Page 1

@

FANUC SERVO AMPLIF IER

DESCRIPTIONS

* series

B-65282EN/06

Page 2

- No part of this manual may be reproduced in any form.

- All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and

Foreign Trade Law”. The export from Japan may be subject to an export license by the

government of Japan.

Further, re-export to another country may be subject to the license of the government of

the country from where the product is re-exported. Furthermore, the product may also be

controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

General Safety Precautions

- When an abnormality such as an alarm or a hardware failure occurs, the operations

described in the specifications are not guaranteed unless otherwise specifically noted.

When action corresponding to the abnormality is specifically described, take the action.

When no action is described, please contact FANUC.

- The signals and functions described in the specifications cannot be used separately for

safety functions unless otherwise described as being usable for the safety functions.

Their specifications are not assumed to be used as the safety functions in this case, an

unexpected danger may be caused. For information about the safety functions, please

contact FANUC.

Generally, the safety functions represent functions that protect the operators from

machine danger.

- A wrong device connection or setting can lead to unpredictable operation. When

starting to operate the machine for the first time after assembling the machine, replacing

components, or modifying parameter settings, exercise the greater care by, for example,

reducing the torque limit value, error detection level, or operating speed or by operating

the machine in such a way that an emergency stop can be made quickly.

Page 3

B-65282EN/06 SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

This "Safety Precautions" section describes the precautions which

must be observed to ensure safety when using FANUC servo

amplifiers (including spindle amplifiers). Users of any control motor

amplifier model are requested to read the "Safety Precautions"

carefully before first using the amplifier. Users should also read the

relevant description in this manual to become fully familiar with the

functions of the servo amplifier.

The users are basically forbidden to do any behavior or action not

mentioned in the "Safety Precautions." They are invited to ask

FANUC previously about what behavior or action is prohibited.

Contents

DEFINITION OF WARNING, CAUTION, AND NOTE ................s-2

WARNINGS AND CAUTIONS RELATING TO MOUNTING .....s-3

Warning...................................................................................... s-3

Caution ....................................................................................... s-5

Note............................................................................................s-7

WARNINGS AND CAUTIONS RELATING TO A PILOT RUN ..s-8

Warning...................................................................................... s-8

Caution ....................................................................................... s-9

WARNINGS AND CAUTIONS RELATING TO

MAINTENANCE ............................................................................s-10

Warning.................................................................................... s-10

Caution ..................................................................................... s-12

Note..........................................................................................s-13

s-1

Page 4

SAFETY PRECAUTIONS B-65282EN/06

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and

preventing damage to the machine. Precautions are classified into

Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning,

Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being

injured or when there is a danger of both the user

being injured and the equipment being damaged if

the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment

being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary

information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-2

Page 5

B-65282EN/06 SAFETY PRECAUTIONS

WARNINGS AND CAUTIONS RELATING TO MOUNTING

Warning

WARNING

- Check the specification code of the amplifier.

Check that the delivered amplifier is as originally ordered.

- Mount a ground fault interrupter.

To guard against fire and electric shock, fit the factory power

supply or machine with a ground fault interrupter (designed for

use with an inverter).

- Securely ground the amplifier.

Securely connect the ground terminal and metal frame of the

amplifier and motor to a common ground plate of the power

magnetic cabinet.

- Be aware of the weight of the amplifier and other

components.

Control motor amplifiers and AC reactors are heavy. When

transporting them or mounting them in the cabinet, therefore, be

careful not to injured yourself or damage the equipment. Be

particularly carefull not to jam your fingers between the cabinet

and amplifier.

- Never ground or short-circuit either the power supply lines

or power lines.

Protect the lines from any stress such as bending. Handle the

ends appropriately.

- Ensure that the power supply lines, power lines, and signal

lines are securely connected.

A loose screw, loose connection, or the like will cause a motor

malfunction or overheating, or a ground fault.

Be extremely careful with power supply lines, motor power lines,

and DC link connections through which a large amount of

current passes, because a loose screw (or poor contact in a

connector or poor connection between a connector terminal and a

cable) may cause a fire.

- Insulate all exposed parts that are charged.

- Never touch the regenerative discharge resistor or radiator

directly.

The surface of the radiator and regenerative discharge unit

become extremely hot. Never touch them directly. An

appropriate structure should also be considered.

s-3

Page 6

SAFETY PRECAUTIONS B-65282EN/06

WARNING

- Close the amplifier cover after completing the wiring.

Leaving the cover open presents a danger of electric shock.

- Confirm that the input voltage meets the specifications of the

amplifier before making connection.

If the input voltage exceeds the specified value (for example, if

the input voltage for a 200-V input amplifier is 400 V), an internal

component may be damaged and burnt out.

- Prevent conductive, flammable, or corrosive foreign matters,

mists, or water droplets from entering the unit

If conductive or flammable foreign matters enter the unit,

explosion or corruption may be caused.

If corrosive or conductive mists or water droplets are attached to

an electronic circuit, unexpected operation may be caused in the

circuit.

The electronic circuit portion must be installed in an environment

of pollution level 2 specified by IEC60664-1. To achieve

pollution level 2 in a severe machine tool environment, it is

generally necessary to install the portion in a cabinet that satisfies

IP54.

s-4

Page 7

B-65282EN/06 SAFETY PRECAUTIONS

Caution

CAUTION

- Do not step or sit on the amplifier.

Also, do not stack unpacked amplifiers on top of each other.

- Use the amplifier in an appropriate environment.

See the allowable ambient temperatures and other requirements,

given in the corresponding descriptions.

- Protect the amplifier from impact.

Do not place anything on the amplifier.

- Do not disassemble the amplifier.

- Do not block the air inlet to the radiator.

- Take appropriate measures to prevent coolant, oil mist, or

chips from being adhered to the radiator and fan motors that

are exposed to the outside of the power magnetics cabinet.

A deposit of coolant, oil mist, or chips on the air inlet will result

in a reduction in the cooling efficiency. In some cases, the

required efficiency cannot be achieved. The deposit may also

lead to a reduction in the useful life of the fan motors or

semiconductors. Especially, when outside air is drawn in, mount

filters on both the air inlet and outlet. These filters must be

replaced regularly.

So, an easy-to-replace type of filter should be used.

- Connect the power supply lines and power lines to the

appropriate terminals and connectors.

- Connect the signal lines to the appropriate connectors.

- Ensure that the cables used for the power supply lines and

power lines are of the appropriate diameter and temperature

ratings.

- Do not apply an excessively large force to plastic parts.

If a plastic section breaks, it may cause internal damage, thus

interfering with normal operation. The edge of a broken section

is likely to be sharp and, therefore, presents a risk of injury.

- Before connecting the power supply wiring, check the supply

voltage.

Check that the supply voltage is within the range specified in this

manual, then connect the power supply lines.

- Ensure that the combination of motor and amplifier is

appropriate.

s-5

Page 8

SAFETY PRECAUTIONS B-65282EN/06

CAUTION

- Ensure that valid parameters are specified.

Specifying an invalid parameter for the combination of motor

and amplifier may not only prevent normal operation of the

motor but also result in damage to the amplifier.

- Ensure that the amplifier and peripheral equipment are

securely connected.

Check that the magnetic contactor, circuit breaker, and other

devices mounted outside the amplifier are securely connected to

each other and that those devices are securely connected to the

amplifier.

- Check that the amplifier is securely mounted in the power

magnetic cabinet.

If any clearance is left between the power magnetic cabinet and

the surface on which the amplifier is mounted, dust entering the

gap may build up and prevent the normal operation of the

amplifier.

- Apply appropriate countermeasures against noise.

Adequate countermeasures against noise are required to maintain

normal operation of the amplifier. For example, signal lines must

be routed away from power supply lines and power lines.

s-6

Page 9

B-65282EN/06 SAFETY PRECAUTIONS

Note

NOTE

- Keep the nameplate clearly visible.

- Keep the legend on the nameplate clearly visible.

- After unpacking the amplifier, carefully check for any

damage.

- Mount the amplifier in a location where it can be easily

accessed periodic inspection and daily maintenance.

- Leave sufficient space around the machine to enable

maintenance to be performed easily.

Do not place any heavy objects such that they would interfere

with the opening of the doors.

- Keep the parameter table and spare parts at hand.

Also, keep the specifications at hand. These items must be stored

in a location where they can be retrieved immediately.

- Provide adequate shielding.

