DOT MATRIX PRINTER

CD-S500 Series

CD-S500A

User's Manual

Table of Contents

COMPLIANCE STATEMENT FOR EUROPEAN USERS ............................................................... 3

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS ...................................................... 3

EMI COMPLIANCE STATEMENT FOR CANADIAN USERS ...................................................... 4

ETAT DE CONFORMITE EMI A L’USAGE DES UTILISATEURS CANADIENS ........................ 5

Important Safety Instructions ......................................................................................................... 6

Notice ................................................................................................................................................ 7

SAFETY INSTRUCTIONS which must be strictry observed! ................................................... 8

Chapter1 Introduction

Features ................................................................................................................. 12

Explanation of the Models ................................................................................ 13

Checking the Accessories ................................................................................. 15

Chapter2 Names and Functions of Parts

................................................................................................................................16

Chapter3 Preparing the Printer

Connections........................................................................................................ 20

Installation............................................................................................................23

Setting the Paper Near End Sensor ................................................................24

Setting the Paper Width and Printing Line Column Number .................... 25

Installing the Ribbon Cassette .........................................................................27

Installing Roll Paper ............................................................................................ 28

Operation when the cover is opened and closed ........................................ 33

Chapter4 Maintenance Mode

HEX Dump Mode ............................................................................................ 35

Soft SW Setting Mode ................................................................................... 35

Initial Factory Shipping Mode ...................................................................... 39

Cut Position Adjustment Mode .................................................................. 40

Error Indicators.................................................................................................... 41

Trouble Shooting ................................................................................................ 43

Chapter5 Appendixes

Specifications ..................................................................................................... 44

Interface ............................................................................................................... 48

2

COMPLIANCE STATEMENT

FOR EUROPEAN USERS

CE marking shows conformity to the following criteria and provisions:

Low Voltage Directive (73/23/EEC)/EN60950-1

EMC Directive (89/336/EEC)/EN55022, EN55024, EN61000-3-2 & EN61000-3-3

FCC COMPLIANCE STATEMENT

FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

CITIZEN is a registered trade mark of CITIZEN WATCH CO., LTD., JAPAN

Company names and product names in this manual are trademarks or

registered trademarks of relevant companies.

Copyright © 2005 CITIZEN SYSTEMS JAPAN CO., LTD.

3

EMI COMPLIANCE STATEMENT

FOR CANADIAN USERS

This Class A digital apparatus complies with Canadian ICES-003.

This equipment generates and uses radio frequency energy and if not installed

and used properly, that is, in strict accordance with the manufacturer's

instructions, may cause interference to radio and television reception. This digital

apparatus does not exceed the Class A limits for radio noise emissions from digital

apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications. This equipment is designed to provide

reasonable protection against such interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

CAUTION : Use shielded cables to connect this device to computers.

Any changes or modifications not expressly approved by the grantee

of this device could void the user's authority to operate the

equipment.

4

ETAT DE CONFORMITE EMI A L’USAGE

DES UTILISATEURS CANADIENS

Cet appareil numérique de la classe A est conforme à la norme

NMB-003 du Canada.

Cet équipment produit et utilise l’énergie à radiofréquences et s’iln’est pas

installé et utilisé correctment, c’esst à dire en accord strict avec les instructions

du fabricant, il risque de provoquer des intérferences avec la réception de la

radio et de latélévision.

Le présent appareil numérique n’émet pas de bruite radio électriques dépassant

les limites applicables aux appareils numériques de la classe A prescrites dans

le Réglement sur le brouillage radioélectrique édicté par le ministère des

Communications du Canada.

Cet équipment est conçu pour fournir une protection satisfaisante contre de

telles interférences dans une installation résidentielle. Cependant, il n’y a pas

de garantie contre les interférences avec les réceptions radio ou télévision,

provoquées par la mise en et hors circuit de l’équipment; aussi, il est demandé

a l’utilisateur d’essayer de corriger l’interférence par l’une ou plus des mesures

suivantes:

• Réorienter l’antenne de réception.

• Installer l’ordinateur autre part, par égard pour le récepteur.

• Brancher l’ordinateur dans une prise de courant différente de façon à ce

que l’ordinateur et le récepteur soient branchés sur des circuits différents.

5

Important Safety Instructions

• Read all of these instructions and save them for later reference.

• Follow all warnings and instructions marked on the product.

• Unplug this product from the wall outlet before cleaning. Do not use liquid or aerosol

cleaners. Use a damp cloth for cleaning.

• Do not use this product near water.

• Do not place this product on an unstable cart, stand or table. The product may fall,

causing serious damage to the product.

• Slots and openings on the cabinet and the back or bottom are provided for ventilation.

To ensure reliable operation of the product and to protect it from overheating, do

not block or cover these openings. The openings should never be blocked by placing

the product on a bed, sofa, rug or other similar surface. This product should never

be placed near or over a radiator or heat register. This product should not be placed

in a built-in installation unless proper ventilation is provided.

• This product should be operated from the type of power source indicated on the

marking label.

If you are not sure of the type of power available, consult your dealer or local power

company.

• This product is equipped with a three-pronged plug, a plug having a third (grounding)

pin. This plug will only fit into a grounding-type power outlet. This is a safety feature.

If you are unable to insert the plug into the outlet, contact your electrician to replace

your obsolete outlet. Do not defeat the safety purpose of the grounding-type plug.

• Do not allow anything to rest on the power cord. Do not locate this product where

the cord will be walked on.

• If an extension cord is used with this product, make sure that the total of the ampere

ratings on the products plugged into the extension cord do not exceed the extension

cord ampere rating. Also, make sure that the total of all products plugged into the

wall outlet does not exceed 15 amperes for 120V outlet and 7.5 amperes for 220V240V outlet.

• Never push objects of any kind into this product through cabinet slots as they may

touch dangerous voltage points or short out parts that could result in a risk of fire or

electric shock. Never spill liquid of any kind on the product.

• Except as explained elsewhere in this manual, don't attempt to service this product

yourself. Opening and removing those covers that are marked "Do Not Remove" may

expose you to dangerous voltage points or other risks. Refer all servicing on those

compartments to service personnel.

6

• The main plug on this equipment must be used to disconnect mains power. Please

ensure that the socket outlet is installed near the equipment and shall be easily

accessible.

• Unplug this product from the wall outlet and refer servicing to qualified service

personnel under the following conditions:

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the product.

C. If the product has been exposed to rain or water.

D. If the product does not operate normally when the operating instructions are

followed. Adjust only those controls that are covered by the operating instructions

since improper adjustment of other controls may result in damage and will often

require extensive work by a qualified technician to restore the product to normal

operation.

