Denon DN-S1200 Service Manual

PROFESSIONAL BUSINESS COMPANY

●

For purposes of improvement, specifications and

design are subject to change without notice.

●

Please use this service manual with referring to the

operating instructions without fail.

●

Some illustrations using in this service manual are

slightly different from the actual set.

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

●

本機の仕様は性能改良のため、予告なく変更すること

があります。

●

補修用性能部品の保有期間は、製造打切後 8 年です。

●

修理の際は、必ず取扱説明書を参照の上、作業を行っ

てください。

●

本文中に使用しているイラストは、説明の都合上現物

と多少異なる場合があります。

Ver. 2

Please refer to the

MODIFICATION NOTICE.

SERVICE MANUAL

MODEL JP E3 E2 EK E2A E2C E1K EUT

DN-S1200

333 3

CD/USB MEDIA PLAYER & CONTROLLER

X0379 V.02 DE/CDM 0902

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

Please heed the points listed below during servicing and inspection.

◎ Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎ Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎ Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

CAUTION

Concerning important safety

parts

◎ Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎ Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

2

DN-S1200

注 意

サービス、点検時にはつぎのことにご注意願います。

◎注意事項をお守りください!

サービスのとき特に注意を必要とする個所については

キャビネット、部品、シャーシなどにラベルや捺印で注意

事項を表示しています。これらの注意書きおよび取扱説明

書などの注意事項を必ずお守りください。

◎感電に注意!

(1) このセットは、交流電圧が印加されていますので通電

時に内部金属部に触れると感電することがあります。

従って通電サービス時には、絶縁トランスの使用や手

袋の着用、部品交換には、電源プラグを抜くなどして

感電にご注意ください。

(2) 内部には高電圧の部分がありますので、通電時の取扱

には十分ご注意ください。

◎分解、組み立て作業時のご注意!

板金部品の端面の『バリ』は、部品製造時に充分管理をし

ておりますが、板金端面は鋭利となっている箇所が有りま

すので、部品端面に触れたまま指を動かすとまれに怪我を

する場合がありますので十分注意して作業して下さい。手

の保護のために手袋を着用してください。

◎指定部品の使用!

セットの部品は難燃性や耐電圧など安全上の特性を持っ

たものとなっています。従って交換部品は、使用されてい

たものと同じ特性の部品を使用してください。特に配線

図、部品表にz印で指定されている安全上重要な部品は

必ず指定のものをご使用ください。

◎部品の取付けや配線の引きまわしは、

元どおりに!

安全上、テープやチューブなどの絶縁材料を使用したり、

プリント基板から浮かして取付けた部品があります。また

内部配線は引きまわしやクランパーによって発熱部品や

高圧部品に接近しないように配慮されていますので、これ

らは必ず元どおりにしてください。

◎サービス後は安全点検を!

サービスのために取り外したねじ、部品、配線などが元ど

おりになっているか、またサービスした個所の周辺を劣化

させてしまったところがないかなどを点検し、外部金属端

子部と、電源プラグの刃の間の絶縁チェックをおこなうな

ど、安全性が確保されていることを確認してください。

(絶縁チェックの方法)

電源コンセントから電源プラグを抜き、アンテナやプラグ

などを外し、電源スイッチを入れます。500V 絶縁抵抗計

を用いて、電源プラグのそれぞれの端子と外部露出金属部

[アンテナ端子、ヘッドホン端子、マイク端子、入力端子

など]との間で、絶縁抵抗値が1 MΩ 以上であることを

確認してください。この値以下のときはセットの点検修理

が必要です。

注 意

本機に使用している多くの電気部品、および機構部品は安

全上、特別な特性を持っています。この特性はほとんどの

場合、外観では判別つきにくく、またもとの部品より高い

定格(定格電力、耐圧)を持ったものを使用しても安全性

が維持されるとは、限りません。安全上の特性を持った部

品は、このサービスマニュアルの配線図、部品表につぎの

ように表示していますので必ず指定されている部品番号

のものを使用願います。

(1) 配線図…zマークで表示しています。

(2) 部品表…zマークで表示しています。

安全上重要な部品について

指定された部品と異なるものを使用した場

合には、感電、火災などの危険を生じる恐

れがあります。

3

DN-S1200

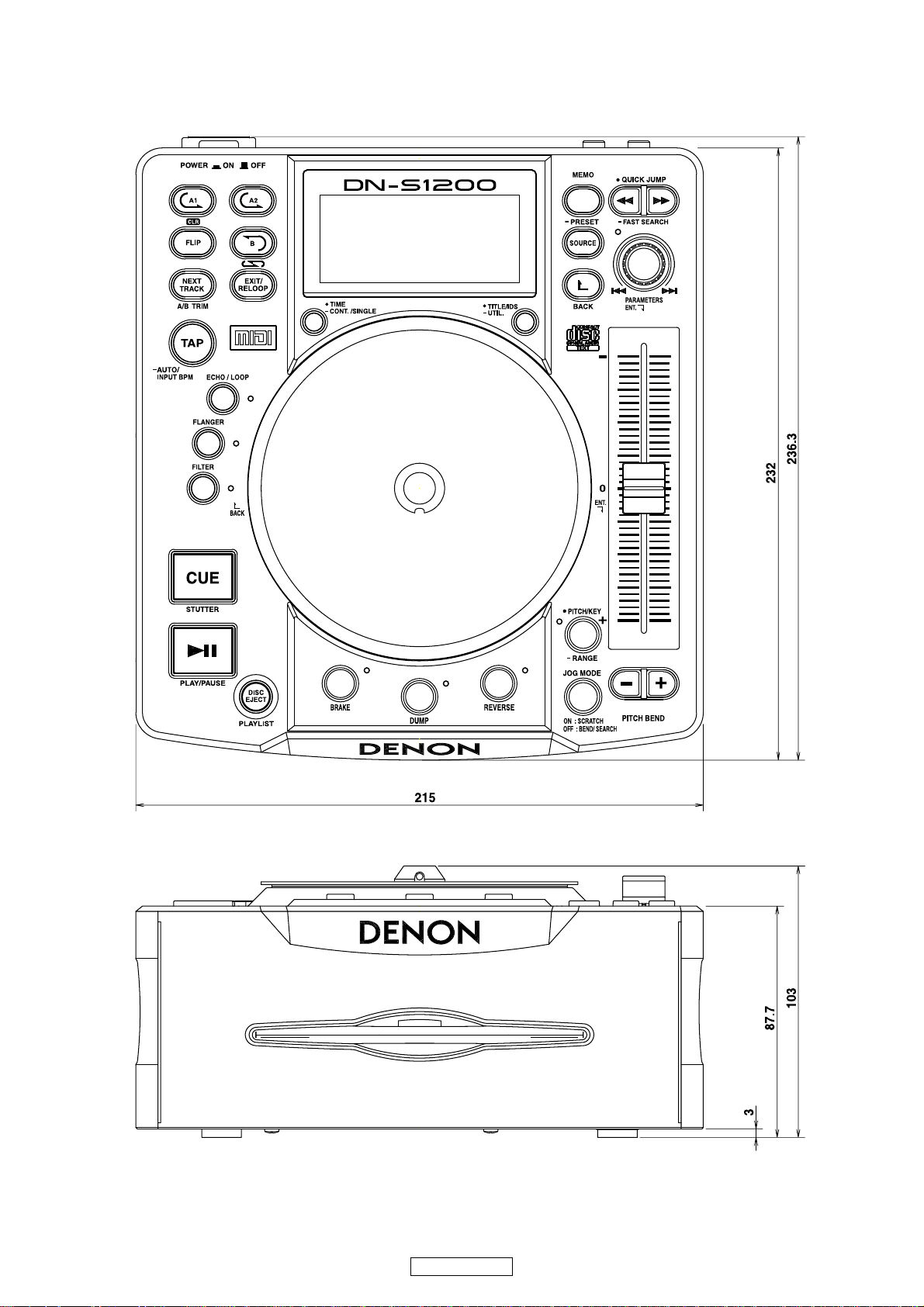

DIMENSION

4

DN-S1200

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling.)

各部のはずしかた

(組み立てるときは、逆の順序でおこなってください。)

Note : Do not fail to pull AC cord from wall outlet before dis-

connect the FFC cable and wire.

If AC cord is remained plugged into wall outlet, power

is kept supplied in the unit, which may cause damage.

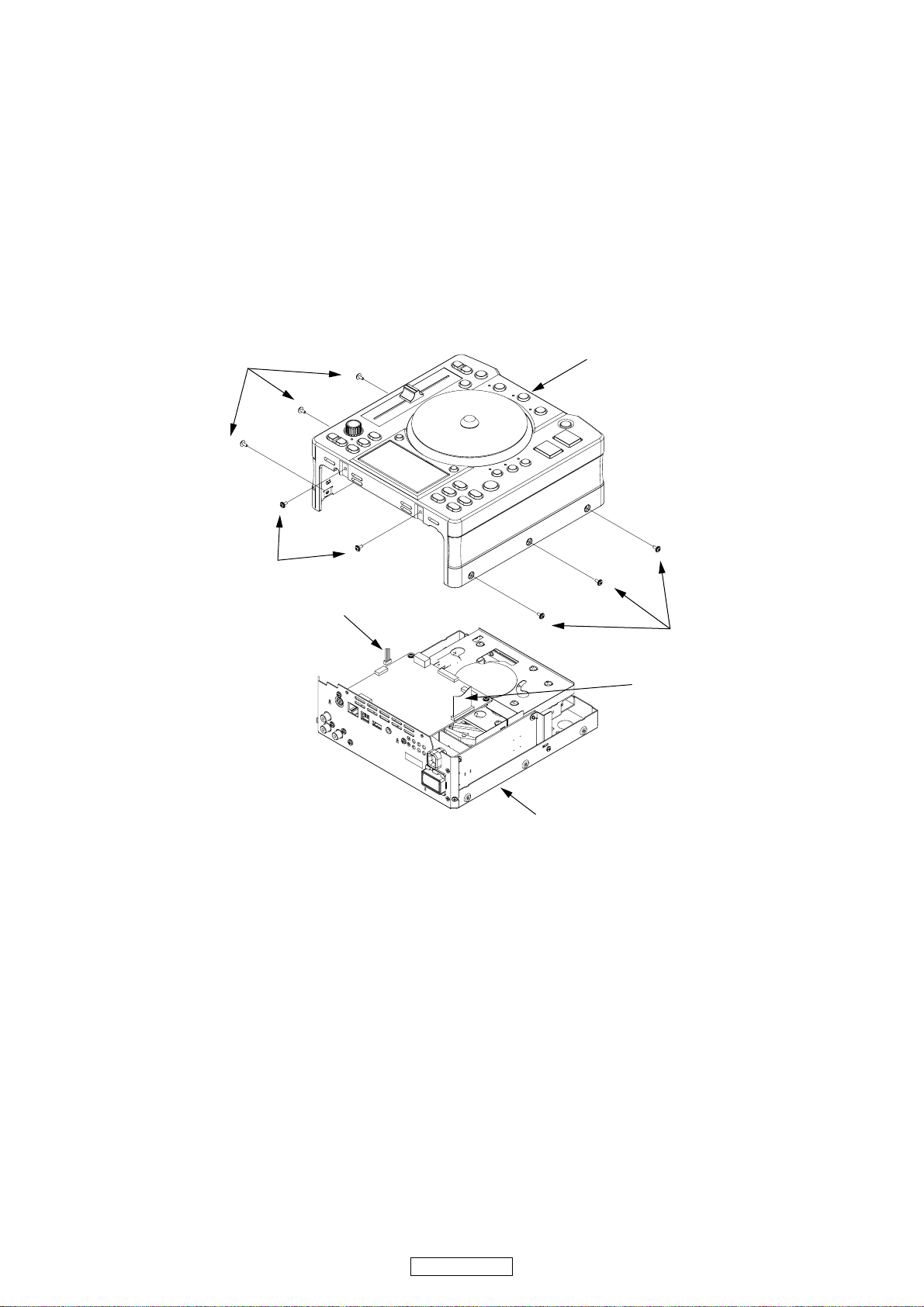

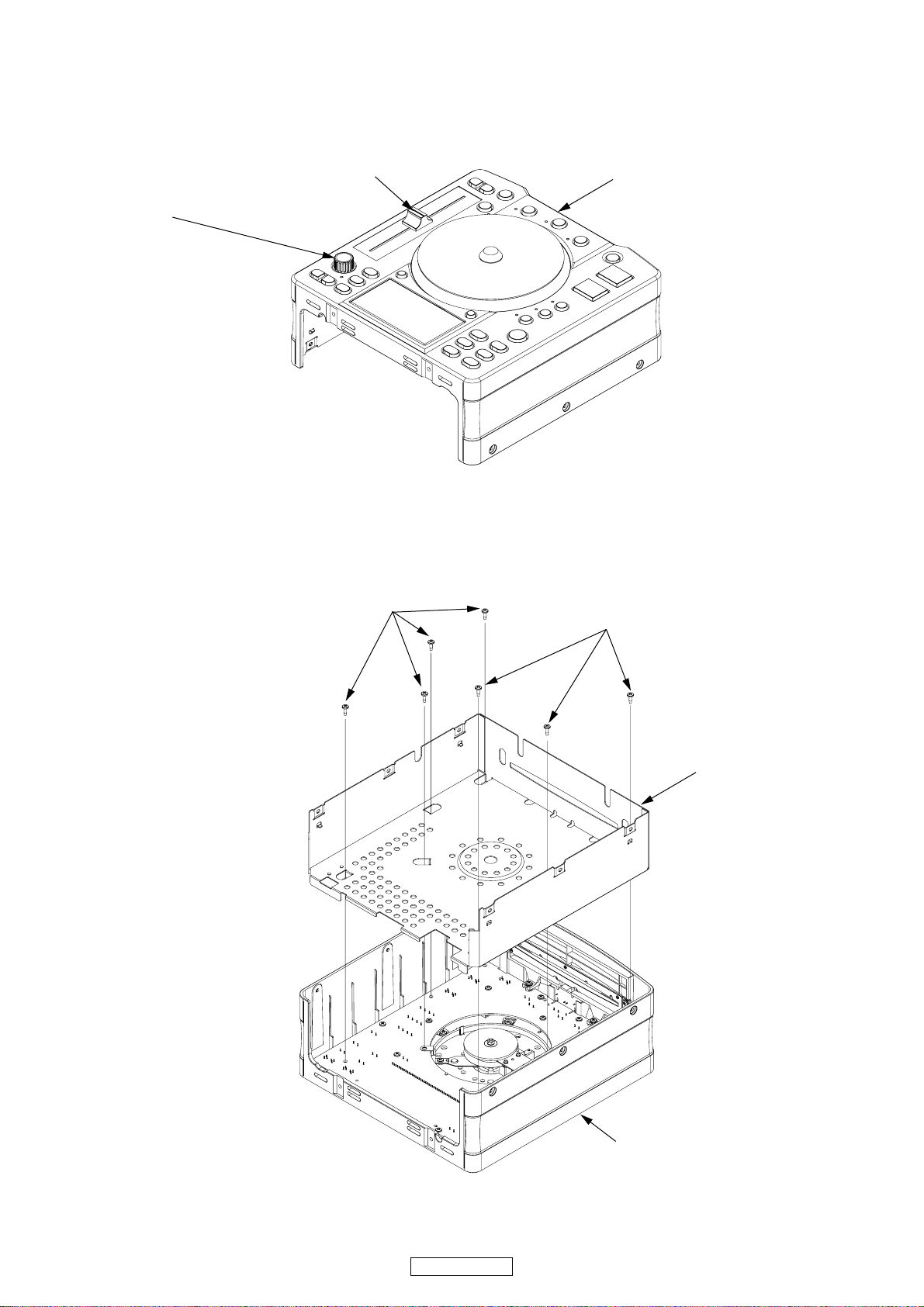

1. TOP CASE Unit

(1) Remove the 3 screws on the each L/R side.

