Page 1

For U.S.A., Canada, Europe

& Korea model

SERVICE MANUAL

MODEL

DOUBLE CD PLAYER

DN-D4000

注 意

サービスをおこなう前に、このサービスマニュアルを

必ずお読みください。本機は、火災、感電、けがなど

に対する安全性を確保するために、さまざまな配慮を

おこなっており、また法的には「電気用品安全法」に

もとづき、所定の許可を得て製造されております。

従ってサービスをおこなう際は、これらの安全性が維

持されるよう、このサービスマニュアルに記載されて

いる注意事項を必ずお守りください。

Please use this service manual with referring to the

operating instructions without fail.

Some illustrations using in this service manual are

slightly different from the actual set.

16-11, YUSHIMA 3-CHOME, BUNKYOU-KU, TOKYO 113-0034 JAPAN

Telephone: 03 (3837) 5321

本機の仕様は性能改良のため、予告なく変更する

ことがあります。

補修用性能部品の保有期間は、製造打切後8年です。

修理の際は、必ず取扱説明書を参照の上、作業を

行ってください。

本文中に使用しているイラストは、説明の都合上

現物と多少異なる場合があります。

X0171V.01 DE/CDM 0303

Page 2

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

LASER RADIATION

Do not stare into beam or view directly with optical instruments, class 3A laser product.

500V

1M

1DN-D4000

(1)

(2)

(1)

(2)

1

Page 3

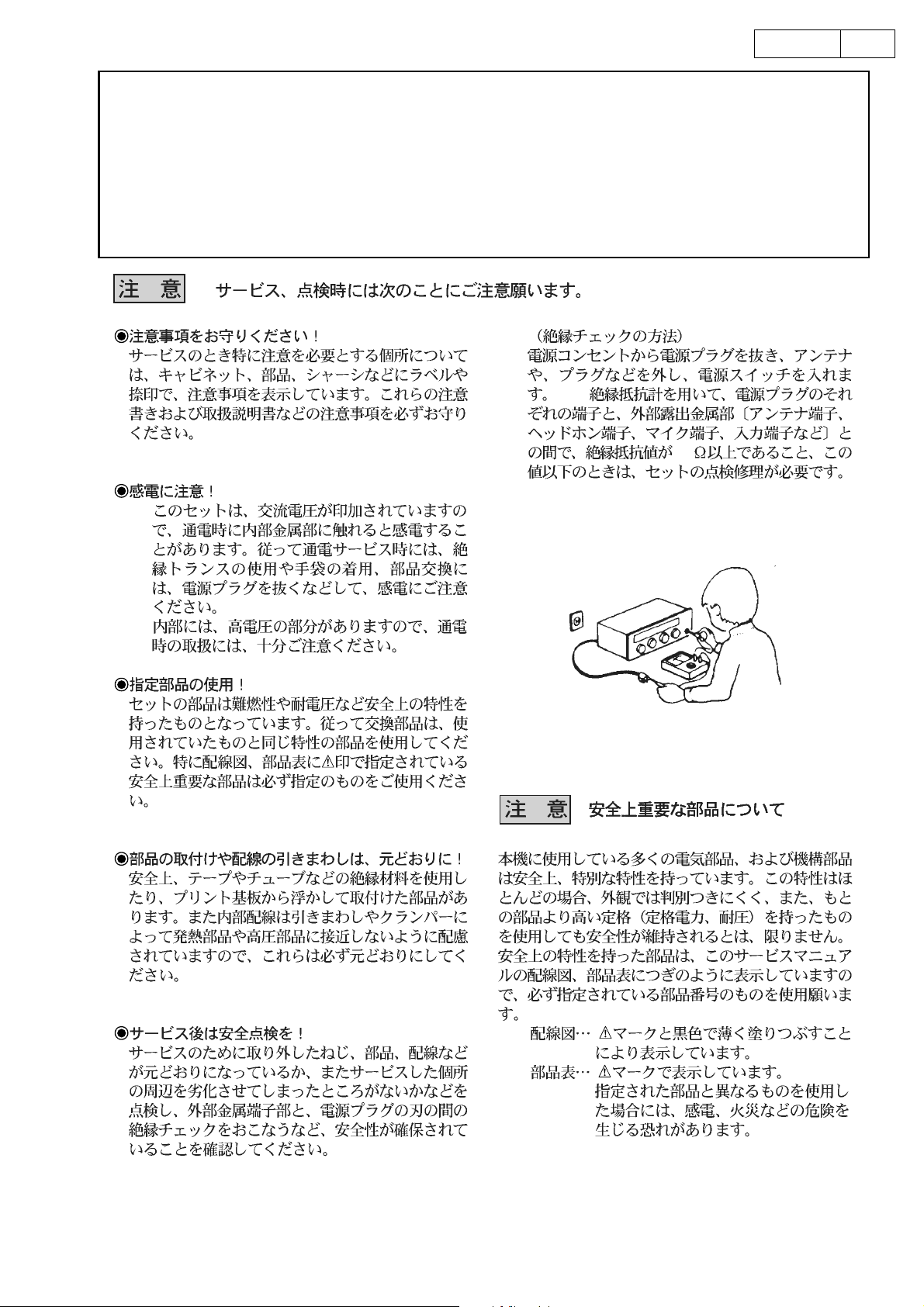

DISASSEMBLY

(Follow the procedure below in reverse order when reassembling)

1. TOP COVER

(1) Remove 4 screws on the both sides, and 1 screw on rear side, then remove 1 upper screw.

(2) Pull up Top Cover.

2DN-D4000

2. FRONT PANEL

(1) Detach 2 Blind Labels on the bottom chassis.

(2) Move CD Mecha Rack in the arrow direction through the label detached chassis opening. Loader Frame comes out.

(3) Pull up Loader Panel while pulling it towards front.

(4) Remove 2 upper screws and 3 lower screws, and 2 screws on both sides.

(5) Detach Front Panel.

2

Page 4

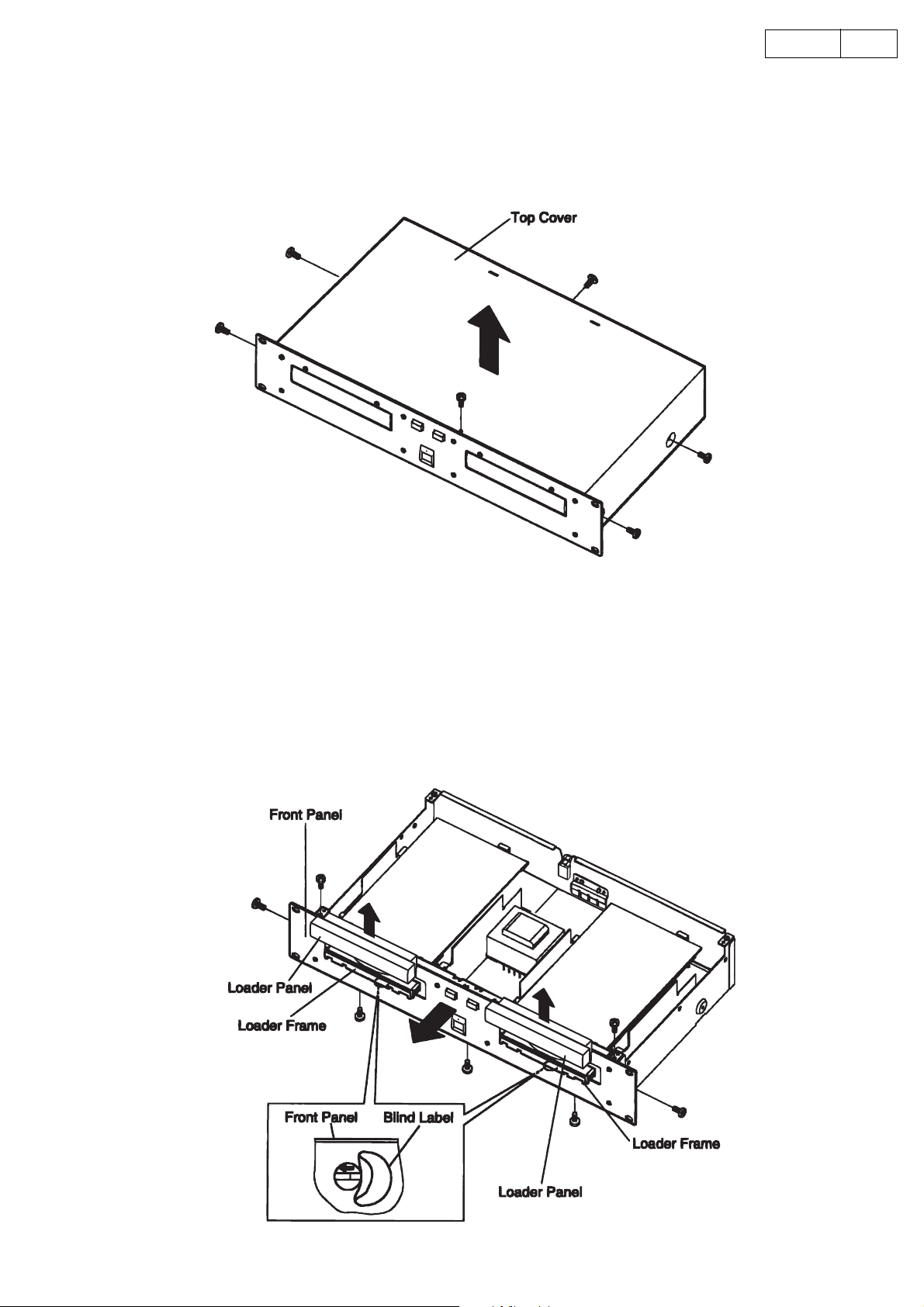

3. MECHANISM UNIT

(1) Disconnect FFC cable.

(2) Rrmove 8 lower screws

(3) Remove 4 screws on rear side.

NOTES:

(a) Do notpull out aslant to prevent the FFC cable from damage.

(b) Do not fail to pull out AC cord from wall outlet befor disconnecting the FFCcable. If the ACcord is remained

plugged into wall outlet, the power is kept supplied in the unit, which may cause danger.

3DN-D4000

4. MAIN P.W.B.

(1) Remove 4 screws.

(2) Disconnect Connector.

(3) Detach Main P.W.B.

3

Page 5

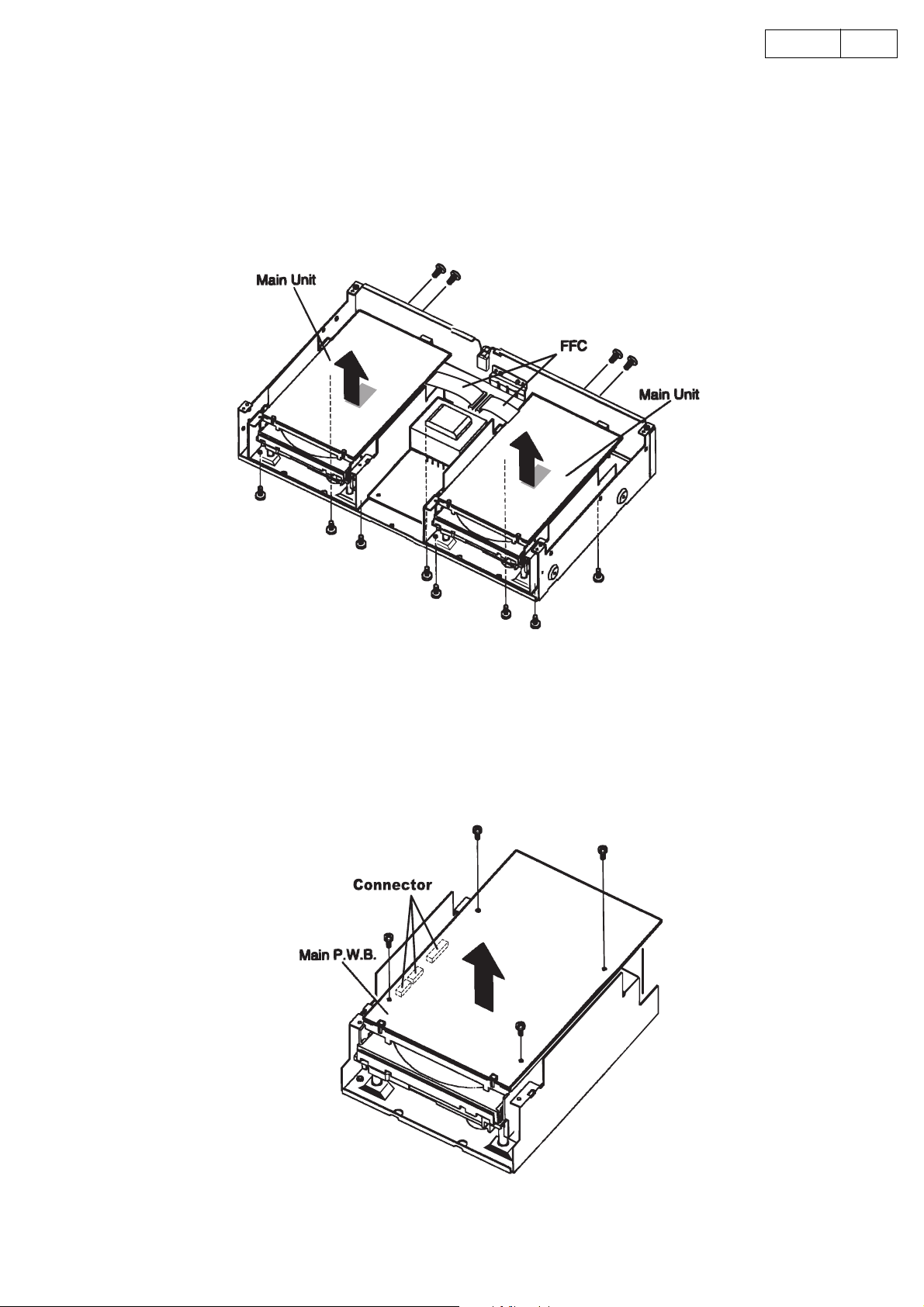

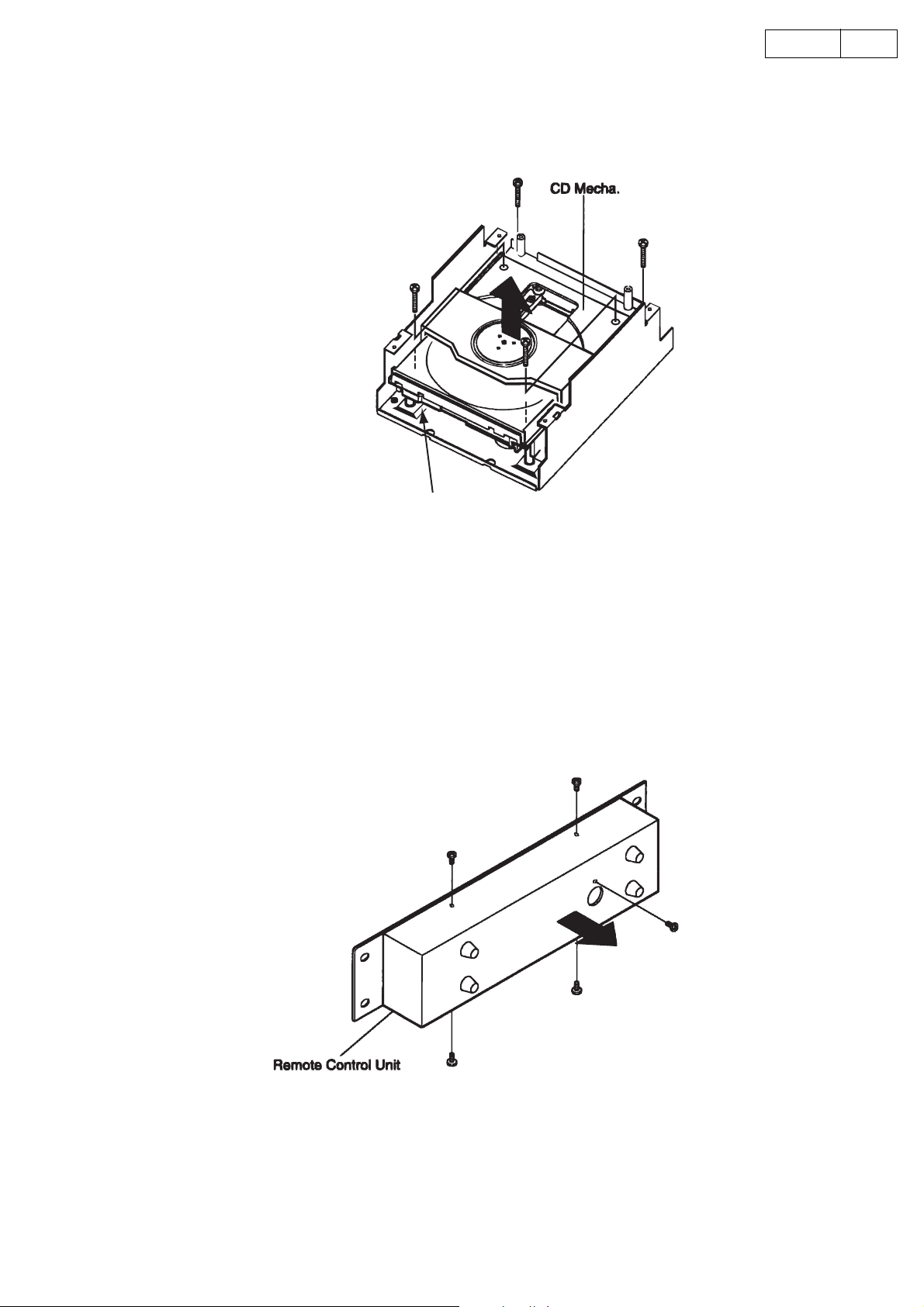

5. CD MECHA.

(1) A gear is turned and a tray is opened.