A cable to be shielded must be securely connected to the ground

plate, using a cable clamp or the like.

s-7

Page 10

SAFETY PRECAUTIONS B-65282EN/06

WARNINGS AND CAUTIONS RELATING TO A PILOT RUN

Warning

WARNING

- Before turning on the power, check that the cables connected

to the power magnetic cabinet and amplifier, as well as the

power lines and power supply lines, are securely connected.

Also, check that no lines are slack.

- Before turning on the power, ensure that the power magnetic

cabinet is securely grounded.

- Before turning on the power, check that the door of the

power magnetic cabinet and all other doors are closed.

Ensure that the door of the power magnetic cabinet containing

the amplifier, and all other doors, are securely closed. During

operation, all doors must be closed and locked.

- Apply extreme caution if the door of the power magnetic

cabinet or another door must be opened.

Only a person trained in the maintenance of the corresponding

machine or equipment should open the door, and only after

shutting off the power supply to the power magnetic cabinet (by

opening both the input circuit breaker of the power magnetic

cabinet and the factory switch used to supply power to the

cabinet). If the machine must be operated with the door open to

enable adjustment or for some other purpose, the operator must

keep his or her hands and tools well away from any dangerous

voltages. Such work must be done only by a person trained in the

maintenance of the machine or equipment.

- When operating the machine for the first time, check that the

machine operates as instructed.

To check whether the machine operates as instructed, first

specify a small value for the motor, then increase the value

gradually. If the motor operates abnormally, perform an

emergency stop immediately.

- After turning on the power, check the operation of the

emergency stop circuit.

Press the emergency stop button to check that the motor stops

immediately, and that the power being supplied to the amplifier

is shut off by the magnetic contactor.

- Before opening a door or protective cover of a machine to

enable adjustment of the machine, first place the machine in

the emergency stop state and check that the motor has

stopped.

s-8

Page 11

B-65282EN/06 SAFETY PRECAUTIONS

Caution

CAUTION

- Note whether an alarm status relative to the amplifier is

displayed at power-up or during operation.

If an alarm is displayed, take appropriate action as explained in

the maintenance manual. If the work to be done requires that the

door of the power magnetic cabinet be left open, the work must

be carried out by a person trained in the maintenance of the

machine or equipment. Note that if some alarms are forcibly reset

to enable operation to continue, the amplifier may be damaged.

Take appropriate action according to the contents of the alarm.

- Before operating the motor for the first time, mount and

adjust the position and speed sensors.

Following the instructions given in the maintenance manual,

adjust the position and speed sensors for the spindle so that an

appropriate waveform is obtained.

If the sensors are not properly adjusted, the motor may not rotate

normally or the spindle may fail to stop as desired.

- If the motor makes any abnormal noise or vibration while

operating, stop it immediately.

Note that if operation is continued in spite of there being some

abnormal noise or vibration, the amplifier may be damaged. Take

appropriate corrective action, then resume operation.

- Observe the ambient temperature and output rating

requirements.

The continuous output rating or continuous operation period of

some amplifiers may fall as the ambient temperature increases. If

the amplifier is used continuously with an excessive load applied,

the amplifier may be damaged.

s-9

Page 12

SAFETY PRECAUTIONS B-65282EN/06

WARNINGS AND CAUTIONS RELATING TO MAINTENANCE

Warning

WARNING

- Read the maintenance manual carefully and ensure that you

are totally familiar with its contents.

The maintenance manual describes daily maintenance and the

procedures to be followed in the event of an alarm being issued.

The operator must be familiar with these descriptions.

- Notes on replacing a fuse or circuit board

1) Before starting the replacement work, ensure that the circuit

breaker protecting the power magnetic cabinet is open.

2) Check that the red LED that indicates that charging is in

progress is not lit.

The position of the charging LED on each model of

amplifier is given in this manual. While the LED is lit,

hazardous voltages are present inside the unit, and thus

there is a danger of electric shock.

3) Some circuit board components become extremely hot. Be

careful not to touch these components.

4) Ensure that a fuse having an appropriate rating is used.

5) Check the specification code of a circuit board to be

replaced. If a modification drawing number is indicated,

contact FANUC before replacing the circuit board.

Also, before and after replacing a circuit board, check its

pin settings.

6) After replacing the fuse, ensure that the screws are firmly

tightened. For a socket-type fuse, ensure that the fuse is

inserted correctly.

7) After replacing the circuit board, ensure that it is securely

connected.

8) Ensure that all power lines, power supply lines, and

connectors are securely connected.

- Take care not to lose any screws.

When removing the case or circuit board, take care not to lose

any screws. If a screw is lost inside the nit and the power is

turned on, the machine may be damaged.

s-10

Page 13

B-65282EN/06 SAFETY PRECAUTIONS

WARNING

- Notes on replacing the battery of the absolute Pulsecoder

Replace the battery only while the power is on. If the battery is

replaced while the power is turned off, the stored absolute

positioning data will be lost. Some αi series servo amplifier

modules have batteries in their servo amplifiers. To replace the

battery of any of those models, observe the following procedure:

Open the door of the power magnetic cabinet; Leave the control

power of the power supply module on; Place the machine in the

emergency stop state so that the power being input to the

amplifier is shut off; Then, replace the battery. Replacement

work should be done only by a person who is trained in the

related maintenance and safety requirements. The power

magnetic cabinet in which the servo amplifier is mounted has a

high-voltage section. This section presents a severe risk of

electric shock.

- Check the number of any alarm.

If the machine stops upon an alarm being issued, check the alarm

number. Some alarms indicate that a component must be replaced.

If the power is reconnected without first replacing the failed

component, another component may be damaged, making it

difficult to locate the original cause of the alarm.

- Before resetting an alarm, ensure that the original cause of

the alarm has been removed.

- Contact FANUC whenever a question relating to

maintenance arises.

s-11

Page 14

SAFETY PRECAUTIONS B-65282EN/06

Caution

CAUTION

- Ensure that all required components are mounted.

When replacing a component or circuit board, check that all

components, including the snubber capacitor, are correctly

mounted. If the snubber capacitor is not mounted, for example,

the IPM will be damaged.

- Tighten all screws firmly.

- Check the specification code of the fuse, circuit board, and

other components.

When replacing a fuse or circuit board, first check the

specification code of the fuse or circuit board, then mount it in

the correct position. The machine will not operate normally if a

fuse or circuit board having other than the correct specification

code is mounted, or if a fuse or circuit board is mounted in the

wrong position.

- Mount the correct cover.

The cover on the front of the amplifier carries a label indicating a

specification code. When mounting a previously removed front

cover, take care to mount it on the unit from which it was

removed.

- Notes on cleaning the heat sink and fan

1) A dirty heat sink or fan results in reduced semiconductor

cooling efficiency, which degrades reliability. Periodic

cleaning is necessary.

2) Using compressed air for cleaning scatters the dust. A

deposit of conductive dust on the amplifier or peripheral

equipment will result in a failure.

3) To clean the heat sink, do so only after turning the power

off and ensuring that the heat sink has cooled to room

temperature. The heat sink becomes extremely hot, such

that touching it during operation or immediately after

power-off is likely to cause a burn. Be extremely careful

when touching the heat sink.

- Notes on removing the amplifier

Before removing the amplifier, first ensure that the power is shut

off. Be careful not to jam your fingers between the power

magnetic cabinet and amplifier.

- Unless otherwise specified, do not insert or remove any

connector while the power is turned on. Otherwise, the

amplifier may fail.

s-12

Page 15

B-65282EN/06 SAFETY PRECAUTIONS

Note

NOTE

- Ensure that the battery connector is correctly inserted.

If the power is shut off while the battery connector is not

connected correctly, the absolute position data for the machine

will be lost.

- Store the manuals in a safe place.

The manuals should be stored in a location where they can be

accessed immediately it so required during maintenance work.

