Page 1

FANUC AC SERVO MOTOR #*s series

FANUC AC SPINDLE MOTOR #* series

FANUC SERVO AMPLIF

MAINTENANCE MANUAL

IER #* series

I/O Link Option

B-65395EN/01

Page 2

Ȧ No part of this manual may be reproduced in any form.

Ȧ All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the

various matters.

However , we cannot describe all the matters which must not be done,

or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in

this manual should be regarded as ”impossible”.

Page 3

B-65395EN/01 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

The "Safety Precautions" section describes the safety precautions

relating to the use of FANUC servo motors and servo amplifiers (βi

SVM). Users of any servo motor or amplifier model are requested to

read the "Safety Precautions" carefully before using the motor or

amplifier.

The users are also requested to read an applicable specification manual

carefully and understand each function of the motor or amplifier for

correct use.

The users are basically forbidden to do any behavior or action not

mentioned in the "Safety Precautions." They are invited to ask FANUC

previously about what behavior or action is prohibited.

Contents

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE ........s-2

1.2 FANUC AC SERVO MOTOR βis series..................................s-3

1.2.1 Warning.........................................................................s-3

1.2.2 Caution ..........................................................................s-6

1.2.3 Note ..........................................................................s-7

1.3 FANUC SERVO AMPLIFIER βi series ...................................s-9

1.3.1 Warnings and Cautions Relating to Mounting .............. s-9

1.3.1.1 Warning.............................................................s-9

1.3.1.2 Caution............................................................s-11

1.3.1.3 Note ................................................................s-13

1.3.2 Warnings and Cautions Relating to a Pilot Run..........s-14

1.3.2.1 Warning...........................................................s-14

1.3.2.2 Caution............................................................s-15

1.3.3 Warnings and Cautions Relating to Maintenance .......s-16

1.3.3.1 Warning...........................................................s-16

1.3.4.2 Caution............................................................s-18

1.3.4.3 Note ................................................................s-19

s-1

Page 4

SAFETY PRECAUTIONS B-65395EN/01

1.1 DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a damage of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

* Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-65395EN/01 SAFETY PRECAUTIONS

1.2 FANUC AC SERVO MOTOR βis series

1.2.1 Warning

WARNING

• Be safely dressed when handling a motor.

Wear safety shoes or gloves when handling a motor as you may

get hurt on any edge or protrusion on it or electric shocks.

• Use a crane or lift to move a motor from one place to another.

A motor is heavy. If you lift the motor by hand, you may get a

backache, or you may be seriously injured when you drop the

motor. A suitable crane or lift must be used to move the motor.

(For the weight of motors, refer to their respective Descriptions.)

When moving a motor using a crane or lift, use a hanging bolt if

the motor has a corresponding tapped hole, or textile rope if it has

no tapped hole.

If a motor is attached with a machine or any other heavy stuff, do

not use a hanging bolt to move the motor as the hanging bolt

and/or motor may get broken.

• Before starting to connect a motor to electric wires, make sure

they are isolated from an electric power source.

A failure to observe this caution is vary dangerous because you

may get electric shocks.

• Be sure to secure power wires.

If operation is performed with a terminal loose, the terminal block

may become abnormally hot, possibly causing a fire. Also, the

terminal may become disconnected, causing a ground fault or

short-circuit, and possibly giving you electric shocks. See the

section in this manual that gives the tightening torque for attaching

power wires and short-bars to the terminal block.

• Be sure to ground a motor frame.

To avoid electric shocks, be sure to connect the grounding

terminal in the terminal box to the grounding terminal of the

machine.

• Do not ground a motor power wire terminal or short-circuit it

to another power wire terminal.

A failure to observe this caution may cause electric shocks or a

burned wiring.

(*) Some motors require a special connection such as a winding

changeover. Refer to their respective motor Descriptions for

details.

s-3

Page 6

SAFETY PRECAUTIONS B-65395EN/01

WARNING

• Do not supply the power to the motor while any terminal is

exposed.

A failure to observe this caution is very dangerous because you

may get electric shocks if your body or any conductive stuff

touches an exposed terminal.

• Do not bring any dangerous stuff near a motor.

Motors are connected to a power line, and may get hot. If a

flammable is placed near a motor, it may be ignited, catch fire, or

explode.

• Do not get close to a rotary section of a motor when it is

rotating.

You may get your clothes or fingers caught in a rotary section, and

may be injured. Before starting a motor, ensure that there is no

stuff that can fly away (such as a key) on the motor.

• Do not touch a motor with a wet hand.

A failure to observe this caution is vary dangerous because you

may get electric shocks.

• Before touching a motor, shut off the power to it.

Even if a motor is not rotating, there may be a voltage across the

terminals of the motor.

Especially before touching a power supply connection, take

sufficient precautions.

Otherwise you may get electric shocks.

• Do not touch any terminal of a motor for a while (at least 5

minutes) after the power to the motor is shut off.

High voltage remains across power line terminals of a motor for a

while after the power to the motor is shut off. So, do not touch any

terminal or connect it to any other equipment. Otherwise, you may

get electric shocks or the motor and/or equipment may get

damaged.

• To drive a motor, use a specified amplifier and parameters.

Driving a motor with other than the specified combinations of an

amplifier and parameters may cause the motor to perform an

unexpected operation; for example, the motor may get out of

control, or produce excessively high torque. This may result in the

motor or machine being damaged. Also, an object such as a

workpiece or tool may fly off due to excessive rotation, possibly

causing injury.

• Do not touch a regenerative discharge unit for a while (at least

30 minutes) after the power to the motor is shut off.

A regenerative discharge unit may get hot when the motor is

running.

Do not touch the regenerative discharge unit before it gets cool

enough. Otherwise, you may get burned.

s-4

Page 7

B-65395EN/01 SAFETY PRECAUTIONS

• When designing and assembling a machine tool, make it

compliant with EN60204-1.

To ensure the safety of the machine tool and satisfy European

standards, when designing and assembling a machine tool, make it

compliant with EN60204-1. For details of the machine tool, refer

to its specification manual.

• Do not touch a motor when it is running or immediately after

it stops.

A motor may get hot when it is running. Do not touch the motor

before it gets cool enough. Otherwise, you may get burned.

• Be careful not get your hair or cloths caught in a fan.

Be careful especially for a fan used to generate an inward air flow.

Be careful also for a fan even when the motor is stopped, because

it continues to rotate while the amplifier is turned on.

• Ensure that motors and related components are mounted

securely.

If a motor or its component slips out of place or comes off when

the motor is running, it is very dangerous.

s-5

Page 8

SAFETY PRECAUTIONS B-65395EN/01

1.2.2 Caution

CAUTION

• FANUC motors are designed for use with machines. Do not

use them for any other purpose.

If a FANUC motor is used for an unintended purpose, it may cause

an unexpected symptom or trouble. If you want to use a motor for

an unintended purpose, previously consult with FANUC.

• Ensure that a base or frame on which a motor is mounted is

strong enough.

Motors are heavy. If a base or frame on which a motor is mounted

is not strong enough, it is impossible to achieve the required

precision.

• Be sure to connect motor cables correctly.

An incorrect connection of a cable cause abnormal heat generation,

equipment malfunction, or failure. Always use a cable with an

appropriate current carrying capacity (or thickness). For how to

connect cables to motors, refer to their respective Descriptions.

• Ensure that motors are cooled if they are those that require

forcible cooling.

If a motor that requires forcible cooling is not cooled normally, it

may cause a failure or trouble. For a fan-cooled motor, ensure that

it is not clogged or blocked with dust and dirt. For a liquid-cooled

motor, ensure that the amount of the liquid is appropriate and that

the liquid piping is not clogged.

For both types, perform regular cleaning and inspection.

• When attaching a component having inertia, such as a pulley,

to a motor, ensure that any imbalance between the motor and

component is minimized.