(2) Remove 4 upper screws.

(3) Detach CD Mecha.

4DN-D4000

6. COVER ( REMOTE CONTROL UNIT )

(1) Remove 5 screws.

NOTE:

(a) Remote Control Unit and its back panel are connected with cables, so pay attention when removing the back pan-

el.

Gear

4

Page 6

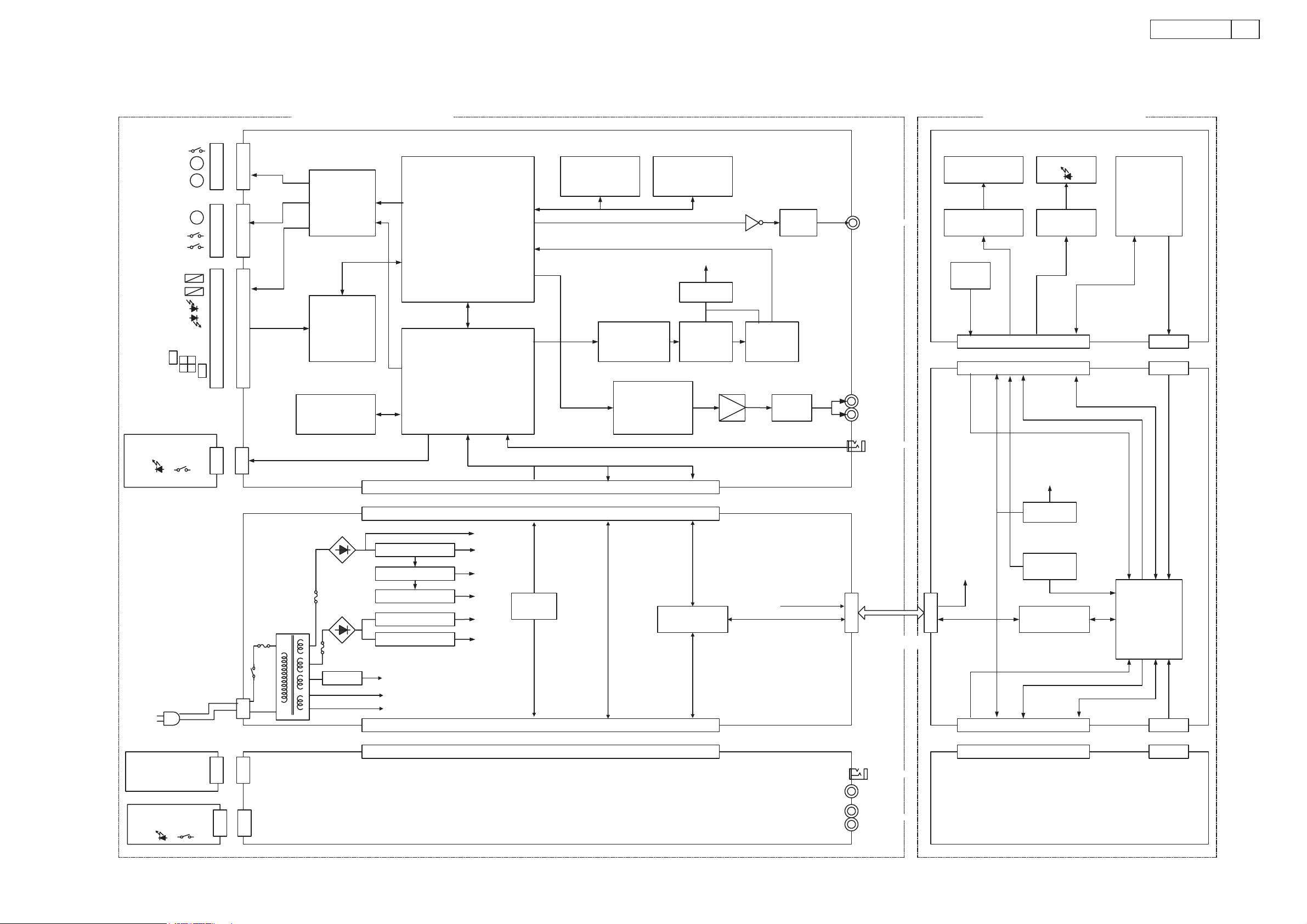

BLOCK DIAGRAM

DN-D4000

6

LIMIT SW

SPINDLE

MOTOR

CLOSE

SW

OPEN SW

FOCUS COIL

TRACKING COIL

MONITOR DIODE

LASER DIODE

DETECT

E

OR

CD MECHA

UNIT 1

LED1

UNIT

A B

D C

<DN-D4000 DOUBLE CD

PLAYER>

MAIN UNIT 1

MSLIDE MOTOR

M

DRIVER

[AN8785SB]

MLOADING MOTOR

F

IC202

HEAD AMP

[AN22002A]

IC203

8M FLASH MEMORY

[ M29W800DB70]

IC 111

DIGITAL SERVO PROCESSOR

[MN6627911AC]

IC201

SYSTEM uCOM

[MN102H60KDA]

IC101

16M DRAM

[M11L1644SA-50T]

IC204

[TC74HCT7007AF]

IC112

[PCM1748E]

[M11L1644SA-50T]

DAC

IC206

16M DRAM

IC210

+9VP

[NJM78L05AT]

IC118

[BU2618FV]

IC113

VCO

[TC9246F]

IC114

PULSE

TRANS

DIG OUT 1

ANA OUT 1TR MUTE

FADER 1

[14-MT-35GN]

FL601

FL DRIVER

[M66005FP]

IC601

PITCH

SLIDE VR

<DN-D4000 REMOTE

CONTROLLER>

PANEL UNIT 1

LED BLOCKFLT

LED CONTROL

[BU2090F]

IC602

REMOTE CPU

KEY

JOG SHUTTLE

TR.SEL

KEY MATRIX

BLOCK

UNIT

AC

CD MECHA

UNIT 2

LED2

UNIT

POWER UNIT

POWER

TRANS

+5V REG (AUDIO)

-5V REG (AUDIO)

-HB REG -HB

+5V REG

+3.3V REG

+1.8V REG

F2

F1

+9VP

+5VD

+3.3VD

+1.8V

+5VA

-5VA

RESET

[PST600C]

IC301

MAIN UNIT 2

BSY , MBSY

[SN74AHCT08PW]

IC302

+9V,-HB,F1,F2

RC TXD,RC RXD

FADER 2

DIG OUT 2

ANA OUT 2

8P MD

CABLE

+9V,-HB,F1,F2

+9V

[NJM7805FA(S)]

IC404

RESET

[PST600C]

IC403

[SN74AHCT08PW]

IC302

PANEL

UNIT 2

REMOTE uCOM

[TMP86CM47U]

IC402

6

Page 7

SERVICE PROGRAM

Required Measuring Implement

1. Reference disc (TCD784 or CO-74176)

1. What is Service Program

Service program is a special program intended for confirming servo functions etc.

2. Contents of Service Program

Switch on the power while pushing the CD1’s PITCH BEND + button and CD2’s OPEN/CLOSE button at the same

time. After actuating the servo program, select an aiming process number with the SELECT knob, A1 button, or A3 button.

Press the SELECT knob to execute the selected process, the process number is then displayed on the track indicator of the

display. To exit from the service program, just switch off the power.

7DN-D4000

SELECT knob

Function

(Character-display)

μcom Version check

(Version No.)

Error Code Check

(Error Data)

Total Running Time

(Total_Time)

Automatic

Servo Adjustment

call

Contents

Check Version with JOG dial.

1. System μcom version No.:

2. RC μ

Turn the JOG dial to display the logging error codes in the occurred order.

“ErrXX_E

10 error logs are memorized at maximum.

Kinds of Error Code, displayed

Error Code Table

Pressing SELECT knob enters to data erase mode. (“Err Clear?” is displayed.)

If the SELECT knob is pushed again, the memorized error data are cleared.

Total time span of servo function that counted by the hour is displayed.

“R.Tim XXXXH”

Note: No time is counted if disc tray is opened within 59 minutes.

Pressing SELECT knob enters to data erase mode. (“Time Clear?” is displayed.)

If the SELECT knob is pushed again, the memorized time data are cleared.

Starts automatic servo adjustment when the SELECT knob is pushed, and after

completing the adjustment, sort of the used disc is indicated. Data is selectable with

the JOG dial.

1. Focus gain data

2. Focus balance data

3. Focus offset data

4. Tracking gain data

5. Tracking balance data

6. Tracking offset data

com version No.: “RC_VerXXXX”

” XX : occurred order E

* * *

“Servo_Data”

“SysVerXXXX”

* * *

: error code

7

Page 8

8DN-D4000

SELECT knob

Function

(Character-display)

Block Error Rate Check

Servo Check

Illumination Check

Contents

Loading a disc by OPEN/CLOSE button.

Press the PLAY/PAUSE button. B.E.R. is displayed.

“E.Rate_XXX XXX : Block Error Rate

You can select the track by the JOG DIAL.

Starts automatic servo checking when the SELECT knob is pushed.

Loading a disc by OPEN/CLOSE button.

“Lchk_Open” : Disc Tray is opened.

“Lchk_Wait” : During check.

“Lchk_OK!!” : Disc Tray is opened.

“LchkErr *** ” : Error(E ***) is occurred.

All illuminations are lit.

All illuminations can be turned off to push the SELECT knob.

Press the SELECT knob again, all illuminations can be lit.

3. TEST MODE

Process No.

(TRACK

Indication)

A1 button

A2 button

Adjustment Item

Adjustment Value indication at

character portions.

Focus Gain 0576 ~ 2304

Focus Balance -050 ~ +050

Focus Offset -005 ~ +005

Tracking Gain 0392 ~1569

Tracking Balance -025 ~ +025

Tracking Offset -005 ~ +005

* Reference data.

Function

(Character-display)

Starting with the PLAY/PAUSE button, it repeats open/close of the tray and

-

-

Heat Run

(H/R1Normal)

Chucking Test

(H/R2_Tray)

playback.

All tracks are played back if the track count is less than 20. Only the first and last

tracks are played back if the tracks are more than 21. When any errors, it stops

and indicates error code (see Error Code Table).

Starting with the PLAY/PAUSE button, it repeats open/close of the tray, servo on,

and TOC read.

The display shows the number of the tray operation. When any errors, it stops and

indicates error code (see Error Code Table).

Contents

8

Page 9

4. Error Code Table

Error Code CONTENTS

E001 Unable to close the loader tray in the regulation time.

E002 Unable to open the loader tray in the regulation time.

E003 Inner circle switch ON error even if the time is over.

E004 Inner circle switch OFF error even if the time is over.

E005 The focus offset adjustment result is outside the regulation range.

E006 Unable to adjust the focus offset in the regulation time.

E007 The tracking offset adjustment result is outside the regulation range.

E008 Unable to adjust the tracking offset in the regulation time.

E009 The FE peak is outside the regulation range.

E00A The FE peak is outside the regulation range.

E00B Unable to adjust the focus rough gain in the regulation time.

E00C The focus rough gain is outside the regulation range.

E00D Unable to actuate focus in the regulation time.

E00E Unable to actuate tracking in the regulation time.

E00F Unable to adjust the tracking rough gain in the regulation time.

E010 The tracking rough gain is outside the regulation range.

E011 Unable to adjust the tracking balance in the regulation time.

E012 The tracking balance adjustment result is outside the regulation range.

E013 Focus servo down during automatic adjustment.

E014 Focus servo down during automatic adjustment.

E015 Unable to adjust the focus balance in the regulation time.

E016 The focus balance adjustment result is outside the regulation range.

E017 Track servo down during automatic adjustment.

E018 Unable to adjust the focus fine gain in the regulation time.

E019 The focus fine gain is outside the regulation range.

E01A Unable to adjust the tracking fine gain in the regulation time.

E01B The tracking fine gain is outside the regulation range.

E01C Unable to adjust automatically in the regulation time.

E01D Unable to read the subcode Q in the regulation time.

E01E Unable to read the TOC in the regulation time.

E01F Focus servo down during search (over the regulation time).

E020 Track servo down during search (over the regulation time).

E0216 * Servo error during search.

E0213 * Search error (over the regulation time).

E022 Discontinuity occurred, during write to the DRAM.

E023 The error which cannot be corrected to the read data.

E024 Unable to do the level detect.

E025 Unable to join data in the regulation time.

E026 The error rate when recording on the memory is over the regulation value.

E027 The subcode jump more than regulation.

E028 Servo error when power is turned on.

E029 Subcode Q error.

E030 Inter face error for both drives.

9DN-D4000

9

Page 10

μCOM VERSION UPGRADE

System µcom can be upgraded in the following manner.

Version Upgrade Method

1.Record the version upgrade software on a CD-R or CD-RW disc,

only as one file with the format ISO9660 Mode-1.

The file name of the supplied version upgrade software should be used as is and this disc needs

to finalize.

2.Hold the disc by the edges and place it on the disc tray.

3.Press the OPEN/CLOSE button to start the version upgrade.

"

Version Up

xxxx : current version

XXXX : upgrade version

4.Press the PLAY/PAUSE button.

"

Now Writing

5.When the version upgrade is finished, "

6.Turn off the power once and turn on again.

Press the OPEN/CLOSE button and remove the disc.

NOTE:

"→"

Push Play!

" → "

Writing-XXX

When the power is turned off before "

" "

xxxx->XXXX

" are displayed.

XXX : count up from 000 to161

Complete!

" are displayed.

" is indicated.

Complete!

" is displayed,

µcom

version is not written correctly.

