Page 1

< Series 0+-MODEL F Plus

For Lathe System

OPERATOR'S MANUAL

B-64694EN-1/01

Page 2

• All specifications and designs are subject to change without notice.

Foreign Exchange and

The export from Japan may be subject to an export license by the

Should you wish to export or re-export these products, please contact FANUC for advice.

to safety.

regarded as “impossible”.

• No part of this manual may be reproduced in any form.

The products in this manual are controlled based on Japan’s “

Foreign Trade Law”.

government of Japan. Further, re-export to another country may be subject to the license

of the government of the country from where the product is re-exported. Furthermore, the

product may also be controlled by re-export regulations of the United States government.

The products in this manual are manufactured under strict quality control. However, when

a serious accident or loss is predicted due to a failure of the product, pay careful attention

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

Page 3

B-64694EN-1/01 SAFETY PRECAUTIONS

SAFETY PRECAUTION

This section describes the safety precautions related to the use of CNC units.

It is essential that these precautions be observed by users to ensure the safe operation of machines

equipped with a CNC unit (all descriptions in this section assume this configuration). Note that some

precautions are related only to specific functions, and thus may not be applicable to certain CNC units.

Users must also observe the safety precautions related to the machine, as described in the relevant manual

supplied by the machine tool builder. Before attempting to operate the machine or create a program to

control the operation of the machine, the operator must become fully familiar with the contents of this

manual and relevant manual supplied by the machine tool builder.

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine.

Precautions are classified into Warning and Caution according to their bearing on safety. Also,

supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly

before attempting to use the machine.

WARNING

Used if a danger resulting in the death or serious injury of the user is expected to

occur if he or she fails to observe the approved procedure.

CAUTION

Used if a danger resulting in the minor or moderate injury of the user or

equipment damage is expected to occur if he or she fails to observe the

approved procedure.

NOTE

Used if a supplementary explanation not related to any of WARNING, and

CAUTION is to be indicated.

Read this manual carefully, and store it in a safe place.

s-1

Page 4

SAFETY PRECAUTIONS B-64694EN-1/01

WARNING

or injury to the user.

GENERAL WARNINGS AND CAUTIONS

1 Never attempt to machine a workpiece without first checking the operation of the

2 Before operating the machine, thoroughly check the entered data.

Operating the machine with incorrectly specified data may result in the machine

3 Ensure that the specified feedrate is appropriate for the intended operation.

The appropriate feedrate varies with the intended operation. Refer to the manual

If a machine is run at other than the correct speed, it may behave unexpectedly,

4 When using a tool compensation function, thoroughly check the direction and

5 The parameters for the CNC and PMC are factory-set. Usually, there is not need

Failure to set a parameter correctly may result in the machine behaving

machine. Before starting a production run, ensure that the machine is operating

correctly by performing a trial run using, for example, the single block, feedrate

override, or machine lock function or by operating the machine with neither a tool

nor workpiece mounted. Failure to confirm the correct operation of the m achine

may result in the machine behaving unexpectedly, possibly causing damage to

the workpiece and/or machine itself, or injury to the user.

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

Generally, for each machine, there is a maximum allowable feedrate.

provided with the machine to determine the maximum allowable feedrate.

possibly causing damage to the workpiece and/or machine itself, or injury to the

user.

amount of compensation.

Operating the machine with incorrectly specified data may result in the machine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user.

to change them. When, however, there is not alternative other than to change a

parameter, ensure that you fully understand the function of the param et er before

making any change.

unexpectedly, possibly causing damage to the workpiece and/or machine itself,

s-2

Page 5

B-64694EN-1/01 SAFETY PRECAUTIONS

CAUTION

1 Immediately after switching on the power, do not touch any of the keys on the

unexpectedly.

2 The OPERATOR’S MANUAL and programming manual supplied with a CNC

machine if in doubt.

3 Some functions may have been implemented at the request of the machine-tool

machine-tool builder for details of their use and any related cautions.

4 The liquid-crystal display is manufactured with very precise fabrication

phenomenon is a common attribute of LCDs and is not a defect.

NOTE

non-volatile memory at registration, modification, or deletion of program s.

MDI unit until the position display or alarm screen appears on the CNC unit.

Some of the keys on the MDI unit are dedicated to maintenance or other special

operations. Pressing any of these keys may place the CNC unit in other than its

normal state. Starting the machine in this state may cause it to behave

unit provide an overall description of the machine's functions, including any

optional functions. Note that the optional functions will vary from one machine

model to another. Therefore, some functions described in the manuals may not

actually be available for a particular model. Check the specification of the

builder. When using such functions, refer to the manual supplied by the

technology. Some pixels may not be turned on or may remain on. This

Programs, parameters, and macro variables are stored in non-volatile memory in

the CNC unit. Usually, they are retained even if the power is turned off.

Such data may be deleted inadvertently, however, or it may prove necessary to

delete all data from non-volatile memory as part of error recovery.

To guard against the occurrence of the above, and assure quick restoration of

deleted data, backup all vital data, and keep the backup copy in a safe place.

The number of times to write machining programs to the non-volatile memory is

limited.

You must use "High-speed program management" when registration and the

deletion of the machining programs are frequently repeated in such case that the

machining programs are automatically downloaded from a personal computer at

each machining.

In "High-speed program management", the program is not saved to t he

s-3

Page 6

SAFETY PRECAUTIONS B-64694EN-1/01

WARNING

1

Coordinate system setting

damage the tool, the machine itself, the workpiece, or cause injury to the user .

4

Inch/metric conversion

to the user.

5

Constant surface speed control

machine itself, the workpiece, or cause injury to the user.

6

Stroke check

workpiece, or causing injury to the user.

WARNINGS AND CAUTIONS RELATED TO PROGRAMM ING

This section covers the major safety precautions related to programming. Before attempting to perform

programming, read the supplied OPERATOR’S MANUAL carefully such that you are fully f amiliar with

their contents.

If a coordinate system is established incorrectly, the machine may behave

unexpectedly as a result of the program issuing an otherwise valid move

command. Such an unexpected operation may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

2

Positioning by nonlinear interpolation

When performing positioning by nonlinear interpolation (positioning by nonlinear

movement between the start and end points), the tool path must be caref ully

confirmed before performing programming. Positioning involves rapid travers e. If

the tool collides with the workpiece, it may damage the tool, the machine itself,

the workpiece, or cause injury to the user.

3

Function involving a rotation axis

When programming polar coordinate interpolation or normal-direction

(perpendicular) control, pay careful attention to the speed of the rotat ion axis.

Incorrect programming may result in the rotation axis speed becoming

excessively high, such that centrifugal force causes the chuck to lose its grip on

the workpiece if the latter is not mounted securely. Such mishap is likely to

Switching between inch and metric inputs does not convert the measurement

units of data such as the workpiece origin offset, parameter, and current

position. Before starting the machine, therefore, determine which measur ement

units are being used. Attempting to perform an operation with invalid data

specified may damage the tool, the machine itself, the workpiece, or cause injury

When an axis subject to constant surface speed control approaches the origin of

the workpiece coordinate system, the spindle speed may become excessively

high. Therefore, it is necessary to specify a maximum allowable speed.

Specifying the maximum allowable speed incorrectly may damage the tool, the

After switching on the power, perform a manual reference position return as

required. Stroke check is not possible before manual reference position return is

performed. Note that when stroke check is disabled, an alarm is not issued even

if a stroke limit is exceeded, possibly damaging the tool, the machine itself, the

s-4

Page 7

B-64694EN-1/01 SAFETY PRECAUTIONS

WARNING

7 I

nterference check for each path

automatic operation and specify the tool number of the tool to be used.

8

Same address command in same block

program command”)

CAUTION

1

Absolute/incremental mode

versa, the machine may behave unexpectedly.

2

Plane selection

descriptions of the respective functions for details.

3

Torque limit skip

be executed without performing a skip.

4

Programmable mirror image

mirror image is enabled.

5

Compensation function

compensation function mode.

Interference check for each path function is perform ed bas ed on t he tool data

specified during automatic operation. If the tool specification does not match the

tool actually being used, the interference check cannot be made correctly,

possibly damaging the tool or the machine itself, or causing injury to the user.

After switching on the power, or after selecting a tool post manually, always start

The G code or M code including the same address cannot be commanded on

the same block. If you use the same address, it may result in t he m ac hine

behaving unexpectedly, possibly causing damage to the workpiece and/or

machine itself, or injury to the user. Command on separate block.(About

address P, refer to the appendix “List of functions include address P in the

If a program created with absolute values is run in incremental mode, or vice

If an incorrect plane is specified for circular interpolation, helical interpolation, or

a canned cycle, the machine may behave unexpectedly. Refer to the

Before attempting a torque limit skip, apply the torque limit. If a torque limit skip

is specified without the torque limit actually being applied, a move command will

Note that programmed operations vary considerably when a programmable

If a command based on the machine coordinate system or a reference position

return command is issued in compensation function mode, compensation is

temporarily canceled, resulting in the unexpected behavior of the machine.

Before issuing any of the above commands, therefore, always cancel

s-5

Page 8

SAFETY PRECAUTIONS B-64694EN-1/01

WARNING

1

Manual operation

injury to the user.

6

Workpiece coordinate system shift

workpiece, or causing injury to the operator.

WARNINGS AND CAUTIONS RELATED TO HANDLING

This section presents safety precautions related to the handling of machine tools. Before attempting to

operate your machine, read the supplied OPERATOR’S MANUAL carefully, such that you are fully

familiar with their contents.

When operating the machine manually, determine the current position of the tool

2

After switching on the power, perform manual reference position return as

3

In manual handle feed, rotating the handle with a large scale factor, such as 100,

4

If override is disabled (according to the specification in a macro variable) during

5

Basically, never attempt an origin/preset operation when the machine is

and workpiece, and ensure that the movement axis, direction, and feedrate have

been specified correctly. Incorrect operation of the machine may damage the

tool, the machine itself, the workpiece, or cause injury to the operator.

Manual reference position return

required.

If the machine is operated without first performing manual reference posit ion

return, it may behave unexpectedly. Stroke check is not possible before manual

reference position return is performed.

An unexpected operation of the machine may damage the tool, the machine

itself, the workpiece, or cause injury to the user.

Manual handle feed

applied causes the tool and table to move rapidly. Careless handling may

damage the tool and/or machine, or cause injury to the user.

Disabled override

threading, rigid tapping, or other tapping, the speed cannot be predicted,

possibly damaging the tool, the machine itself, the workpiece, or causing injury

to the operator.

Origin/preset operation

operating under the control of a program. Otherwise, the machine may behave

unexpectedly, possibly damaging the tool, the machine itself, the tool, or causing

Manual intervention, machine lock, or mirror imaging may shift the workpiece

coordinate system. Before attempting to operate the machine under the c ont rol

of a program, confirm the coordinate system carefully.

If the machine is operated under the control of a program without making

allowances for any shift in the workpiece coordinate system, the machine may

behave unexpectedly, possibly damaging the tool, the machine itself, the

s-6

Page 9

B-64694EN-1/01 SAFETY PRECAUTIONS

WARNING

7

Software operator's panel and menu switches

use the emergency stop button instead of the RESET key to ensure security.

