Denon DN-X600 Service Manual

Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1C E1K EUT

DN-X600

33

DJ MIXER

For purposes of improvement, specifi cations and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

D&M Holdings Inc.

S0080-1V01DM/DG1008

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if fi ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be sure to use parts which have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslation check on the external metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fi res

or other dangerous situations.

2

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

Parts for which "nsp" is indicated on this table cannot be supplied.

1.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

2.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

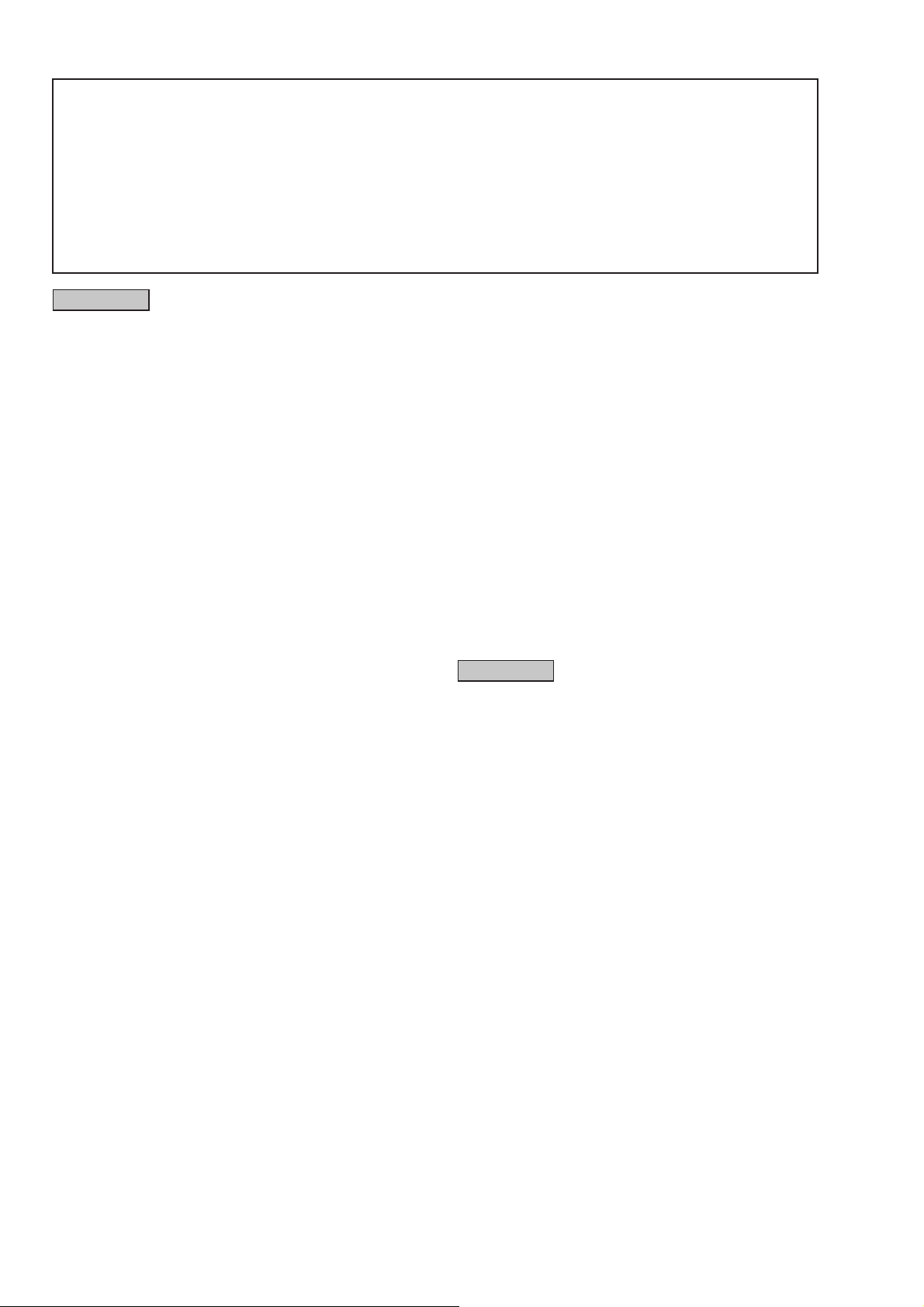

WARNING:

● Resistors

Ex.: RN

* Resistance

● Capacitors

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

14K

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

・ Units:μF.

・ Units:pF

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

2

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Z:±80%

: - 20%

P : +100%

C:±0.25pF

D:±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

TECHNICAL SPECIFICATIONS

n Audio

• PHONO inputs 2 Stereo

Input impedance:

Level:

Signal to Noise ratio: 89 dB

• CD inputs 2 Stereo

Input impedance:

Level: 0 dBV

Signal to Noise ratio: 100 dB

• Equalizer (LINE) 3 Band

Channel EQ Adjustment

Range:

• AUX1 Input 1 Stereo RCA Terminal

Input impedance:

Level: 0 dBV

• EFX RETURN AUX2 inputs 1 Stereo RCA Terminal

Input impedance:

Level: AUX2:0 dBV

• MIC inputs Monaural

MIC:

Input impedance: 5kΩ

Level:

EIN:

CMRR:

• Equalizer (MIC/AUX1)

Adjustment Range: HI (High Range) :

• USB audio inputs 4 Stereo(8 Monaural) 24 bit,

• MASTER output Balanced: Stereo, balanced XLR terminal

DA converter: 32 bit 128-times oversampling

Load impedance: Over 600 Ω

Level: + 4 dBu (Max + 24 dBu)

Frequency response:

THD:

Crosstalk: Less than –100 dB (1 kHz)

Unbalanced: Stereo RCA terminal

Load impedance: 10 kΩ

Level:

• EFX SEND/BOOTH Output

Load impedance:

Level: BOOTH: 0dBu (Max + 20dBu)

(0 dBu=0.775 Vrms,

0 dBV =1 Vrms)

Unbalanced RCA terminal

47 kΩ

–40 dBV(10 mV)

Unbalanced RCA terminal

10 kΩ

HI (High Range)

–∞, –90 dB – +10 dB

MID (Medium Range) :

–∞, –90 dB – +10 dB

LOW (Low Range) :

–∞, –90 dB – +6 dB

10 kΩ

10 kΩ

EFX RETURN:

Balanced XLR

(1: Ground, 2: Hot, 3: Cold)

–

60 – +20 dBu

-126 dBu or less

(Rs=150Ω)

89 dB or more (1 kHz)

2 Band

LOW (Low Range) :–15 – +15dB

Fs:44.1/48/96 kHz

USB B

(1: Ground, 2: Hot, 3: Cold)

advanced segment

20 Hz – 20 kHz(±0.5 dB)

Less than 0.05%

0 dBu (Max + 20dBu)

Stereo RCA terminal

10 kΩ or more

EFX SEND:–10dBV

(Max +10dBV)

:

–

10 dBV

–15 – +15 dB

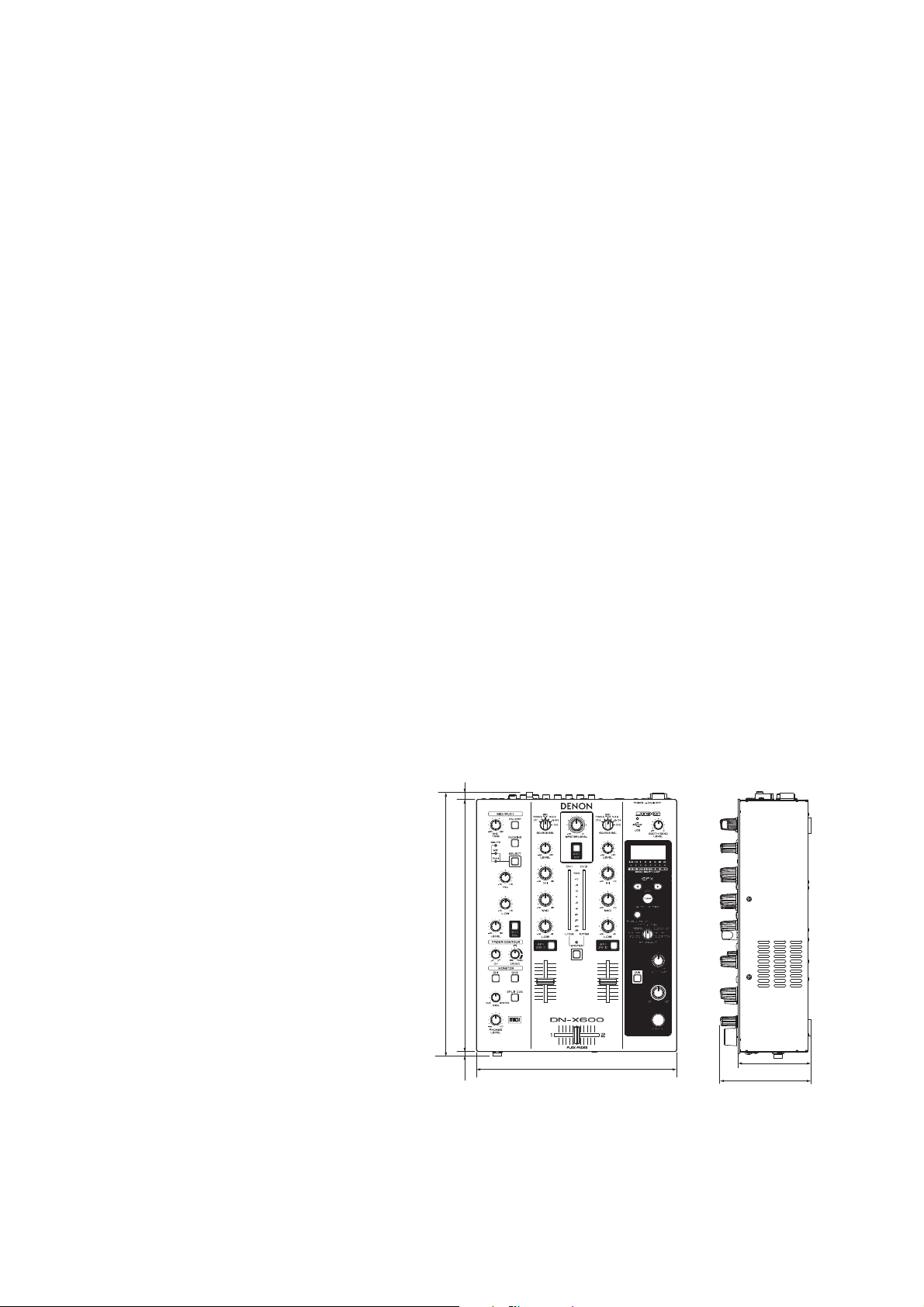

DIMENSION

• Headphone output Stereo

Load impedance: 40 Ω

Level: 100 mW

• USB audio output 4 Stereo(8 Monaural) 24bit,

44.1/48/96 kHz

USB B

n General

USB MIDI I/O: IN:1ch, OUT:1ch MIDI1.0, MIDI

Clock USB B

CH Meter: PPM 10 Point LED-20

dB, Peak

MASTER Meter: PPM 10 Point LED-20

dB, Peak

CH Fader: 45 mm Slim Type fader

Cross Fader: 45 mm FLEX Fader

(Fader Torque Adjustable)

• Power supply

U.S.A. and Canada models: AC 120 V, 60 Hz

European,U.K. and Asia/

Pacifi c models:

Power consumption: 24 W

Operating temperature: +5 °C – +35 °C

Operating humidity: 25 % – 85 %

S

torage temperature: –20 °C – 60 °C

:

AC 230 V, 50 Hz

(Less than 0.3 W during standby)

– + 10

n Dimensions

Width: 250 mm

Height: 315 mm

Depth: 90 mm

Weight: 4.0 kg

9 mm

315 mm

330 mm

90 mm

112 mm

6 mm

250 mm

– + 10

4

CAUTION IN SERVICING

Initializing DN-X600

DN-X600 initialization should be performed when the μcom, peripheral parts of μcom, and Digital P.W.B. are replaced.

1. Turn off the power using POWER ON/OFF button.

2. Press POWER ON/OFF button while simultaneously pressing EFX SEND1 and EFX SEND1 buttons.

3. The Initialization mode can be executed by pressing the TAP button.

The total running time is initialized.

b

Note: • All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to memorize your setting for restoring after the initialization.

