Page 1

FemtoJet express

®

Bedienungsanleitung · Operating Manual

Page 2

Inhalt / Table of contents

Bedienungsanleitung. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operating Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

EG-Konformitätserklärung

EC Conformity Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Inhalt / Table of contents

Nachdruck und Vervielfältigung – auch auszugsweise – nur mit Genehmigung.

No part of this publication may be reproduced without the prior permission of the copyright owner.

©

Copyright

eppendorf is a registered trademark. Printed in Germany

2

2005 Eppendorf AG, Hamburg

Page 3

Table of contents

1 Safety precautions and application .......................................................................... 53

2 Device description ...................................................................................................... 55

2.1 Overview ....................................................................................................................... 56

2.2 Short description .......................................................................................................... 57

2.3 Startup .......................................................................................................................... 60

3 Mode of operation ...................................................................................................... 62

3.1 Display, variable regulators and keypad ....................................................................... 62

3.1.1 Setting the injection parameters ................................................................................... 62

3.1.2 Variable regulators ........................................................................................................ 63

3.1.3 Keypad .......................................................................................................................... 63

3.2 Hand control / foot control ........................................................................................... 66

3.3 Connecting the capillary holder .................................................................................... 67

3.4 Information on working practices ................................................................................. 68

3.4.1 Compensation pressure pc ........................................................................................... 70

3.4.2 Injection pressure pi ...................................................................................................... 70

3.4.3 Injection time ti .............................................................................................................. 70

3.4.4 Clean function ............................................................................................................... 71

3.4.5 Manual or automatic injection ...................................................................................... 71

3.4.6 Constant pressure / constant working pressure............................................................ 71

3.5 The first injection .......................................................................................................... 72

3.6 Connecting an Eppendorf Micromanipulator ............................................................... 73

3.7 Functions ...................................................................................................................... 75

3.7.1 Changing the capillaries ............................................................................................... 75

3.7.2 Setting the pressure unit ...............................................................................................75

3.7.3 Switching on/off the loudspeaker ................................................................................. 75

3.7.4 Switching on/off the background illumination of the display ........................................ 76

3.7.5 Constant pressure ........................................................................................................ 76

4 Cleaning and Service................................................................................................... 77

4.1 Cleaning ........................................................................................................................ 77

4.2 Disinfection ................................................................................................................... 77

4.3 Decontamination prior to shipping ............................................................................... 77

4.4 Service .......................................................................................................................... 77

5 Troubleshooting .......................................................................................................... 78

5.1 Potential errors ............................................................................................................. 78

5.1.1 Self-test ........................................................................................................................ 79

5.2 Warnings ....................................................................................................................... 80

5.3 Error messages .............................................................................................................82

Table of contents

6 Technical data ............................................................................................................. 88

7 Ordering information .................................................................................................. 89

7a Ordering information for North America ................................................................... 92

51

Page 4

Table of contents

8 Index ............................................................................................................................. 95

Appendix A

Operation via a computer ........................................................................................... 97

A.1 Description of interface ................................................................................................. 97

A.2 Commands and queries ............................................................................................... 97

Table of contents

52

Page 5

1 Safety precautions and application

•

Observe operating instructions!

•

The device is only designed for use in the research lab!

•

The FemtoJet express is a lab device. It may only be operated by appropriately qualified lab

personnel.

•

Only use the device for microinjection under observance of all relevant legal regulations!

•

Before plugging in the device, please compare your voltage requirements with the

specifications on the identification plate!

•

The unit may not be connected to a socket that is not grounded! Use the appropriate mains

cable.

•

Electrical connections may be effected only when the device is switched off!

•

The unit may be opened only by authorized service personnel!

Potentially lethal voltage inside the unit.

•

Do not use the unit if damaged. This applies in particular when the mains cable is damaged.

•

The connection of the pressure tube to the high-pressure flasks, compressors or building

pressure systems is not part of these operating instructions! The connection may only be

carried out by trained personnel or tradesmen, taking into account the local regulations.

•

The device may only be operated with dry, non-oiled, pressurized air or purified nitrogen

gas with 4000 hPa to a maximum of 8000 hPa (4 bar – 8 bar, 58 PSI – 116 PSI)!

Other gases are not permitted!

•

Loud hissing may occur when coupling or uncoupling the pressure tube! Don't be alarmed!

When coupling, hold the ears at an adequate distance from the coupling!

•

The pressure tube of the external pressure supply is not permanently UV light resistant.

When using, for example, under a sterile bench with UV sterilization, this should be taken

into account, and the pressure tube should, where necessary, be removed prior to UV

sterilization.

•

This pressure tube may not be bent. The smallest bending radius is 50 mm.

Hold the pressure tube tightly when uncoupling! The brief pressure surge when uncoupling

•

can cause the pressure tube to fly off! Following the uncoupling, the pressure tube remains

under pressure when the pressure is not released using the Standby function!

If the unit is not used in accordance with purpose for which it is intended, its protective

•

function may be impaired.

•

•

Caution!

Take care when mounting glass capillaries or tools!

Mounting must always take place without the use of pressure!

Capillaries which have been mounted incorrectly may break loose under pressure.

Never point mounted capillaries at persons.

Caution!

Take care when using glass capillaries! During mounting or when placed upon a

hard surface, the glass capillaries may break and glass splinters may cause injury.

It is therefore essential to wear eye protection!

1

Safety precautions and application

53

Page 6

1 Safety precautions and application

•

In the case of independently-manufactured capillaries, ensure that the outer diameter of the

capillary corresponds to the specifications of the capillary grip head.

•

Over longer idle periods the device should be separated from the pressurized air supply and

then depressurized using the key and stored switched off!

1

•

Use the unit only for the described purpose! The unit and in particular the high pressure of

the Clean function may not be used for purposes other than microinjection!

•

Transfer

If the device is passed on to someone else, please include the instruction manual.

•

Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

•

Information on the disposal of electrical and electronic devices in the European Community

The disposal of electrical devices is regulated within the European Community by national

regulations based on EU Directive 2002/96/EC on waste electrical and electronic equipment

(WEEE).

According to these regulations, any devices supplied after 13.08.05 in the business-tobusiness sphere, to which this product is assigned, may no longer be disposed of in

municipal or domestic waste. They are marked with the following symbol to indicate this.

•

Safety precautions and application

•

•

•

As disposal regulations within the EU may vary from country to country, please

contact your supplier if necessary.

Use only original Eppendorf accessories. Only original accessory parts may be used.

The only exceptions are auxiliary pieces of equipment recommended by the manufacturer.

Otherwise all claims under guarantee and liability become void immediately. Use other

accessories only if you have a certificate from Eppendorf AG confirming technical safety in

use.

The responsibility for the correct functioning of the device passes onto the owner or user if

the device is maintained or serviced improperly by persons not belonging to the service

team authorized by Eppendorf or if used for a purpose other than that intended. Guarantee

and conditions of liability of the terms of sale and delivery of Eppendorf AG are not

expanded by the above notes.

The Eppendorf AG reserves the right to make technical alterations to this device!

54

Page 7

2 Device description

The FemtoJet® express enables minute quantities of liquid to be injected into cells. The relevant

parameters (injection pressure pi and injection time ti) are set using the variable regulators.

The key or connected hand or foot control or the INJECT key of the connected

micromanipulator are used to trigger these two parameters. If no injections are being

performed, compensation pressure pc is applied permanently.

The connection of an external pressure supply enables faster injections, even with higher

pressure.

2

Device description

55

Page 8

2 Device description

2.1 Overview

2

Device description

1

2

3

4

1 Display

– Displays relevant parameters during injection or setting of parameters.

– Guides operator through functions.

2 Keypad

– To trigger actions.

– To call up the function menu.

– To switch to and from Standby mode.

3 Variable regulators

– To set parameters injection pressure p

– To select functions and parameters in Function mode.

4 Tube connection

– Connect the injection tube for the capillary holder to the device via the bayonet connection.

56

, injection time ti and compensation pressure pc.

i

Page 9

2 Device description

Standard accessories:

1 Pressure tube, 2,5 m, G 1/4-inch for external pressure supply incl. couplings

1 Injection tube, 2 m

1 Universal capillary holder with grip head 0 for capillary diameters

of 1.0 mm and adapter for Femtotips

1 Hand control for triggering injection and the Clean function

1 Femtotips®, Femtotips® II and Microloader

1 Mains cable

1 Operating manual

Optional accessories:

1 Foot control for triggering the Inject function

1 Connecting cable (Interface Cable 5171) to the Micromanipulator 5171 or InjectMan

®

2

Device description

®

57

Page 10

2 Device description

2.2 Short description

Display

Display of all relevant parameters and information.

2

Function keys

Device description

Clean

To apply the maximum pressure for cleaning the capillary to the tube outlet.

Auto / Manu

To switch between manual and automatic time-controlled injection.