- Notes on contacting FANUC

Inform FANUC of the details of an alarm and the specification

code of the amplifier so that any components required for

maintenance can be quickly secured, and any other necessary

action can be taken without delay.

s-13

Page 16

Page 17

B-65282EN/06 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTIONS............................................................................s-1

DEFINITION OF WARNING, CAUTION, AND NOTE ............................................. s-2

WARNINGS AND CAUTIONS RELATING TO MOUNTING ...................................s-3

Warning ...............................................................................................................................s-3

Caution ...............................................................................................................................s-5

Note ...............................................................................................................................s-7

WARNINGS AND CAUTIONS RELATING TO A PILOT RUN ................................s-8

Warning ...............................................................................................................................s-8

Caution ...............................................................................................................................s-9

WARNINGS AND CAUTIONS RELATING TO MAINTENANCE........................... s-10

Warning .............................................................................................................................s-10

Caution .............................................................................................................................s-12

Note .............................................................................................................................s-13

1 CONFIGURATION ..................................................................................1

1.1 FEATURES OF THE SERVO AMPLIFIER αi SERIES.................................. 2

1.2 CONFIGURATION......................................................................................... 3

1.2.1 200-V Input Series....................................................................................................3

1.2.2 400-V Input Series....................................................................................................6

1.3 SERVO AMPLIFIERS.................................................................................... 8

1.4 LINEUP........................................................................................................ 10

2 SPECIFICATIONS................................................................................. 11

2.1 INPUT POWER ...........................................................................................12

2.2 ENVIRONMENTAL CONDITIONS ..............................................................25

2.3 SPECIFICATIONS OF THE MODULES ...................................................... 33

2.3.1 αi PS series .............................................................................................................33

2.3.2 αi SV series ............................................................................................................37

2.3.3 αi SP series .............................................................................................................40

2.4 WEIGHT ...................................................................................................... 43

3 ORDERING INFORMATION ................................................................. 45

3.1 SERVO AMPLIFIER .................................................................................... 46

3.1.1 200-V Input Series..................................................................................................46

3.1.1.1 αi PS series ........................................................................................................ 46

3.1.1.2 αi PS

3.1.1.3 αi SV series ....................................................................................................... 47

3.1.1.4 αi SP series ........................................................................................................ 49

3.1.2 400-V Input Series..................................................................................................50

3.1.2.1 αi PS series ........................................................................................................ 50

3.1.2.2 αi SV series ....................................................................................................... 51

3.1.2.3 αi SP series ........................................................................................................ 53

3.1.3 Others .....................................................................................................................54

3.1.3.1 AC reactor.......................................................................................................... 54

3.1.3.2 AC line filter ...................................................................................................... 56

3.1.3.3 Sub module SW ................................................................................................. 57

series ......................................................................................................46

R

c-1

Page 18

TABLE OF CONTENTS B-65282EN/06

3.1.3.4 Sub module SM .................................................................................................57

3.1.3.5 Connectors ......................................................................................................... 58

3.1.3.6 Fuses .................................................................................................................. 64

3.1.3.7 Power transformer ............................................................................................. 65

3.1.3.8 Regenerative discharge unit............................................................................... 69

3.1.3.9 Cables ................................................................................................................ 70

3.1.3.10 Circuit breaker and magnetic contactor ............................................................. 71

3.1.3.11 Lightning surge protector .................................................................................. 74

3.1.3.12 Noise filter ......................................................................................................... 75

3.1.3.13 Sensors for servo ............................................................................................... 75

3.1.3.14 Sensors for spindle............................................................................................. 76

3.1.3.15 Power line switch unit ....................................................................................... 77

3.1.3.16 Battery for absolute Pulsecoder ......................................................................... 78

4 HOW TO SELECT THE MODULE ........................................................ 79

4.1 HOW TO SELECT THE αi SV SERIES (SERVO AMPLIFIER) ................... 80

4.1.1 200-V Input Series..................................................................................................81

4.1.2 400-V Input Series..................................................................................................82

4.1.3 How to Select the Dynamic Brake Module (DBM) ...............................................83

4.2 HOW TO SELECT THE αi SP series(SPINDLE AMPLIFIER)..................... 84

4.2.1 200-V Input Series..................................................................................................85

4.2.2 400-V Input Series..................................................................................................85

4.3 HOW TO SELECT THE αi PS series (POWER SUPPLY) ..........................86

4.3.1 How to Obtain the αi PS series rated output capability .........................................87

4.3.2 How to Obtain the αi PS series maximum output capability .................................87

4.3.3 How to Obtain the αi PS series peak maximum output capability.........................88

4.3.4 Number of Connected αi SV series and αi SP Series ............................................89

4.3.5 Notes on 400-V Input αi PS series selection ..........................................................89

4.4 HOW TO SELECT THE αi PSR series (POWER SUPPLY, RESISTANCE

DISCHARGE TYPE).................................................................................... 90

4.4.1 How to Obtain the αi PSR series Rated Output Capability.....................................91

4.4.2 How to Obtain the αi PS

4.4.3 Number of Connected αi SV series and αi SP series .............................................92

4.4.4 Selecting a Regenerative Discharge Unit ...............................................................93

4.5 LIST OF MOTOR OUTPUT CAPACITIES FOR αi PS AND αi PSR series

SELECTION ................................................................................................ 96

4.5.1 Servo Motor Continuous Rated Outputs and Maximum Outputs at Acceleration .96

4.5.2 Spindle Motor Continuous Rated Outputs and Maximum Outputs at

Acceleration..........................................................................................................100

series Maximum Output Capability .............................91

R

5 INSTALLATION ..................................................................................102

5.1 LEAKAGE CURRENT ............................................................................... 103

5.2 GROUND................................................................................................... 104

5.2.1 Ground Systems ...................................................................................................104

5.2.2 Grounding Method ...............................................................................................105

5.2.3 Notes on Connecting ............................................................................................107

5.3 NOISE PREVENTION ............................................................................... 108

5.3.1 Separation of Signal Lines ...................................................................................108

5.3.2 Cable Clamp and Shield Processing .....................................................................109

5.3.3 Cabinet .................................................................................................................113

5.3.4 Others ...................................................................................................................116

c-2

Page 19

B-65282EN/06 TABLE OF CONTENTS

5.4 AMPLIFIER INSTALLATION ..................................................................... 117

5.5 AMPLIFIER INSTALLATION NOTES RELATING TO SAFETY

STANDARDS............................................................................................. 118

5.5.1 Requirements of EN and IEC Standards ..............................................................118

5.5.1.1 Classification in standards on insulation design .............................................. 118

5.5.1.2 Protection against electric shock...................................................................... 119

5.5.1.3 Protective grounding........................................................................................ 121

5.5.1.4 EMC................................................................................................................. 121

5.5.1.5 Notes on the emergency stop circuit configuration .........................................121

5.5.1.6 Reduction of load ratio to ambient temperature .............................................. 122

5.5.1.7 Overload protection ......................................................................................... 122

5.5.1.8 External overload protection device ................................................................ 122

5.5.1.9 Over-speed protection...................................................................................... 122

5.5.1.10 24-V power supply ..........................................................................................122

5.5.1.11 Screw tightening torque................................................................................... 122

5.5.2 Requirements of UL Standards ............................................................................123

5.5.2.1 Classification in standards on insulation design .............................................. 123

5.5.2.2 Protection against electric shock...................................................................... 124

5.5.2.3 Protective grounding........................................................................................ 124

5.5.2.4 Overload protection ......................................................................................... 124

5.5.2.5 External overload protection device ................................................................ 124

5.5.2.6 Short-circuit protection.................................................................................... 125

5.5.2.7 Over-speed protection...................................................................................... 125

5.5.2.8 24-V power supply .......................................................................................... 125

5.5.2.9 Screw tightening torque................................................................................... 125

5.6 NOTES ON COOLANT (REFERENCE) .................................................... 126

6 HEAT DISSIPATION ........................................................................... 127

6.1 200-V INPUT SERIES ............................................................................... 128

6.1.1 αi PS series ...........................................................................................................128

6.1.2 αi SV series ..........................................................................................................129

6.1.3 αi SP series ...........................................................................................................133

6.2 400-V INPUT SERIES ............................................................................... 134

6.2.1 αi PS series ...........................................................................................................134

6.2.2 αi SV series ..........................................................................................................135

6.2.3 αi SP series ...........................................................................................................139

7 COOLING ............................................................................................140

8 EXTERNAL DIMENSIONS AND MAINTENANCE AREA ..................141

8.1 OUTLINE DRAWINGS .............................................................................. 142

8.1.1 Outline Drawings of Amplifiers, Panel Cut-out, and Maintenance Area .............142

8.1.2 AC Reactor Unit ...................................................................................................148

8.1.3 AC Line Filter ......................................................................................................158

8.1.4 Power Transformer...............................................................................................159

8.1.5 Regenerative Discharge Unit................................................................................165

8.1.6 Dynamic Brake Module (DBM)...........................................................................168

8.1.7 Circuit Breaker .....................................................................................................170

8.1.8 Magnetic Contactors.............................................................................................172

8.1.9 Lightning Surge Protector ....................................................................................179

8.1.10 Noise Filter ...........................................................................................................182

8.2 PANEL CUT-OUT DIAGRAMS.................................................................. 185

c-3

Page 20

TABLE OF CONTENTS B-65282EN/06

9 CONNECTION..................................................................................... 192

9.1 TOTAL CONNECTION DIAGRAM ............................................................193

9.2 CONNECTOR LOCATION ........................................................................ 195

9.2.1 αi PS series ...........................................................................................................195