(2) Remove 2 screws on the rear side.

(3) Pull up the TOP CASE UNIT and then pull out the 27P

FFC cable and 4P wire cable.

SCREWS

SCREWS

注意: FFCケーブルを抜く前に AC電源コードをコンセント

から抜いて下さい。ACコードがコンセントに接続さ

れていると、Unitに電源が供給され危険です。

1. TOPCASEUNIT

(1) 左右面のねじ各 3 本をはずす。

(2) 後面のねじ 2 本をはずす。

(3) TPOCASEUNIT を引き上げ、27PFFCケーブルと 4P

ワイヤーケーブルを引き抜く。

TOP CASE Assembly

4P wire cable

Rear side

Note : Do not fail to pull AC cord from wall outlet before dis-

connect the FFC cable and wire.

SCREWS

27P FFC cable

BOTTOM CASE UNIT

注意: FFCケーブルとワイヤーを抜く前に、AC コードをコ

ンセントから抜いてください。

5

DN-S1200

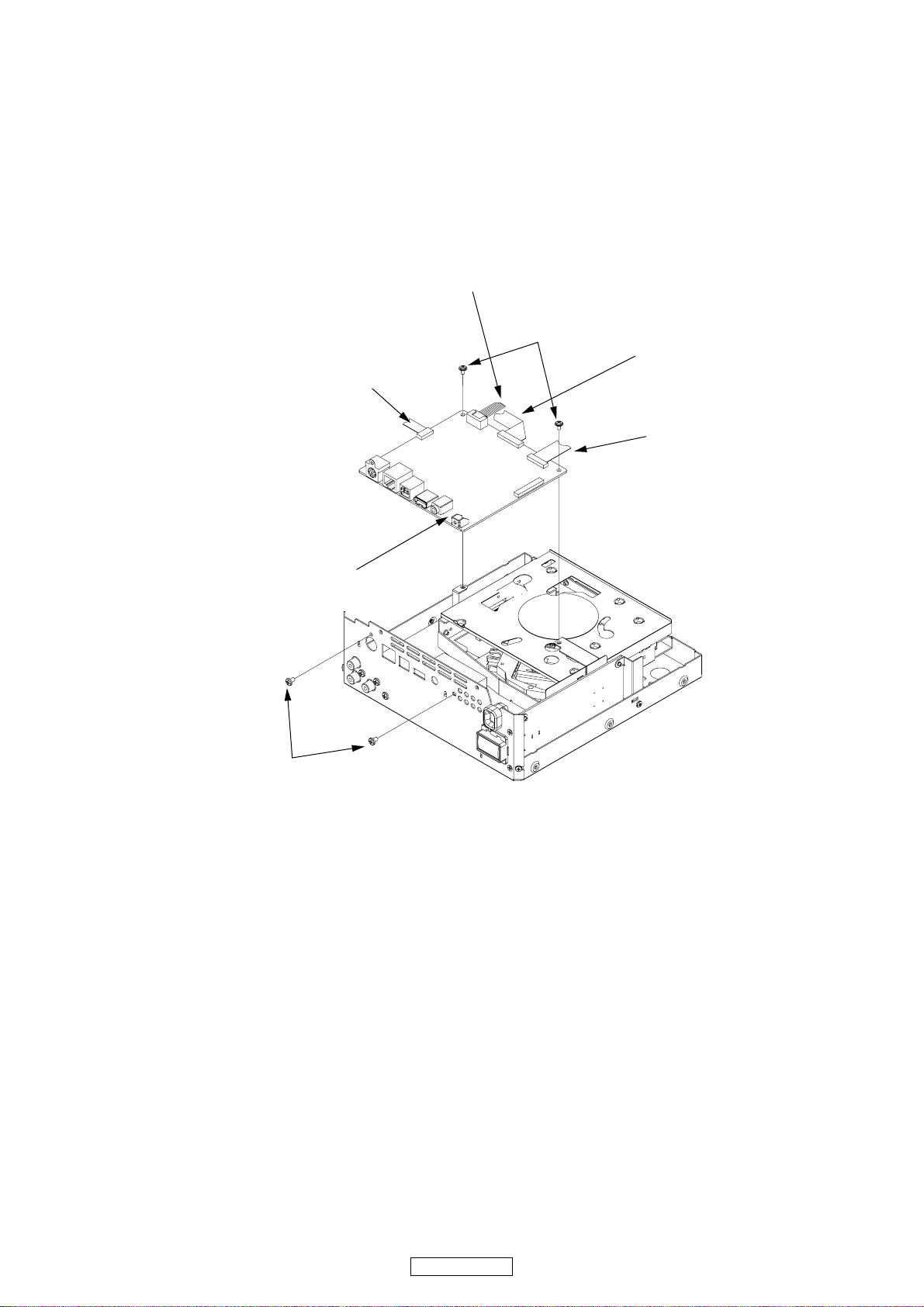

2. MAIN PWB UNIT

(1) Remove the 7P KR wire, 22P FFC cable and 14P FFC

cable on the MAIN PWB UNIT of front side.

(2) Remove the 11P FFC Cable on the Right side of MAIN

PWB UNIT.

(3) Remove the 2 screws on the MAIN PWB UNIT and 2

screws on the rear side.

(4) Pull up the MAIN PWB UNIT and moved the MAIN

PWB UNIT.

2. MAINPWBUNIT

(1) 前側の MAINPWBUNIT7PKRワイヤー、22PFFC ケー

ブルと 14PFFC ケーブルをはずす。

(2) MAINPWBUNIT 右側の 11PFFC ケーブルをはずす。

(3) MAINPWBUNIT のねじ 2 本と後面側のねじ 2 本をは

ずす。

(4) MAINPWBUNIT を引き上げて移動する。

7P KR wire

7P KR wire

11P FFC cable

11P FFC cable

MAIN PWB UNIT

MAIN PWB UNIT

SCREWS

SCREWS

SCREWS

22P FFC cable

SCREWS

22P FFC cable

14P FFC cable

14P FFC cable

Rear side

Rear side

Note : Do not fail to pull AC cord from wall outlet before dis-

connect the FFC cable and wire.

DN-S1200

注意: FFCケーブルとワイヤーを抜く前に、AC コードをコ

ンセントから抜いてください。

6

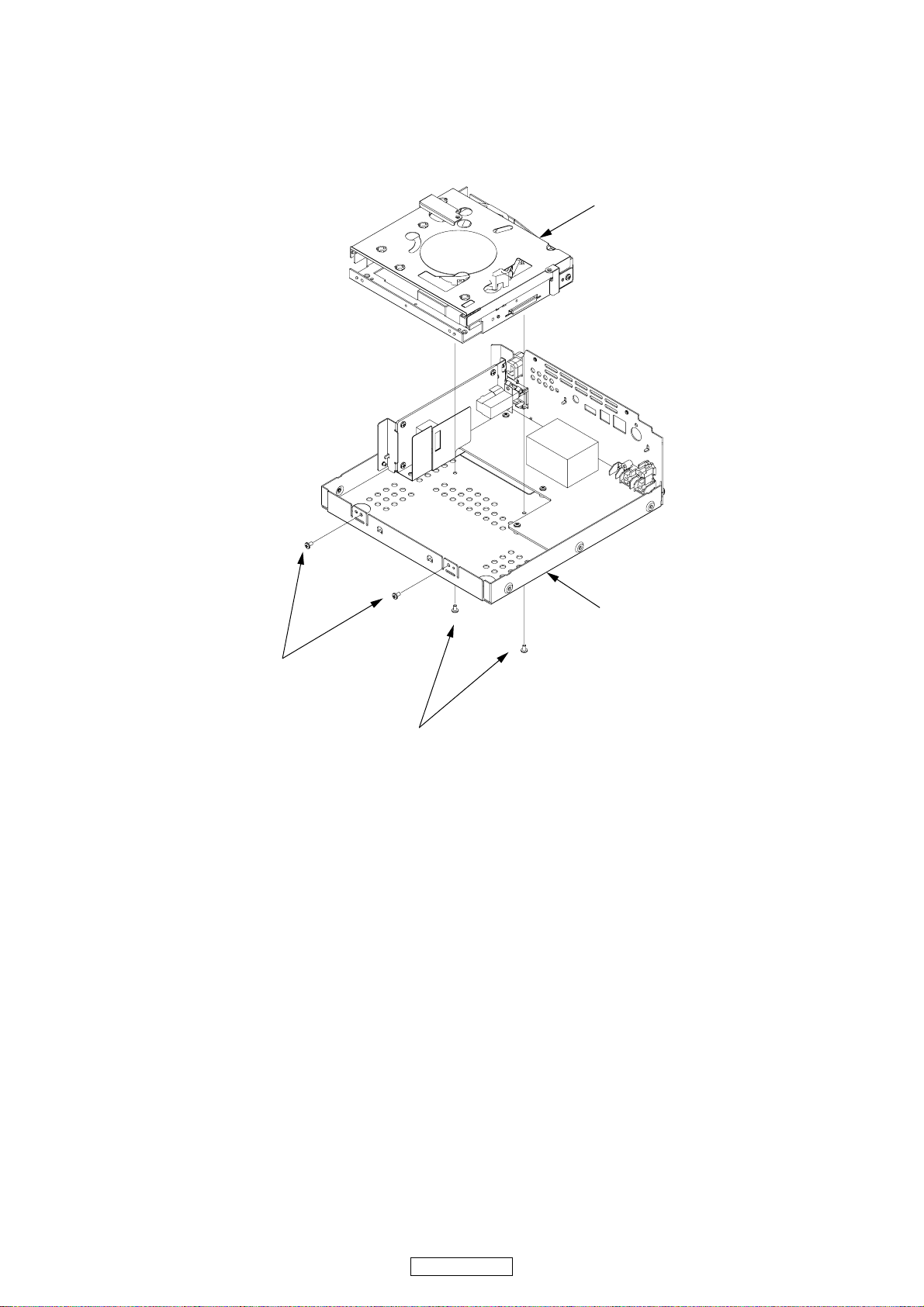

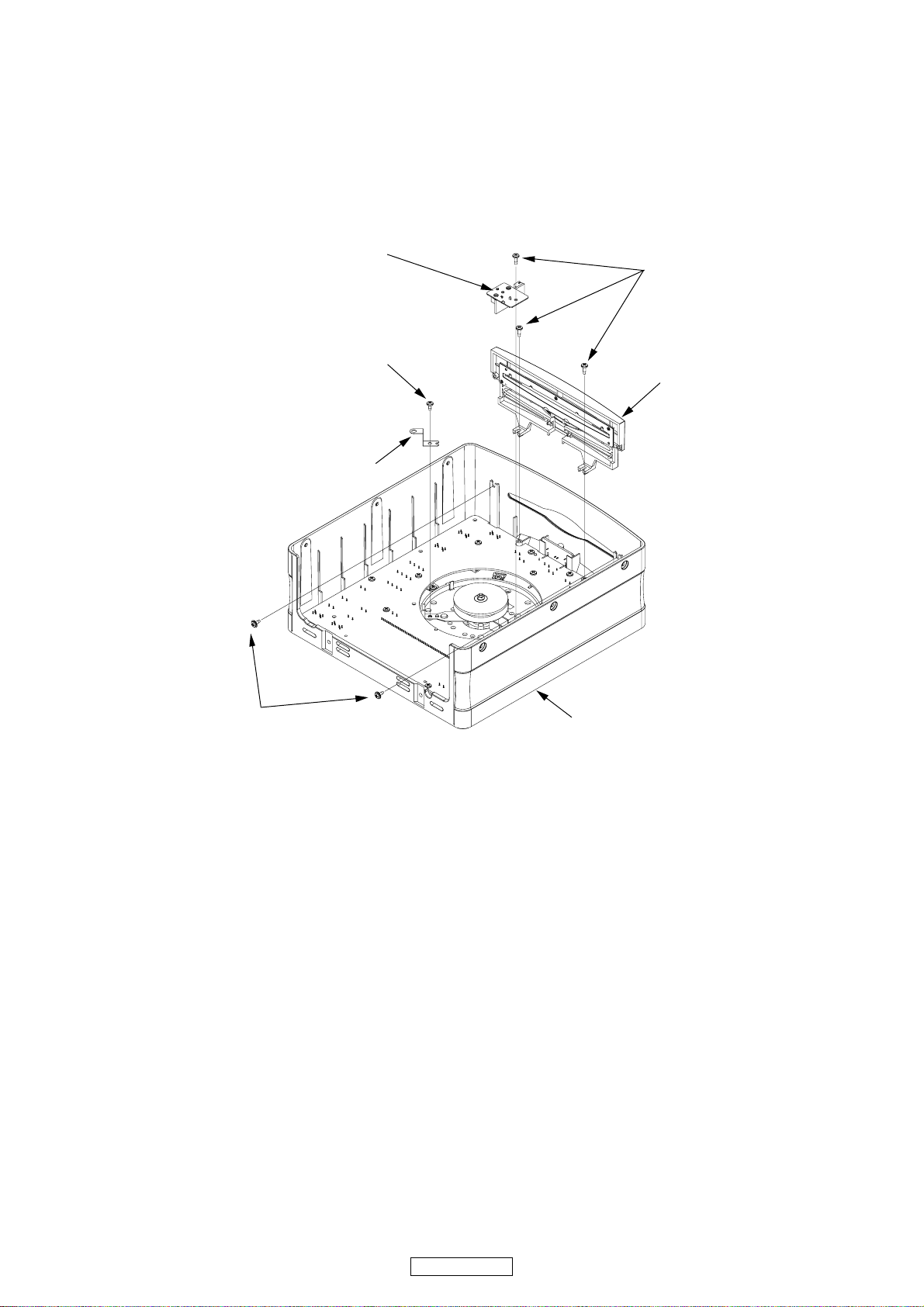

3. CD MECHA UNIT

(1) Remove the 2 screws on the front side and the 2

screws on the bottom side.

(2) Pull up the CD MECHA UNIT and Remove the CD

MECHA UNIT.

