Druck RPS8000, DPS 8000 Specifications

GE

Oil & Gas

RPS/DPS 8000

High Accuracy Resonant

Pressure Sensor

Since 1972, Druck has manufactured precision

pressure sensors with a capability to meet critical

applications in industrial, aerospace, oil and gas,

and research environments. Today, Druck is

part of GE Oil & Gas and has continually worked

to develop and improve on the performance of

our pressure sensors to meet our customers’

requirements.

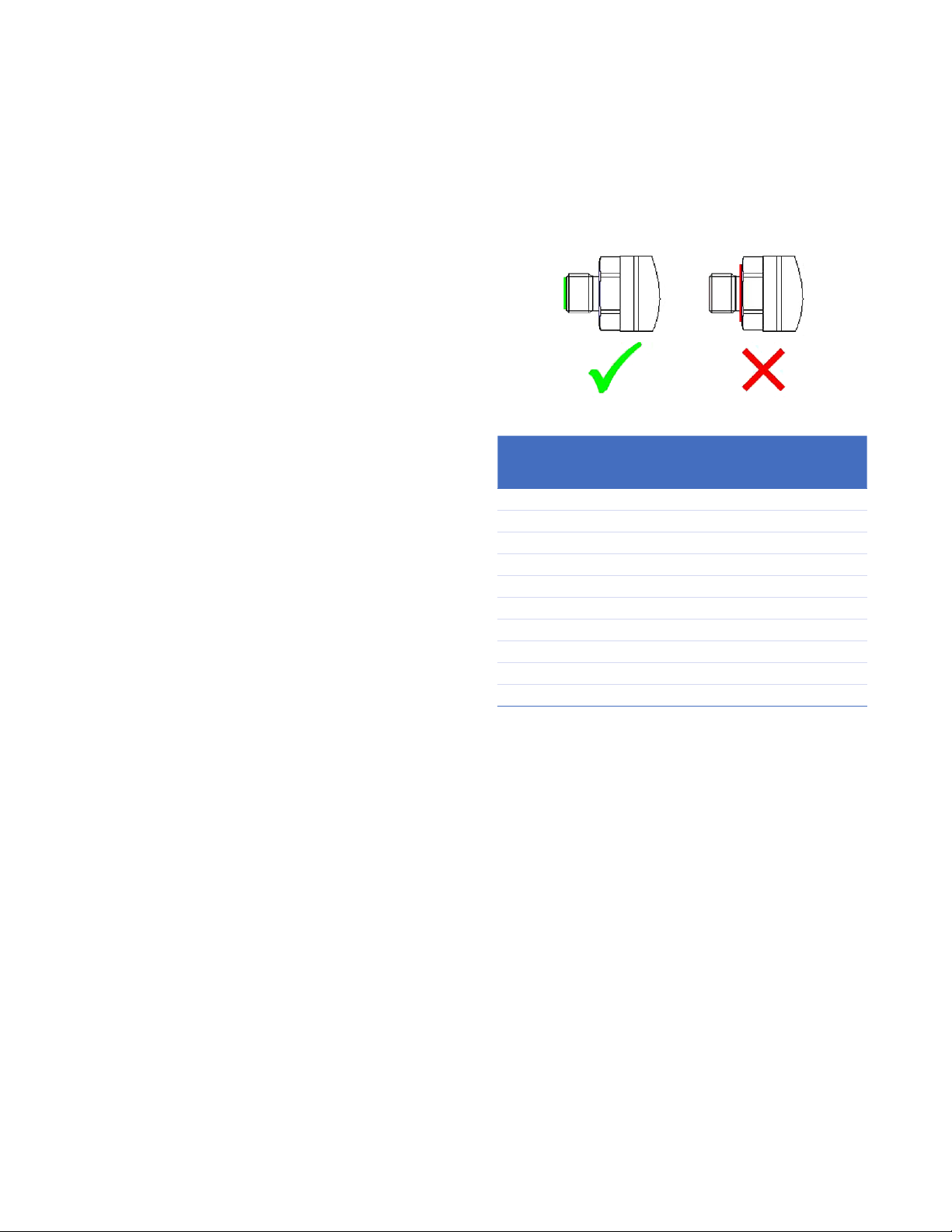

The RPS/DPS 8000 is the rst product to

incorporate the exciting new TERPS technology.

