Windows. This

manual does not attempt to explain basic Windows operations. Those users

who are unfamiliar with Windows should first read the Windows

documentation for an explanation of Windows fundamentals.

FANUC Symbolic CAP T uses the following products, whose copyright is

owned by Microsoft of the USA.

• Microsoft Windows Software Development Kit

• Microsoft Windows Visual C++

• Microsoft Windows Visual Basic

• Microsoft Windows Visual Control Pack

NOTE

Microsoft and Windows are registered trademarks of Microsoft

Corporation of the USA. Visual C++ and Visual Basic are trademarks

of Microsoft Corporation.

Checking the contents of the package

Immediately after opening the package, check that you have received the

following items.

1) Floppy disks

• For OPEN CNC

FANUC Symbolic CAP T Basic module V1 (A08B-9110J550#EN07)

• For Personal computer

FANUC Symbolic CAP T Basic module V1 (A08B-9310J550#EN07)

TM

TM

2) Protector (Only for Personal computer)

FANUC Symbolic CAP T Basic module Protector (A08B-0080-

Page 7

PREFACE B-62824EN/02

p-2

J550#P550)

3) Operator's manual

FANUC Symbolic CAP T Basic module Operator's Manual (this

document)

About this manual

This manual consists of the sections described below.

PREFACE

Describes the use of this manual and related materials.

Also, briefly describes some of the features of FANUC Symbolic CAP

T.

1. SETUP

Describes the environment needed to run FANUC Symbolic CAP T,

and the method of setting up and enabling the use of FANUC

Symbolic CAP T.

2. BASIC OPERATION

Explains how to start and stop FANUC Symbolic CAP T, and

describes its basic operations. Also, briefly describes the functions

provided by the side menu and menu bar.

3. PROGRAMMING EXAMPLE

Provides an example of the operation of FANUC Symbolic CAP T.

4. BLANK FIGURE CREATION

Describes the types of blank figures, and explains their creation.

5. PARTS FIGURE CREATION

Describes how to create parts figure by means of symbolic figure

input.

6. PRE-MACHINING SETTING

Explains how to set the machine's home position and select tooling

data; these operations must be completed before machining definition

can be performed.

7. MACHINING DEFINITION

Describes the specification of machining types, machining area, and

machining conditions, based on the blank and part figures. Also

explains how these items can be determined automatically.

Page 8

B-62824EN/02 PREFACE

p-3

8. NC DATA PREPARATION

Describes how to prepare the NC data for a specified process. Also

explains how to confirm NC data by animated simulation, and how to

print NC data and process list.

9. TOOL PATH EDITING

Explains how to edit tool paths you prepared.

10. SAVING AND LOADING FILE

Describes how to save a newly created program under a specified

name, and how to load a program that was created and saved

previously.

11. CREATING NEW PROGRAM

Describes how to discard an existing program and create a new one.

12. FIGURE CREATION

Explains the basics of figure creation by means of CAD entry.

Also describes how figures are copied and modified.

13. CUTTING CONDITION DATA

Describes how data is registered and modified, including data on the

workpiece, tools, and machining conditions, needed to enable the

automatic setting of machining conditions.

14. CUTTING CONDITION DATA UTILITY

Explains how to input and output cutting condition data.

15. TOOL DATA AND TOOLING DATA

Describes how to select the tool data to be referenced at Machining

Definition, and how to register new tools and modify existing tool

data.

16. TOOL/TOOLING DATA UTILITY

Explains how to input and output tool/tooling data.

17. NC MACHINE SETTING

Describes how to specify the technical data for the machine and

CNC.

18. FILE TRANSFER

Describes how to transfer NC data to the CNC unit or other units.

19. PLOTTING

Describes how to output NC data from the drawing window to the

plotter.

Page 9

PREFACE B-62824EN/02

p-4

20. CAD DATA INPUT/OUTPUT

Describes the exchange of data between Symbolic CAP T and general

CAD software. Also explains the precautions to be observed when

using FANUC Symbolic CAP T to handle data prepared in another

CAD system.

21. FAPT LANGUAGE FIGURE INPUT

Describes a function that is tended to analyze and execute part

program figure definition statements written in FAPT language, and

convert them to figure entities that can to be saved to the Symbolic

CAP figure databases.

22. DIMENSION MEASUREMENT

Explains how to measure coordinates and distances from figures.

23. STANDARD SETTING

Describes the setting of the initial values displayed on each

conversational window.

Notations

24. PARAMETER SETTING

Describes the specification of parameters related to FANUC Symbolic

CAP T, such as the part figures and tool path colors to be prepared,

the sequence in which axes are moved during approach/escape, and

whether data is saved automatically at regular intervals.

25. TOOL BAR SETTING

Describes how to modify the contents of the tool bar.

26. TROUBLESHOOTING

Describes the procedure to be followed if a problem occurs.

Also lists the errors that may occur.

27. APPENDIX

Contains information that should be read as required, such as the

function codes used in NC machine files.

• Product name abbreviations

Major product names are abbreviated as stated below.

FANUC Symbolic CAP T -> Symbolic CAP T

FANUC Symbolic CAP T Basic module -> Basic module

FANUC Symbolic CAP T Basic module

Protector -> Protector

Page 10

B-62824EN/02 PREFACE

p-5

Microsoft Windows -> Windows

• Keys

When a sequence of keys are to be pressed and held down, the keys in the

sequence are indicated with an intervening dash (-), as shown below:

Example) CTRL-ALT-TAB, ALT-F4

• Menus

When a command is to be selected from the menu bars, a right arrow (=>) is

used to link the menus in the sequence, as shown below:

“First menu => second menu => third menu”

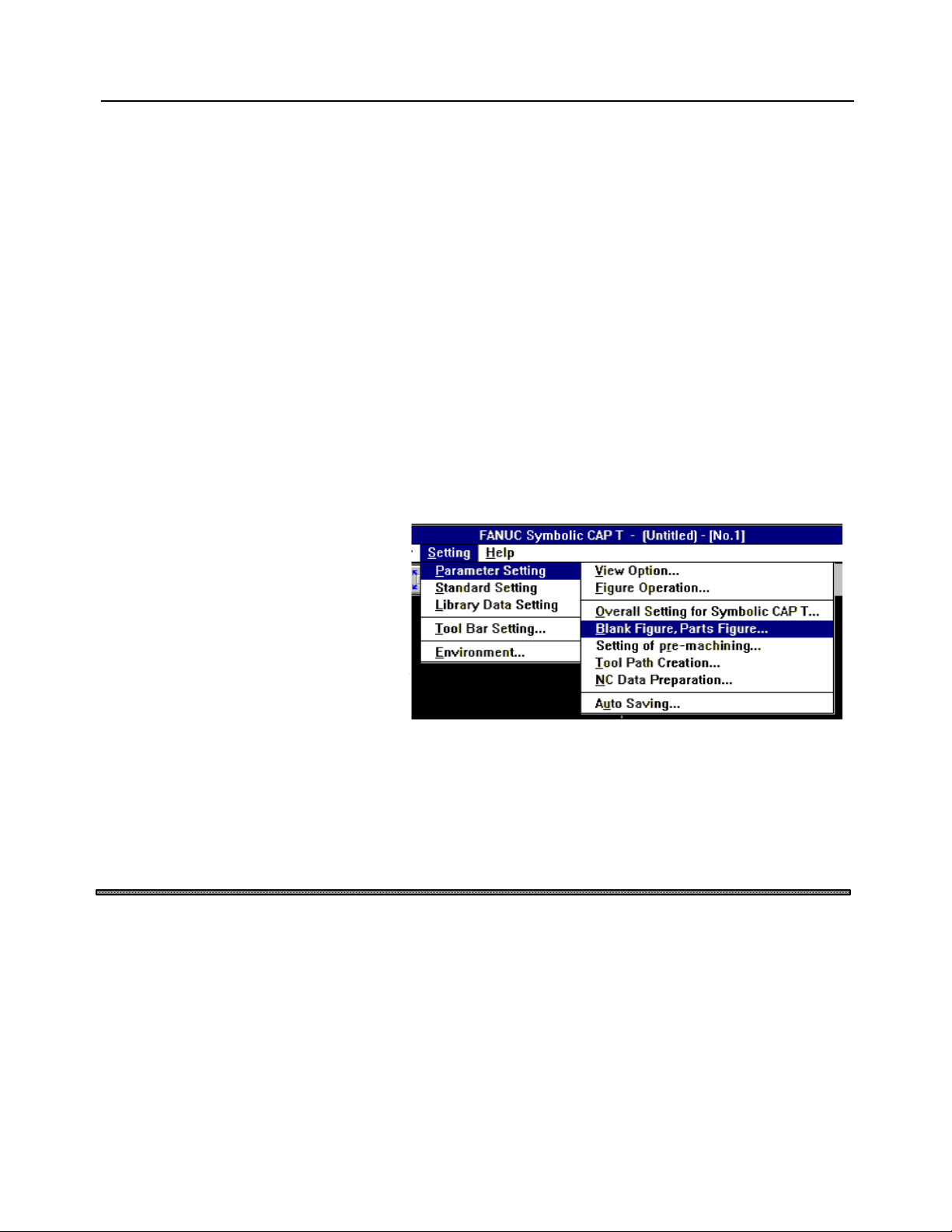

Example) The menus shown below would be indicated as shown below:

“Setting => Parameter Setting => Blank Figure, Parts Figure”

Features of Symbolic CAP T

• Window examples

The windows shown in this document are merely examples. Note that the

window layout and file names used may vary depending on the equipment or

the resolution of the display unit you are using.

