Electrolux PV101 Installation Manual

PV100 SERIES

ELECTRONICALLY CONTROLLED

PROPORTIONAL VALVES

INSTRUCTION

SHEET

M2160-0204

Unpacking

Remove the Packing List and verify that you have

received all equipment, including a PV100 Series

proportional valve, and instruction sheet. If you

have any questions about the shipment, please call

the Customer Service Department at 1-800-622-2378

or 203-359-1660. We can also be reached on the

Internet at www.omega.com

e-mail: cservice@omega.com

When you receive the shipment, inspect the

container and equipment for signs of damage. Note

any evidence of rough handling in transit.

Immediately report any damage to the shipping

agent.

General Description

The OMEGA

®

PV100 Series Electronically

Controlled Proportional Valves are two-way

normally closed valves. When the valve is

deenergized, pressure is sealed off by the force of

the plunger assembly return spring and the seal in

the plunger assembly. When the valve is energized,

the plunger assembly moves upward, permitting

flow through the valve. The valve is direct acting.

Higher current or control signal results in more

plunger movement and more flow.

Installation

Port Identification

Apply inlet pressure to the port marked “P”.

Mounting Position and Pressure Limits

Valves can be mounted directly on piping and are

designed to operate in any position. Two 8-32

tapped mounting holes

1

⁄4” deep are provided in the

base of the body. Line pressure must not exceed the

nameplate rating.

Piping

Remove closures from ports and connect pressure

lines to proper ports. All valves have

1

⁄8" NPTF

fittings. Tightening torque on the

1

⁄8" NPT should

not exceed 38 in-lbs.

Media Filtration

Filtration of air lines is recommended. Install the

filter in the inlet side as close to the valve as

possible. These valves have no sliding fits and are

generally not sensitive to a small amount of foreign

material, however, they do contain soft rubber

inserts. Dirt or foreign material in the media may

cause excessive leakage, excessive wear, or in

exceptional cases, malfunction.

Electrical Connection

Electrical supply must conform to nameplate

rating. Connect coil leads to DC voltage using

standard electrical practice.

Black wire Common Ground

(to Power Supply and Control)

Red wire (+) DC Positive Power Supply

Gray wire (+) Control Signal

If the coil housing is located in an inconvenient

position, the housing nut can be loosened and the

housing rotated to any convenient position. Then

re-tighten the nut to 13 to 35 in-lbs.

Coil Housing Temperature

Standard valves are supplied with coils designed

for continuous duty service. Normal free space

must be provided for proper ventilation. When coil

is energized continuously for long periods of time,

the coil housing will become hot 54 to 71°C (130 to

160°F). The coil is designed to operate continuously

under these conditions. Any excessive heating will

be indicated by smoking and/or odor of burning

insulation.

Lubrication

Lubrication is not required.

Maintenance Instructions

Valves are calibrated at the factory and should not

be disassembled by the user.

