Page 1

Service Manual

Fuller Mid Range Transmissions

TRSM0197

October 2007

Page 2

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Page 3

Caution -

Before towing the vehicle, be sure to lift the rear wheels off the

ground or disconnect the driveline to avoid damage to the

transmission during towing.

1

Page 4

FOREWARD

This manual has been prepared to provide the customer and the maintenance personnel with information and instructions on the maintenance and repair of the CLARK® Transmission.

Extreme care has been exercised in the design, selection of materials and manufacturing of these units. The slight outlay in personal attention and cost required to provide regular and proper lubrication, inspection at stated intervals, and

such adjustments as may be indicated will be reimbursed many times in low cost operation and trouble free service.

In order to become familiar with the various parts of the transmission, its principle of operation, troubleshooting and

adjustments, it is urged that the service person study the instructions in this manual carefully and use it as a reference

when performing maintenance and repair operations.

Whenever repair or replacement of components parts is required, only Clark-approved parts as listed in the applicable

parts manual should be used. Use of “will-fit” or non-approved parts may endanger proper operation and performance

of the equipment. The Clark Equipment Company does not warrant repair or replacement parts, nor failures resulting

from the use thereof, which are not supplied by or approved by the Clark Equipment Company.

IMPORTANT: Always furnish the Distributor with the transmission serial and model number when ordering parts.

1

Page 5

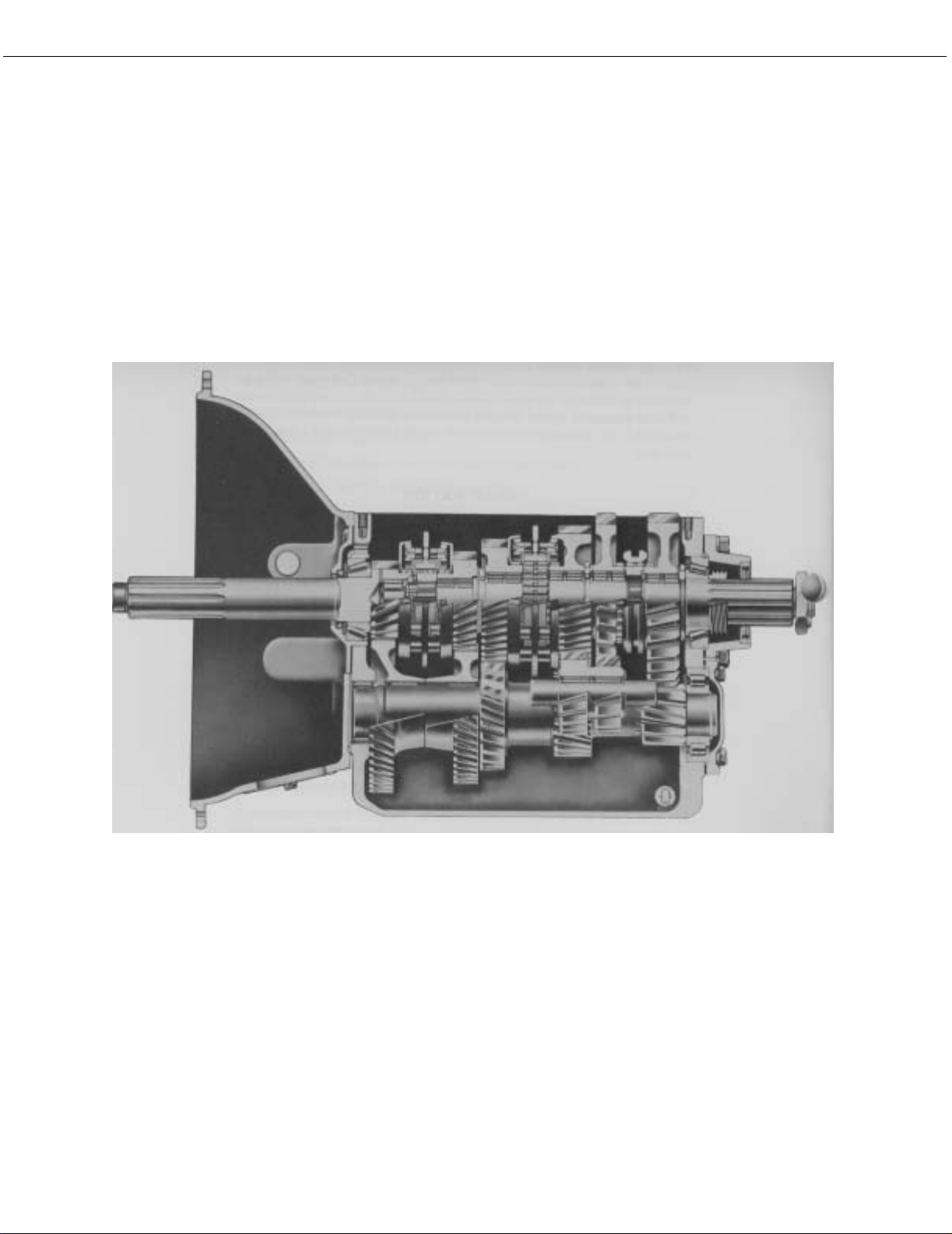

CL550 SERIES TRANSMISSION

The CL550 is a 5-speed forward, 1-speed reverse transmission of advanced design offering you the most efficient

torque capacity-to-weight ratio of any 5-speed transmission in its torque range. Two basic ratios are available as shown

in the table below. The CL551 ratio is designed for use in trucks equipped with a 3 or 4-speed auxiliary transmission

and the CL557 ration is designed for use with trucks equipped with a 2-speed rear axle.

MODELS

Speed

Fifth Direct Direct Direct

Fourth 1.52:1 1.17:1 1.28

Third 2.54:1 1.99:1 2.15

Second 4.35:1 3.68:1 3.68

First 7.52:1 6.82:1 6.36

Reverse 6.27:1 5.30:1 5.30

Constant mesh in all gears, including low and reverse, is a CL550 feature as is helical gearing throughout, including low

and reverse.

The Clark split-pin synchronizer is used in 2nd, 3rd 4th and 5th gears. Greater bearing capacity in the CL550 is achieved

by the use of numerous needle roller bearings, and two tapered roller bearings and one large straight roller bearing at

the rear of the countershaft.

Shift forks have replaceable bronze inserts. The shift pattern is of the standard progression type with all shifts having

the same throw at the lever.

CL551/390V CL557/397V CL558

Page B shows a cutaway drawing of the CL550. Page C shows a cutaway drawing of the 390V.

A

Page 6

CLARK

CL550 TRANSMISSION

B

Page 7

CLARK

390V TRANSMISSION

C

Page 8

THE CLARK SYNCHRONIZER

AND HOW IT WORKS FOR YOU

The Clark split-pin synchronizer prevents the clashing of the gears and increase the speed of shifting.

In a conventional transmission which does not have synchronizers the absence of gear clashing is dependent entirely

on the skill of the truck driver. By double-clutching and split second timing of engine speeds with the gear shifting

movement, a driver can synchronize the speeds of the engaging gears and thereby prevent the damage to gears by

clashing when a fast shift. The splint-pin sychronzier performs the same function with or without the “double-clutching”

operating even though the driver does not accurately time his gear shifting movements. It also mechanically prevents

the driver from completing the shift to the point of gear engagement until the engaging gears have reached the same or

synchronous speeds. This is known as the blocking action of the synchronizer and it is this action that makes the operation of shifting a transmission having synchronizers different from one which does not have synchronizers.

Upon shifting gears in these synchronized transmissions the first part of the gear shift lever movement brings the

blockers into contact. The blockers momentarily prevent further movement of the shift lever and the pressure exerted

by the driver to complete the movement, is transferred by the blockers to the synchronizer providing the force necessary to synchronize the gears being engaged. When the engaging gears have reached the same speed, the blockers

automatically disengage, permitting the gear shift lever movement to be completed. Therefore, to properly shift a synchronized transmission a steady and continuous pressure must be applied by the driver to the shift lever until the shift

is completed. Under normal conditions this action is instantaneous.

Sometimes difficulty is experienced in shifting a synchronizer when the vehicle is standing still. This is caused by the

fact that the disengagement of the blockers requires relative rotation and with the vehicle at rest and with the engine

clutch released, there may be at times, no relative rotation of the engaging gears. Under these conditions, the same continuous pressure should be applied to the shift lever and at the same time, the clutch should be engaged slightly. This

will give sufficient rotation to unblock the synchronizer and allow the shift to be completed without difficulty.

