Page 1

GE

Digital Solutions

© 2014 General Electric Company. All Rights Reserved. Specifications are subject

to change without notice. GE is a registered trademark of General Electric

Company. Other company or product names mentioned in this document may

be trademarks or registered trademarks of their respective companies, which

are not affiliated with GE.

Druck DPI612

Portable Pressure Calibrator

User Manual – 109M4017 Revision A

g

Page 2

User Manual Druck DPI612

Page 2 of 108 [EN] English – 109M4017 Revision A

Revision History

This document supersedes all previously issued versions, providing new

or revised information. The most recent publication can be determined

by comparing the last three characters at the end of the part number

and the date issued.

DPI 612 Portable Pressure Calibrator User Manual

Part Number: 109M4017

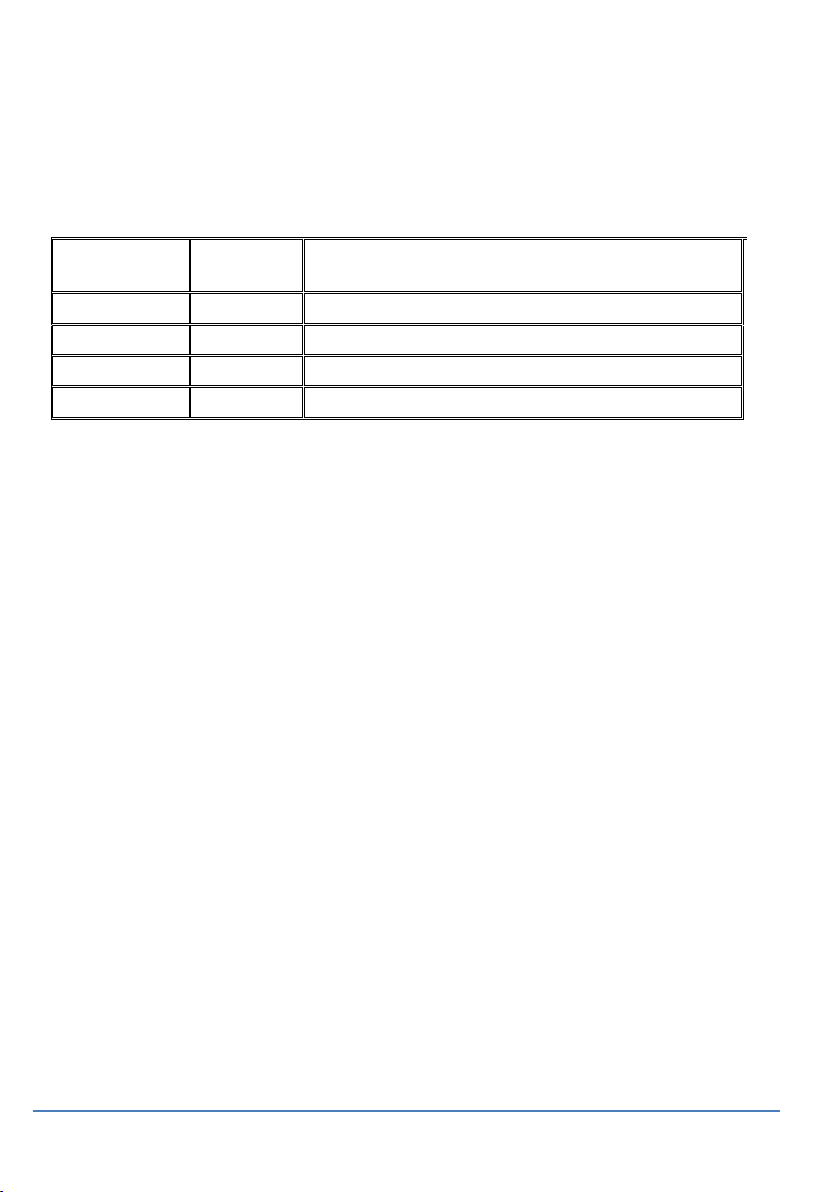

Revision

Level

Date

Issued

General Description of Changes

Revision -

07/08/15

First Release

Revision A

27/09/16

Updated to include Leak Test procedure

Page 3

User Manual Druck DPI612

Page 3 of 108 [EN] English – 109M4017 Revision A

Contents

1 INTRODUCTION .............................................................................................................................. 9

EQUIPMENT IN THE BOX .................................................................................................. 9

OBSERVANCE OF THE USER MANUAL ....................................................................... 9

GENERAL SAFETY PRECAUTIONS ................................................................................. 9

WARNINGS .......................................................................................................................... 11

ELECTRICAL SAFETY ........................................................................................................ 11

RECHARGABLE BATTERY WARNINGS ..................................................................... 12

PRESSURE WARNINGS ................................................................................................... 15

OVERVOLTAGE CATEGORY ........................................................................................... 16

PREPARING THE INSTRUMENT ................................................................................... 16

1.9.1 Initial Checks ............................................................................................................ 16

1.9.2 Install Rechargeable Battery and Cradle ................................................... 16

1.9.3 Install Dry Cell Batteries ..................................................................................... 18

PARTS ..................................................................................................................................... 20

1.10.1 DPI 612 ....................................................................................................................... 20

1.10.2 Test Port ..................................................................................................................... 22

1.10.3 Pressure Release Valve....................................................................................... 23

1.10.4 SELECTOR DPI 612 pFlex & pFlexPro (20 & 100 bar) ............................ 23

1.10.5 Pump ........................................................................................................................... 23

1.10.6 Volume Adjuster ..................................................................................................... 24

1.10.7 Refill Valve ................................................................................................................. 26

1.10.8 Priming Pump DPI612 hFlexPro (1000 bar) ............................................... 26

ACCESSORIES: .................................................................................................................... 27

1.11.1 Carry Case (P/N IO612-CASE-3) ...................................................................... 27

1.11.2 Rechargeable Battery pack (P/N CC3800GE) ........................................... 27

1.11.3 Rechargeable Battery and adaptor kit (P/N IO61X-BAT-KIT) ............ 27

1.11.4 Rechargeable Desktop Charger (P/N CX6100GE) .................................. 27

Page 4

User Manual Druck DPI612

Page 4 of 108 [EN] English – 109M4017 Revision A

1.11.5 Mains Adaptor (P/N IO620-PSU) ..................................................................... 27

1.11.6 USB Cable (P/N IO620-USB-PC) ....................................................................... 28

1.11.7 IDOS to USB Converter (P/N IO620-IDOS-USB) ........................................ 28

1.11.8 USB to RS 232 Cable (P/N IO620-USB-RS232) .......................................... 28

1.11.9 Dirt Moisture Trap 20 bar (P/N IO620-IDT621) ......................................... 28

1.11.10 Dirt Moisture Trap 100 bar (P/N IO620-IDT622) ...................................... 28

1.11.11 Pneumatic Hose (PN IO620-HOSE-P1 / IO620-HOSE-P2) ................... 29

1.11.12 Hydraulic Hose (PN IO620-HOSE-H1 / IO620-HOSE-H2) .................... 29

1.11.13 Low Pressure Pneumatic Hose (PN IOHOSE-NP1 / IOHOSE-NP2) .. 29

1.11.14 Pressure Adaptor set ........................................................................................... 30

1.11.15 Comparator Adaptor (P/N IO620-COMP) .................................................... 30

1.11.16 Pressure Module (P/N IPM620-***) ................................................................ 30

1.11.17 Pressure Relief Valve (PRV) ................................................................................ 31

DRUCK DPI612, MODES ................................................................................................. 32

1.12.1 Power ON ................................................................................................................... 32

1.12.2 Power OFF ................................................................................................................. 32

1.12.3 Power up from Standby Mode ........................................................................ 33

NAVIGATION ....................................................................................................................... 33

1.13.1 Set Date, Time and Language ......................................................................... 33

1.13.2 Themes ....................................................................................................................... 34

1.13.3 DRUCK DPI612 Manual ....................................................................................... 34

SOFTWARE AND FIRMWARE UPGRADES ............................................................... 34

1.14.1 Viewing Software Revision ................................................................................ 34

1.14.2 Upgrading the Software ..................................................................................... 34

1.14.3 Upgrade the Application Software ................................................................ 35

1.14.4 Upgrade the Operating System and Boot Loader Software. ........... 35

MAINTENANCE ................................................................................................................... 36

1.15.1 Cleaning ..................................................................................................................... 36

1.15.2 Replace the Batteries ........................................................................................... 36

Page 5

User Manual Druck DPI612

Page 5 of 108 [EN] English – 109M4017 Revision A

INSTRUMENT RETURN.................................................................................................... 36

1.16.1 Returned Material Procedure .......................................................................... 36

1.16.2 Safety Precautions ................................................................................................ 36

1.16.3 Important Notice ................................................................................................... 37

1.16.4 Instrument Disposal in the European Union ............................................ 37

1.16.5 For more information contact ......................................................................... 37

ENVIRONMENT .................................................................................................................. 37

MARKS AND SYMBOLS ON THE EQUIPMENT ....................................................... 38

2 OPERATIONS ................................................................................................................................. 39