Count

To reset to zero the counter for injections which have been actuated.

58

Inject

To execute automatic or manual injection.

Menu

To switch the device to menu control; selected functions may be executed.

Standby

When the key is pressed briefly:

To switch the device between operating mode and standby mode or vice

versa.

When the key is held down:

As above, but also deairs the valve system.

Page 11

2 Device description

Variable regulator

In the normal operating mode, the parameters for injection are set by the three variable

regulators. The arrangement of the variable regulators corresponds to the arrangement of the

parameters in the two bottom lines of the display:

From left to right: injection pressure pi, injection time ti and compensation pressure pc.

In other operating modes, the variable regulators have either the significance indicated in the

display or no significance at all.

Tube connection

The injection tube for the capillary holder is connected to the device via the bayonet connection.

2

Device description

59

Page 12

2 Device description

2.3 Startup

2

Device description

Fig. 2: Diagram of rear of device

– Electrical connection is effected via the mains socket with integrated mains switch (1).

– The connection to the external pressure supply (2) takes place via the delivered pressure

tube, 2.5 m.

– Connection to an Eppendorf manipulator designed for injection is effected via the 15-pin

interface (3).

– Optional switches (e.g. foot control, hand control) or a computer can be connected to the

9-pin interfaces (4).

4

4

3

2

1

60

Page 13

2 Device description

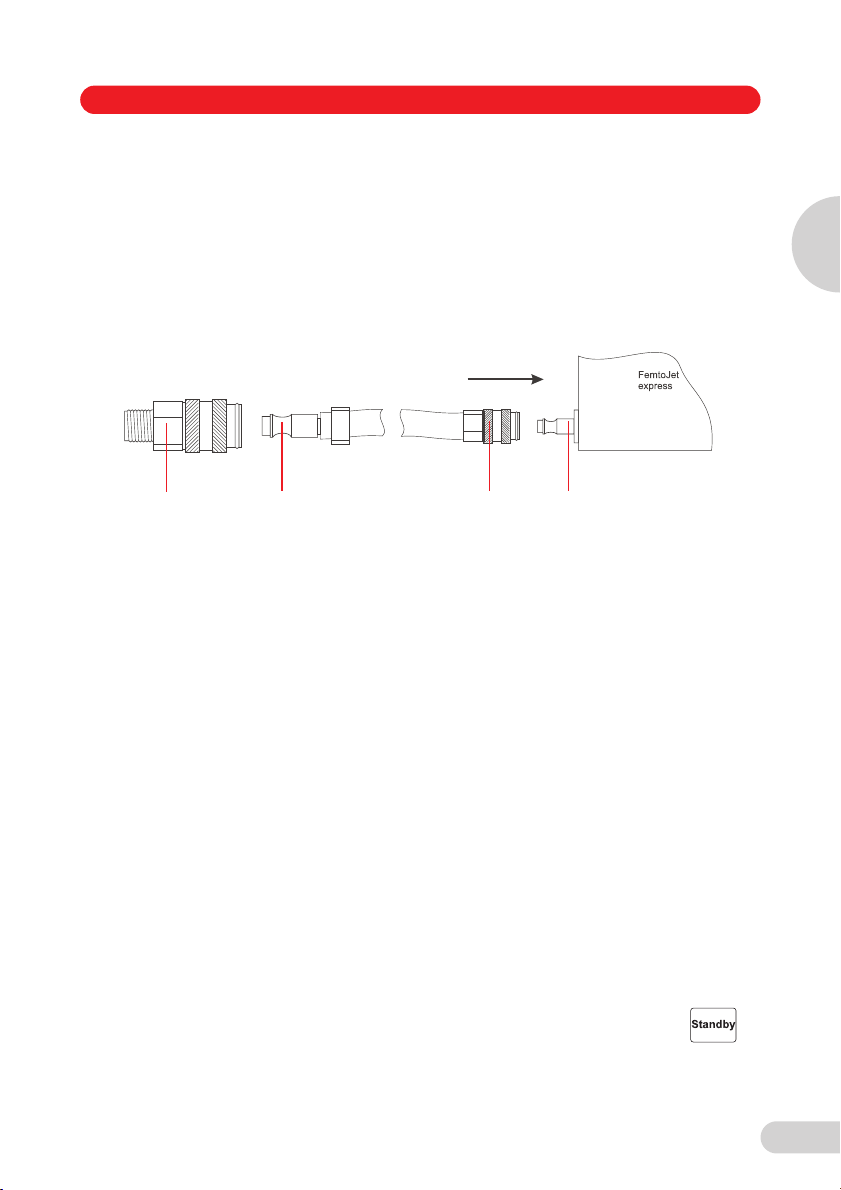

Connection of the external pressure supply

Dry, non-oiled, compressed air or purified nitrogen gas is to be used!

Pressure range from 4000 hPa to a maximum of 8000 hPa (4 bar – 8 bar, 58 PSI – 116 PSI),

constant pressure.

The connection for the external pressure supply is found on the rear side of the device.

Remove the black plastic cap.

The delivered pressure tube can be connected directly to the device.

2

Device description

1

Fig. 3: pressure tube, 2.5 m

1 Quick-lock coupling for mounting on the compressor, building pressure system

(e.g. when no connection system is available in the lab)

2 Plug sleeve, for coupling 1

3 Quick-lock coupling for connection to the FemtoJet

4 Plug sleeve to the FemtoJet® express, for coupling 3

The connection to the compressor, compressed air flask or building system can take place with

the supplied lock coupling (G1/4-inch threaded) or must be adapted by building services to the

existing connections.

The connection of the pressure tube to the high-pressure flasks, compressors or building

pressure systems is not part of these operating instructions!

Switching on the device

Connect the device to the external pressure supply. The injection tube may not be connected

when switching on and during the initialization phase.

Set the mains switch on the rear of the device to "I".

After being switched on, the unit runs through an initialization phase with self-test and valve

adjustment. Duration of approx. 1 minute.

Switching off the device

If it is not going to be used for an extended period, the device is to be separated from the

external pressure supply and to be depressurized via the switch-off routine using the

key. Then switch off the device at the rear.

2

3

®

express

4

61

Page 14

3 Mode of operation

3.1 Display, variable regulators and keypad

Before operating the device for the first time, users should read this section carefully. This

section describes operation of the device only. Handling of the injection capillaries is described

in Section 3.3.

3

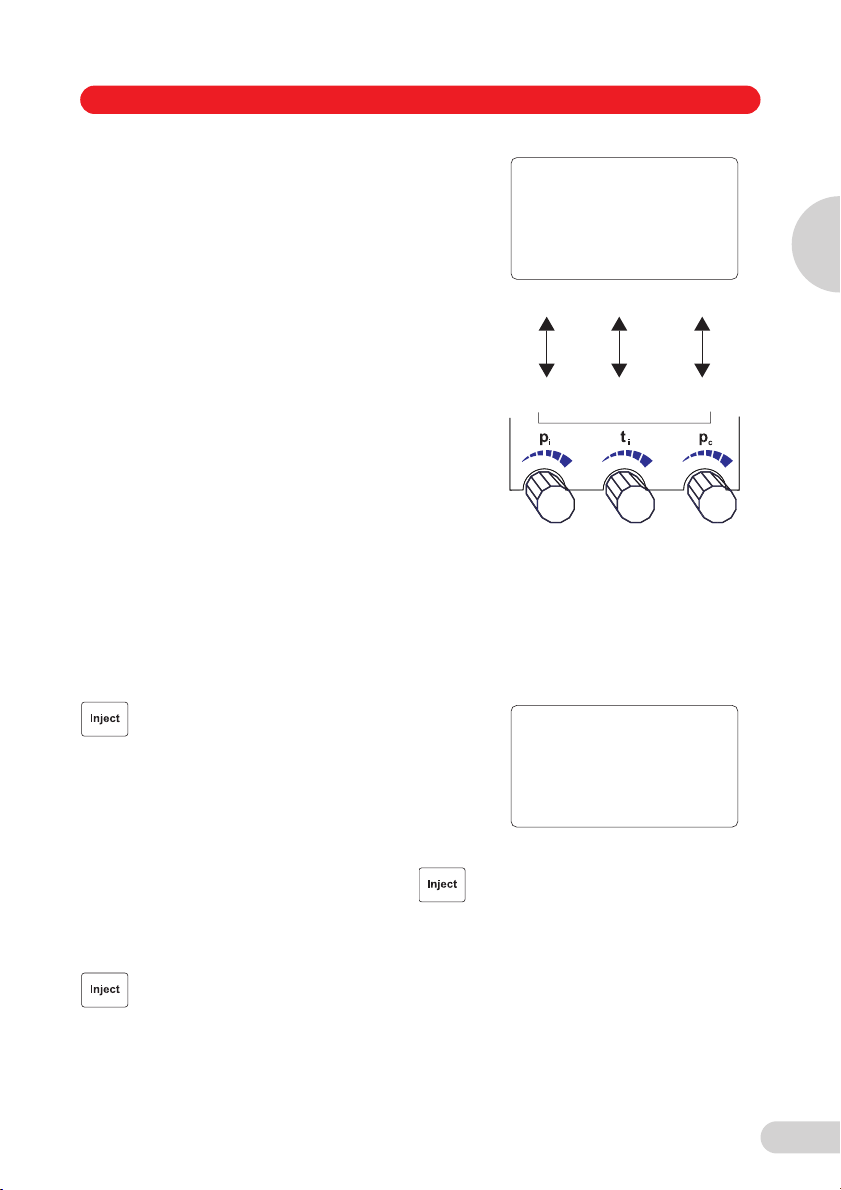

AUTO n= 0

pi= 150 hPa

Supply pressure 5261

pi[hPa] ti[s] pc[hPa]

150 0.2 50

AUTO n= 0

Mode of operation

pi= 2.15 PSI

Supply pressure 76.3

pi[PSI] ti[s] pc[PSI]

2.15 0.2 0.72

3.1.1 Setting the injection parameters

The injection parameters have to be adapted to the injection capillaries used and the cell type

and liquid which are to be injected.