• Operation on Windows

Comfortable operating environment is afforded by Windows which provides

a de facto standard user interface.

Even inexperienced users can use the system by interactive operation using

graphical menus and a mouse.

• User-friendly operating procedure that is easy to use, even by

beginners

Symbolic CAP T is easy even for beginners to use, thanks to its support of

graphical menus (icons) and mouse-driven conversational processing. In

addition, it provides a wealth of help messages.

Page 11

PREFACE B-62824EN/02

p-6

• Operating procedure for experienced operators

Symbolic CAP T commands can be entered from the keyboard, enabling

experienced operators to operate the system quickly.

• Customizing functions

The user can improve the operability or add functions to suit the usage of

customers. Customizing to call frequently used functions by a simple

operation on tool bar is possible.

• One-click switching of the window

The window can be switched between that for machining definition and that

for figure creation simply by clicking a button. Therefore, even if a figure is

found to be missing during machining definition, figure input need not be

repeated from the very beginning.

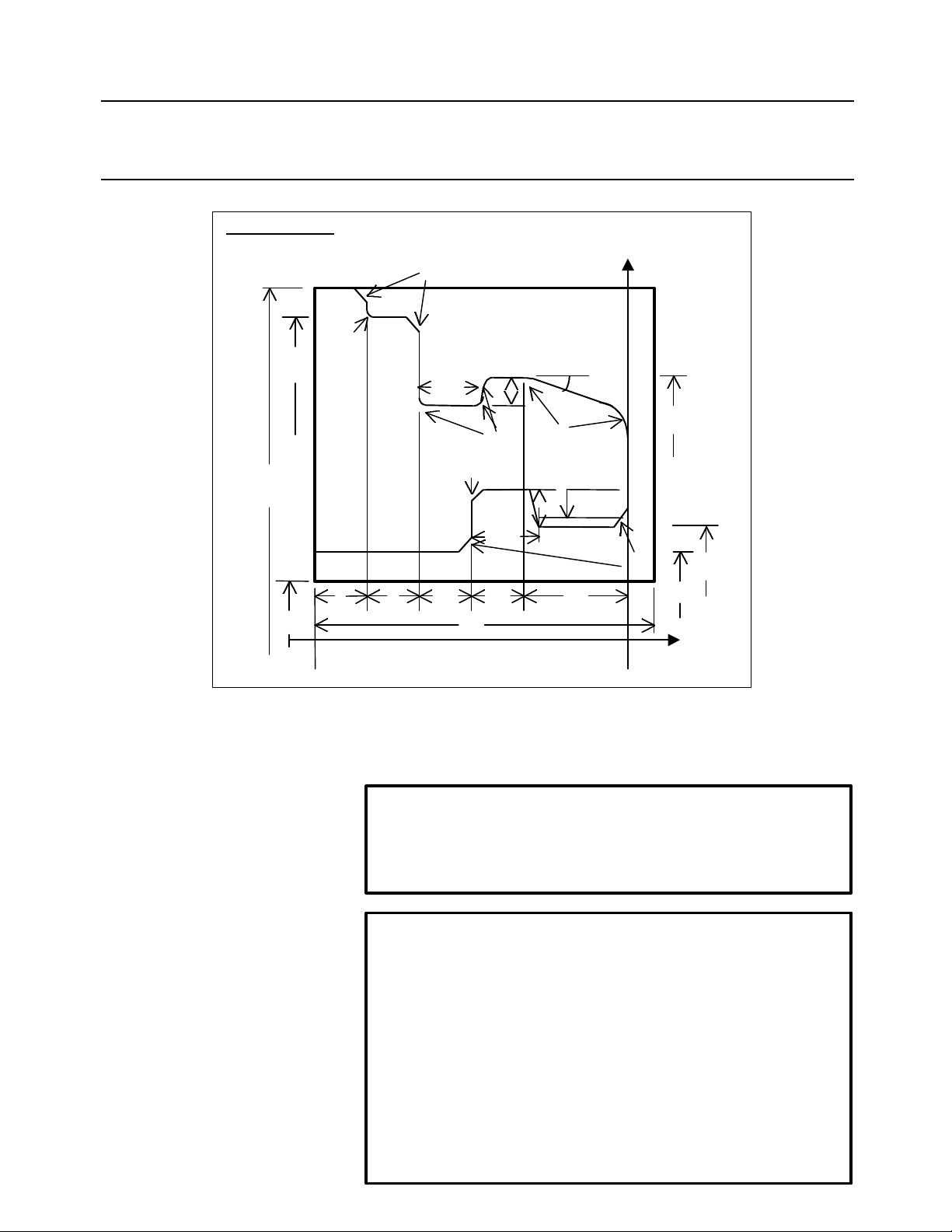

• Symbolic figure input

Blank and parts figure can be entered using conventional symbolic figure

input based on arrows.

• Fully automatic process determination

An optimum machining type, a tool, a portion to be cut, and machining

conditions can be automatically selected simply by entering blank and part

figures. Even beginners can create machining programs quickly and easily.

• Machining simulation

Three-dimensional animated machining simulation and tool path drawing are

performed simultaneously.Animated machining simulation allows the

operator to actually observe the progress of machining. Tool path drawing

enables the operator to check the tool path generated by a machining

program in detail.

• Tool path editing function

The tool path editing function enables editing tool paths generated on

Symbolic CAP T as figure images, using a mouse.

It is possible to re-prepare NC data from edited tool paths.

Page 12

B-62824EN/02

c-1

Table of Contents

SAFETY PRECAUTIONS................................................................................................ s-1

GENERAL WARNINGS AND CAUTIONS RELATING TO USE WITH A CNC...............s-2

GENERAL WARNINGS AND CAUTIONS RELATING TO USE WITH A

PERSONAL COMPUTER................................................................................................s-3

PREFACE........................................................................................................................p-1

Checking the contents of the package.............................................................................................p-1

About this manual ........................................................................................................................... p-2

Notations......................................................................................................................................... p-4

Features of Symbolic CAP T...........................................................................................................p-5

1 SETUP............................................................................................................................ 1

1.1 Prior to Setting Up (Operating Environment) ................................................................................ 1

1.1.1 Prerequisites....................................................................................................................................................1

1.1.2 Other usable devices........................................................................................................................................2

1.2 Setting Up Symbolic CAP T ......................................................................................................... 3

1.2.1 About Setup .....................................................................................................................................................3

1.2.2 Setting up an optional module..........................................................................................................................6

1.2.3 Reinstalling Symbolic CAP T...........................................................................................................................8

1.2.4 About the protector (Only for use with a personal computer) ............................................................................8

2 BASIC OPERATION....................................................................................................... 9

2.1 Fundamentals .............................................................................................................................. 9