COMMON OPERATIONS ................................................................................................. 39

2.1.1 Attach/Remove the device under test ........................................................ 39

2.1.2 Attach a Pressure Relief Valve ........................................................................ 41

2.1.3 Setting a Pressure Relief Valve ....................................................................... 42

DPI 612 PFLEX & PFLEXPRO PNEUMATIC PRESSURE OPERATIONS .......... 43

2.2.1 Introduction .............................................................................................................. 43

2.2.2 Release the Pressure ........................................................................................... 43

2.2.3 Vacuum or Pressure Operation DPI 612 pFlex (20 bar) .................... 44

2.2.1 Release Pressure DPI 612 pFlex (20 bar) ................................................... 44

2.2.2 Vacuum or Pressure Operation DPI 612 pFlexPro (100 bar) ............. 45

2.2.3 Release pressure DPI 612 pFlexPro (100 bar pump) ............................ 47

DPI 612 HFLEXPRO (1000 BAR) HYDRAULIC OPERATIONS. .......................... 47

2.3.1 First Use ..................................................................................................................... 48

2.3.2 Filling and Priming the Pump ........................................................................... 48

2.3.3 Topping up the Hydraulic Fluid ....................................................................... 49

2.3.4 Priming Sequence ................................................................................................. 50

2.3.5 Applying Hydraulic Pressure (1000 bar) ..................................................... 51

2.3.6 Release Hydraulic Pressure (1000 bar pump) ......................................... 52

2.3.7 Drain Excess Hydraulic Fluid ............................................................................ 52

2.3.8 Drain all the Hydraulic Fluid ............................................................................. 53

Page 6

User Manual Druck DPI612

Page 6 of 108 [EN] English – 109M4017 Revision A

CALIBRATOR OPERATIONS ........................................................................................... 55

2.4.1 Basic Calibrator Operation ................................................................................ 55

2.4.2 Set the Function Utility Options ...................................................................... 61

2.4.3 Measurement Display Options ........................................................................ 64

2.4.4 Example Procedures ............................................................................................ 65

PRESSURE CALIBRATION ............................................................................................... 70

2.5.1 Set up a Leak Test ................................................................................................. 71

2.5.2 Set the Pressure Module to Zero .................................................................... 73

2.5.3 Error Indications ..................................................................................................... 73

MEASURE PRESSURE: IDOS OPTION ........................................................................ 73

2.6.1 IDOS Option Assembly Instructions .............................................................. 74

2.6.2 IDOS Function Procedures ................................................................................ 74

3 DATA LOGGING OPERATION .................................................................................................. 76

SET-UP ................................................................................................................................... 77

OPERATION.......................................................................................................................... 78

FILE REVIEW ........................................................................................................................ 79

FILE MANAGEMENT ......................................................................................................... 79

3.4.1 Transfer ...................................................................................................................... 79

3.4.2 Erase ............................................................................................................................ 80

3.4.3 Memory Status ........................................................................................................ 80

DATA FORMAT .................................................................................................................... 80

4 DOCUMENTATION ...................................................................................................................... 82

ANALYSIS .............................................................................................................................. 82

SET-UP ................................................................................................................................... 83

4.2.1 Define the Reference Channel ........................................................................ 83

4.2.2 Define each Input Channel ............................................................................... 83

ANALYSIS FUNCTION ...................................................................................................... 85

RUN PROCEDURE ............................................................................................................. 85

4.4.1 Sequence to Upload and Download file ..................................................... 86

Page 7

User Manual Druck DPI612

Page 7 of 108 [EN] English – 109M4017 Revision A

5 CALIBRATION ................................................................................................................................ 87

GENERAL .............................................................................................................................. 87

CALIBRATION CHECK ...................................................................................................... 87

CALIBRATION ADJUSTMENTS ..................................................................................... 88

BEFORE STARTING ........................................................................................................... 88

PROCEDURES: CURRENT (MEASURE) ....................................................................... 89

PROCEDURES: CURRENT (SOURCE) .......................................................................... 90

PROCEDURES: DC MV/VOLTS (MEASURE) ............................................................. 91

PROCEDURES: DC VOLTS (SOURCE) ......................................................................... 92

PROCEDURES: PRESSURE INDICATOR .................................................................... 93

PROCEDURES: IDOS UPM ............................................................................................. 94

6 ACCESSORY INSTRUCTIONS .................................................................................................. 95

DIRT MOISTURE TRAP 20 BAR (P/N IO620-IDT621) ........................................... 95

6.1.1 Specification: ........................................................................................................... 95

6.1.2 Pressure connections: ......................................................................................... 95

6.1.3 Operation: ................................................................................................................. 95

6.1.4 Cleaning: .................................................................................................................... 96

DIRT MOISTURE TRAP 100 BAR (P/N IO620-IDT622) ........................................ 97

6.2.1 Specification: ........................................................................................................... 97

6.2.2 Pressure connections: ......................................................................................... 97

6.2.3 Operation: ................................................................................................................. 97

6.2.4 Cleaning: .................................................................................................................... 98

7 LEAK TEST PROCEDURES ........................................................................................................ 99

LEAK TEST PROCEDURE FOR DPI612 PFX (UP TO 20BAR) PNEUMATIC ... 99

VACUUM .............................................................................................................................................. 99

LEAK TEST PROCEDURE FOR DPI612 PFP (UP TO 100BAR) PNEUMATIC ......

................................................................................................................................................ 100

VACUUM ............................................................................................................................................ 100

LEAK TEST PROCEDURE FOR DPI612 HFP (UP TO 1000BAR) HYDRAULIC ....

................................................................................................................................................ 101

Page 8

User Manual Druck DPI612

Page 8 of 108 [EN] English – 109M4017 Revision A

8 GENERAL SPECIFICATION .................................................................................................... 102

9 TROUBLESHOOTING ............................................................................................................... 104

DPI 612 PFLEX ................................................................................................................. 104

DPI 612 PFLEXPRO ........................................................................................................ 105

DPI 612 HFLEXPRO ....................................................................................................... 106

GENERAL ........................................................................................................................... 107

10 MANUFACTURER ...................................................................................................................... 108

Page 9

User Manual Druck DPI612

Page 9 of 108 [EN] English – 109M4017 Revision A

1 INTRODUCTION

The Druck DPI612 is a battery-powered instrument for performing

pressure and electrical calibration operations. The Druck DPI612

also supplies the power and user interface functions for all optional

items. The DPI612 uses the PM620 pressure module to allow user

selection of the most suitable pressure range for the task.

EQUIPMENT IN THE BOX

The following are the common items supplied with the Druck DPI612

1/8” NPT & BSP pressure adaptors

Set of four test leads

Safety and Quick Start Guide

Stylus

Hand & Shoulder straps

Refer to DPI612 datasheet for full list of accessories supplied with

each DPI612 model.

OBSERVANCE OF THE USER MANUAL

This manual contains safety and battery installation information for

the Druck DPI612. It is the responsibility of the customer to make

sure that all personnel operating and maintaining the equipment

are correctly trained and qualified. Before using the equipment, read

all sections of this User Manual paying particular attention to all

WARNINGS and CAUTIONS given in the Quick Start Guide.

GENERAL SAFETY PRECAUTIONS

Read and obey all the operator's local health and safety regulations

and safe working procedures or practices when doing a procedure

or task.

Use only the approved tools, consumable materials and spares to

operate and maintain the equipment.

Use equipment only for the purpose for which it is provided.

Page 10

User Manual Druck DPI612

Page 10 of 108 [EN] English – 109M4017 Revision A

Wear all applicable Personal Protective Equipment (PPE).

Do not use sharp objects on the touch-screen.

Observe absolute cleanliness when using the instrument.

Severe damage can be caused if equipment connected to this

instrument is contaminated.

Connect only clean equipment to the instrument. To avoid any

contamination, an external Dirt Moisture Trap (See Section 1.11.9)

is recommended

Some liquid and gas mixtures are dangerous. This includes

mixtures that occur because of contamination. Make sure that the

equipment is safe to use with the necessary media.

Read and obey all applicable WARNING and CAUTIONS signs.

Make sure that:

o All work areas are clean and clear of unwanted tools,

equipment and materials.

o All unwanted consumable materials are disposed in

accordance with local health and safety and

environmental regulations.

o All equipment is serviceable.

Page 11

User Manual Druck DPI612

Page 11 of 108 [EN] English – 109M4017 Revision A

WARNINGS

Do not ignore the specified limits for the instrument or its related

accessories. This can cause injuries.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

impaired.

Do not use the instrument in locations with explosive gas, vapour

or dust. There is a risk of an explosion.

ELECTRICAL SAFETY

The DC input to the DPI612 is rated at 5V (+/-5%) 4 Amps.

External circuits should have appropriate insulation to the mains.

To prevent electrical shocks or damage to the instrument, do not

connect more than 30V CAT I between the terminals or between

the terminals and the ground (earth).

This instrument uses a rechargeable battery pack or standard AA

size batteries. To prevent an explosion or fire do not short circuit.

