Page 1

-

M

-

M

*

*

FANUC Series 0

FANUC Series 0 Mate

ODEL C

START-UP MANUAL

ODEL C

B-64114EN-1/01

Page 2

• No part of this manual may be reproduced in any form.

• All specifications and designs are subject to change without notice.

In this manual we have tried as much as possible to describe all the various matters.

However, we cannot describe all the matters which must not be done, or which cannot be

done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be

regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of

which are registered trademarks of respective owners. However, these names are not

followed by or in the main body.

Page 3

B-64114EN-1/01 PREFACE

PREFACE

This manual describes parameter settings required to start up the

FANUC Series 0i-MODEL C / 0i Mate-MODEL C.

The manual is organized into the following chapters.

Chapter 1 Initialization of the NC parameters related to axis settings

Describes how to make the minimum initialization required

to start up NC axes.

Chapter 2 Initialization of servo parameters

Describes how to make the minimum initialization required

to drive the servo motor.

Chapter 3 Initialization of the other NC parameters

Describes how to make initialization required to start up

the other NCs such as those related to DI/DO.

Chapter 4 Parameters recommended to be set

Describes how to set the parameters required for

high-speed and high-precision machining and the servo

parameters required to be adjusted.

Since "Example of setting" in the following descriptions indicates

reference values for initialization, determine the best setting based on

the characteristics and usage of the machine.

Related manuals

Document name

FANUC Series 0i-MODEL C/0i Mate-MODEL C

START-UP MANUAL

FANUC Series 0i-MODEL C/0i Mate-MODEL C

PARAMETER MANUAL

FANUC Series 0i-MODEL C/0i Mate-MODEL C

CONNECTION MANUAL (FUNCTION)

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βis series

SERVO TUNING PROCEDURE (BASIC)

FANUC AC SERVO MOTOR αis series

FANUC AC SERVO MOTOR αi series

FANUC AC SERVO MOTOR βis series

PARAMETER MANUAL

FANUC AC SPINDLE MOTOR αi series

FANUC AC SPINDLE MOTOR βi series

PARAMETER MANUAL

Document

number

B-64114EN-1 • Initial setting

B-64120EN

B-64113EN-1

B-65264EN

B-65270EN

B-65280EN

Major contents Major usage

• Start up the system

(Software)

• Initial setting

• Setting parameters

• Description of

parameters

• Initial setting

• Setting signals

• Initial setting

• Servo tuning

• Initial setting

• Setting parameters

• Description of

parameters

• Initial setting

• Setting parameters

• Description of

parameters

• Start up the system

(Software)

• Turning the system

(Parameters)

• Setting parameters

(Parameter set supporting

screen)

• Start up the system

(Software)

• Setting parameters (high

speed and high precision)

• Turning the system

(Parameters)

• Start up the system

(Software)

• Turning the system

(Parameters)

• Start up the system

(Software)

• Turning the system

(Parameters)

*

p-1

Page 4

Page 5

B-64114EN-1/01 TABLE OF CONTENTS

TABLE OF CONTENTS

PREFACE....................................................................................................p-1

1 INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS

SETTINGS............................................................................................... 1

1.1 INITIALIZATION PROCEDURE..................................................................... 2

1.2 NC PARAMETERS RELATED TO AXIS SETTINGS .................................... 9

2 INITIALIZATION OF SERVO PARAMETERS ......................................10

2.1 PARAMETER INITIALIZATION FLOW........................................................ 11

2.2 PARAMETER SETTING PROCEDURE ...................................................... 12

3 INITIALIZATION OF THE OTHER NC PARAMETERS ........................19

3.1 INITIALIZATION PROCEDURE................................................................... 20

4 PARAMETERS RECOMMENDED TO BE SET....................................22

4.1 PARAMETERS RELATED TO HIGH-SPEED AND HIGH-PRECISION

OPERATIONS ............................................................................................. 23

4.2 SERVO PARAMETERS REQUIRED TO BE ADJUSTED BASED ON THE

MACHINE CHARACTERISTICS ................................................................. 28

c-1

Page 6

Page 7

B-64114EN-1/011.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGS

1 INITIALIZATION OF THE NC

PARAMETERS RELATED TO AXIS

SETTINGS

- 1 -

Page 8

1.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGSB-64114EN-1/01

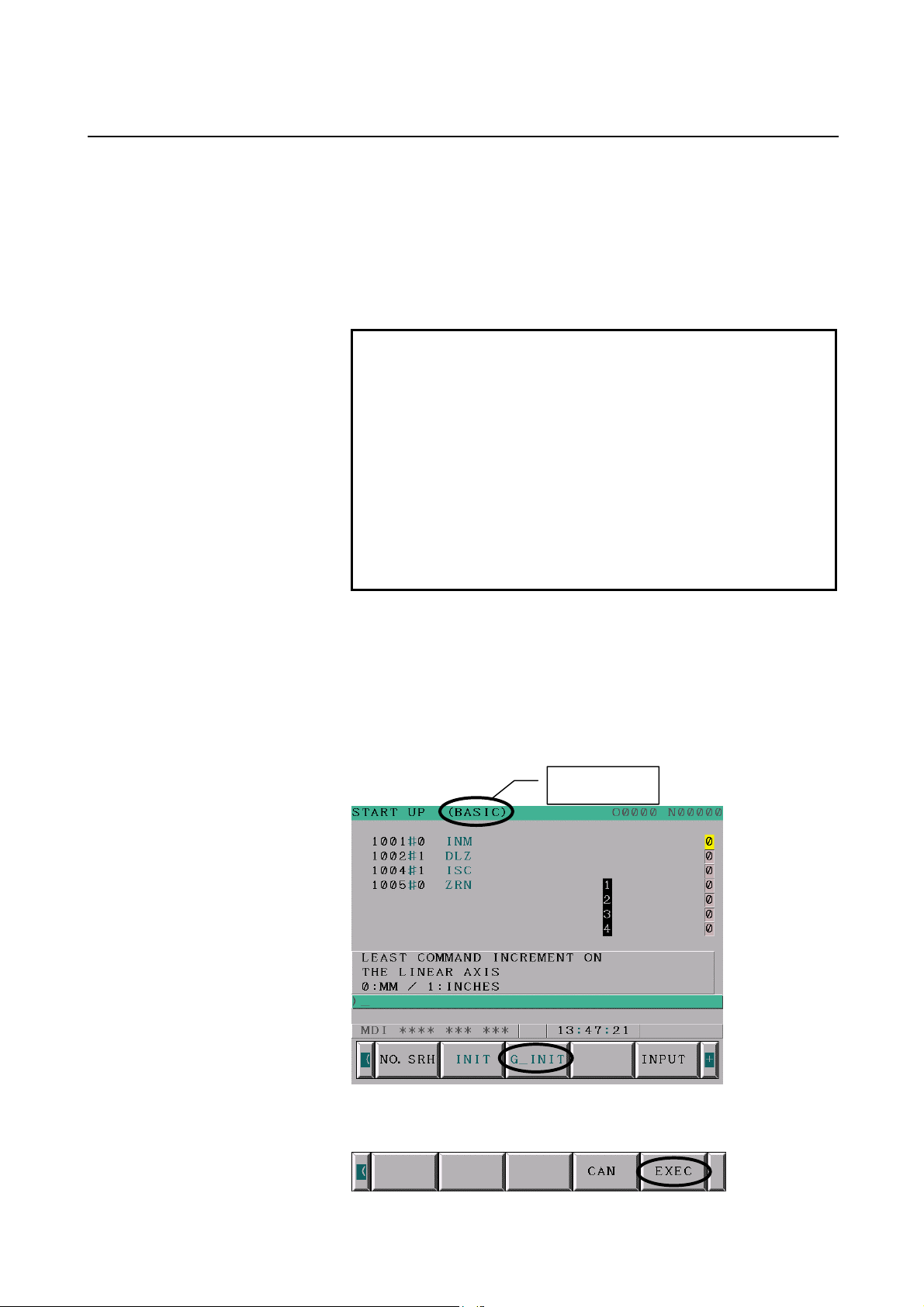

1.1 INITIALIZATION PROCEDURE

(1) Preparation

Switch on the NC in an emergency stop state.

Enable parameter writing (PWE = 1).