If there is a large imbalance, the motor may vibrates abnormally,

resulting in the motor being broken.

• Be sure to attach a key to a motor with a keyed shaft.

If a motor with a keyed shaft runs with no key attached, it may

impair torque transmission or cause imbalance, resulting in the

motor being broken.

s-6

Page 9

B-65395EN/01 SAFETY PRECAUTIONS

1.2.3 Note

NOTE

• Do not step or sit on a motor.

If you step or sit on a motor, it may get deformed or broken. Do not

put a motor on another unless they are in packages.

• When storing a motor, put it in a dry (non-condensing) place

at room temperature (0 to 40°C).

If a motor is stored in a humid or hot place, its components may

get damaged or deteriorated. In addition, keep a motor in such a

position that its shaft is held horizontal and its terminal box is at

the top.

• Do not remove a nameplate from a motor.

If a nameplate comes off, be careful not to lose it. If the nameplate

is lost, the motor becomes unidentifiable, resulting in maintenance

becoming impossible.

For a nameplate for a built-in spindle motor, keep the nameplate

with the spindle.

• Do not apply shocks to a motor or cause scratches to it.

If a motor is subjected to shocks or is scratched, its components

may be adversely affected, resulting in normal operation being

impaired. Be very careful when handling plastic portions, sensors,

and windings, because they are very liable to break. Especially,

avoid lifting a motor by pulling its plastic portion, winding, or

power cable.

• Do not conduct dielectric strength or insulation test for a

sensor.

Such a test can damage elements in the sensor.

• When testing the winding or insulation resistance of a motor,

satisfy the conditions stipulated in IEC60034.

Testing a motor under a condition severer than those specified in

IEC60034 may damage the motor.

• Do not disassemble a motor.

Disassembling a motor may cause a failure or trouble in it.

If disassembly is in need because of maintenance or repair, please

contact a service representative of FANUC.

• Do not modify a motor.

Do not modify a motor unless directed by FANUC. Modifying a

motor may cause a failure or trouble in it.

s-7

Page 10

SAFETY PRECAUTIONS B-65395EN/01

NOTE

• Use a motor under an appropriate environmental condition.

Using a motor in an adverse environment may cause a failure or

trouble in it.

Refer to their respective Descriptions for details of the operating

and environmental conditions for motors.

• Do not apply a commercial power source voltage directly to a

motor.

Applying a commercial power source voltage directly to a motor

may result in its windings being burned. Be sure to use a specified

amplifier for supplying voltage to the motor.

• For a motor with a terminal box, make a conduit hole for the

terminal box in a specified position.

When making a conduit hole, be careful not to break or damage

unspecified portions.

Refer to an applicable Descriptions.

• Before using a motor, measure its winding and insulation

resistances, and make sure they are normal.

Especially for a motor that has been stored for a prolonged period

of time, conduct these checks. A motor may deteriorate depending

on the condition under which it is stored or the time during which

it is stored. For the winding resistances of motors, refer to their

respective Descriptions, or ask FANUC. For insulation resistances,

see the following table.

• To use a motor as long as possible, perform periodic

maintenance and inspection for it, and check its winding and

insulation resistances.

Note that extremely severe inspections (such as dielectric strength

tests) of a motor may damage its windings. For the winding

resistances of motors, refer to their respective Descriptions, or ask

FANUC. For insulation resistances, see the following table.

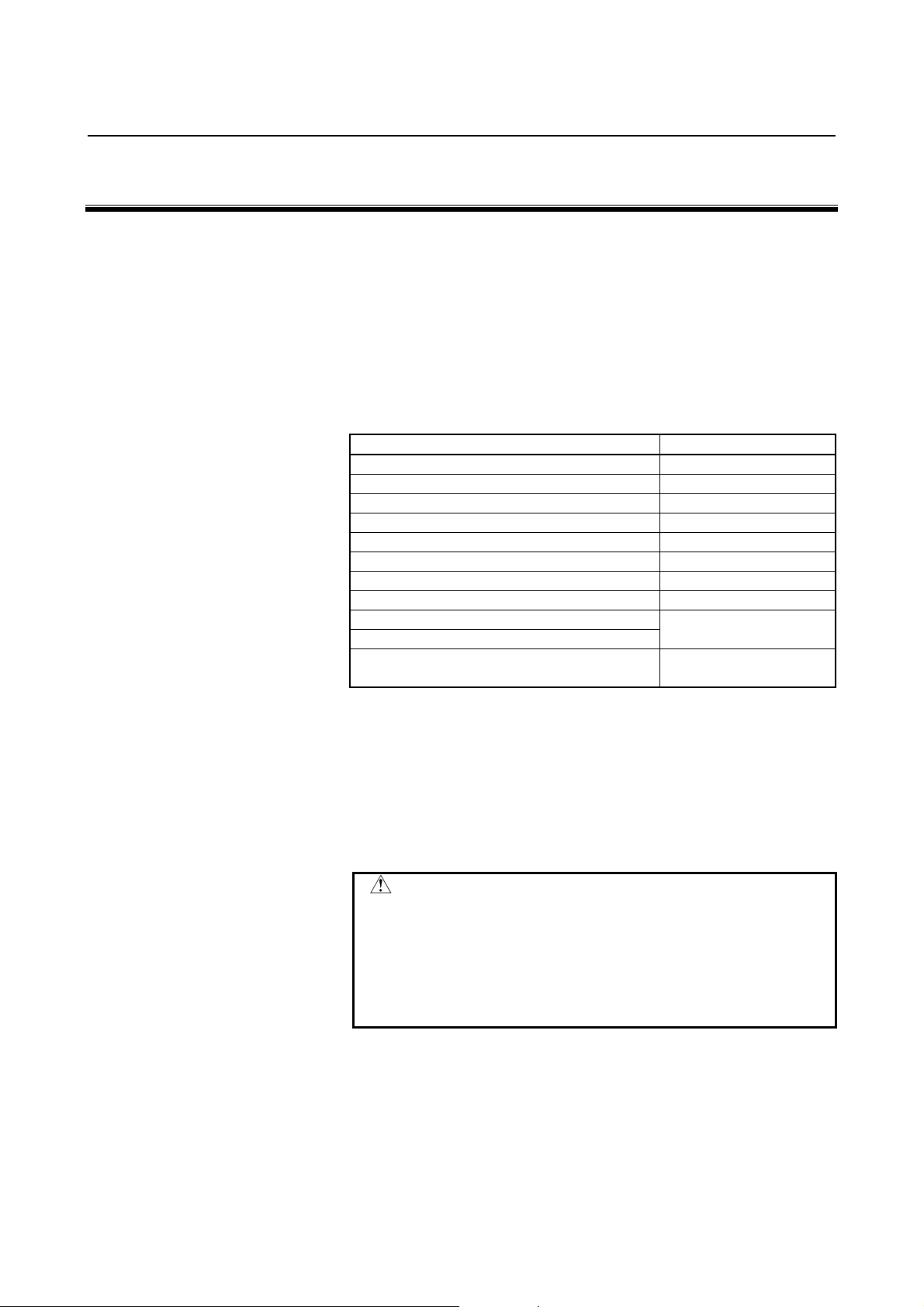

MOTOR INSULATION RESISTANCE MEASUREMENT

Measure an insulation resistance between each winding and

motor frame using an insulation resistance meter (500 VDC).

Judge the measurements according to the following table.

Insulation resistance Judgment

100MΩ or higher Acceptable

10 to 100 MΩ The winding has begun deteriorating. There is no

problem with the performance at present. Be sure

to perform periodic inspection.

1 to 10 MΩ The winding has considerably deteriorated.

Special care is in need. Be sure to perform

periodic inspection.