The power supply input range to the optional power supply unit is

100 – 260Vac, 50 to 60Hz, 250mA, installation category CAT II.

When using the optional power supply unit, position the power

supply so as not to obstruct the supply disconnecting device.

Note that the operating and storage temperature range of the

optional PSU does not match that of the DPI612. Mains PSU

operating temperature range 0°C to +40°C, storage temperature

range -40°C to +70°C.

To make sure the display shows the correct data, disconnect the

test leads before power is set to ON or changing to another

measure or source function.

Keep the leads free from all contaminants.

Page 12

User Manual Druck DPI612

Page 12 of 108 [EN] English – 109M4017 Revision A

RECHARGABLE BATTERY WARNINGS

Do not disassemble or modify the battery pack. The battery pack

can leak electrolyte, overheat, emit smoke, burst and/or ignite.

Do not short-circuit the battery.

Do not transport or store the battery pack together with metal

objects. If short-circuiting occurs, over-current will flow, causing

the battery pack to leak electrolyte, overheat, emit smoke, burst

and/or ignite.

Do not discard the battery pack into fire or heat it.

Do not expose cells or batteries to heat or fire. Avoid storage in

direct sunlight.

Do not use or leave the battery pack near a heat source (+80ºC or

higher).

Do not immerse the battery pack in water. Do not allow it to get

wet.

Do not recharge the battery pack near fire or in extremely hot

weather.

To recharge the battery use the DPI611 and DPI612 internal

charging function or the CX6100GE desktop charger. Do not use

any other charger.

Do not subject the battery pack to mechanical shock.

Do not use an apparently damaged or deformed battery pack.

Do not directly solder the battery pack.

Do not reverse the positive (+) and negative (-) terminals.

Page 13

User Manual Druck DPI612

Page 13 of 108 [EN] English – 109M4017 Revision A

Otherwise, during recharging, the battery pack will be reversecharged, abnormal chemical reactions then may occur, or

excessively high current can flow during discharging, leading to

electrolyte leakage, overheating, smoke emission, bursting and/or

ignition.

Do not force the connection if you cannot easily connect the

battery pack terminals to the battery pack charger. Confirm that

the terminals are correctly oriented.

Do not use the battery pack for a purpose other than powering

either DPI611/DPI612 products.

Do not use any battery which is not designed for use with the

equipment.

Do not connect the battery pack to any other electrical outlet.

Do not mix batteries of different manufacture, capacity, size or

type within the DPI611 or DPI612.

If recharging operation fails to complete even when a specified

recharging time has elapsed, immediately stop further recharging.

Do not put the battery pack into a microwave oven. Rapid heating

or disrupted sealing can lead to electrolyte leakage, overheating,

smoke emission, bursting and/or ignition.

If electrolyte leaks from the battery pack or gives off a bad odour,

remove it from any exposed flame. Otherwise, the leaking

electrolyte may catch fire and the battery pack may emit smoke,

burst or ignite.

If the battery pack gives off an odour, generates heat, becomes

discoloured or deformed, or in any way appears abnormal during

use, recharging or storage, immediately remove it from the

equipment or battery pack charger and stop using it. Otherwise,

the problematic battery pack can develop electrolyte leakage,

overheating, smoke emission, bursting and/or ignition.

Page 14

User Manual Druck DPI612

Page 14 of 108 [EN] English – 109M4017 Revision A

Remove the battery from the equipment when not in use.

Do not remove the battery from its original packaging until

required for use.

Secondary batteries need to be charged before use. Always use

the correct charger and refer to the user manual for proper

charging instructions.

Do not leave a battery on prolonged charge when not in use.

After extended periods of storage, it may be necessary to charge

and discharge the battery several times to obtain maximum

performance.

Do not subject the battery pack to intense sunlight or hot

temperatures, for example in a car during hot weather. Otherwise,

electrolyte leakage, overheating and/or smoke emission can occur.

Also, its guaranteed performance will be lost and/or its service life

will be shortened.

The battery pack incorporates built-in safety devices. Do not use it

in a location where static electricity is present.

The guaranteed recharging temperature range is 0°C to +45ºC. A

recharging operation outside this temperature range can lead to

electrolyte leakage and/or overheating of the battery pack and

may cause damage to it.

In the event of a cell leaking, do not allow the liquid to come in

contact with the skin or eyes. If contact has been made, wash the

affected area with copious amounts of water and seek medical

advice.

Seek medical advice immediately if material or content from a

battery has been swallowed

Keep the battery out of the reach of children.

Keep batteries clean and dry.

Page 15

User Manual Druck DPI612

Page 15 of 108 [EN] English – 109M4017 Revision A

Wipe the battery terminals with a clean dry cloth if they become

dirty.

If you find rust, a bad odour, overheating and/or other irregularities

when using the battery pack for the first time, return it to your

supplier or vendor.

For further information contact the nearest distributor or

representative.

Retain the original product literature for future reference.

PRESSURE WARNINGS

It is dangerous to attach an external source of pressure to a

DPI612 pressure station. Use only the internal mechanisms to set

and control pressure in the pressure station.

To prevent a dangerous release of pressure, isolate and bleed the

system before disconnecting a pressure connection.

To prevent a dangerous release of pressure, make sure that all the

related pipes, hoses and equipment have the correct pressure

rating, are safe to use and are correctly attached.

To prevent damage to the DPI612 calibrator, only use it within the

specified pressure limits.

Do not exceed the maximum pressures stated in the appropriate

component manual for the unit under test.

Reduce pressure at a controlled rate when venting to atmosphere.

Carefully de-pressurize all pipes to atmospheric pressure before

disconnecting and connecting to the unit under test.

Always wear appropriate eye protection when working with

pressure.

Page 16

User Manual Druck DPI612

Page 16 of 108 [EN] English – 109M4017 Revision A

OVERVOLTAGE CATEGORY

The following summary of installation and measurement

overvoltage categories are derived from IEC61010-1. The

overvoltage categories indicate the severity of overvoltage

transients.

Table 1-1

Overvoltage

Category

Description

CAT I

Overvoltage category I has the least severe overvoltage

transients. Generally CAT I equipment is not designed to be

directly connected to the mains supply. Examples of CAT I

equipment are process loop powered devices.

CAT II

Overvoltage category II describes an electrical installation

where typically single phase equipment is connected.

Examples of such equipment are appliances and portable

tools.

PREPARING THE INSTRUMENT

On receipt of the instrument check the contents in the box, listed in

accessories See Section 1.11. It is recommended to retain the box

and packaging for future use.

1.9.1 Initial Checks

Before you use the instrument for the first time:

Make sure that there is no damage to the instrument, and that

there are no missing items; See Section 1.11.

Remove the plastic film that protects the display.

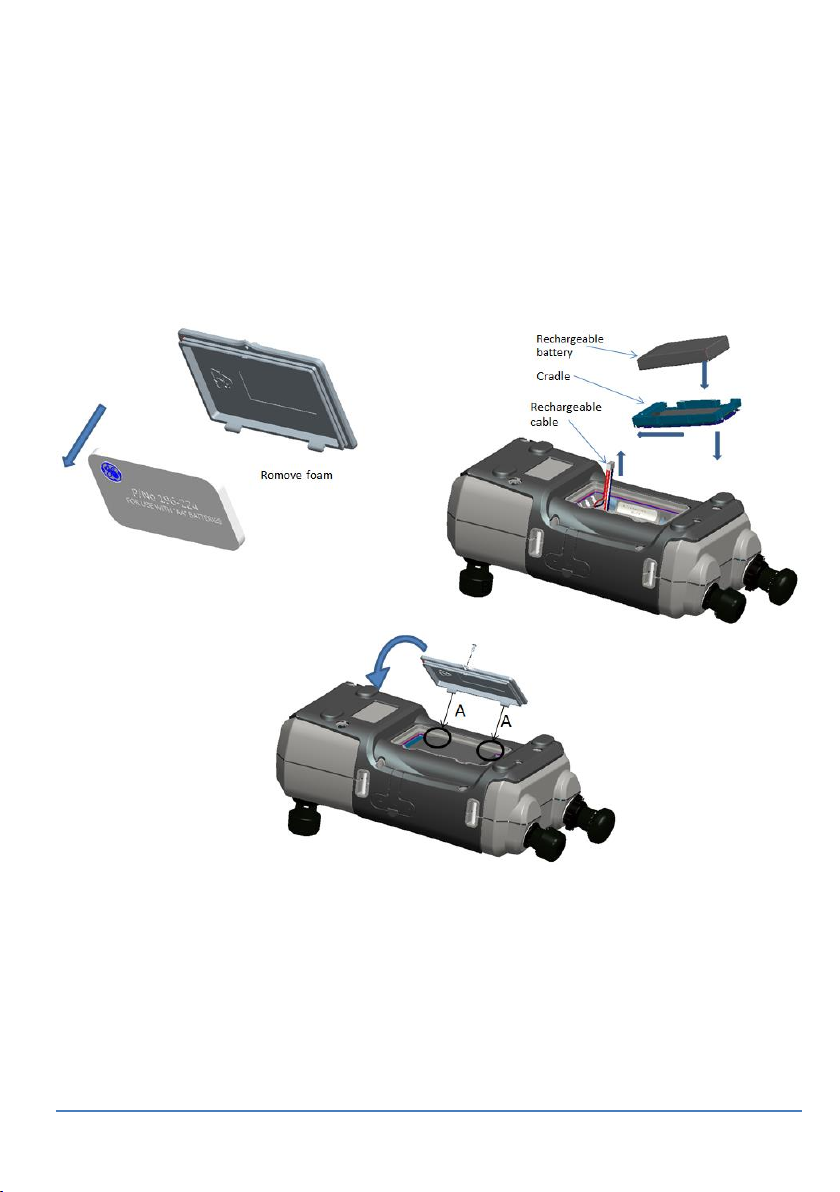

1.9.2 Install Rechargeable Battery and Cradle

For a new unit steps 1-4 will have been completed in the factory

prior to delivery.