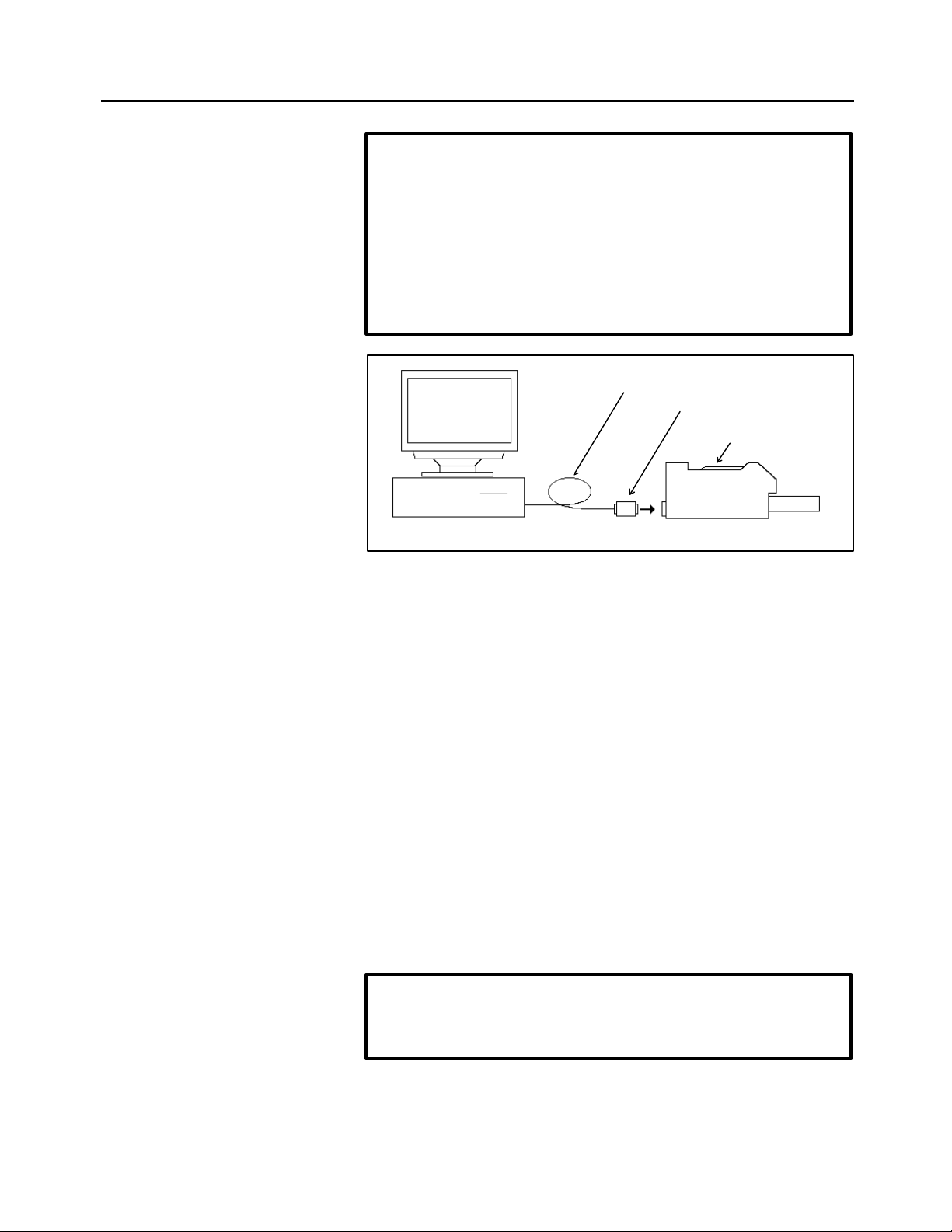

2.1.1 Starting Symbolic CAP T.................................................................................................................................9

2.1.2 Terminating Symbolic CAP T ..........................................................................................................................9

2.1.3 Reading the latest information about Symbolic CAP T .....................................................................................9

2.1.4 Other Symbolic CAP T icons............................................................................................................................9

2.2 Contents of Symbolic CAP T Window ........................................................................................ 11

2.2.1 Title bar.........................................................................................................................................................11

2.2.2 Side menu......................................................................................................................................................12

2.2.3 Menu bar.......................................................................................................................................................13

2.2.4 Tool bar.........................................................................................................................................................13

2.2.5 Drawing window............................................................................................................................................13

2.2.6 Prompt area ................................................................................................................................................... 14

2.2.7 Status window ............................................................................................................................................... 15

2.3 Basic Operation.......................................................................................................................... 16

2.3.1 Using the Help function to become familiar with the operating procedure......................................................................16

2.3.2 Confirming the version...................................................................................................................................16

2.3.3 Modifying the operation flow.........................................................................................................................17

2.4 Functions Provided by Side Menu.............................................................................................. 19

2.4.1 Programming mode........................................................................................................................................19

2.4.2 Figure creation mode .....................................................................................................................................19

2.5 Functions Provided by Menu Bar................................................................................................ 26

2.5.1 File menu ......................................................................................................................................................26

2.5.2 Modify menu ................................................................................................................................................. 27

Page 13

Table of Contents B-62824EN/02

c-2

2.5.3 Edit menu......................................................................................................................................................28

2.5.4 View menu ....................................................................................................................................................30

2.5.5 Auxiliary menu..............................................................................................................................................31

2.5.6 Setting menu..................................................................................................................................................32

2.5.7 Help menu.....................................................................................................................................................33

2.6 Functions Provided by the Tool Bar............................................................................................ 34

2.7 Flow of Operation ....................................................................................................................... 35

2.7.1 Overview of each function..............................................................................................................................35

2.7.2 Overview of data............................................................................................................................................36

2.8 Layers......................................................................................................................................... 38

2.8.1 About layers...................................................................................................................................................38

2.8.2 Major classification of layers..........................................................................................................................38

2.8.3 Figure creation layer setting...........................................................................................................................39

2.9 Drawing Format Setting.............................................................................................................. 40

3 PROGRAMMING EXAMPLE ........................................................................................ 41

3.1 Flow of Operation ....................................................................................................................... 41

3.1.1 Procedure.......................................................................................................................................................41

3.1.2 Explanation of each step ................................................................................................................................ 42

3.1.3 Example of operation.....................................................................................................................................43

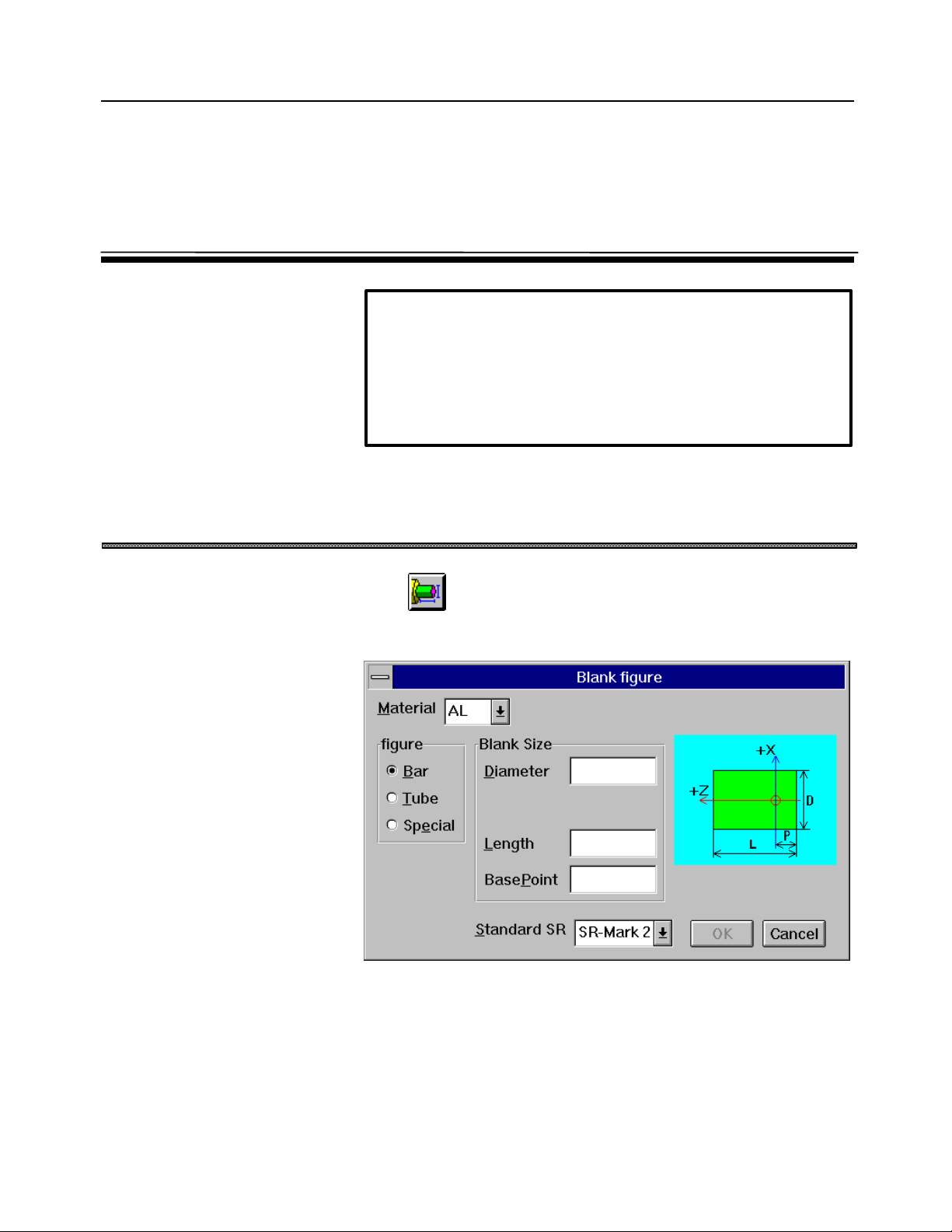

4 BLANK FIGURE CREATION........................................................................................ 54

4.1 Blank Figure Creation................................................................................................................. 54

