Euro-pro 9106 User Manual

Another quality product from

Instruction Manual

Model 9106

SYMBOL INSTRUCTIONS

Raise needle |

Raise presser foot |

Lower presser foot |

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety should always be followed, including the following:

Read all instructions before using this sewing machine.

DANGER -To reduce the risk of electric shock:

1.An appliance should never be left unattended when plugged in.

2.Always unplug this appliance from the electric outlet immediately after using and before cleaning.

3.Always unplug before re-lamping. Replace bulb with same type rated 5 watts.

WARNING -To reduce the risk of burns, fire, electric shock, or injury to persons:

1.Do not allow to be used as a toy. Close attention is necessary when this appliance is used by or near children.

2.Use this appliance only for its intended use as described in this manual. Use only the attachments recommended by the manufacturer as contained in this manual.

3.Never operate this appliance if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. Return the appliance to the nearest authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

4.Never operate the appliance with any air openings block. Keep ventilation openings of the sewing machine and foot controller free from accumulation of lint, dust, and loose cloth.

5.Keep fingers away from all moving parts. Special care is required around the sewing machine needle.

6.Always use the proper needle plate, a wrong needle plate can cause the needle to break.

7.Do not use bent needles.

8.Do not pull or push fabric while stitching. It may deflect the needle causing it to break.

9.Switch the sewing machine off ("O") when making any adjustments in the needle area, such as threading needle, changing needle, threading bobbin, or changing presser foot, and the light.

10.Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the instruction manual.

11.Never drop or insert any object into any opening.

12.Do not use outdoors.

13.Do not operate where aerosol spray products are being used or where oxygen is being administered.

14.To disconnect, turn all controls to the off ("O") position, then remove plug from outlet.

15.Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

SAVE THESE INSTRUCTIONS

This sewing machine is intended for household use only.

I

CONTENTS

PRINCIPAL PARTS OF THE MACHINE ......................................................................................... |

1-2 |

ACCESSORIES ................................................................................................................................. |

3 |

CONNECTING THE MACHINE TO THE POWER SOURCE ......................................................... |

4-5 |

OPERATION BUTTONS AND FOOT CONTROLLER ....................................................................... |

6 |

CHANGING THE PRESSER FOOT................................................................................................... |

7 |

REPLACING THE NEEDLE ............................................................................................................... |

7 |

WINDING THE BOBBIN..................................................................................................................... |

8 |

INSERTING THE BOBBIN ................................................................................................................. |

9 |

THREADING THE UPPER THREAD ............................................................................................... |

10 |

USING THE NEEDLE THREADER .................................................................................................. |

11 |

THREAD TENSION.......................................................................................................................... |

12 |

RAISING UP THE LOWER THREAD............................................................................................... |

13 |

CUTTING THE THREAD.................................................................................................................. |

13 |

TWO-STEP PRESSER FOOT LIFTER............................................................................................ |

14 |

TO RAISE OR DROP THE FEED DOGS......................................................................................... |

14 |

MATCHING NEEDLE/ FABRIC/ THREAD ....................................................................................... |

15 |

QUICK ADJUSTMENT REFERENCE CHART................................................................................. |

16 |

TYPE OF PRESSER FOOT CHART................................................................................................ |

17 |

SELECTING A STITCH .................................................................................................................... |

18 |

MIRROR........................................................................................................................................... |

18 |

AUTO-STOP..................................................................................................................................... |