9.2.2 αi SV series ..........................................................................................................200

9.2.3 αi SP Series ..........................................................................................................203

9.3 CABLE CONNECTION DETAILS .............................................................. 207

9.3.1 αi PS Series Connection Diagram ........................................................................207

9.3.1.1 Details of cable K1 (power supply line) .......................................................... 213

9.3.1.2 Details of short bar K2..................................................................................... 220

9.3.1.3 Details of cable K3 .......................................................................................... 225

9.3.1.4 Details of cable K69 ........................................................................................ 226

9.3.1.5 Details of cable K6 .......................................................................................... 227

9.3.1.6 Details of cable K7 .......................................................................................... 228

9.3.1.7 Details of cable K70 ........................................................................................ 230

9.3.1.8 Detailed description of the connection of cables K41 (for regenerative

discharge resistance), K42 (for thermostat), and K43 (for fan motor) ............231

9.3.1.9 Details of cable K100 (for power failure detection output)............................. 233

9.3.2 αi SV series Connection Diagram ........................................................................234

9.3.2.1 Details of cable K2 .......................................................................................... 237

9.3.2.2 Details of cable K4 .......................................................................................... 237

9.3.2.3 Details of cable K69 ........................................................................................ 237

9.3.2.4 Details of cable K21 ........................................................................................ 238

9.3.2.5 Details of cable K22 ........................................................................................ 243

9.3.2.6 Details of cable K24 ........................................................................................ 248

9.3.2.7 Details of cable K25 ........................................................................................ 249

9.3.2.8 Details of cable K26 ........................................................................................ 250

9.3.2.9 Details of cable K27 ........................................................................................ 251

9.3.2.10 Connecting the battery (for the absolute Pulsecoder)...................................... 252

9.3.2.11 Details of cable K70 ........................................................................................258

9.3.3 αi SP Series Connection Diagram ........................................................................259

9.3.3.1 Details of cable K2 .......................................................................................... 260

9.3.3.2 Details of cable K69 ........................................................................................ 260

9.3.3.3 Details of cable K10 (power cable) .................................................................260

9.3.3.4 Details of cable K70 ........................................................................................ 263

9.3.3.5 Details of cable K11 ........................................................................................ 263

9.3.3.6 Details of cable K12 ........................................................................................ 264

9.3.3.7 Details of cable K14 ........................................................................................ 267

9.3.3.8 Details of cable K16 ........................................................................................ 271

9.3.3.9 Details of cable K17 ........................................................................................ 273

9.3.3.10 Details of cable K33 ........................................................................................281

9.3.3.11 Details of cable K36 ........................................................................................287

9.3.3.12 Details of cable K71 ........................................................................................290

9.3.3.13 Details of cable K86 ........................................................................................293

9.3.3.14 Details of cable K88 ........................................................................................294

9.3.3.15 Details of cable K90 ........................................................................................295

9.3.3.16 Details of cable K96 ........................................................................................296

9.3.3.17 Details of cable K97 ........................................................................................297

9.3.3.18 Spindle Motor Feedback Cable Connection .................................................... 299

9.4 DETAILS OF CONNECTORS ...................................................................301

9.4.1 20-Pin Half-Pitch Connectors ..............................................................................301

9.4.2 Tyco Electronics AMP D-5000 Series Connector................................................302

c-4

Page 21

B-65282EN/06 TABLE OF CONTENTS

10 SPINDLE-RELATED OPTIONS ..........................................................304

10.1 SPINDLE ORIENTATION.......................................................................... 305

10.2 POWER LINE SWITCH CIRCUIT.............................................................. 306

10.2.1 Overview ..............................................................................................................306

10.2.2 Switch Circuit Configuration ...............................................................................306

10.2.3 Power Line Switch Unit .......................................................................................308

10.2.3.1 Specification .................................................................................................... 308

10.2.4 Outside and Mounting Dimension Diagrams.......................................................309

10.2.5 Connection ...........................................................................................................313

10.2.6 Notes.....................................................................................................................314

10.3 SUB MODULE SW .................................................................................... 316

10.3.1 Configuration .......................................................................................................316

10.3.2 Specification.........................................................................................................317

10.3.3 External Dimensions ............................................................................................319

10.3.4 Connector Installation Diagram (for Combination with αi SP 15) ......................321

10.3.5 Connection ...........................................................................................................322

10.4 SUB MODULE SM..................................................................................... 323

10.4.1 Specifications .......................................................................................................324

10.4.2 Outline Drawing ...................................................................................................325

10.4.3 Panel Cut-out........................................................................................................326

10.4.4 Connection ...........................................................................................................326

11 SENSOR.............................................................................................. 327

11.1 SENSOR FOR THE SERVO SYSTEM...................................................... 328

11.1.1 Absolute αiCZ Sensor (Separate Sensor).............................................................328

11.1.1.1 Specifications................................................................................................... 329

11.1.1.2 Connection block diagram (common to three models).................................... 335

11.1.1.3 Connection specifications................................................................................ 336

11.1.1.4 Rotation direction of the absolute αiCZ sensor............................................... 338

11.1.1.5 Installation ....................................................................................................... 340

11.1.1.6 Notes on use..................................................................................................... 345

11.1.1.7 Output signal check method ............................................................................348

11.2 SENSOR FOR THE SPINDLE................................................................... 350

11.2.1 Position Coder ......................................................................................................350

11.2.1.1 αi position coder.............................................................................................. 350

11.2.1.2 α position coder S............................................................................................ 353

11.2.1.3 Installation conditions and notes ..................................................................... 356

11.2.2 αiBZ Sensor (A860-2150-T*** and A860-2155-T***) ......................................358

11.2.3 αiCZ Sensor (for the Spindle)..............................................................................367

11.2.3.1 Names and specification numbers ...................................................................368

11.2.3.2 Absolute maximum ratings.............................................................................. 368

11.2.3.3 Specifications................................................................................................... 368

11.2.3.4 System configuration and connection block diagram...................................... 380

11.2.3.5 Connection specifications................................................................................ 381

11.2.3.6 Rotation direction of the αiCZ sensor ............................................................. 384

11.2.3.7 Machine start-up procedure (outline) .............................................................. 385

11.2.3.8 Installation ....................................................................................................... 386

11.2.3.9 Interpolation error learning.............................................................................. 391

11.2.3.10 Notes................................................................................................................ 392

11.2.3.11 Maintenance target parts.................................................................................. 393

11.2.3.12 Output signal check method ............................................................................ 394

11.2.3.13 Spindle alarms ................................................................................................. 396

c-5

Page 22

TABLE OF CONTENTS B-65282EN/06

APPENDIX

A FITTING A LIGHTNING SURGE PROTECTION DEVICE.................. 399

A.1 200-V INPUT SERIES POWER SUPPLY.................................................. 400

A.2 400-V INPUT SERIES POWER SUPPLY.................................................. 402

A.3 CAUTIONS ................................................................................................ 403

B CABLES ..............................................................................................404

B.1 10-PAIR CABLE ........................................................................................405

B.2 COMPOSITE 7-CORE CABLE .................................................................. 407

B.3 COMPOSITE 10-CORE CABLE ................................................................ 415

B.4 COMPOSITE 12-CORE CABLE ................................................................ 417

B.5 COMPOSITE 16-CORE CABLE ................................................................ 419

B.6 10-PAIR CABLE ........................................................................................420

C EXTERNAL DIMENSIONS OF EACH CONNECTOR......................... 421

D FEEDBACK CABLE LENGTH............................................................ 431

D.1 SPINDLE CABLE LENGTH

(WHEN RECOMMENDED CABLES ARE USED) ..................................... 432

D.2 SERVO CABLE LENGTH

(WHEN RECOMMENDED CABLES ARE USED) ..................................... 433

E POWER LINE FOR SERVO MOTOR AND AMPLIFIER..................... 434

E.1 SELECTING A POWER CABLE................................................................ 435

F MEASURES AGAINST NOISE FROM SERVO AMPLIFIERS ........... 438

F.1 NOISE OCCURRENCE IN SERVO AMPLIFIERS..................................... 439

F.2 NOISE TYPES........................................................................................... 440

F.3 ANTI-NOISE MEASURES......................................................................... 442

F.3.1 Pre-Installation Arrangement ...............................................................................442

F.3.2 Anti-Noise Measures ............................................................................................443

F.3.3 Concrete Examples of Anti-Noise Measures........................................................444

F.3.4 Anti-Noise Measures for Power Supply Equipment and Grounding ...................446

