Page 1

Instructions for useRotor FA-45-48-11, FA-45-20-17, FA-45-6-30seeon p.Fig.Tab.p.

English (EN)Instructions for use

Instructions for use

Rotor FA-45-48-11, FA-45-20-17, FA-45-6-30

English (EN)

This document supplements the operation manual Centrifuge 5804/5804 R/5810/5810 R and

does not replace it. Therefore, please also read the operating manual before starting up the

rotors for the first time. You can find the current version on the Internet at

www.eppendorf.com

.

1 Product description

The rotors FA-45-48-11, FA-45-20-17 and FA-45-6-30 are aerosol-tight fixed-angle rotors for

Centrifuge 5804/5804 R/5810/5810 R.

Rotor Maximum capacity

FA-45-48-11 48 micro test tubes with a volume of 2,0 mL

FA-45-20-17 20 micro test tubes with a volume of 5,0 mL

FA-45-6-30 6 conical tubes with a volume of 50 mL/15 mL

2Safety notes

WARNING! Risk to health due to limited aerosol tightness with incorrect rotor/

rotor lid combination.

Aerosol-tight centrifugation is guaranteed only if the rotors and rotor lids intended for

this purpose are used. The designation of aerosol-tight fixed-angle rotors always

starts with FA.The aerosol-tight rotors and rotor lids of this centrifuge are additionally

marked with a red ring on the rotor and a red rotor lid screw.

For aerosol-tight centrifugation, always simultaneously use rotors and rotor lids

which are marked as aerosol-tight in the centrifuge intended for the corresponding

purpose. The details specifying in which centrifuge you may use the aerosol-tight

rotors and rotor lids can be found on the rotor and, beginning from production

date of October 2003, on the upper side of the rotor lid.

Only use aerosol-tight rotor lids in combination with rotors which are marked on

the rotor lid.

WARNING! Damage to health as a result of limited aerosol tightness and incorrect

usage.

Autoclaving, mechanical stresses and contamination by chemicals or other aggressive

solvents can impair the aerosol-tightness of the rotors and rotor lids.

Check the integrity of the seals of the aerosol-tight rotor lids or caps before each

use.

Only use aerosol-tight rotor lids or caps if the seals are undamaged and clean.

Lightly grease the threads of the rotor lid screw with pivot grease after every

proper autoclaving (121 °C, 20 min.) (int. order no. Int. 5810 350.050, North

America 022634330).

Replace aerosol-tight rotor lids and caps after 50 autoclaving cycles.

For QuickLock rotor lids, the seal must be replaced after 50 autoclaving cycles.

Never store aerosol-tight rotors or buckets closed.

Page 2

Instructions for use

Rotor FA-45-48-11, FA-45-20-17, FA-45-6-30

2

English (EN)

NOTICE! The rotor lid screw may become loose if it is improperly handled.

The lock on aerosol-tight QuickLock rotor lids may become loose if it is used to hold

the rotor.

Never hold or transport the locked rotor on the rotor lid screw.

Always pick up the rotor using both hands.