1. Remove the battery cover by loosening the captive battery cover

fixing screw and lifting the cover upwards.

2. If fitted, remove white battery holder by pulling straight up to

reveal charging cable. Remove foam block from battery cover.

Page 17

User Manual Druck DPI612

Page 17 of 108 [EN] English – 109M4017 Revision A

3. Connect the charging cable to the rechargeable battery cradle.

4. Push the cradle firmly into the battery compartment.

5. Insert the rechargeable battery into the cradle.

6. Replace the battery cover by pressing the lugs inside

the slots (A) and bring down the cover, securing by tightening the

fixing screw. (See Figure 1-1).

7. The battery can be charged by connecting the wall adapter to the

unit or by using the optional desktop charger.

Figure 1-1 Fit Rechargeable Pack

Page 18

User Manual Druck DPI612

Page 18 of 108 [EN] English – 109M4017 Revision A

1.9.3 Install Dry Cell Batteries

1. Remove the battery cover by loosening the captive battery cover

fixing screw and lifting the cover upwards.

2. If the rechargeable battery has been fitted, remove it.

3. If the rechargeable battery cradle has been fitted, remove it by

gently pulling it straight up. Avoid touching the metal contacts on

the cradle. Note the cradle is attached to the unit with the

charging cable.

4. Disconnect the charging cable from the back of the cradle and

keep it loose in the small compartment then fit battery holder.

5. Fit the foam block to the battery cover.

6. Place the batteries in the battery compartment with the correct

+/– position.

Incorrect Insertion of batteries can cause battery failure.

7. Replace the battery cover by pressing the lugs inside

the slots (A) and bring down the cover, securing by tightening the

fixing screw. (See Figure 1-2).

Page 19

User Manual Druck DPI612

Page 19 of 108 [EN] English – 109M4017 Revision A

Figure 1-2 Fit Dry Cell Batteries

Page 20

User Manual Druck DPI612

Page 20 of 108 [EN] English – 109M4017 Revision A

PARTS

1.10.1 DPI 612

9

4

5

5.1

3

10

2.1

1

9

5

12

2.1

11

10

Page 21

User Manual Druck DPI612

Page 21 of 108 [EN] English – 109M4017 Revision A

Figure 1-3 DPI612 Pressure Calibrator

Table 1-2

Item

No.

Description

1

ON or OFF button.

2 PFX only: Pneumatic volume adjuster.

2.1

PFP, HFP models only: Volume adjuster wheel with fold-in handle.

3 Pump mechanism.

3.1

PFX, PFP models only: Pressure/vacuum selector to set the pump

operation: pressure (+), vacuum (-).

4 Test port: To attach the device under test.

5 Pneumatic pressure release valve to release pressure in the system.

Page 22

User Manual Druck DPI612

Page 22 of 108 [EN] English – 109M4017 Revision A

Item

No.

Description

5.1

PFP models only: Pneumatic refill valve. Close it to seal off the device

pressure and refill the pressure mechanism.

6 CH1 connectors for: Voltage (V); Current (mA+, mA-); Switch operation.

7 Isolated CH2 connectors for: Voltage (V); 24 V loop power supply (24

Vo).

8 Liquid Crystal Display (LCD): Color display with touch-screen. To make

a selection, lightly tap on the applicable display area.

9 Optional accessory (not shown): Pressure connection for a relief valve

(PRV). A blanking plug is standard.

10

Pressure and electrical connections for a PM620 module (not shown):

DPI612 models PFX and PFP: Seal the pressure connection with a

blanking plug (Part: IO620-BLANK) or a PM 620 module.

DPI612 HFP models only: The pressure connection seals itself.

11

HFP models only: Hydraulic refill valve (not shown): Close it to seal off

the device pressure and refill the pressure mechanism with fluid.

12

Hand straps

13

+5 V DC power input socket. This supply also charges the optional

battery pack.

14

USB type A connector for connections to external peripherals (USB

flash memory or optional external modules).

15

USB mini-type B connector for communication with a computer.

1.10.2 Test Port

To attach the device under test, the test port uses “Quick

fit” pressure adaptors; See Section 1.11.12. These are easy

to remove, change and install; See Section 2.1.1

(Attach/Remove the device under test).

Figure 1-4

Test port

Page 23

User Manual Druck DPI612

Page 23 of 108 [EN] English – 109M4017 Revision A

1.10.3 Pressure Release Valve

This is a needle point valve that lets you release the

pressure or vacuum, or seal the system.

Figure 1-5

Pressure

Release Valve

1.10.4 SELECTOR DPI 612 pFlex & pFlexPro (20 & 100 bar)

Before you turn the pressure/vacuum selector to + or -, release all the

pressure. Sudden high pressure in the pump mechanism can cause damage.

This control sets the operation of the instrument (pressure

or vacuum). To prevent a pressure leak, turn it fully

clockwise or counter clockwise.

+: Pressure, - : Vacuum

Figure 1-6

Selector

1.10.5 Pump

DPI 612 pFlex (20 bar) Pump

When you have set the operation to pressure or vacuum (See

Section 1.10.4), seal the system (See Section 1.10.3) and use the

pump to set the necessary pressure or vacuum.

You can then make the last adjustments with the volume

adjuster (See Section 1.10.6).

Figure 1-7

20 bar Pump

OPEN CLOSE

Page 24

User Manual Druck DPI612

Page 24 of 108 [EN] English – 109M4017 Revision A

DPI 612 pFlexPro (100 bar) Pump

When you have set the operation to pressure or vacuum (See

Section 1.10.4), seal the system (See Section 1.10.3) and use the

pump to set the necessary pressure or vacuum.

You can then make the last adjustments with the volume

adjuster (See Section 1.10.6).

Figure 1-8

100 bar Pump

DPI 612 hFlexPro (1000 bar) Pump

When you have set the operation to pressure or vacuum

(See Section 1.10.4), seal the system (See Section 1.10.3)

and use the pump to set the necessary pressure or

vacuum.

You can then make the last adjustments with the volume

adjuster (See Section 1.10.6).

Figure 1-9

1000 bar

Pump

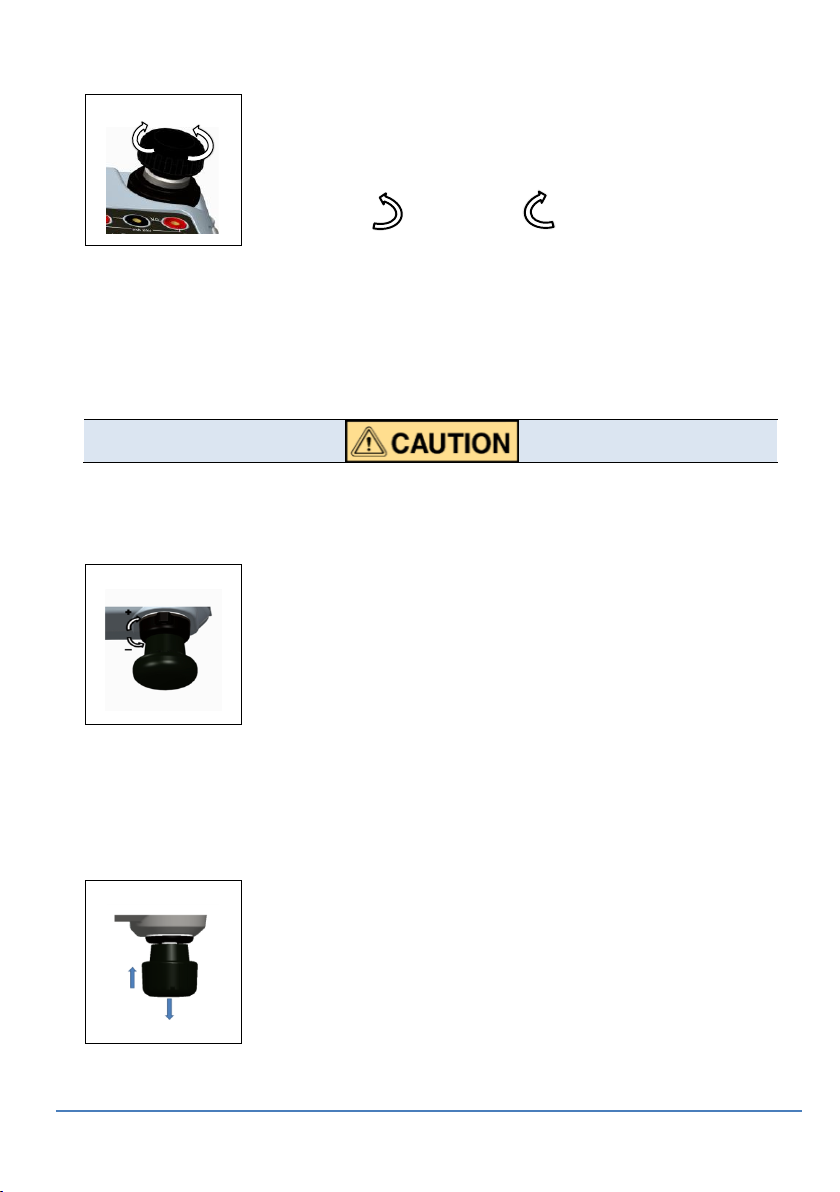

1.10.6 Volume Adjuster

DPI 612 pFlex (20 bar) Volume Adjuster

This control increases or decreases the pressure/vacuum.