E. If the product has been dropped or the cabinet has been damaged.

F. If the product exhibits a distinct change in performance, indicating a need for

service.

Notice

• Before use, be sure to read this manual. And keep it handy for reference when needed.

• The contents of this manual may change without prior notice.

• Reproduction, transfer, or transmission of the contents of this manual without prior

consent is strictly prohibited.

• We are not liable for any damage resulting from the use of the information contained

herein, regardless of errors, omissions, or misprints.

• We are not liable for any problems resulting from the use of optional products and

consumable supplies other than the designated products contained herein.

• Do not handle, disassemble or repair the parts other than those specified in this

manual.

• We are not liable for any damage caused by user's erroneous use of the printer and

inadequate environment.

• Data residing in the printer is temporary. Therefore, all data will be lost if power is

lost. We are not liable for any damage or loss of profits caused by data loss due to

failures, repairs, inspections, etc.

• Please contact us if there are any mistakes or ambiguities within this manual.

• If there are missing or incorrectly collated pages in this manual, contact us to obtain

a new manual.

7

SAFETY INSTRUCTIONS

which must be strictly observed !

• To prevent personal injury or property damage, the following shall be

strictly observed.

• The degree of possible injury and damage due to incorrect use or

improperly following instructions is described below.

Indicates a situation which, if not observed

Warning

and handled properly, could result in death

or serious injury.

Caution

Meaning of symbols

This symbol indicates that something must be handled carefully.

This symbol indicates something that must not be done.

This symbol indicates something that must be done.

8

Indicates a situation which, if not observed

and handled properly, could result in injury.

Warning

Never perform the following. If not avoided, these may cause damage

or trouble to the printer or cause the printer to overheat and release

smoke and cause burns or an electrical shock. If the printer is damaged

or is malfunctioning, be sure to turn the printer off immediately and

remove the power cord from the outlet, then consult our service

personnel.

• Do not place the printer in a poorly ventilated area, or shut off the air vent of

the printer.

• Do not place the printer where chemical reactions occur, such as in laboratories

or where air is mixed with salt or gas.

• Do not use a power voltage or frequency other than those specified.

• Do not plug/unplug the power cord or attach/detach the interface cable by

simply grabbing the power cord or interface cable. Do not pull or carry the

printer when the tension of the power cord or interface cable is increased.

• Do not drop or put foreign matter such as clips and pins into the printer. This

may cause problems.

• Do not plug the power cord into an outlet with many loads.

• Do not spill drinks such as tea, coffee and juice on the printer or spray

insecticide on the printer. If drink or water is spilled, first be sure to turn the

power off and remove the power cord from the outlet, then consult our service

personnel.

• Do not disassemble or modify the printer.

• Do not use this printer when any safety switch built into the product has been

cancelled without solving the problem that activated it. If you do, there is a danger

that the printer will malfunction, injuring, burning, or electrocuting you.

Discard or safely store the plastic packing bag. This bag should be

kept away from children. If the bag is pulled over a child’s head, it may

cause suffocation.

9

General Precautions

Caution

• Prior to operation, read the safety instructions carefully and observe them.

• Do not drop or put foreign matter such as clips and pins into the printer. This

may cause problems.

• Be careful when moving or carrying the printer. Dropping the printer may

cause injury or property damage.

• If this printer is accidentally dropped, be sure to notify a service person; do

not try to repair it yourself.

• Do not open the printer during printing.

• When cleaning the surface of the printer case, do not use the cloth that is

soaked in thinner, trichloroethylene, benzine, ketone or similar chemicals.

• Do not use the printer where there is a lot of oil, iron particles, or dust.

• Do not spill liquids or spray insecticide on the printer.

• Do not jolt or impact to the printer by stepping on, dropping or hitting the

printer.

• Operate the control panel properly. A careless, rough handling may cause

problems or malfunction. Do not use such sharp-edged tool as a ballpoint

pen for operation.

• Be careful of the edges of the plates so injury or property damage is possible.

• If a problem occurs during printing, stop the printer immediately and unplug

the power cord from the outlet.

• When printer trouble occurs, do not try to dissemble it. Instead, consult our

service personnel.

10

Precautions When Installing the Printer

Caution

• Prior to operation, read the safety instructions carefully and observe them.

• Do not use or store the printer near fire, excessive moisture, in direct sunlight,

near an air conditioner or heater or other source of unusually humidity or

excessive dust.

• Do not place the printer where chemical reactions occur, such as in a

laboratory.

• Do not place the printer where air is mixed with salt or gas.

• The printer must sit on a firm, level surface where there is ample ventilation.

Never allow the printer's air vent to be blocked by an object.

• Do not put anything on the top of printer.

• Do not place the printer near a radio or television, and do not use the same

wall outlet for the printer and radio or television. Radio or television reception

could be adversely affected.

• Do not put anything on the power cord or step on it.

• Do not drag or carry the printer with the power cord or interface cable.

• Avoid plugging the power cord into an outlet with many loads.

• Do not bundle the power cord when inserting the plug.

• Always grip the plug housing, not the cord, to plug/unplug the power cord.

• Make certain the power is turned off before connecting/disconnecting the

interface cable.

• Avoid lengthening the signal cable or connecting it to any noise-producing

device. If it is unavoidable, use the shielded cable or twisted pair for each

signal.

• Place the printer near the outlet where the power cord can be unplugged

easily to shut off power.

• Use the AC outlet that accepts a three-pronged plug. Otherwise, static

electricity may be generated and there will be danger of electric shock.

• Do not carry it holding the cover.

Doing this might break its mechanisms or cause it to malfunction.

11

Chapter1

Introduction

Thank you very much for purchasing the Citizen Dot Matrix Printer CD-S500 series.

This printer is a dot matrix printer developed for use with various kinds of data

communication terminals, POS terminals, and kitchen printers.

It can be used for a wide range of applications thanks to its rich selection of functions.

Features

Compact design

A paper drop in mechanism that simplifies paper loading

High speed printing to a maximum of 240cps

Multiple copy printing (original form + 2 copies)

Input buffer available

Black mark sensor mechanism

Versatile printing layout using the page mode

Logo data or text data prepared by the user can be stored in its user

memory

Built-in drawer kick-out interface

Optional auto-cutter (full cut/partial cut)

Capacity for paper with widths of 76.2/69.5/57.5mm

Serial (RS-232C) or Parallel (IEEE and Centronics compliant) interface

is available as a factory option

Selection of functions diversified by its operation panel (Soft SW setting

mode)

Can be wall mounted (optional)

Built-in buzzer

Built-in or external AC adapter types available

Dual color printing (red/black)

12

Explanation of the Models

Models in this series are identified by the following model naming method.