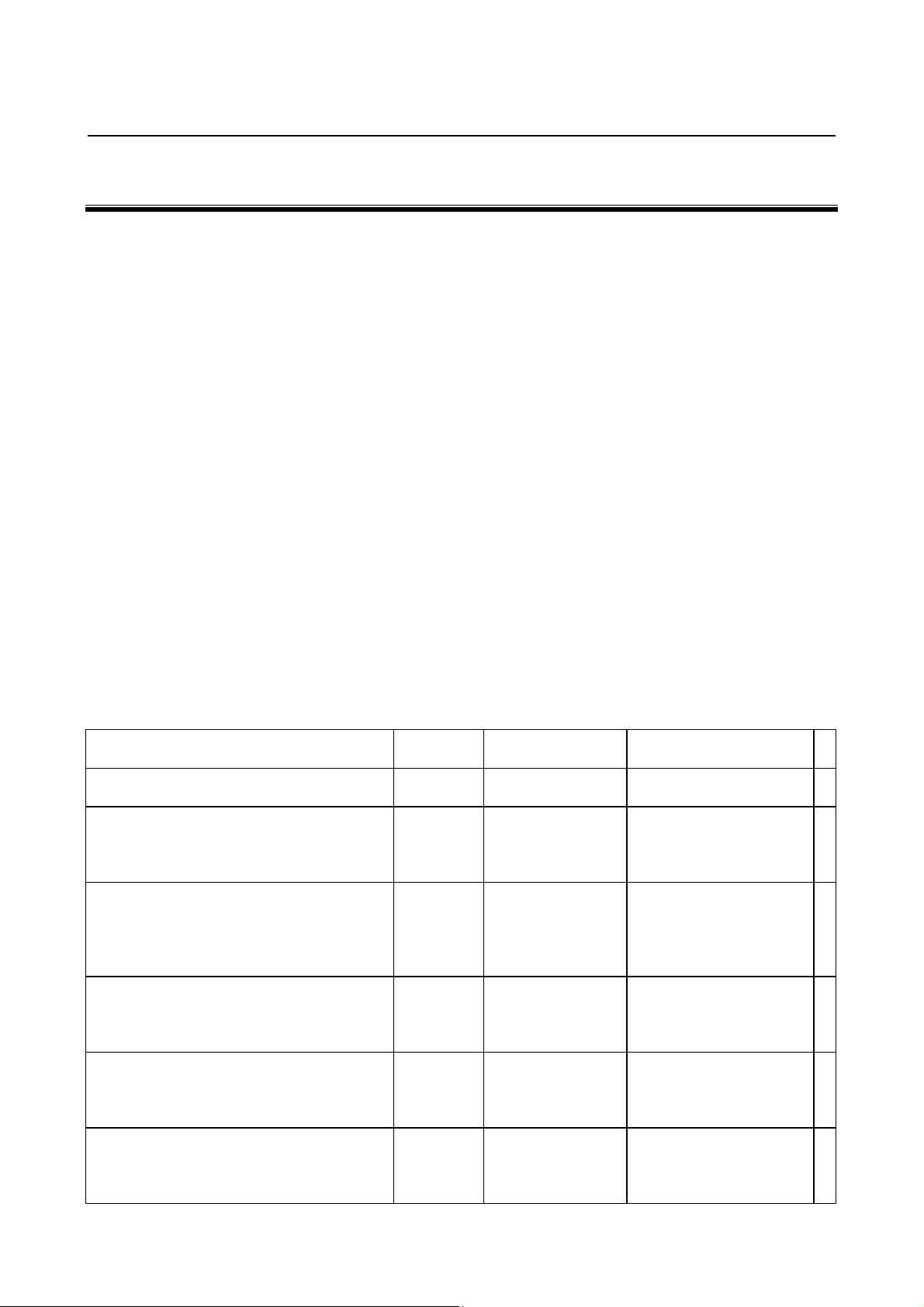

Press the

TUNING screen (parameter set supporting screen) appears.

PARAMETER DIAGNOSTIC PARAMETER TUNING

Press soft key [(OPRT)], move the cursor to the AXIS SETTING item,

and press [SELECT] to display the START UP (parameter setting)

screen (Fig. 1.1 (b)). This screen is used to make the parameter

settings shown below.

function key several times until the PARAMETER

Fig. 1.1 (a) PARAMETER TUNING screen

Fig. 1.1 (b) START UP screen

- 2 -

Page 9

B-64114EN-1/011.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGS

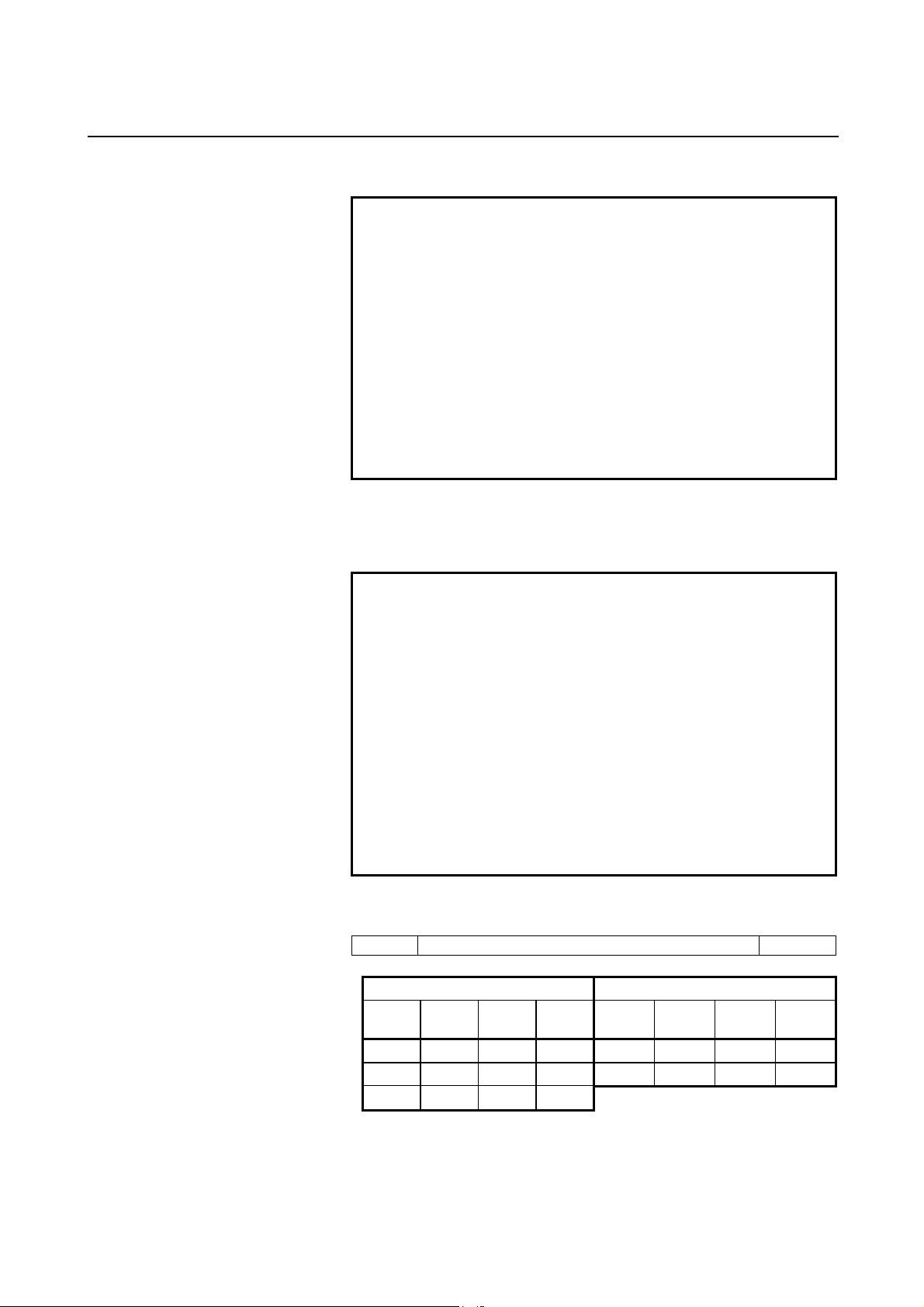

(2) Initialization

Parameters are initialized on the START UP screen. On the START

UP screen, parameters are classified into several groups, each of

which is displayed on successive pages.

Initialization is made for each group. The procedure is described

below.

NOTE

1 Since "Example of setting" in the following

descriptions indicates reference values for

initialization.

Determine the best setting based on the

characteristics and usage of the machine.

2 "Example of setting" in the following descriptions

assumes an increment system of IS-B (bit 1 of

parameter No. 1004 is 0) and metric input (bit 2 of

parameter No. 0000 is 0).

3 For details on the individual parameters, refer to

the parameter manual.

<1> BASIC group

<1>-1 Setting the standard values

The standard values are set for the parameters in the BASIC group.

Press the PAGEUP or PAGEDOWN key several times until the

BASIC group screen appears and then press soft key [G_INIT].