F.3.5 Anti-Noise Devices ..............................................................................................449

F.4 MISCELLANEOUS .................................................................................... 450

G EXAMPLES OF RECOMMENDED POWER MAGNETICS

CABINETS FOR SERVO AMPLIFIER INSTALLATION..................... 451

G.1 OVERVIEW ............................................................................................... 452

G.2 DESCRIPTIONS........................................................................................ 453

G.2.1 Power Magnetics Cabinet Seal-up........................................................................453

G.2.2 Environments for Amplifier Heat Sink Sections ..................................................458

G.2.3 Environments for Amplifier Installation ..............................................................460

H DC LINK TERMINAL BOARD SECTION PROTECTIVE COVER ......462

H.1 OVERVIEW ............................................................................................... 463

H.2 HOW TO MOUNT......................................................................................464

c-6

Page 23

B-65282EN/06 TABLE OF CONTENTS

I POWER FAILURE DETECTION FUNCTION ..................................... 465

I.1 OVERVIEW ............................................................................................... 466

I.2 POWER FAILURE DETECTION SPECIFICATION ................................... 467

I.3 APPLICATION TO PREVENTION OF VERTICAL AXES FROM FALLING

AT POWER FAILURE ...............................................................................469

I.3.1 Procedure..............................................................................................................469

I.3.2 Brake Circuit ........................................................................................................470

I.3.3 Method for Keeping Vertical Axis Motors Energized .........................................473

I.3.4 Cautions................................................................................................................476

I.3.5 Confirming Effect.................................................................................................477

I.3.6 Method for Supplying External Power to the Amplifier......................................479

I.4 USE IN COMBINATION WITH THE DUAL CHECK SAFETY FUNCTION 481

J SENSOR (OLD SPECIFICATIONS)....................................................482

J.1 SENSOR FOR THE SYNCHRONOUS BUILT-IN SERVO MOTOR AND

SEPARATE SENSOR ............................................................................... 483

J.1.1 Absolute αiCZ Sensor (Serial Output, A860-2142-T***)...................................483

J.2 SENSOR FOR THE SPINDLE................................................................... 498

J.2.1.1 αiBZ Sensor (Conventional Dimensions, A860-2120-T***)..........................498

J.2.2 αiCZ Sensor (Analog Output, A860-2140-T***)................................................503

K MAGNETIC SENSOR SIGNAL CONVERSION ADAPTER................515

K.1 ORDERING INFORMATION ..................................................................... 516

K.2 SPECIFICATIONS..................................................................................... 516

K.3 DIMENSIONS............................................................................................ 517

K.4 CONNECTION........................................................................................... 518

K.5 METHOD OF ADJUSTMENT .................................................................... 520

L HARMONIC LEAKAGE CURRENT ....................................................521

c-7

Page 24

Page 25

B-65282EN/06 1.CONFIGURATION

1 CONFIGURATION

Chapter 1, "CONFIGURATION", consists of the following sections:

1.1 FEATURES OF THE SERVO AMPLIFIER αi SERIES.............2

1.2 CONFIGURATION......................................................................3

1.3 SERVO AMPLIFIERS .................................................................8

1.4 LINEUP ......................................................................................10

- 1 -

Page 26

1.CONFIGURATION B-65282EN/06

1.1 FEATURES OF THE SERVO AMPLIFIER αi SERIES

The servo amplifier αi series employs a modular structure, and is

thinner, conserves more space, outputs less heat, and saves more

energy.

Compact

(1) Use of a latest low-loss power device and a newly developed

(2) The width of the amplifier is reduced, and therefore the amplifier

(3) The shape of the cable connector is improved to reduce the

Reduction in cabling

(1) Amplifiers can be connected with one cable.

(2) A ground connection from the motor output terminal block to the

Connector attachment to power lines

(1) Connectors are attached to input power lines and motor power

Improved maintainability

(1) A fan motor can now be replaced in an instant manner, so that

(2) Connectors are attached to input power lines and motor power

(3) The need to perform reference position return operation after

highly-efficient radiator makes it possible to reduce the depth of

the fin to 100 mm, therefore reducing the depth of the amplifier.

requires an average of approximately 30% smaller installation

space in the cabinet than the conventional amplifiers.

length of cable projection into the control board.

flange is included, so external cabling for this connection is no

longer required. (A connection from the top of the flange to the

system ground on the control board is required.)

lines. (For the large-capacity models, terminal blocks are used.)

The time required for power line attachment to and detachment

from the servo amplifier cabinet is substantially reduced.

the time required to replace a fan motor is reduced substantially.

lines, so that the time required for servo amplifier replacement is

reduced substantially.

servo amplifier replacement is eliminated.

The servo amplifier αi series has a built-in backup capacitor in

the Absolute Pulsecoder as standard. The capacitor enables

absolute position detection operation for about 10 minutes, so

that reference position return operation after servo amplifier or

feedback cable replacement is unnecessary.

- 2 -

Page 27

B-65282EN/06 1.CONFIGURATION

1.2 CONFIGURATION

The FANUC αi series consists of the following units and parts:

1.2.1 200-V Input Series

(1) αi PS series (Power Supply).............................................(Basic)

(2) αi PS

(3) αi SV series (Servo Amplifier).........................................(Basic)

(4) αi SP series (Spindle Amplifier).......................................(Basic)

(5) AC reactor.........................................................................(Basic)

(6) Connectors (for connection cables)..................................(Basic)

(7) Fuses ..............................................................................(Basic)

(8) Power transformer .......................................................(Optional)

(9) AC line filter.....................................................................(Basic)

(10) Regenerative discharge unit..............................................(Basic)

(11) DBM (Dynamic brake module)........................................(Basic)

series (Power Supply) [resister discharge type].... (Basic)