Model Number:

CD-S -

Model name

500 : Standard model

50 1 : Built-in auto cutter model

503 : Built-in auto cutter and rewinder

model

Power source type

A: AC adapter type

S: Built-in AC adapter type

Interface

PA : Parallel IEEE1284 compatible

RS : Serial RS-232C compatible

UB: USB

Region (Characters + power cord)

J : Japan

E : Europe

U : North America

C : China

Case Color

WH : Cool white

BK : Black

-

Introduction

Black mark sensor

None : No sensor

M1 : Left sensor for paper reverse

M2 : Right sensor for paper reverse

M3 : Left sensor for paper surface

M4 : Right sensor for paper surface

13

Chapter1

Introduction

Explanation of models

Examples of models

Standard model (AC Adapter type)

CD-S500A--

Auto cutter equipped model

(AC Adapter type)

CD-S501A--

Auto cutter and rewinder equipped

model (AC Adapter type)

Standard model

(Built-in AC adapter type)

CD-S500S--

Auto cutter equipped model

(Built-in AC adapter type)

CD-S501S--

Auto cutter and rewinder equipped

model (Built-in AC adapter type)

14

CD-S503A-- CD-S503S--

Checking the Accessories

Check to make sure that the following accessories are included with your printer.

Printer: 1

AC adapter: 1

(CD-S500A series only)

Power cord: 1

Ribbon cassette: 1

Printer: 1

AC adapter type

Partition: 1

Slip prevention rubber feet: 4

(CD-S500S and CD-S501S only)

Sample roll paper: 1

User’s Manual (this document)

Built-in AC adapter type

* The AC adapter is set inside the AC

adapter case.

AC adapter Power cord Ribbon cassette

Introduction

Partition Sample roll paper User’s Manual

CD-S500

C

D

S

5

0

0

A

User's Manual

(this document)

D

O

T M

A

TRIX PRIN

TER

Series

15

Chapter2

Names and Functions of Parts

Exterior

AC adapter type

Standard and auto cutter equipped

models

6

Names and Functions of Parts

Built-in AC adapter type

1

2

3

4

5

Auto cutter and rewinder equipped

model

6

5

Operation panel

(see page 18)

Rear connectors

(see page 19)

1

2

3

4

Operation panel

(see page 18)

Rear connectors

(see page 19)

7

1 Paper check window

It can be used to check the amount of

paper left on the roll.

2 Rear cover

It can be opened to set or to replace a

paper roll.

3 Rear cover open lever

It is a lever used to open the rear cover.

Pull the lever towards you to open the rear

cover.

4 Front cover

It can be opened to set or replace the

ribbon cassette.

5 Power switch

It turns the printer power on and off.

6 Cutter lock clearing screw hole

When the rear cover cannot be opened

because the blade of the auto cutter

protrudes after a malfunction or as a result

of a paper jam, turn this screw with a

Phillips head screw driver to return the

blade.

7 AC adapter case

This is installed only for the built-in AC

adapter type.

16

Interior

AC adapter type

Standard and auto cutter equipped

model

8

6

Auto cutter and rewinder equipped

model

8

7

1 Platen unit

1

2

4

5

1

2

3

4

5

In the standard and auto cutter equipped

models, it is combined with 8 the auto

cutter.

2 Paper cut bar

It is used to cut the paper manually.

3 Platen open lever

It is a lever used to open the platen unit

on the rewinder equipped model. Open

the platen unit by pulling it towards you.

4 Print head cover

5 Ribbon cassette drive shaft

6 Print head

7 Rewinder shaft

It rewinds the copy side of the copy roll

paper.

8 Auto cutter unit

It automatically cuts the paper after

printing is completed. The cut action is

set by a command in Soft SW Setting

Mode.

Names and Functions of Parts

6

17

Chapter2

Operation Panel

Names and Functions of Parts

5

123 4

1 POWER LED (Green)

It is lit when the power is supplied. When

maintenance mode is set or there is an

error indication, it is either lit or flashing.

2 PAPER OUT LED (Orange)

It is lit in paper out status. When

maintenance mode is set or there is an

error indication, it is either lit or flashing.

3 ERROR LED (Orange)

It is lit when the rear cover or front cover

is open. When maintenance mode is set

or there is an error indication, it is either

lit or flashing.

4 FEED Switch

When this switch is pressed once, paper

feeds (1 line). If it is held down, paper

feeds continuously until it is released.

And when there is a printer error, pressing

this switch can cancel the error status.

5 LED NAME SHEET

This sheet is used reversed according to

the printer installation method. See

Vertical Installation and Wall Mounted

Installation (page 23).

Display when installed horizontally

Display when installed vertically or

wall mounted

18

Rear Connectors

AC adapter type

Parallel (IEEE1284) interface

Serial (RS232C) interface

Built-in AC adapter type

4

1 Interface connector

It is connected to either a serial (RS232C) or parallel (IEEE1284) interface cable.

* A USB interface replaced by a serial or parallel interface will be available as a factory

option.

2 Drawer kick connector

It is connected to a cable from the drawer.

3 Power source connector

It is connected to a cable from the AC adapter.

4 Power source inlet

It is connected to the power cord.

123

Names and Functions of Parts

Others

Built-in Buzzer

A buzzer sounds when the FEED switch is operated and when there is an error.

The buzzer can be switched between enabled and disabled in Soft SW setting mode.

User Memory

Logo data or text data prepared by the user can be stored in memory.

This stored data remains in memory even after the power is turned off.

19

Chapter3

Preparing the Printer

Connections

Connecting the Interface Cable

Turn off the power to the printer and insert the connectors being careful about their

orientation.

Caution

Always hold the connector when pulling out a cable.

Install the interface cable so that it will not be caught on your shoes etc.

Connecting the serial (RS232C) interface cable

Make sure that you insert it firmly and fix it in place by tightening the screw.

Serial (RS232C) interface cable

Connecting the parallel (IEEE1284) interface cable

Make sure that you insert it firmly and fix it in place by turning the attachment screws in

the direction shown by the arrow.

Parallel (IEEE1284) interface cable

20

Connecting the Drawer

Match the top and bottom of the drawer kick connector with the cable terminal and insert

it firmly until you hear a click.

Drawer kick cable

Caution

Connect only a specialized drawer. (Do not connect a telephone line.)

Output is impossible during printing.