3. CDMECHAUNIT

(1) 前面と底面のねじ各 2 本をはずす。

(2) CD MECHA UNIT を引き上げ、取り外す。

CD MECHA. UNIT

Rear Side

SCREWS

BOTTOM CHASSIS

SCREWS

7

DN-S1200

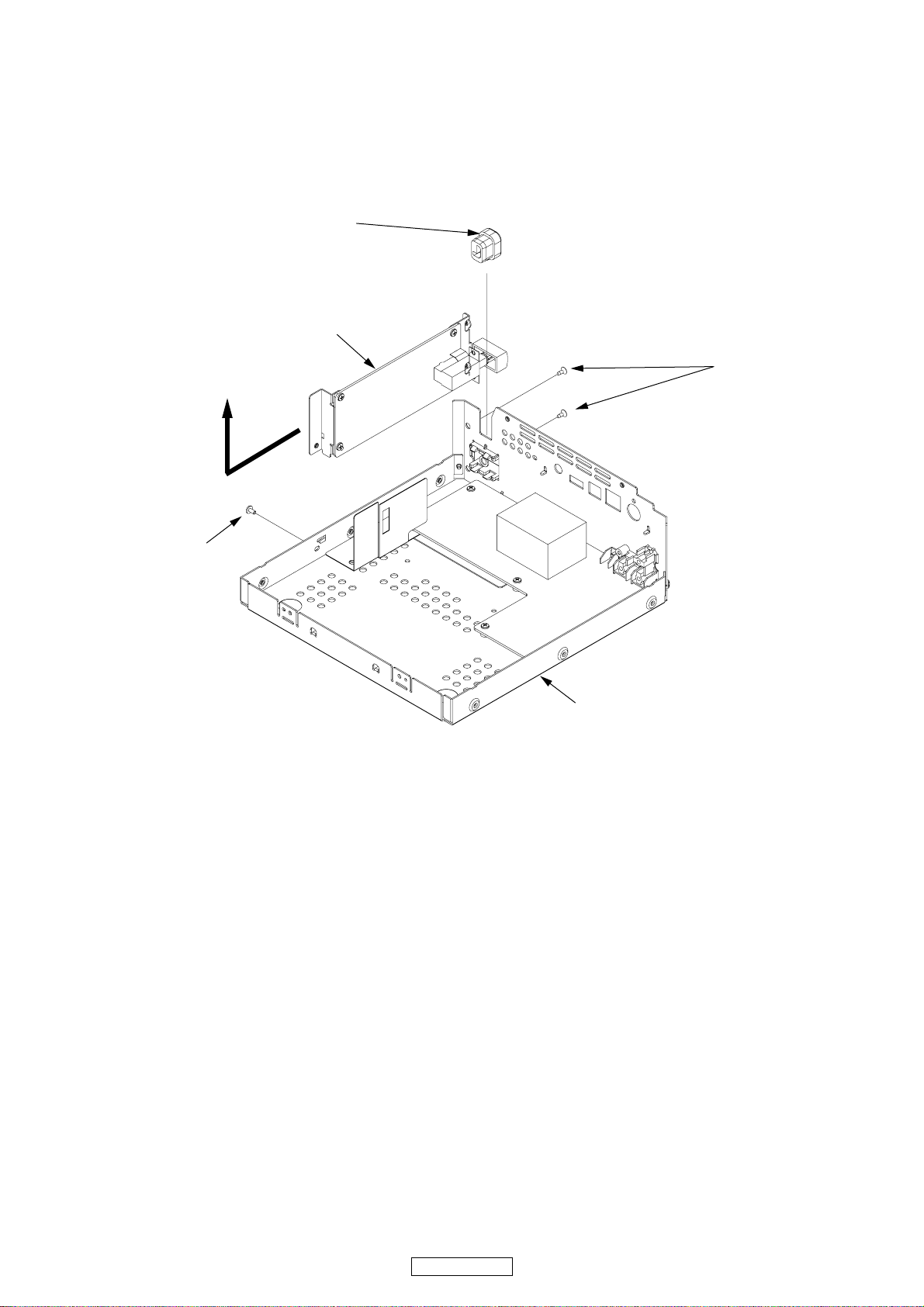

4. POWER PWB UNIT

(1) Remove the 2 screws on the rear side and remove the

screw on the left side.

(2) Pull up the CORD BUSH with AC CORD.

(3) Pull the AC INPUT PWB Unit to the direction of arrow

and remove the AC INPUT PWB Unit and AC CORD.

CORD BUSH

AC INPUT UNIT

4. POWERPWBUNIT

(1) 後面側のねじ 2 本と左側のねじをはずす。

(2) CORDBUSH を ACCORD と一緒に引き上げる

(3) AC INPUT PWB UNIT を矢印の方向に引き出し、AC

CORD と一緒にはずす。

SCREW

Rear Side

SCREW

BOTTOM CHASSIS

8

DN-S1200

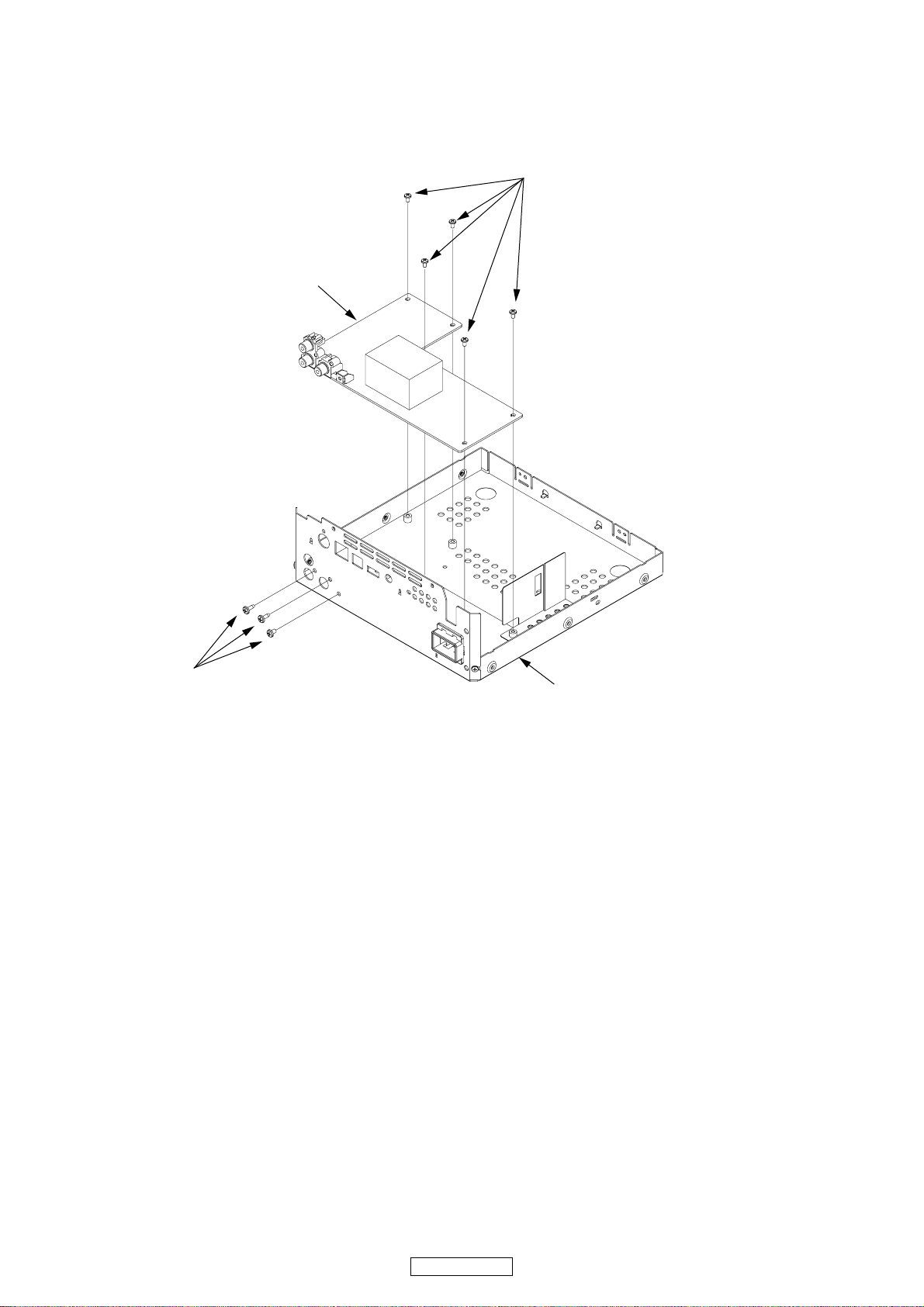

(4) Remove the 5 screws on the POWER PWB Unit.

(5) Remove the 3 screws on the rear side.

(6) Pull up the POWER PWB Unit and remove the POW-

ER PWB Unit.

POWER PWB UNIT

(4) POWERPWBUNITのねじ 5 本をはずす。

(5) 後面側のねじ 3 本をはずす。

(6) POWERPWBUNIT を引き上げはずす。

SCREWS

SCREWS

Rear Side

BOTTOM CASE

9

DN-S1200

5. PANEL PWB UNIT

(1) Pull up the PARAMETER KNOB and FADER KNOB

from TOP CASE UNIT.

5. PANELPWBUNIT

(1) PARAMETERKNOBとFADERKNOB をTOPCASEUNIT

から引き上げる。

FADER KNOB

PARAMETER KNOB

(2) Turn over the TOP CASE UNIT.

(3) Remove the 7 screws on the CHASSIS COVER and

then pull out the CHASSIS COVER.

SCREWS

TOP CASE UNIT

(2) TOP CASE UNIT を逆さまにする。

(3) CHASSISCOVER のねじ 7 本をはずしてから CHASSIS

COVER を引き抜く。

SCREWS

Rear side

SHASSIS COVER

TOP CASE UNIT

10

DN-S1200

(4) Remove the screw on the SENSOR UNIT and then re-

move the SENSOR UNIT.

(5) Remove the screw on the SPACER GND and then re-

move the SPACER GND.

(6) Remove the 2 screws on the rear side and 2 screws

on the FRONT SUB PANEL.

(7) Pull up the FRONT SUB PANEL and remove the

FRONT SUB PANEL.

SENSOR UNIT

SCREW

SPACER GND

(4) SENSORUNITのねじ1本をはずしてからSENSORUNIT

を取りはずす。

(5) SPACERGNDのねじ 1 本をはずしてからSPACERGND

を取りはずす。

(6) 後面側のねじ 2 本と FRONTSUBPANEL のねじ 2 本を

はずす。

(7) FRONTSUBPANEL を引き上げて取りはずす。

SCREWS

FRONT SUB PANEL

SCREWS

Rear Side

TOP CASE UNIT

11

DN-S1200

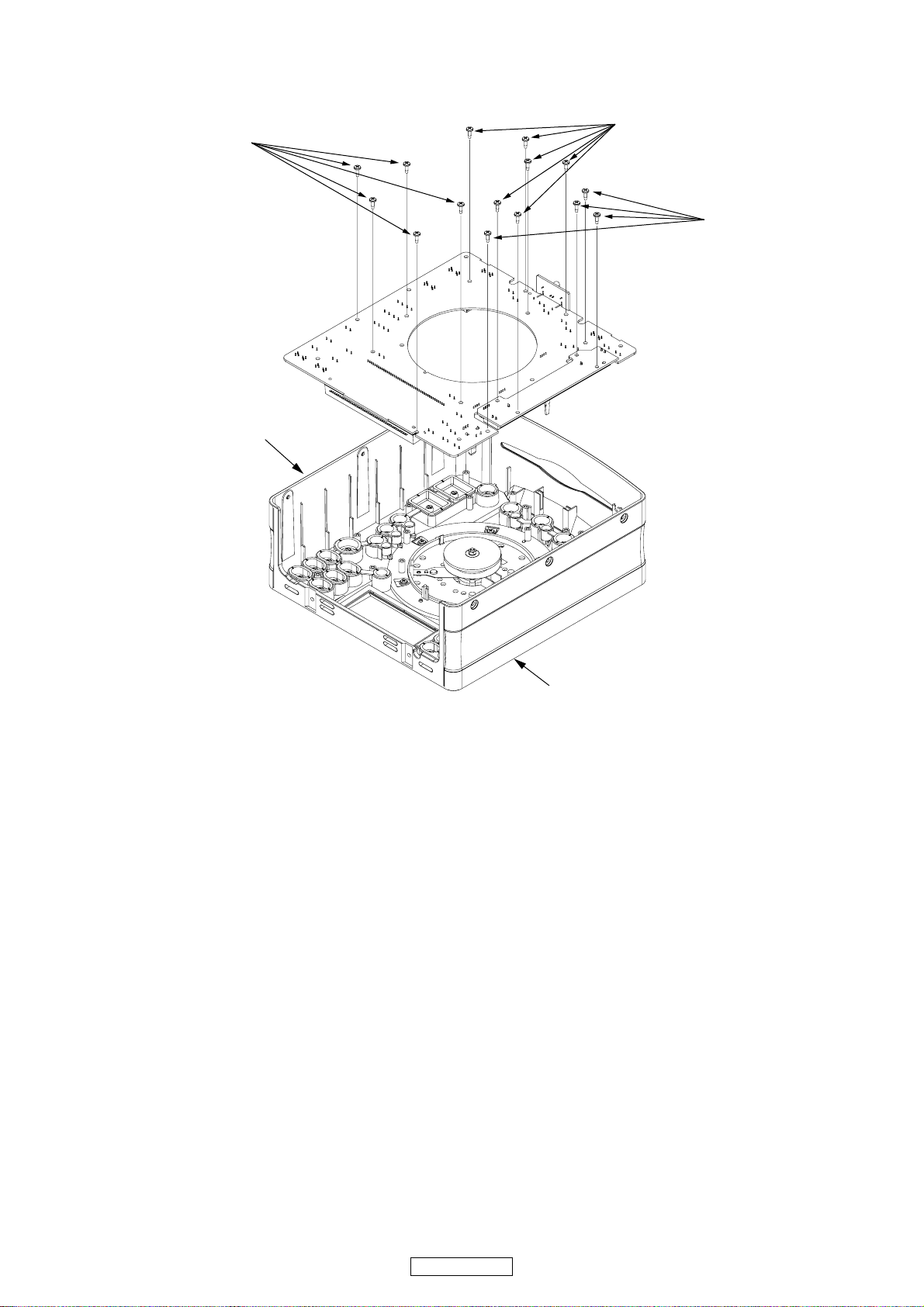

(8) Remove the 15 screws on the PANEL PWB UNIT.

And then remove the PANL PWB UNIT.

SCREWS

PANEL PWB UNIT

(8) PANELPWBUNITのねじ 15本をはずしてから、PANEL

PWBUNIT をはずす。

SCREWS

SCREWS

TOP CASE UNIT

12

DN-S1200

SERVICE MODE

サービスモードについて

1. Turning on the power in the service mode

(1) Turn on the power while pressing the PARAMETERS knob and the button simultaneously.

The following appears on the VFD segment display section:

--Service---

Func t i on CHK

(2) When the PARAMETERS knob is turned clockwise, the display on the lower tier of the VFD segment display section switches

in the following order: "Function CHK" → "CD Drive CHK" → "SW Check" → "Panel CHK" → "Touch MEAS".

The display switches in the opposite order when the PARAMETERS knob is turned counterclockwise.

(3) The displayed mode can be selected by pressing the PARAMETERS knob.

2. Function summary

(1) Checking the operations of the functions (Function CHK)

① Setting initialization (S1200 init)

② D-Link operation check (D-Link Check)

③ Audio signal output (Audio Out)

④ Audio mute check (Mute Check)

⑤ Touch initialization (Touch Init.)

⑥ USB-MIDI command transmission (USB-MIDI)

⑦ USB device operation check (USB Test)

⑧ PS/2 operation check (PS/2 Check)

⑨ Sub microprocessor version up (Sub CPU Ver. UP)

(2) Checking the operations of the CD drive (CD Drive CHK)

① Disk type distinction display (Disc Type)

② Servo data display (Servo Data)

③ Error rate display (Error Rate)

④ Pickup movement (PU Clean)

⑤ Remove the disc (Loader Clean)

⑥ Error code display (Err Code CHK)

⑦ Total running time display (Total Time)

⑧ Heat Run mode1 (H/R1)

⑨ Heat Run mode2 (H/R2)

(3) Checking the operations of the switches (SW Check)

1. サービスモードの立ち上げかた

(1) PARAMETERS ノブと ボタンを同時に押しながら、電源を ON にする。

VFD のセグメント表示部に以下の文字が表示される。

--Service---

Func t i on CHK

(2) PARAMETERSノブを右に回すと VFD のセグメント表示部の下段の表示が "FunctionCHK" → "CDDriveCHK" → "SWCheck"

→ "PanelCHK" → "TouchMEAS" の順で切り替わる。PARAMETERSノブを左に回すと逆の順で表示が切り替わる。

(3) PARAMETERSノブを押すと、表示されているモードを選択できる。

2. 機能概要

(1) 機能動作確認 (FunctionCHK)

① 設定初期化(S1200init)

② D-Link 動作確認(D-LinkCheck)

③ オーディオ信号出力(AudioOut)

④ オーディオミュート確認(MuteCheck)

⑤ タッチ初期化(TouchInit.)