CAUTION

1

Manual intervention

command mode.

2

Feed hold, override, and single block

machine in this case.

3

Dry run

sometimes be higher than the programmed feed rate.

4

Program editing

modify, insert, or delete commands from a machining program while it is in use.

5

PS alarm

the axis movement stops.

Using the software operator's panel and menu switches, in combination with the

MDI unit, it is possible to specify operations not supported by the machine

operator's panel, such as mode change, override value change, and jog feed

commands.

Note, however, that if the MDI unit keys are operated inadvertently, the machine

may behave unexpectedly, possibly damaging the tool, the machine itself, the

workpiece, or causing injury to the user.

8

RESET key

Pressing the RESET key stops the currently running program. As a result, the

servo axes are stopped. However, the RESET key may fail to function for

reasons such as an MDI unit problem. So, when the motors must be stopped,

If manual intervention is performed during programmed operation of the

machine, the tool path may vary when the machine is restarted. Before

restarting the machine after manual intervention, therefore, c onf ir m the settings

of the manual absolute switches, parameters, and absolute/incremental

The feed hold, feedrate override, and single block functions can be disabled

using custom macro system variable #3004. Be careful when operating the

Usually, a dry run is used to confirm the operation of the machine. During a dry

run, the machine operates at dry run speed, which differs from the

corresponding programmed feedrate. Note that the dry run speed may

If the machine is stopped, after which the machining program is edited

(modification, insertion, or deletion), the machine may behave unexpectedly if

machining is resumed under the control of that program. Basically, do not

When a PS alarm is occurred during executing a blolck, the axis movement of

the block is continued to the end of block. After finishing the executing the block,

s-7

Page 10

SAFETY PRECAUTIONS B-64694EN-1/01

WARNING

electric shock hazard.

NOTE

replacement procedure.

WARNING

electric shock hazard.

NOTE

details of the battery replacement procedure.

WARNINGS RELATED TO DAILY MAINTENANCE

1

Memory backup battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

The CNC uses batteries to preserve the contents of its memory, because it must

retain data such as programs, offsets, and parameters even while external

power is not applied.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the contents of the CNC's memory will be lost.

Refer to the Section “Method of replacing battery” in the OPERATOR’S

MANUAL (Common to Lathe/Machining Center System) for details of the batter y

2

Absolute pulse coder battery replacement

When replacing the memory backup batteries, keep the power to the machine

(CNC) turned on, and apply an emergency stop to the machine. Because this

work is performed with the power on and the cabinet open, only those personnel

who have received approved safety and maintenance training may perform this

work.

When replacing the batteries, be careful not to touch the high-voltage circuits

(marked and fitted with an insulating cover).

Touching the uncovered high-voltage circuits presents an extremely dangerous

The absolute pulse coder uses batteries to preserve its absolute position.

If the battery voltage drops, a low battery voltage alarm is displayed on the

machine operator's panel or screen.

When a low battery voltage alarm is displayed, replace the batteries within a

week. Otherwise, the absolute position data held by the pulse coder will be lost.

Refer to the FANUC SERVO AMPLIFIER

i

series Maintenance Manual for

α

s-8

Page 11

B-64694EN-1/01 SAFETY PRECAUTIONS

WARNING

electric shock hazard.

3

Fuse replacement

Before replacing a blown fuse, however, it is necessary to locate and remove the

cause of the blown fuse.

For this reason, only those personnel who have received approved safety and

maintenance training may perform this work.

When replacing a fuse with the cabinet open, be careful not to touch the

high-voltage circuits (marked and fitted with an insulating cover).

Touching an uncovered high-voltage circuit presents an extremely dangerous

s-9

Page 12

Page 13

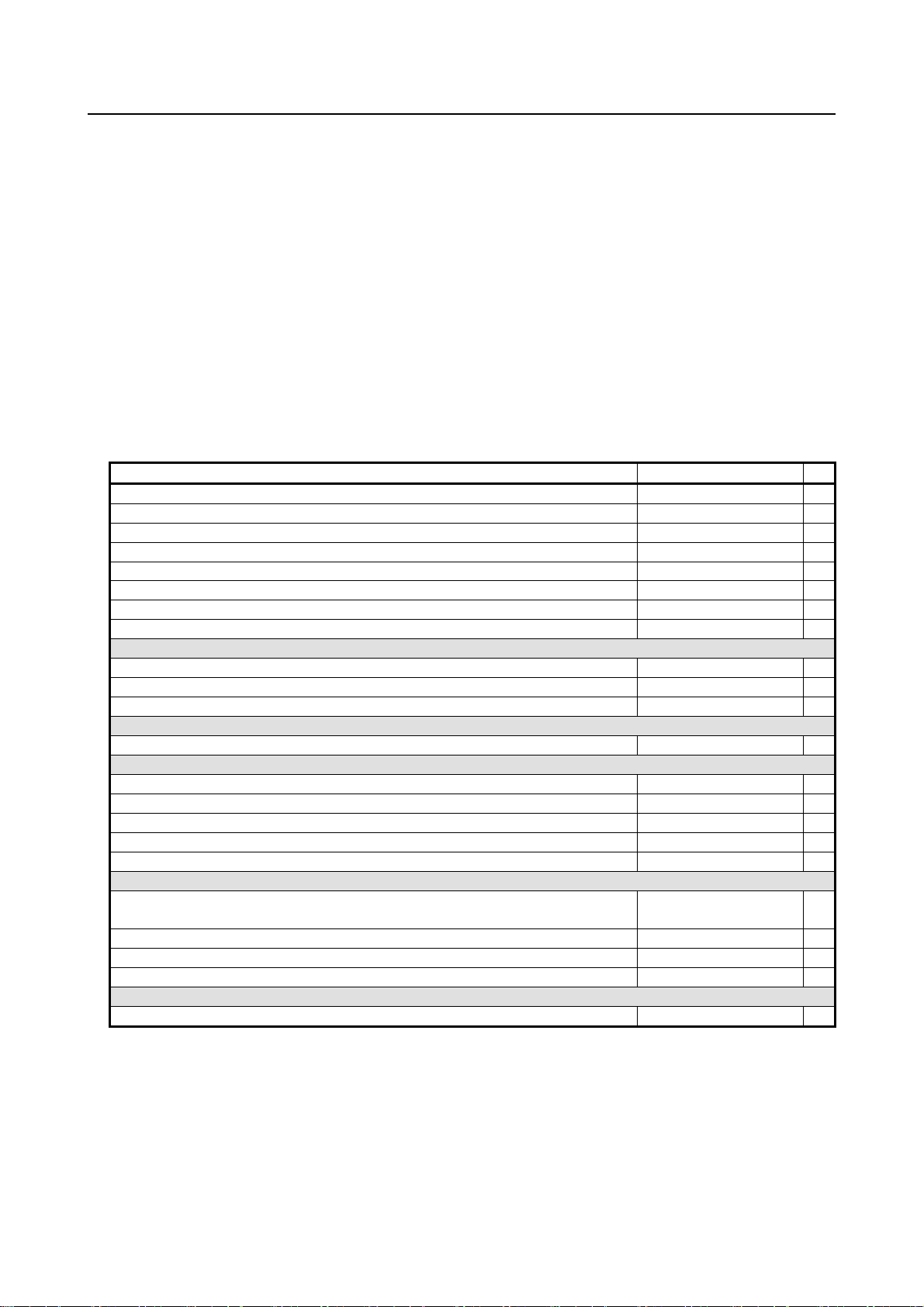

B-64694EN-1/01 TABLE OF CONTENTS

TABLE OF CONTENTS

SAFETY PRECAUTION .............................................................................. s-1

I. GENERAL

1 GENERAL ............................................................................................... 3

1.1 NOTES ON READING THIS MANUAL .......................................................... 6

1.2 NOTES ON VARIOUS KINDS OF DATA ...................................................... 6

II. PROGRAMMING

1 GENERAL ............................................................................................... 9

1.1 OFFSET ........................................................................................................ 9

2 PREPARATORY FUNCTION (G FUNCTION) ...................................... 10

3 INTERPOLATION FUNCTION .............................................................. 15

3.1 THREADING (G32) ..................................................................................... 15

3.2 CONTINUOUS THREADING ....................................................................... 18

3.3 MULTIPLE THREADING ............................................................................. 19

4 FUNCTIONS TO SIMPLIFY PROGRAMMING ..................................... 21

4.1 CANNED CYCLE (G90, G92, G94) ............................................................. 21

4.1.1 Outer Diameter/Internal Diameter Cutting Cycle (G90) ........................................ 22

4.1.1.1 Straight cutting cycle ......................................................................................... 22

4.1.1.2 Taper cutting cycle ............................................................................................ 23

4.1.2 Threading Cycle (G92) ........................................................................................... 24

4.1.2.1 Straight threading cycle ..................................................................................... 24

4.1.2.2 Taper threading cycle ........................................................................................ 27

4.1.3 End Face Turning Cycle (G94) .............................................................................. 30

4.1.3.1 Face cutting cycle .............................................................................................. 30

4.1.3.2 Taper cutting cycle ............................................................................................ 31

4.1.4 How to Use Canned Cycles (G90, G92, G94) ........................................................ 32

4.1.5 Canned Cycle and Tool Nose Radius Compensation ............................................. 34

4.1.6 Restrictio ns on Canned Cycles ............................................................................... 35

4.2 MULTIPLE REPETITIVE CANNED CYCLE (G70-G76) .............................. 37

4.2.1 Stock Removal in Turning (G71) ........................................................................... 38

4.2.2 Stock Removal in Facing (G72) ............................................................................. 53

4.2.3 Pattern Repeating (G73) ......................................................................................... 57

4.2.4 Finishing Cycle (G70) ............................................................................................ 60

4.2.5 End F ace Peck Drilling Cycle (G74) ...................................................................... 64

4.2.6 Outer Diameter / In t ernal Diameter Drilling Cycle (G75) ..................................... 66

4.2.7 Multiple Threading Cycle (G76) ............................................................................ 68

4.2.8 Restrictio ns on Multiple Repetitive Canned Cycle (G70-G76) .............................. 74

4.2.9 Reducing path for Multiple repetitive canned cycle ............................................... 76

4.3 CANNED CYCLE FOR DRILLING ............................................................... 77

4.3.1 Front Drilling Cycle (G83)/Side Drilling Cycle (G87) .......................................... 81

4.3.2 Front Tapping Cycle (G84) / Side Tapping Cycle (G88) ....................................... 85

4.3.3 Front Boring Cycle (G85) / Side Boring Cycle (G89) ........................................... 86

c-1

Page 14

TABLE OF CONTENTS B-64694EN-1/01

4.3.4 Canned Cycle for Drilling Cancel (G80) ................................................................ 87

4.3.5 Canned Cycle for Drilling with M Code Output Improved.................................... 87

4.3.6 Reducing of Waiting Time of Spindle Speed Arrival in the

Canned Cycle for Drilling ...................................................................................... 88