Drawer 1 and drawer 2 cannot be driven simultaneously.

Use a drawer use solenoid that is at least 24Ω. Make sure that the output current

is not higher than 1A. This may cause a malfunction or burn damage.

Install the drawer kick cable so that it will not be caught on your shoes etc.

See page 48 for detailed specifications of the interfaces.

Preparing the Printer

21

Chapter3

p

Preparing the Printer

Connecting the Power

1.Make sure that the printer power

switch is set to OFF.

2.If your printer is an AC adapter type,

insert the AC adapter cable connector

with its flat side upwards into the

power connector on the rear surface

of the printer.

If your printer is a built-in AC adapter

type, insert the plug on the power

cord into the AC inlet on the back

surface of the printer.

Caution

Do not use an AC

adapter other than

the stipulated product

(Model 51AD).

Always hold the connector when

inserting or removing the cable

connector of the AC adapter.

Stretching the power cord by pulling

it will damage it, causing fire, electric

shocks, or a break in the conductor.

When lightening is striking nearby,

remove the plug of the power cord

from the outlet. Lightening will cause

fire or electric shock.

Do not place the power cord near a

heating device. The cover of the power

cord will melt, causing fire or electric

shock.

When the printer will not be used for

a long period, be sure to remove the

plug of the power cord from the outlet

to guarantee safety.

Isolate the AC power source from

other devices that generate noise.

DC 24V

51 AD

ONLY

AC adapter cable

Flat side of the cable is u

AC adapter type

AC inlet

Built-in AC adapter type

.

22

Installation

Protrusion

Part B

This printer can be installed horizontally or vertically and can be wall mounted.

But according to the model you are using, there may be restrictions on how it is installed.

Refer to the following table.

Horizontal Vertical Wall Mount

Standard model (AC adapter type) Yes No Yes*

Standard model (Built-in AC adapter type)

Auto cutter equipped model (AC adapter type) Yes No Yes*

Auto cutter equipped model (Built-in AC adapter type)

Auto cutter and rewinder equipped model

(AC adapter type)

Auto cutter and rewinder equipped model

(

Built-in AC adapter type

*1: Accessory rubber feet must be used to prevent slipping.

*2: The optional specialized wall mount unit is necessary to mount it on the wall.

)

Yes Yes *

Yes Yes *

Yes N o N o

Yes N o N o

1

1

Vertical installation and wall mounted installation

To install the printer vertically or wall mounted, remove the Chassis Platen L Spring used to

open the rear cover. And reverse the LED name sheet on the operation panel to use it with

the vertically installed and wall mounted display.

Removing the Chassis Platen L Spring

1.

Open the rear cover. Do this carefully, because

the cover snaps open vigorously.

2.

Lift part A with the fingers of your right hand.

3.

Switch the Chassis Platen L Spring that you have

raised from your right thumb to your left thumb

to hook the protrusion on the end of the Chassis

Platen L Spring inside part B of the printer.

Part A

2

2

Ye s*

2

2

Ye s*

Chassis Platen

L Spring

Preparing the Printer

Caution

Chassis Platen L Spring with strong

repulsive force is used. Be very careful

that it does not slip off your finger

causing an injury.

LED Name Sheet

Remove and reverse the sheet then reinsert the

protruding part of the center of the sheet in the

printer and push in both ends.

23

Chapter3

Preparing the Printer

Setting the Paper Near End Sensor

Change the sensor location according to the way the printer is installed and the interior

diameter of the roll paper you are using. Referring to the following table, set it at a

location suited to the usage environment by moving it to the left and right while pushing

the concave part of the center of the sensor with your finger. (When shipped from the

factory, it is set at φ24mm.)

Paper near end sensor

When installed

vertically and

wall hung

6

5

4

3

2

When installed horizontally

1

Installation

method

Horizontal

Vertical

(wall mounted)

Remaining roll

paper (mm)

Approx. φ22

Approx. φ24

Approx. φ27

Approx. φ27

Approx. φ24

Approx. φ22

Caution

The remaining roll paper (external diameter of the roll paper) differs greatly

according to the type of roll paper used. Use these values only as guidelines.

When the sensor has detected the remaining roll paper during printing, the printer

stops printing after it has printed all the data that it had received.

If you are using a model with parallel (IEEE1284) interface specifications, you can

select sensor enabled/disabled in Soft SW Setting Mode.

If you are using a model with serial (RS232C) interface specifications, it is always

enabled.

24

Sensor location

1

2

3

4

5

6

Setting the Paper Width and Printing Line Column Number

The printing dot line columns are changed as follows by setting the “Paper Width” of the

roll paper used, the “Number of col.” and the “Font Select” in Soft SW Setting Mode.

For details about setting, see Soft SW Setting Mode (page 35).

When setting Paper Width of 76.2mm

Soft SW Setting Mode

Number of col. Font Select

40/33

42/35

9Ω9 dots 3 dots 33 columns

7Ω9 dots 3 dots 40 columns

9Ω9 dots 2 dots 35 columns

7Ω9 dots 2 dots 42 columns

Paper width: 76.2mm

When Number of col. 40/33 are selected: 400 dots

When Number of col. 42/35 are selected: 386 dots

Space between

characters

Printing line

columns

Full columns

400 dots

386 dots

Preparing the Printer

Paper feed

direction

25

Chapter3

Preparing the Printer

Setting Paper Width and Printing Line Columns

When setting Paper Width of 69.5mm

Soft SW Setting Mode

Number of col. Font Select

40/33

42/35

9Ω9 dots 3 dots 30 columns

7Ω9 dots 3 dots 36 columns

9Ω9 dots 2 dots 32 columns

7Ω9 dots 2 dots 40 columns

When Number of col. 40/33 are selected: 360 dots

When Number of col. 42/35 are selected: 360 dots

Right offset: 40 dots

Space between

characters

Paper width: 76.2mm

Paper width: 69.5mm

When setting Paper Width of 57.5mm

Soft SW Setting Mode

Number of col. Font Select

40/33

42/35

9Ω9 dots 3 dots 25 columns

7Ω9 dots 3 dots 30 columns

9Ω9 dots 2 dots 27 columns

7Ω9 dots 2 dots 33 columns

Space between

characters

Printing line

columns

Printing line

columns

Full columns

360 dots

Paper feed

direction

Full columns

300 dots

298 dots

26

Paper width: 76.2mm

Paper width: 57.5mm

When Number of col. 40/33 are

selected: 300 dots

When Number of col. 42/35 are

selected: 298 dots

Right offset: 100 dots

Paper feed

direction

Installing the Ribbon Cassette

. Open the front cover of the printer.

