Drager Babytherm 8004, Babytherm 8010 Service Manual

Test Certificate

Babytherm

DrägerService

Explanation of Symbols

OK C = Check condition

8004/8010

Installation site:

File no.:

Edition

6132.300

01.2003

Defect/error/fault O = Check function

Spare parts used L = Check for leaks

Report V = Enter value

Accessories missing

∩

For internal use only. For internal use only.

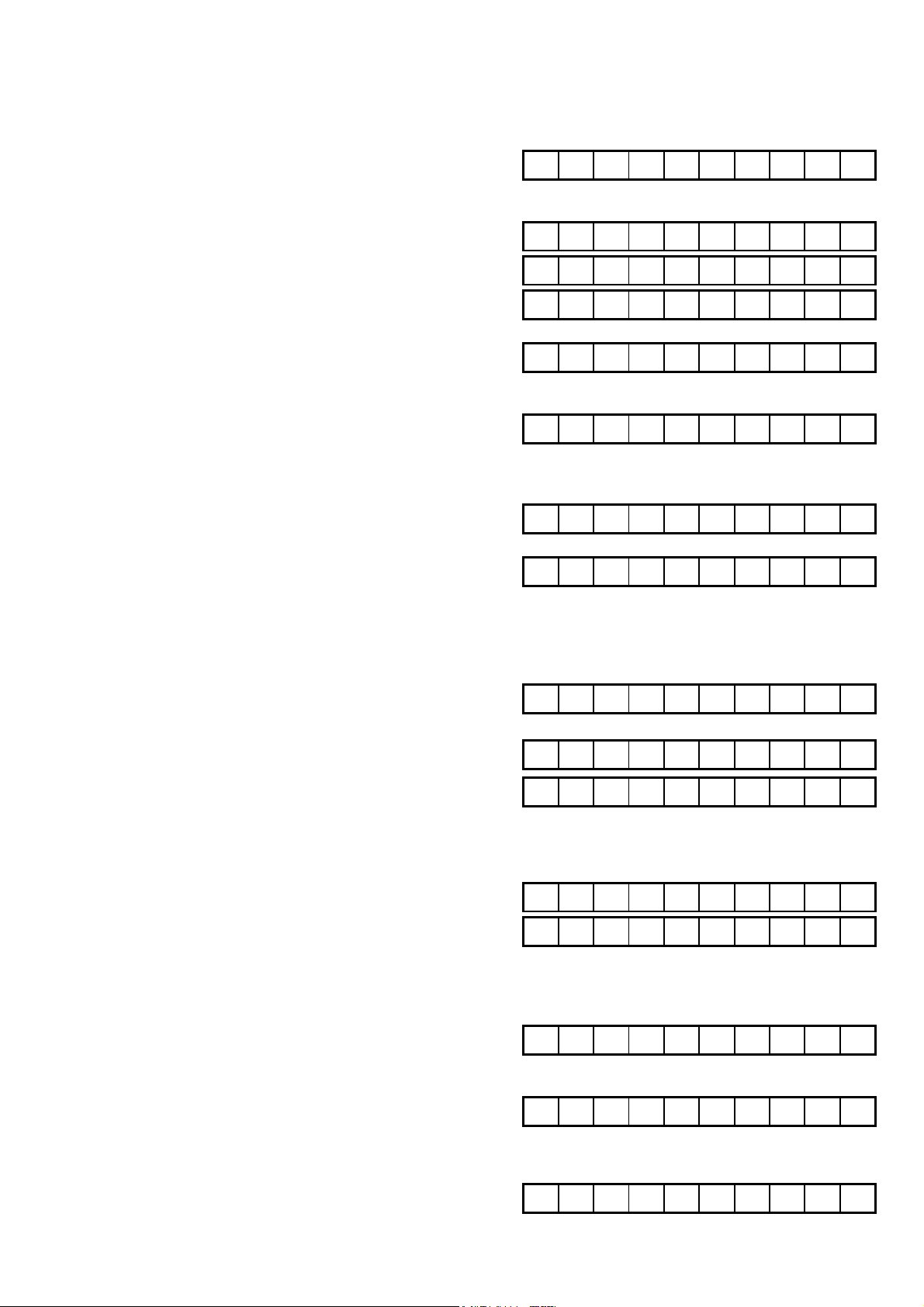

1. Device in general

1.1 Software version

1.2 Options as per name plate

1.3 Operating hours

Serial no.:

Date of delivery/

startup:

Invoice no. or

delivery no.:

Other:

1.4 General condition

1.4.1 Connecting cable of Babytherm

1.4.2 Connecting cable of the column (US version)

Connecting cable of column is

undamaged.