Lower than 1 MΩ Unacceptable. Replace the motor.

s-8

Page 11

B-65395EN/01 SAFETY PRECAUTIONS

1.3 FANUC SERVO AMPLIFIER βi series

1.3.1 Warnings and Cautions Relating to Mounting

1.3.1.1 Warning

WARNING

• Check the specification code of the amplifier.

Check that the delivered amplifier is as originally ordered.

• Mount a ground fault interrupter.

To guard against fire and electric shock, fit the factory power

supply or machine with a ground fault interrupter (designed for

use with an inverter).

• Securely ground the amplifier.

Securely connect the ground terminal and metal frame of the

amplifier and motor to a common ground plate of the power

magnetics cabinet.

• Be aware of the weight of the amplifier and other components.

Some amplifiers, AC reactors and AC line filters are heavy. When

transporting them or mounting them in the cabinet, therefore, be

careful not to injured yourself or damage the equipment. Be

particularly careful not to jam your fingers between the cabinet

and amplifier.

• Never ground or short-circuit either the power supply lines or

power lines.

Protect the lines from any stress such as bending. Handle the ends

appropriately.

• Ensure that the power supply lines, power lines, and signal

lines are securely connected.

A loose screw, loose connection, or the like will cause a motor

malfunction or overheating, or a ground fault.

Be extremely careful with power supply lines, motor power lines,

and DC link connections through which a large amount of current

passes, because a loose screw (or poor contact in a connector or

poor connection between a connector terminal and a cable) may

cause a fire.

• Insulate all exposed parts that are charged.

• Never touch the regenerative discharge resistor or radiator

directly.

The surface of the radiator and regenerative discharge unit become

extremely hot. Never touch them directly. An appropriate

structure should also be considered.

s-9

Page 12

SAFETY PRECAUTIONS B-65395EN/01

WARNING

• Close the amplifier cover after completing the wiring.

Leaving the cover open presents a danger of electric shock.

• Do not disassemble the amplifier.

• Ensure that the cables used for the power supply lines and

power lines are of the appropriate diameter and temperature

ratings.

• Do not apply an excessively large force to plastic parts.

If a plastic section breaks, it may cause internal damage, thus

interfering with normal operation. The edge of a broken section is

likely to be sharp and, therefore, presents a risk of injury.

s-10

Page 13

B-65395EN/01 SAFETY PRECAUTIONS

1.3.1.2 Caution

CAUTION

• Do not step or sit on the amplifier.

Also, do not stack unpacked amplifiers on top of each other.

• Use the amplifier in an appropriate environment.

See the allowable ambient temperatures and other requirements,

given in the corresponding Descriptions.

• Protect the amplifier from corrosive or conductive mist or

drops of water.

Use a filter if necessary.

• Protect the amplifier from impact.

Do not place anything on the amplifier.

• Do not block the air inlet to the radiator.

A deposit of coolant, oil mist, or chips on the air inlet will result in

a reduction in the cooling efficiency. In some cases, the required

efficiency cannot be achieved. The deposit may also lead to a

reduction in the useful life of the semiconductors. Especially,

when outside air is drawn in, mount filters on both the air inlet and

outlet. These filters must be replaced regularly.

So, an easy-to-replace type of filter should be used.

• Connect the power supply lines and power lines to the

appropriate terminals and connectors.

• Connect the signal lines to the appropriate connectors.

• Before connecting the power supply wiring, check the supply

voltage.

Check that the supply voltage is within the range specified in the

Descriptions, then connect the power supply lines.

• Ensure that the combination of motor and amplifier is

appropriate.

• Ensure that valid parameters are specified.

Specifying an invalid parameter for the combination of motor and

amplifier may not only prevent normal operation of the motor but

also result in damage to the amplifier.

• Ensure that the amplifier and peripheral equipment are

securely connected.

Check that the magnetic contactor, circuit breaker, and other

devices mounted outside the amplifier are securely connected to

each other and that those devices are securely connected to the

amplifier.

s-11

Page 14

SAFETY PRECAUTIONS B-65395EN/01

CAUTION

• Check that the amplifier is securely mounted in the power

magnetics cabinet.

If any clearance is left between the power magnetics cabinet and

the surface on which the amplifier is mounted, dust entering the

gap may build up and prevent the normal operation of the

amplifier.

• Apply appropriate countermeasures against noise.

Adequate countermeasures against noise are required to maintain

normal operation of the amplifier. For example, signal lines must

be routed away from power supply lines and power lines.

• Attachment and detachment of connectors

When power is on, avoid attaching and detaching connectors

unless otherwise noted. Otherwise, the amplifier can become

faulty.

s-12

Page 15

B-65395EN/01 SAFETY PRECAUTIONS

1.3.1.3 Note

NOTE

• Keep the nameplate clearly visible.

• Keep the legend on the nameplate clearly visible.

• After unpacking the amplifier, carefully check for any

damage.

• Mount the amplifier in a location where it can be easily

accessed periodic inspection and daily maintenance.

• Leave sufficient space around the machine to enable

maintenance to be performed easily.

Do not place any heavy objects such that they would interfere with

the opening of the doors.

• Keep the parameter table and spare parts at hand.

Also, keep the Descriptions at hand. These items must be stored in

a location where they can be retrieved immediately.

• Provide adequate shielding.

A cable to be shielded must be securely connected to the ground

plate, using a cable clamp or the like.

s-13

Page 16

SAFETY PRECAUTIONS B-65395EN/01

1.3.2 Warnings and Cautions Relating to a Pilot Run

1.3.2.1 Warning

WARNING

• Before turning on the power, check that the cables connected

to the power magnetics cabinet and amplifier, as well as the

power lines and power supply lines, are securely connected.

Also, check that no lines are slack.

A loose screw, loose connection, or the like will cause a motor

malfunction or overheating, or a ground fault. Be extremely

careful with power supply lines, motor power lines, and DC link

connections through which a large amount of current passes,

because a loose screw (or poor contact in a connector or poor

connection between a connector terminal and a cable) may cause a

fire.

• Before turning on the power, ensure that the power magnetics

cabinet is securely grounded.

• Before turning on the power, check that the door of the power

magnetics cabinet and all other doors are closed.

Ensure that the door of the power magnetics cabinet containing the

amplifier, and all other doors, are securely closed. During

operation, all doors must be closed and locked.

• Apply extreme caution if the door of the power magnetics

cabinet or another door must be opened.

Only a person trained in the maintenance of the corresponding

machine or equipment should open the door, and only after

shutting off the power supply to the power magnetics cabinet (by

opening both the input circuit breaker of the power magnetics

cabinet and the factory switch used to supply power to the cabinet).

If the machine must be operated with the door open to enable

adjustment or for some other purpose, the operator must keep his

or her hands and tools well away from any dangerous voltages.

Such work must be done only by a person trained in the

maintenance of the machine or equipment.

• When operating the machine for the first time, check that the

machine operates as instructed.

To check whether the machine operates as instructed, first specify

a small value for the motor, then increase the value gradually. If

the motor operates abnormally, perform an emergency stop

immediately.

• After turning on the power, check the operation of the

emergency stop circuit.

Press the emergency stop button to check that the motor stops

immediately, and that the power being supplied to the amplifier is

shut off by the magnetic contactor.

s-14

Page 17

B-65395EN/01 SAFETY PRECAUTIONS

WARNING

• Before opening a door or protective cover of a machine to

enable adjustment of the machine, first place the machine in

the emergency stop state and check that the motor has

stopped.

s-15

Page 18

SAFETY PRECAUTIONS B-65395EN/01

1.3.2.2 Caution

CAUTION

• Note whether an alarm status relative to the amplifier is

displayed at power-up or during operation.

If an alarm is displayed, take appropriate action as explained in

this manual. If the work to be done requires that the door of the

power magnetics cabinet be left open, the work must be carried out

by a person trained in the maintenance of the machine or

equipment. Note that if some alarms are forcibly reset to enable

operation to continue, the amplifier may be damaged. Take

appropriate action according to the contents of the alarm.