1

Insert your fingers into the dents at

opposite ends of the front cover to

open it with both hands.

2.Turn the ribbon cassette knob in the

direction shown by the arrow to fully

stretch the ribbon.

3.Insert the cassette into the printer

until a click is heard so that the ribbon

is between the paper cut bar and the

print head cover. If it difficult to insert,

turn the ribbon cassette knob again.

Front cover

Preparing the Printer

Paper cut bar

Print head cover

4.Close the front cover.

Caution

Be very careful not to let your hands

touch the print head cover when

replacing the ribbon cassette. When the

print head has become

heated, there is a danger of

it burning your hand.

27

Chapter3

Preparing the Printer

Installing Roll Paper

The following are the types of roll paper that can be used by this printer.

Types: 1P roll paper

2P copy roll paper (1 original + 1 copy)

3P copy roll paper (1 original + 2 copies)

(2P and 3P copy roll paper are only usable on models equipped with auto

cutter and rewinder.)

Paper widths: 76.2 (±0.7)/69.5 (±0.6)/57.5 (±0.5)mm

Roll diameter: φ30mm to φ83mm

Core diameter: Interior diameter φ10

Paper thickness: 1P 0.06 to 0.085mm

Copy paper 0.05 to 0.20mm (total thickness)

But the total thickness that can be cut is from 0.05 to 0.14mm.

Standard and Auto Cutter Equipped Models

+2

mm, exterior diameter φ27mm or less

–0

Installation method

1.Pull the rear cover open lever towards

you to open the rear cover.

2.Set the attached partition in place if

the roll paper you are using is 69.5mm

wide or 57.5mm wide.

Change the paper width by changing

the value set as the width using the

Soft SW Setting Mode.

(See page 35)

Caution

When setting the roll paper, be

careful not to cut your

hand on the edge of

the paper.

Rear cover open lever

Partition

Location set for width of 57.5mm

Location set for width of 69.5mm

28

3.Place the roll paper and pull the end

of the roll paper directly towards you

as shown in the figure.

Hold the center of the roll paper to pull

it as straight as possible so that one of

the sides of the paper does not slacken.

1P roll paper

4.Maintaining tension in the roll paper,

firmly close the rear cover until you

hear a click.

Paper feeds automatically and stops

at the print start position.

Caution

Be very careful not to let

the rear cover catch your

hands when closing the rear

cover.

5.Tear off surplus paper by holding one

side of the end of the roll paper and

pulling it towards you.

Caution

Do not insert any foreign

objects such as a paper clip

into the cutter unit.

Rear cover

Roll paper that is

gently pulled taut.

Preparing the Printer

29

Chapter3

Preparing the Printer

Installing Roll Paper

Auto Cutter and Rewinder Equipped Model

Installation Method

1.Pull the rear cover open lever towards

you to open the rear cover.

Rear cover open lever

2.Then pull the platen open lever

towards you to open the platen unit.

3.Set the attached partition in place if

the copy roll paper you are using is

69.5mm wide or 57.5mm wide.

Change the paper width by changing

the value set as the width using the

Soft SW Setting Mode.

(See page 35)

Caution

When setting the roll paper, be

careful not to cut your

hand on the edge of

the paper.

Platen open lever

Platen unitPlaten unit

Partition

30

Location set for width of 57.5mm

Location set for width of 69.5mm

4.After removing the rewinder shaft,

install the copy roll paper and pull the

end of the roll paper straight towards

you for about 30cm as shown in the

figure.

Hold the center of the roll paper to pull it

as straight as possible so that one of the

sides of the paper does not slacken.

5.Maintaining light tension in the copy

roll paper, firmly close the platen unit

until you hear a click.

Caution

Be very careful not to let

your hands touch the blade

on the paper cutter bar.

Rewinder shaft

2P or 3P copy roll paper

About 30cm

Roll paper that is

gently pulled taut.

Preparing the Printer

Platen unit

Be careful of the paper cut bar.

6.

Set one side of the copy roll paper

(copy side) on the rewinder shaft as

shown in the figure, and tightly wind

it about 2 rotations in the direction

shown by the arrow.

Check to make sure that the copy roll

paper rotates with the rewinder shaft.

Copy roll paper

(copy side)

Rewinder shaft

Protrudes

about 5cm

Wind it about twice

31

Chapter3

Preparing the Printer

Installing roll paper

7. Being careful not to let the copy roll

paper set on the rewinder shaft

slacken, place the roll paper in the

grooves on both sides.

Turn the flange on the rewinder shaft

in the direction shown by the arrow

and make sure that the copy roll

paper rotates with the rewinder shaft.

Taking up slack while checking that

the copy roll paper winds.

8.With the other side of the copy roll

paper (original side) pulled lightly

taut, close the rear cover firmly until

you hear a click.

Hold the center of the roll paper to pull

it as straight as possible so that one of

the sides of the paper does not slacken.

Paper feeds automatically and stops

at the print start position.

Caution

Be very careful not to let

the rear cover catch your

hands when closing the rear

cover.

9.Tear off surplus paper by holding one

side of the end of the roll paper and

pulling it towards you.

Caution

Do not insert any foreign

objects such as a paper clip

into the cutter unit.

Rear cover

Roll paper that is

gently pulled taut.

32

Operation when the cover is opened and closed

Operation when the front cover is opened and closed

Opening: During printing, the printing stops and if it is in red printing status, the ribbon

is switched to the black ribbon status, moves to the centering location, and

becomes the condition you can replace the ribbon cassette.

Closing: If it was red printing status when it was opened, the ribbon returns to red status

and if there is printing data, printing restarts.

Operation when the rear cover is opened and closed

Opening: During printing, the printing stops and the ribbon moves to the centering

location and remains in stand by. On models equipped with a rewinder, if the

cover is opened with paper set, the paper is fed forward about 1 inch then

returns to the centering position.

Closing: After print operation and cut operation have been initialized, it performs paper

feed check, and if there is printing data, printing restarts.

Caution

If a cutter problem is caused by a paper jam etc., the printer may stop with the

cutter blade protruding so that the rear cover cannot be opened. In this case,

press the FEED switch to eliminate the cutter problem without trying to force it

open. If the problem is not eliminated by pressing the switch, insert a screw driver

in the hole on the left side surface of the rear cover and rotate it to manually

restore the cutter blade, then open the cover. (The blade will be restored by turning

it to either the left or the right.)

Be careful of the manual paper cut bar in particular, to make sure that your fingers

are not caught when opening and closing the cover.

