Epson 1000 ICS, CX3200, CX5200, Stylus 2000, Stylus 2500 Technical Brief

...

This technical brief provides detailed information on the Image Quality, Performance, and Flexibility of Epson Scanners.

Image Quality—Factors affecting image quality

Image Quality—Factors affecting image quality

When comparing scanners, hardware resolution and color pixel depth are two features often used to gauge image quality. These two features are important, but there are a number of factors that determine image quality in a scanner, such as the following: (Many of these elements will be discussed in detail in upcoming sections of this document.)

Optical resolution and Precision stepper motor color bit depth

for high quality sub-scan resolution

Dynamic range control

Type of lamp system used

Optic system

Quality of the Analog to Digital converter (ADC); Epson scanners have optimum performance for minimal noise and tight color registration.

Type of focus method

Color vs. monochrome CCD

The Epson Expression® and GT series scanners are Epson’s professional series scanners designed for excellence with respect to image quality, speed, usability, versatility, and durability. These scanners include the highest quality components.

The Epson Perfection® series scanners are designed for home and entry-level corporate and graphics arts users, and are designed with the highest quality components in their price class.

Image Quality—Resolution

Image Quality—Resolution

A scanner’s resolution determines the amount of data that is read by the scanner. As resolution increases, so does the file size. Resolution is measured in a variety of ways.

1.Optical resolution: This is the actual number of pixels read by the CCD (Charge Coupled Device), which measures the intensity of the light that is reflected from the image to be scanned, and converts it to an analog voltage. If a scanner has a resolution of 600 x 2400 dpi, its optical resolution is 600 dpi, which means that it can resolve 600 bits of data per inch.

2.Hardware resolution: Using a precision stepper motor to double-step or

quadruple-step the carriage, the scanner’s sub-scanner resolution can be increased. For example, a scanner can have an optical resolution of 1200 dpi, but a hardware resolution of 1200 x 2400 dpi (because it double-steps the carriage to increase the vertical resolution).

1200 dpi

1200 dpi

dpi 2400

Scanner Technical Brief—Page 1 |

6/07 |

Image Quality—Resolution (cont.)

Image Quality—Resolution (cont.)

3.Interpolated resolution: Interpolation is a method to increase the resolution of an image. It uses a complex algorithm to“add” pixels to an image based on the mathematical probability of surrounding pixels.

For example, if a scanner has a hardware resolution of 1200 x 2400 dpi, and a maximum resolution of 9600 x 9600 dpi, the scanning software uses interpolation to create scanned images with resolutions greater than the hardware resolution.

4.Benefits of higher optical resolution: Higher resolution allows you to scan the following types of images without using interpolation. Using actual image data instead of interpolated data results in more accurate images.

Line Art

When scanning black and white line art, image pixels translate exactly to the printed dots. Therefore, high resolution is required to capture and print the sharp lines and edges of an image.

2 x 2.5 inch |

If enlarged to 8 x |

image scanned |

10 inches,effective |

at 1200 dpi |

resolution:300 dpi |

Enlarging a small original

In order to capture enough detail to enlarge an image, you must increase the scanned resolution in proportion to the increase in image size. If you don’t, then you will have to interpolate image data to maintain the same resolution in the larger image.

Precise pixel editing

Many graphic artists scan images at high resolutions for precise pixel editing. It is always better to capture the image data when the image is being scanned and use true image data than to use interpolation if more data is needed later.

Image Quality—Pixel depth

Image Quality—Pixel depth

Pixel depth refers to the number of bits of data captured for each picture element (pixel). Each pixel can have two states (On or Off); therefore the number of colors or gray scales that a scanner can recognize is computed by taking the pizel depth as an exponent of two. The following charts lists the number of colors recognized for each different scan mode.

Scan mode |

|

|

Number of colors recognized |

|

|

|

|

Bi-level (1 bit per pixel) |

21 |

= 2 colors (black and white) |

|

8-bit gray scale |

28 |

= 256 shades of gray |

|

|

210 |

= 1,024 shades of gray |

|

10-bit gray scale |

|||

|

28 |

= 256 colors |

|

8-bit color (indexed color) |

|||

|

224 |

= 16.7 millions colors |

|

24-bit RGB (8 bits per pixel,per color) |

|||

|

236 |

= Over 68 billion colors |

|

36-bit RGB (12 bits per pixel,per color |

|||

|

248 |

= Over 250 trillion colors |

|

48-bit RGB (16 bits per pixel,per color) |

|||

Scanner Technical Brief—Page 2 |

6/07 |

Image Quality—Pixel depth (cont.)

Image Quality—Pixel depth (cont.)

All Epson scanners have depth, which is the data output color depth:

a 42-bit or 48-bit color depth. but some of the models support 24-bit external color that is sent from the scanner to the computer. Here are the differences between

Key Differences |

42-bit,or 48-bit Internal/ 24-bit External Color |

36-bit,42-bit,or 48-bit Internal and External |

|

Depth |

Color Depth |

How it works |

The scanner captures 42-, or 48-bit image |

The scanner captures 36-, 42-, or 48- |

|

data, but“downsamples” an image to |

bit image data and outputs all data to a |

|

24-bits, keeping the most signifi cant color |

software aplication that supports 48-bit |

|

data. |

image fi les (such as Adobe® Photoshop®). |

|

48-bit capture |

|

|

|

48-bit capture |

24-bit transfer |

48-bit transfer |

|

Image quality Because the scanner captures data that never could have been read by a 24-bit or 30-bit scanner (such as the detail in dark areas and slight color transitions), the scanner delivers more accurate images

With a 48-bit image fi le, you always have access to full image data, which is especially important to graphic artists and designers.