• Before operating the motor for the first time, mount and

adjust the position and speed sensors.

Following the instructions given in this manual, adjust the position

and speed sensors for the spindle so that an appropriate waveform

is obtained.

If the sensors are not properly adjusted, the motor may not rotate

normally or the spindle may fail to stop as desired.

• If the motor makes any abnormal noise or vibration while

operating, stop it immediately.

Note that if operation is continued in spite of there being some

abnormal noise or vibration, the amplifier may be damaged. Take

appropriate corrective action, then resume operation.

• Observe the ambient temperature and output rating

requirements.

The continuous output rating or continuous operation period of

some amplifiers may fall as the ambient temperature increases. If

the amplifier is used continuously with an excessive load applied,

the amplifier may be damaged.

• Unless otherwise specified, do not insert or remove any

connector while the power is turned on. Otherwise, the

amplifier may fail.

s-16

Page 19

B-65395EN/01 SAFETY PRECAUTIONS

1.3.3 Warnings and Cautions Relating to Maintenance

1.3.3.1 Warning

WARNING

• Read this manual carefully and ensure that you are totally

familiar with its contents.

This manual describes daily maintenance and the procedures to be

followed in the event of an alarm being issued. The operator must

be familiar with these descriptions.

• Notes on replacing a fuse or PC board

1) Before starting the replacement work, ensure that the circuit

breaker protecting the power magnetics cabinet is open.

2) Check that the red LED that indicates that charging is in

progress is not lit.

The position of the charging LED on each model of amplifier

is given in the Descriptions. While the LED is lit, hazardous

voltages are present inside the unit, and thus there is a danger

of electric shock.

3) Some PC board components become extremely hot. Be

careful not to touch these components.

4) Ensure that a fuse having an appropriate rating is used.

5) Check the specification code of a PC board to be replaced. If

a modification drawing number is indicated, contact FANUC

before replacing the PC board.

Also, before and after replacing a PC board, check its pin

settings.

6) After replacing a fuse, make sure that the fuse is inserted into

the socket all the way to the root.

7) After replacing the PC board, ensure that it is securely

connected.

8) Ensure that all power lines, power supply lines, and

connectors are securely connected.

• Take care not to lose any screws.

When removing the case or PC board, take care not to lose any

screws. If a screw is lost inside the nit and the power is turned on,

the machine may be damaged.

s-17

Page 20

SAFETY PRECAUTIONS B-65395EN/01

WARNING

• Notes on replacing the battery of the absolute Pulsecoder

Replace the battery only while the power is on. If the battery is

replaced while the power is turned off, the stored absolute

positioning data will be lost. A battery may be mounted on the

servo amplifier of the βi series servo amplifier module. In this

case, before starting to replace the battery, you must open the

power magnetics cabinet door and take the machine to an

emergency stop to shut down the power to the amplifier without

turning off the control power. Replacement work should be done

only by a person who is trained in the related maintenance and

safety requirements. The power magnetics cabinet in which the

servo amplifier is mounted has a high-voltage section. This section

presents a severe risk of electric shock.

• Check the number of any alarm.

If the machine stops upon an alarm being issued, check the alarm

number. Some alarms indicate that a component must be replaced.

If the power is reconnected without first replacing the failed

component, another component may be damaged, making it

difficult to locate the original cause of the alarm.

• Before resetting an alarm, ensure that the original cause of the

alarm has been removed.

• Contact FANUC whenever a question relating to maintenance

arises.

• Notes on removing the amplifier

Before removing the amplifier, first ensure that the power is shut

off. Be careful not to jam your fingers between the power

magnetics cabinet and amplifier.

s-18

Page 21

B-65395EN/01 SAFETY PRECAUTIONS

1.3.3.2 Caution

CAUTION

• Ensure that all required components are mounted.

When replacing a component or PC board, check that all

components, including the snubber capacitor, are correctly

mounted. If the snubber capacitor is not mounted, for example, the

IPM will be damaged.

• Tighten all screws firmly.

• Check the specification code of the fuse, PC board, and other

components.

When replacing a fuse or PC board, first check the specification

code of the fuse or PC board, then mount it in the correct position.

The machine will not operate normally if a fuse or PC board

having other than the correct specification code is mounted, or if a

fuse or PC board is mounted in the wrong position.

• Mount the correct cover.

The cover on the front of the amplifier carries a label indicating a

specification code. When mounting a previously removed front

cover, take care to mount it on the unit from which it was removed.

• Notes on cleaning the heat sink and fan

1) A dirty heat sink or fan results in reduced semiconductor

cooling efficiency, which degrades reliability. Periodic

cleaning is necessary.

2) Using compressed air for cleaning scatters the dust. A deposit

of conductive dust on the amplifier or peripheral equipment

will result in a failure.

3) To clean the heat sink, do so only after turning the power off

and ensuring that the heat sink has cooled to room

temperature. The heat sink becomes extremely hot, such that

touching it during operation or immediately after power-off

is likely to cause a burn. Be extremely careful when touching

the heat sink.

s-19

Page 22

SAFETY PRECAUTIONS B-65395EN/01

1.3.3.3 Note

NOTE

• Ensure that the battery connector is correctly inserted.

If the power is shut off while the battery connector is not

connected correctly, the absolute position data for the machine

will be lost.

• Store the manuals in a safe place.

The manuals should be stored in a location where they can be

accessed immediately it so required during maintenance work.

• Notes on contacting FANUC

Inform FANUC of the details of an alarm and the specification

code of the amplifier so that any components required for

maintenance can be quickly secured, and any other necessary

action can be taken without delay.

s-20

Page 23

B-65395EN/01 PREFACE

PREFACE

Organization of this manual

This manual describes information necessary to maintain FANUC

SERVO AMPLIFIER βi series products, such as a βi SVM and

FANUC SERVO MOTOR βis series products.

Parts I, II, III and IV explain the start-up procedure, operation,

troubleshooting, and maintenance for the βi series SVM.

Part V explains the maintenance for βis series servo motor.

The abbreviations listed below are used in this manual.

Product name Abbreviations

FANUC Series 15i FS15i

FANUC Series 16i FS16i

FANUC Series 18i FS18i

FANUC Series 21i FS21i

FANUC Series 0i FS0i

FANUC Series 30i FS30i

FANUC Series 31i FS31i

FANUC Series 32i FS32i

FANUC Power Mate i-D

FANUC Power Mate i-H

FANUC SERVO AMPLIFIER βi series SVM

Power Supply Module

Servo Amplifier Module

* The manuals shown below provide information related to this

manual. This manual may refer you to these manuals.

FANUC SERVO AMPLIFIER βi series Descriptions B-65322EN

FANUC AC SERVO MOTOR βis series Descriptions B-65302EN

FANUC AC SERVO MOTOR αis/αi/βis series Parameter Manual

B-65270EN

WARNING

When maintaining and inspecting the servo

amplifier module, keep the power turned off and

make sure that the LED (red) on the front panel of

the servo amplifier module that indicates whether

electric charge is in progress is off. (See Appendix

A.)