ON/OFF

FEX SEND1 TAP

FEX SEND2

5

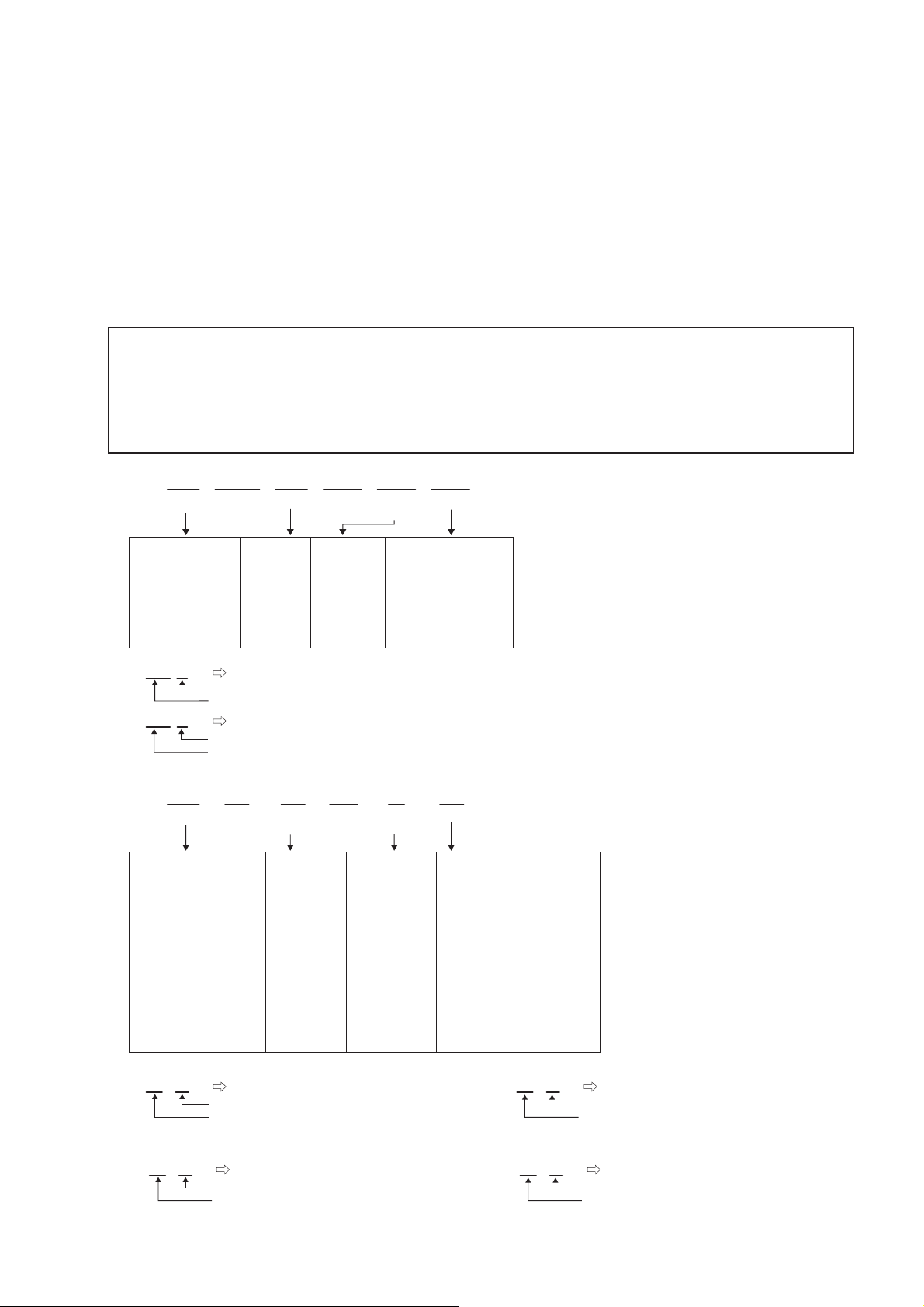

DISASSEMBLY

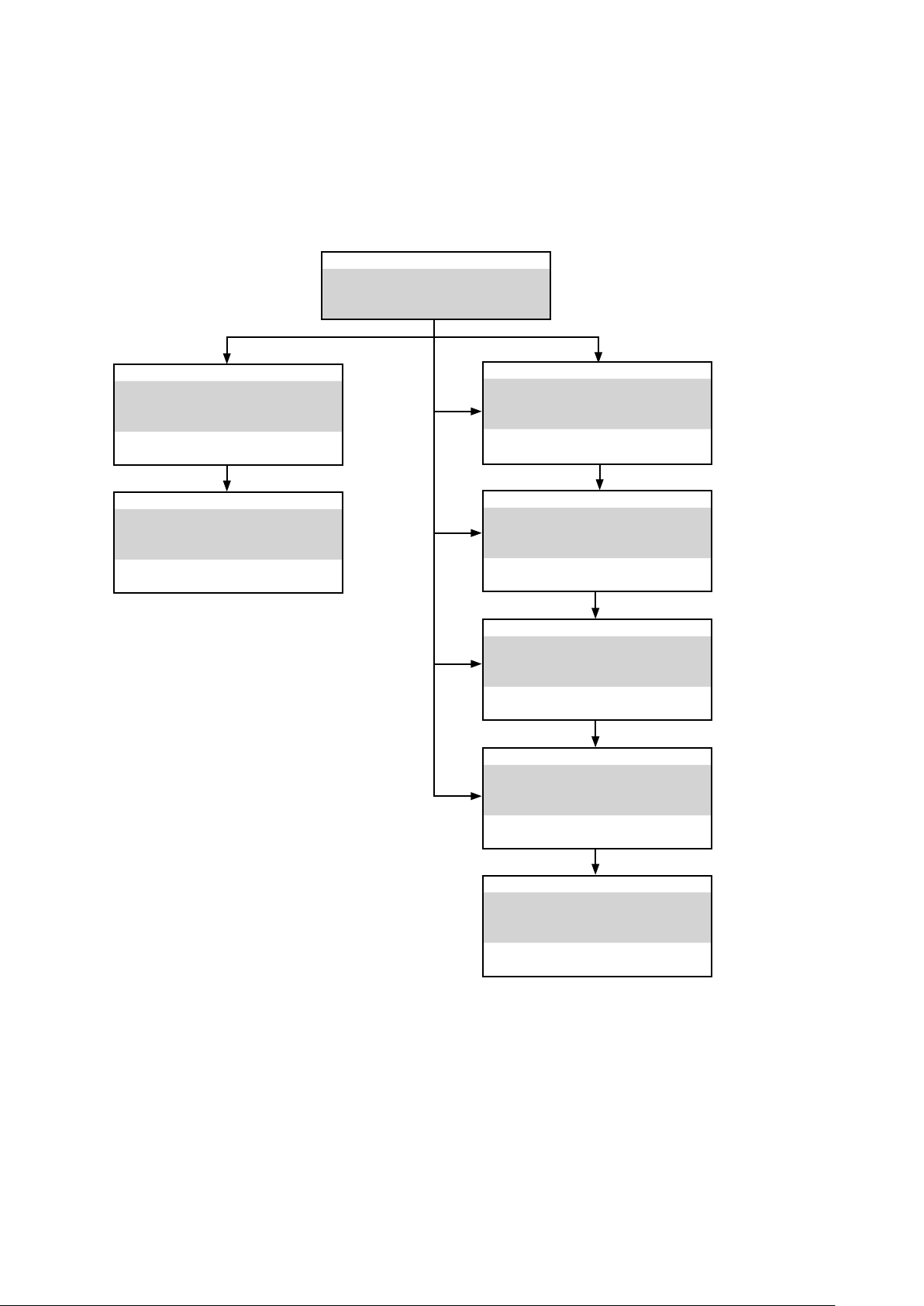

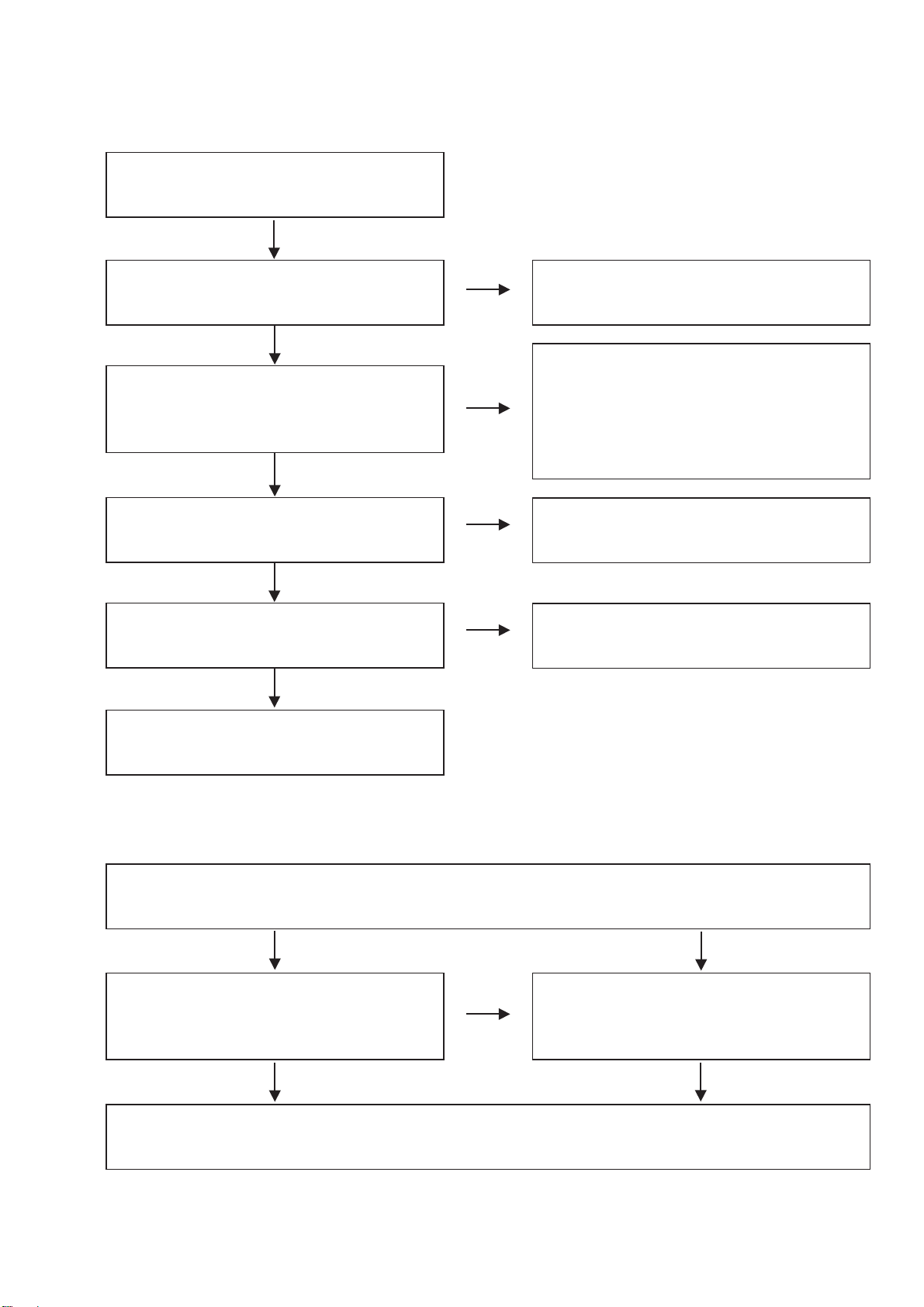

• Disassemble in order of the arrow of the fi gure of following fl ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following fl ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP PANEL SUB ASSY

Refer to "DISASSEMBLY

1.TOP PANEL SUB ASSY"

and "EXPLODED VIEW"

TOP PANEL PWB SUB ASSY

Refer to "DISASSEMBLY

2. TOP PANEL PWB SUB ASSY"

and "EXPLODED VIEW"

TOP PANEL PWB

(Ref. No. of EXPLODED VIEW : B-1)

7SEG PWB

Refer to "DISASSEMBLY

3. 7SEG PWB"

and "EXPLODED VIEW"

7SEG PWB

(Ref. No. of EXPLODED VIEW : B-2)

HEAD PHONE PWB

Refer to "DISASSEMBLY

4. HEAD PHONE PWB"

and "EXPLODED VIEW"

HEAD PHONE PWB

(Ref. No. of EXPLODED VIEW : A-2)

SLIDE SW PWB

Refer to "DISASSEMBLY

5. SLIDE SW PWB"

and "EXPLODED VIEW"

SLIDE SW PWB

(Ref. No. of EXPLODED VIEW : B-4)

MAIN PWB

Refer to "DISASSEMBLY

6. MAIN PWB"

and "EXPLODED VIEW"

MAIN PWB

(Ref. No. of EXPLODED VIEW :C)

MIC PWB

Refer to "DISASSEMBLY

7. MIC PWB"

and "EXPLODED VIEW"

MIC PWB

(Ref. No. of EXPLODED VIEW :B-3)

IO PWB

Refer to "DISASSEMBLY

8. IO PWB"

and "EXPLODED VIEW"

IO PWB

(Ref. No. of EXPLODED VIEW :A-1)