⑥ USB-MIDI コマンド送信(USB-MIDI)

⑦ USB デバイス動作確認(USBTest)

⑧ PS/2 動作確認(PS/2Check)

⑨ サブマイコンのバージョンアップ(SubCPUVerUP)

(2) CD ドライブ動作確認(CDDriveCHK)

① ディスク種類判別表示(DiscType)

② サーボデータ表示(ServoData)

③ エラーレート表示(ErrorRate)

④ ピックアップ移動(PUClean)

⑤ ディスク取り出し(LoaderClean)

⑥ エラーコード表示(ErrCodeCHK)

⑦ トータルランニング時間表示(TotalTime)

⑧ ヒートランモード 1(H/R1)

⑨ ヒートランモード 2(H/R2)

(4) Checking the operations of the panel (Panel CHK)

① PARAMETERS knob

② JOG disc

③ Pitch FADER

④ FADER IN

The functions shown below are always available while in the panel check mode.

⑤ All LEDs lit, All VFD segments Lit/LED DIM, All VFD segments off/All LEDs off, All VFD segments off

(5) Touch measurement (Touch MEAS)

Measurement of the count value when the touch sensor section is not being touched, and measurement and judgment of the

amount of change of the count value when the touch sensor section is being touched.

(3) スイッチ動作確認 (SWCheck)

(4) パネル動作確認 (PanelCHK)

① PARAMETERS ノブ

② JOG ディスク

③ ピッチフェーダ

④FADERIN

以下の機能は、パネルチェックモードにしている間は常に有効。

⑤ LED 全点灯、VFD セグメント全点灯 /LEDDIM、VFD セグメント全消灯 /LED 全消灯、VFD セグメント全消灯

(5) タッチ測定 (TouchMEAS)

タッチ検出部の非タッチ時のカウント値の測定と、タッチ時のカウント値の変化量の測定および判定。

13

DN-S1200

3. Checking the operations of the functions (Function CHK)

(1) Turn the PARAMETERS knob to select "Function CHK" from the service mode's top menu, then press the PARAMETERS knob

to set the function check mode. The following appears on the VFD segment display section:

Func t i on CHK

S1200 i n i t

(2) When the PARAMETERS knob is turned clockwise, the display on the lower tier of the VFD segment display section switches

in the following order: "S1200 init" → "D-Link Check" → "Audio Out" → "Mute Check" → "Touch Init." → "USB-MIDI" → "USB

Test" → "PS/2 Check" → "SubCPU VerUP".

The display switches in the opposite order when the PARAMETERS knob is turned counterclockwise.

(3) The displayed mode can be executed by pressing the PARAMETERS knob.

(4) Press the button to return to the top level of the service mode.

3. ファンクッションチェックモード機能(FunctionCHK)

(1) PARAMETERS ノブを回して、サービスモードの TOP 画面から "FunctionCHK" を選択し、PARAMETERS ノブを押して確定

する。VFD のセグメント表示部に以下の文字が表示される。

Func t i on CHK

S1200 i n i t

(2) PARAMETERSノブを右に回すと VFD のセグメント表示部の下段の表示が "S1200init" → "D-LinkCheck" → "AudioOut" →

"MuteCheck" → "TouchInit." → "USB-MIDI"→"USBTest"→"PS/2Check"→"SubCPUVerUP" の順で切り替わる。

PARAMETERSノブを左に回すと逆の順で表示が切り替わる。

(3) PARAMETERSノブを押すと、表示されているモードを実行する。

(4) ボタンを押すとサービスモードの TOP 階層に戻る。

3.1. Setting initialization (1200 init)

• The contents of the preset memory are set to the factory defaults

(1) Turn the PARAMETERS knob to select "S1200 init" from the “Function CHK” mode's top menu, then press the PARAMETERS

knob to set "S1200 init" mode. The following appears on the VFD segment display section:

S1200 i n i t

Pus h Pa r am.

(2) The Initialization mode can be executed by pressing the PARAMETERS knob. The following appears on the lower tier of the

VFD segment display section:

When initialization is completed:

Comp l e t e !

When initialization is not completed (Time out):

Fa i l

(3) Press the button to return to the top level of the function check mode.

3.2. D-Link operation check (D-Link Check)

• When executed with the drive terminal's Tx and Rx pins connected externally, the loop-back test is performed.

• The device checks whether the transferred and received contents are the same and the results are displayed.

(1) Turn the PARAMETERS knob to select "D-Link Check" from the “Function CHK” mode's top menu, then press the PARAME-

TERS knob to set "D-Link Check" mode. The following appears on the VFD segment display section:

Func t i on CHK

D-L i nk Check

(2) The displayed mode can be executed by pressing the PARAMETERS knob. The following appears on the lower tier of the VFD

segment display section:

When the process has completed normally:

Comp l e t e !

When the process has completed abnormally:

Fa i l

(3) Press the button to return to the top level of the function check mode.

3.1. 設定初期化(S1200init)

・プリセットメモリの内容を工場出荷状態に設定する。

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "S1200init" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

S1200 i n i t

Pus h Pa r am.

(2) PARAMETERSノブを押して初期化を実行する。VFD のセグメント表示部下段に以下の文字が表示される。

初期化完了時

Comp l e t e !

初期化未完了(タイムアウト)時

Fa i l

(3) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

3.2. D-Link 動作確認(D-LinkCheck)

・機器外部で Drive 端子の Tx-Rx 間を接続した状態で実行すると、ループバックテストを実施する。

・送信内容と受信内容が等しいかを確認して、結果を表示する。

PARAMETERS ノブを回して、

(1)

る。VFD のセグメント表示部に以下の文字が表示される。

Func t i on CHK

D-L i nk Check

(2) PARAMETERSノブを押して実行する。VFD のセグメント表示部下段に以下の文字が表示される。

正常終了時

Comp l e t e !

異常終了時

(3) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

"FunctionCHK"

Fa i l

の TOP 画面から "D-LinkCheck" を選択

し PARAMETERS ノブを押して確定す

14

DN-S1200

3.3. Audio signal output (Audio OUT)

• The device's built-in 24 bit/44.1 kHz sampling frequency audio signals are played from ADSP.

(1) Turn the PARAMETERS knob to select "Audio OUT" from the “Function CHK” mode's top menu, then press the PARAMETERS

knob to set "Audio OUT" mode.

Information on the operations is displayed on the upper tier of the VFD segment display, information on the output signal on

the lower tier.

(2) Turn the PARAMETERS knob clockwise and display the signal to be output from ① to ⑨ on the VFD segment display.

Press the PARAMETERS knob while the signal to be output is displayed to set it. The selected signal is output from ADSP.

① 1kHz -6dBFS signals are output from the left and right channels.

Re f e r e n ce

1kHz -6dBFS

② 1kHz 0dBFS signals are output from the left and right channels.

Ma x L e v e l

1kHz 0dBFS

③ 20Hz -6dBFS signals are output from the left and right channels.

Freq. Chara.

20Hz -6dBFS

④ 1kHz -6dBFS signals are output from the left and right channels.

Freq. Chara.

1kHz -6dBFS

⑤ 20kHz -6dBFS signals are output from the left and right channels.

Freq. Chara.

20

⑥ 1kHz - ∞ dBFS signals are output from the left and right channels.

Inf ini ty 0

⑦ 1kHz -6dBFS signals are output from the left and right channels.

Re f e r e n ce

1kHz -6dBFS

⑧ 1kHz -6dBFS signals are output from the left channel.

- ∞ dBFS signals are output from the right channel.

ross Tal k R

C

L:1kHz-6dBFS

⑨ 1kHz -6dBFS signals are output from the right channel.

- ∞ dBFS signals are output from the left channel.

ross Tal k L

C

R:1kHz-6dBFS

Hz - 6dBFS

k

3.3. オーディオ信号出力(AudioOUT)

・ADSP から 24bit44.1kHZ サンプリングのオーディオ信号を出力する。

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "AudioOUT" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部の上段に動作内容、下段に出力される信号の情報を表示する。

(2) PARAMETERSノブを右に回して①〜⑨から出力する信号を VFD のセグメント表示部に表示する。出力する信号の表示中に

PARAMETERS ノブを押して確定する。選択された信号が ADSP から出力される。

① L/R から 1kHz-6dBFS の信号を出力する。

Re f e r e n ce

1kHz -6dBFS

② L/R から 1kHz0dBFS の信号を出力する。

Ma x L e v e l

1kHz 0dBFS

③ L/R から 20Hz-6dBFS の信号を出力する。

Fr eq . Cha r a .

20Hz -6dBFS

④ L/R から 1kHz-6dBFS の信号を出力する。

Fr eq . Cha r a .

1kHz -6dBFS

⑤ L/R から 20kHz-6dBFS の信号を出力する。

Fr eq . Cha r a .

20kHz - 6dBFS

⑥ L/R から 1kHz- ∞ dBFS の信号を出力する。

Inf ini ty 0

⑦ L/R から 1kHz-6dBFS の信号を出力する。

Re f e r e n ce

1kHz -6dBFS

⑧ L から 1kHz-6dBFS の信号を出力する。

R から - ∞ dBFS の信号を出力する。

ross Tal k R

C

L:1kHz-6dBFS

⑨ R から 1kHz-6dBFS の信号を出力する。

L から - ∞ dBFS の信号を出力する。

ross Tal k L

C

R:1kHz-6dBFS

(3) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

(3) Press the button to return to the top level of the function check mode.

15

DN-S1200

3.4. Audio Mute check (Mute Check)

• Switches the hardware's muting circuit on and off.

• Use this procedure to check muting the audio signal selected in [3.3.Audio signal output (Audio OUT)].

(1) Turn the PARAMETERS knob to select "

TERS knob to set "

Mute Check

" mode.

Mute Check

The current muting status is displayed on the VFD segment display.

Mu t e Ch e c k

OFF

or

Mu t e Ch e c k

ON

(2) Turn the PARAMETERS knob clockwise to select "ON", counterclockwise to select "OFF" the mute control mode status.

(3) Press the button to return to the top level of the function check mode.

" from the “Function CHK” mode's top menu, then press the PARAME-

3.4. オーディオミュート確認(MuteCheck)

・ハードウェアのミュート回路の ON/OFF を切り替える。

・「3.3. オーディオ信号出力(AudioOUT)」で選択したオーディオ信号のミュートを確認できる。

PARAMETERS ノブを回して、

(1)

る。

VFD のセグメント表示部に現在の Mute 状態が表示される。

Mu t e Ch e c k

または

Mu t e Ch e c k

(2) PARAMETERSノブを右に回して "ON"、左に回して "OFF" を選択し表示されている状態へミュート制御を切換える。

(3) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

"FunctionCHK"

OFF

ON

の TOP 画面から "MuteCheck" を選択し、PARAMETERS ノブを押して確定す

3.5. Touch initialization (Touch Init.)

• Sets the contents of the EPROM built into the touch sensor IC to the factory defaults.

(1) Turn the PARAMETERS knob to select "Touch Init." from the "Function CHK" mode's top menu, then press the PARAMETERS

knob to set "Touch Init." mode. The following appears on the VFD segment display section:

ouch Ini t .

T

Push Pa r am

(2) The displayed mode can be executed by pressing the PARAMETERS knob. The following appears on the lower tier of the VFD

segment display section:

When initialization is completed:

Comp l e t e !

When initialization is not completed:

Fa i l

(3) Press the button to return to the top level of the function check mode.

note1 : If the operation in step (2) is performed consecutively, it may quit erroneously ("Fail") the second time on. If this happens,

turn the power off then back on, then repeat steps (1) and (2).

note2 : The touch sensor will not operate on sets for which this item has never been performed.

3.6. USB-MIDI command transmission (USB MIDI)

• Sends the MIDI command corresponding to the function selected on the VFD segment display section.

(Refer to [MIDI commands table] for details.)

(1) Turn the PARAMETERS knob to select "USB MIDI" from the “Function CHK” mode's top menu, then press the PARAMETERS

knob to set "USB MIDI" mode.The following appears on the VFD segment display section:

USB - M I D I

CUE

(2) When the PARAMETERS knob is turned clockwise, the display on the lower tier of the VFD segment display section switches

in the following order: "CUE" → "PLAY" → "A1" → "A2".

The display switches in the opposite order when the PARAMETERS knob is turned counterclockwise.

(3) When the PARAMETERS knob is pressed, the MIDI command for the currently displayed mode is transmitted in the USB-MIDI

mode.

(4) To end the USB MIDI mode, turn the power off.

3.5. タッチ初期化(TouchInit.)

・タッチセンサ IC に内蔵された EPROM の内容を工場出荷時の状態に設定する。

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "TouchInit." を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

ouch I n i t .

T

Push Pa r am

(2) PARAMETERSノブを押して実行する。VFD のセグメント表示部下段に以下の文字が表示される。

正常終了時

Comp l e t e !

異常終了時

Fa i l

(3) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

注意 1:(2) の操作を連続でおこなうと 2 回目以降は異常終了("Fail")となる場合があります。この場合は電源を入れ直して、

再度 (1) 〜 (2) の操作を実施してください。

注意 2:当項目を実施した事がない機器ではタッチセンサは動作しません。

3.6. USBMIDI コマンド送信(USBMIDI)

・VFD のセグメント表示部で選択された機能に相当する MIDI コマンドを送信する。(MIDI コマンド表参照 )

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "USBMIDI" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

USB - M I D I

CUE

(2) PARAMETERSノブを右に回すと VFD のセグメント表示部下段の表示が "CUE" → "PLAY" → "A1" → "A2" の順で切り替わる。

PARAMETERSノブを左に回すと逆の順で表示が切り替わる。

(3) PARAMETERSノブを押すと、表示されているモードの MIDI コマンドを USB-MIDI で送信する。

(4) USBMIDI モードを終了する場合は、電源を OFF にする。

16

DN-S1200

3.7. USB device operation check (USB Test)

• Use this procedure to test data writing on the device connected to the USB-A connector.

(1) Turn the PARAMETERS knob to select "USB Test" from the “Function CHK” mode's top menu, then press the PARAMETERS

knob to set "USB Test" mode. The following appears on the VFD segment display section:

USB TEST

PUSH P a r am .

(2) The displayed mode can be executed by pressing the PARAMETERS knob. The following appears on the lower tier of the VFD

segment display section:

Now Te s t i n g

When the USB device is not connected:

Fa i l

(3) The test is completed, the following appears on the lower tier of the VFD segment display section:

When the process has completed normally:

Comp l e t e !

When the process has completed abnormally:

Fa i l

(4) Press the button to return to the top level of the function check mode.

3.7. USB デバイス動作確認(USBTest)

・USBA コネクタに接続されたデバイスのデータ読み書きテストをおこなう。

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "USBTest" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

USB TEST

PUSH P a r am .

(2) PARAMETERSノブを押して実行する。VFD のセグメント表示部下段に以下の文字が表示される。

Now Te s t i n g

USB デバイスが接続されていない場合

Fa i l

(3) テストが終了すると、VFD のセグメント表示部下段に以下の文字が表示される。

正常終了時

Comp l e t e !

異常終了時

Fa i l

(4) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

3.8. PS/2 operation check (PS/2 Check)

• The PS /2 keyboard are set to the factory defaults.

When a PS/2 keyboard is connected, turn the PARAMETERS knob to select "PS/2 Check" from the “Function CHK” mode's top menu,

(1)

then press the PARAMETERS knob to set "PS/2 Check" mode. The following appears on the VFD segment display section:

KB I n

PUSH PARAM

i

t.

(2) The displayed mode can be executed by pressing the PARAMETERS knob. The following appears on the upper tier of the VFD

segment display section (The the lower is cleared):

KB I n i t OK

When the keyboard is not connected, the following appears on the upper tier of the VFD segment display section (The the lower

is cleared):

KB I n i t F a i l

(3) When a key on the keyboard is pressed, the key that was pressed is displayed on the lower tier of the VFD segment display

(A to Z, 0 to 9).

(4) Press the button to return to the top level of the function check mode.