Before you seal the system (See Section 1.10.3), turn this

control to the necessary position:

For equal adjustment, turn it to the middle of

its range.

For maximum adjustment, turn it fully

clockwise or counter clockwise.

When you have set the necessary pressure or vacuum

with the pump (See Section 1.10.5), use the volume

adjuster to make the fine adjustments.

Figure 1-10

20 bar

Volume

Adjuster

Page 25

User Manual Druck DPI612

Page 25 of 108 [EN] English – 109M4017 Revision A

DPI 612 pFlexPro (100 bar) Volume Adjuster

This control increases or decreases the pressure/vacuum.

Before you seal the system (See Section 1.10.3), turn this

control to the necessary position:

For equal adjustment, turn it to the middle of

its range.

For maximum adjustment, turn it fully

clockwise or counter clockwise.

When you have set the necessary pressure or vacuum

with the pump (See Section 1.10.5), use the volume

adjuster to make the fine adjustments.

Figure 1-11

100 bar

Volume

Adjuster

DPI 612 hFlexPro (1000 bar) Volume Adjuster

This control increases or decreases the pressure/vacuum.

Before you seal the system (See Section 1.10.3), turn this

control to the necessary position:

For equal adjustment, turn it to the middle of

its range.

For maximum adjustment, turn it fully

clockwise or counter clockwise.

When you have set the necessary pressure or vacuum

with the pump (See Section 1.10.5), use the volume

adjuster to make the fine adjustments.

Figure 1-12

1000 bar

Volume

Adjuster

Page 26

User Manual Druck DPI612

Page 26 of 108 [EN] English – 109M4017 Revision A

1.10.7 Refill Valve

DPI 612 pFlexPro (100 bar) Refill Valve

When pressurising large volumes this can be used to refill

the pump without releasing pressure from the UUT (see

Section 2.2.2)

Figure 1-13

100 bar Refill

Valve

DPI612 hFlexPro (1000 bar) Refill Valve

When pressurising large volumes this can be used to refill

the pump without releasing pressure from the UUT (see

Section 0)

Figure 1-14

1000 bar

Refill Valve

1.10.8 Priming Pump DPI612 hFlexPro (1000 bar)

This control is used to fill and generate a priming pressure

on the UUT (approx. 10 bar max)

(see Section 0)

Figure 1-15

1000 bar

Priming

Pump

Page 27

User Manual Druck DPI612

Page 27 of 108 [EN] English – 109M4017 Revision A

ACCESSORIES:

1.11.1 Carry Case (P/N IO612-CASE-3)

A tailored fabric carry case with carrying strap allows the DPI612 to

be used without removing it from the case.

1.11.2 Rechargeable Battery pack (P/N CC3800GE)

Use in place of AA cells. The battery pack is charged

within the instrument.

1.11.3 Rechargeable Battery and adaptor kit (P/N IO61X-BAT-KIT)

Kit contains 3.7V Li-ion battery, Cradle, Battery Cover and

power adapter.

1.11.4 Rechargeable Desktop Charger (P/N CX6100GE)

To Charge the Li-ion battery outside of the unit.

1.11.5 Mains Adaptor (P/N IO620-PSU)

A universal input mains adaptor (Input voltage 100 to

240VAC (50/60Hz) and Mains socket adaptors are

provided.

Page 28

User Manual Druck DPI612

Page 28 of 108 [EN] English – 109M4017 Revision A

1.11.6 USB Cable (P/N IO620-USB-PC)

It connects the DPI612 to a PC via a USB port.

1.11.7 IDOS to USB Converter (P/N IO620-IDOS-USB)

It allows connection of an IDOS universal pressure

module to the DPI612. USB Cable (P/N IO620-USB-PC) is

also required to connect the converter to the DPI612

USB port.

1.11.8 USB to RS 232 Cable (P/N IO620-USB-RS232)

It connects the DPI612 to an RS232 interface.

1.11.9 Dirt Moisture Trap 20 bar (P/N IO620-IDT621)

It prevents contamination of the DPI612 PFLEX

pneumatic system and cross contamination from one

device under test to another. The trap connects directly to

the pressure port and replicates the quick fit connection

for compatibility with standard adaptors, adaptor kits and

hoses. User instructions are in section 6.1

1.11.10 Dirt Moisture Trap 100 bar (P/N IO620-IDT622)

It prevents contamination of the DPI612 PFlexPro

pneumatic system and cross contamination from one

device under test to another. The trap connects directly

to the pressure port and replicates the quick fit

connection for compatibility with standard adaptors,

adaptor kits and hoses. User instructions are in section

6.2

Page 29

User Manual Druck DPI612

Page 29 of 108 [EN] English – 109M4017 Revision A

1.11.11 Pneumatic Hose (PN IO620-HOSE-P1 / IO620-HOSE-P2)

A high pressure pneumatic hose rated to 400 bar (5800

psi). The hose connects directly to the DPI612 pressure

port and replicates the quick fit connection for

compatibility with the standard adaptors supplied and

the other adaptor kits.

P/N IO620-HOSE-P1: 1m/3,2ft pneumatic adaptor hose

P/N IO620-HOSE-P2: 2m/6.4ft pneumatic adaptor hose

1.11.12 Hydraulic Hose (PN IO620-HOSE-H1 / IO620-HOSE-H2)

A high pressure Hydraulic hose rated to 1000 bar

(15000 psi). The hose connects directly to the DPI612

pressure port and replicates the quick fit connection for

compatibility with the standard adaptors supplied and

the other adaptor kits.

P/N IO620-HOSE-H1: 1m/3,2ft pneumatic adaptor hose

P/N IO620-HOSE-H2: 2m/6.4ft pneumatic adaptor hose

1.11.13 Low Pressure Pneumatic Hose (PN IOHOSE-NP1 / IOHOSE-NP2)

A low pressure pneumatic hose rated to 20 bar (300 psi). The hose

connects directly to the DPI612 pressure port and replicates the

quick fit connection for compatibility with the standard adaptors

supplied and the other adaptor kits.

P/N IOHOSE-NP1: 1m/3,2ft pneumatic adaptor hose

P/N IOHOSE-NP2: 2m/6.4ft pneumatic adaptor hose

Page 30

User Manual Druck DPI612

Page 30 of 108 [EN] English – 109M4017 Revision A

1.11.14 Pressure Adaptor set

A set of test point adaptors to connect the tool-less quick fit DPI612

pressure port or the extension hoses to the device under test.

P/N IO620-BSP: G1/8 male and G1/4 male, G1/4 female, G3/8

female and G1/2 female.

P/N IO620-NPT: 1/8” male and ¼” male, ¼” female, 3/8” female

and ½” female.

P/N IO620-MET: 14mm female and 20mm female.

1.11.15 Comparator Adaptor (P/N IO620-COMP)

For greater efficiency, two test devices can be

connected at the same time. The adaptor connects to

the pressure port of the DPI612 and provides two outlet

ports. It is compatible with the standard adaptors

supplied and the adaptor kits.

1.11.16 Pressure Module (P/N IPM620-***)

Select the best pressure range for the job from an

extensive list of high accuracy pressure ranges. Ranges

available from 25mbar upto 1000 bar (10 In H2O upto

15000 psi)

Page 31

User Manual Druck DPI612

Page 31 of 108 [EN] English – 109M4017 Revision A

1.11.17 Pressure Relief Valve (PRV)

To give your attached devices overpressure protection

(device under test, PM 620 module), we recommend you

use one of our range of optional PRVs;

Available for pneumatic and hydraulic versions

Page 32

User Manual Druck DPI612

Page 32 of 108 [EN] English – 109M4017 Revision A

DRUCK DPI612, MODES

1.12.1 Power ON

From OFF – momentarily press the power button until the GE Logo

appears.

Figure 1-16 Power Button

1.12.2 Power OFF

Press and Release the Power Button:

Select SWITCH OFF from the POWERDOWN OPTIONS window

displayed.

