Fanuc AC SERVO Motor αis, AC SERVO Motor αi, SERVO AMPLIFIER αi, AC Spindle Motor αi Maintenance Manual

Page 1

FANUC AC SERVO MOTOR @*s series

@

FANUC AC SERVO MOTOR @* series

FANUC AC SPINDLE MOTOR

FANUC SERVO AMPLIF

IER @* series

MAINTENANCE MANUAL

* series

B-65285EN/03

Page 2

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 3

B-65285EN/03 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The "Safety Precautions" section describes the safety precautions

relating to the use of FANUC servo motors, spindle motors, and servo

amplifiers (power supply modules, servo amplifier modules, and

spindle amplifier modules). Users of any servo motor or amplifier

model are requested to read the "Safety Precautions" carefully before

using the servo motor or amplifier.

The users are also requested to read an applicable specification manual

carefully and understand each function of the motor or amplifier for

correct use.

The users are basically forbidden to do any behavior or action not

mentioned in the "Safety Precautions." They are invited to ask FANUC

previously about what behavior or action is prohibited.

Contents

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE.........s-2

1.2 FANUC AC SERVO MOTOR αis/αi series

FANUC AC SPINDLE MOTOR αi series................................s-3

1.2.1Warning ...........................................................................s-3

1.2.2Caution ...........................................................................s-6

1.2.3Note ...........................................................................s-7

1.3 FANUC SERVO AMPLIFIER αi series ...................................s-9

1.3.1Warnings and Cautions Relating to Mounting ..................s-9

1.3.1.1 Warning.............................................................s-9

1.3.1.2 Caution ............................................................s-11

1.3.1.3 Note .................................................................s-13

1.3.2Warnings and Cautions Relating to a Pilot Run ..............s-14

1.3.2.1 Warning...........................................................s-14

1.3.2.2 Caution ............................................................s-15

1.3.3Warnings and Cautions Relating to Maintenance ...........s-16

1.3.3.1 Warning...........................................................s-16

1.3.4.2 Caution ............................................................s-18

1.3.4.3 Note .................................................................s-19

s-1

Page 4

SAFETY PRECAUTIONS B-65285EN/03

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

* Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-65285EN/03 SAFETY PRECAUTIONS

1.2 FANUC AC SERVO MOTOR α

αis/ααααi series

αα

FANUC AC SPINDLE MOTOR ααααi series

1.2.1 Warning

WARNING

- Be safely dressed when handling a motor.

Wear safety shoes or gloves when handling a motor as you may

get hurt on any edge or protrusion on it or electric shocks.

- Use a crane or lift to move a motor from one place to another.

A motor is heavy. If you lift the motor by hand, you may get a

backache, or you may be seriously injured when you drop the

motor. A suitable crane or lift must be used to move the motor.

(For the weight of motors, refer to their respective specification

manuals.)

When moving a motor using a crane or lift, use a hanging bolt if

the motor has a corresponding tapped hole, or textile rope if it has

no tapped hole.

If a motor is attached with a machine or any other heavy stuff, do

not use a hanging bolt to move the motor as the hanging bolt

and/or motor may get broken.

- Before starting to connect a motor to electric wires, make

sure they are isolated from an electric power source.

A failure to observe this caution is vary dangerous because you

may get electric shocks.

- Be sure to secure power wires.

If operation is performed with a terminal loose, the terminal block

may become abnormally hot, possibly causing a fire. Also, the

terminal may become disconnected, causing a ground fault or

short-circuit, and possibly giving you electric shocks. See the

section in this manual that gives the tightening torque for

attaching power wires and short-bars to the terminal block.

- Be sure to ground a motor frame.

To avoid electric shocks, be sure to connect the grounding

terminal in the terminal box to the grounding terminal of the

machine.

- Do not ground a motor power wire terminal or short-circuit it

to another power wire terminal.

A failure to observe this caution may cause electric shocks or a

burned wiring.

(*) Some motors require a special connection such as a winding

changeover. Refer to their respective motor specification

manuals for details.

s-3

Page 6

SAFETY PRECAUTIONS B-65285EN/03

WARNING

- Do not supply the power to the motor while any terminal is

exposed.

A failure to observe this caution is very dangerous because you

may get electric shocks if your body or any conductive stuff

touches an exposed terminal.

- Do not bring any dangerous stuff near a motor.

Motors are connected to a power line, and may get hot. If a

flammable is placed near a motor, it may be ignited, catch fire, or

explode.

- Do not get close to a rotary section of a motor when it is

rotating.

You may get your clothes or fingers caught in a rotary section, and

may be injured. Before starting a motor, ensure that there is no

stuff that can fly away (such as a key) on the motor.

- Do not touch a motor with a wet hand.

A failure to observe this caution is vary dangerous because you

may get electric shocks.

- Before touching a motor, shut off the power to it.

Even if a motor is not rotating, there may be a voltage across the

terminals of the motor.

Especially before touching a power supply connection, take

sufficient precautions.

Otherwise you may get electric shocks.

- Do not touch any terminal of a motor for a while (at least 5

minutes) after the power to the motor is shut off.

High voltage remains across power line terminals of a motor for a

while after the power to the motor is shut off. So, do not touch any

terminal or connect it to any other equipment. Otherwise, you may

get electric shocks or the motor and/or equipment may get

damaged.

- To drive a motor, use a specified amplifier and parameters.

Driving a motor with other than the specified combinations of an

amplifier and parameters may cause the motor to perform an

unexpected operation; for example, the motor may get out of

control, or produce excessively high torque. This may result in the

motor or machine being damaged. Also, an object such as a

workpiece or tool may fly off due to excessive rotation, possibly

causing injury.

s-4

Page 7

B-65285EN/03 SAFETY PRECAUTIONS

- Do not touch a regenerative discharge unit for a while (at

least 30 minutes) after the power to the motor is shut off.

A regenerative discharge unit may get hot when the motor is

running.

Do not touch the regenerative discharge unit before it gets cool

enough. Otherwise, you may get burned.

- Do not touch a motor when it is running or immediately after

it stops.

A motor may get hot when it is running. Do not touch the motor

before it gets cool enough. Otherwise, you may get burned.

- Ensure that motors and related components are mounted

securely.

If a motor or its component slips out of place or comes off when

the motor is running, it is very dangerous.

- Be careful not get your hair or cloths caught in a fan.

Be careful especially for a fan used to generate an inward air flow.

Be careful also for a fan even when the motor is stopped, because

it continues to rotate while the amplifier is turned on.

- When designing and assembling a machine tool, make it

compliant with EN60204-1.

To ensure the safety of the machine tool and satisfy European

standards, when designing and assembling a machine tool, make it

compliant with EN60204-1. For details of the machine tool, refer

to its specification manual.

s-5

Page 8

SAFETY PRECAUTIONS B-65285EN/03

1.2.2 Caution

CAUTION

- FANUC motors are designed for use with machines. Do not

use them for any other purpose.

If a FANUC motor is used for an unintended purpose, it may

cause an unexpected symptom or trouble. If you want to use a

motor for an unintended purpose, previously consult with

FANUC.

- Ensure that a base or frame on which a motor is mounted is

strong enough.

Motors are heavy. If a base or frame on which a motor is mounted

is not strong enough, it is impossible to achieve the required

precision.

- Be sure to connect motor cables correctly.

An incorrect connection of a cable cause abnormal heat

generation, equipment malfunction, or failure. Always use a cable

with an appropriate current carrying capacity (or thickness). For

how to connect cables to motors, refer to their respective

specification manuals.

- Ensure that motors are cooled if they are those that require

forcible cooling.

If a motor that requires forcible cooling is not cooled normally, it

may cause a failure or trouble. For a fan-cooled motor, ensure that

it is not clogged or blocked with dust and dirt. For a liquid-cooled

motor, ensure that the amount of the liquid is appropriate and that

the liquid piping is not clogged.

For both types, perform regular cleaning and inspection.

- When attaching a component having inertia, such as a pulley,

to a motor, ensure that any imbalance between the motor and

component is minimized.

If there is a large imbalance, the motor may vibrates abnormally,

resulting in the motor being broken.

- Be sure to attach a key to a motor with a keyed shaft.

If a motor with a keyed shaft runs with no key attached, it may

impair torque transmission or cause imbalance, resulting in the

motor being broken.

s-6

Page 9

B-65285EN/03 SAFETY PRECAUTIONS

1.2.3 Note

NOTE

- Do not step or sit on a motor.

If you step or sit on a motor, it may get deformed or broken. Do

not put a motor on another unless they are in packages.

- When storing a motor, put it in a dry (non-condensing) place

at room temperature (0 to 40°°°°C).

If a motor is stored in a humid or hot place, its components may

get damaged or deteriorated. In addition, keep a motor in such a

position that its shaft is held horizontal and its terminal box is at

the top.