Group name

The message "DO YOU SET INIT-VALUE" appears.

Press soft key [EXEC].

- 3 -

Page 10

1.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGSB-64114EN-1/01

This sets the standard values for the parameters in the BASIC group.

NOTE

1 The parameters on all pages in the group are set to

the standard values regardless of the page on

which [G_INIT] is selected.

2 Some parameters have no standard value. The

values of these parameters do not change even

after setting the standard values.

3 Setting the standard values may issue "Alarm No.

000 (PLEASE TURN OFF POWER)" the alarm

screen appears, but it is not necessary to turn off

the power. Display the START UP screen again as

described in "(1) Preparation" and then proceed to

the next procedure.

<1>-2 Setting parameters for additional axes

When no additional axes are present, proceed to Step <<1>-3 Setting

parameters without the standard values>

NOTE

1 The standard value settings made in Step <<1>-1

Setting the standard values> includes parameters

for setting the standard value only for the basic

axes (M series: 1st to 3rd axes, T series: 1st to 2nd

axes).

In Step <<1>-2 Setting the parameters for

additional axes>, the additional axis (M series: 4th

and subsequent axes, T series: 3rd and

subsequent axes) portions of the parameters are

set manually.

2 When a parameter number is entered and then soft

key [NO.SRH] is pressed, the cursor moves to the

specified parameter.

Set the following parameters related to additional axes.

1020 Program axis name for each axis Each axis

M series T series

Axis

name

Setting

U 85 A 65 Y 89 B 66

V 86 B 66 A 65 C 67

W 87 C 67

Axis

name

Setting

Axis

name

Setting

Axis

name

Setting

- 4 -

Page 11

B-64114EN-1/011.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGS

1022 Setting of each axis in the basic coordinate system Each axis

Set value Meaning

0 Neither the basic three axes nor a parallel axis

5 Axis parallel to the X axis

6 Axis parallel to the Y axis

7 Axis parallel to the Z axis

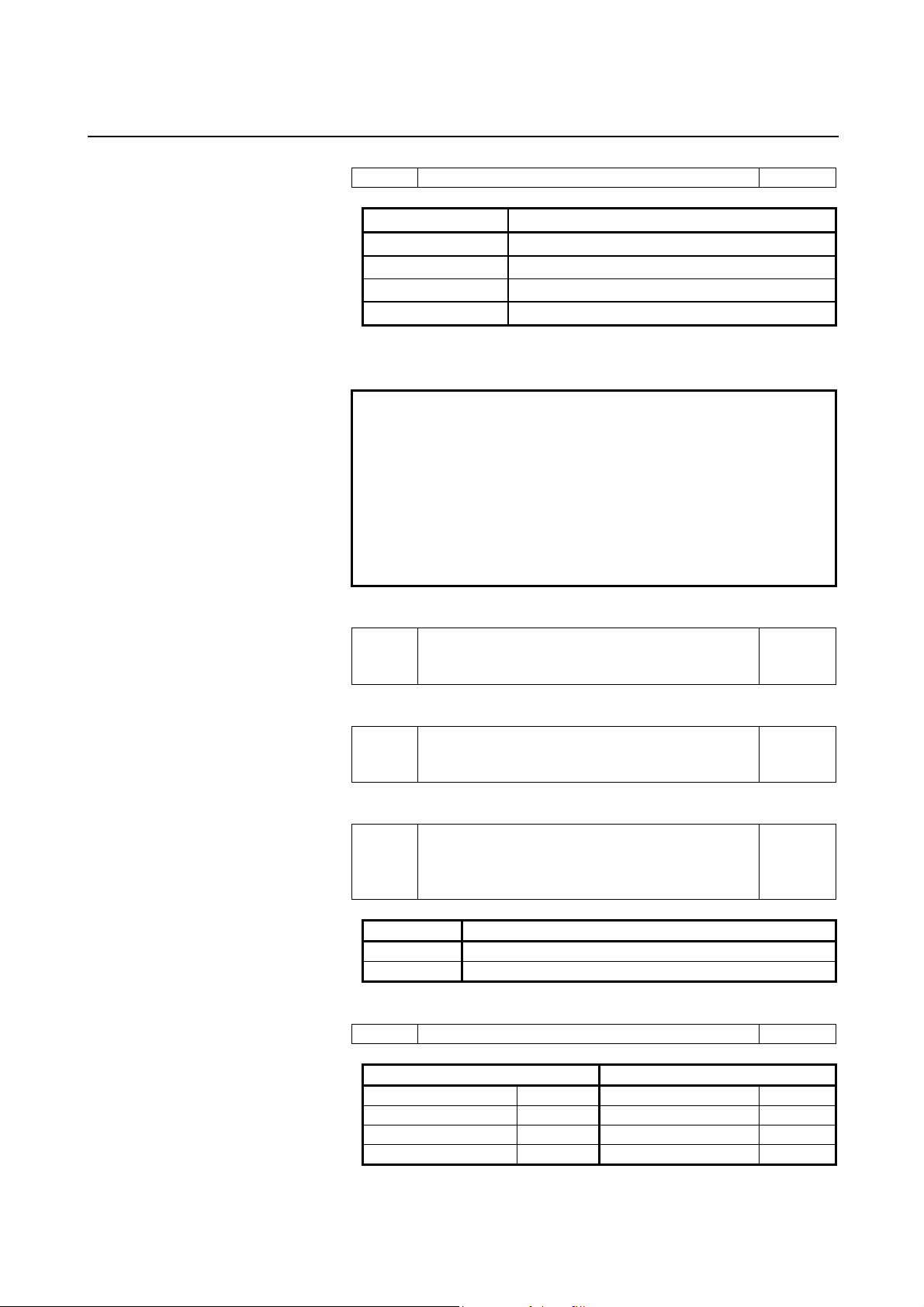

<1>-3 Setting the parameters without the standard values

NOTE

1 Some parameters are not set to the standard value

even after setting the standard value in Step

<<1>-1 Setting the standard values>.

These parameters are set manually in Step <<1>-3

Setting parameters without the standard values>.

2 When a parameter number is entered and then soft

key [NO.SRH] is pressed, the cursor moves to the

specified parameter.

• Set the type of each axis, linear or rotation.

Setting linear or rotation axis.

1006#0

• Set the metric system or inch system as the liner axis output unit.

1001#0

• The least input increment and least command increment are set.

1004#1

IS-B 0.001mm, 0.001deg, or 0.0001inch

IS-C 0.0001mm, 0.0001deg, or 0.00001inch

• Set the servo axis number as shown below.

1023 Number of the servo axis Each axis

1st axis (X axis) 1 1st axis (X axis) 1

2nd axis (Y axis) 2 2nd axis (Z axis) 2

3rd axis (Z axis) 3 3rd axis 3

4th axis 4 4th axis 4

0: Linear axis

1: Rotation axis

Least command increment on the linear axis

0: In mm (metric system machine)

1: In inches (inch system machine)

Setting least input increment and least command

increment

0: IS-B

1: IS-C

Least input increment and least command increment

M series T series

Each axis

All axes

All axes

- 5 -

Page 12

1.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGSB-64114EN-1/01

• Specify whether the position detector is an absolute position

detector.

Position detector

1815#5

0: Other than absolute position detector

1: Absolute position detector

Each axis

• When using reference position return without DOG, set the

following parameters.

When using reference position return without DOG for all axes

Function setting the reference position without DOG

1002#1

0: Disabled

1: Enabled (enabled for all axes)

All axes

When using reference position return without DOG for some

axes

Function setting the reference position without DOG

1005#1

0: Disabled (disabled for each axis)

1: Enabled (enabled for each axis)

Each axis

• Set the following parameters.

Parameter No. Example of setting Description Type

1825 5000 Servo loop gain Each axis

1826 10 In–position width Each axis

1828 7000

Positioning deviation

limit in movement

Each axis

<2> COORDINATE group

<2>-1 Setting the standard values

The standard values are set for the parameters in the COORDINATE

group.

Follow a procedure similar to Step <<1>-1 Setting the standard

values> in <<1> BASIC group>

<2>-2 Setting the parameters without the standard values

Set the following parameters.

Parameter

No.