Opening the rear cover during printing causes malfunctions of the printer head or

cutter unit. Make sure that printing has stopped before you open the rear cover.

To close the rear cover, close it while holding the end of the paper so that the

paper is not slack or bent inside the printer.

Preparing the Printer

33

Chapter4

Maintenance Mode

Maintenance Mode

The settings of the printer can be changed according to its usage environment in

maintenance mode. And it is also possible to change their settings back to the initial

factory shipping setting or to adjust the cut position after printing in this mode.

And the content of the settings can be confirmed in demonstration printing mode.

To change the settings in maintenance mode, print and check the present settings.

Demonstration printing mode

Setting the mode

Turning the power on while pressing the FEED switch with the front cover and the rear

cover both closed starts demonstration printing mode and the “demonstration printing

and the present printing settings” are printed.

Setting maintenance mode

1.Set maintenance mode by turning on

the power while pressing the FEED

switch with the front cover open and

the rear cover closed, then releasing

the FEED switch.

2.The POWER LED flashes as the printer

enters maintenance mode.

Close the front cover in this status.

Flashing

Power switch

Front cover open

FEED switch

Types of maintenance mode

There are the following four types of maintenance mode.

Each mode is selected according to the number of times the FEED switch is pressed from

maintenance mode.

HEX Dump Mode: Press the FEED switch 0 times and reopen and close the front cover.

Soft SW Setting Mode: Press the FEED switch 1 time and reopen and close the front cover.

Initial Factory Shipping Mode: Press the FEED switch 2 times and reopen and close

the front cover.

Cut Position Adjustment Mode: Press the FEED switch 3 times and reopen and close

the front cover.

34

Flashing

Press once

HEX Dump Mode

Setting the mode

If the front cover is reopened and closed

in maintenance mode (POWER LED is

flashing), the POWER LED stops flashing

and remains lit, and the printer enters

HEX Dump Mode.

After printing the title, it stands by to

receive data.

To leave HEX Dump Mode, turn off the

printer power then turn the power on again

with the front and rear covers both closed.

Reopening and closing the front cover:

Flashing Lit

Soft SW Setting Mode

Setting the mode

1.If the FEED switch is pressed once in

maintenance mode (POWER LED is

flashing), the POWER LED and PAPER

OUT LED start flashing.

2.If the front cover is reopened and

closed in this status, the POWER LED

and PAPER OUT LED stop flashing to

and remain lit, and after the title and

top items have printed, it enters Soft

SW Setting Mode.

Maintenance Mode

Reopening and closing the front cover:

Flashing Lit

35

Chapter4

Maintenance Mode

Soft SW Setting Mode

Operating method

Press the FEED switch (less than 2 seconds):

The setting changes.

The present set value is changed and the

same item is reprinted. (Press the FEED

switch, and when the buzzer sounds once,

release it.)

Pressing the FEED switch continuously (2

seconds or more):

Moves to the next item.

It prints the present set value of the next

item. (Press the FEED switch, and when the

buzzer sounds three times, release it.)

Opening/closing the front cover:

After saving the set values, it reprints all

items from the top and returns to normal

power on status.

* If the power is turned off without opening

and closing the front cover, the setting

change is invalid.

* If the paper runs out during the change,

set the paper and close the rear cover to

continue the process.

Operations

Press the

FEED Switch

Press and

hold the FEED

Switch

<Soft-Switch Setting>

Press Feed

Change PARM.

Press Feed For 2S

Next Item

F.Cover Open/Close

Save & Exit

<Soft Control-SW>--------------------

Command Type –EPSON

Number of Col. –40/33

Font Select –7

Paper Plies –OFF

Paper End –ENB

Paper Near-End –ENB

Slashed Zero –OFF

Print Direct. –BI-DIR

Auto LF –OFF

Code Page –437

Buffer Size –4K

Init Signal –ENB

Buzzer –ON

<Interface-SW>------------------------

Baud Rate –9600

Data Length –8bit

Parity Bit –NONE

Stop Bit –1bit

Protocol –DTR

<Mechanical-SW>--------------------

Paper Width –76.2

Auto-Cutter –PAR.

Color Ribbon –ON

Take-Up Device –ON

Black Mark –DIS

Command Type –EPSON

Command Type –STAR

Number of Col. –40/33

×

9

36

Press and

hold the FEED

Switch

Font Select –7

×

9

Press the

FEED Switch

Font Select –9

×

9

Example of a change of the Command Type to

STAR and the Font Select to 9×9.

Setting Mode Table

Soft Control-SW

Set item Initial value Setting value Remarks

Command Type EPSON EPSON

Number of Col. 40/33 40/33

Font Select 7x9 7Ω9

Paper Plies OFF OFF

Paper End ENB ENB

Paper Near-End ENB ENB

Slashed Zero OFF OFF

Print Direct. BI-DIR BI-DIR

Auto LF OFF OFF

Code Page 437

STAR

CBM1

CBM2

42/35

9Ω9

DIS

DIS

ON

UNI-DIR

ON

437,

KATAKANA,

850, 860

863, 865

852, 866

857, 858

WPC1252

The emulation is selected from EPSON/STAR/

CBM1/CBM2.

Number of full dot in full column is 200 dots. For the

number of line columns based on the paper width, see

“Setting the Paper Width and Printing Line Column Number”.

The initial font size is selected immediately after the

power is turned on.

Copy mode is selected.

OFF/2P/3P can be selected. But when 3P is set, the

2P

printing speed is low.

3P

The PE signal enabled/disabled is set at paper end when

only the centro-interface is set as enabled. During

enabled status, BUSY, PE, FAULT are output and printing

stops at paper out. During disabled status, only BUSY is

output and printing stops at paper out.

The PE signal enabled/disabled is set at paper near end

when only the centro-interface is set as enabled. During

enabled status, PE, FAULT are output and printing

continues. During disabled status, nothing is output and

printing continues.

It sets whether or not slash is used with the numeral 0

(zero).

Designates printing direction. When BI-DIR is selected,

printing starts from the closer of the left and right ends

of the next printing line from the print stop location.

During UNI-DIR printing is usually done from the left end.

The LF operation during CR code reception is selected.

When ON, LF does not operate; when OFF, LF operates.

CR: Carriage Return LF: Line Feed

The code page is selected.

Maintenance Mode

37

Chapter4

Maintenance Mode

Soft SW Setting Mode

Set item Initial value Setting value Remarks

Buffer Size

Init Signal

Buzzer

4k

ENB

ON

40byte

4Kbyte

ENB

DIS

ON

OFF

The receiving buffer size is selected.