3.9. Sub microprocessor version up (SubCPU VerUP)

• Use this procedure to load the contents of the Flash ROM's Sub CPU program area into the main unit's Sub CPU.

(1) Turn the PARAMETERS knob to select "SubCPU VerUP" from the “Function CHK” mode's top menu, then press the PARAM-

ETERS knob to set "SubCPU VerUP" mode. The following appears on the VFD segment display section:

SubCPU VerUP

Ve r UP? OK

(2) When the PARAMETERS knob is turned, the display on the lower tier of the VFD segment display section switches in the "OK"

or "Cancel".

(3) Display "OK", then press the PARAMETERS knob to start loading.The following appears on the lower tier of the VFD segment

display section:

Now Ve r UP

Don ‘ t PowOFF

3.8. PS/2 動作確認(PS/2Check)

・PS/2 キーボードを工場出荷時の状態に設定する。

(1) PS/2 キーボードを接続してから PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "PS/2Check" を選択し

PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

KB I n

PUSH PARAM

i

t.

(2) PARAMETERSノブを押して実行する。VFD のセグメント表示部に以下の文字が表示される。( 下段はクリアされる)

KB I n i t OK

キーボードが接続されていない場合は、VFD のセグメント表示部に以下の文字が表示される。( 下段はクリアされる)

KB I n i t F a i l

(3) キーボードからキーを入力すると VFD のセグメント表示部の下段に入力したキー (A-Z,0-9) を表示する。

(4) ボタンを押すとファンクッションチェックモードの TOP 階層に戻る。

3.9. サブマイコンのバージョンアップ(SubCPUVerUP)

・FlashROM から SubCPU(AVR)プログラムエリアの内容を SubCPU(AVR)に書き込む。

(1) PARAMETERS ノブを回して、"FunctionCHK" の TOP 画面から "SubCPUVerUP" を選択し PARAMETERS ノブを押して確定

する。VFD のセグメント表示部に以下の文字が表示される。

SubCPU VerUP

Ve r UP? OK

(2) PARAMETERSノブを回すと VFD のセグメント表示部の下段の表示が "OK" または "Cancel" に切り替わる。

(3) "OK" を表示させ、PARAMETERSノブを押して書き込みを開始する。VFD のセグメント表示部に以下の文字が表示される。

Now Ve r UP

Don ‘ t PowOFF

17

DN-S1200

(4) When writing ends, the following appears on the lower tier of the VFD segment display section:

When the process has completed normally:

Comp l e t e !

PleasePowOFF

When the process has completed abnormally:

Fa i l : XXXXXX

Push Pa r am

(XXXXXX: Error)

(5) Display "Canceled", then press the PARAMETERS knob to stop loading.The following appears on the lower tier of the VFD

segment display section:

Can ce l ed

PleasePowOFF

(6) It is not possible to return to the top layer in the function check mode by pressing the button.

(4) 書き込みが終了すると、VFD のセグメント表示部に下段以下の文字が表示される。

正常終了時

Comp l e t e !

PleasePowOFF

異常終了時

Fa i l : XXXXXX

Push Pa r am

(XXXXXX:エラー)

(5) "Canceled" を表示させ、PARAMETERSノブを押して書き込みを終了する。VFD のセグメント表示部に以下の文字が表示さ

れる。

Can ce l ed

PleasePowOFF

(6) ボタンを押してもファンクッションチェックモードの TOP 階層に戻ることはできない。

4. Checking the operations of the CD drive (CD Drive CHK)

(1) Turn the PARAMETERS knob to select "CD Drive CHK" from the service mode's top menu, then press the PARAMETERS

knob to set the function check mode. The following appears on the VFD segment display section:

--Service---

CD D r i v e CHK

(2) When the PARAMETERS knob is turned clockwise, the display on the lower tier of the VFD segment display section switches

in the following order: "Disc Type" → "Servo Data" → "Error Rate" → "PU Clean"→ "Loader Clean"→ "ErrorCode CHK" → "Total

Time" →"H/R1"→"H/R2". The display switches in the opposite order when the PARAMETERS knob is turned counterclockwise.

(3) The displayed mode can be executed by pressing the PARAMETERS knob.

(4) Press the button to return to the top level of the service mode.

4.1. Disk type distinction display (Disc Type)

(1) Turn the PARAMETERS knob to select "Disc Type" from the “CD Drive CHK” mode's top menu, then press the PARAMETERS

knob to set "Disc Type" mode.

(2) The currently loaded disc is identified, and "No Disc", "CD-DA", "CD-RW" or "Unknown" is displayed on the lower tier of the

VFD segment display.

(3) Press the button to return to the top level of the CD Drive check mode.

4.2. Servo data display (Servo Data)

• The automatic adjustment value of the servo is displayed.

(1) Turn the PARAMETERS knob to select "Servo Data" from the “CD Drive CHK” mode's top menu, then press the PARAME-

TERS knob to set "Servo Data" mode.

(2) When the PARAMETERS knob is turned clockwise, the display item is displayed on the upper tier of the VFD segment display,

the data on the lower tier, switching in the order ① to ⑮ . The display switches in the opposite order when the PARAMETERS

knob is turned counterclockwise.

① Focus gain data

② Focus balance data

③ Focus offset data

④ Focus digital AC/BD data

⑤ Analog AC/BD data of focus

⑥ Tracking gain data

⑦ Tracking balance data

⑧ Tracking offset data

⑨ Tracking digital AC/BD data

⑩ Analog AC/BD data of tracking

⑪ SD offset data

⑫ RF offset data

⑬ RF gain data

⑭ VCO offset data

⑮ VCO gain data

(3) With ① to ⑮ selected, press the DISC EJECT/Playlist button to eject the disc, then reload the disc for readjust the servo.

(4) Press the button to return to the top level of the CD Drive check mode.

(5) When automatic adjustment is completed, the CD indicator lights.

4. CD ドライブチェックモード(CDDriveCHK)

(1) PARAMETERS ノブを回して、サービスモードの TOP 画面から "CDDriveCHK" を選択し、PARAMETERS ノブを押して確定す

る。VFD のセグメント表示部に以下の文字が表示される。

--Service---

CD D r i v e CHK

(2) PARAMETERSノブを右に回すと VFD のセグメント表示部の下段の表示が "DiscType" → "ServoData" → "ErrorRate" → "PU

Clean" → "LoaderClean" → "ErrorCodeCHK" → "TotalTime" → "H/R1" → "H/R2" の順で切り替わる。PARAMETERSノブを左

に回すと逆の順で表示が切り替わる。

(3) PARAMETERSノブを押すと、表示されているモードを実行する。

(4) ボタンを押すとサービスモードの TOP 階層に戻る。

4.1. ディスク種類判別表示(DiscType)

(1) PARAMETERS ノブを回して、"CDDriveCHK" の TOP 画面から "DiscType" を選択し PARAMETERS ノブを押して確定する。

(2) 現在挿入されているディスクを識別し、"NoDisc"、"CD-DA"、"CD-RW"、"unKnown" のいずれかを、VFD セグメント表示

部の下段に表示する。

(3) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

4.2. サーボデータ表示(ServoData)

・サーボの自動調整値を表示する。

(1) PARAMETERS ノブを回して、"CDDriveCHK" の TOP 画面から "ServoData" を選択し PARAMETERS ノブを押して確定する。

(2) PARAMETERSノブを右に回すと VFD セグメント表示部の上段に表示項目、下段にデータが表示され、①〜⑮の順で切り替

わる。PARAMETERSノブを左に回すと逆の順で表示が切り替わる。

① フォーカスゲインデータ

② フォーカスバランスデータ

③ フォーカスオフセットデータ

④ フォーカスデジタル AC/BD データ

⑤ フォーカスアナログ AC/BD データ

⑥ トラッキングゲインデータ

⑦ トラッキングバランスデータ

⑧ トラッキングオフセットデータ

⑨ トラッキングデジタル AC/BD データ

⑩ トラッキングアナログ AC/BD データ

⑪ SD オフセットデータ

⑫ RF オフセットデータ

⑬ RF ゲインデータ

⑭ VCO オフセットデータ

⑮ VCO ゲインデータ

(3) ①〜⑮を選択した状態で DISCEJECT/Playlist ボタンを押してディスクを排出し、

整をおこなう。

(4) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

(5) 自動調整が終了すると、CD インジケータが点灯する。

再度ディスクを挿入すると

サーボの自動調

18

DN-S1200

4.3. Error rate display (Error Rate)

• The error rate of C2 is displayed.

(1) Turn the PARAMETERS knob to select "Error Rate" from the "CD Drive CHK" mode's top menu, then press the PARAMETERS

knob to set "Error Rate" mode.

(2) Play a CD and display the total number of C2 errors per second.

(3) "TOC Reading" is displayed on the lower tier of the VFD segment display if the CD's TOC has not yet been read.

(4) When the TOC has been read, "C2-ERR" is displayed on the upper tier of the VFD segment display, and the total number of

C2 errors per second is displayed on the lower tier.

(5) Press the Quick Jump button to perform the track search operation.

(6) Press the button to return to the top level of the CD Drive check mode.

4.3. エラーレート表示(ErrorRate)

・C2 のエラーレート表示する。

(1) PARAMETERS ノブを回して、"CDDriveCHK" の TOP 画面から "ErrorRate" を選択し PARAMETERS ノブを押して確定する。

(2) CD を再生させ、1 秒間の C2 エラーの合計を表示させる。

(3) CD の TOC を読んでいなければ VFD セグメント表示部の下段に "TOCReading" が表示される。

(4) TOC 読み込み終了で、VFD セグメント表示部上段に "C2ERR"、下段に 1 秒間の C2 エラーの合計を表示する。

(5) QuickJump ボタンを押すとトラックサーチをおこなう。

(6) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

4.4. Pickup movement (PU Clean)

• Move the pickup lens to any position.

(1) Turn the PARAMETERS knob to select "PU Clean" from the "CD Drive CHK" mode's top menu, then press the PARAMETERS

knob to set "PU Clean" mode. The following appears on the VFD segment display section:

PU C l e a n

PUSH BEN

+& -

D

(2) Press the PITCH BEND button to move the pickup lens. The pickup lens stops moving when the PITCH BEND button is re-

leased.

(3) Press the button to return to the top level of the CD Drive check mode.

4.5. Remove the disc (Loader Clean)

• Turn the loading motor in the direction of disc ejection.

(1) Turn the PARAMETERS knob to select "Loader Clean" from the "CD Drive CHK" mode's top menu, then press the PARAM-

ETERS knob to set "Loader Clean" mode. The following appears on the VFD segment display section:

Loade r C l ean

PUSH SEARCH+

(2) Press the button and turn the loading motor in the direction of disc ejection. The motor stops turning when the button

is released.

(3) Press the button to return to the top level of the CD Drive check mode.

4.6. Error code display (Error Code CHK)

(1) Turn the PARAMETERS knob to select "Error Code CHK" from the "CD Drive CHK" mode's top menu, then press the PARAM-

ETERS knob to set "Error Code CHK" mode. The following appears on the VFD segment display section:

Er ror Da t a

XX_ EYYY

(XX:Error logging number, EYYY:Error code, not error:turn off)

(2) Up to 10 errors occurring in the CD mode are stored in the MEMO memory.

※ The errors remain stored in the memory until they are cleared, and once they are cleared up to 10 new errors are stored.

(3) Turn the PARAMETERS knob to check the error logging data.

When the PARAMETERS knob is pressed, "Error Clear?" is displayed on the lower tier of the VFD segment display. When the

PARAMETERS knob is pressed again at this time, all the data is cleared. Turn the PARAMETERS knob to cancel.

(4) Refer to [4.10. error code table] for details of the error code.

4.4. ピックアップ移動(PUClean)

・ピックアップレンズを任意の場所へ移動する。

(1) PARAMETERS ノブを回して、"CDDriveCHK" の TOP 画面から "PUClean" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

PU C l e a n

PUSH BEN

+& -

D

(2) PITCHBEND ボタンを押して、ピックアップレンズを移動する。PITCHBEND ボタンを離すと移動を停止する。

(3) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

4.5. ディスク取り出し(LoaderClean)

・ローディングモータをディスク排出方向へ回転させる。

PARAMETERS ノブを回して、

(1)

"CDDriveCHK"

の TOP 画面から "LoaderClean" を選択し PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

Loade r C l ean

PUSH SEARCH+

(2) ボタンを押して、ローディングモーターを DISC 排出方向に回転させる。 ボタンを離すと回転を停止する。

(3) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

4.6. エラーコード表示(ErrorCodeCHK)

(1)

PARAMETERS ノブを回して、

る。

VFD のセグメント表示部に以下の文字が表示される。

Er ror Da t a

XX_ EYYY

(XX: エラーロギング番号、EYYY: エラーコード、エラーがない場合消灯 )

(2) CD モードで発生したエラーを MEMO 用のメモリに 10 個まで記憶する。

※ メモリされたエラーは消去されるまで保存され、消去されると再び10個まで記憶する。

PARAMETERS

(3)

ノブを回してエラーロギングデータを確認できる。

"ErrorClear?" を表示する。さらに

る。

(4) エラーコードの内容は、「4.10.ヒートランモード」を参照。

"CDDriveCHK"

PARAMETERS

の TOP 画面から "ErrorCodeCHK" を選択し PARAMETERS ノブを押して確定す

PARAMETERS

ノブを押すと VFD セグメント表示部下段に

ノブを押すと、全データを消去し、パラメータノブを回すとキャンセルす

19

DN-S1200

4.7. Total running time display (Total Time)

(1) Turn the PARAMETERS knob to select "Total Time" from the "CD Drive CHK" mode's top menu, then press the PARAME-

TERS knob to set "Total Time" mode. The following appears on the VFD segment display section:

To t a l T ime

XXXXXh

(XXXXX:Total running time, Time [h])

When the PARAMETERS knob is pushed, it switches to the Total Time deletion mode.

(2)

The following appears on the VFD segment display section:

Time Clear

Can c e l

(3) When the PARAMETERS knob is turned, the display on the lower tier of the VFD segment display section switches in the "OK"

or "Cancel".

(4) Display "OK", then press the PARAMETERS knob to set. The total time is cleared and the display returns to as it was in step (1).

(5) Display "Cancel", then press the PARAMETERS knob to set.

(6) Press the button to return to the top level of the CD Drive check mode.

The display returns to as it was in step (1).

4.7. トータルランニング時間表示(TotalTime)

(1)

PARAMETERS ノブを回して、

VFD のセグメント表示部に以下の文字が表示される。

To t a l T ime

XXXXXh

(XXXXX:トータルランニング時間、時間:h)

PARAMETERS ノブを押すと、TotalTime 消去モードに切り替わる。

(2)

VFD のセグメント表示部に以下の文字が表示される。

Time Clear

Canc e l

(3)

PARAMETERS

ノブを回すと VFD セグメント表示部下段が "OK" または "Cancel" に切り替わる。

(4) "OK" を表示させてから、

(5) "Cancel" を表示させてから、

(6) ボタンの押すと CD ドライブチェックモードの TOP 階層に戻る。

"CDDriveCHK"

PARAMETERS

PARAMETERS

の TOP 画面から "TotalTime" を選択する。

ノブを押して確定すると TotalTime を消去し、(1) に戻る。

ノブを押して確定すると (1) に戻る。

4.8. Heat Run mode1 (H/R1)

(1) Turn the PARAMETERS knob to select "H/R1" from the "CD Drive CHK" mode's top menu.

When the disc is recognized, the following appears on the VFD segment display section:

Hea t Ru n 1

Push P l ay

When the disc is not recognized, or when the disc is not inserted, the following appears on the VFD segment display section:

Hea t Ru n 1

Readi ng

(2) When the /13

The following appears on the VFD segment display section:

★★

( ★ : Track Title Text, XXXXX : Operation count)

When there is no Text, The following appears on the VFD segment display section:

Track YY

(YY : Track number, XXXXX :

(3) The usual time and track number display. Press the TIME button, the time display is switched.