18 |

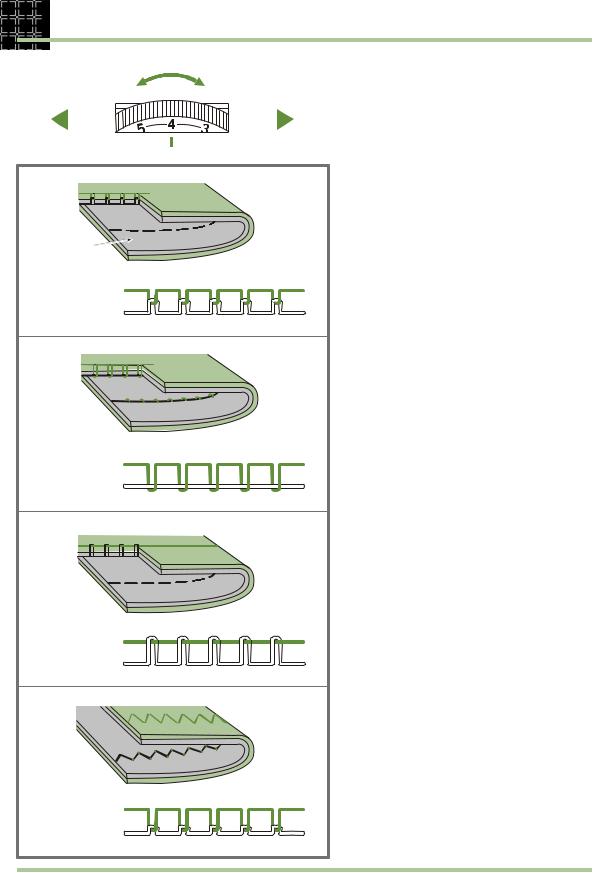

ADJUSTING THE STITCH LENGTH ............................................................................................... |

19 |

ADJUSTING THE STITCH WIDTH/ NEEDLE POSITION ............................................................... |

19 |

MEMORY |

|

Program........................................................................................................................................ |

20 |

Sew Prog...................................................................................................................................... |

21 |

Sewing sample ............................................................................................................................. |

21 |

USEFUL SKILLS |

|

Sewing corners............................................................................................................................. |

22 |

Reverse ........................................................................................................................................ |

22 |

Free arm....................................................................................................................................... |

22 |

Sewing on the heavy fabric .......................................................................................................... |

23 |

STRAIGHT STITCHES AND NEEDLE POSITION .......................................................................... |

24 |

ZIGZAG STITCHES ......................................................................................................................... |

24 |

STRETCH STITCH .......................................................................................................................... |

25 |

OVERCASTING STITCHES ............................................................................................................ |

26 |

BLIND HEM/LINGERIE STITCH ...................................................................................................... |

27 |

BUTTON SEWING ........................................................................................................................... |

28 |

BUTTONHOLE STITCHING ....................................................................................................... |

29-31 |

DARNING......................................................................................................................................... |

32 |

FAGOTING....................................................................................................................................... |

33 |

PATCHWORK STITCH..................................................................................................................... |

33 |

ZIPPER INSERTION................................................................................................................... |

34-35 |

NARROW HEMMING....................................................................................................................... |

36 |

CORDING ........................................................................................................................................ |

37 |

SATIN STITCH SEWING ................................................................................................................. |

38 |

QUILTING......................................................................................................................................... |

39 |

GATHERING .................................................................................................................................... |

40 |

SMOCKING...................................................................................................................................... |

41 |

FREE MOTION DARNING, EMBROIDERY AND MONOGRAMMING....................................... |

42-43 |

SCALLOP STITCH........................................................................................................................... |

44 |

TWIN NEEDLE (OPTIONAL) ........................................................................................................... |

45 |

WALKING FOOT (OPTIONAL) ........................................................................................................ |

46 |

MAINTENANCE .......................................................................................................................... |

47-48 |

REPLACING THE LIGHT BULB....................................................................................................... |

48 |

TROUBLE SHOOTING GUIDE........................................................................................................ |