6

About the photos used for descriptions in the "DISASSEMBLY" section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***"

at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

Direction of photograph: A

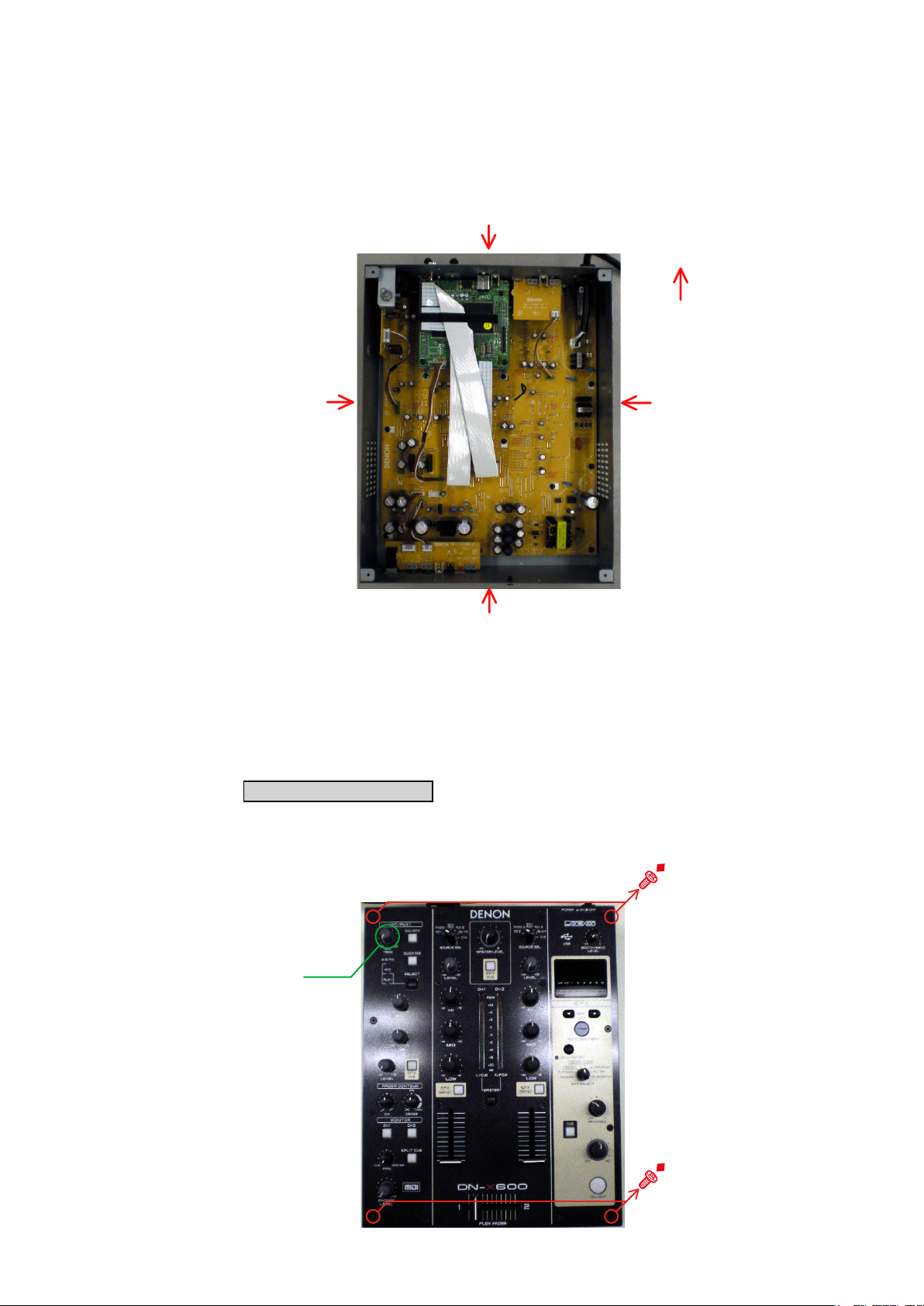

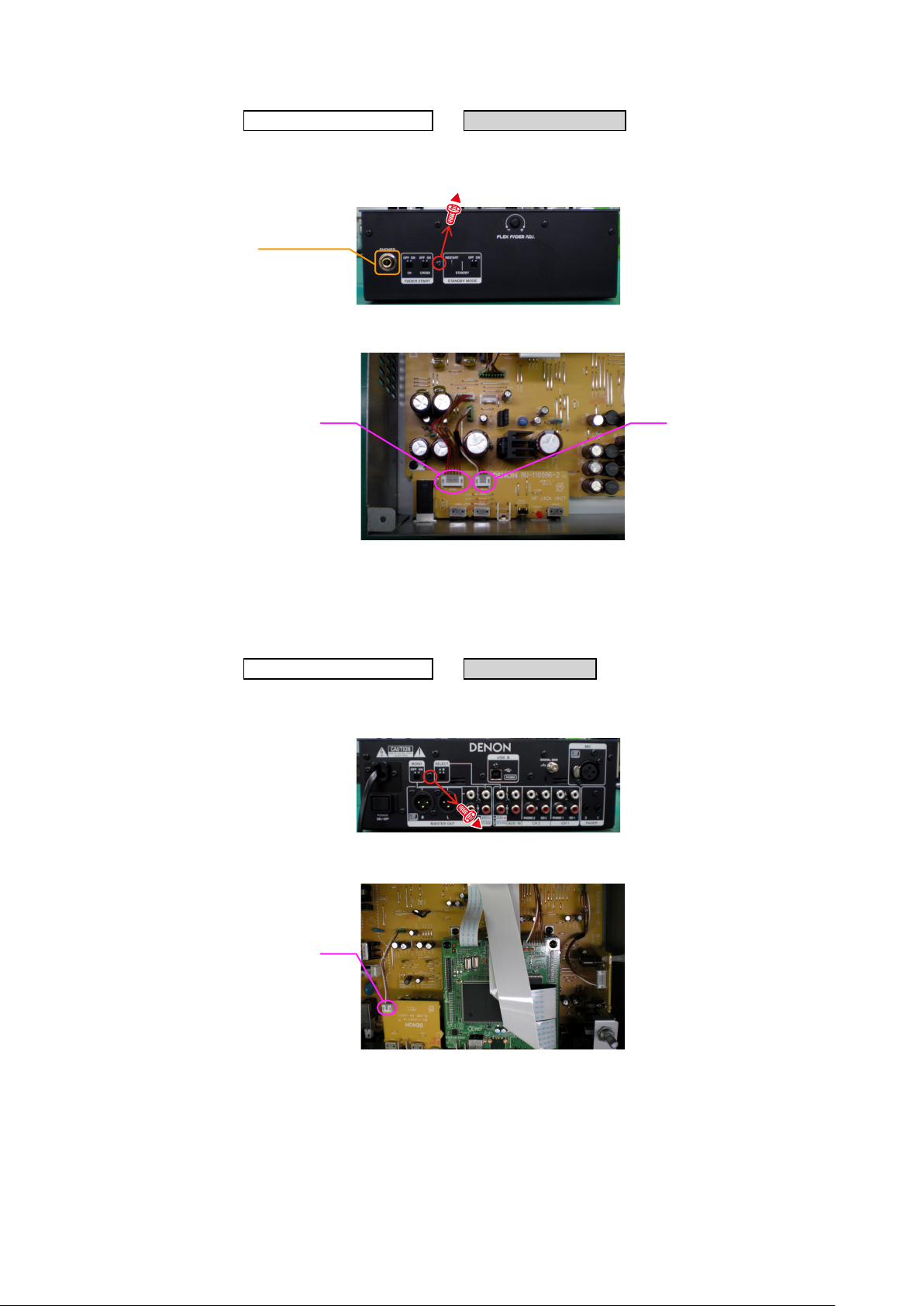

1. TOP PANEL SUB ASSY

TOP PANEL SUB ASSYProceeding :

(1) Remove the screws and the knobs.

KNOB

7

(2) Remove the screws.

Direction of photograph: B

Direction of

photograph: C

Direction of photograph: A

(3) Disconnect the connector wire and FFC Cable, then loose the wire clamper.

TOP CHASIS SUB ASSY

Direction of

photograph: D

FFC cable

Direction of photograph: A

N041

WIRE CLAMPER

BOTTOM CHASSIS SUB ASSY

8

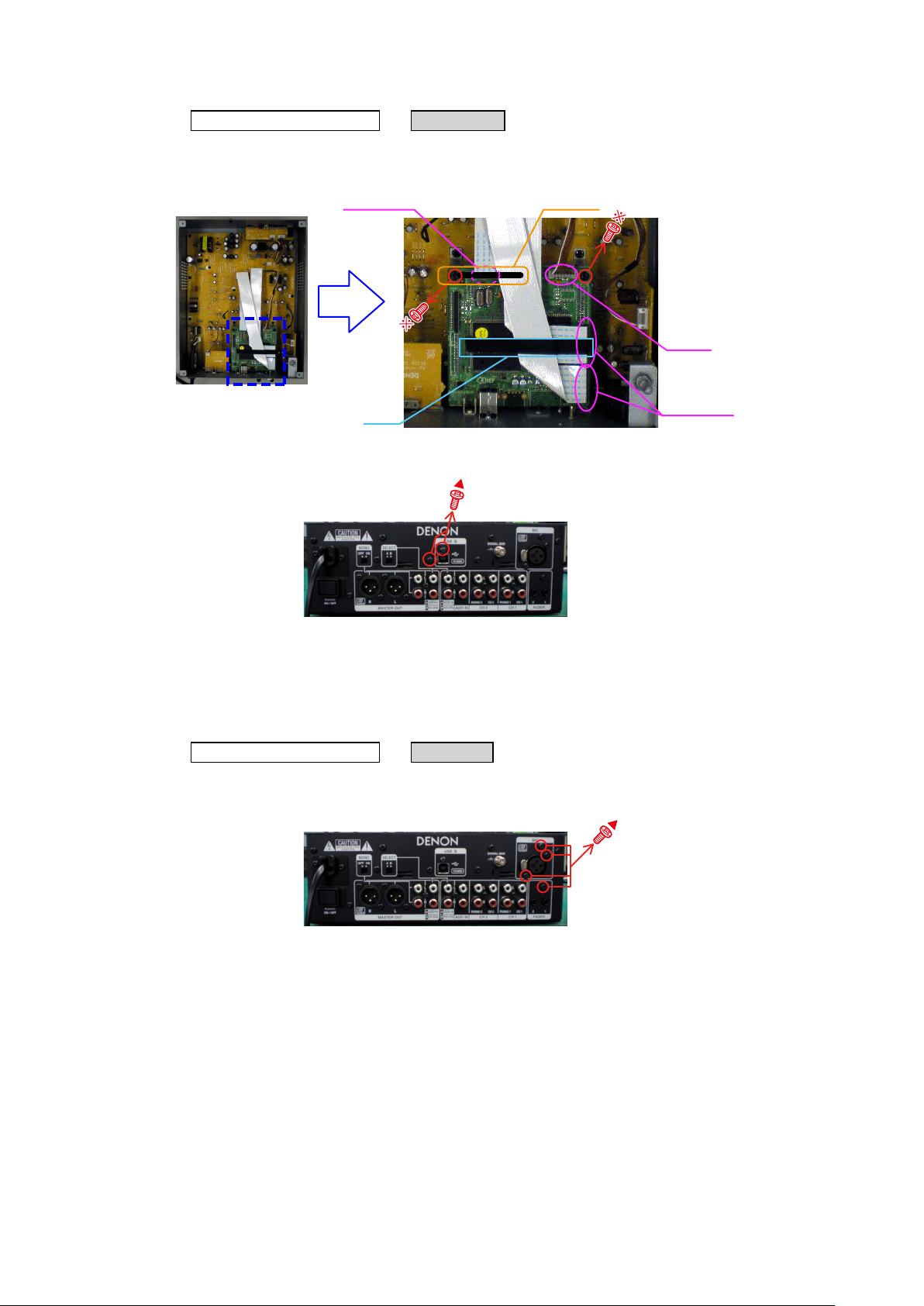

2. TOP PANEL PWB SUB ASSY

Proceeding :

(1) Remove the knobs.

(2) Remove the screws.

TOP PANEL SUB ASSY

KNOB

TOP PANEL PWB SUB ASSY

→

(3) Remove the Nuts, LENS LED and LENS RING, then disconnect the connector wire.

LENS LED

NUT

LENS RING VOL

N041

9

(4) Remove the secrews, then remove the STAY GND.