D

Page 9

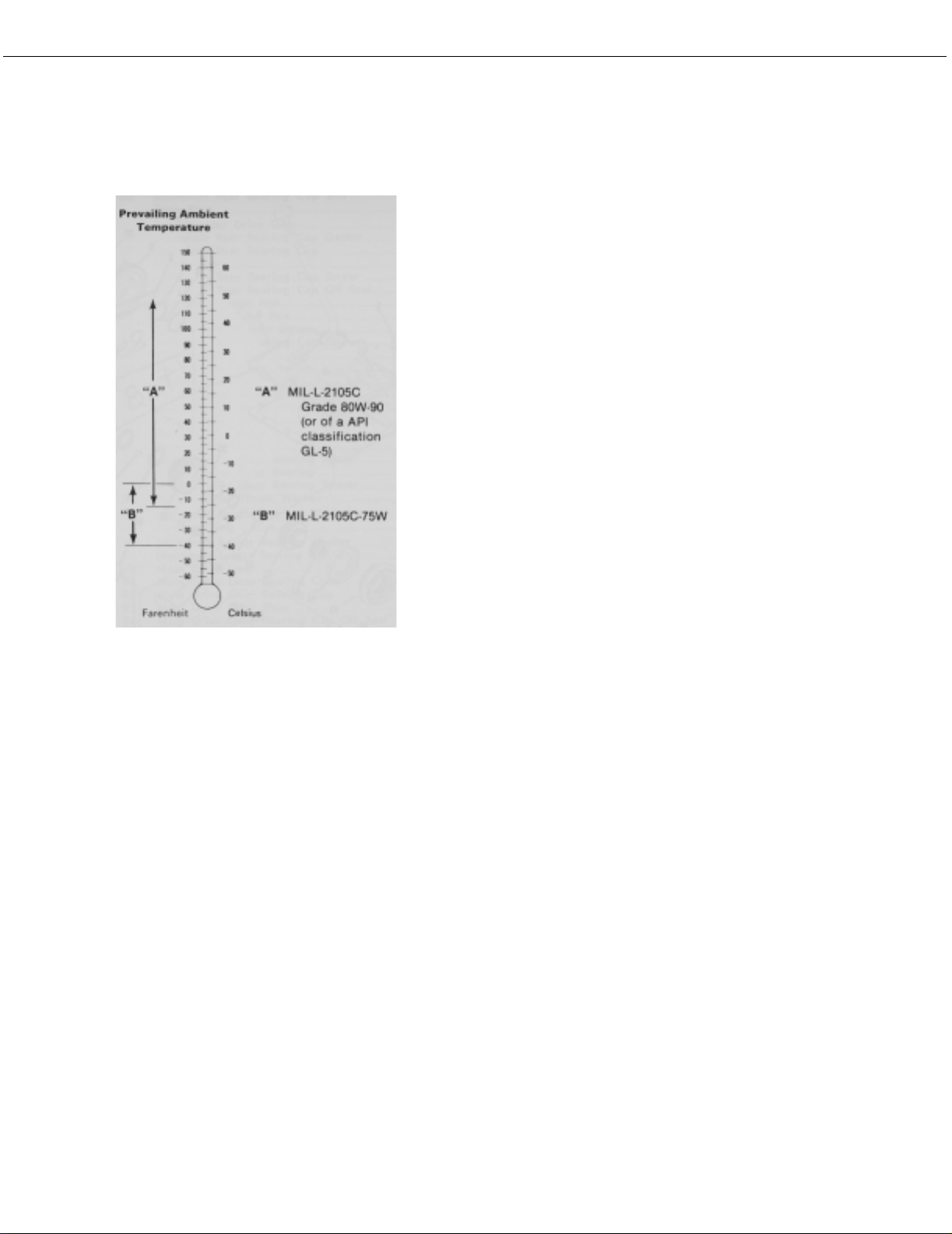

RECOMMENDED LUBRICANTS FOR CLARK

MANUALLY SHIFTED TRANSMISSIONS

*Mil-L-2105C Extreme Pressure Lubricant (or API classification GL-5)

of the SAE viscosity recommended in the chart at the right is preferred.

All lubricants should be backed by the reputation of a well-know supplier. It is important to specify EP lubricants of the MIL-L-2105C type

only, or of a API classification GL-5.

*Do not use extreme pressure lubricants other than MIL-L-2105C or

of a API classification GL-5.

Many EP lubricants contain highly-active chemical compounds that

have been formulated to perform satisfactorily in specific types of

applications. Severe corrosion, residual deposits, and inadequate

lubrication may result from improper application. Use of EP lubricants

other that MIL-L-2105C or of a API classification GL-5 may result in

failure and/or impaired operation.

DRAINING ECONOMY - The object in draining the transmission oil

periodically is to eliminate possible bearing surface abrasion and

attendant wear. Minute particles of metal, the product of normal wear

in service, are deposited in and circulate with the transmission oil. The

oil changes chemically, due to its repeated heating and cooling, also

the terrific churning it undergoes in the presence of air. It is desirable

to drain out this used oil after the first 1,000 miles (1609,0 Km) of service (regardless of type of service). Subsequent drains should be

made every 24,000 miles (38616,0 Km) or six (6) months (whichever

comes first) for highway service, and every 8,000 to 10,000 miles [12872,0-16090,0 Km] or six (6) months (whichever

comes first) “on-off” highway and “pick-up and delivery” types of service. Do this only when the transmission is thoroughly warm.

FLUSHING - After draining, flushing is desirable. Replace the drain plug and fill the transmission to the proper level with

a light flushing oil. Drive the transmission for a short period at fast idle in such a manner that the gears in the transmission are rotating without load. This washes out the old oil clinging to the interior of the gear case, covers and shifter

rails. BE SURE TO DRAIN OUT ALL of the flushing oil before attempting to refill with new oil. This flushing procedure is

most important after first drain.

REFILL - First, removal all dirt around the filler plug, Then refill with new oil of a grade recommended for the existing

season and prevailing service. Fill to the bottom of the level testing plug positioned on the side of the transmission. DO

NOT OVERFILL, as the excess quantity will serve no useful purpose. If the oil level is too high, it will cause excessive oil

churning and high oil temperature and possible leakage.

INSPECTION - Oil level inspection should be made every 6,000 miles [9654,0 Km] which usually coincides with the

vehicle manufacturers chassis lube procedure. Always clean around filler plug before inspection. Add sufficient oil to

maintain correct level.

E

Page 10

CLARK

F

Page 11

CapscrewCL550-SERIES TRANSMISSION

ITEM DESCRIPTION QTY.

1 Control Cover Gasket...............................................................1

2 Lockwasher............................................................................14

3 Control Cover Screw..............................................................14

4 Control Cover Assembly ..........................................................1

5 Mainshaft Reverse Gear Bearing Spacer..................................1

6 Mainshaft Reverse Gear Roller Bearing..................................48

7 Mainshaft Reverse Gear Bearing Spacer..................................1

8 Mainshaft Reverse Gear Roller Bearing..................................48

9 Mainshaft Reverse Gear...........................................................1

10 1st & Reverse Shift Hub Sleeve...............................................1

11 Shift Hub Sleeve Retainer Ring................................................1

12 1st & Reverse Shift Hub ..........................................................1

13 Mainshaft 1st Gear Bearing Spacer..........................................1

14 Mainshaft 1st Gear Roller Bearing .........................................44

15 Mainshaft 1st Gear Bearing Spacer..........................................1

16 Mainshaft 1st Gear Roller Bearing .........................................44

17 Mainshaft 1st Gear...................................................................1

18 Split Washer Retainer Ring......................................................1

19 Mainshaft Rear Bearing Cone...................................................1

20 Ball...........................................................................................1

21 Split Washer Retainer Ring......................................................1

22 Mainshaft 2nd & Reverse Gear Split Washer ...........................2

23 Mainshaft 2nd Gear..................................................................1

24 Mainshaft 2nd Gear Bearing Spacer.........................................1

25 Mainshaft 2nd Gear Roller Bearing ........................................48

26 Mainshaft 2nd Gear Bearing Spacer.........................................1

27 Mainshaft 2nd Gear Roller Bearing ........................................48

28 Mainshaft.................................................................................1

29 2nd & 3rd Synchronizer Assembly ..........................................1

30 3rd Gear Synchronizer Cup......................................................1

31 Mainshaft 3rd Gear Roller Bearing**.....................................48

32 Mainshaft 3rd Gear Bearing Spacer ** ....................................1

33 Mainshaft 3rd Gear Roller Bearing**.....................................48

34 Mainshaft 3rd Gear Bearing Spacer** .....................................1

35 Mainshaft 3rd Gear..................................................................1

36 Ball**.......................................................................................1

37 Mainshaft 3rd Gear Locating Washer.......................................1

38 Mainshaft 3rd Gear Retainer Ring............................................1

39 Mainshaft 4th Gear Roller Bearing**.....................................34

40 Mainshaft 4th Gear Bearing Spacer**......................................1

41 Mainshaft 4th Gear Roller Bearing**.....................................34

42 Mainshaft 4th Gear ..................................................................1

43 4th & 5th Shift Hub Sleeve.......................................................1

18A - Mainshaft Rear Bearing Split Washer**................1

G

Page 12

ITEM Description QTY.