The following injection parameters can be set using the variable regulators:

Injection pressure p

Injection time t

Compensation pressure p

The settings are in increments of 1 hPa/0.1 s. The display can show hPa or psi, as required.

The setting and internal pressure conversion are always performed in hPa. Rounding for the

display in psi can result in increments of 0.01 to 0.02 psi.

The display of pressure in psi varies according to the size of the value (e.g.: 9.99 may also

appear in the display as 10.0).

Note:

An adjustment of pi or pc above the internally adjacent system pressure ps doesn't make sense.

The values for pi, pc should lie at least 500 hPa (7.2 PSI) below the system pressure in order to

ensure secure valve regulation.

Slight deviations between the nominal value (specified value) and displayed compensation

pressure pc (actual value) may occur for technical reasons. The relevant value is the actual value

measured.

Display

The display shows the following:

1st line:

injection mode AUTO or MANU,

counter n for number of injections performed

2nd line (bold):

The most-recently set parameter or relevant parameter

Middle line:

In the device, adjacent maximum system pressure p

Bottom lines:

Parameters which affect injection

Compensation pressure p

the normal mode is displayed as an actual measured value.

The arrangement of the three parameters shown, pi, ti, pc,

corresponds to the arrangement of the variable regulators.

0; 5 – 6,000 hPa (0.00; 0.07 – 87.0 psi)

i

0.1 – 99.9 s

i

0; 5 – 6,000 hPa (0,00; 0.07 – 87.0 psi)

c

which is applied permanently in

c

.

s

62

Page 15

3 Mode of operation

The following settings are used as a basis for initial

injection experiments using Femtotip® / Femtotip® II:

Display:

p

left-hand variable regulator: 150 hPa

i

ti central variable regulator: 0.5 s

pcright-hand variable regulator: 50 hPa

Variable regulators:

3.1.2 Variable regulators

The variable regulators are set so that when they are turned slowly, the values are changed by

1 hPa / 0.1 second per notch (0.01 – 0.02 psi).

If the regulators are turned faster, the values are altered in larger increments.

3.1.3 Keypad

Inject

AUTO n= 0

pi= 150 hPa

pi[hPa] ti[s] pc[hPa]

150 0.5 50

AUTO - INJECT n= 0

3

Mode of operation

Performs automatic or manual injection. Automatic

injection is controlled via the injection time ti, and the

injection pressure pi is used. In the second line, injection

time ti is counted down from the nominal value.

Manual injection is performed for as long as the key is held down. Injection pressure p

used. In the second line, injection time ti is counted upwards from 0.0.

If the FemtoJet® express is connected to the Eppendorf Micromanipulator InjectMan® NI 2,

5171 or Inject Man® the injection movement of the micromanipulator is also started via the

key. Both units then combine as a system to perform semi-automatic microinjection.

Alternatively, the INJECT key of the connected micromanipulator or the hand / foot control can

be used.

If synchronization is set to "limit" (SYNC = LIMIT) in the INJECT function of the micromanipulator, semi-automatic injection can only be triggered via the micromanipulator.

Supply pressure 5261

pi[hPa] ti[s] pc[hPa]

0.4 s

150 0.6 50

i

is

63

Page 16

3 Mode of operation

Clean

CLEAN n= 0

The maximum available pressure for cleaning is applied

at the tube outlet for as long as the key is held down.

3

Once the key is released, the pressure drops to

compensation pressure pc again. The pressure curve is

shown in the form of a bar.

Auto / Manu

To switch between manual and automatic,

time-controlled injection.

In the case of manual injection, time is counted upwards

from 0.0 seconds. The parameter ti is not displayed in the

Mode of operation

bottom two lines in order to emphasize that the time

cannot be set via the variable regulators in this case.

Count

To reset to zero the counter for injections which have

been actuated.

Menu

To switch the device to menu control; selected functions

may be executed.

In the first line, FUNC indicates that the device is in the

function menu and shows which function number is

active.

The second line contains the function description

(e.g. "Select pressure unit").

The third line requests an action (e.g. press the ,

key to change the pressure unit).

Current status: [hPa]

The two bottom lines show information about which

action is assigned to which variable regulator

(e.g. other functions can be selected using left-hand

variable regulator pi).

≡≡≡≡≡≡≡≡≡≡≡≡≡≡≡_____

Supply pressure 5261

pi[hPa] ti[s] pc[hPa]

150 0.2 50

MANU - INJECT n= 0

0.4 s

Supply pressure 5261

pi[hPa] pc[hPa]

150 50

FUNC 1

Push Inject to select

Pressure Unit hPa

Turn pi to

select function

PSI

64

Page 17

3 Mode of operation

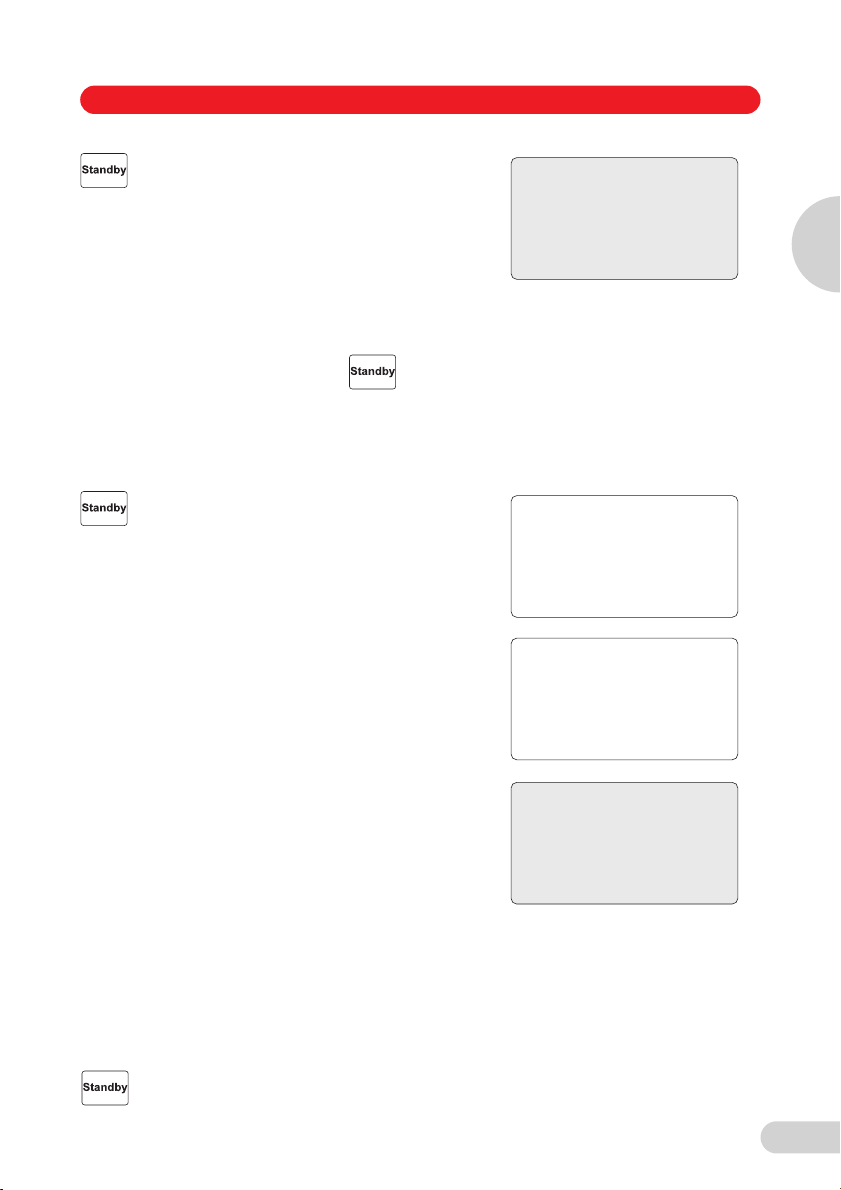

Standby

in the case of a brief interruption

When key is pressed briefly:

The device switches to the Standby mode without

deairing. The illumination of the display switches off.

