Electrolux PW1M Installation Manual

.0

USA |

CONTENTS |

|

|

|

|

A |

SAFETY INSTRUCTIONS ................................................................................ |

Pag. |

4 |

ENGLISH |

|

B |

GENERAL RECOMMENDATIONS |

Pag. |

5 |

||

|

|||||

B1 |

HANDLING ................................................................................................................................ |

Pag. |

5 |

|

|

B2 |

UNPACKING ............................................................................................................................. |

Pag. |

5 |

|

|

B3 |

DISPOSAL OF PACKING MATERIAL....................................................................................... |

Pag. |

6 |

|

|

B4 |

TECHNICAL DATA.................................................................................................................... |

Pag. |

7 |

|

|

C |

INSTALLATION AND START-UP INSTRUCTIONS ........................................ |

Pag. |

11 |

|

|

C1 |

WATER CONNECTION............................................................................................................. |

Pag. |

11 |

|

|

C2 |

ELECTRICAL CONNECTION ................................................................................................... |

Pag. |

11 |

|

|

C3 |

WARNING MESSAGES DISPLAYED ON THE CONTROL PANEL ......................................... |

Pag. |

12 |

|

|

C4 |

DETERGENT/RINSE-AID DISPENSERS AND SETTINGS...................................................... |

Pag. |

12 |

|

|

C5 |

SETTING THE DISPENSERS................................................................................................... |

Pag. |

13 |

|

|

D |

USER INSTRUCTIONS..................................................................................... |

Pag. |

15 |

|

|

D1 |

STARTING................................................................................................................................. |

Pag. |

15 |

|

|

D2 |

WASH CYCLES......................................................................................................................... |

Pag. |

16 |

|

|

D3 |

OPERATION.............................................................................................................................. |

Pag. |

16 |

|

|

D4 |

END OF WORK AND DAILY CLEANING.................................................................................. |

Pag. |

18 |

|

|

D5 |

MAINTENANCE......................................................................................................................... |

Pag. |

19 |

|

|

E |

TROUBLESHOOTING...................................................................................... |

Pag. |

22 |

|

3

A |

SAFETY INSTRUCTIONS |

To reduce the risk of fire, electrical shock, or injury when using your potwasher, please follow these basic precautions including the following:

•Read all instructions before using your potwasher.

•This Manual does not cover every possible condition and situation that may occur. Use common sense and caution when installing, operating and maintaining this appliance.

•Do not sit, stand or lean on the door or racks of a potwasher.

•Store potwasher detergent and rinse agents in clearly marked packages with MSDS (Material Safety Data Sheets) sheets in a safe place.

•FOR YOUR SAFETY DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUID IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

•Your potwasher uses hot water to clean and sanitize a variety of wares. Machine surfaces and wares become hot during and immediately following normal operations. Operators should use caution when loading and unloading wares from the machine.

•Do not touch the heating element during or immediately after use.

•The installation of this unit must conform to local codes or, in the absence of local codes, to all National Codes governing plumbing, sanitation, safety and good trade practices.

•BEFORE SERVICING, DISCONNECT THE ELECTRICAL SERVICE AND PLACE A RED TAG AT THE DISCONNECT SWITCH TO INDICATE WORK IS BEING DONE ON THAT CIRCUIT.

•NOTICE: CONTACT YOUR AUTHORIZED SERVICE COMPANY TO PERFORM MAINTENANCE AND REPAIRS.

•NOTICE: Using any parts other than genuine factory manufactured parts relieves the manufacturer of all warranty and liability.

•NOTICE: Manufacturer reserves the right to change specifications at any time without notice.

•WARNING: The equipment warranty is not valid unless the appliance is installed, started and demonstrated under the supervision of a factory trained installer.

•WARNING: The unit must be installed by Personnel who are qualified to work with electricity and plumbing. Improper installation can cause injury to personnel and/or damage to the equipment. The unit must be installed in accordance with applicable codes.

SAVE THESE INSTRUCTIONS

4

B |

GENERAL RECOMMENDATIONS |

WARNING

CAREFULLY READ THE INSTALLATION OPERATING AND MAINTENANCE INSTRUCTIONS BEFORE INSTALLING THIS APPLIANCE. INCORRECT INSTALLATION, ADAPTATIONS OR ALTERNATIONS COULD CAUSE DAMAGE TO PROPERTY OR PERSONAL INJURY. FAILURE TO COMPLY WITH THESE INSTRUCTIONS, ABUSE RESULTING IN DAMAGE AND IMPROPER INSTALLATION WILL VOID WARRANTY AND RESPONSIBILITIES OF THE MANUFACTURER.

