Page 1

GE Infrastructure

Sensing

DPI 820

Druck Dual Input

Thermometer

DPI 820 is a GEDruck product .

GEDruck has joined other GE

high-technology sensing

businesses under a new name

_

GE Infrastructure Sensing.

Features

• Temperature test and measurement

• Batch sampling and environmental monitoring

• Comparison test against reference sensor

• Laboratory standard

The DPI 800 Series is a complete range of advanced, robust

and simple to use hand-held instruments. Highly cost effective, these tools are ideal for test/calibration of many popular process parameters. Advanced features and technical

innovations address more applications in less time and deliver results you can rely on.

• Single, dual or differential readings

• Wide probe compatibility for general measurement

and specialist applications

• Advanced Cold Junction compensation virtually

eliminates errors due to ambient temperature changes

• Data logging with adjustable period or manual

recording

• Large backlit display, menu driven interface

• RS232 interface for PC or serial printer

• Robust and weatherproof

• Compact , simple to use, easy t o carry

• Convenient , one-handed operation

• Secure grip, impact resistant, elast omer

protected

• Plug/play connector for Intelligent Digital Output

Sensor (IDOS™) Universal Measurement Modules

Applications

g

Page 2

GE Infrastructure

Sensing

Type P P RTD °F (°C) TC mA/V Hz

Indicator (measure pressure) !!

Calibrator (measure or source) !! ! ! ! ! !

Thermometer (dual input T1, T2, T1 - T2) !

Dual Capability

mA measure with 24 V loop power !! !! !

Switch test !! !! !

HART resistor !! !! !

IDOS Universal Measurement Modules !!!! ! !! ! !!

Features

Programmable step and ramp output !! !! ! ! !

Hold, scaling, max/min/avg, filter, alarm, !!!! ! !! ! !!

tare

25 pressure units, flow scaling, leak test !!"" " "" " ""

1000 point data memory, RS232 #### ! ## # ##

Applications

Measurement and monitoring !!!! ! !! ! !!

Indicator, controller and recorder testing !!!! !! ! !!

Transmitter maintenance and calibration !! !! !

Process loop set-up and maintenance !! !! !

Switch, trip and safety system testing !! !! !

!Optional (please refer to IDOS datasheet) "When f itt ed with IDOS pressure module

#Optional (please refer to accessories IO800E)