STAY GND

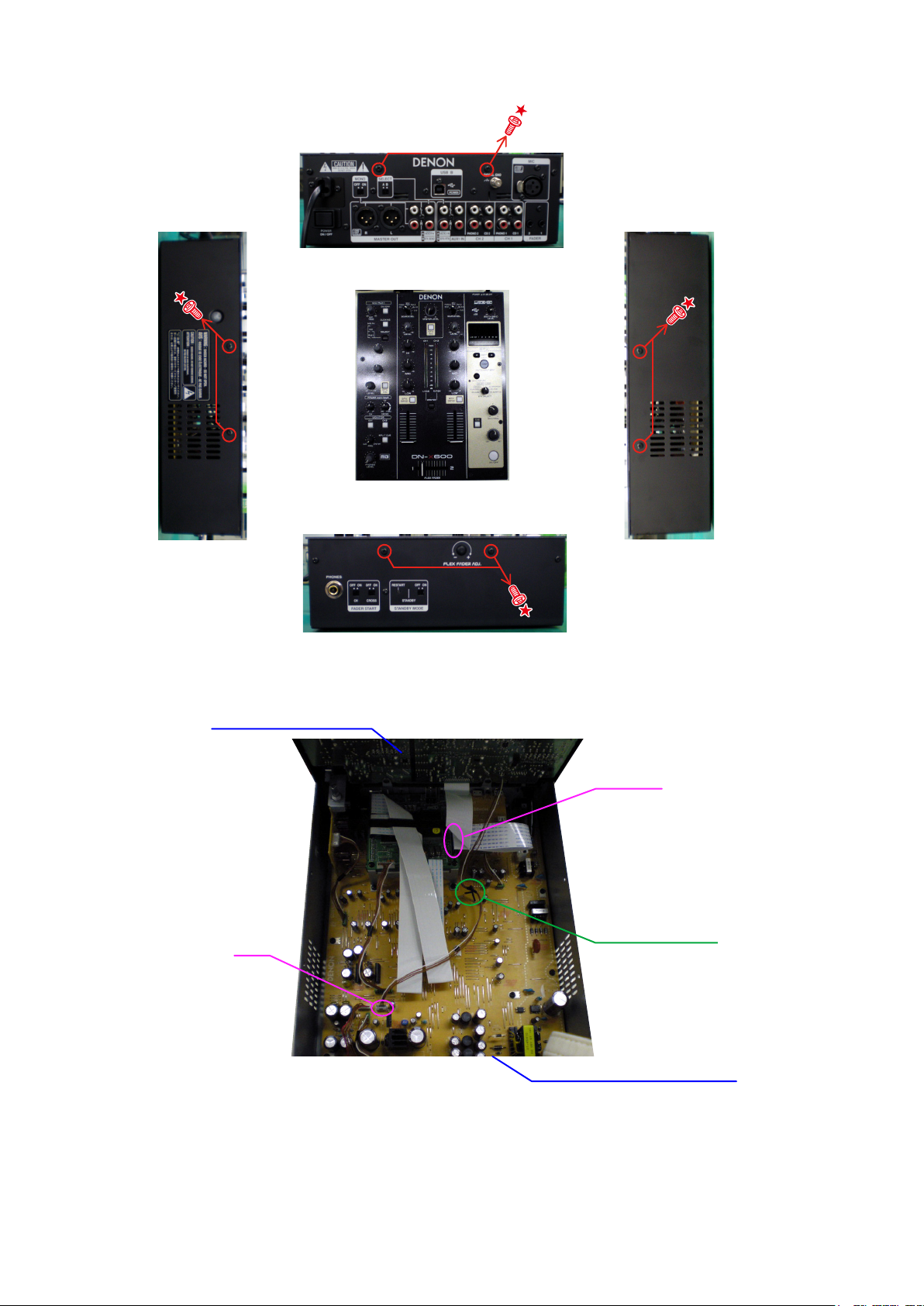

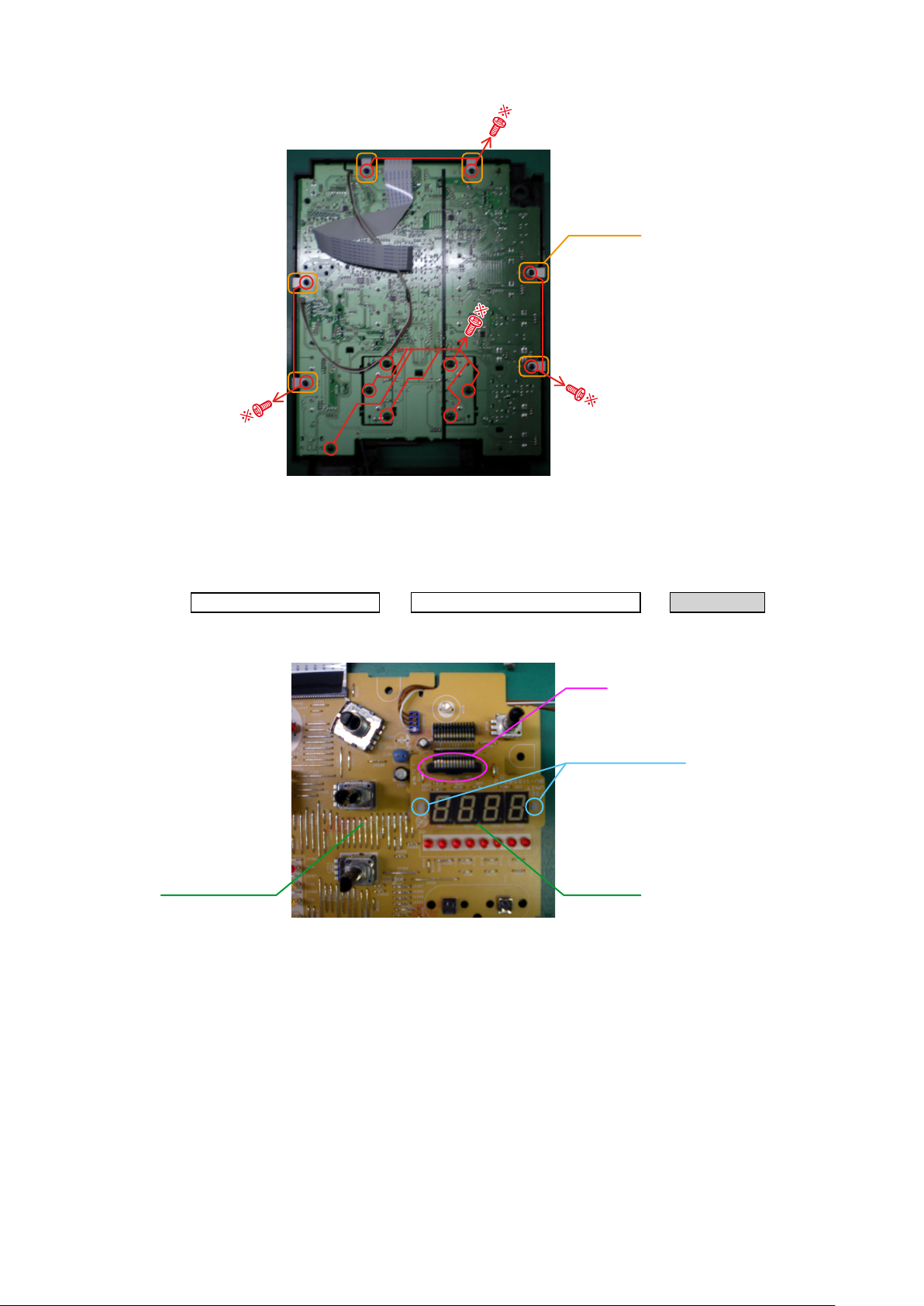

3. 7SEG PWB

Proceeding :

(1) Disconnect the connector wire, then remove the PCB SUPPORT.

TOP PANEL SUB ASSY

TOP PANEL PWB SUB ASSY

→

→

N132

PCB SUPPORT

7SEG PWBTOP PANEL PWB

7SEG PWB

10

4. HEAD PHONE PWB

Proceeding :

(1) Remove the screw, Nuts and Washers.

Direction of photograph: A

(2) Disconnect the connector wires.

TOP PANEL SUB ASSY

NUT/WASHE

HEAD PHONE PWB

→

N044N068

5. SLIDE SW PWB

Proceeding :

(1) Remove the screws.

Direction of photograph: B

(2) Disconnect the connector wires.

TOP PANEL SUB ASSY

N031

SLIDE SW PWB

→

11

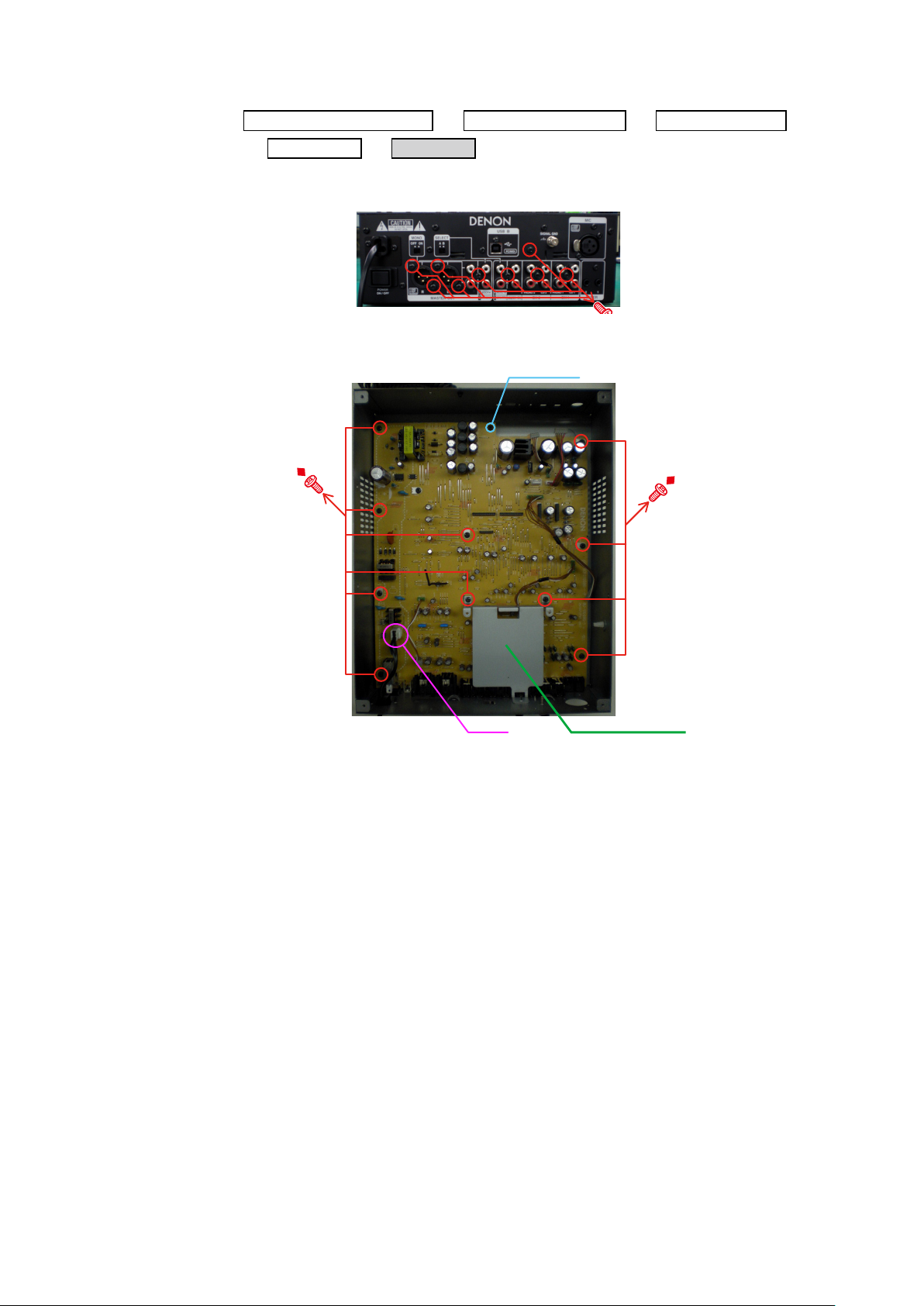

6. MAIN PWB

Proceeding :

(1) Disconnect the connector wire and FFC Cable, and remove the tape.

(2) Remove the screws.

TOP PANEL SUB ASSY

FFC Cable

tape

MAIN PWB

→

Clamper

CY081

FFC Cable

Direction of photograph: B

7. MIC PWB

Proceeding :

(1) Remove the screws.

Direction of photograph: B

TOP PANEL SUB ASSY

→

MIC PWB

12

8. IO PWB

Proceeding :

(1) Remove the screws.

Direction of photograph: B

(2) Disconnect the connector wires.

TOP PANEL SUB ASSY

MAIN PWB

→

MIC PWB

→

HEAD PHONE PWB

→

SUPPORT

SLIDE SW PWB

→

N021 STAY PWB MAIN

13

SPECIAL MODE

1. Special mode setting button

Press the POWER ON button to turn on while pressing buttons A and B.

b

Mode Button A Button B Contents

Version display, LED Check, SW CHECK, VR Check, Total running

Service Mode 1 4

Version Up Mode 2 3 Firmware Update

2. Service Mode setting button

Press the POWER ON button to turn on while pressing buttons 1 and 4.

b

Select the desired mode and rotate button 5.

No. Mode Button 7 Entry Exit Contents

1 Version display REVERB 6 5

2 LED Check FLANGER 6 5

3 SW Check ECHO 6 -

4 VR Check DELAY 6 5

Tatal RunningTime

5

Display

ROM/RAM Access

6

test

USB MIDI OUT

7

test

8 EUP mode test B.SCRATCH 6 -

LOOP 6 5 Total running time displayed. (Max65000hours)

B.BREAKER 6 -

FILTER 6 5

Display order

«_SYS»→«xxxx(system Ver.)»→«_dSP»→«xxxx(DSP Ver.)» ever 1 sec.

All on

q

DIM mode

w

All off

e

Greeen lights up

r

Umber lights up

t

Red lights up

y

Blue lights up

u

7SEG lights up

i

Max Load mode

o

TYP lights up mode

Q0

Button displays the number of tests. Press the button and go to the countdown. The

corresponding button is pressed, LED turns off. SW all the press, «PASS» appears.

Checking the operation of each panel VR.

Turned the volume amount will display in resolution number 1024.

Displays the number corresponding to the selected location of the source selector.

Displays the number corresponding to the position of slide switch.

FlashROM (2MB) and SD-RAM (8MB) then Reads to accessible. Address (space cache

disabled), and two bytes for each increment.

Press BEAT button.Select run or escape.

Press TAP button.Press the button that is displayed during the run. Start the Access test.

"When a PC is not connected state, «FAIL» appears.

Press BEAT button.Select the command button to send.

Press TAP button.USB-Midi sends the selected command."

"EUP switch ON state.

Press BEAT button.Select run or escape.

Press TAP button.Press the button that is displayed during the run. Start the EUP mode."

time (Clear total runnig time), ROM/RAM Access test, USB MIDI OUT

test, EUP mode test

1 5 62 3 4 7

14

2.1. Version display

EFX SERECTOR is REVERB and press TAP button.

Display order

«_SYS»→«xxxx(system Ver.)»→«_dSP»→«xxxx(DSP Ver.)» ever 1 sec.

Press [EFX SEND / RETURN] button:Back to the Service Top.

2.2. LED Check

EFX SERECTOR is FLANGER and press TAP button.

Press TAP button to order, and the following mode.

All on

q

All LED (7SEG including) is lit (using LED lights do not light them all on at the same time)

DIM mode

w

All the lights DIM (DIM lines). Other (7SEG included) is off

DIM : EFX SEND(1~2), Monitor (1~2), EFX CUE, EFX ON, EFX SEND/RETURN, USB

All off

e

All LED (7SEG included) to full off.

Greeen lights up

r

Other Off (7SEG including.)

Umber lights up

t

Other Off (7SEG including.)

Red lights up

y

Other Off (7SEG including.)

Blue lights up

u

Other Off (7SEG including.)

7SEG lights up

i

«000.0» displayed. [BEAT> ]- Each time you press the button to count up.Other Off .