- Do not remove a nameplate from a motor.

If a nameplate comes off, be careful not to lose it. If the nameplate

is lost, the motor becomes unidentifiable, resulting in

maintenance becoming impossible.

For a nameplate for a built-in spindle motor, keep the nameplate

with the spindle.

- Do not apply shocks to a motor or cause scratches to it.

If a motor is subjected to shocks or is scratched, its components

may be adversely affected, resulting in normal operation being

impaired. Be very careful when handling plastic portions, sensors,

and windings, because they are very liable to break. Especially,

avoid lifting a motor by pulling its plastic portion, winding, or

power cable.

- Do not conduct dielectric strength or insulation test for a

sensor.

Such a test can damage elements in the sensor.

- When testing the winding or insulation resistance of a motor,

satisfy the conditions stipulated in IEC60034.

Testing a motor under a condition severer than those specified in

IEC34 may damage the motor.

- Do not disassemble a motor.

Disassembling a motor may cause a failure or trouble in it.

If disassembly is in need because of maintenance or repair, please

contact a service representative of FANUC.

- Do not modify a motor.

Do not modify a motor unless directed by FANUC. Modifying a

motor may cause a failure or trouble in it.

s-7

Page 10

SAFETY PRECAUTIONS B-65285EN/03

NOTE

- Use a motor under an appropriate environmental condition.

Using a motor in an adverse environment may cause a failure or

trouble in it.

Refer to their respective specification manuals for details of the

operating and environmental conditions for motors.

- Do not apply a commercial power source voltage directly to a

motor.

Applying a commercial power source voltage directly to a motor

may result in its windings being burned. Be sure to use a specified

amplifier for supplying voltage to the motor.

- For a motor with a terminal box, make a conduit hole for the

terminal box in a specified position.

When making a conduit hole, be careful not to break or damage

unspecified portions.

Refer to an applicable specification manual.

- Before using a motor, measure its winding and insulation

resistances, and make sure they are normal.

Especially for a motor that has been stored for a prolonged period

of time, conduct these checks. A motor may deteriorate depending

on the condition under which it is stored or the time during which

it is stored. For the winding resistances of motors, refer to their

respective specification manuals, or ask FANUC. For insulation

resistances, see the following table.

- To use a motor as long as possible, perform periodic

maintenance and inspection for it, and check its winding and

insulation resistances.

Note that extremely severe inspections (such as dielectric strength

tests) of a motor may damage its windings. For the winding

resistances of motors, refer to their respective specification

manuals, or ask FANUC. For insulation resistances, see the

following table.

MOTOR INSULATION RESISTANCE MEASUREMENT

Measure an insulation resistance between each winding and

motor frame using an insulation resistance meter (500 VDC).

Judge the measurements according to the following table.

Insulation resistance Judgment

100MΩ or higher Acceptable

10 to 100 MΩ The winding has begun deteriorating. There is no

problem with the performance at present. Be sure

to perform periodic inspection.

1 to 10 MΩ The winding has considerably deteriorated.

Special care is in need. Be sure to perform

periodic inspection.

Lower than 1 MΩ Unacceptable. Replace the motor.

s-8

Page 11

B-65285EN/03 SAFETY PRECAUTIONS

1.3 FANUC SERVO AMPLIFIER α

αi series

αα

1.3.1 Warnings and Cautions Relating to Mounting

1.3.1.1 Warning

WARNING

- Check the specification code of the amplifier.

Check that the delivered amplifier is as originally ordered.

- Mount a ground fault interrupter.

To guard against fire and electric shock, fit the factory power

supply or machine with a ground fault interrupter (designed for

use with an inverter).

- Securely ground the amplifier.

Securely connect the ground terminal and metal frame of the

amplifier and motor to a common ground plate of the power

magnetics cabinet.

- Be aware of the weight of the amplifier and other

components.

Control motor amplifiers and AC reactors are heavy. When

transporting them or mounting them in the cabinet, therefore, be

careful not to injured yourself or damage the equipment. Be

particularly carefull not to jam your fingers between the cabinet

and amplifier.

- Never ground or short-circuit either the power supply lines or

power lines.

Protect the lines from any stress such as bending. Handle the ends

appropriately.

- Ensure that the power supply lines, power lines, and signal

lines are securely connected.

A loose screw, loose connection, or the like will cause a motor

malfunction or overheating, or a ground fault.

Be extremely careful with power supply lines, motor power lines,

and DC link connections through which a large amount of current

passes, because a loose screw (or poor contact in a connector or

poor connection between a connector terminal and a cable) may

cause a fire.

- Insulate all exposed parts that are charged.

s-9

Page 12

SAFETY PRECAUTIONS B-65285EN/03

WARNING

- Never touch the regenerative discharge resistor or radiator

directly.

The surface of the radiator and regenerative discharge unit

become extremely hot. Never touch them directly. An appropriate

structure should also be considered.

- Close the amplifier cover after completing the wiring.

Leaving the cover open presents a danger of electric shock.

- Do not disassemble the amplifier.

- Ensure that the cables used for the power supply lines and

power lines are of the appropriate diameter and temperature

ratings.

- Do not apply an excessively large force to plastic parts.

If a plastic section breaks, it may cause internal damage, thus

interfering with normal operation. The edge of a broken section is

likely to be sharp and, therefore, presents a risk of injury.

s-10

Page 13

B-65285EN/03 SAFETY PRECAUTIONS

1.3.1.2 Caution

CAUTION

- Do not step or sit on the amplifier.

Also, do not stack unpacked amplifiers on top of each other.

- Use the amplifier in an appropriate environment.

See the allowable ambient temperatures and other requirements,

given in the corresponding descriptions.

- Protect the amplifier from corrosive or conductive mist or

drops of water.

Use a filter if necessary.

- Protect the amplifier from impact.

Do not place anything on the amplifier.

- Connect the power supply lines and power lines to the

appropriate terminals and connectors.

- Connect the signal lines to the appropriate connectors.

- Do not block the air inlet to the radiator.

A deposit of coolant, oil mist, or chips on the air inlet will result in

a reduction in the cooling efficiency. In some cases, the required

efficiency cannot be achieved. The deposit may also lead to a

reduction in the useful life of the semiconductors. Especially,

when outside air is drawn in, mount filters on both the air inlet and

outlet. These filters must be replaced regularly.

So, an easy-to-replace type of filter should be used.

- Before connecting the power supply wiring, check the supply

voltage.

Check that the supply voltage is within the range specified in this

manual, then connect the power supply lines.

- Ensure that the combination of motor and amplifier is

appropriate.

- Ensure that valid parameters are specified.

Specifying an invalid parameter for the combination of motor and

amplifier may not only prevent normal operation of the motor but

also result in damage to the amplifier.

- Ensure that the amplifier and peripheral equipment are

securely connected.

Check that the magnetic contactor, circuit breaker, and other

devices mounted outside the amplifier are securely connected to

each other and that those devices are securely connected to the

amplifier.

s-11

Page 14

SAFETY PRECAUTIONS B-65285EN/03

CAUTION

- Check that the amplifier is securely mounted in the power

magnetics cabinet.

If any clearance is left between the power magnetics cabinet and

the surface on which the amplifier is mounted, dust entering the

gap may build up and prevent the normal operation of the

amplifier.

- Apply appropriate countermeasures against noise.

Adequate countermeasures against noise are required to maintain

normal operation of the amplifier. For example, signal lines must

be routed away from power supply lines and power lines.

s-12

Page 15

B-65285EN/03 SAFETY PRECAUTIONS

1.3.1.3 Note

NOTE

- Keep the nameplate clearly visible.

- Keep the legend on the nameplate clearly visible.

- After unpacking the amplifier, carefully check for any

damage.

- Mount the amplifier in a location where it can be easily

accessed periodic inspection and daily maintenance.

- Leave sufficient space around the machine to enable

maintenance to be performed easily.

Do not place any heavy objects such that they would interfere

with the opening of the doors.

- Keep the parameter table and spare parts at hand.

Also, keep the specifications at hand. These items must be stored

in a location where they can be retrieved immediately.

- Provide adequate shielding.

A cable to be shielded must be securely connected to the ground

plate, using a cable clamp or the like.

s-13

Page 16

SAFETY PRECAUTIONS B-65285EN/03

1.3.2 Warnings and Cautions Relating to a Pilot Run

1.3.2.1 Warning

WARNING

- Before turning on the power, check that the cables connected

to the power magnetics cabinet and amplifier, as well as the

power lines and power supply lines, are securely connected.

Also, check that no lines are slack.

A loose screw, loose connection, or the like will cause a motor

malfunction or overheating, or a ground fault. Be extremely

careful with power supply lines, motor power lines, and DC link

connections through which a large amount of current passes,

because a loose screw (or poor contact in a connector or poor

connection between a connector terminal and a cable) may cause a

fire.