"STANDBY" appears in the display with the suffix

"Supply pressure = rxyz" as a code for system pressure

ps being maintained.

Application:

For temporary interruptions or use of as a Reset

function.

When key is pressed again:

The device is reactivated and runs through a warm-up

routine. This lasts approximately one minute.

Standby

with deairing of pressure accumulator

Hold down the key (approx. 2 seconds; the display

moves to "STANDBY"):

The device switches to the Standby mode. The valve

system is completely deaired, the illumination of the

display switches off.

In addition to WAIT, the display also instructs that the

compressed air supply is to be separated from the

device. At the same time, some of the system pressure is

released in order to support this instruction.

A noise can be heard at this stage.

"STANDBY" appears in the display with the note

"Supply pressure = x" (x ~ 0).

Application:

For correct shutdown, with deairing of the entire pressure

system in the event of longer periods of non-use or

standstill (weekend or storage) with subsequent

switch-off using the mains switch.

Press the key again:

The device is reactivated and runs through the warm-up

routine.

STANDBY

3

Supply pressure 6789

Mode of operation

Hold standby

to exhaust

WAIT

Close supply pressure

Supply pressure 5261

STANDBY

Supply pressure 0

Reset

To reset the device to the initial mode by pressing the

key briefly or via the mains switch.

65

Page 18

3 Mode of operation

3.2 Hand control / foot control

3

Mode of operation

The functions of the hand / foot control correspond to the

functions of the and keys on the FemtoJet® express.

The function of the foot control corresponds to the

key.

66

Page 19

3 Mode of operation

3.3 Connecting the capillary holder

Universal capillary holder

The universal capillary holder is used to locate the injection capillaries. Prefabricated Eppendorf

Femtotips® / Femtotips® II (6) are screwed into the universal capillary holder using the adapter

(5). To do so, the adapter for Femtotips® (5) is first screwed into the front rotatable knurled

screw (4) and then the Femtotip® / Femtotip® II is attached. If self-pulled capillaries are to be

attached, the grip head 0 (7) needs to be screwed loosely into the front rotatable knurled screw

(4). The self-pulled capillary is pushed into the front opening of the grip head through the two

O-rings and fixed in position by tightening the grip head.

2

1

Universal capillary holder

1 Tube connection

2 Rear knurled screw

3 Tension piece

4 Front knurled screw, rotatable

5 Adapter for Femtotips

6 Femtotip® / Femtotip® II

7 Grip head 0, plastic, with two O-rings and sealing washers

3456

7

®

(microcapillaries for microinjection)

3

Mode of operation

Connecting the universal capillary holder

The two-meter-long injection tube is connected to the switched on FemtoJet® express (1) via

the bayonet joint (2). The pressure tube (3) is screwed to the rear knurled screw (4) of the

universal capillary holder. Femtotips® / Femtotips® II are fitted at the front end of the universal

capillary holder (5) or independently-manufactured capillaries are clamped with the aid of the

appropriate grip head.

2

1

34 5

67

Page 20

3 Mode of operation

Other accessories

3

3.4 Information on working practices

The following pressures can be used:

Mode of operation

Name Pressure range Comments

Grip head 0,

incl. 2 sets of O-rings and sealing washers.

Using grip head 0 supplied, capillaries with an outer diameter of 1.0 mm

to 1.1 mm can be used. In the case of outer diameters which differ from

these measurements, the relevant grip heads can be ordered as

non-standard accessories for the universal capillary holder

(see Section 7, Ordering information). The transparent grip head allows

the user to visually monitor the position of the capillary.

Compensation

pressure pc

Injection pressure p

Clean pressure maximum

Constant working

pressure pw

System pressure p

[supply pressure]

The usual values for the permanent compensation pressure P

for Femtotips® and similar capillaries. The FemtoJet® express shows good, constant values

within this range Immediately after the device is switched on and maintains the balance between undesired absorption of medium on the one hand and excessive loss of the liquid to be

injected on the other hand.

Quite low Pc values are sometimes advisable for special applications (e.g. capillaries with an

interior diameter of 5 µm and greater)! In order to be able to also work precisely and efficiently

here, the FemtoJet® express should be switched on app. 60 to 90 minutes before beginning the

experiment to guarantee the correct thermal settings. A pressure setting below 5 hPa is not

possible. You may merely also set 0 hPa.

i

s

0; 5 – 6,000 hPa

0.00; 0.07 – 87.0 psi

0; 5 – 6,000 hPa

0.00; 0.07 – 87.0 psi

up to 7,000 hPa

maximum up to 102 psi

0; 5 – 6,000 hPa

0.00; 0.07 – 87.0 psi

maximum

up to 7,000 hPa

maximum up to 102 psi

Or up to 500 hPa less than the

system pressure p

Or up to 500 hPa less than the

system pressure p

Or up to 500 hPa less than the

system pressure p

Select Function 4 via the

key.

This is used directly for

.

are between 30 – 50 hPa

c

s

s

s

68

Page 21

3 Mode of operation

An internal self-calibration of 3 seconds for more precise adjustment of the pressure takes

place every 10 minutes. No injection is carried out during this time.

Injection can continue as usual following the self-calibration.

An already activated injection will be carried out by the FemtoJet express. The self-calibration

takes place afterward.

Message during the self-calibration on the display of the FemtoJet express:

3

WAIT

A brief signal sounds at the beginning and end of the

self calibration

If the FemtoJet express is connected with the InjectMan NI 2, the following message appears on

the display of the micromanipulator:

Warning 001

Check Injector and cable

calibration.

Press the joystick button again to repeat the injection.

Press joystick button

Self-calibration intervals:

– In the first hour after the machine is switched on: every 10 minutes.

– Afterwards: Every 30 min at pc < 30 hPa or every 15 min at pc > 30 hPa

following the last activation.

Mode of operation

69

Page 22

3 Mode of operation

3.4.1 Compensation pressure pc

The compensation pressure pc ensures that no medium flows into the capillary. Capillary forces

would make liquid flow out of the cell culture dish into the injection capillary and thus dilute the

injection material. To prevent this, a permanent compensation pressure pc is set. This should be

3

selected so that there is a permanent slight flow-out of liquid from the injection capillary. The

individual pressure level can be determined in a preliminary test. For example, a fluorescent dye

can be added to the capillary to enable outflow to be monitored directly. The pressure required

is heavily dependent on the surface tension and viscosity of the injection material. Experience

has shown that compensation pressures of between 30 hPa and 300 hPa (0.44 – 4.4 psi) are

appropriate values for ready-to-use Eppendorf Femtotips® injection capillaries.

Capillary suction

Compensation pressure p

c

Mode of operation

Hydrostatic pressure P

Pressure in the capillaries

3.4.2 Injection pressure p

Injection pressure pi is applied during the injection process. This pressure is generally higher

than the compensation pressure. In many cases, a pressure between 50 hPa and 500 hPa

(0.73 – 7.2 psi) is appropriate for Femtotips®. The volume injected is dependent on the injection

pressure and the injection time. The injection pressure must be greater than the internal

pressure of the cell into which injection should take place. However, if the cell or the cell nucleus

swell up during injection, the injection pressure is too high.

3.4.3 Injection time t

Injection time ti gives the period for which injection pressure pi is maintained. ti is usually

selected from a range between approx. 0.3 s and 1.5 s. The relevant factor for the injected

volume is the product of the injection pressure and the injection time.

Depending on the setting on the Eppendorf Micromanipulator which is connected, the injection

time ti is measured from the point at which the key is pressed. The injection pressure is

built up immediately, so it is already present

during the injection movement and during penetration of the cell. Once the end of injection time

has been reached, the device switches to compensation pressure pc. At the same time, the

micromanipulator is moved back into the working level. When "Injection at Z limit" is set,

measurement of the injection time ti does not begin until the Z limit has been reached. Once ti

has elapsed, the FemtoJet® switches back to pc and the micromanipulator moves back into its

starting position in the working level

i

i

hyd

70

Page 23

3 Mode of operation

3.4.4 Clean function

The Clean function is used to flush out blocked capillaries. The maximum available pressure is

applied to the outlet with the key. It is applied for as long as the key is pressed.

The maximum pressure of the FemtoJet® express is in the range of 7,000 hPa (102 psi) within

the range of the displayed system pressure. The value cannot be changed.

The pressure curve up to maximum pressure appears in the display in the form of a bar chart.

By pressing the key briefly, a lower pressure can also be obtained.