4.3.7 Precautions for Operators ....................................................................................... 90

4.4 CANNED CYCLE OVERLAP FOR DRILLING ............................................. 91

4.5 RIGID TAPPING .......................................................................................... 99

4.5.1 Front Face Rigid Tapping Cycle (G84) / Side Face Rigid Tapping Cycle (G88) 100

4.5.2 Peck Rigid Tapping Cycle (G84 or G88) ............................................................. 106

4.5.3 Canned Cycle Cancel (G80) ................................................................................. 110

4.5.4 Override during Rigid Tapping ............................................................................ 111

4.5.4.1 Extraction override .......................................................................................... 111

4.5.4.2 Override signal ................................................................................................ 112

4.6 CANNED GRINDING CYCLE (FOR GRINDING MACHINE) ..................... 113

4.6.1 Traverse Grinding Cycle (G71) ............................................................................ 115

4.6.2 Traverse Direct Constant-Size Grinding Cycle (G72) ......................................... 117

4.6.3 Oscillation Grinding Cycle (G73) ........................................................................ 119

4.6.4 Oscillation Direct Constant-Size Grinding Cycle (G74) ...................................... 121

4.7 CHAMFERING AND CORNER R .............................................................. 123

4.8 MIRROR IMAGE FOR DOUBLE TURRET (G68, G69 ) ............................. 128

4.9 DIRECT DRAWING DIMENSION PROGRAMMING ................................. 130

5 COMPENSATION FUNCTION ............................................................ 135

5.1 TOOL OFFSET .......................................................................................... 135

5.1.1 Tool Geometry Offset and Tool Wear Offset ....................................................... 135

5.1.2 T Code for Tool Offset ......................................................................................... 136

5.1.3 Tool Selection....................................................................................................... 136

5.1.4 Offset Number ...................................................................................................... 136

5.1.5 Offset .................................................................................................................... 137

5.1.6 Y Axis Offset ........................................................................................................ 140

5.1.6.1 Support of arbitrary axes for Y axis offset ...................................................... 140

5.1.7 Second Geometry Tool Offset .............................................................................. 140

5.1.8 4th/5th Axis Offset ............................................................................................... 143

5.2 OVERVIEW OF TOOL NOSE RADIUS COMPENSATION (G40-G42) ..... 145

5.2.1 Imaginary Tool Nose ............................................................................................ 146

5.2.2 Direction of Imaginary Tool Nose ....................................................................... 148

5.2.3 Offset Number and Offset Value .......................................................................... 149

5.2.4 Workpiece Position and Move Command ............................................................

5.2.5 Notes on Tool Nose Radius Compensation .......................................................... 155

5.3 OVERVIEW OF CUTTER COMPENSATION (G40-G42) .......................... 158

5.4 DETAILS OF CUTTER OR TOOL NOSE RADIUS COMPENSATION ...... 163

5.4.1 Overview .............................................................................................................. 163

5.4.2 Tool Movement in Start-up .................................................................................. 167

5.4.3 Tool Movement in Offset Mode ........................................................................... 172

5.4.4 Tool Movement in Offset Mode Cancel ............................................................... 190

5.4.5 Prevention of Overcutting Due to Cutter or Tool Nose Radius Compensation ... 197

5.4.6 Interference Check ............................................................................................... 200

5.4.6.1 Operation to be performed if an interference is judged to occur ..................... 203

5.4.6.2 Interference check alarm function ................................................................... 204

5.4.6.3 Interference check avoidance function ............................................................ 205

5.4.7 Cutter or Tool Nose Radius Compensation for Input from MDI ......................... 210

5.5 VECTOR RETENTION (G38) .................................................................... 211

5.6 CORNER CIRCULAR INTERPOLATION (G39) ........................................ 212

150

c-2

Page 15

B-64694EN-1/01 TABLE OF CONTENTS

5.7 EXTENDED TOOL SELECTION ............................................................... 214

5.8 AUTOMATIC TOOL OFFSET (G36, G37) ................................................. 217

5.9 COORDINATE SYSTEM ROTATION (G68.1, G69.1) ............................... 221

6 MEMORY OPERATION USING Series 15 FORMAT ......................... 226

6.1 ADDRESSES AND SPECIFIED RANGE FOR Series 15 PROGRAM

FORMAT ................................................................................................... 226

6.2 SUBPROGRAM CALLING ........................................................................ 227

6.3 CANNED CYCLE ....................................................................................... 227

6.3.1 Outer Diameter/Internal Diameter Cutting Cycle (G90) ...................................... 228

6.3.1.1 Straight cutting cycle ....................................................................................... 228

6.3.1.2 Taper cutting cycle .......................................................................................... 229

6.3.2 Threading Cycle (G92) ......................................................................................... 230

6.3.2.1 Straight threading cycle ................................................................................... 230

6.3.2.2 Taper threading cycle ...................................................................................... 233

6.3.3 End Face Turning Cycle (G94) ............................................................................ 236

6.3.3.1 Face cutting cycle ............................................................................................ 236

6.3.3.2 Taper cutting cycle .......................................................................................... 237

6.3.4 How to Use Canned Cycles .................................................................................. 239

6.3.5 Canned Cycle and Tool Nose Radius Compensation ........................................... 240

6.3.6 Restrictio ns on Canned Cycles ............................................................................. 241

6.4 MULTIPLE REPETITIVE CANNED CYCLE .............................................. 243

6.4.1 Stock Removal in Turning (G71) ......................................................................... 244

6.4.2 Stock Removal in Facing (G72) ........................................................................... 254

6.4.3 Pattern Repeating (G73) ....................................................................................... 258

6.4.4 Finishing Cycle (G70) .......................................................................................... 260

6.4.5 End F ace Peck Drilling Cycle (G74) .................................................................... 264

6.4.6 Outer Diameter / In t ernal Diameter Drilling Cycle (G75) ................................... 266

6.4.7 Multiple Threading Cycle (G76 <G code system A/B>)

(G78 <G code system C>) .................................................................................... 268

6.4.8 Restrictions on Multiple Repetitive Canned Cycle .............................................. 274

6.5 CANNED CYCLE FOR DRILLING ............................................................. 275

6.5.1 High-speed Peck Drilling Cycle (G83.1) ............................................................. 280

6.5.2 Drilling Cycle, Spot Drilling Cycle (G81) ........................................................... 281

6.5.3 Drilling Cycle, Counter Boring (G82) ................................................................. 282

6.5.4 Peck Drilling Cycle (G83) .................................................................................... 283

6.5.5 Tapping Cycle (G84) ............................................................................................ 285

6.5.6 Boring Cycle (G85) .............................................................................................. 286

6.5.7 Boring Cycle (G89) ................................................................

6.5.8 Canned Cycle for Drilling Cancel (G80) .............................................................. 288

6.5.9 Precautions to be Taken by Operator ................................................................... 288

6.6 Canned Cycle Overlap for Drilling .............................................................. 289

.............................. 287

7 MUITI-PATH CONTROL FUNCTION .................................................. 294

7.1 BALANCE CUT (G68, G69) ....................................................................... 294

III. OPERATION

1 DATA INPUT/OUTPUT ....................................................................... 299

1.1 INPUT/OUTPUT ON EACH SCREEN ....................................................... 299

1.1.1 Inputting and Outputting Y-axis Offset Data ....................................................... 299

1.1.1.1 Inputting Y-axis offset data ............................................................................. 299

1.1.1.2 Outputting Y-axis offset data ........................................................................... 300

c-3

Page 16

TABLE OF CONTENTS B-64694EN-1/01

1.1.2 Inputting and Outputting Tool Offset / 2nd Geometry Data ................................ 301

1.1.2.1 Inputting tool offset / 2nd geometry data ......................................................... 301

1.1.2.2 Outputting tool offset / 2nd geometry data ...................................................... 302

1.1.3 Inputting and Outputting 4th/5th Axis Offset Data .............................................. 303

1.1.3.1 Inputting 4th/5th axis offset data ..................................................................... 303

1.1.3.2 Outputting 4th/5th axis offset data .................................................................. 304

1.2 INPUT/OUTPUT ON THE ALL IO SCREEN .............................................. 307

1.2.1 Inputting and Outputting Y-axis Offset Data ....................................................... 307

1.2.2 Inputting and Outputting Tool Offset / 2nd Geometry Tool Offset ..................... 309

2 SETTING AND DISPLAYING DATA ................................................... 311

2.1 SCREENS DISPLAYED BY FUNCTION KEY

2.1.1 Setting and Displaying the Tool Offset Value ..................................................... 311

2.1.2 Direct Input of Tool Offset Value Measured........................................................ 315

2.1.3 Direct Input of Tool Offset Value Measured B .................................................... 318

2.1.4 Counter Input of Offset value ............................................................................... 320

2.1.5 Setting the Workpiece Coordinate System Shift Value ........................................ 321

2.1.6 Setting Tool Offset/Second Geometry Tool Offset Values .................................. 325

2.1.7 Setting the Y-Axis Offset ..................................................................................... 328

2.1.8 Setting the 4th/5th Axis Offset ............................................................................. 334

2.1.9 Chuck and Tail Stock Barriers ............................................................................. 339

................................... 311

APPENDIX

A LIST OF FUNCTIONS INCLUDE ADDRESS P IN THE PROGRAM

COMMAND .......................................................................................... 351

A.1 LIST OF FUNCTIONS INCLUDE ADDRESS P IN THE ARGUMENT

OF G CODE .............................................................................................. 351

A.2 LIST OF FUNCTIONS INCLUDE ADDRESS P IN THE ARGUMENT

OF M AND S CODE .................................................................................. 354

c-4

Page 17

I. GENERAL

Page 18

Page 19

B-64694EN-1/01 GENERAL 1. GENERAL

NOTE

machine tool builder.