10DN-D4000

10

Page 11

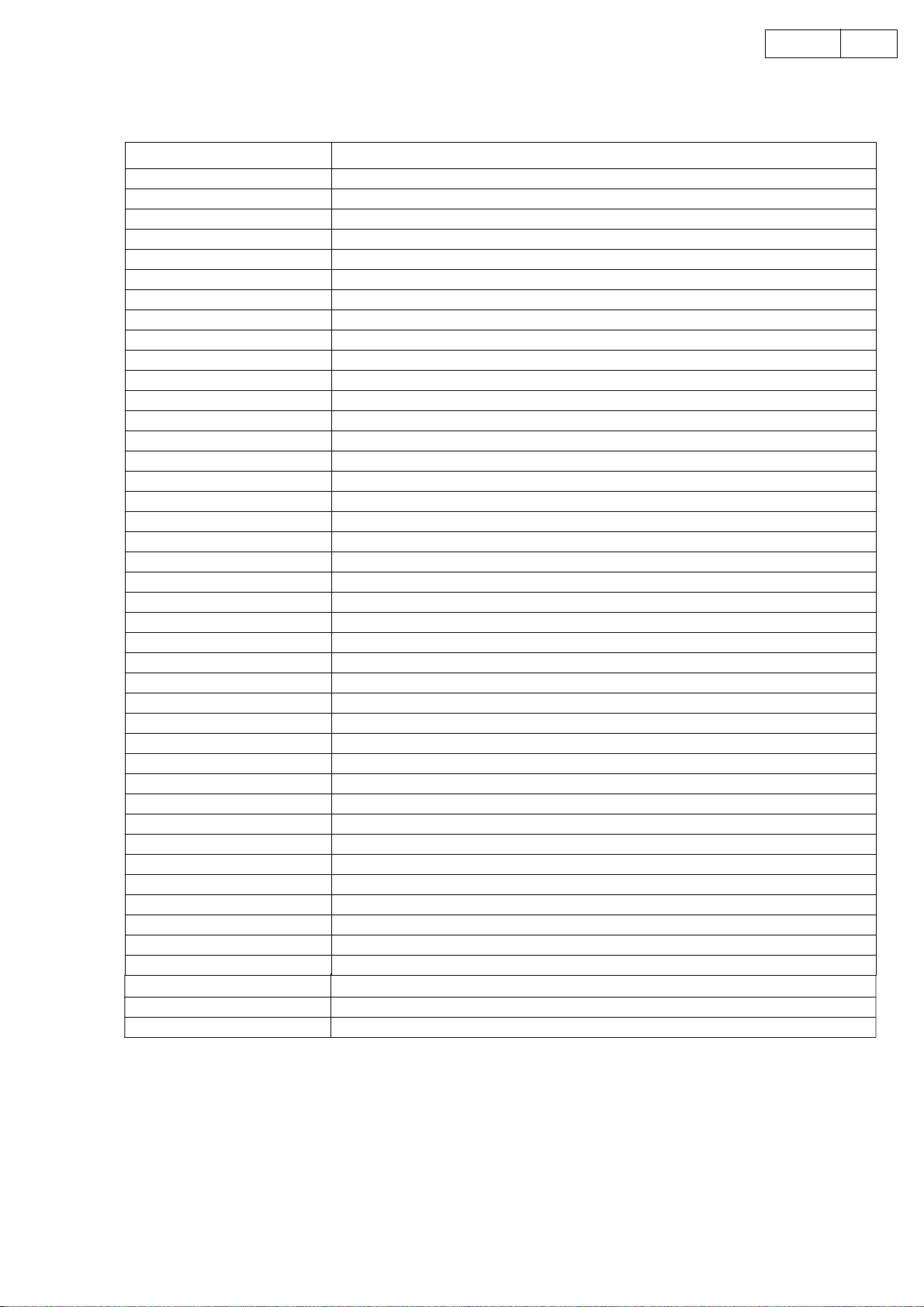

SEMICONDUCTORS

IC’s

MN102H60KDA

(IC101)

11DN-D4000

75

76

100

1

51

50

26

25

MN102H60KDA Terminal Function

Pin

Pin Name Symbol I/O DET Ext Res Ini Function

No.

1 P60, WAIT, SBT2 PCDMUTE O - Pd L L Mute for analog 'L': Mute ON

2 P61, _RE RD- O - Pu H - Read signal

3 P62, _WEL WR- O - Pu H - Write signal

4 P63, _WE, _WEH Reserved O - - Hi-Z L Not used.

5 _CS0,TM13OA FLASHROMCS- O - Pu H - Chip select signal

(MASK ROM operation : Input port)

6 _CS1, TM13OB Reserved O - - Hi-Z L Not used.

7 _CS2, TM14OA Reserved O - - Hi-Z L Not used.

8 _CS3, TM14OB PLOAD O - - Hi-Z H OPEN/CLOSE signal (PWM out put)

(During Pnrst=

'L', out put PWM(50%))

9 P54, _BREQ Reserved O - - Hi-Z L Not used.

10 P55, _BRACK Reserved O - - Hi-Z L Not used.

11 P56, ALE, _ALE,

MON2 I - - Hi-Z - Monitor signal 2

_BSTRE, TM15IA

12 P57,_WORD WORD- I - L L - Data bit bus width select 'L': 16bit

13 P20,A00,SBT2 A00 A/O - - Unfix - Address bus

14 P21,A01,SBI2 A01 A/O - - Unfix - Address bus

15 P22,A02,SBO2 A02 A/O - - Unfix - Address bus

16 P23,A03 A03 A/O - - Unfix - Address bus

17 Vdd Vdd - - - - - Power supply(+3.3V)

18 BOSC,BIBT1,BIBT2,

Reserved O - - L L Not used.

PB0

19 Vss Vss - - - - - GND(0V)

20 XI,PB1 PCE O - Pd L L Latch output

21 XO XO - - - - - Not used. OPEN

22 Vdd Vdd - - - - - Power supply(+3.3V)

23 OSCI OSCI I - - - - Not used.

24 OSCO OSCO O - - - - OSCI output

25 MODE MODE I - L L - Mode select 'L': Processor mode

11

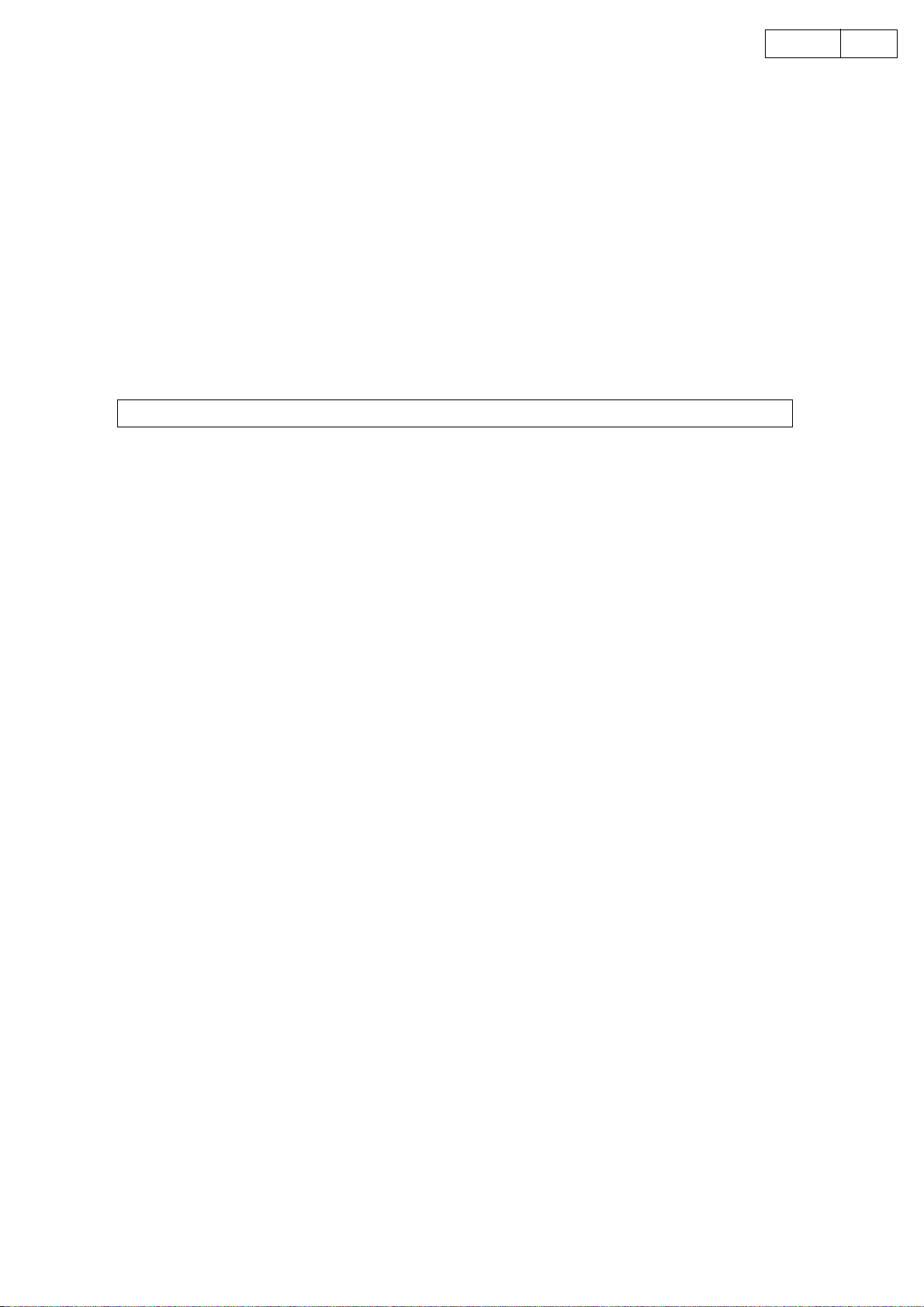

Page 12

Pin

Pin Name Symbol I/O DET Ext Res Ini Function

No.

26 P24,A04,TM15IA A04 A/O - - Unfix - Address bus

27 P25,A05 A05 A/O - - Unfix - Address bus

28 P26,A06 A06 A/O - - Unfix - Address bus

29 P27,A07 A07 A/O - - Unfix - Address bus

30 P30,A08,_KI0 A08 A/O - - Unfix - Address bus

31 P31,A09,_KI1 A09 A/O - - Unfix - Address bus

32 P32,A10,_KI2 A10 A/O - - Unfix - Address bus

33 P33,A11,_KI3 A11 A/O - - Unfix - Address bus

34 AVDD AVDD - - - - - Analog power supply terminal

35 P34,A12,_KI4 A12 A/O - - Unfix - Address bus

36 P35,A13,_KI5 A13 A/O - - Unfix - Address bus

37 P36,A14,_KI6 A14 A/O - - Unfix - Address bus

38 P37,A15,_KI7 A15 A/O - - Unfix - Address bus

39 P40,A16 A16 A/O - - Unfix - Address bus

40 P41,A17 A17 A/O - - Unfix - Address bus

41 P42,A18 A18 A/O - - Unfix - Address bus

42 P43,A19 A19 A/O - - Unfix - Address bus

43 Vref- Vref- - - - - - Standard analog power supply

44 P44,AN4,A20 POPEN I - - Unfix - OPEN switch 'L': Switch ON

45 P45,AN5,A21 PCLOSE I - - Unfix - CLOSE switch 'L': Switch ON

46 P46,AN6,STOP,A22 PLIMITSW I - - Hi-Z - Inner circle SW 'L': Switch ON

47 P47,AN7,WDOUT,

A23

48 P80,TM14OA PEJECTSW I - Pu H - Eject switch 'L': Switch ON

49 P81,TM14OB PTLED O - Pd L L Toray LED 'H': Light 1 / 'L': Turn Off

50 P82,TM0IO,SBI2,

SBT3,SCL3

51 P83,TM4IO,SBI3 RxD I - Pu H - Serial port (Receive)

52 P84,TM7IO,SBO3,

SDA3

53 P85,TM9IOA,SBO2,

SBT4,SCL4

54 Vref+ Vref+ - - - - - Standard analog power supply

55 P86,TM9IOB,SBI4 PMECHRxD I - - Hi-Z - Serial port (Receive)

56 P87,TM9IC,SBO4,

SDA4

57 P90,TM8IOA,BIBT1,

_DMAREQ1

58 P91,TM10IOA,

BIBT2,_DMAACK1

59 P92,TM10IOB,

_DMAREQ0

60 P93,TM10IC,

_DMAACK0

61 Vss Vss - - - - - GND(0V)

62 P94,AN0 PMBSYOUT O - - Hi-Z H Mechanism microcomputer

63 P95,AN1 PMBSYIN I - - Hi-Z - Mechanism microcomputer

64 P96,AN2 PRCBSYOUT O - - Hi-Z H Communication Busy signal output

PCDSEL I - H/L H/L - CD mecha select switch

'L': Mecha 1 / 'H': Mecha 2

PDMUTE O - Pu H H Mute for digital 'H': Mute ON

(76.8kbps 5V -> 3.3V)

TxD O - Pu H H Serial port (Transmission)

(76.8kbps , Use ATC function)

PMD O - Pu L L DAC(PCM1748) control signal : Data

PMECHTxD O - - Hi-Z H Serial port (Transmission)

(76.8kbps , Use ATC function)

PMC O - Pd L L DAC(PCM1748)

control signal : Clock

PML O - Pd L L DAC(PCM1748)

control signal : Latch

PLRCK I Ed - Hi-Z - LRCK : Use for time code creation

during MP3 playback.

PNRST O - Pd L L Round IC reset signal

Communication Busy signal output

'H':BUSY

Communication Busy signal input

between RC and Mecha 'H':BUSY

12DN-D4000

12

Page 13

Pin

Pin Name Symbol I/O DET Ext Res Ini Function

No.

65 P97,AN3 PRCBSYIN I - - Hi-Z - Communication Busy signal input

between RC and Mecha

66 Vdd Vdd - - - - - Power supply(+3.3V)

67 P70,SBT0,_RAS PMCLK O - - Hi-Z H DSP interface Clock

(clock synchronous formula)

68 P71,SBI0,_CAS,_LCASPSTAT I - - Hi-Z - DSP interface Reception

(clock synchronous formula)

69 P72,SBO0,_UCAS PMDAT O - - Hi-Z H DSP interface Transmission

(clock synchronous formula)

70 P73,SBT1,DUMX PTXTCLK O - - Hi-Z H Use during CD-TEXT data read

(clock synchronous formula)

71 P74,SBI1 PTXTD I - - Hi-Z - Use during CD-TEXT data read

(clock synchronous formula)