3.4.5 Manual or automatic injection

In the Manu operating mode, injection is performed for as long as the key or hand / foot

control is held down. The duration (ti) of injection is measured and shown in the display. In the

case of combination with an Eppendorf Micromanipulator, the injection movement is triggered.

In the Auto operating mode, the built-in timer facilitates a reproducible injection time.

The injection runs automatically for the duration of set time ti. It is triggered by the key or

the hand / foot control being pressed briefly. During injection, the Inject key is

inactive, i.e. pressing it again has no effect. In combination with an Eppendorf Micromanipulator, the automatic injection procedure can also be triggered from the operating panel of the

micromanipulator.

3.4.6 Constant pressure / constant working pressure

Using the Constant Pressure function, it is possible to select a higher pressure permanently if

required. This function is helpful when special injection techniques require either a high pressure

up to a maximum of 6,000 hPa (87 psi) or a permanent flow of injection solution

(see Section 3.7.5). Control accuracy drops in the pressure range from 2,000 – 6,000 hPa

(29 – 87 psi).

3

Mode of operation

71

Page 24

3 Mode of operation

3.5 The first injection

The following are available:

3

• Adherent cells in a Petri dish,

• Injection liquid (purified, e.g. by centrifugation),

• Femtotips

• Microloader,

• 0.5 – 10 µl pipette to take the Microloader,

• A universal capillary holder on the micromanipulator which has been preadjusted with a

Femtotip®.

Filling the Femtotips® with the Microloader:

Mode of operation

– Select function 0 "Capillary exchange" by pressing . Connect the pressure tube.

– Aspirate approximately 0.5 – 5.0 µl of centrifuged injection fluid with the Microloader

without touching the base of the vessel. Using the Microloader, fill the Femtotip® through

the rear opening, inserting the tip approximately up to the centre of the Femtotips

releasing the fluid there.

– Hold the Femtotip® vertically, loosen the cap by turning it and allow it to drop vertically.

– Screw the Femtotip® into the capillary holder.

– Complete Function 0 by pressing Compensation pressure is applied.

– Move the capillary into the cell medium (Petri dish) with the micro-manipulator.

– Focus the cells with the microscope, position the capillary slightly above the cells but do

not allow it to come into contact with the base of the Petri dish. Focus the capillary.

– Using the key, check that the capillary is not blocked. Either the fluid can be seen

flowing out or it is rendered visible by the fluorescent substance it entrains.

As a rule, any air bubbles present are blown out.

– Perform a sample injection using the preset parameters (e.g. pi ~ 150 hPa, ti ~ 0.5 s,

~ 50 hPa, corresponding to pi ~ 2.18 psi, ti ~ 0.5 s, pc ~ 0.73 psi). Injection can be

p

c

monitored visually when the cell size changes by approx. 5 % to 10 % or via fluorescence.

If required, adapt parameters p

®

/ Femtotips® II; other capillaries as an alternative

and/or ti.

i

®

and

72

Page 25

3 Mode of operation

3.6 Connecting an Eppendorf Micromanipulator

Connection to an Eppendorf Micromanipulator designed for automated injection is effected with

the 15-pin interface.

12 3 4 56

FemtoJet® express (rear) with all connection options, with InjectMan® NI 2

1 Foot control (optional) with Inject function

2 Hand control with Inject and Clean functions

3 FemtoJet® express

4 Micromanipulator InjectMan® NI 2

5 Connection socket of micromanipulator for Interface cable FemtoJet

6 Interface cable FemtoJet® express (accessories: InjectMan® NI 2)

7 Interface of FemtoJet® express to micromanipulator

7

3

Mode of operation

73

Page 26

3 Mode of operation

12 3 4 5 6

3

FemtoJet® express (rear) with all connection options, with power unit 5171 / InjectMan 5179

Mode of operation

1 Foot control (optional) with Inject function

2 Hand control with Inject and Clean functions

3 FemtoJet® express

4 Micromanipulator 5171 or InjectMan

5 Connection socket of micromanipulator for

Transmission cable 5246 ("Y cable")

6 Transmission cable 5246

(accessory for Micromanipulator 5171 and InjectMan®)

7 Interface cable 5171 (optional)

(Connection from FemtoJet® express to Transmission cable 5246 "Y cable")

8 Interface of FemtoJet® express to micromanipulator

8

7

®

74

Page 27

3 Mode of operation

3.7 Functions

The Function menu is called up using the key. One of seven functions is selected using

left-hand variable regulator pi.

The relevant functionality is assigned to the variable regulators in the bottom line of the display.

Exit the Function menu by pressing the key again.

In cases of error, pressure control is switched off from within the Function menu. Then exit the

Menu using the key.

Function 6, self-test, is described in Section 5, "Troubleshooting".

Function 5 is not planned for the FemtoJet® express.

3.7.1 Changing the capillaries

FUNC 0

Change capillary

Capillary may be

changed now

Turn pi to

select function

3.7.2 Setting the pressure unit

FUNC 1

Push Inject to select

Pressure Unit hPa PSI

Turn pi to

select function

FUNC 0

When this function is called up, the pressure tube is

deaired and any pressure present in the system is let out.

Once the capillary has been changed, exit the function

using the key or variable regulator p

pressure control will restart.

FUNC 1

The other pressure unit is selected using the key

and all pressure values are converted.

The pressure unit currently selected (in this case: hPa)

is underlined.

;

i

3

Mode of operation

3.7.3 Switching on/off the loudspeaker

FUNC 2

Push Inject to select

Beeper ON OFF

Turn pi to

select function

FUNC 2

Use the key to switch the loudspeaker on or off.

The currently selected setting (in this case: ON) is

underlined. Acoustic error messages are not emitted if the

setting is OFF.

75

Page 28

3 Mode of operation

3.7.4 Switching on/off the background illumination of the display

FUNC 3

Push Inject to select

3

Mode of operation

Illumination ON OFF

Turn pi to

select function

3.7.5 Constant pressure

FUNC 4

Continuous flow

INJECT = start

Turn pi to

select function

FUNC 3

Use the key to switch the illumination on or off. The

currently selected setting (in this case: ON) is underlined.

In the normal operating mode, illumination switches off after

three minutes if no operating control has been actuated.

When an operating control is actuated, the illumination

lights up again.

FUNC 4

This function can be used to apply a constant working

pressure pw in the range from 5 to 6,000 hPa (87.0 psi) at

the pressure outlet. The pressure unit psi can also be used.

FUNC 4

Continuous flow

pw= 50 hPa

Supply pressure 5261

Turn pi to pw[hPa]

select function 50

76

The working pressure pw is set with the right-hand variable

regulator (p

characters. The actual value is shown in the bottom right of

the display.

The Clean function can be activated. The pressure of the

Clean function is shown in the bottom right of the display in

the form of pw.

), the specified value is shown in large

c

Page 29

4 Cleaning and Service

4.1 Cleaning

Before cleaning the FemtoJet® express disconnect the plug.

Ensure that no fluids enter into the inside of the injector in order to avoid short-circuits in the

electrical installation as well as corrosion.

Wipe painted parts and aluminum surfaces using a cloth and mild detergent and then with a dry

cloth.

Warning: Do not use any corrosive, solvent or abrasive detergents or polishes.

4.2 Disinfection

Clean the FemtoJet

Wipe every part of the FemtoJet® express, including accessories and connector cables, with

disinfectant like alcohol (ethanol, isopropanol) or alcoholic disinfection media.

Spray disinfection is not advisable, as disinfectants can enter into the microinjector.

The disinfection method used must comply with current disinfection

regulations and guidelines.

4.3 Decontamination prior to shipping

If the device is to be inspected, repaired or calibrated by the service partners of the

Eppendorf AG, it must be free of hazardous substances and clean!

A decontamination certificate must accompany the FemtoJet

A printed form ("Decontamination certificate for return of goods" and general instructions for

decontamination are available at our www.eppendorf.com homepage.

The serial number of the device must be entered in the decontamination certificate.

®

express before disinfecting.

®

express.

4

Cleaning and Service

4.4 Service

Warranty or service is taken over by the supplier or the service partner of the

Eppendorf AG.

77

Page 30

5 Troubleshooting

5.1 Potential errors

– Pressure loss due to capillary not fitted with capillary holder connected.

Solution: Connect the capillary or select Function 0,

5

– Capillary is blocked.

Solution: Press the key for long enough.

Change capillary via the key and variable regulator pi.

Change capillary.

Purify injection fluid (e.g. by means of centrifugation).

– System pressure ps (or external pressure) sinks to

less than 4,000 hPa (58 PSI). This is represented by

Troubleshooting

the instruction avove the entry Supply pressure in the

display.

If an injection or cleaning is activated in this status,

this will trigger Warning 1 (Chapter 5.2).

– Valve rattles

Solution: Connect tube to filled capillary.