44 4th & 5th Synchronizer Cup.....................................................1

45 4th & 5th Synchronizer Assembly............................................1

46 4th & 5th Synchronizer Cup.....................................................1

47 4th & 5th Shift Hub Bearing ....................................................1

48 4th & 5th Shift Hub Bearing Race............................................1

49 Name Plate Screw....................................................................2

50 Name Plate...............................................................................1

51 Countershaft Gear Retainer Ring .............................................1

52 Countershaft Drive Gear...........................................................1

53 Countershaft 4th Gear..............................................................1

54 Countershaft Gear Key.............................................................2

55 Countershaft ...........................................................................1

56 Oil Baffle ..................................................................................1

57 Countershaft Rear Bearing.......................................................1

58 Countershaft Rear Bearing Outer Retainer Ring.......................1

59 Countershaft Rear Bearing Retainer Ring ................................1

60 Countershaft Rear Bearing Cap Gasket....................................1

61 Countershaft Rear Bearing Cap................................................1

62 Lockwasher..............................................................................4

63 Rear Bearing Capscrew............................................................4

64 Mainshaft Rear Bearing Cup & Snap Ring ...............................1

65 Speedometer Drive Gear..........................................................1

66 Mainshaft Rear Bearing Cap Gasket.........................................1

67 Mainshaft Rear Bearing Cap.....................................................1

68 Lockwasher..............................................................................3

69 Mainshaft Rear Bearing Capscrew ...........................................3

70 Mainshaft Rear Bearing Cap Oil Seal........................................1

71 Mainshaft Flange Nut ...............................................................1

72 Speedometer Tube Nut.............................................................1

73 Speedometer Driven Gear........................................................1

74 Mainshaft Rear Bearing Capscrew ...........................................1

75 Lockwasher..............................................................................1

76 Reverse Idler Lockscrew..........................................................1

77 Reverse Idler Shaft Lock..........................................................1

78 Reverse Idler Shaft ..................................................................1

79 Reverse Idler Thrust Washer ...................................................1

80 Reverse Idler Gear Bearing Spacer...........................................1

81 Reverse Idler Gear Bearing ....................................................26

82 Reverse Idler Gear ..................................................................1

83 Reverse Idler Gear Bearing Spacer...........................................1

84 Reverse Idler Gear Bearing ....................................................26

85 Reverse Idler Gear Bearing Spacer...........................................1

86 Reverse Idler Thrust Washer....................................................1

87 Mainshaft Spigot Bearing Washer Retainer Ring.....................1

ITEM Description QTY.