PMi

βi SVM, SVM,

p-1

Page 24

Page 25

B-65395EN/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

PREFACE....................................................................................................p-1

I. START-UP PROCEDURE

1 OVERVIEW ............................................................................................. 3

2 CONFIGURATIONS ................................................................................ 4

2.1 CONFIGURATIONS ...................................................................................... 5

2.2 MAJOR COMPONENTS ............................................................................... 6

2.2.1 Servo Amplifier Modules.........................................................................................6

3 START-UP PROCEDURE.......................................................................7

3.1 START-UP PROCEDURE (OVERVIEW) ......................................................8

3.2 CONNECTING THE POWER........................................................................ 9

3.2.1 Checking the Voltage and Capacity of the Power....................................................9

3.2.2 Connecting a Protective Ground ..............................................................................9

3.2.3 Selecting the Ground Fault Interrupter That Matches the Leakage Current ............9

3.3 INITIALIZING PARAMETERS

(SWITCHES AND DUMMY CONNECTORS) .............................................. 10

3.4 PARAMETER INITIALIZATION ................................................................... 11

4 CONFIRMATION OF THE OPERATION ..............................................15

4.1 CHECK PROCEDURE ................................................................................16

5 PERIODIC MAINTENANCE OF SERVO AMPLIFIER ..........................19

5.1 BATTERY FOR THE ABSOLUTE PULSECODER ...................................... 20

5.2 PERIODIC MAINTENANCE OF SERVO AMPLIFIER ................................. 28

II. HANDLING

1 OVERVIEW ........................................................................................... 33

1.1 SERVO AMPLIFIER MODULE INTERFACE............................................... 34

1.2 FANUC I/O LINK INTERFACE AREA.......................................................... 34

1.3 INTERFACE ................................................................................................35

1.3.1 Peripheral Equipment Control Interface.................................................................35

1.3.2 Direct Command Interface .....................................................................................35

1.3.3 Interface Switching.................................................................................................35

1.4 CAUTIONS ON USING THE POWER MATE CNC .....................................36

c-1

Page 26

TABLE OF CONTENTS B-65395EN/01

2 SIGNAL DESCRIPTIONS .....................................................................37

2.1 DO/DO SIGNALS ........................................................................................38

2.1.1 Peripheral Equipment Control Interface.................................................................38

2.1.2 Direct Command Interface .....................................................................................40

2.2 SIGNALS (LISTED IN GROUPS) ................................................................ 42

2.3 SIGNAL DETAILS........................................................................................ 44

2.3.1 Preparation Completion..........................................................................................44

2.3.2 Reset and Emergency Stop.....................................................................................45

2.3.3 Alarm ......................................................................................................................46

2.3.4 Mode Selection.......................................................................................................47

2.3.5 Jog Feed..................................................................................................................47

2.3.6 Status Signals .........................................................................................................48

2.3.7 Feedrate ..................................................................................................................52

2.3.8 Interlock .................................................................................................................54

2.3.9 Reference Position Return......................................................................................54

2.3.10 Automatic Operation..............................................................................................55

2.3.11 Clamp and Unclamp (for the Peripheral Equipment Control Interface Only)........56

2.3.12 Servo-off.................................................................................................................57

2.3.13 Peripheral Equipment Control Function Code and Related Information ...............58

2.3.14 Direct Command Function Code and Related Information....................................62

2.3.15 Direct Input Signals ................................................................................................68

3 PERIPHERAL EQUIPMENT CONTROL............................................... 71

3.1 COMMAND FORMAT FOR PERIPHERAL EQUIPMENT CONTROL ......... 72

3.2 PERIPHERAL EQUIPMENT CONTROL PROCEDURE.............................. 73

3.2.1 Specifying Operation Using a Function Code........................................................73

3.2.2 Receiving Response Data .......................................................................................73

3.3 FUNCTION CODES ....................................................................................74

3.3.1 Function Codes.......................................................................................................74

3.4 DETAILS OF FUNCTION CODES............................................................... 76

3.4.1 ATC/Turret Control................................................................................................76

3.4.2 Point Positioning Control .......................................................................................78

3.4.3 Reference Position Return......................................................................................80

3.4.4 Reference Position Setting

(when the Reference Position External Setting Function is Used).........................82

3.4.5 Positioning Control (Absolute/Incremental Specification, for Skip Function) ......84

3.4.6 Speed Control.........................................................................................................86

3.4.6.1 Overview ........................................................................................................... 86

c-2

Page 27

B-65395EN/01 TABLE OF CONTENTS

3.4.6.2 System configuration ......................................................................................... 86

3.4.6.3 Peripheral equipment control command format................................................. 87

3.4.6.4 Command timing chart ......................................................................................89

3.4.6.5 Parameter ........................................................................................................... 92

3.4.6.6 Signal ................................................................................................................ 94

3.4.6.7 Alarm ................................................................................................................ 94

3.4.6.8 Others ................................................................................................................ 95

3.4.7 Coordinate System Setting .....................................................................................96

3.4.8 Rewriting of Parameters .........................................................................................97

3.4.8.1 Overview ........................................................................................................... 97

3.4.8.2 System configuration ......................................................................................... 97

3.4.8.3 Peripheral equipment control command format................................................. 98

3.4.8.4 Command timing chart ......................................................................................99

3.4.8.5 Alarm ................................................................................................................ 99

3.4.8.6 Parameter ........................................................................................................... 99

3.4.9 Control of the Point Data External Setting Function............................................100

3.4.10 Teaching-based Data Setting Control...................................................................101

3.5 REFERENCE POSITION RETURN FUNCTION WITH DOGS.................. 102

3.5.1 Explanation of Function .......................................................................................102

3.5.1.1 Reference position return operation (grid method).......................................... 102

3.5.1.2 Deceleration limit switch installation condition .............................................. 103

3.5.1.3 Tip .............................................................................................................. 104

3.5.2 Parameter..............................................................................................................105

3.6 UPGRADING OF THE ROTATION AXIS CONTROL FUNCTION ............ 106

3.6.1 Function for Specifying the Direction of Rotation Axis High-speed Reference

Position Return.....................................................................................................106

3.6.1.1 Explanation of function ................................................................................... 106

3.6.1.2 Parameter ......................................................................................................... 106

3.6.2 Rotation Axis Rotation Direction Sign Specification Function ...........................107

3.6.2.1 Explanation of function ................................................................................... 107

3.6.2.2 Example of program ........................................................................................ 107

3.6.2.3 Parameter ......................................................................................................... 107

3.7 UPGRADING OF THE CLAMP/UNCLAMP CONTROL FUNCTION .........108

3.7.1 Start of the Timer Counting Until Servo-off in Clamp Processing ......................108

3.7.1.1 Explanation of function ................................................................................... 108

3.7.1.2 Parameter ......................................................................................................... 108

3.7.2 Disabling of Clamp Processing When Jog Operation is Stopped ........................108

3.7.2.1 Explanation of function ................................................................................... 108

3.7.2.2 Parameter ......................................................................................................... 108

3.8 UPGRADING OF THE RESPONSE DATA READ FUNCTION .................109

3.8.1 Overview ..............................................................................................................109

c-3

Page 28

TABLE OF CONTENTS B-65395EN/01

3.8.2 Details of Function ...............................................................................................109

3.8.3 DI/DO Signals ......................................................................................................110

3.8.4 Parameter..............................................................................................................111

3.8.5 Notes ....................................................................................................................112

3.9 IMPROVEMENT OF TURRET/MAGAZINE NUMBER OUTPUT............... 114

3.9.1 Overview ..............................................................................................................114

3.9.2 Details of Function ...............................................................................................114

3.9.3 Signal ....................................................................................................................118

3.9.4 Parameter..............................................................................................................120

3.9.4.1 Related parameters........................................................................................... 121

3.10 MANUAL HANDLE INTERFACE ............................................................... 124

3.10.1 Overview ..............................................................................................................124

3.10.2 Details of Function ...............................................................................................124

3.10.3 Signal ....................................................................................................................125

3.10.3.1 Signal on the servo amplifier module .............................................................. 125

3.10.3.2 Signal on the CNC (host)................................................................................. 126

3.10.4 Parameter..............................................................................................................127