Selects enabled (ENB)/disabled (DIS) of the printer

initialized signal (PRIME) during centro-interface.

Selects enabled (ENB)/disabled (DIS) of the 25pin reset

signal during serial interface.

Selects buzzer sound when an abnormality occurs as

enabled (ON)/disabled (OFF).

Interface-SW (Displayed only when the serial board is mounted)

Set item Initial value Setting value Remarks

Baud Rate

Data Length

Parity Bit

Stop Bit

Protocol

9600

8 bit

NONE

1 bit

DTR

19200

9600

4800

2400

1200

8 bit

7 bit

NONE

EVEN

ODD

1 bit

2 bit

DTR

X-ON-OFF

Sets the baud rate of the serial interface.

Sets the character length of the serial interface.

Sets the communication parity of the serial interface.

Sets the stop bit of the serial interface.

Mechanical-SW

Set item Initial value Setting value Remarks

Paper Width

Auto-Cutter

Color Ribbon

76.2

PAR.

ON

76.2

69.5

57.5

OFF

FREE

FULL

PAR.

ON

OFF

Selects the paper size.

Selects the cutter operation.

When it is OFF, the FULL/PAR. commands do not start

cutting.

In FREE status, cutting is done according to the

FULL/PAR. commands.

In FULL status, full cut is always done by both the

FULL/PAR. commands.

In PAR status, partial cutting is always done by both the

FULL/PAR. commands.

Selects the color function.

During OFF, the change color command is ignored.

38

Set item Initial value Setting value Remarks

g

Take-Up Device

Black Mark

ON

DIS

ON

OFF

DIS

TYPE1

TYPE2

Selects the rewinder function.

During OFF, the rewinder motor does not operate.

Selects enabled (TYPE1, TYPE2)/disabled (DIS) of the

black mark control function.

In TYPE1 status, auto paper length measuring operation

is done and the black mark is fed to the paper cut

position when the power is turned on.

GS FF/FF commands are available in the status.

It is used for formatting the black mark at the edge of

the page.

In TYPE2 status, measuring operation is not done when

the power is turned on.

The auto paper length paper measuring, initial paper

positioning and paper cutting operations are controlled

by the command from a host PC.

FS(L command only is available in the status.

It is used for formatting the black mark in the middle of

the page. (TYPE2 status is not available in STAR and

CBM1/2 modes.)

Concerning Mechanical-SW operation

Functions that are not supported by the specifications at time of shipping have no

impact on printer operation even when the settings are changed.

Examples)Items set for the Auto-Cutter in models that are not equipped with an

Auto-Cutter.

Change of the setting of the Take-Up Device in models to which rewinder

specifications do not apply.

Maintenance Mode

Concerning Auto-Cutter operation

The minimum cutting interval is 1/2 inch (3 lines with 6LPI).

Once a cut command has been executed, even if a command is sent before the paper

has fed at least 1/2 inch, the cut command is ignored so the cut action cannot be

executed.

Initial Factory Shipping Mode

Setting the mode

1.Pressing the FEED switch twice in

maintenance mode (POWER LED is

flashing) causes the POWER LED, PAPER

OUT LED, and the ERROR LED to begin

to flash.

Flashin

Press twice

39

Chapter4

g

Maintenance Mode

Initial Factory Shipping Mode

2. Reopening and closing the front cover in

this status switches the POWER LED,

PAPER OUT LED, and the ERROR LED

from flashing to continuously lit status.

3. Pressing the FEED switch for 3 seconds or

more restores settings to the factory

shipping (initialized) status.

Cut Position Adjustment Mode

Setting the mode

1.Pressing the FEED switch 3 times in

maintenance mode (POWER LED is

flashing) causes the POWER LED and

the ERROR LED to begin to flash.

2.Reopening and closing the front cover

in this status switches the POWER LED

and the ERROR LED from flashing to

continuously lit status and enters Cut

Position Adjustment Mode.

Operating Method

Pressing the FEED switch (less than 2

seconds):

The present value is changed in units of

±1/144.

Opening and closing the front cover:

The ± of the adjustment direction changes.

Immediately after entering adjustment

mode, the value is changed in the +

direction. Opening then closing the front

cover changes the ± of the adjusted value.

Reopening and closing the front cover:

Flashing Lit

Flashin

Reopening and closing the front cover:

Flashing Lit

Pressing and holding the FEED Switch (2

seconds or more):

The present value is saved and the printer

enters normal power on status.

Cutter Amendment : +000

Cut position

Adjustment range: –035 to +035

Initial value: +000

Press 3 times

Paper feed

direction

40

Error Indicators

When this printer malfunctions or jams etc., the type of problem is indicated by a buzzer

and by lit or flashing LED on the operating panel.

In error status, the error indication can be cancelled by pressing the FEED switch.

Error indicator table

Type of Error LED indicator Operation and restoration method

Paper end POWER Lit

PAPER OUT Lit

ERROR Off

Paper near end POWER Lit

PAPER OUT

ERROR Off

Rear/front cover

open

Head hot POWER Lit

HP abnormal POWER

Black mark

abnormal

Cutter abnormal

position detection

Hardware abnormal

RAM read-write

Hardware abnormal

FROM read-write

24V abnormal POWER Off

POWER Lit

PAPER OUT

ERROR Lit

PAPER OUT

ERROR

PAPER OUT

ERROR

POWER

PAPER OUT

ERROR

POWER

PAPER OUT

ERROR

POWER Off

PAPER OUT

ERROR

POWER Off

PAPER OUT

ERROR

PAPER OUT Off

ERROR

Depends on status

Depends on status

• There are no RS232C communication error or front cover opened/closed detection

indicators.

• If the buzzer setting is OFF in Soft SW Setting Mode, the buzzer does not sound.

: Lit, : Off

During printing, printing stops and the printer goes

offline. Replace the paper and close the cover to

return the printer online.

In centro-interface, when the Paper Near-End on the

Soft SW is set as enabled, PE, FAULT are output and

printing continues. When it is set as disabled, nothing

is output and printing continues.

During printing, printing is immediately stopped and

the printer goes offline. Close the cover to restore the

printer to online status.

Cooling starts. After the temperature has fallen, it is

automatically restored and printing restarts.

The buzzer continues to sound until the error is

cancelled by the FEED switch.

The printer goes offline. Remove the paper jam or

other problem and press the FEED switch to restore

the printer to online status.

The buzzer continues to sound until the error is

cancelled by the FEED switch.

Turn off the power then turn it on again. If the error

continues, notify the dealer where you purchased the

printer or service personnel after turning off the power.