H

Page 13

88 Mainshaft Spigot Bearing Washer............................................1

89 Mainshaft Spigot Bearing.......................................................14

90 Main Drive Gear ......................................................................1

91 Main Drive Gear Bearing Cone.................................................1

92 Main Drive Gear Bearing Cup...................................................1

93 Main Drive Gear Bearing Shim..............................................AR

94 Main Drive Gear Bearing Cap Oil Seal......................................1

95 Main Drive Gear Bearing Cap...................................................1

96 Lockwasher..............................................................................4

97 Bearing Capscrew....................................................................4

98 P.T. O. Cover Plate Screw.........................................................6

99 P.T. O. Cover Plate....................................................................1

100 P.T. O. Cover Plate Gasket........................................................1

101 Transmission Case...................................................................1

102 Countershaft Pilot Bearing.......................................................1

103 Clutch Housing to Case Stud ...................................................2

104 Pedal Shaft Grease Fitting........................................................2

105 Pedal Shaft Bushing.................................................................1

106 Clutch Housing Cover..............................................................1

107 Clutch Housing Cover Screw Lockwasher................................2

108 Clutch Housing Cover Screw ...................................................2

109 Bushing....................................................................................1

110 Bushing....................................................................................1

111 Clutch Housing To Case Stud Nut............................................6

112 Clutch Housing To Case Stud Lockwasher...............................6

113 Bushing....................................................................................1

114 Clutch Housing ........................................................................1

115 Clutch Housing To Case Stud...................................................4

116 P.T. O. Cover Plate Screw.........................................................6

117 P.T. O. Cover Plate....................................................................1

118 P.T. O. Cover Plate Gasket........................................................1

119 Magnetic Drain Plug ................................................................1

120 Filler Plug.................................................................................1

***- Not used on all models

AR - As Required

I

Page 14

CLARK

J

Page 15

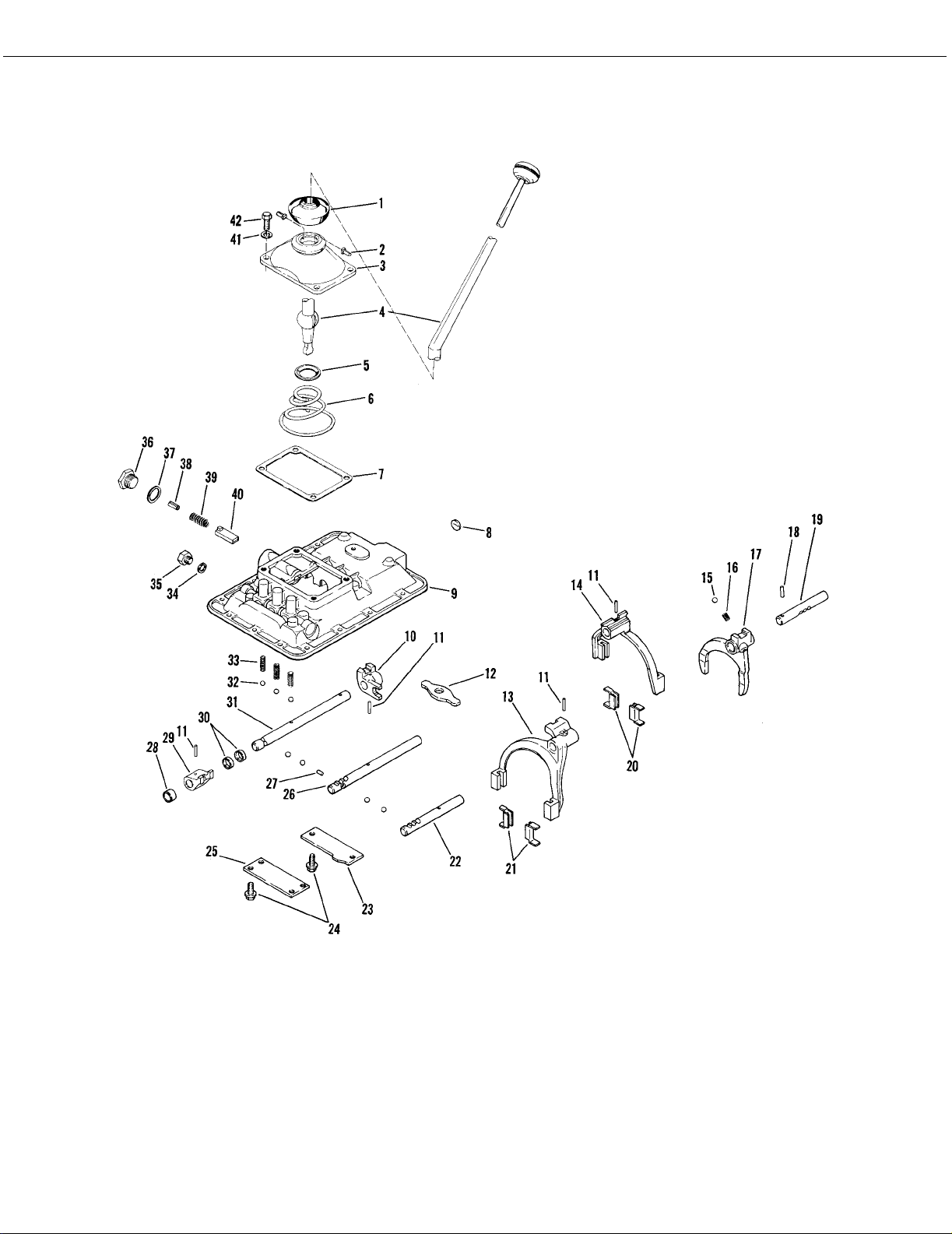

CL550-SERIES CONTROL PARTS GROUP

ITEM Description QTY

1 Gear Shift Lever Dust Cover.....................................................1

2 Gear Shift Lever Pivot Pin........................................................2

3 Control Top ..............................................................................1

4 Gear Shift Lever.......................................................................1

5 Gear Shift Lever Support Washer.............................................1

6 Support Spring ........................................................................1

7 Control Top or Remote Control Gasket ....................................1

8 Expansion Plug........................................................................1

9 Shift Rail Housing....................................................................1

10 1st & Reverse Rocker Lug .......................................................1

11 Shift Fork Lock Pin...................................................................4

12 1st & Reverse Rocker Arm ......................................................1

13 4th & 5th Shift Fork.................................................................1

14 2nd & 3rd Shift Fork ................................................................1

15 Mesh Lock Ball ........................................................................1

16 1st & Reverse Mesh Lock Spring.............................................1

17 1st & Reverse Shift Fork .........................................................1

18 1st & Reverse Shift Fork Rail Lock Pin ....................................1

19 1st & Reverse Shift Rail ..........................................................1

20 Shift Fork Bushing ...................................................................2

21 Shift Fork Bushing ...................................................................2

22 4th & 5th Shift Rail ..................................................................1

23 Rear Rail Support ....................................................................1

24 Rail Support Screw..................................................................6

25 Front Rail Support....................................................................1

26 2nd & 3rd Shift Rail .................................................................1

27 Inter-Lock Cross Pin ................................................................1

28 1st Gear Shift Stop Space (wide) .............................................1

29 1st & Gear Shift Lug................................................................1

30 1st & Gear Shift Stop Spacer ..................................................1

K

Page 16

ITEM Description QTY

31 1st & Reverse Shift Rail...........................................................1

32 Mesh & Inter-Lock Ball ..........................................................10

33 Mesh Lock Spring....................................................................3

34 Back-up Switch Hole Plug Gasket............................................1

35 Back-up Switch Hole Plug........................................................1

36 1st & Reverse Latch Plunger Springer Plug.............................1

37 1st & Reverse Latch Plunger Plug Gasket................................1

38 1st & Reverse Latch Plunger Stop...........................................1

39 1st & Reverse Latch Plunger Spring.......................................1

40 1st & Reverse Latch Plunger ..................................................1

41 Control Top Screw ...................................................................4

42 Screw Lockwasher

L

Page 17

CLARK

M

Page 18

CL550-SERIES TRANSMISSION

ITEM DESCRIPTION QTY.

1 Control Cover Gasket...............................................................1

2 Lockwasher............................................................................14

3 Control Cover Screw..............................................................14

4 Control Cover Assembly ..........................................................1

5 Mainshaft Reverse Gear Bearing Spacer..................................1

6 Mainshaft Reverse Gear Roller Bearing..................................48

7 Mainshaft Reverse Gear Bearing Spacer..................................1

8 Mainshaft Reverse Gear Roller Bearing..................................48

9 Mainshaft Reverse Gear...........................................................1

10 1st & Reverse Shift Hub Sleeve...............................................1

11 Shift Hub Sleeve Retainer Ring................................................1

12 1st & Reverse Shift Hub ..........................................................1

13 Mainshaft 1st Gear Bearing Spacer..........................................1

14 Mainshaft 1st Gear Roller Bearing .........................................44

15 Mainshaft 1st Gear Bearing Spacer..........................................1

16 Mainshaft 1st Gear Roller Bearing .........................................44

17 Mainshaft 1st Gear...................................................................1

18 Mainshaft Rear Bearing Thrust or Split Washer Retainer Ring.1

19 Mainshaft Rear Bearing Cone...................................................1

20 Ball...........................................................................................1

21 Split Washer Retainer Ring......................................................1

22 Mainshaft 2nd & Reverse Gear Split Washer ...........................2

23 Mainshaft 2nd Gear..................................................................1

24 Mainshaft 2nd Gear Bearing Spacer.........................................1

25 Mainshaft 2nd Gear Roller Bearing ........................................48

26 Mainshaft 2nd Gear Bearing Spacer.........................................1

27 Mainshaft 2nd Gear Roller Bearing ........................................48

28 Mainshaft.................................................................................1

29 2nd & 3rd Synchronizer Assembly ..........................................1

30 3rd Gear Synchronizer Cup......................................................1

31 Mainshaft 3rd Gear .................................................................1

32 Mainshaft 3rd Gear Locating Washer.......................................1

33 Mainshaft 3rd Gear Retainer Ring............................................1

34 Mainshaft 4th Gear .................................................................1

35 4th & 5th Shift Hub Sleeve.......................................................1

36 4th & 5th Synchronizer Cup.....................................................1

37 4th & 5th Synchronizer Assembly............................................1

38 4th & 5th Synchronizer Cup.....................................................1

39 4th & 5th Shift Hub Bearing ....................................................1

40 4th & 5th Shift Hub Bearing Race............................................1

41 Name Plate Screw....................................................................2

42 Name Plate...............................................................................1

43 Countershaft Gear Retainer Ring .............................................1

18A - Mainshaft Split Washer** .....................................1

O

Page 19

ITEM Description QTY.

44 Countershaft Drive Gear...........................................................1

45 Countershaft 4th Gear..............................................................1

46 Countershaft Gear Key.............................................................2

47 Countershaft ...........................................................................1

48 Oil Baffle ..................................................................................1

49 Countershaft Rear Bearing.......................................................1

50 Countershaft Rear Bearing Outer Retainer Ring.......................1

51 Countershaft Rear Bearing Retainer Ring ................................1

52 Countershaft Rear Bearing Cap Gasket....................................1

53 Countershaft Rear Bearing Cap................................................1

54 Lockwasher..............................................................................4

55 Rear Bearing Capscrew............................................................4

56 Mainshaft Rear Bearing Cup & Snap Ring ...............................1

57 Speedometer Drive Gear..........................................................1

58 Mainshaft Rear Bearing Cap Gasket.........................................1

59 Mainshaft Rear Bearing Cap.....................................................1

60 Lockwasher..............................................................................3

61 Mainshaft Rear Bearing capscrew............................................3

62 Mainshaft Rear Bearing Cap Oil Seal........................................1

63 Mainshaft Flange Nut ...............................................................1

64 Speedometer Tube Nut.............................................................1

65 Speedometer Driven Gear........................................................1

66 Mainshaft Rear Bearing capscrew............................................1

67 Lockwasher..............................................................................1

68 Reverse Idler Lockscrew..........................................................1

69 Reverse Idler Shaft Lock..........................................................1

70 Reverse Idler Shaft ..................................................................1

71 Reverse Idler Thrust Washer ...................................................1

72 Reverse Idler Gear Bearing Spacer...........................................1

73 Reverse Idler Gear Bearing ....................................................26

74 Reverse Idler Gear ..................................................................1

75 Reverse Idler Gear Bearing Spacer...........................................1

76 Reverse Idler Gear Bearing ....................................................26

77 Reverse Idler Gear Bearing Spacer...........................................1

78 Reverse Idler Thrust Washer....................................................1

79 Mainshaft Spigot Bearing Washer Retainer Ring.....................1

80 Mainshaft Roller Bearing Washer.............................................1

81 Mainshaft Roller Bearing........................................................14

82 Main Drive Gear ......................................................................1

83 Main Drive Gear Bearing Cone.................................................1

84 Main Drive Gear Bearing Cup...................................................1

85 Main Drive Gear Bearing Shim..............................................AR

86 Main Drive Gear Bearing Cap Oil Seal......................................1

87 Main Drive Gear Bearing Cap...................................................1

ITEM Description QTY.