Pressure control is designed for the tube connected.

– No communication with the micromanipulator.

Solution: Check cables and connections.

AUTO n= 0

pi= 150 hPa

Apply supply pressure

Supply pressure 3999

pi[hPa] ti[s] pc[hPa]

150 0.2 50

78

Page 31

5 Troubleshooting

5.1.1 Self-test

FUNC 6

Self-Test

INJECT = Complete

CLEAN = Leak only

Turn pi to

select function

FUNC 6

The FemtoJet® is checked for leaks in the self-test.

This self-test can also be used if a leak is suspected.

The test runs automatically.

The pressure tube must be connected to a closed capillary

(e.g. melted closed or filled) for the pressure control to work

properly.

5

Troubleshooting

FUNC 6

Self-Test

Ps leak _____ _____ hPa

Pw leak _____ _____ hPa

Injection _____ _____ hPa

ps=7000 pw= 18 hPa

FUNC 6

Self-Test

Ps leak _____ _____ hPa

Pw leak _____ _____ hPa

ps=7000 pw= 18 hPa

key: Complete self-test

– In the case of two different pressures, checks for leaks

in the pressure accumulator (ps) and for the internal

tightness of the valves.

– Checks for leaks in the area of working pressure (pw)

in the case of two different pressures.

– Checks behavior during injection

at different pressures (short continuous test).

If certain values are outside the specified range, an error

message is emitted. If this recurs, inform Service.

key: Self-test to search for leaks

– Checks for leaks in the pressure accumulator (p

) in the

s

case of two different pressures, as well as for inner

tightness of the valves.

– Checks for leaks in the area of working pressure (pw) in

the case of two different pressures.

If certain values are outside the specified range, an error

message is emitted. If this recurs, inform Service.

79

Page 32

5 Troubleshooting

5.2 Warnings

As a rule, warnings are emitted if certain operating conditions are not (yet) reached or if an

action is not possible.

5

Acknowledge the warning with the key and the unit will return to normal status.

INJECT = Continue

Troubleshooting

WARNING 002

Check capillary

e.g. broken/missing ?

Warning 2

Compensation pressure cannot be maintained.

Possible cause:

Capillary or capillary holder not attached or only connected

loosely.

Solution:

Check all connections and tighten.

Activate Function 0 to change the capillary and when the

capillary holder is open.

WARNING 003

Switch on manipulator

or disconnect cable

INJECT = Continue

WARNING 004 4133

Supply pressure

is instable

please switch off/on

INJECT = Continue

Warning 3

Micromanipulator does not react.

A micromanipulator is connected but does not react to a

start pulse from the FemtoJet

®

express.

Possible cause:

Micromanipulator is switched off.

INJECT function on manipulator is not released.

No limit is set on the micromanipulator.

In the INJECT function on the micromanipulator,

synchronization is set to limit (SYNC = LIMIT).

Solution:

Switch on the micromanipulator and make it operational.

Disconnect the cable to micromanipulator.

With SYNC = LIMIT, trigger semi-automatic injection via the

micromanipulator only.

Warning 4

The attached external pressure has changed greatly. When

switched on, the automatic valve adjustment took place for

a different pressure (displayed value to upper right).

Solution:

Switch device off and on again. The automatic valve adjustment will be carried out with the present pressure.

Note:

This warning is issued only once. Pressing the

key will remove the error message. It will

generally be possible to continue work. However, optimal

valve regulation should not be anticipated.

80

Page 33

5 Troubleshooting

WARNING 005

Supply pressure

is too low

INJECT = Continue

WARNING 006 4202

Supply pressure

is lower than +500 hPa

INJECT = Continue

Warning 5

External pressure is insufficient.

The minimum supply pressure required for an injection or

the Clean function was not present when the function was

triggered.

Possible cause:

There is no external pressure supply, it is not connected or

supplies too little pressure (< 4,000 hPa).

Solution:

Connect external pressure supply and select the external

pressure within the range from 4,000 – 8,000 hPa.

Warning 6

Injection pressure (or compensation pressure) is close top

the external pressure.

An injection pressure is required that is not at least

500 hPa below the external pressure (value displayed to

the upper right).

Possible cause:

External pressure is set too low.

Injection pressure has been (accidentally) set too high.

Injection pressure has been intentionally so set.

Solution:

Increase external pressure or reduce injection pressure.

Note:

This warning is issued only once. Pressing the

key will remove the error message. It will

generally be possible to continue work. However, optimal

valve regulation should not be anticipated.

5

Troubleshooting

WARNING 007

Supply pressure

is too low

INJECT = Continue

Warning 7

External pressure is insufficient.

Possible cause:

There is no external pressure supply, it is not connected or

supplies too little pressure (< 4,000 hPa).

Solution:

Connect external pressure supply and select the external

pressure within the range from 4,000 – 8,000 hPa.

81

Page 34

5 Troubleshooting

5.3 Error messages

Error messages are emitted if certain operating conditions are not reached or the device records

a deviation from specified conditions.

5

Acknowledge the error message with the key and the unit will return to normal status.

The measures described under “Solution” should be carried out. If the error message recurs

after acknowledgement with the key, inform Service.

Some errors can only occur in connection with the FemtoJet® 5247 device (with internal

compressor).

Supply pressure

Troubleshooting

cannot be reached

INJECT = Continue

Supply pressure is

INJECT = Continue

ERROR 010

ERROR 011

too high

Error 10

Supply pressure cannot be reached

The compressor runs without the maximum supply

pressure being reached.

Possible cause:

High compensation pressure when the capillary holder is

not attached or is poorly attached.

Technical cause:

Compressor does not start up. Leak in compressor or

pressure accumulator.

Solution:

Check the capillary holder and tube for leaks or tighten up

the tube connections.

Service.

Error 11

Supply pressure is too high

Supply pressure has exceeded the maximum permissible

supply pressure.

Possible cause:

Internal pressure limiter is defective.

Supply pressure is not relieved by the relevant standby

function.

Technical defect.

Solution:

Service.

Switch off using the key (hold down for approximately two seconds).

82

Page 35

5 Troubleshooting

ERROR 012

Supply pressure

does not fall

INJECT = Continue

ERROR 013

Supply pressure

does not raise

INJECT = Continue

ERROR 014

Supply pressure

leak is too high

INJECT = Continue

ERROR 015

Supply pressure

leak is too high

INJECT = Continue

ERROR 016

Valve 1 pressure

leak is too high

INJECT = Continue

Error 12

Supply pressure does not drop far enough

Possible cause: Technical defect

Solution: Service

Error 13

Supply pressure does not rise

Possible cause: Technical defect

Solution: Service

Error 14

Massive leak in pressure accumulator

Possible cause: Technical defect

Solution: Service

Error 15

Leak in pressure accumulator

Possible cause: Technical defect

Solution: Service

Error 16

Leak through Valve V1 is too large

Possible cause: Technical defect

Solution: Service

5

Troubleshooting

ERROR 020

Working pressure

cannot be reached

INJECT = Continue

Error 20

Working pressure has not been reached

Compressor runs without supply pressure being reached

within a specific time.

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check the capillary. Check the capillary holder and tube for

leaks or tighten up the tube connections.

Service.

83

Page 36

5 Troubleshooting

5

Troubleshooting

INJECT = Continue

Compensation pressure

INJECT = Continue

INJECT = Continue

ERROR 021

Inject pressure

cannot be reached

ERROR 022

cannot be reached

ERROR 023

Inject pressure

overflow too large

Error 21

Injection pressure has not been reached

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check capillary. Check capillary holder and tube for leaks or

tighten up tube connections.

Service.

Error 22

Compensation pressure has not been reached

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check capillary. Check capillary holder and tube for leaks or

tighten up tube connections.

Service.

Error 23

Increase in working pressure is smaller than required

Possible cause: Technical defect

Solution: Service

INJECT = Continue

INJECT = Continue

84

ERROR 024

Working pressure

does not rise

ERROR 025

Working pressure

does not fall

Error 24

No increase in working pressure

Possible cause: Technical defect

Solution: Service

Error 25

No drop in working pressure

Possible cause: Technical defect

Solution: Service

Page 37

5 Troubleshooting

ERROR 026

Working pressure

leak is too high

INJECT = Continue

ERROR 027

Working pressure

leak is too high

INJECT = Continue

ERROR 028

Working pressure

leak is too high

INJECT = Continue

Error 26

Working pressure leak rate is too high

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check capillary. Check capillary holder and tube for leaks or

tighten up tube connections.

Service.

Error 27

Working pressure leak rate is too high

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check capillary. Check capillary holder and tube for leaks or

tighten up tube connections.

Service.

Error 28

Working pressure leak rate is too high

Possible cause:

Capillary holder not attached or poorly attached.

(Broken) capillary with large opening.

Technical defect.

Solution:

Check capillary. Check capillary holder and tube for leaks or

tighten up tube connections.