- Before turning on the power, ensure that the power magnetics

cabinet is securely grounded.

- Before turning on the power, check that the door of the power

magnetics cabinet and all other doors are closed.

Ensure that the door of the power magnetics cabinet containing

the amplifier, and all other doors, are securely closed. During

operation, all doors must be closed and locked.

- Apply extreme caution if the door of the power magnetics

cabinet or another door must be opened.

Only a person trained in the maintenance of the corresponding

machine or equipment should open the door, and only after

shutting off the power supply to the power magnetics cabinet (by

opening both the input circuit breaker of the power magnetics

cabinet and the factory switch used to supply power to the

cabinet). If the machine must be operated with the door open to

enable adjustment or for some other purpose, the operator must

keep his or her hands and tools well away from any dangerous

voltages. Such work must be done only by a person trained in the

maintenance of the machine or equipment.

- When operating the machine for the first time, check that the

machine operates as instructed.

To check whether the machine operates as instructed, first specify

a small value for the motor, then increase the value gradually. If

the motor operates abnormally, perform an emergency stop

immediately.

- After turning on the power, check the operation of the

emergency stop circuit.

Press the emergency stop button to check that the motor stops

immediately, and that the power being supplied to the amplifier is

shut off by the magnetic contactor.

s-14

Page 17

B-65285EN/03 SAFETY PRECAUTIONS

- Before opening a door or protective cover of a machine to

enable adjustment of the machine, first place the machine in

the emergency stop state and check that the motor has

stopped.

s-15

Page 18

SAFETY PRECAUTIONS B-65285EN/03

1.3.2.2 Caution

CAUTION

- Note whether an alarm status relative to the amplifier is

displayed at power-up or during operation.

If an alarm is displayed, take appropriate action as explained in

the maintenance manual. If the work to be done requires that the

door of the power magnetics cabinet be left open, the work must

be carried out by a person trained in the maintenance of the

machine or equipment. Note that if some alarms are forcibly reset

to enable operation to continue, the amplifier may be damaged.

Take appropriate action according to the contents of the alarm.

- Before operating the motor for the first time, mount and

adjust the position and speed sensors.

Following the instructions given in the maintenance manual,

adjust the position and speed sensors for the spindle so that an

appropriate waveform is obtained.

If the sensors are not properly adjusted, the motor may not rotate

normally or the spindle may fail to stop as desired.

- If the motor makes any abnormal noise or vibration while

operating, stop it immediately.

Note that if operation is continued in spite of there being some

abnormal noise or vibration, the amplifier may be damaged. Take

appropriate corrective action, then resume operation.

- Observe the ambient temperature and output rating

requirements.

The continuous output rating or continuous operation period of

some amplifiers may fall as the ambient temperature increases. If

the amplifier is used continuously with an excessive load applied,

the amplifier may be damaged.

- Unless otherwise specified, do not insert or remove any

connector while the power is turned on. Otherwise, the

amplifier may fail.

s-16

Page 19

B-65285EN/03 SAFETY PRECAUTIONS

1.3.3 Warnings and Cautions Relating to Maintenance

1.3.3.1 Warning

WARNING

- Read the maintenance manual carefully and ensure that you

are totally familiar with its contents.

The maintenance manual describes daily maintenance and the

procedures to be followed in the event of an alarm being issued.

The operator must be familiar with these descriptions.

- Notes on replacing a fuse or PC board

1) Before starting the replacement work, ensure that the circuit

breaker protecting the power magnetics cabinet is open.

2) Check that the red LED that indicates that charging is in

progress is not lit.

The position of the charging LED on each model of amplifier

is given in this manual. While the LED is lit, hazardous

voltages are present inside the unit, and thus there is a danger

of electric shock.

3) Some PC board components become extremely hot. Be

careful not to touch these components.

4) Ensure that a fuse having an appropriate rating is used.

5) Check the specification code of a PC board to be replaced. If

a modification drawing number is indicated, contact FANUC

before replacing the PC board.

Also, before and after replacing a PC board, check its pin

settings.

6) After replacing the fuse, ensure that the screws are firmly

tightened. For a socket-type fuse, ensure that the fuse is

inserted correctly.

7) After replacing the PC board, ensure that it is securely

connected.

8) Ensure that all power lines, power supply lines, and

connectors are securely connected.

- Take care not to lose any screws.

When removing the case or PC board, take care not to lose any

screws. If a screw is lost inside the nit and the power is turned on,

the machine may be damaged.

s-17

Page 20

SAFETY PRECAUTIONS B-65285EN/03

WARNING

- Notes on replacing the battery of the absolute pulse coder

Replace the battery only while the power is on. If the battery is

replaced while the power is turned off, the stored absolute

positioning data will be lost. Some series servo amplifier modules

have batteries in their servo amplifiers. To replace the battery of

any of those models, observe the following procedure: Open the

door of the power magnetics cabinet; Leave the control power of

the power supply module on; Place the machine in the emergency

stop state so that the power being input to the amplifier is shut off;

Then, replace the battery. Replacement work should be done only

by a person who is trained in the related maintenance and safety

requirements. The power magnetics cabinet in which the servo

amplifier is mounted has a high-voltage section. This section

presents a severe risk of electric shock.

- Check the number of any alarm.

If the machine stops upon an alarm being issued, check the alarm

number. Some alarms indicate that a component must be replaced.

If the power is reconnected without first replacing the failed

component, another component may be damaged, making it

difficult to locate the original cause of the alarm.

- Before resetting an alarm, ensure that the original cause of

the alarm has been removed.

- Contact FANUC whenever a question relating to

maintenance arises.

- Notes on removing the amplifier

Before removing the amplifier, first ensure that the power is shut

off. Be careful not to jam your fingers between the power

magnetics cabinet and amplifier.

s-18

Page 21

B-65285EN/03 SAFETY PRECAUTIONS

1.3.3.2 Caution

CAUTION

- Ensure that all required components are mounted.

When replacing a component or PC board, check that all

components, including the snubber capacitor, are correctly

mounted. If the snubber capacitor is not mounted, for example, the

IPM will be damaged.

- Tighten all screws firmly.

- Check the specification code of the fuse, PC board, and other

components.

When replacing a fuse or PC board, first check the specification

code of the fuse or PC board, then mount it in the correct position.

The machine will not operate normally if a fuse or PC board

having other than the correct specification code is mounted, or if a

fuse or PC board is mounted in the wrong position.

- Mount the correct cover.

The cover on the front of the amplifier carries a label indicating a

specification code. When mounting a previously removed front

cover, take care to mount it on the unit from which it was

removed.

- Notes on cleaning the heat sink and fan

1) A dirty heat sink or fan results in reduced semiconductor

cooling efficiency, which degrades reliability. Periodic

cleaning is necessary.

2) Using compressed air for cleaning scatters the dust. A

deposit of conductive dust on the amplifier or peripheral

equipment will result in a failure.

3) To clean the heat sink, do so only after turning the power off

and ensuring that the heat sink has cooled to room

temperature. The heat sink becomes extremely hot, such that

touching it during operation or immediately after power-off

is likely to cause a burn. Be extremely careful when touching

the heat sink.

s-19

Page 22

SAFETY PRECAUTIONS B-65285EN/03

1.3.3.3 Note

NOTE

- Ensure that the battery connector is correctly inserted.

If the power is shut off while the battery connector is not

connected correctly, the absolute position data for the machine

will be lost.

- Store the manuals in a safe place.

The manuals should be stored in a location where they can be

accessed immediately it so required during maintenance work.

- Notes on contacting FANUC

Inform FANUC of the details of an alarm and the specification

code of the amplifier so that any components required for

maintenance can be quickly secured, and any other necessary

action can be taken without delay.

s-20

Page 23

B-65285EN/03 PREFACE

PREFACE

Organization of this manual

This manual describes information necessary to maintain FANUC

servo amplifier αi series products, such as a power supply module,

servo amplifier module, and spindle amplifier module and FANUC

servo motor αis/αi series and FANUC spindle motor αi series

products.

Part I explains the start-up procedure, and part II focuses on

troubleshooting.

Part III explains the maintenance for servo motor and spindle motor.

The abbreviations listed below are used in this manual.