P

Page 20

88 Bearing Capscrew Lockwasher................................................4

89 Bearing Capscrew....................................................................4

90 P.T. O. Cover Plate Screw.........................................................6

91 P.T. O. Cover Plate....................................................................1

92 P.T. O. Cover Plate Gasket........................................................1

93 Transmission Housing .............................................................1

94 Countershaft Pilot Bearing.......................................................1

95 Clutch Housing to Case Stud ...................................................2

96 Grease Fitting...........................................................................2

97 Bushing....................................................................................1

98 Clutch Housing Cover..............................................................1

99 Cover Lockwasher ...................................................................2

100 Cover Screw.............................................................................2

101 Bushing....................................................................................1

102 Bushing....................................................................................1

103 Clutch Housing To Case Stud Nut............................................6

104 Clutch Housing To Case Stud Lockwasher...............................6

105 Bushing....................................................................................1

106 Clutch Housing ........................................................................1

107 Clutch Housing To Case Stud...................................................4

108 P.T. O. Cover Plate Screw.........................................................6

109 P.T. O. Cover Plate....................................................................1

110 P.T. O. Cover Plate Gasket........................................................1

111 Magnetic Drain Plug ................................................................1

112 Filler Plug.................................................................................1

Q

Page 21

CLARK

N

Page 22

390V-SERIES CONTROL PARTS GROUP

ITEM Description QTY

1 Gear Shift Lever Dust Cover.....................................................1

2 Gear Shift Lever Pivot Pin........................................................2

3 Control Top ..............................................................................1

4 Gear Shift Lever.......................................................................1

5 Gear Shift Lever Support Washer.............................................1

6 Support Spring ........................................................................1

7 Control Top or Remote Control Gasket ....................................1

8 Control Cover...........................................................................1

9 1st & Reverse Rocker Arm ......................................................1

10 1st & Reverse Shift Fork & Rail Assembly...............................1

11 Rear Rail Support ....................................................................1

12 Rear Rail Support Capscrew Lockwasher ................................2

13 Rear Rail Support Capscrew ....................................................4

14 Front Rail Support Capscrew ...................................................4

15 Front Rail Support Capscrew Lockwasher ...............................4

16 Front Rail Support....................................................................1

17 2nd & 3rd, 4th & 5th Shift Fork Bushing .................................4

18 4th & 5th Shift Fork & Rail Ass’y (Includes Item #17) .............1

19 2nd & 3rd Shift Fork & Rail Ass’y (Includes Item #17) ............1

20 Interlock Cross Pin ..................................................................1

21 Interlock Tapered Pin Support..................................................2

22 Interlock Tapered Pin ...............................................................2

23 1st & Reverse Shift Rail...........................................................1

24 Mesh Lock Poppet Rails..........................................................4

25 Poppet Springs........................................................................4

26 Reverse Latch Plunger.............................................................1

27 Plunger Spring.........................................................................1

28 Plunger Spring Retaining Plug.................................................1

29 Control Top or Remote Control Capscrew................................4

R

Page 23

S

Page 24

CLARK

390V/CL550 SERIES ASSEMBLY INSTRUCTIONS

T

Page 25

OVERHAUL OF TRANSMISSION ASSEMBLY

The instructions contained herein cover the disassembly

and reassembly of the transmission in a sequence that

would normally be followed after the unit has been

removed from the machine and is to be completely overhauled.

DISASSEMBLY OF THE TRANSMISSION:

CAUTION: Cleanliness is of extreme importance and an

absolute must in the repair and overhaul of this unit.

Before attempting any repairs, the exterior of the unit

must be thoroughly cleaned to prevent the possibility of

dirt and foreign matter entering the mechanism

Figure 1- Remove shift lever control top or remote control assembly.

Figure 2-Remove control cover capscrews and control

cover.

Figure 3 - Remove rear mainshaft bearing cap bolts.

Figure 4 - Remove rear mainshaft bearing cap and

speedometer drive gear.

1

Page 26

Figure 5 - Tap on main drive gear to move mainshaft to

the rear about ¼” [6,35 mm]. Use pry bars as shown to

remove rear bearing cup and locating ring.

Figure 6 - Remove main drive gear cap bolts.

Figure 8 - Remove main drive gear and bearing assem-

bly.

Figure 9 - Using a hoist (if available) and a heavy rope,

lift mainshaft assembly from transmission case. Mainshaft can be removed by hand, but is quite difficult to

handle.

Figure 7 - Using a soft hammer, tap on threaded end of

mainshaft. Move mainshaft toward main drive gear. From

front of transmission, remove main drive gear bearing

cap and shims.

Figure 10 - Remove reverse idler lock and countershaft

rear bearing cap bolts.

2

Page 27

Figure 11 - Remove countershaft rear bearing cap.

Figure 14 - Remove countershaft rear bearing retainer

ring.

Figure 12 - Using a suitable puller, remove reverse idler

shaft.

Figure 13 -Remove reverse idler gear and thrust washers.

NOTE: Idler gear has loose needle rollers in it. Do NOT

lose these rollers.

Figure 15 - Pry countershaft to the rear. Using a suitable

puller, remove countershaft bearing

Figure 16 - Countershaft rear bearing removed. Note oil

baffle position. Remove oil baffle.

3

Page 28

Figure 17 - Remove countershaft assembly from transmission case. Countershaft front pilot bearing has lose

needle rollers. Use caution as NOT to lose these rollers.

Figure18 - Position mainshaft in a suitable stand. A vise

may be used if soft jaw are utilized.

Figure 20 - Remove shift hub thrust bearing and bearing

race.

Figure 21 - Remove 4th & 5th shift hub sleeve and 4th

speed synchronizer cup.

Figure 19 - Remove 5th speed synchronizer cup and 4th

& 5th speed synchronizer assembly.

Figure 22 - Remove 4th speed gear. Use caution as NOT

to lose needle rollers under gear.

NOTE: Units built before serial number 045451YJ will

not have needle rollers under 3rd & 4th speed mainshaft gears.

4

Page 29

Figure 23 - Remove 3rd gear retaining ring.

Figure 24 - Remove 3rd gear thrust washer. Use caution

as NOT to lose lock ball.

Figure 26 - Remove 3rd gear synchronizer cup and synchronizer assembly. NOTE: There is a variation in the

mainshaft 1st gear retention. One version has a split

washer and a split washer retainer ring. Using a threelegged puller (as shown in Figure 27), pull against split

washer retainer ring to remove rear bearing

Figure 27 - Remove mainshaft rear bearing, as shown.

(See Note after Figure 26).

The other version mainshaft 1st gear retention is a thrust

washer between 1st gear and the rear bearing. In this version, there is not enough room to get a puller behind the

thrust washer and it will be necessary to pull on the 1st

gear (as shown in Figure 28).

Figure 25 - Remove 3rd speed gear. Use caution as NOT

to lose needle rollers under gear.

NOTE: Units built before serial number 045451YJ will

not have needle rollers under 3rd & 4th speed mainshaft gears.

Figure 28 - Remove rear mainshaft bearing and 1st gear,

as shown. Use caution as NOT to lose needle rollers

under 1st gear. (See Note after Figure 26).

5

Page 30

Figure 29 - Remove rear bearing and split washer

retainer ring.

Figure 31 - Remove 1st gear. Use caution as NOT to lose

needle rollers under 1st gear. Ist gear was removed in

Figure 28 for thrust washer retention. Further disassembly of the mainshaft will be identical in both versions.

Figure 32 - Remove 1st & Reverse shift hub sleeve

retainer ring.

Figure 30 - Remove 1st gear split washer

Figure 33 - Remove shift hub and sleeve.

6

Page 31

Figure 34 - Remove reverse gear. Use caution as NOT to

lose needle rollers under reverse gear.

Figure 37 - Remove 2nd gear. Use caution as NOT to lose

needle rollers under 2nd gear.

See Cleaning and Inspection Section, Page 24.