3.10.4.1 Parameter on the servo amplifier module ........................................................ 127

3.10.4.2 Parameter on the CNC (host)........................................................................... 127

4 DIRECT COMMANDS......................................................................... 128

4.1 DIRECT COMMAND FORMAT .................................................................129

4.2 DIRECT COMMAND CONTROL PROCEDURE .......................................131

4.2.1 Direct Command Control Procedure ....................................................................131

4.2.2 Instruction Command Control (EBUF, EBSY, and ECNT).................................132

4.2.3 Response Command Control (EOREND, EOSTB, EOPC, USR1, and ECONT)133

4.2.4 Command Completion Notification (ECF) ..........................................................133

4.2.5 Alarm (DAL)........................................................................................................134

4.2.6 Direct Command Execution Result ......................................................................134

4.3 LIST OF DIRECT COMMANDS................................................................. 135

4.4 DETAILS OF DIRECT COMMAND FUNCTIONS ...................................... 136

4.4.1 Signal Operation Commands................................................................................136

4.4.2 Parameter..............................................................................................................137

4.4.3 Status Read...........................................................................................................140

4.4.4 Axis Movement Commands.................................................................................154

4.5 THIRTY-TWO-BLOCK BUFFERING OPERATION ................................... 167

4.5.1 Overview ..............................................................................................................167

4.5.2 Memory Registration Procedure...........................................................................167

c-4

Page 29

B-65395EN/01 TABLE OF CONTENTS

4.5.3 Operation Procedure.............................................................................................168

5 EXTERNAL PULSE INPUT FUNCTION ............................................. 169

5.1 OVERIVIEW ..............................................................................................170

5.2 DETAILED DESCRIPTION........................................................................ 171

6 UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(OPTIONAL FUNCTION) ....................................................................172

6.1 OVERVIEW ...............................................................................................173

6.2 SERIES AND EDITIONS OF APPLICABLE SERVO SOFTWARE............ 174

6.3 SETUP METHOD ...................................................................................... 175

6.3.1 Overview ..............................................................................................................175

6.3.2 Details of the Setup Method .................................................................................176

6.4 SIGNAL .....................................................................................................180

6.5 PARAMETER ............................................................................................181

6.6 ALARM ...................................................................................................... 183

6.7 DIAGNOSIS............................................................................................... 183

7 QUICK STOP FUNCTION...................................................................184

7.1 OVERVIEW ...............................................................................................185

7.2 SERIES AND EDITIONS OF APPLICABLE SERVO SOFTWARE............ 185

7.3 SETTING METHOD................................................................................... 185

7.4 PARAMETER ............................................................................................186

III. TROUBLESHOOTING

1 OVERVIEW ......................................................................................... 189

2 ALARM NUMBERS AND BRIEF DESCRIPTIONS ............................190

3 ACTION AGAINST NOISE..................................................................201

3.1 NOTES ON CONNECTING THE GROUND SYSTEMS ............................ 203

3.2 NOTES ON SELECTING THE SPARK KILLER ........................................206

IV. MAINTENANCE OF SERVO AMPLIFIER MODULES

1 HOW TO REPLACE THE FUSES AND PRINTED CIRCUIT

BOARDS .............................................................................................211

1.1 HOW TO REPLACE THE FUSES AND PRINTED CIRCUIT BOARDS..... 212

1.1.1 Ordering Number of Printed Circuit Board..........................................................214

1.1.2 Fuse Locations......................................................................................................214

1.2 HOW TO REPLACE THE FAN MOTOR.................................................... 215

c-5

Page 30

TABLE OF CONTENTS B-65395EN/01

1.2.1 For Fan Motors for Internal Agitation for SVM1-4i and SVM1-20i ...................215

1.2.2 For Fan Motors for Internal Agitation for SVM1-40i and SVM1-80i .................216

1.2.3 External-Fan Motor ..............................................................................................217

V. SERVO MOTOR MAINTENANCE

1 SERVO MOTOR MAINTENANCE ......................................................221

1.1 RECEIVING AND KEEPING AC SERVO MOTORS ................................. 222

1.2 DAILY INSPECTION OF AC SERVO MOTORS ....................................... 223

1.3 PERIODIC INSPECTION OF AC SERVO MOTORS ................................ 225

1.4 REPLACING THE PULSECODER ............................................................ 228

1.5 SPECIFICATION NUMBERS OF REPLACEMENT PARTS...................... 230

APPENDIX

A SERVO AMPLIFIER MODULE FRONT VIEW .................................... 233

B PARAMETER LIST .............................................................................235

B.1 CONTROLLED-AXIS PARAMETERS .......................................................242

B.2 COORDINATE SYSTEM AND STROKE LIMIT PARAMETERS ............... 243

B.3 FEEDRATE PARAMETERS ...................................................................... 247

B.4 ACCELERATION/DECELERATION CONTROL PARAMETERS .............. 250

B.5 INPUT/OUTPUT SIGNALS PARAMETERS .............................................. 253

B.6 SERVO PARAMETERS ............................................................................ 264

B.7 DIGITAL SERVO STANDARD PARAMETER TABLE ............................... 286

C DIAGNOSIS LISTS .............................................................................288

C.1 SIGNALS SENT FROM CNC (HOST) TO SERVO AMPLIFIER

MODULE ................................................................................................... 289

C.1.1 Peripheral Equipment Control Interface (DRC = 0).............................................289

C.1.2 Direct Command Interface (DRC = 1).................................................................289

C.2 SIGNALS SENT FROM SERVO AMPLIFIER MODULE TO CNC (HOST) 290

C.2.1 Peripheral Equipment Control Interface (DRC = 0).............................................290

C.2.2 Direct Command Interface (DRC = 1).................................................................290

C.3 SERVO POSITIONAL DEVIATION AMOUNT

(SERVO AMPLIFIER MODULE)................................................................ 291

C.4 ACCELERATION/DECELERATION DELAY AMOUNT

(SERVO AMPLIFIER MODULE)................................................................ 291

C.5 FUNCTION BIT (SERVO AMPLIFIER MODULE)...................................... 291

C.6 DIRECT INPUT SIGNAL STATUSES (SERVO AMPLIFIER MODULE).... 291

c-6

Page 31

B-65395EN/01 TABLE OF CONTENTS

D POWER MATE CNC MANAGER FUNCTIONS .................................. 292

D.1 POWER MATE CNC MANAGER FUNCTIONS

(Series 16, 18, 21, Power Mate) ................................................................ 293

D.1.1 Overview ..............................................................................................................293

D.1.2 I/O Link Connection.............................................................................................293

D.1.3 Function Selection and Termination ....................................................................293

D.1.3.1 Selection .......................................................................................................... 293

D.1.3.2 Function Selection Soft Key............................................................................ 294

D.1.3.3 Termination...................................................................................................... 294

D.1.3.4 Disabling the Power Mate CNC Manager Functions ...................................... 294

D.1.3.5 Parameter Setting............................................................................................. 295

D.1.3.6 Restriction........................................................................................................ 296

D.1.4 Function Overview ...............................................................................................297

D.1.4.1 Soft key status transition diagram.................................................................... 297

D.1.4.2 Screen configuration........................................................................................ 299

D.1.4.3 Operations of an Active Slave ......................................................................... 301

D.1.5 FUNCTION DETAILS ........................................................................................302

D.1.5.1 System Configuration ...................................................................................... 302

D.1.5.2 Parameters........................................................................................................ 304

D.1.5.3 Diagnosis ......................................................................................................... 306

D.1.5.4 Absolute Coordinate ........................................................................................ 307

D.1.5.5 Machine Coordinates ....................................................................................... 308

D.1.5.6 Alarms ............................................................................................................. 308

D.1.6 Alarm Display on the Power Mate CNC Manager...............................................309

D.2 POWER MATE CNC MANAGER FUNCTION (Series 30i, 31i, 32i).......... 310

D.2.1 Screen Display......................................................................................................311

D.2.2 Inputting and Outputting Parameters....................................................................317

D.2.3 Parameters ............................................................................................................319

D.2.4 Warning................................................................................................................320