R

- 3 -

Page 28

1.CONFIGURATION B-65282EN/06

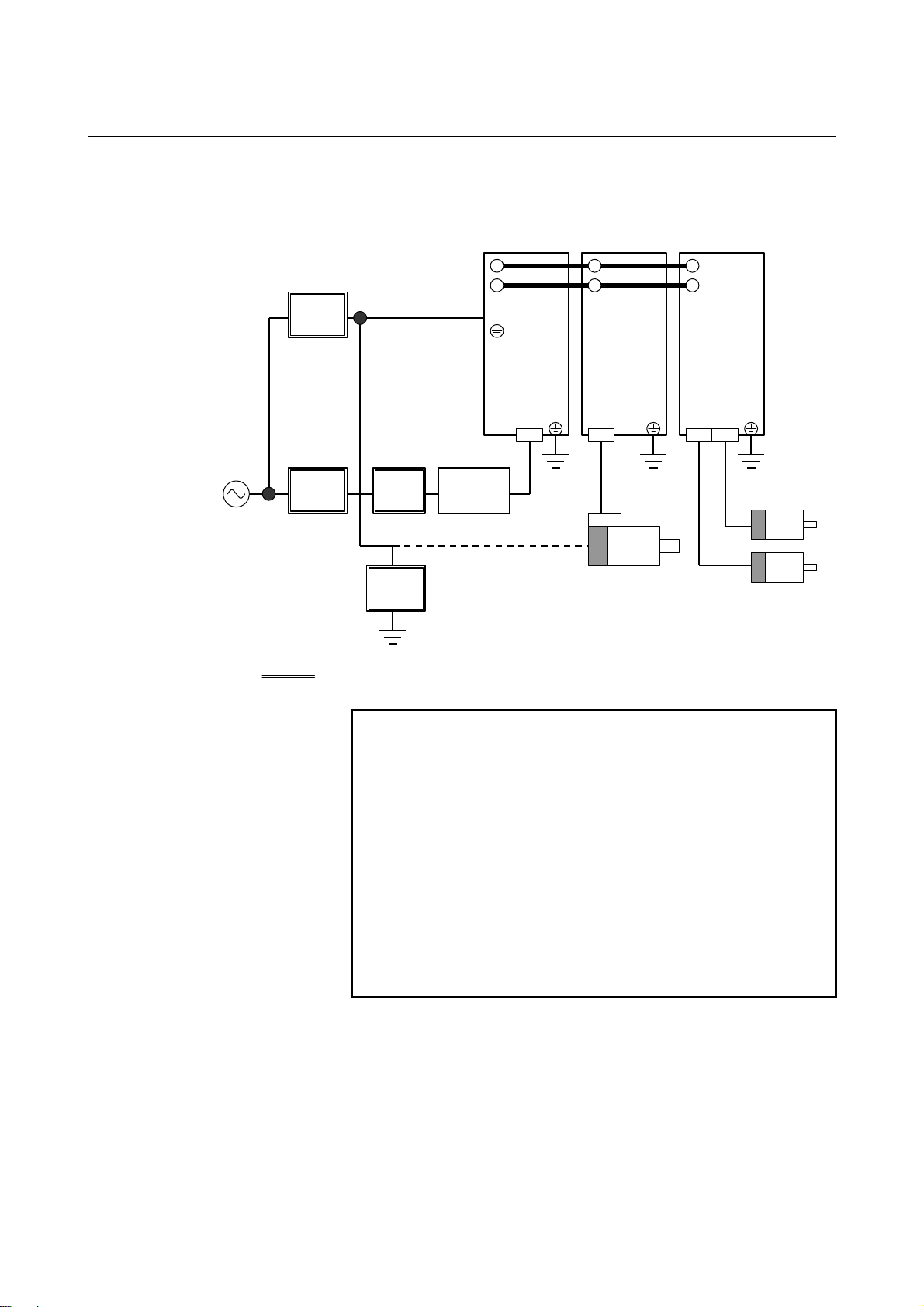

φ

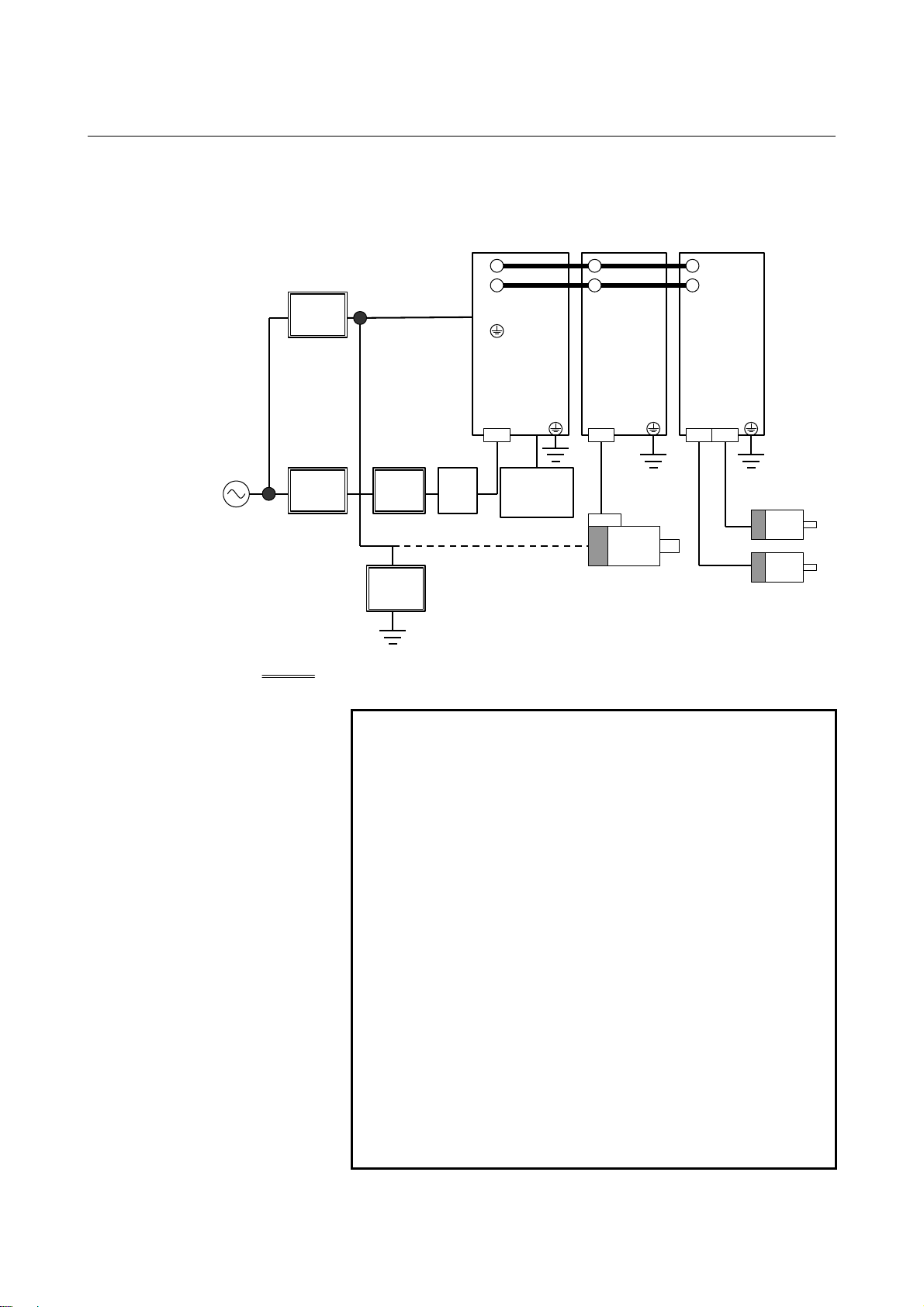

Basic configuration using αi PS (example)

Common Power

Supply

i PS

α

Spindle Amplifier

i SP

α

Servo Amplifier

i SV

α

DC link

(300VDC)

200 to 240 VAC

3φ

Circuit

breaker 2

Circuit

breaker 1

Units prepared by the machine tool builder

Magnetic

contactor

Lightning

surge

protector

NOTE

1 For how to use the αi PS together with the αi SV

and α

MODULE".

2 A magnetic contactor, AC line filter, and circuit

breakers are always required.

3 To protect the unit from surge currents caused by

lightning, connect surge absorbers between lines,

and between the lines and ground, at the power

inlet of the power magnetic cabinet. See

APPENDIX A for details.

4 When using the 3φ fan motor, breaker 2 can be

shared.

200R,200S

1φ

AC reactor

(note 4)