72 P75,SBO1 PMLD O - - Hi-Z H DSP interface latch

73 TEST1 TEST1 I - Pu - - Pull up 33 - 50K

74 TEST2 TEST2 I - Pu - - Pull up 33 - 50K

75 _NMI _NMI I Lv Pu H - Need to pull up

76 PA0,_IRQ0 PBLKCK I Ed - Hi-Z - Sub code clock interruption

77 PA1,_IRQ1 PDQSY I Ed - Hi-Z - CD-TEXT DQSY Interruption

78 PA2,_IRQ2 PFADECUE I - Pu H - Fader signal input (CUE)

'L' : Input YES

79 PA3,_IRQ3 PFADER ST I - Pu H - Fader signal input (PLAY)

'L' : Input YES

80 PA4,_IRQ4,TM15IB PCHGOFT O - Pu H L Off track signal

81 PA5,ADSEP ADSEP I - H H H H': Address data separation mode /

'L': Address data common mode

82 _RST RST- I Lv - L - Reset signal 'L': RESET

83 Vdd Vdd - - - - - Power supply(+3.3V)

84 P00,D00,AD00 D00 D/O - - Hi-Z - Data bus

85 P01,D01,AD01 D01 D/O - - Hi-Z - Data bus

86 P02,D02,AD02 D02 D/O - - Hi-Z - Data bus

87 P03,D03,AD03 D03 D/O - - Hi-Z - Data bus

88 P04,D04,AD04 D04 D/O - - Hi-Z - Data bus

89 P05,D05,AD05 D05 D/O - - Hi-Z - Data bus

90 P06,D06,AD06 D06 D/O - - Hi-Z - Data bus

91 P07,D07,AD07 D07 D/O - - Hi-Z - Data bus

92 Vss Vss - - - - - GND(0V)

93 P010,D08,AD08,TM

8IOB

94 P011,D09,AD09,TM

8IC

95 P012,D10,AD10,TM

11IOA

96 P013,D11,AD11,TM

11IOB

97 P014,D12,AD12,TM

11IC

98 P015,D13,AD13,TM

12IOA

99 P016,D14,AD14,TM

12IOB

100 P017,D15,AD15,TM

12IC

D08 D/O - - Hi-Z - Data bus

D09 D/O - - Hi-Z - Data bus

D10 D/O - - Hi-Z - Data bus

D11 D/O - - Hi-Z - Data bus

D12 D/O - - Hi-Z - Data bus

D13 D/O - - Hi-Z - Data bus

D14 D/O - - Hi-Z - Data bus

D15 D/O - - Hi-Z - Data bus

13DN-D4000

13

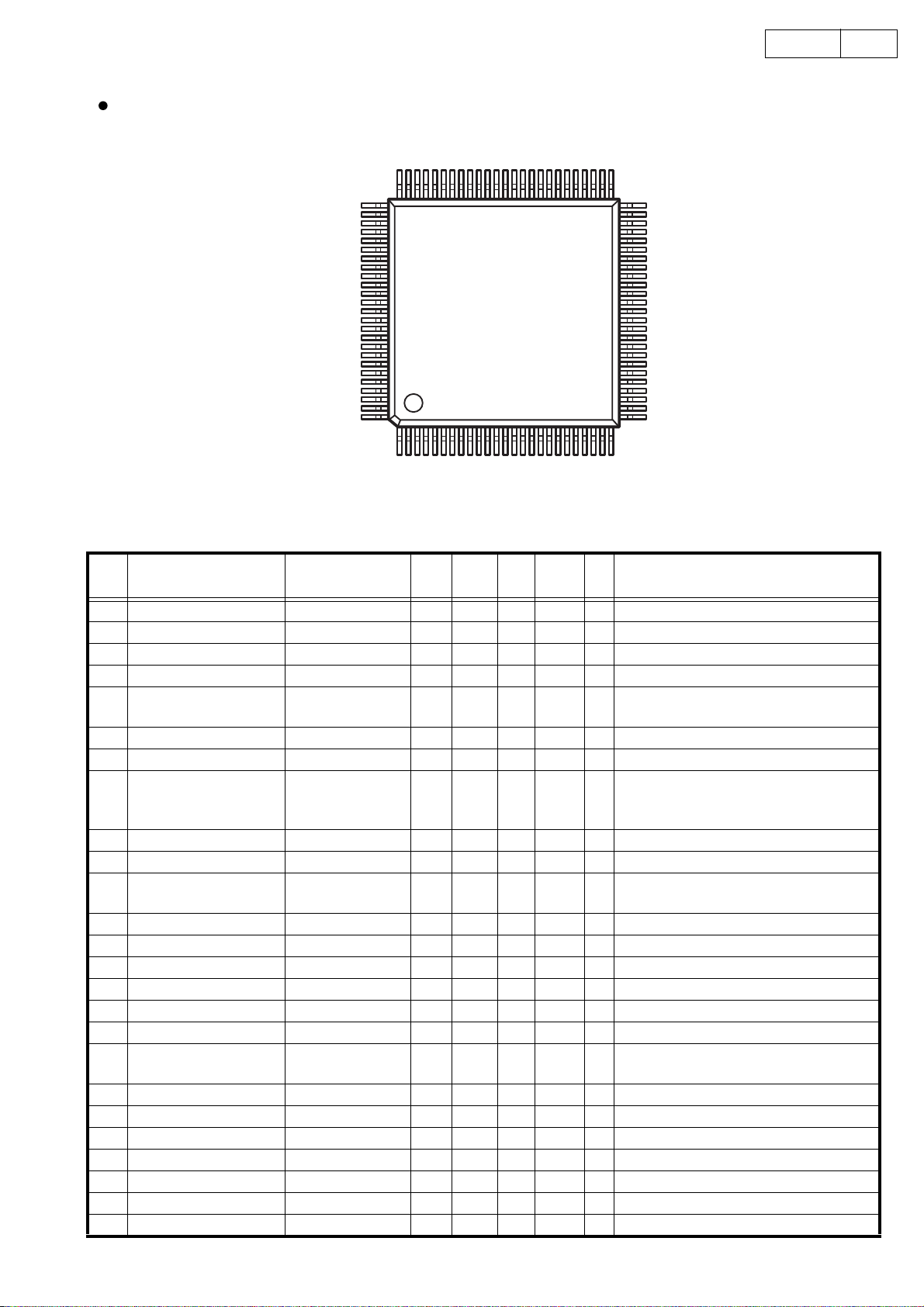

Page 14

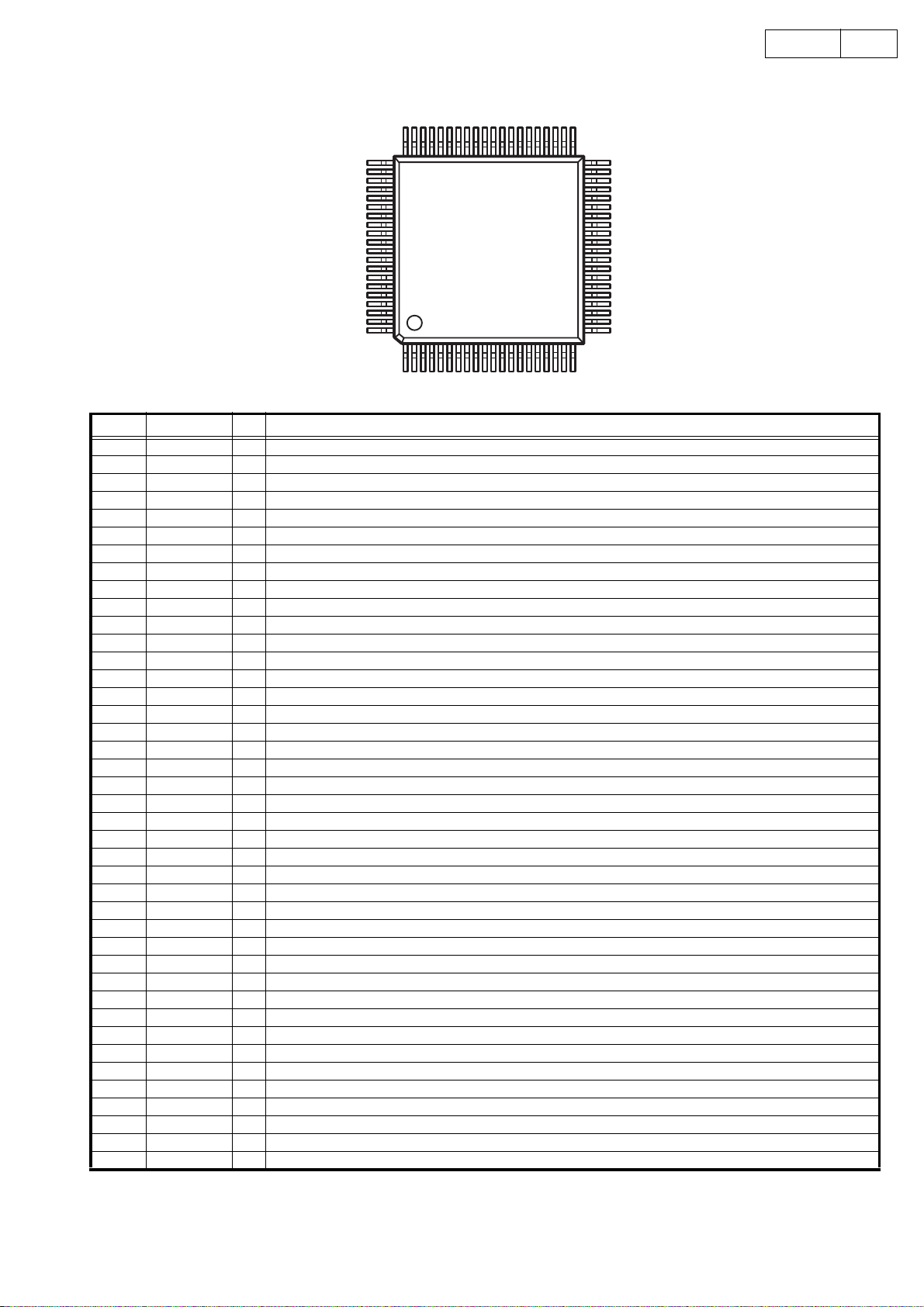

MN6627911AC

(IC201)

61

60

14DN-D4000

41

40

80

1

20

MN6627911AC Terminal Function

Pin No. Pin Name I/O Function

1 DRVDD I Power supply for DRAM interface (Pin No.2 - 18, 80)

2 D0 I/O Data I/O signal 0 for DRAM

3 D1 I/O Data I/O signal 1 for DRAM

4 WE O Write enable signal for DRAM

5 RAS O RAS control signal for DRAM

6 D2 I/O Data I/O signal 2 for DRAM

7 D3 I/O Data I/O signal 3 for DRAM

8 CAS O CAS control signal 0 for DRAM

9 A10 O Address signal 10 for DRAM

10 A8 O Address signal 8 for DRAM

11 A7 O Address signal 7 for DRAM

12 A6 O Address signal 6 for DRAM

13 A5 O Address signal 5 for DRAM

14 A4 O Address signal 4 for DRAM

15 A9 O Address signal 9 for DRAM

16 A0 O Address signal 0 for DRAM

17 A1 O Address signal 1 for DRAM

18 A2 O Address signal 2 for DRAM

19 A3 O Address signal 3 for DRAM

20 DVSS2 I GND for digital

21 DVDD2 I Power supply for digital

22 SPOUT O Spindle motor drive signal

23 TRVP O Traverse drive signal

24 TRVM O Not used

25 TRP O Tracking drive

26 GCNTL O Gain control signal for CD-RW

27 FOP O Focus drive

28 CHGICO O EQ select signal

29 IOVDD1 I Power supply for IO

30 TBAL O Tracking balance adjust

31 FBAL O Focus balance adjust

32 FE I Focus error signal (Analog input)

33 TE I Tracking error signal (Analog input)

34 RFENV I RF envelope signal (Analog input)

35 OFT I Off track signal H : OFF TRACK

36 NRFDET I RF detect signal H : DETECT

37 BDO I Drop out signal H : DROP OUT

38 LDON O Laser ON signal H : ON

39 ARF I RF signal

40 IREF I Standard current input terminal

41 ADPVCC I Voltage for power supply monitor

21

14

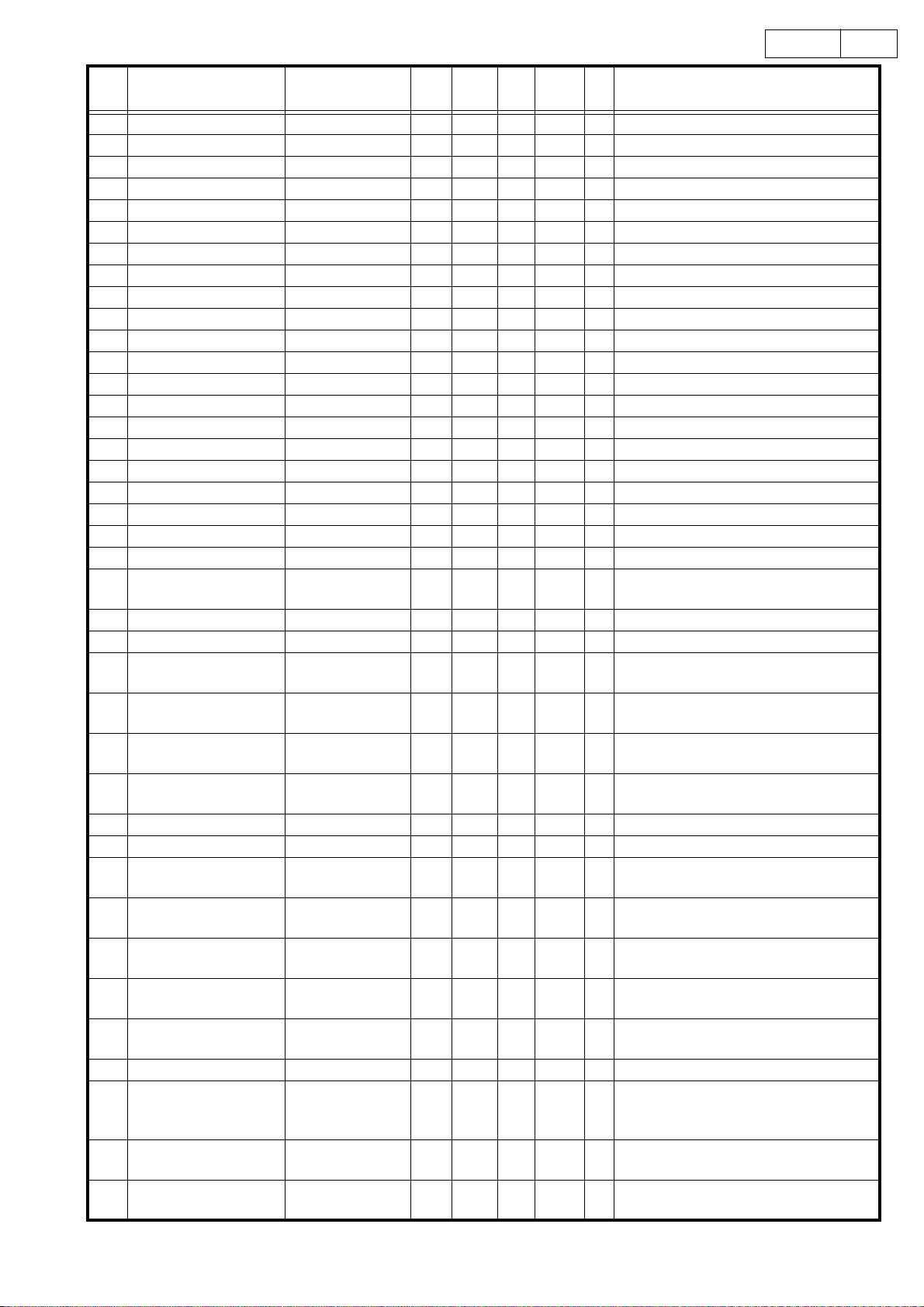

Page 15

Pin No. Pin Name I/O Function

42 DSLF O Loop filter for DSL

43 RFSW I Loop filter for DSL

44 PLLF O Loop filter for PLL

45 PLLFO O Loop filter for PLL

46 AVDD2 I Power supply for analog (DSL, PLL, AD)

47 AVSS2 I GND for analog (DSL, PLL, AD)

48 OUTL O Not used

49 AVSS1 I GND for analog (Audio output)

50 OUTR O Not used

51 AVDD1 I Power supply for analog (Audio output)

52 DVSS3 I GND for digital

53 DVDD3 I Power supply for digital

54 TMOD2 I Test terminal L : Normal

55 MON2 O Serial monitor signal 2

56 BCLK O Bit clock for serial data

57 SRDATA O Serial data signal

58 LRCK O L, R discernment signal

59 IOVDD2 I Power supply for IO

60 TX O Digital audio interface signal

61 MCLK I ucon command clock signal

62 MDATA I ucon command data signal

63 MLD I ucon command load signal L : LOAD

64 BLKCK O Sub code block clock signal (f=75Hz : Normal speed playback)

65 PWMSEL I PWM output mode select L : Direct H : 3 values

66 SMCK O Not used

67 SBCK I Not used

68 STAT O Status signal

69 NRST I Reset L : RESET

70 SPPOL O Not used

71 PMCK O Not used

72 DQSY O Pack signal for CD TEXT data

73 TXTD O CD TEXT data signal

74 TXTCK O Ext. clock signal input for CD TEXT resister

75 NTEST I Test terminal H : Normal

76 X2 O Not used

77 X1 I 16.9344MHz input terminal

78 DVSS1 I GND for digital

79 DVDD1 I Power supply for digital

80 MON1 O Serial monitor signal

15DN-D4000

15

Page 16

TMP86CM47U (RC: IC102, 202)

16DN-D4000

33

34

23

22

TOP VIEW

44

1

TMP86CM47U Terminal Function

Pin

Pin Name Symbol I/O DET Ext Res Ini Function

No.