49 |

II

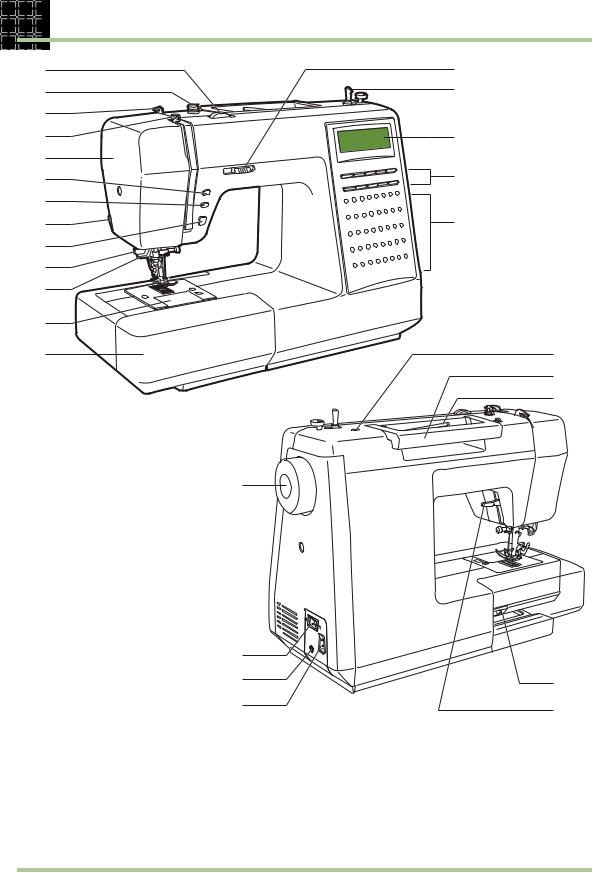

PRINCIPAL PARTS OF THE MACHINE

1 |

14 |

2 |

15 |

3 |

|

4 |

16 (A) |

5 |

17 (B) |

6 |

|

7 |

18 (C) |

8 |

|

9 |

|

10 |

|

11 |

|

12 |

|

13 |

|

1. |

Tension dial |

|

2. |

Bobbin thread guide |

|

3. |

Upper thread guide |

|

4. |

Thread take-up lever |

19 |

5. |

Face plate |

|

6. |

Needle up/down position |

|

|

button |

|

7. |

Auto-lock button |

|

8. |

Thread cutter |

|

9. |

Reverse button |

|

10. Buttonhole lever |

|

|

11. Auto needle threader |

20 |

|

12. Needle plate |

21 |

|

13. Sewing table and |

22 |

|

accessory box |

|

|

14. Speed limiting adjustment |

|

|

lever |

19. Handwheel |

24. Handle |

15. Bobbin winder |

20. Main power switch |

25. Horizontal spool pin |

16. LCD (Liquid crystal display) |

21. Foot controller connector |

26. Drop feed lever |

17. Function of buttons |

22. Power cord |

27. Presser foot lifter |

18. Stitch selection buttons |

23. Hole for second spool pin |

|

23

24

25

26

27

1

PRINCIPAL PARTS OF THE MACHINE

A. LCD (Liquid crystal display)

Needle up/ down position |

Auto-Stop Bobbin winding |

||

|

Reverse |

Mirror |

Buttonhole lever |

Normal sewing Program memory

Program memory Sewing program

Sewing program

Normal |

Presser foot |

Program

Needle position

Needle position

Sew Prog.

Pattern number Stitch length Stitch width

B. Function of buttons

Selected function |

Mirror |

Stitch width adjustment |

Verify-MEM |

Stitch length adjustment |

|

Clear-MEM |

Auto-Stop |

Stitch width adjustment |

Enter-MEM |

Stitch length adjustment |

|

C. Pattern chart

The portion marked in green on the chart below shows the one unit of each pattern.