1240

1241

1320

1321

Description Type

Coordinate value of the first reference

position on in the machine coordinate

system

Coordinate value of the second

reference position in the machine

coordinate system

Coordinate value of stored stroke

check 1 in the positive direction

Coordinate value of stored stroke

check 1 in the negative direction

Each

axis

Each

axis

Each

axis

Each

axis

Unit of

data

Increment

system

Increment

system

Increment

system

Increment

system

- 6 -

Page 13

B-64114EN-1/011.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGS

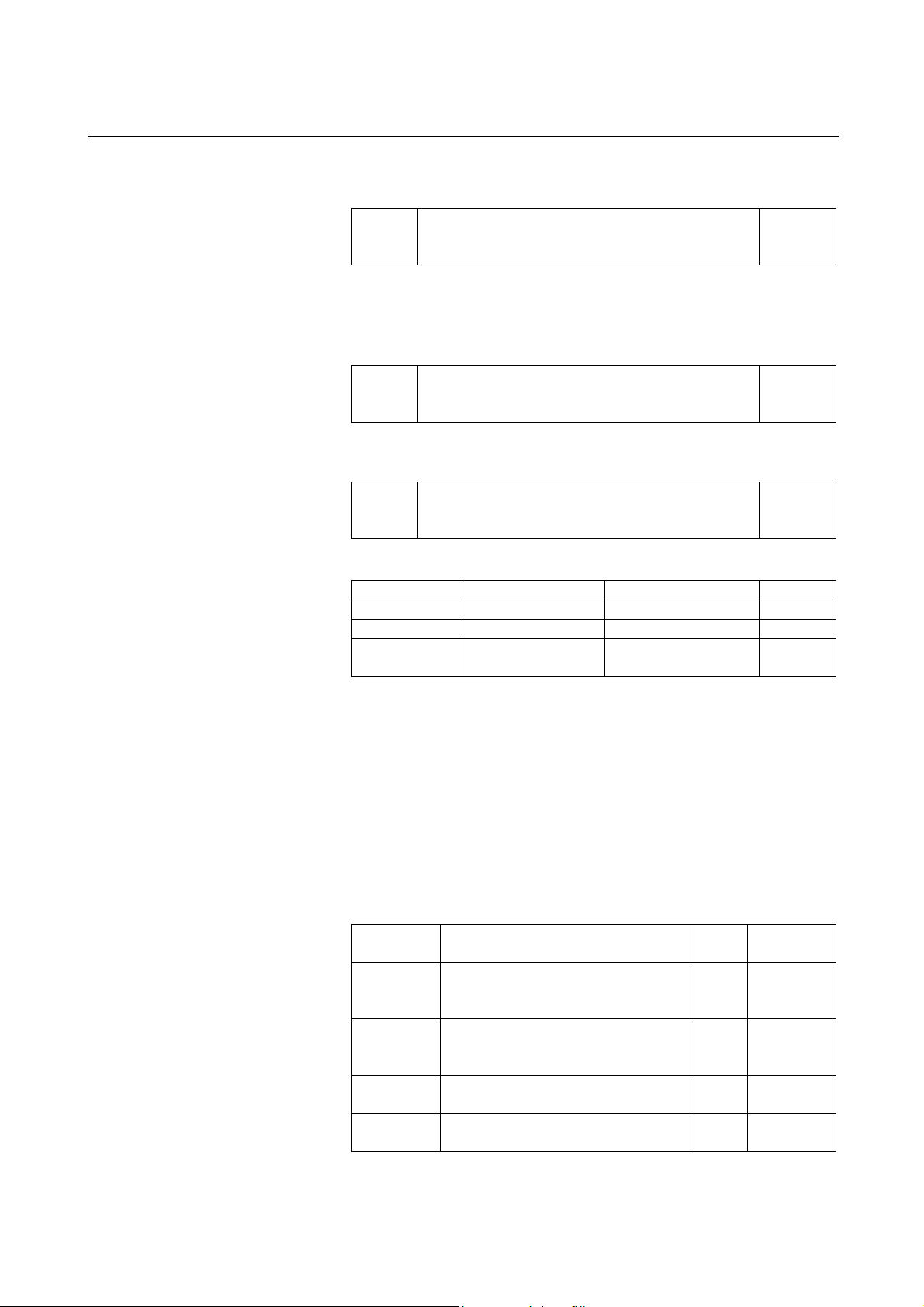

<3> FEED RATE group

<3>-1 Setting the standard values

The standard values are set for the parameters in the FEED RATE

group.

Follow a procedure similar to Step <<1>-1 Setting the standard

values> in <<1> BASIC group>

<3>-2 Setting the parameters without the standard values

Set the following parameters.

Parameter

No.

1410 1000 Dry run rate All axes

1420 8000 Rapid traverse rate Each axis

1421 1000 F0 rate of rapid traverse override Each axis

1422 10000 Maximum cutting feedrate All axes

1423 1000 Feedrate in jog feed Each axis

1424 5000 Manual rapid traverse rate Each axis

1425 150

Example of

setting

Description Type

FL rate of the reference position

return

Each axis

<4> ACC./DEC. (Acceleration/Deceleration) group

Set the following parameters.

Parameter

No.

1620 100

1622 32

1624 100

Example of

setting

Description Type

Time constant used for linear

acceleration/deceleration in rapid

traverse

Time constant

aceeleration/deceleration in

cutting feed

Time constant

aceeleration/deceleration in jog

feed

Each axis

Each axis

Each axis

- 7 -

Page 14

1.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGSB-64114EN-1/01

(3) Restarting the NC

Turn off and back on the NC power. This completes the initialization

of the NC parameters related to axis settings.

NOTE

1 To operate the servo axis, it is necessary to set the

following signals in addition to the above

parameters. For details on each signal, refer to the

Connection Manual (Function).

Address Symbol Signal name

G008#0 *IT Interlock signal for all

axes

G008#4 *ESP Emergency stop signal

G008#5 *SP Feed hold signal

G010,G011 *JV Manual feedrate

override signal

G012 *FV Feedrate override signal

G114 *+L1 to *+L8 Overtravel signals

G116 *-L1 to *-L8 Overtravel signals

G130 *IT1 to *IT8 Interlock signal for each

axis

2 Manual Setting 1 is used as the FSSB setting

method in this manual. When using Manual Setting

1, it is not necessary to use the FSSB (AMP) and

FSSB (AXIS) items on the parameter setting aid

screen.

In Manual Setting 1, restrictions are imposed on

the functions and settings that can be used. The

restrictions and details on FSSB settings, refer to

the FSSB settings section in the Connection

Manual (Function).

- 8 -

Page 15

B-64114EN-1/011.INITIALIZATION OF THE NC PARAMETERS RELATED TO AXIS SETTINGS

1.2 NC PARAMETERS RELATED TO AXIS SETTINGS

This section lists the parameters to be set during initialization of the

NC parameters related to axis settings. For details on each parameter,

refer to the parameter manual.

Group Parameter No. Summary

Least command increment on the linear axis

BASIC

COORDINATE

FEED RATE

ACC./DEC.

1001#0

1002#1

1004#1

1005#1

1006#0

1020 Program axis name for each axis

1022 Setting of each axis in the basic coordinate system

1023 Number of the servo axis

1815#5

1825 Servo loop gain for each axis

1826 In–position width for each axis

1828 Positioning deviation limit in movement for each axis

1240

1241

1320 Coordinate value of stored stroke check 1 in the positive direction

1321 Coordinate value of stored stroke check 1 in the negative direction

1410 Dry run rate

1420 Rapid traverse rate for each axis

1421 F0 rate of rapid traverse override for each axis

1422 Maximum cutting feedrate (common to all axes)

1423 Feedrate in jog feed for each axis

1424 Manual rapid traverse rate for each axis

1425 FL rate of the reference position return for each axis

1620

1622

1624 Time constant aceeleration/deceleration in jog feed for each axis

0: In mm (metric system machine)

1: In inches (inch system machine)

Function setting the reference position without DOG

0: Disabled

1: Enabled (enabled for all axes)

Setting least input increment and least command increment

0: IS-B

1: IS-C

Function setting the reference position without DOG

0: Disabled (disabled for each axis)

1: Enabled (enabled for each axis)

Setting linear or rotation axis.

0: Linear axis

1: Rotation axis

Position detector

0: Other than absolute position detector

1: Absolute position detector

Coordinate value of the first reference position on in the machine

coordinate system for each axis

Coordinate value of the second reference position in the machine

coordinate system for each axis

Time constant used for linear acceleration/deceleration in rapid

traverse for each axis

Time constant aceeleration/deceleration in cutting feed for each

axis

- 9 -

Page 16

2.INITIALIZATION OF SERVO PARAMETERS B-64114EN-1/01

2 INITIALIZATION OF SERVO

PARAMETERS

- 10 -

Page 17

B-64114EN-1/01 2.INITIALIZATION OF SERVO PARAMETERS

A

(

f

g

2.1 PARAMETER INITIALIZATION FLOW

Make the following settings on the servo setting screen and servo

adjustment screen.

In emergency stop state, switch on NC.

Initialization bits

Motor No.

MR

CMR

Move direction

Reference counter

Use the separate detector.