(4) If disc being used has less than 20 tracks, play all tracks. If disc has 21 or more tracks, skip to final track after playback of first

track has finished.

(5) Once playback is completed, automatically eject and reload the disk and repeat the playback operation in step (4).

(6) When there is an error, The following appears on the VFD segment display section:

Track

E * * * XXXXX

(YY:Track number, XXXXX:

(7) To end the Heat Run1 mode, turn the power off.

button is pressed, Heat Run1 mode is started.

....

XXXXX

XXXXX

★

Operation count)

Y

Y

Operation count, E***:Error code)

4.8. ヒートランモード 1(H/R1)

(1)

PARAMETERS ノブを回して、

ディスクが認識された場合は、VFD のセグメント表示部下段に以下の文字が表示される。

Hea t Ru n 1

Push P l a y

ディスクが認識されていない場合、またはディスクが挿入されていない場合は、VFD のセグメント表示部に以下の文字が表

示される。

Hea t Ru n 1

Rea d i n g

(2)/13

ボタン

を押して、ヒートラン 1 を開始する。

VFD のセグメント表示部に以下の文字が表示される。

★★

....

XXXXX

( ★:TrackTitleText、XXXXX:動作回数 )

Text がない場合は VFD のセグメント表示部に以下の文字が表示される。

Track YY

XXXXX

(YY:トラック番号、XXXXX:動作回数 )

(3) 通常のトラック番号とタイムを表示する。TIME ボタンを押すと、タイム表示が切り替わる。

(4) 使用ディスクが 20トラック以内の時は全トラックを再生し、21トラック以上の時は、1トラックと最終トラックを再生す

る。

(5) 再生終了後には、自動的にディスクを排出し、再び引き込み、(4)の再生動作をおこなう。

(6) エラーが起きた場合、VFD のセグメント表示部下段に以下の文字を表示する。

Track

E * * * XXXXX

(YY:トラック番号、XXXXX:動作回数、E***:エラーコード)

(7) ヒートランモード 1 を終了する場合は、電源を OFF にする。

"CDDriveCHK"

★

Y

Y

の TOP 画面から

"H/R1"

を選択する。

20

DN-S1200

4.9. Heat Run mode1 (H/R2)

(1) Turn the PARAMETERS knob to select "H/R2" from the "CD Drive CHK" mode's top menu.

The following appears on the VFD segment display section:

Hea t Ru n 2

Push P l ay

(2) When disc is inserted the /13

The following appears on the VFD segment display section:

Hea t Ru n 2

XXXXX

(XXXXX :

Operation count)

(3) The disc is drawn in, loading is performed and the TOC is read.

(4) Once reading of the TOC is completed, the disc is ejected and the eject operation is completed.

(5) The operation is repeated automatically from (3).

(6) When there is an error, The following appears on the VFD segment display section:

Hea t Ru n 2

E * * * XXXX

(XXXXX :

Operation count, E*** : Error code)

(7) To end the Heat Run2 mode, turn the power off.

button is pressed, first of Heat Run2 mode is started.

4.9. ヒートランモード 2(H/R2)

(1)

PARAMETERS ノブを回して、

VFD のセグメント表示部に以下の文字が表示される。

Hea t Ru n 2

Push P l a y

(2)

ディスクを挿入し、/13

VFD のセグメント表示部に以下の文字が表示される。

Hea t Ru n 2

XXXXX

(XXXXX:動作回数 )

(3) ディスクを引き込み、ローディングをおこない、TOC を読み込む。

(4) TOC の読み込みを終了したら、ディスクを排出し、EJECT を完了する。

(5) (3) からの動作を自動で繰り返す。

(6) エラーが起きた場合、VFD のセグメント表示部下段に以下の文字を表示する。

Hea t Ru n 2

E * * * XXXX

(XXXXX:動作回数、E***:エラーコード)

(7) ヒートランモード 2 を終了する場合は、電源を OFF にする。

"CDDriveCHK"

ボタン

を押すとヒートラン 2 の 1 回目を開始する。

の TOP 画面から "H/R" を選択する。

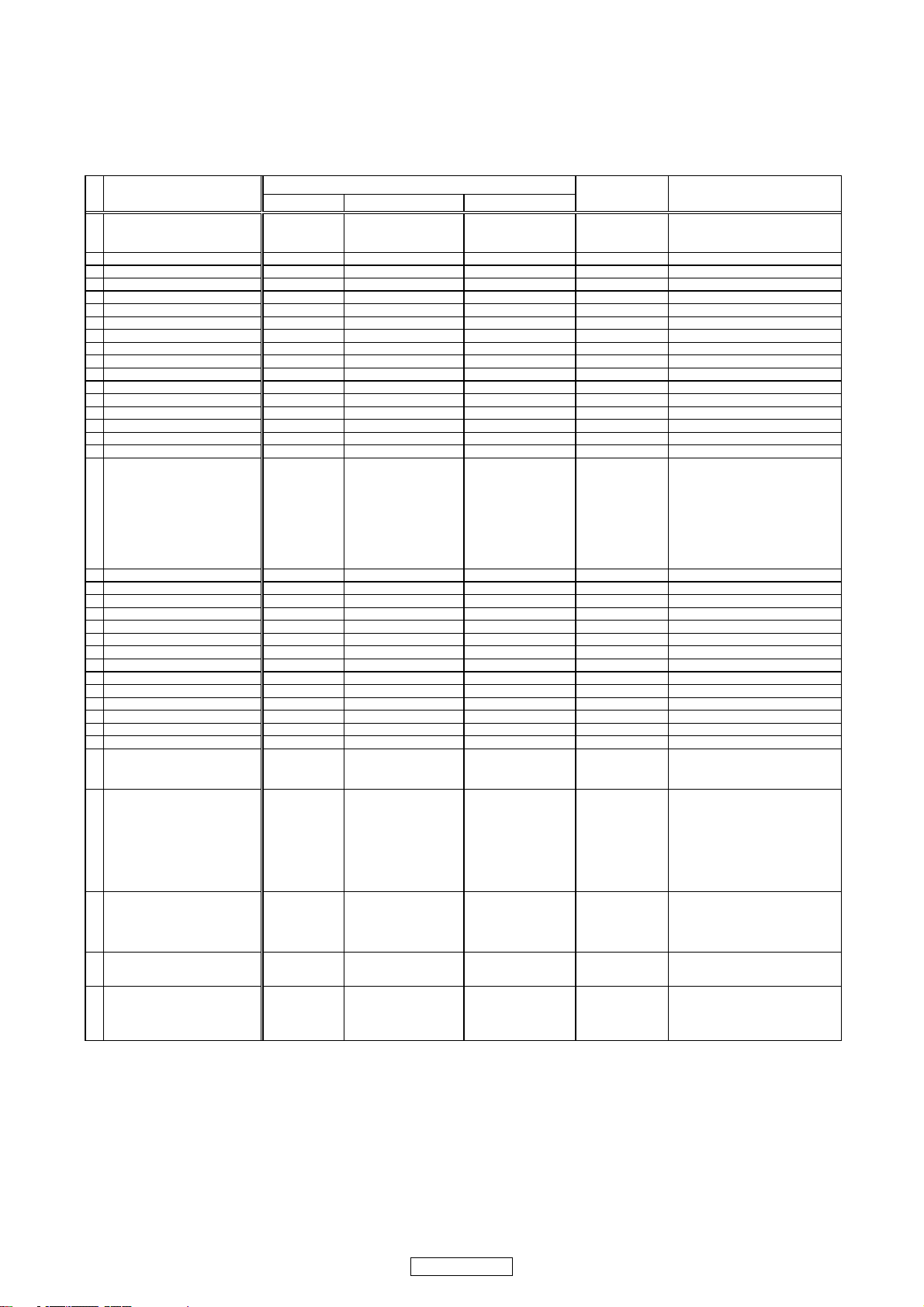

4.10.Error code table

Error code Error contents

E100 Disc cannot be detected

E110 Communications cannot be established with the servo DSP

E111 Tr balance measurement time-out

E112 Automatic RF rough gain adjustment not completed

E113 GFS does not start after focus search

E114 Data CD (CD-ROM) detected

E115 Automatic RF fine adjustment time-out

E300 TOC cannot be read within provided time

E301 Sub code cannot be read when reading TOC

E400 Disc loading not completed

E401 Disc eject not completed

E500 Inner circumference switch does not turn on when pick moved to inner circumference

E502 Inner circumference switch does not turn off when pick moved

EA00 Failure to open file

EA01 MP3 decoding error

EF10 SSI returned to idle status during data reading

EF11 SSI underflow occurred

EF12 SSI overflow occurred

EF20 Failure in link processing when reading data

4.10.エラーコード表

エラーコード エラー内容

E100 DISC が検出できない

E110 サーボ゙ DSP と通信できない

E111 Tr バランス測定タイムアウト

E112 RF 粗ゲイン自動調整が終了しない

E113 フォーカスサーチ後 GFS が立たない

E114 データ CD(CD-ROM) を検出

E115 RF 精調整のタイムアウト

E300 TOC が規定時間内に読めない

E301 TOC リード中にサブコードが読めない

E400 Disc ローディングが終了しない

E401 Disc イジェクト終了がしない

E500 PU 内周移動で内周 SW が ON しない

E502 PU 移動で内周 SW が OFF しない

EA00 ファイルオープンに失敗

EA01 MP3 デコードエラー

EF10 データ読込中に SSI がアイドル状態に戻った

EF11 SSI アンダーフロー発生

EF12 SSI オーバーフロー発生

EF20 データ読込時、リンク処理に失敗

21

DN-S1200

5. Checking the operations of the switches (SW Check)

(1) Turn the PARAMETERS knob to select "SW Check" from the service mode's top menu, then press the PARAMETERS knob

to set the "SW Check" mode.

Se r v i ce

SW C h e c k

(2) All the VFD characters are lights.

The following appears on the VFD segment display section.

FNE123 T B<>

CPD BDR J - +

(3) When each switch is pushed

Brake → Turn off the "B" in the sixth place of lower tier.

Dump → Turn off the "D" in the seventh place of lower tier.

Reverse → Turn off the "R" in the eighth place of lower tier.

Echo/Loop → Turn off the "1" in the fourth place of upper tier.

Flanger → Turn off the "2" in the fifth place of upper tier.

Filter → Turn off the "3" in the sixth place of upper tier.

Eject/PLAYLIST → Turn off the "D" in the third place of lower tier.

Fast Search → Turn off the "<" and ">" in the eleventh and twelfth place of upper tier.

BACK → Turn off the "B" in the tenth place of upper tier.

PITCH BEND → Turn off the "-" and " +" in the eleventh and twelfth place of lower tier.

TIME → Turn off the "T." .

MEMO → Turn off the "MEMO".

TITLE → Turn off the "T" in the eighth place of upper tier.

SOURCE → Turn off the "CD".

FLIP → Turn off the "F" in the first place of upper tier.

A1, A2 → Turn off the "A1" and "A2", respectively.

B → Turn off the "B" in the A1.

EXIT → Turn off the "E" in the third place of upper tier.

CUE, PLAY → Turn off the "C" and "P" in the first and second place of lower tier.

JOG MODE → Turn off the "J" in the tenth place of lower tier.

PITCH → Turn off the "KEY ADJ".

TAP → Turn off the "BPM".

NEXT TRACK → Turn off the "N" in the second place of upper tier.

The following appears on the VFD segment display section.

5. スイッチ動作確認(SWCheck)

(1) PARAMETERS ノブを回して、サービスモードの TOP 画面から "SWCheck" を選択し、PARAMETERS ノブを押して確定する。

VFD のセグメント表示部に以下の文字が表示される。

---Servis---

SW C h e c k

(2) VFD のキャラクタを全点灯する

VFD のセグメント表示部に以下の文字が表示される。

FNE1 2 3 T B< >

CPD BDR J - +

(3) 各スイッチを押すと

Brake → 下段 6 桁目の B を消灯する。

Dump → 下段 7 桁目の D を消灯する。

Reverse → 下段 8 桁目の R を消灯する。

Echo/Loop → 上段 4 桁目の 1 を消灯する。

Flanger → 上段 5 桁目の 2 を消灯する。

Filter → 上段 6 桁目の 3 を消灯する。

Eject/PLAYLIST → 下段 3 桁目の D を消灯する。

FastSearch → 上段 11、12 桁目の<、>を消灯する。

BACK → 上段 10 桁目の B を消灯する。

PITCHBEND → 下段 11、12 桁目の−、+を消灯する。

TIME → T. を消灯する。

MEMO → MEMO を消灯する。

TITLE → 上段 8 桁目の T を消灯する。

SOURCE → CD を消灯する。

FLIP → 上段 1 桁目の F を消灯する。

A1、A2 → A1、A2 を各々消灯する。

B → A1 の B を消灯する。

EXIT → 上段 3 桁目の E を消灯する。

CUE、PLAY → 下段 1、2 桁目の C、P を消灯する。

JOGMODE → 下段 10 桁目の J を消灯する。

PITCH → KEYADJ を消灯する。

TAP → BPM を消灯する。

NEXTTRACK → 上段2桁目のNを消灯する。

Once all the switches have been pressed, The following appears on the VFD segment display section.

(4)

Comp l e t e !

Press Param

(5) Press the PARAMETERS knob while "Complete" is displayed to return to the top level of the switch check mode.

(6) Press the PARAMETERS knob while checking to return to the top layer in the service mode.

6. Checking the operation of the panel (Panel CHK)

(1) Turn the PARAMETERS knob to select "Panel CHK" from the service mode's top menu, then press the PARAMETERS knob

to set the "Panel CHK" mode.

The following appears on upper tier of the VFD segment display section:(Count value display mode)

PFCFP

(2) Display of the status and results of the various control elements on the panel surface and external input from the rear side.

PARAMETERS knob → The segment on the right side of the "P" column at the upper left of the VFD segment display section

toggles between white and black each time the PARAMETERS knob is pressed.

When the PARAMETERS knob is turned, -> (clockwise) or <- (counterclockwise) is displayed.

JOG disc → When a touch is detected, the center of the scratch marker at the bottom right of the VFD display

section lights.

The left and right display sections of the scratch marker light according to the direction of rotation.

The jog rev count detection result is displayed on the frame count display section.

Pitch FADER → The pitch signal's AD conversion value is displayed on the pitch display section.

The center tap value is displayed in three digits on the track number display section.

<Spec of OK judgment>

Fader value : MAX 1018 or more, MIN 3 or less

Central click position : Central tap value ± 25

Central tap value : 435〜589

(4) 全てのスイッチが押されると、VFD のセグメント表示部に以下の文字が表示される。

Comp l e t e !

Press Param

(5) "Complete!" が表示された状態で、PARAMETERS ノブを押すと、スイッチチェックモードの TOP 階層に戻る。

(6) チェックの途中で、PARAMETERS ノブを押すと、サービスモードの TOP 階層に戻る。

6. パネル動作確認(PanelCHK)

(1)

PARAMETERS ノブを回して、サービスモードの TOP 画面から "PanelCHK" を選択し、PARAMETERS ノブを押して確定する。

VFD のセグメント表示部上段に以下の文字が表示される。

PFCFP

(2) パネル面に配置された各種操作子、およびリアサイドからの外部入力の状態と結果を表示する。

PARAMETERSノブ → PARAMETERS ノブを押すごとに、VFD のセグメント表示部の左上の "P" 欄の右隣のセグメントを

白⇔黒でトグル表示する。PARAMETERSノブを回転させると、回転方向に応じて、->(右回転)、

<-(左回転)を表示する。

JOG ディスク → タッチ検出時に VFD の表示部の右下にあるスクラッチマーカの中心が点灯する。

回転方向に応じて、スクラッチマーカの左右の表示部が点灯する。

JOG の回転数の検出結果を、フレームカウントの表示部分に表示する。

ピッチフェーダ → ピッチの表示部にピッチ信号の AD 変換値を表示 (0 〜 1023) する。

センタータップ値はトラックナンバーの表示部にて 3 桁で表示する。

< OK 判定スペック>

フェーダ値 : 最大 1018以上、最小 3以下

フェーダのクリック点センタータップ値 : センタータップ値±25

センタータップ値 : 435〜589

22

DN-S1200

FADER IN → The segment display sections at the sides of FADER IN CUE and FADER IN PLAY on the VFD

segment display section are displayed as black while the CUE and PLAY fade-in signals are being

detected, respectively.

