Maintenance Manual

B-62545EN/02

FANUC Series 0-TD/0-GCD

FANUC Series 0-MD/0-GSD

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

The export of this product is subject to the authorization of the government of the country

from where the product is exported.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

s–1

SAFETY PRECAUTIONS

This section describes the safety precautions related to the use of CNC units. It is essential that these precautions

be observed by users to ensure the safe operation of machines equipped with a CNC unit (all descriptions in this

section assume this configuration).

CNC maintenance involves various dangers. CNC maintenance must be undertaken only by a qualified

technician.

Users must also observe the safety precautions related to the machine, as described in the relevant manual supplied

by the machine tool builder.

Before checking the operation of the machine, take time to become familiar with the manuals provided by the

machine tool builder and FANUC.

Contents

1. DEFINITION OF WARNING, CAUTION, AND NOTE s–2. . . . . . . . . . . . . . . . . . . . . . . .

2. WARNINGS RELATED TO CHECK OPERATION s–3. . . . . . . . . . . . . . . . . . . . . . . . . .

3. WARNINGS RELATED TO REPLACEMENT s–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. WARNINGS RELATED TO PARAMETERS s–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. WARNINGS AND NOTES RELATED TO DAILY MAINTENANCE s–7. . . . . . . . . . . . .

SAFETY PRECAUTIONS

B–62545EN/02

s–2

1

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the maintenance personnel (herein referred

to as the user) and preventing damage to the machine. Precautions are classified into W arnings and

Cautions according to their bearing on safety. Also, supplementary information is described as a

Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user

being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not

observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

Read this manual carefully, and store it in a safe place.

B–62545EN/02

SAFETY PRECAUTIONS

s–3

2

WARNINGS RELATED TO CHECK OPERATION

WARNING

1.

When checking the operation of the machine with the cover removed

(1) The user’s clothing could become caught in the spindle or other components, thus

presenting a danger of injury . When checking the operation, stand away from the machine

to ensure that your clothing does not become tangled in the spindle or other components.

(2) When checking the operation, perform idle operation without workpiece. When a

workpiece is mounted in the machine, a malfunction could cause the workpiece to be

dropped or destroy the tool tip, possibly scattering fragments throughout the area. This

presents a serious danger of injury . Therefore, stand in a safe location when checking the

operation.

2.

When checking the machine operation with the power magnetics cabinet door opened

(1) The power magnetics cabinet has a high–voltage section (carrying a

mark). Never

touch the high–voltage section. The high–voltage section presents a severe risk of electric

shock. Before starting any check of the operation, confirm that the cover is mounted on

the high–voltage section. When the high–voltage section itself must be checked, note that

touching a terminal presents a severe danger of electric shock.

(2) Within the power magnetics cabinet, internal units present potentially injurious corners and

projections. Be careful when working inside the power magnetics cabinet.

3.

Never attempt to machine a workpiece without first checking the operation of the machine.

Before starting a production run, ensure that the machine is operating correctly by performing

a trial run using, for example, the single block, feedrate override, or machine lock function or

by operating the machine with neither a tool nor workpiece mounted. Failure to confirm the

correct operation of the machine may result in the machine behaving unexpectedly, possibly

causing damage to the workpiece and/or machine itself, or injury to the user.

4.

Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

SAFETY PRECAUTIONS

B–62545EN/02

s–4

W ARNING

5.

Ensure that the specified feedrate is appropriate for the intended operation. Generally , for each

machine, there is a maximum allowable feedrate. The appropriate feedrate varies with the

intended operation. Refer to the manual provided with the machine to determine the maximum

allowable feedrate. If a machine is run at other than the correct speed, it may behave

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

6.

When using a tool compensation function, thoroughly check the direction and amount of

compensation.

Operating the machine with incorrectly specified data may result in the machine behaving

unexpectedly , possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

B–62545EN/02

SAFETY PRECAUTIONS

s–5

3

WARNINGS RELATED TO REPLACEMENT

WARNING

1.

Always turn off the power to the CNC and the main power to the power magnetics cabinet. If

only the power to the CNC is turned off, power may continue to be supplied to the serve section.

In such a case, replacing a unit may damage the unit, while also presenting a danger of electric

shock.

2.

When a heavy unit is to be replaced, the task must be undertaken by two persons or more. If

the replacement is attempted by only one person, the replacement unit could slip and fall,

possibly causing injury.

3.

After the power is turned off, the servo amplifier and spindle amplifier may retain voltages for

a while, such that there is a danger of electric shock even while the amplifier is turned off. Allow

at least twenty minutes after turning off the power for these residual voltages to dissipate.

4.

When replacing a unit, ensure that the new unit has the same parameter and other settings as the

old unit. (For details, refer to the manual provided with the machine.) Otherwise, unpredictable

machine movement could damage the workpiece or the machine itself, and present a danger of

injury .

SAFETY PRECAUTIONS

B–62545EN/02

s–6

4

WARNINGS RELATED TO PARAMETERS

WARNING

1.

When machining a workpiece for the first time after modifying a parameter, close the machine

cover. Never use the automatic operation function immediately after such a modification.

Instead, confirm normal machine operation by using functions such as the single block function,

feedrate override function, and machine lock function, or by operating the machine without

mounting a tool and workpiece. If the machine is used before confirming that it operates

normally , the machine may move unpredictably , possibly damaging the machine or workpiece,

and presenting a risk of injury.

2.

The CNC and PMC parameters are set to their optimal values, so that those parameters usually

need not be modified. When a parameter must be modified for some reason, ensure that you

fully understand the function of that parameter before attempting to modify it. If a parameter

is set incorrectly, the machine may move unpredictably, possibly damaging the machine or

workpiece, and presenting a risk of injury.

B–62545EN/02

SAFETY PRECAUTIONS

s–7

5

WARNINGS AND NOTES RELATED TO DAILY

MAINTENANCE

WARNING

1.

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. If this work is performed with the power on and

the cabinet open, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

and

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The CNC uses batteries to preserve the contents of its memory , because it must retain data such as

programs, offsets, and parameters even while external power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

contents of the CNC’s memory will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

SAFETY PRECAUTIONS

B–62545EN/02

s–8

W ARNING

2.

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine (CNC) turned on,

and apply an emergency stop to the machine. If this work is performed with the power on and

the cabinet open, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing the batteries, be careful not to touch the high–voltage circuits (marked

and

fitted with an insulating cover).

Touching the uncovered high–voltage circuits presents an extremely dangerous electric shock

hazard.

NOTE

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the machine operator’s panel

or CRT screen.

When a low battery voltage alarm is displayed, replace the batteries within a week. Otherwise, the

absolute position data held by the pulse coder will be lost.

To replace the battery, see the procedure described in Section 2.8 of this manual.

B–62545EN/02

SAFETY PRECAUTIONS

s–9

W ARNING

3.

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the cause of the

blown fuse.

For this reason, only those personnel who have received approved safety and maintenance

training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the high–voltage circuits

(marked

and fitted with an insulating cover).

Touching an uncovered high–voltage circuit presents an extremely dangerous electric shock

hazard.

B–62545EN/02

PREFACE

p–1

PREFACE

1. CRT/MDI display and operation

This chapter covers those items, displayed on the CRT, that are related to

maintenance. A list of all supported operations is also provided at the end

of this chapter.

2. Hardware

This chapter covers hardware–related items, including the hardware

configuration, connection, and NC status indicated on printed circuit

boards. A list of all units is also provided as well as an explanation of how

to replace each unit.

3. Data input/output

This chapter describes the input/output of data, including programs,

parameters, and tool compensation data, as well as the input/output

procedures for conversational data.

4. Interface between the NC and PMC

This chapter describes the PMC specifications, the system configuration,

and the signals used by the PMC.

5.Digital servo

This chapter describes the servo tuning screen and how to adjust the

reference position return position.

6. Trouble shooting

This chapter describes the procedures to be followed in the event of

certain problems occurring, for example, if the power cannot be turned on

or if manual operation cannot be performed. Countermeasures to be

applied in the event of alarms being output are also described.

APPENDIX

The appendix consists of a list of all alarms, as well as a list of

maintenance parts.

This manual does not provide a parameter list. If necessary, refer to the

separate PARAMETER MANUAL.

This manual describes all optional functions. Refer to the manual

provided by the machine tool builder for details of any options with which

the installed machine tool is provided.

This manual can be used with the following models. The abbreviated

names may be used.

Description of

this manual

PREFACE

B–62545EN/02

p–2

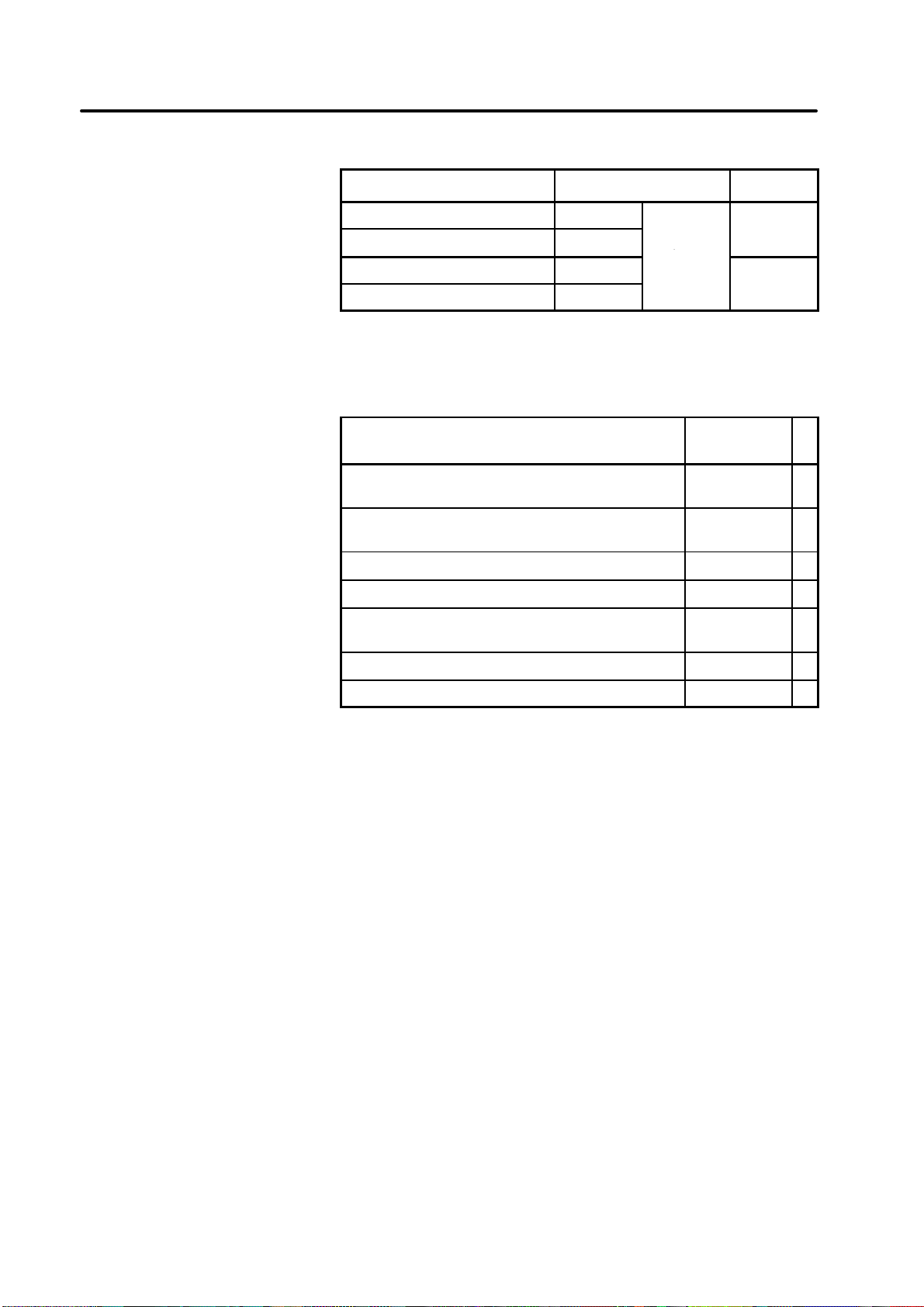

The models covered by this manual, and their abbreviations are :

Product name Abbreviations Series

FANUC Series 0–TD 0–TD

FANUC Series 0–GCD 0–GCD

–

T

series

FANUC Series 0–MD 0–MD

Seri

es 0–

D

FANUC Series 0–GSD 0–GSD

M

series

The table below lists manuals related to the FANUC Series 0–D.

In the table, this manual is marked with an asterisk (*).