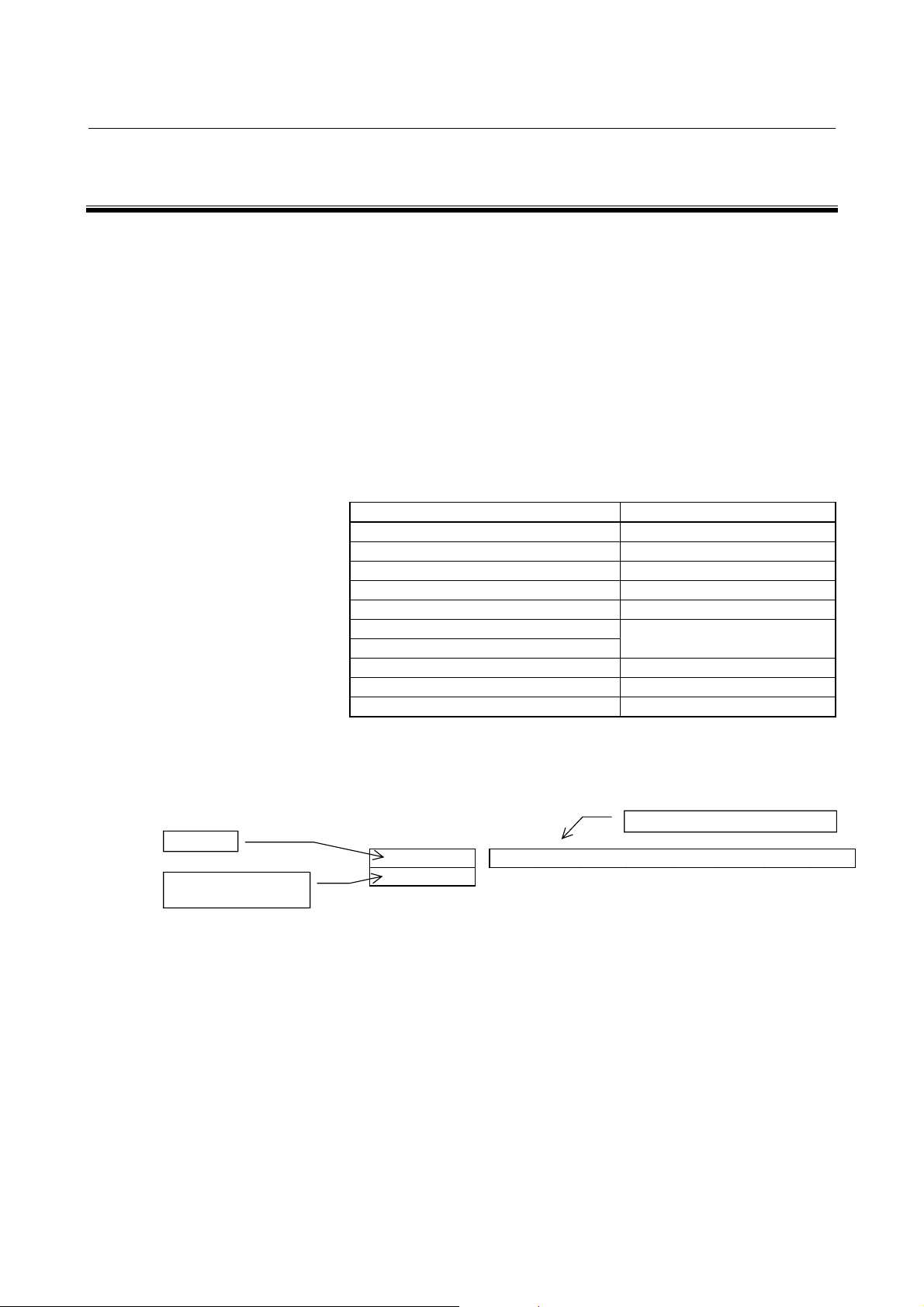

Product name Abbreviations

FANUC Series 15i FS15i

FANUC Series 16i FS16i

FANUC Series 18i FS18i

FANUC Series 21i FS21i

FANUC Series 0i FS0i

FANUC Power Mate i-D

FANUC Power Mate i-H

Power Supply Module PSM

Servo Amplifier Module SVM

Spindle Amplifier Module SPM

PMi

Series 15

Series 16i, 18i, 21i, 0i, PM

i

* In this manual, the parameter numbers of servo parameters are

sometimes indicated without CNC product names as follows:

Servo parameter function name or bit

No. 1877 (FS15i)

i

No. 2062 (FS16i)

Overload protection coefficient (OVC1)

* The manuals shown below provide information related to this

manual. This manual may refer you to these manuals.

FANUC SERVO AMPLIFIER αi series Descriptions B-65282EN

FANUC AC SERVO MOTOR αis/αi series Descriptions B-65262EN

FANUC AC SPINDLE MOTOR αi series Descriptions B-65272EN

FANUC AC SERVO MOTOR αis/αi series Parameter Manual

B-65270EN

FANUC AC SPINDLE MOTOR αi series Parameter Manual

B-65280EN

p-1

Page 24

Page 25

B-65285EN/03 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS.......................................................................... s-1

PREFACE.................................................................................................. p-1

I. START-UP PROCEDURE

1 OVERVIEW ............................................................................................3

2 CONFIGURATIONS ...............................................................................4

2.1 CONFIGURATIONS ......................................................................................5

2.2 MAJOR COMPONENTS................................................................................7

2.2.1 Power Supply Modules............................................................................................ 7

2.2.2 Servo Amplifier Modules........................................................................................ 8

2.2.3 Spindle Amplifier Modules ..................................................................................... 9

3 START-UP PROCEDURE....................................................................11

3.1 START-UP PROCEDURE (OVERVIEW) ....................................................12

3.2 CONNECTING THE POWER ......................................................................13

3.2.1 Checking the Voltage and Capacity of the Power................................................. 13

3.2.2 Connecting a Protective Ground............................................................................ 14

3.2.3 Selecting the Ground Fault Interrupter That Matches the Leakage Current......... 14

3.3 INITIALIZING SERVO PARAMETERS........................................................15

4 CONFIRMATION OF THE OPERATION..............................................16

4.1 POWER SUPPLY MODULE........................................................................17

4.1.1 Checking the Status LEDs..................................................................................... 18

4.1.2 Check Terminal on the Printed-circuit Board ....................................................... 19

4.1.3 The PIL LED (Power ON Indicator) Is Off........................................................... 21

4.1.4 Checking Method when Magnetic Contactor Is not Switched On........................ 22

4.2 SERVO AMPLIFIER MODULE ....................................................................23

4.2.1 Checking the STATUS Display ............................................................................ 24

4.2.2 VRDY-OFF Alarm Indicated on the CNC Screen ................................................ 25

4.2.3 Method for Observing Motor Current ................................................................... 26

4.3 SPINDLE AMPLIFIER MODULE .................................................................29

4.3.1 STATUS Display................................................................................................... 30

4.3.2 Troubleshooting at Startup .................................................................................... 31

4.3.2.1 The PIL LED (power-on indicator) is off...........................................................31

4.3.2.2 The STATUS display is blinking with "--." .......................................................32

c-1

Page 26

TABLE OF CONTENTS B-65285EN/03

4.3.2.3 The motor does not turn..................................................................................... 33

4.3.2.4 A specified speed cannot be obtained. ...............................................................33

4.3.2.5 When cutting is not performed, the spindle vibrates, making noise. .................. 34

4.3.2.6 An overshoot or hunting occurs. ........................................................................34

4.3.2.7 Cutting power weakens or acceleration/deceleration slows down...................... 35

4.3.3 Status Error Indication Function ........................................................................... 36

4.3.4 Checking the Feedback Signal Waveform ............................................................ 39

4.3.4.1 Mi, MZi, and BZi sensors ..................................................................................40

4.3.4.2 α position coder S ..............................................................................................41

4.3.5 Spindle Check Board............................................................................................. 42

4.3.5.1 Spindle check board specifications ....................................................................42

4.3.5.2 Check board connection..................................................................................... 42

4.3.5.3 Check terminal output signals ............................................................................44

4.3.6 Observing Data Using the Spindle Check Board .................................................. 46

4.3.6.1 Overview............................................................................................................ 46

4.3.6.2 Major characteristics .......................................................................................... 46

4.3.6.3 Observation method ...........................................................................................46

4.3.6.4 Specifying data to be monitored......................................................................... 47

4.3.6.5 Address descriptions and initial values (SPM)...................................................48

4.3.6.6 Principles in outputting the internal data of the serial spindle............................49

4.3.6.7 Data numbers .....................................................................................................53

4.3.6.8 Example of observing data.................................................................................56

4.3.7 Checking Parameters Using the Spindle Check Board.......................................... 57

4.3.7.1 Overview............................................................................................................ 57

4.3.7.2 Checking parameters .......................................................................................... 57

4.3.8 Observing Data Using the SERVO GUIDE .......................................................... 58

4.3.8.1 Overview............................................................................................................ 58