Count up«000.0»→«111.1»→«222.2»…→«999.9»→«000.0»

Max Load mode

o

Maximum light on the actual use. Power used to evaluate

MIC EFX INS, MAS EFX INS, AUX1 SELECT, SIG/PK(Red), DUCKING(Red) Lights other than those described to

the left.

Displayed «288.8».

TYP lights up mode

Q0

Immediately after assuming power. Power used to evaluate

ON : MASTER LEVEL, TAP, DRY/WET, BEAT(1), MIC SELECT

DIM : CH EFX SEND(1~2), Monitor (1~2), EFX CUE, EFX ON

Displayed «123.4».

Press [TAP] button :back to

.

q

Press [EFX SEND / RETURN] button:Back to the Service Top.

2.3. SW CHECK

• EFX SERECTOR is ECHO and press TAP button.

(1) Panel conduct the confi rmation button. (17 total)

(2) First, displayed «__17»

(3) Initially, all the LED lights below.

MIC ON/OFF, DUCKING, AUX1, MIC EFX INS, SPLIT CUE, Monitor CH1, Monitor CH2, EFX SEND(CH1~CH2),

CH/MAS Meter SEL, MAS EFX INS, TAP, EFX CUE, EFX SEND/RETURN, EFX ON/OFF, BEAT(16,32)

(4) Press the button corresponding to the button or LED, BEAT turns off the display unit. And to count the number that is

displayed.Do nothing when you press the button is the same.

(5) When you press the button all, «PASS» appears. Press EFX SEMD / RETURN button return to Service Top.

When you stop in the middle, press and hold the TAP button to return to the Service Top.

b

15

2.4. VR Check

• EFX SERECTOR is DELAY and press TAP button.

(1) Checking the operation of each panel VR.

(Total 19, CH Fader 2, X Fader 1, Selector 3, Slide switch 5)

(2) Turned the volume amount will display in resolution number 1024.

(3) Displays the number corresponding to the selected location of the source selector.

(4) Displays the number corresponding to the position of slide switch.

(5) Press EFX SEMD / RETURN button return to Service Top.

Displayed selector number or switch number.

b

SOURCE SEL FEX SELECT FADER START

Selector Display Selector Display Selector Display

CH1 CD 1_00 EFX Reverb 3_00 FAD START 4_00 /4_01

CH1 PHONO 1_01 EFX Flanger 3_01 XFAD START 5_00 / 5_01

CH1 AUX1 1_02 EFX Echo 3_02 EUP ON/OFF 6_00 / 6_01

CH1 AUX2 1_03 EFX Delay 3_03 *OFF:00, ON:01

CH1 USB 1_04 EFX Loop 3_04

CH1 DVS 1_05 EFX B.B 3_05 MONO

CH2 CD 2_00 EFX Filter 3_06 Selector Display

CH2 PHONO 2_01 EFX B.S 3_07 STEREO/MONO 7_00 / 7_01

CH2 AUX1 2_02 *STEREO:00, MONO:01

CH2 AUX2 2_03

CH2 USB 2_04 SELECT

CH2 DVS 2_05 Selector Display

SND/BOOTH 8_00 / 8_01

* BOOTH:00, SND:01

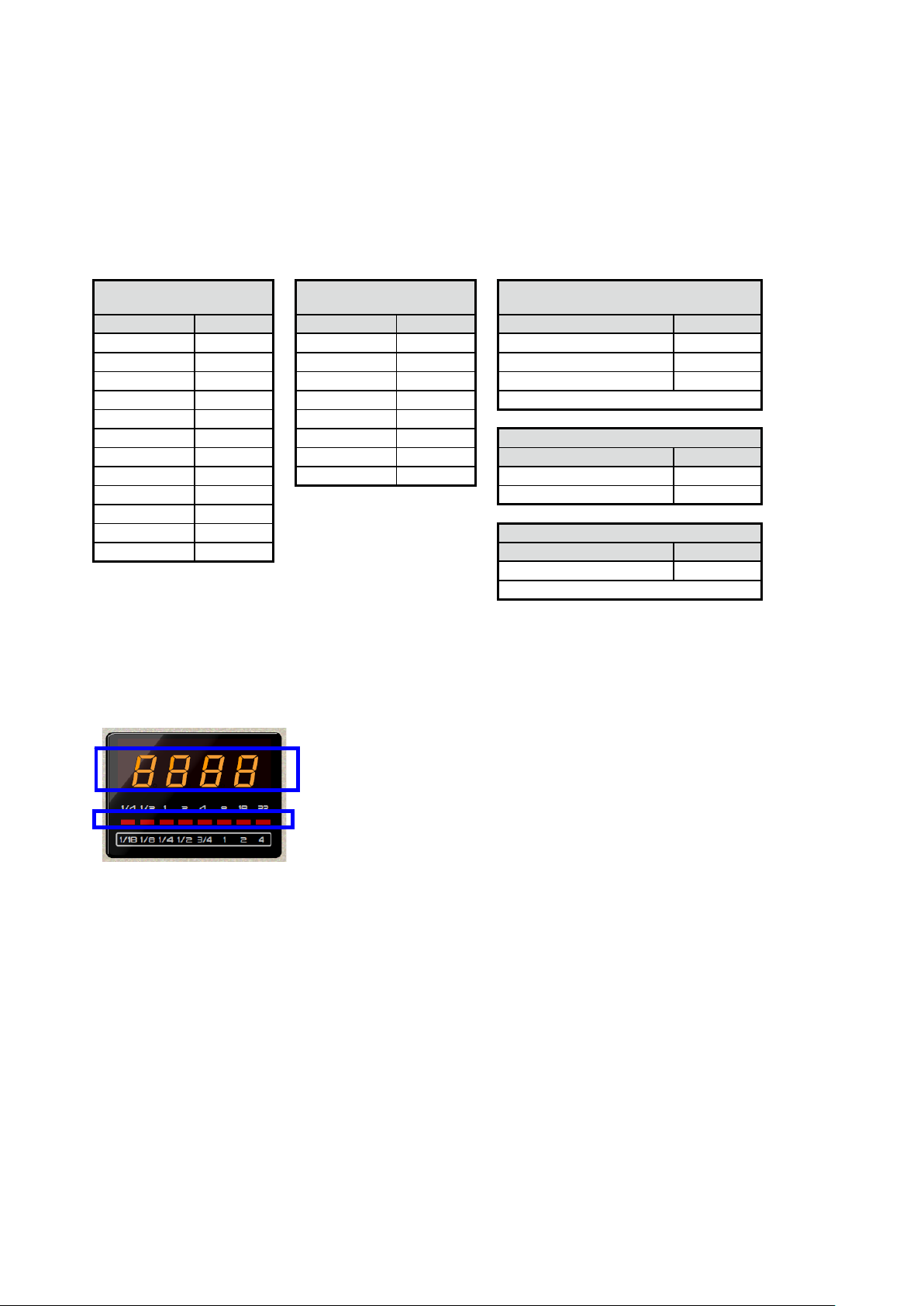

2.5. Tatal RunningTime Display

• EFX SERECTOR is LOOP and press TAP button.

(1) Total running time displayed. (Max65000hours) How to view below.

One-thousand place to 7SEG «xxxx» and display.

The number of ten-thousand, BEAT LED display

indicates the number is lit from the left.

The total time recorded every hour. If the power off in less than an hour do not count.

b

To clear the total running time. The factory mode state. Or, do the following methods.

---To clear the total running time--

(1) Press TAP button. (Total running time while displaying the button is pressed)

(2) Press BEAT button.

(3) «_run» In the display, the TAP button is pressed.

Total running time to 0. And, Total running time to return to the display.

b

16

2.6. ROM/RAM Access test

• EFX SERECTOR is B.BREAKER and press TAP button.

(1) Press BEAT button, select «_run». Presse TAP button.

(2) FlashROM (2MB) and SD-RAM (8MB) then Reads to accessible. Address (space cache disabled), and two bytes for

each increment.

The power of this test can not be terminated unless OFF.

b

2.7. USB MIDI OUT test

• EFX SERECTOR is FILTER and press TAP button.

(1) Press BEAT button, select the command sent to PC.

[Display:«Snd1»]:(EfxSnd1(*)) → [Displya:«CUE1»]:(Ch1 Cue) → [Display:«b-UP»]:(Beat Up) → [

[Display:«tAP»]:(Efx Tap)

(2) Press TAP button, sends the selected USB-Midi command.

(3) When a PC is not connected state, «FAIL» appears.

2.8. EUP mode test

• EUP switch ON state.

EFX SERECTOR is B.SCRATCH and press TAP button.

(1) Press BEAT button, select «run».

(2) Press TAP button. Start EUP mode.

To exit, press Restart button or turn off.

b

17

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, confi rm contents of the following.

PWB Name Ref. No. Description

MAIN IC103 EN29LV160BB-70TIP B

After replaced

A : Mask ROM (With software). No need write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you should be

write-in of the new software to the microprocessor or fl ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or fl ash ROM.

Refer to "Update procedure" or "writing procedure", when you should be write-in the software.

After

replaced

Remark

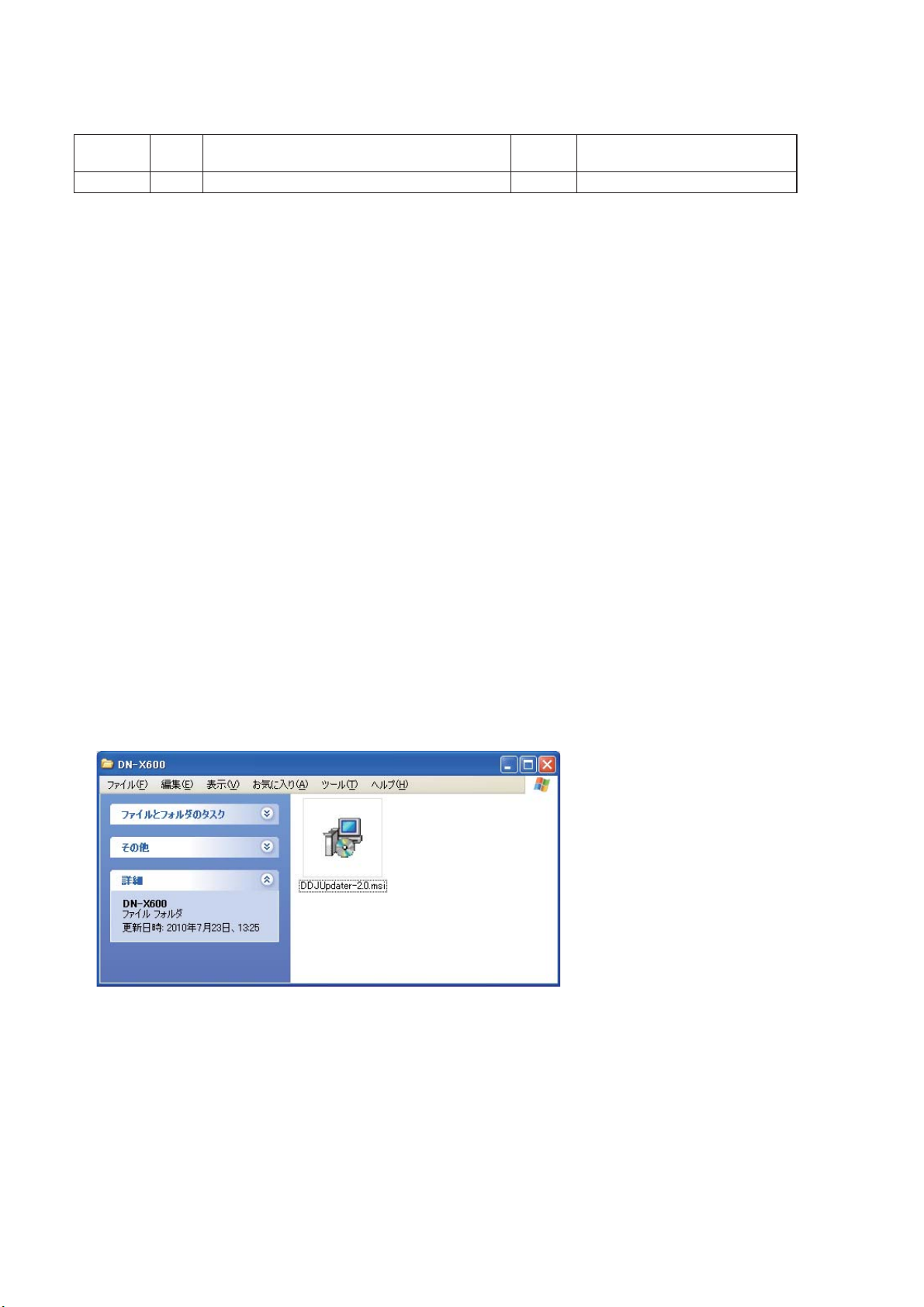

VERSION UPGRADE PROCEDURE OF FIRMWARE

1. preparation

(1) Connect the computer by USB cable.