Table 1 Manuals related to the FANUC Series 0–D

Manuals name

Specification

number

FANUC Series 0–TD/MD/GCD/GSD

CONNECTION MANUAL (HARDWARE)

B–62543EN

FANUC Series 0–TD/MD/GCD/GSD

CONNECTION MANUAL (FUNCTION)

B–62543EN–1

FANUC Series 0–TD/GCD OPERATOR’S MANUAL B–62544EN

FANUC Series 0–MD/GSD OPERATOR’S MANUAL B–62574EN

FANUC Series 0–TD/MD/GCD/GSD

MAINTENANCE MANUAL

B–62545EN

*

FANUC Series 0–TD/GCD PARAMETER MANUAL B–62550EN

FANUC Series 0–MD/GSD PARAMETER MANUAL B–62580EN

Applicable models

Manuals related to

Series 0–D

B–62545EN/02

Table of Contents

c–1

SAFETY PRECAUTIONS s–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREFACE p–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLAY AND OPERATION OF CRT/MDI 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1.1 Screen Transition Triggered by The Function Key 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 POWER–ON SCREEN DISPLAY 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 DIAGNOSTIC FUNCTIONS 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.1 How to Display the Diagnosis Screen 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3.2 Display of the CNC Internal Status 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 NC STATUS DISPLAYS 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 LIST OF OPERATIONS 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 CONTROL UNIT 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1 Configuration of the Control Unit 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 COMPLETE CONNECTION DIAGRAM 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1 Precautions 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 INTER–MACHINE CONNECTION 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.1 CRT/MDI Unit 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.2 Reader/Puncher Interface 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.3 Manual pulse Generator 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.4 Servo Interface 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.5 Serial Spindle Interface 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.6 Analog Spindle Interface 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.7 Position Coder Interface 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.8 External Environmetal Requirements of Cabinet 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.9 Installation Condition of CNC and Servo Unit 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.10 Power Capacity 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.11 Action Against Noise 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 LEDS ON PRINTED–CIRCUIT BOARDS 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 PRINTED–CIRCUIT BOARD UNIT LIST 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.1 Structure 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.2 Construction 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5.3 Printed board unit list 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 BATTERY REPLACEMENT METHOD 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.1 CNC Memory Backup Battery Replacement 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6.2 Absolute Pulse Coder Batteries 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 DETAILS OF POWER SUPPLY 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.1 Details of Power Supply Unit AI (A16B–1212–0100) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7.2 CE Marking Correspond Details of Power Supply Unit AI (A16B–1212–0950) 71. . . . . . . . . . . . . . . . .

2.7.3 Fuses 77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 MAINTENANCE OF HEAT PIPE TYPE HEAT EXCHANGER 78. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. DATA INPUT/OUTPUT 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1 DATA INPUT/OUTPUT 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Locating the File 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Outputting CNC Parameters 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.3 PMC Parameter Output 83. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.4 Program Output 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62545EN/02

Table of Contents

c–2

3.1.5 Offset Value Output 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.6 CNC Parameter Input 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.7 PMC Parameter Input 85. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.8 Program Input 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.9 Offset Value Input 86. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.10 Parameters Related to Data Input/Output 87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. INTERFACE BETWEEN NC AND PMC 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1 PMC SCREEN 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.1.1 PMCLAD SCREEN 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 SIGNAL AND SYMBOL TABLE 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. DIGITAL SERVO 103. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 INITIAL SETTING SERVO PARAMETERS 104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 SERVO TUNING SCREEN 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.1 Parameter Setting 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2.2 Displaying Servo Tuning Screen (Exa.: Incase of X axis) 107. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 ADJUSTING REFERENCE POSITION (DOG METHOD) 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3.1 General 109. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4 DOGLESS REFERENCE POSITION SETTING 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.1 General 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.2 Operation 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.4.3 Associated Parameters 112. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. TROUBLESHOOTING 113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1 CORRECTIVE ACTION FOR FAILURES 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Investigating the Conditions Under which Failure Occurred 115. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2 POWER CANNOT BE SWITCHED ON 117. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 NO MANUAL OPERATION NOR AUTOMATIC OPERATION CAN BE EXECUTED 118. . . . . . . .

6.4 JOG OPERATION CANNOT BE DONE 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 HANDLE OPERATION CANNOT BE DONE 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.6 AUTOMATIC OPERATION CANNOT BE DONE 127. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.7 CYCLE START LED SIGNAL HAS TURNED OFF 134. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.8 NO DISPLAY APPEARS ON THE SCREEN WHEN THE POWER IS SWITCHED ON 136. . . . . . . .

6.9 ALARM 85 TO 87 (READER/PUNCHER INTERFACE ALARM) 138. . . . . . . . . . . . . . . . . . . . . . . . .

6.10 REFERENCE POSITION DEVIATES 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.11 ALARM 90 (REFERENCE POSITION RETURN IS ABNORMAL) 142. . . . . . . . . . . . . . . . . . . . . . . .

6.12 ALARM 3n0 (REQUEST FOR REFERENCE POSITION RETURN) 144. . . . . . . . . . . . . . . . . . . . . . .

6.13 ALARM 3n1 TO 3n6 (ABSOLUTE PULSE CODER IS FAULTY) 145. . . . . . . . . . . . . . . . . . . . . . . . . .

6.14 ALARM 3n7 TO 3n8 (ABSOLUTE PULSE CODER BATTERY IS LOW) 146. . . . . . . . . . . . . . . . . . .

6.15 ALARM 3n9 (SERIAL PULSE CODER IS ABNORMAL) 147. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.16 ALARM 400, 402 (OVERLOAD) 148. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.17 ALARM 401, 403 (*DRDY SIGNAL TURNED OFF) 150. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.18 ALARM 404 AND 405 (*DRDY SIGNAL TURNED ON) 151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.19 ALARM 4n0 (EXCESSIVE POSITION ERROR AMOUNT DURING STOP) 152. . . . . . . . . . . . . . . .

6.20 ALARM 4n1 (EXCESSIVE POSITION ERROR DURING MOVE) 153. . . . . . . . . . . . . . . . . . . . . . . . .

6.21 ALARM 4n4 (DIGITAL SERVO SYSTEM IS ABNORMAL) 155. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62545EN/02

c–3

6.22 ALARM 4n6 (DISCONNECTION ALARM) 165. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.23 ALARM 4n7 (DIGITAL SERVO SYSTEM IS ABNORMAL) 166. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.24 ALARM 700 (OVERHEAT AT CONTROL SIDE) 167. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.25 ALARM 408 (THE SPINDLE SERIAL LINK DOES NOT START NORMALLY.) 168. . . . . . . . . . . . .

6.26 ALARM 409 (SPINDLE ALARM) 169. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.27 ALARM 998 (ROM PARITY ERROR) 170. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.28 ALARMS 910 TO 916 (RAM PARITY ERRORS) 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.29 ALARM 920 (WA TCH DOG OR RAM PARITY) 172. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.30 ALARM 941 (INCORRECTL Y INSTALLED MEMORY PRINTED–CIRCUIT BOARD) 173. . . . . . .

6.31 ALARM 930 (CPU ERROR) 174. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.32 ALARMS 945 AND 946 (SERIAL SPINDLE COMMUNICATION ERRORS) 175. . . . . . . . . . . . . . . .

6.33 ALARM 950 (BLOWN FUSE) 176. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

APPENDIX

A. ALARM LIST 179. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.1 LIST OF ALARM CODES 180. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B. LIST OF MAINTENANCE PARTS 199. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.1 MAINTENANCE PARTS 200. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

1

1

DISPLAY AND OPERATION OF CRT/MDI

This chapter describes how to display various screens by the function

keys. The screens used for maintenance are respectively displayed.

1.1 FUNCTION KEYS AND SOFT KEYS 2. . . . . . . . . . . . .

1.2 POWER–ON SCREEN DISPLAY 6. . . . . . . . . . . . . . . . .

1.3 DIAGNOSTIC FUNCTIONS 7. . . . . . . . . . . . . . . . . . . . .

1.4 NC STATUS DISPLAYS 12. . . . . . . . . . . . . . . . . . . . . . . .

1.5 LIST OF OPERATIONS 13. . . . . . . . . . . . . . . . . . . . . . . .

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

2

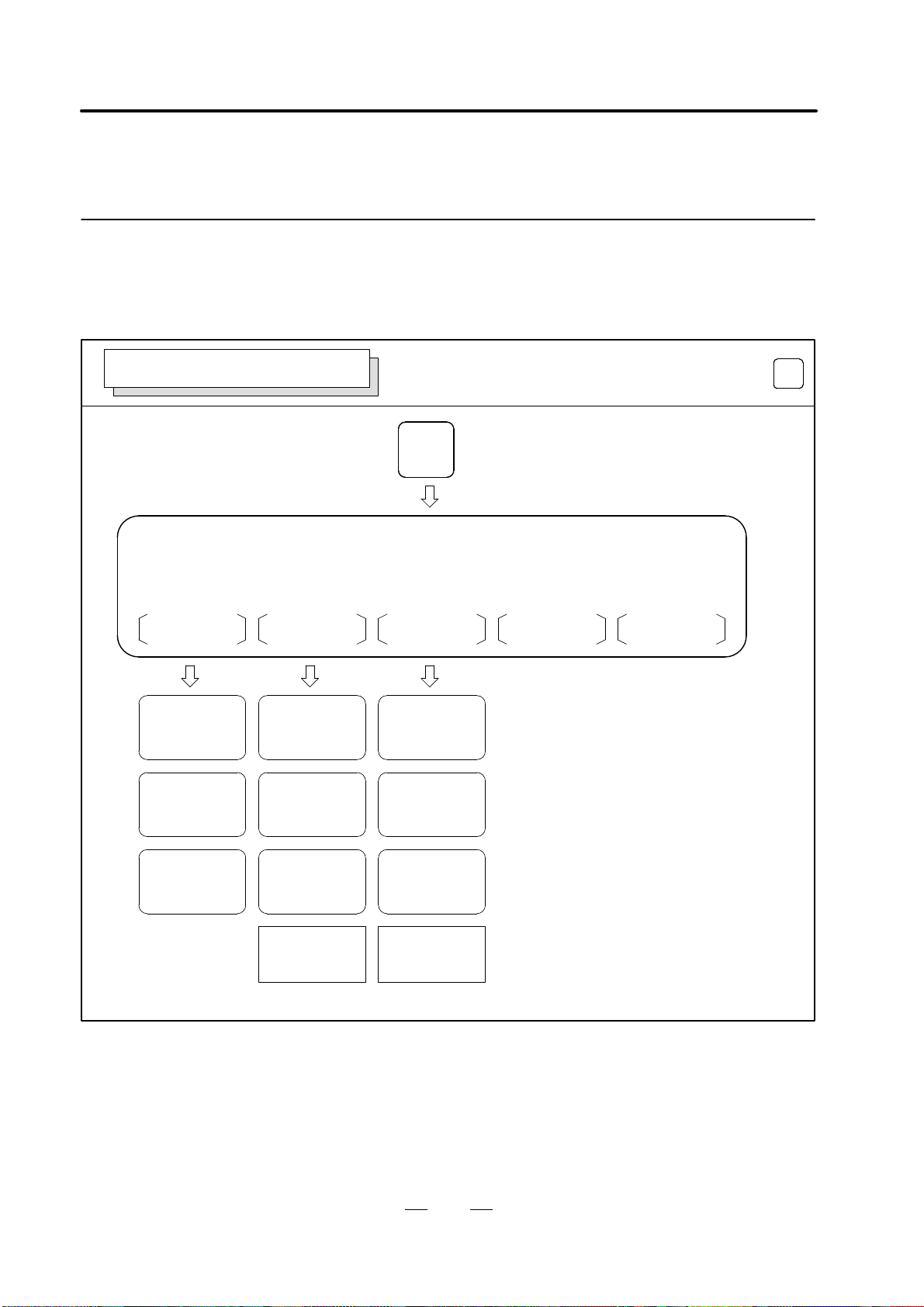

Operations and soft key display status for each function key are described

below:

POS

POS

POSITION DISPLAY SCREEN

Current position screen

Total position display of each coordinate system

ABS REL ALL

Display of run time

and parts count

Display of run time

and parts count

Display of run time

and parts count

1.1

FUNCTION KEYS

AND SOFT KEYS

1.1.1

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

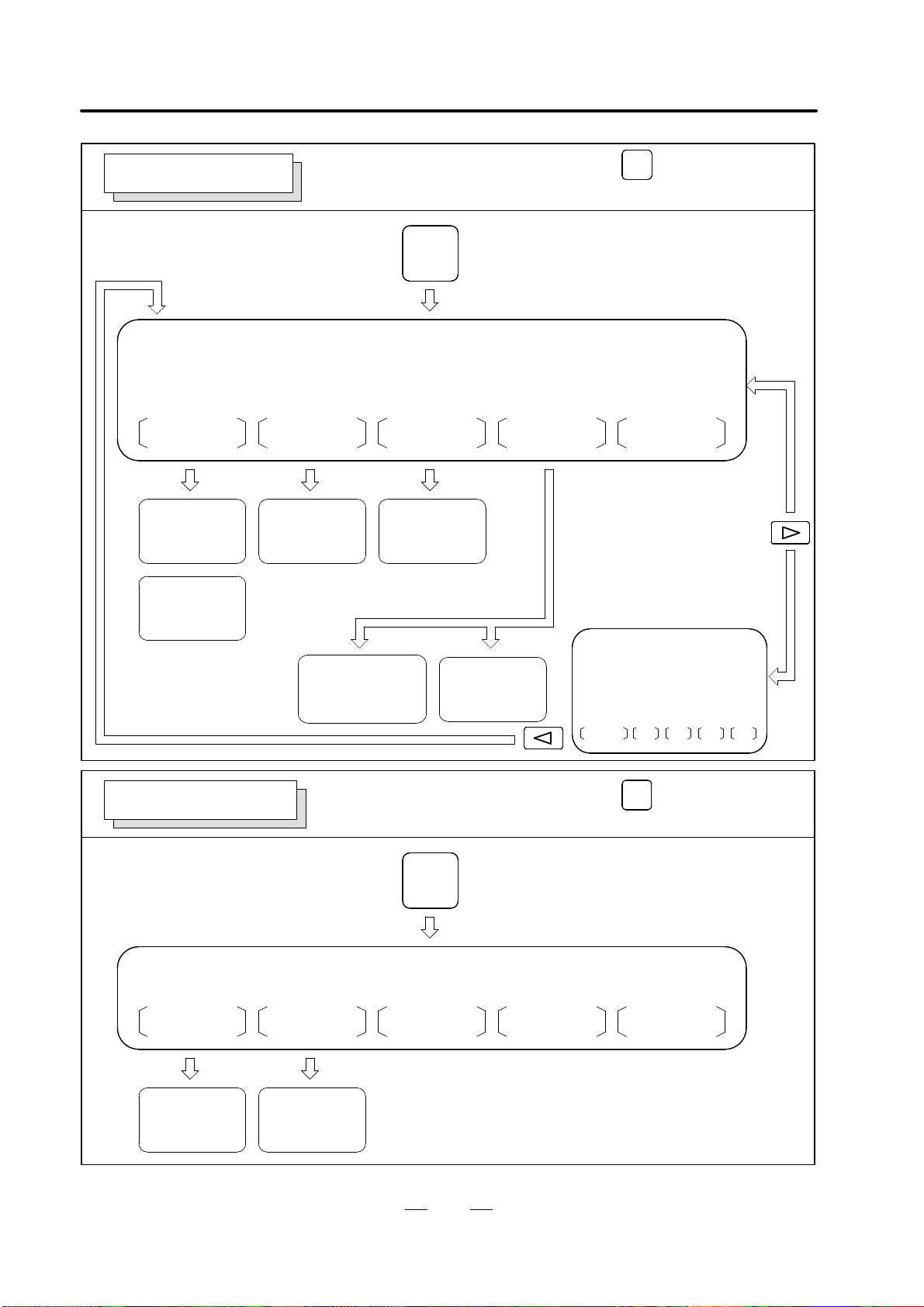

3

Program screen

Display of proĆ

gram contents

Display of current

block and modal

data

PRGRM CURRNT NEXT CHECK

PROG

Screen transition triggered by the function key

in the AUTO or MDI mode

PROG

PROGRAM SCREEN

Display of current

block and next

block

Program being

executed Absolute/

Relative coordinate

value Distance to go

modal values

Display of program

number and seĆ

quence number

Command

for MDI operation

* : Displayed in MDI mode

AUTO (MDI) *

*

Program screen

BG–EDT

Program editing

screen

Program memory

and program diĆ

rectory

PRGRM LIB EDIT

PROG

Program screen

PROGRAM SCREEN

Screen transition triggered by the function key

in the EDIT mode

PROG

I/O

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

4

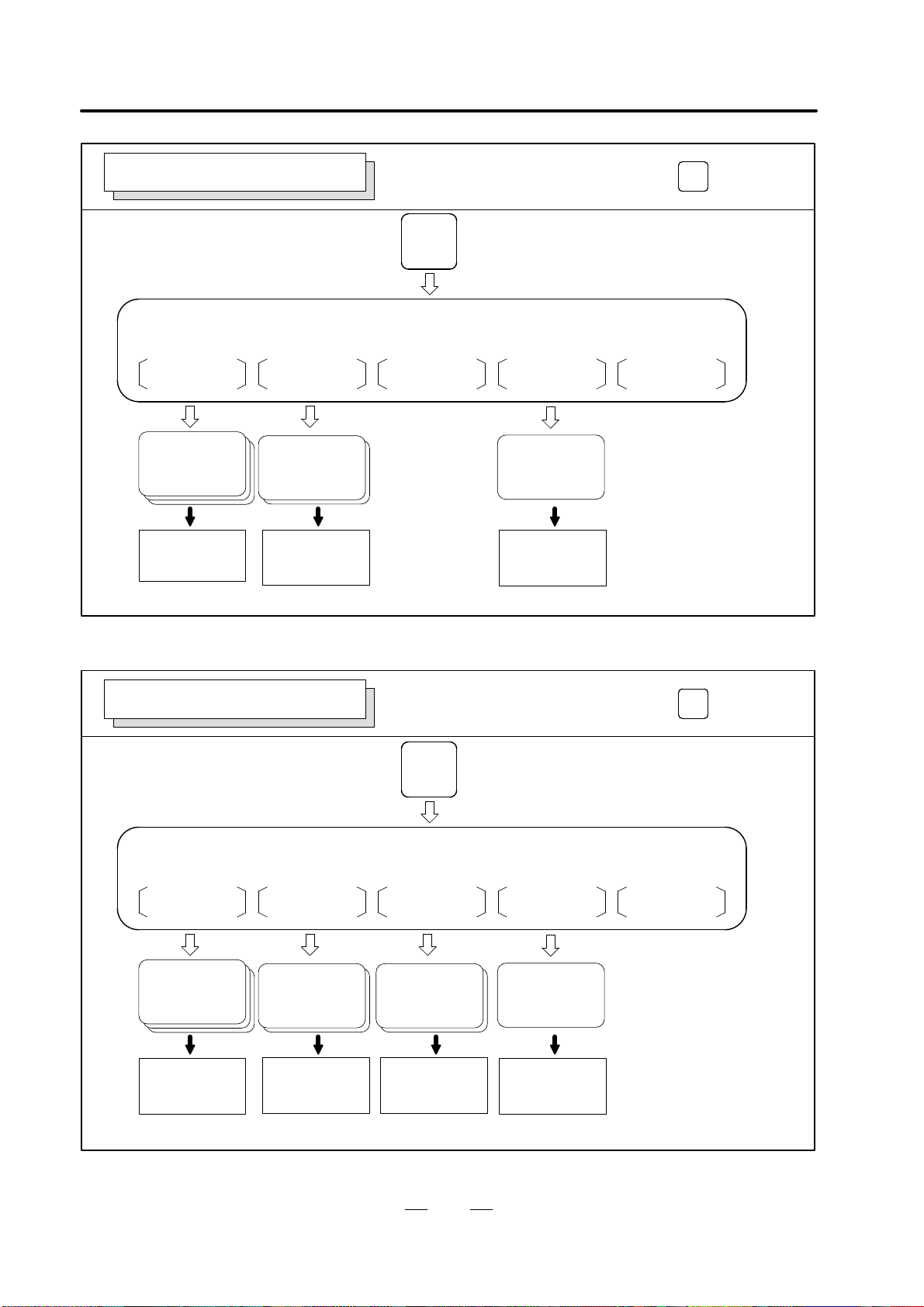

Tool offset value

Display of tool

offset value

OFFSET MACRO OPR

Screen transition triggered by the function key

(Machining Center)

OFFSET

SETTING

OFFSET

SETTING

OFFSET/SETTING SCREEN

Setting of tool

offset data

Setting macro

variables

Display of

macro variables

Display of workpiece coordinate system

Setting of workpiece original

offset value

Tool offset value

Display of tool

offset value

(Wear)

WEAR

GEOMETRY

WORK MACRO

Screen transition triggered by the function key

(Lathe)

OFFSET

SETTING

OFFSET

SETTING

OFFSET/SETTING SCREEN

Setting of tool

offset data

(Wear)

Setting of tool

offset value

(Geometry)

Display of tool

offset value

(Geometry)

Display of

macro variables

Setting of macro

variable

Setting of work

shift value/work

coordinate

Display of setĆ

ting of work shift

value/work

coordinate

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

5

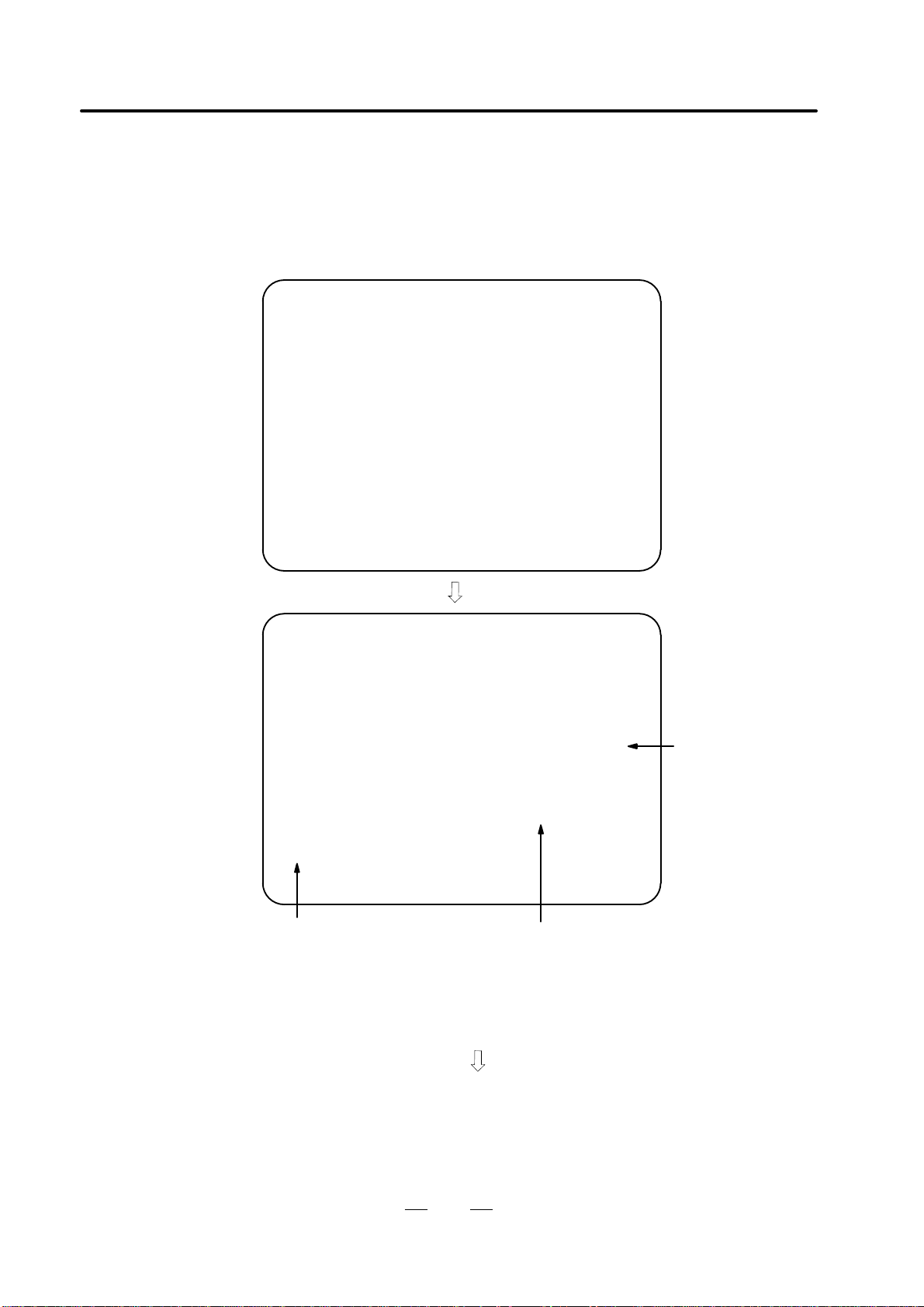

DGNOS

PARAM

Parameter screen

PARAM DGNOS SV–PRM

DGNOS

PARAM

PARAMETER/DIAGNOSIS SCREEN

(Lathe)

*

Setting of pitch

error compensation data

Setting of setting

data

Display of servo

setting screen

Display of servo

adjusting

screen

* :Setting parameter (No.0389#0).

Servo setting/adjusting screen are not displaied.

Alarm screen

OPR

Screen transition triggered by the function key

OPR

ALARM

ALARM SCREEN

Setting of software operator’s

panel

ALARM

MESSAGE

Display of software operator’s panel

Display of

operator message

OPR

ALARM

Display of

alarm screen

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

6

– The CRT screen displays differ slightly between the M and T systems.