4.3.8.2 Usable series and editions ..................................................................................58

4.3.8.3 List of spindle data that can be observed using the SERVO GUIDE................. 58

4.3.8.4 About the spindle control and spindle status signals..........................................59

4.3.8.5 Example of observing data.................................................................................60

5 PERIODIC MAINTENANCE OF SERVO AMPLIFIER..........................61

5.1 BATTERY FOR THE ABSOLUTE PULSECODER......................................62

5.2 PERIODIC MAINTENANCE OF SERVO AMPLIFIER .................................69

II. TROUBLESHOOTING

1 OVERVIEW ..........................................................................................75

2 ALARM NUMBERS AND BRIEF DESCRIPTIONS ..............................76

2.1 FOR Series 15i ............................................................................................77

2.1.1 Servo Alarm........................................................................................................... 77

c-2

Page 27

B-65285EN/03 TABLE OF CONTENTS

2.1.2 Spindle Alarm........................................................................................................ 79

2.2 FOR Series 16i, 18i, 20i, 21i, 0i, AND Power Mate i...................................81

2.2.1 Servo Alarm........................................................................................................... 81

2.2.2 Spindle Alarm........................................................................................................ 83

3 TROUBLESHOOTING AND ACTION ..................................................85

3.1 POWER SUPPLY MODULE (PSM, PSMR) ................................................86

3.1.1 Alarm Code 1 (PSM)............................................................................................. 86

3.1.2 Alarm Code 2 (PSM, PSMR) ................................................................................ 87

3.1.3 Alarm Code 3 (PSM)............................................................................................. 87

3.1.4 Alarm Code 4 (PSM, PSMR) ................................................................................ 87

3.1.5 Alarm Code 5 (PSM, PSMR) ................................................................................ 88

3.1.6 Alarm Code 6 (PSM, PSMR) ................................................................................ 88

3.1.7 Alarm Code 7 (PSM, PSMR) ................................................................................ 88

3.1.8 Alarm Code 8 (PSMR) .......................................................................................... 89

3.1.9 Alarm Code A (PSM)............................................................................................ 89

3.1.10 Alarm Code E (PSM, PSMR)................................................................................ 89

3.1.11 Alarm Code H (PSMR) ......................................................................................... 90

3.2 SERVO AMPLIFIER MODULE ....................................................................91

3.2.1 Alarm Code 1......................................................................................................... 93

3.2.2 Alarm Code 2......................................................................................................... 93

3.2.3 Alarm Code 5......................................................................................................... 93

3.2.4 Alarm Code 6......................................................................................................... 94

3.2.5 Alarm Code F ........................................................................................................ 94

3.2.6 Alarm Code P ........................................................................................................ 94

3.2.7 Alarm Code 8......................................................................................................... 95

3.2.8 Alarm Codes 8., 9., and A. .................................................................................... 96

3.2.9 Alarm Codes 8., 9., and A. .................................................................................... 96

3.2.10 Alarm Codes b, c, and d ........................................................................................ 97

3.2.11 Alarm Code "-" Blinking....................................................................................... 98

3.2.12 Alarm Code U........................................................................................................ 99

3.2.13 Alarm Code L ...................................................................................................... 100

3.3 SERVO SOFTWARE .................................................................................101

3.3.1 Servo Adjustment Screen .................................................................................... 101

3.3.2 Diagnosis Screen ................................................................................................. 103

3.3.3 Overload Alarm (Soft Thermal, OVC)................................................................ 104

3.3.4 Feedback Disconnected Alarm............................................................................ 105

3.3.5 Overheat Alarm ................................................................................................... 106

c-3

Page 28

TABLE OF CONTENTS B-65285EN/03

3.3.6 Invalid Servo Parameter Setting Alarm............................................................... 106

3.3.7 Alarms Related to Pulsecoder and Separate Serial Detector............................... 107

3.3.8 Other Alarms ....................................................................................................... 110

3.4 SPINDLE AMPLIFIER MODULE ...............................................................112

3.4.1 Alarm Code 01..................................................................................................... 112

3.4.2 Alarm Code 02..................................................................................................... 113

3.4.3 Alarm Code 03..................................................................................................... 114

3.4.4 Alarm Code 06..................................................................................................... 114

3.4.5 Alarm Code 07..................................................................................................... 115

3.4.6 Alarm Code 09..................................................................................................... 116

3.4.7 Alarm Code 12..................................................................................................... 117

3.4.8 Alarm Code 15..................................................................................................... 118

3.4.9 Alarm Code 18..................................................................................................... 118

3.4.10 Alarm Codes 19 and 20 ....................................................................................... 118

3.4.11 Alarm Code 21..................................................................................................... 119

3.4.12 Alarm Code 24..................................................................................................... 119

3.4.13 Alarm Code 27..................................................................................................... 120

3.4.14 Alarm Code 29..................................................................................................... 121

3.4.15 Alarm Code 31..................................................................................................... 122

3.4.16 Alarm Code 32..................................................................................................... 122

3.4.17 Alarm Code 34..................................................................................................... 122

3.4.18 Alarm Code 36..................................................................................................... 123

3.4.19 Alarm Code 37..................................................................................................... 123

3.4.20 Alarm Code 41..................................................................................................... 124

3.4.21 Alarm Code 42..................................................................................................... 124

3.4.22 Alarm Code 46..................................................................................................... 124

3.4.23 Alarm Code 47..................................................................................................... 125

3.4.24 Alarm Code 50..................................................................................................... 125

3.4.25 Alarm Codes 52 and 53 ....................................................................................... 126

3.4.26 Alarm Code 54..................................................................................................... 126

3.4.27 Alarm Code 55..................................................................................................... 126

3.4.28 Alarm Code 56..................................................................................................... 126

3.4.29 Alarm Code 66..................................................................................................... 127

3.4.30 Alarm Code 69..................................................................................................... 127

3.4.31 Alarm Code 70..................................................................................................... 127

3.4.32 Alarm Code 71..................................................................................................... 127

3.4.33 Alarm Code 72..................................................................................................... 127

c-4

Page 29

B-65285EN/03 TABLE OF CONTENTS

3.4.34 Alarm Code 73..................................................................................................... 128

3.4.35 Alarm Code 74..................................................................................................... 128

3.4.36 Alarm Code 75..................................................................................................... 128

3.4.37 Alarm Code 76..................................................................................................... 129

3.4.38 Alarm Code 77..................................................................................................... 129

3.4.39 Alarm Code 78..................................................................................................... 129

3.4.40 Alarm Code 79..................................................................................................... 129

3.4.41 Alarm Code 81..................................................................................................... 130

3.4.42 Alarm Code 82..................................................................................................... 131

3.4.43 Alarm Code 83..................................................................................................... 131

3.4.44 Alarm Code 84..................................................................................................... 132

3.4.45 Alarm Code 85..................................................................................................... 132

3.4.46 Alarm Code 86..................................................................................................... 132

3.4.47 Alarm Code 87..................................................................................................... 132

3.4.48 Alarm Code 88..................................................................................................... 132

3.4.49 Alarm Codes A, A1, and A2................................................................................ 132

3.4.50 Alarm Code b0..................................................................................................... 133

3.4.51 Alarm Codes C0,C1, and C2 ............................................................................... 133

3.4.52 Alarm Code C3.................................................................................................... 133

3.4.53 Other Alarms ....................................................................................................... 134

3.5 αCi SERIES SPINDLE AMPLIFIER MODULE ..........................................135

3.5.1 Alarm Code 12..................................................................................................... 135

3.5.2 Alarm Code 35..................................................................................................... 136

4 HOW TO REPLACE THE FUSES AND PRINTED CIRCUIT

BOARDS ............................................................................................137

4.1 HOW TO REPLACE THE FUSES AND PRINTED CIRCUIT BOARDS ....138

4.1.1 Ordering Number of Printed Circuit Board......................................................... 139

4.1.2 Fuse Locations..................................................................................................... 140

4.1.2.1 PSM .............................................................................................................. 140

4.1.2.2 SVM .............................................................................................................. 141

4.1.2.3 SPM ..............................................................................................................142

4.2 HOW TO REPLACE THE FAN MOTOR.................................................... 143

4.2.1 Internal-Fan Motor Replacement Procedure Common to 60, 90, and 150 mm

Wide Units........................................................................................................... 143