3φ

fan motor

3

Spindle motor

Servo motor

i SP, see Chapter 4, "HOW TO SELECT THE

- 4 -

Page 29

B-65282EN/06 1.CONFIGURATION

φ

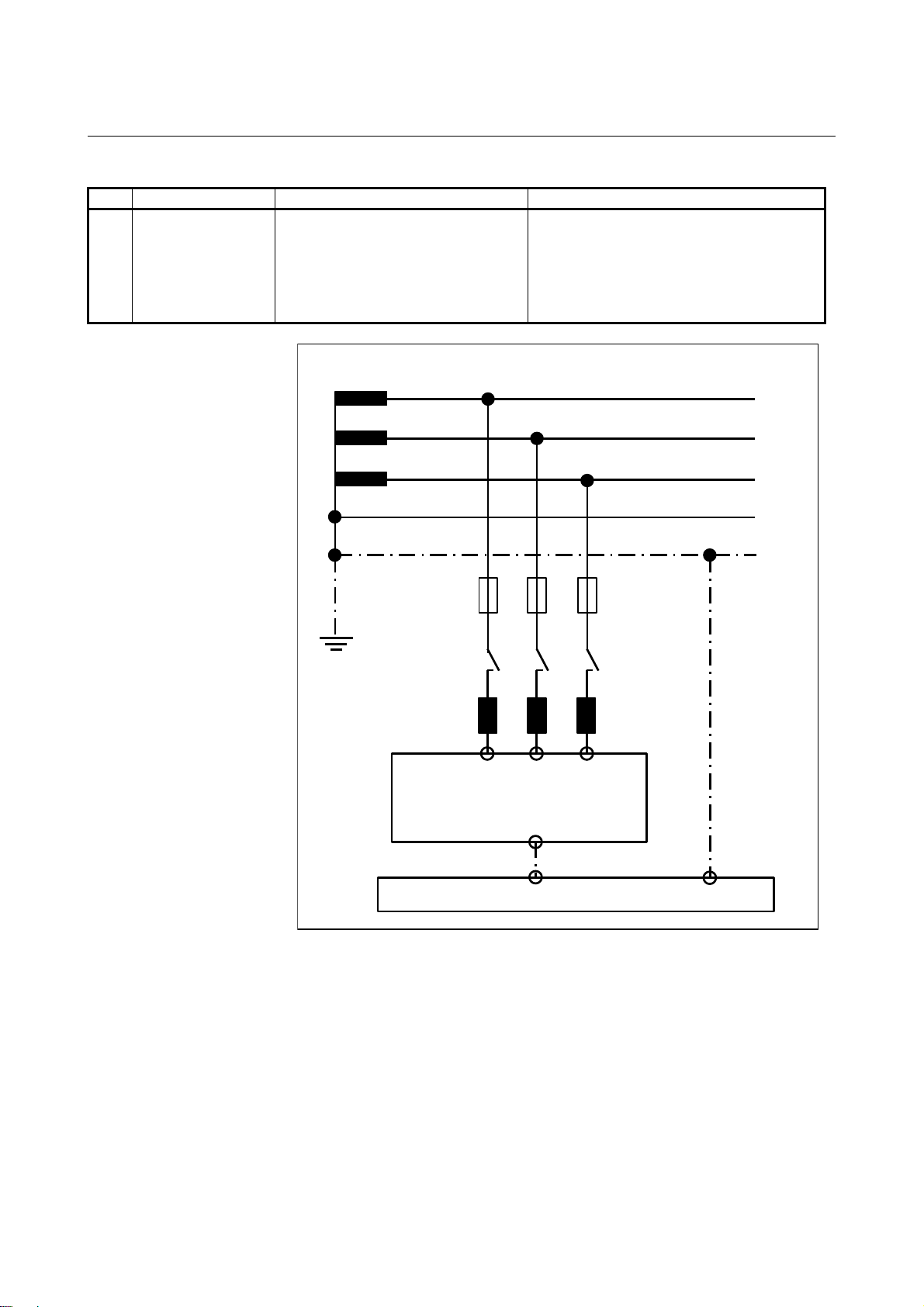

Basic configuration using αi PSR (example)

Common Power

supply

i PS

α

R

Spindle amplifier

i SP

α

Servo amplifier

i SV

α

DC link

(300VDC)

200 to 240 VAC

3φ

Circuit

breaker 2

Circuit

breaker 1

Units prepared by the machine tool builder

Magnetic

contactor

Lightning

surge

protector

(note 5)

NOTE

1 For how to use the αi PSR together with the αi SV

and α

MODULE".

2 A magnetic contactor, AC line filter, and circuit

breakers are always required.

3 To protect the unit from surge currents caused by

lightning, connect surge absorbers between lines,

and between the lines and ground, at the power

inlet of the power magnetic cabinet. See

APPENDIX A for details.

4 When an insulating transformer is installed,

high-frequency noise to the Power Supply is

reduced, so the AC line filter is not required. If the

insulating transformer is installed outside the power

magnetic cabinet, and the cable connecting the

amplifier is exposed, the cable must be covered

with a grounded metal duct, or an AC line filter

must be installed.

5 When using the 3φ fan motor, breaker 2 can be

shared.

200R,200S

1φ

AC

line

filter

Regenerative

3

φ

discharge

unit

fan motor

3

Spindle motor

Servo motor

i SP, see Chapter 4, "HOW TO SELECT THE

- 5 -

Page 30

1.CONFIGURATION B-65282EN/06

1.2.2 400-V Input Series

(1) αi PS series (Power Supply).............................................(Basic)

(2) αi SV series (Servo Amplifier).........................................(Basic)

(3) αi SP series (Spindle Amplifier).......................................(Basic)

(4) AC reactor.........................................................................(Basic)

(5) Connectors (for connection cables)..................................(Basic)

(6) Fuses ..............................................................................(Basic)

(7) DBM (Dynamic brake module)........................................(Basic)

- 6 -

Page 31

B-65282EN/06 1.CONFIGURATION

φ

Basic configuration using αi PS (example)

Common Power

Supply

i PS

α

Spindle Amplifier

i SP

α

Servo Amplifier

i SV

α

DC link

(300VDC)

200 to 240 VAC

3φ

400 to 480 VAC

3φ

Circuit

breaker 2

Lightning

surge

protector

Circuit

breaker 1

Circuit

breaker 3

Units prepared by the machine tool builder

Magnetic

contactor

Lightning

surge

protector

NOTE

1 For the control Power Supply, single–phase

200VAC is required.

2 For how to use the αi PS together with the αi SV

and α

MODULE".

3 A magnetic contactor, AC line filter, and circuit

breakers are always required.

4 To protect the unit from surge currents caused by

lightning, connect surge absorbers between lines,

and between the lines and ground, at the power

inlet of the power magnetic cabinet. See

APPENDIX A for details.

5 Measures must be taken to detect the operation

(trip) of circuit breaker 3.

6 When using the 3φ fan motor, breaker 2 can be

shared.

200R,200S

1

φ

AC reactor

Lightning

surge

protector

(note 6)

3φ

fan motor

3

Spindle motor

Servo motor

i SP, see Chapter 4, "HOW TO SELECT THE

- 7 -

Page 32

1.CONFIGURATION B-65282EN/06

1.3 SERVO AMPLIFIERS

αi PS series (Power Supply)

The αi PS series power supplies are used as a main power supply of

motor power and as a common power supply to supply control power

to servo amplifiers. Select an appropriate Power Supply according to

the output levels of the servo motor and spindle motor used.

There are three types of α

<1> 200-V input series

This Power Supply is designed to provide a main power

supply of 200 to 240 V. The module uses power regeneration

that returns energy to the power supply during motor

deceleration (regeneration).

<2> 400-V input series

This Power Supply can be connected to a main power supply

of 400 to 480V without a transformer. The module uses power

regeneration that returns energy to the power supply during

motor deceleration (regeneration). It is used together with a αi

SV series and αi SP series of the 400-V input series.

<3> αi PS

series

R

This Power Supply is designed to provide a main power

supply of 200 to 240 V. The module uses resistance

regeneration that allows energy to be consumed by resistance

during motor deceleration (regeneration).

<4> Regenerative discharge unit

This unit is a resistance used to consume energy during motor

deceleration (regeneration). This unit is required whenever the

is used.

αi PS

R

αi PS - x HV

(A) (B) (C)

(A) Model name: PS = Power Supply

PS

(B) Rated output: Numeric value representing a continuous rating in kW

(C) For a 400-V input series, "HV" is added.

i PS series, as follows:

= Power Supply (resister discharge type)

R

- 8 -

Page 33

B-65282EN/06 1.CONFIGURATION

αi SV series (Servo Amplifier)

The αi SV series amplifiers are used to drive a servo motor. Select an

appropriate amplifier according to the servo motor connected.

There are two types of α

i SV series, as follows:

<1> 200-V input series

This Amplifier drives a servo motor of the 200-V input series.

Amplifiers for one axis, two axes, and three axes are available.

<2> 400-V input series

This Amplifier drives a servo motor of the 400-V input series.

Amplifiers for one axis and two axes are available.

αi SV x / x / x HV L

(A) (B) (C) (D) (E)(F)

(A) Model name: SV = Servo amplifier

(B) L-axis maximum output current value [Apeak]

(C) M-axis maximum output current value [Apeak]

(D) N-axis maximum output current value [Apeak]

(E) For an amplifier supporting 400-V input, "HV" is added.

(F) For an amplifier supporting HRV4 control, "L" is added.

αi SP series (Spindle Amplifier)

The αi SV series amplifiers are used to drive a spindle motor. Select

an appropriate amplifier according to the spindle motor connected.

There are two types of α

<1> 200-V input series

This Amplifier drives a spindle motor of the 200-V input

series.

<2> 400-V input series

This Amplifier drives a spindle motor of the 400V input

series.

αi SP x HV

(A) (B) (C)

(A) Model name: SP = Spindle amplifier module

(B) Output: Numeric value representing the 30-minutes rating of

a matching standard motor (αi) in kW

(C) For an amplifier supporting 400-V input, "HV" is added.

i SP series, as follows:

- 9 -

Page 34

1.CONFIGURATION B-65282EN/06

1.4 LINEUP

Input

Size

60mm-wide

Without external

fin

60mm-wide

With external fin

90mm-wide

With external fin

With external fin

With external fin

power

supply

200V 3 4, 20 4/4, 4/20

400V 10HV 10/10HV

200V 5.5 5.5 2.2, 5.5 40, 80

400V 5.5HV 20HV

200V 11, 15 11, 15 160L

400V 11HV, 18HV 11HV, 15HV 80HVL

200V 26, 30, 37 22, 26, 30, 37 360 150mm-wide

400V 30HV, 45HV 30HV, 45HV 180HV

200V 55 45, 55 300mm-wide

400V 75HV, 100HV 75HV, 100HV 360HV

αi PS αi PS

R

αi SP αi SV

20/20

20/40, 40/40

160, 20L

40L, 80L

40HV

80HV

10HVL

20HVL

40HVL

40/80, 80/80

20/20L

20/40L

40/40L

20/20HV

10/10HVL

80/160

160/160

40/80L

80/80L

20/40HV

40/40HV

40/80HV

80/80HV

20/20HVL

20/40HVL

40/40HVL

4/4/4

20/20/20

20/20/40

- 10 -

Page 35

B-65282EN/06 2.SPECIFICATIONS

2 SPECIFICATIONS

Chapter 2, "SPECIFICATIONS", consists of the following sections:

2.1 INPUT POWER..........................................................................12

2.2 ENVIRONMENTAL CONDITIONS.........................................25

2.3 SPECIFICATIONS OF THE MODULES..................................33

2.4 WEIGHT.....................................................................................43

- 11 -

Page 36

2.SPECIFICATIONS B-65282EN/06

A

r

A

−

2.1 INPUT POWER

Power supply of 200-V input series

(1) Power specification

Item Specification

Main power supply

voltage

Power supply voltage for

the control

Allowable voltage

deviation

Instantaneous power

failure guarantee time

Power frequency 50/60Hz, ±1Hz

Power supply unbalance ±5% of the rated voltage or less

Power supply impedance

(Note)

NOTE

When the power supply impedance is high, and the

voltage variation exceeds the specified values, an

alarm (DC link undervoltage alarm or DC link

overvoltage alarm) can be issued in αi PS, or the

output of the motor can decrease.