1.Carefully read this instructions booklet, as it contains important advice for safe installation, operation and maintenance. Keep this booklet handy in a safe place for future reference.

2.The installation instructons contained herein are for the use of qualified installation and service personnel only. Installation or service by other than qualified personnel may result in damage to the appliance and/or injury to the operator. FAILURE TO COMPLY WITH INSTALLATION INSTRUCTION OR IMPROPER INTALLATION WILL VOID WARRANTY AND RESPONSIBLITIES OF THE MANUFACTURE.

3.The equipment warranty is not valid unless the unit is installed, started and demonstrated under the supervision of a factory trained installer.

4.Switch off the appliance in the event of failure or malfunctioning at the main circuit breaker.

Only have the appliance repaired by an Authorized Service Center and be sure to ask for OEM original spare parts.

NOTICE FOR SHIPPING DAMAGE

•The container should be examined for damage before and during unloading.

•The freight carrier has assumed responsibility for its safe transit and delivery.

•If damaged equipment is received, either apparent or concealed, a claim must be made with the delivering carrier. Apparent damage or loss must be noted on the freight bill at the time of delivery.

•The freight bill must then be signed by the carrier representative (Driver). If the bill is not signed, the carrier may refuse the claim. The supply can supply the necessary forms.

•A request for inspection must be made to the carrier within 15 days if there is concealed damage or loss that is not apparent until after the equipment is uncrated. The carrier should arrange an inspection.

•Be certain to hold all contents plus all packing material. Under no circumstances should a damaged appliance be returned to the manufacturer without prior notice and written authorization.

B1 HANDLING

Use suitable means to move the appliance: a lift truck or fork pallet trucks (the forks should reach more than halfway beneath the appliance).

B2 UNPACKING

Wear protective gloves to unpack.

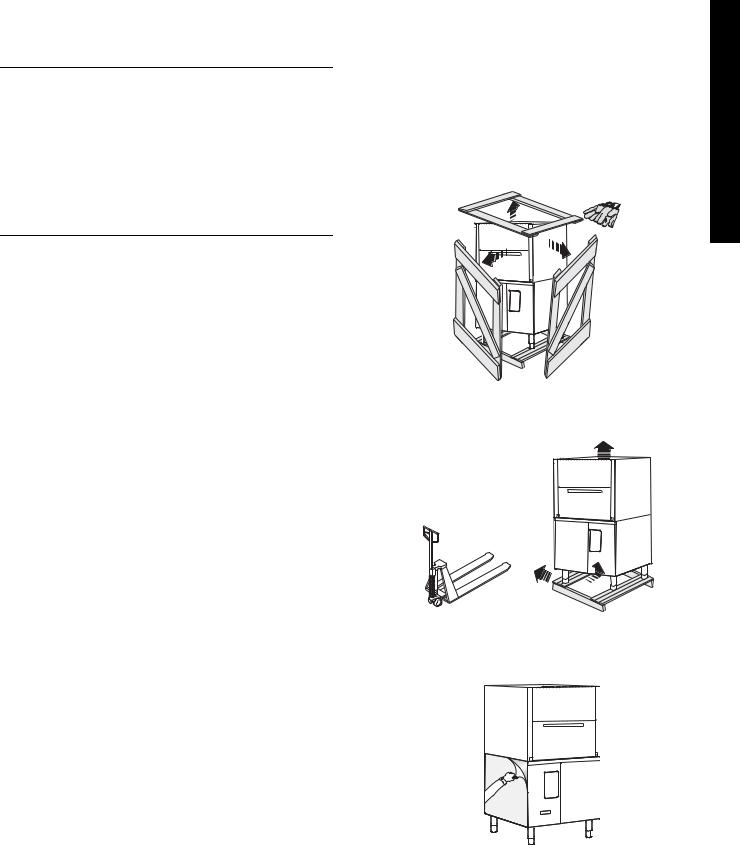

Figure 1

Lift the appliance using a lift truck,

Figure 2

remove the base and position the appliance where it is to be installed.