4.2.2 External-Fan Motor Replacement Procedure for 60 and 90 mm Wide Units ..... 144

4.2.3 External-Fan Motor Replacement Procedure for 150 mm Wide Unit................. 145

4.2.4 External-Fan Motor Replacement Procedure for 300 mm Wide Unit................. 146

c-5

Page 30

TABLE OF CONTENTS B-65285EN/03

III. MOTOR MAINTENANCE

1 SERVO MOTOR MAINTENANCE......................................................149

1.1 RECEIVING AND KEEPING AC SERVO MOTORS .................................150

1.2 DAILY INSPECTION OF AC SERVO MOTORS .......................................151

1.3 PERIODIC INSPECTION OF AC SERVO MOTORS ................................153

1.4 REPLACING THE PULSECODER ............................................................156

1.5 SPECIFICATION NUMBERS OF REPLACEMENT PARTS......................158

2 SPINDLE MOTOR MAINTENANCE...................................................159

2.1 PREVENTIVE MAINTENANCE .................................................................160

2.2 MAINTENANCE PARTS............................................................................163

2.3 ALLOWABLE RADIAL LOAD ....................................................................167

c-6

Page 31

I. START-UP PROCEDURE

Page 32

Page 33

B-65285EN/03 START-UP PROCEDURE 1.OVERVIEW

1 OVERVIEW

This part describes the units and components of the FANUC servo

amplifier αi series. It also explains the following information necessary

to start up the control motor amplifier:

• Configurations

• Start-up procedure

• Confirmation of the operation

• Periodic maintenance of servo amplifier

- 3 -

Page 34

2.CONFIGURATIONS START-UP PROCEDURE B-65285EN/03

2 CONFIGURATIONS

- 4 -

Page 35

B-65285EN/03 START-UP PROCEDURE 2.CONFIGURATIONS

2.1 CONFIGURATIONS

The FANUC servo amplifier αi series consists of the units and

components listed below:

(1) Power supply module (PSM) (basic)

(2) Servo amplifier module (SVM) (basic)

(3) Spindle amplifier module (SPM) (basic)

(4) AC reactor (basic)

(5) Connectors (for connecting cables) (basic)

(6) Fuses (option)

(7) Power transformer (option)

- 5 -

Page 36

2.CONFIGURATIONS START-UP PROCEDURE B-65285EN/03

φ

Constituent (example)

200 to 240VAC

3φ

Circuit

breaker 2

Circuit

breaker 1

Magnetic

contactor

Lightning

surge

protector

1φ

AC reactor

200R,200S

Lightning

surge

protector

Power supply

module

PSM

3φ

3

fan motor

Spindle amplifier

module

SPM

Spindle motor

Servo amplifier

module

SVM2

DC link

(300V DC)

Servo motor

Units prepared by the machine tool builder

NOTE

1 See Chapter 4 in the Servo Amplifier αi series

Descriptions for details of how to combine the power

supply module, servo amplifier modules, and spindle

amplifier modules.

2 A magnetic contactor, AC reactor, and circuit

breakers are always required.

3 To protect the unit from surge currents caused by

lightning, connect surge absorbers between lines,

and between the lines and ground, at the power inlet

of the power magnetics cabinet. See APPENDIX A in

the Servo Amplifier αi series Descriptions

(B-65282EN) for details.

- 6 -

Page 37

B-65285EN/03 START-UP PROCEDURE 2.CONFIGURATIONS

2.2 MAJOR COMPONENTS

2.2.1 Power Supply Modules

(1) Power supply modules (PSM, 200VAC-input, power regeneration type)

Model

PSM-5.5i

PSM-11i

PSM-15i

PSM-26i

PSM-30i

PSM-37i

PSM-55i

Order

specification

A06B-6110-H006 A06B-6110-C006 A16B-2203-0640 A20B-2100-0760

A06B-6110-H011 A06B-6110-C011 A16B-2203-0641 A20B-2100-0760

A06B-6110-H015 A06B-6110-C015 A16B-2203-0642 A20B-2100-0760

A06B-6110-H026 A06B-6110-C026 A16B-2203-0630 A20B-2100-0761

A06B-6110-H030 A06B-6110-C030 A16B-2203-0631 A20B-2100-0761

A06B-6110-H037 A06B-6110-C037 A16B-2203-0632 A20B-2100-0761

A06B-6110-H055 A06B-6110-C055

Unit specification Wiring board specification

A20B-1008-0081

(Driver PCB) A20B-2003-0420

(2) Power supply modules (PSM, 400VAC-input, power regeneration type)

Model

PSM-11HVi

PSM-18HVi

PSM-30HVi

PSM-45HVi

PSM-75HVi

PSM-100HVi

Order

specification

A06B-6120-H011 A06B-6120-C011 A16B-2203-0647 A20B-2100-0760

A06B-6120-H018 A06B-6120-C018 A16B-2203-0648 A20B-2100-0760

A06B-6120-H030 A06B-6120-C030 A16B-2203-0636 A20B-2100-0761

A06B-6120-H045 A06B-6120-C045 A16B-2203-0637 A20B-2100-0761

A06B-6120-H075 A06B-6120-C075

A06B-6120-H100 A06B-6120-C100

Unit specification Wiring board specification

A20B-1008-0086

(Driver PCB) A20B-2003-0420

A20B-1008-0087

(Driver PCB) A20B-2003-0420

Printed circuit board

specification

A20B-2100-0761

Printed circuit board

specification

A20B-2100-0761

A20B-2100-0760

(3) Power supply modules (PSMR, 200VAC-input, resistance regeneration type)

Model

PSMR-3i

PSMR-5.5i

Order

specification

A06B-6115-H003 A06B-6115-C003 A16B-2203-0781

A06B-6115-H006 A06B-6115-C006 A16B-2203-0782

Unit specification

Printed circuit board

specification

- 7 -

Page 38

2.CONFIGURATIONS START-UP PROCEDURE B-65285EN/03

2.2.2 Servo Amplifier Modules

(1) Single-axis servo amplifier modules (SVM1, 200VAC-input)

Model Order specification Unit specification

SVM1-20i

SVM1-40i

SVM1-80i

SVM1-160i

SVM1-360i

A06B-6114-H103 A06B-6114-C103 A16B-2203-0691

A06B-6114-H104 A06B-6114-C104 A16B-2203-0660

A06B-6114-H105 A06B-6114-C105 A16B-2203-0661

A06B-6114-H106 A06B-6114-C106 A16B-2203-0662

A06B-6114-H109 A06B-6114-C109 A16B-2203-0625 A20B-2100-0830

Wiring board

specification

(2) Two-axis servo amplifier modules (SVM2, 200VAC-input)

Model Order specification Unit specification

SVM2-4/4i

SVM2-20/20i

SVM2-20/40i

SVM2-40/40i

SVM2-40/80i

SVM2-80/80i

SVM2-80/160i

SVM2-160/160i

A06B-6114-H201 A06B-6114-C201 A16B-2203-0692

A06B-6114-H205 A06B-6114-C205 A16B-2203-0695

A06B-6114-H206 A06B-6114-C206 A16B-2203-0670

A06B-6114-H207 A06B-6114-C207 A16B-2203-0671

A06B-6114-H208 A06B-6114-C208 A16B-2203-0672

A06B-6114-H209 A06B-6114-C209 A16B-2203-0673

A06B-6114-H210 A06B-6114-C210 A16B-2203-0674

A06B-6114-H211 A06B-6114-C211 A16B-2203-0675

Wiring board

specification

Printed circuit board

specification

A20B-2100-0740

Printed circuit board

specification

A20B-2100-0741

(3) Three-axis servo amplifier modules (SVM3, 200VAC-input)

Model Order specification Unit specification

SVM3-4/4/4i

SVM3-20/20/20i

SVM3-20/20/40i

A06B-6114-H301 A06B-6114-C301 A16B-2203-0696

A06B-6114-H303 A06B-6114-C303 A16B-2203-0698

A06B-6114-H304 A06B-6114-C304 A16B-2203-0680

Wiring board

specification

(4) Single-axis servo amplifier modules (SVM1, 400VAC-input)

Model Order specification Unit specification Wiring board specification

SVM1-10HVi

SVM1-20HVi

SVM1-40HVi

SVM1-80HVi

SVM1-180HVi

SVM1-360HVi

A06B-6124-H102 A06B-6124-C102 A16B-2203-0803

A06B-6124-H103 A06B-6124-C103 A16B-2203-0800

A06B-6124-H104 A06B-6124-C104 A16B-2203-0801

A06B-6124-H105 A06B-6124-C105 A16B-2203-0802

A06B-6124-H106 A06B-6124-C106 A16B-2203-0629 A20B-2100-0831

A06B-6124-H109 A06B-6124-C109

A20B-1008-0099

(Driver PCB) A20B-2003-0420

(5) Two-axis servo amplifier modules (SVM2, 400VAC-input)

Model Order specification Unit specification

SVM2-10/10HVi

SVM2-20/20HVi

SVM2-20/40HVi

SVM2-40/40HVi

SVM2-40/80HVi

SVM2-80/80HVi

A06B-6124-H202 A06B-6124-C202 A16B-2203-0815

A06B-6124-H205 A06B-6124-C205 A16B-2203-0810

A06B-6124-H206 A06B-6124-C206 A16B-2203-0811

A06B-6124-H207 A06B-6124-C207 A16B-2203-0812

A06B-6124-H208 A06B-6124-C208 A16B-2203-0813

A06B-6124-H209 A06B-6124-C209 A16B-2203-0814

Wiring board

specification

Printed circuit board

specification

A20B-2100-0742

Printed circuit board

specification

A20B-2100-0740

A20B-2100-0830

Printed circuit board

specification

A20B-2100-0741

- 8 -

Page 39

B-65285EN/03 START-UP PROCEDURE 2.CONFIGURATIONS

2.2.3 Spindle Amplifier Modules

The order specification varies according to the sensor (function) used.