No.1815#1=1)

Set flexible feed gear. Set flexible feed gear.

Number of velocity pulses 8192

Number of position pulses Ns

00000000

See (2)-<2> in Sec. 2.2.

00000000

See (2)-<4> in Sec. 2.2.

111 (Clockwise as viewed from detector)

-111 (Counterclockwise as viewed from detector)

See (2)-<8> in Sec. 2.2.

Which system is being used?

See (2)-<5> in Sec. 2.2.

Number of velocity pulses 8192

Number of position pulses 12500

Semi-closed Closed loop

For the phase A/B separate

detector and serial linear scale:

Ns: Number of feedback pulses per motor

revolution, received from the separate

detector

End of parameter settin

Turn powerof

- 11 -

Page 18

2.INITIALIZATION OF SERVO PARAMETERS B-64114EN-1/01

2.2 PARAMETER SETTING PROCEDURE

(1) Preparation

Switch on the NC in an emergency stop state.

Enable parameter writing (PWE = 1).

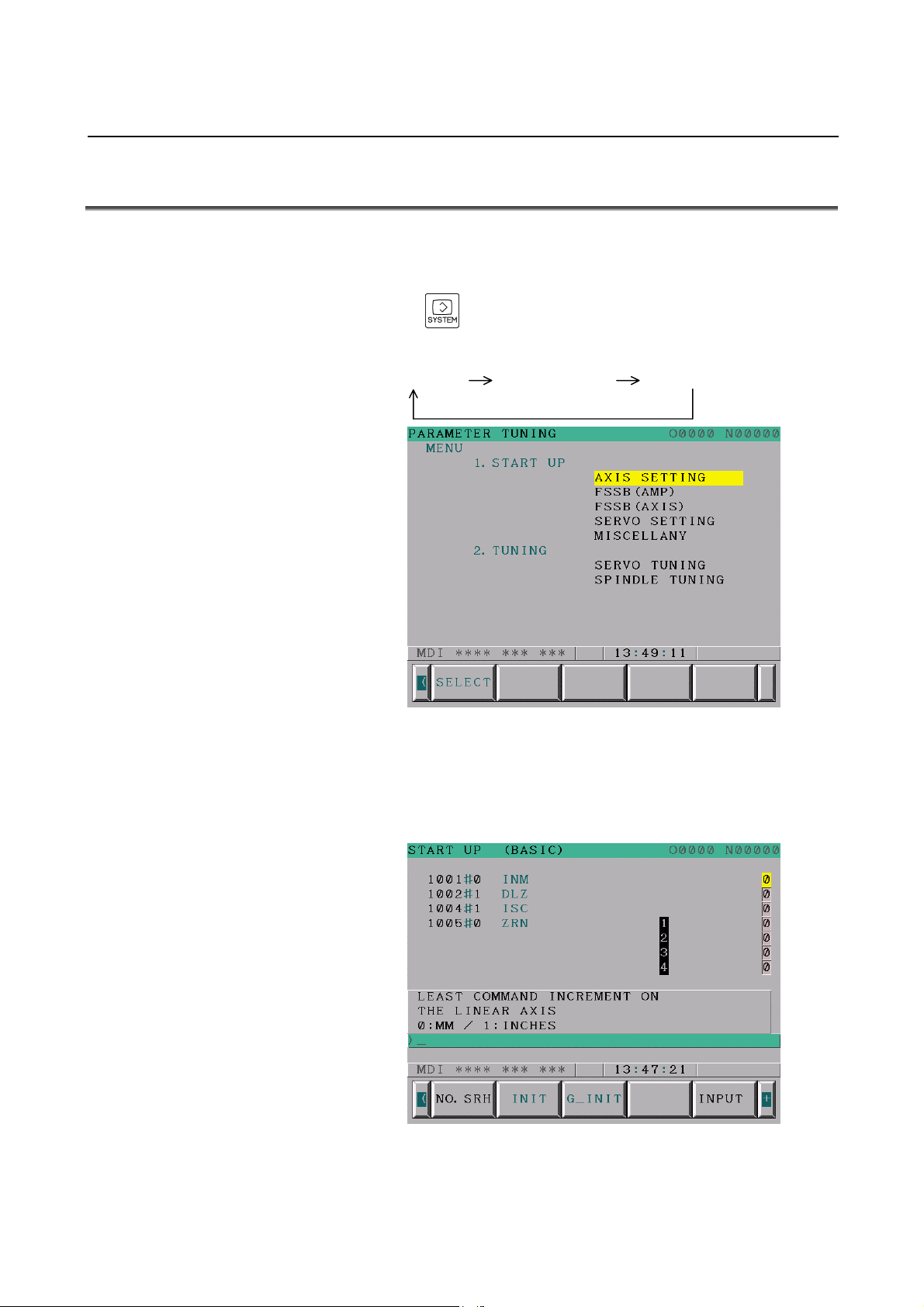

Press the

function key several times until the PARAMETER

TUNING screen (parameter set supporting screen) appears.

PARAMETER DIAGNOSTIC PARAMETER TUNING

Fig. 2.2 (a) PARAMETER TUNING screen

Press soft key [(OPRT)], move the cursor to the SERVO SETTING

item, and press [SELECT] to display the Servo setting screen (Fig. 2.2

(b)). When the screen appears, move the cursor to the item to be set

and directly enter data.

Servo set

<1>

INITIAL SET BITS

<2>

Motor ID No.

<3>

AMR

<4>

CMR

<5>

Feed gear N

<5>

(N/M) M

<6>

Direction Set

<7>

Velocity Pulse No.

<7>

Position Pulse No.

<8>

Ref. counter

Fig. 2.2 (b) Servo setting screen

X axis

00000000

00000000

258

100

111

8192

12500

10000

2

1

Z axis

00000000

258

00000000

2

1

100

111

8192

12500

10000

- 12 -

Page 19

B-64114EN-1/01 2.INITIALIZATION OF SERVO PARAMETERS

(2) Initialization

Start initialization. Set <1> to <8> on the servo setting screen and turn

off and back on the CNC power.

For full-closed systems, first set the following parameter.

#7 #6 #5 #4 #3 #2 #1 #0

1815 OPTx

↑ Set 1.

OPTx(#1) The separate position detector is:

0: Not to be used ← For semi-closed systems

1: To be used ← For full-closed systems

<1> Initialization bit

Initialization bit 00000000

When initialization is completed successfully, DGPR (#1) is set to 1

and PRMC (#3) is set to 1 automatically the next time the CNC power

is turned off and back on.

<2> Motor ID No. setting

Specify the motor ID number.

Select the motor number of the αis/αi/βis series servo motor to be

used in the following table. The motor number consists of a motor

model, a motor drawing number (4-digit number in the middle of

A06B-****-B***), and the maximum current value of the driving

amplifier.

i

Motor model

α12/4000is

α22/4000is

α30/4000is

α40/4000is

α12/3000i

α22/3000i

α30/3000i

α40/3000i

α40/3000i FAN

i

s/

series servo motor

α

α

α2/5000is

α4/5000is

α8/4000is

α1/5000i

α2/5000i

α4/4000i

α8/3000i

Motor

specification

0212 20A 262

0215 40A 265

0235 80A 285

0238 80A 288

0265 160A 315

0268 160A 318

0272 160A 322

0202 20A 252

0205 20A 255

0223 40A 273

0227 40A 277

0243 80A 293

0247 80A 297

0253 160A 303

0257 160A 307

0258 160A 308

Maximum current

value of the

driving amplifier

Motor type No.

- 13 -

Page 20

2.INITIALIZATION OF SERVO PARAMETERS B-64114EN-1/01

i

s series servo motor

β

Motor model

β0.2/

β0.3/

β0.4/

β0.5/

β1/

5000

β2/

4000

β4/

4000

β8/

3000

β12/

3000

β22/

2000

5000

5000

5000

5000

specification

is

is

is

is

is

is

is

is

is

is

Motor

0210 4A 260

0211 4A 261

0114 20A 280

0115 20A 281

0116 20A 282

0061

0063

0075

0078 40A 272

0085 40A 274

Maximum current

value of the

driving amplifier

20A 253

40A 254

20A 256

40A 257

20A 258

40A 259

Motor type No.

<3> AMR setting

This parameter corresponds to the number of poles of the servo motor.

For the αis/αi/βis motor, be sure to set 00000000.

αis/αi/βis servo motor

00000000

<4> CMR setting

Set CMR with the scale of a distance the NC instructs the machine to

move.

Setting value = (Command unit / Detection unit) × 2

CMR 2

Usually, set CMR with 2, because command unit = detection unit.

<5> Flexible feed gear setting

Set the parameters of the flexible field gear.