DN-X600 : Type B

(2) UPDATEER

Dowload Dennon SDI site.

for Windows : DDJUpdater-2.0.msi

for Mac : DDJ Updater.app

(3) Latest Firmware

Dowload Dennon SDI site.

fi le : X600FW.BIN

2. Installing the fi rmware update program for Windows

Upgrade program for Macintosh is installed on your Mac by copied the DDJ Updater.app.

b

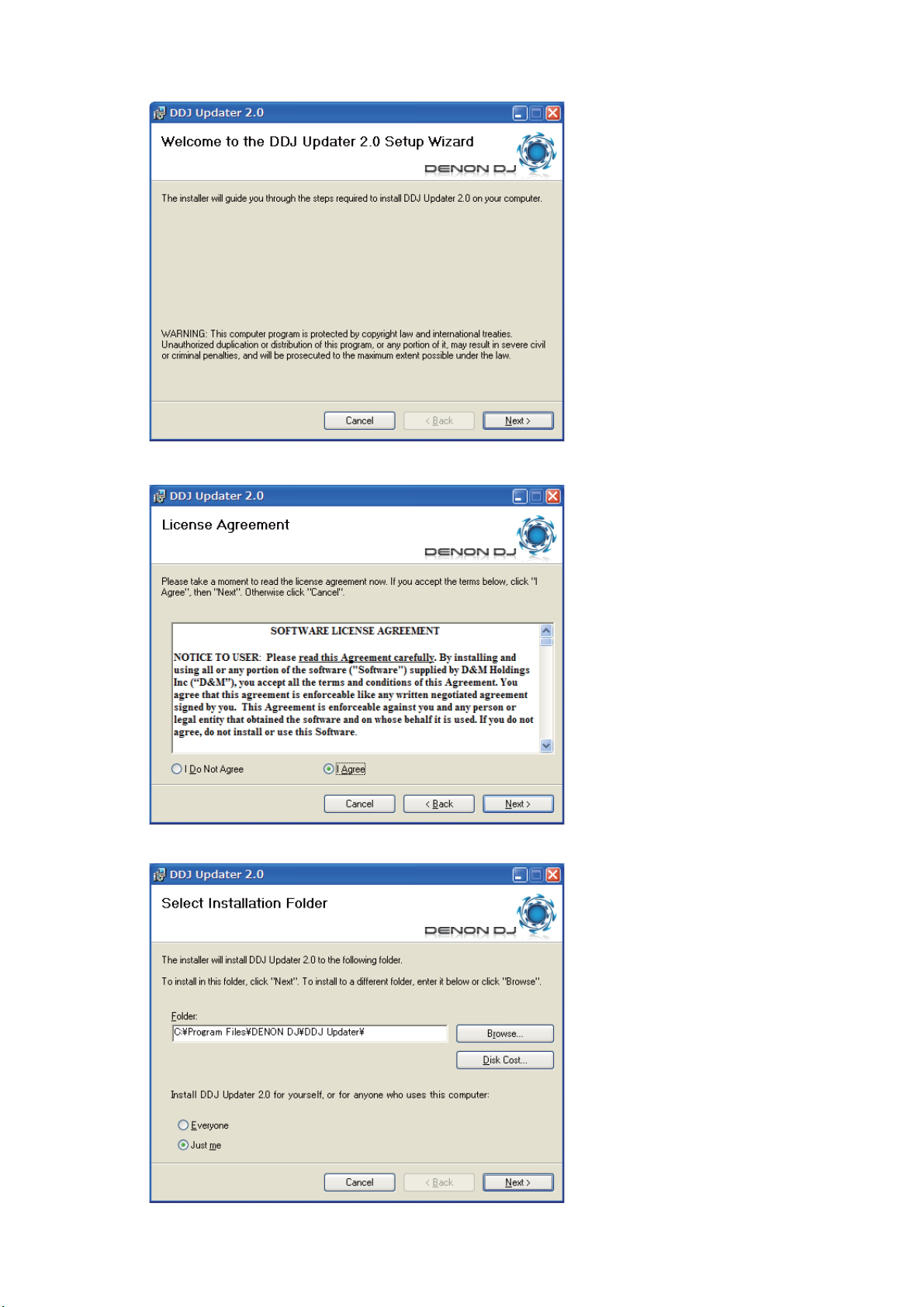

(1) Double click the DDJUpdater-2.0.msi

18

(2) Click the Next.

(3) Check the I accept the terms of the license agreement,and Click the Next.

(4) Click the Next.

19

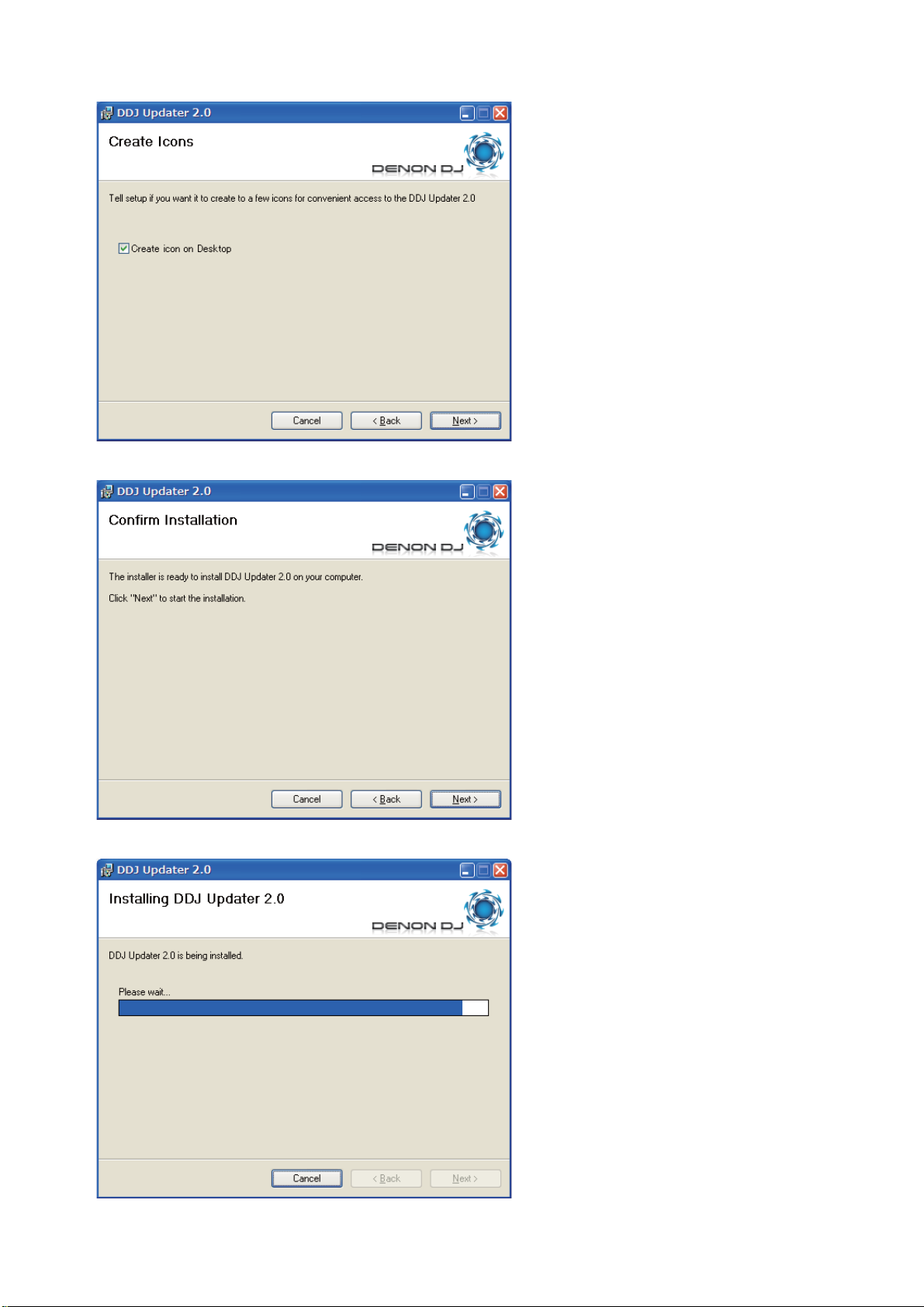

(5) Click the Next.

(6) Click the Next.

(7) The Setup Status bar appears.

20

(8) Click the Close.

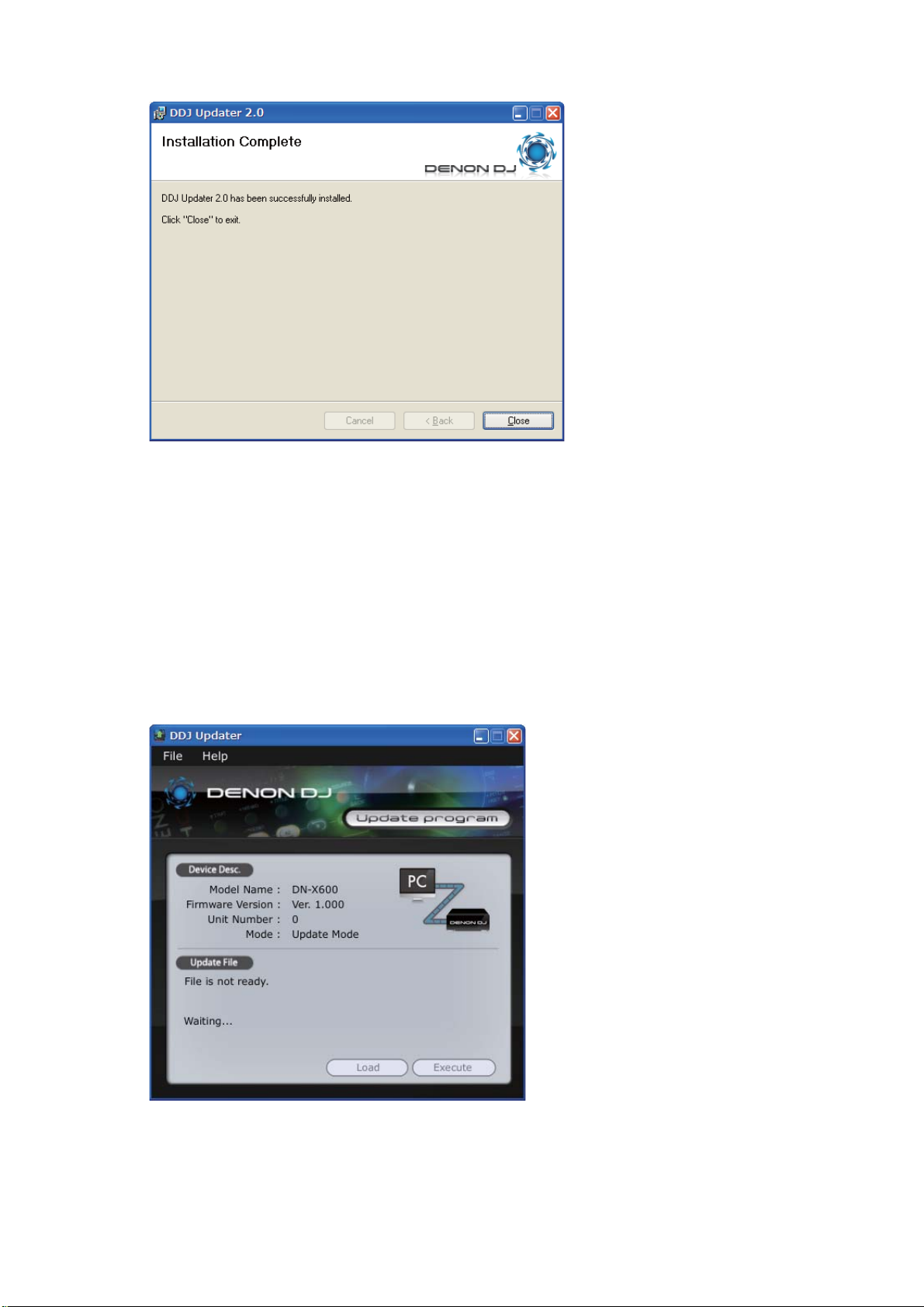

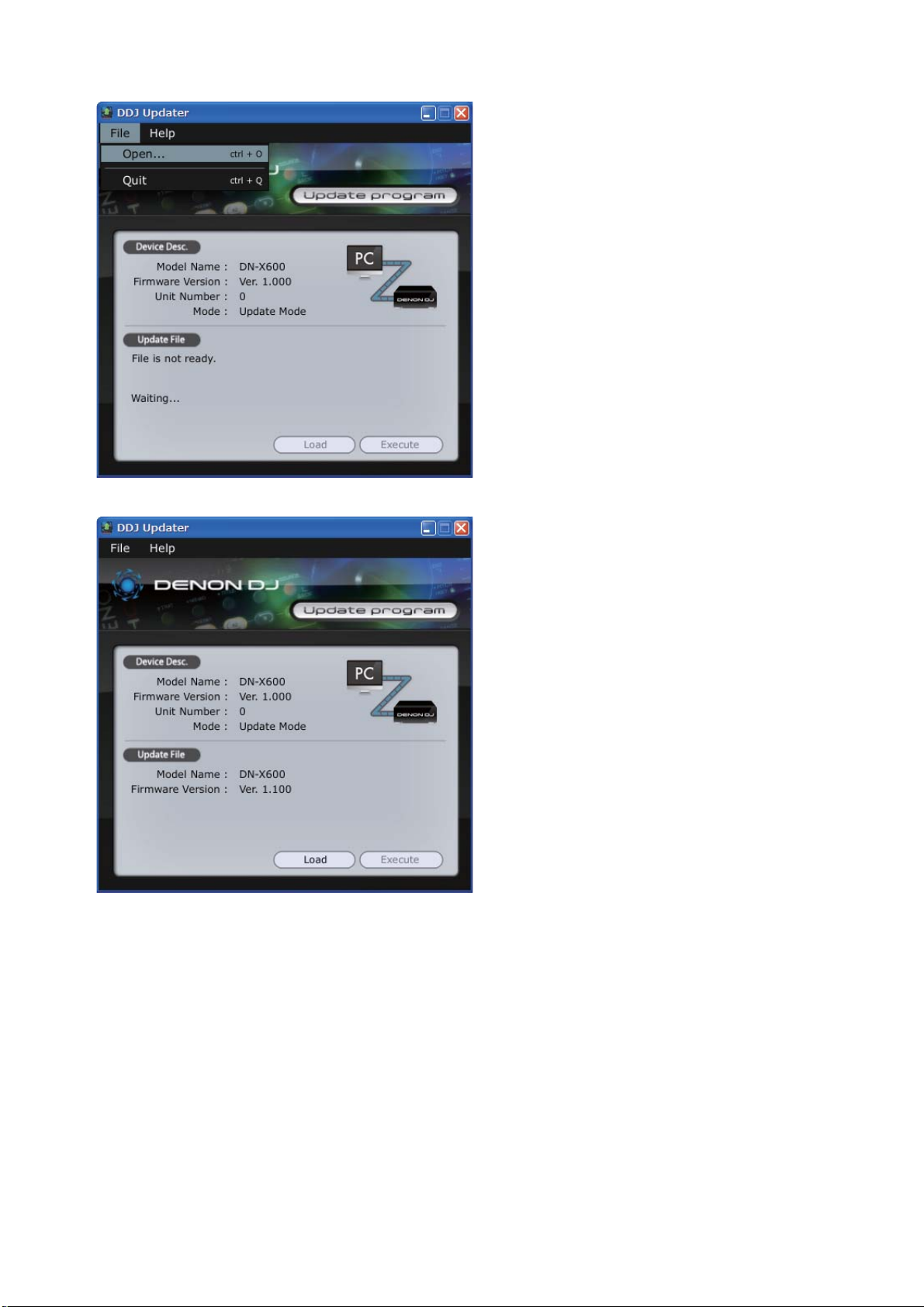

3. Update Firmware

[Caution]

During the loading and upgrading the power OFF and set, PC or please do not remove the cable connection. Also,

please press the button of a keyboard and computer sets.

