Page 1

Calibration Software

for Portable Calibrators

• Windows based software

• Maintenance scheduling utility

• Calibration certificates including custom logo

• Compatible with FCINTF hardware drivers

• Stores instrument details, procedures, results

Intecal is a new calibration management software platform

developed to maintain & control a calibration environment to the

highest standards of metrology. The Intecal for Industry package has

been adapted for the process industry especially where portable

calibrators are used to validate plant instrumentation.

Free download of fully functioning 25 tag version at

www.ge-intecal.com

Intecal for Industry

GE Infrastructure

Sensing

Page 2

Intecal for Industry is an easy to use calibration management

software application for generating calibration procedures,

scheduling work and documenting results. It has been developed

to help meet the increasing demands of industry.

We offer the most comprehensive range of pressure and

temperature test and calibration equipment; when used with

Intecal for Industry significant cost savings can be realized by:

• Increasing calibration/maintenance productivity

• Optimizing product quality

• Minimizing production costs

• Reducing the burden of ISO9000, etc

• Reducing documentation time and errors

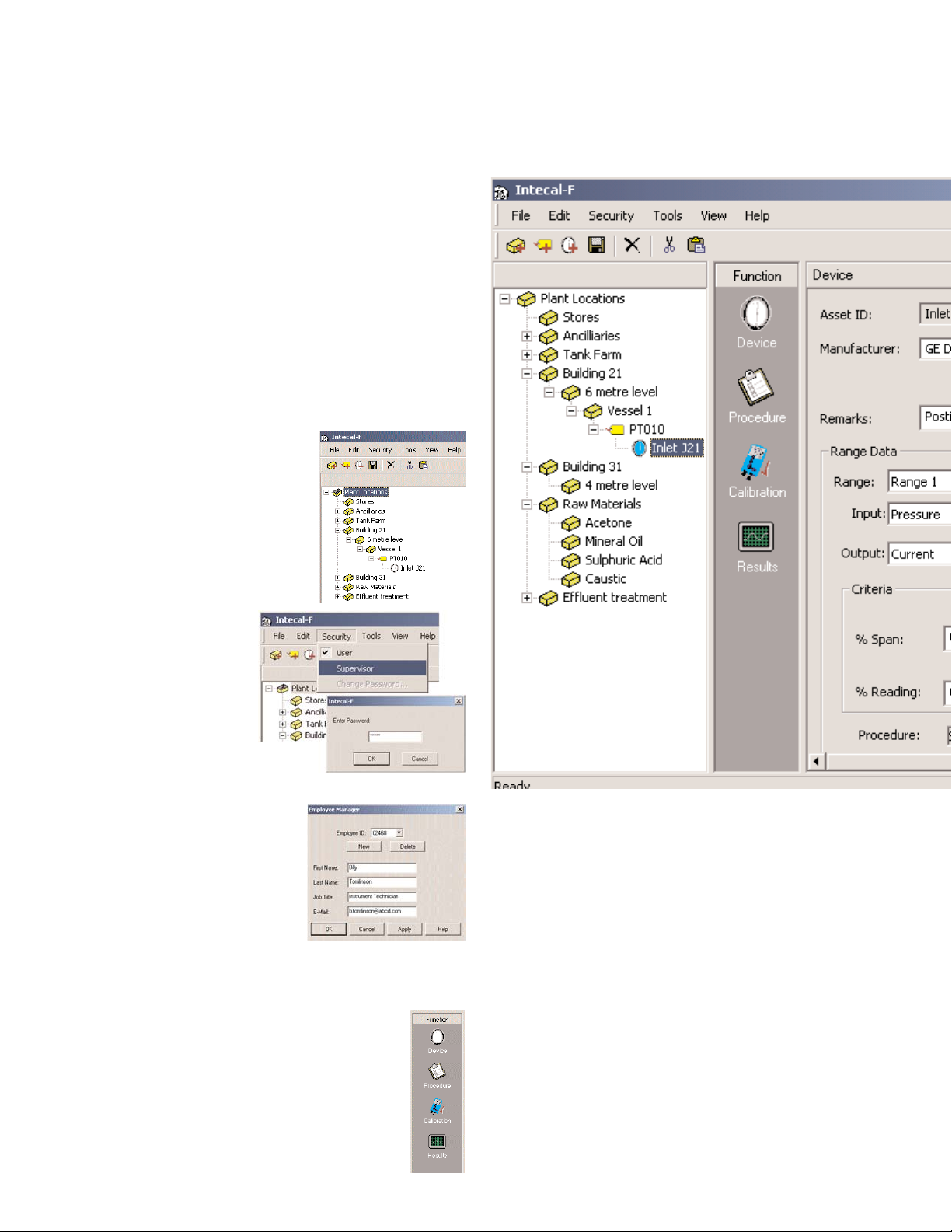

Database Architecture

Intecal for Industry uses the popular

explorer tree structure to view nested

locations. This philosophy is simple to

learn and enables plant areas and process

instrumentation to be organized and

managed effectively.