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

29 |

30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

40 |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2

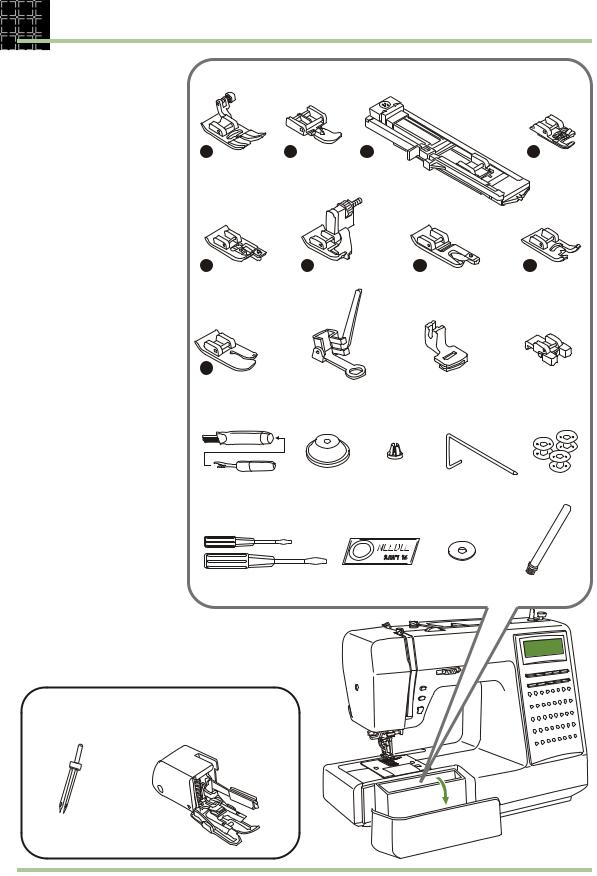

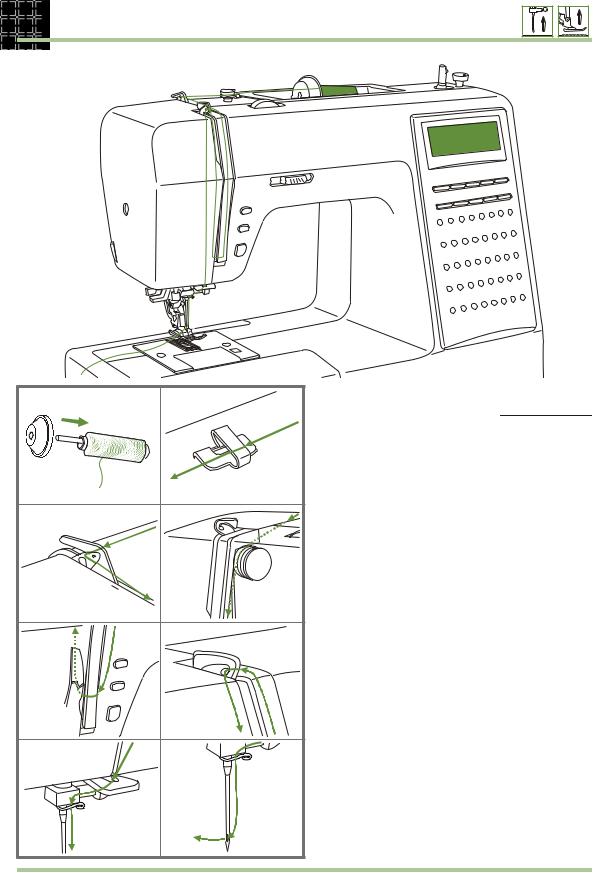

ACCESSORIES

Standard

1.All purpose foot (T)

2.Zipper foot (I)

3.Buttonhole foot (D)

4.Cording foot (M)

5.Overcasting foot (E)

6.Blind hem foot (F)

7.Hemmer foot (K)

8.Satin stitch foot (A)

9.Quilting foot (P) 10.Darning/ Embroidery foot 11.Gathering foot

12.Button sewing foot 13.Brush/ Seam ripper 14.Spool holder (Large) 15.Spool holder (Small) 16.Seam guide 17.Bobbin(3x) 18.Screwdriver (L & S) 19.Pack of needle 20.Spool pin felt 21.Second spool pin