Figure 1-17 Power Down Options

SWITCH OFF – Full power down of DPI612 – Recommended if unit is

not going to be used for several hours (Requires full reboot on next

power up).

GO TO STANDBY– DPI612 placed in standby mode – Reduced power

consumption from operating mode – recommended if unit is to be

inactive for short periods. (DPI612 has fast turn on from STANDBY

mode).

CANCEL – Touch CANCEL option if you do not want to Switch Off or

Standby the instrument.

Power ON/OFF

Page 33

User Manual Druck DPI612

Page 33 of 108 [EN] English – 109M4017 Revision A

1.12.3 Power up from Standby Mode

When powered-up from standby mode the instrument always opens

the last screen shown before going into standby mode.

NAVIGATION

On power up the DPI612 displays the Dashboard. The user should

select the desired option by touching the appropriate icon. Function

screens are navigated by swiping a finger from right to left while

touching the screen. List menus are navigated by swiping a finger

up and down while touching the screen.

Figure 1-18 Dash Board

1.13.1 Set Date, Time and Language

To access Date, Time and Language menus

Select:

Note: The DPI612 will maintain the date and time for 30 days after

being left without batteries. In case of loss of date and time, replace

the batteries, connect the mains adaptor to the DPI612 and keep it

turned on for 50 hours to fully recharge the clock battery.

DASHBOARD >> SETTINGS >> DATE

Page 34

User Manual Druck DPI612

Page 34 of 108 [EN] English – 109M4017 Revision A

1.13.2 Themes

Two themes are available: Dark and Light; select the correct theme

for the light level.

Select:

1.13.3 DRUCK DPI612 Manual

Select the Help icon on the Dashboard to access the manual. The

manual can be downloaded onto a memory stick for viewing or

printing on a remote PC.

SOFTWARE AND FIRMWARE UPGRADES

1.14.1 Viewing Software Revision

The software revisions running on the DPI612 can be viewed by

selecting:

Note: If the software revision number is highlighted red then an

upgrade is available.

1.14.2 Upgrading the Software

Follow the website instructions to download the files onto a USB

flash memory drive.

www.gemeasurement.com

Enter the calibration PIN: 5487; Select the button and continue

upgrade with one of these operations.

DASHBOARD >> SETTINGS >> THEME

DASHBOARD >> HELP

DASHBOARD >> SETTINGS >> STATUS

>> SOFTWARE BUILD

DASHBOARD >> SETTINGS

>> ADVANCED

Page 35

User Manual Druck DPI612

Page 35 of 108 [EN] English – 109M4017 Revision A

1.14.3 Upgrade the Application Software

1. Copy the ‘AMC’ application folder into the root of a USB

flash memory device.

2. Put the USB flash memory drive into the USB type A

connector.

3. Select:

4. Follow the on-screen instructions.

1.14.4 Upgrade the Operating System and Boot Loader Software.

1. Copy the ‘OS’ folder into the root of a USB flash memory

device.

2. Put the USB flash memory drive in the USB type A

connector.

3. Select:

4. Follow the on-screen instructions.

Note: The boot loader can only be upgraded as part of an operating

system upgrade.

Notes:

If a mistake is made during upgrade and there are no files to

upload, follow the on-screen instructions and complete the

procedure.

When an upgrade completes normally, the initial operation of the

touch screen may be slower (a period of approximately 30

seconds).

To make sure the upgrade completed correctly, use the Status

menu.

Page 36

User Manual Druck DPI612

Page 36 of 108 [EN] English – 109M4017 Revision A

MAINTENANCE

The DPI612 instrument contains no user serviceable parts and

should be returned to a GE service centre or an approved service

agent for all repairs.

For more information, contact our customer service department at

www.gemeasurement.com

1.15.1 Cleaning

Do not use solvents or abrasive materials.

Clean the case and display with a lint-free cloth and a weak

detergent solution.

1.15.2 Replace the Batteries

To replace the batteries, See Section 1.9.2. Then re-attach the cover.

All the configuration options stay in memory.

INSTRUMENT RETURN

1.16.1 Returned Material Procedure

If the instrument is unserviceable and requires a repair return to a

GE Service Center or approved Service Agents.

Web site: www.gemeasurement.com Contact the GE Service Center,

either by phone, fax or E-mail to obtain a Returned Material

Authorization (RMA) number, providing the following information:

Product (i.e. Druck DPI612)

Serial number

Details of defect/work to be undertaken

Operating conditions

1.16.2 Safety Precautions

Provide information if the product has been in contact with any

hazardous or toxic substances and, the relevant MSDS and or

COSHH references and precautions to be taken when handling.

Page 37

User Manual Druck DPI612

Page 37 of 108 [EN] English – 109M4017 Revision A

1.16.3 Important Notice

Do not use unauthorized sources to service this equipment as this

will affect the warranty and may not guarantee further

performance.

When discarding used equipment and batteries, obey all the local

health and safety procedures.

1.16.4 Instrument Disposal in the European Union

Do not dispose this product or its battery as household waste.

Use an approved organization that collects and/or recycles the

applicable item.

1.16.5 For more information contact

GE Sensing customer service department:

www.gemeasurement.com

ENVIRONMENT

The following conditions apply for both shipping and storage:

Temperature Range -20°C to +70°C (-40°F to +158°F)

Altitude up to 15,000 feet (4,570 meters).

Page 38

User Manual Druck DPI612

Page 38 of 108 [EN] English – 109M4017 Revision A

MARKS AND SYMBOLS ON THE EQUIPMENT

Complies with European Union directives

USB ports: Type A; Mini Type B connector

Ground (Earth)

DC adaptor polarity: the Centre of the plug is

negative

Page 39

User Manual Druck DPI612

Page 39 of 108 [EN] English – 109M4017 Revision A

2 OPERATIONS

Common Operations

2.1.1 Attach/Remove the device under test

Pressurized gases are dangerous. Before you attach or disconnect pressure

equipment, safely release all the pressure

To prevent damage to the instrument, do not let dirt get into the pressure

mechanism. Before you attach equipment, make sure it is clean or use the

applicable dirt trap.

The test port uses “Quick fit” pressure adaptors; See

Section 1.11 (Accessories). These are easy to remove,

change and install (See 1.11.14).

Figure 2-1

Pressure Port

Page 40

User Manual Druck DPI612

Page 40 of 108 [EN] English – 109M4017 Revision A

a. Procedure (to Attach)

Figure 2-2 Attach / Remove Pressure connections

Table 2-1

Step

Procedure

1

Remove the adaptor

2

Use an applicable seal for the pressure connection:

a. NPT type: Use an applicable sealant on the thread.

b. BSP (parallel) type: We recommend a bonded seal at

the bottom.

c. BSP (parallel type, 100 bar (1500 psi) or less: a bonded

seal at the top is permitted.

3

Attach the adaptor to the device; if necessary use one of

the alternative adaptors listed in Section 1.11

(Accessories), then tighten to the applicable torque.

b. (G)/BSPP

P≥100 bar

c. (G)/BSPP

P≤100 bar

Pressure Port

a. NPT

1 2 3

Page 41

User Manual Druck DPI612

Page 41 of 108 [EN] English – 109M4017 Revision A

Step

Procedure

4

Re-attach the adaptor to the test port and tighten it until

it is hand tight only.

b. Procedure (to Remove)

To remove a device, first release the pressure (See Section 2.2.2). You

can then do steps 4, 3, and 1 mentioned in Section2.1.1. But do the

operations in the reverse order.

2.1.2 Attach a Pressure Relief Valve

Optional accessory; see Section 1.11.17. Use a pressure relief valve

(PRV) to set a limit to the pressure you can apply to the pressure

devices attached to the pressure station. The PRV is set at the

factory to operate at the maximum pressure specified on the label.

If the pressure in the instrument is more than the relief pressure set

for the PRV, the PRV controls a slow release of the unwanted

pressure. The correct PRV helps prevent overpressure and damage

to the attached devices.

Pneumatic

Step 1

Step 2

Choose a clean, dry PRV

with the correct pressure

value for the devices you

are using and tighten it

into position (hand tight

only).

Choose a clean, dry PRV

with the correct pressure

value for the devices you

are using and tighten it

into position (hand tight

only).

Note: Before you put it into storage, make sure it is clean and dry.

Page 42

User Manual Druck DPI612

Page 42 of 108 [EN] English – 109M4017 Revision A

Hydraulic

In its normal condition, the DPI 612 hFlexPro contains hydraulic fluid. To

make sure it does not spill out, seal the system and put it on its side before

you install a PRV.

1 2 3

4

Step

Procedure

1

Seal the system.

2

Put the instrument on its side.

3

Remove the blanking plug or, if applicable, the PRV you

are using. To collect possible drops of hydraulic fluid, put

it in a container.

Note: Before you put it into storage, make sure it is clean

and dry.

4

Choose a clean, dry PRV with the correct pressure value

for the devices you are using and tighten it into position

(hand tight only).