Flexible feed gear (numerator) N

Flexible feed gear (denominator) M

- 14 -

Page 21

B-64114EN-1/01 2.INITIALIZATION OF SERVO PARAMETERS

<5>-1 Semi-closed feedback loop

Examples of flexible field gear settings (gear ratio: 1 to 1)

Ball screw lead (N/M) Detection

unit

1µm 6/1000 8/1000 10/1000 12/1000 16/1000 20/1000

0.5 µm 12/1000 16/1000 20/1000 24/1000 32/1000 40/1000

0.1 µm 60/1000 80/1000 100/1000 120/1000 160/1000 200/1000

6mm 8mm 10mm 12mm 16mm 20mm

(Expression of calculation of parameters)

Set the pulse skipping rate assuming that the number of pulses

generated per motor turn is 1000000, regardless of the type of the

pulse coder.

Flexible feed

gear

Number of pulses

required per motor turn

Flexible feed gear

Necessary position feedback

pulses per motor revolution

1,000,000 fraction)

1,000,000 pulses generated

per motor turn (fixed)

(as irreducible

NOTE

The maximum specifiable value (after reduction) of

the flexible field gear is 32767 for both the

numerator and denominator.

Example of setting (1)

If the ball screw used in direct coupling has a lead of 10 mm/rev and

the detection unit is 1 µm

The number of pulses generated per motor turn (10 mm) is:

10/0.001 = 10,000 (pulses)

Numerator of flexible field gear 10,000 1

Denominator of flexible field gear

Example of setting (2)

If the gear reduction ratio between the rotation axis motor and table is

10:1 and the detection unit is 1/1000 degrees

• The table rotates through 360/10 (=36) degrees when the motor

makes one turn.

• Since the detection unit is 1/1000 degrees, the number of position

pulses generated per motor turn is:

(36 degrees per motor turn)/(Detection unit of 1/1000 degrees) =

36000 pulses

Therefore, the flexible gear setting is as shown below.

Numerator of flexible field gear 36,000 36

Denominator of flexible field gear

=

=

1,000,000

1,000,000

=

100

=

100

- 15 -

Page 22

2.INITIALIZATION OF SERVO PARAMETERS B-64114EN-1/01

<5>-2 Full-closed feedback loop

Example of flexible field gear settings (N/M)

Scale resolution Detection

unit

1 µm 1/1 1/2 1/10 1/20

0.5 µm - 1/1 1/5 1/10

0.1 µm - - 1/1 1/2

1 µm 0.5 µm 0.1 µm 0.05 µm

(Expression of calculation of parameters)

Set the pulse skipping rate for the number of scale output pulses

Flexible feed

gear

Scale output pulses Pulses for position control

(detection unit)

Flexible feed gear

Pulses for position control

(as irreducible

Scale output pulses fraction)

Example of setting

To detect a distance of 1 µm using a 0.5 µm scale, set the following:

• The number of scale output pulses for movement of 1 µm is:

1 µm/0.5 µm = 2

• Since the detection unit is 1 µm, the number of pulses used for

position control is 1.

Therefore, the flexible field gear setting is:

Numerator of flexible field gear 1 pulse 1

Denominator of flexible field gear

=

2 pulses

=

2

<6> Motor rotation direction setting

111 Clockwise as viewed from the Pulsecoder

-111 Counterclockwise as viewed from the Pulsecoder

When the direction is

clockwise as viewed

from the pulsecoder,

set -111.

- 16 -

FANUC

When the direction is

counterclockwise as

viewed from the

pulsecoder, set 111.

Page 23

B-64114EN-1/01 2.INITIALIZATION OF SERVO PARAMETERS

<7> Specify the number of velocity pulses and the number of position pulses.

<7>-1 Semi-closed feedback loop

Number of velocity pulses 8192 (Fixed value)

Number of position pulses 12500 (Fixed value)

<7>-2 Full-closed feedback loop (Parallel type or Serial liner scale)

Number of velocity pulses 8192 (Fixed value)

Number of position pulses

Set the number of pulses fed back from the separate detector (before

processing of the flexible field gear) when the motor rotates one turn.

Example 1 :

If the ball screw used in direct coupling has a lead of 10 mm and

the separate detector used has a resolution of 0.5 µm (= 0.0005

mm) per pulse

Number of

feedback pulses

per motor 1rev.

==

Therefore, the setting of the number of position pulses is 20000.

When the calculated number of position pulses is greater than

32767, set the number of position pulses by using the position

pulse conversion factor (No. 2185) to multiply the parameter of

the number of position pulses by the parameter of the conversion

factor.

2024 Number of position pulses

2185 Position pulse conversion factor

Example 2 :

If the ball screw used in direct coupling has a lead of 16 mm and

the separate detector used has a resolution of 0.1 µm (= 0.0001

mm) per pulse

Number of

feedback pulses

per motor 1rev.

==

Number of feedback pulses from the

scale per motor turn

Ball screw lead =

10mm

20000

Scale resolution

= 0.0005mm

Ball screw lead =

16mm

160,000

Scale resolution

= 0.0001mm

- 17 -

Page 24

2.INITIALIZATION OF SERVO PARAMETERS B-64114EN-1/01

Therefore, the setting of the number of position pulses is 160000.

The value exceeds 32767 and cannot be entered as the number of

position pulses on the servo setting screen.

In this case, make settings as shown below.

No.2024 = 16,000

No.2185 = 10

(When the value of No. 2024 multiplied by the value of No. 2185

is 160000, another setting is allowed.)

<8> Reference counter setting

Specify the reference counter.

The reference counter is used in making a return to the reference

position by a grid method.

<8>-1 Semi-closed feedback loop

Count on the reference

counter

Example of setting

αi/βi Pulsecoder and semi-closed loop (1-µm detection)

Ball screw lead

(mm/revolution)

10

20

Number of position pulses corresponding to a

=

single motor revolution

Necessary number of

position pulses

(pulse/revolution)

10000

20000

Reference

counter

10000

20000

Grid width

(mm)

10

20

<8>-2 Full-closed feedback loop

Reference counter

setting

Example of setting

Example 1 :

When the Z-phase interval is 50 mm and the detection unit is 1

µm: Reference counter setting = 50,000/1 = 50,000

Example 2 :

When a rotation axis is used and the detection unit is 0.001°:

Reference counter setting = 360/0.001 = 360,000

Example 3 :

When a linear scale is used and a single Z phase exists:

Set the reference counter to 10000, 50000, or another round

number.

Turn off and back on the NC power. This completes the initialization

of the servo parameters.