– The screen displays shown below are for reference purposes only. Some

of these displays may not appear depending on the installed options and

actual system configuration.

NOT READY

0 4 7 1 – 0 5

Automatically switched

NOT READY

0 4 7 1 – 0 5

PMC: XXXX – XX

CNC software edition

and version displays,

which also appear

also on the program

list screen

Indicates that the servo system

is not ready to operate, that is,

it is inoperable.

Type of other software in use

PMC : Sequence programs created by the machine

tool builder

– This display does not appear if no other software is

available.

– The displays shown above remain on the screen if the machine is brought to an emer

gency stop.

An ordinary position display is restored when the machine is released from an emergency stop state.

1.2

POWER–ON SCREEN

DISPLAY

D Slot state screen

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

7

(1) Press the

DGNOS

PARAM

key several times, or the [Diagnosis] soft key.

If the CNC does not respond to a command, it is possible to determine the

status of the CNC.

0700

DGN

#7 #6

CSCT#5CITL#4COVZ#3CINP#2CDWL#1CMTN#0CFIN

#6 CSCT The CNC is waiting for the spindle speed reached signal (SAR) to be

turned on after cutting feed begins or an S command is read.

0120

DGN

#7 #6 #5 #4

SAR

#3 #2 #1 #0

SAR 0 The spindle speed has not reached the specified speed.

#7 #6 #5 #4 #3 #2

SCTO

#1 #0

0024

PRM

SCTO 1 : The spindle speed reached signal will be checked.

0 : The spindle speed reached signal will not be checked.

Delay timer for checking the spindle speed reached signal [ms]0110

PRM

#5 CITL An interlock (disable axis movement) signal has been input.

[0–MD and 0–GSD]

PRM

49#0

PRM

08#7

PRM

15#2

PRM

12#1

Signal name DGN number

1 — — — *MITX, Y, Z 142.0 to 7

— 1 — — *ITX, Y, Z, 4 128.0 to 3

— 0 0 0 *ILK (all axes)

— 0 0 1 *ILK (Z–axis only)

117.0

— 0 1 0 *RILK (all axes)

— 0 1 1 *RILK (Z–axis only)

008.5

1.3

DIAGNOSTIC FUNCTIONS

1.3.1

How to Display the

Diagnosis Screen

1.3.2

Display of the CNC

Internal Status

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

8

[0–TD and 0–GCD]

#7 #6 #5 #4 #3 #2 #1

STLK

#0

0120

DGN

STLK 1 : The start lock is in effect.

#7 #6 #5 #4 #3

IT4

#2

IT3

#1

ITZ

#0

ITX

0128

DGN

IT 1 : The start lock for the corresponding start lock is in effect.

#7 #6 #5

–MIT2#4+MIT2#3–MIT1#2+MIT1

#1 #0

0008

DGN

*PRM Valid only when bit 7 (EDILK) of PRM 024 = 1.

#4 COVZ The override signal is 0%.

#7 #6 #5 #4 #3

*OV8#2*OV4#1*OV2#0*OV1

0121

DGN

When bit 4 of PRM 003=0 1 1 1 1

When bit 4 of PRM 003=1 0 0 0 0

#3 CINP A position check is being performed.

DGN 800 to Positional deviation > PRM 500 to Ef fective area

– Probable causes include errors in the servo circuit or machine load.

#2 CDWL A dwell command (G04) is being executed.

#1 CMTN An axis move command is being executed automatically.

#0 CFIN The M, S, T, or B function is being executed (has not been completed).

#7

HSIF

#6 #5 #4 #3 #2 #1 #0

0045

PRM

HSIF The M, S, T , and B code processing uses either of the following interfaces.

1 : High–speed interface

0 : Ordinary interface

Override 0%

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

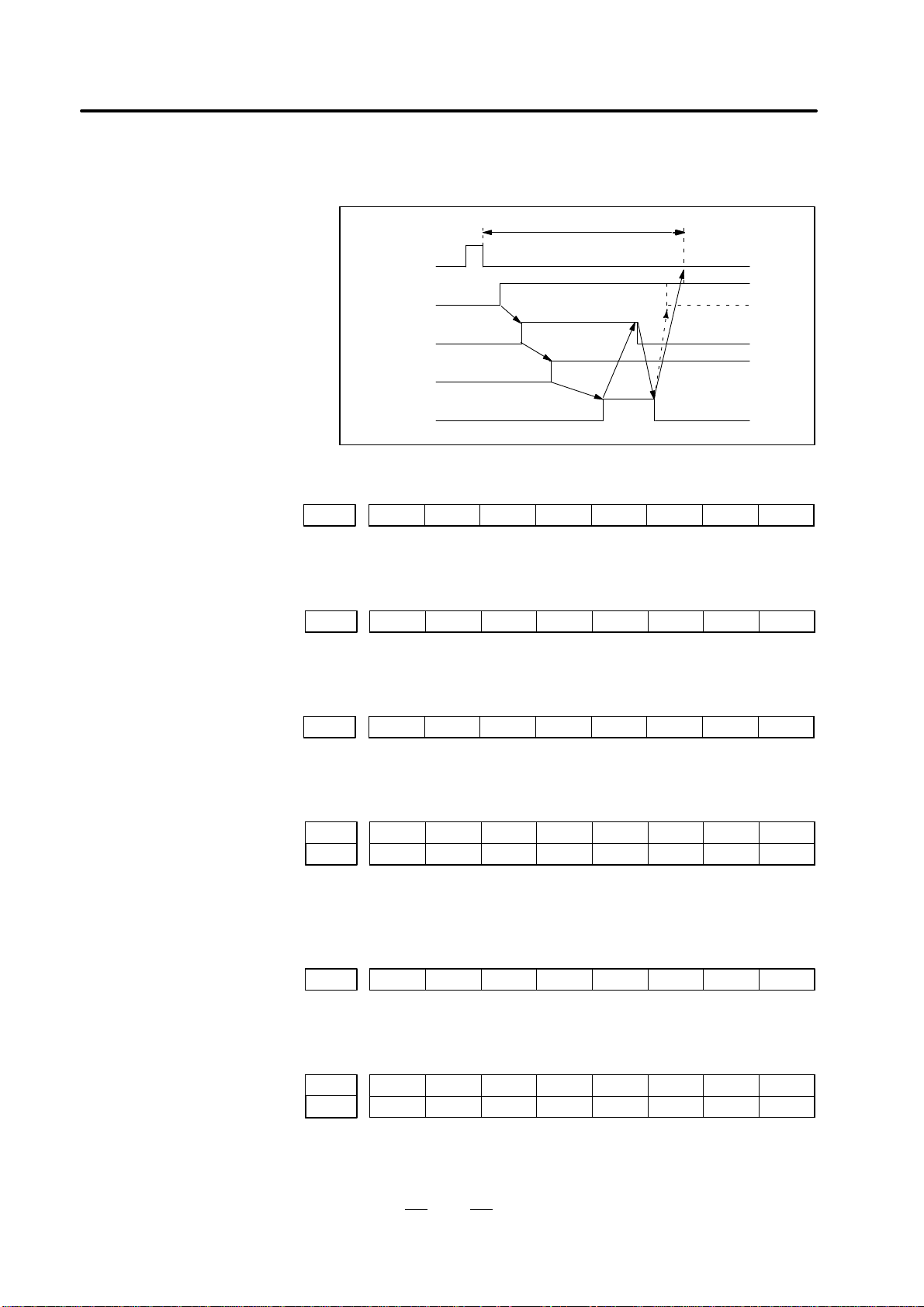

9

Read auxiliary

function

Auxiliary function code

(BCD)

Strobe (MF, SF,..)

Operation of function

Completion (FIN)

DGN 700.0=1

To the next block

S

and T

functions

M function

#7 #6 #5 #4 #3

TF

#2

SF

#1 #0

MF

0150

DGN

Strobe signals

#7 #6 #5

MF3

#4

MF2

#3 #2 #1 #0

0157

DGN

MF2, MF3 Strobe signal for multiple M functions per block

#7 #6 #5 #4 #3

FIN

#2 #1 #0

0120

DGN

FIN Auxiliary function completion (common to M, S, T and B)

#7

M28

#6

M24

#5

M22

#4

M21

#3

M18

M38

#2

M14

M34

#1

M12

M32

#0

M11

M31

0151

DGN

0157

DGN

– M31 to M38 are the BCD code corresponding to the third digit with the

3–digit M function.

#7

S28

#6

S24

#5

S22

#4

S21

#3

S18

#2

S14

#1

S12

#0

S11

0152

DGN

– This signal is not used for the 4–digit S function.

#7

T28

T48

#6

T24

T44

#5

T22

T42

#4

T21

T41

#3

T18

T38

#2

T14

T34

#1

T12

T32

#0

T11

T31

0153

DGN

0156

DGN

– T31 to T48 are the BCD code corresponding to the fourth and third

digits with the 4–digit T function.

[Ordinary interface]

D Operation sequence of

auxiliary functions

[M function]

[2–digit S function only]

[T function]

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

10

#7

BF1

#6

BF2

#5 #4 #3 #2 #1 #0

0150

DGN

BF1 Strobe signal for the 3 low–order digits of the B code

BF2 Strobe signal for the 3 high–order digits of the B code

#7

B28

#6

B24

#5

B22

#4

B21

#3

B38

B18

#2

B34

B14

#1

B32

B12

#0

B31

B11

0154

DGN

0155

DGN

– For the 6–digit B function, code signals are output for every three digits.

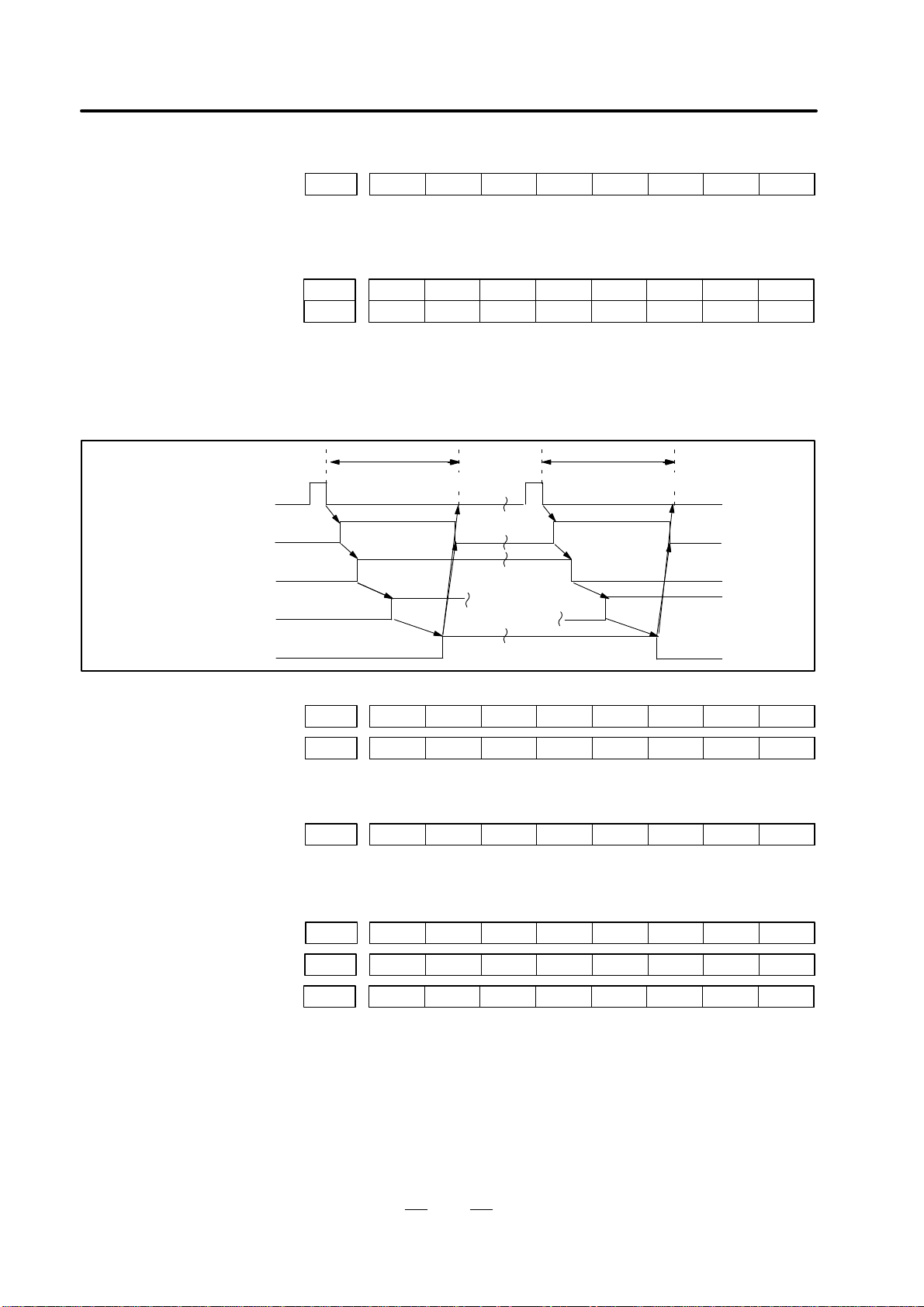

DGN 700.0=1 DGN 700.0=1

To the next block To the next block

Read auxiliary function

Auxiliary function code (BCD)

Strobe (MF, SF ,..)