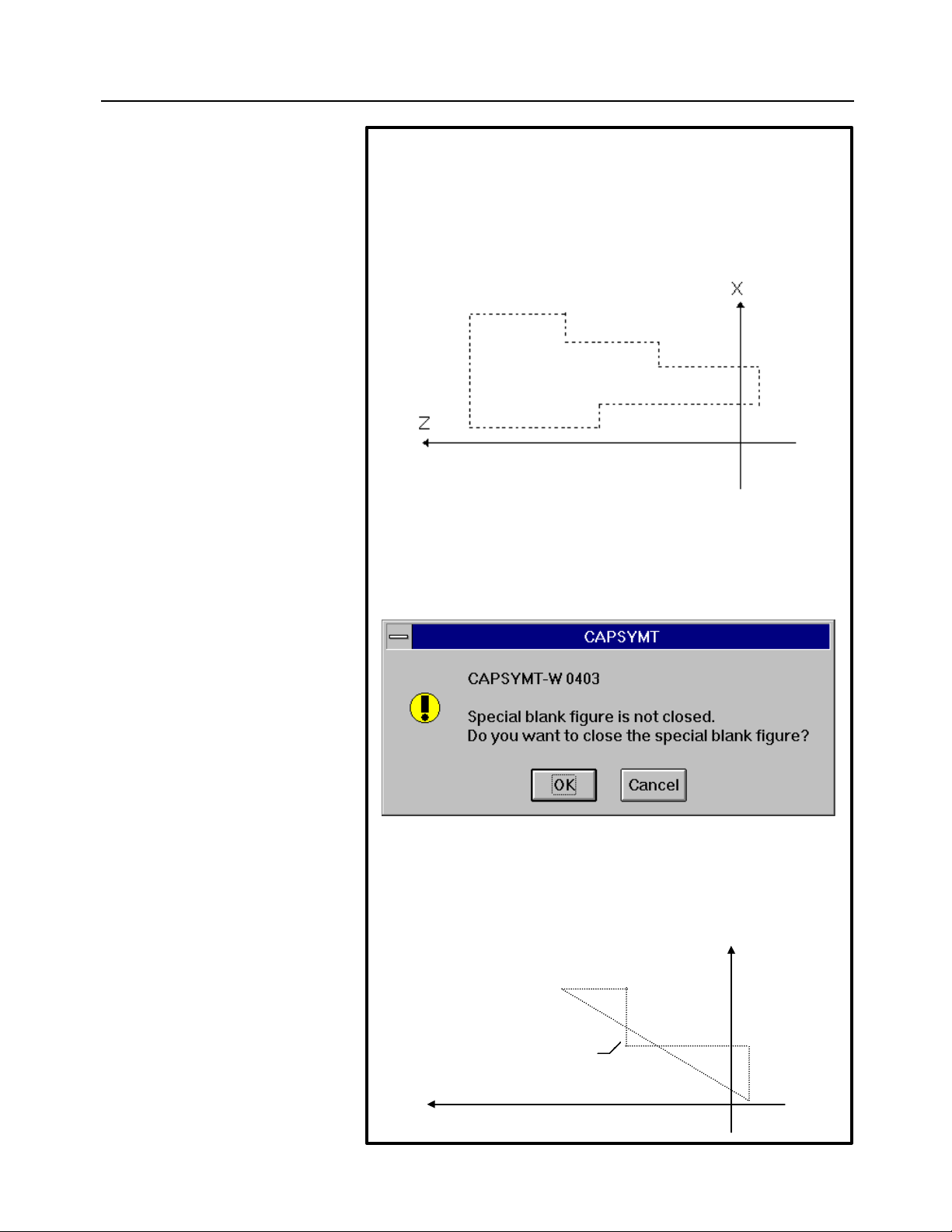

4.2 Special Figure............................................................................................................................ 56

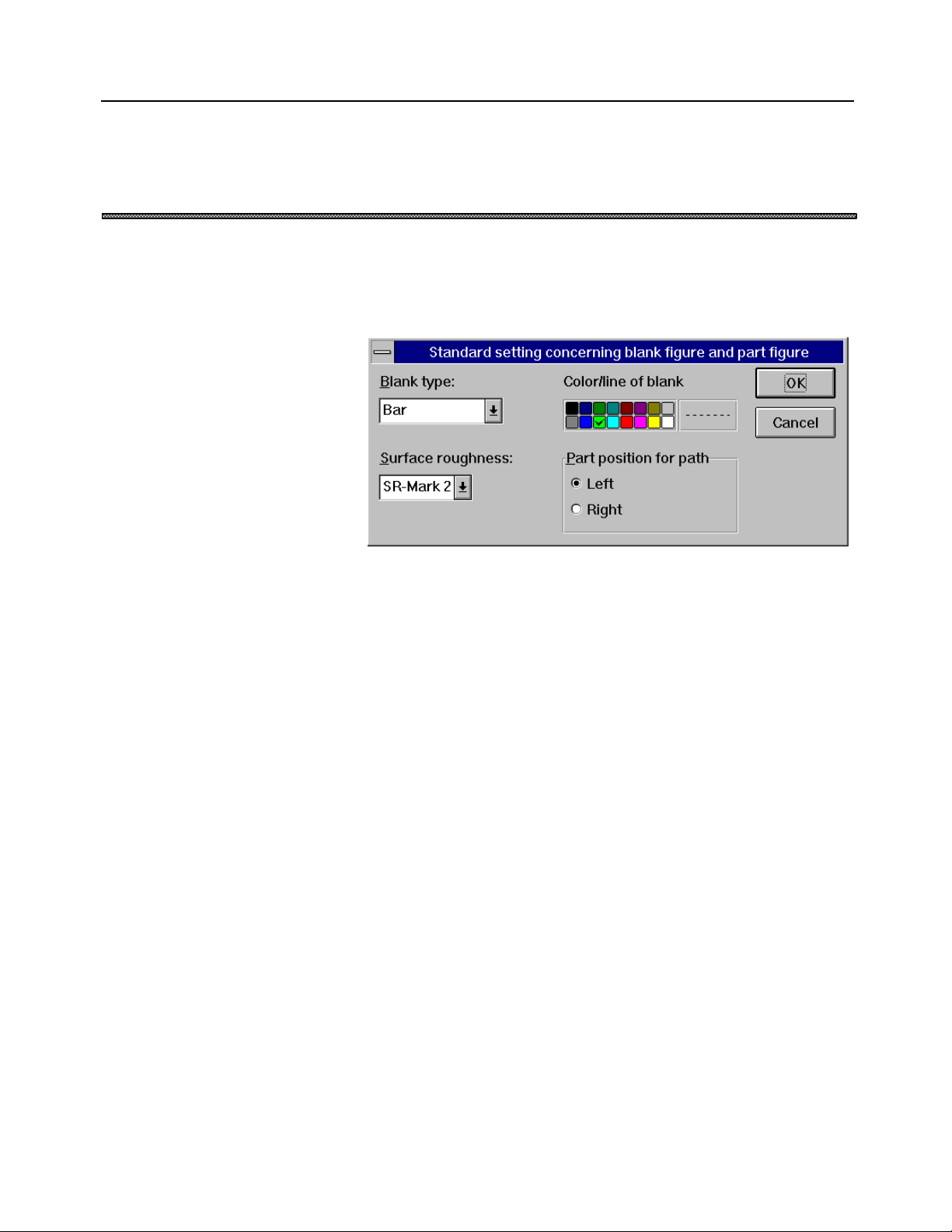

4.3 Blank Figure Color/Line Type Modification ................................................................................. 58