A greater color bit depth generally results in more accurate color reproduction, smoother gradations with fewer sudden shifts in color, and detailed shadows and highlights.

Image Quality—Epson ColorTrue® Imaging System |

|

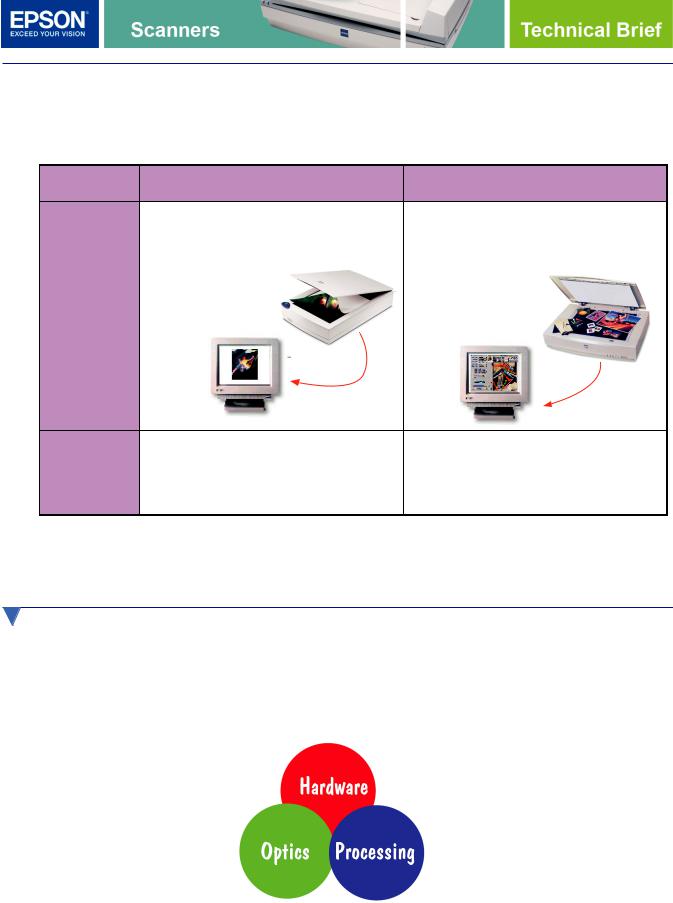

Epson scanners use the Epson ColorTrue II Imaging System which is made up of three main elements |

|

(hardware, optics, and processing) and result in superior image quality with fast processing speeds. |

|

Precise scan carriage |

|

Simultaneous RGB scanning |

|

High resolution CCD |

Pixel optimization |

Custom glass lenses |

Custom ASIC |

Scanner Technical Brief—Page 3 |

6/07 |

Image Quality—Epson ColorTrue® Imaging System (cont.)

Image Quality—Epson ColorTrue® Imaging System (cont.)

Through a combination of these hardware, optics, and processing features, the Epson ColorTrue Imaging System and Epson ColorTrue II Imaging System deliver scanned images with:

Smooth gradations |

|

|

|

|

Accurate colors |

|

|

|

|

||

Smooth edges and |

|

|

|

|

Greater detail in |

|

|

|

|

highlights |

|

minimal color fringing |

|

|

|

|

|

|

|

|

|

Sharp image quality |

|

Greater detail in shadows |

|

|

|

|

|

|

|

|

|

without distortion |

|

|

|

|

|

|

|

|

|

|

|

|

1.Hardware components: Epson scanners use a precise scan carriage with better motors to achieve subscan resolutions that are double or quadruple the scanner’s optical resolution. Additionally, Epson scanners capture Red, Green, and Blue simultaneously, versus other scanners that use one-pass scanning but alternate Red, Green, and Blue lights for each line of a scan. Epson advantages are:

Better color registration

Faster scanning speeds

Higher quality sub-scan resolutions

Epson Method |

Single-Pass Alternate RGB Method |

(1/2 or 1/4 step carriage movement) |

(1/2 step carriage movement) |

Simultaneous RGB Capture |

Red Capture |

|

|

One pass |

Green Capture |

|

|

|

Blue Capture |

|

One pass |

2.Optics: Epson scanners use custom lenses that are designed specifically to work with Epson technology and the scanner’s CCD. These lenses feature:

Larger“sweet spot” and precision lenses for reduced distortion

Accurately aligned lens elements to control sharpness

Glass lenses (versus plastic lenses used by many competitors) which offer better reflective qualities, providing greater image quality.

Better image quality than competitive off-the-shelf lenses

because Epson scanners feature custom-made lenses that |

Small“sweet spot” |

Larger“sweet |

match the CCD. |

can allow edge |

spot”minimizes |

|

distortion |

distortion |

Scanner Technical Brief—Page 4 |

6/07 |

Loading...

Loading...