TAP button → When the TAP button is pressed, the display toggles in the following order: All LEDs lit + VFD all lit

→ LED DIM lit + VFD off → LED off + normal VFD display

※ This function is always available while in the "Panel CHK" mode.

(3) Press button to return to the top level of the CD drive check mode.

7. Touch measurement mode (Touch MEAS)

(1)

Turn the PARAMETERS knob to select "Touch MEAS" from the service mode's top menu, then press the PARAMETERS

knob to set the "Touch MEAS" mode.

T_***R_***

B_***L_***

*** : Current touch count value is displayed.

(T : TOP, B : BOTTOM, R : RIGHT, L : LEFT)

The average of the count values acquired for the first four times measurements are made after this mode is set is calculated

and used as the reference value.

<Spec of OK judgment>

Count display value when not touched : 100~300

(2) When the PARAMETERS knob is turned clockwise, the display of the VFD segment display section switches in the following

order. (Difference display mode)

T

B

***R▲***

▲

***L

▲

*** : (Reference value) - (Current touch count value) is displayed.

<Spec of OK judgment>

Difference when not touched and when touched : 50 more

CAUTION : Don’t use these modes

(3) When in the difference display mode, the display of the VFD segment display section switches in the following order. (Operation

result display mode)

X_ * * * Y* * *

Re * * * Ab * * *

(4) When in the difference display mode, the display of the VFD segment display section switches in the following order.

(Peak hold of operation result display mode)

※When the PARAMETERS knob is pressed, the value of Peak Hold is initialized in this mode.

eak Ho l d

P

Re * * * Ab * * *

(5) If no touch is detected in 1 second, the count is reset using the average of the values of 4 touches each 250 msec within that

second as the reference value.

(6) Press button to return to the top level of the touch measurement mode.

The following appears on the VFD segment display section:(Count value display mode)

***

▲

フェーダイン → CUE、PLAY のフェーダイン信号を検出している間は、VFD のセグメント表示部のそれぞれ FADER

INCUE、FADERINPLAY の隣のセグメント表示部を黒で表示する。

TAP ボタン → TAP ボタンを押すと、LED 全点灯 +VFD 全点灯→ LEDDIM 点灯 +VFD 消灯→ LED 全消灯 +VFD 通

常表示の順番でトグル動作する。

※ PanelCHK モード中は、本機能が常に有効。

(3) ボタンを押すと CD ドライブチェックモードの TOP 階層に戻る。

7. タッチ測定モード (TouchMEAS)

(1) PARAMETERS ノブを回して、サービスモードの TOP 画面から "TouchMEAS" を選択し、PARAMETERS ノブを押して確定する。

VFD セグメント表示部に以下の文字が表示される。(カウント値表示モード)

T_***R_***

B_***L_***

***:現在のタッチカウント値を表示する。

(T:TOP、B:BOTTOM、R:RIGHT、L:LEFT)

本モードに入ってから最初の 4 回の測定で取得したカウント値の平均を算出して、基準値とする。

< OK 判定スペック>

非タッチ時のカウント表示値 : 100 〜 300

(2) PARAMETERSノブを右に回すと、VFD のセグメント表示部の表示が以下の表示に切り替わる。(差分表示モード)

T

B

***:( 基準値 )-( 現在のタッチカウント値 ) を表示する。

< OK 判定スペック>

非タッチとタッチ時の差分 : 50 以上

注意 : 本モードは使用しないで下さい

(2)

差分表示モード

(3)

示モード)

X_ * * * Y* * *

Re * * * Ab * * *

(4) (3)

演算結果表示モード

(演算結果のピークホールド表示モード)

※本モードで PARAMETERSノブを押すとピークホールドの値を0に初期化する

eak Ho l d

P

Re * * * Ab * * *

(5) 一秒間タッチ検出がないと、その間の 250msec ごとの 4 回分のタッチの値の平均値を基準値として再設定する。

(6) ボタンを押すとタッチ測定モードの TOP 階層に戻る。

***R▲***

▲

***L

▲

***

▲

で PARAMETERSノブを右に回すと、VFD のセグメント表示部の表示が以下の表示に切り替わる。(演算結果表

で PARAMETERSノブを右に回すと、

VFD のセグメント表示部の表示が以下の表示に切り替わる。

23

DN-S1200

---MEMO---

24

DN-S1200

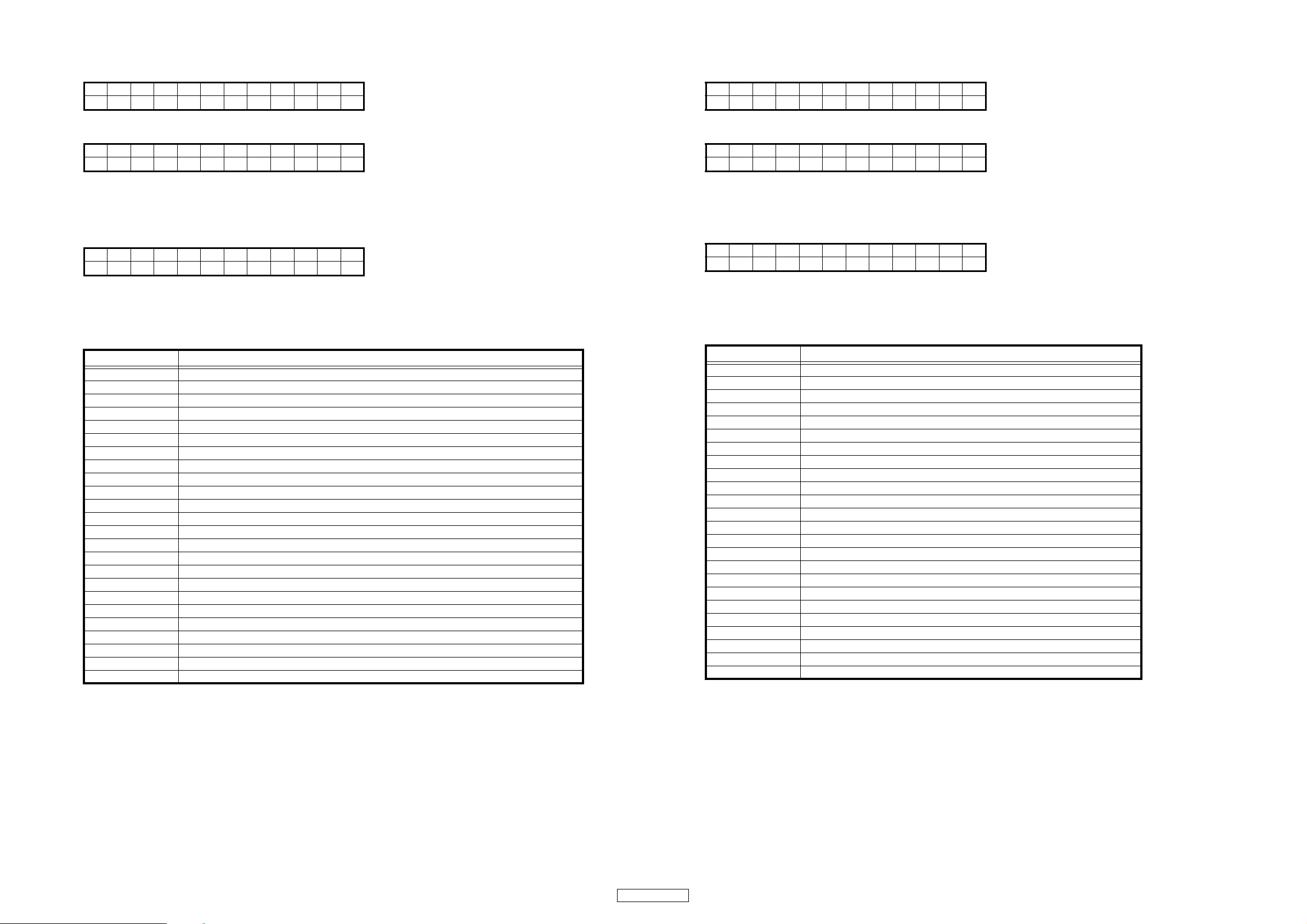

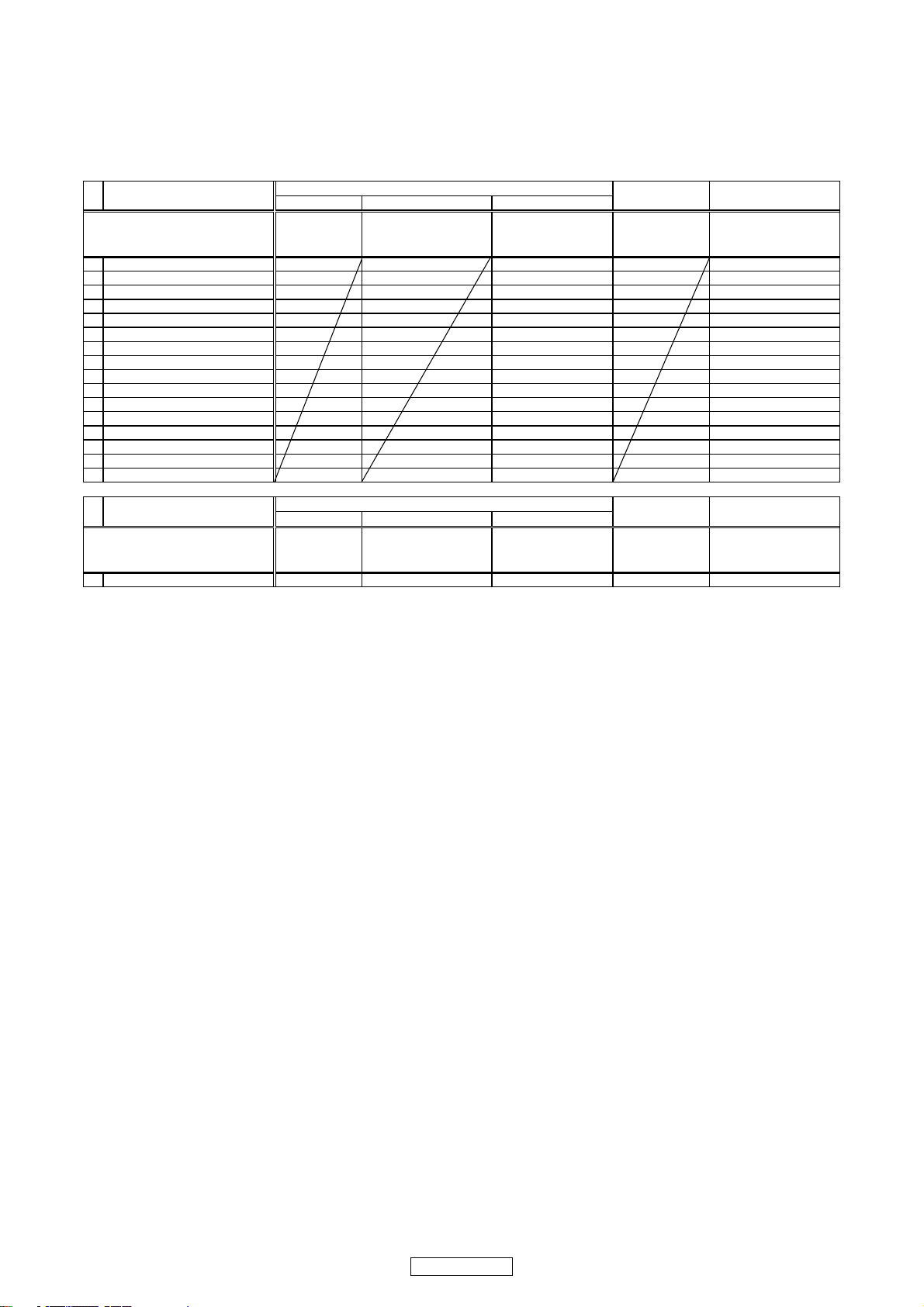

MIDI COMMANDS

4

(

)

(1) Data transmission

The panel operation data is transmitted by MIDI command, as per the table below.

(1) 送信データ

パネル操作データの送信は、以下の表に従い、MIDIコマンドを送信する。

F Send command to PC (PC にコマンドを送る )

items

1 Disc Eject

2 JOG mode

3 Pitch/KEY

4 TAP

5 Pitch Bend+

6 Pitch Bend7 Fast search+

8 Fast search-

9 ECHO/LOOP

10 FLANGER

11 FILTER

12 TIME

13 MEMO/PRESET

14 TITLE/ID3

15 NEXT Track

16 Parameters KNOB SW

17 BACK

18 SOURCE mode

Command Number Value

SW ON : 0x9n

SW OFF : 0x8n

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

MIDI command

0x01

0x04

0x05

0x07

0x08

0x09

0x10

0x11

0x12

0x13

0x14

0x23

0x24

0x25

0x27

0x28

0x30

0x31

SW ON : 0x40

SW OFF : 0x00

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

Message䇭type Notes

Note ON/OFF

MIDI spec ON/OFF

0x9n+0x04/0x00 or

0x9n+0x04/0x8n+0x0

push [SOURCE] button->Change

to SOURCE mode

When SOURCE mode off

->PC should send all display data

to Controller

19 FLIP

20 A1

21 A2

22 B

23 EXIT/Reloop

24 Cue

25 Play

26 BRAKE

27 DUMP

28 REVERSE

29 JOG UP

30 JOG DOWN

31 JOG LEFT

32 JOG RIGHT

33 Jogwheel touch

34 Preset mode

35 Jogwheel fwd/rev 0xBn 0x51

Parameters KNOB

36

Increment/Decrement

37 Pitch Slider 0xEn 0xll䋨LSB) 0xmm䋨MSB) Pitch bend change

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

0x36

0x37

0x38

0x39

0x40

0x42

0x43

0x44

0x45

0x46

0x47

0x48

0x49

0x50

0x51

0x52

0x54

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

㸡㸡

Reverse 0x3F䌾0x01

Foward 0x41䌾0x7F

slow->fast

㶎relative data

Increment 0x00

Decrement 0x7F

Control change 䊶1480Pulse/cycle

㸡

Jog touch= UP or DOWN or LEFT

->PC should send all display data

or RIGHT det.