2.1.3 Setting a Pressure Relief Valve

The PRV is set at the factory to operate at the maximum pressure

specified on the label (on the plastic cap). For the adjustable range,

refer to data sheet.

If necessary, use these steps to adjust the relief pressure:

Step

Procedure

1

Attach an applicable PM 620 module.

2

Remove the plastic cap from the end of the PRV

3

Set the necessary pressure with the pressure station

Page 43

User Manual Druck DPI612

Page 43 of 108 [EN] English – 109M4017 Revision A

Step

Procedure

4

When the pressure in the pressure station is at the new

PRV pressure, turn the adjustment screw until the PRV

operates:

counter clockwise decreases the operating pressure

clockwise increases the operating pressure

5

Do steps 3 and 4 until the PRV operates at the correct

pressure. Then press the plastic cap back into position.

DPI 612 pFlex & pFlexPro PNEUMATIC PRESSURE OPERATIONS

2.2.1 Introduction

This section gives examples of how to connect and use

the DPI612 pressure calibrator for the necessary

pressure or vacuum operations.

Before you start:

Read and understand the “Safety” section.

Make sure that there is no damage to the

instrument and there are no missing items.

Note: Use only original parts supplied by the

manufacturer.

Figure 2-3

DPI612

Pressure

Calibrator

2.2.2 Release the Pressure

To release all the pressure in this instrument, open the

pressure release valve counter clockwise (1 turn).

To control a change in pressure conditions (for example,

to go to or through another test pressure) use the volume

adjuster (See Section 1.10.6) or open and close the

pressure release valve.

Figure 2-4

Pressure

Release Valve

Page 44

User Manual Druck DPI612

Page 44 of 108 [EN] English – 109M4017 Revision A

2.2.3 Vacuum or Pressure Operation DPI 612 pFlex (20 bar)

1 2 3 4 5

Figure 2-5 Vacuum or Pressure operation

2.2.1 Release Pressure DPI 612 pFlex (20 bar)

Open the pressure release valve counter clockwise (1 turn)

Table 2-2

Table 2-3

Step

Procedure (Vacuum)

Step

Procedure (Pressure)

1

Set to vacuum operation

(-).

1 Set to Pressure operation

(+).

2

To do equal adjustments

(up or down) at the end of

the procedure, turn the

volume adjuster to the

middle of its range of

operation.

2 To do equal adjustments

(up or down) at the end of

the procedure, turn the

volume adjuster to the

middle of its range of

operation.

3

Seal the system.

3 Seal the system.

4

Use the pump to set the

maximum vacuum or set

the vacuum you want to

adjust.

4 Use the pump to set the

maximum pressure or set

the pressure you want to

adjust.

5

Adjust the vacuum

(+ decrease; - increase).

5 Adjust the pressure

(+ decrease; - increase).

Page 45

User Manual Druck DPI612

Page 45 of 108 [EN] English – 109M4017 Revision A

Figure 2-6

Pressure

Release

2.2.2 Vacuum or Pressure Operation DPI 612 pFlexPro (100 bar)

1 2 3 4 5

6 7 8 9 10

Figure 2-7 Vacuum or Pressure operation

Page 46

User Manual Druck DPI612

Page 46 of 108 [EN] English – 109M4017 Revision A

Table 2-4

Table 2-5

Step

Procedure (Vacuum)

Step

Procedure (Pressure)

1

Set to vacuum operation

(-).

1 Set to Pressure operation

(+).

2

To do equal adjustments

(up or down) at the end of

the procedure, turn the

volume adjuster to the

middle of its range of

operation.

2 To do equal adjustments

(up or down) at the end of

the procedure, turn the

volume adjuster fully

counter clockwise.

3

Seal the system.

3 Seal the system.

4

Use the pump to set the

maximum vacuum or set

the vacuum you want to

adjust.

4 Use the pump to

pressurise the system (up

to ≈20 bar)

5

Adjust the vacuum

(+ decrease; - increase).

5 Open the refill valve (1

turn)

6 Increase the pressure

with the volume adjuster

7 If increasing pressure the

limit of travel is reached,

close the refill valve

8 Wind the volume adjuster

fully counter clockwise.

There is no change in

pressure.

9 Refill the pressure

mechanism with the

pump (≈15 cycles)

10

Wind the volume adjuster

clockwise until the

pressure starts to

increase

11

Continue to do steps 7 to

10 until you get the

necessary pressure.

Page 47

User Manual Druck DPI612

Page 47 of 108 [EN] English – 109M4017 Revision A

2.2.3 Release pressure DPI 612 pFlexPro (100 bar pump)

Open the refill

valve fully

counter-clockwise

Open the pressure

release valve

counter-clockwise

(1 turn)

1 2

DPI 612 hFlexPro (1000 bar) HYDRAULIC OPERATIONS.

PRESSURIZED GASES AND FLUIDS ARE DANGEROUS. BEFORE

CONNECTING OR DISCONNECTING PRESSURE EQUIPMENT, SAFELY

RELEASE ALL THE PRESSURE.

ENSURE THAT THE SYSTEM IS BLED OF EXCESS AIR BEFORE

OPERATION. (IF THE ITEM UNDER TEST HAS A LARGE VOLUME,

PRE-FILL WITH THE PRESSURE FLUID TO ENSURE THAT TRAPPED

AIR IS KEPT TO A MINIMUM).

To prevent damage to the pressure station, do not let dirt get into

the pressure mechanism. Before connecting equipment, make

sure it is clean.

Ice in the pressure mechanism can cause damage. If the

temperature is less than 4°C (39°F), drain all water from the

instrument.

Page 48

User Manual Druck DPI612

Page 48 of 108 [EN] English – 109M4017 Revision A

2.3.1 First Use

When using the DPI 612 hFlexPro pressure calibrator for the first

time, fill the reservoir with the correct hydraulic fluid. Fill and prime

the pressure station.

Fluid Type

Demineralised water or a mineral oil (Recommended ISO viscosity

grade ≤ 22).

2.3.2 Filling and Priming the Pump

Ensure the sensor and test ports are clear before starting this

procedure.

1 2 3 4 5

x5 6 7 8 9

10

11

12

13

Step

Procedure

1

Turn the Refill valve fully counter-clockwise

2

Turn the Volume adjuster fully clockwise.

3

Turn the Release Valve Stem fully counter-clockwise.

4

Remove the Priming pump piston/Release valve stem

assembly

5

Fill the reservoir with the recommended fluid, to ≈25mm from

the top.

Page 49

User Manual Druck DPI612

Page 49 of 108 [EN] English – 109M4017 Revision A

6

Re-fit the Priming pump piston/Release valve stem assembly

7

Turn the Release Valve Stem fully clockwise.

8

Turn the Refill valve fully clockwise, until finger tight.

9

Turn the Volume adjuster fully counter-clockwise.

10

Turn the Volume adjuster 5 turns clockwise.

11

Operate the Priming pump until the air is expelled and fluid is

visible at the Test port.

12

Fit the “Item under test” to the Test port use the existing

adaptor or the applicable AMC adaptor and applicable seals.

13

Operate the Priming pump and prime the system to a

maximum pressure of 10 bar.

2.3.3 Topping up the Hydraulic Fluid

It will be necessary to top up the hydraulic fluid from time to time or

if the device under test has a large fluid capacity. The DPI612 allows

this to be done at any time.

1 2 3

4

Step

Procedure

1

To seal off all the pressure in the test port and the pressure

module connection, close the refill valve

2

Remove the hydraulic pressure release valve

3

Refill the reservoir with the same fluid, to ≈25mm from the

top.

4

Seal the system and continue with the normal pressure

procedure;

Page 50

User Manual Druck DPI612

Page 50 of 108 [EN] English – 109M4017 Revision A

2.3.4 Priming Sequence

1 2 3

4

5 6 7

8

Step

Procedure

1

Turn the Volume Adjuster counter-clockwise. (See Section

1.9.7)

2

Turn the Volume Adjuster 10 turns clockwise

3

Close Release Valve.

4

Close Refill Valve clockwise, finger tight (See Section 1.9.8).

5

Operate Priming Pump until liquid is seen coming from the

open test port / end of hose.

6

Connect IUT to open test port / end of hose.

7

Operate Priming Pump until pressure is indicated (max 10

bar)

8

Operate Volume Adjuster & Refill Valve to achieve required

pressure. (See Section 2.3.5)

Note: If priming a long hose keep the open end of hose vertical to

reduce trapping air.

Page 51

User Manual Druck DPI612

Page 51 of 108 [EN] English – 109M4017 Revision A

2.3.5 Applying Hydraulic Pressure (1000 bar)

1 2 3

4

Step

Procedure

1

To seal the system

2

Close the refill valve and then wind the volume adjuster fully

clockwise and counter clockwise until the pressure starts to

increase.

Continue the clockwise/counter clockwise sequence until you

get the necessary pressure OR for full control, go to step 3.

The counter clockwise operation refills the pressure

mechanism but there is no change in pressure to the device

under test or the PM 620 module (if applicable).

Note: At higher pressures, it is easier to turn the wheel if you

fold in the handle; see Section 1.4.5.