1.4.3 Control unit

1.4.3.1 Attachment

1.4.3.2 Fuses

The fuses are as specified on the rating

plate.

1.4.3.3 Membrane keypad

1.4.3.4 ON/OFF switch

1.4.3.5 Plug-in connector

C

C

C

C

C

C

C

1/17

1.4.4 Mains voltage distributor (located underneath base plate)

The fuses are as specified on the rating

plate.

1.4.5 Trolley and column

C

1.4.5.1 Pedals of height adjustment (optional)

1.4.5.2 2 x castor 125 mm (2M 20792)

1.4.5.3 2 x lockable castor 125 mm (2M 20794)

1.4.5.4 4 x cap (2M 20348) on tube ends of trolley. The cap holds the castors.

1.4.6 Mattress heater

1.4.6.1 Sealing of heating plate

1.4.7 Mattress

1.4.7.1 Foam mattress, Babytherm 8004

(2M 21012).

1.4.7.2 Gel mattress, Babytherm 8010 (2M

20827)

Important: Repair small fissures on

surface using adhesive tape or repair set

for gel mattress 2M 21324.

1.4.8 Hook rail with hook 2 M 21293 beneath the top part of the mattress tray (option)

C

C

C

C

C

C

C

C

1.4.9 Grip strip 2M 21468 on top part of mattress tray (option)

1.4.10 Canopy 2M 21030 (option)

1.4.10.1 Thermometer 2M11111

Comparative measurement in water bath,

permissible deviation 0.4 °C, water bath

20 – 35 °C.

1.4.10.2 Holder for canopy (2M 21342)

1.4.11 Bottom part of mattress tray

The bottom part of the mattress tray is

secured to the base plate with 4 Allen

screws.

1.4.12 Bottom part of mattress tray

1.4.12.1 Corners 2M 21390 for mounting of panel.

1.4.12.2 Panels, 4 x (15 cm or 23 cm height)

The panels engage securely in the

corners.