System Security

To prevent unauthorized editing of data,

Intecal for Industry utilizes a 2 tier

password protected security

system. Database management

is exclusive to the supervisor,

while the user is permitted to

create work orders and transfer

data between PC and Field

Calibrators.

Employee Manager

Authorized employees are issued

with a User ID, this embodies their

unique e-signature that is used to invoke

calibration procedures and save result

files. The employee name is

automatically populated on the

Calibration Report.

Instrument Records

The 'function' pane is the direct portal to

the device database containing the following:

Manufacturer, model number and serial number of the instrument,

the input and output range data and calibration pass/fail

criteria.

Generic test procedures giving Quality uniformity and work

orders to assist resource planning.

Archived calibration history and reports, including as

found/as left data complete with graphs.

Intecal for Industry Software System

Intecal for Industry provides all the features for

efficient calibration management:

• Simple to use

• Supports Tag numbers and Asset numbers

• Compatible with Druck field calibrators and

3rd party calibrators using FCINTF

• Manual data entry

• Time based calibration scheduling

• Historical records

• Export types .pdf, .doc, and .xls.

• Supports simple multi-user environments

• Multi-language version available

• Comprehensive on-line help

Page 3

Time Based Schedule

A time based search engine

quickly identifies devices due

or overdue for calibration.

This simple but powerful

resource management tool

helps plan routine calibration

and outage maintenance.

Field Calibration

Our portable documenting

calibrators and 3rd party calibrators

using the FCINTF protocol can be

programmed with object lists and

test procedures. In the field these

routines will prompt the technician

as to the settings and automatically

record the results, promoting

uniformity and eliminating human

errors.

Manual Data Entry

Calibrators and test

equipment without serial

communications, for

example, deadweight

testers, are supported

with a manual data entry

facility. Calibration results

are entered as the test

proceeds or alternatively

results recorded from field calibrators can be entered later. This

feature provides total compatibility with existing equipment and

allows the full benefits of automated calibration to be realized at a

later date as older equipment is replaced by documenting

calibrators.

Calibration Reports

The calibration certificates

can be printed or exported

in a clear logical format

that complies with the

requirements of quality

approvals such as

ISO9000. As Found and As

Left results are detailed in

numerical and graphical

form including Pass/Fail

status and important

information about the

device calibrated, the

calibrator used and the

technician.

Page 4

Calibration Standards

Our instruments are calibrated with precision equipment traceable to international

standards.

Related Products

Portable field calibrators

We manufacture a wide range of portable pressure, temperature and electrical field

calibrators. A selection of these are shown below.

Laboratory and workshop instruments

We also manufacture a wide range of pressure indicators and controllers. This includes

industrial deadweight testers, high precision controllers and primary standard piston

gauges.

Pressure Transducers and transmitters

An extensive range of pressure transducers and transmitters are available, including

the RTX and Smart/Hart® STX process pressure transmitters.

Intecal for Industry System Requirements

OS Windows 98SE, 2000, ME, NT4 and XP

CPU Intel 486, 66MHz or greater (Pentium recommended)

Memory 16Mbyte or greater (32Mbyte recommended)

Hard Disc Space:

CD Install: 20Mbyte for Installation, then 10MByte for expanding database.

Download: Same as for CD plus 15Mbyte for temporary install files.

Ordering Information

Please state the following:

1. Intecal for Industry (S781-013) .

2. Language, please confirm with factory representative for availability.

Supplied as CD ROM, Internet access required for Installation key.

Continuing development sometimes necessitates specification changes without

notice.

Related Products

DPI 605 High Precision Portable Pressure Calibrator

• 0.025% Rdg accuracy

• 300 psi pneumatic pressure source

• External ranges to 10,000 psi

• RS 232 interface

• Barometric reference

MCX II High Precision Multifunction Calibrator

• T/C’s, RTD’s, mA, mV/V, ohms, frequency

• Pressure to 5000 psi

• Switch testing

• PCMCIA card and RS 232

• Smart HART

®

communicator

DPI 615 Series Portable Pressure Calibrators

• Low pressure differential version

• 300 psi pneumatic source

• 0.025% F.S. accuracy

• RS 232 interface

TRX II Portable Multifuntion Calibrator

• T/C’s, RTD’s, mA, mV/V, ohms, frequency

• Pressure to 10,000 psi

• Switch testing

• PCMCIA card and RS 232

• Smart HART

®

communicator

DPI 325 Series High Pressure Pneumatic Calibrator

• 0.025% FS accuracy

• Generates pneumatic pressures to 3000 psi

• Self contained rechargeable gas cylinder

• RS 232 interface

• Up to 11 sensors per instrument

• Dual channel readout: pressure and electrical

T 203 746 0400 • F 203 746 2494

www.gesensing.com

All specifications are subject to change for product improvement without notice. GE®is a registered trademark of General Electric Co.

Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective companies,

which are not affiliated with GE.

© 2004. All rights reserved. PDSA179 09/04

Intecal for Industry

Loading...

Loading...