TERPS is a resonant silicon pressure sensor

technology platform that provides an order of

magnitude greater accuracy and stability than

current pressure measurement technologies

available. The new TERPS technology also extends

the pressure range capability to high pressures

and, by incorporating true pressure media

isolation, greatly improves its suitability for use in

harsh environments.

Features:

• High Precision, ±0.01% FS over compensated

temperature range

• High Stability, ±100 ppm FS/year

• Wide temperature range, up to -40°C to +125°C

(-40° to 257°F)

In addition to providing the performance and

packaging improvements available with TERPS,

the RPS/DPS 8000 product line takes advantage

of best practices to oer a wide range of pressure

and electrical connections to enable a level of

customization for your specic requirements never

before available in the performance class of this

sensor.

The combination of the power of the TERPS

technology and the quality, reliability and exibility

of the RPS/DPS 8000 Series oers a truly unique

solution for high accuracy and high stability

pressure measurement requirements.

• Media isolated construction, suitable for use in

harsh environments

• Multiple Output congurations, RS-232, RS-485,

USB 2.0, CAN Bus, Frequency & Diode (TTL)

• Wide selection of pressure & electrical

connections to suit specic requirements

Specications

Measurement

Base Pressure Ranges

• 0 to 2 bar (0 to 30 psi) absolute

• 0 to 7 bar (0 to 100 psi) absolute

• 0 to 14 bar (0 to 200 psi) absolute

• 0 to 20 bar (0 to 300 psi) absolute

• 0 to 35 bar (0 to 500 psi) absolute

• 0 to 70 bar (0 to 1000 psi) absolute

Note: Values in psi are approximate.

The base range selected is the next range up from

the requested calibrated range.Units are converted to

bar for selection; e.g., 30 psi = 2.07 bar. A 7 bar base

pressure range will be selected.

Calibrated Ranges

Any zero-based range between 1 and 70 bar (14.5 to

1000 psi) can be specied. (Performance will be of the

full scale of the base pressure range selected.)

Barometric ranges are available in the RPS/DPS 8100

series. The lowest calibrated pressure is 35 mbar

absolute.

Overpressure

1.5X FS

Sensor Failure Pressure

2.0X FS

Pressure Containment

• Ranges to 7 bar (100 psi), 70 bar (1,000 psi)

• Ranges to 70 bar (1,000 psi), 200 bar (3,000 psi)

Supply and Output

Electronics

Option

1 6 to 28 Frequency &

A 7 to 28 RS485 16.5 quiescent, 32 max

B 9 to 28 RS232 16.5 quiescent, 32 max

C 7.5 to 30 CAN Bus 25 quiescent, 32 max

U 4.8 to 5.2 USB 2.0 40 quiescent, 100 max

1. Jitter less than 20 ns

2. Full temparature range

3. Square wave pressure signal, 25 kHz nominal, 4-10 kHz span

4. Forward voltage diode, 0.5 to 0.7 V @ 25°C (77°F), typically

–2 mV/°C nominal

Supply

Voltage

(V DC)

Output Current

Consumption

(mA)

3.5

Diode TTL

(1,3,4)

(2)

Response Time

< 300 msec for pressure change from 10% to 90% FS

Supply Response

TTL: Accurate to specication within 500 ms of power

up, over all operating temperatures

RS232/RS485/CAN Bus/USB: Accurate to specication

within 10 min of power-up

Electrical Protection

RS232/485/CAN Bus/TTL:Connecting V

between any combinations of pins on the connector will

not damage the unit

supply

and GND

Insulation

500 V DC

Performance

There are two levels of performance specication:

standard and Improved

Specications include combined eects of non-linearity,

hysteresis, repeatability and temperature errors over

the compensated temperature range, and over the base

pressure range of 35 mbar to the full scale pressure.

Accuracy Code Precision

A1- Standard 0.02% FS

A2- Improved 0.01% FS

• For Frequency & Diode output, the above accuracies

are achievable by using a polynomial curve t

algorithm and coecient data supplied with sensor.