C

CO

O

C

C

C

CO

2/17

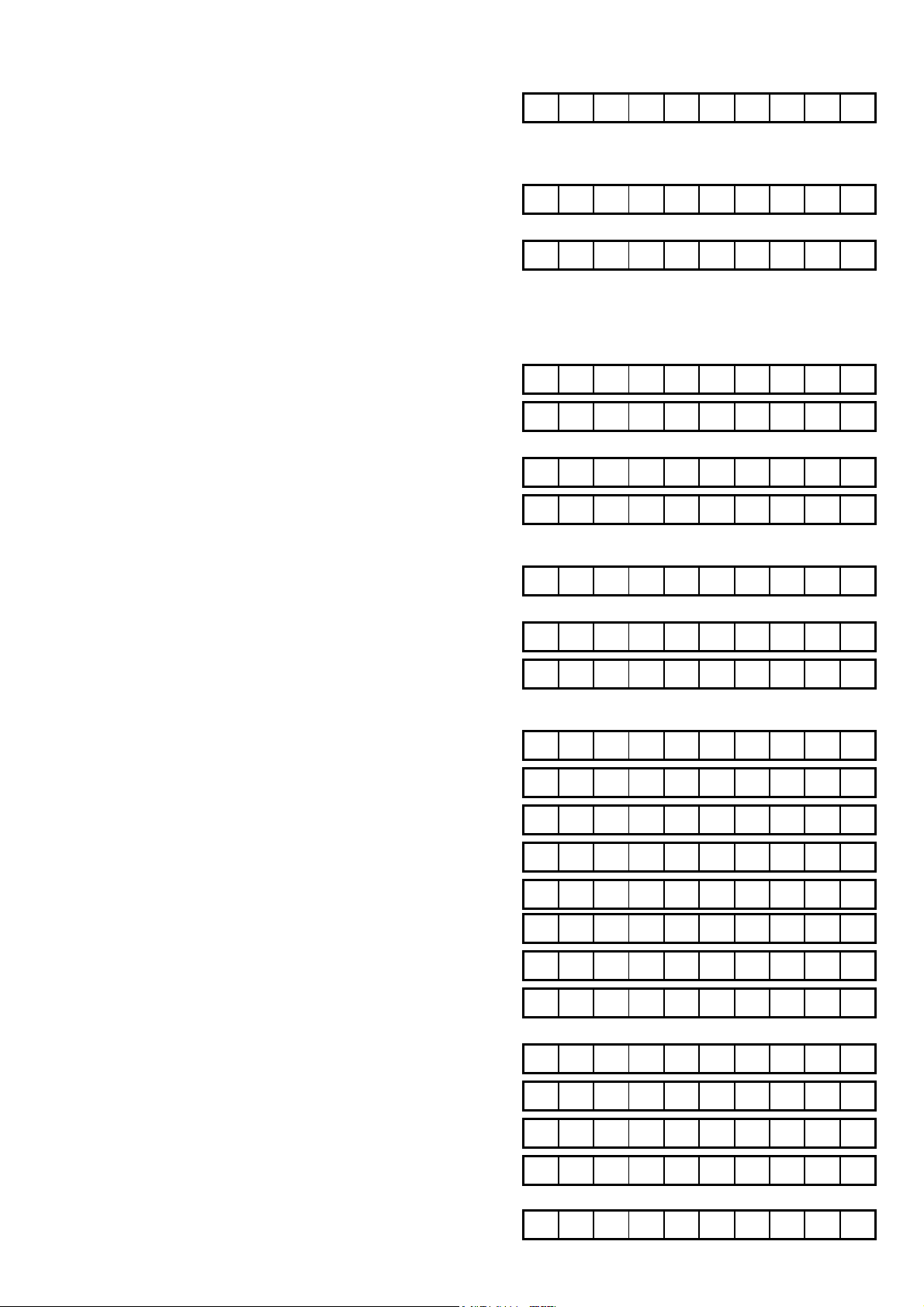

1.4.12.3 Hose ducts (2M 20434)

1.4.12.4 Only with 23 cm face panel at the rear:

Lock (2M 13042)

Injector (2M 14190)

Label with flow table (2M 21147)

1.4.13 Inside panel 2 M 20936 (height approx. 70 mm)

1.4.14 Mattress tray tilt adjustment

1.4.14.1 Resetting springs (8300445)

Resetting springs for locking lever are

fitted.

C

C

C

C

1.4.15 X-ray drawer (Babytherm 8004, option)

1.4.16 Core and peripheral skin-temperature sensor connector

1.4.17 Protective screen (radiant heater)

1.4.18 Suction

1.4.18.1 Replace bacterial filter CH 102.

1.4.19 Grip strip accessory rail (2M 20860)

1.4.20 Swivel cupboard with attachment (option)

1.4.21 Stand.

1.4.22 Tray for monitor

1.4.23 Rail for tray

1.4.24 Compact rail 2M 85337 (option)

*

(set of 5 6723976)

Retighten screws of stand.

C

C

C

C

C

C O

C

C

C

C

1.4.25 Carrying frame (M 25858)

1.4.25.1 Jar holder

1.4.26 Connecting hose

1.4.27 Secretion suction hose (M 25780)

1.4.28 Secretion sightglass or finger tip (M

07582)

1.4.29 Container, 2 x (M 20091)

1.4.30 Cylinder cap 2M 85012 with valve

1.4.31 Float (M 26007)

1.4.32 Pressure-limiting valve with mica washer

R 17329 (option)

C

C

C

C

C

C

C

C

COL

3/17

1.4.33 Ejector

1.4.34 Power with pediatric bronchial suction

device 2M 85045 up to 0.5 bar; power with

rail clamp up to 0.5 bar.

1.4.35 Power with bronchial suction device 2M 21187, fixed. Power up to 0.5 bar

1.4.36 Pipeline system connecting tube (follow national regulations!)

CO

CO

CL

1.4.37 O

1.4.38 O

distributor for central supply

2

distributor for O2 compressed-gas

2

cylinder

1.4.39 O

1.4.40 O

compressed-gas cylinder (B 02352)

2

compressed-gas cylinder (B 02533)

2

1.4.41 AIR distributor for central supply

1.4.42 Infusion holder (2M 21514)

1.4.43 Holder for ventilation hoses (2M 21191)

1.4.44 Ventilator hose holder (84 10080)

1.4.45 Ventilator

Carry out check according to respective

Test Certificate.

1.4.46 Additional monitoring devices

C

C

C

C

C

C

C

C

Carry out checks according to respective

Test Certificate.

2. Replacement articles to be used

2.1 Halogen lamp

Replace halogen lamp after 1000

operating hours.

Important: After replacing the halogen

lamp, use Customer Service Mode (CSM)

to reset operating hours to zero.

2.2 Suction

2.2.1 Bacterial filter CH102

Replace bacterial filter CH102 (set of 5

6723976).