Standard |

|

|

|

|

1 |

2 |

3 |

|

4 |

T |

I |

D |

|

M |

006186008 |

006905008 |

006102008 |

|

006813008 |

5 |

6 |

7 |

|

8 |

E |

F |

K |

|

A |

006907008 |

006904008 |

006900008 |

006172008 |

|

9 |

10 |

11 |

|

12 |

P |

|

|

|

|

006916008 |

006016008 |

006917008 |

006914008 |

|

13 |

14 |

15 |

16 |

17 |

006099008 |

R12373210 |

TA10943209 |

006008001 |

006084009 |

18 |

19 |

|

20 |

21 |

006012008 |

006014148 |

006015009 |

R60033210 |

Optional

22.Twin needle

23.Walking foot

Optional

22 |

23 |

006020008

006185008

3

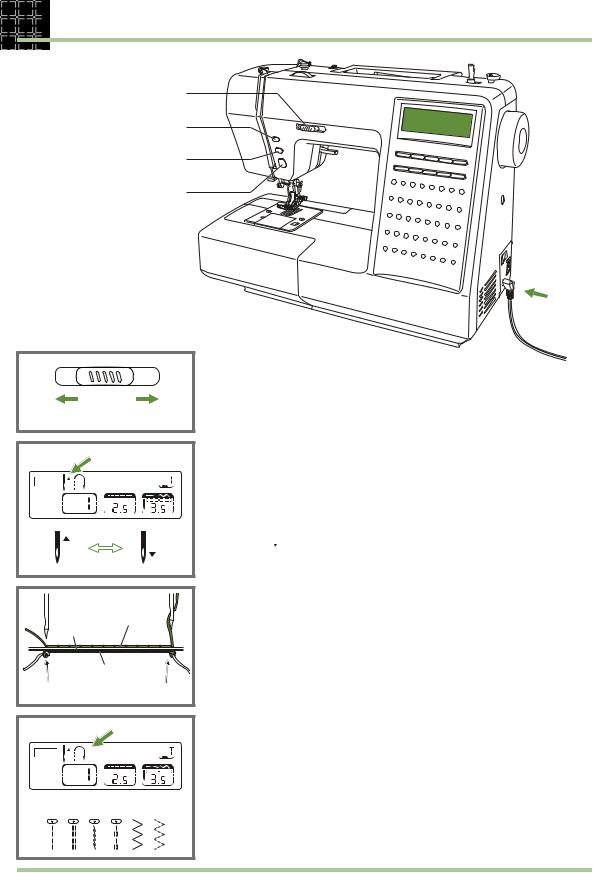

CONNECTING THE MACHINE TO THE POWER SOURCE

OFF |

ON |

Connecting the machine

Before connecting the power supply, make sure that the voltage and frequency shown on the machine is conforming with your electrical power.

Place the machine on a stable table.

1.Connect the power line cord to the machine by inserting the 2-hole plug into the terminal box.

2.Connect the power line plug to the electric outlet.

3.Turn on the power switch.

4.The sewing lamp will light up when the switch is turned on.

To disconnect, turn the power switch to the off position, then remove plug from outlet.

Polarized plug information

This appliance has a polarized plug (one blade wider than the other), to reduce the risk of electrical shock; this plug will fit in a polarized outlet only one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician. Do not modify the plug in any way.

4

CONNECTING THE MACHINE TO THE POWER SOURCE

Foot control

With the sewing machine turned off, insert the foot control plug into its connector on the sewing machine. Turn on the sewing machine, and then slowly depress the foot control to start sewing. Release the foot control to stop the sewing machine.

Note: The setting of the speed control lever will limit the maximum speed of the machine.

Attention: Consult a qualified electrician if in doubt as how to connect the machine to the power source. Unplug the power cord when the machine is not in use.

The appliance must be used with the foot controller 4C-337G manufactured by MATSUSHITA ELECTRIC (TAIWAN) CO., LTD.

Message and beeping sound

The computer will automatically adjust the needle upper position when the machine is switch on, and automatically adjust the needle lower position when you start sewing. Please note that it is a normal phenomenon if you hear a sound coming from the machine (machine adjusting sound) and feel that the sewing is being delayed. It's not dangerous to sew.

-When operating correctly: 1 beep

-When operating incorrectly: 3-short beeps

-When the sewing machine is in trouble and can't sew: 6 seconds short beeps

It means that the thread is twisted or jammed and the hand wheel axle can't move. Please look through the "Trouble shooting guide" on page 49 to find the solution. After the problem has been solved, the machine will continue to sew.

Note: If the problem is still not solved, please contact your local dealer.

Attention: During the sewing, if the thread get jammed inside the hook stopping the needle from moving and you continue pressing the foot control, the security switch will stop the machine completely. In order to restart the sewing machine, you will have to turn the on/off switch to the OFF position and the ON again.

5

OPERATION BUTTONS AND FOOT CONTROLLER

Speed limiting adjustment lever

Needle up/down position button

Auto-lock button

Reverse button

Slow |

Fast |

LCD |

|

Normal |

|

Speed limiting adjustment lever

Slide the lever to change the maximum speed of the sewing machine.