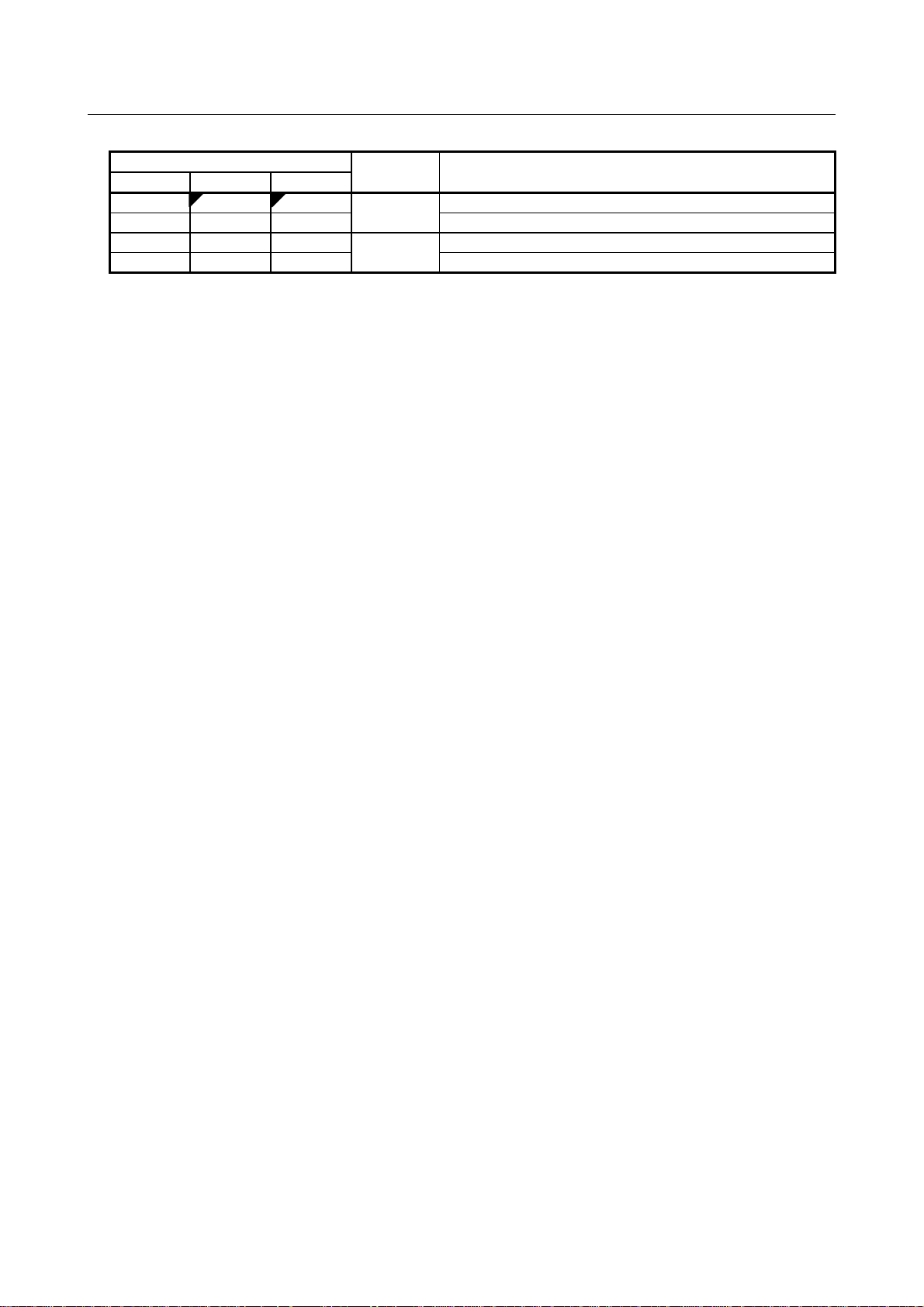

Model name

Abbreviation

NOTE

1 For an explanatory purpose, the following descriptions may be used according to

- 0i-TF Plus : Lathe system (T series)

2 Some functions described in this manual may not be applied to some products.

For details, refer to the DESCRIPTIONS (B-64692EN).

1 GENERAL

This manual consists of the following parts:

About this manual

I. GENERAL

Describes chapter organization, applicable models, related manuals, and notes for reading this

manual.

II. PROGRAMMING

Describes each function: Format used to progr am functions in the NC language, characteristics, and

restrictions.

III. OPERATION

Describes the manual operation and automatic operation of a machine, procedures for inputting and

outputting data, and procedures for editing a program.

APPENDIX

Describes supplementary materials.

1 This manual describes the functions that can operate in the lathe system path

control type. For other functions not specific to the lathe system, r efer to the

OPERATOR'S MANUAL (Common to Lathe System/Machining Center System)

(B-64694EN).

2 Some functions described in this manual may not be applied to some products.

For detail, refer to the DESCRIPTIONS manual (B-64692EN).

3 This manual does not detail the parameters not mentioned in the text. For details

of those parameters, refer to the PARAMETER MANUAL (B-64700EN).

Parameters are used to set functions and operating conditions of a CNC

machine tool, and frequently-used values in advance. Usually, the machine tool

builder factory-sets parameters so that the user can use the machine t ool easily.

4 This manual describes not only basic functions but also optional functions. Look

up the options incorporated into your system in the manual written by the

Applicable models

This manual describes the following models that are 'Nano CNC'.

'Nano CNC system' which realizes high precision machining can be constructed by combining these

models and high speed, high precision servo controls.

In the text, the abbreviations indicated below may be used.

FANUC Series 0i-TF Plus 0i-TF Plus Series 0i-F Plus Series 0i

the CNC model :

- 3 -

Page 20

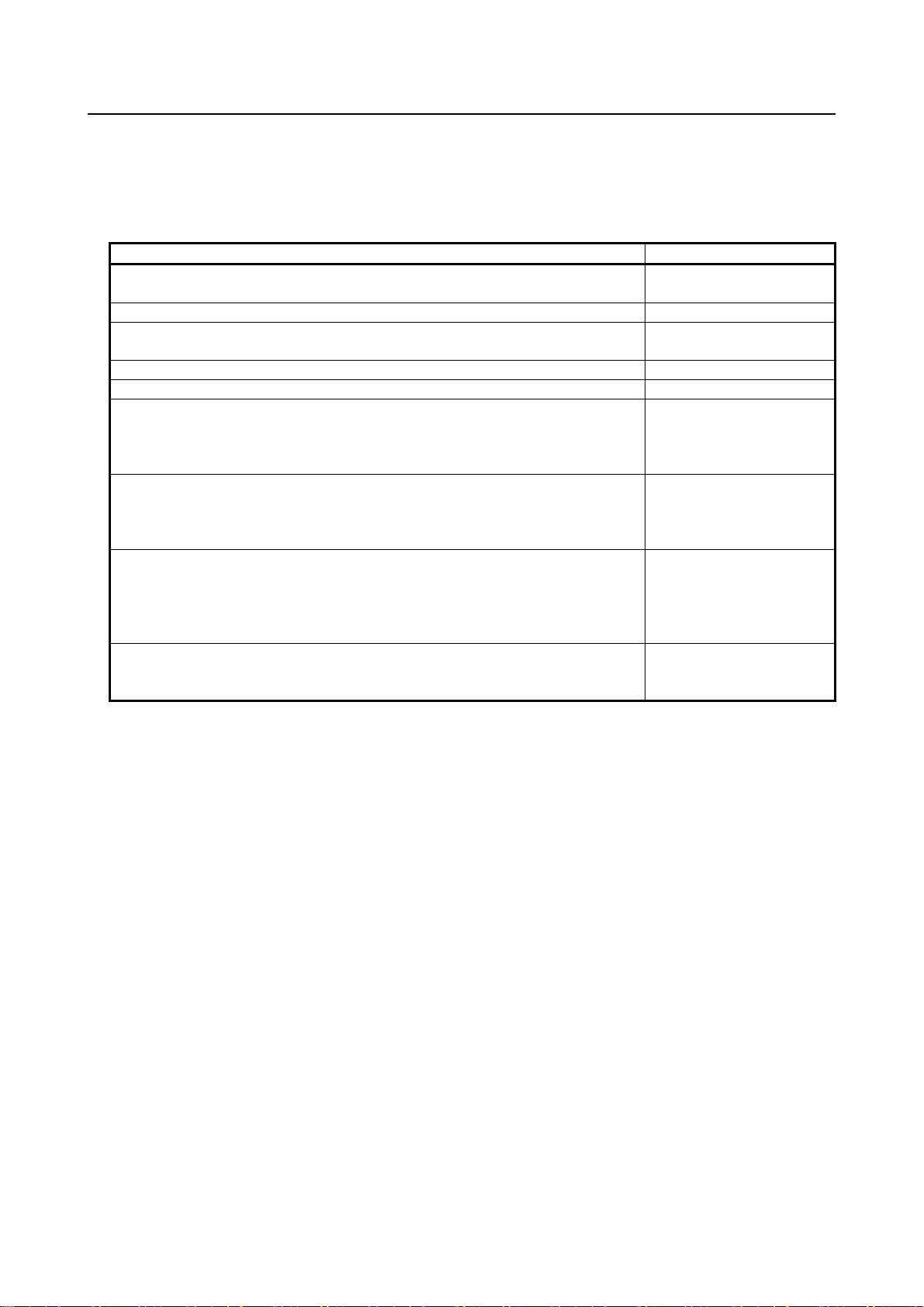

1. GENERAL GENERAL B-64694EN-1/01

Manual name

Specification number

DESCRIPTIONS

B-64692EN

CONNECTION MANUAL (HARDWARE)

B-64693EN

CONNECTION MANUAL (FUNCTION)

B-64693EN-1

OPERATOR’S MANUAL (Common to Lathe System/Machining Center System)

B-64694EN

OPERATOR’S MANUAL (For Lathe System)

B-64694EN-1

*

OPERATOR’S MANUAL (For Machining Center System)

B-64694EN-2

MAINTENANCE MANUAL

B-64695EN

PARAMETER MANUAL

B-64700EN

Programming

Macro Executor PROGRAMMING MANUAL

B-63943EN-2

Macro Compiler PROGRAMMING MANUAL

B-66263EN

C Language Executor PROGRAMMING MANUAL

B-63943EN-3

PMC

PMC PROGRAMMING MANUAL

B-64513EN

Network

PROFIBUS-DP Board CONNECTION MANUAL

B-63993EN

Fast Ethernet / Fast Data Server OPERATOR’S MANUAL

B-64014EN

DeviceNet Board CONNECTION MANUAL

B-64043EN

FL-net Board CONNECTION MANUAL

B-64163EN

CC-Link Board CONNECTION MANUAL

B-64463EN

Operation guidance function

MANUAL GUIDE i (Common to Lathe System/Machining Center System)

OPERATOR’S MANUAL

MANUAL GUIDE i (For Machining Center System) OPERATOR’S MANUAL

B-63874EN-2

MANUAL GUIDE i (Set-up Guidance Functions) OPERATOR’S MANUAL

B-63874EN-1

MANUAL GUIDE 0i OPERATOR’S MANUAL

B-64434EN

Dual Check Safety

Dual Check Safety CONNECTION MANUAL

B-64483EN-2

Special symbols

This manual uses the following symbols:

- IP_

Indicates a combination of axes such as X_ Y_ Z_

In the underlined position following each address, a numeric value such as a coordinate value is placed

(used in PROGRAMMING.).

- ;

Indicates the end of a block. It actually corresponds to the ISO code LF or EIA code CR.

Related manuals of Series 0i-F Plus

The following Table 1(a) lists the manuals related to Series 0i-F Plus. This manual is indicated by an

asterisk(*).