4/17

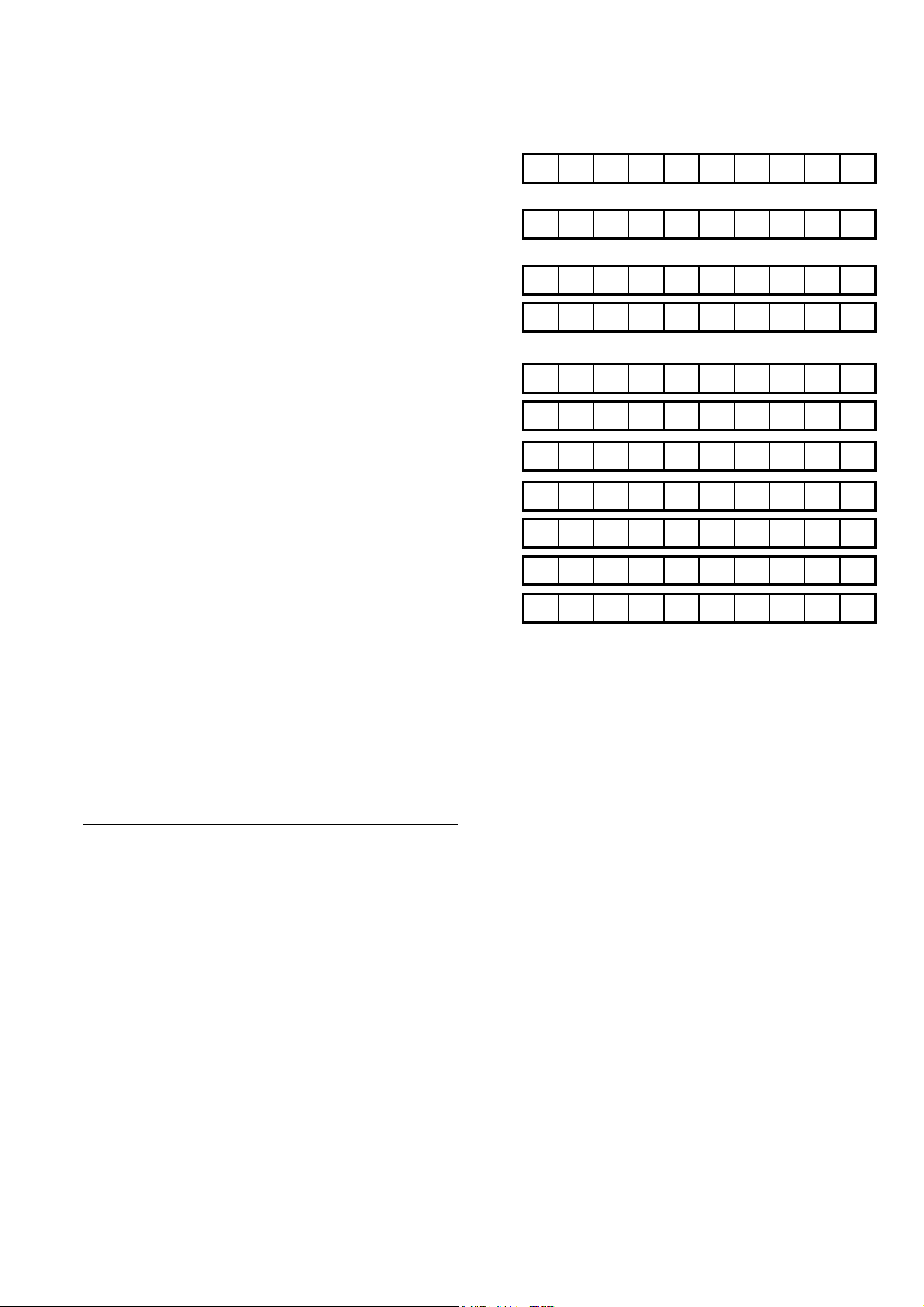

3. Electrical safety

3.1 Protective earth conductor resistance test(s)

3.1.1 Trolley, height adjustment, column and attachment of control unit

The protective earth conductor resistance

of the trolley, height adjustment, column

and attachment of the control unit should

be less than 0.2 ohms.