MAINSHAFT REASSEMBLY

Figure 35 - Remove 2nd gear split washer retainer ring.

Figure 36 - Remove 2nd gear split washer. CAUTION: Do

NOT lose locating ball. This is to prevent split washer

from spinning.

Figure 38 - With clutching teeth of 3rd gear down, coat

inside diameter of gear with a high quality heavy grease.

This will hold needle rollers in position while assembling.

Lay up first row of needle rollers.

NOTE: Units built before serial number 045451YJ will

not have needle rollers under 3rd & 4th speed mainshaft gears.

Figure 39 - Position roller spacer on first row of rollers.

7

Page 32

Figure 40 - Lay up second row of needle rollers.

Figure 41 - Position outer roller spacer on second row of

rollers. Grease rollers to hold in place.

Figure 43 - Using caution as NOT to catch the needle rollers on the edge of a spline or snap ring groove, install 3rd

gear on mainshaft.

Figure 44 - Install 3rd speed thrust washer lock ball,

washer and washer retainer ring.

NOTE: Thrust washer for units with needle bearings

under 3rd gear is thicker than washer for units without

needle bearings under 3rd gear. (.280/.282 with needles, .240/.238 without needles).

Figure 42

Figure 45 -Turn mainshaft over. Install 3rd gear synchro-

nizer cup and 2nd & 3rd synchronizer assembly.

8

Page 33

Figure 46 - With clutching teeth of 2nd gear down, coat

inside diameter of gear with a high quality heavy grease.

This will hold needle rollers in position while assembling.

Lay up first row of needle rollers.

Figure 47 - Position roller spacer on first row of rollers.

Figure 49 - Position outer roller spacer on second row of

rollers. Grease rollers to hold in place.

Figure 50

Figure 48 - Lay up second row of needle rollers.

Figure 51 - Using caution as NOT to catch the needle roll-

ers on the edge of a spine or snap ring groove install 2nd

gear on mainshaft.

9

Page 34

Figure 52 - Position 2nd gear split washer locating ball in

shaft. Install split washer in washer groove with ends of

washer together at locating ball.

Figure 55 - Lay up first row of needle rollers on spacer.

Figure 53 - Install split washer retainer ring over split

washer.

Figure 54 - With clutching teeth of Reverse gear up, coat

inside diameter of gear with a high quality heavy grease.

This will hold needle rollers in position while assembling.

Insert one roller spacer.

Figure 56 - Position roller spacer on first row of rollers.

Figure 57 - Lay up second row of needle rollers. Grease

rollers to hold in place.

10

Page 35

REVERSE

Figure 58

Figure 59 - Using caution as NOT to catch the needle roll-

ers on the edge of a spline or snap ring groove, install

Reverse gear on mainshaft.

Figure 61 - Install shift hub sleeve retainer ring.

Figure 62 - With clutching teeth of 1st gear down, follow

same procedure used in Figures 54 thru Figure 57 to

install needle rollers and spacers. Install 1st gear on

mainshaft.

Figure 60 - Position 1st and Reverse shift hub sleeve and

hub on mainshaft. NOTE: Counterbore in shift hub sleeve

must be up.

1st GEAR

Figure 63

11

Page 36

Figure 64 - Position 1st gear split washer in groove of

mainshaft. NOTE: If a 1st gear thrust washer is used in

place of the split washer, position thrust washer on shaft

and proceed with Figure 66.

Figure 65 - Install split washer retaining ring over split

washer.

Figure 67 - With clutching teeth of 4th gear down, coat

inside diameter of gear with a high quality heavy grease.

This will hold need rollers in position while assembling.

Lay up first row of needle rollers.

NOTE: Units built before serial number 045451YJ will

not have needle rollers under 3rd & 4th speed mainshaft gears.

Figure 68 - Position roller spacer on first row of rollers.

Figure 66 - Using a suitable bearing driver and soft ham-

mer install mainshaft rear taper bearing. Be certain bearing race is tight against split washer.

Figure 69 - Lay up second row of needle rollers.

12

Page 37

4th GEAR

Figure 70

Figure 71 - Turn gear over and using caution as NOT to

catch the needle rollers on the edge of shaft, install 4th

speed gear.

Figure 73 - Install 4th & 5th synchronizer assembly and

5th speed synchronizer cup on shaft.

Figure 74 - Grease thrust bearing and install bearing and

bearing race on mainshaft.

Figure 72 - Position 4th gear synchronizer cup on clutching teeth of 4th gear. NOTE: Chamfer on I.D. of 4th & 5th

shift hub sleeve must go down. Install shift hub sleeve on

shaft.

Figure 75 - Mainshaft assembly complete.

13

Page 38

Figure 76 - If main drive gear taper bearing is to be

removed (split puller shown in Figure 76) is recommended.

Figure 77 - Remove pilot bearing washer retainer ring.

Remove bearing washer. Use caution as NOT to lose

roller bearings.

MAIN DRIVE GEAR REASSEMBLY

Figure 79 - Install roller bearing washer and retainer ring.

Figure 80 - If the countershaft, drive gear or 4th gear is

to be replaced (Figure 80 shows direction of drive gear

and 4th gear hubs).

Figure 78 - Press new taper bearing on drive gear. Turn

gear over. Using a high quality heavy grease, coat roller

bearing surface. Place rollers in grease as shown.

Figure 81 - If countershaft front bearing is to be replaced,

remove clutch housing and drive front bearing from

transmission case. Apply a light coat of Loctite 510 on

the outer diameter of the new bearing. Install in transmission case as shown with end of bearing .001-.007 below

the face of case. Clutch housing is reassembled temporarily on transmission case to facilitate reassembly of

transmission, but will be removed again later on to set

mainshaft taper bearing end play.

14

Page 39

ROUND RAIL SHIFT CONTROL DISASSEMBLY

Figure 82 - Remove front and rear rail support cap-

screws.

Figure 85 - Remove 2nd & 3rd shift fork and rail assembly. CAUTION: Do NOT lose interlock cross pin.

Figure 83 - Remove front and rear rail supports.

Figure 84 - Remove the 4th & 5th shift fork and rail

assembly.

Figure 86 - Remove 1st & Reverse shift fork, rail and lug

assembly.

Figure 87 - Using a small magnet, remove the 1st &

Reverse shift fork rod lock pin.

15

Page 40

Figure 88 - Remove 1st & Reverse shift fork and rail

assembly.

Figure 89 - Remove 1st & Reverse rocker arm.

Figure 91 - If the 2nd, 3rd, 4th or 5th shift fork bushing is

to be replaced, remove worn bushings from fork. Install

new bushing and bend bushing tab over top and bottom

of fork.

Figure 92 - Remove reverse latch plunger, pin and

spring.

See Cleaning and Inspection Section, page 30.

REASSEMBLY

Figure 90 - Remove mesh lock spring and lock ball, 3

each. Remove crossover interlock balls, 4 each.

Figure 93 - Install reverse latch plunger, spring, pin and

plunger spring plug.

16

Page 41

Figure 94 - Position crossover interlock balls in cover

cross bores. (2) balls in cover cross bore between 1st &

Reverse rail groove, and 2nd & 3rd rail groove, and (2)

balls in cover cross bore between 2nd & 3rd rail groove,

and 4th & 5th rail groove. (See Figure 94-A).

Figure 94-A

Figure 96 - Position 1st & Reverse rocker arm on pivot

pin.

Figure 97 - Install 1st & Reverse shift fork and rail

assembly in control housing. Install shift rail lock pin to

position rail in control housing.

Figure 95 - Position the mesh lock spring and ball, 3

each, in spring pockets. (See Figure 94-A).

Figure 98 - Install 1st & Reverse shift lug, rocker lug,

shift rail and spacers in rail groove over mesh lock ball

and spring. NOTE: Position widest spacer between shift

lug and front support. (2) narrower spacers between the

shift lug and center support.

17

Page 42

Figure 99 - Install interlock cross pin in 2nd & 3rd shift

rail. Position 2nd & 3rd shift rail and fork assembly in rail

groove over mesh lock ball and spring. Make certain

cross pin is in position in rail. (See Figure 94-A).

Figure 100 - Position the 4th & 5th shift rail and fork

assembly in rail groove over mesh lock ball and spring.

Figure 102 - Tighten support capscrews 20 - 25 ft.lbs.

torque [27,2 - 33,8 N.m].

