Denon DN-X1600 Service Manual

Ver. 3

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK K2A E1C E1K EUT

DN-X1600

P P

DJ MIXER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

D&M Holdings Inc.

S0144-1V03DM/DG1009

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Heed the cautions!

◎

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to hee d these cau sions an d the

cautions indicated in the handling instructions.

Caution concerning electric shock!

◎

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid el ectric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

Please heed the points listed below during servicing and inspection.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if ngers

are moved across them. Use gloves to protect your hands.

Only use designated parts!

◎

The set's parts have spe cific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be su re t o us e pa rt s wh ic h ha ve the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

Inspect for safety after servicing!

◎

Ch eck that al l screws , parts and wi res remove d or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

condu ct an insl at ion ch eck on t he ext er nal metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special saf ety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2)

Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, res

or other dangerous situations.

2

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

2.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

● Resistors

Ex.: RN

* Resistance

Capacitors

●

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

2

Indicates number of zeros after effective number.

・ Units:μF.

・ Units:pF

2-digit effective number.

2

14K

Shape

and performance

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F : ±1%

G : ±2%

J : ±5%

K : ±10%

M : ±20%

Z : ±80%

: - 20%

P : +100%

C : ±0.25pF

D : ±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

TECHNICAL SPECIFICATIONS

n AUDIO (0 dBu = 0.775 Vrms, 0 dBV = 1 Vrms)

• PHONO inputs Stereo x 3 Unbalanced RCA terminal

Input impedance: 47 kΩ/kohms

Level: –40 dBV (10 mV)

• CD inputs Stereo x 5 Unbalanced RCA terminal

Input impedance:

Level: 0 dBV

• Equalizer (LINE) Band x 3

Channel equalization adjustment range:

HI: –∞,–90 dB to +10 dB

MID: –∞,–90 dB to +10 dB

LOW: –∞,–90 dB to +6 dB

• RETURN inputs Monaural x 2 1/4" TS terminal

Input impedance: 10 kΩ/kohms

Level: –10dBV/0dBV (Default: –10dBV)

• MIC inputs Monaural x 2

MIC1: Balanced XLR

(1: Ground, 2: Hot, 3: Cold)

MIC2: Balanced 1/4" TRS jack

(Tip: hot, ring: cold, sleeve: ground)

Input impedance: 5 kΩ

Level: –60 to –20 dBu

EIN:

CMRR: More than 89 dB (1 kHz)

• Equalizer (MIC) Band x 2

Adjustment range: HI: –15 to +15 dB

LOW: –15 to +15 dB

• USB audio inputs

Fs: 44.1 kHz, 48 kHz, 96 kHz USB B

• MASTER output

Balanced: Stereo, balanced XLR terminal

(1: Ground, 2: Hot, 3: Cold)

DA converter: 32-bit 128x oversampling advanced

Load impedance: More than 600 Ω

Level: +4dBu (Max.: +24 dBu)

Frequency response: 20 Hz to 20 kHz (±0.5 dB)

THD: Less than 0.05%

Crosstalk: Less than –100 dB (1 kHz)

Unbalanced: Stereo RCA terminal

Load impedance: 10 kΩ

Level: 0 dBu (Max.: +20 dBu)

• REC output Stereo Unbalanced RCA terminal

Load impedance: 10 kΩ

Level: –10 dBV (Max.: +10 dBV)

• BOOTH output Stereo

(Tip: hot; ring: cold, sleeve: ground)

Load impedance: More than 600 Ω

Level: +4 dBu (Max.: +24 dBu)

• SEND output Monaural x 2

Load impedance: 10 kΩ

Level: –10 dBV (Max.: +10 dBV)

• Headphones output Stereo

Load impedance: 40 Ω

Level: 150 mW

• Digital coaxial output

(Fs: 44.1 kHz, 48 kHz, 96 kHz)

• USB audio output Stereo x 4 (monaural x 8) 24 bit,

44.1 kHz, 48 kHz, 96 kHz USB B

10 kΩ/kohms

Less than –126 dBu (Rs = 150 Ω)

Stereo x 4 (monaural x 8) 24 bit,

segment converter

Balanced 1/4" TRS terminal

Unbalanced 1/4" TS terminal

Stereo RCA terminal, IEC958 Consumer

n GENERAL

USB MIDI I/O: IN: 1ch, OUT: 1ch MIDI1.0,

MIDI Clock USB B

MIDI OUT: OUT: 1ch MIDI1.0,

MIDI Clock 5pin DIN

Channel level meters:

peak display

Cue master level meters:

peak display

Channel Fader: 60 mm Slim Type fader

Crossfader:

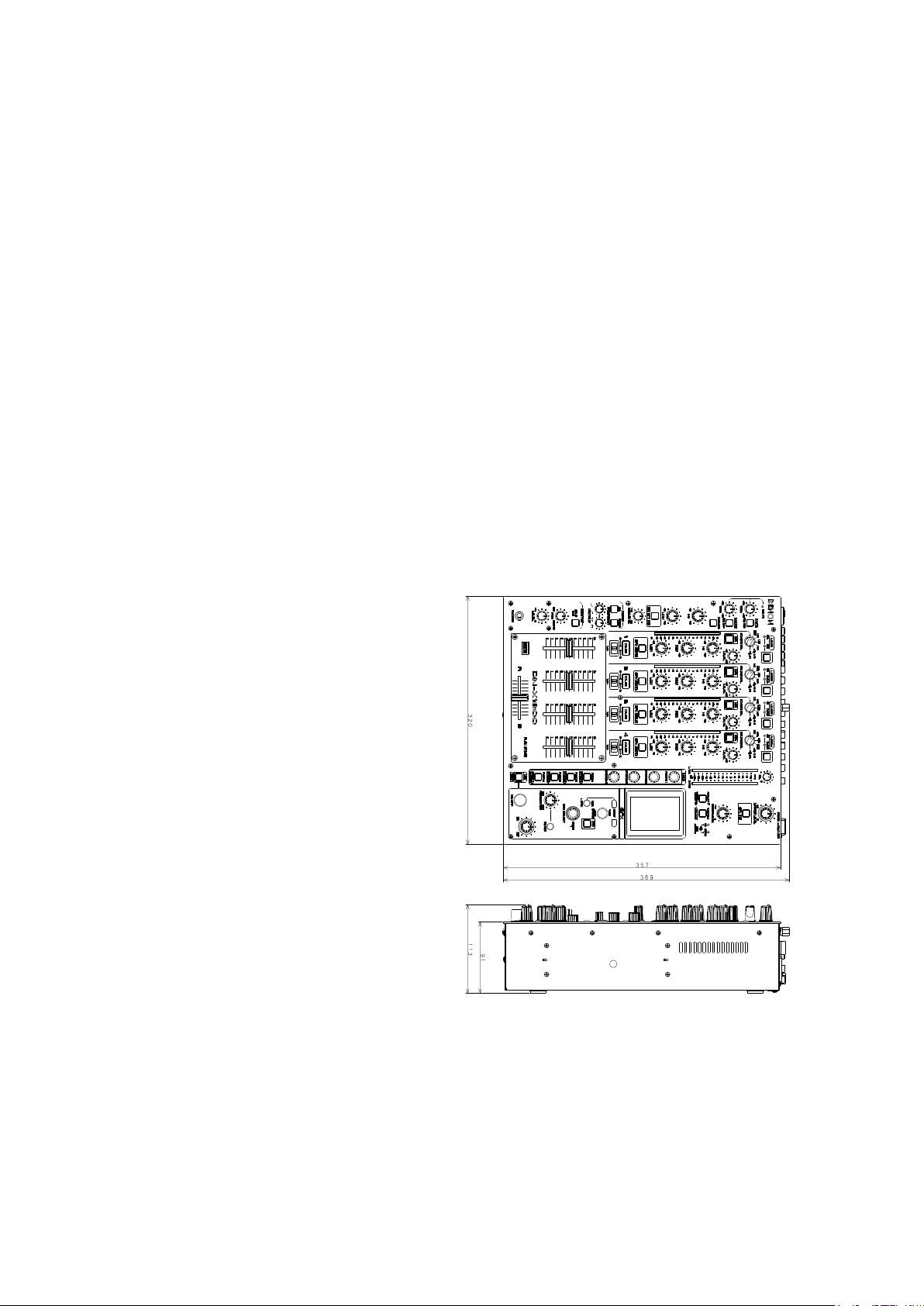

Dimensions: 320(W) x 357(D) x 91(H) mm

Weight: 6.2 Kg (13.7 lbs)

Supply voltage: AC 120 V, 60 Hz(U.S.A. and Canada

AC 230 V, 50 Hz (European models)

Power consumption: 34 W

Operational temperature:

+5ºC to +35ºC(+41 F to +95 F)

Operational humidity: 25% to 85%

Storage temperature: –20ºC to +60ºC(-4 F to +140 F)

n DIMENSION

PPM 16-point LEDs from –40 to +10 dB,

PPM 16-point LEDs from –40 to +10 dB,

45 mm FLEX Fader (Fader Torque Adjustable)

(12”5/8 (W) x 14”1/16 (D) x 3”5/8 (H))

models)

4

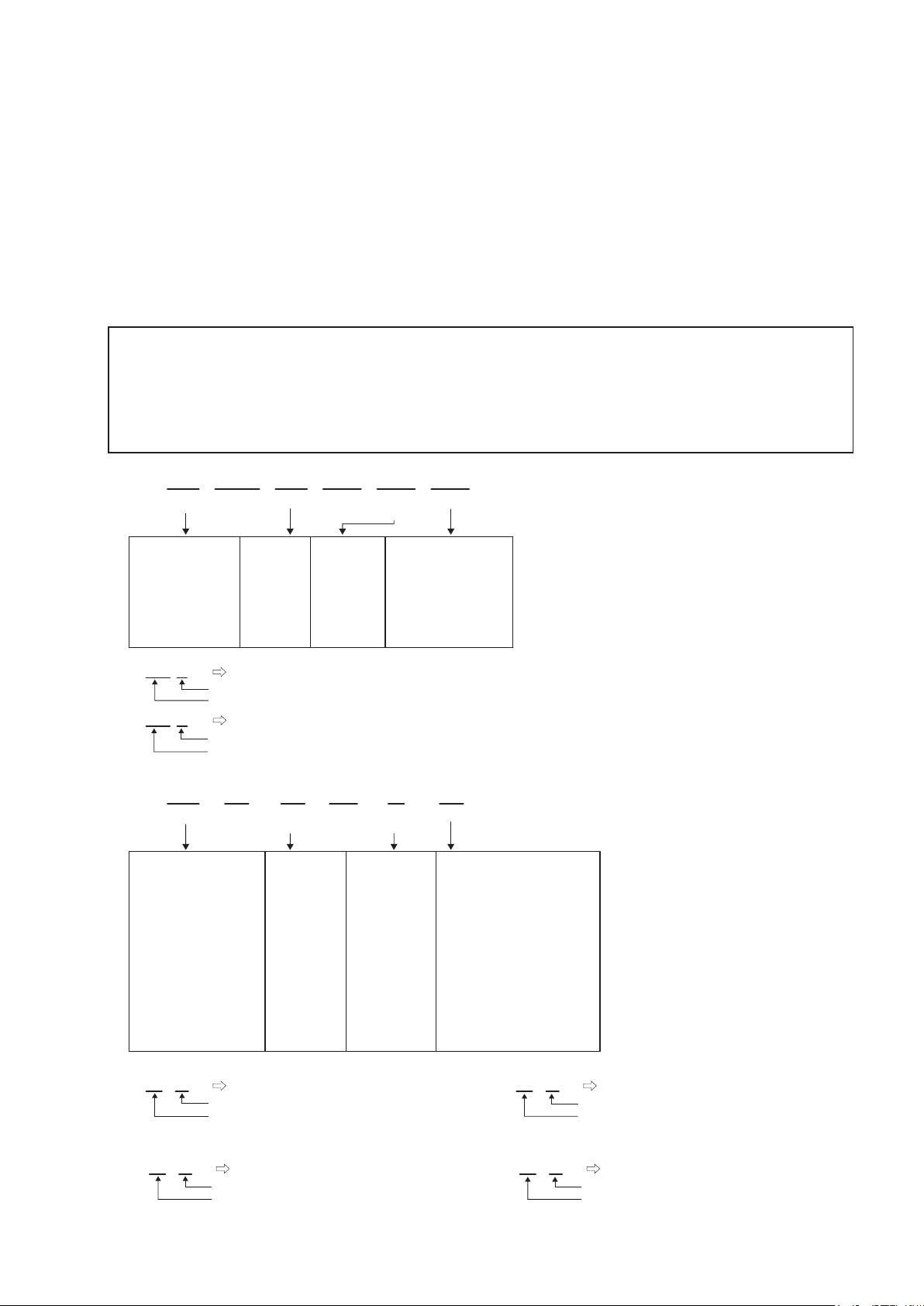

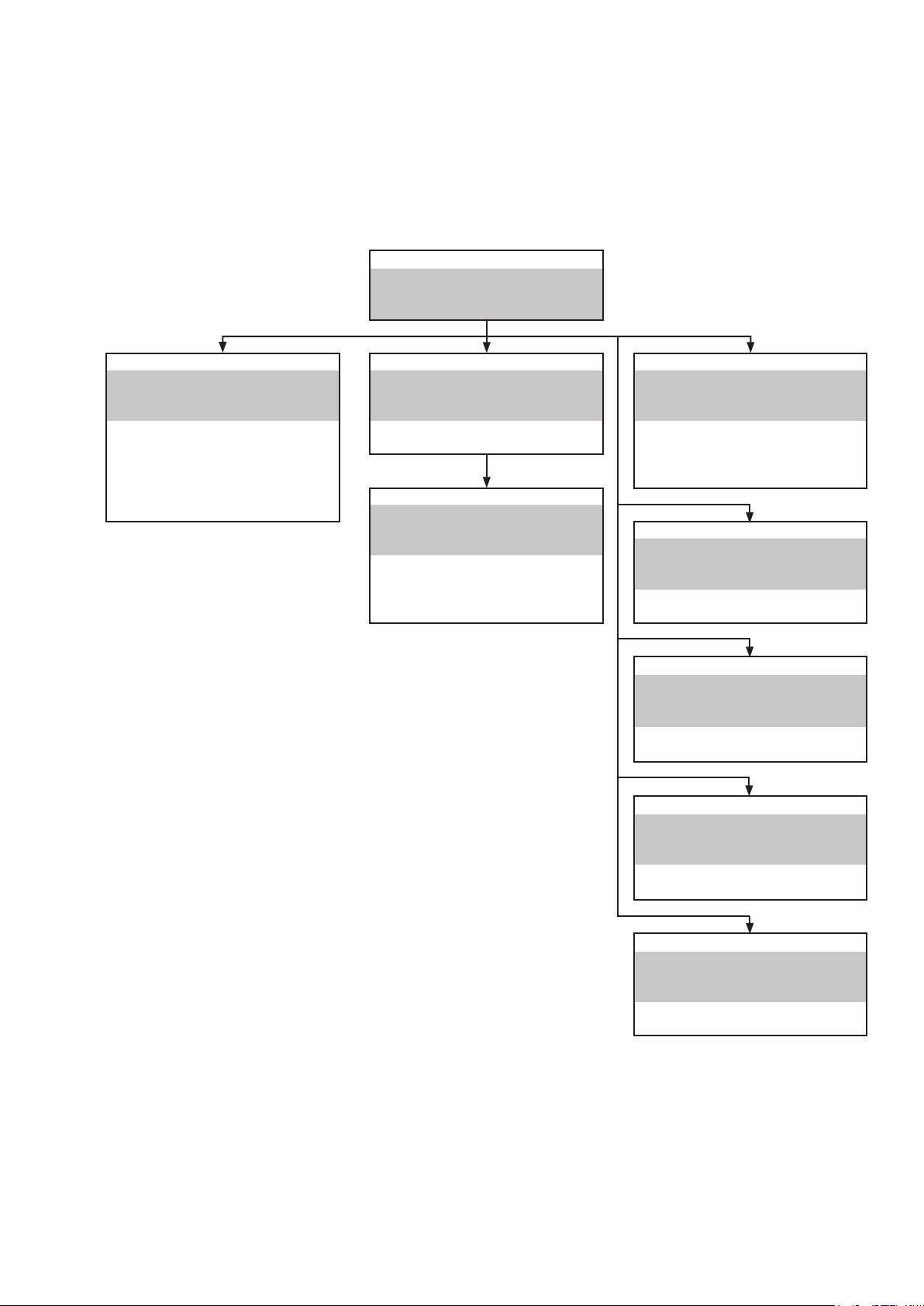

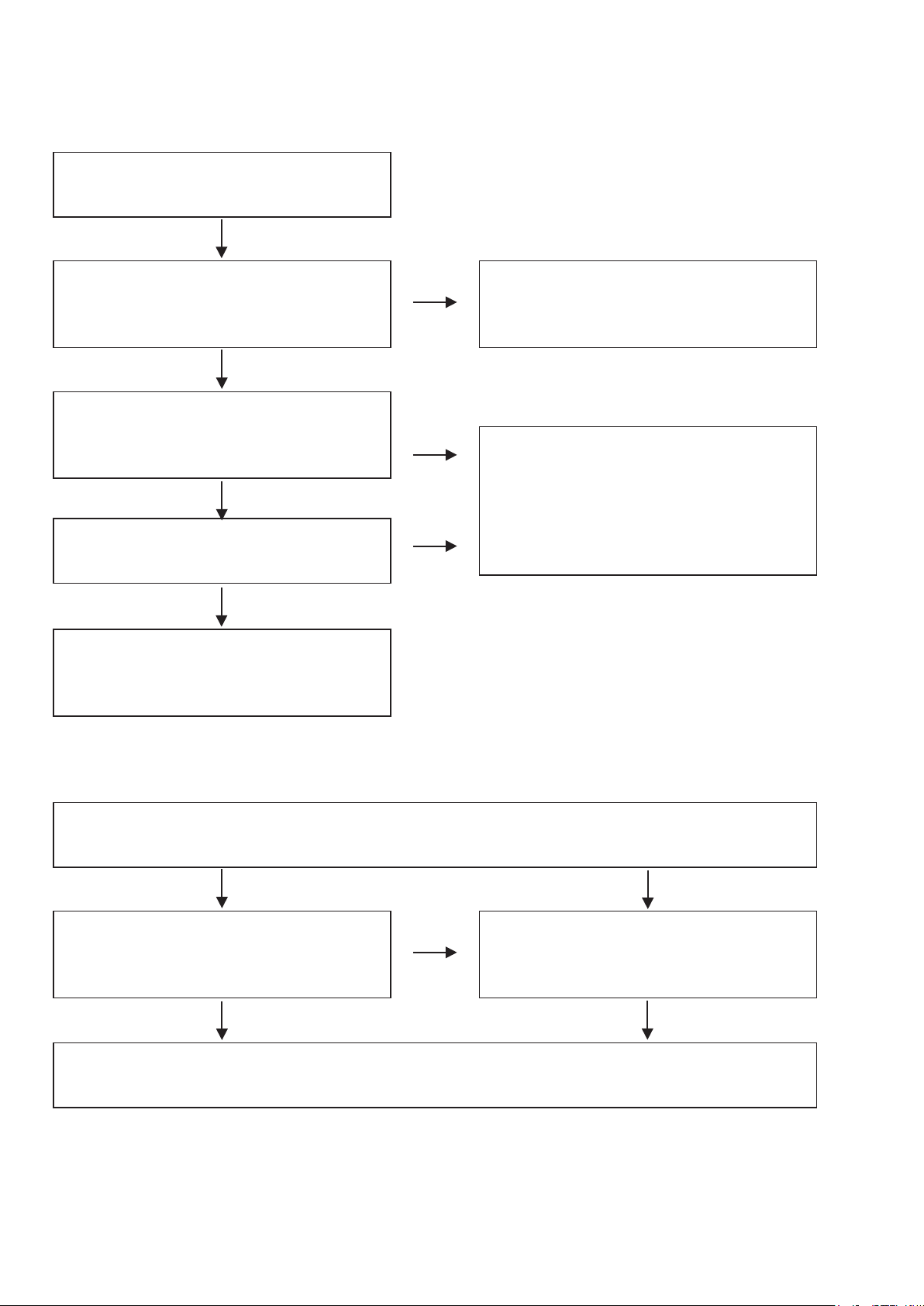

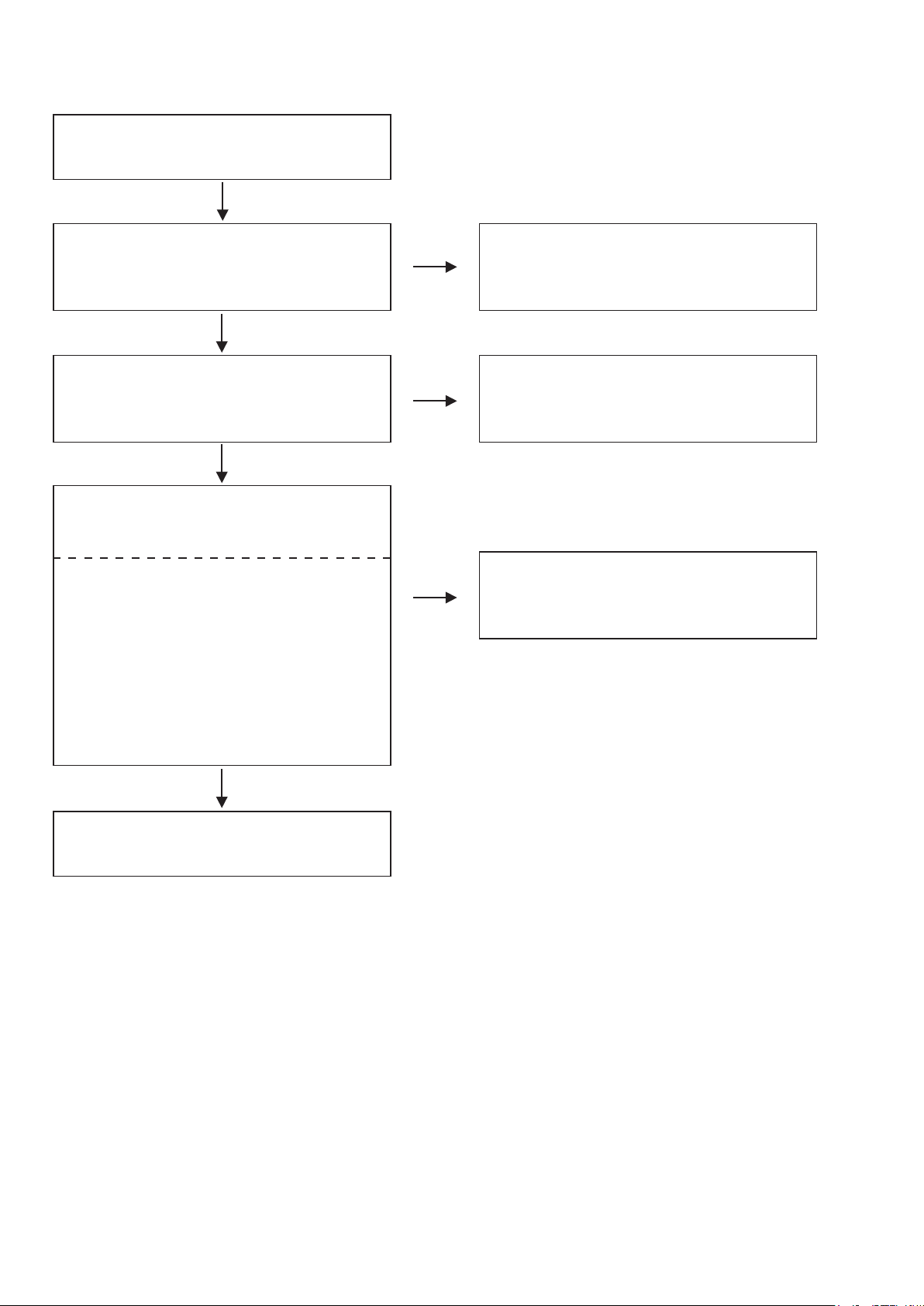

DISASSEMBLY

• Disassemble in order of the arrow of the gure of following ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP CHASSIS SUB ASSY

Refer to "DISASSEMBLY

1.TOP CHASSIS SUB ASSY"

and "EXPLODED VIEW"

TOP PANEL UNIT INPUT UNIT FADER UNIT

Refer to "DISASSEMBLY Refer to "DISASSEMBLY Refer to "DISASSEMBLY

2.TOP PANEL UNIT" 3. INPUT UNIT" 5. FADER UNIT"

and "EXPLODED VIEW" and "EXPLODED VIEW" and "EXPLODED VIEW"

PANEL1 UNIT INPUT UNIT CH FADER UNIT

(Ref. No. of EXPLODED VIEW : B-1) (Ref. No. of EXPLODED VIEW : D) (Ref. No. of EXPLODED VIEW : C-3~6)

EFFECT UNIT FLAX FADER UNIT

(Ref. No. of EXPLODED VIEW : F) (Ref. No. of EXPLODED VIEW : 55)

SPLIT UNIT OUTPUT UNIT, MAIN UNIT

(Ref. No. of EXPLODED VIEW : B-2) Refer to "DISASSEMBLY

4. OUTPUT UNIT, MAIN UNIT" HP UNIT

and "EXPLODED VIEW" Refer to "DISASSEMBLY

OUTPUT UNIT 6. HP UNIT"

(Ref. No. of EXPLODED VIEW : E-1) and "EXPLODED VIEW"

MAIN UNIT HP UNIT

(Ref. No. of EXPLODED VIEW : F) (Ref. No. of EXPLODED VIEW :C-2)

MIC UNIT

Refer to "DISASSEMBLY

7. MIC UNIT"

and "EXPLODED VIEW"

MIC UNIT

(Ref. No. of EXPLODED VIEW : E-2)

AC INPUT UNIT

Refer to "DISASSEMBLY

8. AC INPUT UNIT"

and "EXPLODED VIEW"

AC INPUT UNIT

(Ref. No. of EXPLODED VIEW : A-1)

POWER UNIT

Refer to "DISASSEMBLY

9. POEWR UNIT"

and "EXPLODED VIEW"

POWER UNIT

(Ref. No. of EXPLODED VIEW : A-2)

5

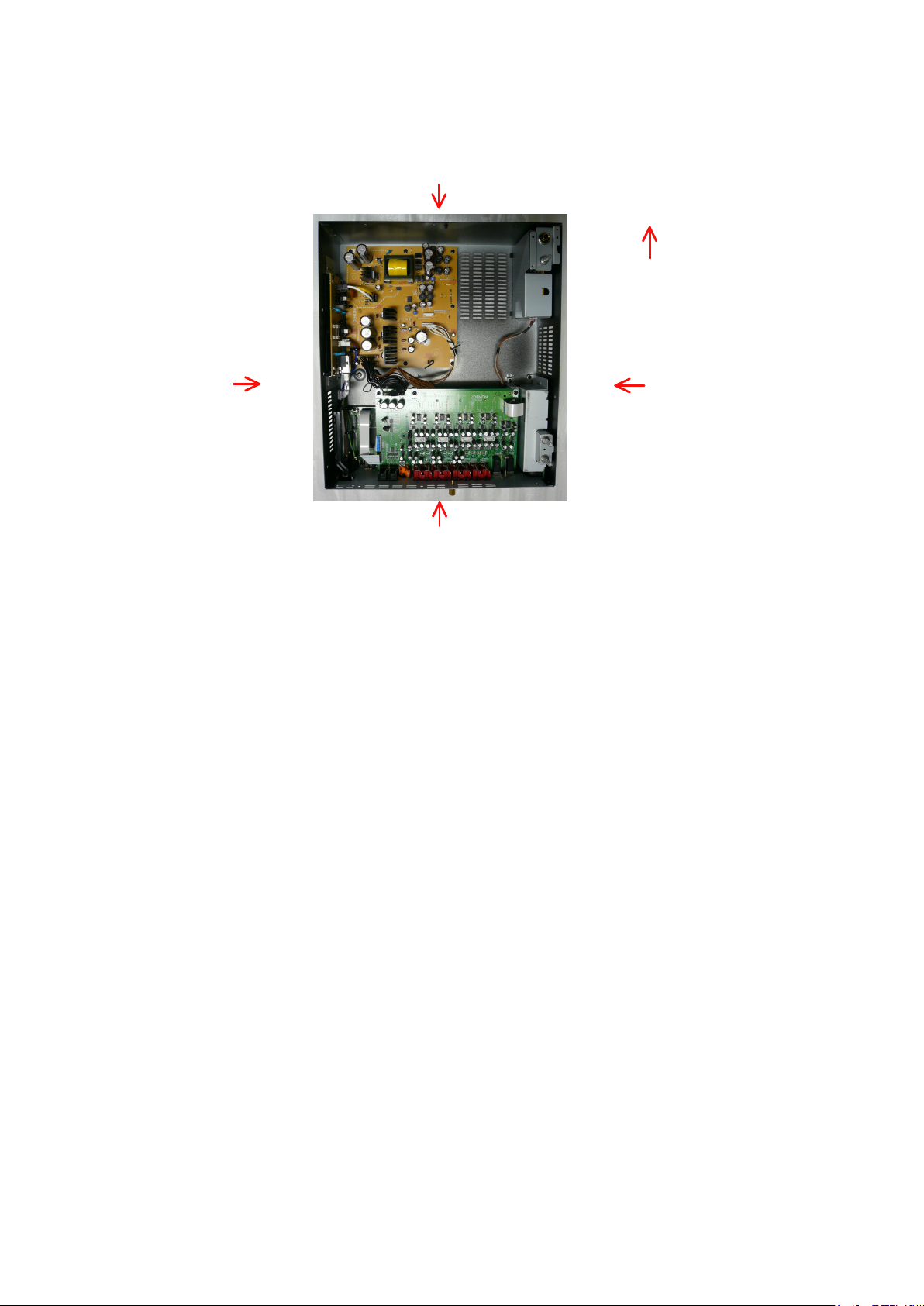

About the photos used for descriptions in the DISASSEMBLY" section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph:

***" at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: C

Direction of photograph: B

Front side

Direction of photograph: D

Direction of photograph: A

6

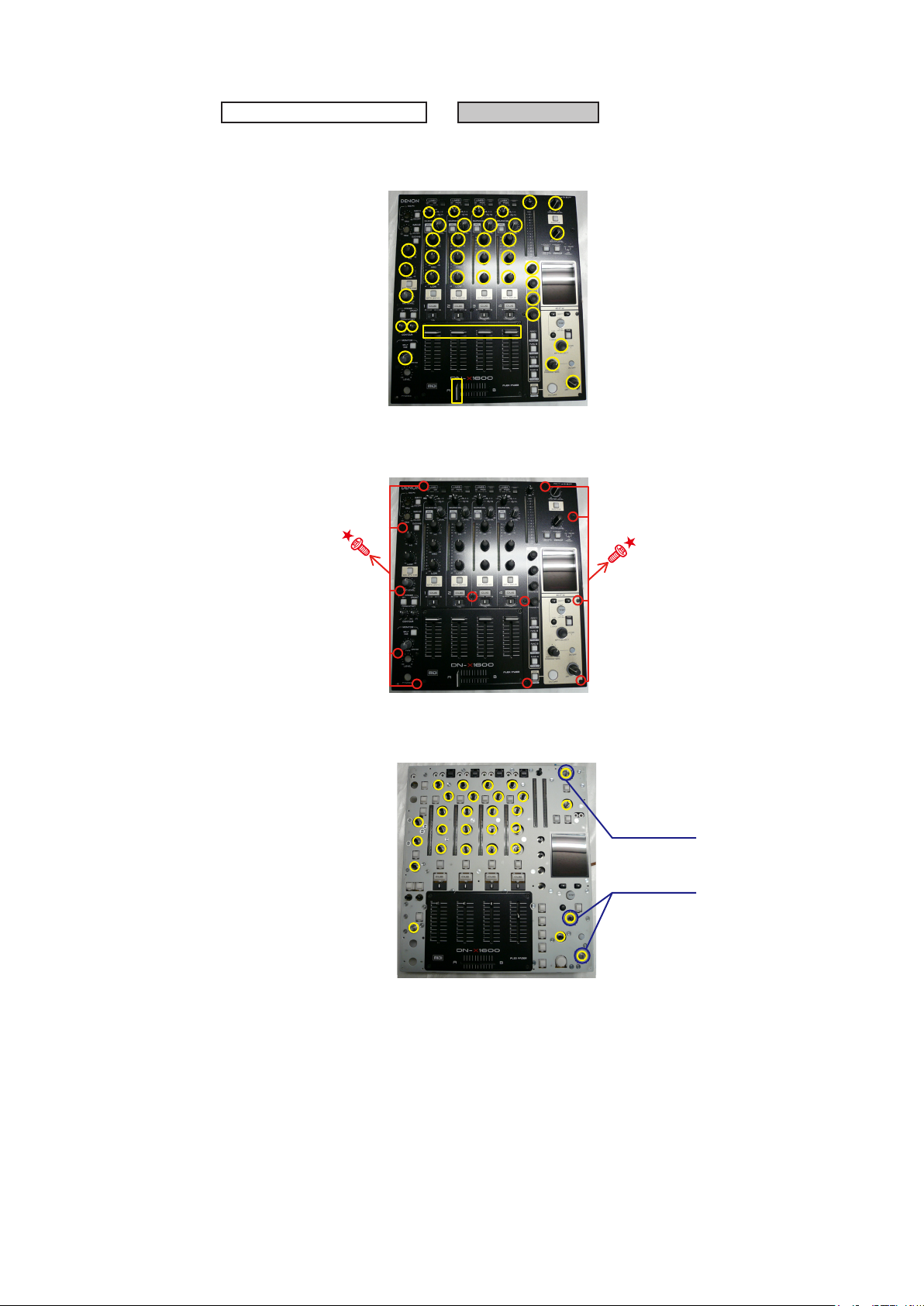

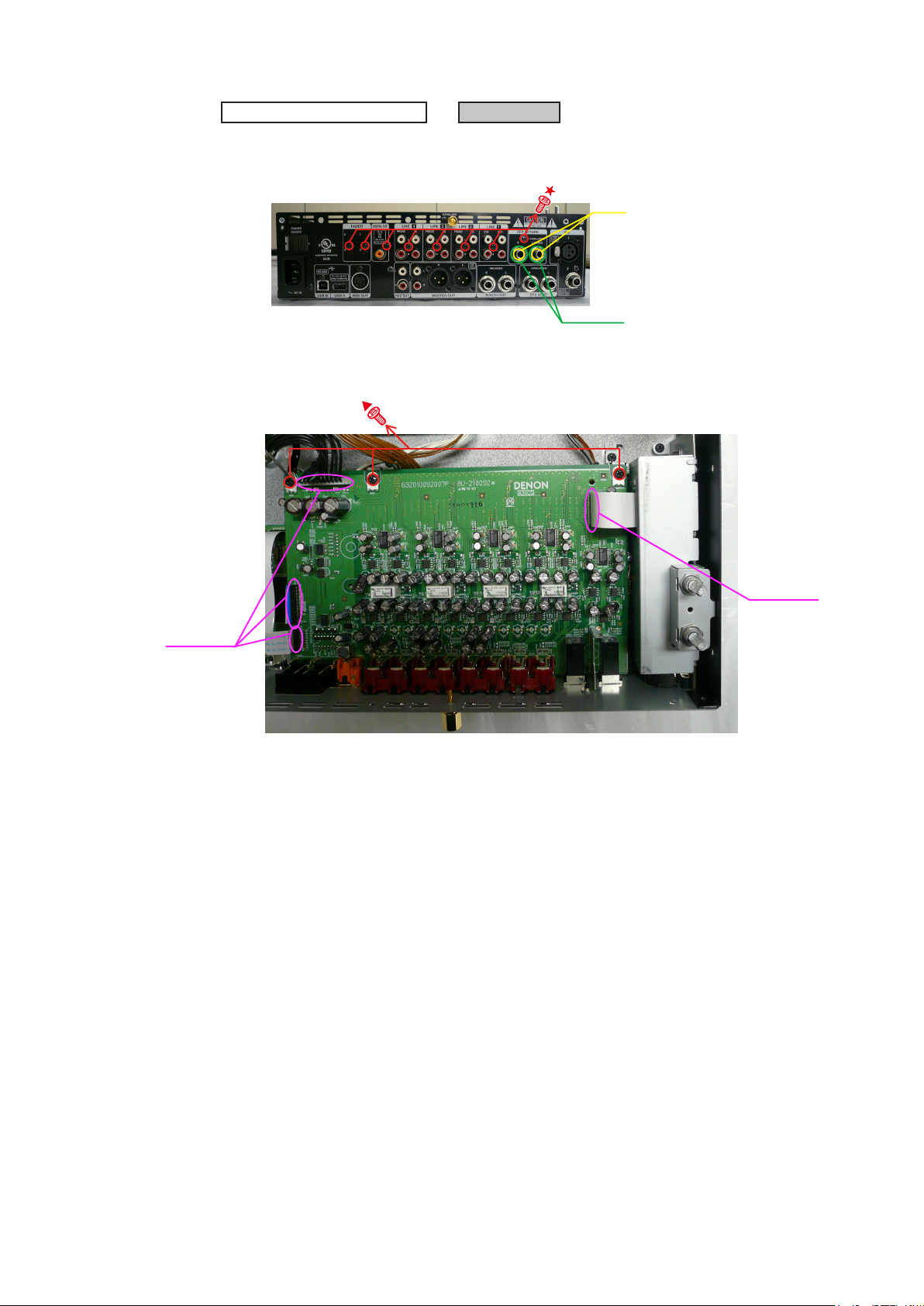

1. TOP CHASSIS SUB ASSY

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the screws and the knobs.

KNOB

KNOB

(2) Remove the screws.

Direction of photograph: A

Direction of photograph: B

Direction of photograph: C

Direction of photograph: D

7

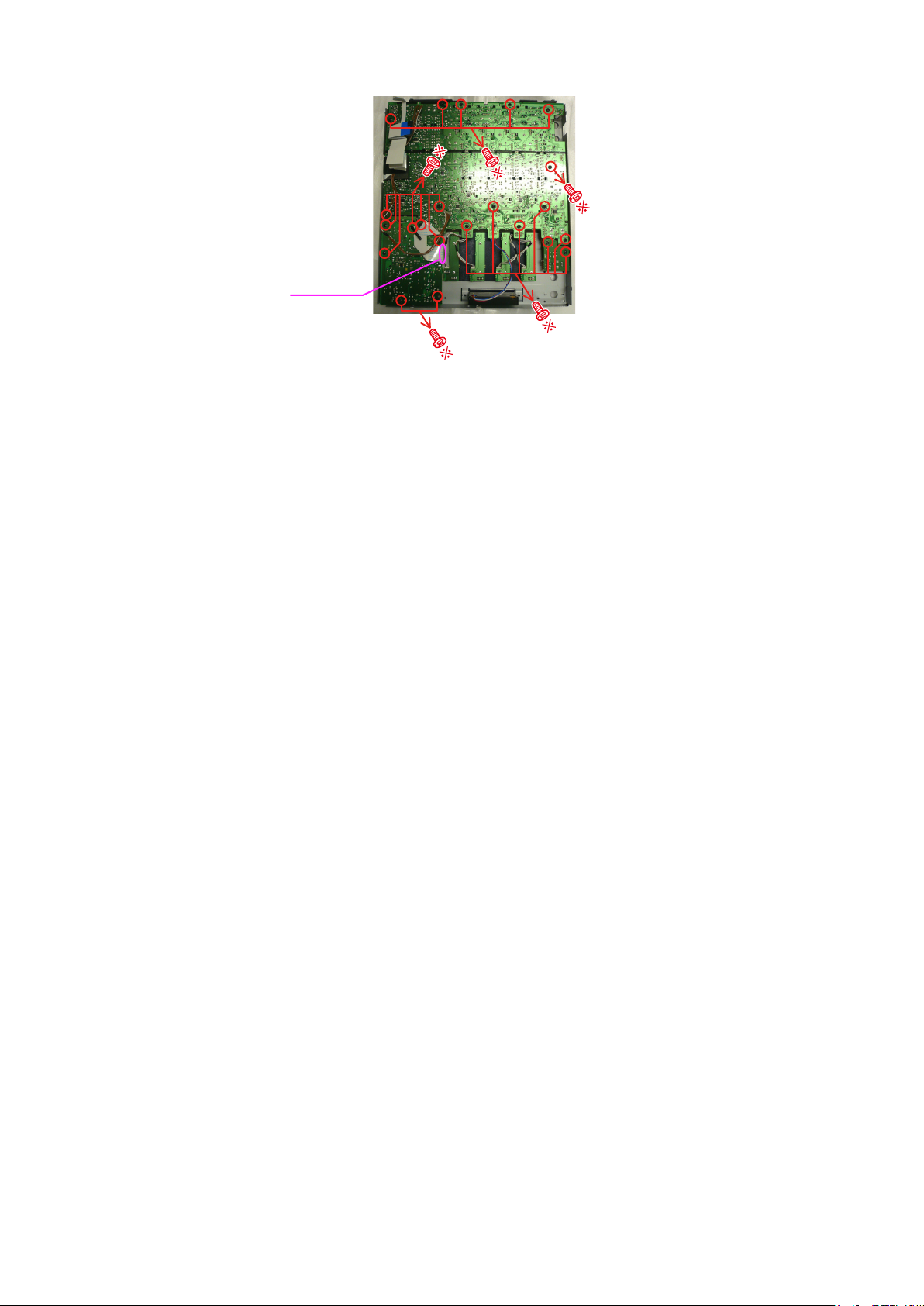

(3) Disconnect the connector wire and FFC Cable, and remove the sheet. Open the wire clamper.

SHEET

WIRE CLAMPER

FFC Cable

Direction of photograph: B

CX071

8

2. TOP PANEL UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the knobs.

(2) Remove the screws.

TOP PANEL UNIT

→

(3) Remove the Nuts and Lens rings.

LENS RING

LENS RING

9

(4) Disconnect the FFC Cable. Remove the secrews.

FFC Cable

10

3. INPUT UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the screws. Remove the Nuts and Washers.

Direction of photograph: A

(2) Remove the screws.Disconnect the FFC Cables.

→

INPUT UNIT

NUT

WASHER

FFC Cable

FFC Cable

11

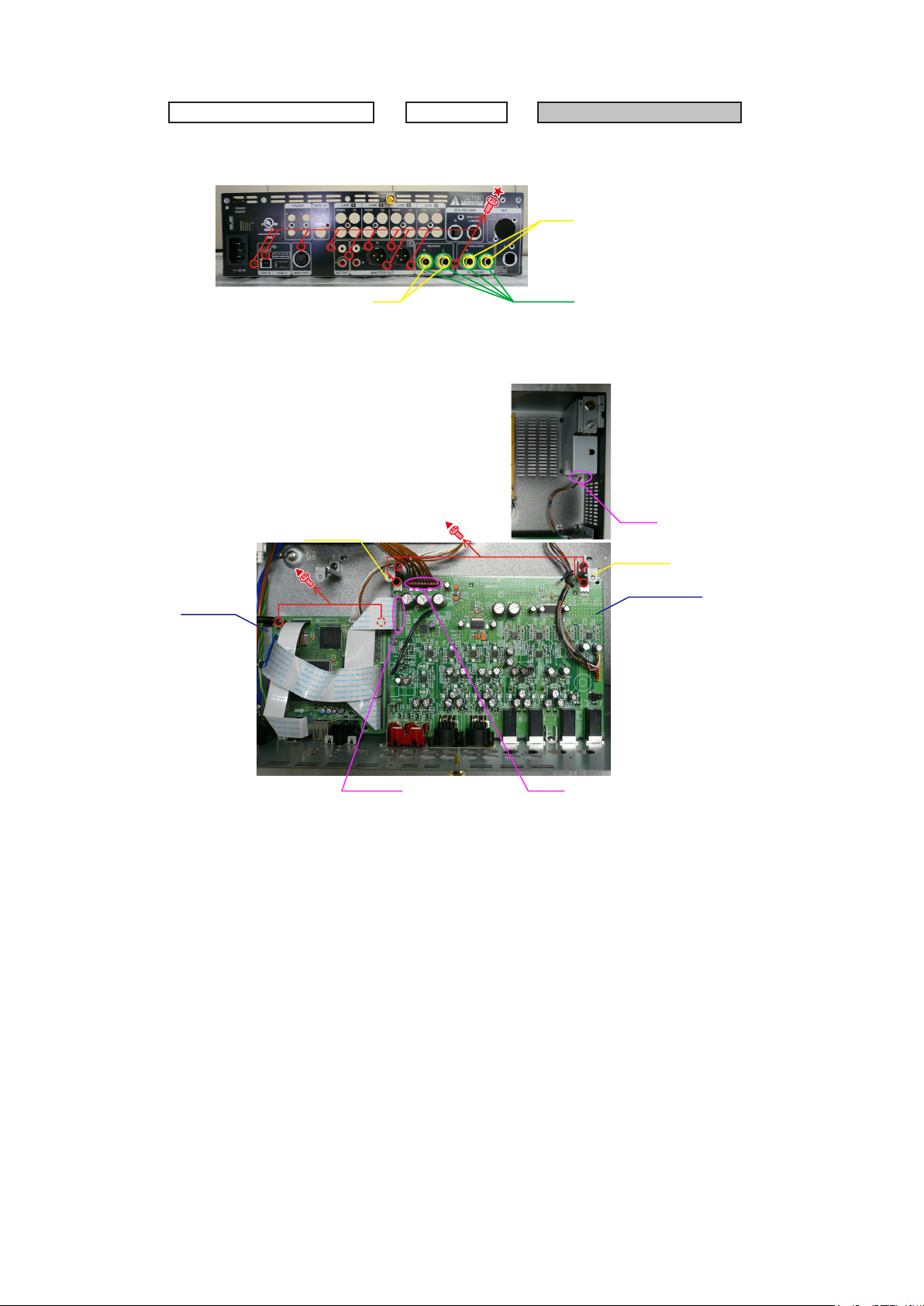

4. OUTPUT UNIT, MAIN UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the screws. Remove the Nuts and Washers.

Direction of photograph: A

(2) Remove the screws. Disconnect the FFC Cables and the connectors.

STAY PWB

INPUT UNIT

→

OUTPUT UNIT, MAIN UNIT

→

NUT

WASHERNUT

CY102

STAY PWB

MAIN UNIT

OUTPUT UNIT

FFC Cable CX101

12

5. FADER UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the screws.

(2) Remove the screws. Disconnect the connector wires.

→

FADER UNIT

CONNECTOR

CONNECTOR

13

6. HP UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Disconnect the connector wire. Remove the Nuts.

→

HP UNIT

NUT

CY102

(2) Remove the screws.

Direction of photograph: D

14

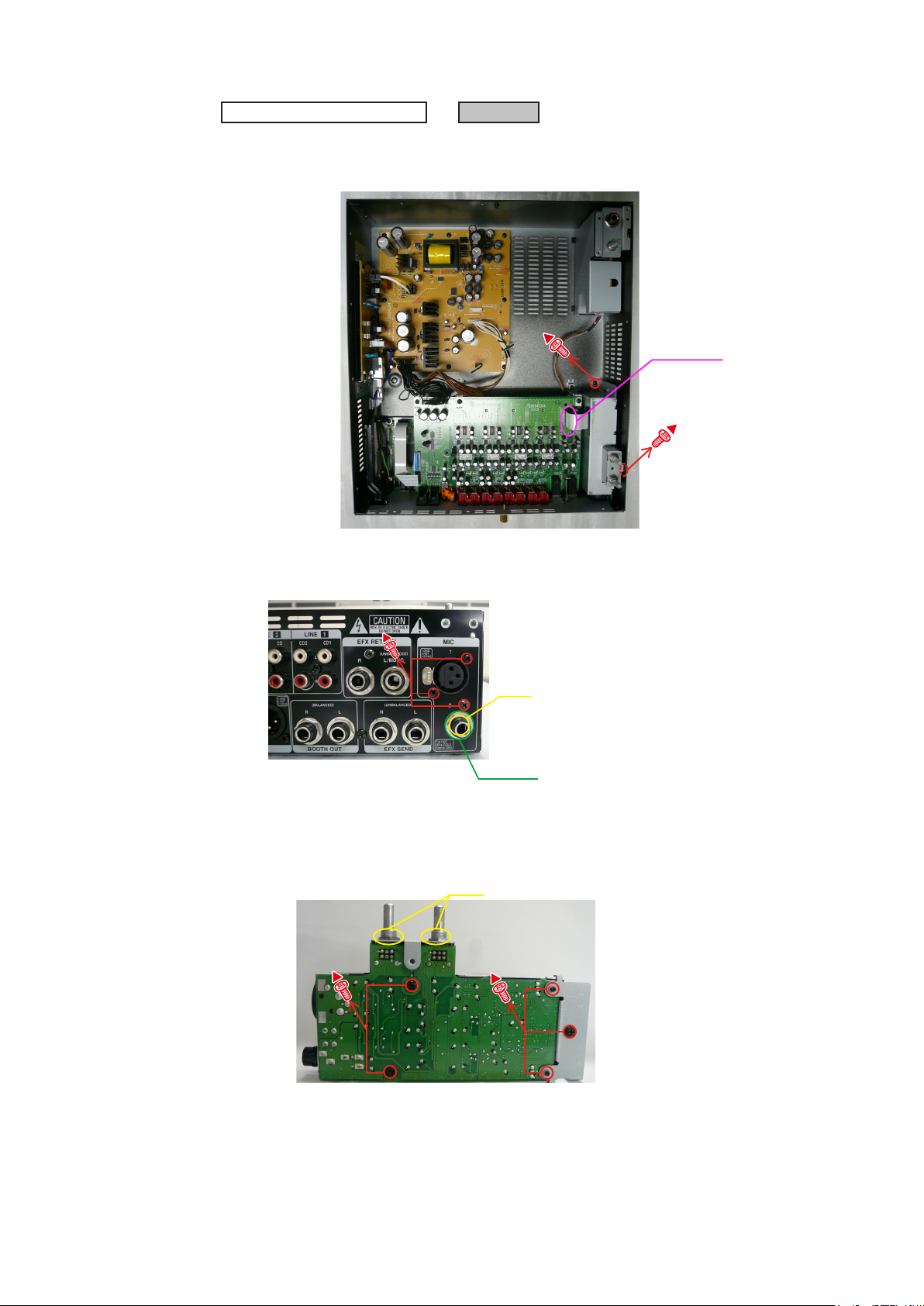

7. MIC UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Remove the screw. Disconnect the FFC Cable.

→

MIC UNIT

FFC Cable

(2) Remove the screws. Remove the Nut and Washer.

Direction of photograph: D

(3) Remove the screws.

Direction of photograph: D

NUT

WASHER

NUT

15

8. AC INPUT UNIT

Proceeding : TOP CHASSIS SUB ASSY

(1) Disconnect the connector wires and LINK.

AC INPUT UNIT

→

AC INPUT UNIT

(2) Remove the screws.

Direction of photograph: C

LINK

CX021

CX022

Direction of photograph: D

9. POWER UNIT

Proceeding : TOP CHASSIS SUB ASSY

Please refer to "EXPLODED VIEW" for the disassembly method of POWER P.W.B. UNIT.

POWER UNIT

→

16

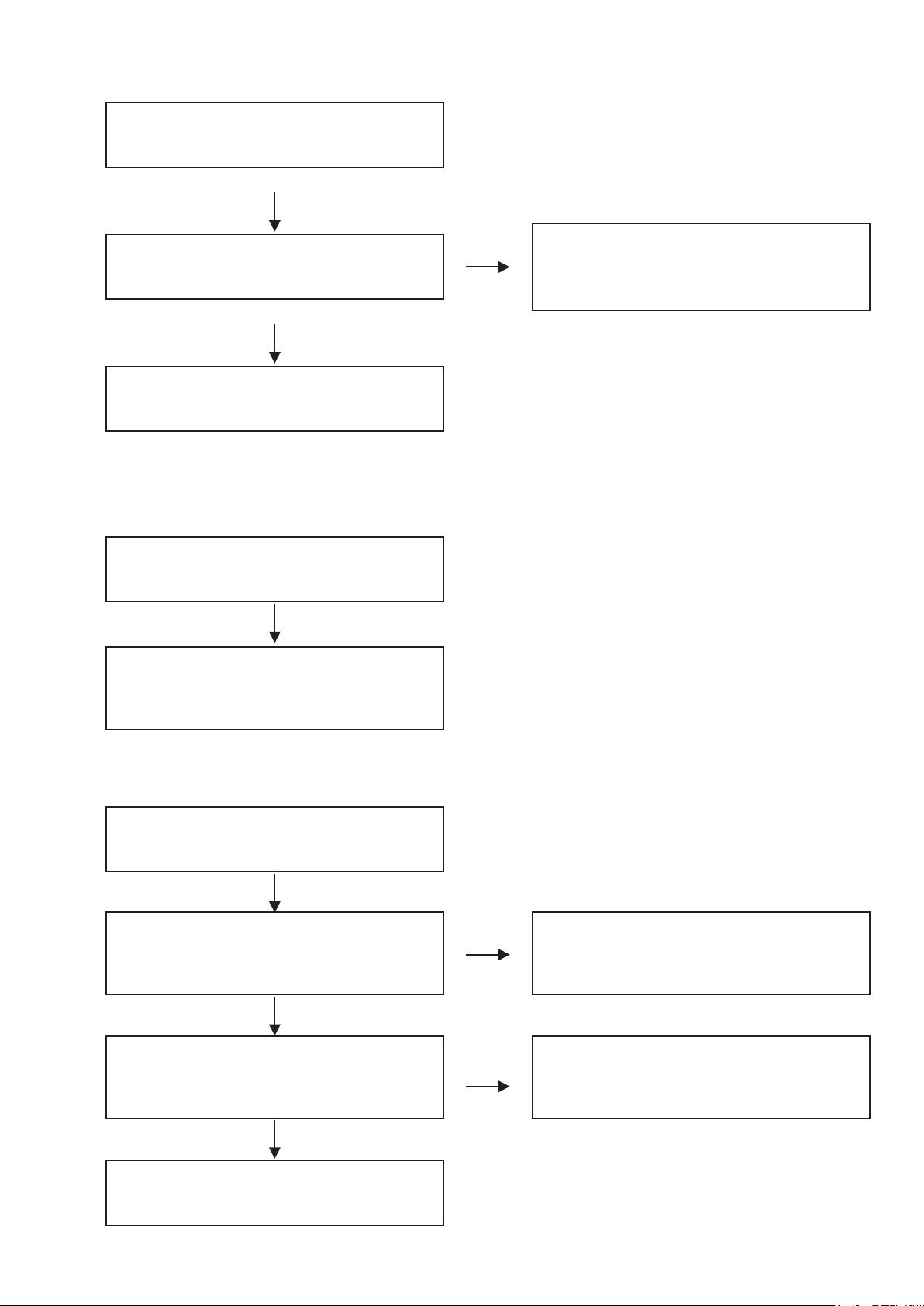

SERVICE MODE

1. Launching the service mode and selecting the check mode

PressingtheMIC1ON/OFFandMICEFXINSbuttonsimultaneously,turnonthepower.KeeppressingtheMIC1ON/

・

OFFandMICEFXINSbuttonuntil[DENON]isdisplayed.Whentheservicemodeisset,theservicemode'stopmenu

appears.

Thecommunicationsmodeissetwhenthepoweristurnedoffthenturnedbackon.

※

Contentsofthedisplayontheservicemode'stopmenu

・

1)Func

2)SWChk

3)VRChk

4)LEDChk

TurntheEFXSELECTcontroltoselecteachcheckmode,thenpresstheEFXSELECTcontroltoseteachcheck

・

mode.

2. Mode

2.1. Func (Function Mode)

With "Func" is displayed, press the EFX SELECT control.

(Items marked * are for design inspection. Do not use them for servicing purposes.)

・ Contentsofthedisplayonthefunctionmode'smenu

1)USBR/W

2)MIDIout

3)ROM/RAM

4)Initial

Thecontentsofthepresetmemoryaresettothefactorydefaults.

①

②

③

5)RunTime

①

Tocleartheaccumulatedpowerontime.

・

②

③

④

6)Version

Firmwareversionisdisplayed.

「

「

*(fordesigninspection)

*(fordesigninspection)

*(fordesigninspection)

"Cancel"isdisplayedinash.

TurntheEFXSELECTcontroltoselect"OK".

With"OK"displayedinash,presstheEFXSELECTcontroltoexecuteinitialization."Done!"isdisplayedwhen

initializationiscompleted.

WhenpresstheEFXSELECTcontrol,accumulatedpowerontimeisdisplayed.(Max:65000h

PresstheEFXSELECTcontrolwithaccumulatedpowerontimeisdisplayed,"Clear?"isdisplayed.

TurntheEFXSELECTcontroltoselect"OK".

With"OK"isdisplayedinash,presstheEFXSELECTcontroltoerasethetotaltimeofpoweron."Done!"is

displayedwhenerasureiscompleted.

SYS****

DSP****

」

」

)

PresstheTime(Back)buttontoreturntothetopmenuoftheservicemode.

2.2. SW Chk (Panel switch Check)

With "SW Chk" is displayed, press the EFX SELECT control

Checktheoperationsoftheswitches.

・

1)Intheinitialstatus,characterisdisplayedontheVFD.

2)Whenaswitchispressed,thecharactercorrespondingtotheswitchdisappears.

3)Whenallswitchesarepressed,"Finish!"isdisplayed.

4)PresstheEFXSELECTcontrolwith"Finish!"isdisplayedtoreturntothetopmenuoftheservicemode.

WhentheTAPbuttonispressedwhilethe"SWChk"modeisbeingexecuted,theservicemode'stopmenu

※

reappears.

PresstheTime(Back)buttontoreturntothetopmenuoftheservicemode.

17

2.3. VR Chk (Panel volume Check))

With "VR Chk" is displayed, press the EFX SELECT control

ChecktheoperationsoftheVR.

・

TurntheVR,VRnameandvalueof"0"~"1023"aredisplayedontheVFD.

Checktheoperationsoftherotaryencoder.

・

Whentherotaryencoderisturned,therotaryencodernameand"<"(counterclockwise)or">"(clockwise)are

displayedontheVFD.

Whentherotaryencoderwithaswitchispressed,therotaryencodernameand“■”aredisplayedontheVDF.

ChecktheoperationsofthefaderVR.

・

MovethefaderVR,faderVRnameandvalueof"0"~"1023"aredisplayedontheVFD.

ChecktheoperationsoftheslideSW.

・

MovetheslideSW,slideSWnameand"A"(Left),"T"(Center),"B"(Right)aredisplayedontheVFD.

Note:TheheadphonesLEVEL,MIC1TRIM,MIC2TRIMcontrolareananalogVR,sothereisnoVRnameandvalue

display.

PresstheTime(Back)buttontoreturntothetopmenuoftheservicemode.

2.4. LED Chk (Panel LED Check)

With "LED Chk" is displayed, press the EFX SELECT control

(Items marked * are for design inspection. Do not use them for servicing purposes.)

CheckthelightingoftheLED.

・

WhentheTAPbuttonispressed,themodechangesintheordershownbelow.

1)ALLLight:AllLEDsLight.

2)Dimmer:ThedimmerfunctionLEDsaresettothedimmerlitstatus.

CUE1、CUE2、CUE3、CUE4、EFEXSEND(LINE1)、EFEXSEND(LINE2)、EFEXSEND(LINE3)、EFEX

SEND(LINE4)、CUE(EFX)、EFEXON/OFF、PARAMETERSON/OFF

3)Green:OnlygreenLEDlight.

4)Amber:OnlyorangeLEDlight.

5)Red:OnlyredLEDlight.

6)Blue:OnlyblueLEDlight.

7)MaxON

8)Typical*:Fixedformloadlighting(fordesigninspection)

Maximumloadlighting(fordesigninspection)

*:

PresstheTime(Back)buttontoreturntothetopmenuoftheservicemode.

18

VERSION UPGRADE PROCEDURE OF FIRMWARE

Usetheproceduredescribedbelowtoupdatethermwaretoanewerversion.

Storetheleforupdatingthermware(lename:X1600FW.BIN)intherootdirectoryofUSBdevice.

・

IftheleforupdatingthermwareisstoredonaUSBdevice,connecttheUSBdevicetotheUSBAterminal.

・

Note:DonotturnoffthepowerordisconnecttheUSBcableortheUSBdevicewhilethermwareisbeingupdated.

Ifrmwareupdatingisnotcompletednormally,someoperationsmaynolongerbeguaranteedtoworkanditmay

notbepossibletoupdatethermwareagain.

1)TurnonthepowerwhilepressingtheMIC2ON/OFFandDUCKINGbuttonsimultaneously.(Versionupmode)

2)PresstheUTILITYbuttonaccordingtothescreendisplay.

3)"****->****"isscrolldisplayed.

4)PresstheMIDICLKbuttontobeginupdating.(Approximately40secondarerequiredforupdatingtobecompleted.)

5)"Finish!"and"Ver****"aredisplayedwhenrmwareupdatingiscompleted.

6)TurnthepoweroffanddisconnecttheUSBdevicefromtheUSBport.

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

WhenreplacedoftheU-PRO(Microprocessor)ortheFlashROM,conrmcontentsofthefollowing.

PWB Name Ref. No. Description

MAIN IC103 EN29LV160BB-70TIP B FILENAME:X1600FW.BIN

Afterreplaced

A:MaskROM(Withsoftware).Noneedwrite-inofsoftwaretothemicroprocessor.

B:FlashROM(Withsoftware).Usually,noneedwrite-inofsoftware.But,whenthesoftwarewasupdated,youshouldbe

write-inofthenewsoftwaretothemicroprocessororashROM.Pleasecheckthesoftwareversion.

C:EmptyFlashROM(Withoutsoftware).Youshouldbewrite-inofthesoftwaretothemicroprocessororashROM.

Referto"Updateprocedure"or"writingprocedure",whenyoushouldbewrite-inthesoftware.

After

replaced

Remark

19

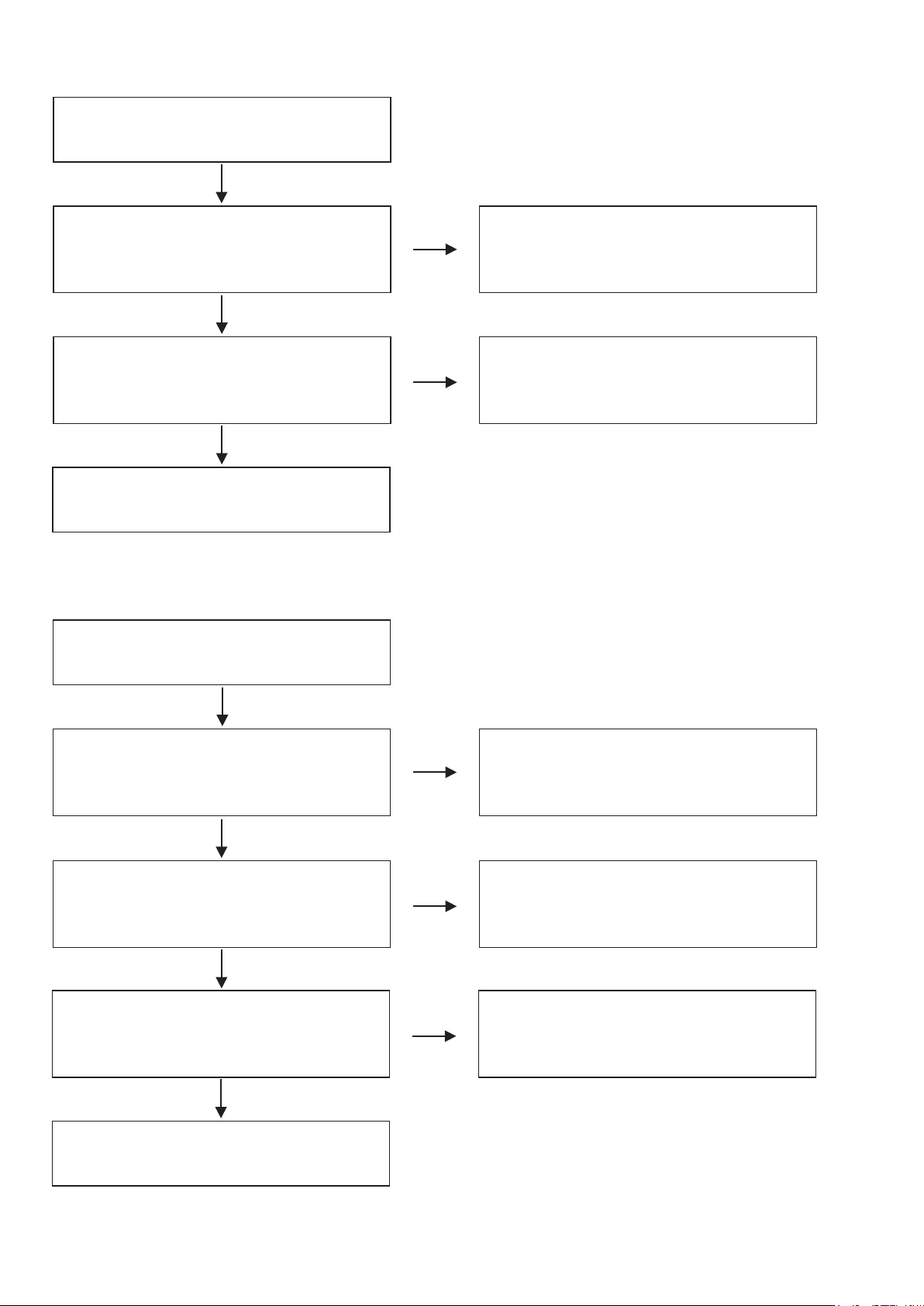

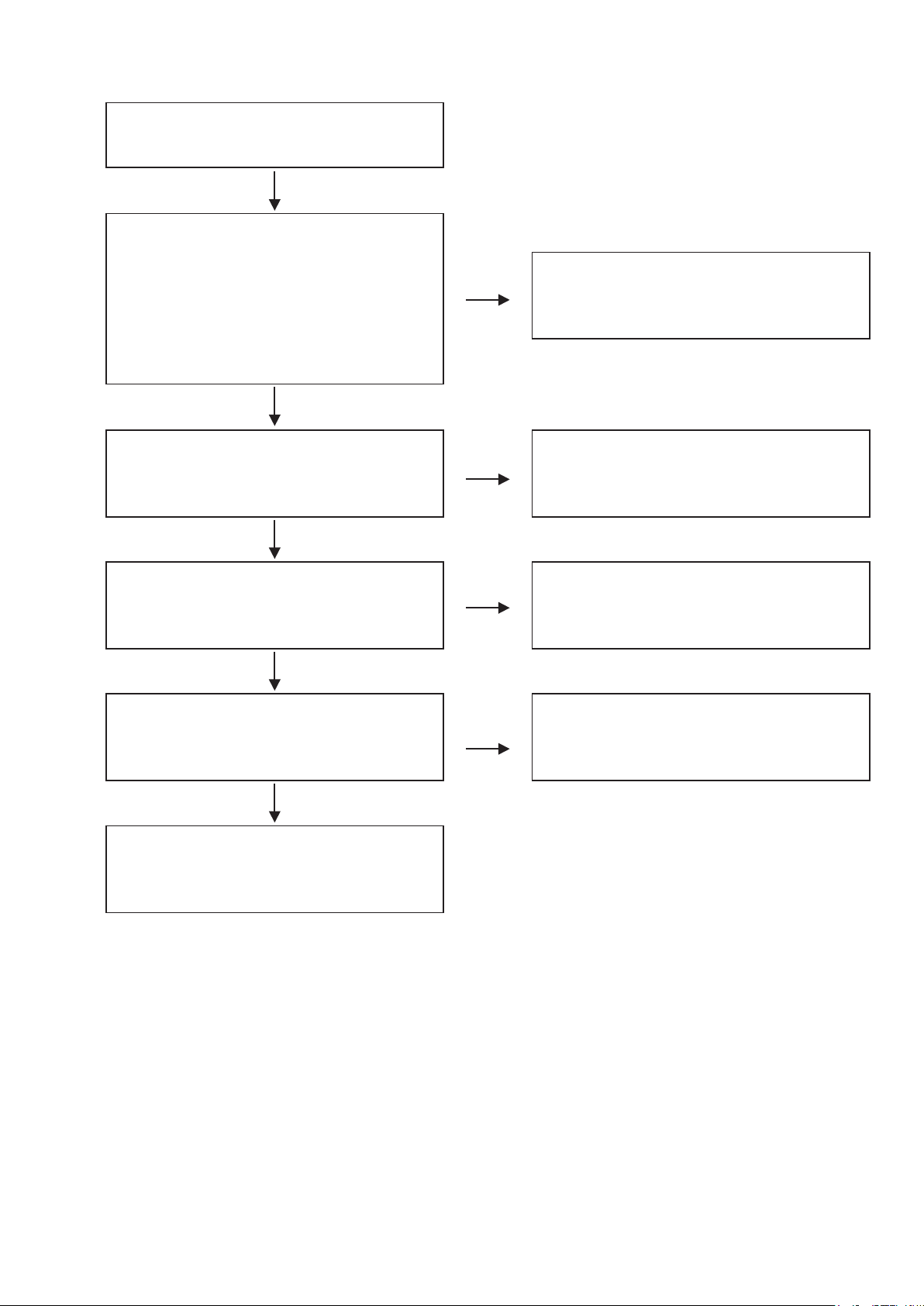

TROUBLE SHOOTING

FLOW CHART NO.1 (8U-110068-1, -2:POWER UNIT)

The power cannot be turned on.

O.K.

N.G.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is normal state restored when once unplugged

power cord is plugged again after several seconds?

O.K.

Is the +3.3V line voltage normal?

O.K.

Check each rectifying circuit of the secondary

circuit and replace it if defective.

FLOW CHART NO.2 (8U-110068-1, -2:AC INPUT UNIT, POWER UNIT)

The fuse blows out.

N.G.

N.G.

Check if there is any leak or short-circuiting on

the primary circuit component, and replace it if

defective.

(C901,C902,C903,C906,C907,C908,L901,L902,T901

)

O.K.

Check the presence that the primary component

is leaking or shorted and replace it if defective.

O.K.

After servicing, replace the fuse.

N.G.

20

O.K.

Check the presence that the rectifying diode

or circuit is shorted in each rectifying circuit of

secondary side, and replace it if defective.

O.K.

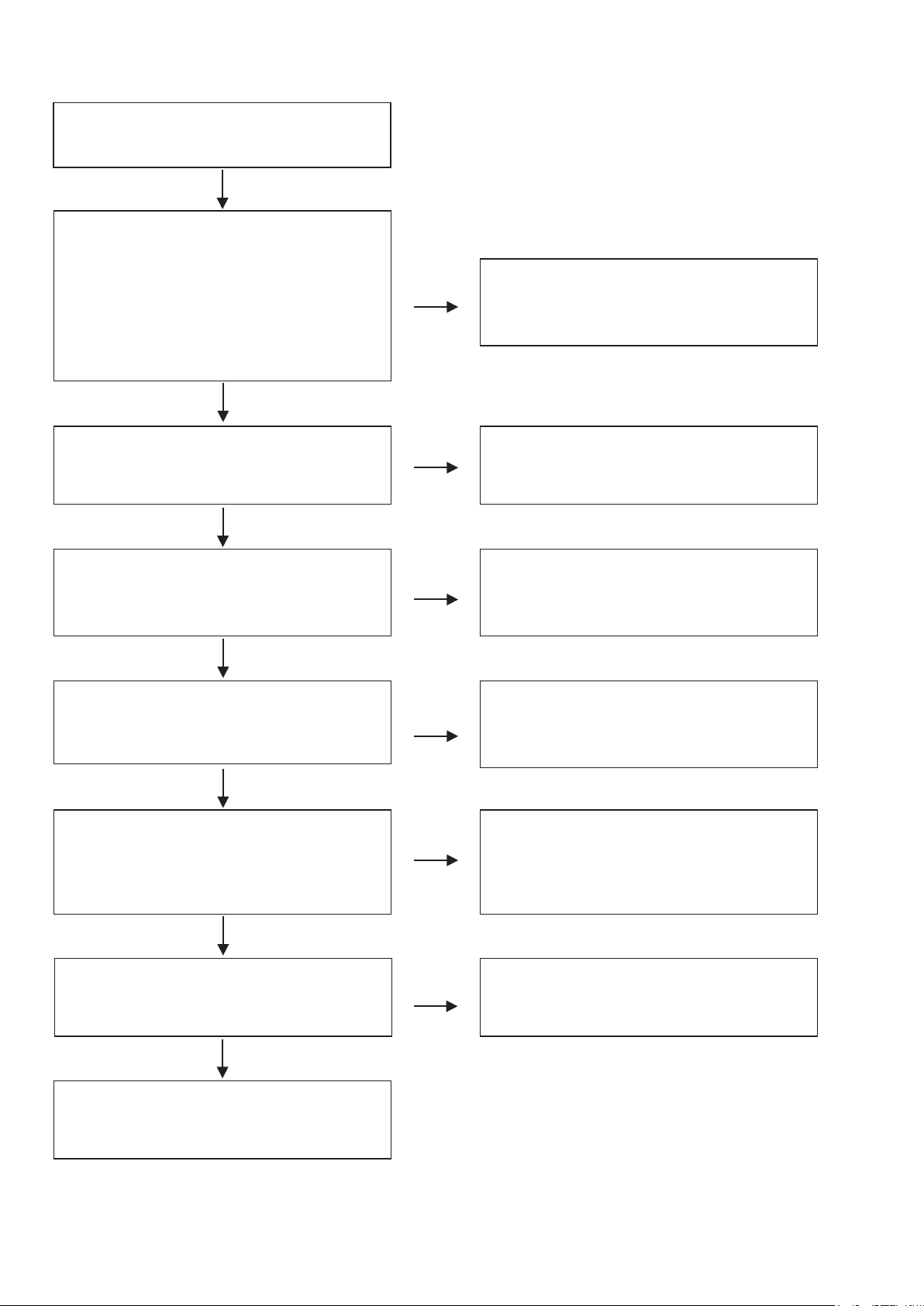

FLOW CHART NO.3 (8U-110068-1, -2:POWER UNIT)

+1.2V is not outputted.

O.K.

Is the +5V line voltage normal?

O.K.

Check IC903 and the periphery circuit, and replace

it if defective

FLOW CHART NO.4 (8U-110068-1, -2:POWER UNIT)

+3.3V is not outputted.

O.K.

See FLOW CHART

NO.1 <Is the +3.3V line voltage normal?>

N.G.

Check if there is any leak or short-circuiting on the

primary circuit component, and replace it if

defective.

(C901,C902,C903,C906,C907,C908,L901,L902,T901)

FLOW CHART NO.5 (8U-110068:POWER UNIT)

+15VA is not outputted.

O.K.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is the voltage of +15V or more supplied to IN

terminal of IC907

O.K.

Check IC907 and the periphery circuit, and replace

it if defective.

N.G.

N.G.

Check D924 and replace it if defective.

21

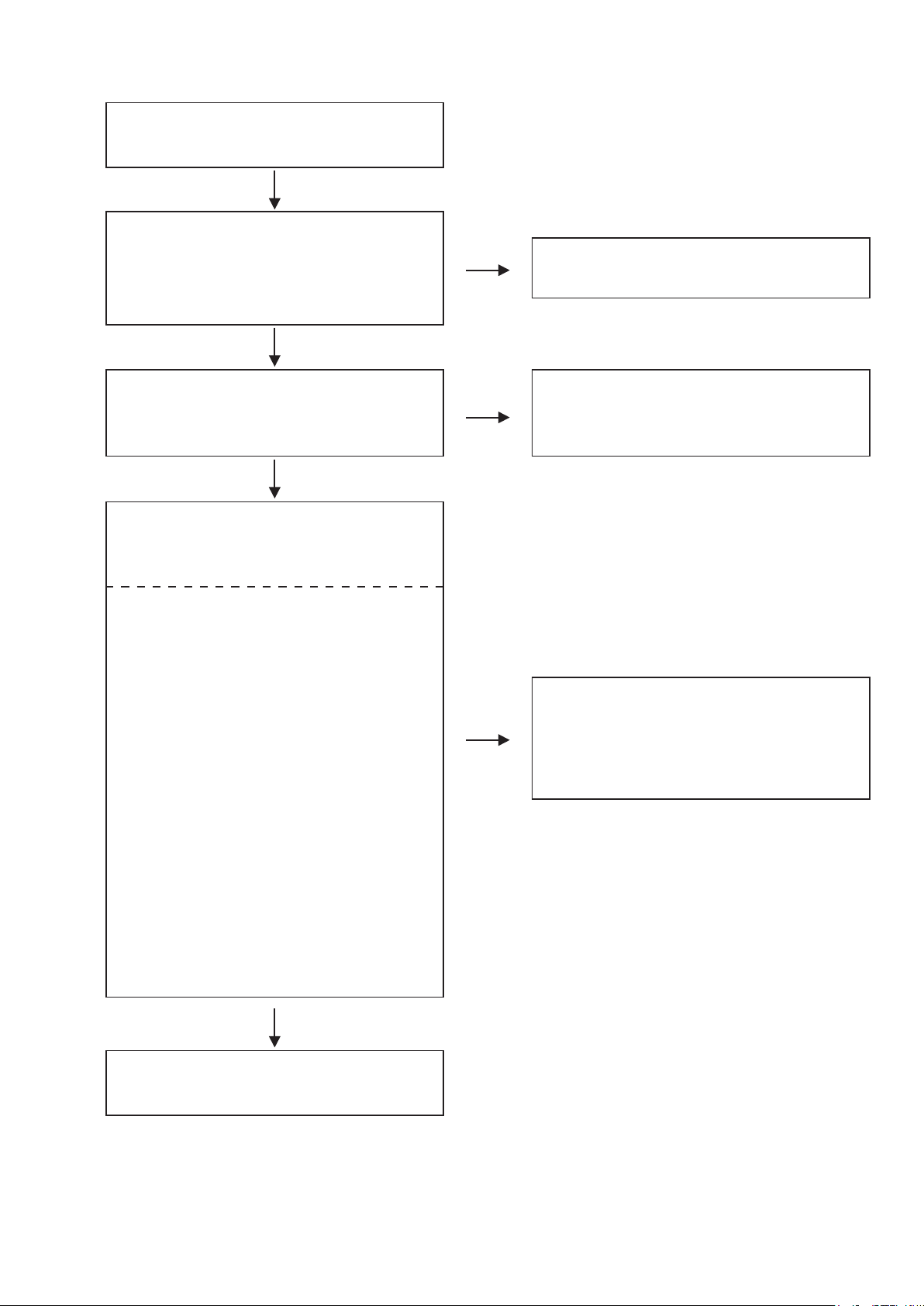

FLOW CHART NO.6 (8U-110068:POWER UNIT)

-15VA is not outputted.

O.K.

Is the fuse normal? See FLOW CHART NO.2 <The fuse blows out.>

O.K.

Is the voltage of -15V or less supplied to IN terminal

of IC906?

O.K.

Check IC906 and the periphery circuit, and replace

it if defective.

FLOW CHART NO.7 (8U-310012:MAIN UNIT, 8U-110068:POWER UNIT)

The VFD display does not light up.

N.G.

N.G.

Check D925 and replace it if defective.

O.K.

Is +5V voltage supplied to 1pin of CX071 on

POWER UNIT?

O.K.

Is +3.3V voltage supplied to 3pin of CX071 on

POWER UNIT?

O.K.

Ia signal outputted from FL_CLK,FL_DATA,FL_

CS,FL_RST terminals of IC104 on MAIN UNIT?

O.K.

Replace the VFD display.

N.G.

N.G.

N.G.

Check the +5V line and service it if defective.

Check the +3.3V line and service it if defective.

Replace IC104.

22

FLOW CHART NO.8 (8U-110069-1:PANEL UNIT)

The key operation is not functioning.

O.K.

Are the contact point and the installation state of

the key switches (S401,S402,S404~S426,S441),

rotary switches (S433~S436), slide switches

(S427,S428,S438,S439), encoder switches (S442

S445) nomal?

~

O.K.

N.G.

Re-install the switches correctly or replace the poor

switch.

Does LED(LD101~LD107, LD109~LD231,

LD401) light correctly ?

O.K.

When pressing each key switches, turning rotary

switches and switching slide switches, do the

voltage of each pin of IC406, IC407(shown below)

increase?

Key switches

S401,404,410,414,418,422 :IC406 11pin

S405,411,415,419,423,425 :IC406 12pin

S426

S402,406,408,412,416,420 :IC406 5pin

S407,409,413,417,421,424,441 :IC406 6pin

Rotary switches

S433,434,435,436 :IC406 11pin

S433,434,435,436 :IC406 12pin

S433,434,435,436 :IC406 13pin

S433,434,435,436 :IC406 14pin

S433,434,435,436 :IC406 3pin

S433,434,435,436 :IC406 4pin

Slide switches

S427,428,438,439 :IC406 5pin

S427,428,438,439 :IC406 6pin

Encoder switches(pressing)

S442 :IC406 5pin

S443 :IC406 6pin

S444 :IC407 11pin

S445 :IC407 12pin

Encoder switches(turning)

S442,443,444,445

IC406 14pin

:

IC407 3,4,13,14pin

:

N.G.

N.G.

Check the TR101~TR116 and their periphery, and

service it if detective.

Check the key switches (S401,S402,S404

S426,S441), and rotary switches (S433~S436),

slide switches (S427,S428,S438,S439), encoder

switches (S442~S445) and their periphery, and

service it if detective.

~

Replace IC406 or IC407.

O.K.

23

FLOW CHART NO.9 (8U-110070-1:EFECT UNIT)

The key operation is not functioning.

O.K.

Are the contact point and the installation state of

the key switches (S601~S611, S613) normal?

O.K.

Does LED (LD601~LD616) light correctly?

O.K.

When pressing each key switches, pressing and

turning encoder switches, do the voltage of each pin

of IC406, IC407on the 8U-110069-1 board (shown

below) increase?

Key switches

S605,609

S601,606,610 :IC406 5pin

S602,611

S603,607

S604,608,613 :IC407 12pin

Encoder switches(pressing)

S614 :IC407 6pin

Encoder switches(turning)

S614 :IC407 5pin

S614 :IC407 6pin

IC406 4pin

:

IC406 6pin

:

IC407 11pin

:

N.G.

N.G.

N.G.

Re-install the switches correctly or replace the poor

switch.

Check the TR114~TR116 and their periphery, and

service it if detective.

Check the key switches (S601~S611,S613) and

encoder switches (S614) and their periphery, and

service it if detective.

O.K.

Replace IC406 or IC407 on the 8U-110069-1 board.

24

FLOW CHART NO.10 (8U-210093:OUTPUT UNIT)

Function of sound for master output do not operate

normally.

O.K.

Set the line input selector button to "CD".

・

Set the fader assign switch to "THRU".

・

Set the channel fader to "MAX".

・

Set the master level control to "MAX".

・

Are audio signals output to IC101 25pin(left

channel) and 17pin(right channel)when an audio

signal of 1 kHz 0 dBV is input externally to the CD

input?

However, current output.

O.K.

N.G.

Check the input signal from CY232 to IC101 and

their periphery, and service it if detective.

When the input signal is correct, IC101 is replaced.

Are the audio signals outputted to 7pin and 1pin

of IC103(Lch), IC104(Rch), IC105(Lch) and

IC106(Rch)?

O.K.

Are the audio signals outputted to 7pin(COLD) and

1pin(HOT) of IC107(Lch), IC109(Rch)?

O.K.

Is 20pin of CY232 (MUTE control signal)H, and has

been the TR104 collector (MUTE drive signal)

L(-15V)?

O.K.

Check periphery circuit of JK101,JK102 from 7pin

and 1pin of IC107,IC109, and replace it if defective.

N.G.

N.G.

N.G.

Check periphery circuit of IC103,IC104,IC105,IC106

from 25pin、17pin of IC101, and service it if

defective. When the periphery circuit is correct,

IC103,IC104 or IC105,IC106 is replaced.

Check periphery circuit of IC107,IC109 from 7pin

and 1pin of IC105,IC106, and service it if defective.

When the periphery circuit is correct, IC107or

IC109 is replaced.

Check TR111~TR114 and the periphery circuit,

and service it if defective.

25

FLOW CHART NO.11 (8U-210092:INPUT UNIT)

Function of sound for master output do not operate

normally.

O.K.

Set the line input selector button to "CD".

・

Set the fader assign switch to "THRU".

・

Set the channel fader to "MAX".

・

Set the master level control to "MAX".

・

Are audio signals output to IC102 7pin(left channel),

1pin(right channel)when an audio signal of 1 kHz 0

dBV is input externally to the CD input?

O.K.

N.G.

Check the input signal from JK101 to IC108 and

their periphery, and service it if detective.

When the input signal is correct, IC108 is replaced.

Is 2pin of CY231 (RELAY control signal)L, and has

been the TR109 collector (RELAY signal) H(+5V)?

O.K.

Are the audio signals outputted to 5pin(Lch) and

6pin(Rch) of RL101?

O.K.

Are the audio signals outputted to 7pin and 1pin of

IC103(Lch), IC104(Rch)?

O.K.

Are the digital audio signals(0-3.3V) outputted from

15pin(DATA) of IC105(L/Rch)?

N.G.

N.G.

N.G.

N.G.

Check TR109 and the periphery circuit, and service

it if defective.

Check periphery circuit of RL101 from IC108, and

service it if defective.

When the input signal is correct, RL101 is replaced.

Check periphery circuit of IC103,IC104 from 5pin

and 6pin of RL101, and service it if defective.

When the input signal is correct, IC103,IC104 is

replaced.

Check that IC105 9pin is "L" (with Fs: 44.1 k/ 48

k),"H" (with Fs: 96 k) and that 19pin is "H". Check

the signal input to 16pin, 17pin and 18pin.

If there is no input signal, repair the defective part.

When the input signal is correct, IC105 is replaced.

O.K.

Are the digital audio signals outputted from 3pin of

IC206?

O.K.

Check periphery circuit of 12pin of CY231 from

3pin of IC206, and replace it if defective.

N.G.

26

Check IC206 and the periphery circuit, and service

it if defective.

When the input signal is correct, IC206 is replaced.

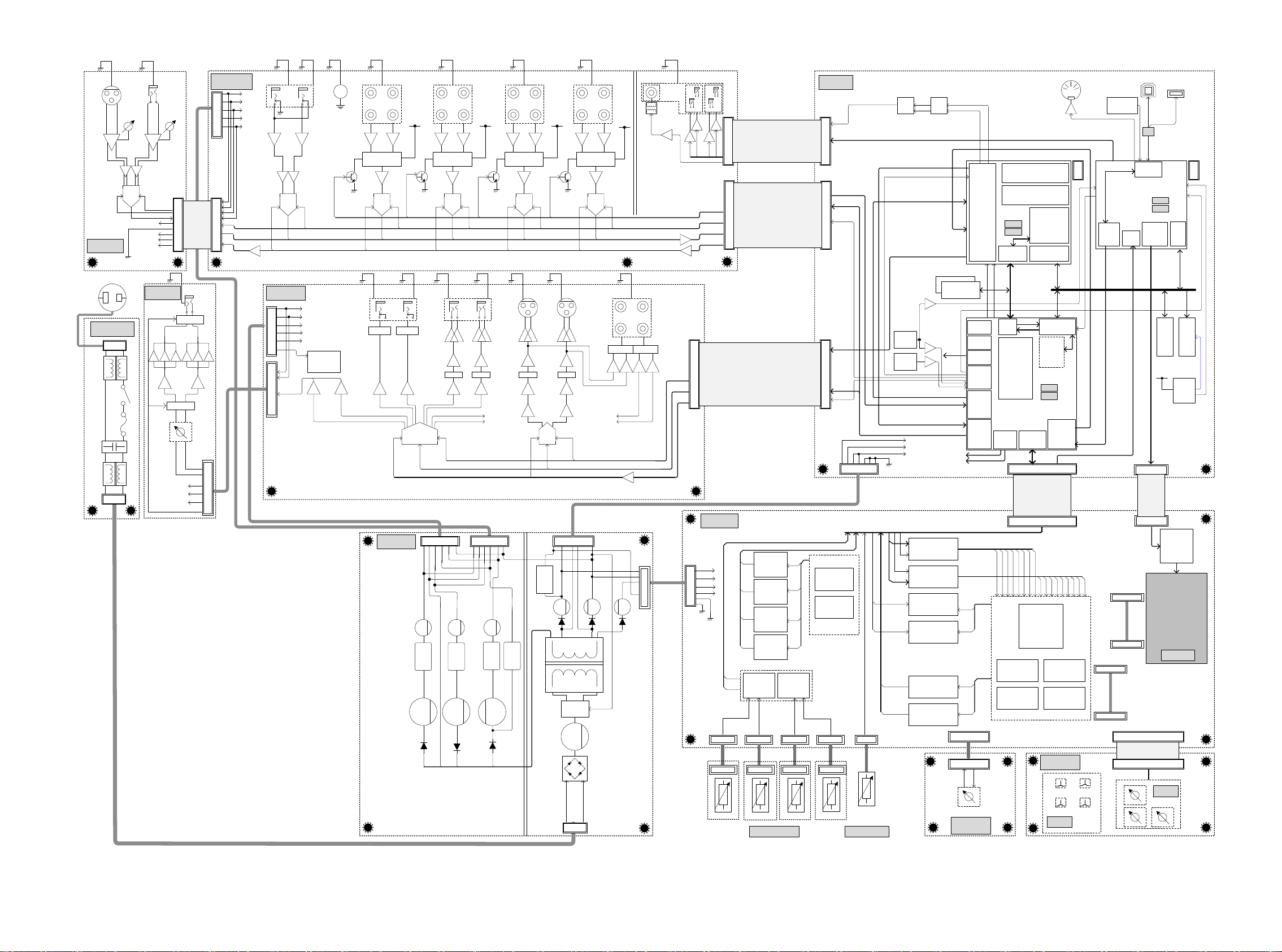

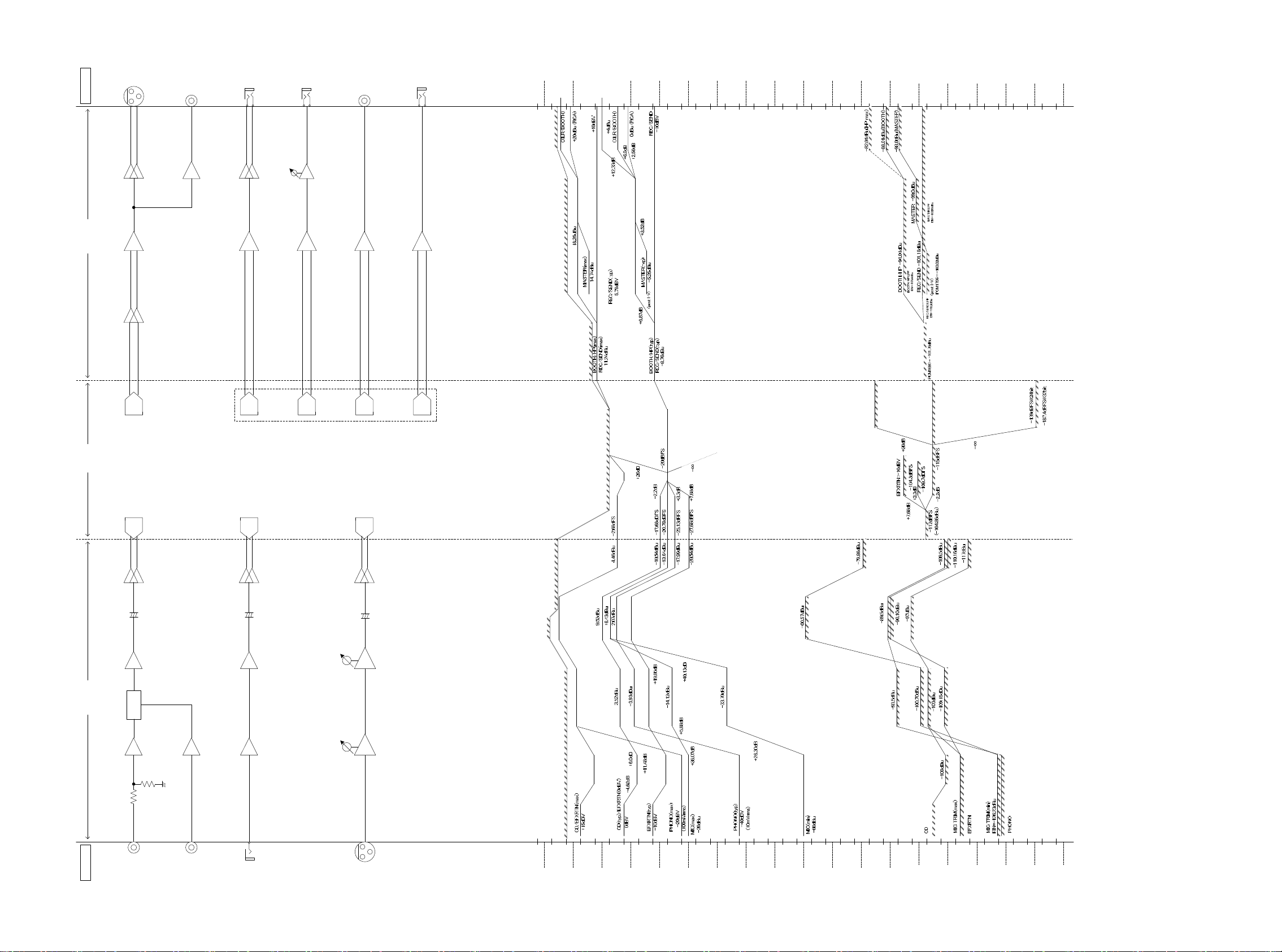

DNX1600 BLOCK DIAGRAM

BLOCK DIAGRAM

MIC1 MIC2

PCM1804

8U-210093-2

MIC UNIT

AC INLET

8U-110068-1

AC INPUT UNIT

2pin VH

HA HA

Diff

ADC

+3.3V

+5VA

+15V

-15V

S.DGND

8U-110070-2

HP UNIT

CX181 CY181

TR

CX021

TR

CX022

2pin VH

MUTE

+15V

-15V

MUTE

18pin FFC P1.0 Si

PHONES

MUTE

CY102

8U-210092

INPUT UNIT

12pin EH

CX121

18pin FFC P1.0 Si

10P-KR

+15V

-15V

+5VA

RL_5V

+3.3V

EFFECT RETURN

L(MONO) R

S.AGND

Diff

ADC

8U-210093-1

OUTPUT UNIT

CX101

10pin EH

10P-SAN

CW102

+15V

-15V

+5VA

RL_5V

+3.3V

CD1 CD2 CD PHONO CD PHONO CD PHONO

GND(PHONO)

MUTE(TR)

MUTE

Cirkit

LINE1 LINE2 LINE3 LINE4

RL_5V

ST

ST

ST

Relay Relay Relay Relay

ST

RL_GND RL_GND RL_GND RL_GND

Diff

PCM1804 PCM1804 PCM1804 PCM1804PCM1804

ADC

EFFECT SEND

L R

TR

MUTEMUTE

Diff

8U-110068-2

POWER UNIT

CW101

DAC

4ST

+15V

PCM1690

24bit

10P-SCN

REG

Diff

RL_5V RL_5V

RIAA

ST

ST

ADC

BOOTH

L R

MUTE MUTE

Σ+LPFΣ+LPFΣ+LPFΣ+LPFΣ+LPFΣ+LPF

REC_Lch

REC_Rch

12P-SCN

REG

-15V

BTLBTL

LDO

+5VA

ST

RIAA

ST

ST

Diff

ADC

MASTER

L

BTL BTL

MUTE MUTE

Σ+LPF Σ+LPF

I-V I-V

Diff

DAC

PCM1795

CW121

1.2V DCDC

RL_5V

ST

ST

Diff

ADC

R

32bit

DA CTL

DA Signal DATA

MCLK/BCK/LRCK for DA

8pin PH

CX081

+5V

+3.3V

AC-DC

RL_5V

RIAA

ST

Relay

AD CTL

AD Signal DATA

MCLK/BCK/LRCK for ADC

MASTER REC

TR

MUTE MUTE

REC_Lch

REC_Rch

+34V

Feed Back

DIGITAL OUT

FADER ST

1 2

CY232

CX071 CW071

7pin KR

3 4

Fader

13pin FFC P1.0 Si

SPDIF

CY131 CX131

23pin FFC P1.0 Si

CY231

23pin FFC P1.0 Si

8U-110069-1

PANEL UNIT

8-1

CW045

Multiplexer

Multiplexer

Multiplexer

Multiplexer

2-1

Multiplexer

(TC4051)

8-1

(TC4051)

8-1

(TC4051)

8-1

(TC4051)

TC4053

+5V

+3.3V

+34V

+1.2V

7pin DA

FLGND

LEDGND

CW046

Multiplexer

CW043

2-1

8U-310012

MAIN UINT

Fader

13pin FFC P1.0 Si

ADC DATA

LRCK/BCK

ADMCLK

23pin FFC P1.0 Si

CX231

LRCK/BCK

23pin FFC P1.0 Si

DAMCLK

CX232

CY081

VR x 10

VR(C) x 17

CW042 CX044

MIDI OUT USB B

DATA

SRCDIT

LRCK/BCK

USB Audio I2S

DGND

16.9344M

24.576

MHz

CS

CS

24

24

3

3

710LRCK/BCK

AHCLK

OUTD1-4

DAC DATA

Hz

OUTD1-4

ADC DATA

710LRCK/BCK

ADC_DAC LRCK/BCK

+5V

+1.2V

+3.3V

3

3-8 DEC

SN74HCT138APW

3

3-8 DEC

SN74HCT138APW

S/P

DRIVER

TB62777FNG

S/P

DRIVER

TB62777FNG

P/S Buffer

SN74LV165APW

P/S Buffer

SN74LV165APW

16MBx16bit

16MBx16bit

SDRAM

SDRAM

DIT

ADDA

MUTE/RST

ADDA CTL

McASP

0

DIR

IF

SRC

IF

DIT

IF

CLK

SEL

LINE

SEL

ADDA

LRCK

BCK

8

8

8

8

8

8

MIX/VR/EQ ect...

DJ EFX

DSP

DA710

+3.3V

+1.2V

EMIF

RST

MCLK

EMIF

32bit

24bit

FIFO REG

CPU IF

(REG_CS2)

FPGA Spartan3A (XC3S400A)

LED/SW

ADDA

MTX

CTL

25pin FFC P1.0 Si8pin PH

CX252

25pin FFC P1.0 Si

CY252

LED x 147

TACT SW x 38

SLIDE SW x 4

AUTO

BPM

UHPI

FFT

4,000LE

+3.3V

+1.2V

SSI-DSP

Buffer

TDM-I2S

SELECTOR x 4

ENC x 5

32bit

UHPI

16bit

14pin

MCLK 16.9344M

4ch TDM

CW082

EHR-44P-SAN4P-SAN 4P-SAN 4P-SAN

48MHz

CPU(USB)

DMA

SH7263

SSI

0/1

ADC

32bit

MAIN BUS

RST(soft)

x2

CX072

CY072

CZ041

4pin DA

4pin DA

CW041

CZ031

3pin DA

3pin DA

CW031

23pin FFC P1.0 Si8pin KR

USB SW

USB CTL

+3.3V

CPU

+1.2V

VFD_IF

32bit 16bit

7pin FFC P1.0 Si

7pin FFC P1.0 Si

BN061GINK

USB A

14pin

RST

Audio CLK

BUS

I/O

32bit

SDRAM

8MBx32bit

1MB F-ROM

+5V

RST

VFD

Cirkit

VFD

CX233

2pin VH

CY022

27

PHR-4 PHR-4 PHR-4 PHR-4

CH FADER

X-FADER

8pin DS

CY082

8U-110069-2

SPLIT UNIT

8U-110070-1

EFFECT UNIT

FUNC1 FUNC2

FUNC3 FUNC4

MIDI

23pin FFC P1.0 Si

CY233

EFX

LEVEL DIAGRAM

+30

(XLR)

+4dBu(typ)

MASTER OUT

BTL

+6.0dB

0dB

Σ

SUM

I-V

Rf=1.5kohm

(RCA)

+0dBu(typ)

MASTER OUT

+2.59dB

PAD+AMP

(-3.41+6.0)

+4dBu(typ)

BOOTH OUT

BTL

+6.0dB

Σ

SUM

+6.87dB

HP OUT

VR

-∞~+12dB

SUM

+6.87dB

REC OUT

150mW@40hom

Σ

-10dBV(typ)

0dB

Σ

SUM

EFX SEND

-10dBV(typ)

0dB

Σ

SUM

[dBu]

+30

[dBV]

+20

+10

+24dBu

BTL

VOE=±13.5V=+21.81dBu

Diff

Clip Level

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

+10dBu (HP)

-120

-130

-130

-140

-140

-150

-150

DAC

32bit

PCM1795

ADC

PCM1804

PAD

-20.06dB

+

+2.5V

Offset

Diff

+6.0dB

Analog AnalogDigital

RELAY

DAC

PCM1690

ADC

PCM1804

PAD

-20.06dB

+

+2.5V

Offset

Diff

+6.0dB

DAC

DAC

ADC

PCM1804

PAD

-20.06dB

+

+2.5V

Offset

DAC

0dBFS

(+7.14dBu)

Clip Level

[dBFS] [dBFS]

Vcom=+2.5Voffset

Diff

※ 22Hz-20kHz(SPCL), A-Weighted, FS96kHz

Typical Noise Level ※ Typical Noise Level ※

Amp

+6.0dB

PAD

-4.62dB

INPUT OUTPUT

CD1~4

0dBV(typ)

RIAA

+36.07dB

10mV(typ)

PHONO1~4

Amp

+6.0dB

0dBV(typ)

EFX RETURN

HA HA

1st 2nd

+6.0dB~+26.5dB +18.0dB~+40.0dB

Diff

MIC

-60~-20dBu

VOE=±13.5V=+21.81dBu

Clip Level

+30

+30

+20

+20

[dBV]

[dBu]

+10

+10

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

-140

0

-10

-20

-30

-40

-50

-60

-70

-80

-90

-100

-110

-120

-130

-140

-150

-150

28

2

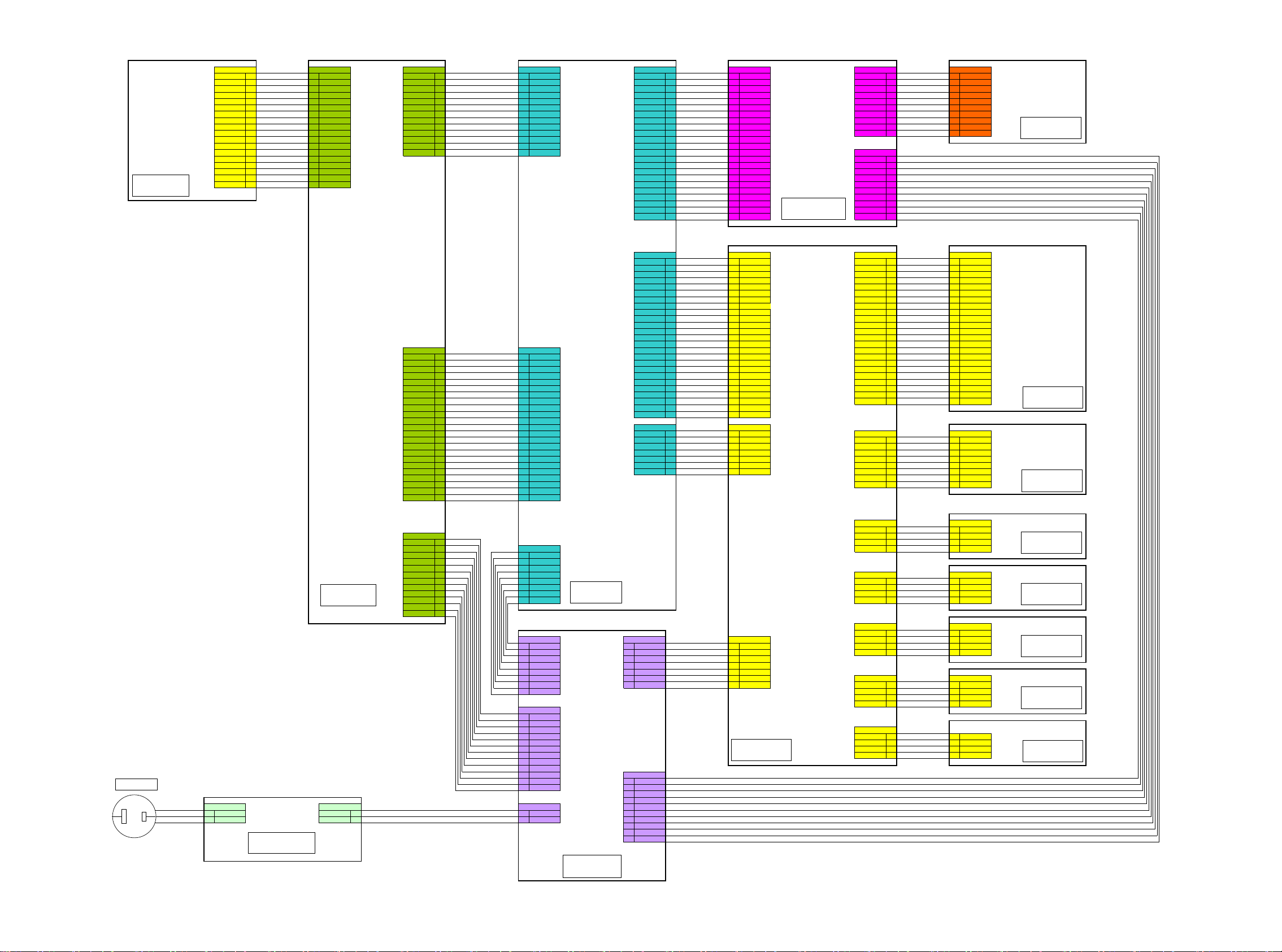

DNX1600 WIRING DIAGRAM

WIRING DIAGRAM

MIC UNIT

8U-210093-2

CX181 CY181 CY131 CX131 CX232 CY232 CW102 CY102

S.DGND 1 1 S.DGND GND 1 1 GND GND 1 1 GND HP_L 1 1 HP_L

A_RST 2 2 A_RST CUE1 2 2 CUE1 A_RST 2 2 A_RST AG_L 2 2 AG_L

AD_ORS0 3 3 AD_ORSD PLAY1 3 3 PLAY1 DA_SCK 3 3 DA_SCK AG_R 3 3 AG_R

ADLRCK 4 4 ADLRCK CUE2 4 4 CUE2 DA_TX 4 4 DA_TX HP_R 4 4 HP_R

ADBCK 5 5 ADBCK PLAY2 5 5 PLAY2 DA_CS1 5 5 DA_CS1 GND 5 5 GND

S.DGND 6 6 S.DGND GND 6 6 GND DA_CS2 6 6 DA_CS2 +15V 6 6 +15V

MICDAT 7 7 MICDAT CUE3 7 7 CUE3 NC 7 7 -15V 7 7 -15V

S.DGND 8 8 S.DGND PLAY3 8 8 PLAY3 GND 8 8 GND RL_MUTE 8 8

ADMCLK 9 9 ADMCLK CUE4 9 9 CUE4 DALRCK 9 9 DALRCK 9 9

S.DGND 10 10 S.DGND PLAY4 10 10 PLAY4 DABCK 10 10 DABCK 10 10

S.AGND 11 11 S.AGND GND 11 11 GND MASTDAT 11 11 MASTDAT

+15V 12 12 +15V SPDIF 12 12 SPDIF BOOTDAT 12 12 BOOTDAT

S.AGND 13 13 S.AGND GND 13 13 GND GND 13 13 GND

-15V 14 14 -15V RECDAT 14 14 RECDAT +15V 1

+5VA 15 15 +5VA PHONDAT 15 15 PHONDAT AGND 2

S.AGND 16 16 S.AGND EFXSDAT 16 16 EFXSDAT AGND 3

+3.3V 17 17 +3.3V GND 17 17 GND -15V 4

S.DGND 18 18 S.DGND SND_DET_L 18 18 RE_5V 5

CY231 CX231

GND 1 1 GND GND 16 16 DGND SD6 16 16 SD6

RELAY1 2 2 RELAY1 BLINK 17 17 BLINK SD5 17 17 SD5

RELAY2 3 3 RELAY2 SCK 18 18 SCK SD8 18 18 SD8

RELAY3 4 4 RELAY3 LEDDAT 19 19 LEDDAT SD7 19 19 SD7

RELAY4 5 5 RELAY4 SD0 20 20 SD0 SD14 20 20 SD14

GND 6 6 GND SD1 21 21 SD1 SD9 21 21 SD9

A_RST 7 7 A_RST LCD_BLL 22 22 LCD_BLL SD15 22 22 SD15

AD_OSR0 8 8 AD_OSR0 GND 23 23 DGND DGND 23 23 DGND

ADLRCK 9 9 ADLRCK LCD_RLH 24 24 LCD_BLH

ADBCK 10 10 ADBCK GND 25 25 DGND

GND 11 11 GND

ADDAT1 12 12 ADDAT1

ADDAT2 13 13 ADDAT2 D.GND 1 1 FL_DGND

ADDAT3 14 14 ADDAT3 LCD_B0 2 2 FL_CLK SL0 1 1 SL0

ADDAT4 15 15 ADDAT4 LCD_B1 3 3 FL_GND LD7 2 2 LD7

GND 16 16 GND LCD_B2 4 4 FL_DATA DGND 3 3 DGND

EFXRDAT 17 17 EFXRDAT LCD_B3 5 5 FL_CS SD7 4 4 SD7

MICDAT 18 18 MICDAT LCD_B4 6 6 FL_RST DGND 5 5 DGND

RTN_DET_L 19 19 RTN_DET_L D.GND 7 7 FL_DGND VR1-3 6 6 VR1-3

RTN_DET_R 20 20 RTN_DET_R DGND 7 7 DGND

GND 21 21 GND +3.3V 8 8 +3.3V

ADMCLK 22 22 ADMCLK

GND 23 23 GND

NC 19 19 RE_GND 6

RE_MUTE 20 20 RE_MUTE +5VA 7

GND 21 21 GND AGND 8

DAMCLK 22

GND 23 23 GND DGND 10

CX252 CY252 CX233 CY233

GND 1 1 DGND ADJVOL 1 1 ADJVOL

VR_DAT1 2 2 VR_DAT1 DRY/WETV 2 2 DRY/WETV

VR_DAT2 3 3 VR_DAT2 DGND 3 3 DGND

VR_DAT3 4 4 VR_DAT3 +3.3V 4 4 +3.3V

VR_DAT4 5 5 VR_DAT4 SL13 5 5 SL13

GND 6 6 DGND SL14 6 6 SL14

GND 7 7 DGND SL15 7 7 SL15

FADER_DAT

GND 9 9 DGND LD11 9 9 LD11

XFADER 10 10 XFADER LD12 10 10 LD12

GND 11 11 DGND LD13 11 11 LD13

SC0 12 12 SC0 LD14 12 12 LD14

SC1 13 13 SC1 LD15 13 13 LD15

SC2 14 14 SC2 LD8 14 14 LD8

SC3 15 15 SC3

8 8 FADER_DAT2 AGND 8 8 AGND

CX072 CY072

22 DAMCLK +3V3 9

OUTPUT UNIT

8U-210093-1

CX101

DGND 15

CW082 CY082

MUTE

15 DGND

HP UNIT

8U-110070-2

EFFECT UNIT

8U-110070-1

SPLIT UNIT

8U-110069-2

AC INLET

CX121

+15V 1 NC 3 3 NC

+15V 2

P.AGND 3 8 PFAIL

P.AGND 4 7 +1.2V

-15V 5 6 +1.2V

-15V 6

RL_5V 7 4 +3.3V +3.3V 1 1 +3.3V

INPUT UNIT

8U-210092

CX021 CX022 CY022

1 HOT COLD 1 1 COLD 5 RE_5V

2 COLD HOT 2 2 HOT 4 -15V

RL_GND 8 3 DGND PITCH 2 2 PITCH

+5VA 9 2 +5VD NC 3 3 NC

P.AGND. 10 1 +5VD DGND 4 4 DGND

+3V3 11

P.DGND 12

POWER SW

CY081

5 DGND

MAIN UNIT

8U-310012A

CX081 CX071 CW071

1 +5VD 1 +5VD 1 +5V NC 3 3 NC

2 +5VD 2 DGND 2 AGND DGND 4 4 DGND

3 GND 3 +3V3 3 +3.3V

4 +3V3 4 DGND 4 AGND

5 DGND 5 +34V 5 34V

6 +1V2 6 DGND 6 FL_GND

7 +1V2 7 +1V2 7 +1.2V +3.3V 1 1 +3.3V

8 PFAIL PITCH 2 2 PITCH

CW121

1 +15V

2 +15V

3 AGND

4 AGND +3.3V

5 -15V DGND 2 2 DGND

6 -15V NC 3 3 NC

7 RE_5V +3.3V 4 4 +3.3V

8 RE_GND

9 +5VA

10 AGND

11 +3V3 10 DGND

12 DGND 9 +3V3

CW101

8 AGND

7 +5VA

6 RE_GND

3 AGND

2 AGND

1 +15V

UNIT

POWER UNIT

8U-110068-2

PANEL1 UNIT

8U-110069-1

CW046 CX046

+3.3V 1 1 +3.3V

PITCH 2 2 PITCH

DGND 4 4 DGND

CW045 CX045

CW043 CX043

+3.3V 1 1 +3.3V

PITCH 2 2 PITCH

CW042 CX042

NC 3 3 NC

DGND 4 4 DGND

CX044

1 1 +3.3V

FEDER UNIT

8U-110070-3

FEDER UNIT

8U-110069-4

FEDER UNIT

8U-110069-5

FEDER UNIT

8U-110069-6

CROSS

FADER

29

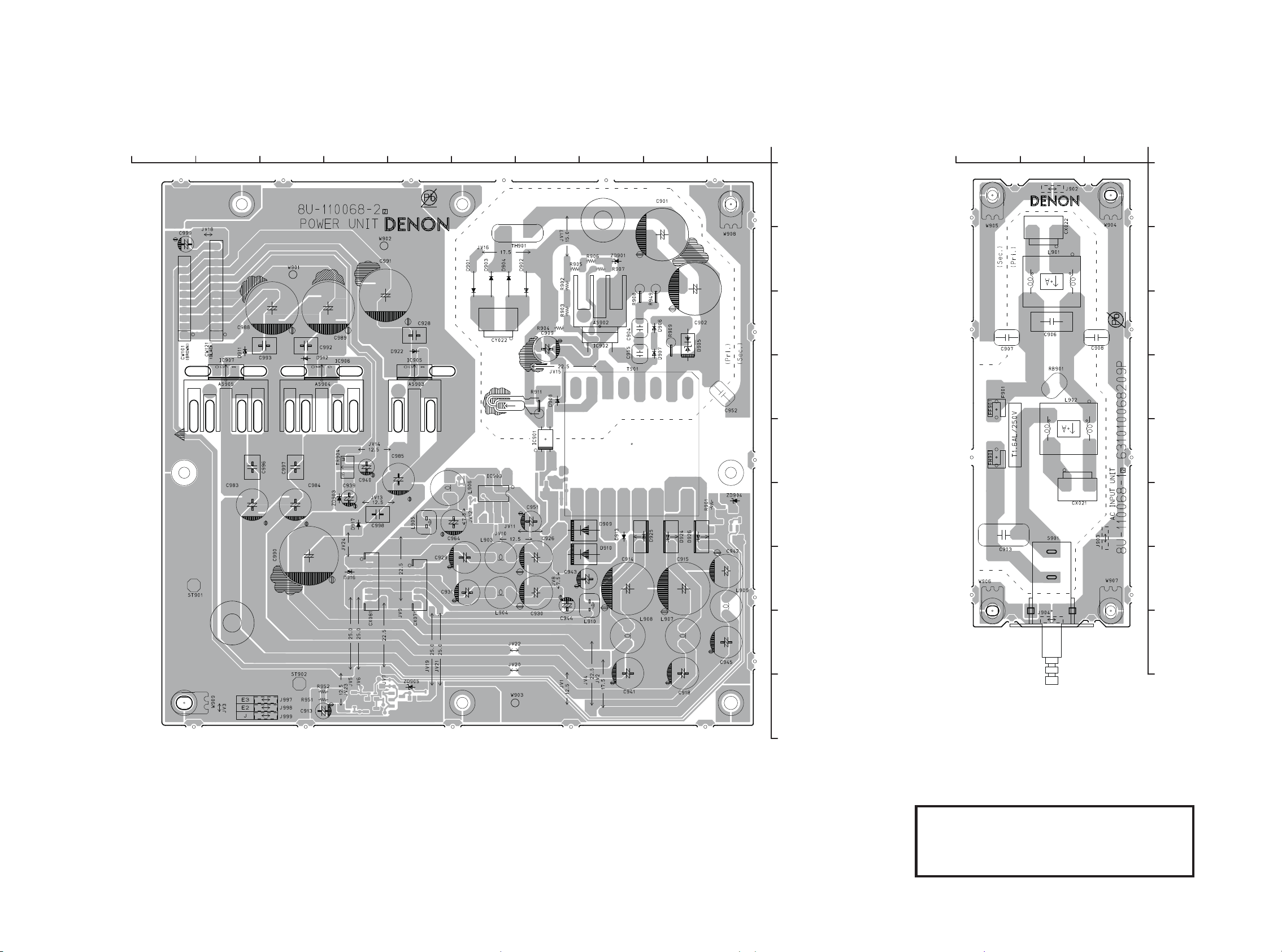

PRINTED WIRING BOARDS

8U-110068-2 (COMPONENT SIDE) 8U-110068-1 (COMPONENT SIDE)

1817161514131211109

321

A

C

F

B

D

A

B

C

D

E

E

F

G

H

I

G

H

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

30

Loading...

Loading...