Behavior of function

Completion (MFIN,...)

#7

BF1

#6

BF2

#5 #4 #3

TF

#2

SF

#1 #0

MF

0150

DGN

BFIN1 BFIN2 TFIN SFIN MFIN0115

DGN

MFIN, SFIN, TFIN Function completion signals

#7 #6 #5

CRST

#4 #3 #2 #1 #0

0701

DGN

#5 CRST The emergency stop signal (*ESP), external reset signal (ERS), reset &

rewind signal (RRW), or MDI reset button is on.

#7 #6 #5 #4

*ESP

#3 #2 #1 #0

0021

DGN

ERS *ESP0121

DGN

RRW0104

DGN

*ESP 0 : The emergency stop signal is on.

ERS 1 : The external reset signal is on.

RRW 1 : The reset & rewind signal is on.

– There is no DGNOS display for the MDI reset button.

[3–/6–digit B function]

[High–speed interface]

D Auxiliary–function

operation sequences

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

11

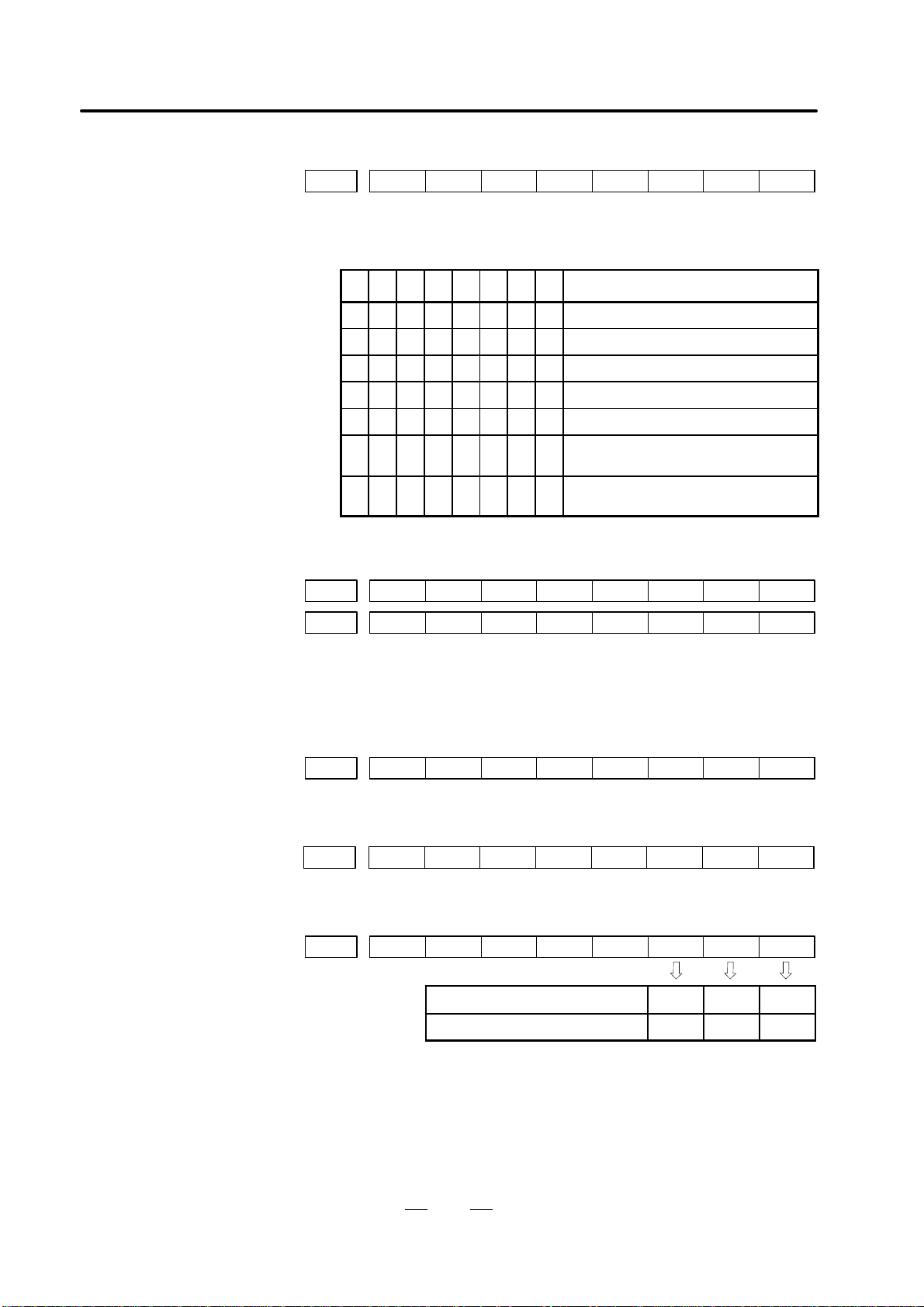

#7

STP#6REST#5EMS#4RRW#3RSTB

#2 #1 #0

CSU

0712

DGN

This diagnosis information is valid only if automatic operation is

terminated when it should not be. The information indicates the reason

why the cycle start lamp (STL) is off.

#7 #6 #5 #4 #3 #2 #1 #0 Reason

1 1 1 0 0 0 0 1 The emergency stop signal (*ESP) was input.

1 1 0 0 0 0 0 0 The external reset (ERS) signal was input.

1 1 0 1 0 0 0 0 The reset & rewind (RRW) signal was input.

1 1 0 0 1 0 0 0 The MDI reset button was pressed.

1 0 0 0 0 0 0 1 A servo alarm occurred.

1 0 0 0 0 0 0 0 The feed hold (*SP) signal was input, or

another manual mode was selected.

0 0 0 0 0 0 0 0 The machine stopped in a single–function

block.

. All these bits are cleared to 0 when the power is switched on.

#7 #6 #5 #4

*ESP

#3 #2 #1 #0

0021

DGN

ERS *SP *ESP0121

DGN

*ESP 0 The emergency stop signal is on.

ERS 1 The external reset signal is on.

*SP 0 The feed hold signal is on.

#7 #6

RRW

#5 #4 #3 #2 #1 #0

0104

DGN

RRW 1 The reset & rewind signal is on.

#7 #6 #5 #4 #3 #2 #1

SBK

#0

0116

DGN

SBK 1 : The single block signal is on.

#7 #6 #5 #4 #3 #2

MD4#1MD2#0MD1

0122

DGN

Automatic operation (AUTO) 0 0 1

Manual data input (MDI) 0 0 0

– If the program ends with M02 or M03, the machine may enter state 1

or 2 in the above table depending on the processing adopted by the

machine tool builder.

*(1)

*(2)

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

12

[ ABS ] [ REL ] [ ALL ] [ HNDL ] [ ]

ACTUAL POSITION (ABSOLUTE)

ACT.F 3000 MM/M S 0 T

NOT READY ALM BAT BUF AUTO

O0010 N0000

X 123.456

Y 363.233

Z 0.000

MDI Manual data input

AUTO Automatic operation (memory– or tape–based operation)

EDIT Memory editing

HNDL Manual handle feed

JOG Jog feed

TJOG Teach–in jog feed

THND Teach–in handle feed

STEP Manual incremental feed

ZRN Manual reference position return

Alarm Indicates the current alarm.

BAT Indicates that the battery voltage is dropping.

Input Indicates that data is being input.

Output Indicates that data is being output.

Search Indicates that a search is being carried out.

Editing Indicates that some other miscellaneous editing operation

(such as insertion or modification) is under way.

Collation Indicates that a program is being collated.

LSK Indicates the state of label skipping during data input.

BUF Indicates that the next block to be executed has been read.

NOT READY Indicates that the machine is in the emergency stop

state.