Figure 3

Remove the protective film and ensure that the packaging material is disposed of correctly in compliance withthe regulations in force in the country where the product is to be used.

ENGLISH

5

B3 DISPOSAL OF PACKING MATERIAL

All the packaging materials are environmentally safe and friendly. They maybe kept without fear or danger. They may be recycled or burned in a special waste incineration plant. Recyclable plastic components are marked as follows:

|

polyethylene |

external wrapping film, |

PE |

|

instruction bag. |

|

polypropy- |

top packaging panels, |

PP |

lene |

straps. |

|

polystyrene |

protective surround ele- |

PS |

foam |

ments. |

Wood and cardboard components may be disposed of according to local regulations in force. Appliances that have reached the end of their service life should be suitably disposed of. The appliance should be dismantled according to regulations in force. All metal parts are in stainless steel (AISI 304) and are removable. Plastic parts are marked with the symbol of the material.

6

B4 |

TECHNICAL DATA |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

MODEL |

WT830M/PW1M |

WT830H/PW1MH |

WT850M/PW2M |

|

|

|

|

|

|

|

|

|

|

Supply voltage: |

208 V, 3 ph, 60 Hz 45 amp |

208 V, 3 ph, 60 Hz 45 amp |

208 V, 3 ph, 60 Hz 56 amp |

|

|

|

Total Watts |

14.8 kW |

14.8 kW |

17.5 kW |

|

ENGLISH |

|

Boiler heating elements |

12.0 kW |

12.0 kW |

12.0 kW |

|

||

|

|

|||||

Tank heating elements |

12.0 kW |

12.0 kW |

12.0 kW |

|

|

|

Water supply pressure |

7.25 - 101 psi/50 - 700 kPa |

7.25 - 101 psi/50 - 700 kPa |

7.25 - 101 psi/50 - 700k Pa |

|

|

|

Water supply temperature |

122°F/50°C |

122°F/50°C |

122°F/50°C |

|

|

|

Water supply hardness |

140 ppm/14°fH max |

140 ppm/14°fH max |

140 ppm/14°fH max |

|

|

|

Rinse cycle water consumption |

1.6 gallons/6.2 liters |

1.6 gallons/6.2 liters |

3.2 gallons/12 liters |

|

|

|

Boiler capacity |

4.8 gallons/18 liters |

4.8 gallons/18 liters |

4.8 gallons/18 liters |

|

|

|

Tank capacity |

25.1 gallons/95 liters |

25.1 gallons/95 liters |

39.6 gallons/150 liters |

|

|

|

Standard cycle time with water supply at |

360/600/900 seconds |

360/600/900 seconds |

360/600/900 seconds |

|

|

|

122°F/50°C |

|

|

|

|

|

|

Legal noise level Leq |

<70 dB |

<70 dB |

<70 dB |

|

|

|

Minimum Supply - Circuit Ampacity |

48 amp |

48 amp |

62 amp |

|

|

|

Net weight |

441 lb/200 kg |

476 lb/216 kg |

661 lb/300 kg |

|

|

|

Shipping weight |

606 lb/275 kg |

628 lb/285 kg |

849 lb/385 kg |

|

|

|

Shipping width |

44 1/16“ / 1120 mm |

44 1/16“ / 1120 mm |