[Method of checking power supply impedance]

C power

supply

Three-phase 200 VAC to 240 VAC

Single-phase 200 VAC to 240 VAC (input from

connector CX1A)

-15% to +10% (including voltage variation due

to load)

3ms

The voltage variation must be within ±7% when

a maximum output is produced for voltage at

non-load time (power running and regeneration).

R

L+

S

L-

T

G

L+

L- U V

Motor

W

G

i

C voltmete

E

i

α

PS

10

EE

(%)7(%)100

<×

0

α

SV

i

α

SP

E0 : Voltage at non-load time

E1 : Voltage at maximum output time (power running and

regeneration)

(2) The power supply for αi PS control (power supply input of

CX1A) must be turned on before or at the same time when the

CNC is turned on. For the timing of power-on at the same time

when the CNC is turned on, refer to the chapter of the power

supply in the hardware connection manual of the CNC used.

- 12 -

Page 37

B-65282EN/06 2.SPECIFICATIONS

(3) It is recommended that a capacitor unit for power-factor

improvement not be installed. This is because the capacitor unit

for power-factor improvement may adversely affect power

regeneration.

(4) The rated output of the motor is guaranteed for the rated input

voltage. If the input voltage changes, the rated output may not

appear even when the input voltage change is within the

allowable range.

(5) When the power supply is used in an area where the input

voltage is not within the range of 200 to 240 VAC, a power

transformer is required. When a power transformer is to be

provided by the user, the power must satisfy the specifications

listed below.

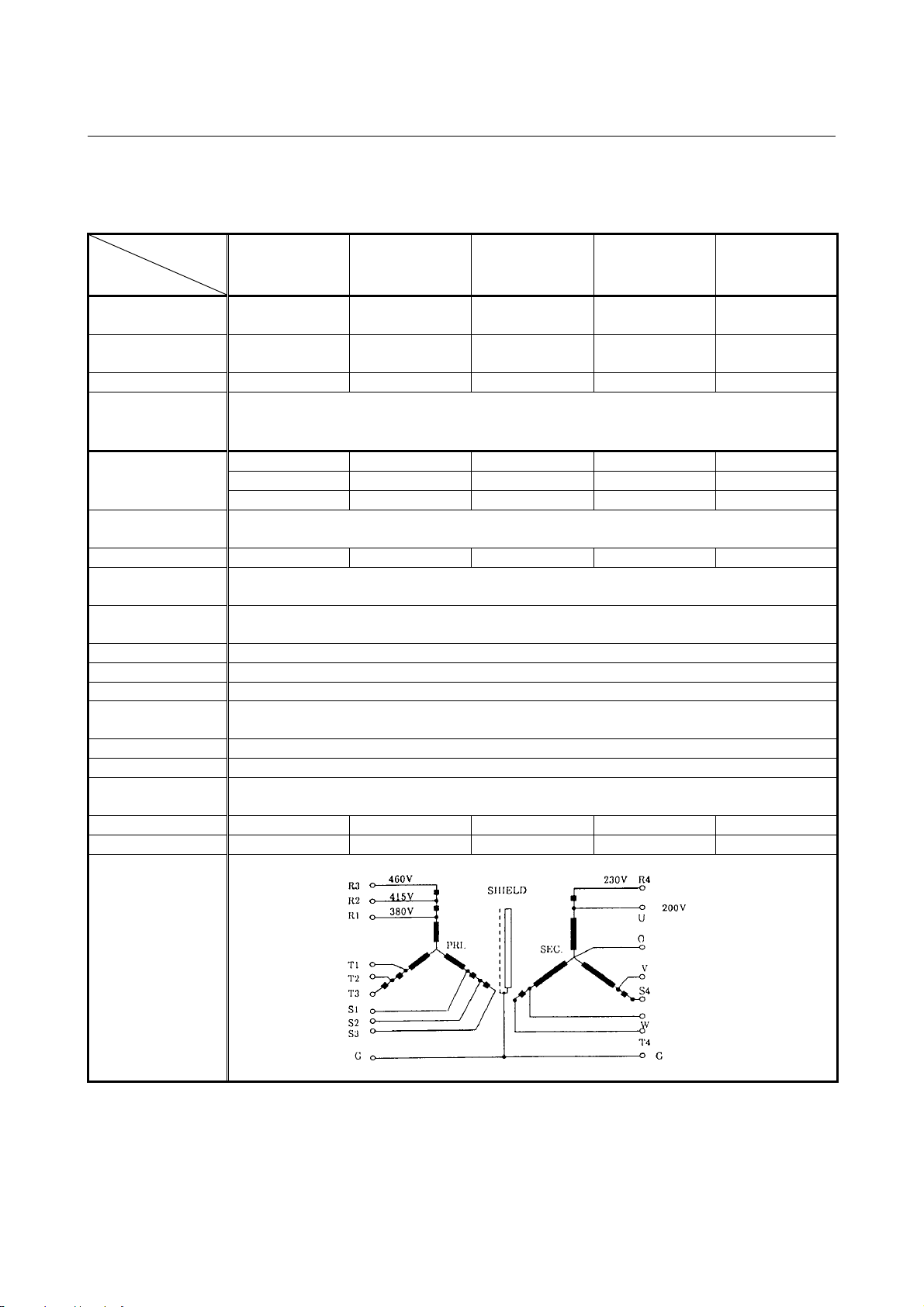

αiPS

α

Rated capacity (kVA)

Secondary current (A)

Secondary output

voltage

Secondary voltage

regulation

Secondary voltage

deviation

iPS

5.5

9 17 22 37 44 53 64 79

26 49 63 106 127 153 185 228

αiPS

11

Rated capacity

Secondary current

Secondary output

voltage

Secondary voltage

regulation

Secondary voltage

deviation

iPS

α

(kVA)

(A)

αiPS

15

R

αiPS

26

iPS

α

(2kW output)

3.5 5 9 12

10 14.5 26 35

αiPS

200 to 240V

3

R

αiPS

30

5%

±3%

(3kW output)

37

αiPSR 3

200 to 240V

αiPS 55

(45kW output)

αiPSR 5.5

(5.5kW output)

5%

±3%

αiPS 55

(55kW output)

αiPSR 5.5

(7.5kW output)

* The secondary current indicates the current value observed when

the secondary output voltage is 200 V.

(6) Ground

The main circuit and 200V control power supply must be

grounded through the neutral point or one phase of the

three-phase power supply.

(7) Noise filter

To satisfy the EMC regulation enforced in the EU countries, a

noise filter must be installed in the power supply input section.

- 13 -

Page 38

2.SPECIFICATIONS B-65282EN/06

A

r

A

−

Power supply of 400-V input series

(1) Power specification

Item Specification

Three-phase 400 VAC to 480 VAC

Star connection, neutral grounding (For

details, see Items (5) and (6).)

Main power supply

voltage

Power supply voltage for

the control

Allowable voltage

deviation

Instantaneous power

failure guarantee time

Power frequency 50/60Hz, ±1Hz

Power supply unbalance ±5% of the rated voltage or less

Power supply impedance

(Note)

N

Single-phase 200 VAC to 240 VAC (input

from connector CX1A)

(For details, see Item (7).)

-15% to +10% (including voltage variation

due to load)

3ms

The voltage variation must be within ±7%

when a maximum output is produced for

voltage at non-load time (power running

and regeneration).

NOTE

When the power supply impedance is high, and the

voltage variation exceeds the specified values,

alarm (DC link undervoltage alarm or DC link