3.1.2 Mattress heater (Babytherm 8010)

The protective earth conductor resistance

to the aluminum plate of the mattress

heater should be infinite

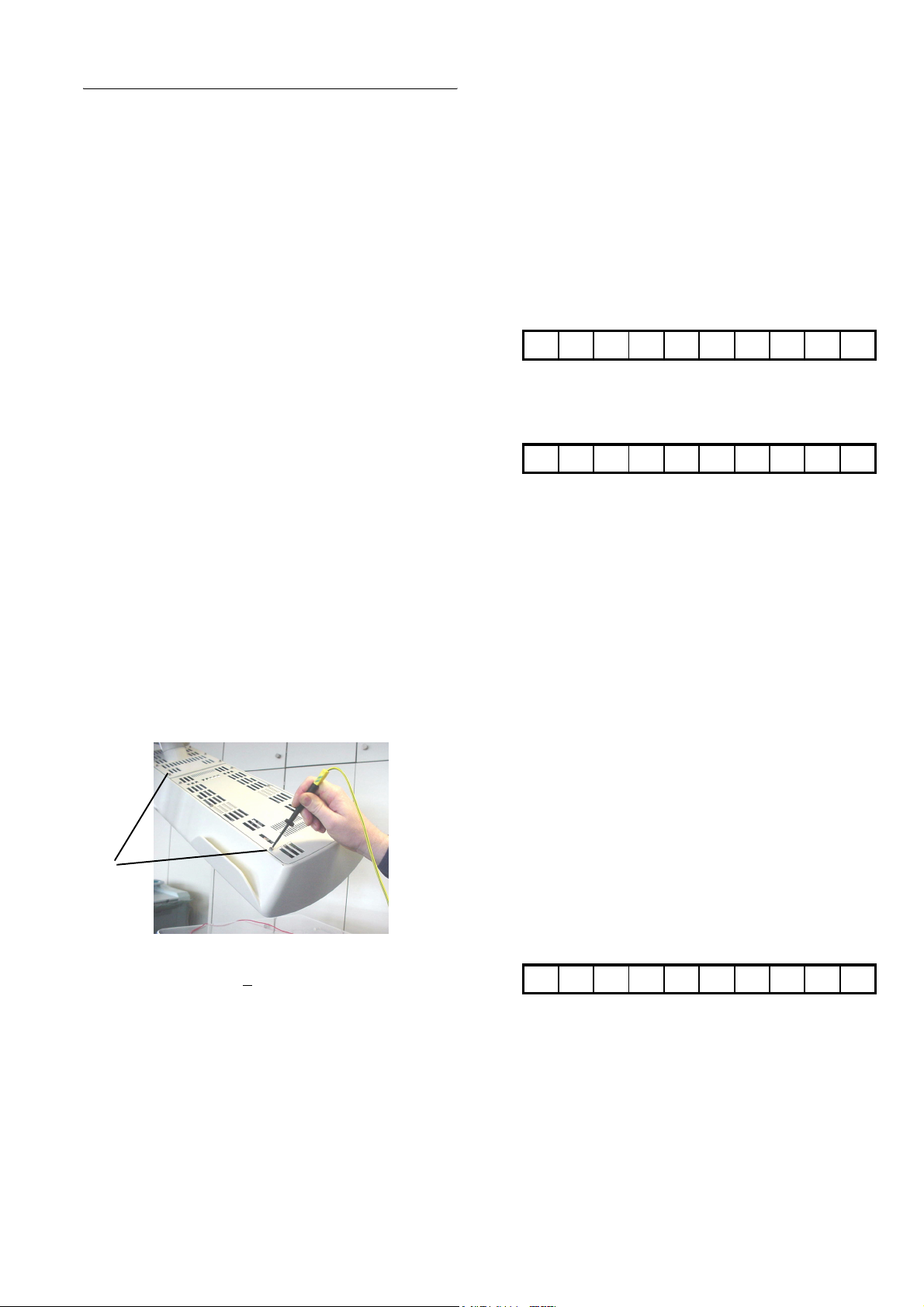

3.1.3 Radiant heater

Use the test probe to measure the

following protective earth conductor

resistances:

ohms.

O

O

3.1.3.1 Screws

Measure at screws (1).

(Note: The screws are located on the top

side of the radiant heater.)

1

The protective earth conductor resistance

should be <

0.2 ohms.

O

5/17

3.1.3.2 Screw of protective screen

Measure at screw (2).

(Note: The radiant heater should be in its

normal position.)

2

The protective earth conductor resistance

should be <

3.1.3.3 Screw of protective screen

0.2 ohms.

O

Measure at screw (3).

(Note: The radiant heater should be in

its swivel end position.)

3

The protective earth conductor resistance

should be <

0.2 ohms.

O

6/17

Loading...

Loading...