Z-phase (reference-position) interval divided by

=

the detection unit

- 18 -

Page 25

B-64114EN-1/01 3.INITIALIZATION OF THE OTHER NC PARAMETERS

3 INITIALIZATION OF THE OTHER NC

PARAMETERS

- 19 -

Page 26

3.INITIALIZATION OF THE OTHER NC PARAMETERS B-64114EN-1/01

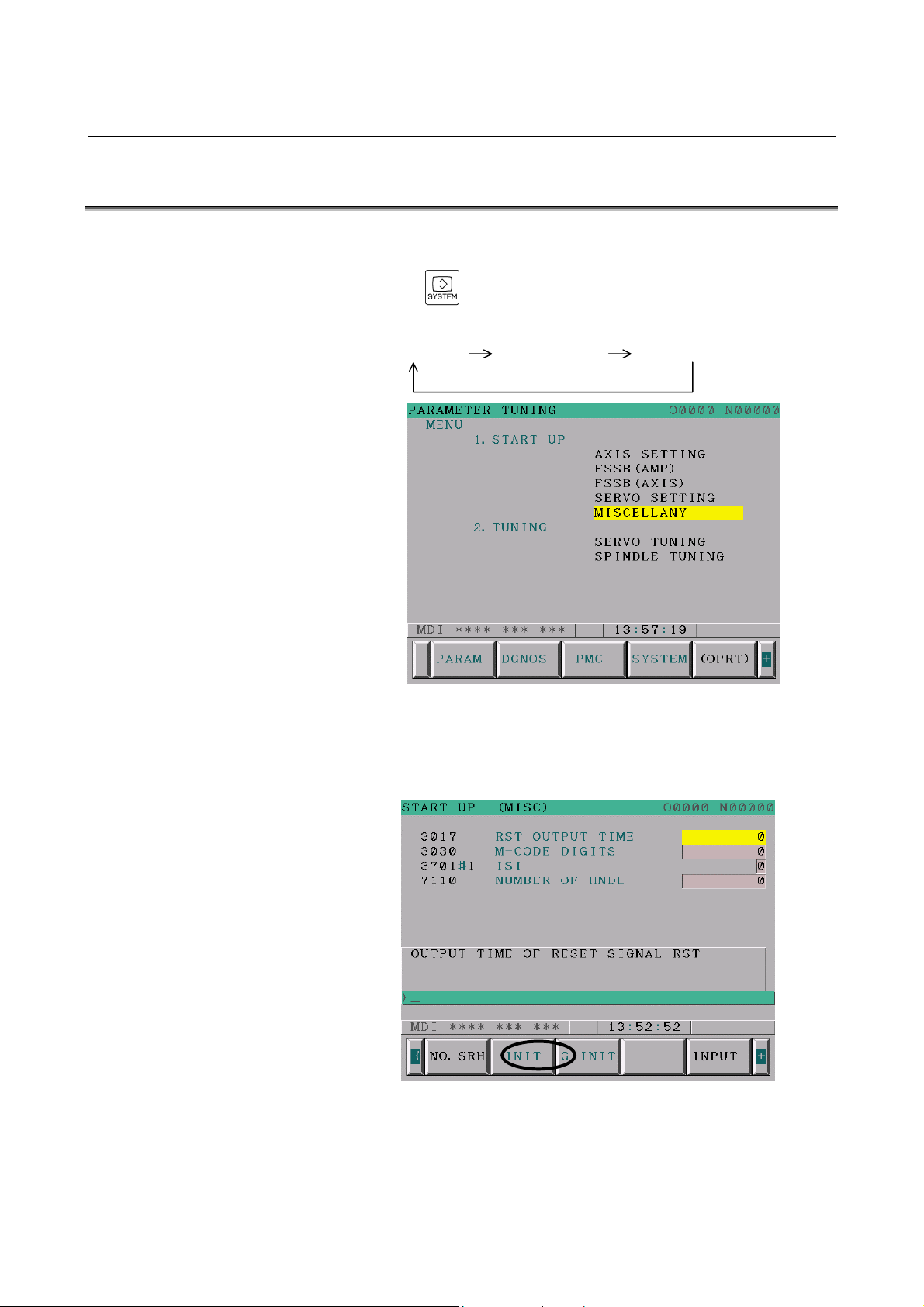

3.1 INITIALIZATION PROCEDURE

Switch on the NC in an emergency stop state.

Enable parameter writing (PWE = 1).

Press the

TUNING screen (parameter set supporting screen) appears.

PARAMETER DIAGNOSTIC PARAMETER TUNING

Press soft key [(OPRT)], move the cursor to the MISCELLANY item,

and press [SELECT] to display the parameter setting (START UP

(MISC)) screen (Fig. 3.1 (b)).

function key several times until the PARAMETER

Fig. 3.1 (a) PARAMETER TUNING screen

Fig. 3.1 (b) START UP (MISC) screen

Press soft key [G_INIT].

The message "DO YOU SET INIT-VALUE" appears.

- 20 -

Page 27

B-64114EN-1/01 3.INITIALIZATION OF THE OTHER NC PARAMETERS

Press soft key [EXEC].

This completes the initialization of the other servo parameters.

- 21 -

Page 28

4.PARAMETERS RECOMMENDED TO BE SET B-64114EN-1/01

4 PARAMETERS RECOMMENDED TO BE

SET

(1) Parameters related to high-speed and high-precision operations

This section describes the parameters recommended to be set for

the AI advanced preview control specification and AI contour

control specification.

The parameter list also shows the servo-related parameters.

(2) Minimum servo parameters required to be adjusted

This section describes the minimum servo parameters required to

be adjusted based on the machine characteristics.

NOTE

First enter the standard settings.

To reduce the machining time, use a parameter for

speed priority I. To further reduce the machining

time, use a parameter for speed priority II.

When using a speed priority parameter, however,

the machining precision decreases.

- 22 -

Page 29

B-64114EN-1/01 4.PARAMETERS RECOMMENDED TO BE SET

4.1 PARAMETERS RELATED TO HIGH-SPEED AND

HIGH-PRECISION OPERATIONS

[Functions related to high-speed and high-precision operations]

High-speed and

high-precision functions

Series 0i Mate-MC

Series 0i-MC

Acceleration/deceleration

before interpolation

Type

Velocity control

Automatic corner

deceleration

Arc radius-based velocity

control

Acceleration-based velocity

control

AI advance preview

control

(AI-APC)

○

○ ○

Linear

Linear/Bell-shaped

○ ○

○ ○

○ ○

*1 Options are required to perform bell-shaped

acceleration/deceleration before interpolation and

bell-shaped acceleration/deceleration after cutting

feed interpolation.

AI contour control

(AICC)

(*1)

- 23 -

Page 30

4.PARAMETERS RECOMMENDED TO BE SET B-64114EN-1/01

(1) AI advanced preview control

- Parameters to be set based on the machine type

Standard setting value

Parameter No.

1432 - - - Maximum cutting feedrate (mm/min) for each axis

1620 - - -

1621 - - -

1730 3250 5150 7275 Feedrate upper limit (mm/min) for arc radius R

1731 5000 5000 5000

1732 100 100 100

1768 24 24 24

1770 10000 10000 10000

1771 240 80 40

1783 400 500 1000

1784 - - -

1785 320 112 56

Standard

setting

Speed

priority I

Speed

priority II

Time constant (ms) for linear-shaped Acc./Dec. in

rapid-traverse for each axis

Time constant T2 (ms) for bell-shaped Acc./Dec. in

rapid-traverse for each axis

Arc radius R (1

upper limit

Arc radius-based feedrate clamp lower speed limit

(mm/min)

Time constant (ms) for Acc./Dec. after cutting feed

interpolation

Maximum cutting feedrate (mm/min) during Acc./Dec.

before interpolation

Time (ms) allowed before a maximum cutting feedrate

during Acc./Dec. before interpolation is reached

Allowable speed difference (mm/min) in

acceleration-dependent on speed difference at corners

Speed (mm/min) at occurrence of overtravel alarm

To be specified according to the overrun distance at

overtravel

Parameter (ms) for determining an allowable

acceleration in determining acceleration-dependent

speed. The parameter is to be set with the time

allowed before a maximum cutting feedrate (parameter

No.1432) is reached.

A maximum cutting feedrate of 10000 mm/min is used

as the standard setting value.

Description

µm) for arc radius-based feedrate

- Parameters for which a fixed value is set

Parameter No.

1602#6,#3

Standard setting

value

#6,#3

1,0

Description

Acc./Dec. after interpolation is of a linear type (to be specified when

FAD is used)

- 24 -

Page 31

B-64114EN-1/01 4.PARAMETERS RECOMMENDED TO BE SET

- Parameters for which a fixed value is set (servo-related parameters)

Parameter No.

1825 5000 Position gain

2003 #3 1 Enables PI function

2003 #5 1 Enables backlash acceleration

2005 #1 1 Enables feed-forward

2006 #4 1 Uses the latest feedback data for velocity feedback.

2007 #6 1 Enables FAD (Fine Acc./Dec.)

2009 #7 1 Enables backlash acceleration stop

2016 #3 1 Enables variable proportional gain in the stop state

2017 #7 1 Enables velocity loop high cycle management function

2021 128 Load inertia ratio

2067 1166 TCMD filter

2069 50 Velocity feed-forward coefficient

2071 20 Period during which backlash acceleration remains effective

2082 5 (1µm detection)

2092 10000 Advanced preview (position) feed-forward coefficient

2107 150 Cutting load inertia ratio override (in % units)

2109 16 FAD time constant

2119 2 (1µm detection)

2202 #1 1 Cutting/rapid traverse velocity loop gain switching

2209 #2 1 Enables FAD of linear type.

Standard setting

value

Description

Timing at which the backlash acceleration is stopped (specified in

detection units)

For variable proportional gain function in the stop state : judgment level

for stop state (specified in detection units)

- Parameters to be set when using HRV3 (high-speed HRV current control)

To use servo HRV3 control, make the following settings.

Parameter No.

2013#0 1

2334 150 Current loop gain magnification for high-speed HRV current control

2335 200

Standard setting

value

In the G05.1Q1 command, high-speed HRV control (Current control

cycle 62.5

Velocity gain override (in % units) when high-speed HRV current control

is in use

µs)

Description

- 25 -

Page 32

4.PARAMETERS RECOMMENDED TO BE SET B-64114EN-1/01

(2) AI contour control

- Parameters to be set based on the machine type

Parameter

No.