Table 1 (a) Related manuals of Series 0i-F Plus

- 4 -

B-63874EN

Page 21

B-64694EN-1/01 GENERAL 1. GENERAL

Manual name

Specification number

FANUC AC SERVO MOTOR αi series DESCRIPTIONS

FANUC AC SPINDLE MOTOR αi-B / βi-B series DESCRIPTIONS

B-65452EN

FANUC AC SERVO MOTOR βi series DESCRIPTIONS

FANUC SERVO AMPLIFIER αi-B series DESCRIPTIONS

B-65412EN

FANUC SERVO AMPLIFIER βi-B series DESCRIPTIONS

B-65422EN

FANUC AC SERVO MOTOR αi series

MAINTENANCE MANUAL

MAINTENANCE MANUAL

FANUC AC SERVO MOTOR αi series

PARAMETER MANUAL

PARAMETER MANUAL

Related manuals of SERVO MOTOR αi/βi series

The following Table 1(b) lists the manuals related to SERVO MOTOR αi/βi series

Table 1 (b) Related manuals of SERVO MOTOR αi/βi series

FANUC AC SERVO MOTOR αi-B series

FANUC AC SERVO MOTOR βi-B series

FANUC AC SPINDLE MOTOR αi series

FANUC SERVO AMPLIFIER αi series

FANUC AC SERVO MOTOR βi series

FANUC AC SPINDLE MOTOR βi series

FANUC SERVO AMPLIFIER βi series

FANUC AC SERVO MOTOR βi series

FANUC LINEAR MOTOR LiS series

FANUC SYNCHRONOUS BUILT-IN SERVO MOTOR DiS series

FANUC AC SPINDLE MOTOR αi/βi series,

BUILT-IN SPINDLE MOTOR Bi series

B-65262EN

B-65302EN

B-65285EN

B-65325EN

B-65270EN

B-65280EN

The above servo motors and the corresponding spindles can be connected to the CNC covered in this

manual.

This manual mainly assumes that the FANUC SERVO MOTOR αi series of servo motor is used. For

servo motor and spindle information, refer to the manuals for the servo motor and spindle that are actually

connected.

- 5 -

Page 22

1. GENERAL GENERAL B-64694EN-1/01

CAUTION

attempted.

CAUTION

non-volatile memory at registration, modification, or deletion of program s.

1.1 NOTES ON READING THIS MANUAL

1 The function of an CNC machine tool system depends not only on the CNC, but on

the combination of the machine tool, its magnetic cabinet, the servo system, the

CNC, the operator's panels, etc. It is too difficult to describe the function,

programming, and operation relating to all combinations. This manual generally

describes these from the stand-point of the CNC. So, for details on a particular

CNC machine tool, refer to the manual issued by the machine tool builder, which

should take precedence over this manual.

2 In the header field of each page of this manual, a chapter title is indicated so that

the reader can reference necessary information easily.

By finding a desired title first, the reader can reference necessary parts only.

3 This manual describes as many reasonable variations in equipment usage as

possible. It cannot address every combination of features, options and commands

that should not be attempted.

If a particular combination of operations is not described, it should not be

1.2 NOTES ON VARIOUS KINDS OF DATA

Machining programs, parameters, offset data, etc. ar e s t ored in the CNC unit

internal non-volatile memory. In general, these contents are not lost by the

switching ON/OFF of the power. However, it is possible that a state can occur

where precious data stored in the non-volatile memory has to be deleted,

because of deletions from a maloperation, or by a failure restoration. In order to

restore rapidly when this kind of mishap occurs, it is recommended that you

create a copy of the various kinds of data beforehand.

The number of times to write machining programs to the non-volatile memory is

limited.

You must use "High-speed program management" when registration and the

deletion of the machining programs are frequently repeated in such case that the

machining programs are automatically downloaded from a personal computer at

each machining.

In "High-speed program management", the program is not saved to t he

- 6 -

Page 23

II. PROGRAMMING

Page 24

Page 25

B-64694EN-1/01 PROGRAMMING 1. GENERAL

Workpiece

Standard

tool

Rough

cutting

tool

Finishing

tool

Grooving

tool

Threading

tool

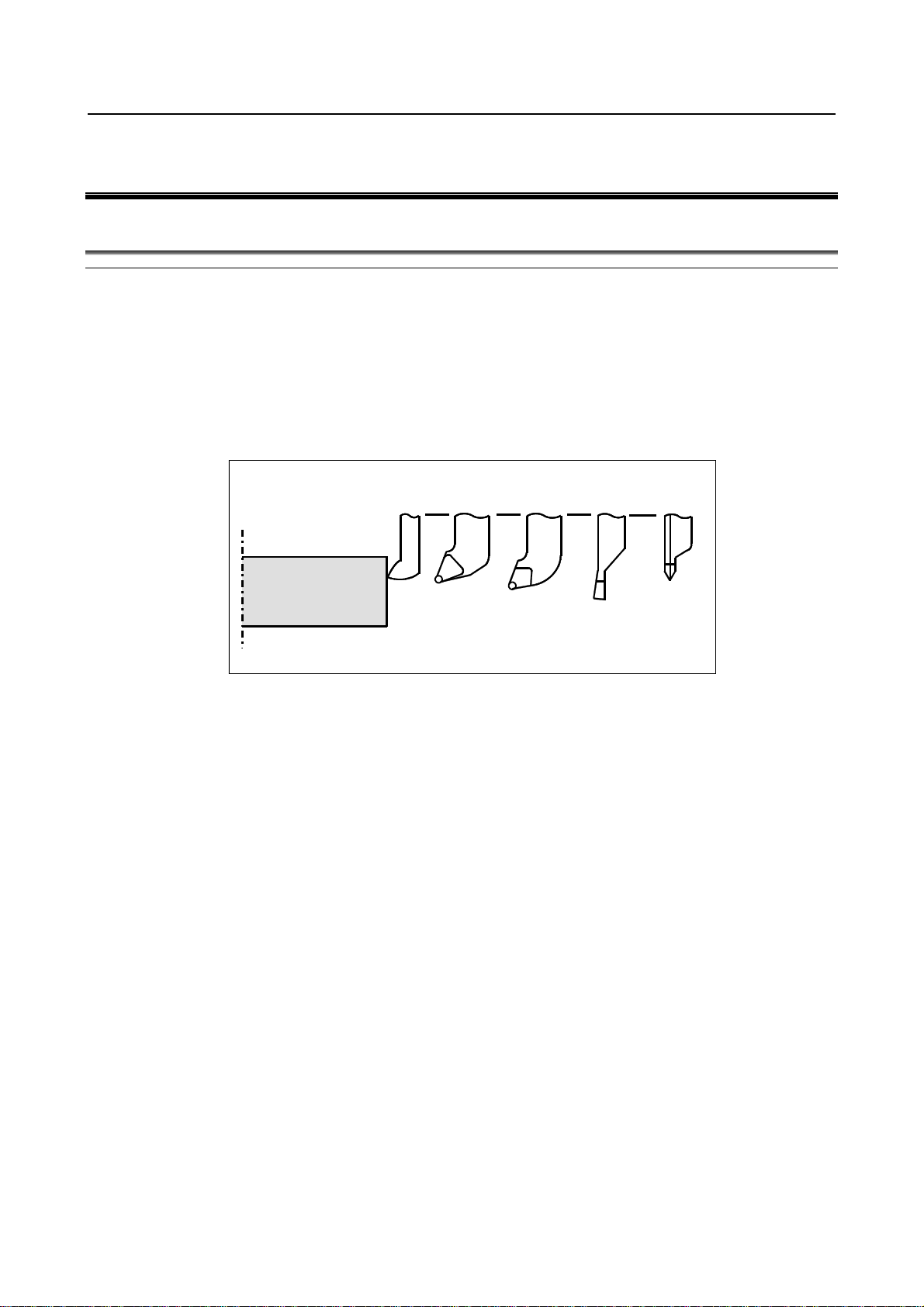

1 GENERAL

1.1 OFFSET

Explanation

- Tool offset

Usually, several tools are used for machining one workpiece. The tools have different tool length. It is

very troublesome to change the program in accordance with the tools.

Therefore, the length of each tool used should be measured in advance. By setting the differ ence between

the length of the standard tool and the length of each tool in the CNC (see Chapter, “Setting and

Displaying Data” in the OPERATOR’S MANUAL (Common to Lathe System/Machining Center

System)), machining can be performed without altering the program even when the tool is changed. This

function is called tool offset. (Refer to the section of Section 5.1 “TOOL OFFSET”.)

Fig. 1.1 Tool offset

- 9 -

Page 26

PROGRAMMING B-64694EN-1/01

2. PREPARATORY FUNCTION

(G FUNCTION)

Type

Meaning

One-shot G code

The G code is effective only in the block in which it is specified.

Modal G code

The G code is effective until another G code of the same group is specified.

(Example)

G01 and G00 are modal G codes in group 01.

G01 X_ ;

Z_ ; G01 is effective in this range.

X_ ;

G00 Z_ ; G00 is effective in this range.

X_ ;

G01 X_ ;

:

2 PREPARATORY FUNCTION (G FUNCTION)

A number following address G determines the meaning of the command for the concerned block.

G codes are divided into the following two types.

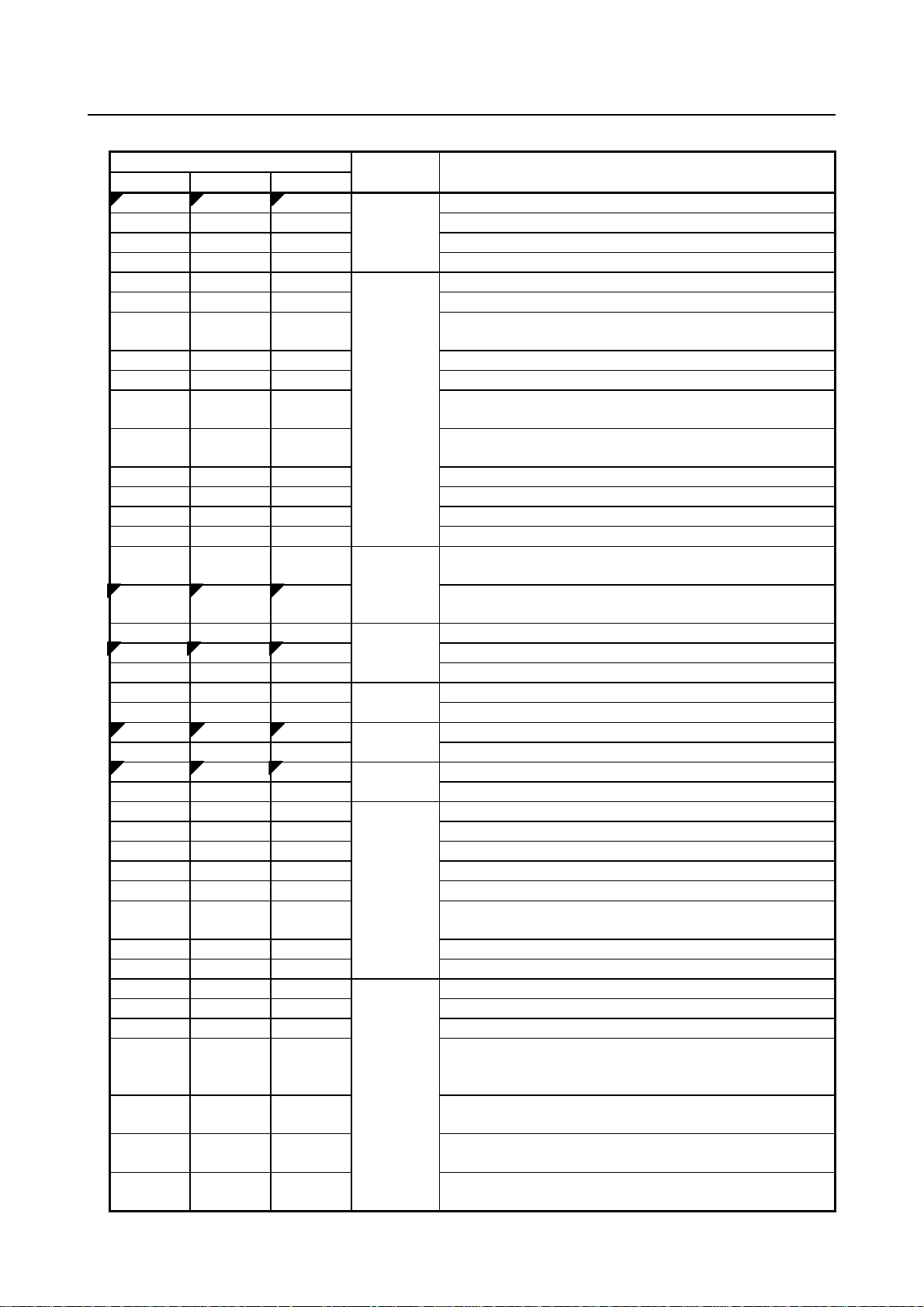

There are three G code systems in the lathe system : A,B, and C (Table 2 (a) ). Select a G code system

using bits 6 (GSB) and 7 (GSC) parameter No. 3401.