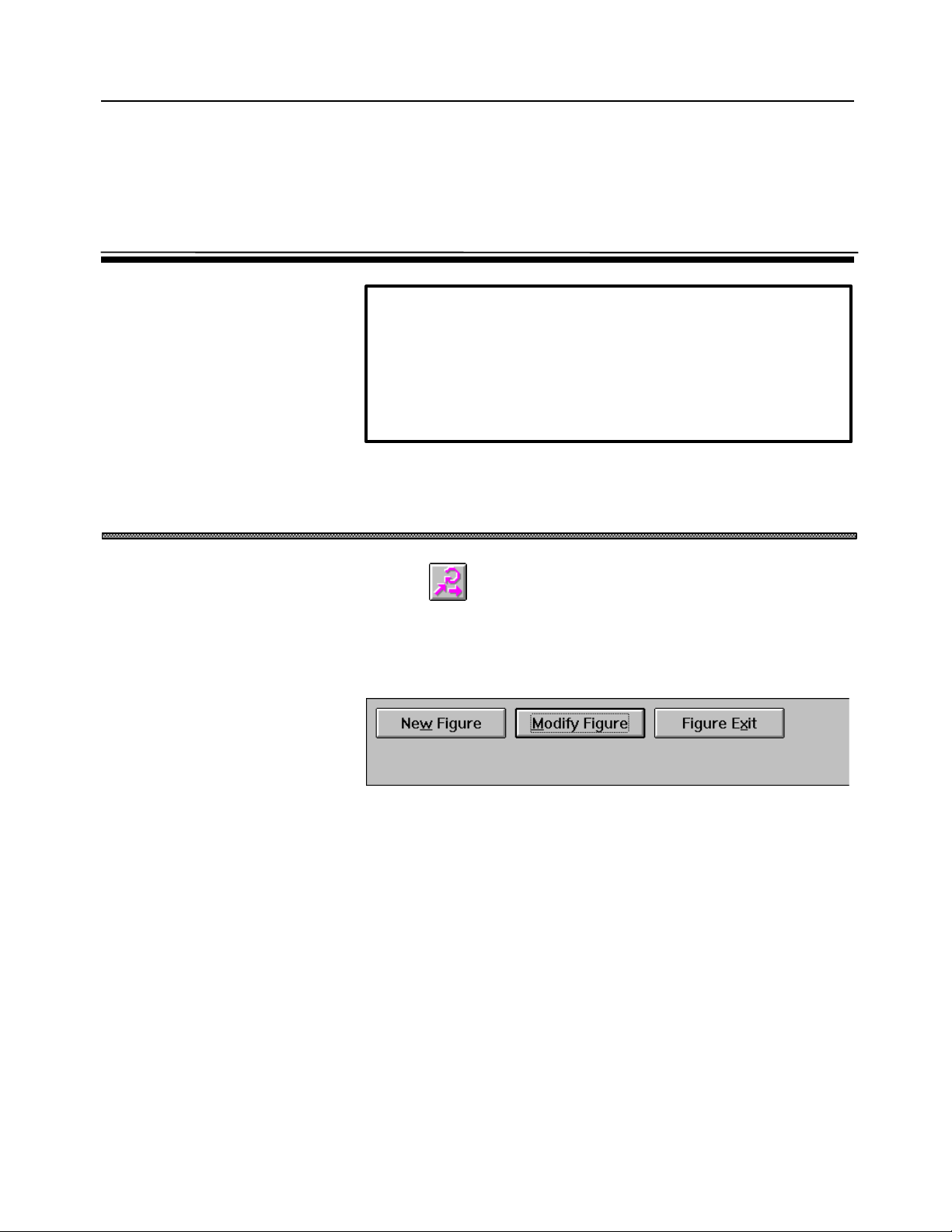

5 PARTS FIGURE CREATION........................................................................................ 59

5.1 Turning Figure Creation.............................................................................................................. 59

5.2 Symbolic Input Method ............................................................................................................... 61

5.2.1 Entity selection..............................................................................................................................................61

5.2.2 Symbolic figure data input ............................................................................................................................. 62

5.2.3 Symbolic Figure data editing.......................................................................................................................... 78

5.2.4 Symbolic figure creation by figure reference................................................................................................... 80

6 PRE-MACHINING SETTING......................................................................................... 84

6.1 Selecting Tooling Data............................................................................................................... 85

6.2 Selecting an NC Machine File .................................................................................................... 86

6.3 Setting the Home Position.......................................................................................................... 87

6.4 Setting the Index Position........................................................................................................... 88

6.5 Setting the Chuck....................................................................................................................... 89

6.5.1 Setting items of the chuck..............................................................................................................................89

6.5.2 Chuck figure registration/edit window............................................................................................................91

7 MACHINING DEFINITION............................................................................................. 93

7.1 Machining Definition Window ..................................................................................................... 94

7.2 Selecting the Machining Type..................................................................................................... 95

7.3 Specifying the Cutting Area and Condition Data......................................................................... 97

7.3.1 Specifying the Cutting Area ........................................................................................................................... 97

Page 14

B-62824EN/02 Table of Contents

c-3

7.3.2 Location of the division point and the cutting area ........................................................................................101

7.3.3 Condition setting..........................................................................................................................................105

7.3.4 Specifying Another Area..............................................................................................................................107

7.4 Changing and Modifying the Machining Process........................................................................109

7.5 Defining New Machining Process ..............................................................................................111

7.6 Fully Automatic Determination ..................................................................................................112

8 NC DATA PREPARATION ......................................................................................... 115

8.1 Preparing and Displaying NC Data............................................................................................115

8.2 NC Data Preparation Window....................................................................................................116

8.3 Process Order Editing Window..................................................................................................119

8.4 NC Data Preparation Data Setting Window ...............................................................................121

8.5 Animation Window ....................................................................................................................122

8.6 Data Setting Window for Animated Simulation..........................................................................124

8.7 Writing NC Data to a Floppy Disk and Transferring NC Data to a Peripheral Device .................125

8.8 Printing NC Data and a Process Table ......................................................................................126

9 TOOL PATH EDITING................................................................................................ 127

9.1 Tool Path Editing.......................................................................................................................127

9.1.1 Tool paths subjected to editing .....................................................................................................................127

9.1.2 Unit of editing .............................................................................................................................................128

9.1.3 Coordinate system used for tool path editing ................................................................................................128

9.1.4 Editing......................................................................................................................................................... 128

9.2 Execution of Tool Path Editing ..................................................................................................129

9.3 Tool Path Editing Dialog Box.....................................................................................................130

9.3.1 Machining process list .................................................................................................................................130

9.3.2 Selecting a tool path for editing....................................................................................................................130

9.3.3 Deleting tool paths .......................................................................................................................................131

9.3.4 Terminating tool path editing.......................................................................................................................131

9.4 Editing Movement Entities.........................................................................................................132

9.4.1 Adding movement entities............................................................................................................................ 132

9.4.2 Erasing movement entities ........................................................................................................................... 133

9.4.3 Trimming/Extending movement entities .......................................................................................................133

9.4.4 Undoing/redoing editing...............................................................................................................................133

9.4.5 Specifying start entities ................................................................................................................................134

9.4.6 Checking tool paths for continuity................................................................................................................135

9.4.7 Listing entities.............................................................................................................................................136

9.4.8 Canceling movement entity editing...............................................................................................................136

9.4.9 Terminating movement entity editing...........................................................................................................137

10 SAVING AND LOADING FILE.................................................................................. 138

10.1 Saving a File...........................................................................................................................138

10.2 Loading a File..........................................................................................................................139

11 CREATING NEW PROGRAM................................................................................... 140

12 FIGURE CREATION................................................................................................. 141

12.1 Types of Figures......................................................................................................................141

12.2 Specifying a Radius, Distance, and Angle ...............................................................................142

Page 15

Table of Contents B-62824EN/02

c-4

12.3 Specifying Positions................................................................................................................143

12.4 Selecting Entities.....................................................................................................................145

12.5 Coordinate System..................................................................................................................147

12.5.1 World coordinate system............................................................................................................................147

12.5.2 Machining plane coordinate system............................................................................................................147

12.6 Modifying Figures by Extension/Trimming...............................................................................148

12.7 Copying Figures......................................................................................................................149

12.8 Creating Polygons...................................................................................................................155

12.9 Fitting Curve ...........................................................................................................................156

12.9.1 Creation method of a fitting curve .............................................................................................................. 156

12.9.2 Adjusting the creation method of a fitting curve..........................................................................................156

12.10 Offset....................................................................................................................................159

12.10.1 Outward offset for a corner....................................................................................................................... 159

12.10.2 Inward offset for a corner .........................................................................................................................160

13 CUTTING CONDITION DATA.................................................................................. 162

13.1 Overview.................................................................................................................................162

13.2 Functions ................................................................................................................................164

13.3 Starting of Editing Cutting Condition Data................................................................................165

13.4 Adding a Material Name..........................................................................................................166

13.5 Deleting a Material Name [Edit Cutting Condition Data]...........................................................168

13.6 Editing Cutting Condition Data.................................................................................................169

13.6.1 Modifying cutting condition data on a machining type basis........................................................................169