Available Models

*Specify Control Signal: MA for 4-20 MADC

5V for 0-5 VDC

10V for 0-10 VDC

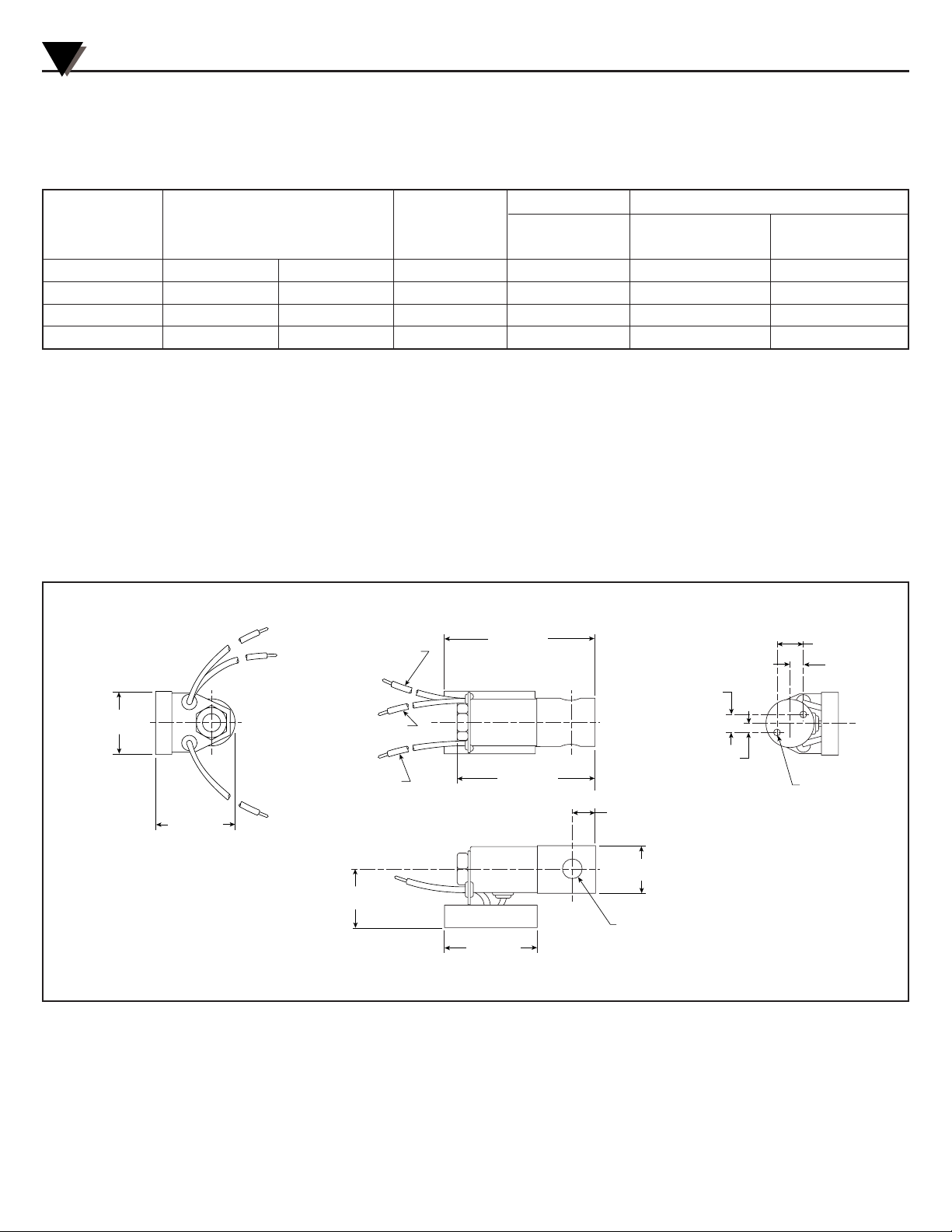

Dimensions

PV100 Series Proportional Valves

Flow Ranges, SCCM

Model Orifice Maximum At Maximum At

Number Millimeters Inches

C

v Pressure Pressure 10 PSI

PV101-(*) .80 1/32 0.02 200 PSI 0-50,000 0-8,000

PV102-(*) 1.19 3/64 0.045 100 PSI 0-65,000 0-17,000

PV103-(*) 1.59 1/16 0.08 60 PSI 0-75,000 0-30,000

PV104-(*) 1.98 5/64 0.12 40 PSI 0-80,000 0-45,000

35.05 ±0.38

(1.38 ±0.015)

45.47 ±0.51

(1.79 ±0.02)

84.07 ±1.0

(3.31 ±0.04)

10.1

(0.396)

5.0

(0.198)

RED

POSITIVE

BLACK

COMMON

GRAY

CONTROL

ELECTRICAL TERMINATIONS

RED - DC POWER SUPPLY (+)

GRAY - CONTROL SIGNAL (+)

BLACK - COMMON (TO POWER

SUPPLY AND CONTROL SIGNAL)

74.45 ±0.51

(3.01 ±0.02)

50.80 ±0.51

(2.00 ±0.02)

15.0

(0.59)

7.5

(0.295)

13.46

(0.53)

P

32.51

(1.28)

26.92 DIA.

(1.06 DIA.)

1/8 NPT

2 PLC'S

#8-32 NC-2B TH'D

2 PLC'S

DIMENSIONS mm (inches)

2

Loading...

Loading...