70 7/8“ / 1800 mm |

|

|

|

Shipping height |

86 5/8“ / 2200 mm |

94 1/2“ / 2400 mm |

86 5/8“ / 2200 mm |

|

|

|

Shipping depth |

43 5/16“ /1100 mm |

43 5/16“ /1100 mm |

43 5/16“ /1100 mm |

|

|

|

|

|

|

|

|

|

|

|

|

Table 1 |

|

|

|

|

|

|

|

|

|

||

MODEL |

WT830M/PW1M |

WT830H/PW1MH |

WT850M/PW2M |

|

|

|

|

|

|

|

|

|

|

Supply voltage: |

240 V, 3 ph, 60 Hz 39 amp |

240 V, 3 ph, 60 Hz 39 amp |

240 V, 3 ph, 60 Hz 49 amp |

|

|

|

Total Watts |

14.8 kW |

14.8 kW |

17.5 kW |

|

|

|

Boiler heating elements |

12.0 kW |

12.0 kW |

12.0 kW |

|

|

|

Tank heating elements |

12.0 kW |

12.0 kW |

12.0 kW |

|

|

|

Water supply pressure |

7.25 - 101 psi/50 - 700 kPa |

7.25 - 101 psi/50 - 700 kPa |

7.25 - 101 psi/50 - 700k Pa |

|

|

|

Water supply temperature |

122°F/50°C |

122°F/50°C |

122°F/50°C |

|

|

|

Water supply hardness |

140 ppm/14°fH max |

140 ppm/14°fH max |

140 ppm/14°fH max |

|

|

|

Rinse cycle water consumption |

1.6 gallons/6.2 liters |

1.6 gallons/6.2 liters |

3.2 gallons/12 liters |

|

|

|

Boiler capacity |

4.8 gallons/18 liters |

4.8 gallons/18 liters |

4.8 gallons/18 liters |

|

|

|

Tank capacity |

25.1 gallons/95 liters |

25.1 gallons/95 liters |

39.6 gallons/150 liters |

|

|

|

Standard cycle time with water supply at |

360/600/900 seconds |

360/600/900 seconds |

360/600/900 seconds |

|

|

|

122°F/50°C |

|

|

|

|

|

|

Legal noise level Leq |

<70 dB |

<70 dB |

<70 dB |

|

|

|

Minimum Supply - Circuit Ampacity |

41 amp |

41 amp |

54 amp |

|

|

|

Net weight |

441 lb/200 kg |

476 lb/216 kg |

661 lb/300 kg |

|

|

|

Shipping weight |

606 lb/275 kg |

628 lb/285 kg |

849 lb/385 kg |

|

|

|

Shipping width |

44 1/16“ / 1120 mm |

44 1/16“ / 1120 mm |

70 7/8“ / 1800 mm |

|

|

|

Shipping height |

86 5/8“ / 2200 mm |

94 1/2“ / 2400 mm |

86 5/8“ / 2200 mm |

|

|

|

Shipping depth |

43 5/16“ /1100 mm |

43 5/16“ /1100 mm |

43 5/16“ /1100 mm |

|

|

|

|

|

|

|

|

|

|

Table 2

Standard cycle time may vary should the inlet water temperature be different from that indicated above.

7

|

|

|

|

|

|

|

|

|

|

|

|

|

|

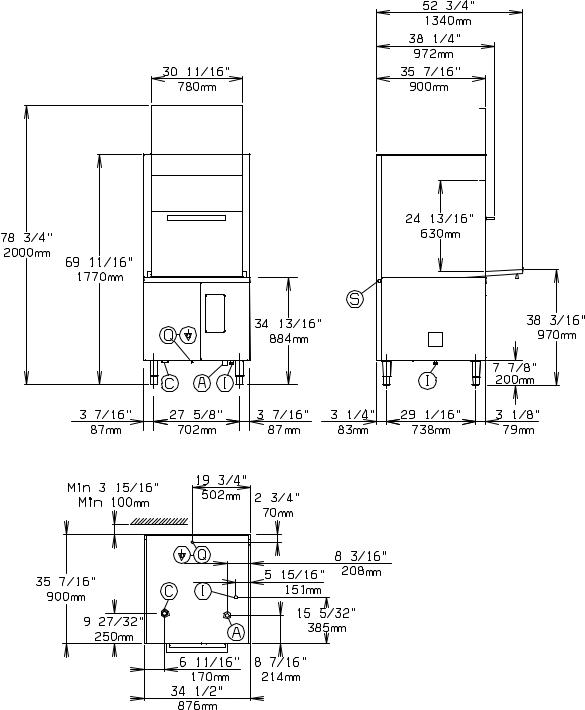

Figure 4 Installation diagram PW1M |

|

Legend Figure 4 |

|||

A |

- Water inlet pipe with 3/4”dia/19mm fittings |

||

C |

- Outlet pipe 1 5/8” ID /40 mm (^) –11/16” ID /18 mm (*). |

||

I |

- |

Power supply |

|

S |

- |

Detergent connection |

|

Q |

- |

Equipotential (Ground) screw |

|

(^) |

- Only for model with free-fall drainage |

||

(*) |

- Only for model with drain pump |

||

8

Loading...

Loading...