13.6.2 Adding cutting condition data..................................................................................................................... 170

13.6.3 Modifying cutting condition data................................................................................................................175

13.6.4 Deleting cutting condition data...................................................................................................................175

13.6.5 Changing the order of the tool types ........................................................................................................... 175

13.6.6 Deleting cutting condition data on a machining type basis ..........................................................................175

13.7 Calculating Method of the Machining Condition Data ...............................................................176

14 CUTTING CONDITION DATA UTILITY.................................................................... 179

14.1 Functions ................................................................................................................................179

14.2 Starting the Cutting Condition Data Utility................................................................................180

14.3 Selecting Utility Functions .......................................................................................................181

14.4 Outputting Cutting Condition Files...........................................................................................182

14.5 Inputting Cutting Condition Files..............................................................................................184

14.6 Changing Cutting Condition Files ............................................................................................186

14.7 Uniting Cutting Condition Files ................................................................................................189

15 TOOL DATA AND TOOLING DATA ........................................................................ 192

15.1 Overview.................................................................................................................................192

15.2 Functions ................................................................................................................................194

15.3 Starting of Tool Data/Tooling Data Editing...............................................................................195

15.4 Addition of Tooling Data..........................................................................................................196

15.5 Deleting a Tooling ...................................................................................................................198

15.6 Modification of the Tooling Data..............................................................................................199

15.6.1 Adding or inserting the tool data for a tool into the tooling data..................................................................199

15.6.2 Registering a new tool and adding or inserting the data into the tooling data............................................... 200

Page 16

B-62824EN/02 Table of Contents

c-5

15.6.3 Modifying tool registered in the tooling data ..............................................................................................202

15.6.4 Duplicating a tool in tooling data................................................................................................................202

15.6.5 Changing the order of the tools in the tooling data......................................................................................202

15.6.6 Deleting tooling from the tooling data ........................................................................................................203

15.6.7 Registering a new tool and adding or inserting tool data.............................................................................203

15.6.8 Modifying tool registered in the tool data ................................................................................................... 203

15.6.9 Duplicating the tool in the tool data............................................................................................................ 203

15.6.10 Changing the order of the tools in the tool data .........................................................................................204

15.6.11 Deleting tool from the tool data................................................................................................................204

15.6.12 Adding or deleting a tool material name only............................................................................................ 204

16 TOOL/TOOLING DATA UTILITY............................................................................. 205

16.1 Functions ................................................................................................................................205

16.2 Starting the Tool/Tooling Data Utility.......................................................................................206

16.3 Selecting Utility Functions .......................................................................................................207

16.4 Outputting Tool/Tooling Files...................................................................................................208

16.5 Inputting Tool/Tooling Files .....................................................................................................210

16.6 Changing Tooling Files ............................................................................................................212

17 NC MACHINE SETTING........................................................................................... 214

17.1 NC Machine File.....................................................................................................................214

17.2 Overview of NC Data Preparation Procedure ..........................................................................215

17.3 Modifying the NC Data Output Format.....................................................................................216

17.4 Machine Specifications............................................................................................................219

17.4.1 NC machine name......................................................................................................................................219

17.4.2 Home position/index position .....................................................................................................................219

17.4.3 Total number of axes/number of simultaneously controlled axes .................................................................219

17.4.4 Feedrate.....................................................................................................................................................220

17.4.5 Spindle speed.............................................................................................................................................220

17.4.6 Whether to use the ATC function ............................................................................................................... 220

17.5 CNC Specifications .................................................................................................................221

17.5.1 Address setting ..........................................................................................................................................221

17.5.2 G code ....................................................................................................................................................... 222

17.5.3 M code.......................................................................................................................................................222

17.5.4 Arbitrary character string ...........................................................................................................................223

17.5.5 Specifying required functions.....................................................................................................................223

17.6 NC Data Format......................................................................................................................225

17.6.1 Example of referencing NC data formats....................................................................................................225

17.6.2 Timing of NC data format reference...........................................................................................................226

17.7 Example of NC Data Output....................................................................................................239

17.8 NC Machine Setting Tool Operation ........................................................................................241

17.9 Customization .........................................................................................................................242

17.9.1 File configuration.......................................................................................................................................242

17.9.2 Modifying initial values ............................................................................................................................. 243

17.9.3 Modifying setting item names ....................................................................................................................244

17.9.4 Deleting setting items ................................................................................................................................245

17.9.5 Adding setting items .................................................................................................................................. 246

18 FILE TRANSFER...................................................................................................... 247

18.1 Function Outline......................................................................................................................247

Page 17

Table of Contents B-62824EN/02

c-6

18.1.1 Application software..................................................................................................................................247

18.1.2 Devices to which data can be transmitted ................................................................................................... 247

18.1.3 Data format that can be transmitted ............................................................................................................248

18.1.4 Transmission protocols...............................................................................................................................248

18.1.5 File operation functions.............................................................................................................................. 248

18.2 Activating the File Transmission Tool......................................................................................249

18.2.1 Activation using the Symbolic CAP T output function ................................................................................249

18.2.2 Activating only the File Transmission Tool ................................................................................................250

18.2.3 Activating the File Transmission Manager .................................................................................................250

18.3 File Transmission Tool Window ...............................................................................................251

18.3.1 Menus........................................................................................................................................................251

18.3.2 File specification areas...............................................................................................................................252

18.3.3 Buttons......................................................................................................................................................252

18.3.4 Operation guide .........................................................................................................................................252

18.4 Operating Procedure...............................................................................................................253

18.4.1 Selecting the device and setting the transmission conditions.......................................................................253

18.4.2 Specifying files .......................................................................................................................................... 253

18.4.3 Selecting a command .................................................................................................................................254

18.4.4 Changing the contents of the transmission operation...................................................................................254

18.4.5 Starting transmission..................................................................................................................................255

18.4.6 Checking the transmission status................................................................................................................255

18.4.7 Ending the transmission operation..............................................................................................................256

18.5 Outline of Processing for Each Function ..................................................................................257

18.5.1 Send ..........................................................................................................................................................257

18.5.2 Receive ......................................................................................................................................................257

18.5.3 Delete........................................................................................................................................................257

18.5.4 Clear.......................................................................................................................................................... 258

18.5.5 Rename......................................................................................................................................................258

18.5.6 Read-only and read/write ...........................................................................................................................258

18.5.7 Refresh......................................................................................................................................................259

18.6 Setting Transmission Conditions..............................................................................................260

18.6.1 Setting procedure.......................................................................................................................................260

18.6.2 Specifying the device and plotter ................................................................................................................263

18.6.3 Standard setting files..................................................................................................................................263

18.6.4 Setting the communication conditions ........................................................................................................264

18.6.5 Setting the transmission control conditions .................................................................................................265

18.6.6 Setting reception control conditions............................................................................................................266

18.7 Transmission Schedule Management......................................................................................268

18.7.1 Contents of the window.............................................................................................................................. 268

18.7.2 Changing the schedule ...............................................................................................................................269

18.7.3 Exiting the File Transmission Manager......................................................................................................270

18.8 Example Transmission Procedures .........................................................................................271

18.8.1 Transmission to and from the CNC ............................................................................................................271

19 PLOTTING................................................................................................................ 272

19.1 Setting Up a Plotter.................................................................................................................272

19.2 Procedures..............................................................................................................................274

20 CAD DATA INPUT/OUTPUT.................................................................................... 277

20.1 CAD Data Input/Output............................................................................................................277

Page 18

B-62824EN/02 Table of Contents

c-7

20.1.1 CAD data...................................................................................................................................................277

20.1.2 Handling of CAD data by this system.........................................................................................................278

20.2 DXF File Input/Output..............................................................................................................279

20.2.1 Overview of DXF....................................................................................................................................... 279

20.2.2 DXF file input ...........................................................................................................................................282

20.2.3 Setting the input conversion method ...........................................................................................................284

20.2.4 DXF file output.......................................................................................................................................... 289

20.2.5 Setting the output conversion method.........................................................................................................291

20.3 Handling CAD Data Efficiently .................................................................................................295

20.4 Conversion Specifications for DXF File Input/Output...............................................................296

20.4.1 DXF input conversion specifications ..........................................................................................................296

20.4.2 DXF output conversion specifications.........................................................................................................298

21 FAPT LANGUAGE FIGURE INPUT ......................................................................... 301

21.1 Overview.................................................................................................................................301

21.1.1 Figure types that can be input..................................................................................................................... 301

21.1.2 FAPT statement types that can be input......................................................................................................301

21.2 Operation................................................................................................................................302

21.2.1 Start-up...................................................................................................................................................... 302

21.2.2 Part program selection................................................................................................................................302