Needle up/ down position button

With the Needle up/ down position button, you decide whether the needle shall stop in the up position or in the material when you stop sewing. Press the button so that the arrow, on the LCD Screen, will point upward

and the needle will stop in the up position. When you press the button so that the arrow points downward

and the needle will stop in the up position. When you press the button so that the arrow points downward  , the machine will stop with the needle in the material.

, the machine will stop with the needle in the material.

When you turn on the machine, the needle is always in the highest position.

Upper thread

Fabric

Bobbin thread

Start |

Stop |

LCD |

|

Normal |

|

Only for pattern 1-6 |

|

Auto-Lock button

At the end of a seam, the machine will immediately sew 3 locking stitches, when the Auto-Lock button is pressed, then automatically stop.

It will sew 3 locking stitches automatically when one of the patterns 1~4 is being selected.

Reverse button (Only for pattern 1-6)

When pattern 1-6 are selected, the machine will sew in reverse while the reverse button is pressed. The machine sews forward when the button is released. For continuous reverse, press the button twice in a quick succession before starting to sew. To sew forward again, press the button once more.

An arrow  on the LCD display indicates reverse sewing.

on the LCD display indicates reverse sewing.

6

CHANGING THE PRESSER FOOT

|

a |

a |

|

|

|

|

e |

c |

|

b |

|

|

|

|

|

d |

f |

1 |

b |

|

2 |

|

|

e |

|

g |

|

|

|

3 |

4 |

|

Attaching the presser foot holder (1)

Raise the presser foot bar (a). Attach the presser foot holder (b) as illustrated.

Attaching the presser foot (2)

Lower the presser foot holder (b) until the cut-out (c) is directly above the pin

(d).

Raise the lever (e).

Lower the presser foot holder (b) and the presser foot (f) will engage automatically.

Removing the presser foot (3)

Raise the presser foot.

Raise the lever (e) and the foot will disengages.

Attaching the seam guide (4)

Attach the seam guide (g) in the slot as illustrated. Adjust according to need for hems, pleats, etc.

Attention: Turn power switch to off ("O") when carrying out any of the above operations!

REPLACING THE NEEDLE

B

A

Change the needle regularly, especially if it is showing signs of wear and causing problems.

Insert the needle following the illustrated instructions.

A.Loosen the needle clamp screw and tighten again after inserting the new needle.

The flat side of the shaft should be towards the back.

B.Insert the needle as far up as it will go.

Attention: Turn power switch to off ("O").

Needles must be in perfect condition.

Problems can occur with:

-Bent needles

-Blunt needles

-Damaged points

7

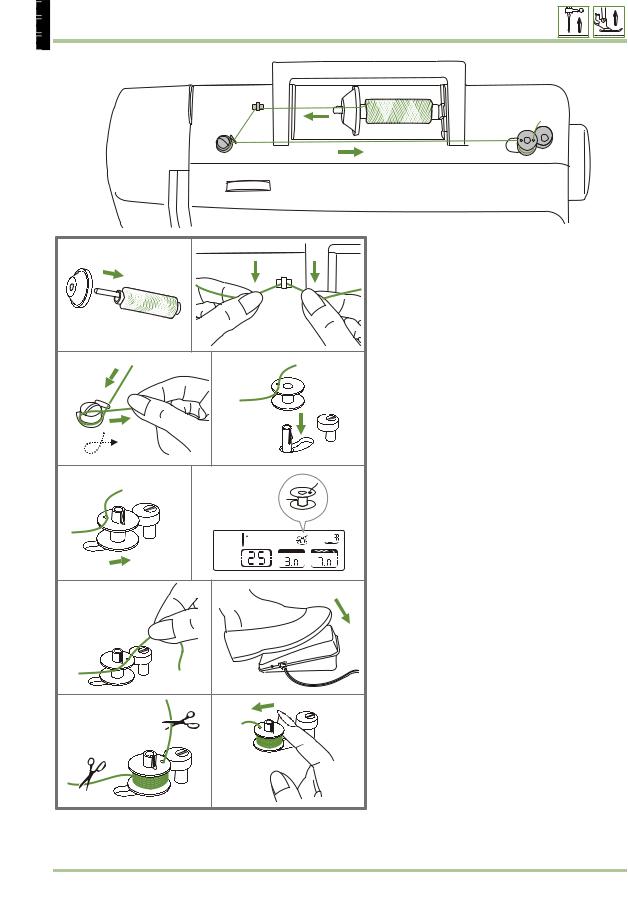

WINDING THE BOBBIN

1

|

2 |

|

3 |

1 |

2 |

3 |

4 |

|

Normal |

5 |

6 |

7 |

8 |

9 |

10 |

4~10

1.Place the thread and spool holder onto the spool pin. For smaller spools of thread, place spool holder with the small side next to the spool or use the small spool holder.

2.Snap the thread into the thread guide.

3.Wind the thread clockwise around the bobbin winder tension discs.

4.Thread the bobbin as illustrated and it on the spindle.

5.Push the bobbin to the right.

6.When the bobbin winder spindle is

push to the right, "bobbin winding position", the symbol  is shown on the LCD screen. It will disappear from

is shown on the LCD screen. It will disappear from

the LCD screen when the bobbin winder spindle is push to the left, "sewing position".

7.Hold the end of the thread.

8.Press on the foot control to start the sewing machine.

9.After the bobbin has wind few turns stop the machine and cut the thread near the hole of the bobbin. Continue filling the bobbin until it is full. The bobbin winder will stop automatically when the bobbin is full.

Stop the machine and cut the thread.

10.Push the bobbin winder spindle to the left and remove the bobbin.

Please Note: When the bobbin winder spindle is in "bobbin winding" position, the machine will not sew and the hand wheel will not turn. To start sewing, push the bobbin winder spindle to the left (sewing position).

8

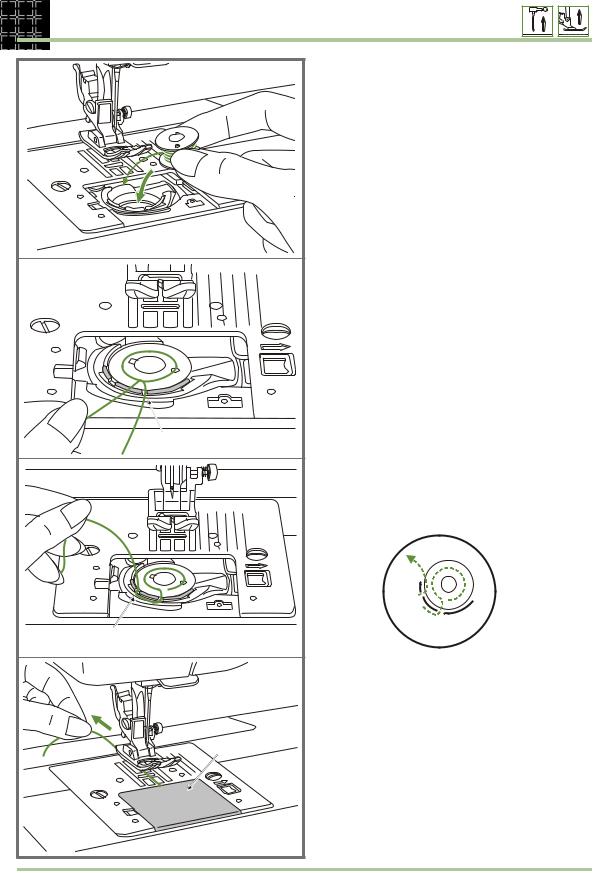

INSERTING THE BOBBIN

1 |

|

2 |

A |

|

|

3 |

B |

|

|

|

C |

4 |

|

|

9 |

When inserting or removing the bobbin, the needle must be fully raised.

1.Insert the bobbin in the bobbin case with the thread running in a counterclockwise direction (arrow).

2. Pull the thread through the slit (A).

3.Pull the thread toward the left and along the inside of the spring until it slips into the notch (B) being sure that the thread does not slip out of the slit (A).

B

A

4.Pull out about 15 cm (6 inches) of thread and attach the bobbin cover plate. (C)

Attention: Turn power switch to off ("O") before inserting or removing the bobbin.