Long push [MEMO] button

->Change to Preset mode

When preset mode off

to Controller

mmll :14bit data

0x0000(min)

->0x4000(middle)

->0x7F7F

max

㶎n=MIDI CH = 0 to F

25

DN-S1200

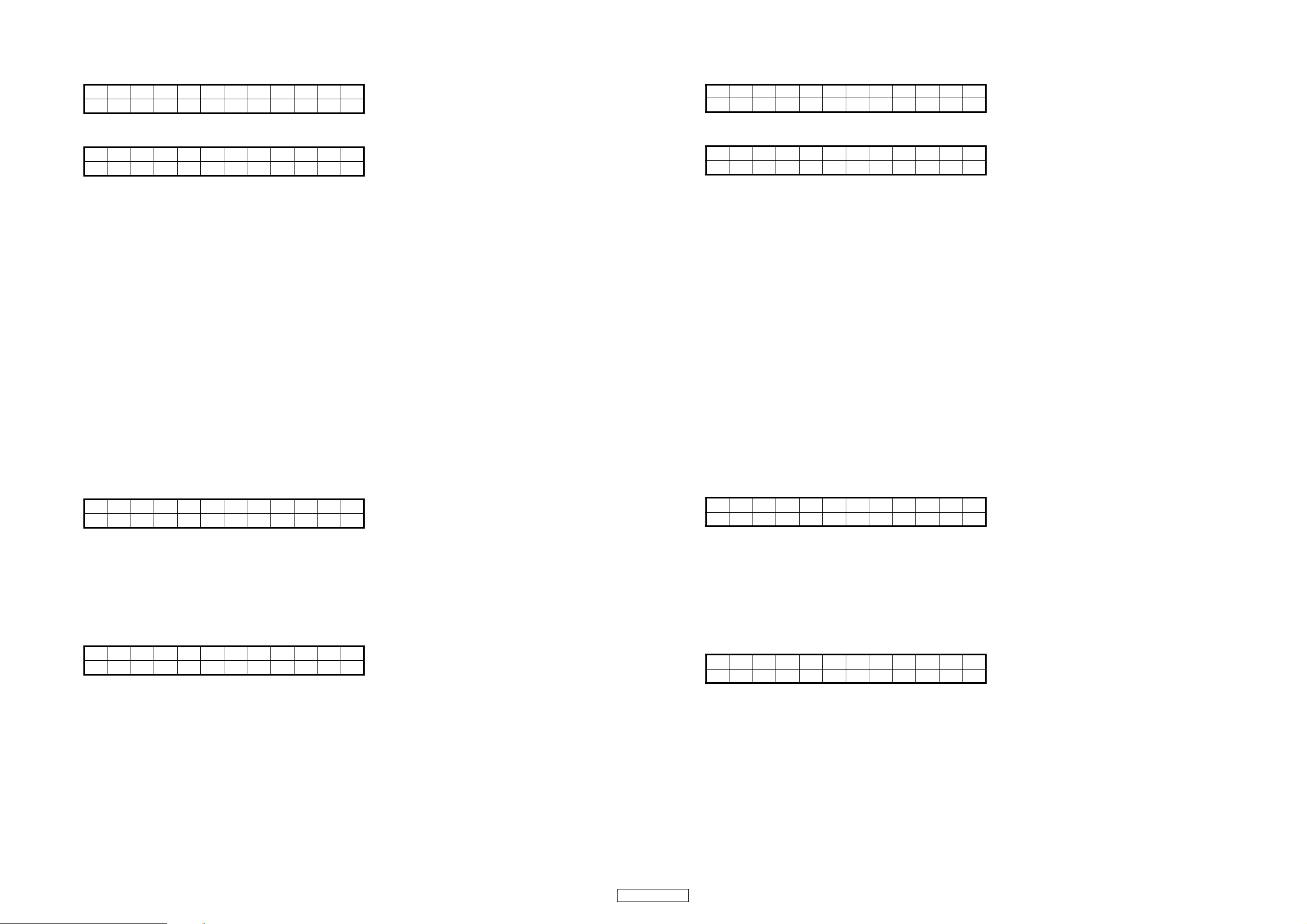

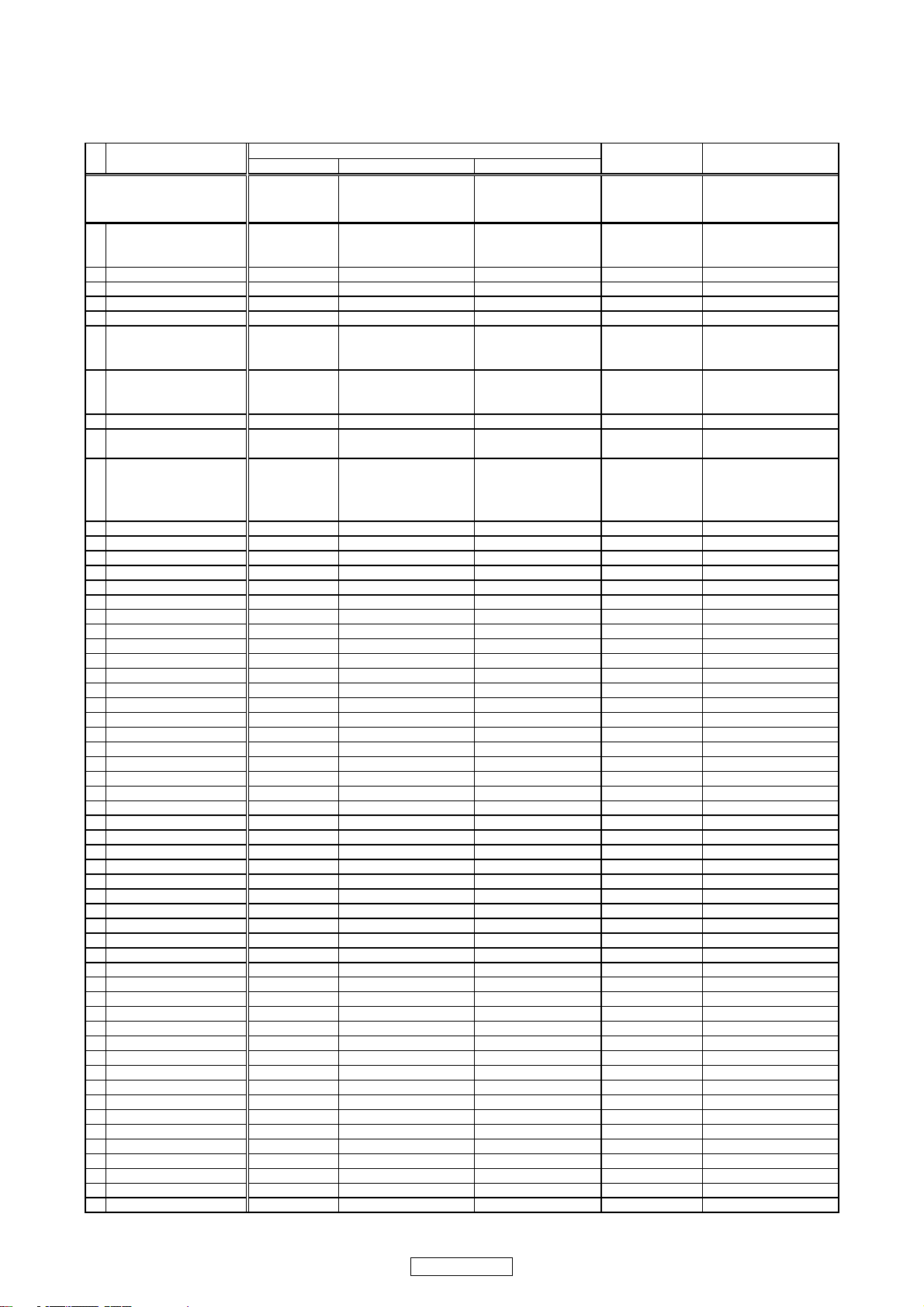

(2) Data reception

p

r

LED data reception

The panel operation data is transmitted by MIDI command, as per the table below.

(2) 受信データ

LED受信データ

パネルの LEDは以下の表に従い MIDIコマンドでオン、オフ、ブリンクが設定できる。

F Receive command for LED (LED のコマンドを受け取る )

items

LED 0xBn

1 Disc Eject 0x01

2 JOG mode 0x06

3 Pitch/KEY 0x07

4 ECHO/LOOP 0x0B

5 FLANGER 0x0D

6 FILTER 0x0F

7 Parameter KNOB 0x1E

8A1 0x24

9 A1 Dimmer 0x3E

10 A2 0x25

11 A2 Dimmer 0x3F

12 Cue 0x26

13 Play 0x27

14 BRAKE 0x28

15 DUMP 0x29

16 REVERSE 0x3A

Command Number Value

MIDI command

ON TRG : 0x4A

OFF TRG : 0x4B

Blink ON TRG : 0x4C

㸣 Control Change

Message䇭type Notes

items

㪦㫋㪿㪼㫉㫊 0xBn

1 Pitch slider request 0xBn 0x4A 0x3C Control Change return

Command Number Value

MIDI command

ON TRG : 0x4A

OFF TRG : 0x4B

Blink ON TRG : 0x4C

Message䇭type Notes

㸣

Control Change

itch slide

26

DN-S1200

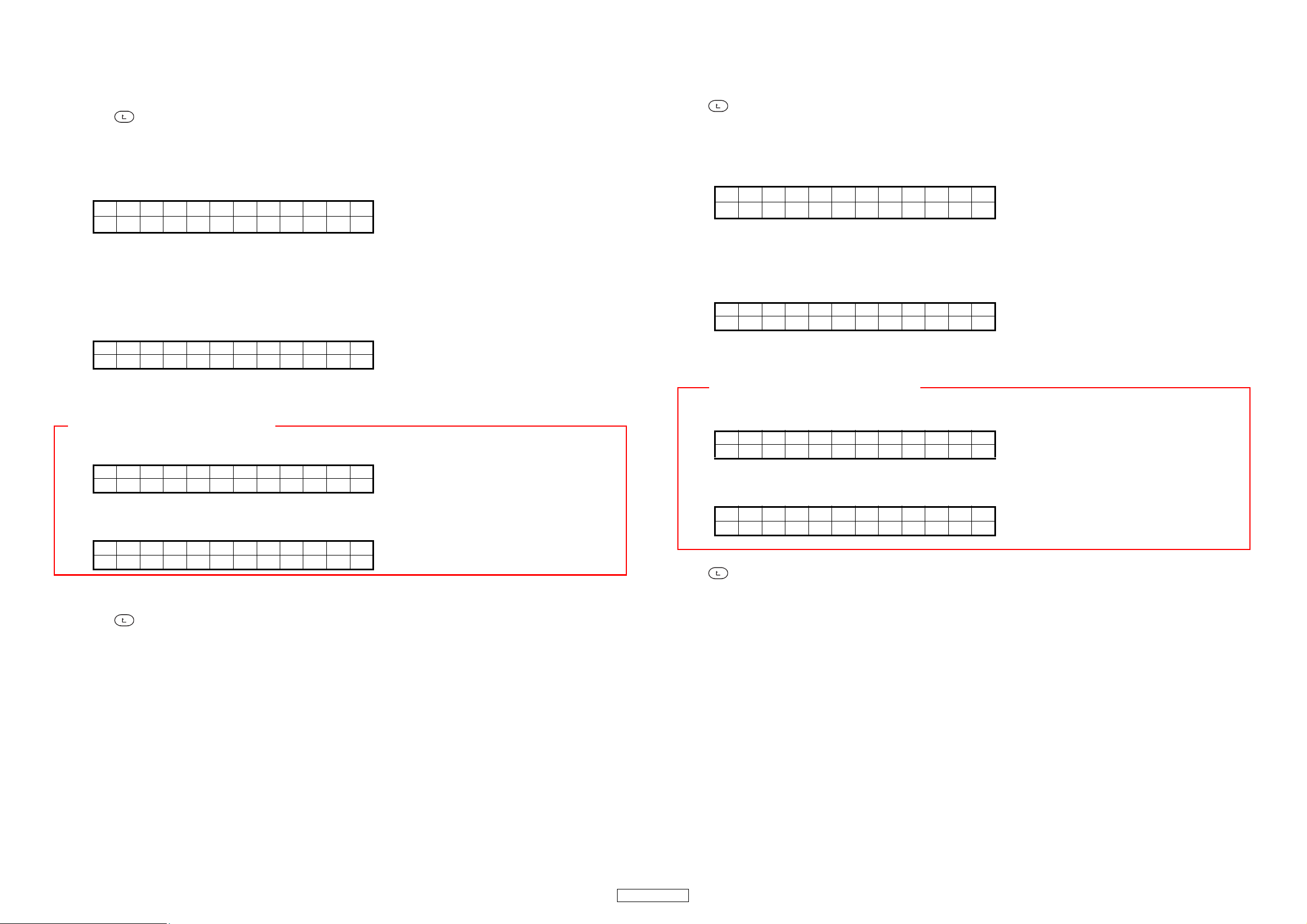

(3) VFD parameter data reception

,

,

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

The time-related display and segment display can be set by MIDI command, as per the table below.

(3) VFDパラメータデータ受信

時間関連表示とセグメント表示部は以下の表に従い、MIDIコマンドで設定できる。

F Receive command for VFD Parameter (VFD パラメータのコマンドを受け取る )

items

VFD Parameter 0xBn

1 Tr number MSB 0xBn 0x40

2 Tr number LSB

3 Time mini

4 Time sec

5 Time frame

6 Pitch POL

7 Pitch MSB

8 Pitch LSB

9 Track Position

10 Segment 1-1 MSB

11 Segment 1-2 MSB

12 Segment 1-3 MSB

13 Segment 1-4 MSB

14 Segment 1-5 MSB

15 Segment 1-6 MSB

16 Segment 1-7 MSB

17 Segment 1-8 MSB

18 Segment 1-9 MSB

19 Segment 1-10 MSB

20 Segment 1-11 MSB

21 Segment 1-12 MSB

22 Segment 1-1 LSB

23 Segment 1-2 LSB

24 Segment 1-3 LSB

25 Segment 1-4 LSB

26 Segment 1-5 LSB

27 Segment 1-6 LSB

28 Segment 1-7 LSB

29 Segment 1-8 LSB

30 Segment 1-9 LSB

31 Segment 1-10 LSB

32 Segment 1-11 LSB

33 Segment 1-12 LSB

34 Se

ment 2-1 MSB

ment 2-2 MSB

35 Se

36 Se

ment 2-3 MSB

37 Se

ment 2-4 MSB

38 Se

ment 2-5 MSB

39 Se

ment 2-6 MSB

40 Se

ment 2-7 MSB

41 Se

ment 2-8 MSB

42 Se

ment 2-9 MSB

43 Se

ment 2-10 MSB

44 Se

ment 2-11 MSB

45 Se

ment 2-12 MSB

46 Se

ment 2-1 LSB

ment 2-2 LSB

47 Se

48 Se

ment 2-3 LSB

49 Se

ment 2-4 LSB

50 Se

ment 2-5 LSB

51 Se

ment 2-6 LSB

52 Se

ment 2-7 LSB

53 Se

ment 2-8 LSB

54 Se

ment 2-9 LSB

55 Se

ment 2-10 LSB

56 Se

ment 2-11 LSB

57 Se

ment 2-12 LSB

Command Number Value

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

㸡

MIDI command

ON TRG : 0x4D

OFF TRG : 0x4E

Blink ON TRG : 0x4F

0x41

0x42

0x43

0x44

0x45

0x46

0x47

0x48 normal

0x49 reverse

0x01 0x00䌾0x0F

0x02

0x03

0x04

0x05

0x07

0x08

0x09

0x0A

0x0B

0x0C

0x0D

0x21

0x22

0x23

0x24

0x25

0x27

0x28

0x29

0x2A

0x2B

0x2C

0x2D

0x0E

0x0F

0x10

0x11

0x12

0x13

0x14

0x15

0x16

0x17

0x18

0x19

0x2E

0x2F

0x30

0x31

0x32

0x33

0x34

0x35

0x36

0x37

0x38

0x39

Message䇭type Notes

㸣

0-99

100-109䋺"-0”to"-9"

110 :"--"

100-109䋺"-0”to"-9"

110 :"--"

111 :" "

㸡㸡

㸡㸡

㸡㸡

㸡㸡

' 0x00

'+' 0x01

'-' 0x02

0-99

111 :" "

㸡㸡

0-100 %

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

㸡㸡 㸡

Control Change

Control Change

㸡

㸡

㸡

㸡

ASCII+original MSB

㶎Segment command

must be sent to a pair

in order of MSB,LSB.

ASCII+original LSB

ASCII+original MSB

ASCII+original LSB

27

DN-S1200

Loading...

Loading...