1 VSS VSS - - - - - GND (0V)

2 XIN XIN I - - - - Oscillation input

3 XOUT XOUT O - - - - Oscillation output

4 TEST TEST I - - - - Fixed to L

5 VDD VDD - - - - - Power (+5.0V)

6 P21 LCLK1 O - Pu H L CD1:BU2090F-CLK

7 P22 LCLK2 O - Pu H L CD2:BU2090F-CLK

8 /RST /RST I - - - - ucon reset

9 P20 /FLRST O - Pd H L CD1/2:M66005FP-/RST

10 P00 NC I - - Hi-Z 11 P01 NC I - - Hi-Z 12 RXD RXD I - - H Data receive from main unit

13 TXD TXD O - - H H Data send to main unit

14 P04 DATA O - Pu H H CD1/2:M66005FP-DATA &

15 P05 NC I - - Hi-Z 16 P06 FLCLK O - Pu H H CD1/2:M66005FP-CLK

17 P07 NC I - - Hi-Z 18 P17 /FLCS2 O - Pu H H CD2:M66005FP-/CS

19 P16 /FLCS1 O - Pu H H CD1:M66005FP-/CS

20 P15 /KEYOUT5 O - Pu H H Key scan signal 5

21 P14 /KEYOUT4 O - Pu H H Key scan signal 4

22 P13 /KEYOUT3 O - Pu H H Key scan signal 3

23 P12 /KEYOUT2 O - Pu H H Key scan signal 2

24 P11 /KEYOUT1 O - Pu H H Key scan signal 1

25 P10 /KEYOUT0 O - Pu H H Key scan signal 0

26 AIN0 PIT1 A/I - - - - CD1: Pitch input

27 AIN1 PITC1 A/I - - - - CD1: Pitch center value signal

28 AIN2 PIT2 A/I - - - - CD2: Pitch input

29 AIN3 PITC2 A/I - - - - CD2: Pitch center value signal

30 P34 JOG10 I - Pu - H CD1: JOG

31 P35 JOG11 I - Pu - H CD1: JOG

32 P36 JOG20 I - Pu - H CD2: JOG

33 P37 JOG21 I - Pu - H CD2: JOG

11

12

BU2090F-DATA

16

Page 17

Pin

Pin Name Symbol I/O DET Ext Res Ini Function

No.

34 VAREF 5V I - - - - Power (+5.0V), Analog ref.V for A/D

conversion

35 AVDD 5V I - - - - Power (+5.0V), for A/D conversion

circuit only

36 AVSS 0V I - - - - GND (0V), Analog GND for A/D

conversion

37 P40 /KEYIN0 I - Pu - H CD1: Key scan input 0

38 P41 /KEYIN1 I - Pu - H CD1: Key scan input 1

39 P42 /KEYIN2 I - Pu - H CD1: Key scan input 2

40 P43 /KEYIN3 I - Pu - H CD1: Key scan input 3

41 P44 /KEYIN4 I - Pu - H CD2: Key scan input 0

42 P45 /KEYIN5 I - Pu - H CD2: Key scan input 2

43 P46 /KEYIN6 I - Pu - H CD2: Key scan input 3

44 P47 /KEYIN7 I - Pu - H CD2: Key scan input 3

17DN-D4000

17

Page 18

AN8785SB

(IC202)

18DN-D4000

1

7

8

14 15

AN22002A

(IC203)

L: All mute

Hiz: ch2,4 ON

H: Active

28

22

21

Standby

16

Standby

Band-gap

Vcc/Vref

Reser Circuit

1.25V

+

-

7

IN2+

0.1µ

(2.5V)

PVcc2

10

[ Loading ]

D2+

D2-

M

12 11

-

-

+

-

+

9

ch.4 SW

H:2.5V

L or

IN2-

HIZ

+

8

:Vref

[ Traverse ]

D4-

18

-+-

21

IN4

[ Others ]

D4+

[ Spindle ]

D3-

D3+

PVcc3

[ Focus ]

D1-

D1+

[ Tracking ]

D5-

D5+

PVcc1

MM

17

14

13

-+-

+

-

+

switch

15

PGnd2

20

IN3

CAGC

+

-

+

ARF

19

CBD0

1

28

-+-+-

-

+

23 27

IN1

PGnd1

C0FTR

BD0

26

+

0FTR

IN5

25

24

Protection

Circuit

4

IN-

-

+

-

+

22

2

SVcc

+

-

SGnd-Fin

5

IN+

3

OUT

6

Vref

RFN

1

16

32

A

+

C

-

+

A

B

+

17

D

-

+

F

-

+

E

-

+

32

C

31

B

30

D

29

27

E

F

28

VREF

17

5

4

RFOUT

RF_EQ

AMP GCA BCA

AMP GCA BCA

AMP

AMP

+

-

6

NRFDET

GCA

GCA

8

7

RFIN

AGC BD0 0FTR

BCA

BCA

12

SUB

SUB

13

3TENV

-

+

-

+

14

9

CEA

10

3TOUT

15

NRFDET

FEN

22

23

FEOUT

TEN

21

20

TEOUT

TEBPF

11

19

VDET

-

+

LD

VDET

18

2

18

PD

1

TBAL

GCTL

24

26

FBAL

25

3

16

VCCGND

Page 19

BU2618FV (IC113)

19DN-D4000

19

Page 20

M66005FP (IC601)

D I G

1 1

1

2

D I G

1 0

3

D I G

0 9

D I G

0 8

4

D I G

0 7

5

D I G

0 6

6

D I G

0 5

7

D I G

0 4

8

9

D I G

0 3

D I G

0 2

1 0

D I G

0 1

1 1

D I G

0 0

1 2

1 3

R E S E T

C S

1 4

1 5

S C K

S D A T A

1 6

P I

1 7

P O

1 8

1 9

V c c 1

2 0

X

o u t

2 1

X

i n

2 2

V s s

S E G

2 3

3 5

2 4

S E G

3 4

S E G

3 3

2 5

S E G

3 2

2 6

S E G

3 1

2 7

2 8

S E G

3 0

S E G

2 9

2 9

S E G

2 8

3 0

S E G

2 7

3 1

V p S E G

3 2

D I G

6 4

6 3

D I G

6 2

D I G

D I G

6 1

6 0

V c c 2

5 9

S E G

S E G

5 8

S E G

5 7

5 6

S E G

5 5

S E G

5 4

S E G

5 3

S E G

5 2

S E G

5 1

S E G

5 0

S E G

4 9

S E G

4 8

S E G

4 7

S E G

4 6

S E G

4 5

S E G

S E G

4 4

4 3

S E G

4 2

S E G

4 1

S E G

S E G

4 0

3 9

S E G

3 8

S E G

S E G

3 7

S E G

3 6

3 5

S E G

3 4

S E G

3 3

1 2

1 3

1 4

1 5

0 0

0 1

0 2

0 3

0 4

0 5

0 6

0 7

0 8

0 9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

2 4

2 5

2 6

C h i p S e l e c t I n p u t

S h i f t C l o c k I n p u t

S e r i a l D a t a I n p u t

R e s e t I n p u t

C l o c k I n p u t

C l o c k O u t p u t

S C K

S D A T A

R E S E T

X O U T

20DN-D4000

D i s p l a y C o d e R e g i s t e r

( 8 - b i t x 1 6 )

c o d e

1 4

C S

S e r i a l

1 5

R e c e p t i o n

C i r c u i t

1 6

1 3

C l o c k

2 1

X I N

2 0

G e n e r a t i o n

C i r c u i t

w r i t e

C o d e /

C o m m a n d

C o n t r o l C i r c u i t

D i s p l a y C o n t r o l

R e g i s t e r

R A M

w r i t e

c o d e s e l e c t

D i s p l a y C o n t r o l l e r

C G R O M

( 3 5 - b i t x 1 6 0 )

D e c o d e rD e c o d e r

C G R O M

( 3 5 - b i t x 1 6 )

S e g m e n t

O u t p u t

C i r c u i t

O u t p u t P o r t

( 2 - b i t )

D i g i t O u t p u t

C i r c u i t

S E G

0 0

5 9

2 6

S E G

3 3

3 1

2 3

1 8

1 7

1 2

1

6 4

6 1

S E G

S E G

P 0

P 1

D I G

D I G

D I G

D I G

2 7

3 5

O u t p u t P o r t

0 0

1 1

D i g i t O u t p u t

1 2

1 5

S e g m e n t

O u t p u t

M66005FP Terminal Function

Symbol Name Function

RESET Reset Input

CS Chip Select Input

SCK Shift Clock Input

SDATA Serial Data Input

X

IN

OUT

X

DIG 00~

DIG 15

SEG 00~

SEG 35

Clock Input

Clock Output

Digit Output

Segment Output

P0, P1

V

CC1

V

CC2

Vss

Vp

(Forwarding connection of segment output terminal.)

in the right figure indicates 1 dot of segment, the figure in shows the segment output

terminal number (00~35) to be connected.

Initialzes internal state of M66005.

Able to communicate with MCU in "L" mode.

Command from MCU will be disregareded in "H" mode.

Shifts input data at rise from "L" to "H".

Inputs character code or command data needed to display from MSB.

Sets oscillation frquency by connecting external resistor and capacitor (maximum

oscillation frequency fosc (max)=1MHz). Also feasible to apply external clock. In this case,

inject external clock to Xin terminal and open Xout terminal.

Connect to digit terminal of VFD. DIG00~DIG15 correspond to the 1st figure to 16th figure

respectively.

Connect to segment terminal of VFD. For corresponding SEG00~SEG35 to segment

terminal of VFD, refer to the figure right.

Output port (static operation).

Positive power supply terminal for internal logic.

Positive power supply terminal for high tension output port.

GND terminal.

Negative power supply terminal for VFD drive.

00 01 02 03 04

05 06 07 08 09

10 11 12 13 14

15 16 17 18 19

20 21 22 23 24

25 26 27 28 29

30 31 32 33 34

20

35

Page 21

TC9246F (IC114)

V DD

LOCK

S2

S1

M2

1611521431341251161079

M1

21DN-D4000

CKO

Vss

Lock Ditection

Circuit

Microcomputer Interface

Programmable Counter

VAR

Phase

Comparator

REF

PD

REF

DDA

V

BU2090F (IC602)

1V

SS

2DATA

3CLOCK

4Q0

5Q1

6Q2

7Q3

8Q4

12-bit Shift Register

VCO

AMPI

AMPO

Control Circuit

Latch

Output Buffer

(Open Drain)

V SSA

Selector

XI

8

XO

16

V

DD

15

Q11

14

Q10

13

Q9

12

Q8

11

Q7

10

Q6

9

Q5

21

Page 22

PCM1748 (IC206)

22DN-D4000

BCK

DATA

LRCK

DGND

V

V

V

OUT

V

OUT

BCK

LRCK

DATA

ML

1

2

3

4

5

DD

6

CC

7

L

8

R

PCM1748

Serial

Input

I/F

16

SCK

15

ML

14

MC

13

MD

12

ZEROL/NA

11

ZEROR/ZEROA

10

V

COM

9

AGND

8x

Oversampling

Digital Filter

with

Function

Controller

Enhanced

Multi-Level

Delta-Sigma

Modulator

DAC

Output Amp and

Low-Pass Filter

V

L

OUT

V

COM

MC

MD

SCK

TRANSISTORS

DTA114EK

DTC114EK

DTC114YK

DTC143EK

B

TOP

VIEW

E

Function

Control

I/F

System Clock

Manager

System Clock

Zero Detect

ZEROL

DAC

ZEROR

DTC114EK

DTA114EK DTC114YK

DTC143EK

C

PNP Type

R1

B

R2

C

E

DTA114EK

R1

10kohm

R2

10kohm

NPN Type

B

R1

Output Amp and

Low-Pass Filter

Power Supply

DD

V

DGND

C

R2

E

CC

V

AGND

DTC114EK

DTC114YK

DTC143EK

V

R1 R2

10kohm

10kohm

4.7kohm

R

OUT

10kohm

47kohm

4.7kohm

22

Page 23

FL DISPLAY

14-MT-35GN (FL601)

74 44

23DN-D4000

1

39

Pin Connection

7

7

7

7

7

7

7

7

7

6

6

6

6

6

6

6

6

6

6

5

5

5

5

5

5

5

5

5

5

4

4

4

4

4

4

4

Pin No.

Connection

Pin No.

Connection

NOTE: 1) F1 , F2 Filament 2) NP No Pin 3) DL Datum Line 4) 1G~14G Grid

5) IC Internal Connection 6) NC No Connection

8

7

6

5

N

N

N

N

P

P

P

P

1F2F3 4 5

NPN

11

P

4

I

C

1

3

G

3

2

1

2

N

G

C

6 7 8

1

P

4

3

G

7

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

5

4

3

2

1

0

9

8

7

6

P

1

1

1

0

9

8

7

6

5

4

3

2

1

N

N

N

N

N

N

G

G

G

G

G

G

G

G

G

G

G

C

C

C

1

1

1

1

1

1

16171

1

2

0

1

2

3

4

P

P

P

4

5

6

5

P

P

P

7

8

9

Segment Designation

S1

1-1 2-1 3-1 4-1 5-1

1-2 2-2 3-2 4-2 5-2

1-3 2-3 3-3 4-3 5-3

1-4 2-4 3-4 4-4 5-4

1-5 2-5 3-5 4-5 5-5

1-6 2-6 3-6 4-6 5-6

1-7 2-7 3-7 4-7 5-7

9

P

P2P

P

3

1

3

8

8

9

P

P

1

1

0

1

S2 S3

2

0

1

P

P

1

1

2

3

N

C

C

C

C

2

2

2

2

2

3

4

5

P

P

P

P

1

1

1

1

4

5

6

7

P

3

N

6

C

2

2

6

7

P

P

1

1

8

9

e

(11G~14G)

f

P

3

5

2

8

2

2

0

PP

3

4

2

9

2

2

1

d

P

P

3

3

3

3

3

2

1

0

3

3

3

3

0

1

2

3

1

1

1

1

2

2

2

2

2

3

4

5

a

b

g

c

4

5

4

3

2

P

P

N

2

2

N

P

9

8

P

3

3

36373

4

5

1

1

NPN

2

2

P

6

7

4

1

N

P

8

F

2

4

0

N

P

3

9

F

2

S2

S2

(14G)

S1S1

(10G~1G)

23

Page 24

Anode Connection

24DN-D4000

24

Page 25

PRINTED WIRING BOARDS

GU-3523 DRIVE P.W.B. UNIT

DN-D4000

25

25

COMPONENT SIDE

Page 26

DN-D4000

26

26

FOIL SIDE

Page 27

POWER SUPPLY UNIT

DN-D4000

27

27

COMPONENT SIDE

Page 28

DN-D4000

28

28

FOIL SIDE

Page 29

NOTE FOR PARTS LIST

l Part indicated with the mark " " are not always in stock and possibly to take a long period of time for supplying, or in

some case supplying of part may be refused.

l When ordering of part, clearly indicate "1" and "I" (i) to avoid mis-supplying.

l Ordering part without stating its part number can not be supplied.

l Part indicated with the mark " " is not illustrated in the exploded view.

l Not including Carbon Film ±5%, 1/4W Type in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

WARNING:

Parts marked with this symbol

Use ONLY replacement parts recommended by the manufacturer.

have critical characteristics.

29DN-D4000

ll

Resistors

l

ll

Ex.: RN 14K 2E 182 G FR

Type Shape Power Resist- Allowable Others

and per- ance error

formance

t

RD : Carbon 2B : 1/8W F : ±1% P :Pulse-resistant type

RC : Composition 2E : 1/4W G : ±2% NL : Low noise type

RS : Metal oxide film 2H : 1/2W J : ±5% NB : Non-burning type

RW : Winding 3A : 1W K : ±10% FR : Fuse-resistor

RN : Metal film 3D : 2W M : ±20% F : Lead wire forming

RK : Metal mixture 3F : 3W

Resistance

1 8 2 ⇒ 1800 ohm = 1.8 kohm

s

s

• Units: ohm

1 R 2 ⇒ 1.2 ohm

s

s

• Units: ohm

t

3H : 5W

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

t

t

ll

Capacitors

l

ll

Ex.: CE 04W 1H 2R2 M BP

Type Shape Dielectric Capacity Allowable Others

and per- strength error

formance

t

CE : Aluminum foil 0J : 6.3V F : ±1% HS: High stability type

electrolytic

CA : Aluminum solid 1A : 10V G : ±2% BP : Non-polar type

electrolytic

CS : Tantalum electrolytic 1C : 16V J : ±5% HR: Ripple-resistant type

CQ : Film 1E : 25V K : ±10% DL : For change and discharge

CK : Ceramic 1V : 35V M : ±20% HF : For assuring high

CC : Ceramic 1H : 50V Z : +80% U : UL part

CP : Oil 2A : 100V –20% C : CSA part

CM : Mica 2B : 125V P : +100% W : UL-CSA type

CF : Metallized 2C : 160V –0% F : Lead wire forming

CH : Metallized 2D : 200V C : ±0.25pF

Capacity (electrolyte only)

2 2 2 ⇒ 2200µ F

s

s

• Units: µF.

2 R 2 ⇒ 2.2µF

s

s

• Units: µF.

Capacity (except electrolyte)

2 2 2 ⇒ 2200pF=0.0022µF

s

s

(More than 2) Indicates number of zeros after effective number.

• Units: pF.

2 2 1 ⇒ 220pF

s

s

(0 or 1) Indicates number of zeros after effective number.

• Units: pF.

• When the dielectric strength is indicated in AC, "AC" is included after the dieelectric

strength value.

t

2E : 250V D : ±0.5pF

2H : 500V = : Others

2J : 630V

Indicates number of zeros after effective number.

2-digit effective number.

1-digit effective number.

2-digit effective number, decimal point indicated by R.

2-digit effective number.

2-digit effective number.

t

t

requency

29

Page 30

PARTS LIST OF P.W.B. UNIT ASS'Y

Note:Thesymbolsinthecolumn"Remarks"indicatethefollowingdestinations.

E3:U.S.A.model,CsnadamodelE2K:Koriamodel

E2:Europemodel

GU-3523 DRIVE P.W.B. UNIT ASS'Y

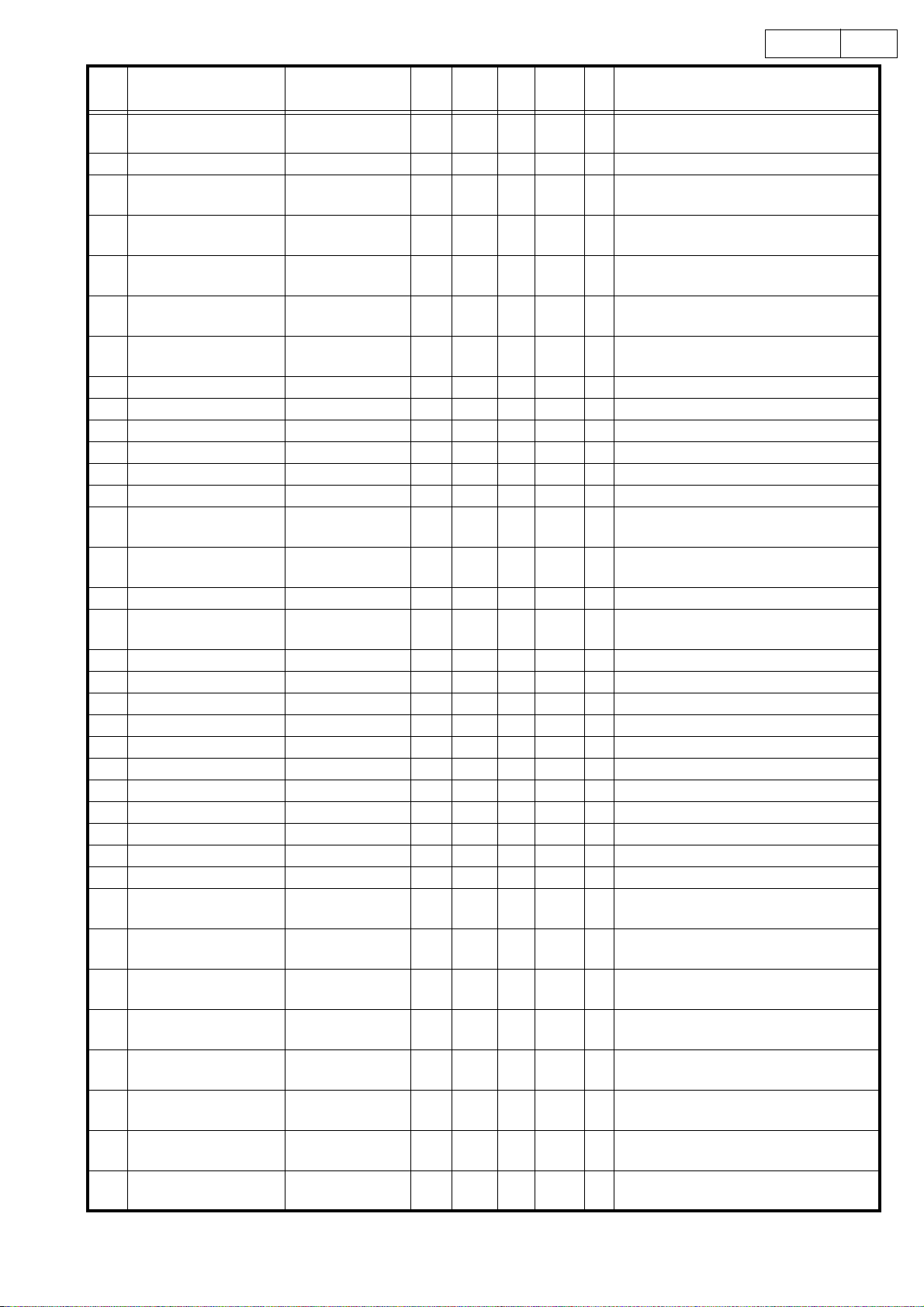

Ref. No. Part No. Part Name Remarks New

SEMICONDUCTORS GROUP

IC101 262 3171 000 MN102H60KDA

IC111 GEN6411 D4000 SYSTEM ROM 8M FLASH

IC112 262 2376 903 TC74HCT7007AF(TP1)

IC113 262 2651 903 BU2618FV(E2)

IC114 262 1883 905 TC9246F-TP1

IC118 263 0432 907 NJM78L05AT

IC201 262 3158 007 MN6627911AC

IC202 262 3159 909 AN8785SB

IC203 262 3160 901 AN22002A

IC204 262 2881 003 16M DRAM(3.3V)

IC206 262 3166 905 PCM1748E(TAPE)

IC207 263 0615 902 BA15218F-DXE2

IC208 262 1953 903 TC7WU04F

IC210 262 2881 003 16M DRAM(3.3V)

IC601 262 2951 904 M66005FP

IC602 262 2745 903 BU2090F(E2)

30DN-D4000

TR110 269 0082 902 DTC114EKT96

TR112 269 0083 901 DTA114EKT96

TR113 269 0048 904 DTC143EK-T96

TR201 272 0125 904 2SB709A

TR202 269 0144 905 DTC114YK-T146

TR204 273 0460 905 KTC2875B-RTK

TR206 273 0460 905 KTC2875B-RTK

D103 276 0717 903 1SS355 TE-17

D104 276 0438 949 MA151WK (TAPE)

D106 276 0559 909 DAP202KT146

D107 276 0438 949 MA151WK (TAPE)

D108 276 0559 909 DAP202KT146

D601 276 0559 909 DAP202KT146

ZD105 276 0450 901 HZS2B-1TD

LD601 393 9606 909 SEL6927A(TP5)

LD605 393 9543 910 SLR-325MC (GRN) TAPE

LD607 393 9543 907 SLR-325VC (RED) TAPE

LD609 393 9543 910 SLR-325MC (GRN) TAPE

RESISTORS GROUP

R103 247 2009 983 RM73B--103JT

R104 247 2003 989 RM73B--330JT

R105 247 2018 903 RM73B--0R0KT

R107 247 2011 942 RM73B--473JT

R109 247 2009 983 RM73B--103JT

R110 247 2003 989 RM73B--330JT

R112 247 2005 903 RM73B--101JT

R113 247 2009 912 RM73B--512JT

R114 247 2009 983 RM73B--103JT

30

Page 31

Ref. No. Part No. Part Name Remarks New

R117 247 2003 989 RM73B--330JT

R118 247 2006 960 RM73B--471JT

R119 247 2009 983 RM73B--103JT

R121 247 2009 912 RM73B--512JT

R122 247 2008 968 RM73B--332JT

R123 247 2008 913 RM73B--202JT

R124 247 2007 943 RM73B--102JT

R127 247 2011 942 RM73B--473JT

R128 247 2018 903 RM73B--0R0KT

R130 247 2009 925 RM73B--562JT

R131 247 2013 940 RM73B--334JT

R132 247 2011 942 RM73B--473JT

R134 247 2003 989 RM73B--330JT

R157 247 2005 903 RM73B--101JT

R161 247 2003 989 RM73B--330JT

R163 247 2018 903 RM73B--0R0KT

R164 247 2009 983 RM73B--103JT

R166 247 2005 903 RM73B--101JT

R169 247 2018 903 RM73B--0R0KT

R171 247 2009 925 RM73B--562JT

R173 247 2012 925 RM73B--104JT

R175 247 2012 912 RM73B--913JT

R176 247 2012 983 RM73B--184JT

R177 247 2005 903 RM73B--101JT

R178 247 2013 937 RM73B--304JT

R179 247 2008 939 RM73B--242JT

R180 247 2009 912 RM73B--512JT

R182 247 2007 943 RM73B--102JT

R183 247 2005 903 RM73B--101JT

R186 247 2007 943 RM73B--102JT

R188 247 2004 920 RM73B--470JT

R191 247 2014 965 RM73B--105JT

R193 247 2014 965 RM73B--105JT

R195 247 2005 903 RM73B--101JT

R201 247 2008 968 RM73B--332JT

R203 247 2010 972 RM73B--243JT

R205 244 2043 937 RS14B3A100JNBST(S)

R206 247 2010 927 RM73B--153JT

R207 247 2006 986 RM73B--561JT

R208 247 2010 927 RM73B--153JT

R210 247 2007 943 RM73B--102JT

R211 247 2010 985 RM73B--273JT

R212 247 2007 943 RM73B--102JT

R214 247 2010 985 RM73B--273JT

R215 247 2011 900 RM73B--333JT

R216 247 2010 927 RM73B--153JT

R217 247 2010 969 RM73B--223JT

R218 247 2011 926 RM73B--393JT

R219 247 2010 927 RM73B--153JT

R220 247 2009 925 RM73B--562JT

R222 247 2007 943 RM73B--102JT

R223 247 2009 925 RM73B--562JT

R224 247 2018 903 RM73B--0R0KT

R225 247 2012 925 RM73B--104JT

R227 247 2009 983 RM73B--103JT

R229 247 2012 925 RM73B--104JT

R231 247 2009 983 RM73B--103JT

R232 247 2012 925 RM73B--104JT

R234 247 2008 984 RM73B--392JT

R236 247 2009 983 RM73B--103JT

R238 247 2001 981 RM73B--4R7KT

31DN-D4000

31

Page 32

Ref. No. Part No. Part Name Remarks New

R239 247 2011 926 RM73B--393JT

R240 247 2008 955 RM73B--302JT

R241 247 2007 969 RM73B--122JT

R242 247 2006 986 RM73B--561JT

R243 247 2018 903 RM73B--0R0KT

R244 247 2014 949 RM73B--824JT

R245 247 2009 967 RM73B--822JT

R247 247 2003 989 RM73B--330JT

R248 247 2018 903 RM73B--0R0KT

R249 247 2009 941 RM73B--682JT

R250 247 2010 956 RM73B--203JT

R251 247 2011 997 RM73B--753JT

R252 247 2018 903 RM73B--0R0KT

R254 247 2018 903 RM73B--0R0KT

R255 247 2005 903 RM73B--101JT

R256 247 2004 991 RM73B--910JT

R259 247 2014 965 RM73B--105JT

R264 247 2003 947 RM73B--220JT

R265 247 2011 942 RM73B--473JT

R267 247 2009 983 RM73B--103JT

R275 247 2010 956 RM73B--203JT

R276 247 2007 943 RM73B--102JT

R277 247 2014 965 RM73B--105JT

R278 247 2004 975 RM73B--750JT

R279 247 2018 903 RM73B--0R0KT

R282 247 2009 925 RM73B--562JT

R283 247 2010 901 RM73B--123JT

R284 247 2012 925 RM73B--104JT

R286 247 2007 943 RM73B--102JT

R289 247 2009 983 RM73B--103JT

R294 247 2003 989 RM73B--330JT

R296 247 2005 945 RM73B--151JT

R601 247 2018 903 RM73B--0R0KT

R605 247 2009 983 RM73B--103JT

R607 247 2006 902 RM73B--331JT (1608)

R609 247 2005 987 RM73B--221JT

R611 247 2006 902 RM73B--331JT (1608)

R613 247 2005 987 RM73B--221JT

R615 247 2006 902 RM73B--331JT (1608)

R617 247 2007 972 RM73B--132JT

RA106 247 9002 909 MNR14=330JE0AB

RA115 247 9002 909 MNR14=330JE0AB

32DN-D4000

VR601 211 0908 003 SLIDE VOLUME

CAPACITORS GROUP

C101 257 0512 903 CK73F1E104ZT

C102 254 4300 963 CE04W0J101MT(SRE)

C103 257 0511 904 CK73F1H103ZT

C104 257 0512 903 CK73F1E104ZT

C107 254 4533 921 CE04W0J101MT SMG/RE3

C108 257 0512 903 CK73F1E104ZT

C110 254 4533 921 CE04W0J101MT SMG/RE3

C111 257 0512 903 CK73F1E104ZT

C112 257 0511 904 CK73F1H103ZT

C113 257 0512 903 CK73F1E104ZT

C114 254 4536 915 CE04W1A470MT SMG/RE3

C115 257 0512 903 CK73F1E104ZT

32

Page 33

Ref. No. Part No. Part Name Remarks New

C117 254 4538 955 CE04W1C221MT SMG/RE3

C130 254 4302 958 CE04W1A470MT(SRE)

C131 254 4299 964 CE04W1C470MT(SRE)

C132 257 0512 903 CK73F1E104ZT

C135 257 0512 903 CK73F1E104ZT

C136 257 0503 967 CC73CH1H150JT

C138 257 0511 904 CK73F1H103ZT

C139 254 4300 963 CE04W0J101MT(SRE)

C140 257 0511 904 CK73F1H103ZT

C141 257 0512 903 CK73F1E104ZT

C143 254 4300 989 CE04W0J331MT(SRM)

C146 257 0512 903 CK73F1E104ZT

C147 257 0511 904 CK73F1H103ZT

C148 257 0507 992 CC73CH1H391JT

C149 257 0508 917 CC73CH1H471JT

C152 257 0506 951 CC73CH1H101JT

C154 254 4305 955 CE04W1HR68MT(SRE)

C156 257 0512 903 CK73F1E104ZT

C157 254 4300 989 CE04W0J331MT(SRM)

C158 257 0512 903 CK73F1E104ZT

C160 257 0511 904 CK73F1H103ZT

C161 257 0512 903 CK73F1E104ZT

C169 257 0512 903 CK73F1E104ZT

C183 257 0511 904 CK73F1H103ZT

C186 257 0512 903 CK73F1E104ZT

C201 257 0512 903 CK73F1E104ZT

C202 257 0509 929 CK73B1H102KT

C203 257 0512 903 CK73F1E104ZT

C204 257 0509 929 CK73B1H102KT

C205 257 0516 909 CK73B1E223KT

C206 257 0512 903 CK73F1E104ZT

C207 256 1058 984 CF93A1H124JT (JL)

C208 254 4302 958 CE04W1A470MT(SRE)

C209 257 0512 903 CK73F1E104ZT

C210 254 4300 963 CE04W0J101MT(SRE)

C211 257 0512 903 CK73F1E104ZT

C215 254 4538 900 CE04W1C100MT SMG/RE3

C217 257 0509 990 CK73B1H222KT

C221 254 4302 916 CE04W1A100MT(SRE)

C222 257 0516 909 CK73B1E223KT

C224 257 0512 903 CK73F1E104ZT

C227 257 0512 903 CK73F1E104ZT

C228 254 4302 958 CE04W1A470MT(SRE)

C229 257 0506 935 CC73CH1H820JT

C231 254 4302 958 CE04W1A470MT(SRE)

C233 254 4300 989 CE04W0J331MT(SRM)

C234 257 0512 903 CK73F1E104ZT

C236 256 1059 912 CF93A1H224JT (JL)

C237 257 0512 903 CK73F1E104ZT

C238 257 0501 914 CK73B1H123KT

C239 257 0510 947 CK73B1H562KT

C240 257 0516 909 CK73B1E223KT

C241 257 0501 927 CK73B1H153KT

C242 257 0506 948 CC73CH1H910JT

C243 257 0512 903 CK73F1E104ZT

C244 254 4300 963 CE04W0J101MT(SRE)

C245 257 0507 950 CC73CH1H271JT

C246 257 0506 993 CC73CH1H151JT

C250 257 0512 903 CK73F1E104ZT

C251 254 4305 997 CE04W1H3R3MT(SRE)

C252 254 4300 963 CE04W0J101MT(SRE)

33DN-D4000

33

Page 34

Ref. No. Part No. Part Name Remarks New

C253 257 0512 903 CK73F1E104ZT

C257 254 4302 916 CE04W1A100MT(SRE)

C259 257 0512 903 CK73F1E104ZT

C260 257 0509 929 CK73B1H102KT

C261 254 4524 956 CE04W1H2R2MT SMG/RE3

C263 257 0507 976 CC73CH1H331JT

C267 257 0512 903 CK73F1E104ZT

C269 254 4536 928 CE04W1A101MT SMG/RE3

C270 257 0501 901 CK73B1H103KT (1608)

C271 257 0512 903 CK73F1E104ZT

C272 254 4538 926 CE04W1C330MT SMG/RE3

C273 257 0501 901 CK73B1H103KT (1608)

C274 257 0512 903 CK73F1E104ZT

C275 254 4538 900 CE04W1C100MT SMG/RE3

C276 257 0501 901 CK73B1H103KT (1608)

C277 257 0512 903 CK73F1E104ZT

C279 257 0512 903 CK73F1E104ZT

C280 254 4300 963 CE04W0J101MT(SRE)

C281 257 0513 902 CK73F1A105ZT

C282 254 4300 963 CE04W0J101MT(SRE)

C283 257 0513 902 CK73F1A105ZT

C284 257 0512 903 CK73F1E104ZT

C287 254 4538 900 CE04W1C100MT SMG/RE3

C289 257 0512 903 CK73F1E104ZT

C290 254 4538 900 CE04W1C100MT SMG/RE3

C291 257 0512 903 CK73F1E104ZT

C293 254 4299 964 CE04W1C470MT(SRE)

C294 254 4193 947 CE04W1C101MT (SRA)

C295 257 0512 903 CK73F1E104ZT

C297 257 0511 904 CK73F1H103ZT

C601 257 0512 903 CK73F1E104ZT

C603 257 0509 929 CK73B1H102KT

C604 257 0512 903 CK73F1E104ZT

C605 257 0506 951 CC73CH1H101JT

C606 257 0511 920 CK73F1H473ZT

C607 254 4302 958 CE04W1A470MT(SRE)

C608 257 0512 903 CK73F1E104ZT

C611 257 0512 903 CK73F1E104ZT

34DN-D4000

OTHER PARTS GROUP

CX41 205 0355 046 4P KR CON BASE(L)

CX51 205 0343 058 5P CONN.BASE(KR-PH)

CX62 205 0343 061 6P CONN.BASE(KR-PH)

CX161 205 0892 033 16P FFC BASE (P=1)

CX231 205 0880 003 23P FFC CON.BASE

CX232 205 0849 044 20P CON BASE(BTMK-S)

FB121 235 0106 908 CHIP EMIFIL (21A05)

FB123 235 0106 908 CHIP EMIFIL (21A05)

FB125 235 0106 908 CHIP EMIFIL (21A05)

FB202 235 0106 908 CHIP EMIFIL (21A05)

FL601 393 8070 002 FLT (14-MT-35GN) *

JK103 204 8672 003 2P PIN JACK (FG)

JK201 204 8593 001 1P PIN JACK(OR,NI)

JK202 204 8421 005 MINI JACK

34

Page 35

Ref. No. Part No. Part Name Remarks New

S601 212 0352 018 JOG-SHUTTLE

S604 212 5604 907 TACT SWITCH-TA(ALPS)

S608 212 5604 907 TACT SWITCH-TA(ALPS)

S612 212 5604 907 TACT SWITCH-TA(ALPS)

S616 212 5604 907 TACT SWITCH-TA(ALPS)

S623 212 0410 002 ROTARY ENCODER-JOG

T201 231 8063 009 PULSE TRANS

X101 399 0880 900 CSTLS32M0X53

X102 399 0595 004 X'TAL(8.4672MHZ)

35DN-D4000

★

461 1159 003 FL SPACER *

35

Page 36

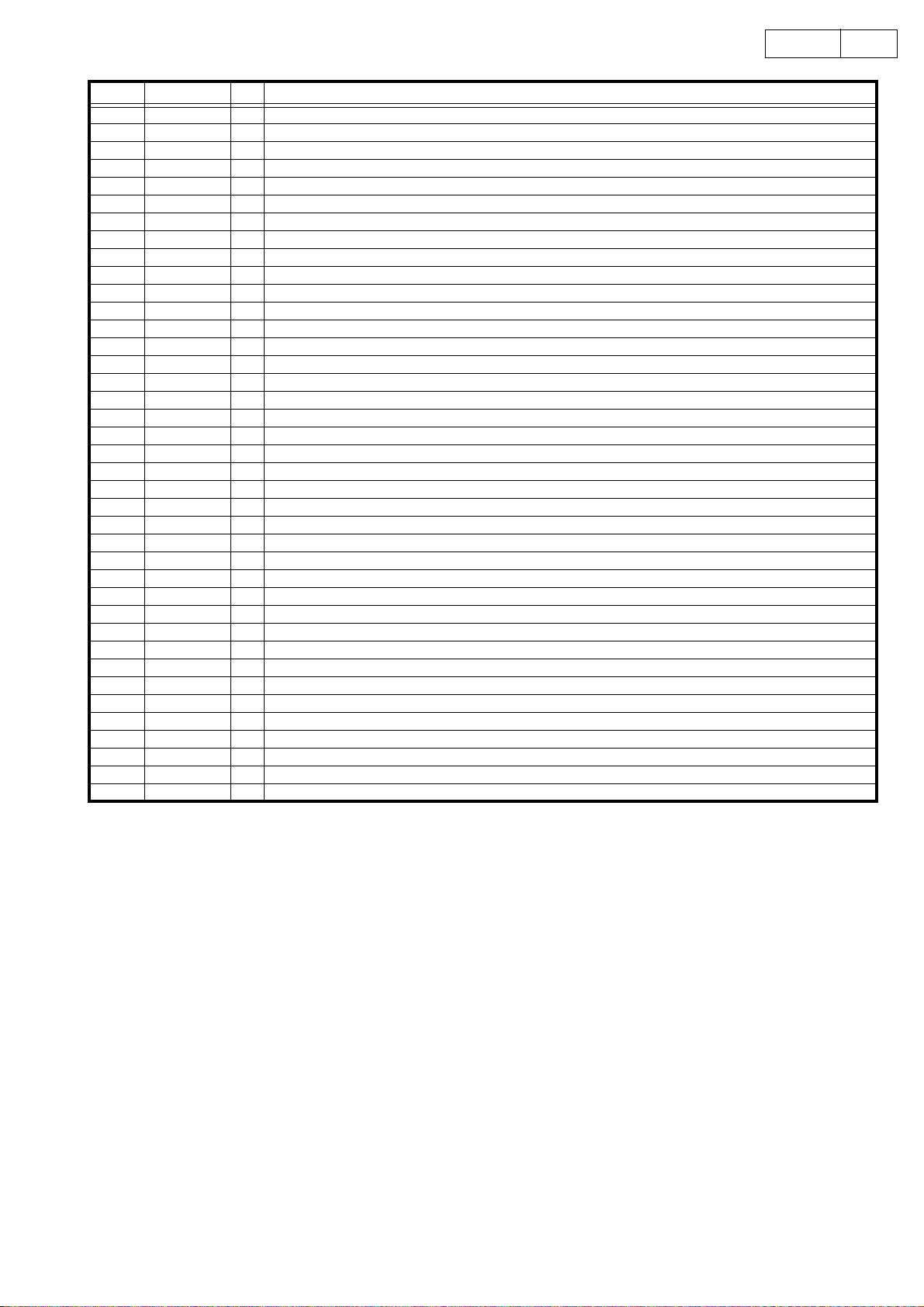

POWER SUPPLY UNIT ASS’Y

Ref. No. Part No. Part Name Remarks New

SEMICONDUCTORS GROUP

IC301 263 0913 905 PST600C TP

IC302 262 2813 903 SN74AHCT08PW-EL2

IC303 263 1178 901 AN80L18RMS

IC308 263 1048 002 BA033T

IC309,310 263 0809 006 NJM7805FA(S)

IC311 263 0554 005 NJM7905FA

IC401 262 2813 903 SN74AHCT08PW-EL2

IC402 262 3275 003 TMP86CM47U-4R26

IC403 263 0913 905 PST600C TP

IC404 263 0809 006 NJM7805FA(S)

TR301 272 0083 004 2SB1185(E/F)

D302 276 0559 909 DAP202KT146

D303 276 0438 949 MA151WK (TAPE)

D304 276 0550 908 1SR139-200T-62

D305,306 276 0623 000 D3SBA20

D307 276 0550 908 1SR139-200T-62

D401 276 0559 909 DAP202KT146

D402 276 0438 949 MA151WK (TAPE)

36DN-D4000

ZD301 276 0760 921 MTZJ4.3B T77

ZD302 276 0762 916 MTZJ27B T77

LD301,302 393 9627 904 SEL1410E(TP3)

LD303 393 9543 907 SLR-325VC (RED) TAPE

RESISTORS GROUP

R301 247 2006 915 RM73B--271JT

R302 247 2007 943 RM73B--102JT

R303 247 2018 903 RM73B--0R0KT

R307 247 2009 983 RM73B--103JT

R308 247 2003 947 RM73B--220JT

R309 247 2007 943 RM73B--102JT

R310 247 2003 947 RM73B--220JT

R311 247 2010 985 RM73B--273JT

R312 247 2008 942 RM73B--272JT

R313,314 247 2009 983 RM73B--103JT

R318,319 247 2006 962 RM73B--680JT

R320 247 2005 903 RM73B--101JT (1608)

R401,402 247 2007 943 RM73B--102JT

R403,404 247 2003 947 RM73B--220JT

R405,406 247 2018 903 RM73B--0R0KT

R407,408 247 2003 947 RM73B--220JT

R409 247 2009 983 RM73B--103JT

R410,411 247 2003 947 RM73B--220JT

R412 247 2018 903 RM73B--0R0KT

R413 247 2007 943 RM73B--102JT

R414 247 2003 947 RM73B--220JT

R415 247 2007 943 RM73B--102JT

R416 247 2003 947 RM73B--220JT

R419 247 2007 943 RM73B--102JT

R420,421 247 2003 947 RM73B--220JT

R422 247 2007 943 RM73B--102JT

R425-428 247 2009 983 RM73B--103JT

36

Page 37

Ref. No. Part No. Part Name Remarks New

R429 247 2006 915 RM73B--271JT

R430-439 247 2009 983 RM73B--103JT

R441-449 247 2009 983 RM73B--103JT

R458 247 2009 983 RM73B--103JT

CAPACITORS GROUP

C301-310 257 0512 903 CK73F1E104ZT

C311 254 4536 944 CE04W1A331MT SMG/RE3

C312 257 0509 929 CK73B1H102KT

C313 257 0512 903 CK73F1E104ZT

C314 254 4538 942 CE04W1C101MT SMG/RE3

C315 257 0512 903 CK73F1E104ZT

C316 254 4535 929 CE04W1J470MT SMG/RE3

C317-320 257 0512 903 CK73F1E104ZT

C322 257 0512 903 CK73F1E104ZT

C323-327 254 4536 931 CE04W1A221MT SMG/RE3

C328 254 4538 955 CE04W1C221MT SMG/RE3

C329 254 4540 707 CE04W1J331MC SMG/RE3

C331-335 257 0512 903 CK73F1E104ZT

C336 254 4442 711 CE04W1C103MC(SMG)

C337,338 254 4539 718 CE04W1C222MC SMG/RE3

C343 253 8022 707 CK45F2EAC103MC

C344,345 257 0512 903 CK73F1E104ZT

C346 254 4541 942 CE04W1E101MT SMG/RE3

C401 257 0512 903 CK73F1E104ZT

C402 257 0501 901 CK73B1H103KT (1608)

C403 257 0509 929 CK73B1H102KT

C404 254 4536 931 CE04W1A221MT SMG/RE3

C405 257 0512 903 CK73F1E104ZT

C406 254 4302 958 CE04W1A470MT(SRE)

C407-410 257 0512 903 CK73F1E104ZT

C412 254 4538 955 CE04W1C221MT SMG/RE3

C413,414 257 0512 903 CK73F1E104ZT

C415 254 4536 931 CE04W1A221MT SMG/RE3

C416 257 0512 903 CK73F1E104ZT

C611 254 4536 931 CE04W1A221MT SMG/RE3

C612,613 257 0512 903 CK73F1E104ZT

37DN-D4000

OTHER PARTS GROUP

CW41 203 6369 027 4P KR-DA CONN CORD

CW42 205 0343 045 4P CONN.BASE(KR-PH)

CW201 205 0850 046 20P CON BASE(BTMK-P)

CW231 205 0880 003 23P FFC CON.BASE

CX111 205 1135 003 8P MD BASE (F-S)

CY21 205 0581 001 2P VH CONNECTOR BASE

CY41 203 6369 027 4P KR-DA CONN CORD

CY42 205 0343 045 4P CONN.BASE(KR-PH)

CY111 205 1135 003 8P MD BASE (F-S)

CY201 205 0850 046 20P CON BASE(BTMK-P)

CY231 205 0880 003 23P FFC CON.BASE

F601 206 1087 057 FUSE (ET0.4A) E3

!

!

206 1087 031 FUSE (ET0.25A) E2

37

Page 38

Ref. No. Part No. Part Name Remarks New

FH305,306 202 0040 909 FUSE CLIP (TAPE)

L301 235 0159 007 PLH10AN3711ROP2B

S301 212 1176 015 POWER SWITCH(TV-5)

S302,303 212 5604 907 TACT SWITCH-TA(ALPS)

X401 399 0805 901 CSTLS16M0X53-A0

38DN-D4000

★

★

513 3904 007 THERMAL LABEL(5X23)

GEN6256-1 FUSE LABEL SUB ASS'Y E2

38

Page 39

EXPLODED VIEW OF REMOTE CONTROL UNIT

DN-D4000

39

39

Page 40

PARTS LIST OF EXPLODED VIEW (REMOTE CONTROL UNIT)

Ref. No. Part No. Part Name Remarks Q'ty New

1 441 1984 009 RC FRONT SUB PANEL 1 *

2 144 2832 107 RC FRONT PANEL 1 *

3 143 1072 004 LENS 4

4 475 1178 009 3W-B 6

6 146 2312 005 WINDOW 2 *

7 119 0122 101 R.KEY (PLAY/PAUSE) 2 *

8 119 0121 102 R.KEY (FUNCTION) 2 *

10 105 1350 119 COVER 1 *

13 104 0270 006 FOOT 4

14 112 0910 105 SHUTTLE RING 2 *

15 112 0911 104 JOG DIAL 2 *

16 113 1840 206 SLIDE KNOB 2

17 112 0820 017 KNOB (MARU) 2

★

★

SCREWS

203 6407 031 4P KR-KR CON CORD 1

203 6407 044 4P KR-KR CON CORD 1

40DN-D4000

5 471 9050 020 3X6 FHHS MFZNII-B 6

9 473 7002 005 3X6 CBTS(S)-Z 20

11 471 8010 113 SPECIAL SCREW 4

12 471 1832 000 M3-SEMS SCREW(6W) 1

40

Page 41

EXPLODED VIEW OF CHASSIS AND CABINET

101

DN-D4000

WARNING:

Parts marked with this symbol have critical

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

41

1-1

107

19

102

112

31

35

103

9

36

103

101

108

2-1

11

10

7

12

102

106

13

18

34

105

17

16

14

16

33

32

15

30

101

20

21

104

101

108

102

101

112

8

101

19

110

31

101

3

16

106

4

101

18

17

13

105

16

14

16

32

15

102

101

101

27

109

110

110

28

29

110

23

109

24

109

29

2-3

102

6

101

101

5

4

34

111

4

2-4

26

101

25

101

22

109

110

109

23

109

110

101

27

1-1

107

33

41

Page 42

PARTS LIST OF EXPLODED VIEW (CHASSIS AND CABINET)

Note:Thesymbolsinthecolumn"Remarks"indicatethefollowingdestinations.

E3:U.S.A.model,CsnadamodelE2K:Koriamodel

E2:Europemodel

42DN-D4000

Ref.No. PartNo. PartName Remarks

1 GU-3523 DRIVE P.W.B. UNIT 2

1-1 DRIVE P.W.B. UNIT -

1-2 PANEL UNIT for RC unit -

2 GU-3524 POWER SUPPLY UNIT E3 1

GU-3524A POWER SUPPLY UNIT E2, E2K 1

2-1 POWER UNIT -

2-2 CPU UNIT for RC unit -

2-3 LED 1 UNIT -

2-4 LED 2 UNIT -

3 411 2033 000 CHASSIS 1 *

4 461 0706 127 FOOT SHEET 2

5 513 3175 001 BLIND LABEL 2

6 412 4921 003 PWB BRACKET 1

7 412 4343 102 TRANS BRACKET 1

8 105 1431 009 BACK PANEL E3 1

8 105 1431 012 BACK PANEL E2, E2K 1

!

!

!

!

!

!

!

!

★

★

★

★

★

★

9 233 6452 003 POWER TRANS 1 *

10 412 2814 057 CARD SPACER (L=12) 1

11 412 2814 086 CARD SPACER (L=14.8) 1

12 412 9371 001 SPRING PLATE 1

13 337 0100 006 CD MECHA(CD11FTA3N) 2

14 412 5028 109 MECHA BRACKET 2 *

15 445 0033 005 WIRE CLAMP BAND 2

16 445 8028 009 CORD HOLDER 4

17 461 1153 009 FFC COVER 2 *

18 479 0003 025 PUSH RIVET 2

19 441 1985 008 HARD GASKET 2 *

20 206 2155 001 AC CORD W/CON.E3 E3 1

20 206 2089 106 AC CORD W/CON.E2 E2 1

20 206 2178 004 KOREA AC CORD VH E2K 1

21 445 0084 009 CORD BUSH E3 1

21 445 0056 008 CORD BUSH E2, E2K 1

22 441 1983 000 FRONT SUB PANEL 1 *

23 415 0910 004 BLIND SHEET 2 *

24 144 2831 108 FRONT PANEL 1 *

25 146 2275 003 P.SW KNOB GUIDE ASSY 1

26 119 0096 004 RUBBER KEY (C) 2

27 461 0740 002 SHEET 2

28 113 1689 001 P.SW KNOB 1

29 146 2311 006 LOADER PANEL 2 *

30 102 0663 002 TOP COVER 1 *

31 009 0143 032 23P FFC CABLE 2

32 203 8305 047 5P KR-KR CON.CORD CX51 2

33 204 0307 062 6P KR-KR CON CORD CX62 2

34 009 0241 031 16P FFC CABLE CX161 2

35 206 1087 057 FUSE (ET0.4A) E3 F601 1

35 206 1087 031 FUSE (ET0.25A) E2, E2K F601 1

36 461 1161 004 PROTECT COVER E3 1

109 475 1178 009 3W-B 12

513 3826 004 E2 LASER CAUTION E2, E2K 2

415 0790 075 UL TUBE (14.3) BK E2, E2K 1

445 0033 005 WIRE CLAMP BAND E2, E2K 1

GEN6335 R.SHEET E3 SUB ASS'Y E3 1

GEN6356 R.SHEET E2 SUB ASS'Y E2, E2K 1

513 3564 007 RATING LABEL BASE 1

Q'ty

New

42

Page 43

43DN-D4000

★

★

SCREWS

Ref.No. PartNo. PartName Remarks

513 3326 009 BAR CODE LABEL FILM 1

GEN6154 MANUFAC.DATE SUB ASS E3 1

101 473 7015 018 3X8 CBTS (S)-B 30

102 473 7002 005 3X6 CBTS(S)-Z 14

103 473 7004 003 4X8 CBTS (S)-Z 4

104 471 3303 029 3X6 CBS-B 1

105 473 7508 017 3X10 CBTS (P)-B 2

106 473 7032 004 3X25 CPTS(S)-Z 4

107 473 7033 003 3X32 CBTS-S (B) 4 *

108 477 0064 107 FIXING SCREW 4

110 471 9050 020 3X6 FHHS MFZNII-B 12

111 471 8010 100 SPECIAL SCREW 1

112 477 0263 005 3P. SWELLING SCREW 4

Q'ty

New

43

Page 44

EXPLODED VIEW OF CD MECHANISM UNIT (CD11FTA3N)

3

44DN-D4000

4

20

12

3

8

16

7

6

2

17

16

11

1

10

9

PARTS LIST OF CD MECHANISM UNIT

Ref. No. Part No. Part Name Remarks

1 964 0009 006 Frame chassis 1

2 964 0009 103 Magnet plate 1

3 964 0009 200 Rubber cushion 2

4 964 0009 307 Rubber cushion 2

5 964 0009 404 Magnet holder 1

6 964 0009 501 Drive gear 1

7 964 0009 608 Slide gear 1

8 964 0009 705 Pulley gear 1

9 964 0009 802 Square belt 1

10 964 0009 909 Magnet 1

Q'ty

15

13

Ref. No. Part No. Part Name Remarks

11 964 0010 008 Mecha lifter 1

12 964 0010 105 Loading table 1

13 964 0010 901 Loading motor 1

14 964 0010 202 5P Plug 1

15 964 0010 309 Push switch 2-1 2

16 964 0010 406 Cushion 9

17 964 0010 503 Cushion 2

18 964 0010 600 Motor P.W.B. 2

19 964 0010 707

20 964 0011 007 Mecha DA11T3CN 1

18

14

19

5

Screw 3×8 SCR S-TPG BIN

Q'ty

1

44

Page 45

PACKING VIEW

45DN-D4000

PARTS LIST OF PACKING & ACCESSORIES

Note:Thesymbolsinthecolumn"Remarks"indicatethefollowingdestinations.

E3:U.S.A.model,CsnadamodelE2K:Koriamodel

E2:Europemodel

Ref. No. Part No. Part Name Remarks Q'ty New

201 503 1001 507 CUSHION 2

202 503 1010 404 CUSHION (RC) 2

203 505 0102 092 STYLEN PAPER 1

204 505 0102 021 STYLEN PAPER 1

205 505 0038 030 POLY COVER 1

206 203 2360 004 2P PIN CORD 2

207 204 2869 016 8P MD CON.CORD(L) 1 *

208 511 4031 009 INST. MANUAL 1

209 501 2237 002 CARTON CASE 1

★

★

★

★

515 0945 007 WARRANTY (COM.) E3 1

515 0923 207 S.S.LIST COM.(EX) 1

-CONT.CARD(L) 1

- BAR CODE LABEL 1

45

Page 46

WIRING DIAGRAM

C

O

C

C

DN-D4000 DOUBLE CD PLAYER REMOTE CONTROLLER

DN-D4000

46

LOAD- 1 1 LOAD- /EJECT 2 2 /EJECT GU−3524−3

LOAD+ 2 2 LOAD+ TLED 3 3 TLED LED1 UNIT

OPEN 3 3 OPEN GND 4 4 GND

GND 4 4 GND

CLOSE 5 5 CLOSE CY201 CX232

GND 1 1 GND KEYOUT0 4 17 KEYOUT0

LIMITSW+ 2 2 LIMITSW+ CX231 CY231 JOG11 5 16 JOG11

SL+ 3 3 SL+ -5VA 1 23 -5VA JOG10 6 15 JOG10

SL- 4 4 SL- AGND 2 22 AGND PITC1 7 14 PITC1

SP+ 5 5 SP+ +5VA 3 21 +5VA PIT1 8 13 PIT1

SP- 6 6 SP- +9VP 4 20 +9VP KEYOUT5 9 12 KEYOUT5 GU−3523−2

D MECHA MAIN UNIT PGND 6 18 PGND LCLK1 11 10 LCLK1

VREF1 1 1 VREF1 +3.3V 8 16 +3.3V DATA 13 8 DATA

VCC 2 2 VCC +3.3V 9 15 +3.3V FLCLK 14 7 FLCLK

E 3 3 E DGND 10 14 DGND FLRST 15 6 FLRST

D 4 4 D +5VD 11 13 +5VD GND 16 5 GND

A 5 5 A +5VD 12 12 +5VD +5V 17 4 +5V

B 6 6 B +1.8V 13 11 +1.8V F2 18 3 F2

C 7 7 C CDSEL 14 10 CDSEL F1 19 2 F1

F 8 8 F MECHRXD 15 9 MECHRXD -HB 20 1 -HB

GND 9 9 GND MECHTXD 16 8 MECHTXD

LD 10 10 LD MBSYOUT 17 7 MBSYOUT

NC 11 11 NC MBSYIN 18 6 MBSYIN CY042 CX042

LPD 12 12 LPD RCBSYOUT 19 5 RCBSYOUT KEYIN0 1 1 KEYIN0

F+ 13 13 F+ RCBSYIN 20 4 RCBSYIN KEYIN1 2 2 KEYIN1

T- 14 14 T- RXD 21 3 RXD KEYIN2 3 3 KEYIN2

T+ 15 15 T+ TXD 22 2 TXD KEYIN3 4 4 KEYIN3

F- 16 16 F- /RST 23 1 /RST CX111 CY111

LOAD- 1 1 LOAD- -5VA 1 23 -5VA KEYOUT3 1 20 KEYOUT3

LOAD+ 2 2 LOAD+ AGND 2 22 AGND KEYOUT2 2 19 KEYOUT2

OPEN 3 3 OPEN +5VA 3 21 +5VA KEYOUT1 3 18 KEYOUT1

GND 4 4 GND +9VP 4 20 +9VP KEYOUT0 4 17 KEYOUT0

CLOSE 5 5 CLOSE +9VP 5 19 +9VP JOG21 5 16 JOG21

GND 1 1 GND +3.3V 9 15 +3.3V KEYOUT5 9 12 KEYOUT5 GU−3523−2

LIMITSW+ 2 2 LIMITSW+ DGND 10 14 DGND KEYOUT4 10 11 KEYOUT4 PANEL UNIT

SL+ 3 3 SL+ +5VD 11 13 +5VD LCLK2 11 10 LCLK2

SL- 4 4 SL- +5VD 12 12 +5VD FLCS2 12 9 FLCS2

SP+ 5 5 SP+ +1.8V 13 11 +1.8V DATA 13 8 DATA

SP- 6 6 SP- CDSEL 14 10 CDSEL FLCLK 14 7 FLCLK

D MECHA MAIN UNIT MECHTXD 16 8 MECHTXD GND 16 5 GND

VREF1 1 1 VREF1 MBSYIN 18 6 MBSYIN F2 18 3 F2

VCC 2 2 VCC RCBSYOUT 19 5 RCBSYOUT F1 19 2 F1

E 3 3 E RCBSYIN 20 4 RCBSYIN -HB 20 1 -HB

D 4 4 D RXD 21 3 RXD

A 5 5 A TXD 22 2 TXD

B 6 6 B /RST 23 1 /RST CW042 CX042

C7 7C KEYIN4 1 1 KEYIN4

F8 8F KEYIN5 2 2 KEYIN5

GND 9 9 GND KEYIN6 3 3 KEYIN6

LD 10 10 LD KEYIN7 4 4 KEYIN7

NC 11 11 NC

LPD 12 12 LPD

F+ 13 13 F+ CX041 CY041

T- 14 14 T- +3.3V 1 1 +3.3V

T+ 15 15 T+ /EJECT 2 2 /EJECT GU−3524−4

F- 16 16 F- TLED 3 3 TLED LED2 UNIT

CX051 +3.3V 1 1 +3.3V

CX062 KEYOUT1 3 18 KEYOUT1

GU−3523−1 +9VP 5 19 +9VP KEYOUT4 10 11 KEYOUT4 PANEL UNIT

CX161 PGND 7 17 PGND FLCS1 12 9 FLCS1

CX051 CX231 CW231 8.5V 8 8 8.5V CW201 CX232

CX061 +3.3V 8 16 +3.3V PIT2 8 13 PIT2

GU−3523−1 MECHRXD 15 9 MECHRXD FLRST 15 6 FLRST

CX062 MBSYOUT 17 7 MBSYOUT +5V 17 4 +5V

CX041 CW041

KEYOUT3 1 20 KEYOUT3

KEYOUT2 2 19 KEYOUT2

RC TXD 1 1 RC TXD

RC RXD 2 2 RC RXD

GU−3524−1 F1 4 4 F1 GU−3524−2

P

WER UNIT GND 5 5 GND

PGND 6 18 PGND JOG20 6 15 JOG20

PGND 7 17 PGND PITC2 7 14 PITC2

GND 4 4 GND

F1 3 3 F1

-HB 6 6 -HB

F2 7 7 F2

PU UNIT

46

Page 47

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol

characteristics.

Use ONLY replacement parts recommended by the

manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you

make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds

0.5 milliamps, or if the resistance from chassis to either

side of the power cord is less than 460 kohms, the unit is

defective.

WARNING:

DO NOT return the unit to the customer until the problem

is located and corrected.

NOTICE

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM

M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD.

P=MICRO-MICRO FARAD

EACH VOLTAGE AND CURRENT ARE MEASURED AT

NO SIGNAL INPUT CONDITION.

CIRCUIT AND PARTS ARE SUBJECT TO CHANGE

WITHOUT PRIOR NOTICE.

have critical

47DN-D4000

1. k k M M

2. F p pF

3.

4.

47

Page 48

DN-D4000

48

1

2

3

45

6

7

8

SCHEMATIC DIAGRAMS (1/3)

A

B

C216

CK6800P

C230

OPEN

C

D

REC SIGNAL LINE

E

SCHEMATIC DIAGRAMS (1/3)

GU-3523-1

48

Page 49

DN-D4000

49

1

2

3

45

6

7

8

SCHEMATIC DIAGRAMS (2/3)

A

B

D614

1SS355

C

D

E

SCHEMATIC DIAGRAMS (2/3)

GU-3523-2

49

Page 50

DN-D4000

50

1

2

3

45

6

7

8

SCHEMATIC DIAGRAMS (3/3)

A

B

C

D

E

SCHEMATIC DIAGRAMS (3/3)

GU-3524-1

GU-3524-2

GU-3524-3

GU-3524-4

50

Loading...

Loading...