(1) Connect the USB cable from PC to the unit.

(2) Press the POWER ON button to turn on while pressing buttons DUCKING and SELECT.

(3) Confi rm the USB indicator is blue and “UP” is displayed in the panel.

When the driver installation screen appears, please install a driver from the unit.

(4) Run the “DDJ Updater” on desktop of PC.

21

(5) Click the File menu. And click the Open. Select the latest fi rmware.

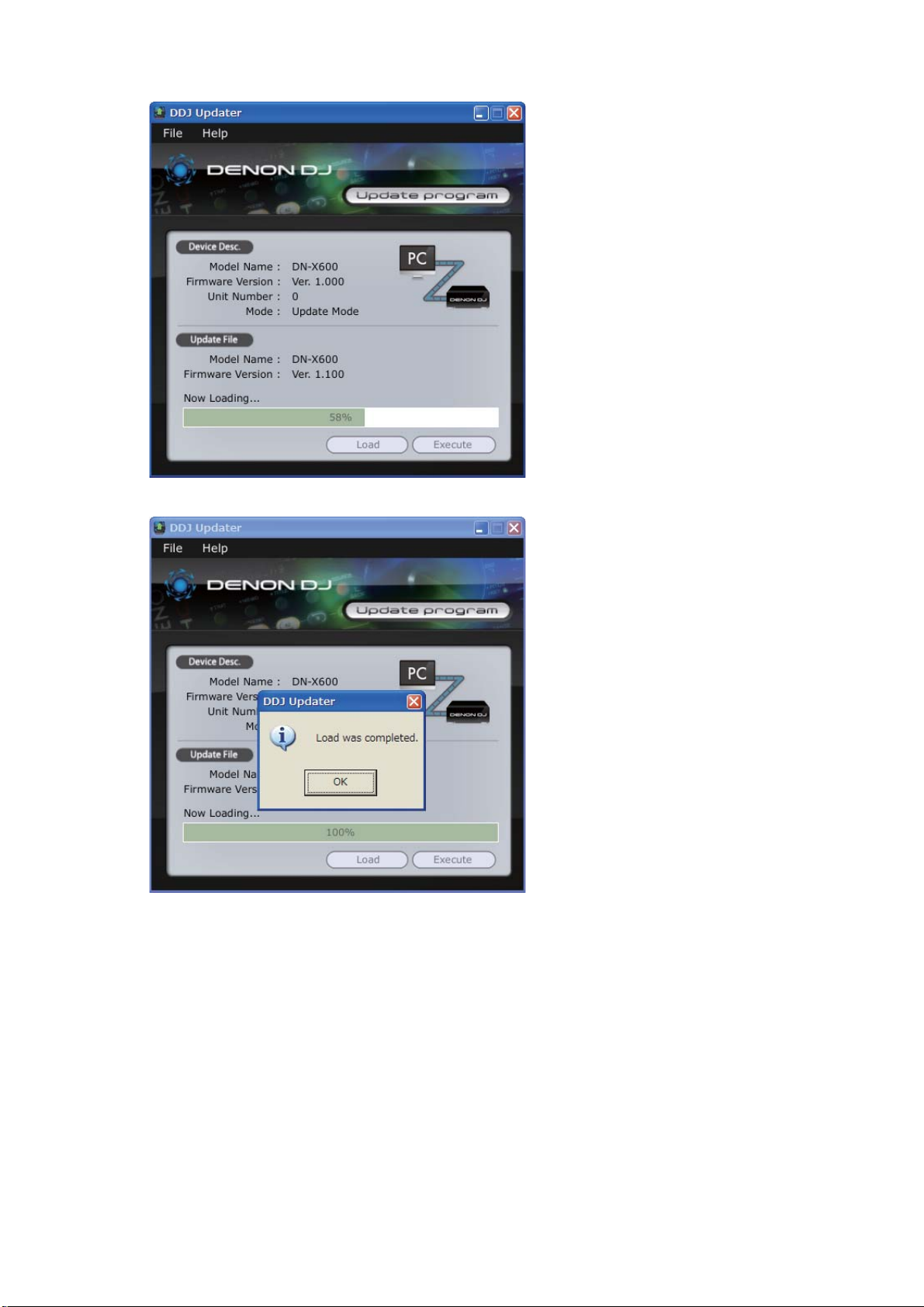

(6) Click the Load.

22

(7) The Setup Status bar appears.

(8) Click the OK.

23

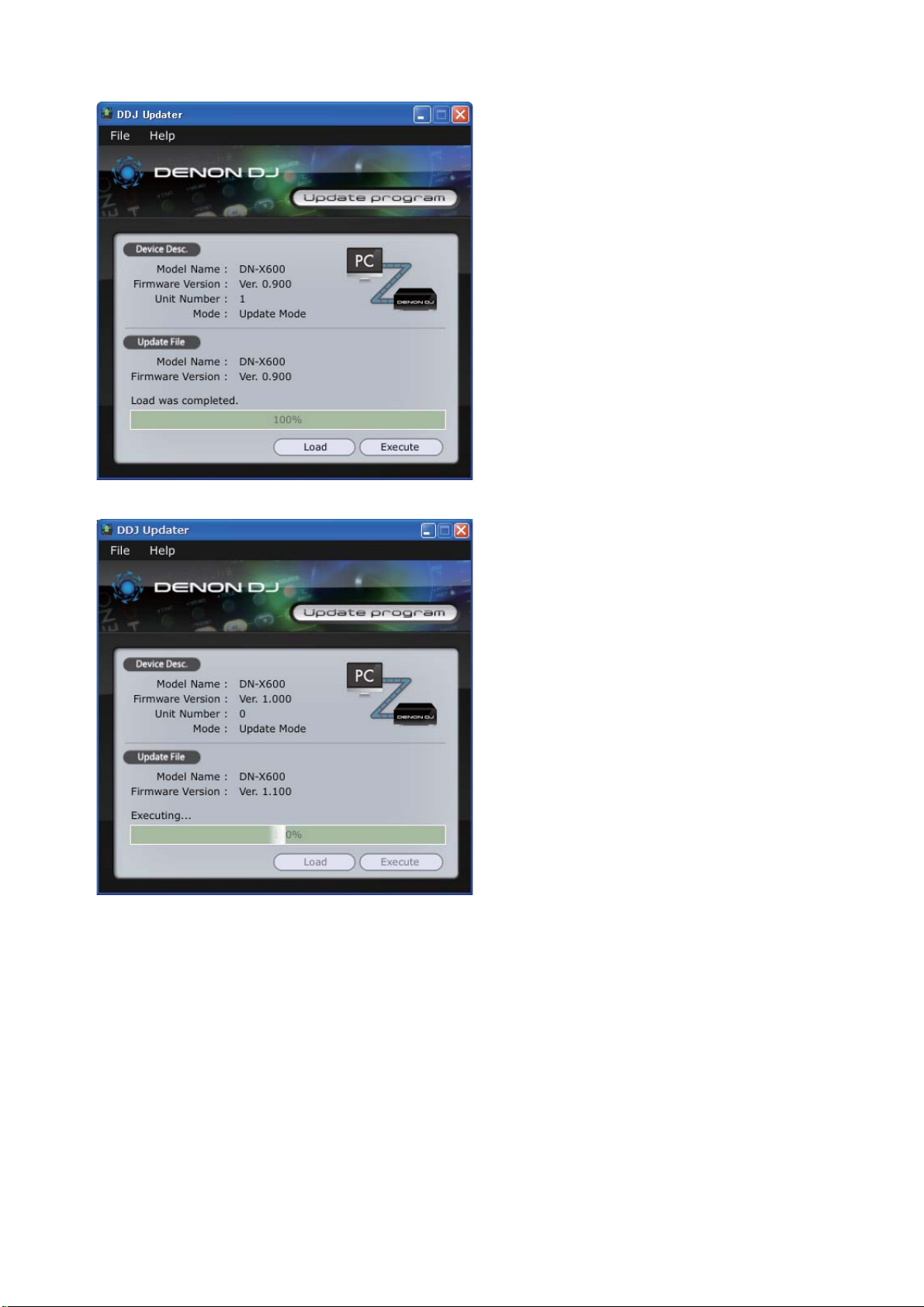

(9) Click the Execute.

(10) The Setup Status bar appears.

24

(11) Click the OK.

(11) Confi rm “donE” is displayed in the panel.

Failure to upgrade to the unit "FAIL" is displayed.

Failure to upgrade to the PC "Version up was not completed." is displayed.

Then "Execute" click again.

25

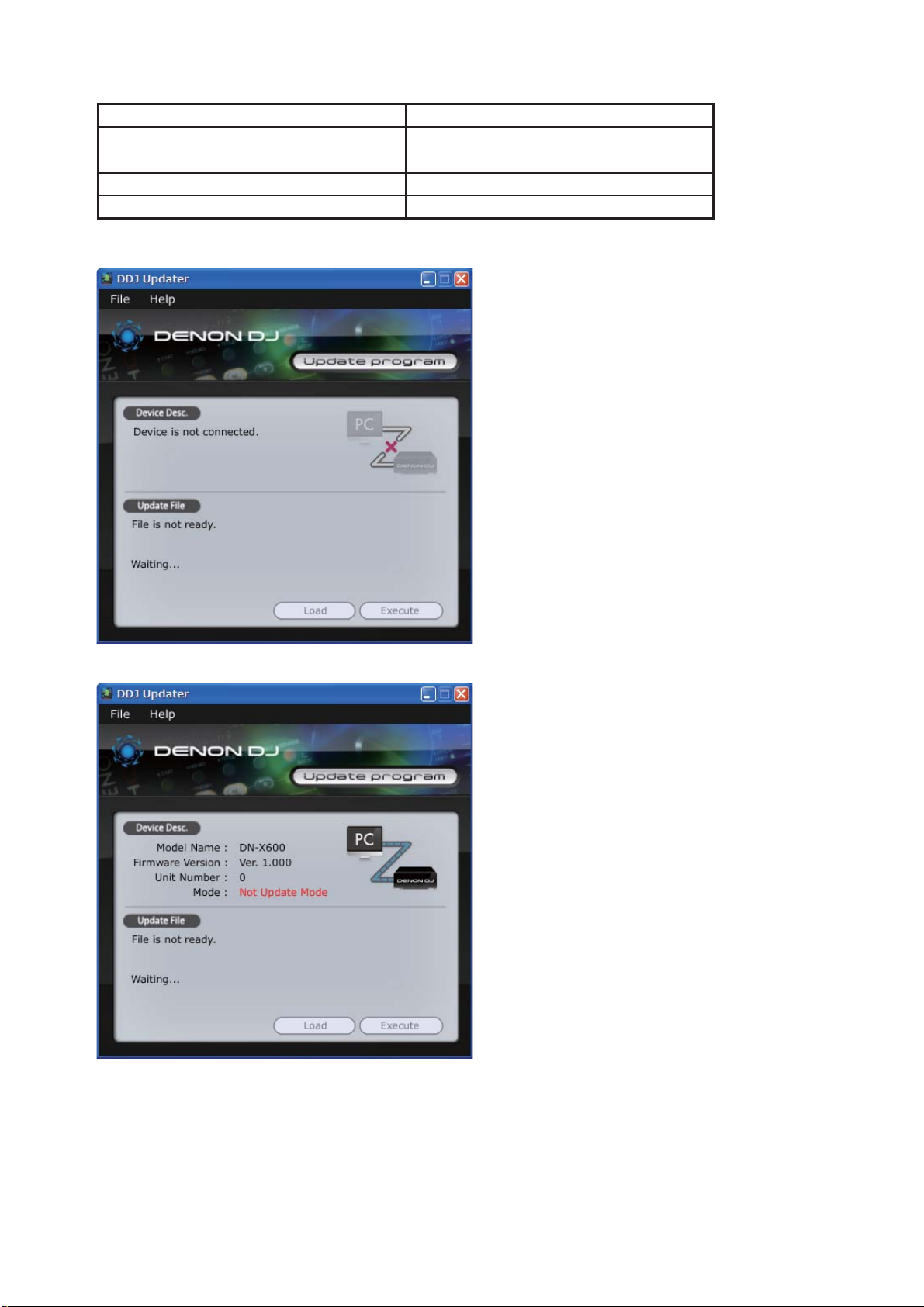

4. Error message & trabuleshooting

Message Solution

File is invalid. Please select the update fi le for this unit.