1.4

NC STATUS DISPLAYS

(1)Current mode

(2) Alarm conditions

(3) Other status displays

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

13

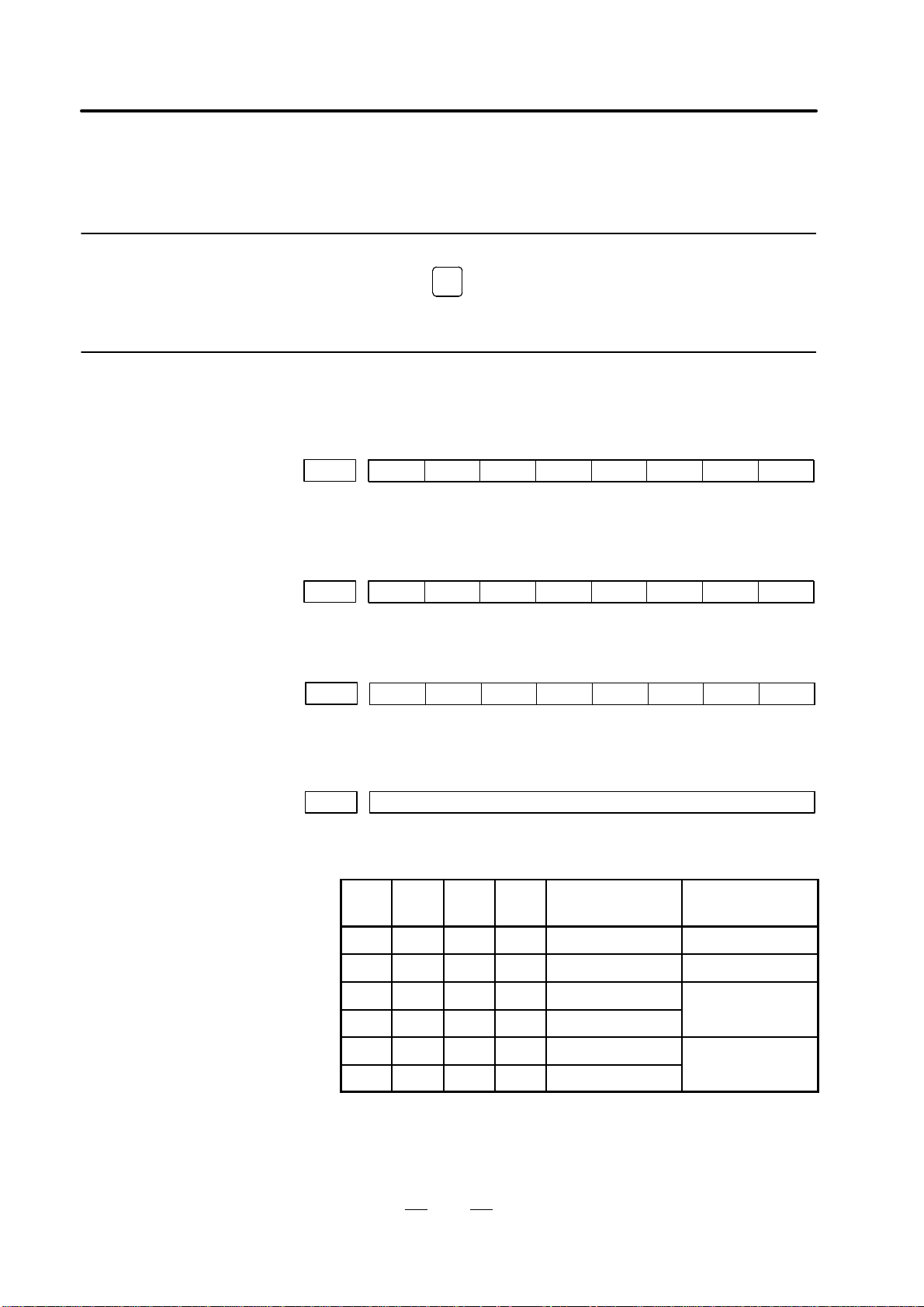

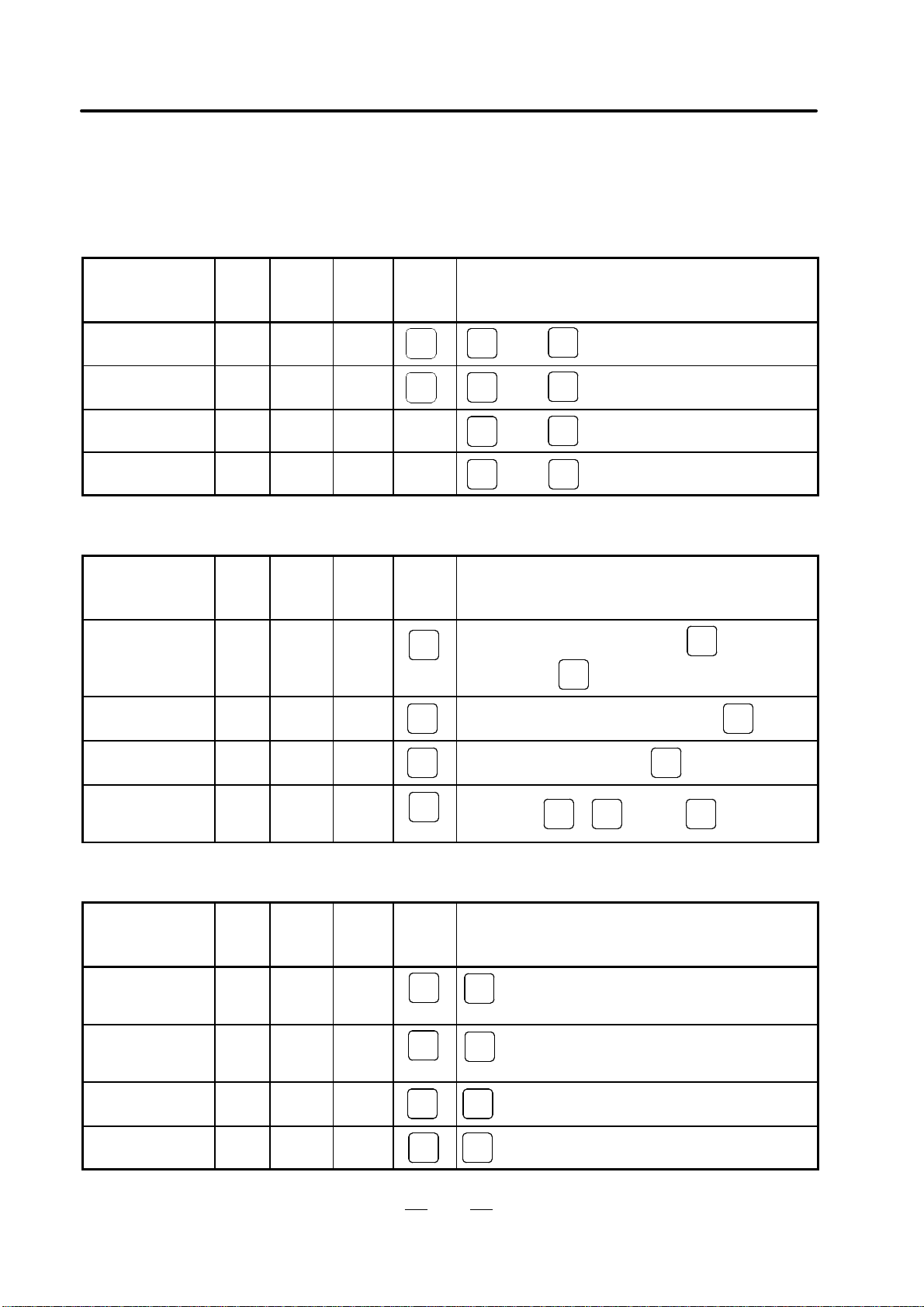

Reset

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Resetting run hour

–

POS

→

R

CAN

Resetting no. of

machined parts

–

POS

→

P

CAN

Resetting OT alarm

At Pow-

er ON

–

and

P

CAN

Resetting alarm 100

–

– CAN

and

RESET

Registration from MDI

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Inputting

parameters

f MDI

(PARAM)

SYSTEM

Parameter no.→[NO.SRH]→Data→

→ PWE =0 →

INPUT

RESET

Inputting offset

values

–

OFFSET

Offset number→[NO.SRH]→Offset value→

INPUT

Inputting setting

data

MDI

OFFSET

SETTING

Setting no.→[NO.SRH]Data→

INPUT

Input of PMC

parameters

f f MDI

(DGNOS)

SYSTEM

Setting no.→→→Data→

INPUTINPUT

DGNOS

PARAM

Registration from tape

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Inputting

parameters

(tape→memory)

f EDIT

(DGNOS)

SYSTEM

INPUT

Input of PMC

parameter

f f EDIT

(DGNOS)

SYSTEM

INPUT

Inputting offset

values

EDIT

OFFSET

INPUT

Registration of

program

f

EDIT/

AUTO

PRGRM

INPUT

1.5

LIST OF OPERATIONS

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

14

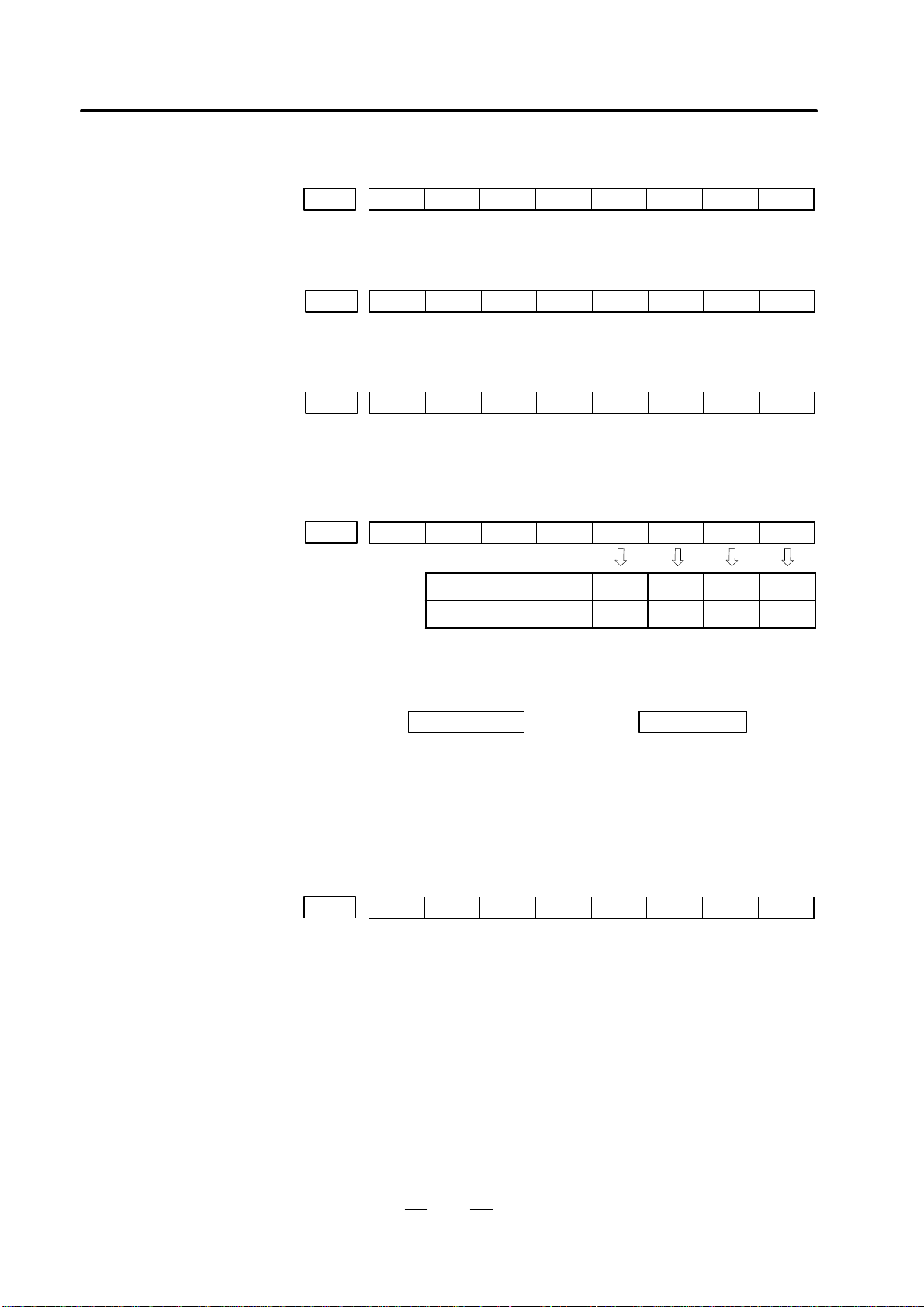

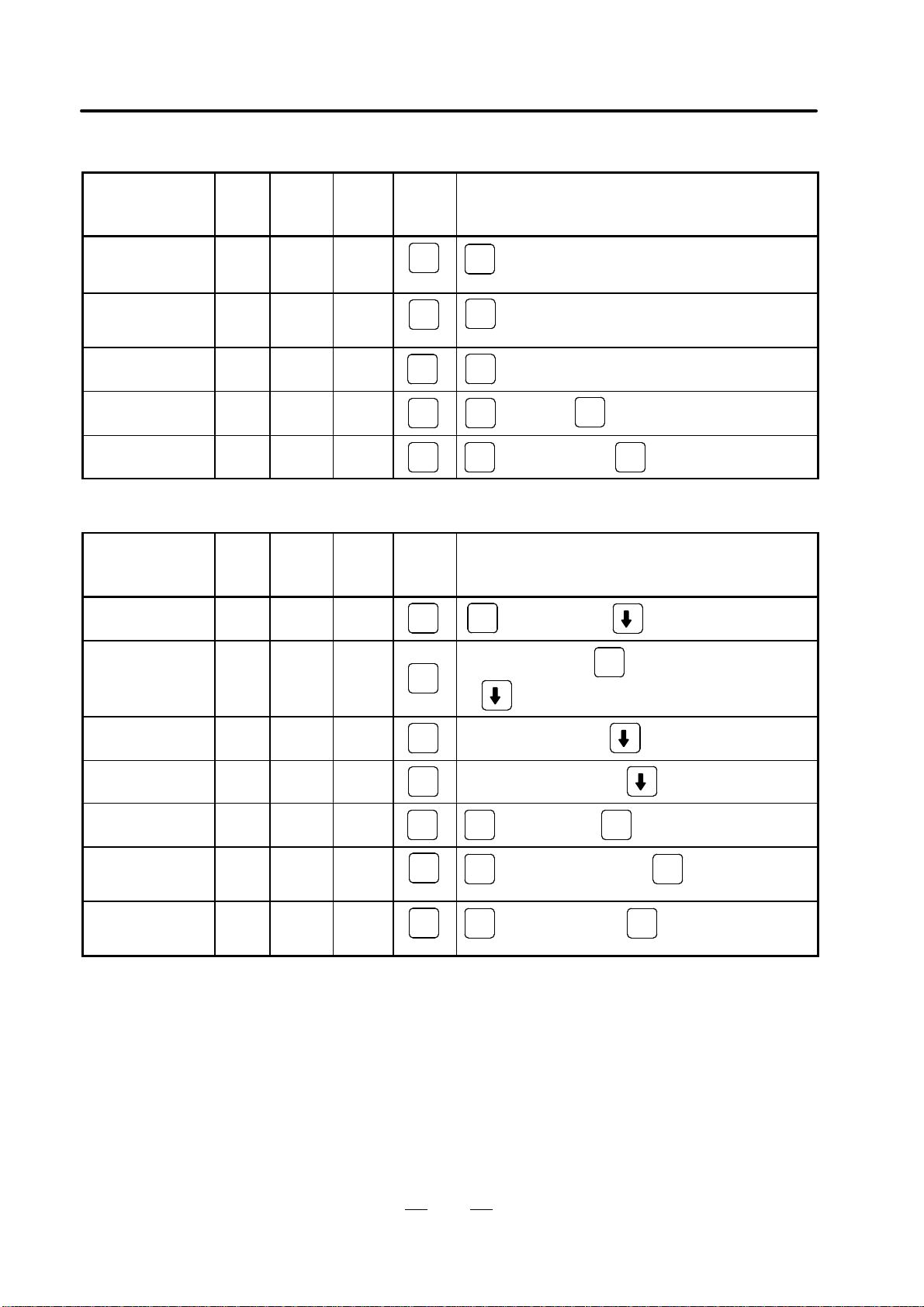

Punch out

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Punch of parameter EDIT

(PARAM)

SYSTEM

OUTPUT

Punch of PMC

parameter

EDIT

(DGNOS)

SYSTEM

OUTPUT

Punch of offset EDIT

OFFSET

SETTING

OUTPUT

Punch of all

programs

EDIT

PROG

→ –999 →

O

OUTPUT

Punch of one

program

EDIT

PROG

→Program no.→

O

OUTPUT

Search

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Searching a

program number

EDIT/

AUTO

PROG

→Program no.→ (cursor key)

O

Searching a

sequence number

AUTO

PROG

Program no. search→→Sequence number

→ (cursor key)

N

Searching an

address word

EDIT

PROG

Data to be searched→ (cursor key)

Searching an

address only

EDIT

PROG

Address to be searched→ (cursor key)

Searching an offset

number

–

OFFSET

SETTING

→Offset no.→

INPUT

NO.

Searching a

diagnostic number

–

(DGNOS)

SYSTEM

→Diagnostic number→

INPUT

NO.