DPI 800

DPI 832

DPI 841

DPI 842

DPI 802

DPI 811

DPI 812

DPI 820

DPI 821

DPI 822

DPI 820

Specifications

DPI 820 Dual Input Thermometer

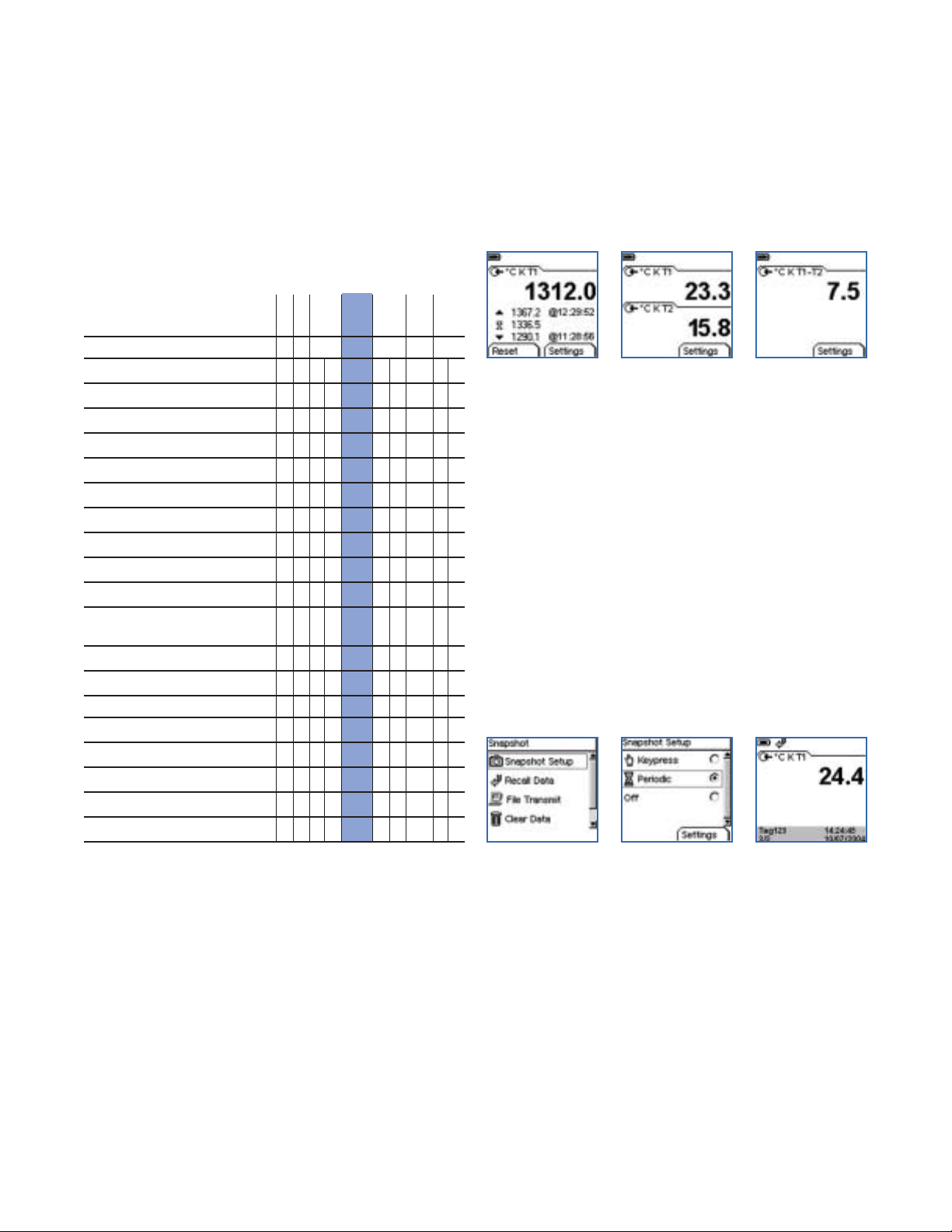

Two sensor inputs, T1 and T2, allow individual measurement or simultaneous comparisons. For differential

applications; e.g. heating boiler bypass, T1 minus T2 can

be displayed

Interchangeable Probes and Wide Thermocouple

Compatibility

Allow general temperature measurement or the use of

special sensors for demanding applications; e.g. high

temperature, hygienic and aggressive media

Temperature Test and Measurement

Periodic Data Logging

Records processes and systems over time

Manual Logging

Record screen snapshots for batch sampling and environmental monitoring. All data is date/time stamped.

Review Data

On-screen or upload to a PC via RS232 interface (see

accessories for lead). No software purchase is necessary

as standard Microsoft®applications provide data transfer (HyperTerminal) and analysis (Excel). Alternatively,

print directly to a compatible serial printer.

Temperature Data Logging, Analysis

and Documentation

Advanced Features

Hold, maximum/minimum/average, (with time stamp),

tare (offset) and damping filt er facil itate syst em checks

and troubleshooting

Data Logging

Memory: 1000 single or 750 dual reading screens with

date and time

Header Tag: 6 user characters to identify groups of

readings

RS232: 19.2 k baud, 8 data bits, 1 stop bit, no parity,

Xon/Xoff

Data Output: Comma separated ASCII

Page 3

GE Infrastructure

Sensing

DPI 820

Specifications

DPI 820 specifications

*Accuracy includes operation from 50°F to 86°F (10°C to 30°C), one year stability and

calibration uncertainty.