Test Cover for Double Shift

Pry 4th & 5th shift fork and rail out of neutral position.

Try to pry 1st & Reverse shift fork and rail out of neutral

position. 1st & Reverse fork should NOT shift. If it does,

interlock cross pin or interlock cross over balls were not

assembled correctly. Disassemble cover and correct

cross over. (See Figure 94-A).

FABRICATED RAIL SHIFT CONTROL DISASSEMBLY

Figure 101 - Position front rail support over shift rails

and install capscrews. Position rear support over rails

and install capscrews.

Figure 103 - With control cover in neutral, pry 4th & 5th

shift fork to 4th speed position (toward the rear of cover).

18

Page 43

Figure 104 - Remove front rail support capscrews.

Figure 105 - Remove front rail support.

Figure 107 - Note position of interlock tapered pins for

reassembly.

Figure 108 - Remove rear rail support capscrews.

Figure 106 - Remove interlock tapered pin supports.

Figure 109 - Remove rear rail support.

19

Page 44

Figure 110 - Remove 1st & Reverse shift fork and rail

assembly.

Figure 111 - Remove 4th, 5th, 2nd & 3rd shift fork and

rail assembly (See caution in Figure 112).

Figure 113 - Remove 1st & Reverse shift rail.

Figure 114 - Remove mesh lock poppet balls, quantity 4.

Figure 112 - Use caution as NOT to lose interlock cross

pin, interlock tapered pins or mesh lock poppet balls.

Figure 115 - Remove poppet springs, quantity 4.

20

Page 45

Figure 116 - Remove 1st & Reverse rocker arm.

Figure 117 - Remove reverse latch plunger spring retain-

ing plug.

Figure 119 - If fork bushings are worn, secure fork in a

vise equipped with soft jaws and remove worn bushings

with a drift. Install new bushings in fork. Turn fork over

on anvil of vise and secure bushing in fork using a prick

punch and upsetting bushing metal on outside of fork.

Figure 118 - Remove reverse latch plunger spring and

plunger.

Figure 120 - Position 1st & Reverse rocker arm on pivot

pin as shown.

21

Page 46

Figure 121 - Install reverse latch plunger, spring and

retaining plug. Tighten plug securely.

Figure 122 - Install poppet springs, quantity 4.

Figure 124 - Align one tapered interlock cross pin with

hole in 1st & Reverse shift rail. Position rail on poppet

ball with rail in neutral position.

Figure 125 - Note position of tapered interlock cross pin

in relation to rail.

Figure 123 - Install mesh lock poppet balls, quantity 4.

Note 1st & Reverse shift fork rail poppet ball in pocket.

Figure 126 - Install interlock cross pin in 2nd & 3rd shift

rail.

22

Page 47

Figure 127 - Position 2nd & 3rd shift rail on poppet rail in

neutral position with interlock pin aligned with 1st interlock tapered pin.

Figure 128 - Install 2nd interlock tapered pin. Align pin

with interlock cross pin hole.

Figure 130 - Slightly raise rear of 4th & 5th shift rail and

align 2nd interlock tapered pin with cross hole in 4th &

5th shift rail.

Figure 131 - Note position of tapered interlock pins and

shift rails.

Figure 129 - Position 4th & 5th shift fork and rail on poppet ball in neutral.

Figure 132 - Install 1st & Reverse shift fork and rail

assembly on poppet ball in a neutral position. Align 1st &

Reverse rocker arm in notch at rear of rail as shown.

23

Page 48

Figure 133 - Position rear rail support

Figure 134 - Install rail support capscrews and washers.

Tighten capscrews slightly.

Figure 136 - Position front rail support and install capscrews and washers.

Figure 137 - Tighten front and rear support capscrews

20-25 ft.lbs. torque [27,1 - 33,8 N.m.]. Tap 4th & 5th

shift fork and rail assembly forward to a neutral position.

Figure 135 - Install interlock tapered pin supports. Tap

4th & 5th shift fork to the rear. (4th speed position).

Figure 138 - Coat countershaft pilot bearing needle rollers with heavy grease to hold in place until countershaft

is installed.

24

Page 49

Figure 139 - Tip rear of countershaft down and into

transmission case. Feed rear of countershaft through rear

countershaft bearing bore. Move countershaft forward

and into pilot bearing. CAUTION: Do NOT disrupt countershaft needle bearing.

Figure 140 - Position rear bearing oil baffle as shown and

start rear bearing.

Figure 142 - Install countershaft rear bearing retainer

ring.

Figure 143 - Use heavy grease on reverse idler thrust

washers to hold in place. Position tang of washer in

groove in housing.

Figure 141 - Drive rear bearing on countershaft and into

rear bearing bore. NOTE: Countershaft drive gear must be

supported on each side with a ¼” [6,35mm] flat bar to

prevent damage to countershaft pilot bearing.

Figure 144 - Coat inside diameter of reverse idler gear

with high quality heavy grease. This will hold needle rollers in position while assembling. Insert one roller spacer.

25

Page 50

Figure 145 - Lay up first row of needle rollers in spacer.

Figure 148 - Position roller spacer on second row of roll-

ers. Grease rollers to hold in place.

Figure 146 - Position roller spacer on first row of rollers.

Figure 147 - Lay up second row of needle rollers.

Figure 149

Figure 150 - Carefully position reverse idler gear in hous-

ing. Use caution as NOT to disrupt needle rollers. Insert

idler shaft through case and idler gear needle rollers.

NOTE: Idler shaft lock groove MUST line up with lock

screw hole. Drive shaft into position. Install shaft lock

and capscrew.

26

Page 51

Figure 151- Coat a new gasket on both sides with Loctite

510. Position gasket on countershaft bearing cap. Install

bearing cap and bolts. Tighten bolts 20 - 25 ft.lbs. torque

[27,2 - 33,8 N.m.]

Figure 152 - Install mainshaft assembly into transmission case as shown.

Figure 154 - Using a soft hammer, tap rear bearing cup

until cup locating ring is against housing.

Figure 155 - Coat O.D. of oil seal with Loctite 510 and

press seal in mainshaft rear bearing cap with lip of seal

down. Coat a new gasket on both sides with Loctite 510.

Position gasket on mainshaft rear bearing cap. Use caution as not to cover oil return grooves in bearing cap.

Install bearing cap with oil grooves lined up with oil holes

in case.

Figure 153 - Position mainshaft rear bearing cup in

housing bore.

Figure 156 - Install bearing cap bolts. Tighten bolts 35 45 ft.lbs. torque [47,5 - 61,0 N.m.].

27

Page 52

MINSHAFT TAPER BEARING ADJUSTMENT

The mainshaft rear taper bearing and main drive gear

taper bearing must have a .002 to .008 [0,051-0,203mm]

end play after assembly of transmission is complete.

The mainshaft rear taper bearing and bearing cup are not

adjustable.

The main drive gear taper bearingcup is located in the

main drive gear bearing cap. The taper bearing end play

is regulated by shim pack between the bearing cap and

transmission housing.

The following procedure is recommended to achieve a

proper taper bearing end play.

Figure 159 - Position main drive gear bearing cap on

main drive gear. Lube oil groove in cap at the top.

Figure 157- Remove transmission clutch housing.

With main drive gear needle rollers in place and greased,

position main drive gear in housing bore. Alogn clutching

teeth on main drive gear with teeth in 5th speed synchronizer cup.

Figure 158 - Coat O.D. of oil seal with Loctite 510 and

install with lip of seal up in main drive gear bearing cap.

Figure 160 - Install two capscrews 180 Degrees apart

and torque screws to 15 inch lbs. [1.7 N.M.].

Figure 161 - Turn main drive gear and mainshaft by hand

back and forth to seat taper bearings.

27

Page 53

Figure 162 - Recheck bearing capscrews and tighten to

30 inch lbs. torque [3,4 N.m.].

Figure 163 - Using a taper gauge at a capscrew, as

shown, record gap between bearing cap and housing.

Example: .035 [0,88mm].

Figure 165 - Using example .035 - .037 --average .036 +

.016 = .052 shim pack, position shim pack and main

drive gear bearing cap on main drive gear. Lube oil

groove in bearing cap MUST be at the top.

Figure 166 - Install capscrews and tighten 15 - 20 ft.lbs.

torque [20,4 - 27,1 N.m.].