Searching a

parameter number

–

(PARAM)

SYSTEM

→Parameter no.→

INPUT

NO.

B–62545EN/02

1. DISPLA Y AND OPERATION OF CRT/MDI

15

Edit

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Display of memory

capacity used

EDIT

PROG

PRGRM

Deleting all

programs

f EDIT

PROG

→–9999→

O

DELETE

Deleting a program f EDIT

PROG

→Program no.→

O

DELETE

Deleting several

blocks

f EDIT

PROG

→Sequence no.→

N

DELETE

Deleting a block f EDIT

PROG

→

EOB

DELETE

Deleting a word f EDIT

PROG

Searching a word to be deleted→

DELETE

Changing a word f EDIT

PROG

Searching a word to be changed→New Data→

ALTER

Inserting a word f EDIT

PROG

Searching a word immediately before a word to be

searched→New Data→

INSERT

Collation

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Collating memory EDIT

PROG

INPUT

Input/Output with FANUC Cassette

Function

Data

protec-

tion

key

Param-

eter

write=1

Mode

Func-

tion

button

Operation

Registeration of

program

f

EDIT/

AUTO

PROG

→File no.→→

N

INPUT INPUT

Output of all

program

EDIT

PROG

→–9999→

O

OUTPUT

Output of

a program

EDIT

PROG

→Program no.→

O

OUTPUT

Heading a file

EDIT/

AUTO

PROG

→File no.→

N

INPUT

Deleting a file f EDIT

PROG

→File no.→

N

OUTPUT

Collating a program

EDIT/

AUTO

PROG

→File no.→→

N

INPUT INPUT

1. DISPLA Y AND OPERATION OF CRT/MDI

B–62545EN/02

16

Clear

Function

Data

prote-

ction

key

Param-

eter

write=1

Mode

Func-

tion

key

Operation

Memory all clear At

power

ON

AND

RESET DELETE

Parameter clear

f

At

Power

ON

RESET

Clearing a program

f

At

Power

ON

DELETE

B–62545EN/02

2. HARDWARE

17

2

HARDW ARE

This chapter describes structure of CNC control section, connection of

units and the functions of PCBs and modules mounted on PCBs.

2.1 CONTROL UNIT 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 COMPLETE CONNECTION DIAGRAM 19. . . . . . . . . .

2.3 INTER–MACHINE CONNECTION 25. . . . . . . . . . . . . .

2.4 LEDS ON PRINTED–CIRCUIT BOARDS 56. . . . . . . . .

2.5 PRINTED–CIRCUIT BOARD UNIT LIST 57. . . . . . . . .

2.6 BATTERY REPLACEMENT METHOD 62. . . . . . . . . . .

2.7 DETAILS OF POWER SUPPLY 64. . . . . . . . . . . . . . . . . .

2.8 MAINTENANCE OF HEAT PIPE TYPE

HEAT EXCHANGER 78. . . . . . . . . . . . . . . . . . . . . . . . . .

2. HARDWARE

B–62545EN/02

18

Each control P.C.B. of Series 0–D is mounted in the slot as follows.

Available series is in parenthesis.

MEM slot

I/O slot

AXE slot

PMC slot

Power

supply

unit

Memory

card

Internal

I/O card

C6 (TD,

GCD)

C7 (all)

E2 (TD)

E3 (TD, MD)

1st to 4th

card

Type–A

(TD, MD)

Type–B

(All)

PMC–M

Package

3 of TD

and MD

can use

Power

supply unit

AI (All)

CE marking

AI (TD, MD)

NOTE

Connection position of this figure are depended on each printed board.

2.1

CONTROL UNIT

2.1.1

Configuration of the

Control Unit

B–62545EN/02

2. HARDWARE

19

The complete connection diagram shows examples of connecting all PC

boards that can fit into the slots of the master PC board. Some slots can

accept two or more PC boards which are connected to different devices.

This drawing shows two or more identical slot names, but actual

individual slots on the master PC board have different names. See the

connection of each slot according to the PC board to be fitted into the slot.

The diagram shows the connection of all PC boards that can be fitted into

the slots. In the actual unit, the PC boards to be mounted are determined

by the model and optional functions. Note that all the PC boards shown

in the diagram are not always mounted.

2.2

COMPLETE CONNECTION DIAGRAM

2.2.1

Precautions

2. HARDWARE

B–62545EN/02

20

CAP

Power supply

unit AI

CP1

CP2

CP2

CP3

CP14

CP15

BK3.F

BK3.F

BK3.F

BWG6.F

BN3.F

BN6.F

H50.F

H20.F

H50.F

H50.F

H50.F

I/O C6–C7

M1

M2

M18

M19

M20

C6

C7

I/O

CAP

(Continued)

Servo magnetic

contactor

ON/OFF switch

Single–phase 200–VAC

input

200–V AC output

(spare)

24–VDC output

24–VDC output

(display unit using 24 VDC)

H50.M

H50.M

H50.M

H20.M

H50.M

Power magnetics cabinet

MasterPC board

(spare)

For CE marking power

supply

unit AI

CP1

CP3

CP2

CP4

CP6

CP5

AHX3.F

AHX3.F

AHX3.F

AL Y6.F

ALX3.F

AL Y3.F

Servo magnetic

contactor

ON/OFF switch

Single–phase 200–VAC

input

200–V AC output

(spare)

24–VDC output

24–VDC output

(spare)

H50.F

H20.F

H50.F

H50.F

H50.F

I/O E2, E3

M201

M202

M218

M219

M220

E2

E3

I/O

H50.M

H50.M

H50.M

H20.M

H50.M

Power magnetics cabinet

(display unit using 24 VDC)

B–62545EN/02

2. HARDWARE

21

COP5

M5

(Continued)

H20.M

Memory card

D25.F

Relay connector

RS–232–C I/O unit (channel 0, channel 1)

Manual pulse generator

(first unit)

H20.M

M26

H20.F

H20.F

Spindle control

circuit

(analog control)

Spindle motor

S analog output (analog spindle)

Spindle

Position

coder

H20.F

M27

M12

CN11A Spindle control

circuit (Digital control)

CN11B First unit

S serial output (serial spindle)

OPT OPT

OPT

CN11A Spindle control

circuit (Digital control)

CN11B Second unit

OPT

Battery for memory

backup

BWG3.F

CPA7

(For memory PC board)

Spindle motor

Spindle

Position

coder

Spindle motor

Spindle

Position

coder

H20.F

H20.F

CCX5

M3

MEM

CN1 Display (CRT)

KM1 MDI unit

H20.M

H20.F

2. HARDWARE

B–62545EN/02

22

(Continued)

1st to 4th axis

control

CN1 Servo amplifier

(Digital control)

First axis

H20.M

H20.F

M184

AXE

AC

servo motor

H20.F

M185

(Command)

(Velocity/position feedback) Serial pulse coder

A/B–phase pulse coder

(Servo system of semi–closed loop)

CN1 Servo amplifier

(Digital control)

First axis

H20.M

H20.F

M184

AC

servo motor

H20.F

M186

(Command)

(Velocity feedback)

Servo system of closed loop

H20.F

M185

(Position feedback)

Linear scale,

separate pulse coder

H20.M

M187

H20.F

M188

H20.F

M189

Second–axis servo amplifier, motor, pulse

coder, scale

(Same as the connection of the first axis)

H20.M

M194

H20.F

M195

H20.F

M196

Third–axis servo amplifier, motor, pulse coder,

scale

(Same as the connection of the first axis)

H20.M

M197

H20.F

M198

H20.F

M199

Fourth–axis servo amplifier, motor, pulse coder,

scale

(Same as the connection of the first axis)

BWG3.F

CPA9

Battery for absolute pulse coder (for first to

fourth axes)

(Continued)

Serial pulse coder

A/B–phase pulse coder

B–62545EN/02

2. HARDWARE

23

(Continued)

1st to 4th axis

control

JS1B Servo amplifier

(Digital control)

First axis

HF20.F

HF20.F

JS1A

AXE

AC

servo motor

HF20.F

(Command)

(Velocity/position

feedback)

Serial pulse coder

(Servo system of semi–closed loop)

JS1B Servo amplifier

(Digital control)

First axis

H20.M

H20.F

AC

servo motor

H20.F

M186

(Command)

(Velocity feedback)

Servo system of closed loop

(Position feedback)

Linear scale,

separate pulse coder

HF20.F

JS2A

H20.F

M189

Second–axis servo amplifier, motor, pulse

coder, scale

(Same as the connection of the first axis)

HF20.F

JS3A

H20.F

M196

Third–axis servo amplifier, motor, pulse coder,

scale

(Same as the connection of the first axis)

HF20.F

JS4A

H20.F

M199

Fourth–axis servo amplifier, motor, pulse coder,

scale

(Same as the connection of the first axis)

BWG3.F

CPA9

Battery for remote type absolute pulse coder

(for first to fourth axes)

(Continued)

Serial pulse coder

(Type B interface control PC board)

JF1

JS1A

JF1

2. HARDWARE

B–62545EN/02

24

(Continued)

PMC–M

*Both Package 3 of 0–TD and 0–MD can use only.

PMC

B–62545EN/02

2. HARDWARE

25

1 RVDO

2 HSYN

3 VSYN

4 GVDO

11 0V

12 0V

13

14

5 BVDO

6

7

8 0V

15

16

17

18

9 0V

10 0V

19

20

Control unit

Memory card CCX5

(MR–20RMD)

1 RVDO

2 HSYN

3 VSYN

4 GVDO

0V

0V

5 BVDO

6

7

8 0V

9 0V

10 0V

RVDO

1

2

3

4

1

8

4

11

RVDO

0V

GVDO

0V

Maximum cable length: 50 m

Recommended cable material : A66L–0001–0219 coaxial cable

Recommended cable order number: A02B–0098–K825 (7 m)

CRT unit

CN1

(MR–20RM)

H20.F H20.F

Cable wiring

0V

GVDO

0V

BVDO

5

6

18

14

5

12

2

9

BVDO

0V

HSYNC

0V

0V

HSYNC

0V

12

16

3

10

VSYNC

0V

0V

VSYNC

11

12

13

14

15

16

17

18

19

20

2.3

INTER–MACHINE

CONNECTION

2.3.1

CRT/MDI Unit

D Video signal interface

2. HARDWARE

B–62545EN/02

26

Use a power cable containing conductors of 30/0.18 (0.8 mm2) or greater .

(1) 9″ monochrome CRT

1

2

3 0V

4 0V

5 +24V

6 +24V

Power supply unit

CP15 (SMS6RN–4)

9″ CRT unit

(monochrome)

CN2 (SMS6RN–4)

Cable side connector (CP15)

Housing: Japan Burndy SMS6PN–5

Contact: Japan Burndy RC16M–23T3 or

RC16M–SCT3

J38

1

2

3 0V

4 0V

5 +24V

6 +24V

Recommended cable: A02B–0072–K814 (7 m)

1 +24V

2 0V

3

For CE marking

Power supply unit

CP15 (SMS6RN–4)

9″ CRT unit

(monochrome)

CN2 (SMS6RN–4)

Cable side connector (CP15)

Housing: Japan Burndy SMS6PN–5

Contact: Japan Burndy RC16M–23T3 or

RC16M–SCT3

J38

1

2

3 0V

4 0V

5 +24V

6 +24V

Recommended cable: A02B–0120–K820 (5 m)

Cable side connector (CP5)

Housing: JAPAN AMP 2–178288–3

Contact: JAPAN AMP 1–175218–5

Some separate display units have soft keys. These units have flat cables

for the soft keys. Connect the soft key cable to connector KM2 of a

separate MDI unit.

KM2

Separate display unit

Separate MDI unit

The flat cable is about 500 mm long.

D Connecting the display

unit power supply

D Connecting the soft key

cable of a separate

display unit

B–62545EN/02

2. HARDWARE

27

1 *KCM08

2 *KCM00

3 *KCM01

4 *SW06

11 *SW05

12 *SW03

13 *SW01

14 *KCM04

5 *SW04

6 *SW02

7 *SW00

8 *KCM02

15 *KCM05

16 *KCM06

17 *KCM07

18

9 *KCM03

10 *SW07

19

20

Control unit

Memory card M3

(MR–20RMD) (MR–20RFM)

*KCM08

(01)

(02)

(03)

(04)

Use unified shield cable and the length is 50m or less.