1432 - - - Maximum cutting feedrate (mm/min) for each axis

1620 - - -

1621 - - -

1730 3250 5150 7275 Feedrate upper limit (mm/min) for arc radius R

1731 5000 5000 5000

1732 100 100 100

1768 24 24 24

1770 10000 10000 10000

1771 240 80 40

1772 64 48 32

1783 400 500 1000

1784 - - -

1785 320 112 56

Standard setting value

Standard

setting

Speed

priority I

Speed

priority II

Description

Time constant (ms) for linear-shaped Acc./Dec. in

rapid-traverse for each axis

Time constant T2 (ms) for bell-shaped Acc./Dec. in

rapid-traverse for each axis

Arc radius R (1

limit

Arc radius-based feedrate clamp lower speed limit

(mm/min)

Time constant (ms) for Acc./Dec. after cutting feed

interpolation

Maximum cutting feedrate (mm/min) during Acc./Dec.

before interpolation

Time (ms) allowed before a maximum cutting feedrate

during Acc./Dec. before interpolation is reached

Time constant (ms) for bell-shaped Acc./Dec. before

interpolation (portion with the time fixed)

Allowable speed difference (mm/min) in

acceleration-dependent on speed difference at corners

Speed (mm/min) at occurrence of overtravel alarm

To be specified according to the overrun distance at

overtravel

Parameter (ms) for determining an allowable

acceleration in determining acceleration-dependent

speed. The parameter is to be set with the time allowed

before a maximum cutting feedrate (parameter No.1432)

is reached.

A maximum cutting feedrate of 10000 mm/min is used as

the standard setting value.

µm) for arc radius-based feedrate upper

- Parameters for which a fixed value is set

Parameter

No.

1602#6,#3

1603#7 1

7050#5 1 To be set to the standard setting value.

7050#6 0 To be set to the standard setting value.

7052#0 0/1 To be set to 1 for the PMC and Cs axes.

Standard setting

value

#6,#3

1,0

1,1

Description

Acc./Dec. after interpolation is of a linear type (if bell-shaped Acc./Dec.

before interpolation is used)

Acc./Dec. after interpolation is of a bell-shaped type (if linear-shaped

Acc./Dec. before interpolation is used)

Acc./Dec. before interpolation is of a bell-shaped type (0: Linear-shaped

Acc./Dec. before interpolation)

- 26 -

Page 33

B-64114EN-1/01 4.PARAMETERS RECOMMENDED TO BE SET

- Parameters for which a fixed value is set (servo-related parameters)

Parameter No.

1825 5000 Position gain

2003 #3 1 Enables PI function

2003 #5 1 Enables backlash acceleration

2005 #1 1 Enables feed-forward

2006 #4 1 Uses the latest feedback data for velocity feedback.

2009 #7 1 Enables backlash acceleration stop

2016 #3 1 Enables variable proportional gain in the stop state

2017 #7 1 Enables velocity loop high cycle management function

2021 128 Load inertia ratio

2067 1166 TCMD filter

2069 50 Velocity feed-forward coefficient

2071 20 Period during which backlash acceleration remains effective

2082 5 (1µm detection)

2092 10000 Advanced preview (position) feed-forward coefficient

2107 150 Cutting load inertia ratio override (in % units)

2119 2 (1µm detection)

2202 #1 1 Cutting/rapid traverse velocity loop gain switching

Standard setting

value

Description

Timing at which the backlash acceleration is stopped (specified in

detection units)

For variable proportional gain function in the stop state : judgment

level for stop state (specified in detection units)

- Parameters to be set when using HRV3 (high-speed HRV current control)

To use servo HRV3 control, make the following settings.

Parameter No.

2013#0 1

2334 150 Current loop gain magnification for high-speed HRV current control

2335 200

Standard setting

value

In the G05.1Q1 command, high-speed HRV control (Current control

cycle 62.5

Velocity gain override (in % units) when high-speed HRV current

control is in use

µs)

Description

- 27 -

Page 34

4.PARAMETERS RECOMMENDED TO BE SET B-64114EN-1/01

4.2 SERVO PARAMETERS REQUIRED TO BE ADJUSTED

BASED ON THE MACHINE CHARACTERISTICS

This section describes the minimum servo parameters required to be

adjusted after the above parameter were set.

Make the following settings and then check the machine operation and

machining. If a problem occurs, change parameters as described in the

Adjustment field.

Parameters required to be adjusted to find the optimal value

Parameter

No.

2021 128

1825 5000 Position gain

2048 100 Backlash acceleration

Setting at

tuning start

Description Adjustment

Load inertia ratio (LDINT)

(velocity gain)

(Note 1)

When vibrations occur during movement of the axis,

reduce the setting to 128 → 64 → 0 in that order.

If vibrations do not disappear even when the load

inertia ratio is reduced to 0, reduce the position gain

(No. 1825) values for all axes to 5000

3000 in that order.

When a protrusion is found at the position where the

axis movement direction is reversed, increase the

setting in steps of 50.

When a depression is found, decrease the setting in

steps of 50.

→ 4000 →

NOTE

1 There is the following relationship between the load

inertia ratio and velocity loop gain (%).

Velocity loop gain (%)

= (1 + load inertia ratio/256) × 100

Example of conversion:

Velocity loop gain 150% -----Load inertia ratio 128

Velocity loop gain 200% -----Load inertia ratio 256

Velocity loop gain 250% -----Load inertia ratio 384

Velocity loop gain 300% -----Load inertia ratio 512

The servo guide (servo adjustment tool using PC) is useful to observe

the vibration state or a protrusion/depression during reversal of the

direction. Examples of observation of waveforms are shown below.

- 28 -

Page 35

B-64114EN-1/01 4.PARAMETERS RECOMMENDED TO BE SET

A

A

Change in the waveform depending on the load inertia ratio (velocity

gain) setting and position gain setting

dequate load inertia ratio (velocity gain)

Excessive load inertia ratio (velocity gain)

High-frequency vibrations are found.

dequate position gain

Motor speed

Torque c ommand

Low load inertia ratio (velocity gain)

The circle shape is not good and there are

big quadrant protrusions.

Motor speed

Torque c ommand

Excessively high position gain

Hunting is found during axis movement

Low position gain

There is a long delay in acceleration/deceleration.

- 29 -

Page 36

4.PARAMETERS RECOMMENDED TO BE SET B-64114EN-1/01

A

A

Change in the circle shape depending on the backlash acceleration

setting

dequate backlash acceleration

Excessive backlash acceleration

Depression occurs.

Small backlash acceleration

protrusion remains.

- 30 -

Page 37

B-64114EN-1/01 INDEX

INDEX

<A>

ACC./DEC. (Acceleration/Deceleration) group................7

AI advanced preview control ..........................................24

AI contour control...........................................................26

AMR setting....................................................................14

<B>

BASIC group.....................................................................3

<C>

CMR setting .................................................................... 14

COORDINATE group.......................................................6

<F>

FEED RATE group...........................................................7

Flexible feed gear setting ................................................14

Full-closed feedback loop .........................................16, 18

Full-closed feedback loop (Parallel type or Serial liner

scale).........................................................................17

Functions related to high-speed and high-precision

operations.................................................................. 23

PARAMETERS RECOMMENDED TO BE SET..........22

PARAMETERS RELATED TO HIGH-SPEED AND

HIGH-PRECISION OPERATIONS ......................... 23

Parameters required to be adjusted to find the optimal

value.......................................................................... 28

Parameters to be set based on the machine type........ 24, 26

Parameters to be set when using HRV3

(high-speed HRV current control).......................25, 27

<R>

Reference counter setting ................................................18

Restarting the NC..............................................................8

<S>

Semi-closed feedback loop.................................. 15, 17, 18

SERVO PARAMETERS REQUIRED TO BE

ADJUSTED BASED ON THE MACHINE

CHARACTERISTICS ..............................................28

Specify the number of velocity pulses and the number

of position pulses. .....................................................17

<I>

Initialization ................................................................ 3, 13

Initialization bit............................................................... 13

INITIALIZATION OF SERVO PARAMETERS........... 10

INITIALIZATION OF THE NC PARAMETERS

RELATED TO AXIS SETTINGS..............................1

INITIALIZATION OF THE OTHER NC

PARAMETERS ........................................................ 19

INITIALIZATION PROCEDURE .............................2, 20

<M>

Motor ID No. setting ....................................................... 13

Motor rotation direction setting.......................................16

<N>

NC PARAMETERS RELATED TO AXIS SETTINGS... 9

<P>

PARAMETER INITIALIZATION FLOW..................... 11

PARAMETER SETTING PROCEDURE.......................12

Parameters for which a fixed value is set .................. 24, 26

Parameters for which a fixed value is set

(servo-related parameters)...................................25, 27

i-1

Page 38

Page 39

Revision Record

FANUC Series 0i-MODEL C / Series 0i Mate-MODEL C START-UP MANUAL (B-64114EN-1)

Mar., 2005

01

Edition Date Contents Edition Date Contents

Page 40

Loading...

Loading...