21.2.3 FAPT language figure input .......................................................................................................................303

21.2.4 Settings related to the FAPT language figure input function .......................................................................304

21.2.5 Displaying the progress of input processing................................................................................................305

21.2.6 Displaying input information......................................................................................................................306

21.3 Cautions and Restrictions........................................................................................................307

22 DIMENSION MEASUREMENT ................................................................................. 308

22.1 Dimension Measurement Function ..........................................................................................308

22.2 Measurable Dimensional Values..............................................................................................309

22.3 Activating Dimension Measurement ........................................................................................310

22.4 Measuring Coordinates............................................................................................................311

22.5 Distance between Two Points..................................................................................................313

22.6 Distance between Point and Entity ..........................................................................................314

22.7 Circle/Arc Radius.....................................................................................................................315

22.8 Angles Formed by Two Lines ..................................................................................................316

22.9 Displaying Measurements........................................................................................................317

22.10 Cautions................................................................................................................................318

23 STANDARD SETTING.............................................................................................. 319

23.1 Standard Setting for Blank Figure and Parts Figure.................................................................319

23.2 Standard Setting for NC Data Preparation...............................................................................320

24 PARAMETER SETTING........................................................................................... 321

24.1 Parameter Setting for View......................................................................................................321

24.2 Parameter Setting for Figure Operation...................................................................................322

24.3 Parameter Setting for Overall Setting of Symbolic CAP T.......................................................324

24.4 Parameter Setting for Blank Figure and Part Figure ................................................................324

24.5 Parameter Setting for Pre-Machining Setting...........................................................................325

Page 19

Table of Contents B-62824EN/02

c-8

24.6 Parameter Setting for Machining Definition .............................................................................325

24.7 Parameter Setting for Machining Condition Automatic Decision ..............................................326

24.8 Parameter Setting for Tool Path Creation................................................................................331

24.9 Parameter Setting for NC Data Preparation .............................................................................332

24.10 Parameter Setting for Auto Saving........................................................................................333

25 TOOL BAR SETTING............................................................................................... 334

25.1 Tool Bar Setting ......................................................................................................................334

25.1.1 Storing the tool bar definition file...............................................................................................................334

25.1.2 Creating icons............................................................................................................................................ 334

25.1.3 Displaying the Tool Bar Setting window ....................................................................................................334

25.1.4 Registering menu items..............................................................................................................................335

25.1.5 Deleting buttons/spaces.............................................................................................................................. 335

25.1.6 Inserting spaces.......................................................................................................................................... 335

25.1.7 Changing icons ..........................................................................................................................................335

25.1.8 Saving settings/returning to the normal state ..............................................................................................336

25.1.9 Discarding the settings/returning to the normal state ..................................................................................336

26 TROUBLESHOOTING.............................................................................................. 337

26.1 Before Trouble Occurs ............................................................................................................337

26.2 If Trouble Occurs.....................................................................................................................338

26.3 Error Messages.......................................................................................................................339

26.3.1 Abbreviations of functions..........................................................................................................................340

26.3.2 Messages related to blank and parts figure preparation ...............................................................................341

26.3.3 Messages related to pre-machining settings................................................................................................345

26.3.4 Messages concerning machining surface setting..........................................................................................347

26.3.5 Messages related to machining definition...................................................................................................347

26.3.6 Messages related to NC data preparation....................................................................................................351

26.3.7 Messages concerning the milling library.....................................................................................................363

26.3.8 Messages related to loading part files .........................................................................................................366

26.3.9 Messages related to cutting condition setting ..............................................................................................369

26.3.10 Messages related to tool and tooling data..................................................................................................375

26.3.11 Other messages........................................................................................................................................379

27 APPENDIX................................................................................................................ 382

27.1 Function Codes.......................................................................................................................382

27.1.1 NC data format setting function codes (special functions)........................................................................... 382

27.1.2 NC data format setting function codes (move command words) ..................................................................382

27.1.3 NC data format setting function codes (G codes).................................................................................... 385

27.1.4 NC data format setting function codes (integer words)................................................................................389

27.1.5 NC data format setting function codes (special codes) ................................................................................389

27.1.6 NC data format setting function codes (M codes)........................................................................................ 390

27.1.7 NC data format setting function codes (S codes)......................................................................................... 391

27.1.8 NC data format setting function codes (T codes).........................................................................................391

27.1.9 NC data format setting function codes (outputting arbitrary character strings).............................................391

27.1.10 NC data format setting function codes (modal clearing)............................................................................392

27.2 Pre/Postprocessor Macro Syntax.............................................................................................393

27.2.1 General ......................................................................................................................................................393

27.2.2 Components............................................................................................................................................... 393

27.2.3 Structure.................................................................................................................................................... 395

Page 20

B-62824EN/02 Table of Contents

c-9

27.2.4 Declare statement ......................................................................................................................................397

27.2.5 Expression and assignment ........................................................................................................................398

27.2.6 Control statement.......................................................................................................................................400

27.2.7 Procedure statement................................................................................................................................... 402

27.2.8 EL statement..............................................................................................................................................405

27.2.9 Preprocessor pseudo instruction .................................................................................................................405

27.2.10 Restrictions ..............................................................................................................................................406

Page 21

B-62824EN/02 1. SETUP

-1-

1 SETUP

1.1 Prior to Setting Up (Operating Environment)

1.1.1 Prerequisites

The following operating environment is needed to run Symbolic CAP T.

• Computer

FANUC open CNC (with HSSB personal computer connection), or personal

computer

CPU: i486TMDX or higher (math co-processor required)

Memory: 12 MB or more

Floppy disk: 3.5-inch, 1.44MB

Hard disk: Total capacity of 80 MB or more (20 MB or more of

dedicated area and 32 MB or more of swap file area)

• Display unit

Resolution: 640 × 480 dots or higher

Color: 256 colors

• Keyboard and mouse

(Essential for use with a personal computer)

• Parallel-interface printer cable

(Essential for use with a personal computer)

• Microsoft Windows Version 3.1 or higher, set to enhanced

mode

NOTE

For use with a personal computer, printer cable is required to

connect the protector.

Page 22

1. SETUP B-62824EN/02

-2-

1.1.2 Other usable devices

• Printer

Windows printer driver

• Plotter

Only for use with a personal computer

NOTE

The plotter having the command system of HP-GL is supported. HPGL2 or other command system is not supported.

Page 23

B-62824EN/02 1. SETUP

-3-

1.2 Setting Up Symbolic CAP T

1.2.1 About Setup

Start with the setup of the Symbolic CAP T basic module. (When the basic

module has already been set up, and only the optional module is to be set up,

no additional setup is required for the basic module.)

• Preparation

(1) First, create a directory on the hard disk to which the Symbolic CAP

T system program will be stored. (Example: C:\CAP T)

NOTE

Do not set up Symbolic CAP T in the root directory (\).

CAUTION

If other programs, such as FANUC PC FAPT, have already been set

up, do not set up Symbolic CAP T in the same directory as these

programs.

If the same directory is used, both programs may malfunction.

(2) After making sure that the computer and printer are switched off,

attach the protector for the Symbolic CAP T basic module.

NOTE

The open CNC architecture does not require this procedure.

CAUTION

The computer and printer must be switched off while the protector is

being attached.

If the protector is attached or detached while the computer and

printer are switched on, the computer, printer, or protector may be

damaged.

Page 24

1. SETUP B-62824EN/02

-4-

NOTE

If other programs, such as FANUC PC FAPT, have already been set

up, their protectors can be assembled into the Symbolic CAP T basic

module protector. The protectors to be assembled into the Symbolic

CAP T basic module protector must be attached before installing

Super CAP T. They can be removed after a setting has been made

such that they are assembled into the Symbolic CAP T protector.

They can be connected in any order.