Generally, OPERATOR’S MANUAL describes the u se of G code system A, except when the described

item can use only G code system B or C. In such cases, the use of G code system B or C is described.

Explanation

1. When the clear state (bit 6 (CLR) of parameter No. 340 2) is set at power-up or reset, the modal G

codes are placed in the states described below.

(1) The modal G codes are placed in the states marked wit h

(2) G20 and G21 remain unchanged when the clear state is set at power-up or reset.

(3) Which status G22 or G23 at power on is set by bit 7 (G23) of parameter No. 3402. However,

G22 and G23 remain unchanged when the clear state is set at reset.

(4) The user can select G00 or G01 by setting bit 0 (G01) of parameter No. 3402.

(5) When G code system B or C is used, setting bit 3 (G91) of parameter No. 3402 determines

which code, either G90 or G91, is effectiv e.

2. G codes other than G10 and G11 are one-shot G codes.

3. When a G code not listed in the G code list is specified, or a G code that has no corresponding

option is specified, alarm PS0010, “IMPROPER G-CODE” occurs.

4. Multiple G codes can be specified in the same block if each G code belongs to a different group. If

multiple G codes that belong to the same group ar e specified in th e same block, only the last G cod e

specified is valid.

5. If a G code belonging to group 01 is specified in a for drilling, the canned cycle for drilling is

cancelled. This means that the same state set by specifying G80 is set. Note that the G codes in

group 01 are not affected by a G code specifying a canned cycle.

6. When G code system A is used, absolute or incr emental programming is specified not by a G code

(G90/G91) but by an address word (X/U, Z/W, C/H, Y/V). Only the initial level is provided at the

return point of the canned cycle for drilling..

7. G codes are indicated by group.

as indicated in Table 2(a).

- 10 -

Page 27

B-64694EN-1/01 PROGRAMMING

2. PREPARATORY FUNCTION

Table 2(a) G code list

G code system

A B C

G00

G00

G00

Positioning (Rapid traverse)

G01

G01

G01

Linear interpolation (Cutting feed)

G02

G02

G02

Circular interpolation CW or helical interpolation CW

G03

G03

G03

Circular interpolation CCW or helical interpolation CCW

G04

G04

G04

Dwell

G04.1

G04.1

G04.1

G code preventing buffering

contour control)

G05.1

G05.1

G05.1

AI contour control

G05.4

G05.4

G05.4

HRV3 on/off

(G107)

(G107)

(G107)

command)

G09

G09

G09

Exact stop

G10

G10

G10

Programmable data input

G10.6

G10.6

G10.6

Tool retract and recover

G11

G11

G11

Programmable data input mode cancel

(G112)

(G112)

(G112)

(G113)

(G113)

(G113)

G17

G17

G17

XpYp plane selection

G18

G18

G18

ZpXp plane selection

G19

G19

G19

YpZp plane selection

G20

G20

G70

Input in inch

G21

G21

G71

Input in mm

G22

G22

G22

Stored stroke check function on

G23

G23

G23

Stored stroke check function off

G25

G25

G25

Spindle speed fluctuation detection off

G26

G26

G26

Spindle speed fluctuation detection on

G27

G27

G27

Reference position return check

G28

G28

G28

Return to reference position

G28.2

G28.2

G28.2

In-position check disable reference position return

G29

G29

G29

Movement from reference position

G30

G30

G30

2nd, 3rd and 4th reference position return

return

G31

G31

G31

Skip function

G31.8

G31.8

G31.8

EGB-axis skip

G32

G33

G33

Threading

G34

G34

G34

Variable lead threading

G35

G35

G35

Circular threading CW

(G36) of parameter No. 3405 is set to 0)

No. 3405 is set to 0)

No. 3405 is set to 1)

No. 3405 is set to 1)

Group Function

01

(G FUNCTION)

G05 G05 G05

G07.1

G08 G08 G08

G12.1

G13.1

G07.1

G12.1

G13.1

G07.1

G12.1

G13.1

00

21

16

06

09

AI contour control (command compatible with high precision

Cylindrical interpolation

AI contour control (advanced preview control compatible

Polar coordinate interpolation mode

Polar coordinate interpolation cancel mode

G30.2 G30.2 G30.2

G36 G36 G36

G37 G37 G37

G37.1 G37.1 G37.1

G37.2 G37.2 G37.2

08

00

01

In-position check disable 2nd, 3rd, or 4th reference position

Circular threading CCW (When bit 3 (G36) of param eter No.

3405 is set to 1) or Automatic tool offset (X axis) (When bit 3

Automatic tool offset (Z axis) (When bit 3 (G36) of parameter

Automatic tool offset (X axis) (When bit 3 (G36) of parameter

Automatic tool offset (Z axis) (When bit 3 (G36) of parameter

- 11 -

Page 28

PROGRAMMING B-64694EN-1/01

2. PREPARATORY FUNCTION

(G FUNCTION)

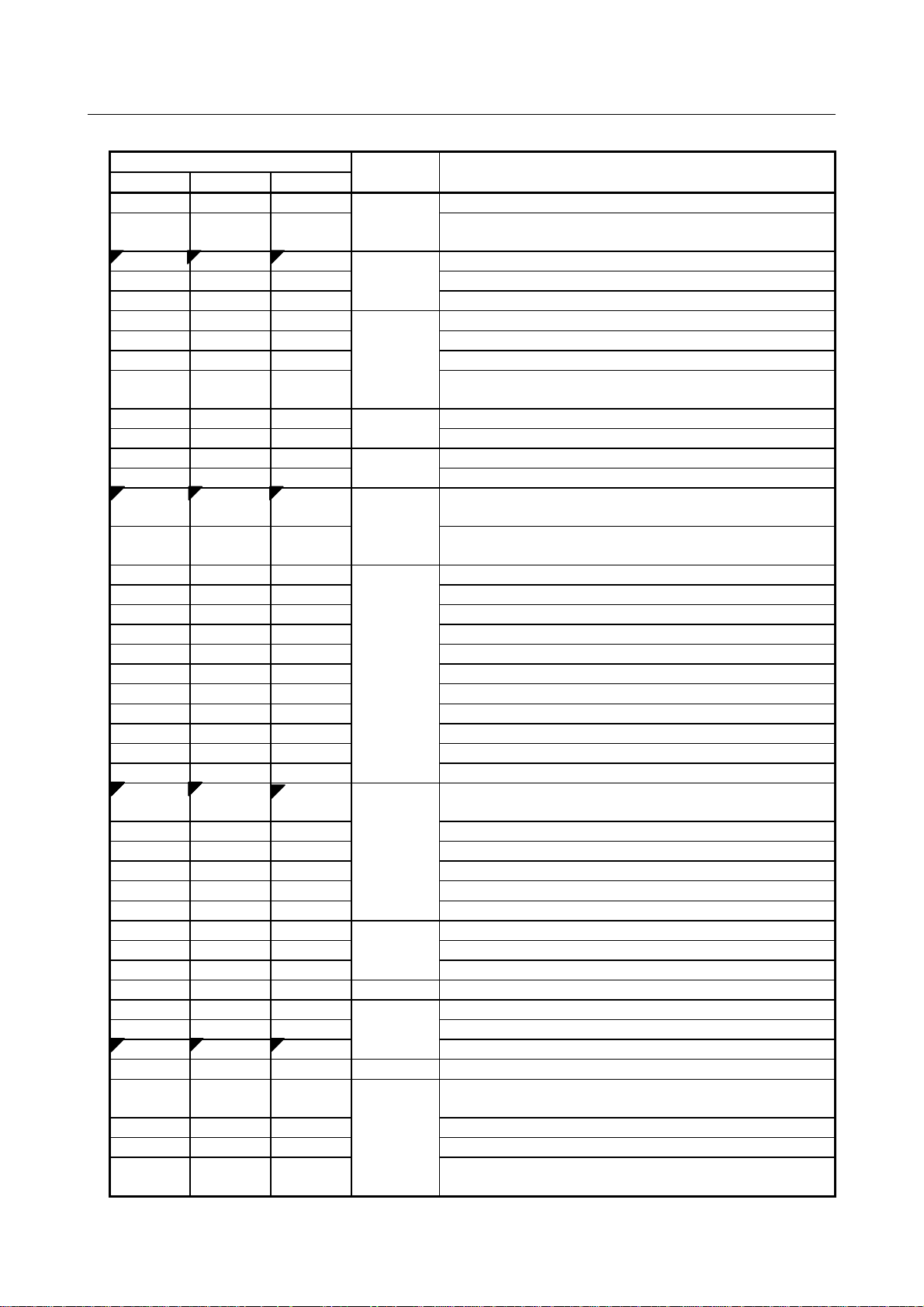

Table 2(a) G code list

G code system

A B C

G38

G38

G38

Tool radius/tool nose radius compensation: with vector held

interpolation

G40

G40

G40

Tool radius/tool nose radius compensation : cancel

G41

G41

G41

Tool radius/tool nose radius compensation : left

G42

G42

G42

Tool radius/tool nose radius compensation : right

G40.1

G40.1

G40.1

Normal direction control cancel mode

G41.1

G41.1

G41.1

Normal direction control left on

G42 .1

G42 .1

G42 .1

Normal direction control right on

(G44.7)

(G44.7)

(G44.7)

(Bit 3 (TCT) of parameter No. 5040 mus t be "1".)