Load failed. Check the connection, and retry Please try again step 1).

Loaded data is invalid. Check the fi le Please select the update fi le for this unit.

Version up was not completed Please try again step 1).

(1) Unit is not connected or if the unit is not upgraded mode as shown below. Please try again step (1).

(2) If the fi le version is not loaded "File is not ready." Is displayed. Please try again step (5).

[Caution]

During the loading and upgrading the power OFF and set, PC or please do not remove the cable connection. Also,

please press the button of a keyboard and computer sets.

26

TROUBLE SHOOTING

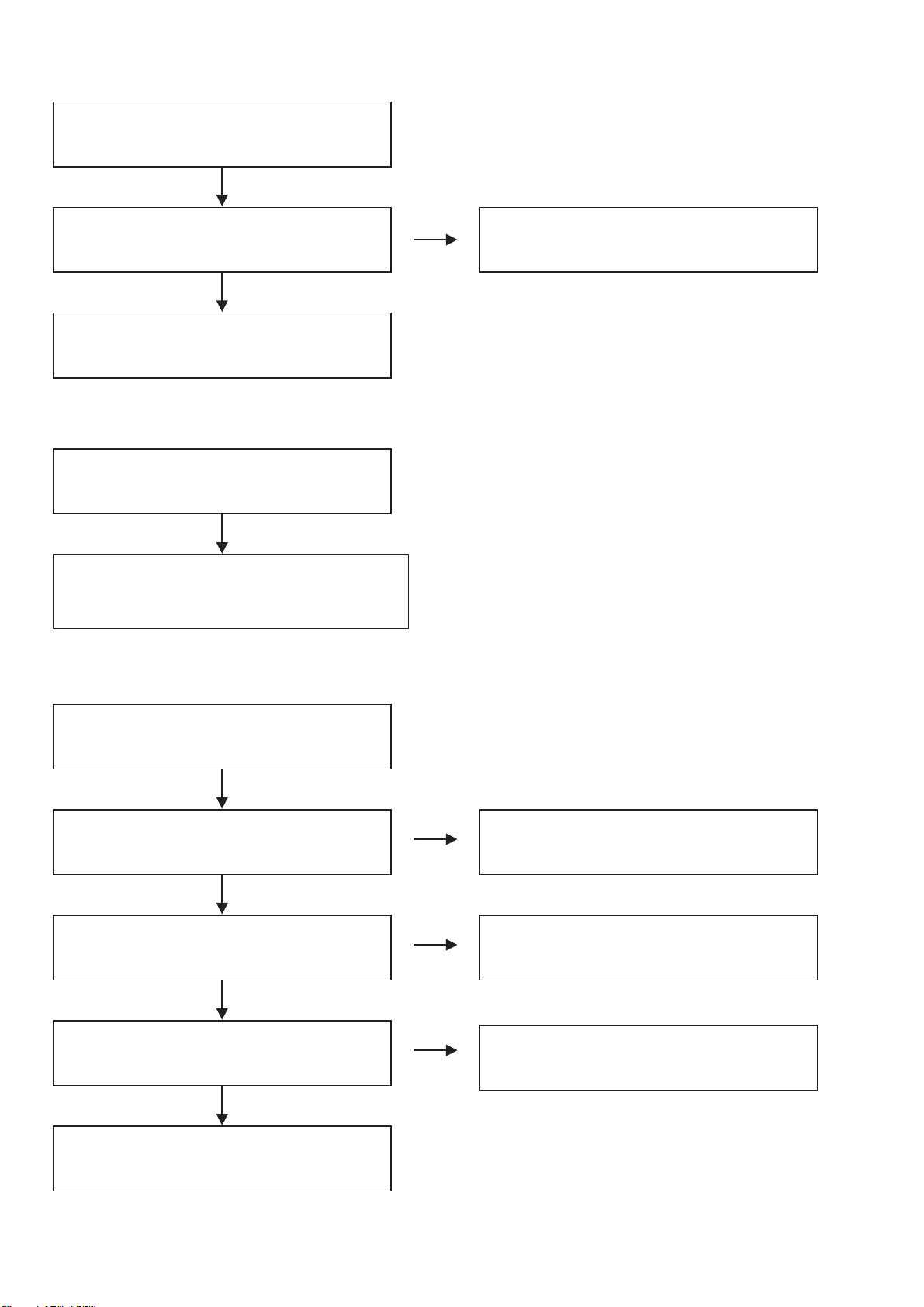

FLOW CHART NO.1 (8U-110086-1 : IN/OUT/PWR UNIT)

The power cannot be turned on.

O.K.

N.G.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

O.K.

Is the +3.4V line voltage normal?

O.K.

Is the +3.3V line voltage normal?

O.K.

Check each rectifying circuit of the secondary

circuit and replace it if defective.

N.G.

N.G.

N.G.

Check if there is any leak or short-circuiting on

the primary circuit component, and replace it if

defective.

C5100,C5101,C5102,C5103,C5104,C5106,

(

C5107,C5108,C5110,C5527,D5100,D5101,D5102,

D5103,D5104,D5105,D5106,D5500,

T5100,T5501

Check D5110,C5131,C5132,L5105 and replace it if

defective.

Check Q5105,Q5510,Q5511,C5525 and replace it

if defective.

)

L5100,L5104,

FLOW CHART NO.2 (8U-110086-1 : IN/OUT/PWR UNIT)

The fuse blows out.

O.K.

Check the presence that the primary component

is leaking or shorted and replace it if defective.

O.K.

After servicing, replace the fuse.

N.G.

27

O.K.

Check the presence that the rectifying diode

or circuit is shorted in each rectifying circuit of

secondary side, and replace it if defective.

O.K.

FLOW CHART NO.3 (8U-110086-1 : IN/OUT/PWR UNIT)

+1.2V is not outputted.

O.K.

Is the +3.3V line voltage normal?

O.K.

Check U5102 and the periphery circuit, and replace

it if defective

FLOWCHARTNO.4(8U-110086-1:IN/OUT/PWRUNIT)

+3.3V is not outputted.

O.K.

See FLOW CHART

NO.1 <Is the +3.3V line voltage normal?>

N.G.

See FLOW CHART NO.1

<Is the +3.3V line voltage normal?>

FLOW CHART NO.5 (8U-110086-1 : IN/OUT/PWR UNIT)

+15V is not outputted.

O.K.

N.G.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is the voltage of +15V or more supplied to collector

terminal of Q5104

O.K.

Is the voltage of +15V or more supplied to collector

terminal of Q5107

O.K.

N.G.

N.G.

Check D5113,L5102,C5116,C5124,C5517 and

replace it if defective.

Check Q5104,Q5108,Q5502,Q5512,D5119 and

replace it if defective.

Check Q5107 and the periphery circuit, and replace

it if defective.

28

FLOW CHART NO.6 (8U-110086-1 : IN/OUT/PWR UNIT)

-15V is not outputted.

O.K.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is the voltage of +15V or more supplied to collector

terminal of Q5110

O.K.

Is the voltage of +15V or more supplied to collector

terminal of Q5106

O.K.

Check Q5106 and the periphery circuit, and replace

it if defective.

FLOW CHART NO.7 (8U-110086-1 : IN/OUT/PWR UNIT,8U-110086-2 : HP JACK UNIT)

N.G.

N.G.

N.G.

Check D5115,L5103,C5117,C5125,C5518 and

replace it if defective.

Check Q5110,Q5109,Q5502,Q5512,D5120 and

replace it if defective.

The FADER START signal is not outputed.

O.K.

• S3800 and S3801 are turned on.

Is +3.3V voltage supplied to 19pin, 20pin of N231?

O.K.

Are the signals outputted to 18pin(PLAY1),

16pin(CUE1), 14pin(PLAY2), and 12pin(CUE2) of

U3400?

O.K.

Check periphery circuit of K3502,K3503 from

U3400, and service it if defective.

N.G.

N.G.

See FLOW CHART NO.9 <The slide switch

operation is not functioning.>

Check periphery circuit of U3400 from N131, and

service it if defective. When the periphery circuit is

correct, U3400 is replaced.

29

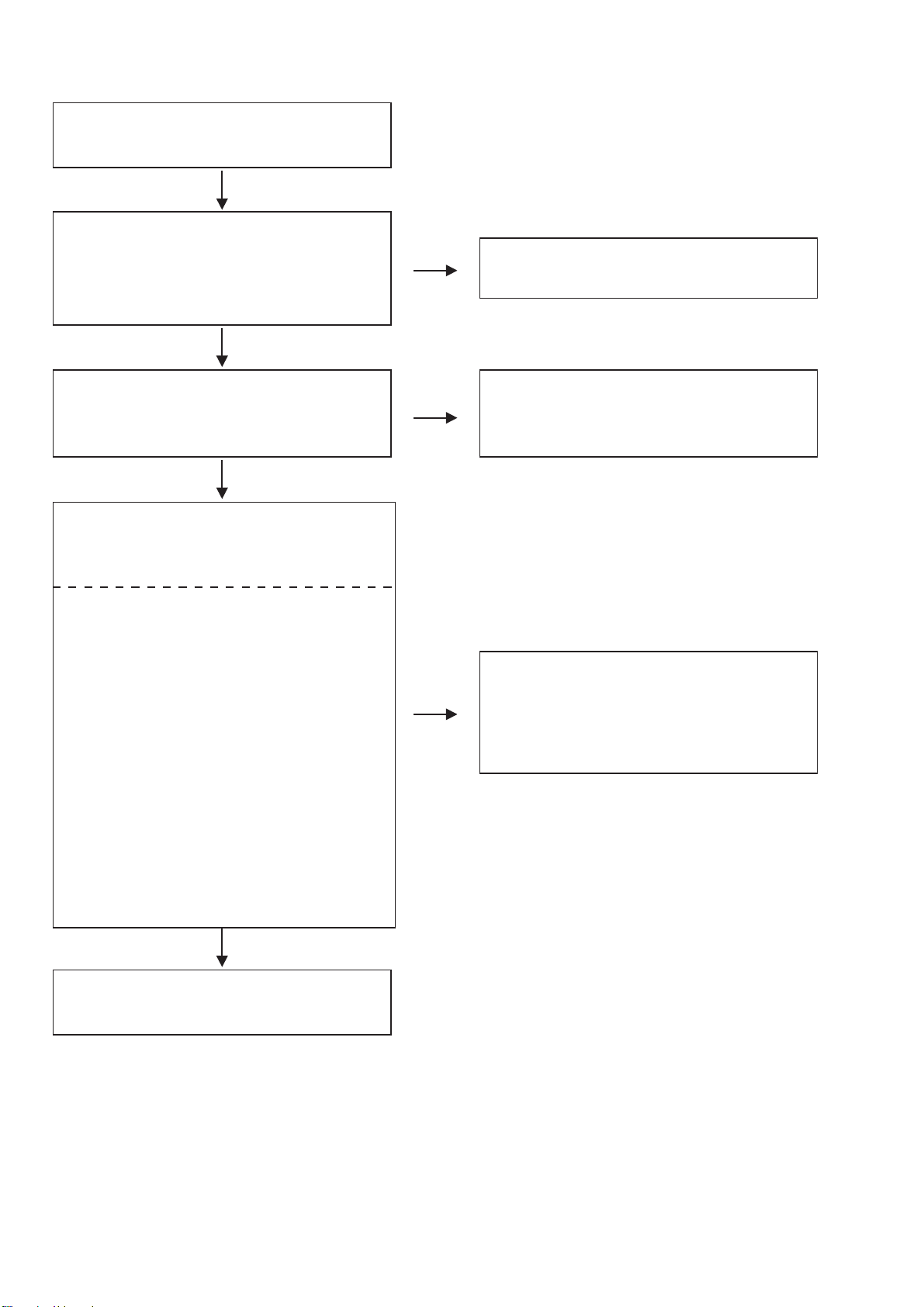

FLOW CHART NO.8 (8U-110087-1 : PANEL UNIT)

The key operation is not functioning.

O.K.

Are the contact point and the installation state of

the key switches (S401~S411,S413,S414,S416,

S418~S420), rotary switches (S433,S434,S437)

nomal?

O.K.

Does LED(D105~D111,D113~D156) light correctly?

O.K.

When pressing each key switches and turning rotary

switches, do the voltage of each pin of U404(shown

below) increase?

Key switches

S401,S403,S407

S402,S408,S418 : U404 12pin

S405,S419 : U404 13pin

S404,S410,S420 : U404 14pin

S406 : U404 3pin

S414 : U404 4pin

S409,S411,S413 : U404 5pin

S416 : U404 6pin

Rotary switches

S433,S434,S437 : U404 11pin

S433,S434,S437 : U404 12pin

S433,S434,S437 : U404 13pin

S433,S434,S437 : U404 14pin

S433,S434,S437 : U404 3pin

S433,S434,S437 : U404 4pin

S437 : U404 5pin

S437 : U404 6pin

:U404

11pin

N.G.

N.G.

N.G.

Re-install the switches correctly or replace the poor

switch.

Check the Q101~Q114 and their periphery, and

service it if detective.

Check the key switches (S401~S411,S413,S

414,S416,S418~S420), and rotary switches

(S433,S434,S437) and their periphery, and service

it if detective.

Replace U404.

O.K.

30

Loading...

Loading...