Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E2C E1K EUT

DN-X1100

33

DJ MIXER

●

For purposes of improvement, specifications and design are subject to change without notice.

●

Please use this service manual with referring to the operating instructions without fail.

●

Some illustrations using in this service manual are slightly different from the actual set.

PROFESSIONAL BUSINESS COMPANY

X0409 V.01 DE/CDM 0901

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerning important safety

parts

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

DN-X1100

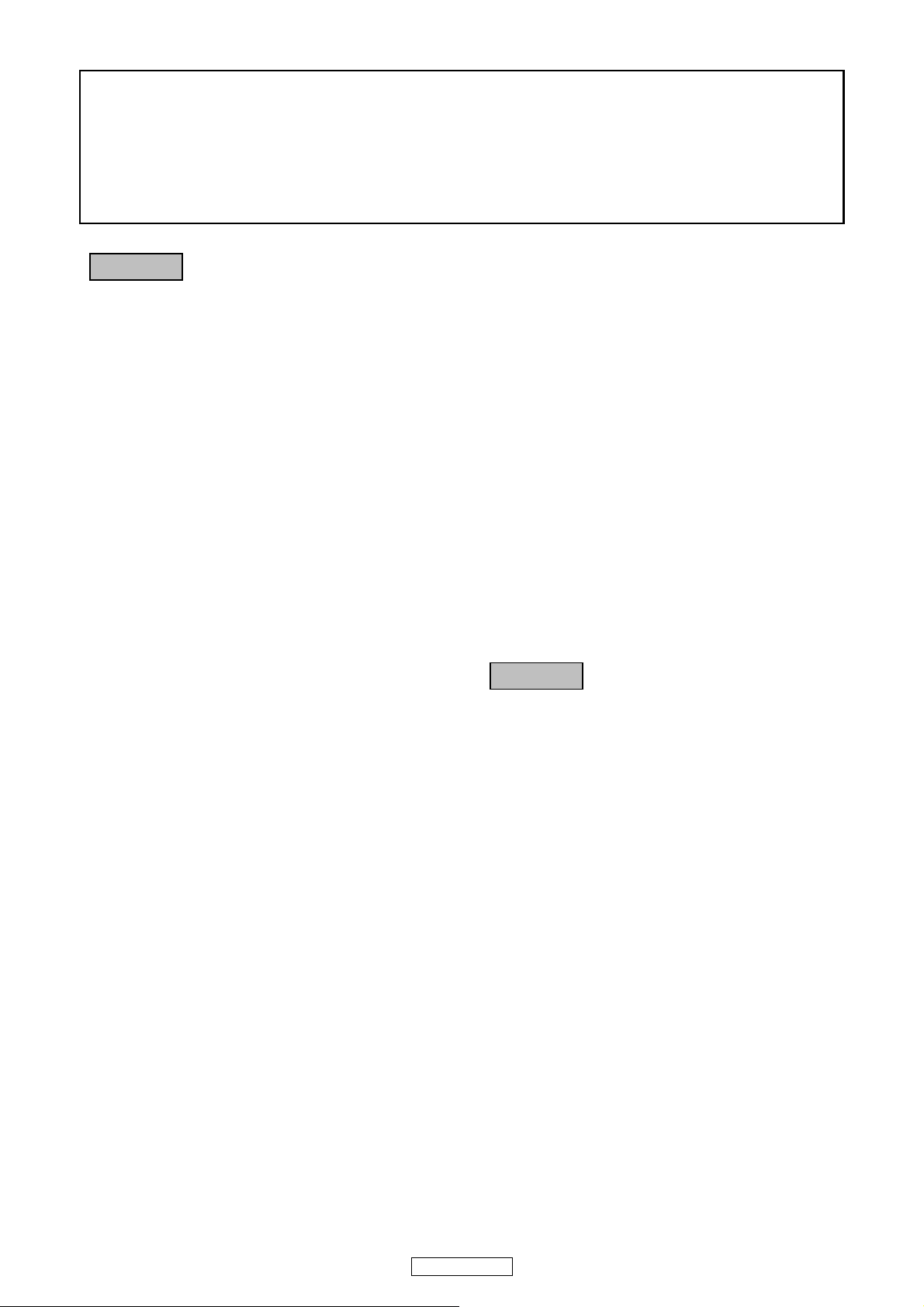

DIMENSION

374mm

357mm

320 mm

114 mm

92.5 mm

3

DN-X1100

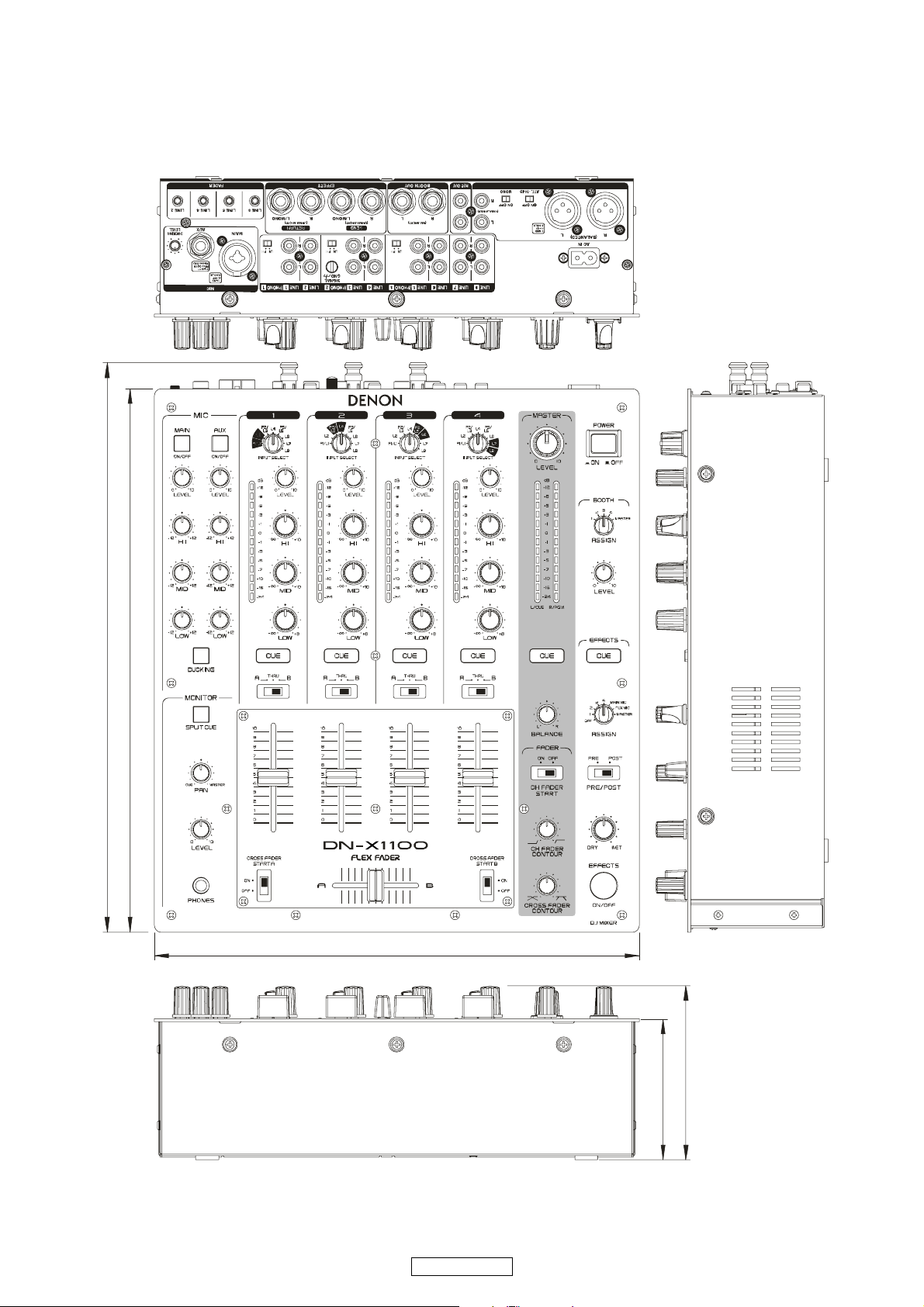

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as they

were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Flat cable (Broken line)

Broken line

AC Line cable twist

It draws it to the

chassis side

Flat cable

DN-X1100

FFC line left the

AC line

4

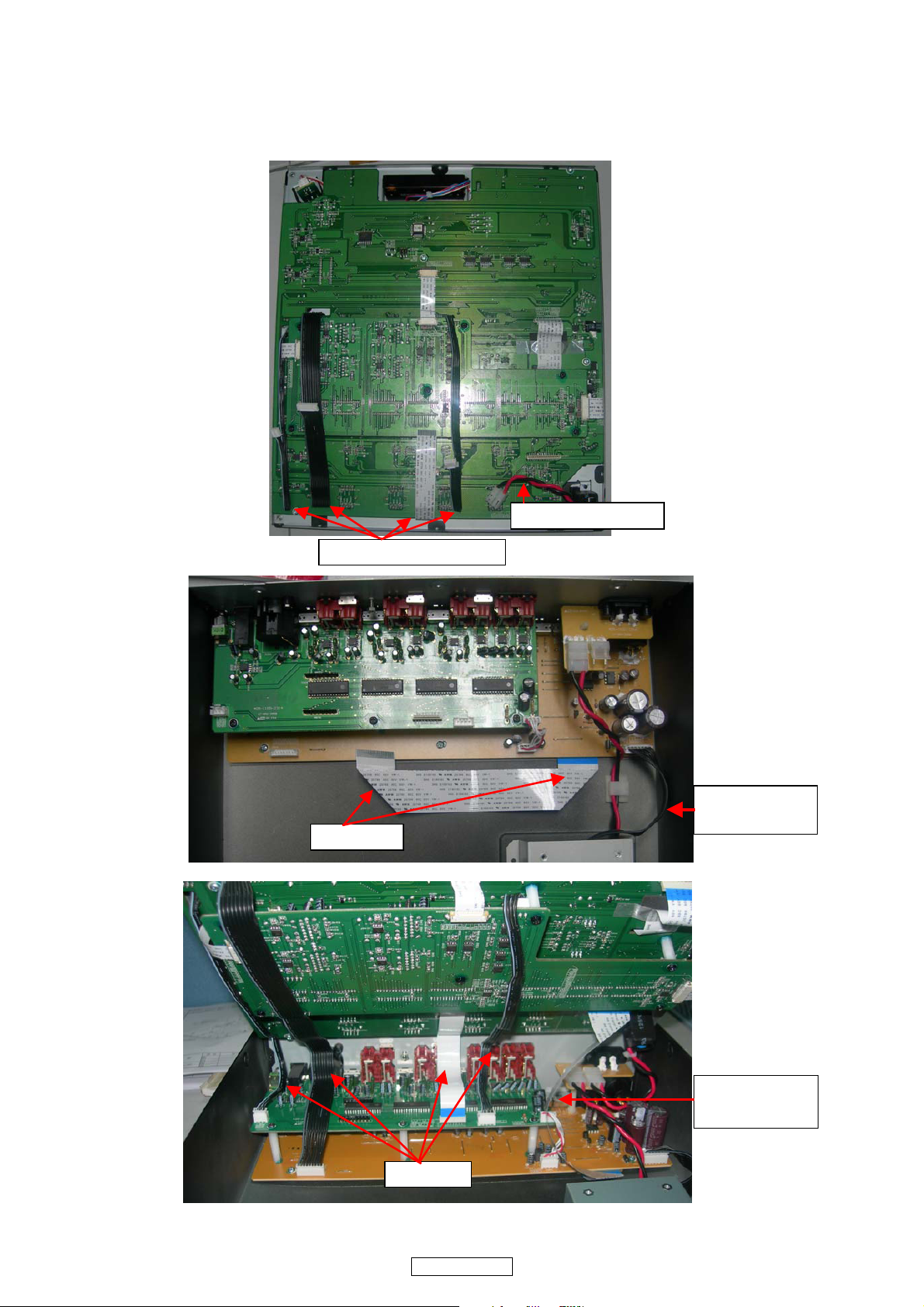

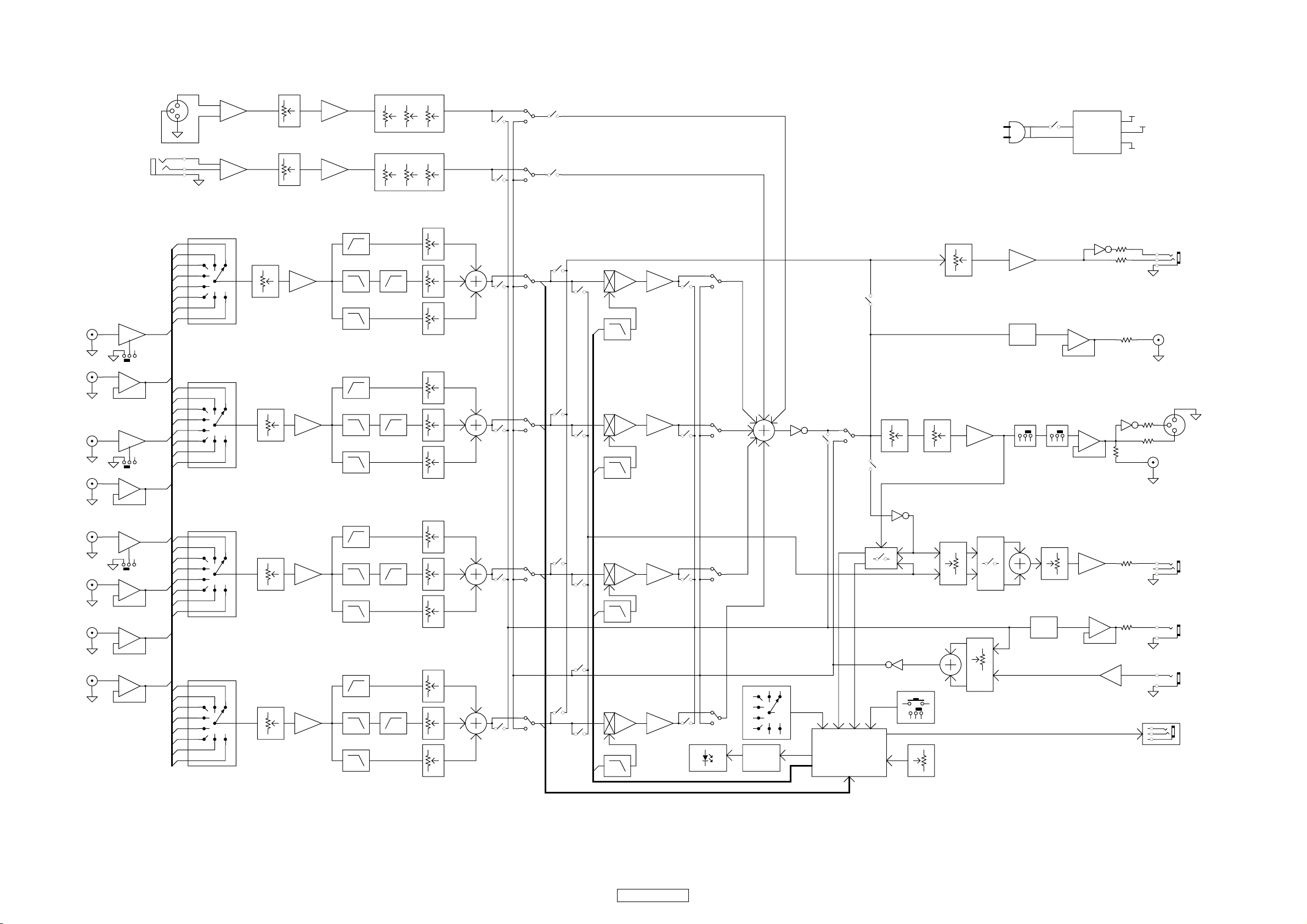

BLOCK DIAGRAM

PH1/LINE1

LINE2

PH2/LINE3

LINE4

AMP

0,36dB

PH LIN E

2C11

BUFFER

AMP

PH LIN E

2

C1

1

BUFFER

MAI N MI C IN

AUX MIC IN

(-14dBV)

(-20dB)

CH1 GAIN

3

1

CH2 GAIN

MAI N MI C L EVEL

31

AUX MIC LEVEL

31

2

31

2

2

2

12dB

AMP

AMP

(-2dBV)

12dB

18.5dB

AMP

AMP

(-2dBV)

(-1.5dBV)

HPF

LPF

LPF

HPF

LPF

LPF

2

H

C

3

G

1

3

4

5

6

3

4

5

6

LC78211

LC78211

AMP

40dB

AMP

40dB

2

1

A

C1

7

8

2

1

A

C1

7

8

MAIN MIC EQ

3123

AUX MIC EQ

3123

HPF

HPF

MID

1

1

HILOW MID

2312

HILOW

3

2

1

HI

31

MID

3

1

LOW

3

1

HI

31

MID

3

1

LOW

31

1 2

1 2

(-2dBV)

1 2

1 2

MAIN MIC FX

1

A

2

AUX MIC FX

1

A

2

1

A

2

CH1 PRE FX

1

A

2

CH2 PRE FX

1 2

C1

C1

1 2

BOOTH 1

C1

BOOTH 2

C1

OFF

OFF

1 2

1 2

AMP

4.85dB

ATT.

-6.37dB

MONO/ST

2C11

POWER SW.

1 2

(+2.85dBV)

(-8.17dBV)

ATT - 10dB

2

C1

1

SWITCHING

POWER SUPPLY

BUFFER

BUFFER

ON

ON

BOOTH LEVEL

31

1 2

CUE1

1 2

CUE2

VCA

VCA

(-11.54dBV)

-3dB

LPF

LPF

9.54dB

AMP

AMP

(-1.8dBV)

1 2

(-1.8dBV)

1 2

1

A

C1

2

CH1 POST FX

1

A

C1

2

CH2 POST FX

INV.

(-1.8dBV)

1 2

MASTER FX

1

A

2

C1

BOOTH

MASTER

1 2

(-1.8dBV)

MASTER BAL.

12

CUE MASTER

MASTER L EVEL

31

31

2

2

-3.4dB

AC IN

2

AMP

(+1.73dBV)(-5.2dBV)

6.93dB

INV.

15V

-15V

300

300

1K

INV.

AV=1.74dB

1K

(+0.9dBV)

5V

(5.07dBm)

(-9dBV)

300

300

3

2

1

(4.87dBm)

3

L

BOOTH OUT

R

G

REC OUT

1

G

C

H

MASTER BAL . OUT

2

MASTER OUT

(-2dBV)

2

2

2

2

2

2

2

(-1.5dBV)

/PH3LINE5

LINE6

LINE7

LINE8

AMP

PH LIN E

2

C11

BUFFER

BUFFER

BUFFER

LC78211

3

4

5

6

LC78211

3

4

5

6

INV. AV=3.5dB.

HPF

2

1

A

CH3 GAIN

C1

7

8

2

1

A

C1

8

7

3

1

CH4 GAIN

31

AMP

2

AMP

2

LPF

LPF

HPF

LPF

LPF

HPF

HPF

31

3

1

3

1

3

1

31

3

1

HI

MID

LOW

HI

MID

LOW

2

BOOTH 3

1 2

1

2

2

2

2

2

1 2

1 2

A

2

CH3 PRE FX

1

A

2

CH4 PRE FX

C1

C1

BOOTH 4

1 2

1 2

CUE3

FX CU E

1 2

1 2

CUE4

(+1.5dBV)

VCA

VCA

LPF

SPLIT CUE

AMP

LPF

AMP

I EVEL METERS

(-1.8dBV)

1 2

(-1.8dBV)

1 2

CH4 POST F X

NDCATORS & L

1

A

C1

2

CH3 POST F X

1

A

C1

2

SWITCHES

2

3

4

5

6

7

LED DRIVER

1

A

C1

8

PWM

PFL

L/CUE

1 2

INV.

KEYS & SWITHES

R/PGM

2C11

CPU

(+1.7dBV)

MASTER

CUE

(+1.5dBV)

31

2

CUE PAN

2

FAD ERS & VRS

SPLIT CUE

31

1 2

FX PAN

2

(-2dBV)

31

CUE LEVEL

2

ATT.

-10.39dB

31

(-12.39dBV)

AMP

6dB

(-2dBV)

BUFFER

(+7dBV)

AMP

33

3

(+1dBV)

L

2

1

1K

13.22dBV)

(-

1

3

1

3

2

1

L

R

G

3

R

G

L

G

L

G

PHONES OUT

SEND

RETURN

PLAY CONTROL

5

DN-X1100

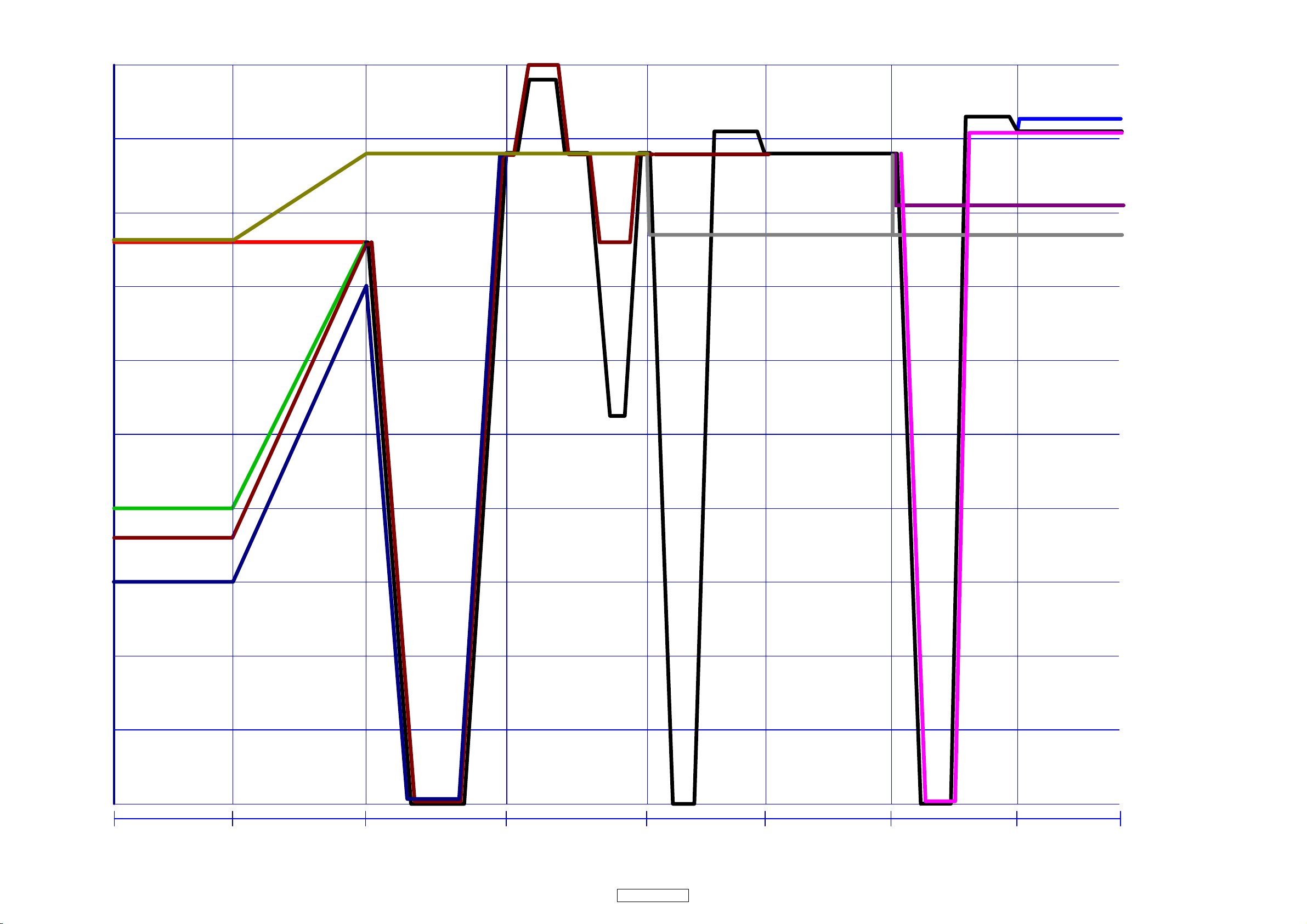

LEVEL DIAGRAM

10dBV

0dBV

BALANCED OUT

UNBALANCED OUT

PHONES OUT

-10dBV

-20dBV

-30dBV

-40dBV

-50dBV

RETURN INPUT

LINE INPUT

PHONO INPUT

REC OUT

SEND OUT

-60dBV

-70dBV

-80dBV

-90dBV

MAIN MIC INPUT

AUX MIC INPUT

INPUT PRE. AMP

MAIN MIC GAIN

AUX MIC GAIN

INPUT GAIN

MIC EQ

CH. EQ

FADER

MIX

CUE LEVEL

MASTER LEVEL

OUTPUT

6

DN-X1100

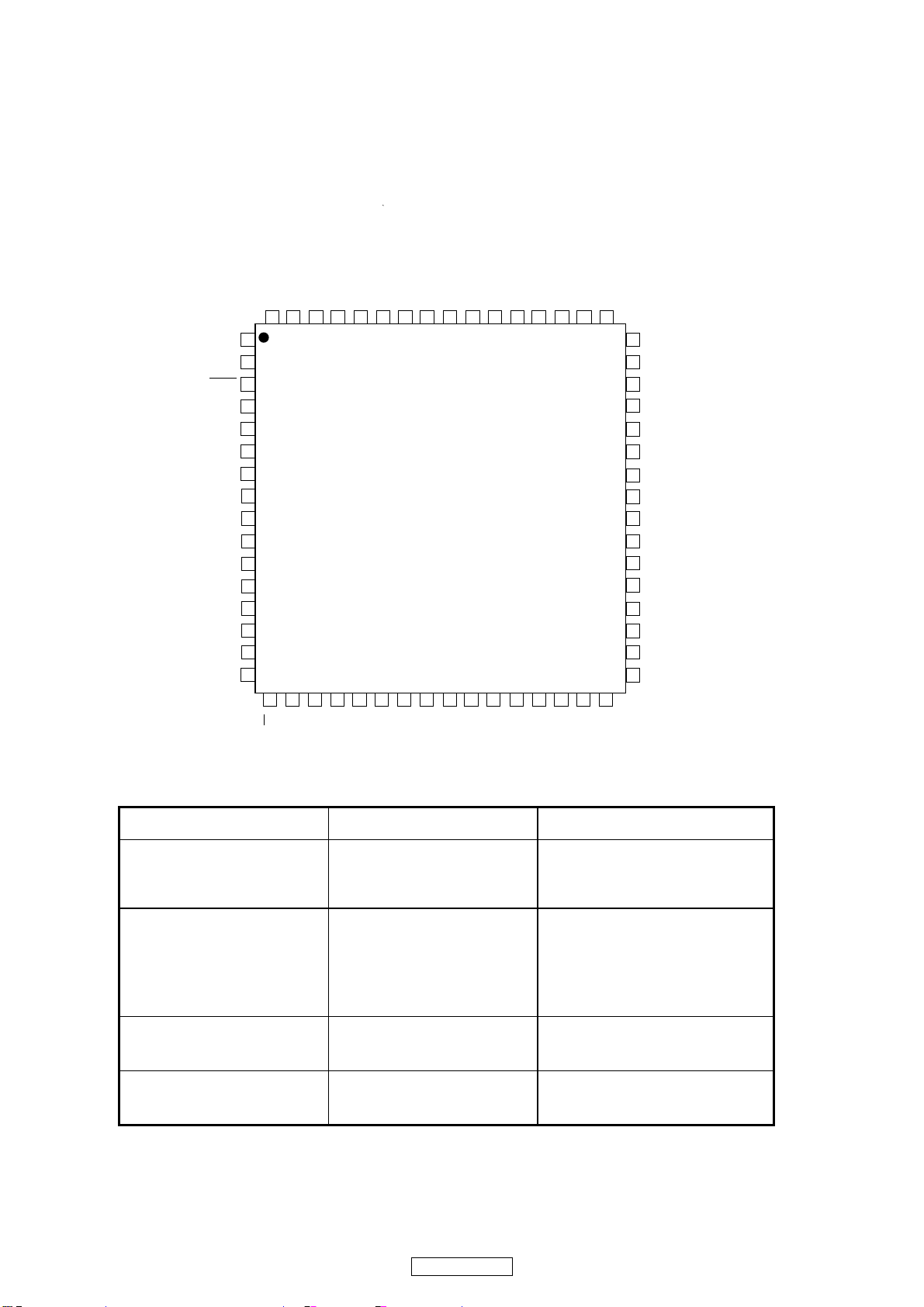

SEMICONDUCTORS

(

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

MC9S08AW32CPUE (IC801)

PTC4

IRQ

RESET

PTF0/TPM1CH2

PTF1/TPM1CH3

PTF2/TPM1CH4

PTF3/TPM1CH5

PTF4/TPM2CH0

PTC6

PTF7

PTF5/TPM2CH1

PTF6

PTE0/TxD1

PTE1/RxD1

PTE2/TPM1CH0

PTE3/TPM1CH1

PTC5/RxD2

64

63 62 61

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

17

PTE4/SS1

PTC3/TxD2

PTC2/MCLK

19

PTE6/MOSI1

PTE5/MISO1

PTC1/SDA1

20 21 22

PTE7/SPSCK1

PTC0/SCL1

59

60

SS

V

SS

V

58

64-Pin LQFP

23

DD

V

BKGD/MS

PTG6/EXTAL

PTG5/XTAL

56

57

64-Pin QFP

PTG2/KBI1P2

PTG1/KBI1P1

PTG0/KBI1P0

REFH

REFL

V

V

27

26

PTA024PTA125PTA2

PTD5/AD1P13

PTD6/TPM1CLK/AD1P14

PTD7/KBI1P7/AD1P15

28 29 30 31

PTA4

PTA3

PTD4/TPM2CLK/AD1P12

PTG4/KBI1P4

49

505152535455

PTA5

47

46

45

44

43

42

41

40

39

38

37

36

35

34

32

PTA6

PTG3/KBI1P3

48

PTD3/KBI1P6/AD1P11

PTD2/KBI1P5/AD1P10

V

SSAD

V

DDAD

PTD1/AD1P9

PTD0/AD1P8

PTB7/AD1P7

PTB6/AD1P6

PTB5/AD1P5

PTB4/AD1P4

PTB3/AD1P3

PTB2/AD1P2

PTB1/AD1P1

PTB0/AD1P0

PTA7

33

SYMPTOM POSSIBLE CAUSE CORRECTION ACTION

The power fails to switch on

when the POWER switch is set to

on

No output

Poor power plug connection at the

AC outlet

1) Improper outlet cable

connections

2) Improper amplifier operation

3) Improper setup of input cable

Connection and switch

Insert the power plug firmly into the

AC outlet

1) Connect the output cable correctly

2) Check amplifier setup

3) Correct the position of input cable

and switch correctly

Hum Loose cable connections Firmly connect all audio plugs

Line / Phono switch reversed Poor power plug connection Connection the input cable correctly

7

DN-X1100

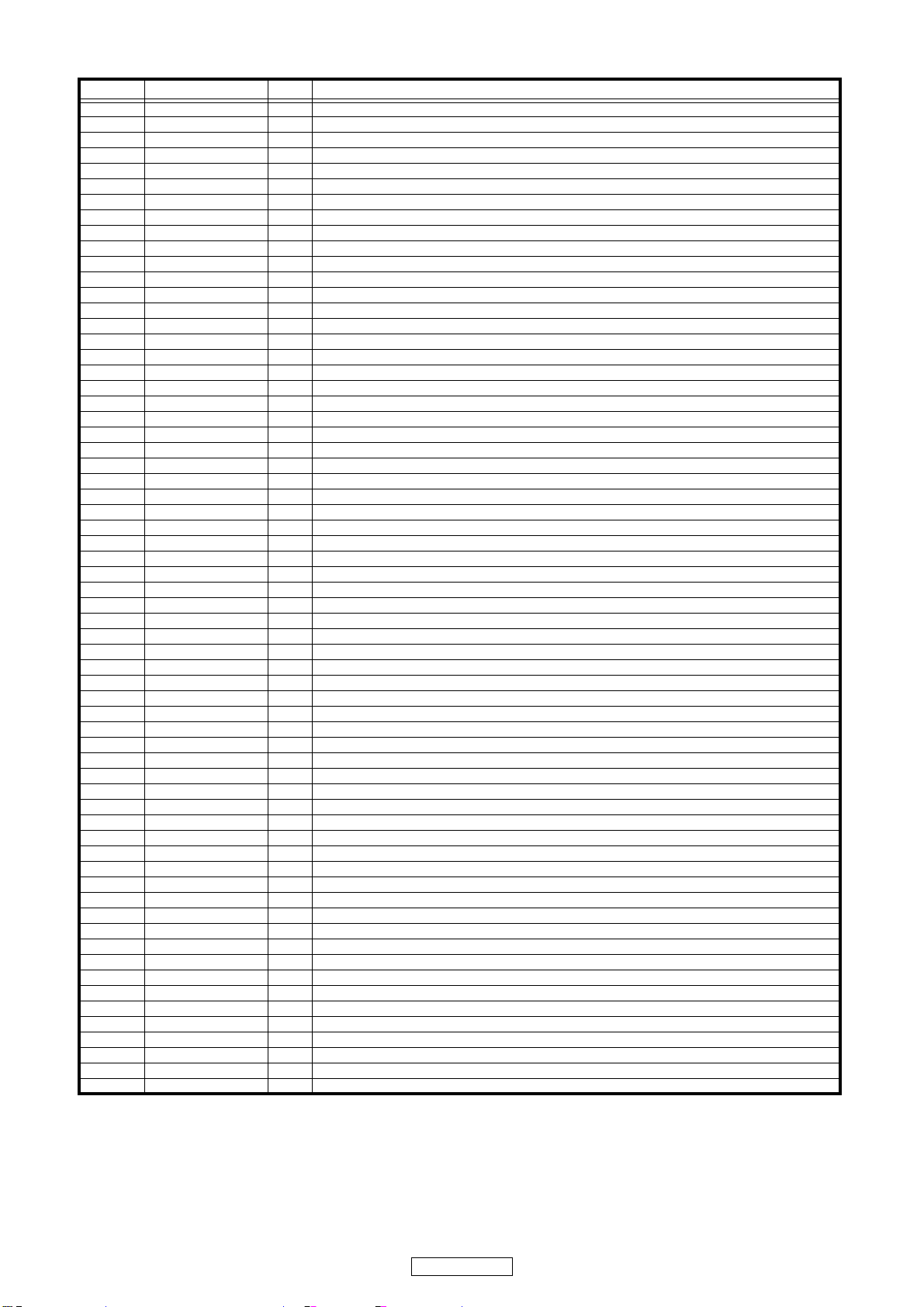

MC9S08AW32CPUE Terminal Function

Pin No. Pin Name I/O I/O Function

1 PC3B' O LINE6 FADER CONTROL OUT

2IRQ

3 RESET

4 PWM1' O CH 1 VCA CONTROL

5 PWM2' O CH 2 VCA CONTROL

6 PWM3' O CH 3 VCA CONTROL

7 PWM4' O CH 4 VCA CONTROL

8 PC4A' O LINE8 FADER CONTROL OUT

9 PC4B' O LINE8 FADER CONTROL OUT

10 JDET I EFFECT SEND/RETURN IN

11 CHFS I CH FADER START SW IN

12 PRE/POST I PRE/POST SW INPUT

13 CFSA/TX I CROSS FADER START A SW IN

14 CFSB/RX I CROSS FADER START B SW IN

15 KFXON I EFFECTS ON IN

16 - 17 CE1 O LC78211,LC78212,LC78213 CONTROL PIN

18 CE2 O LC78211,LC78212,LC78213 CONTROL PIN

19 DI O LC78211,LC78212,LC78213 CONTROL PIN

20 CL O LC78211,LC78212,LC78213 CONTROL PIN

21 VSS

22 VDD

23 DS O Level Meter LED CONTROL OUT

24 STCP O Level Meter LED CONTROL OUT

25 SHCP O Level Meter LED CONTROL OUT

26 1A I CF ASSIGN1 IN

27 1B I CF ASSIGN1 IN

28 2A I CF ASSIGN2 IN

29 2B I CF ASSIGN2 IN

30 3A I CF ASSIGN3 IN

31 3B I CF ASSIGN3 IN

32 4A I CF ASSIGN4 IN

33 4B I CF ASSIGN4 IN

34 LM1 I CH1 Level Meter A/D IN

35 LM2 I CH2 Level Meter A/D IN

36 LM3 I CH3 Level Meter A/D IN

37 LM4 I CH4 Level Meter A/D IN

38 LML I LCH Level Meter A/D IN

39 LMR I RCH Level Meter A/D IN

40 KEY2 I CUE KEY A/D IN

41 CF I CROSS FADER VR A/D IN

42 KEY1 I CUE1 DUCK MIC KEY A/D IN

43 DIMMER I DUCK LEVEL A/D IN

44 VDDAD

45 VSSAD

46 CHF1 I CH1 FADER VR A/D IN

47 CHF2 I CH2 FADER VR A/D IN

48 CDOUT' O IC DATA OUT

49 CCLK' O IC CLK

50 CHF3 I CH3 FADER VR A/D IN

51 CHF4 I CH4 FADER VR A/D IN

52 CDIN' I IC DATA IN

53 /CSAD I IC DATA IN

54 VREFH AD5V

55 VREFL ADGND

56 BKGD

57 XTAL

58 XTAL

59 VSS

60 PC1A' O LINE2 FADER CONTROL OUTPUT

61 PC1B' O LINE2 FADER CONTROL OUTPUT

62 PC2A' O LINE4 FADER CONTROL OUTPUT

63 PC2B' O LINE4 FADER CONTROL OUTPUT

64 PC3A' O LINE6 FADER CONTROL OUTPUT

8

DN-X1100

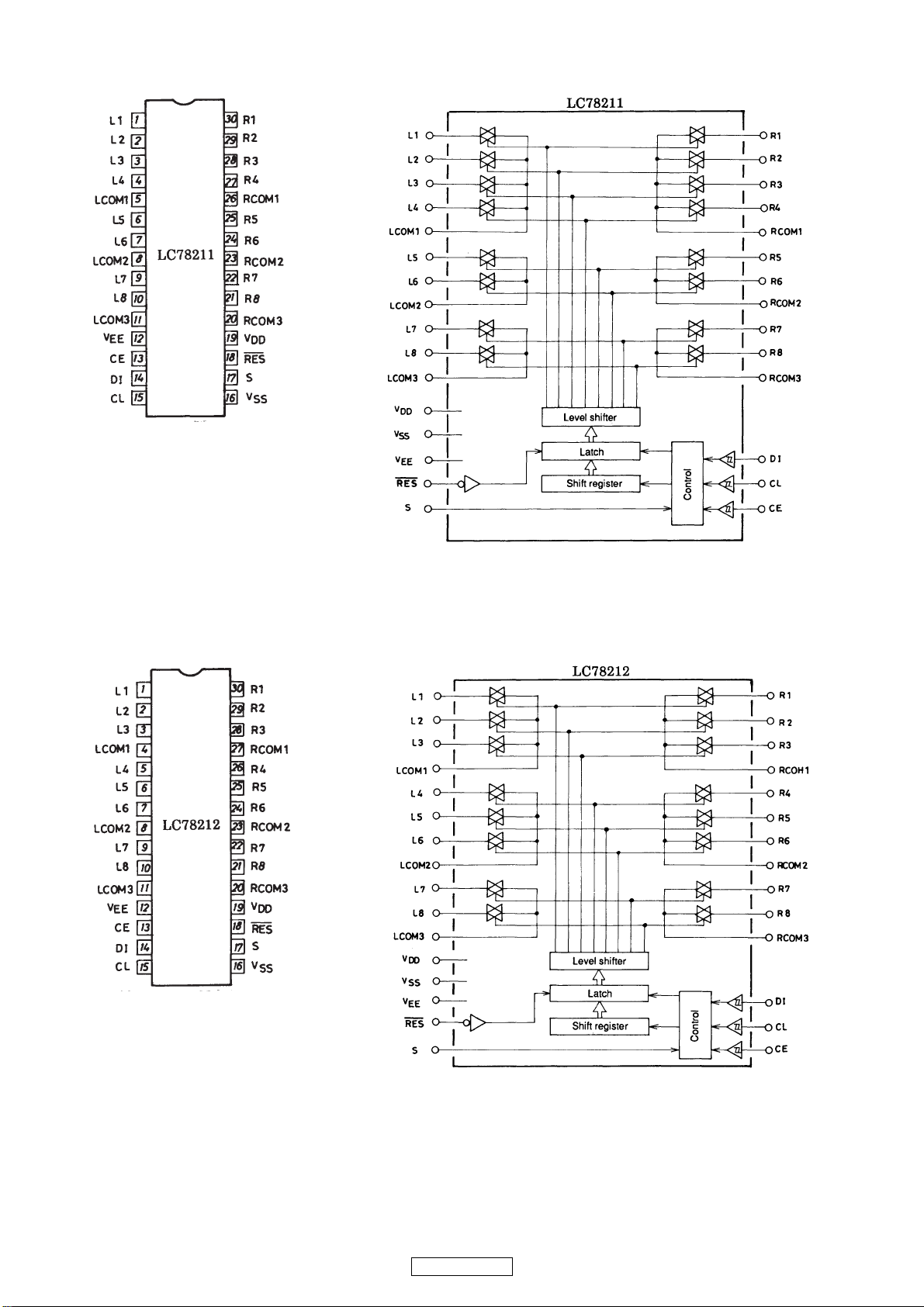

LC78211-E (IC116,216,316,416)

LC78212-E (IC610,611,612,615)

9

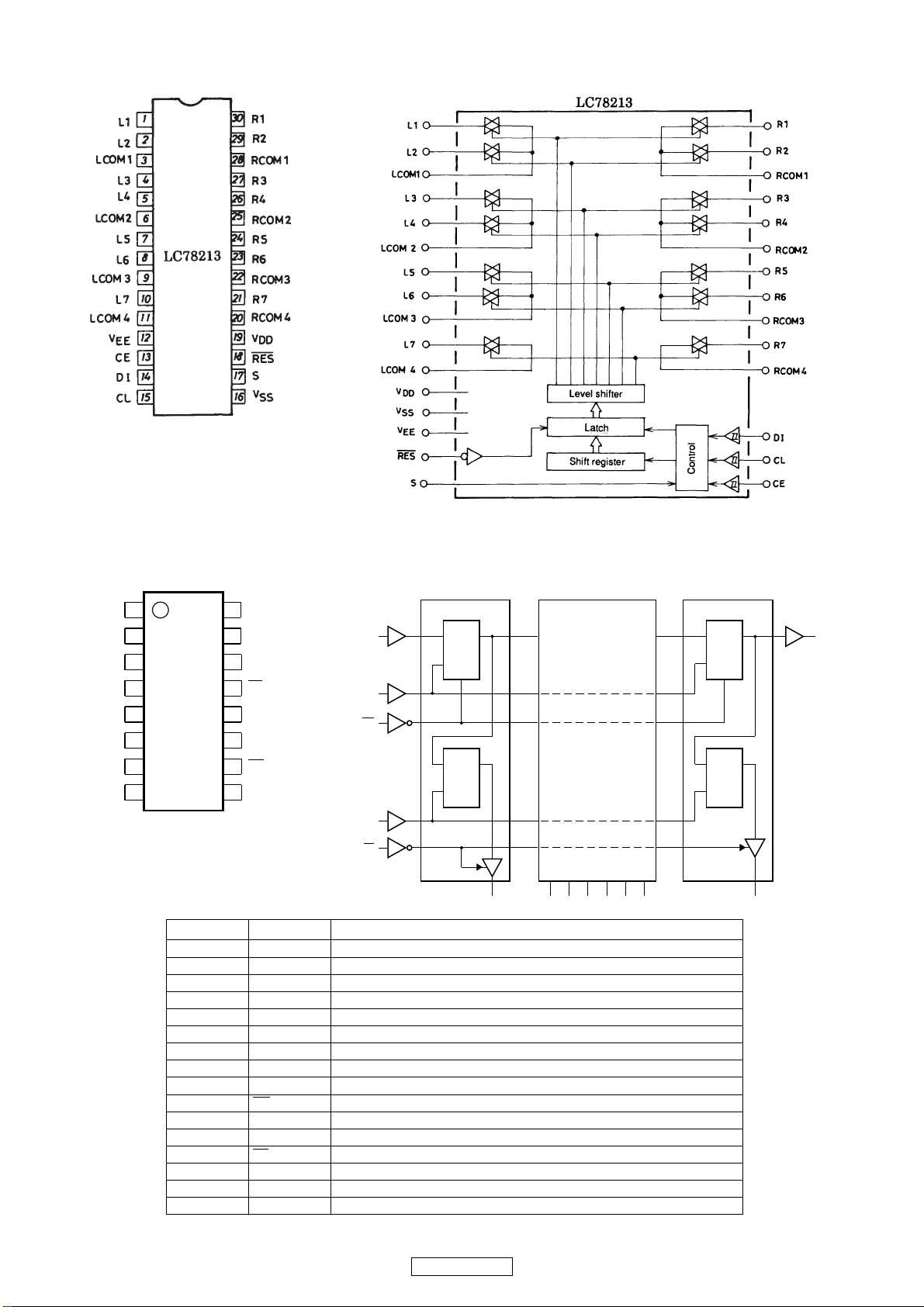

DN-X1100

LC78213-E (IC613,614,166,617)

f

74HC595D (IC804,805,806,807)

Q1

Q2

Q3

Q4

Q5

Q6

Q7

GND

1

2

3

4

595

5

6

7

8

16

15

14

13

12

11

10

9

V

CC

Q0

DS

OE

ST_CP

SH_CP

MR

Q7'

PIN SYMBOL DESCRIPTION

1 Q1 parallel data output

2 Q2 parallel data output

3 Q3 parallel data output

4 Q4 parallel data output

5 Q5 parallel data output

6 Q6 parallel data output

7 Q7 parallel data output

8 GND ground (0 V)

9 Q7’ serial data output

10

MR master reset (active LOW)

11 SH_CP shift register clock input

12 ST_CP storage register clock input

13

OE output enable (active LOW)

14 DS serial data input

15 Q0 parallel data output

16 V

CC

ull pagewidth

DS

SH_CP

MR

ST_CP

OE

positive supply voltage

STAGE 0 STAGES 1 to 6 STAGE 7

DCPQ

FF0

R

DCPQ

LATCH

DQ

Q0

Q1 Q2 Q3 Q4 Q5 Q6 Q7

DCPQ

FF7

R

DCPQ

LATCH

Q7'

MLA010

10

DN-X1100

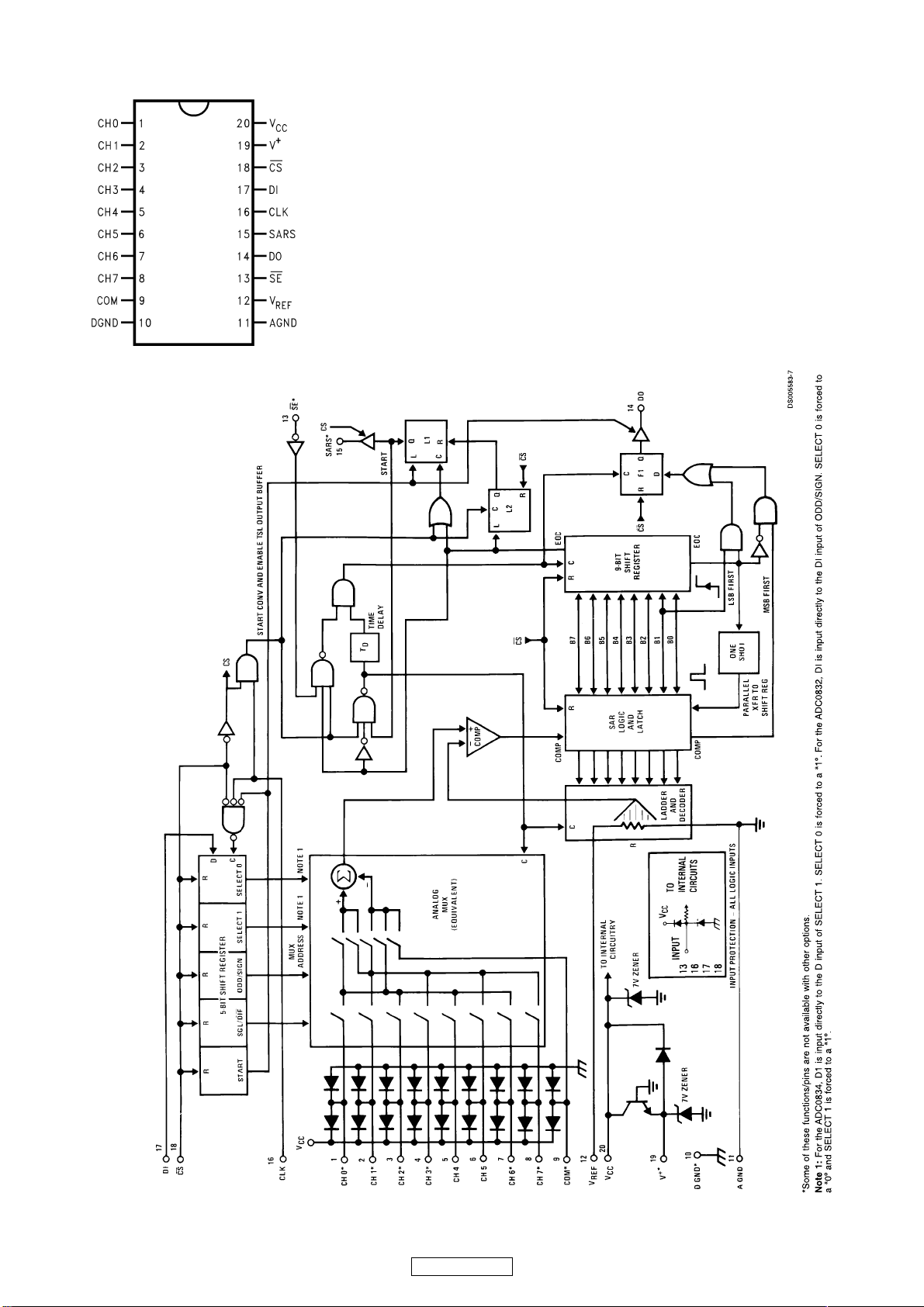

ADC0838CCWM (IC802)

BLOCK DIAGRAM

11

DN-X1100

--MEMO--

12

DN-X1100

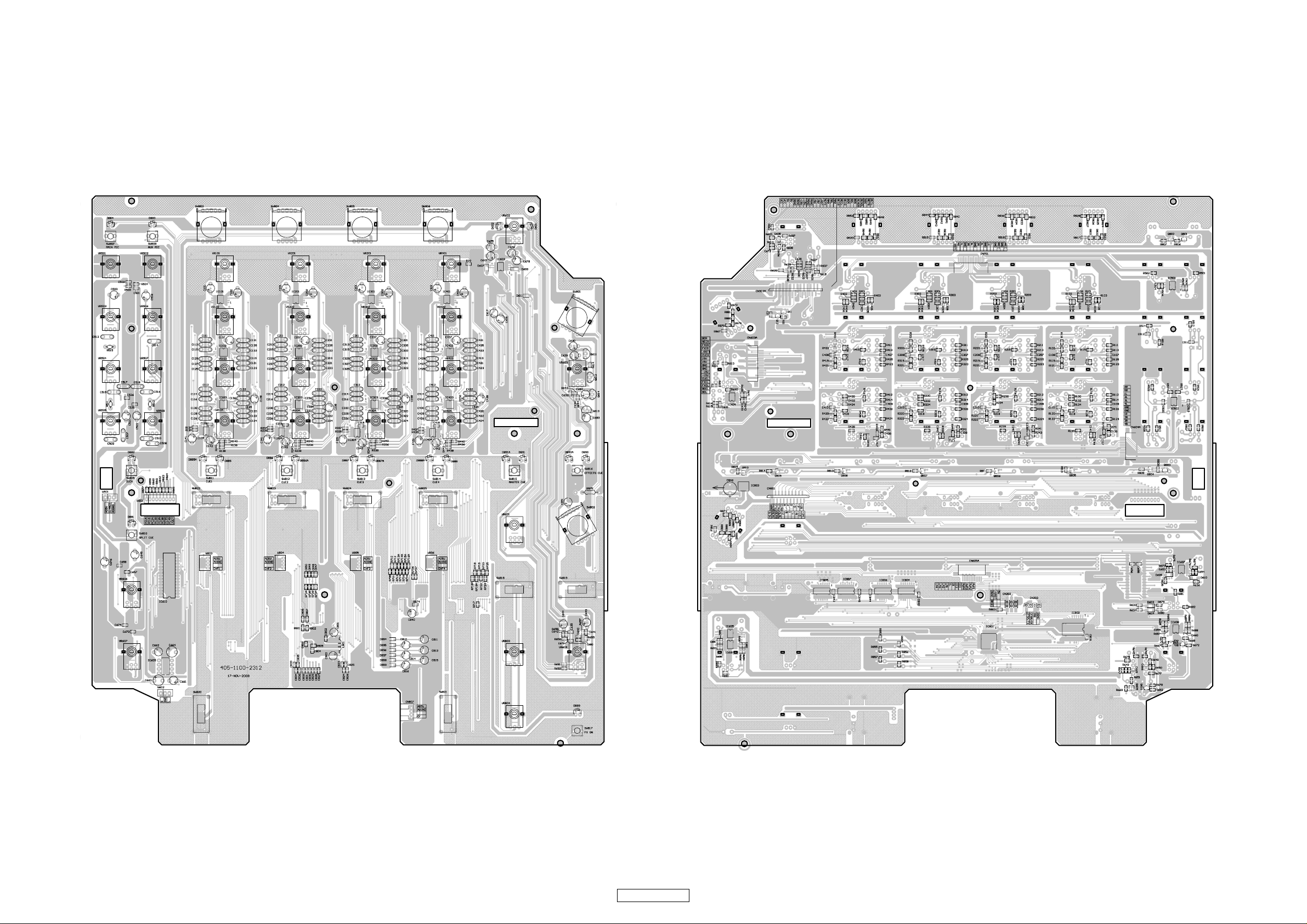

PRINTED WIRING BOARDS

MIXER P.W.B. UNIT

COMPONENT SIDE

FOIL SIDE

13

DN-X1100

TRANSFER P.W.B. UNIT

COMPONENT SIDE

14

DN-X1100

FOIL SIDE

IO P.W.B. UNIT

COMPONENT SIDE

15

DN-X1100

FOIL SIDE

POWER/PHONE P.W.B. UNIT

COMPONENT SIDE

16

DN-X1100

FOIL SIDE

LEVEL METER P.W.B. UNIT

COMPONENT SIDE

17

DN-X1100

FOIL SIDE

CH FADER P.W.B. UNIT AC P.W.B. UNIT

COMPONENT SIDE

FOIL SIDECOMPONENT SIDE

18

DN-X1100

NOTE FOR PARTS LIST

1.

Parts for which "nsp" is indicated on this table cannot be supplied.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

2.

Ordering part without stating its part number can not be supplied.

3.

Part indicated with the mark "★" is not illustrated in the exploded view.

4.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

5.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

WARNING:

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

● Resistors

Ex.: RN

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

* Resistance

2

14K

Shape

and performance

Indicates number of zeros after effective number.

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm18

182

Resistance

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

FR

Others

: Units: ohm

● Capacitors

Ex.: CE

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

* Capacity (electrolyte only)

2

Indicates number of zeros after effective number.

・ Units:μF.

2-digit effective number.

1.2ohm1R 2

1-digit effective number.

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

2200μF22

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

3R2

CapacityMAllowable

error

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Z:±80%

: - 20%

P : +100%

C:±0.25pF

D:±0.5pF

= : Others

Others

BP

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

2.2μF2R

1-digit effective number.

2-digit effective number, decimal point indicated by R

* Capacity (except electrolyte)

2

・ Units:pF

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

2200pF=0.0022μF22

Indicates number of zeros after efective number.

(More than 2)

2-digit effective number.

1

・ Units:pF

Indicates number of zeros after effective numver.

(0 or 1)

2-digit effective number.

19

DN-X1100

220pF22

PARTS LIST OF P.W.B. UNIT

* Parts for which "nsp" is indicated on this table cannot be supplied.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3: U.S.A. & Canada model E2: Europe model

MIXER & TRANSFER P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC101 00D9587059407 IC(BA15218F/BA15218FE2)

IC102,103 00D9587035900 IC(NJM-2060V-TE1)

IC104 00D9587059407 IC(BA15218F/BA15218FE2)

IC105 00D9587036103 IC(M51132L)

IC107 00D9587059407 IC(BA15218F/BA15218FE2)

IC11 00D9410022103 IC(7812)

IC110 00D9587059106 IC(NJM-4558M)

IC112 00D9587059106 IC(NJM-4558M)

IC201 00D9587059407 IC(BA15218F/BA15218FE2)

IC202,203 00D9587035900 IC(NJM-2060V-TE1)

IC204 00D9587059407 IC(BA15218F/BA15218FE2)

IC205 00D9587059601 IC(M51132L)

IC207 00D9587059407 IC(BA15218F/BA15218FE2)

IC212 00D9587059106 IC(NJM-4558M)

IC301 00D9587059407 IC(BA15218F/BA15218FE2)

IC302,303 00D9587035900 IC(NJM-2060V-TE1)

IC304 00D9587059407 IC(BA15218F/BA15218FE2)

IC305 00D9587059601 IC(M51132L)

IC307 00D9587059407 IC(BA15218F/BA15218FE2)

IC310 00D9587059106 IC(NJM-4558M)

IC312 00D9587059106 IC(NJM-4558M)

IC401 00D9587059407 IC(BA15218F/BA15218FE2)

IC402,403 00D9587035900 IC(NJM-2060V-TE1)

IC404 00D9587059407 IC(BA15218F/BA15218FE2)

IC405 00D9587059601 IC(M51132L)

IC407 00D9587059407 IC(BA15218F/BA15218FE2)

IC412 00D9587059106 IC(NJM-4558M)

IC501 00D9587058903 IC(NJM-2068M)

IC502 00D9587059407 IC(BA15218F/BA15218FE2)

IC601-608 00D9587059407 IC(BA15218F/BA15218FE2)

IC609 00D9580073804 INTEGRATED CIRCUIT(NJM-4556AD)

IC610-612 00D9587058806 IC(LC78212)

IC613,614 00D9587058408 IC(LC78213)

IC615 00D9587058806 IC(LC78212)

IC616,617 00D9587058408 IC(LC78213)

IC618 00D9587059407 IC(BA15218F/BA15218FE2)

IC801 941243001180S CONTROL IC ASS'Y

IC(MC9S08AW32CPUE)

IC802 00D9587058000 IC(ADC0838CCWM)

IC803 00D9587058204 IC(BA033FP)

IC804-807 00D9587058709 IC(74HC595D/74AHC595D/74AHC595DR)

417-QMX2-167

417-PRO1000-502

417-QMX2-167

417-SA12-487

417-QMX2-167

417-BJ1900L-231

417-PS2-577

417-PS2-577

417-QMX2-167

417-PRO1000-502

417-QMX2-167

417-SA12-487

417-QMX2-167

417-PS2-577

417-QMX2-167

417-PRO1000-502

417-QMX2-167

417-SA12-487

417-QMX2-167

417-PS2-577

417-PS2-577

417-QMX2-167

417-PRO1000-502

417-QMX2-167

417-SA12-487

417-QMX2-167

417-PS2-577

417-M5-582

417-QMX2-167

417-QMX2-167

417-3113-018

417-HMA2200-5030

417-DRM120-510

417-HMA2200-5030

417-DRM120-510

417-QMX2-167

704-X1100-8186 *

417-900-747

417-CTB200-500

417-HDJ9800-643

Q11 00D9587057506 TRANSISTOR(DTA124EKA)

Q12 00D9587057700 TRANSISTOR(DTC114EKAT146)

Q605-610 00D9410046406 TRANSISTOR(2SC4695-TB-E)

Q611,612 00D9587034707 TRANSISTOR(2SC2878-B)

Q613 941219001170S TRANSISTOR(2SB892S(T))

Q614 90M-HT400500R TRANSISTOR(2SD1207/2SD1207S(T))

20

DN-X1100

416-CTB200-178

416-HDJ2460-234

416-DAIA-273

416-AMC110A-5017

416-1360S-017A

416-1360S-016

*

Ref. No. Part No. Part Name Remarks Q'ty New

Q801-810 00D9587057700 TRANSISTOR(DTC114EKAT146)

416-HDJ2460-234

D101,102 00D9587056701 DIODE(RB160M-30)

D201,202 00D9587056701 DIODE(RB160M-30)

D301,302 00D9587056701 DIODE(RB160M-30)

D401,402 00D9587056701 DIODE(RB160M-30)

D601,602 00D9587051706 LED(RED,LTL-16KE)

D603,604 00D9587056701 DIODE(RB160M-30)

D607-610 00D9587056701 DIODE(RB160M-30)

D611 00D9410046901 SWITCHING DIODE(1SS355)

D881 00D9587052006 LED ( LTL1CHJSDNN,YELLOW )

D882 941263001070S LED(LTL1CHKGKNN,GREEN)

D883,884 941263001060S LED(LTL1CHJEDNN,RED)

D885-888 00D9587052006 LED ( LTL1CHJSDNN,YELLOW )

D885A-888A 00D9587052006 LED ( LTL1CHJSDNN,YELLOW )

D889-891 00D9587052006 LED ( LTL1CHJSDNN,YELLOW )

D890A,891A 00D9587052006 LED ( LTL1CHJSDNN,YELLOW )

D894-899 00D9410046901 SWITCHING DIODE(1SS355)

RESISTORS GROUP

R13 nsp CARBON FILM RESISTOR(1.5 OHM)

RB601,602 nsp

THICK FILM RESISTOR NETWORKS(47K OHM,J)

414-900-208

414-900-208

414-900-208

414-900-208

410-CD6000-122

414-900-208

414-900-208

414-CD1000-075

410-HDJ2000-162

410-TT2A3SL-250

410-DJ5000-253

410-HDJ2000-162

410-HDJ2000-162

410-HDJ2000-162

410-HDJ2000-162

414-CD1000-075

412-U101-1179

412-X1100-1338

*

*

CAPACITORS GROUP

C21 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C25 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C26 941134001250S ELEC. CAPACITOR(220uF/25V)

C101,102 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C103,104 nsp CHIP CAPACITOR(1000pF/50V,K)

C105,106 nsp CHIP CAPACITOR(15pF/50V,J)

C107-110 nsp CHIP CAPACITOR(1000pF/50V,K)

C111,112 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C113-116 00D9587053801 POLYESTER CAPACITOR(0.0018uF/100V,J)

C117,118 nsp CHIP CAPACITOR(1000pF/50V,K)

C119,120 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C121,122 00D9587054703 POLYESTER CAPACITOR(820pF/50V,J)

C123,124 nsp POLYESTER CAPACITOR(0.0047uF/100V,J)

C125,126 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C127-130 00D9587054402 POLYESTER CAPACITOR(0.022uF/100V,J)

C131,132 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C133,134 00D9587054305 POLYESTER CAPACITOR(0.01uF/100V,J)

C135,136 00D9587054606 POLYESTER CAPACITOR(0.056uF/100V,J)

C137,138 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C139,140 nsp CHIP CAPACITOR(33pF/50V,J)

C141,142 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C143,144 nsp CHIP CAPACITOR(1000pF/50V,K)

C145,146 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C147 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C149 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C150 nsp CHIP CAPACITOR(1000pF/50V,K)

C151 nsp CHIP CAPACITOR(0.33uF/16V,Z)

C152 nsp CHIP CAPACITOR(0.22uF/50V,J)

C153,154 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

413-DCM280-773

413-DCM280-773

413-X1100-1123

413-SPPW3-235

413-DCM280-768

413-007USB-781

413-DCM280-768

413-900-937

413-900-932

413-DCM280-768

413-900-937

413-EFX2-886

413-HT8015-159

413-SPPW3-083

413-900-939

413-SPPW3-083

413-900-938

413-900-941

413-SPPW3-235

413-900-926

413-SPPW3-236

413-DCM280-768

413-SPPW3-234

413-SPPW3-236

413-DCM280-773

413-DCM280-768

413-007USB-782

413-900-942

413-SPPW3-234

*

21

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

C155,156 nsp CHIP CAPACITOR(1000pF/50V,K)

C157,158 nsp CHIP CAPACITOR(33pF/50V,J)

C159,160 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C177,178 nsp CHIP CAPACITOR(1000pF/50V,K)

C201,202 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C203,204 nsp CHIP CAPACITOR(1000pF/50V,K)

C205,206 nsp CHIP CAPACITOR(15pF/50V,J)

C207-210 nsp CHIP CAPACITOR(1000pF/50V,K)

C211,212 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C213 00D9587053801 POLYESTER CAPACITOR(0.0018uF/100V,J)

C214-216 00D9587053801 POLYESTER CAPACITOR(0.0018uF/100V,J)

C217,218 nsp CHIP CAPACITOR(1000pF/50V,K)

C219,220 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C221,222 00D9587054703 POLYESTER CAPACITOR(820pF/50V,J)

C223,224 nsp POLYESTER CAPACITOR(0.0047uF/100V,J)

C225,226 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C227-230 00D9587054402 POLYESTER CAPACITOR(0.022uF/100V,J)

C231,232 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C233,234 00D9587054305 POLYESTER CAPACITOR(0.01uF/100V,J)

C235,236 00D9587054606 POLYESTER CAPACITOR(0.056uF/100V,J)

C237,238 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C239,240 nsp CHIP CAPACITOR(33pF/50V,J)

C241,242 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C243,244 nsp CHIP CAPACITOR(1000pF/50V,K)

C245,246 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C247 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C249 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C250 nsp CHIP CAPACITOR(1000pF/50V,K)

C251 nsp CHIP CAPACITOR(0.33uF/16V,Z)

C252 nsp CHIP CAPACITOR(0.22uF/50V,J)

C253,254 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C255,256 nsp CHIP CAPACITOR(1000pF/50V,K)

C257,258 nsp CHIP CAPACITOR(33pF/50V,J)

C259,260 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C301,302 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C303,304 nsp CHIP CAPACITOR(1000pF/50V,K)

C305,306 nsp CHIP CAPACITOR(15pF/50V,J)

C307-310 nsp CHIP CAPACITOR(1000pF/50V,K)

C311,312 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C313-316 00D9587053801 POLYESTER CAPACITOR(0.0018uF/100V,J)

C317,318 nsp CHIP CAPACITOR(1000pF/50V,K)

C319,320 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C321,322 00D9587054703 POLYESTER CAPACITOR(820pF/50V,J)

C323,324 nsp POLYESTER CAPACITOR(0.0047uF/100V,J)

C325,326 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C327-330 00D9587054402 POLYESTER CAPACITOR(0.022uF/100V,J)

C331,332 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C333,334 00D9587054305 POLYESTER CAPACITOR(0.01uF/100V,J)

C335,336 00D9587054606 POLYESTER CAPACITOR(0.056uF/100V,J)

C337,338 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C339,340 nsp CHIP CAPACITOR(33pF/50V,J)

C341,342 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C343,344 nsp CHIP CAPACITOR(1000pF/50V,K)

C345,346 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C347 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C349 nsp CHIP CAPACITOR(0.1uF/50V,Z)

413-DCM280-768

413-900-926

413-HT801K-191

413-DCM280-768

413-SPPW3-235

413-DCM280-768

413-007USB-781

413-DCM280-768

413-900-937

413-900-932

413-900-932

413-DCM280-768

413-900-937

413-EFX2-886

413-HT8015-159

413-SPPW3-083

413-900-939

413-SPPW3-083

413-900-938

413-900-941

413-SPPW3-235

413-900-926

413-SPPW3-236

413-DCM280-768

413-SPPW3-234

413-SPPW3-236

413-DCM280-773

413-DCM280-768

413-007USB-782

413-900-942

413-SPPW3-234

413-DCM280-768

413-900-926

413-HT801K-191

413-SPPW3-235

413-DCM280-768

413-007USB-781

413-DCM280-768

413-900-937

413-900-932

413-DCM280-768

413-900-937

413-EFX2-886

413-HT8015-159

413-SPPW3-083

413-900-939

413-SPPW3-083

413-900-938

413-900-941

413-SPPW3-235

413-900-926

413-SPPW3-236

413-DCM280-768

413-SPPW3-234

413-SPPW3-236

413-DCM280-773

22

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

C350 nsp CHIP CAPACITOR(1000pF/50V,K)

C351 nsp CHIP CAPACITOR(0.33uF/16V,Z)

C352 nsp CHIP CAPACITOR(0.22uF/50V,J)

C353,354 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C355,356 nsp CHIP CAPACITOR(1000pF/50V,K)

C357,358 nsp CHIP CAPACITOR(33pF/50V,J)

C359,360 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C377,378 nsp CHIP CAPACITOR(1000pF/50V,K)

C401,402 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C403,404 nsp CHIP CAPACITOR(1000pF/50V,K)

C405,406 nsp CHIP CAPACITOR(15pF/50V,J)

C407-410 nsp CHIP CAPACITOR(1000pF/50V,K)

C411,412 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C413-416 00D9587053801 POLYESTER CAPACITOR(0.0018uF/100V,J)

C417,418 nsp CHIP CAPACITOR(1000pF/50V,K)

C419,420 00D9587054208 POLYESTER CAPACITOR(0.0082uF/100V,J)

C421,422 00D9587054703 POLYESTER CAPACITOR(820pF/50V,J)

C423,424 nsp POLYESTER CAPACITOR(0.0047uF/100V,J)

C425,426 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C427-430 00D9587054402 POLYESTER CAPACITOR(0.022uF/100V,J)

C431,432 00D9587056109 POLYESTER CAPACITOR(0.1uF/63V,J)

C433,434 00D9587054305 POLYESTER CAPACITOR(0.01uF/100V,J)

C435,436 00D9587054606 POLYESTER CAPACITOR(0.056uF/100V,J)

C437,438 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C439,440 nsp CHIP CAPACITOR(33pF/50V,J)

C441,442 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C443,444 nsp CHIP CAPACITOR(1000pF/50V,K)

C445,446 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C447 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C449 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C450 nsp CHIP CAPACITOR(1000pF/50V,K)

C451 nsp CHIP CAPACITOR(0.33uF/16V,Z)

C452 nsp CHIP CAPACITOR(0.22uF/50V,J)

C453,454 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C455,456 nsp CHIP CAPACITOR(1000pF/50V,K)

C457,458 nsp CHIP CAPACITOR(33pF/50V,J)

C459,460 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C501,502 nsp CHIP CAPACITOR(1000pF/50V,K)

C503 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C504 nsp CHIP CAPACITOR(12pF/50V J)

C505 nsp CHIP CAPACITOR(15pF/50V,J)

C506 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C507-510 00D9587054509 POLYESTER CAPACITOR(0.039uF/100V,J)

C511,512 nsp CHIP CAPACITOR(270pF/50V,J)

C513,514 00D9587053908 POLYESTER CAPACITOR(0.0033uF/100V,J)

C515-518 00D9587054101 POLYESTER CAPACITOR(0.0056uF/100V,J)

C519,520 nsp CHIP CAPACITOR(22pF/50V,J)

C521,522 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C525-628 nsp CHIP CAPACITOR(1000pF/50V,K)

C601-616 nsp CHIP CAPACITOR(1000pF/50V,K)

C617,618 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C619,620 nsp CHIP CAPACITOR(1000pF/50V,K)

C621,622 nsp CHIP CAPACITOR(33pF/50V,J)

C623,624 nsp CHIP CAPACITOR(47pF/50V,J)

C629,630 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C631,632 nsp CHIP CAPACITOR(1000pF/50V,K)

413-DCM280-768

413-007USB-782

413-900-942

413-SPPW3-234

413-DCM280-768

413-900-926

413-HT801K-191

413-DCM280-768

413-SPPW3-235

413-DCM280-768

413-007USB-781

413-DCM280-768

413-900-937

413-900-932

413-DCM280-768

413-900-937

413-EFX2-886

413-HT8015-159

413-SPPW3-083

413-900-939

413-SPPW3-083

413-900-938

413-900-941

413-SPPW3-235

413-900-926

413-SPPW3-236

413-DCM280-768

413-SPPW3-234

413-SPPW3-236

413-DCM280-773

413-DCM280-768

413-007USB-782

413-900-942

413-SPPW3-234

413-DCM280-768

413-900-926

413-HT801K-191

413-DCM280-768

413-SPPW3-236

413-DCM280-809

413-007USB-781

413-SPPW3-236

413-900-940

413-U5000-1004

413-900-934

413-900-936

413-CR701-5161

413-SPPW3-235

413-DCM280-768

413-DCM280-768

413-SPPW3-235

413-DCM280-768

413-900-926

413-007USB-784

413-HT801K-191

413-DCM280-768

23

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

C633,634 nsp CHIP CAPACITOR(120pF/50V,J)

C639,640 nsp CHIP CAPACITOR(1000pF/50V,K)

C641,642 nsp CHIP CAPACITOR(22pF/50V,J)

C643,644 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C645,646 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C647,648 nsp CHIP CAPACITOR(22pF/50V,J)

C649,650 nsp CHIP CAPACITOR(1000pF/50V,K)

C651,652 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C653,654 nsp CHIP CAPACITOR(22pF/50V,J)

C655-658 nsp CHIP CAPACITOR(1000pF/50V,K)

C659,660 nsp CHIP CAPACITOR(22pF/50V,J)

C661,662 00D9587055304 ELEC. CAPACITOR(4.7uF/50V,M)

C663,664 941134001280S ELEC. CAPACITOR(100uF/25V,M)

C665,666 nsp CHIP CAPACITOR(47pF/50V,J)

C669,670 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C672 nsp CHIP CAPACITOR(0.01uF/50V,K)

C673,674 nsp CHIP CAPACITOR(1000pF/50V,K)

C675-678 941134001290S ELEC. CAPACITOR(0.22uF/50V,M)

C679,680 nsp CHIP CAPACITOR(1000pF/50V,K)

C681,682 nsp CHIP CAPACITOR(22pF/50V,J)

C683,684 941134001300S ELEC. CAPACITOR(22uF/25V,M)

C801 00D9587054907 ELEC. CAPACITOR(100uF/10V,M)

C802 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C803 00D9587054907 ELEC. CAPACITOR(100uF/10V,M)

C804 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C807-809 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C811-814 00D9587056206 ELEC. CAPACITOR(1uF/50V,M)

C815,816 90M-EJ000100R ELEC. CAPACITOR(0.47uF/50V,M)

C819 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C823-836 nsp CHIP CAPACITOR(0.01uF/50V,K)

C840 00D9587030701 ELEC. CAPACITOR(2.2uF/50V,M)

C842-845 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C846 941134000530S ELEC. CAPACITOR(470uF/10V,M)

C847-850 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C851 00D9587054907 ELEC. CAPACITOR(100uF/10V,M)

413-900-930

413-DCM280-768

413-CR701-5161

413-SPPW3-236

413-HT801K-191

413-CR701-5161

413-DCM280-768

413-SPPW3-236

413-CR701-5161

413-DCM280-768

413-CR701-5161

413-HT801K-191

413-X050-1068

413-007USB-784

413-SPPW3-236

413-DCM280-771

413-DCM280-768

413-SPPW3-305

413-DCM280-768

413-CR701-5161

413-CDMIX2-631

413-HMA2200-5017

413-DCM280-773

413-HMA2200-5017

413-DCM280-773

413-DCM280-773

413-SPPW3-234

413-SPPW3-233

413-DCM280-773

413-DCM280-771

413-DV300-5156

413-DCM280-773

413-HT8015-169

413-DCM280-773

413-HMA2200-5017

*

*

*

*

OTHER PARTS GROUP

CN202 nsp

CN203 nsp 4P 2.54 SERIES STRIP PIN HEADER(H=6mm)

CN603A,603B 00D9587049802 17P 1.0 FFC CONNECTOR(52207-1785)

CN604A,605A 90M-YJ003030R 12P 1.0 FFC CONNECTOR(52207-1285)

CN604B,605B 90M-YJ003030R 12P 1.0 FFC CONNECTOR(52207-1285)

CN701 00D9410047308 16P 1.0 FFC CONNECTOR(52207-1685)

CN801 941644001140S 21P 1.0 FFC CONNECTOR(52808-2170)

CN807 00D9587066306 4P SOCKET(CKM2001WR-4P)

CN903A 941644001150S 28P 1.0 FFC SOCKET(52808-2870)

L801 941115001080S INDUCTOR(10uH,AL0204ST-100K-S-A)

SW801 941663001050S ROATRY SW(SR1712F-0105-25F0A-N9-N)

SW802-806 941663001040S ROATRY SW(SR1712F-0108-25F0A-N9-N)

SW807-817 941662001160S TACT SW(SFKHVBE3525-HF

SW818-821 941664001020S SLIDE SW(SKA-12-12)

SW822-825 941664001030S SLIDE SW(SKA-13-12B)

2*3P 2.54 SERIES STRIP PIN HEADER(H=6mm) 424-SDJ2-142

24

DN-X1100

424-HDJ9700-069

404-900-2107

404-4001-2235

404-4001-2235

404-HV3423K-583

404-S300-2531

404-DCM270E3-878A

404-X1100-3059

415-HMD5000-097

403-X1100-347

403-X1100-346

403-DCM270X-101A

403-QMX1-063A

403-X1100-345

*

*

*

*

*

*

*

*

Ref. No. Part No. Part Name Remarks Q'ty New

VR101 00D9410059707 ROTARY VR(20K(A)*2)

VR102-104 941679001120S ROTARY VR(20K(3B)*2)

VR201 00D9410059707 ROTARY VR(20K(A)*2)

VR202-204 941679001120S ROTARY VR(20K(3B)*2)

VR301 00D9410059707 ROTARY VR(20K(A)*2)

VR302-304 941679001120S ROTARY VR(20K(3B)*2)

VR401 00D9410059707 ROTARY VR(20K(A)*2)

VR402-404 941679001120S ROTARY VR(20K(3B)*2)

VR501,502 941679001090S ROTARY VR(20K(A))

VR503-508 941679001110S ROTARY VR(50K(B))

VR601 00D9410059309 ROTARY VR(50K(MN)*2)

VR602 00D9587059805 ROTARY VR(20KA*2)

VR603 00D9410059707 ROTARY VR(20K(A)*2)

VR604 941679001130S ROTART VR(50K(3B)*2)

VR606 00D9410059202 ROTARY VR(50K(3B)*2)

VR607 00D9410059707 ROTARY VR(20K(A)*2)

VR803,804 941679001100S ROTARY VR(20K(B))

418-X050-446

418-X1100-530

418-X050-446

418-X1100-530

418-X050-446

418-X1100-530

418-X050-446

418-X1100-530

418-X1100-527

418-X1100-529

418-X050-332

418-900-284

418-X050-446

418-X1100-550

418-X050-252

418-X050-446

418-X1100-528

*

*

*

*

*

*

*

*

W501 nsp 3P 2.5 CONNECTOR WIRE(L=250mm)

W602 nsp 3P 2.5 CONNECTOR WIRE(L=60mm)

W702 nsp 4P 2.5 CONNECTOR WIRE(L=250mm)

W803-806 nsp 4P 2.0 CONNECTOR WIRE(L=55mm)

W901 nsp 9P 2.0 CONNECTOR WIRE(L=310mm)

941606000980S 12P 1.0 FFC CABLE(L=70mm) CN605A-605B

941606000990S 12P 1.0 FFC CABLE(L=70mm) CN604A-604B

941606001000S 17P 1.0 FFC CABLE(L=60mm) CN603A-603B

941606001010S 16P 1.0 FFC CABLE(L=150mm) CN701

00D9587062203 LED HOLDER D601,602

nsp SPACER SUPPORT(H-17)

nsp CUSHION

00D9410019501

SCREW(SAE1018,φ3*L8*P0.5)

404-MCX-2026

404-MU12-2661

404-X1100-3073

404-X1100-3079

404-X1100-3078

406-SDJ1F-968

406-X1100-1033

406-X1100-1034

406-X1100-1035

504-CDT1000-091

504-SPANDMK2-156

612-390-234

602-2002-085

*

*

*

*

25

DN-X1100

IO P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC114,115 00D9410021609 IC(NJM-4580M-TE2)

IC116 00D9587059203 IC(LC78211-E)

IC214,215 00D9410021609 IC(NJM-4580M-TE2)

IC216 00D9587059203 IC(LC78211-E)

IC314,315 00D9410021609 IC(NJM-4580M-TE2)

IC316 00D9587059203 IC(LC78211-E)

IC414,415 00D9410021609 IC(NJM-4580M-TE2)

IC416 00D9587059203 IC(LC78211-E)

IC511 00D9587058903 IC(NJM-2068M)

RESISTORS GROUP

R07,08 nsp CARBON FILM RESISTOR(100 OHM,1/4W,J)

RB701,702 nsp

CAPACITORS GROUP

C005,006 nsp CHIP CAPACITOR( 220pF/50V)

C007-010 nsp CHIP CAPACITOR(100pF/50V,J)

C011,012 nsp CHIP CAPACITOR( 220pF/50V)

C013-024 nsp CHIP CAPACITOR(100pF/50V,J)

C031,032 nsp CHIP CAPACITOR(100pF/50V,J)

C17,18 00D9587030604 ELEC. CAPACITOR(220uF/25V,M)

C193,194 nsp CHIP CAPACITOR(100pF/50V,J)

C195,196 nsp CHIP CAPACITOR(1000pF/50V,K)

C197,198 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C293,294 nsp CHIP CAPACITOR(100pF/50V,J)

C295,296 nsp CHIP CAPACITOR(1000pF/50V,K)

C297,298 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C393,394 nsp CHIP CAPACITOR(100pF/50V,J)

C395,396 nsp CHIP CAPACITOR(1000pF/50V,K)

C397,398 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C493,494 nsp CHIP CAPACITOR(100pF/50V,J)

C495,496 nsp CHIP CAPACITOR(1000pF/50V,K)

C497,498 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C541,542 nsp CHIP CAPACITOR( 220pF/50V)

C543,544 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C545,546 nsp CHIP CAPACITOR(22pF/50V,J)

C547,548 nsp CHIP CAPACITOR(1000pF/50V,K)

C549,565 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C551,552 nsp CHIP CAPACITOR( 220pF/50V)

C555,556 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C563,564 nsp CHIP CAPACITOR(22pF/50V,J)

C701,702 nsp CHIP CAPACITOR(100pF/50V,J)

C703,704 nsp E/C(47uF/16V,M)

C705,706 00D9587053607 POLYESTER CAPACITOR(0.012uF/50V,J)

C707,708 00D9587055401 POLYESTER CAPACITOR(0.0033uF/100V,J)

C709,710 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C711,712 nsp CHIP CAPACITOR(1000pF/50V,K)

C713,714 nsp CHIP CAPACITOR(100pF/50V,J)

C715,716 nsp E/C(47uF/16V,M)

C717,718 00D9587053607 POLYESTER CAPACITOR(0.012uF/50V,J)

C719,720 00D9587055401 POLYESTER CAPACITOR(0.0033uF/100V,J)

C721,722 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

THICK FILM RESISTOR NETWORKS(10K OHM,J)

417-ST150-599

417-QFX19-629

417-ST150-599

417-QFX19-629

417-ST150-599

417-QFX19-629

417-ST150-599

417-QFX19-629

417-M5-582

412-PMSE1-279

412-900-978

413-007USB-787

413-DCM280-767

413-007USB-787

413-DCM280-767

413-DCM280-767

413-DV300-292

413-DCM280-767

413-DCM280-768

413-SPPW3-236

413-DCM280-767

413-DCM280-768

413-SPPW3-236

413-DCM280-767

413-DCM280-768

413-SPPW3-236

413-DCM280-767

413-DCM280-768

413-SPPW3-236

413-007USB-787

413-SPPW3-236

413-CR701-5161

413-DCM280-768

413-SPPW3-235

413-007USB-787

413-SPPW3-236

413-CR701-5161

413-DCM280-767

413-CDVD2001-265

413-3113-060

413-KT300-103

413-SPPW3-236

413-DCM280-768

413-DCM280-767

413-CDVD2001-265

413-3113-060

413-KT300-103

413-SPPW3-236

26

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

C723,724 nsp CHIP CAPACITOR(1000pF/50V,K)

C725,726 nsp CHIP CAPACITOR(100pF/50V,J)

C727,728 nsp E/C(47uF/16V,M)

C729,730 00D9587053607 POLYESTER CAPACITOR(0.012uF/50V,J)

C731,732 00D9587055401 POLYESTER CAPACITOR(0.0033uF/100V,J)

C733,734 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C735,736 nsp CHIP CAPACITOR(1000pF/50V,K)

C737,738 nsp CHIP CAPACITOR(100pF/50V,J)

C739,740 nsp CHIP CAPACITOR(1000pF/50V,K)

C741,742 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C777-784 nsp CHIP CAPACITOR(1000pF/50V,K)

OTHER PARTS GROUP

CN501 00D9587066403 3P SOCKET(CKM2501WV)

CN701A 00D9587048706 16P 1.0 FFC CONNECTOR(52808-1670)

CN702 941644000540S 4P SOCKET(CKM2501WV)

413-DCM280-768

413-DCM280-767

413-CDVD2001-265

413-3113-060

413-KT300-103

413-SPPW3-236

413-DCM280-768

413-DCM280-767

413-DCM280-768

413-SPPW3-236

413-DCM280-768

404-HV3500K-623A

404-900-2077

404-HV3500K-629A

*

JK101 00D9587067907 4P RCA JACK

JK201 00D9587067907 4P RCA JACK

JK301 00D9587067907 4P RCA JACK

JK401 941643001240S 4P RCA JACK

JK501 00D9587061408 7P MIC JACK

JK502 00D9587037607 4P PHONE JACK

SW101 00D9587048308 SLIDE SW(SSSF122NA1-HF,6PIN)

SW201 00D9587048308 SLIDE SW(SSSF122NA1-HF,6PIN)

SW301 00D9587048308 SLIDE SW(SSSF122NA1-HF,6PIN)

VR509 941679001190S ROTARY VR(10K(B))

W902 nsp 4P 2.5 CONNECTOR WIRE(L=50mm)

nsp JACK GROUND PLATE

nsp GROUND PLATE JK401

nsp BRACKET(L TYPE)

00D9580046103 SCREW(3*5 P=0.5)

420-900-213A

420-900-213A

420-900-213A

420-QMX1-094A

420-VPS1-187

420-Q3433-107

403-QMX1-060

403-QMX1-060

403-QMX1-060

418-X1100-526

404-HPR200-3061

300-300-1171

300-QFX19-811

300-HDJ7000-472

602-B300-041

*

*

27

DN-X1100

POWER P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC04 00D9410045601 IC(BD4745G/BD4745G-TR)

IC701 00D9587059407 IC(BA15218F/BA15218FE2)

IC703 00D9587058602 IC(NJM4580D)

IC704 00D9587059407 IC(BA15218F/BA15218FE2)

IC705 00D9587058602 IC(NJM4580D)

IC907,908 00D9587059407 IC(BA15218F/BA15218FE2)

417-HDJ2000-503

417-QMX2-167

417-HDJ2400-318

417-QMX2-167

417-HDJ2400-318

417-QMX2-167

Q01 00D9587057603 TRANSISTORS(2SC3330U-AC)

Q02 00D9587057807

Q03 941219001170S TRANSISTOR(2SB892S(T),MP)

Q04 90M-HT400500R TRANSISTOR(2SD1207/2SD1207S(T))

Q701-708 00D9410046406 TRANSISTOR(2SC4695-TB-E,SOT23/CP)

Q709-712 00D9587034707 TRANSISTOR(2SC2878-B)

Q903,904 00D9587034707 TRANSISTOR(2SC2878-B)

Q909,910 00D9580040507 TRANSISTOR(2SC1740SRTP)

D103-106 00D9587034503 DIODE(1N4002(GW)-TP/1N4002TA)

D11-15 00D9410046901 SWITCHING DIODE(1SS355)

D203-206 00D9587034503 DIODE(1N4002(GW)-TP/1N4002TA)

D303-306 00D9587034503 DIODE(1N4002(GW)-TP/1N4002TA)

D403-406 00D9587034503 DIODE(1N4002(GW)-TP/1N4002TA)

ZD01 00D9580075501 ZENER DIODE(MTZJ10-B)

ZD02 00D9587057001 ZENER DIODE(MTZJ5.6-B)

CAPACITORS GROUP

C03,04 941134001210S ELEC. CAPACITOR(2200uF/35V)

C05 941134001220S ELEC. CAPACITOR(2200uF/16V)

C06 00D9587030701 ELEC. CAPACITOR(2.2uF/50V,M

C07,08 00D9587054907 ELEC. CAPACITOR(100uF/10V,M)

C09,10 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C11 00D9587056400 ELEC. CAPACITOR(22uF/16V,M)

C12 00D9587054800 ELEC. CAPACITOR(1000uF/16V,M)

C027,028 nsp CHIP CAPACITOR(100pF/50V,J)

C187-189 nsp CHIP CAPACITOR(470pF/50V,J)

C190,191 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C287-289 nsp CHIP CAPACITOR(470pF/50V,J)

C290,291 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C387-389 nsp CHIP CAPACITOR(470pF/50V,J)

C390,391 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C487-489 nsp CHIP CAPACITOR(470pF/50V,J)

C490,491 nsp CHIP CAPACITOR(0.1uF/50V,Z)

C743,744 nsp CHIP CAPACITOR(1000pF/50V,K)

C745,746 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C747-750 nsp CHIP CAPACITOR(470pF/50V,J)

C751,752 nsp CHIP CAPACITOR(1000pF/50V,K)

C753,754 nsp CHIP CAPACITOR(33pF/50V,J)

C755,756 941134001230S ELEC. CAPACITOR(47uF/50V)

C757,758 nsp CHIP CAPACITOR(470pF/50V,J)

C761,762 941134001230S ELEC. CAPACITOR(47uF/50V)

C763,764 nsp CHIP CAPACITOR(470pF/50V,J)

C765,766 nsp CHIP CAPACITOR(1000pF/50V,K)

C767,768 nsp CHIP CAPACITOR(47pF/50V,J)

TRANSISTOR(DTA124TS/2SA1589/DTA124TSATP)

416-DJ1900-023

416-KE200S-024

416-1360S-017A

416-1360S-016

416-DAIA-273

416-AMC110A-5017

416-AMC110A-5017

416-3113-007

414-DV300-5014

414-CD1000-075

414-DV300-5014

414-DV300-5014

414-DV300-5014

414-SPPW3-061

414-HT8033-032

413-X1100-1124

413-X1100-1125

413-DV300-5156

413-HMA2200-5017

413-SPPW3-235

413-SPPW3-236

413-F202-001

413-DCM280-767

413-007USB-786

413-DCM280-773

413-007USB-786

413-DCM280-773

413-007USB-786

413-DCM280-773

413-007USB-786

413-DCM280-773

413-DCM280-768

413-SPPW3-235

413-007USB-786

413-DCM280-768

413-900-926

413-X1100-1126

413-007USB-786

413-X1100-1126

413-007USB-786

413-DCM280-768

413-007USB-784

*

*

*

*

*

28

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

C769,770 nsp E/C(47uF/16V,M)

C771,772 nsp CHIP CAPACITOR(470pF/50V,J)

C773,774 nsp E/C(47uF/16V,M)

C775,776 nsp CHIP CAPACITOR(470pF/50V,J)

C953,954 nsp CHIP CAPACITOR(330pF/50V,J)

C955-958 nsp CHIP CAPACITOR(1000pF/50V,K)

C959,960 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C961,962 nsp CHIP CAPACITOR(470pF/50V,J)

C963,964 00D9587056303 ELEC. CAPACITOR(10uF/25V,M)

C965,966 CHIP CAPACITOR(22pF/50V,J)

OTHER PARTS GROUP

CN04 nsp 7P SOCKET(CKM2501WV-7P)

CN901 nsp 9P SOCKET(CKM2001WV-9P)

CN902 nsp 4P SOCKET(CKM2501WV-4P)

CN903A 941644000950S 28P 1.0 FFC SOCKET(52207-2885)

413-CDVD2001-265

413-007USB-786

413-CDVD2001-265

413-007USB-786

413-900-925

413-DCM280-768

413-SPPW3-235

413-007USB-786

413-SPPW3-235

413-CR701-5161

404-DV300-507A

404-CDMIX2-1200A

404-HV3500K-629A

404-X1100-3153

*

JK102 00D9587037306 3P HEADPHONE JACK

JK202 00D9587037306 3P HEADPHONE JACK

JK302 00D9587037306 3P HEADPHONE JACK

JK402 00D9587037306 3P HEADPHONE JACK

JK701 941643001240S 4P RCA JACK

JK703,704 00D9587067703 3P XLR JACK(94M-008P5-G)

JK707,708 00D9587060807 3P PHONE JACK

JK903-906 00D9587037607 4P PHONE JACK

L01 00D9587057108

SW701,702 00D9587048308 SLIDE SW(SSSF122NA1-HF,6PIN)

nsp GROUND PLATE JK701

nsp JACK GROUND PLATE

941606000960S 28P 1.0 FFC CABLE(L=200mm) CN903A

nsp SPACER SUPPORT(H-28)

00D9410019501

BEAD CORE(RH03506ST-B,65Ω/100MHz)

SCREW(SAE1018,φ3*L8*P0.5)

420-HDJ7100-063

420-HDJ7100-063

420-HDJ7100-063

420-HDJ7100-063

420-QMX1-094A

420-900-204

420-HMJ1001-5034

420-Q3433-107

415-HV3500K-090

403-QMX1-060

300-QFX19-811

300-300-1171

406-X1100-1036

504-X1100-240

602-2002-085

*

*

29

DN-X1100

LEVEL METER P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

Q818-836 00D9587057302

TRANSISTOR(2SA1037AKT146R/2SA1037AKR) 416-CDN88-045

D801 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D802-806 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D807-812 00D9587051803 CHIP LED(LTST-C190KGKT)

D813 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D814-818 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D819-824 00D9587051803 CHIP LED(LTST-C190KGKT)

D825 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D826-830 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D831-836 00D9587051803 CHIP LED(LTST-C190KGKT)

D837 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D838-842 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D843-848 00D9587051803 CHIP LED(LTST-C190KGKT)

D849 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D850-854 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D855-860 00D9587051803 CHIP LED(LTST-C190KGKT)

D861 00D9587052103 CHIP LED(RED,LTST-C190KRKT)

D862-866 00D9587052200 CHIP LED(YELLOW,LTST-C190KSKT6)

D867-872 00D9587051803 CHIP LED(LTST-C190KGKT)

D901-906 00D9587051803 CHIP LED(LTST-C190KGKT)

CAPACITORS GROUP

C820,821 00D9587054907 ELEC. CAPACITOR(100uF/10V,M)

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-HDJ9700-214

410-HDJ9700-226

410-CD900-249

410-CD900-249

413-HMA2200-5017

OTHER PARTS GROUP

CN801A 941644001270S

941606001200S 21P 1.0 FFC CABLE(L=120mm) CN801A

941423001320P LED BASE ASS'Y

941423001340P TRANSPARENT MEDIA ADAPTER

21P 1.0 FFC SOCKET(52207-2185,SMD90°)

404-X1100-3060

406-X1100-1039

701-1100-4474

100-1100-2605

*

*

*

30

DN-X1100

PHONE P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

CAPACITORS GROUP

C667,C668 nsp CHIP CAPACITOR(2200pF/50V,J)

OTHER PARTS GROUP

CN602 00D9587066403 3P SOCKET(CKM2501WV)

413-007USB-788

404-HV3500K-623A

JK601 00D9587037209 3P HEADPHONE JACK

nsp JACK GROUND PLATE JK601

420-CDMIX1-086

300-300-1171

CH FADER P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

OTHER PARTS GROUP

CN803 00D9587066306

VR105 941674000970S SLIDE VR(50K(0B)*2)

4P SOCKET(CKM2001WR-4P,90°WHITE)

404-DCM270E3-878A

418-900-326

AC P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

OTHER PARTS GROUP

CN02,03 00D9410022501

2P 3.96 SOCKET(8674S-02,90°,WHITE)

404-BEAT6-1598

*

AC1 00D9410050405

AC1 00D9410049801

nsp SPACER SUPPORT(TCBS-35)

AC SOCKET(SO-222-14P,2P,DIP90°)

AC SOCKET(SO-222-14RP,2P,DIP90°)

E2

E3

404-HDJ2200E-969

404-DJ2-021

504-X1100-246

31

DN-X1100

--MEMO--

32

DN-X1100

---MEMO---

33

DN-X1100

EXPLODED VIEW

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by

the manufacturer.

WARNING:

印の部分は安全を維持するために重要

な部品です。従って交換時は必ず指定の

部品を使用してください。

34

DN-X1100

PARTS LIST OF EXPLODED VIEW

* Parts for which "nsp" is indicated on this table cannot be supplied.

P.W.B. ASS'Y for which "nsp" is indicated on this table cannot be supplied. When repairing the P.W.B. ASS'Y, check the board parts table and order replacement parts

*

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3: U.S.A. & Canada model E2: Europe mode

Ref. No. Part No. Part Name Remarks Q'ty New

1 nsp FRONT BOARD ASS'Y

2 nsp BASE ASS'Y

3 00D9587069303 CROSS FADER &CS FIXED PLATE ASS'Y

3-1 - CS TYPE FIXED PLATE

3-2 -

3-3 -

4 nsp POWER & DIXED PLATE ASS'Y

4-1 nsp FIXED COVER ASS'Y

z 4-2 941694000780P SWITCHING POWER(AC100/240V,47/63Hz)

4-3 nsp ISOLATION

4-4 nsp HOLDFAST(L=250mm)

4-5 nsp SCREW(3*5 P=0.5)

4-6 941612000930S 3N2P 3.96 CONNECTOR WIRE(L=290mm)

4-7 941612000940S 7P 2.5 CONNECTOR WIRE(L=120mm)

5 nsp IO PCB ASS'Y

6 nsp POWER PCB ASS'Y

7 nsp AC PCB ASS'Y E2

7 nsp AC PCB ASS'Y E3

8 nsp PHONE PCB ASS'Y

9 nsp LEVEL METER PCB ASS'Y

10 941674000830P CH VR FIXED PLATE & CH FADER PCBASS'Y

10-1 - CH FADER PCB ASS'Y

10-2 - CH FIXED PLATE

10-3 -

11 nsp MIXER & TRANSFER PCB ASS'Y

11-1 - MIXER PCB ASS'Y

11-2 - TRANSFER PCB ASS'Y

11- 3 -

12 00D9410057301 POWER KNOB

90M09CW259020

13

14 00D9587013401 PUSH KNOB

15 941412000790P SQUARE KNOB

16 00D9587046106 JACKET

17 00D9587046203 LARGE ROTARY KNOB(ABS)

18 941411000800P CUE BUTTON

19 941412000850P ROUND KNOB

20 941412000860P SMALL ROTARY KNOB(ABS)

21 412510032008P ROTARY KNOB(PP BLUE,TPR BLACK)

22 412510031005P ROTARY KNOB(PP BLUE,TPR BLACK)

23 nsp GROUND PIN

24 941402000820P FRONT PANEL

25 941406000900P BACK BOARD E2

25 941406000910P BACK BOARD E3

26 941409001310P VR BOARD

z 27 00D9580008303 POWER SW(SDDLB1017U-HF,L=18)

30 00D9587056002 AC SAFETY CAPACITOR(0.01uF/250V,M,BULK,Y5V)

31 00D9587037500 RCA ADAPTOR PLUG(A028)

32 nsp SHIPPING LABEL E2

32 nsp SHIPPING LABEL E3

CROSS FADER(LPA-4815LT-B50KΩ)

SCREW(SAE1018,ISOF,φ3*L4*P0.5)

SCREW(SAE1018,ISOF,φ3*L4*P0.5)

SCREW(SAE1018,φ3*L8*P0.5)

KNOB PROTECTOR

703-1100-1212

703-1100E2-1213

704-900-5730

300-900-1248

418-900-305

602-SA12-414

704-X1100-8292

703-TU3-1197B

411-TU3-702

501-1100-2207

504-X1100-243

602-B300-041

404-X1100-3108

404-X1100-3106

704-X1100-8163

704-X1100-8164

704-X1100-8311

704--X1100-8165

704-X1100-8166

704-X1100-8168

704-X1100-8170

704-X1100-8167

300-1100-1647

602-SA12-414

704-X1100-8185

704-X1100-8161

704-X1100-8162

602-2002-085

100-HDJ2000-1641

100-HDJ2000-1642

100-300-2231

100-1100-2301A

100-900-2302

100-900-2303

100-1100-2602

100-1100-2603

100-1100-2619

100-1100-2633

100-1100-2634

200-DJ100-231

300-1100-1643

300-1100E2-1644

300-1100E3-1644

300-1100-1646

403-A100-005

413-S250-747

420-Q3433-106

701-X1100E2-3655

701-X1100E3-3655

1

1

1

1

1

2

1

1

1*

1

1

4

1*

1*

1

1

1

1

1

1

4*

4

4

8

1

1

1

6

1

1

5

4*

1

1

6*

1*

6*

13

18

1

1*

1*

1*

1*

1

1

6

1

1

.

35

DN-X1100

Ref. No. Part No. Part Name Remarks Q'ty New

33 nsp ISOLATION(304*99*0.5t)

34 nsp WIRE MOUNT(FW-2-3M,WHITE)

35 nsp NUT(M3*P0.5)

36 nsp

37 nsp HIMILON

38 00D9587045107

39 nsp CUSHION(26*10mm,t=0.5mm)

40 nsp CUSHION(BLACK,30*37*0.3t)

41 nsp CUSHION(BLACK,30*16*0.3t)

42 nsp CUSHION(t=0.5mm)

43 nsp CUSHION(t=0.5mm)

44 nsp SCREW(3*5 P=0.5)

45 nsp

46 nsp SCREW(SAE1018,PTP,M3*10)

47 nsp

48 nsp

49 nsp

50 nsp SCREW(JMP,2.6*5,ZB)

51 nsp SCREW(STN,3*8,ZB)

52 nsp

53 nsp SCREW(CTF,3*7)

54 nsp

55 nsp

56 nsp SCREW(BTK,3*5)

57 941612000920S 3N2P 3.96 CONNECTOR WIRE(L=120mm)

58 nsp MUTE SHEET

WASHER(φ8*3.2*1t,NI)

FOOT(PORON,BLACK,φ15*3t)

SCREW(SAE1018,φ3*L8*P0.5)

SCREW(SAE1018,JMP,φ2.6*L3*P0.45)

SCREW(SAE1018,ISOB,φ3*L8*P0.5)

SCREW(SAE1018,BTB,φ3*L5)

SCREW(SAE1018,PTB,φ3*L8)

SCREW(SAE1018,WBTP,φ3*L5,CAP=φ7)

SCREW(SAE1018,WBTP,φ2.6*L8,CAP=φ6)

501-1100-2180

504-ST100-118

601-A100-004

606-Q2221-122

612-HDJ100-045

612-HV3500K-055

612-Q2422-103

612-1100-313

612-1100-314

612-1100-317

612-1100-318

602-B300-041

602-2002-085

602-MK7-131

602-KM500-155

602-HP1010K-178

602-QMX2BPM-322

602-HDJ9700-425

602-BEAT4-449

602-DJ5500-452

602-AKS4-496A

602-900-564

602-900-565

602-BTK3005-666B

404-X1100-3107

604-900-361

1

1

1

1

4

4

8

4

2

1

4

10

3

6

16

3

18

11

4

5

17

10

21

3

1*

1

36

DN-X1100

PACKING VIEW

z

z

PARTS LIST OF PACKING & ACCESSORIES

* Parts for which "nsp" is indicated on this table cannot be supplied.

* The parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canada model E2 : Europe mode

Ref. No. Part No. Part Name Remarks Q'ty New

1 941533000750P POLYFOAM F

2 941533000810P POLYFOAM B

3 941535000840P SOFT BAG(450*460+120mm)

4 nsp I/B ASS'Y E2

4 nsp I/B ASS'Y E3

4-1 nsp SERVICE SHEET(515-0923-401)

4-2 941541000050P I/B

4-3 nsp WARRANTY CARD(515-0966-109) E3

4-4 nsp PE BAG(240*340mm)

5 00D9587051308 2P RCA CORD(L=1000mm)

z 6 00D9587051201 3.5mm STEREO CORD-NI

7 nsp POLYBAG(120*250mm)

z 8 00D9410044204 AC POWER CORD(L=1900mm+/-50mm,VDE,TYPE) E2

z 8 00D9410044107 AC CORD(L=1900+/-50mm,UL) E3

10 941531000770P GIFT BOX

11 nsp SHIPPING LABEL E2

11 nsp SHIPPING LABEL E3

506-1100-501F

506-1100-501B

509-RMX40-164A

701-DX1100E2-4483

701-DX1100E3-4484

502-300E2-1771A

502-DX1100E-2672

502-100E3-1772

505-DJ2500H-014

408-DV300-5001

408-900-065

505-HM500A-049

409-DJ2-070A

409-DJ2-069A

507-1100-3022

701-X1100E2-3655

701-X1100E3-3655

1*

1*

1*

1

1

1

1*

1

1

2

2

1

1

1

1*

1

1

37

DN-X1100

WIRING DIAGRAM

CROSS FADER PCB

PHONE PCB

CN602

W501

W602

CN604B

W803

W901

CN604A

TRANSFER PCB

CN803

W804

CN803

CN605A

CN605B

CN701

W805

W702

CN803

W806

CN807

MIXER PCB

CH FADER PCB * 4

CN803

CN801

TO LED PCB CN801A

CN603B

CN603A

CN903A

POWER SW

CN501

I/O PCB

CN901

CN701A

POWER PCB

CN702

W902

CN902

CN03

CN2

CN1

CN02

CN903A

AC PCB

CN04

POWER & DIXED PLATE ASS'Y

38

DN-X1100

--MEMO--

39

DN-X1100

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you

make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps,

or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is

located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM

M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD.

P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT

NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE.

40

DN-X1100

C541

JK502

220P

3

L

4

S

2

R

1

G

AUX MIC

CHASSIS

JK501

MAIN MIC (COMPO)

3

L

2

R

1

G

3

1

JK101A

PH1

JK101B

LINE2

JK201A

PH2

JK201B

LINE4

JK301A

PH3

JK301B

LINE6

JK401A

LINE7

JK401B

LINE8

C542

220P

C551

C552

220P

2

CHASSIS

CHASSIS

CHASSIS

CHASSIS

CHASSIS

87654321

15V1

R567

22/16

C009

100P

C547

0.001

IC511B

1K

R569

100K

R193

51K

LN

R194

51K

R191

100

R189

51K

R190

51K

100

R291

100

R289

51K

R290

51K

LN

100

R391

100

R389

51K

R390

51K

R392

R491

100

R489

51K

R490

51K

100

R493

51K

R494

51K

5

C712

0.001

C195

0.001

C196

C724

0.001

0.001

C296

0.001

C736

0.001

C395

0.001

0.001

C739

0.001

C740

0.001

C495

0.001

C496

0.001

0.001

C295

C396

C548

C006

220P

R179

453

R180

453

R279

453

R280

453

C017

100P

R379

453

R380

453

2068

6

4 8

C563

22P

3

2

C711

0.001

R181

C702

C005

100P

R182

C706 .012

5

6

3 IC114A

2

C723

C011

220P

R281

C012

220P

R282

5

6

3

2

C735

0.001

R381

C018

100P

5

6

3

2

5

6

3

2

5

6

3

2

C546

270K

220P

270K

0.001

270K

270K

270K

C730

.012

22P

2068

C564

5

6

C705

.012

3

2

5

6

C717

.012

3

2

5

6

C729

.012

3

2

-15V1

22P

4580

4 8

4580

4580

4 8

IC214A

4580

4580

4 8

IC314A

4580

4580

4 8

IC414A

4580

8

4580

4

IC415A

4580

IC511A

15V1

4580

4 8

4580

15V1

8

4580

4

4580

15V1

8

4580

4

4580

270K

IC415B

15V

IC114B

-15V

C718

.012

15V

IC214B

-15V

R382

15V

IC314B

-15V

15V

IC414B

-15V

15V

-15V

7

R570

100K

IC115B

-15V1

IC115A

-15V1

IC215A

IC315B

-15V1

IC315A

1

R564

100K

7

R183

22K

C707

C709

22/16

.0033

C710

1

R184

22/16

22K

C708

.0033

C197

7

22/16

C198

1

22/16

IC215B

C721

7

22/16

R283

22K

C719

.0033

C722

1

R284

22/16

22K

C720

.0033

C297

7

22/16

C298

1

22/16

C733

7

22/16

R383

22K

C731

.0033

C734

1

22/16

R384

22K

C732

.0033

C397

7

22/16

C398

1

22/16

C741

7

22/16

C742

1

22/16

C497

7

22/16

C498

1

22/16

C545

22P

0.001

R568

1K

R563

100K

R561

1K

R562

1K

C556

22/16

R195

100

C701

100P

C11

2

C703

47/16

SW101

LN/PH

3

4

C2

R196

100

C704

47/16

C193

100P

C194

100P

R192

100

R295

100

C713

100P

R293

51K

2C11

C715

47/16

LN

SW201

LN/PH

C714

4

3

C2

100P

C716

47/16

C293

100P

C294

100P

R292

100

R395

100

C725

R393

100P

51K

2C11

C727

47/16

SW301

LN/PH

C726

4C23

100P

C728

47/16

C393

100P

C394

100P

100

C737

100P

C738

100P

R492

100

R495

C493

100P

C494

100P

R496

100

C549

10/25

C565

10/25

IC116

L1

L2

L3

L4

LCOM1

RCOM1

L5

L6

LCOM2

RCOM2

L7

L8

LCOM3

RCOM3

VEE

VDD

CE

DI

CL15VSS

C778

0.001

L1

L2

L3

L4

LCOM1

RCOM1

L5

L6

LCOM2

RCOM2

L7

L8

LCOM3

RCOM3

VEE

VDD

CE

DI

CL15VSS

C780

0.001

L1

L2

L3

L4

LCOM1

RCOM1

L5

L6

LCOM2

RCOM2

L7

L8

LCOM3

RCOM3

VEE

VDD

CE

DI

CL15VSS

C782

0.001

L1

L2

L3

L4

LCOM1

RCOM1

L5

L6

LCOM2

RCOM2

L7

L8

LCOM3

RCOM3

VEE

VDD

CE

DI

CL15VSS

C784

RB702

47KX8

30

R1

29

R2

28

R3

27

R4

26

25

R5

24

R6

23

22

R7

21

R8

20

19

18

/RES

17

S

16

30

R1

29

R2

28

R3

27

R4

26

25

R5

24

R6

23

22

R7

21

R8

20

19

18

/RES

17

S

16

30

R1

29

R2

28

R3

27

R4

26

25

R5

24

R6

23

22

R7

21

R8

20

19

18

/RES

17

S

16

30

R1

29

R2

28

R3

27

R4

26

25

R5

24

R6

23

22

R7

21

R8

20

15V-15V

19

18

/RES

C783

17

S

0.001

16

0.001

15V-15V

C777

0.001

15V

C779

0.001

15V-15V

RB701

47KX8

LC78211

1

2

3

4

5

6

7

8

9

10

11

12

CE1

DI

CL

-15V

CE1

DI

CL

CE2

DI

CL

13

14

IC216

1

2

3

4

5

6

7

8

9

10

11

12

13

14

LC78211

IC316

1

2

3

4

5

6

7

8

9

10

11

12

13

14

LC78211

IC416

1

2

3

4

5

6

7

8

9

10

11

12

13

CE2

14

DI

CL

LC78211

C781

0.001

10KB

3

CN501

2VR509

AD5V

1

DIMMER

2

ADGND

1

3

3P

CN701

AMIC

1

2

MMIC

3

4

1L

5

1R

6

7

2L

TO MIX PCB

8

2R

9

10

3L

11

3R

12

13

4L

14

4R

15

/RST2

16

16P

CN702

CE1

1

CE1

CE2

2

CE2

15V1

R07

100/.25W

0/25

2

C17

2

100/.25W

C18

220/25

-15V1

TO 405-1100-2313

DI

3

DI

CL

4

CL

15V

4P

W902

15V

1

PGND

2

TO POWER PCB

3

R08

-15V

4

-15V

4P

405-1100-2315405-1100-2314

RET L(MONO)

SEND L(MONO)

JK903

RET R

JK905

JK906

SEND R

JK707

BOOTH L

JK708

BOOTH R

L CH

R CH

L CH

R CH

MASTER L

MASTER R

AC CORD

PLAY CONTROL1

PLAY CONTROL1

Q909

C1740

CHASSIS

CHASSIS

Q910

C1740

CHASSIS

CHASSIS

CHASSIS

CHASSIS

JK701A

REC OUT

JK701B

MASTER OUT

JK703

CHASSIS

JK704

CHASSIS

JK102

3

L

2

R

1

G

C187

470P

JK302

3

L

2

R

1

G

C387

470P

3

L

4

S

2

R

1

G

3

L

4JK904

S

2

R

1

G

3

L

4

S

2

R

1

G

3

L

4

S

2

R

1

G

3

L

2

R

1

G

3

L

2

R

1

G

3

1

2

6

4

5

2

3

1

2

3

1

405-1100-2316

AC1

N

L

2P

C188

470P

C388

470P

C027

R952

2.2M

470P

JDET

R951

2.2M

100P

C028

100P

C961

C962

470P

C776

CHASSIS

CHASSIS

C189

470P

C389

470P

R929

51K

R930

51K

15V

C771

470P

C772

470P

C775

470P

470P

C747

470P

C748

470P

C749

470P

C750

470P

C757

470P

C758

470P

C763

470P

C764

470P

0.01/250V

Q903

CN02

15V

C2878

C2878

W02

R185

R186

R385

R386

Q904

C2878

1K

1K

1K

1K

R931

100

C953

330P

Q703

C2878

R943

13K

R932

100

C954

330P

Q706

C2878

C190

C390

Q709

C2878

C2878

C2878

0.1

0.1

R944

13K

Q711

C2878