• Sensors are calibrated against standards traceable to

UKAS operating to better than 100 ppm.

Compensated Temperature Ranges:

There are four compensated temperature ranges

available:

-10 to +50°C

-40 to +85°C

-40 to +125°C (TTL and CAN bus only)

-55 to 125°C (TTL and CAN bus only)

Temperature Eects

All temperature eects are included in the accuracy

statement.

Long Term Stability

Standard: ±0.02% FS/annum

Improved: ±0.01% FS/annum

Note: Unless otherwise specied, specications are at the

reference conditions of 25°C (77°F) ±5°C (±9°F) and 1 bar

(14 psi).

Orientation (g) Sensitivity

Less than 0.2 mbar/g

Physical Specications

Storage Temperature Range

As compensated temperature range.

Please ensure that only the intended sealing face is

used when mounting the sensor. Failure to comply with

this requirement may aect performance or calibration

accuracy.

Operating Temperature Range

As compensated temperature range.

Pressure Media

Fluids compatible with 316L stainless steel and

Hastelloy C276

Ingress Protection

See Electrical Connector section

Vibration

BS EN 60068-2-6 (2008) Sine sweeps 5 Hz to 2 kHz,

levels to 20g

n

BS EN 60068-2-64 random 10 Hz to 2kHz to 4gn RMS for

1 hour each axis

Less than 0.02% FS effect at any time

Shock

DO-160E 9 (Figure 7.2) 20 gn 11 ms terminal

saw-tooth prole

Humidity

MIL-STD-810D Method 507.2 Procedure III

(Aggravated humidity environment, 65°C, 95% RH)

Pressure Connector

Available Options are:

• G1/4 Female

• G1/4 Male Flat

• G1/4 Male 60° Internal Cone

• G1/8 Male 60° Internal Cone

• 1/4 NPT Female

• 1/4 NPT Male

• 1/8 NPT Male

• M20 x 1.5 Male (3mm bore)

• M14 x 1.5 60° Internal Cone

• M12 x 1 Internal Cone

• 7/16-20 UNF Male 74° External Cone

• G1/2 Male

• G1/4 Quick Connect

• 1/2 NPT Male

• G1/4 Male Flat Long

• 7/16-20 UNF Female

• Depth Cone (G1/4 Female)

• 7/16-20 UNF Male Short Flat

• 3/8-24 UNJF

• Other pressure connectors may be available.

Contact GE to discuss your requirement.

Male threaded pressure connectors must not be sealed

or constrained against the face at the base of the

thread. The forward cone or at face should always be

used, as indicated below.

Electrical Connector

Code

Description Max Operating

No.

0 No Connector -55 to +125 -67 to +257 -

1 Cable Gland -40 to +80 -40 to +176 65

2 Raychem Cable -55 to +125 -67 to +257 65

3 Polyurethane Depth -40 to +80 -40 to +176 68

4 Hytrel Depth -40 to +80 -40 to +176 68

6 Bayonet MIL-C-26482 -55 to +125 -67 to +257 *

C 1/2 NPT Conduit -40 to +80 -40 to +176 67

G M12 X 15-pin -55 to +125 -67 to +267 *

H PTFE Cable (Orange) -55 to +125 -67 to +267 54

M Micro USB socket -40 to +85 -40 to +176 -

Temp. Range

°C °F

IP

Rating

* Hermetically sealed connectors with a maximum leak

rate of 1 x 10

-6

cc/s at 1 atmosphere. High IP rated

mating connectors are available.

Certications

• CE Marked

• RoHS

• EMC Standards:

BS EN 61000-6-1: 2007, Susceptibility - Light Industrial

BS EN 61000-6-2: 2005, Susceptibility - Heavy

Industrial

BS EN 61000-6-3: 2007, Emissions - Light Industrial

BS EN 61000-6-4: 2007, Emissions - Heavy Industrial

BS EN 61326-1: 2013, Electrical Equipment for

Measurement, Control and Laboratory Use EMC requirements

BS EN 61326-2-3:2013 Requirements for pressure

transducers

Loading...

Loading...