Service.

5

Troubleshooting

ERROR 030

Sensoroffset supply

is too low

INJECT = Continue

Error 30

Sensor offset supply pressure is too low

Possible cause: Technical defect

Solution: Service

85

Page 38

5 Troubleshooting

5

INJECT = Continue

INJECT = Continue

Troubleshooting

INJECT = Continue

INJECT = Continue

INJECT = Continue

ERROR 031

Sensoroffset supply

is too high

ERROR 032

Sensoroffset work

is too low

ERROR 033

Sensoroffset work

is too high

ERROR 034

Valve 1 offset

is too low

ERROR 035

Valve 1 offset

is too high

Error 31

Sensor offset supply pressure is too high

Possible cause: Technical defect

Solution: Service

Error 32

Sensor offset working pressure is too low

Possible cause: Technical defect

Solution: Service

Error 33

Sensor offset working pressure is too high

Possible cause: Technical defect

Solution: Service

Error 34

Valve 1 offset is too low

Possible cause: Technical defect

Solution: Service

Error 35

Valve 1 offset is too high

Possible cause: Technical defect

Solution: Service

INJECT = Continue

86

ERROR 036

Valve 2 offset

is too low

Error 36

Valve 2 offset is too low

Possible cause: Technical defect

Solution: Service

Page 39

5 Troubleshooting

ERROR 037

Valve 2 offset

is too high

INJECT = Continue

ERROR 040

Self-Calibration

is missing

INJECT = Continue

ERROR 041

Fullscale Calibration

is missing

INJECT = Continue

Error 37

Valve 2 offset is too high

Possible cause: Technical defect

Solution: Service

Error 40

Self-calibration is missing

Possible cause: Technical defect

Solution: Service

Error 41

Full-scale calibration is missing

Possible cause: Technical defect

Solution: Service

5

Troubleshooting

87

Page 40

6 Technical data

Voltage/Frequency: 100 V – 240 V ± 10 %, 50 – 60 Hz

Set voltage: adapts automatically

Fuse for 100 – 240 V: T1.0 A, 250 V (2 pcs.)

6

Leistungsaufnahme: 20 W

Max. current consumption: < 0.5 A

Protection class: I

Overvoltage category: II (IEC 61010-1)

Pollution degree: 2 (IEC 664)

Ambient temperature: 15 °C – 35 °C

Technical data

Ambient relative humidity: max. 70 %

Weight: 4.5 kg

Dimensions: Width: 220 mm

Minimum external pressure

to be supplied: > 4,000 hPa ( 60 PSI), constant

Maximum external pressure

to be supplied: < 8,000 hPa (120 PSI), constant

Injection time t

Injection pressure pi: 0; 5 – max. 6 000 hPa (87 PSI),

Compensation pressure pc: 0; 5 – max. 6 000 hPa (87 PSI),

Regulating accuracy: 1 % of value set in each case,

Clean rinsing pressure: max. approx. 7,000 hPa (102 psi)

RS 232 computer Baud rate: 9,600

interface: Start bit: 1

Depth: 170 mm

Height: 280 mm

: 0.0 – 99.9 s

i

in 0.1 s increments

in 1 hPa (0.01 – 0.02 psi) increments

in 1 hPa (0.01 – 0.02 psi) increments

at least ± 1 hPa

Data bits: 8

Parity: non

Stopbit: 2

Technical specifications subject to change!

88

Page 41

7 Ordering information

Order no.

FemtoJet® express

100 V – 240 V ± 10 %, 50 – 60 Hz

Fully programmable microinjector incl. connection for external

pressure supply. For injection of smallest amounts of liquid into living cells.

Delivery package:

1 FemtoJet

1 Power cable

1 Universal capillary holder

1 Pressure tube, 2.5 m, incl. connection for external pressure supply,

incl. coupling G 1/4-inch

1 Injection tube, 2 m

1 Hand control for remote control

10 Femtotips® / Femtotips® II (injection capillaries)

10 Microloader

1 Operating Manual

Version Europe 5248 000.017

Version USA and Canada 5248 000.050

Version UK / Hongkong 5248 000.033

Version Japan 5248 000.041

Version Australia 5248 000.076

Version China 5248 000.084

®

express

5248 200.008

5247 617.002

7

Ordering information

Accessories (not standard)

Foot control FemtoJet

Interface cable PC

for control and for program updates

Interface cable FemtoJet®

for connection to the InjectMan® NI 2

Interface cable 5171

for connection to the micromanipulator 5171 or InjectMan® 5179

20 Femtotips

20 Femtotips® II 5242 957.000

200 Microloader 5242 956.003

Filling Stand 5242 009.012

1 Injection tube, 2 m, for universal capillary holder 5246 164.004

Universal capillary holder

(incl. grip head 0, adapter for Femtotips® and spare O-rings)

®

®

5247 623.002

5325 620.007

5181 070.015

5247 622.006

5242 952.008

5176 190.002

89

Page 42

7 Ordering information

Grip head 0 for universal capillary holder;

for microcapillaries with an outer diameter of 1.0 to 1.1 mm

7

Grip head 1 for universal capillary holder;

for microcapillaries with an outer diameter of 1.2 to 1.3 mm

Grip head 2 for universal capillary holder;

for microcapillaries with an outer diameter of 1.4 to 1.5 mm

Grip head 3 for universal capillary holder

for microcapillaries with an outer diameter of 0.7 to 0.9 mm

O-ring set

for grip heads 0 to 3 with extraction tool

Service kit

for grip head and capillary holder, consisting of O-ring set,

adapter for Femtotip

Ordering information

Micromanipulation

InjectMan® NI 2

Micromanipulator for automatic injection in adherent cells

in combination with FemtoJet

Version Europe 5181 000.017

Version USA and Canada 5181 000.025

Version UK / Hongkong 5181 000.033

Version Japan 5181 000.041

Version Australia 5181 000.076

Version China 5181 000.084

®

and clamping piece (for 5171, 5179)

®

Order no.

5176 210.003

5176 212.006

5176 214.009

5176 207.002

5176 196.000

5176 195.004

®

TransferMan

Proportional micromanipulator for microinjection

in suspension cells

Version Europe 5188 000.012

Version USA and Canada 5188 000.020

Version UK / Hongkong 5188 000.039

Version Japan 5188 000.047

Version Australia 5188 000.071

Version China 5188 000.080

90

NK 2

Page 43

7 Ordering information

Order no.

PatchMan NP 2

Micromanipulator for electrophysiology or other applications

Version Europe 5183 000.014

Version USA and Canada 5183 000.022

Version UK / Hongkong 5183 000.030

Version Japan 5183 000.049

Version Australia 5183 000.073

Version China 5183 000.081

7

Ordering information

Transmission cable 5246

"Y cable" for connection with the interface cable 5171

Foot control for microinjection,

connectable to transmission cable 5246 "Y cable"

5246 621.006

5211 058.007

91

Page 44

7a Ordering information for North America

FemtoJet® express

100 V – 240 V ± 10 %, 50 – 60 Hz

7a

Fully programmable microinjector incl. connection for external pressure

supply. For injection of smallest amounts of liquid into living cells.

Delivery package:

1 FemtoJet

1 Power cable

1 Universal capillary holder

1 Pressure tube, 2.5 m, incl. connection for external pressure supply,

incl. coupling G 1/4-inch

1 Injection tube, 2 m

1 Hand control for remote control

10 Femtotips® / Femtotips® II (injection capillaries)

10 Microloader

1 Operating Manual

Version USA and Canada 920010521

Version Europe 5248 000.017

Version UK / Hongkong 5248 000.033

Version Japan 5248 000.041

Version Australia 5248 000.076

Ordering information for North America

Version China 5248 000.084

®

express

Order no.

920011993

920010512

Accessories (not standard)

Foot control FemtoJet

Interface cable PC

for control and for program updates

Interface cable FemtoJet®

for connection to the InjectMan® NI 2

Interface cable 5171

for connection to the micromanipulator 5171 or InjectMan® 5179

20 Femtotips

20 Femtotips® II 930000043

200 Microloader 930001007

Filling Stand 930000051

1 Injection tube, 2 m, for universal capillary holder 920007431

Universal capillary holder

(incl. grip head 0, adapter for Femtotips® and spare O-rings)

92

®

®

920005098

015160501

920005845

5247 622.006

930000035

920007392

Page 45

7a Ordering information for North America

Order no.