Attention: Turn power switch to off ("O") before inserting or removing the bobbin.

THREADING THE UPPER THREAD

|

3 |

2 |

1 |

|

|

||

|

|

|

|

|

|

6 |

|

|

|

4 |

|

|

|

5 |

|

|

|

7 |

|

|

|

8 |

|

|

|

|

It is important to carry out the threading |

|

|

|

correctly as by not doing so several sewing |

|

|

|

problems could result. |

|

|

|

Start by raising the needle to its highest point, |

|

|

|

and also raise the presser foot to release the |

|

|

|

tension discs. |

1 |

2 |

|

1. Lift up the spool pin. Place the spool of |

|

|

|

thread on the spool pin so that the thread |

|

|

|

comes from the front of the spool place the |

|

|

|

spool cap at the end of the spool pin. |

|

|

|

2. Draw the thread from the spool through the |

|

|

|

upper thread guide. |

|

|

|

3. Guide the thread around the thread guide |

3 |

4 |

|

pulling the thread through the pre-tension |

|

|

|

spring as illustrated. |

|

|

|

4. Thread the tension module by passing the |

|

|

|

thread between the silver discs. |

|

|

|

5. Then, down and around the check spring |

|

|

|

holder. |

|

|

|

6. At the top of this movement, pass the thread |

5 |

6 |

|

from right to the left through the slotted eye of |

|

the take-up lever and then downwards again. |

||

|

|

|

|

|

|

|

7. Pass the thread behind the flat, horizontal |

|

|

|

thread guide. |

|

|

|

8. Now take the thread behind the needle |

|

|

|

clamp guide and then down to the needle |

|

|

|

which should be threaded from the front to |

7 |

8 |

|

the back. Pull out about 10cm (4 inches) of |

|

thread to the rear beyond the needle eye. |

||

|

|

|

10 |

USING THE NEEDLE THREADER

1 |

2 |

3 |

4 |

11 |

Raise the needle to its highest position.

Lower the presser foot.

1.Lower the needle threader lever slowly and draw the thread through the thread guide as illustrated and then to the right.

2.The needle threader automatically turns to the threading position and the hook pin passes through the needle eye.

3. Take the thread in front of the needle.

4.Hold the thread loosely and release the lever slowly. The hook will turn and pass the thread through the needle eye in forming a loop.

Pull the thread through the needle eye.

Attention: Turn power switch to the off position ("O").

THREAD TENSION

Loose |

Tight |

Surface

Surface

Reverse side

Upper thread

Bobbin thread

1

Surface

Surface

Reverse  side

side

Upper thread

Bobbin thread

2

Surface

Surface

Reverse  side

side

Upper thread

Bobbin thread

3

Surface

Surface

Reverse

side

side

Upper thread

Bobbin thread

4

-Basic thread tension setting: "4"

-To increase the tension, turn the dial to the next number up. To reduce the tension, turn the dial to the next number down.

-Proper setting of tension is important to good sewing.

-There is no single tension setting appropriate for all stitch functions, thread on fabric.

-90% of all sewing will be between "3" and "5" ("4" is basic setting).

-For all decorative sewing you will always obtain a nicer stitch and less fabric puckering when the upper thread appears on the bottom side of your fabric.

1.Normal thread tension for straight stitch sewing.

2.Thread tension is too loose for straight stitch sewing. Turn dial to higher number.

3.Thread tension is too tight for straight stitch sewing. Turn dial to lower number.

4.Normal thread tension for zig zag and decorative sewing.

12

RAISING UP THE LOWER THREAD

1 |

2 |

3 |

1.Hold the upper thread with the left hand. Turn the handwheel towards you (counterclockwise) lowering, then raising the needle.

2.Gently pull on the upper thread to bring the bobbin thread up through the needle plate hole. The bobbin thread will come up in a loop.

3.Pull both threads to the back under the presser foot.

CUTTING THE THREAD

Raise the presser foot. Remove the fabric, draw the threads to the left side of the face cover and cut using the thread cutter.

The threads are cut at the proper length for starting the next seam.

13

Loading...

Loading...