Type Standard *Accuracy Range

K IEC 584 1.1°F (0.6°C) -454°F to 2498°F (-270°C to 1370°C)

J IEC 584 0.9°F (0.5°C) -346°F to 2192°F (-210°C to 1200°C)

T IEC 584 0.6°F (0.3°C) -454°F to 752°F (-270°C to 400°C)

B IEC 584 1.8°F (1.0°C) 122°F to 3308°F (50°C to 1820°C)

R IEC 584 1.8°F (1.0°C) -58°F to 3216°F (-50°C to 1769°C)

S IEC 584 2.5°F (1.4°C) -58°F to 3216°F (-50°C to 1769°C)

E IEC 584 0.7°F (0.4°C) -454°F to 1832°F (-270°C to 1000°C)

N IEC 584 1.1°F (0.6°C) -454°F to 2372°F (-270°C to 1300°C)

L DIN 43710 0.6°F (0.3°C) -328°F to 1652°F (-200°C to 900°C)

U DIN 43710 0.6°F (0.3°C) -328°F to 1112°F (-200°C to 600°C)

C 1.8°F (1.0°C) 32°F to 4208°F (0°C to 2320°C)

D 1.8°F (1.0°C) 32°F to 4523°F (0°C to 2495°C)

Accuracies quoted for mid range and do not include sensor error

Operating Temperature

14°F to 122°F (-10°C to 50°C)

Storage Temperature

-4°F to 158°F (-20°C to 70°C)

Humidity

0% to 90% non-condensing, Def Stan 66-31m 8.6 Cat III

Shock and vibration

BS EN61010:2001, Def Stan 66-31, 8.4 Cat III

EMC

BS EN61326-1:1998 + A2:2001

Safety

Electrical BS EN61010:2001. CE marked

Display

Graphic LCD with backlight . Resolution 99999

Size (l x w x h) and Weight

7.1 in x 3.3 in x 2 in (180 mm x 85 mm x 50 mm),

14 oz (400 g)

Batteries

3 AA alkaline, >80 hours use

DPI 800 Series Common Specif ication

Intelligent Digital Output Sensor (IDOS)

Universal Pressure Modules are available from 10 in H2O

to 10,000 psi (25 mbar to 700 bar).

Total Flexibility

IDOS modules can be used with any compatible instrument; for example, a DPI 820 thermometer can become

a fully featured pressure indicator or can read pressure

and temperature simultaneously.

Plug and Play

Modules are interchangeable between instruments,

requiring no set-up or instrument calibration.

Please refer to IDOS UPM data sheet.

IDOS Flexibility

Temperature Coefficient

14°F to 50°F, 86°F to 122°F; 0.005°F/°F

(-10°C to 10°C, 30°C to 50°C; 0.01°C/°C)

4.5°F (2.5°C)

32°F (0°C)

0 5 10 15 tmins

C/J error due to 54°F (30°C) transient change

DPI 820

Leading competitor

Unique Cold Junction Compensation

Virtually el iminat es ambient temperature errors. (Pat ent

pending). 0.4°F (0.2°C) maximum error for 86°F (30°C)

change in ambient temperature

Thermocouple connectors

Mini-jack sockets for T1 and T2 inputs

Page 4

GE Infrastructure

Sensing

g

DPI 820

Specifications

©2005 GEInfrastructure Sensing, Inc. All rights reserved.

920-113A

All specifications are subject to change for product improvement without notice. GE

®

is a registered trademark of General Electric Co. Other company or product names

mentioned in this document may be trademarks or registered trademarks of their

respective companies, which are not affiliated with GE.

Accessories

IO800A

Soft fabric carrying case with accessory pocket

IO800B

Belt clip, wrist strap/hanging loop and bench stand

IO800C

NiMh batteries with charger (charged externally)

IO800D

RS232 lead: DPI 800 to PC 9 way ‘D’ type

Ordering Information

Please state the model number DPI 820 and accessories

as separate items.

Each unit is supplied with batteries, calibration certificate,

user guide and two general purpose type ‘K’ bead thermocouples range -103°F to 482°F (-75°C to 250°C) Class I.

Related Products

GEis a world leader in the design and manufacture of

pressure, temperature and electrical f ield cal ibrators,

laboratory/workshop calibration equipment and pressure sensors.

www.gesensing.com

Loading...

Loading...