3Operation

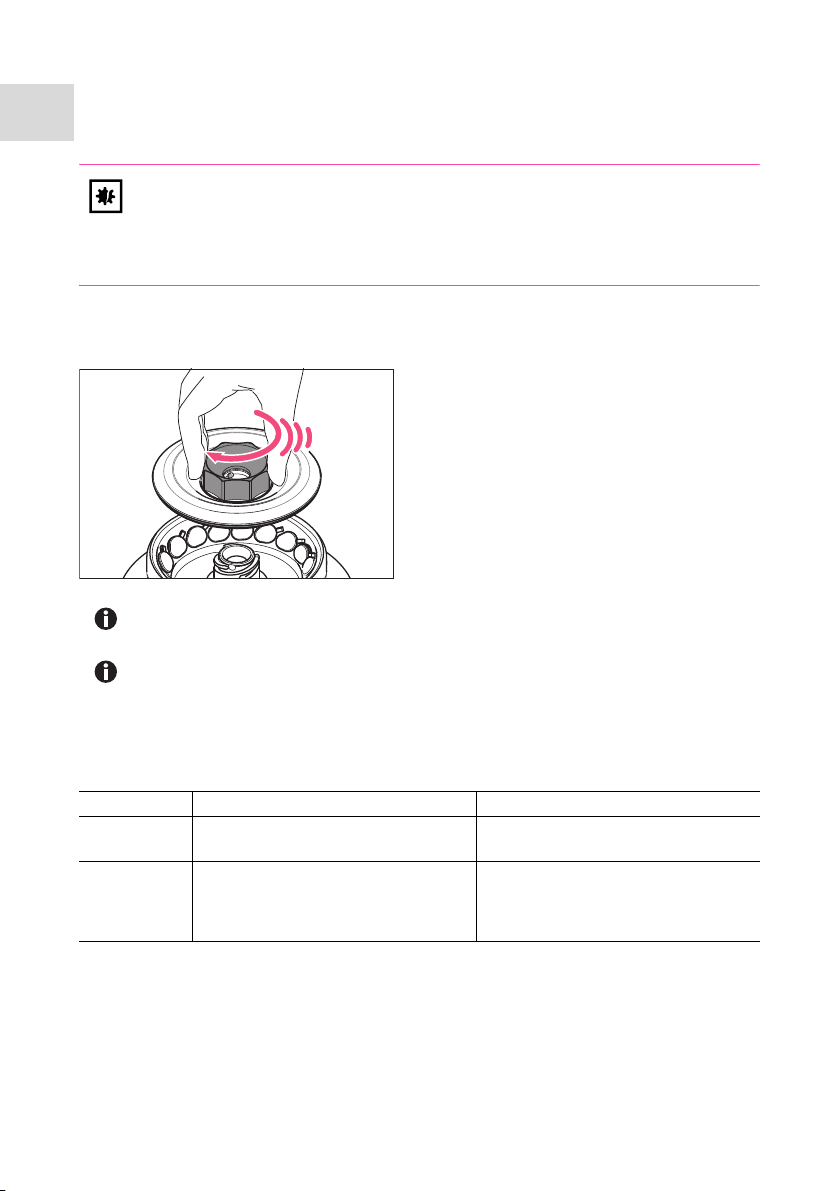

3.1 Closing the QuickLock rotor lid

1. Check that the outer sealing ring is seated

correctly in the groove.

2. Vertically fit the rotor lid on the rotor.

3. To lock the rotor, turn the red rotor lid

screw clockwise, beyond an audible click

until the stop is reached.

The rotor is not closed properly until an audible click is heard!

If the closing system is difficult to operate apply a thin layer of pivot grease to the

pins in the rotor lid screw.

3.2 Retrofitting older centrifuges You can view the software version on your device’s display shortly after switching on the

device. Retrofitting may only be carried out by a trained service technician. If you require

retrofitting, please contact your dealer.

Rotor Operation possible without retrofit Retrofit of older devices possible

FA-45-48-11

FA-45-20-17

FA-45-6-30 from serial number 60 000 onwards 5804/5804 R/5810:

from software version 8.4 onwards from software version 7.0 onwards

from serial number 10 000 onwards

5810 R:

from serial number 12 000 onwards

Page 3

Rotor FA-45-48-11, FA-45-20-17, FA-45-6-30

Instructions for use

English (EN)

4 Replacing the rotor lid seal

4.1 Removing the seal

Lift the rubber seal from the groove. If necessary, use a blunt lever, for instance the rounded

side of a paper clip.

Please take care not to damage the seal.

4.2 Inserting the seal

NOTICE! Faulty sealing when the seal is handled incorrectly.

Uniformly insert the seal.

Do not pull the seal lengthwise.

1. Check the integrity of the seal.

Do not use any damaged, discolored or dirty seals.

2. Insert the seal in one location along the groove and spread with the fingers along the outer

edge of the lid until the seal is fully seated in the groove.

3. Place the lid on the rotor and close the lid.

4. Remove the lid and check that the seal is seated correctly

If the seal is too long or too short remove it from the groove and repeat the inserting

process.

3

Page 4

Instructions for use

Rotor FA-45-48-11, FA-45-20-17, FA-45-6-30

English (EN)

5 Technical Data

Rotor FA-45-48-11

Max. g-force (rcf)/speed (rpm):

Outer ring

Inner ring

Max. load per bore:

19 083 × g/13 000 rpm

16 816 × g/13 000 rpm

3.75 g

(Adapter, tube and contents)

Max. centrifugation radius:

Outer ring

Inner ring

10.1 cm

8.9 cm

Rotor FA-45-20-17

Max. g-force (rcf)/speed (rpm): 20 913 × g/13 100 rpm

Max. load per bore:

9.5 g

(Adapter, tube and contents)

Max. centrifugation radius: 10.9 cm

Rotor FA-45-6-30

Do not use Corning

®

50 mL PET Centrifuge Tubes. After centrifugation, the tubes

may get stuck in the rotor bores.

Max. g-force (rcf)/speed (rpm):

without adapter

with adapter for conical tubes 15 mL

Max. load per bore:

5804/5804 R/5810

16 639 × g/11 000 rpm

16 233 × g/11 000 rpm

5810 R

20 133 × g/12 100 rpm

19 642 × g/12 100 rpm

75 g

(Adapter, tube and contents)

Max. centrifugation radius:

without adapter

with adapter for conical tubes 15 mL

12.3 cm

12.0 cm

More technical data and order numbers can be found in the operating manual of Centrifuge

5804/5804 R/5810/5810 R.

Corning is a registered trademark of Corning Inc., Corning, NY, USA.

Your local distributor: www.eppendorf.com/contact

Eppendorf AG · 22331 Hamburg · Germany

eppendorf@eppendorf.com · www.eppendorf.com

and the Eppendorf logo are registered trademarks of Eppendorf AG.

®

5820 715.960-02/072013

©2013 • Eppendorf

Loading...

Loading...