G50

G92

G92

Coordinate system setting or max spindle speed clamp

G50.3

G92.1

G92.1

Workpiece coordinate system preset

G50.1

G50.1

G50.1

Programmable mirror image cancel

G51.1

G51.1

G51.1

Programmable mirror image

G50.2

(G250)

G50.2

(G250)

G50.2

(G250)

(G251)

(G251)

(G251)

G50.4

G50.4

G50.4

Cancel synchronous control

G50.5

G50.5

G50.5

Cancel composite control

G50.6

G50.6

G50.6

Cancel superimposed control

G51.4

G51.4

G51.4

Start synchronous control

G51.5

G51.5

G51.5

Start composite control

G51.6

G51.6

G51.6

Start superimposed control

G52

G52

G52

Local coordinate system setting

G53

G53

G53

Machine coordinate system setting

G53.1

G53.1

G53.1

Tool axis direction control

G53.2

G53.2

G53.2

Selecting a machine coordinate system with feedrate

G53.6

G53.6

G53.6

Tool center point retention type tool axis direction contr ol

(G54.1)

(G54.1)

(G54.1)

G55

G55

G55

Workpiece coordinate system 2 selection

G56

G56

G56

Workpiece coordinate system 3 selection

G57

G57

G57

Workpiece coordinate system 4 selection

G58

G58

G58

Workpiece coordinate system 5 selection

G59

G59

G59

Workpiece coordinate system 6 selection

G61

G61

G61

Exact stop mode

G63

G63

G63

Tapping mode

G64

G64

G64

Cutting mode

G65

G65

G65

00

Macro call

G66

G66

G66

Macro modal call A

G66.1

G66.1

G66.1

Macro modal call B

G67

G67

G67

Macro modal call A/B cancel

G68

G68

G68

04

Mirror image on for double turret or balance cutting mode

system conversion mode on

G68.2

G68.2

G68.2

Tilted working plane indexing command

G68.3

G68.3

G68.3

Tilted working plane indexing command by tool axis direction

multi-command)

Group Function

G39 G39 G39

G43.7

G51.2

G43.7

G51.2

G43.7

G51.2

01

07

19

00

22

20

Tool radius/tool nose radius compensation: corner roundi ng

Tool offset

Polygon turning cancel

Polygon turning

G54

G68.1 G68.1 G68.1

G54

G54

00

Workpiece coordinate system 1 selection

14

15

12

Coordinate system rotation start or 3-dimensional coordinate

G68.4 G68.4 G68.4

17

Tilted working plane indexing command (incremental

- 12 -

Page 29

B-64694EN-1/01 PROGRAMMING

2. PREPARATORY FUNCTION

Table 2(a) G code list

G code system

A B C

coordinate system conversion mode off

G70

G70

G72

Finishing cycle

G71

G71

G73

Stock removal in turning

G72

G72

G74

Stock removal in facing

G73

G73

G75

Pattern repeating cycle

G74

G74

G76

End face peck drilling cycle

G75

G75

G77

Outer diameter/internal diameter drilling cycle

G76

G76

G78

Multiple-thread cutting cycle

G71

G71

G72

Traverse grinding cycle

G72

G72

G73

Traverse direct sizing/grinding cycle

G73

G73

G74

Oscillation grinding cycle

G74

G74

G75

Oscillation direct sizing/grinding cycle

Electronic gear box : synchronization cancellation

G81.1

G81.1

G81.1

00

High precision oscillation function

G80.4

G80.4

G80.4

Electronic gear box: synchronization cancellation

G81.4

G81.4

G81.4

Electronic gear box: synchronization start

G80.5

G80.5

G80.5

Electronic gear box 2 pair: synchronization cancellation

G81.5

G81.5

G81.5

Electronic gear box 2 pair: synchronization start

Electronic gear box : synchronization start

G82

G82

G82

Counter boring (FS15-T format)

G83

G83

G83

Cycle for face drilling

G83.1

G83.1

G83.1

High-speed peck drilling cycle (FS15-T format)

G83.5

G83.5

G83.5

High-speed peck drilling cycle

G83.6

G83.6

G83.6

Peck drilling cycle

G84

G84

G84

Cycle for face tapping

G84.2

G84.2

G84.2

Rigid tapping cycle (FS15-T format)

G85

G85

G85

Cycle for face boring

G87

G87

G87

Cycle for side drilling

G87.5

G87.5

G87.5

High-speed peck drilling cycle

G87.6

G87.6

G87.6

Peck drilling cycle

G88

G88

G88

Cycle for side tapping

G89

G89

G89

Cycle for side boring

G90

G77

G20

Outer diameter/internal diameter cutting cycle

G92

G78

G21

Threading cycle

G94

G79

G24

End face turning cycle

G91.1

G91.1

G91.1

00

Maximum specified incremental amount check

G96

G96

G96

Constant surface speed control

G97

G97

G97

Constant surface speed control cancel

G96.1

G96.1

G96.1

Spindle indexing execution (waiting for completion)

G96.2

G96.2

G96.2

Spindle indexing execution (not waiting for completion)

G96.3

G96.3

G96.3

Spindle indexing completion check

G96.4

G96.4

G96.4

SV speed control mode ON

G98

G94

G94

Feed per minute

G99

G95

G95

Feed per revolution

Group Function

G69 G69 G69

04

Mirror image off for double turret or balance cutt ing mode

cancel

(G FUNCTION)

G69.1 G69.1 G69.1 17

00

01

G80 G80

G81 G81 G81

G80

10

28

27

Coordinate system rotation cancel or 3-dimensional

Canned cycle cancel for drilling

Spot drilling (FS15-T format)

10

01

02

00

- 13 -

Page 30

PROGRAMMING B-64694EN-1/01

2. PREPARATORY FUNCTION

(G FUNCTION)

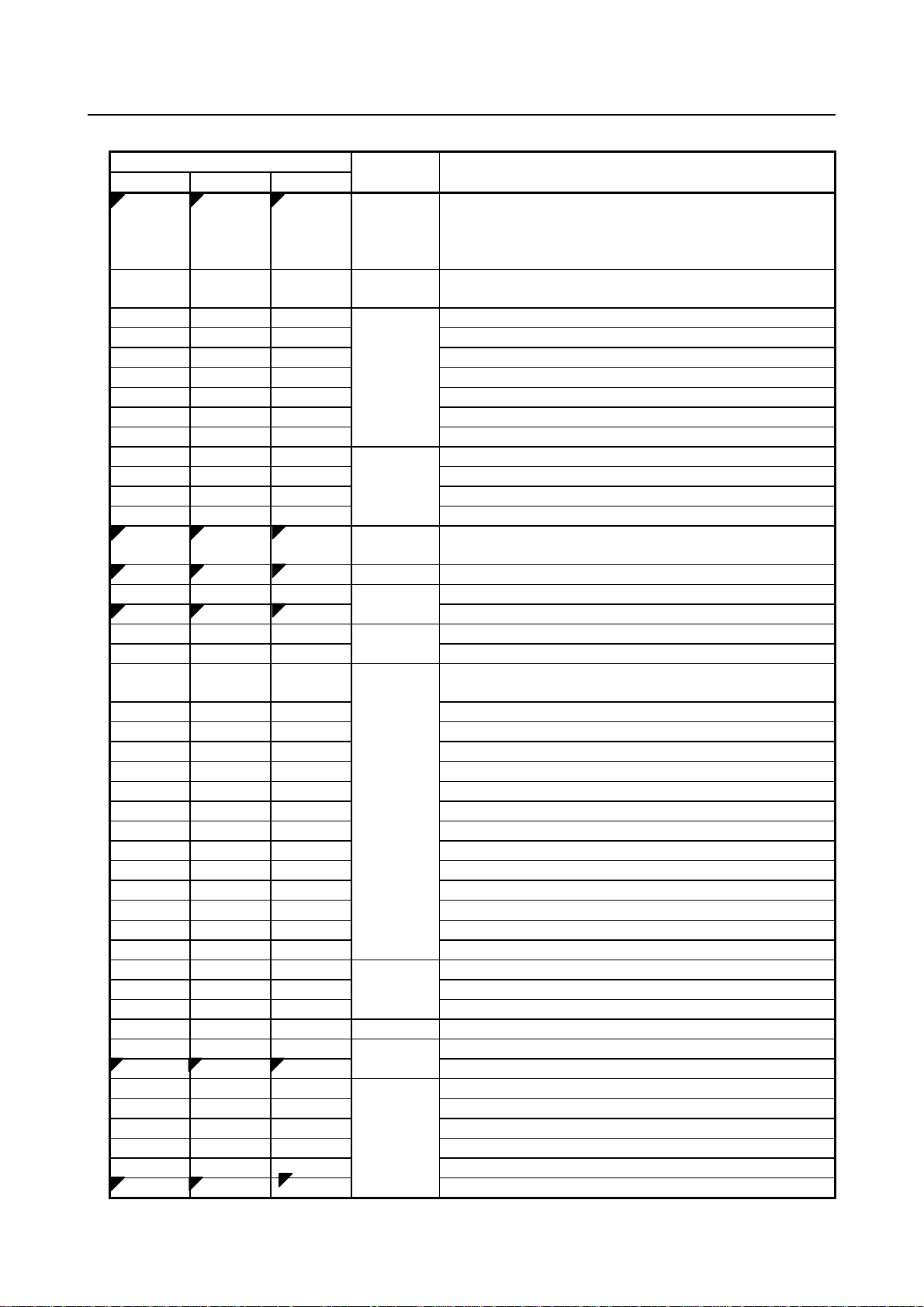

Table 2(a) G code list

G code system

A B C

-

G90

G90

Absolute programming

-

G91

G91

Incremental programming

-

G98

G98

Canned cycle : return to initial level

-

G99

G99

Canned cycle : return to R point level

Group Function

03

11

- 14 -

Page 31

B-64694EN-1/01 PROGRAMMING 3. INTERPOLATION FUNCTION

L

Straight thread

L

L

Tapered

screw

Scroll thread

X

X axis

Z

δ

2

a

Start point

L

δ

1

End point_

0

Z axis

G32IP_F_;

IP_: End point

F _: Lead of the long axis

(always radius programming)

3 INTERPOLATION FUNCTION

3.1 THREADING (G32)

Tapered screws and scroll threads in addition to equal lead straight th reads can be cut by using a G32

command.

The spindle speed is read from the position coder on the spindle in real time and converted to a cutting

feedrate for feed-per minute mode, which is used to move the tool.

Format

Fig. 3.1 (a) Thread types

Fig. 3.1 (b) Example of threading

- 15 -

Page 32

3. INTERPOLATION FUNCTION PROGRAMMING B-64694EN-1/01

X

Tapered thread

LX

a

LZ

Z

a≤45° lead is LZ

a≥45° lead is LX

Least command increment

Metric input

0.0001 to 500.0000 mm

Inch input

0.000001 to 9.999999 inch

Explanation

In general, threading is repeated along the same tool path in rough cutting through finish cutting for a

screw. Since threading starts when the position coder mounted on the spindle outputs a

one-spindle-rotation signal, threading is started at a fixed point and the tool path on the workpiece is

unchanged for repeated threading. Note that the spindle speed must remain constant from rough cutting

through finish cutting. If not, incorrect thread lead will occur.

Fig. 3.1 (c) LZ and LX of a tapered thread

In general, the lag of the servo system, etc. will produce somewhat incorrect leads at the starting and

ending points of a thread cut. To compensate for this, a threading length somewhat longer than required

should be specified.