Recommended cable : A02B–0050–K803 (7m) or A02B–0098–K803 (7m)

Recommended cable material : A66L–0001–0041 (7/0. 18, 20 core)

MDI unit

KM1

H20.F H20.M

Cable connection

*SW06

*KCM01

*KCM00

*SW04

(05)

(06)

(07)

(08)

*KCM02

*SW00

*SW02

(09)

(10)

*SW07

*KCM03

(11)

*SW05

*SW03

(12)

(13)

(14)

(15)

*KCM05

*KCM04

*SW01

(16)

(17)

*KCM07

*KCM06

Shield

1 *KCM08

2 *KCM00

3 *KCM01

4 *SW06

11 *SW05

12 *SW03

13 *SW01

14 *KCM04

5 *SW04

6 *SW02

7 *SW00

8 *KCM02

15 *KCM05

16 *KCM06

17 *KCM07

18

9 *KCM03

10 *SW07

19

20

*KCM08

*SW06

*KCM01

*KCM00

*SW04

*KCM02

*SW00

*SW02

*SW07

*KCM03

*SW05

*SW03

*KCM05

*KCM04

*SW01

*KCM07

*KCM06

(01)

(02)

(03)

(04)

(05)

(06)

(07)

(08)

(09)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

D Connection to MDI unit

MDI unit interface

2. HARDWARE

B–62545EN/02

28

1

FG SD RD RS CS DR SG CD

2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

ER +24V

Interconnection connector signal arrangement

CNC

FG

Interconnection

cable

Interconnection connector

Connector: DBM–25S (Japan Aviation Electronics)

Lock hardware: D20418–J2 (Japan Aviation Electronics)

Cable–end connector

Connector: DBM–25P

(Japan Aviation Electronics)

Lock hardware: DB–C2–J9

(Japan Aviation Electronics)

Control unit

M5 (MR–20RFD)

1

2

3

4

11

12

13

14 +24V

5 ER

6

7

8 RD

15

16 CD

17 SG

18 DR

9 SD

10

19 CS

20 RS

CAUTION

1 The machine tool builder is requested to provide the

interconnection connectors and cables.

2 Use a common shielded cable for the signal cable.

Recommended cable specification: A66L–0001–0041

2.3.2

Reader/Puncher Interface

B–62545EN/02

2. HARDWARE

29

Control unit

M12 Honda Tsushin MR–20RMD

1 0V

2 0V

3 0V

4 +5V

11

12

13

14

5 +5V

6 +5V

7

8 HA1

15

16

17

18

9 HB1

10

19

20

3

+5V4+0V5HA16HB1

M3 screw terminal

Manual pulse generator (for the first axis)

J24

Cable: Cable with common shielded conductors, 7/0.18 (0.2 mm2) or thicker

Recommended cable conductor specification: A66L–001–0041

A02B–0050–K802 (7 m) is usable for J24.

Honda Tsushin

Manual pulse generator

(for the first axis)

HA1

+5V

M12(6)

M12(1)

M12(2)

M12(3)

M12(8)

M12(9)

M12(5)

M12(4)

HB1

Control unit

+5V

2

3

0V

HA1

4

5

HB1 6

Similarly to the pulse coder, the manual pulse generator is designed to

operate on 5 VDC. So, any voltage drop relative to the supply voltage

must be kept to within 0.2 V (total drop through the 0 V and 5 V lines).

Namely:

0.2 y

0.1 R 2L

m

where 0.1 : Current required by the manual pulse generator

R : Wire resistance per unit length [Ω/m]

m : Number of wires in the 0 V or 5 V cable

L : Cable length [m]

Thus,

L x

m

R

2.3.3

Manual pulse Generator

Manual pulse generator

cable

2. HARDWARE

B–62545EN/02

30

This section describes the servo interface between the Series 0–D and the

a and b series servo amplifier and servo motor.

The Series 0–D supports two types of axis control cards according to the

type of servo interface.

D Axis control card of type A interface

(It can be used by 0–TD and 0–MD)

D Axis control card of type B interface

Axis control card of type A interface Axis control card of type B interface

Axis name Command

Semi–

closed

loop

Closed loop

Command

Semi–

closed

loop

Closed loop

Feedback

Position

feedback

Velocity

feedback

Feedback

Position

feedback

Velocity

feedback

1st axis M184 M185 M186 M185 JS1A JFn M186 JFn

2nd axis M187 M188 M189 M188 JS2A JFn M189 JFn

3rd axis M194 M195 M196 M195 JS3A JFn M196 JFn

4th axis M197 M198 M199 M198 JS4A JFn M199 JFn

For a type B interface axis control card, the feedback or velocity feedback

cable is connected to the JFn connector on the servo amplifier, where n

varies with the servo amplifier being used.

2.3.4

Servo Interface

D Outline

D Connector names

B–62545EN/02

2. HARDWARE

31

Battery

unit

Pulse

coder

Servo

motor

Servo amplifier

Power

Type A interface axis

control card

Command

Feedback

The battery unit is not required when an incremental pulse coder is used.

(when an absolute pulse coder and relay unit are used)

Battery

unit

Pulse

coder

Servo

motor

Servo amplifier

Power

Type A interface axis

control card

Command

Feedback

Relay

unit

D Semi–closed loop

system

D Semi–closed loop

system

2. HARDWARE

B–62545EN/02

32

Pulse

coder

Servo

motor

Servo amplifier

Power

Type B interface axis

control card

Command/

Feedback

Battery

unit

The battery unit is not required when an incremental pulse coder is used.

Use the servo amp. for type B interface or set common amp. to the B type.

Feedback

Pulse

coder

Servo

motor

Servo amplifier

Power

Type A interface axis

control card

Command

Remote

pulse coder

Battery

unit

The battery unit is not required when an incremental pulse coder is used.

Velocity feedback

Position feedback

D Semi–closed loop

system

D Closed loop system

B–62545EN/02

2. HARDWARE

33

(when an absolute pulse coder and relay unit are used)

Pulse

coder

Servo

motor

Servo amplifier

CN1

Power

Series 0 axis control

card

Command

Velocity feedback

Remote

pulse coder

Battery

unit

Relay

unit

Position feedback

Pulse

coder

Servo

motor

Servo amplifier

CN1

Power

Type B interface axis

control card

Command/

Velocity feedback

Remote

pulse coder

Battery

unit

Position feedback

Velocity feedback

The battery unit is not required when an incremental remote pulse coder is used.

D Closed loop system

D Closed loop system

2. HARDWARE

B–62545EN/02

34

(1) Servo amplifier interface

This section describes each servo amplifier interface, taking that for

the first axis as an example.

(1)–1 In case of type A interface

01

02

03

04

05

06

07

*PWMAn

COMAn

*PWMBn

COMBn

*PWMCn

COMCn

*DRDYn

08

09

10

11

12

13

IRn

GDRn

ISn

GDSn

*MCONn

GNDn

14

15

16

17

18

19

20

*PWMDn

COMDn

*PWMEn

COMEn

*PWMFn

COMFn

Type A interface axis

control card M184

(MR–20RF)

01

02

03

04

05

06

07

08

09

10

IRn

GDRn

*PWMAn

COMAn

*PWMBn

COMBn

*PWMCn

COMCn

*MCONn

Servo amplifier JV1B (L–axis),

JV2B (M–axis)

CN1

n: axis number

Connector: MR–20LMH (HONDA, 20–pin, male) Connector: PCR–E20FA (HONDA, 20–pin,

half–pitch) or equivalent

Cable connection

IRn

GDRn

*PWMAn

COMAn

*PWMBn

COMBn

*PWMCn

COMCn

*MCONn

ISn

GDSn

*PWMDn

COMDn

*PWMEn

COMEn

*PWMFn

COMFn

*DRDYn

8

9

1

2

3

4

5

6

12

10

11

14

15

16

17

18

19

7

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

20

IRn

GDRn

*PWMAn

COMAn

*PWMBn

COMBn

*PWMCn

COMCn

*MCONn

ISn

GDSn

*PWMDn

COMDn

*PWMEn

COMEn

*PWMFn

COMFn

*DRDYn

Shield

Recommended cable material A66L–0001–0284#10P (#28AWG 10pairs)

Recommended cable specification A02B–0098–K841 (5m)

11

12

13

14

15

16

17

18

19

20

ISn

GDSn

*PWMDn

COMDn

*PWMEn

COMEn

*PWMFn

COMFn

*DRDYn

B–62545EN/02

2. HARDWARE

35

CAUTION

T o protect the signals from external noise, assign the cable’s

central pairs to each pair of current feedback signal and

ground signal (i.e., IRn and GDRn, and ISn and GDSn).

Otherwise, external noise may result in uneven feed or

abnormal sound.

For connection on control motor amplifier α series or β series,

refer to the Descriptions manual.

2. HARDWARE

B–62545EN/02

36

(1)–2 Interface to the servo amplifier

:MCONn

GDRn

01

03

IRn

02

:PWMAn

:PWMCn

04

06

0V

05

0V

:PWMEn

08

07

0V

:MCONn

09

:DRDYn

10

GDSn

11

13

ISn

12

:ENBLn

PDn

14

16

0V

15

:PDn

PREQn

18

17

:PREQn

0V

19

0V

20

Servo Amplifier Module

Type B interface axis control card

JS1A (PCR–EV20MDT)

JS1B (L axis) JS2B (M axis)

JS3B (N axis) (PCR–EV20MDT)

01

03

02

04

06

05

08

07

09

10

11

13

12

14

16

15

18

17

19

20

GDRn

IRn

:PWMAn

:PWMCn

0V

0V

:PWMEn

0V

:DRDYn

GDSn

ISn

:ENBLn

PDn

0V

:PDn

PREQn

:PREQn

0V

0V

Connector: PCR–E20FA etc.

(HONDA 20 pin half pitch)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Shield

IRn

GDRn

:PWMAn

0V

:PWMCn

0V

:PWMEn

0V

:DRDYn

:MCONn

ISn

GDSn

:ENBLn

0V

PDn

:PDn

PREQn

:PREQn

0V

0V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

IRn

GDRn

:PWMAn

0V

:PWMCn

0V

:PWMEn

0V

:DRDYn

:MCONn

ISn

GDSn

:ENBLn

0V

PDn

:PDn

PREQn

:PREQn

0V

0V

CABLE WIRING

RECOMMENDED CABLE MATERIAL A66L–0001–0284#10P(#28WAG 10 pair)

RECOMMENDED CABLE SPECIFICATION A02B–0120–K800(5m)

NOTE

1 The total length of the cable between the CNC and amplifier and that between the amplifier and

motor shall not exceed 50m.

2 As the current feedback lines (IRn and ISn), use the middle twisted pair of the recommended

cable. If any other pair is used, abnormal noise or oscillation may occur.

3 Use a servo unit which supports the type–B interface. When using a servo unit which supports

both the type–A and type–B interfaces, select the type–B interface. For details, refer to the

manual supplied with the servo unit. If the interface setting is incorrect, a servo alarm (AL401

V READY OFF) will be issued.

B–62545EN/02

2. HARDWARE

37

(2) Internal type pulse coder (Serial pulse coder interface)

The connector to which the feedback cable from the built–in pulse

coder is connected varies with the servo interface type.

For the type A interface, connect the feedback cable to the feedback

connector on the axis control card (for example, M185 for the first

axis).

For the type B interface, connect the feedback cable to the feedback

connector on the servo amplifier (for example, JF1 for the first axis).

(2)±1 α series motor (α3/3000 to α150/2000)

A

D

G

K

N

S

V

01

02

03

04

05

06

07

REQ

*REQ

SD

*SD

08

09

10

11

12

13

14

15

16

17

18

19

20

0V

0V

0VB

+5V

+5V

+5V

+6VB

Series 0–D (control unit)

Type A interface axis control card

M185

(MR–20RM)

SD

*SD

*REQn

+5V

0V

0VB

C

F

J

M

R

U

REQ

+5V

+6VB

Pulse coder

(MS3102A–22–29P)

Connector: MR–20LFH (HONDA, 20–pin, female) Connector: MS3106A20–29SW or

MS3108B20–29SW

Cable connection

SD

*SD

REQ

*REQ

+5V

+5V

+5V

0V

0V

0V

+6VB

(16)

(17)

(14)

(15)

(04)

(05)

(06)

(01)

(02)

(03)

(07)

(A)

(D)

(F)

(G)

(J)

(K)

(N)

(T)

(S)

(R)

(H)

Shield

B

E

H

L

P

T

SHILD

0V

SD

*SD

REQ

*REQ

+5V

+5V

0V

0V

0VB

+6VB

SHLD

Cable material: +5V, 0V

Two or more wires each having a cross–sectional area of at least 0.5 mm

2

(when the cable length is 14 m or less)

: +6VB, 0VB One or more wires each having a cross–sectional area of at least 0.5 mm

2

: SD, *SD, REQ, *REQ Twisted pair wires each having a cross–sectional area of at least 0.18 mm

2

J23n

These wires do not have to be connected for

an incremental pulse coder.

NOTE

The voltage resistance for +5 V must not exceed 0.5Ω, total for both ways.

2. HARDWARE

B–62545EN/02

38

(2)±2 α series motor (α1/3000, α2/2000, or α2/3000)

01

02

03

04

05

06

07

REQ

*REQ

SD

*SD

08

09

10

11

12

13

14

15

16

17

18

19

20

0V

0V

0V

+5V

+5V

+5V

+6VB

Series 0–D (control unit)

Type A interface axis control card

M185

(MR–20RM)

Pulse coder