Grip head 0 for universal capillary holder;

for microcapillaries with an outer diameter of 1.0 to 1.1 mm

Grip head 1 for universal capillary holder;

for microcapillaries with an outer diameter of 1.2 to 1.3 mm

Grip head 2 for universal capillary holder;

for microcapillaries with an outer diameter of 1.4 to 1.5 mm

Grip head 3 for universal capillary holder

for microcapillaries with an outer diameter of 0.7 to 0.9 mm

O-ring set

for grip heads 0 to 3 with extraction tool

Service kit

for grip head and capillary holder, consisting of O-ring set,

adapter for Femtotip

Micromanipulation

InjectMan® NI 2

Micromanipulator for automatic injection in adherent cells

in combination with FemtoJet

Version USA and Canada 920000029

Version Europe 5181 000.017

Version UK / Hongkong 5181 000.033

Version Japan 5181 000.041

Version Australia 5181 000.076

Version China 5181 000.084

®

and clamping piece (for 5171, 5179)

®

920007414

920007708

920007716

920007406

920005870

920005888

7a

Ordering information for North America

®

TransferMan

Proportional micromanipulator for microinjection

in suspension cells

Version USA and Canada 920000011

Version Europe 5188 000.012

Version UK / Hongkong 5188 000.039

Version Japan 5188 000.047

Version Australia 5188 000.071

Version China 5188 000.080

NK 2

93

Page 46

7a

7a Ordering information for North America

Order no.

PatchMan NP 2

Micromanipulator for electrophysiology or other applications

Version USA and Canada 920000037

Version Europe 5183 000.014

Version UK / Hongkong 5183 000.030

Version Japan 5183 000.049

Version Australia 5183 000.073

Version China 5183 000.081

Transmission cable 5246

"Y cable" for connection with the interface cable 5171

Foot control for microinjection,

connectable to transmission cable 5246 "Y cable"

Ordering information for North America

920012043

920005047

94

Page 47

8 Index

A

Adapter for Femtotips 67

Anschluss

Micromanipulator 73

Universalkapillarenhalters 67

Application 53

automatische Injektion 71

B

Bedienung über den Computer 97

C

Clean 57

function 71

pressure 69

Cleaning 77

Commands 97

Compensation pressure 55, 62

Compressor 82, 84

D

Device

description 60

rear of 60

Disinfection 77

Display 56, 58, 62

G

Grip head 67, 68

H

Hand control 73

I

Information on working practices 69

Injection

automatic 63, 71

first 72

manual 63

movement 70

parameters 62

pressure pi 55, 69

time ti 55, 70

interface 73

K

Key

Auto / Manu 58, 64

Clean 58, 64

Count 58, 64

Inject 58, 63

Menu 58, 64

Standby 58, 65

Keypad 56, 63

8

Index

E

Error 82

messages 82

potential 78

F

Foot control 55, 57, 60

Function 58

Functions 75

keys 66

menu 64

L

Loudspeaker 75

M

mains switch 60

Manuelle Injektion 71

Mode of operation 62

O

Ordering information 89

Overview 56

95

Page 48

8 Index

8

Index

P

Pressure

pressure accumulator 65

supply, external 61

tube 57, 67

Q

Query 97

R

Reset 58, 65

function 65

S

Safety precautions 53

Self-test 79

checks for leaks 79

complete 79

Short description 58

Standby with deairing 65

Startup 60

Switch

off 61

on 61

System pressure 62, 78

U

Universal capillary holder 67

V

Variable regulator 55, 56, 59, 62, 64, 75

T

Taste

Clean 58

Count 58

Standby 58

Technical data 88

Tension piece 67

Troubleshooting 78

Tube connection 56, 59

96

Page 49

9 Appendix A

Operation via a computer

Certain commands and queries (Section 6.2) can be transmitted to the unit using the optional

cable / PC interface.

A.1 Description of interface

®

A computer can be connected to the remote control of the FemtoJet

two RS 232 interfaces. Parameters can be entered or read out via the computer.

The computer is connected by the special cable / PC interface cable.

The computer to be connected must comply with EN 60950 / UL 1950 standards.

The serial interface of the computer should be set to the following transmission parameters:

Baud rate: 9,600

Start bit: 1

Dat bits: 8

Parity: non

Stop bit: 2

Only ASCII symbols (incl. CR/LF) which can be represented are transmitted. Therefore a

terminal program, for example, is suitable for remote control.

A.2 Commands and queries

The commands to be sent are defined with the following structure:

Commands to enter parameters: "Cxxx=ssssssssss"

Commands to execute and to read out parameters: "Cxxx"

C: Command

xxx: Code for the executing command

=: Separation for the following input parameters

ssssssssss: Input parameters

In response to any command, the device provides a symbol string of a similar structure:

"Axxx" for answers without output parameter

"Axxx=rrrrrrrrrr" for responses with output parameter

A: Answer

express via one of the

9

Appendix A

If the command is faulty, an error message is returned instead of the answer:

"ERR=eee"

ERR: Error

=: Separation

eee: Error number

Lower and upper case letters can be used.

97

Page 50

9 Appendix A

9

Appendix A

Command to enter

parameters

[C]

Short acoustic signal 003 1 – 254 Number of signals

Long acoustic signal 004 1 – 254 Number of signals

Automatic injection (inject at ti) 010 0; 1 – 999 Injection time in 1/10 seconds

Set injection counter n to 0 012 – – – No parameter input

Perform Clean 013 1 – 100 Time in 1/10 seconds

Execute Standby 014 0 or 1 0 = short

Switch acoustic signal on/off 040 0 or 1 Status:

Set pressure unit 041 0 or 1 Unit:

Set injection time t

Set compensation

pressure pc

Set injection pressure pi 044 0; 5 – 6,000 / 87 Pressure in hPa/psi

Set background illumination 045 0 or 1 0 = off

Dewater 046 – – – No parameter input

042 1 – 999 Injection time

i

Code

[xxx]

043 0; 5 – 6,000 / 87 Pressure in hPa/psi

Input

parameter

[ssssssssss]

Meaning of

input parameters

0: injection time set on the

FemtoJet

1 = long

0 = off / 1 = on

0 = hPa / 1 = psi

in 1/10 seconds

1 = on

®

98

Page 51

9 Appendix A

Command to read out

parameters

Query program version 101 Versions number x.xx

Query bleeper 150 Status:

Query pressure unit 151 Unit:

Query injection time ti 152 Injection time

Query compensation pressure pc 153 Pressure in hPa /psi 0 – 6,000 / 87

Query injection pressure pi 154 Pressure in hPa /psi 0 – 6,000 / 87

Query background illumination 155 Status:

Error no. for incorrect

operating construction

ERR = [eee]

060 The first character is not

061 The 2nd to 4th character

062 The 5th character is not =. Check entry parameters.

063 The parameter is not within

064 The command is not known. Check entry parameters.

Code

[C]

[xxx]

Cause Solution

a c or C.

is not a digit.

the permitted range.

Significance of

output parameter

0 = off / 1 = on

0 = hPa / 1 = psi

in 1/10 seconds

0 = off / 1 = on

Output parameter

[A]

0 or 1

0 or 1

1 – 999

0 or 1

Check entry parameters.

Change entry.

Check entry parameters.

Change entry.

Change entry.

Check entry parameters.

Change entry.

Change entry.

[rrrrrrrrrr]

9

Appendix A

99

Page 52

9 Appendix A

9

Appendix A

Other error numbers as well as the error cause and solution are described in Section 5,

"Troubleshooting". During remote control, no error texts appear in the FemtoJet® express

display.

Error no. during execution

ERR = [eee]

070 FemtoJet

071 FemtoJet® express is not

072 The command is not

073 This command cannot be

074 The connected micro-

Cause Solution

®

express is not

in routine mode.

ready.

finished within the

scheduled time.

executed at the moment,

because of insufficient

storage pressure.

See: Warning 001

manipulator did not

respond.

See: Warning 003

Check FemtoJet® express.

Bring FemtoJet® express into

routine operation.

Eliminate error.

Check FemtoJet® express or

micromanipulator.

As necessary, wait or eliminate

error.

Check FemtoJet® express or

micromanipulator.

Eliminate error.

Check FemtoJet® express.

Eliminate error.

Check micromanipulator.

Eliminate error.

100

Page 53

Page 54

Page 55

Eppendorf Offices

SPAIN

SWITZERLAND

UNITED KINGDOM

USA

OTHER COUNTRIES

ASEAN

Eppendorf AG

Regional Office in Malaysia

Tel. +60 3 8023 2769

Fax +60 3 8023 3720

E-Mail: eppendorf@eppendorf.com.my

Internet: www.eppendorf.com.my

AUSTRALIA / NEW ZEALAND

Eppendorf South Pacific Pty. Ltd.

Tel. +61 2 9889 5000

Fax +61 2 9889 5111

E-mail: Info@eppendorf.com.au

Internet: www.eppendorf.com.au

AUSTRIA

Eppendorf AG

c/o Schott Austria

Tel. +43 1 29017560

Fax +43 1 290175620

E-Mail: gilch.p@eppendorf.de

Internet: www.eppendorf.com

BRAZIL

Eppendorf do Brasil Ltda.

Tel. +55 11 30 95 93 44

Fax +55 11 30 95 93 40