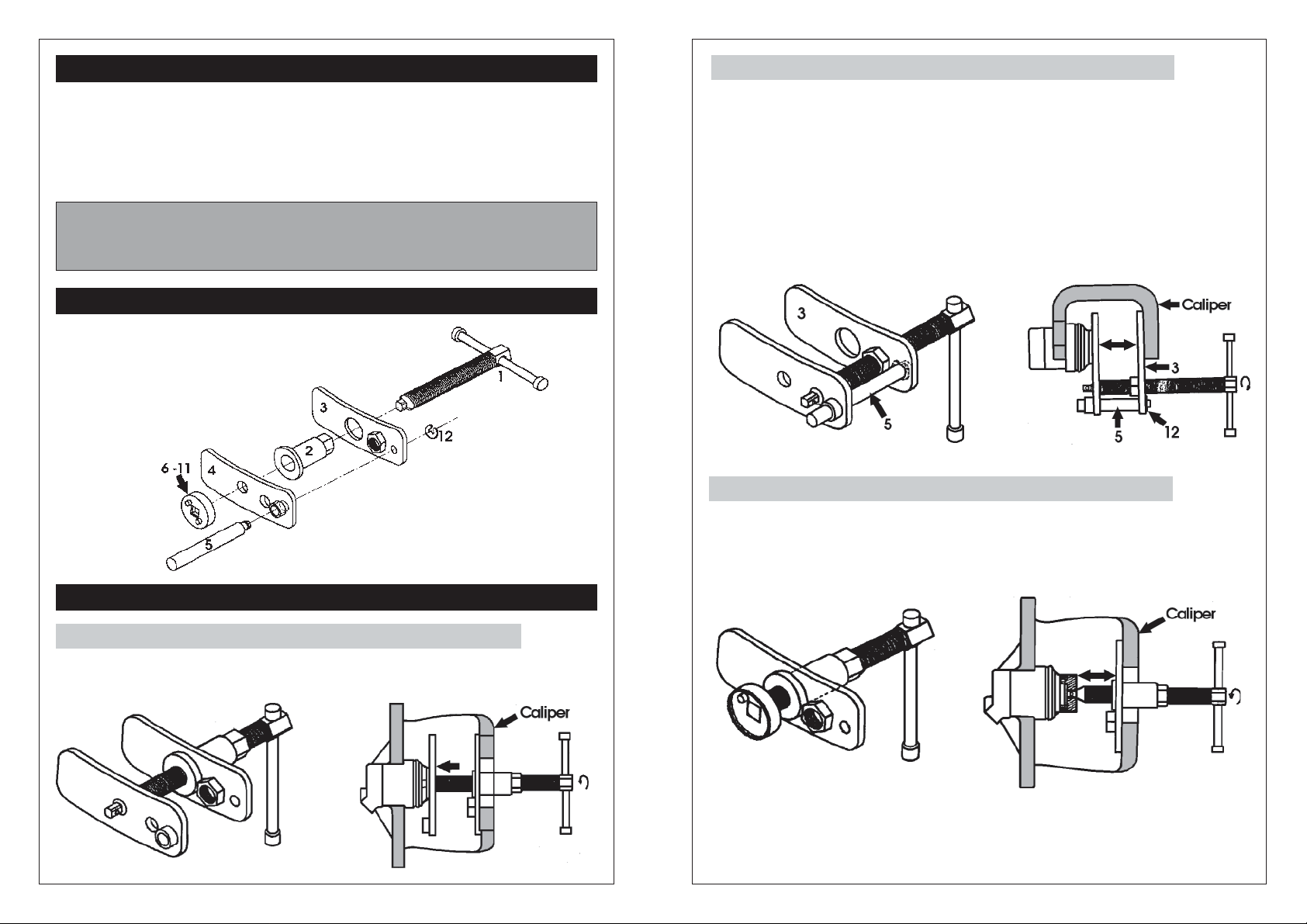

COMPONENTS

Item Description Part No.

1 Handle ...................................................................................... ZHCHT45601

2 Collar ........................................................................................ ZHCHT45602

3 Threaded Plate ........................................................................ ZHCHT45603

4 Plate .......................................................................................... ZHCHT45604

5 Shaft .......................................................................................... ZHCHT45605

6 Piston Adapter 63mm.............................................................. ZHCHT45606

7 Piston Adapter 53mm.............................................................. ZHCHT45607

8 Piston Adapter 47mm.............................................................. ZHCHT45608

9 Piston Adapter 50mm.............................................................. ZHCHT45609

10 Piston Adapter 42mm.............................................................. ZHCHT45610

11 Piston Adapter 35mm.............................................................. ZHCHT45611

12 Clip............................................................................................ ZHCHT45612

For Spare Parts and Service, please contact your nearest dealer,

or CLARKE International, on one of the following numbers.

P ARTS & SER VICE TEL: 020 8988 7400

or e-mail as follows:

P ARTS: Parts@clarkeinternational.com

DISC BRAKE

PISTON WIND BA CK TOOL

MODEL No: CHT 456

Part No: 1801456

GUARANTEE

This CLARKE product is guaranteed against faulty manufacture for a period of

12 months from the date of purchase. Please keep your receipt as proof of

purchase. This guarantee is invalid if the product is found to have been abused

or tampered with in any way, or not used for the purpose for which it was

intended.

Faulty goods should be returned to their place of purchase, no product can

be returned to us without prior permission.

This guarantee does not effect your statutory rights.

GENERAL CONSIDERATIONS

1. Be aware that as the pistons are pushed back into their cylinders, hydraulic oil will be

forced back into the reservoir . Take precautions to clean up any overspill. Any spillage

must be thoroughly cleaned away. NEVER remove trhe oil reservoir filter.

2. Do not operate the brake pedal with the brake pads removed.

3. Work on one brake assembly at a time, i.e. complete the installation of the brake

pads before moving tom another wheel hub.

WARNING:

The vehicle must be properly prepared, and adequately supported on axle

stands, on firm level ground, before any operation using this tool is performed.

ASSEMBLY

Assembly of the various components is

according to the illustration... depending

upon the applications, as shown

below.

2. Calipers with no direct access to the piston

i.e. closed type of caliper.

Assemble as shown, then turn the handle clockwise to push the piston back into

the cylinder.

NOTE:

1. Before shaft 5 can be threaded into plate 3, the clip 12 must be removed.

Ensure it is replaced, in order to lock the shaft to the plate, before use.

2. When the threaded shaft is turned in order to position the two plates between the i

inner face of the caliper and the piston, the assembly may ‘jam’. Squeezing the

ends of the plates together and maintaining pressure, wil l overcome this problem

3. Calipers with piston on a screw thread

METHODS OF USE

1. Calipers withdirect access to the piston

Assemble as shown, then turn the handle clockwise to push the piston back into

the cylinder.

Assemble as shown, selecting the appropriate piston adapter (item 6 - 11) to fit

on to the square drive on the end of the Threaded shaft (1).

Ensure the pegs on the piston adapter fit snugly in the coresponding holes in the

piston, then turn the handle clockwise to screw the piston back into the cylinder.

NOTE:

When the brake pads have been replaced, ensure the hydraulic oil reservoir is

topped up before pressing the brake pedal, and if several applications of the

pedal are required to restore the pads to their correct position, check the level

before each application or have an assistant top up the level as it recedes.

Loading...

Loading...