Table 3.1 (a) lists the ranges for specifyin g the thread lead.

Table 3.1 (a) Ranges of lead sizes th at can be specified

- Continuous threading

The "continuous threading" is effective for G32.

Limitation

- Tool Retract and Recover

When the major axis for threading is specified as th e retraction axis, retraction is not performed. In this

case, after a block that does not specify threading is executed, an alarm PS0429, “ILLEGAL

COMMAND IN G10.6” is issued and the tool sto ps.

- Chamfering and Corner R

Chamfering or corner R cannot be specified in a block in which thread cutting is specified. If tool offset is

specified, alarm PS0050, “CHF/CNR NOT ALLOWED IN THRD BLK”, is issued.

- Tool offset

Tool offset cannot be specified in a block in which thread cutting is specified. If tool offset is specified,

alarm PS0509, “TOOL OFFSET COMMAND IS NOT AVAILABLE”, i s issued.

- 16 -

Page 33

B-64694EN-1/01 PROGRAMMING 3. INTERPOLATION FUNCTION

Z axis

X axis

δ

2

δ

1

30

70

The following values are used in programming :

Thread lead :4mm

δ1=3mm

δ2=1.5mm

Depth of cut :1mm (cut twice)

(Metric input, diameter programming)

G00 U-62.0 ;

G32 W-74.5 F4.0 ;

G00 U62.0 ;

W74.5 ;

U-64.0 ;

(For the second cut, cut 1mm more)

G32 W-74.5 ;

G00 U64.0 ;

W74.5 ;

1. Straight threading

Z axis

X axis

δ

2

δ

1

The following values are used in programming :

Thread lead : 3.5mm in the direction of the Z axis

δ

1

=2mm

δ2=1mm

Cutting depth in the X axis direction is 1mm (cut twice)

(Metric input, diameter programming)

G00 X 12.0 Z72.0 ;

G32 X 41.0 Z29.0 F3.5 ;

G00 X 50.0 ;

Z 72.0 ;

X 10.0 ;

(Cut 1mm more for the second cut)

G32 X 39.0 Z29.0 ;

G00 X 50.0 ;

Z 72.0 ;

f50

f43

f14

2.Tapered threading

40

30

0

CAUTION

1 Feedrate override is effective (fixed at 100%) during threading.

execution of the first block not specifying threading.

Example

2 It is very dangerous to stop feeding the thread cutter without stopping the

spindle. This will suddenly increase the cutting depth. Thus, the feed hold

function is ineffective while threading. If the feed hold button is pressed during

threading, the tool will stop after a block not specifying threading is executed as

if the SINGLE BLOCK button were pushed. However, Feed hold lamp signal

SPL turns to “1” immediately after feed hold signal *SP is set to “1”. Then, when

the tool stops, the signal SPL turns to “0” (Single Block stop status).

3 When the FEED HOLD button is pressed again in the first block after threading

mode that does not specify threading (or the button has been held down), the

tool stops immediately at the block that does not specify threading.

4 When threading is executed in the single block status, the tool stops after

- 17 -

Page 34

3. INTERPOLATION FUNCTION PROGRAMMING B-64694EN-1/01

CAUTION

5 When the mode was changed from automatic operation to manual operation

MANUAL (Common to Lathe System/Machining Center System) (B-64694EN).

G32

G32

G32

during threading, the tool stops at the first block not specifying threading as

when the feed hold button is pushed as mentioned in Warning 3.

However, when the mode is changed from one automatic operation mode to

another, the tool stops after execution of the block not specifying threading as for

the single block mode in Note 4.

6 When the previous block was a threading block, cutting will start immediately

without waiting for detection of the one-spindle-rotation signal even if the present

block is a threading block.

(Example)

G00 Z0.0 X50.0 ; One-rotation signal is

G32 Z10.0 F_ ; : Detected

Z20.0 ; : Not detected

G32 Z30.0 ; : Not detected

7 Because the constant surface speed control is effective during scroll thread or

tapered screw cutting and the spindle speed changes, the correct thread lead

may not be cut. Therefore, do not use the constant surface speed contr ol dur ing

threading. Instead, use G97.

8 A movement block preceding the threading block must not specify chamfering or

corner R.

9 A threading block must not specifying chamfering or corner R.

10 The spindle speed override function is disabled during threading. The spindle

speed is fixed at 100%.

11 Thread cycle retract funct ion is inef f ec t ive to G32.

12 If tool offset (with t he T c ode or G43.7) is specified in during of the threading

mode, or in a block for threading, alarm PS0509, “TOOL OFFSET COM MAND

IS NOT AVAILABLE”, is issued.

13 The leads of a thread are generally incorrect , due to automatic acceleration and

deceleration. Thus distance allowances must be made to the extent in the

program. Refer “INCORRECT THREADED LENGTH” in the OPERATOR’S

3.2 CONTINUOUS THREADING

Threading blocks can be programmed successively to eliminate a discontinuity due to a discontinuous

movement in machining by adjacent blocks.

Explanation

Since the system is controlled in such a manner th at the synchro nism with the spindle does not deviate in

the joint between blocks wherever possible, it is possible to performed special threading operation in

which the lead and shape change midway.

Fig. 3.2 (a) Continuous threading (Example of G32 in G code system A)

Even when the same section is repeated for threadin g while changing the depth of cu t, this sy stem allows

a correct machining without impairing the threads.

- 18 -

Page 35

B-64694EN-1/01 PROGRAMMING 3. INTERPOLATION FUNCTION

L

L : Lead

(Threading)

(Increment: 0.001 degrees, Valid setting range: 0 to 360 degrees)

- Available threading commands

G32: Threading (G code system A)

G33: Threading (G code system B/C)

G34: Variable lead threading

G35, G36: Circular threading

- Start angle

The address Q (Angle for shifting the threading start angle) is only effective the first threading command

block of continuous threading.

In the continuous threading, the addresses Q of the threading in the blocks after the first are ignored.

3.3 MULTIPLE THREADING

Using the Q address to specify an angle b etween the one-spindle-rotation signal and the start of threading

shifts the threading start angle, making it possible to produce multiple-thread screws with ease.

Format

Explanation

- Available threading commands

Limitation

- Threading start angle

Fig. 3.3 (a) Multiple thread screws.

G32 IP _ F_ Q_ ;

IP : End point

F_ : Lead in longitudinal direction

G32 IP _ Q_ ;

Q_ : Angle for shifting the threading start angle

G32: Threading

G34: Variable lead threading

G35, G36: Circular threading

G76/G78: Multiple threading cycle (Only when the FS15 tape format is used.)

G92: Threading cycle

The threading start angle is not a continuous state (modal) value. It must be specified each time it is used.

If a value is not specified, 0 is assumed.

- 19 -

Page 36

3. INTERPOLATION FUNCTION PROGRAMMING B-64694EN-1/01

Program for producing double-threaded screws (w i th threading start angles of 0

Cutting start point of 2nd

Cutting start point of 1st

180°

Z axis

δ

δ

1

15

30

Thread lead :4mm

Threading start angle of 2nd :180 degree

- Threading start angle increment

The threading start angle (Q) increment is 0.001 degrees. Note that no decimal point can be specified.

Example:

For a shift angle of 180 degrees, specify Q180000.

Q180.000 cannot be specified, because it contains a decimal point.

Note: Q1 is the command of 0.001 degree for the angle for shifting the threading start angle, regardless of

the setting of the followings.

- Increment system IS-A/B/C(Parameter No.1013#1-#0)

- Pocket calculator type decimal point programming (Bit 0(DPI) of parameter No.3401)

- The least input increment is 10 times greater than the least command increment (Bit 7(IPR) of

parameter No.1004)

- Specifiable threading start angle range

The threading start angle (Q) of between 0 and 360000 (in 0.001-degree units) can be specified. If a value

greater than 360000 (360 degrees) is specified, it is rounded down to 360000 (360 degrees).

If a minus value is specified, it works as a plus value.

Example:

If Q-90000 (-90 degrees) is specified, it works as Q9000 0 (90 degrees).

- Direction of start angle

The direction of start angle is changed by the direction of spindle rotation because it is delayed from

one-spindle- rotation signal.

- Multiple threading cycle (G76 (G code system A/B)) (G78 (G code system C))

The address Q of the G76/G78 multiple threading cycle command is used for the minimum cutting depth

or the depth of cut in 1st cut. For this reason, the angle for shifting the threading start angle can not be

commanded.

However, if the FS15 tape format is used, in G76 /G78 multiple thread ing cycle, th e address Q is possi ble

to specify the angle for shifting the threading start angle.

Example

and 180 degrees)

G00 X40.0 ;

G32 W-38.0 F4.0 Q0 ;

G00 X72.0 ;

W38.0 ;

X40.0 ;

G32 W-38.0 F4.0 Q180000 ;

G00 X72.0 ;

W38.0 ;

2

δ1=5mm

δ2=3mm

Depth of cut :1mm

(Metric input, diameter programming)

Threading start angle of 1st :0 degree

- 20 -

Page 37

B-64694EN-1/01 PROGRAMMING

4. FUNCTIONS TO SIMPLIFY

PROGRAMMING

NOTE

XY plane: Y-axis direction

4 FUNCTIONS TO SIMPLIFY PROGRAMMING

4.1 CANNED CYCLE (G90, G92, G94)

There are three canned cycles: the outer diameter/internal diameter cutting canned cycle (G90), the

threading canned cycle (G92), and the end face turning canned cycle (G94).

1 Explanatory figures in this section use the ZX plane as the selected plane,

diameter programming for the X-axis, and radius programming for the Z-axis.

When radius programming is used for the X-axis, change U/2 to U and X/2 to X.

2 A canned cycle can be performed on any plane (including parallel axes for plane

definition). When G-code system A is used, however, U, V, and W cannot be set

as a parallel axis.

3 The direction of the length means the direction of the first axis on the plane as

follows:

ZX plane: Z-axis direction

YZ plane: Y-axis direction

XY plane: X-axis direction

4 The direction of the end face means the direction of the second axis on the

plane as follows:

ZX plane: X-axis direction

YZ plane: Z-axis direction

- 21 -

Page 38

PROGRAMMING B-64694EN-1/01

4. FUNCTIONS TO SIMPLIFY

PROGRAMMING

G90X(U)_Z(W)_F_;

F_ : Cutting feedrate

X/2

X axis

Z axis

2(F)

3(F)

1(R)

4(R)

Z

W

U/2

A’

A

(R)....Rapid traverse

(F)....

Cutting feed

NOTE

cycle start button once.

4.1.1 Outer Diameter/Internal Diameter Cutting Cycle (G90)

This cycle performs straight or taper cutting in the direction of the length.

4.1.1.1 Straight cutting cycle

Format

X_,Z_ : Coordinates of the cutting end point (point A' in the Fig. 4.1.1.1 (a)) in the direction

of the length

U_,W_ : Travel distance to the cutting end point (point A' in the Fig. 4.1.1.1 (a)) in the

direction of the length

Explanation

- Operations

A straight cutting cycle performs four operations: