Page 1

Ver. 1

SERVICE MANUAL

MODEL JP E3 E2 EK EA E1 E1K E1C

DN-SC2000

33

USB MIDI CONTROLLER

For purposes of improvement, specifi cations and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

D&M Holdings Inc.

S0102-1V01DM/DG1009

Copyright 2010 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. if the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, in each power ON, OFF and STANDBY

mode, if applicable.

CAUTION

Please heed the points listed below during servicing and inspection.

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis,etc., have cautions indicated

on labels. be sure to heed these causions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching

internal metal parts when the set is energized could

cause electric shock. Take care to avoid electric

shock, by for example using an isolating transformer

and gloves when servicing while the set is energized,

unplugging the power cord when replacing parts, etc.

(2) Tere are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when manufacturing parts

from sheet metal, there may in some rare cases be burrs

on the edges of parts which could cause injury if fi ngers

are moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). For replacement

parts, be sure to use parts which have the same

poroperties. In particular, for the important safety parts

that are marked z on wiring diagrams and parts lists, be

sure to use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally!

For safety seasons, some parts use tape, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wores omsode amd clamps

are used to keep wires away from heating and high

voltage parts, so be sure to set everything back as it was

originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or

disconnected for servicing have been put back in their

original positions, inspect that no parts around the area

that has been serviced have been negatively affected,

conduct an inslation check on the external metal

connectors and between the blades of the power plug,

and otherwise check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on.

Using a 500V insulation resistance tester, check that the

inplug and the externally exposed metal parts (antenna

terminal, headphones terminal, input terminal, etc.) is

1MΩ or greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these

properties are difficult to distinguish by sight, and using

replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be poreserved. Parts with safety

properties are indicated as shown below on the wiring

diagrams and parts lists is this service manual. Be sure to

replace them with parts with the designated part number.

(1) Schematic diagrams ......Indicated by the z mark.

(2) Parts lists ......Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fi res

or other dangerous situations.

2

Page 3

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacture

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL

INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

r.

NOTE FOR PARTS LIST

Parts for which "nsp" is indicated on this table cannot be supplied.

1.

When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

2.

3.

Ordering part without stating its part number can not be supplied.

4.

Part indicated with the mark "★" is not illustrated in the exploded view.

5.

Not including General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

Not including General-purpose Carbon Chip Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

● Resistors

Ex.: RN

* Resistance

● Capacitors

Ex.: CE

* Capacity (electrolyte only)

* Capacity (except electrolyte)

・ When the dielectric strength is indicated in AC,"AC" is included after the dieelectric strength value.

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

14K

Type

RD : Carbon

RC : Composition

RS : Metal oxide film

RW: winding

RN : Metal film

RK : Metal mixture

: Units: ohm

Type

CE : Aluminum foil

electrolytic

CA : Aluminium solid

electrolytic

CS : Tantalum electrolytic

CQ : Film

CK : Ceramic

CC : Ceramic

CP : Oil

CM: Mica

CF : Metallized

CH : Metallized

・ Units:μF.

・ Units:pF

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

04W

Shape

and performance

2

Indicates number of zeros after effective number.

2-digit effective number.

2

Indicates number of zeros after efective number. (More than 2)

2-digit effective number.

2E

Power

2B : 1/8 W

2E : 1/4 W

2H : 1/2 W

3A : 1 W

3D : 2 W

3F : 3 W

3H : 5 W

1800ohm=1.8kohm1 8

1.2ohm1 R 2

1H

Dielectric

strength

0J : 6.3 V

1A : 10 V

1C : 16 V

1E : 25 V

1V : 35 V

1H : 50 V

2A : 100 V

2B : 125 V

2C : 160 V

2D : 200 V

2E : 250 V

2H : 500 V

2J : 630 V

2200μF2 2

2200pF=0.0022μF2 2

182

Resistance

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

3R2

CapacityMAllowable

G

Allowable

error

P : Pulse-resistant type

NL : Low noise type

NB : Non-burning type

FR : Fuse-resistor

F : Lead wire forming

error

F:±1%

G:±2%

J:±5%

K:±10%

M:±20%

Z:±80%

: - 20%

P : +100%

C:±0.25pF

D:±0.5pF

= : Others

FR

Others

BP

Others

HS : High stability type

BP : Non-polar type

HR : Ripple-resistant type

DL : For change and discharge

HF : For assuring high requency

U : UL part

C : CSA part

W : UL-CSA part

F : Lead wire forming

2

・ Units:μF.

1

・ Units:pF

2.2μF2 R

1-digit effective number.

2-digit effective number, decimal point indicated by R

220pF2 2

Indicates number of zeros after effective numver. (0 or 1)

2-digit effective number.

3

Page 4

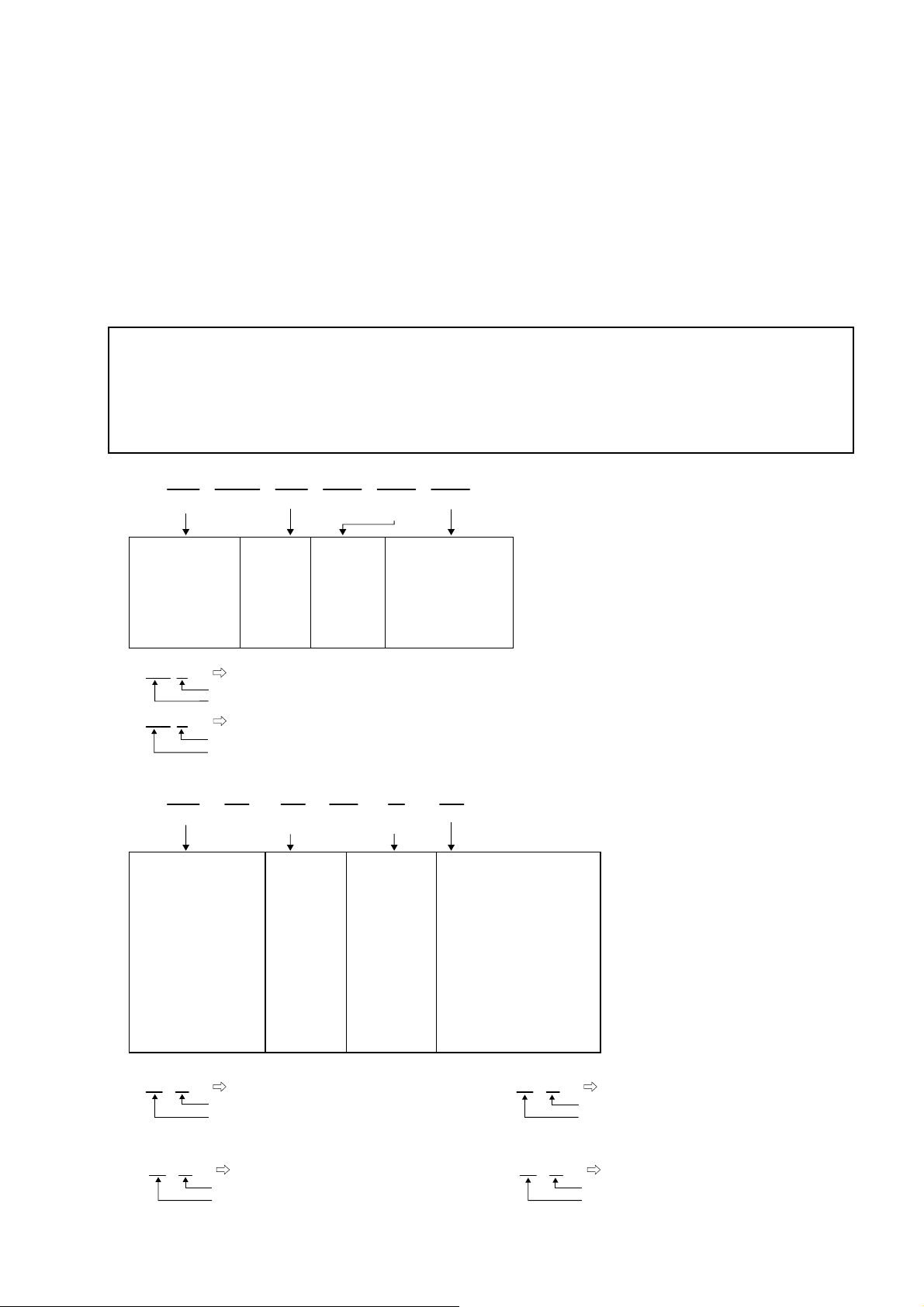

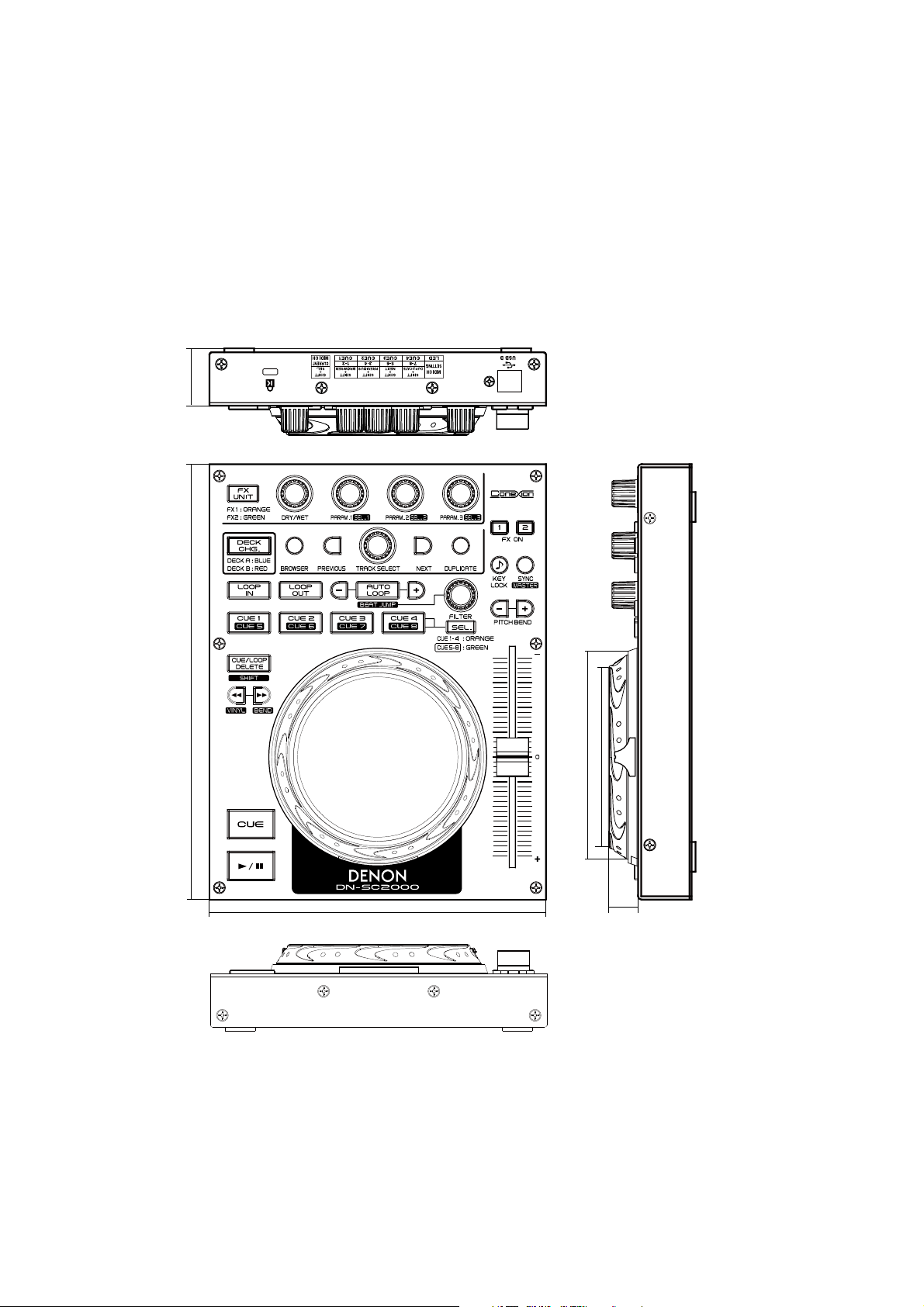

TECHNICAL SPECIFICATIONS

General

n

Type: USB MIDI Controller

Dimensions: 170 (W) x 30 (H) x 220 (D) mm

(6-11/16” x 1-3/16” x 8-21/32”)

Weight: 1.3 kg (2 Ibs 13.86 oz)

Power supply: 5 V (USB Bus Power)

Current consumption: 450 mA

Operational temperature: 5 – 35 °C

Operational humidity: 25 – 85 %

Storage temperature: –20 – 60 °C

USB I/F

n

USB connector: USB 2.0 (Full Speed)

USB MIDI I/O 1 port

DIMENSION

30

220

170

φ91

φ103.3

15

4

Page 5

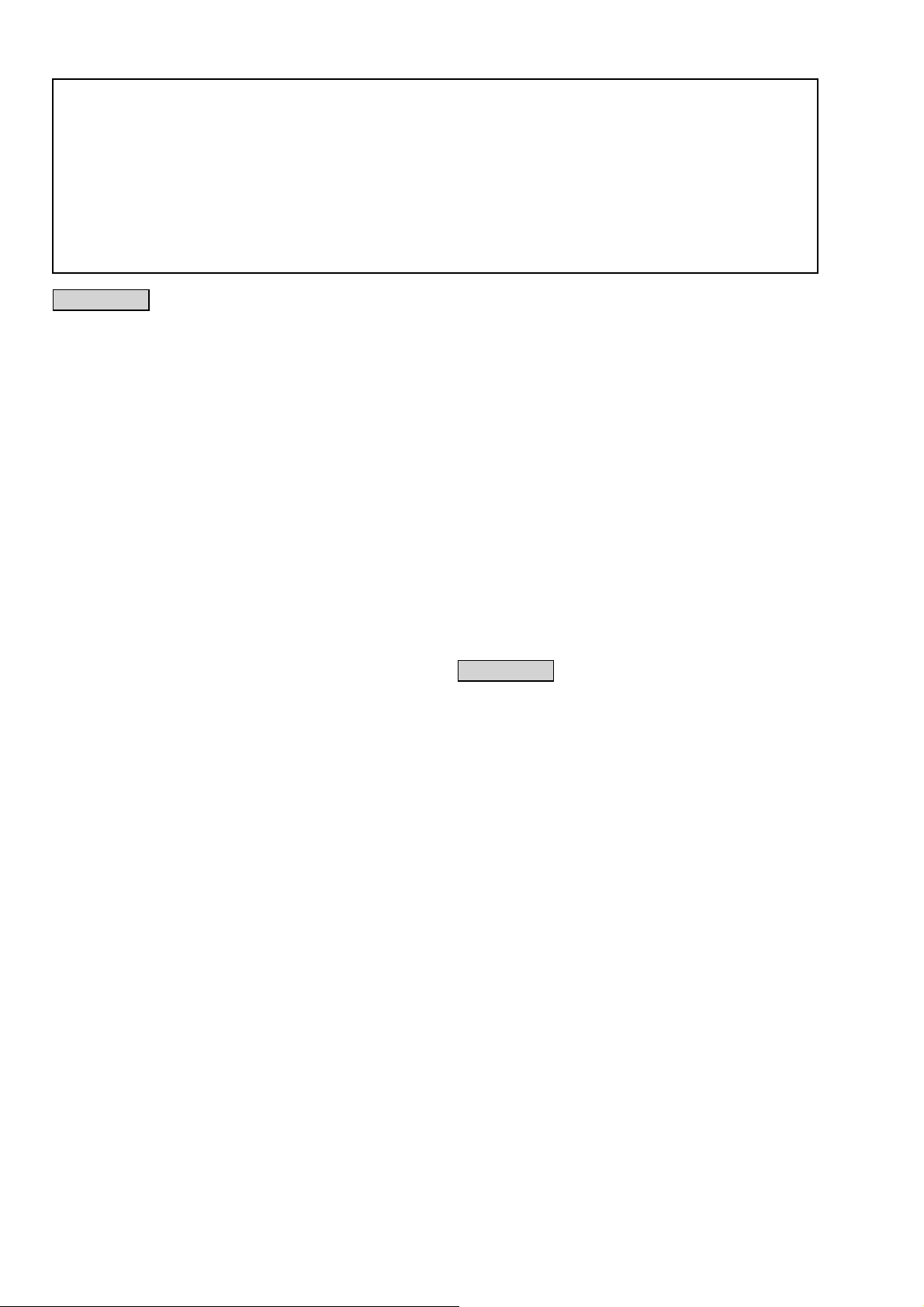

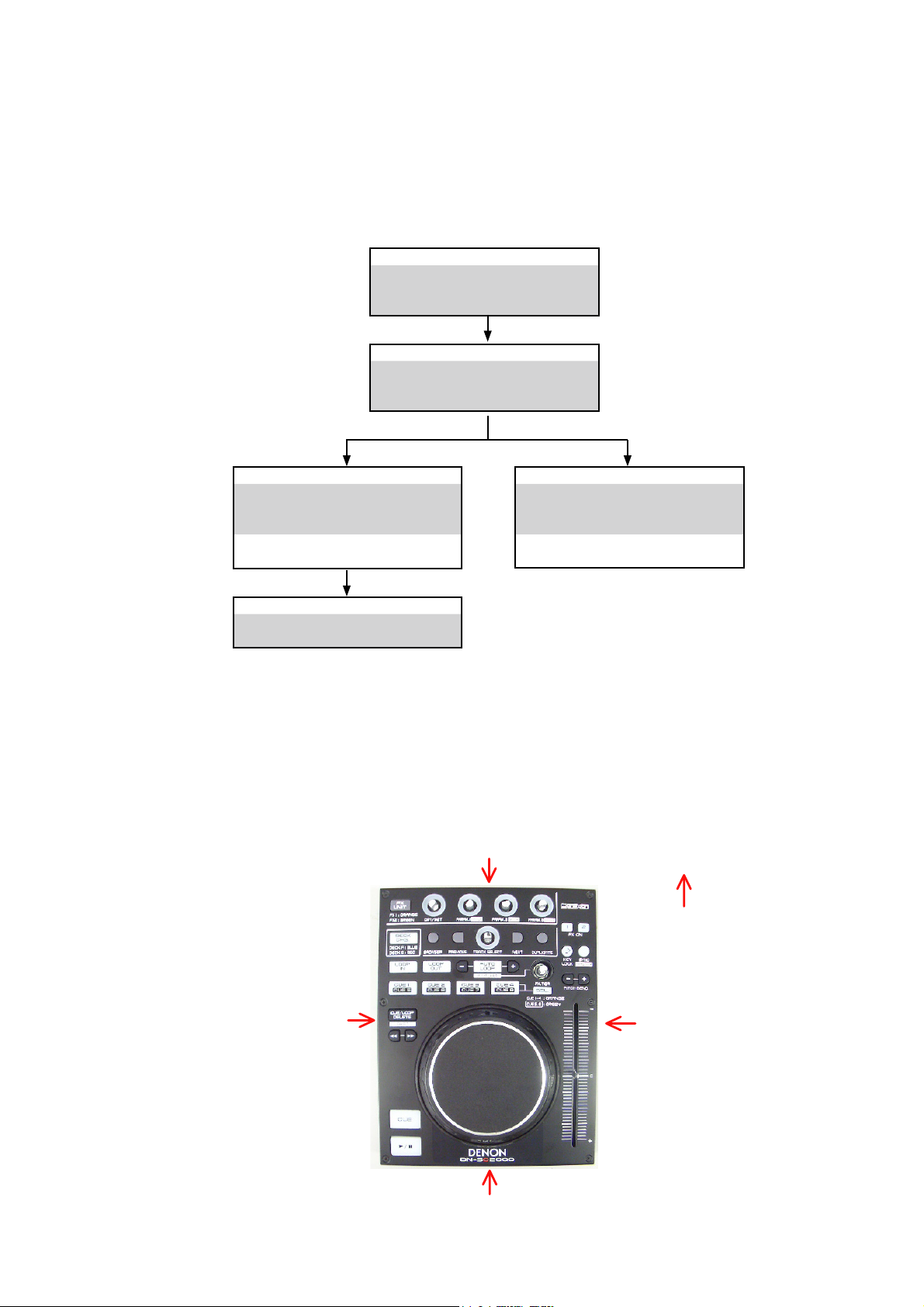

DISASSEMBLY

• Disassemble in order of the arrow of the fi gure of following fl ow.

• In the case of the re-assembling, assemble it in order of the reverse of the following fl ow.

• In the case of the re-assembling, observe "attention of assembling" it.

• If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly

as they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP PANEL

Refer to "DISASSEMBLY

1. TOP PANEL"

and "EXPLODED VIEW"

INNER PANEL

Refer to "DISASSEMBLY

2. INNER PANEL"

and "EXPLODED VIEW"

CONTROL PCB ASS'Y

Refer to "DISASSEMBLY

3. CONTROL PCB ASS'Y

and "EXPLODED VIEW"

CONTROL PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 3)

RUBBER BUTTON

Refer to "DISASSEMBLY

and "EXPLODED VIEW"

SENSOR PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 4)

WHEEL ASS'Y

Refer to "DISASSEMBLY

4. WHEEL ASS'Y"

and "EXPLODED VIEW"

About the photos used for descriptions in the DISASSEMBLY" section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***"

at the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: B

Front side

Direction of photograph: C

Direction of photograph: D

Direction of photograph: A

5

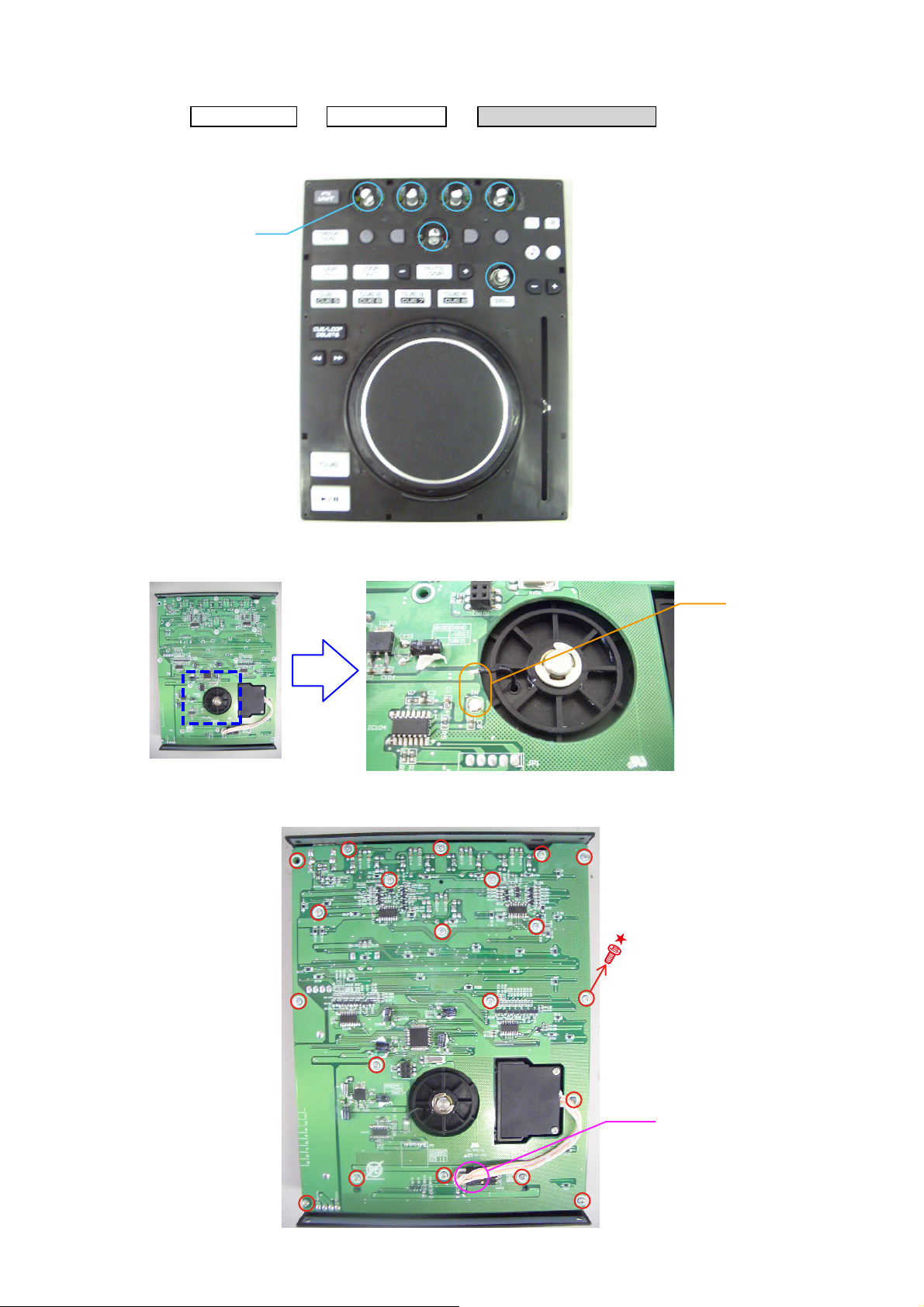

Page 6

1. TOP PANEL

(1) Remove the screws.

TOP PANELProceeding :

Direction of photograph: B

Direction of

photograph: C

Direction of

photograph: D

Direction of photograph: A

6

Page 7

2. INNER PANEL

TOP PANELProceeding :

(1) Remove the knobs.

KNOB

INNER PANEL

→

(2) Remove the screws.

Direction of photograph: B

Direction of photograph: A

7

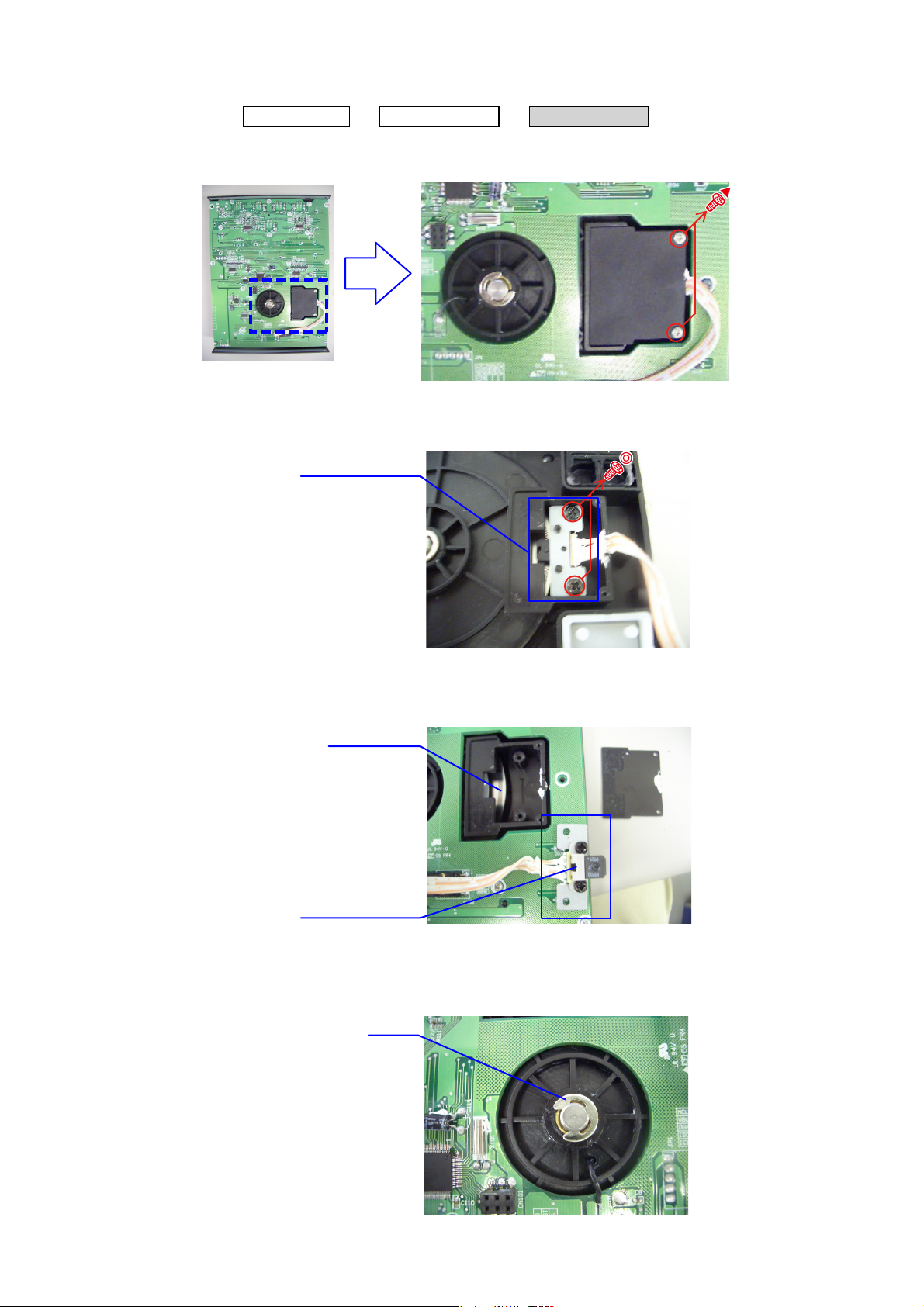

Page 8

3. CONTROL PCB ASS'Y

TOP PANELProceeding :

(1) Remove the Nuts.

(2) Remove the solder.

NUT

INNER PANEL

→

CONTROL PCB ASS'Y

→

(3) Disconnect the connector wire, then remove the screws.

Solder

CN102

8

Page 9

4. WHEEL ASS'Y

TOP PANELProceeding :

(1) Remove the screws.

(2) Remove the screws.

INNER PANEL

→

SENSOR PCB ASS'Y

WHEEL ASS'Y

→

(3) Remove the SENSOR PCB ASS'Y.

Note:

(4) Remove the E RING.

Note:

Donotcomeoutofthebearingwhenyoutransformashaft.

DonotdamagetheWHEELPLATE.

WHEEL PLATE

SENSOR PCB ASS'Y

Donotholddownthecircumferenceoftheshaftwithatool.

E RING

9

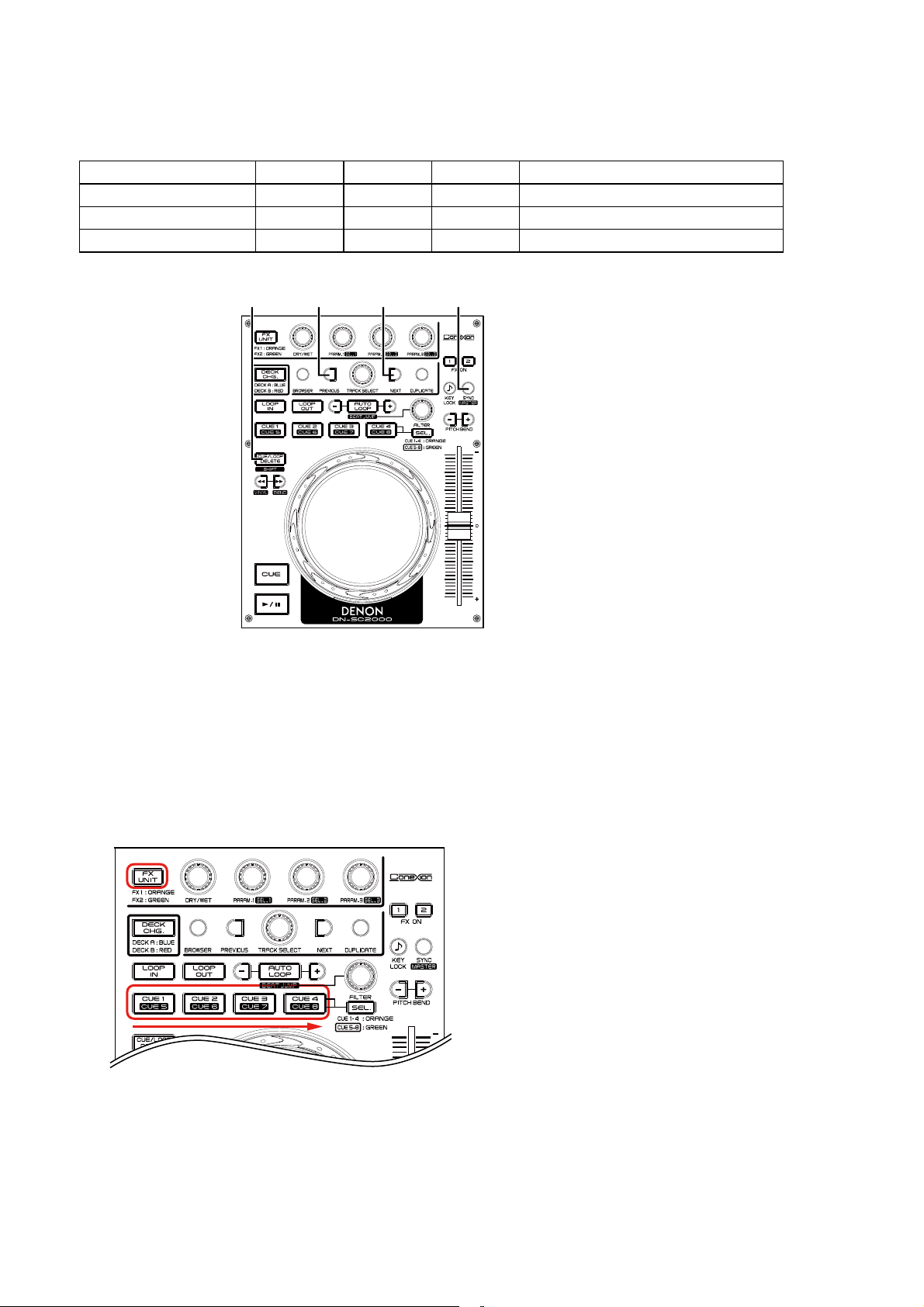

Page 10

SPECIAL MODE

1. Special mode setting

Connect to PC while pressing buttons A, B and C.

Mode A B C

Version Up Mode 1 2 3 Firmware Upgrade

Version Display 1 3 4 Firmware version display

Test Mode 1 2 4 LED(Button) Check

1 2 3 4

Contents

2. Version Up Mode

(1) Pressing (SHIFT+NEXT+PREVIOUS) at the same time, then connect SC2000 to PC for F/W version processing.

(2) DN-SC2000 will enter updating mold. CUE-1 will light to indicate “Update Ready.”

(3) PC Operation System will pop-up a new hard disc, named DN-SC2000.

(4) Copy updated fi le (EX: DN-SC2000_v1.13.bin), and paste on “DN-SC2000” hard disc.

(5) It will start updating. After updating successfully, DN-SC2000 will switch to Midi Controller automatically.

(6) Firmware updating State

CUE-1: Update Ready, CUE-2: Update Data(0%), CUE-3: Update Data(50%), CUE-4: Update Data(100%)

FX UNIT: Update Success (* If it doesn’t light, it means “Updating Error”)

(7) Upon completion of the upgrade, it automatically restarts, start in Normal mode.

Upgrade will end in about 10 seconds.

Note:

Please do not switch off the PC during update of Firmware. In addition, please do not take off a USB cable.

10

Page 11

3. Version Display

Press (SHIFT+NEXT+SYNC) at the same time, then connect SC2000 to PC to check the light buttons that represent F/W

version.

Press (Shift) to retrurn to Normal Mode.

How to read the version number

Firmware Version Leds (Ver X .YZ)

X:The first digit numeric display.

1

234

1

2

1

34

2

3

4

56 7 8 9

For example, Ver 1.13

DRY/WET(1) knob

FX ON 1(1) button

DECK CHG.(1), LOOP IN(2), LOOP OUT(3) button

Five places of LED turns on

Y:The second digit numeric display.

Z:The third digit numeric display.

11

Page 12

4. Test Mode

(1) Press ing (SHIFT+PREVIOUS+SYNC) at the same time, then connect SC2000 to PC to start Test Moe.

(2) When you enter the test mode LED lights. The combination of LED A and B in two ways for each combination,

→i are lit and blinking patterns.

q

A pattern lit

q

A pattern blink

e

(A pattern of fl ashing lights part)

A pattern dimmer

t

B pattern lit

w

B pattern blink

r

B pattern of fl ashing lights part

(

B pattern dimmer

y

)

A pattern dimmer blink

u

(A dimmer part fl ashing)

(3) (PREVIOUS) button is pressed, the above

Recconnect SC2000 to PC to retrurn to Normal Mode.

q

B pattern dimmer blink

i

(B dimmer part fl ashing)

→i repeat the pattern.

12

Page 13

ABOUT REPLACE THE MICROPROCESSOR WITH A NEW ONE

When replaced of the U-PRO (Microprocessor) or the Flash ROM, confi rm contents of the following.

PWB Name Ref. No. Description

MAIN IC101 MC9S08JM32CLH B P/N : 941243004230P

After replaced

A : Mask ROM (With software). No need write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need write-in of software. But, when the software was updated, you should be

write-in of the new software to the microprocessor or fl ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should be write-in of the software to the microprocessor or fl ash ROM.

Refer to "Update procedure" or "writing procedure", when you should be write-in the software.

Refer to "SPECIAL MODE : 2.Version Up Mode" for the procedure of the fi rmware update.

b

After

replaced

Remark

13

Page 14

TROUBLE SHOOTING

FLOW CHART NO.1 (MAIN UNIT)

The power cannot be turned on.

YES

Is the USB cable or the USB terminal of the PC side normal?

YES

Check JK101 and the periphery circuit, and replace it if defective.

FLOW CHART No.2 (MAIN UNIT)

+3.3V is not outputted.

YES

Is the +5V line voltage normal?

YES

Check JK101 and the periphery circuit, and replace it if defective.

FLOW CHART No.3 (MAIN UNIT)

NO

NO

Reconnect normally.

Refer to FLOW CHART NO.1 [The

power cannot be turned on.]

The key operation is not functioning.

YES

Are the contact point and the installation state of the key

switches(SW101~SW134) normal?

YES

Does LED (D153A~D183A/D153B~D183B) light correctly ?

YES

When pressing each key switches, do the voltage of each pin of

IC101(shown below) decrease?

SW133, SW125, SW119, SW113, SW107, SW101 : IC101 61 pin

SW134, SW126, SW120, SW114, SW108, SW102 : IC101 1 pin

SW131, SW127, SW121, SW115, SW109, SW103 : IC101 63 pin

SW132, SW122, SW116, SW110, SW104 : IC101 64 pin

SW129, SW123, SW117, SW111, SW105 : IC101 62 pin

SW130, SW124, SW118, SW112, SW106 : IC101 60 pin

YES

NO

NO

NO

Re-install the switches

(SW101~SW134)

Check Q105~Q108 and the periphery

circuit,and replace it if defective.

Check the key switches

(SW101~SW134) and their periphery,

and service it if detective

Replace IC101.

14

Page 15

FLOW CHART No.4 (MAIN UNIT)

The key operation is not Touch sence functioning.

YES

Are the contact point and the installation state of the JOG Wheel

Top panel normal?

YES

Is signal output from IC104 pin No.5?

Doesn't Touch : 0V / Touch : 5V

YES

Replace IC101.

NO

Replace the JOG wheel.

NO

Replace IC104

15

Page 16

BLOCK DIAGRAM

KEY

LED

PIC16F616

WHEEL

(P.I.)

74595

LED DRIVER

MC9S08JM32

MCU

USB JACK

2

3 1

PITCH VR

ENCODER

1 2

16

Page 17

17

CONTROL UNIT (COMPONENT SIDE) SENSOR UNIT (COMPONENT SIDE)

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

987654321

L

K

J

I

H

G

F

E

D

C

B

A

PRINTED WIRING BOARDS

21

A

B

Page 18

18

CONTROL UNIT (FOIL SIDE)

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

123454789

L

K

J

I

H

G

F

E

D

C

B

A

Page 19

19

DB5

DB3

DB2

DB1

KR5

KR4

DB0

D156A

CUE1/5

Q11Q22Q33Q44Q55Q66Q77GND

8

DSO

9

MR

10

SHCP

11

STCP

12

OE13DS

14

Q0

15

VCC

16

IC105

74595

R113A

270

C122

0.1

D154A

CUE

D155A

CUE1/5

/OE

STCP

SHCP

DS

C109

0.1

C110

0.1

C126

100/10

R107

1M

X101

12M

C112

33P

C113

33P

R108

10K

C107

0.1

R106

0

L103

10uH

R105

NC

R104

NC

C111

100/10

BKGD

1 2

3 4

5 6

CN101

HEADER 3X2(LPP->NC)

/URST

AD

R114A

110

R115A

110

DB4

SW113

FAST SEARCH-

SW114

LOOP OUT

SW115

PREVIOUS

SW116

+

SW107

PLAY

SW108

DELETE/SHIFT

SW109

SW110

AUTO LOOP

SW111

SEL

SW112

KEY LOCK

SW101

CUE

SW102

FAST SEARCH+

SW103

CUE2/6

D

SW117

CUE4/8

SW118

PITCH+

VBUS

SW104

CUE3/7

SW105

PITCH-

Q11Q22Q33Q44Q55Q66Q77GND

8

DSO

9

MR

10

SHCP

11

STCP

12

OE13DS

14

Q0

15

VCC

16

IC106

74595

R117A

110

C123

0.1

/OE

STCP

SHCP

D158A

CUE2/6

R116A

110

D157A

CUE2/6

C106

0.47

C105

4.7/10

R102

30

R101

30

CHASSIS

PTC4

1

IRQ/TPMCLK

2

RESET

3

PTF0/TPM1CH2

4

PTF1/TPM1CH3

5

PTF2/TPM1CH4

6

PTF3/TPM1CH5

7

PTF4/TPM2CH0

8

PTC6

9

PTF7

10

PTF5/TPM2CH1

11

PIF6

12

PTE0/TxD1

13

PTE1/RxD1

14

PTE2/TPM1CH0

15

PTE3/TPM1CH1

16

PTE4/MISO117PTE5/MOSI118PTE6/SPSCK119PTE7/SS120VDD21VSS22USBDN23USBDP24VUSB3325PTG0/KBIP026PTG1/KBIP127PTA028PTA129PTA230PTA331PTA4

32

PTA5

33

PTB0/MISO2/ADP0

34

PTB1/MOSI2/ADP1

35

PTB2/SPSCK2/ADP2

36

PTB3/SS2/ADP3

37

PTB4/KBIP4/ADP4

38

PTB5/KBIP5/ADP5

39

PTB6/ADP6

40

PTB7/ADP7

41

PTD0/ADP8/ACMP+

42

PTD1/ADP9/ACMP–

43

VDDAD

44

VREFH

45

VREFL

46

VSSAD

47

PTD2/KBIP2/ACMPO

48

PTD3/KBIP3/ADP10

49

PTD4/ADP11

50

PTD551PTD652PTD7

53

PTG2/KBIP654PTG3/KBIP7

55

BKGD/MS

56

PTG4/XTAL

57

PTG5/EXTAL

58

VSSOSC

59

PTC0/SCL

60

PTC1/SDA

61

PTC2

62

PTC3/TxD263PTC5/RxD2

64

IC101

MC9S08JM32

1

2 3

4

L101

ACM2012

L102

BEAD

C102

0.1

C101

10/16

KR3

KR2

SW125

FX UNIT

SW126

DECK CHG.

SW119

CUE1/5

SW120

LOOP IN

SW121

BROWSER

SW122

NEXT

SW123

DUPLICATE

SW124

FX ON1

KR1

KR0

SW106

SYNC

EN2B

EN2A

C1300.01

C1290.01

1234

5

SW130

FIL TER

D172A

PRA2

Q11Q22Q33Q44Q55Q66Q77GND

8

DSO

9

MR

10

SHCP

11

STCP

12

OE13DS

14

Q0

15

VCC

16

IC107

74595

R129A

270

C124

0.1

D170A

TRACK SEL.

D171A

PRA2

/OE

STCP

SHCP

R130A

110

R131A

110

D172B

PRA2

D170B

TRACK SEL.

D171B

PRA2

D156B

CUE1/5

D154B

CUE

D155B

CUE1/5

D158B

CUE2/6

D157B

CUE2/6

3.3V

C103

10/16

IGO

IC103

BA33T

C104

0.1

VBUS

R113B

270

R114B

110

R115B

110

R129B

270

R130B

110

R131B

110

R116B

110

R117B

110

DB5

DB0

DB4

DB2

DB3

DB1

EN2A

EN6A

STCPDSSHCP

/OE

R103

10K

C108 0.1

D101

EDZC6.8B

D102

EDZC6.8B

D103

EDZC6.8B

D104

EDZC6.8B

C114

2.2/50

NC

1

SUB

2

GND

3

VO

4

VCC

5

IC102

BD4740G

R110

10K

Q102

C114ES

Q104

C114ES

Q103

C114ES

Q105

C114ES

Q106

C114ES

Q118

C114ES

Q119

C114ES

Q120

C114ES

R146

100

R147

100

R148

100

R149

100

D152

SMAJ-6.0A

D141

1SS355

D142

1SS355

D143

1SS355

D144

1SS355

R109

10K(LPP->0)

D111

1SS355

D105

1SS355

D117

1SS355

D123

1SS355

D129

1SS355

D135

1SS355

D106

1SS355

D112

1SS355

D118

1SS355

D124

1SS355

D130

1SS355

D136

1SS355

D107

1SS355

D113

1SS355

D119

1SS355

D125

1SS355

D131

1SS355

D132

1SS355

D126

1SS355

D120

1SS355

D114

1SS355

D108

1SS355

D133

1SS355

D127

1SS355

D121

1SS355

D115

1SS355

D109

1SS355

D128

1SS355

D122

1SS355

D116

1SS355

D110

1SS355

D134

1SS355

Q11Q22Q33Q44Q55Q66Q77GND

8

DSO

9

MR

10

SHCP

11

STCP

12

OE13DS

14

Q0

15

VCC

16

IC108

74595

C125

0.1

/OE

STCP

SHCP

DSO

DSO

DSO

DSO

D174A

PRA3

R132A

110

R133A

110

D174B

PRA3

D173B

PRA3

R132B

110

R133B

110

Q121

C114ES

Q122

C114ES

D173A

PRA3

VCC

1

RA5

2

RA4

3

RA3

4

RC5

5

RC4

6

RC37RC2

8

RC1

9

RC0

10

RA2

11

RA1

12

RA0

13

GND

14

IC104

PIC16F616

C1

0.1

R1

2.4K

R2

1K

R5

20K

R7

51K

C3

1u/16V

WHEEL

WHEEL

1

2

3

4

5

JP1

IC

MCLR

VBUS

ISCPDAT

ICSPCLK

DGND

WHEEL

D

VBUS

C8

1/16

IN

1

2

3

4

CN102

4P

VBUS

JW2

JW1

CHB

1

VCC

2

CHA

3

GND

4

M301

WHEEL ENCODER

1

2

3

4

W102

4P

D166A

DRY/WET

R119A

110

R123A

270

R122A

330

R121A

110

R120A

110

D161A

LOOP OUT

D162A

LOOP IN

D163A

DECK CHG.

D164A

DECK CHG.

D165A

DRY/WET

D160A

CUE3/7

R118A

110

R124A

110

R125A

110

D159A

CUE3/7

R127A

110

D168A

PRA1

R126A

110

D167A

PRA1

D182A

SYNC

R135A

110

R139A

110

R138A

110

R137A

110

R136A

270

D177A

AUTO LOOP

D178A

CUE4/8

D179A

FX UNIT

D180A

FX UNIT

D181A

KEY LOOK

D176A

FX ON2

R134A

110

R140A

110

R141A

330

D175A

FX ON1

D177B

AUTO LOOP

D179B

FX UNIT

D180B

FX UNIT

D166B

DRY/WET

D161B

LOOP OUT

D162B

LOOP IN

D165B

DRY/WET

D160B

CUE3/7

D159B

CUE3/7

D168B

PRA1

D167B

PRA1

R118B

110

R119B

110

R120B

110

R121B

110

R124B

110

R125B

110

R136B

270

R138B

110

R139B

110

R126B

110

R127B

110

Q107

C114ES

Q108

C114ES

Q109

C114ES

Q110

C114ES

Q111

C114ES

Q112

C114ES

Q114

C114ES

Q113

C114ES

Q115

C114ES

Q116

C114ES

Q123

C114ES

Q124

C114ES

Q125

C114ES

Q126

C114ES

Q127

C114ES

Q128

C114ES

Q129

C114ES

Q130

C114ES

R151

100

R152

100

R154

100

D146

1SS355

D147

1SS355

D149

1SS355

R150

100

D145

1SS355

R153

100

D148

1SS355

R145

100

D140

1SS355

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED12

LED13

LED14

LED15

LED16

LED17

LED18

LED19

LED20

LED21

LED22

LED23

LED24

LED25

LED26

LED27

LED28

LED29

LED30

VB

1

D-

2

D+

3

DGND

4

CHASSIS

5

CHASSIS

6

JK101

MIDI USB(B Type)

R112A

110

D153A

PLAY

R128A

330

D169A

TRACK SEL.

D169B

TRACK SEL.

D153B

PLAY

R112B

110

R128B

330

Q101

C114ES

Q117

C114ES

R144

100

D139

1SS355

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LED9

LED10

LED11

LED12

LED13

LED14

LED15

LED16

LED17

LED18

LED19

LED20

LED21

LED22

LED23

LED24

LED25

LED26

LED27

LED28

LED29

LED30

R111

10K

A3A1

A2A4

B3B1

B2B4

VR101

10KBX2

PITCH

AD5V

C115

3300P

C116

3300P

AD VR0

AD VR1

JW1

JW2

KR0

KR1

KR2

KR3

KR4

AD VR1

AD VR0

WHEEL

KR5

3.3V

CLED1

CLED2

CLED3

CLED4

CLED9

CLED10

CLED11

CLED5

CLED8

CLED7

CLED6

CLED1

CLED2

CLED3

CLED4

CLED5

CLED6

CLED7

CLED8

CLED9

CLED10

CLED11

VBUS

EN1B

EN1A

C1280.01

C1270.01

1234

5

SW129

TRACK SEL.

EN4B

EN4A

C138 0.01

C137 0.01

1234

5

SW134

PRA1

EN3B

EN3A

C1360.01

C1350.01

1234

5

SW133

DRY/WET

EN6B

EN6A

C134 0.01

C133 0.01

1234

5

SW132

PRA3

EN5B

EN5A

C132 0.01

C131 0.01

1234

5

SW131

PRA2

EN5A

EN1A

EN4A

EN3A

EN4B

EN3B EN1B

EN2B

EN5B

EN6B

405-HDJ9800-1020

R143A

330

D184A

JOG WHEEL

D184B

JOG WHEEL

R143B

330

Q132

C114ES

R155A

270

D186A

JOG WHEEL

D186B

JOG WHEEL

R155B

270

Q134

C114ES

JOG WHEEL LED1

JOG WHEEL LED2

JOG WHEEL LED1

JOG WHEEL LED2

R142A

110

D183A

CUE4/8

D183B

CUE4/8

R142B

110

Q131

C114ES

LED31

LED31

D137

1SS355

SW127

FX ON2

R123B

270

R122B

330

D163B

DECK CHG.

D164B

DECK CHG.

R137B

110

D178B

CUE4/8

R134B

110

D175B

FX ON1

R135B

110

D176B

FX ON2

D182B

SYNC

D181B

KEY LOOK

R140B

110

R141B

330

D150

EDZC6.8B

FU1 1A

EN2B

EN2A

EN1B

EN1A

EN4B

EN4A

EN3B

EN3A

EN6B

EN6A

EN5B

EN5A

R158

5.6K

R156

5.6K

R166

5.6K

R164

5.6K

R162

5.6K

R160

5.6K

R159

5.6K

R157

5.6K

R167

5.6K

R165

5.6K

R163

5.6K

R161

5.6K

GND POWER + POWER -

87654321

A

B

C

D

E

F

SCHEMATIC DIAGRAMS (1/1)

Page 20

Grease:

Product name : RS Paste

Maker : DAIZO corporation(Nichimoly)

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by

the manufacturer.

WARNING:

EXPLODED VIEW & POINTS OF

GREASING

20

Page 21

PARTS LIST OF EXPLODED VIEW

zParts for which "nsp" is indicated on this table cannot be supplied.

z

P.W.B. ASS'Y for which "nsp" is indicated on this table cannot be supplied. When repairing the P.W.B. ASS'Y, check the board parts table and order replacement parts.

zPart indicated with the mark " ★ " is not illustrated in the exploded view.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canada model E2 : Europe model EA : Australia model

Ref. No. Part No. Part Name Remarks Q'ty New

1 nsp FRAME COVER ASS'Y 701-2000-4921 1

1-1 941443004100P FRAME PLASTIC ASS'Y 701-2000-4816 1 *

1-2 nsp JACKET COVER 100-2000-2775 1

1-3 nsp PULLEY SPRING 603-PROS2-256A 1

2 nsp WHEEL ASS'Y 701-2000-4922 1

2-1 941412004120P WHEEL & PLATE ASS'Y 701-2000-4815 1 *

2-1-1 nsp WHEEL & SHAFT ASS'Y 701-2000-4815 1

2-1-2 nsp WHEEL PLATE 300-2000-1833 1

2-1-3 nsp SPRING(SUS304,Φ0.3,L=6) 603-M1-384 1

2-1-4 nsp SCWER(SAE1018,STS,2.0*3) 602-STS2003-677 1

2-2 941483004110P ENCODER PLATE 300-PROS2-848 1 *

2-3 nsp ENCODER FIXED PLATE 300-PROS2-851 1

2-4 nsp SCREW(PTBΦ2*L6) 602-PROS2-363 6

3 nsp CONTROL PCB ASS'Y 704-SC2000-9495 1

4 nsp SENSOR PCB ASS'Y 704-CDI600-7990 1

5 nsp PUSH BUTTON 100-700-2679 1

6 nsp JOG TUNING KNOB 100-1000S-2736 6

7 941483004110P JACKET RING 100-2000-2774 5 *

8 nsp SENSOR FIXED PLATE(SECC,1.2t) 300-HDJ9800-981 1

9 941402004030P TOP COVER 300-2000-1830 1 *

10 nsp BASE 300-2000-1831 1

11 nsp USB CABLE(L=1000mm) 408-IM-081 1

12 nsp DUST-PROOF SLICE 501-HDJ9800-1648 1

13 941411003840P SOFT KNOB 604-2000-549 1 *

14 941411003850P 6 KEY SOFT KNOB 604-2000-550 1 *

15 941411003860P 2 KEY SOFT KNOB 604-2000-551 1 *

16 nsp PULLEY WASHER(Φ1.6*6*0.25t) 606-F200-003 1

17 nsp E RING 606-DJ3000-105 1

18 nsp F00T(PORON,BLACK,Φ15*3t) 612-HV3500K-055 4

19 nsp FIBROUS(Φ4.6*6.2*0.3t) 612-1000S-348 1

20 nsp SCREW(SAE1018,PTP,M2.6*L8) 602-SL24F-099 20

21 nsp SCREW(Φ5,L=8) 602-HP1010K-182 18

22 nsp SCREW(SAE1018,ISOP,M3*5L*P0.5) 602-MP3-324 2

23 nsp SCREW(PTBΦ2*L6) 602-PROS2-363 2

24 nsp SCREW(SAE1018,PTBΦ3*L8) 602-DJ5500-452 2

25 nsp SCREW(C1018,ISOF,M2*5) 602-ISOF2005-686B 1

26-1 nsp BAR CODE-MAKE DATE(24*8mm,t=0.1mm) 701-SC2000-4916 1

26-2 nsp BAR CODE-SERIAL NO.(46*8mm,t=0.1mm)

21

Page 22

PACKING VIEW

6

5

2

4

7

8

3

8

PARTS LIST OF PACKING & ACCESSORIES

zParts for which "nsp" is indicated on this table cannot be supplied.

zPart indicated with the mark " ★ " is not illustrated in the exploded view.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canada model E2 : Europe model EA : Australia model

Ref. No. Part No. Part Name Remarks Q'ty New

1 941533004050P POLYFOAM D 506-2000-589D 1 *

2 941533004060P POLYFOAM U 506-2000-589U 1 *

3 941535004070P SOFT BAG 509-2000-284 1 *

4 nsp USB CABLE(L=1000mm) 408-IM-081 1

4 nsp POLYBAG(120*250mm) 505-HM500A-049 1

5 941541004080P I/B 502-DSC2000-3008 1 *

5 941543004250P QUICK GUIDE 502-DSC2000-3019 1 *

6 941531004090S GIFT BOX 507-SC2000-3206 1 *

7 nsp BAR CODE(86'*209mm,t=0.1mm) 701-SC2000EM-4916 1

7-1 - BAR CODE-SERIAL NO.(FOR GIFT BOX) - -

7-2 - BAR CODE-SERIAL NO.(FOR OUT CARTON) - -

22

Page 23

SEMICONDUCTORS

PTF2/TPM1CH4

1

2

3

4

5

6

7

8

RESET

PTF0/TPM1CH2

PTF3/TPM1CH5

PTF4/TPM2CH0

PTC6

PTF7

V

USB33

USBDP

USBDN

V

SS

V

DD

PTE7/SS1

PTE6/SPSCK1

PTB7/ADP7

PTD0/ADP8/ACMP+

PTD1/ADP9/ACMP–

V

DDAD

V

REFH

PTB1/MOSI2/ADP1

PTB6/ADP6

PTD5

PTG2/KBIP6

PTC5/RxD2

PTG4/XTAL

BKGD/MS

PTG3/KBIP7

PTD2/KBIP2/ACMPO

PTD6

PTD7

43

42

41

40

39

38

18 19 20 21 22

23

505152535455

17

32

33

49

48

64

9

PTF5/TPM2CH1

10

PTF6

11

PTE0/TxD1

16

PTE3/TPM1CH1

PTG0/KBIP024PTG1/KBIP1

25

PTA0

26

PTA1

27

PTB5/KBIP5/ADP5

37

PTB4/KBIP4/ADP4

36

PTB3/SS2/ADP3

35

PTB2/SPSCK2/ADP2

34

PTG5/EXTAL

56

V

SSOSC

57

PTC0/SCL

58

PTC1/SDA

59

PTF1/TPM1CH3

12

PTE1/RxD1

13

14

15

PTE2/TPM1CH0

PTA2

28 29 30 31

V

REFL

44

45

46

V

SSAD

47

PTC3/TxD2

63 62 61

PTC2

60

PTC4

IRQ/TPMCLK

PTE4/MISO1

PTE5/MOSI1

PTA3

PTA4

PTB0/MISO2/ADP0

PTA5

PTD4/ADP11

PTD3/KBIP3/ADP10

64-Pin QFP/LQFP

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC's

MC9S08JM32 (IC101)

23

Page 24

MC9S08JM32 Block Diagram

PTD4/ADP11

PTD5

PTD6

PTC1/SDA

PTC0/SCL

V

SS

V

DD

PTE3/TPM1CH1

PTE2/TPM1CH0

PTA5– PTA0

PTE0/TxD1

PTE1/RxD1

PTD1/ADP9/ACMP–

PTD0/ADP8/ACMP+

PTC6

PTC5/RxD2

PTC4

PTC3/TxD2

PTC2

PORT A

PORT C

PORT D

PORT E

8-BIT KEYBOARD

INTERRUPT MODULE (KBI)

IIC MODULE (IIC)

8-/16-BIT SERIAL PERIPHERAL

INTERFACE MODULE (SPI1)

USER Flash (IN BYTES)

USER RAM (IN BYTES)

ON-CHIP ICE AND

DEBUG MODULE (DBG)

MC9S08JM60 = 60,912

HCS08 CORE

CPUBDC

NOTES:

1. Port pins are software configurable with pullup device if input port.

2. Pin contains software configurable pullup/pull-down device if IRQ is enabled

(IRQPE = 1). Pull-down is enabled if rising edge detect is selected (IRQEDG = 1)

3. IRQ does not have a clamp diode to V

DD

. IRQ must not be driven above VDD.

4. Pin contains integrated pullup device.

5. When pin functions as KBI (KBIPEn = 1) and associated pin is configured to enable the

pullup device, KBEDGn can be used to reconfigure the pullup as a pull-down device.

2-CHANNEL TIMER/PWM

MODULE (TPM2)

PTB5/KBIP5/ADP5

PORT B

PTE5/MOSI1

PTE4/MISO1

PTE6/SPSCK1

PTE7/SS1

HCS08 SYSTEM CONTROL

RESETS AND INTERRUPTS

MODES OF OPERATION

POWER MANAGEMENT

VOLTAGE

REGULATOR

COP IRQ LVD

LOW-POWER OSCILLATOR

MULTI-PURPOSE CLOCK

GENERATOR (MCG)

RESET

V

SSAD

V

DDAD

V

REFH

ANALOG-TO-DIGITAL

CONVERTER (ADC)

6-CHANNEL TIMER/PWM

MODULE (TPM1)

PTD7

6

PTB4/KBIP4/ADP4

PTG3/KBIP7

PTG2/KBIP6

PORT G

12-CHANNEL, 12-BIT

BKGD/MS

PTF3/TPM1CH5

PTF2/TPM1CH4

PTF0/TPM1CH2

PTF1/TPM1CH3

PORT F

PTF5/TPM2CH1

PTF4/TPM2CH0

PTF6

PTF7

INTERFACE MODULE (SCI1)

SERIAL COMMUNICATIONS

INTERFACE MODULE (SCI2)

SERIAL COMMUNICATIONS

PTG0/KBIP0

PTG1/KBIP1

MC9S08JM32 = 32,768

V

REFL

PTG4/XTAL

PTG5/EXTAL

IRQ/TPMCLK

RxD2

TxD2

SDA

SCL

8

KBIPx

KBIPx

TPMCLK

SPSCK1

SS1

MISO1

MOSI1

TPMCLK

TPM1CH1

TPM1CH0

RxD1

TxD1

EXTAL

XTAL

4

4

USB SIE

USB ENDPOINT

RAM

FULL SPEED

USB

TRANSCEIVER

USBDP

USBDN

MISO2

SS2

SPSCK2

MOSI2

PTB1/MOSI2/ADP1

PTB0/MISO2/ADP0

PTB7/ADP7

PTB6/ADP6

8-/16-BIT SERIAL PERIPHERAL

INTERFACE MODULE (SPI2)

REAL-TIME COUNTER

(RTC)

PTB3/SS2/ADP3

PTB2/SPSCK2/ADP2

TPM1CHx

4

TPM2CH1

TPM2CH0

4

ANALOG COMPARATOR

(ACMP)

SYSTEM

USB 3.3-V VOLTAGE REGULATOR

V

USB33

MC9S08JM60 = 4096

MC9S08JM32 = 2048

ACMPO

ACMP+

ACMP–

PTD3/KBIP3/ADP10

PTD2/KBIP2/ACMPO

V

SSOSC

24

Page 25

MC9S08JM32 Device Pin Assignment

No Name Symbol I/O Function

1 PTC4 PTC4 O Port C I/O

2 IRQ/TPMCLK NC NC External Interrupt Pin

3 RESET RESET Development system can directly reset the MCU system

4 PTF0/TPM1CH2 PTF0 I Port F I/O

5 PTF1/TPM1CH3 PTF1 I Port F I/O

6 PTF2/TPM1CH4 PTF2 I Port F I/O

7 PTF3/TPM1CH5 PTF3 I Port F I/O

8 PTF4/TPM2CH0 PTF4 I Port F I/O

9 PTC6 NC NC Port C I/O

10 PTF7 PTF7 O Port F I/O

11 PTF5/TPM2CH1 PTF5 I Port F I/O

12 PTF6 PTF6 O Port F I/O

13 PTE0/TxD1 NC NC Port E I/O

14 PTE1/RxD1 NC NC Port E I/O

15 PTE2/TPM1CH0 TPM1CH0 I TIMER/PWM MODULE (TPM1)

16 PTE3/TPM1CH1 TPM1CH1 I TIMER/PWM MODULE (TPM1)

17 PTE4/MISO1 PTE4 O Port E I/O

18 PTE5/MOSI1 PTE5 O Port E I/O

19 PTE6/SPSCK1 PTE6 O Port E I/O

20 PTE7/SS1 PTE7 O Port E I/O

21 VDD VDD The primary power supply pins for the MCU

22 VSS VSS The primary power supply pins for the MCU

23 USBDN USBDN I/O Differential USB signaling

24 USBDP USBDP I/O Differential USB signaling

25 VUSB33 VUSB33 3.3V USB voltage regulator output or 3.3V USB transceiver/resistor

26 PTG0/KBIP0 PTG0 I Port G I/O

27 PTG1/KBIP1 PTG1 I Port G I/O

28 PTA0 PTA0 O Port A I/O

29 PTA1 PTA1 O Port A I/O

30 PTA2 PTA2 O Port A I/O

31 PTA3 PTA3 O Port A I/O

32 PTA4 PTA4 O Port A I/O

33 PTA5 PTA5 O Port A I/O

34 PTB0/MISO2/ADP0 PTB0 I Port B I/O

35 PTB1/MOSI2/ADP1 PTB1 I Port B I/O

36 PTB2/SPSCK2/ADP2 PTB2 I Port B I/O

37 PTB3/SS2/ADP3 PTB3 I Port B I/O

38 PTB4/KBIP4/ADP4 PTB4 I Port B I/O

39 PTB5/KBIP5/ADP5 PTB5 I Port B I/O

40 PTB6/ADP6 ADP6 I 12-Bit Analog-To-Digital Converter(ADC)

41 PTB7/ADP7 ADP7 I 12-Bit Analog-To-Digital Converter(ADC)

42 PTD0/ADP8/ACMP+ PTD0 I Port D I/O

43 PTD1/ADP9/ACMP– PTD1 I Port D I/O

44 VDDAD VDDAD The analog power supply pins for the MCU

45 VREFH VREFH The voltage reference high inputs respectively for the ADC module

46 VREFL VREFL The voltage reference low inputs respectively for the ADC module

47 VSSAD VSSAD The analog power supply pins for the MCU

48 PTD2/KBIP2/ACMPO PTD2 O Port D I/O

49 PTD3/KBIP3/ADP10 ADP10 I 12-Bit Analog-To-Digital Converter(ADC)

50 PTD4/ADP11 PTD4 O Port D I/O

51 PTD5 PTD5 O Port D I/O

52 PTD6 PTD6 O Port D I/O

25

Page 26

No Name Symbol I/O Function

53 PTD7 PTD7 O Port D I/O

54 PTG2/KBIP6 PTG2 I Port G I/O

55 PTG3/KBIP7 PTG3 I Port G I/O

56 BKGD/MS BKGD Background/Mode Select

57 PTG4/XTAL XTAL External Oscillator

58 PTG5/EXTAL EXTAL External Oscillator

59 VSSOSC VSSOSC Low-Power Oscillator

60 PTC0/SCL PTC0 O Port C I/O

61 PTC1/SDA PTC1 O Port C I/O

62 PTC2 PTC2 O Port C I/O

63 PTC3/TxD2 PTC3 O Port C I/O

64 PTC5/RxD2 PTC5 O Port C I/O

26

Page 27

PIC16F616 (IC104)

RA5/T1CKI/OSC1/CLKIN

RA4/AN3/T1G

/OSC2/CLKOUT

RA3/MCLR

RC5/CCP1/P1A

RC4/C2OUT/P1B

RC3/AN7/C12IN3-/P1C

VDD

/VPP

1

2

3

4

5

6

7

14

13

12

11

10

9

PIC16F616/16HV616

8

VSS

RA0/AN0/C1IN+/ICSPDAT

RA1/AN1/C12IN0-/V

RA2/AN2/T0CKI/INT/C1OUT

RC0/AN4/C2IN+

RC1/AN5/C12IN1-

RC2/AN6/C12IN2-/P1D

REF/ICSPCLK

PIC16F616 Poin Summary

I/O Pin Analog Comparators Timer CCP Interrupts Pull-ups Basic

RA0 13 AN0 C1IN+ — — IOC Y ICSPDAT

RA1 12 AN1/V

REF

RA2 11 AN2 C1OUT T0CKI — INT/IOC Y —

(1)

RA3

4— — — — IOCY

RA4 3 AN3 — T1G — IOC Y OSC2/CLKOUT

RA5 2 — — T1CKI — IOC Y OSC1/CLKIN

RC0 10 AN4 C2IN+ — — — — —

RC1 9 AN5 C12IN1- — — — — —

RC2 8 AN6 C12IN2- — P1D — — —

RC3 7 AN7 C12IN3- — P1C — — —

RC4 6 — C2OUT — P1B — — —

RC5 5 — — — CCP1/P1A — — —

— 1 — — — — — — V

—14 — — — — — — V

Note 1: Input only.

2: Only when pin is configured for external MCLR

C12IN0- — — IOC Y ICSPCLK

(2)

MCLR/V

DD

SS

PP

.

PIC16F616 Device Pin Assignment

Pin No Pin NAME Symbol I/O FUNCTION

1 VDD VBAS POWER

2 RA5 RA5 I Timer1 clock input

3 RA4 RA4 O NC

4 RA3 MCLR I BACKGROUND HEADER

5 RC5 RC5 O PWM output

6 RC4 RC4 O Comparator C2 output

7 RC3 RC3 O NC

8 RC2 RC2 O NC

9 RC1 RC1 O NC

10 RC0 RC0 I Comparator C2 non-inverting input

11 RA2 PA2 O NC

12 RA1 ICSPCLK I Comparators C1 and C2 inverting input/BACKGROUND HEADER

13 RA0 ISCPDAT O BACKGROUND HEADER

14 VSS DGND POWER

27

Page 28

PIC16F616 Block Diagram

OSC1/CLKIN

OSC2/CLKOUT

T1G

Program

Bus

Internal

Oscillator

Block

Configuration

Flash

2K X 14

Program

Memory

14

Instruction Reg

Instruction

Decode &

Control

Timing

Generation

13

Program Counter

Direct Addr

8

Start-up Timer

MCLR

INT

8-Level Stack

(13-Bit)

Power-up

Timer

Oscillator

Power-on

Reset

Watchdog

Timer

Brown-out

Reset

VDD

VSS

RAM Addr

7

Data Bus

RAM

128 Bytes

File

Registers

9

Addr MUX

8

FSR Reg

STATUS Reg

3

8

Shunt Regulator

(PIC16HV616 only)

MUX

ALU

W Reg

Indirect

Addr

8

PORTA

RA0

RA1

RA2

RA3

RA4

RA5

PORTC

RC0

RC1

RC2

RC3

RC4

RC5

T1CKI

T0CKI

Analog-To-Digital Converter

AN4

AN5

AN6

VREF

AN7

Timer0

Comparator Voltage Reference

Absolute Voltage Reference

AN0

AN1

AN2

AN3

Timer1

Timer2

2 Analog Comparators

and Reference

C2IN+

C2OUT

C1OUT

ECCP

C1IN+

C12IN0-

C12IN1-

C12IN2-

C12IN3-

CCP1/P1A

P1B

P1C

P1D

28

Page 29

PARTS LIST OF P.W.B. UNIT

zParts for which "nsp" is indicated on this table cannot be supplied.

zThe parts listed below are for maintenance only, might differ from the parts used in the unit in appearances or dimensions.

Note: The symbols in the column "Remarks" indicate the following destinations.

E3 : U.S.A. & Canada model E2 : Europe model EA : Australia model

CONTROL P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

SEMICONDUCTORS GROUP

IC101 941243004230P

IC102 941239003100S IC(BD4740G-TR,SMP5) 417-9000-740

IC103 00D9587058204 IC(BA033FP-E2,TO-252-3) 417-CTB200-500

IC104 941243004220P IC(PIC16F616-|/SL,SOIC-16) 417-RMP3-936 *

IC105-108 00D9587058709

Q101-132 00D9587057700 TRANSIST0R(DTC114EKAT146,SMT3) 416-HDJ2460-234

Q134 00D9587057700 TRANSIST0R(DTC114EKAT146,SMT3) 416-HDJ2460-234

D101-104 nsp ESD DIODE(EDZCTE616.8B,150MW/,6.93V,EMD2) 414-RMP3-285

D105-137 nsp

D139-149 nsp

D150 nsp ESD DIODE(EDZCTE616.8B,150MW/,6.93V,EMD2) 414-RMP3-285

D152 nsp TVS DIODE(SMAJ6.0A,400W,6.0V,DO-214AC) 414-UDJ200-284

CONTROL IC ASS'Y

(MC9S08JM32CLH,LQFP-64)

IC(74HC595D/74AHC595D/74AHC595DR

/74HC595D@118,SO-16)

SWITCHING DIODE

(ISS355,TE-17,100mA,90V,UMD2)

SWITCHING DIODE

(ISS355,TE-17,100mA,90V,UMD2)

NOTE :

When update Firmware,

please confi rm a last

version in SDI.

Use the service board

after updating it.

704-SC2000-9496 *

417-HDJ9800-643

414-CD1000-075

414-CD1000-075

D169A 941263004170P LED(LTL-1 CHTBK4,3.1Φ,BLUE) 410-CDI600-357 *

D169B 941263004170P LED(LTL-1 CHTBK4,3.1Φ,BLUE) 410-CDI600-357 *

D184A 941263004170P LED(LTL-1 CHTBK4,3.1Φ,BLUE) 410-CDI600-357 *

D184B 941263004170P LED(LTL-1 CHTBK4,3.1Φ,BLUE) 410-CDI600-357 *

D166A 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D166B 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D168A 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D168B 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D172A 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D172B 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D174A 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D174B 941263004180P LED(YELLOW GREEN,LTL1CHJGDNN) 410-DJ5000-252 *

D170A 941263001060S LED(LTL1CHJEDNN,RED) 410-DJ5000-253

D170B 941263001060S LED(LTL1CHJEDNN,RED) 410-DJ5000-253

D186A 941263001060S LED(LTL1CHJEDNN,RED) 410-DJ5000-253

D186B 941263001060S LED(LTL1CHJEDNN,RED) 410-DJ5000-253

D165A 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D165B 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D167A 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D167B 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D171A 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D171B 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D173A 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D173B 941263004190P LED(LTL1CHJSDNN,YELLOW) 410-HDJ2000-162 *

D169A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D169B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

29

Page 30

Ref. No. Part No. Part Name Remarks Q'ty New

D184A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D184B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D170A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D170B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D186A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D186B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D166A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D166B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D168A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D168B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D172A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D172B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D174A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D174B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D165A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D165B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D167A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D167B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D171A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D171B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D173A nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D173B nsp LED HOLDER(LED3-1A-B,H=1.5mm,BLACK) 504-HDJ2000-097 *

D155A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D155B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D158A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D158B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D160A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D160B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D178A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D178B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D161A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D161B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D162A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D162B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D175A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D175B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D180A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D180B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D181A 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D181B 941263002610S CHIP LED(YELLOW,JA-3020Y,3*2) 410-F300-377

D154A 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D154B 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D164A 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D164B 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D177A 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D177B 941263003110S CHIP LED(JA-3020R,3*2,RED) 410-MIX101-373

D153A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D153B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D156A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D156B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D157A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D157B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

30

Page 31

Ref. No. Part No. Part Name Remarks Q'ty New

D159A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D159B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D183A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D183B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D179A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D179B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D176A 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D176B 941263002620S CHIP LED(JA-3020YG,3'2,YELLOW/GREEN) 410-MIX101-374

D163A 941263002010S CHIP LED(JA-3020B,3*2,BLUE) 410-S700-375 *

D163B 941263002010S CHIP LED(JA-3020B,3*2,BLUE) 410-S700-375 *

D182A 941263002010S CHIP LED(JA-3020B,3*2,BLUE) 410-S700-375 *

D182B 941263002010S CHIP LED(JA-3020B,3*2,BLUE) 410-S700-375 *

RESISTORS GROUP

R112A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R112B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R114A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R114B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R116A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R116B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R118A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R118B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R121A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R121B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R134A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R134B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R135A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R135B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R137A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R137B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R140A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R140B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R142A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R142B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R124A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R124B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R127A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R127B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R130A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R130B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R133A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R133B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R115A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R115B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R117A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R117B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R119A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R119B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R120A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R120B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R125A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R125B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

31

Page 32

Ref. No. Part No. Part Name Remarks Q'ty New

R126A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R126B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R131A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R131B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R132A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R132B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R138A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R138B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R139A nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R139B nsp CHIP RESISTOR(110OHM,J,1/10W,TP 0603,50V) 412-11-1255

R122A nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R122B nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R141A nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R141B nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R128A nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R128B nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R143A nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R143B nsp CHIP RESISTOR(330OHM,1/10W,J,TP 0603,50V) 412-900-983

R113A nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R113B nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R123A nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R123B nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R136A nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R136B nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R129A nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R129B nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R155A nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R155B nsp CHIP RESISTOR(270 OHM,1/10W,0603,J,TP,50V) 412-007USB-698

R1 nsp CHIP RESISTOR(2.4Kohm,1/10W,J,TP 0603,50V) 412-MH2-1135

R2 nsp CHIP RESISTOR(1KOHM,1/10W,J,TP 0603,50V) 412-CDVD2001-540

R5 nsp

R7 nsp CHIP RESISTOR(51KOHM,1/10W,J,TP 0603,50V) 412-900-977

R101,102 nsp CHIP RESISTOR(30OHM,0603,J,1/10W,TAPING) 412-HC1000S-1413

R103 nsp CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V) 412-CDVD2001-534

R106 nsp CHIP RESISTOR(0 OHM,1/10W, 0603,J,TP,50V) 412-CDVD2001-552

R107 nsp CHIP RESIST0R(1 M OHM,1/10W,0603J,TP ,50V) 412-CDVD2001-546

R108 nsp CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V) 412-CDVD2001-534

R109 nsp CHIP RESISTOR(0 OHM,1/10W, 0603,J,TP,50V) 412-CDVD2001-552

R110,111 nsp CHIP RESISTOR(10K OHM,1/10W,0603,J,TP ,50V) 412-CDVD2001-534

R144-154 nsp CHIP RESISTOR(100 OHM,1/10W, 0603,J,TP,50V) 412-CDVD2001-530

R156-167 nsp CHIP RESISTOR(5.6K OHM,1/10W,0603,J,TP ,50V) 412-CDVD2001-537

VR101 941674004200P SLIDE VR(10KB*2,RF60112L4101) 418-SC2000-621 *

CHIP RRESISTOR(20K OHM,1/10W,0603,J,TP ,50V)

412-DCM280-726

CAPASITORS GROUP

C1 nsp CHIP CAPACITOR(0.1uF/50V,M,0603 TYPE,Y5V) 413-DCM280-890

C3 nsp CHIP CAPACITOR(1uF/16V,Z,0603 TYPE,Y5V) 413-007USB-797 *

C8 nsp CHIP CAPACITOR(1uF/16V,Z,0603 TYPE,Y5V) 413-007USB-797 *

C101 941134001550S ELEC. CAPACITOR(10uF/16V,M,105 ºC ,TAPING 4*7) 413-DV300-5155

C102 nsp CHIP CAPACITOR(0.1uF/50V,M,0603 TYPE,Y5V) 413-DCM280-890

C103 941134001550S ELEC. CAPACITOR(10uF/16V,M,105 ºC ,TAPING 4*7) 413-DV300-5155

C104 nsp CHIP CAPACITOR(0.1uF/50V,M,0603 TYPE,Y5V) 413-DCM280-890

C105 941134000520S ELEC.CAPACITOR(4.7uF/25V,MINI) 413-SMX701-712

32

Page 33

Ref. No. Part No. Part Name Remarks Q'ty New

C106 nsp CHIP CAPACITOR(0.47uF/50V Y5V/0603 SMD) 413-CDVD2001-751

C107-110 nsp CHIP CAPACITOR(0.1uF/50V,M,0603 TYPE,Y5V) 413-DCM280-890

C111 00D9587054907

C112,113 nsp CHIP CAPACITOR(33pF/50V,J,0603 TYPE,NPO) 413-007USB-783

C114 00D9587030701

C115,116 nsp CHIP CAPACITOR(3300pF/50V,K,0603 TYPE,X7R) 413-DCM280-770

C122-125 nsp CHIP CAPACITOR(0.1uF/50V,M,0603 TYPE,Y5V) 413-DCM280-890

C126 00D9587054907

C127-138 nsp CHIP CAPACITOR(0.01uF/50V,J,0603 TYPE,NPO) 413-DCM280-889

OTHER PARTS GROUP

FU1 941652004240P CHIP FUSE(1A/30V,0603 TYPE) 422-HC1000-108 *

JK101 941643004210P USB JACK(USB-B(F),90°,DIP) 420-007USB-150 *

CN102 nsp 4P 2.54 STRIP PIN HEADER(H=5.58mm,90°,DIP) 424-SC2000-152

L101 nsp TDK COMMON MODE FILTERS(ACM2012-900-2P-T) 415-FU800-305

L102 nsp BEAD CORE(A70512003, T-26mm) 415-HV3500K-090

L103 941111004240P INDUCTOR(10uH T-26mm) 415-MPG100-047 *

ELEC. CAPACITOR

(100uF/10V,M,105 ºC ,TAPING 5*7,MINI)

ELEC. CAPACITOR

(2.2uF/50V,M,105 ºC ,TAPING 4*7,MINI

ELEC. CAPACITOR

(100uF/10V,M,105 ºC ,TAPING 5*7,MINI)

413-HMA2200-5017

413-DV300-5156 *

413-HMA2200-5017

SW101-127 941662004200P TACT SW(SFKHMMW2720T,4PIN,H=7,SMD) 403-ID-329 *

SW129-134 941667004160P ENCODER(RE111F-41B1-19F-20P-030,L=19) 403-SC2000-380 *

X101 nsp QUARTZ CRYSTAL(CSA-309,12MHz,3*9) 427-KMD3500-047

nsp GROUND PLATE 300-2000-1832

nsp VR CUSHTI0N(0.5t,BLACK) 612-2000-015 *

SENSOR P.W.B. UNIT ASS'Y

Ref. No. Part No. Part Name Remarks Q'ty New

OTHER PARTS GROUP

W102 nsp 4P 2.5 CONNECTOR WIRE(L=130mm,UL20080#26) 404-CD1600-3027 1

M301 nsp IC(HEDS-9700#F51) 417-PS2-504 1

33

Loading...

Loading...