D.2.5 Note ....................................................................................................................321

E SERVO CHECK BOARD ....................................................................322

c-7

Page 32

Page 33

I. START-UP PROCEDURE

Page 34

Page 35

B-65395EN/01 START-UP PROCEDURE 1.OVERVIEW

1 OVERVIEW

This part describes the units and components of the FANUC servo

amplifier. It also explains the following information necessary to start

up the servo amplifier:

• Configurations

• Start-up procedure

• Confirmation of the operation

• Periodic maintenance of servo amplifier

- 3 -

Page 36

2.CONFIGURATIONS START-UP PROCEDURE B-65395EN/01

2 CONFIGURATIONS

- 4 -

Page 37

B-65395EN/01 START-UP PROCEDURE 2.CONFIGURATIONS

r

2.1 CONFIGURATIONS

A system using FANUC servo amplifier βi series SVMs consists of the

following units and parts:

(1) Servo amplifier module (SVM) (basic)

(2) AC line filter (basic)

(3) Connectors (for connecting cables) (basic)

(4) Fuses (option)

(5) Power transformer (option)

Constituent (example)

Control power

supply

24VDC ± 10%

3φ

200 to 240 VAC

or

1φ

220 to 240 VAC

(4A or 20A models

only)

Circuit

breker

βiseries

SVM

Magnetic

contacto

: Basic

: Option

: Units prepared by the machine tool builder

AC line

filter

Servo

motor

NOTE

1 A circuit breakers, magnetic contactor, and AC line

filter are always required.

2 To protect the unit from surge currents caused by

lightning, connect surge absorbers between lines,

and between the lines and ground, at the power inlet

of the power magnetics cabinet.

3 The AC line filter is different from the AC reactor,

which is designed for another purpose. Substituting

one for the other or using one as both the filter and

reactor is not allowed.

βi series

SVM

Servo

motor

- 5 -

Page 38

2.CONFIGURATIONS START-UP PROCEDURE B-65395EN/01

2.2 MAJOR COMPONENTS

2.2.1 Servo Amplifier Modules

(1) Servo amplifier module (SVM1)

Model Order specification Unit specification

SVM1-4i

SVM1-20i

SVM1-40i

SVM1-80i

A06B-6132-H001 A06B-6132-C001 A20B-2101-0090

A06B-6132-H002 A06B-6132-C002 A20B-2101-0091

A06B-6132-H003 A06B-6132-C003 A16B-3200-0512

A06B-6132-H004 A06B-6132-C004 A16B-3200-0513

Wiring board

specification

Printed circuit board

specification

A20B-8101-0200

- 6 -

Page 39

B-65395EN/01 START-UP PROCEDURE 3.START-UP PROCEDURE

3 START-UP PROCEDURE

- 7 -

Page 40

3.START-UP PROCEDURE START-UP PROCEDURE B-65395EN/01

3.1 START-UP PROCEDURE (OVERVIEW)

Make sure that the specifications of the CNC, servo motors, servo

amplifiers, and other units you received are exactly what you ordered,

and these units are connected correctly. Then, turn on the power.

(1) Before turning on the circuit breaker, check the power supply voltage

connected.

Make sure that the protective ground is connected. Also make sure that

the selected ground fault interrupter is appropriate for the leakage

current that is anticipated.

→ See Section 3.2.

↓

(2) Before the system can be used, some switches and dummy connectors

require setting. So, check the necessary settings.

→ See Section 3.3.

↓

(3) Start the servo amplifier module.

↓

(4) Start the CNC.

↓

(5) Set up parameters.

- 8 -

Page 41

B-65395EN/01 START-UP PROCEDURE 3.START-UP PROCEDURE

3.2 CONNECTING THE POWER

3.2.1 Checking the Voltage and Capacity of the Power

Before connecting the power, you should measure the AC power

voltage.

Table 3.2.1(a) Action for the AC power (200-V input type)

Permissible

[kVA]

[kVA]

Nominal

voltage

3-phase

200 to

240VAC

1-phase

220 to

240VAC

Action

SVM1-4i, SVM1-20i

SVM1-40i, SVM1-80i

Permitted.

Note) If the voltage is below the rated value,

the rated output may not be obtained.

SVM1-4i, SVM1-20i

Single-phase input is permitted when the power

supply is 380 to 415 VAC to neutral grounding.

SVM1-4i, SVM1-20i

SVM1-40i, SVM1-80i

Not permitted.

Use an insulating transformer to adjust the input

voltage.

SVM1-4i SVM1-20i SVM1-40i SVM1-80i

0.2 1.9 3.9 6.2

22

voltage

fluctuation

width

-15%

+10%

-15%

+10%

Other than the above

Table 3.2.1 (b) list the input power specification. Use a power source

with sufficient capacity so that the system will not malfunction due to a

voltage drop even at a time of peak load.

Table 3.2.1 (b) AC power voltage specifications (200-V input type)

Model

Nominal voltage rating 200 to 240VAC -15%, +10%

Power source frequency 50/60Hz ±1Hz

Power source capacity

(for the main circuit)

Power source capacity

(for the control circuit)

3.2.2 Connecting a Protective Ground

Check that the protective ground line is connected correctly.

3.2.3 Selecting the Ground Fault Interrupter That Matches the

Leakage Current

Check that a correct ground fault interrupter is selected.

- 9 -

Page 42

3.START-UP PROCEDURE START-UP PROCEDURE B-65395EN/01

3.3 INITIALIZING PARAMETERS (SWITCHES AND DUMMY

CONNECTORS)

SVM1-4i, SVM1-20i

• When no regenerative resistor is used

Connect connector CXA20 by using a dummy connector.

See FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

(B-65322EN).

SVM1-40i, SVM1-80i

• Switch (SW) setting

The regenerative resistor alarm level is set. The setting condition

varies depending on the regenerative resistor used (the built-in

regenerative resistor or separate regenerative resistor). Perform

the setting properly.

WARNING

Incorrect setting can damage the regenerative

resistor.

See FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

(B-65322EN).

• When the built-in regenerative resistor is used

Connect connector CXA20 by using a dummy connector.

Connect connector CZ6 by using a dummy connector.

See FANUC SERVO AMPLIFIER βi series DESCRIPTIONS

(B-65322EN).

- 10 -

Page 43

B-65395EN/01 START-UP PROCEDURE 3.START-UP PROCEDURE

3.4 PARAMETER INITIALIZATION

(1) Preparation prior to servo parameter initialization

Before servo parameter initialization, check the following:

<1> Servo motor model (Example: β8/3000is)

<2> Amount of travel per motor rotation (Example: 10 mm/motor

revolution)

At first, decide "detection unit", for example detection unit = 1µm.

Next, calculate number of pulses per motor revolution with

"detection unit" and "amount of travel per motor revolution".

(Number of pulses per motor revolution)

= (Amount of travel per motor revolution) / (Detection unit)

Example)

In case detection unit = 1µm, amount of travel per motor

revolution =10mm

10mm/1µm=10000

Then, number of pulses per motor revolution = 10000

pulses/revolution

(2) Procedure for servo parameter initialization

<1> Turn on the power to the servo amplifier module.

<2> Turn on the power to the host controller in the emergency

stop state.

<3> Perform parameter initialization from the CNC.

Set values for the parameters listed below. (See <5> to <9>.)

Example Parameter number

Motor type number 258 No.125

CMR 2 No.32

Numerator for the number of

pulses per revolution

Denominator for the number of

pulses per revolution

Direction of travel 111 No.31

Reference counter capacity 10000 No.180

<4> Set initialization bit DGPR to 0.

b7 b6 b5 b4 b3 b2 b1 b0

No.12 DGPR

When this bit is set to 0, a power disconnection request alarm

(alarm No. 0) is issued. However, 5 to 9 below can be set.