Figure 164 - Using taper gauge at other capscrew as

shown. Record gap. Example: .037 [0,93 mm] average

between one capscrew and the other would be .036

[0,91mm]. Using .036 as the average gap between the

bearing cap and housing add .016 [0,40 mm]. Example

.036 + .016 will give a shim pack of .052 [1,32 mm]. This

shim pack example would give a mainshaft end play of

.002 - .008 [0,051 - 0,203 mm].

28

Page 54

Figure 167 - Place transmission in vertical position, with

main drive gear pointing down. Install transmission output flange and torque the nut. Roll main drive gear and

mainshaft to seat front and rear taper bearings. Position a

dial indicator as shown. Pry on output flange to get mainshaft end play. End play must be between .002 - .008

[0,05 - 0,02]. Add shims for more end play or remove

shims for less end play. NOTE: Each time a change is

made, retorque stud nuts and roll mainshaft. Apply Loctite 510 to both sides of each shim.

Using the main drive gear bearing cap as an alignment

guide, install the clutch housing to the transmission

housing. Tighten stud nuts securely.

With new gasket in position and transmission in neutral,

position control cover over gears, aligning shift forks in

shift cover with gear shift hubs. If control cover is in neutral and transmission is in neutral, transmission drive

gear should turn without output shaft turning.

Figure 169 - With special shift lever control top gasket in

position install control top or remote control assembly on

control cover.Tighten screws 20 - 25 ft. lbs. torque [27,1

- 33,8 N.m].

CLEANING AND INSPECTION

CLEANING

Cleaning all parts thoroughly using solvent type cleaning

fluid. It is recommended that parts be immersed in cleaning fluid and moved up and down slowly until all old

lubricant and foreign material is dissolved and parts are

thoroughly cleaned.

CAUTION: Care should be exercised to avoid skin rashes,

fire hazards, and inhalation of vapors when using solvent

type cleaners.

Housings:

Clean interior and exterior of housings, bearing caps, etc.

thoroughly. Cast parts may be cleaned in hot solution

tanks with mild alkali solutions providing these parts do

not have ground or polished surfaces. Parts should

remain in solution long enough to be thoroughly cleaned

and heated. This will aid the evaporation of the cleaning

solution and rinse water. Parts cleaned in solution tanks

must be thoroughly rinsed with clean water to remove all

traces of alkali. Cast parts may also be cleaned with

steam cleaner.

Figure 168 - When installing control assembly, install

and tighten center rear screw first, center front screw

second and then remaining screws. Tighten screws 20 25 ft. lbs. torque [27,1 - 33,8 N.m].

CAUTION: Care should be exercised to avoid inhalation of

vapors and skin rashes when using alkali cleaners.

All parts cleaned must be thoroughly dried immediately

by using moisture-free compressed air or soft, lintless

absorbent wiping rages free of abrasive materials such as

metal filings, contaminated oil or lapping compound.

INSPECTION

The importance of careful and thorough inspection of all

parts cannot be overstressed. Replacement of all parts

showing indication of wear or stress will eliminate costly

and avoidable failures at a later date.

29

Page 55

Gears and Shafts:

If magno-flux process is available, use process to

check parts. Examine teeth on all gears carefully for wear,

pitting, chipping, nicks, cracks, or scores. If gear teeth

show spots where case hardening is worn through or

cracked, replace with new gear. Small nicks may be

removed with suitable hone. Inspect shafts to make certain they are not sprung, bent, or splines twisted, and that

shaft are true.

Housing, Covers, Etc.:

Inspect housings, covers, and bearing caps to be certain they are thoroughly cleaned and that mating surfaces, bearing bores, etc., are free from nicks or burrs.

Check all parts carefully for evidence of cracks or condition which would cause subsequent oil leaks or failures.

Bearings:

Carefully inspect all rollers and balls for wear, chipping

or nicks to determine if any abnormal conditions exist.

Causes of abnormal wear must be corrected before

transmission is returned to service. Discard bearings.

Oil Seals, Gaskets, Etc.:

Replacement of spring load oil seals. “O”- rings, metal

sealing rings, gaskets and snap rings is more economical

when unit is disassembled than premature overhaul to

replace these parts at a future time. Further, loss of lubricant through a worn seal may result in failure of other

more expensive parts of the assembly. Sealing members

should be handled carefully, particularly when being

installed. Cutting, scratching, or curling under of lip of

seal seriously impairs its efficiency.

30

Page 56

TROUBLESHOOTER’S TRANSMISSION CHECKLIST

1. NOISE ARISING IN NEUTRAL

Misalignment of transmission

Worn transmission bearings

Scuffed gear tooth contact surfaces on gears

Worn mainshaft gear bushings

Worn or rough reverse idler gear

Sprung or work countershaft

Excessive backlash in constant mesh gear

Work mainshaft pilot bearing

Incorrect lubricant

Low lubricant level

Noisy main drive gear bearing

2. NOISE ARISING IN GEAR

Worn or rough mainshaft rear bearing

Excessive end play on mainshaft gears

Noisy speedometer gears

(See Conditions under #1)

3. NOISE ARISING OUTSIDE

Out-of-balance fan

Defective torsional dampener

Out-of-balance crankshaft

Out-of-balance flywheel

Out-of-balance clutch assembly

Loose engine mountings

Worn universal joints

U-joints improperly installed (Out of phase)

Misaligned or sprung driveshaft

Incorrect driveshaft assembly

Out-of-balance driveshaft

Out-of-balance parking brake drum

5. STICKING IN GEAR

Improperly operating clutch

Shift hubs tight on shift hub splines

Misaligned mainshaft

Improper linkage adjustment

6. SLIPPING OUT OF DIRECT

Misaligned of transmission on engine

Worn drive gear teeth

Worn clutching teeth on shift hub or drive gear

Insufficient tension on detent balls

Improper linkage adjustment

Excessive shift lever whip action

Worn torque lock on shift hub sleeve

7. SLIPPING OUT OF OTHER SPEEDS

Excessive clearance between mainshaft gear and

mainshaft, or worn needle bearings

Excessive end play of mainshaft gear on mainshaft

Worn clutching teeth

Weak detent ball springs

Improper linkage adjustment

Worn torque lock on shift hub sleeve.

8. LOSS OF LUBRICANT

Lubricant level too high

Damaged gaskets

Damaged or worn oil seals

Cracked transmission housing

Use of incorrect lubricant

Oil return holes under bearing caps plugged

4. DIFFICULT SHIFTING

Improperly operating clutch (Does not release

properly)

Shift hubs tight on Shift hub sleeve splines

Damaged pointing on clutching teeth

Misaligned mainshaft

Damaged or worn synchronizer assembly

Improper linkage adjustment

Worn or sprung shift fork

9. BEARING FAILURES

Use of incorrect lubricants

Improper bearing adjustment

Improper reassembly in unit overhaul

Lack of cleanliness in unit overhaul

Foreign particles in transmission

31

Page 57

Copyright Eaton Corporation, 2012.

Eaton hereby grant their customers,

vendors, or distributors permission

to freely copy, reproduce and/or

distribute this document in printed

format. It may be copied only in

its entirety without any changes or

modifications. THIS INFORMATION

IS NOT INTENDED FOR SALE OR

RESALE, AND THIS NOTICE MUST

REMAIN ON ALL COPIES.

Note: Features and specifications

listed in this document are subject to

change without notice and represent

the maximum capabilities of the

software and products with all options

installed. Although every attempt has

been made to ensure the accuracy of

information contained within, Eaton

makes no representation about the

completeness, correctness or accuracy

and assumes no responsibility for

any errors or omissions. Features and

functionality may vary depending on

selected options.

For spec’ing or service assistance,

call 1-800-826-HELP (4357) or visit

www.eaton.com/roadranger.

In Mexico, call 001-800-826-4357.

Roadranger: Eaton and trusted partners

providing the best products and services in the

industry, ensuring more time on the road.

Eaton Corporation

Vehicle Group

P.O. Box 4013

Kalamazoo, MI 49003 USA

800-826-HELP (4357)

www.eaton.com/roadranger

Printed in USA

Page 58

For parts or service call us

Pro Gear & Transmission, Inc.

1 (877) 776-4600

(407) 872-1901

parts@eprogear.com

906 W. Gore St.

Orlando, FL 32805

Loading...

Loading...