(1) ααααi series spindle amplifier modules (SPM, 200VAC-input)

TYPE A

Model Order specification Unit specification Wiring board specification

SPM-2.2i

SPM-5.5i

SPM-11i

SPM-15i

SPM-22i

SPM-26i

SPM-30i

SPM-45i

SPM-55i

A06B-6111-H002 A06B-6111-C002 A16B-2203-0650 A20B-2100-0800

A06B-6111-H006 A06B-6111-C006 A16B-2203-0651 A20B-2100-0800

A06B-6111-H011 A06B-6111-C011 A16B-2203-0652 A20B-2100-0800

A06B-6111-H015 A06B-6111-C015 A16B-2203-0653 A20B-2100-0800

A06B-6111-H022 A06B-6111-C022 A16B-2203-0620 A20B-2100-0800

A06B-6111-H026 A06B-6111-C026 A16B-2203-0621 A20B-2100-0800

A06B-6111-H030 A06B-6111-C030 A16B-2203-0622 A20B-2100-0800

A06B-6111-H045 A06B-6111-C045

A06B-6111-H055 A06B-6111-C055

A20B-1008-0090

(Driver PCB) A20B-2003-0420

A20B-1008-0091

(Driver PCB) A20B-2003-0420

Printed circuit board

specification

A20B-2100-0800

A20B-2100-0800

TYPE B

Model Order specification Unit specification Wiring board specification

SPM-2.2i

SPM-5.5i

SPM-11i

SPM-15i

SPM-22i

SPM-26i

SPM-30i

SPM-45i

SPM-55i

A06B-6112-H002 A06B-6111-C002 A16B-2203-0650 A20B-2100-0801

A06B-6112-H006 A06B-6111-C006 A16B-2203-0651 A20B-2100-0801

A06B-6112-H011 A06B-6111-C011 A16B-2203-0652 A20B-2100-0801

A06B-6112-H015 A06B-6111-C015 A16B-2203-0653 A20B-2100-0801

A06B-6112-H022 A06B-6111-C022 A16B-2203-0620 A20B-2100-0801

A06B-6112-H026 A06B-6111-C026 A16B-2203-0621 A20B-2100-0801

A06B-6112-H030 A06B-6111-C030 A16B-2203-0622 A20B-2100-0801

A06B-6112-H045 A06B-6111-C045

A06B-6112-H055 A06B-6111-C055

A20B-1008-0090

(Driver PCB) A20B-2003-0420

A20B-1008-0091

(Driver PCB) A20B-2003-0420

(2) ααααi series spindle amplifier modules (SPM, 400VAC-input)

TYPE A

Model Order specification Unit specification Wiring board specification

SPM-5.5HVi

SPM-11HVi

SPM-15HVi

SPM-30HVi

SPM-45HVi

SPM-75HVi

SPM-100HVi

A06B-6121-H006 A06B-6121-C006 A16B-2203-0820 A20B-2100-0800

A06B-6121-H011 A06B-6121-C011 A16B-2203-0821 A20B-2100-0800

A06B-6121-H015 A06B-6121-C015 A16B-2203-0822 A20B-2100-0800

A06B-6121-H030 A06B-6121-C030 A16B-2203-0627 A20B-2100-0800

A06B-6121-H045 A06B-6121-C045 A16B-2203-0628 A20B-2100-0800

A06B-6121-H075 A06B-6121-C075

A06B-6121-H100 A06B-6121-C100

A20B-1008-0096

(Driver PCB) A20B-2003-0420

A20B-1008-0097

(Driver PCB) A20B-2003-0420

Printed circuit board

specification

A20B-2100-0801

A20B-2100-0801

Printed circuit board

specification

A20B-2100-0800

A20B-2100-0800

- 9 -

Page 40

2.CONFIGURATIONS START-UP PROCEDURE B-65285EN/03

TYPE B

Model Order specification Unit specification Wiring board specification

SPM-5.5HVi

SPM-11HVi

SPM-15HVi

SPM-30HVi

SPM-45HVi

SPM-75HVi

SPM-100HVi

A06B-6122-H006 A06B-6121-C006 A16B-2203-0820 A20B-2100-0801

A06B-6122-H011 A06B-6121-C011 A16B-2203-0821 A20B-2100-0801

A06B-6122-H015 A06B-6121-C015 A16B-2203-0822 A20B-2100-0801

A06B-6122-H030 A06B-6121-C030 A16B-2203-0627 A20B-2100-0801

A06B-6122-H045 A06B-6121-C045 A16B-2203-0628 A20B-2100-0801

A06B-6122-H075 A06B-6121-C075

A06B-6122-H100 A06B-6121-C100

A20B-1008-0096

(Driver PCB) A20B-2003-0420

A20B-1008-0097

(Driver PCB) A20B-2003-0420

Printed circuit board

specification

A20B-2100-0801

A20B-2100-0801

(3) ααααCi series spindle amplifier modules (SPMC, 200VAC-input)

Model Order specification Unit specification Wiring board specification

SPMC-2.2i

SPMC-5.5i

SPMC-11i

SPMC-15i

SPMC-22i

A06B-6116-H002 A06B-6111-C002 A16B-2203-0650 A20B-2100-0802

A06B-6116-H006 A06B-6111-C006 A16B-2203-0651 A20B-2100-0802

A06B-6116-H011 A06B-6111-C011 A16B-2203-0652 A20B-2100-0802

A06B-6116-H015 A06B-6111-C015 A16B-2203-0653 A20B-2100-0802

A06B-6116-H022 A06B-6111-C022 A16B-2203-0620 A20B-2100-0802

Printed circuit board

specification

- 10 -

Page 41

B-65285EN/03 START-UP PROCEDURE 3.START-UP PROCEDURE

3 START-UP PROCEDURE

- 11 -

Page 42

3.START-UP PROCEDURE START-UP PROCEDURE B-65285EN/03

3.1 START-UP PROCEDURE (OVERVIEW)

Make sure that the specifications of the CNC, servo motors, servo

amplifiers, and other units you received are exactly what you ordered,

and these units are connected correctly. Then, turn on the power.

(1) Before turning on the circuit breaker, check the power supply

voltage connected.

→ See Section 3.2.

(2) Some types of PSM, SVM, and SPM require settings before the

system can be used. So check whether you must make settings.

→ See Section 3.3.

(3) Turn on the power, and set initial parameters on the CNC.

For the initialization of servo parameters, refer to the following

manual:

FANUC AC SERVO MOTOR αis/αi series Parameter Manual

(B-65270EN)

For the initialization of spindle parameters, refer to the following

manual:

FANUC AD SPINDLE MOTOR αi series Parameter Manual

(B-65280EN)

(4) For start-up adjustment and troubleshooting, see Chapter 4.

• Method of using optional wiring boards for adjustment of the

PSM, SVM, and SPM

• Spindle sensor adjustment values

- 12 -

Page 43

B-65285EN/03 START-UP PROCEDURE 3.START-UP PROCEDURE

3.2 CONNECTING THE POWER

3.2.1 Checking the Voltage and Capacity of the Power

Before connecting the power, you should measure the AC power

voltage.

Table 3.2.1(a) Action for the AC power (200-V input type)

AC power

voltage

170 to 264 V 200 to 240 V

264 V or more 380 to 550 V

Table 3.2.1(b) Action for the AC power (400-V input type)

AC power

voltage

340 to 528 V 400 to 480 V

Nominal

voltage

Nominal

voltage

Action

These power lines can be connected directly

to the system.

Note) If the voltage is below the rated value,

the rated output may not be obtained.

This power line must be connected through

an insulation transformer to step down the

voltage to 200 V.

Action

These power lines can be connected directly

to the system.

Note) If the voltage is below the rated value,

the rated output may not be obtained.

Table 3.2.1 (c) and (b) list the input power specification for the power

supply module. Use a power source with sufficient capacity so that the

system will not malfunction due to a voltage drop even at a time of peak

load.