Start initialization

(The power to the CNC is not turned on until 11.)

10000 No.105

1 No.106

DGPR (b1) = 0

- 11 -

← DGPR is automatically set to 1 when the

power is turned off then back on.

Page 44

3.START-UP PROCEDURE START-UP PROCEDURE B-65395EN/01

<5> Set a motor type number.

In parameter No. 125, set the motor type number of the servo

motor to be used.

SVM1-4i

Motor model

Motor

specification

Motor type number

SVM1-20i

Motor model

Motor

specification

Motor type number

Motor model

Motor

specification

Motor type number

Motor model

Motor

specification

Motor type number

SVM1-40i

Motor model

Motor

specification

Motor type number

SVM1-80i

Motor model

Motor

specification

Motor type number

β0.2/5000is β0.3/5000is

0111 0112

260 261

α1/5000i β2/4000is α2/5000i β4/4000is β8/3000is

0202 0061 0205 0063 0075

252 253 255 256 258

α2/5000is α4/5000is αC4/3000i αC8/2000i β0.4/5000is

0212 0215 0221 0226 0114

262 265 271 276 280

β0.5/5000is β1/5000is

0115 0116 0241

281 282 291

αC12/2000i

β12/3000is α4/4000i β22/2000is α8/3000i αC22/2000i

0078 0223 0085 0227 0246

272 273 274 277 296

α8/4000is α12/4000is α12/3000i α22/3000i αC30/1500i

0235 0238 0243 0247 0251

285 288 293 297 301

<6> Set CMR.

In parameter No. 32, set a factor by which the amount of

travel specified in the CNC is multiplied for the servo

system.

CMR = Command unit/detection unit

When CMR is 1 to 48

Setting = CMR x 2

When CMR is 1/2 to 1/27

Usually, CMR = 1. So, set 2.

- 12 -

Setting = 1/CMR + 100

Page 45

B-65395EN/01 START-UP PROCEDURE 3.START-UP PROCEDURE

<7> Set the number of pulses per revolution

The number of pulses per revolution is calculated with

reduction ratios or leads of the ball screws and detection unit.

(Number of pulses per motor revolution)

= (amount of travel per motor revolution) / (detection unit)

Numerator for the number of pulses

per rotation

Denominator for the number of

pulses per rotation

(Parameter No. 179) (>32767)

(Parameter No. 105) (≤32767)

=

(Parameter No. 106) (≤32767)

=

(Parameter No. 106) (≤32767)

Example of setting)

Example: 10um detection in semi-closed loop

Ball screw lead Number of pulses per rotation

Numerator/denominator

10 (mm/rev)

20 (mm/rev)

30 (mm/rev)

10mm/10µm=1000/1

20mm/10µm=2000/1

30mm/10µm=3000/1

Example of setting)

1/100 degree detection with a deceleration ratio of 10:1 for a

rotation axis

Every time the motor makes one rotation, the table rotates through 360/10

degrees. The number of pulses per motor rotation is 360/10 ÷ (1/100) = 3600

pulses, so set the ollowing:Numerator = 3600, Denominator = 1

<8> Set the direction of motor travel in parameter No. 31.

111 Clockwise as viewed from the pulse coder

-111 Counterclockwise as viewed from the pulse coder

<9> Set the reference counter capacity. (Parameter No. 180)

Set the reference counter capacity when performing a

reference position return operation based on the grid method.

Set the number of position pulses per motor rotation, or set

that number divided by an integer.

Example of setting)

αi pulse coders, semi-closed loop (1µmm detection)

Ball screw lead

10mm/revolution

20

30

Number of

pulses per motor

revolution

10000/1

20000/1

30000/1

Reference

counter

10000

20000

30000

Grid width

10mm

20mm

30mm

- 13 -

Page 46

3.START-UP PROCEDURE START-UP PROCEDURE B-65395EN/01

<10>Turn off/on both CNC and servo amplifier module and servo

parameter initialization is finished.

This completes servo parameter initialization.

<11>If you use αi pulse coder as an absolute pulse coder, some

procedures described below are needed.

1 Set the following parameter, then turn off / on the host

CNC and servo amplifier module.

b7 b6 b5 b4 b3 b2 b1 b0

No.11 APCX ABSX

APCX (#7) Absolute position detector is

0 : not used 1 : used

ABSX (#0) Position of machine and position of absolute pulse coder is

0 : not matched 1 : matched

2 Make sure that a battery is connected to the absolute

pulse coder, and turn the power to the host CNC and

servo amplifier module off and on again.

3 A reference position return request is indicated.

4 Rotate the servo motor through one or more rotations by

jogging and so on.

5 Turn the power to the host CNC and servo amplifier

module off, then back on again.

6 CNC requires the reference position return again.

7 Perform reference position return. The ABSX is set to 1

after finishing the reference position return.

- 14 -

Page 47

B-65395EN/01 START-UP PROCEDURE 4.CONFIRMATION OF THE OPERATION

4 CONFIRMATION OF THE OPERATION

- 15 -

Page 48

4.CONFIRMATION OF THE OPERATION START-UP PROCEDURE B-65395EN/01

4.1 CHECK PROCEDURE

1. Turn on the power.

When the LED indicates data other than or

Refer to the explanation of troubleshooting in Part III.

2. The LED indicates

3. The emergency stop state is released.

The LED does not indicate

Check the *ESP signal applied to the servo amplifier module.

Check the *ESP signal applied through the I/O link.

4. The LED indicates

5. Issue a command from the host controller.

6. Check the operation of the servo motor.

An alarm is issued.

Refer to the explanation of troubleshooting in Part III.

The motor does not rotate.

Check the command.

Check the parameter settings.

Check *RILK applied to the servo amplifier module.

The motor malfunctions.

Check the standard setting parameters are correctly set.

Check the setting value of No.100(load inertia) and No.107(position loop gain).

- 16 -

Page 49

B-65395EN/01 START-UP PROCEDURE 4.CONFIRMATION OF THE OPERATION

Table 4.1 LED Indications and Meanings

LED indication State Description

Blinking

Blinking

Indication other

than the above

Servo amplifier

module not ready

Servo amplifier

module ready

Command being

executed

Parameters being

loaded

Alarm

This indicates that control power (+24

VDC) is supplied. No alarm is issued, but

the motor is not activated.

This indicates that the motor is activated,

and that commands can now be accepted.

This indicates that an accepted command

is now being executed.

This indicates that parameters are being

loaded in a batch from the power mate

CNC manager.

An alarm is issued. For information about

alarms, see the explanation of

troubleshooting in Part III.

- 17 -

Page 50

4.CONFIRMATION OF THE OPERATION START-UP PROCEDURE B-65395EN/01

LED

LED

4/20A

40/80A

- 18 -

Page 51

B-65395EN/01 START-UP PROCEDURE 5.PERIODIC MAINTENANCE OF SERVO AMPLIFIER

5 PERIODIC MAINTENANCE OF SERVO

AMPLIFIER

- 19 -

Page 52

5.PERIODIC MAINTENANCE OF SERVO AMPLIFIER START-UP PROCEDURE B-65395EN/01

5.1 BATTERY FOR THE ABSOLUTE PULSECODER

The battery unit for the absolute Pulsecoder can be connected using

[Connection scheme 1] and [Connection scheme 2] explained below.

[Connection scheme 1]

Supplying power from one battery unit to more than one SVM

Battery case

A06B-6050-K060

SVM SVM

CXA19B CXA19B

CXA19A CXA19A

Battery

A06B-6050-K061

Connector

A06B-6130-K201

• If a low battery voltage or a battery voltage of 0 V is indicated by

an APC (absolute Pulsecoder) alarm, replace the battery.

If a battery voltage of 0 V is indicated, you need to make a zero

point return.

If a battery voltage of 0 V is indicated, you need to make a zero

point return.