3

For full control, open the refill valve (1 turn). You can now

increase (+) or decrease (-) the pressure with the volume

adjuster.

4

If you increase pressure and get to the limit of travel, close

the refill valve again and wind the volume adjuster fully

counter clockwise.

5

Continue to do steps 2 to 4 until you get the necessary

pressure

Page 52

User Manual Druck DPI612

Page 52 of 108 [EN] English – 109M4017 Revision A

2.3.6 Release Hydraulic Pressure (1000 bar pump)

1 2

Open the refill valve

fully counterclockwise

Open the pressure

release valve

counter-clockwise

(1 turn)

2.3.7 Drain Excess Hydraulic Fluid

If you add more hydraulic fluid during the pressure procedure, drain

this fluid out of the device when the pressure procedure is complete.

Note: If it is safe and there is no risk of contamination, you can leave

the hydraulic fluid inside the device.

Preparation

To drain the device, we recommend these items:

the applicable skin and eye protection

a container that is large enough to hold the hydraulic fluid and

prevent contamination of the work surface

applicable materials to make sure the instrument and the area

stay clean; see Chapter 6 (Maintenance procedures)

Procedure

1 Release the pressure (Section 2.3.6Release Hydraulic Pressure

(1000 bar pump)).

2 Remove the device (Section2.1.1) but do not let fluid spill onto the

DPI 612 hFlexPro.

3 If necessary, drain the hydraulic fluid from the device under test.

Page 53

User Manual Druck DPI612

Page 53 of 108 [EN] English – 109M4017 Revision A

Note: To discard the hydraulic fluid, obey all the local health and

safety procedures.

2.3.8 Drain all the Hydraulic Fluid

In some conditions, it is necessary to fully drain the hydraulic fluid

from your DPI 612 hFlexPro pressure calibrator; for example:

if you are using water and the storage or operating temperature is

going to be less than 4°C (39°F)

if there is a long period of storage

if there is unwanted material in the hydraulic fluid

Preparation

To drain the instrument, we recommend these items:

the applicable skin and eye protection

a container that is large enough to hold the hydraulic fluid and

prevent contamination of the work surface

applicable materials to make sure the instrument and the area

stay clean;

Page 54

User Manual Druck DPI612

Page 54 of 108 [EN] English – 109M4017 Revision A

Procedure

1

2 3 4

Step

Procedure

1

If applicable, release the pressure (Section 2.3.6) and remove

the device (Section 2.1.1).

2

Remove the hydraulic pressure release valve.

3

Wind the volume adjuster wheel fully clockwise; this moves

the fluid out of the pressure mechanism

4

Put a container below the instrument then tilt the instrument

up until all the fluid has come out. To discard the hydraulic

fluid, obey all the local health and safety procedures.

Note: Fluid comes out of the test port and the connection for the

pressure release valve.

5

To flush out fluids that contain unwanted material, refill the

system and repeat steps 3 and 4.

Note: To prevent contamination use only one type of hydraulic fluid

in the instrument.

Page 55

User Manual Druck DPI612

Page 55 of 108 [EN] English – 109M4017 Revision A

CALIBRATOR OPERATIONS

2.4.1 Basic Calibrator Operation

1. Select:

2. Select the channel by performing the following tasks.

Swipe to the TASK MENU by swiping the display from right to left.

Figure 2-8 Task Menu

a. Saving Tasks

At any point within the TASK MENU the currently active tasks can be

saved to FAVOURITES by selecting Save Task.

Note: Saved Function is what is currently active in the calibrator

window. It is NOT a selected Task – refer to COPY TASK to copy

selected Task to the favourites

DASHBOARD >> CALIBRATOR

Page 56

User Manual Druck DPI612

Page 56 of 108 [EN] English – 109M4017 Revision A

b. Calibrator

I. Select CALIBRATOR from the TASK MENU.

This will allow the user to select from commonly used

combinations of functions.

Figure 2-9 Calibrator

II. Select the required function by touching either the

appropriate text or diagram. The DPI612 will set the functions

and return to the main Calibrator screen.

Page 57

User Manual Druck DPI612

Page 57 of 108 [EN] English – 109M4017 Revision A

Figure 2-10 Calibrator with selected option

III. Functions can be copied to FAVOURITES by selecting as

shown in Figure 2-10 and selecting Copy Task .

If the required task is not available as a Default, a new task

should be created using CUSTOM TASK.

c. Favourites

I. Selecting FAVOURITES from the TASK MENU allows selection

of all SAVED and COPIED tasks.

Page 58

User Manual Druck DPI612

Page 58 of 108 [EN] English – 109M4017 Revision A

Figure 2-11 Favourites

II. Select the required function by touching either the

appropriate text or diagram. The DPI612 will set the functions

and return to the main calibrator screen.

III. Task can be deleted by selecting DELETE .

d. Custom Task

I. Select the CUSTOM TASK option from TASK MENU.

This will allow you to set up the Electrical, Pressure and USB

(IDOS) channels.

Page 59

User Manual Druck DPI612

Page 59 of 108 [EN] English – 109M4017 Revision A

Figure 2-12 Task Settings Menu

II. Select to enter the CHANNEL SETTINGS menu.

is used for pressure measurements. (See Section 2.5)

IDOS is used for external IDOS sensors. (See Section 2.6)

Page 60

User Manual Druck DPI612

Page 60 of 108 [EN] English – 109M4017 Revision A

Figure 2-13 Channel Settings Menu

III. Setup a channel for measurement

DIRECTION selects Source or measure for the selected

function.

FUNCTION selects the function required.

(E.g.: Current or Voltage). For more options, scroll down the menu

by swiping the display from bottom to top.

UNITS selects the type of unit required, (E.g.: Volts, Amps), please

note that there may only be 1 type of unit available in particular

Functions.

UTILITY selects the required utility (See Section 2.4.2 for details).

CAPTION allows the user to change the caption, if required.

CAPTION RESET allows the user to reset the caption.

Once all settings have been selected, press the button at the

bottom of the screen to return to the TASK SETTINGS screen.

Please note for the settings to be set the user must also press the

button in the TASK SETTINGS menu.

Repeat the above if another channel is required.

Page 61

User Manual Druck DPI612

Page 61 of 108 [EN] English – 109M4017 Revision A

2.4.2 Set the Function Utility Options

For each function only one utility may be active. Not all source and

measure functions have associated utilities. For all options, the

button resets the additional readings.

a. Max/Min. Avg

This utility is only available with measure functions.

The additional values displayed show the minimum, maximum, and

average values of the input signal.

Figure 2-14 Max/Min Example

b. Switch Test

This utility is available with pressure functions.

The additional values displayed show signal values (measure or

source) when the instrument detects a switch opening and closing.

Page 62

User Manual Druck DPI612

Page 62 of 108 [EN] English – 109M4017 Revision A

The difference between the two values is displayed as hysteresis

value for the switch. This utility can be used with Ramp Automation,

where the rising signal causes the switch to change state and the

falling signal causes the switch to resume its’ original state.

Figure 2-15 Switch Test Example

c. Relief Valve

This utility is only available with measure functions.

This utility tests circuits or mechanisms that have a cut-out response

when an input reaches a defined threshold value. The utility allows

the user to select a mode of operation which can be rising or falling.

The utility displays additional values that represent the maximum

and minimum values achieved by the input signal.

Page 63

User Manual Druck DPI612

Page 63 of 108 [EN] English – 109M4017 Revision A

Figure 2-16 Relief Valve Example

Figure 2-17 Relief Valve Utility

Rising

Max

Min

Falling

Max

Min

Page 64

User Manual Druck DPI612

Page 64 of 108 [EN] English – 109M4017 Revision A

2.4.3 Measurement Display Options

There are 2 display views in the CALIBRATOR screen when multiple

channels are in use:

Figure 2-18 displays a reduced view of all the selected

channels.

Figure 2-18 Calibration Window – Reduced View

Figure 2-19 displays an expanded view of the selected

channel and minimizes the remaining channels.

Page 65

User Manual Druck DPI612

Page 65 of 108 [EN] English – 109M4017 Revision A

Figure 2-19 Calibration Window - Expanded View

The display options can be changed by pressing the channel the

user wants to display in expanded view.

Selecting displays all channels in the reduced view.

2.4.4 Example Procedures

a. Example Procedure: Measure or Source Current with internal

loop power

Figure 2-20 shows CH1 set-up to measure or source a

current with internal loop power.

Note: Loop drive is provided by connecting to the 2 red

terminals on the front of the DPI612 and enabling Current

(24V) as the electrical function.

Page 66

User Manual Druck DPI612

Page 66 of 108 [EN] English – 109M4017 Revision A

Figure 2-20 Measure current on CH1. Range ±55 mA

1. Set the applicable software options.

2. Complete the electrical connections and continue with

the measure or source operation.

3. Source only (Automation). Set the applicable output

value.

b. Example Procedure: Measure Voltage

Figure 2-21 shows CH1 set-up to measure a DC voltage

(±30 V) or DC mV (±2000 mV).

Figure 2-21 Measure DC Volts or DC mV on CH1.

Page 67