Table 3.2.1 (b) AC power voltage specifications (200-V input type)

Model

Nominal voltage rating 200 to 240 VAC -15%,+10%

Power source frequency 50/60 Hz ±1 Hz

Power source capacity (for the

main circuit) [kVA]

Power source capacity (for the

control circuit) [kVA]

Table 3.2.1 (b) AC power voltage specifications (200-V input type)

Model

Nominal voltage rating

(for the main circuit)

Nominal voltage rating

(for the control circuit)

Power source frequency 50/60Hz ±1Hz

Power source capacity (for the

main circuit) [kVA]

Power source capacity (for the

control circuit) [kVA]

PSM

-5.5i

9 172237445379

PSM

-11HVi

17 26 44 64 107 143

PSM

-11i

PSM

-18HVi

PSM

-15i

PSM

-30HVi

PSM

-26i

PSM

-45HVi

400 to 480VAC -15%,+10%

200 to 240VAC -15%,+10%

PSM

0.7

PSM

-75HVi

0.7

-30i

PSM

-37i

PSM

-100HVi

PSM

-55i

- 13 -

Page 44

3.START-UP PROCEDURE START-UP PROCEDURE B-65285EN/03

3.2.2 Connecting a Protective Ground

Refer to the items in Chapter 5, "Installation," in "FANUC SERVO

AMPLIFIER αi series Descriptions" B-65282EN, and check that the

protective ground line is connected correctly.

3.2.3 Selecting the Ground Fault Interrupter That Matches the

Leakage Current

Refer to the items in Chapter 5, "Installation," in " FANUC SERVO

AMPLIFIER αi series Descriptions" B-65282EN, and check that a

correct ground fault interrupter is selected.

- 14 -

Page 45

B-65285EN/03 START-UP PROCEDURE 3.START-UP PROCEDURE

3.3 INITIALIZING PARAMETERS

(1) Servo amplifier module

For the initialization of servo parameters, refer to the following

manual:

FANUC AC SERVO MOTOR αis/αi series Parameter Manual

(B-65270EN)

(2) Spindle amplifier module

For the initialization of spindle parameters, refer to the following

manual:

FANUC AC SPINDLE MOTOR αi series Parameter Manual

(B-65280EN)

- 15 -

Page 46

4.CONFIRMATION OF THE OPERATION START-UP PROCEDURE B-65285EN/03

4 CONFIRMATION OF THE OPERATION

- 16 -

Page 47

B-65285EN/03 START-UP PROCEDURE 4.CONFIRMATION OF THE OPERATION

A

A

4.1 POWER SUPPLY MODULE

Check each item according to the procedure described below.

1. Supply control power (200 VAC) to the power supply module

at the emergency stop state.

2. Check the STATUS LEDs. See Section 4.1.1.

OK

See Section 3.1 of Part II.

3. Release the system from emergency stop state.

4. Make sure that the MCC is turned on.

OK NG

See Subsec. 4.1.4.

5. Check the operation of the servo and spindle motors.

larm occurs.

larm occurs.

- 17 -

Page 48

4.CONFIRMATION OF THE OPERATION START-UP PROCEDURE B-65285EN/03

4.1.1 Checking the Status LEDs

Position of the

STATUS LEDs

No. STATUS LEDs Description

The STATUS display LED is off.

1

2

3

4

5

Control power has not been supplied.

The control power circuit is defective. See Section

4.1.3.

Not ready

The main circuit is not supplied with power (MCC

OFF).

Emergency stop state

Ready

The main circuit is supplied with power (MCC ON).

The PSM is operable.

Warning state (the dot at the bottom right lights.)

A failure has occurred in the PSM. The PSM can

keep operating. However it will enter an alarm state

after a certain period of time.

See Section 3.1 of Part II.

Alarm state

The PSM is not operable.

See Section 3.1 of Part II.

- 18 -

Page 49

B-65285EN/03 START-UP PROCEDURE 4.CONFIRMATION OF THE OPERATION

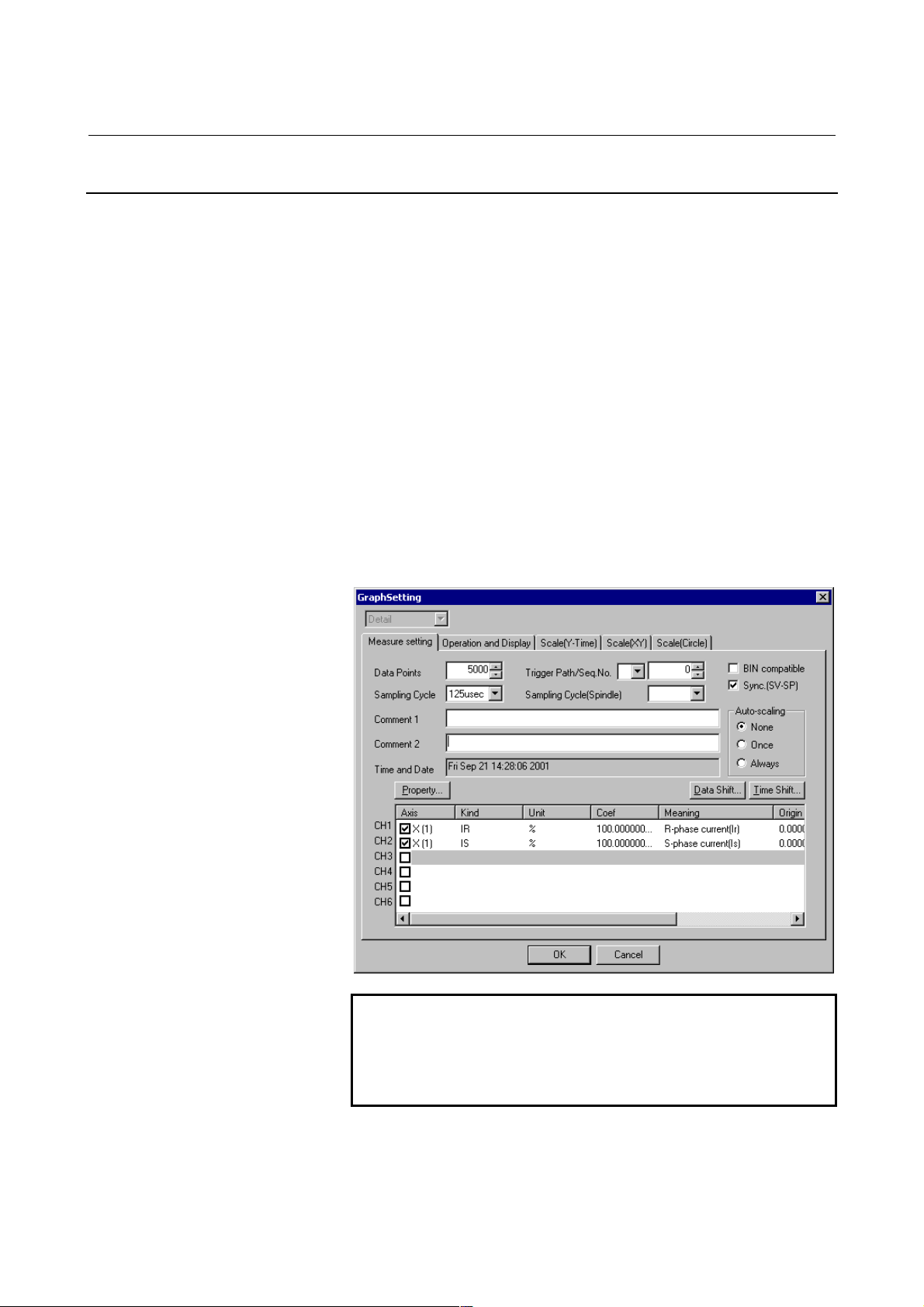

4.1.2 Check Terminal on the Printed-circuit Board

The input current check signal is output to connector JX1B. To observe

the output, use the servo check pin board A06B-6071-K290 (see

below).

Table 4.1.2(a) Check pins

Check

pin

IR

IS

0V

Description

L1 phase (R-phase)

current

L2 phase (S-phase)

current

Reference point of

observation

Table 4.1.2 (b) IR and IS current conversion value

Model Current conversion

PSM-5.5i

PSM-11i

PSM-15i

PSM-26i

PSM-30i

PSM-37i

PSM-55ii

PSM-11HVi

PSM-18HVi

PSM-30HVi

PSM-45HVi

PSM-75HVi

PSM-100HVi

Location of

observation

JX1B-pin1

JX1B-pin2

JX1Bpin12,14,16

133A/1V (2.5 V at the center)

133A/1V (2.5 V at the center)

200A/1V (2.5 V at the center)

266A/1V (2.5 V at the center)

333A/1V (2.5 V at the center)

400A/1V (2.5 V at the center)

666A/1V (2.5 V at the center)

100A/1V (2.5 V at the center)

133A/1V (2.5 V at the center)

200A/1V (2.5 V at the center)

266A/1V (2.5 V at the center)

400A/1V (2.5 V at the center)

466A/1V (2.5 V at the center)