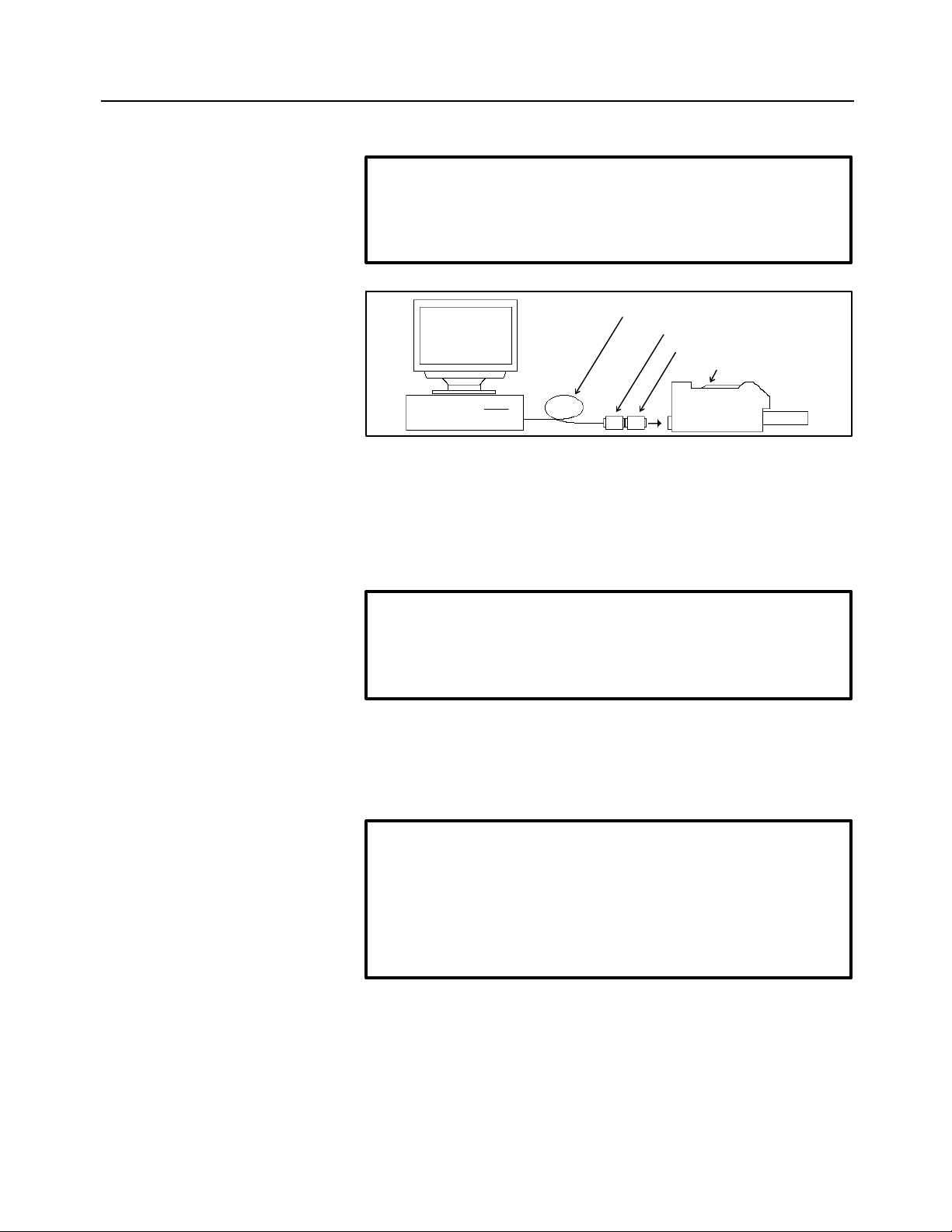

Printer Cable

Protector

Printer

(3) Switch on the computer and start Windows.

• Setup procedure

(1) Insert the basic module floppy disk (labeled FANUC Symbolic CAP

T Basic module Vx Disk#1) into the floppy drive (where x in Vx is a

numeral).

(2) Select File => Run menu of Program Manager for Windows 3.1, or

select Start => Run menu of Task Bar for Windows 95.

(3) Key in drive-name:\SETUP (where drive-name is the name of the

3.5-inch floppy drive into which the floppy disk has been inserted).

Then, click OK.

(4) When the installation process prompts you to specify where Symbolic

CAP T is to be installed, key in the name of the directory where

Symbolic CAP T is to be installed, then press the Continue button.

(5) When the installation process prompts you to specify the data file to

be set up, select a data file, then click Continue.

NOTE

When setting up Symbolic CAP T for the first time, all data files must

be registered.

(6) Installing the sysytem files to the hard disk begins. As the

installation progress, you will be prompted to insert the next floppy

disk. Insert the next disk, then click OK. Repeat this until all of the

floppy disks have been processed.

Page 25

B-62824EN/02 1. SETUP

-5-

(7) When the installation process prompts you to specify the directory

into which each type of data is to be stored, change the directory

name as required, then click OK.

NOTE

When it is necessary to change a directory name, select the desired

data type from the list, then click Change. After selecting or keying in

a new drive name and directory name, click OK.

Even once setup has been completed, the data directory can be

changed by selecting “Setting => Environment” from the Symbolic

CAP T menu.

(8) A prompt is displayed to inquire whether the optional module is to be

set up. Click the Yes or No button.

NOTE

When you click the Yes button, the prompt as provided in step (4) is

displayed. Insert the optional module floppy disk labeled Disk#1,

reenter the installation destination directory name, then select the

Continue button. (The optional module must be installed in the same

directory as for the basic module.) For details, see Section 1.2.2,

“Setting up an optional module.”

(9) Finally, a prompt appears asking whether you want to assemble the

protectors of other softwares, such as FANUC PC FAPT, into the

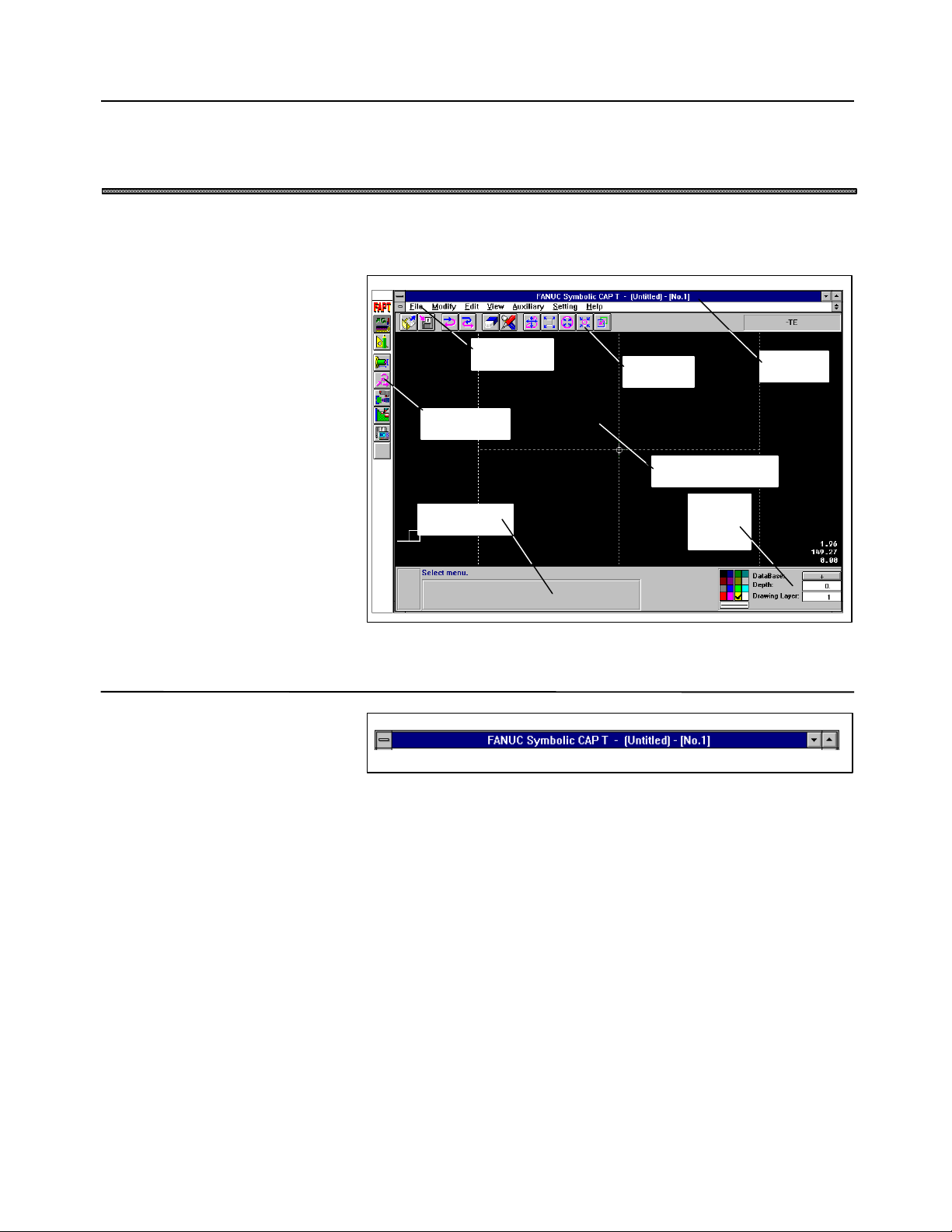

protector of the Symbolic CAP T basic module. Click Yes or No, as