Maintenance Mode

41

Chapter4

Maintenance Mode

Clearing a Paper Jam

Clearing method

1.Turn off the power and open the rear

cover.

If the rear cover cannot be opened

When there is a cutter problem, the

printer may stop with the cutter blade

protruding so that pressing the FEED

switch fails to clear the error. When this

happens, restore the cutter blade

manually by inserting a screwdriver into

the hole on the left side surface of the

rear cover and rotating it, then open

the cover (the blade will be restored

whether you turn it to the left or right).

Turn the screw driver so that the

projections on both ends of the blade

of the cutter are returned to the back

of the printer (direction shown by the

arrow).

End of the blade of the cutter

Rear cover

Front cover

Paper cut bar

2.Remove all the jammed paper

(temporarily remove the roll paper

that is installed in the printer).

3.Close the rear cover and turn on the

power. The auto cutter operation will

be initialized and the error cleared.

Caution

When removing the jammed paper, be

careful not to touch the area around the

print head nor the cutter blade. If you

do you will be burned or cut.

42

Cutter lock clearing screw hole

Trouble Shooting

When there is trouble with this printer, take action to clear up the trouble according

to the following table.

If this action does not clear up the trouble, notify the dealer where you purchased

the printer or service personnel.

Symptom Check Action

Paper jam

1

Rear cover

2

does not open

Check for a jam at the paper

ejection opening. If you cannot

open the rear cover, do check

number 2.

Check to see if the blade of the

auto cutter is protruding.

Remove all the jammed paper.

Remove the roll paper from the printer and put it

back again.

Insert a Phillips screwdriver (+) into the cutter

lock cancel use feed hole on the printer and turn

it clockwise or counter clockwise. (Use a #1

screwdriver.)

Rotate the screwdriver while watching the paper

ejection opening and stop turning it when both

ends of the blade are fully retracted. (→ P.42)

Caution

Do not try to force the rear cover to open. If

you do, the printer will be damaged and you

will be cut by the blade.

Maintenance Mode

Ribbon does

3

not feed

correctly

The paper is

4

not cut

Turn the knob on the ribbon

cassette.

Check to make sure that the

rear cover and front cover are

closed.

After turning the knob until the ribbon feeds

smoothly, reset the ribbon cassette.

If you cannot turn the knob, the ribbon may be

jammed inside the cassette. If the situation does

not improve, replace it with a new ribbon

cassette.

If one of the covers is open, close it. If the paper

still cannot be cut after you have closed the

cover, notify the dealer where you purchased the

printer or service personnel.

43

Chapter5

Printing mode Serial impact dot matrix

Printing direction Bi-directional

Head pins 9 pins (φ: 0.3mm, Pin interval; 1/72inch)

Printing line columns

Font configuration 7Ω9 or 9Ω9 dots

Character types ASCII (96 characters), International characters, Katakana

Panel/switches 1 switch (FEED), 3 LED (POWER/PAPER OUT/ERROR), 1 buzzer

Printing speed Printing: 240CPS (3P paper 200CPS)

Paper feed Friction feed

Paper Types: 1P roll paper

Ribbon Method: special ribbon cassette

Interface Standard model: 2 models, either RS232C or IEEE1284

Emulation ESC/POS (Page mode)

Appendixes

Specifications

Paper width of 76.2mm 40/42 or 33/35 columns

Paper width of 69.5mm 36/40 or 30/32 columns

Paper width of 57.5mm 30/33 or 25/27 columns

200/400 dots (full dot/including half dot)

Code pages:

Through-put: 76.2mm wide, 40 columns (7Ω9+3sp, 6LPI) 5.0LPS

Minimum pitch: 1/144 inch

Paper feed speed: 40LPS (6LPI)

Paper widths: 76.2 / 69.5 / 57.5 (±0.5)mm

Roll diameter: φ30mm to φ83mm

Core diameter: Interior diameter φ10 mm, exterior diameter φ27mm or less

Paper thickness: 1P 0.06 to 0.085mm

* No glue on the core or end of the paper.

Colors: Single color (purple, black), 2 color (black and red)

Life: Purple, approx. 4 million characters (continuous printing at 25°C)

Black, approx. 3 million characters (continuous printing at 25°C)

Red/black, black 1.5 million characters, Red 750,000 characters

CBM mode, STAR mode

437, KATAKANA, 850, 860, 863, 865, 852, 866, 857, 858, WPC1252

69.5mm wide, 36 columns (7Ω9+3sp, 6LPI) 5.4LPS

57.5mm wide, 30 columns (7Ω9+3sp, 6LPI) 6.0LPS

2P copy roll paper (1 original + 1 copy)

3P copy roll paper (1 original + 2 copies)

* When 3P, printing speed falls 16%

+2

–0

Copy paper 0.05 to 0.20mm (total thickness)

But the total thickness that can be cut is from 0.05 to 0.14mm.

44

Data buffer Receiving buffer: 40 or 4K bytes

NV bit image: 128K bytes

User NV memory: 8K

Features Paper-drop-in style

Auto cutter function (full cut/partial cut)

Rewinder function

Black mark sheet compatible

Copy (2P/3P) paper compatible

DKD (Drawer Kick Driver) function

ASB (Auto Status Back) function

Power CD-S500A type

Input: DC24V, 1.0A

CD-S500S type

Input: AC100V–240V, 0.55A–0.35A, 50/60 Hz

Power consumption: 24W

External dimensions Standard model: 156(W) x 247.7(D) Ω 132(H) mm

156 247.7

AC adapter and rewinder equipped model: 156(W) x 277.7(D) Ω 196.7(H) mm

132

156 277.7

Appendixes

196.7

45

Chapter5

Specifications

Appendixes

Printer weight Standard model: 2.20kg

Environmental

conditions

Durability 7.5 million lines (MCBF)

Applicable standard UL, C-UL, FCC Class A, TÜV-GS, CE Marking, CCC

Auto cutter equipped model: 2.30kg

Auto cutter and rewinder equipped model: 2.45kg

But these exclude the AC adapter, AC case, ribbon, and paper.

During operation: Temperature 0 to 50°C

During storage : Temperature –20 to 70°C

90

50

Relative humidity (%)

10

Head lifetime 150 million characters

Cutter lifetime 1 million cuts

Humidity 10 to 90%RH (no condensation)

Humidity 5 to 90%RH (no condensation)

0 35 50

Environmental temperature (°C)

Ribbon Cassette

Cassette shape Single color specification, color (purple) : IR-31P

Two color specification, colors (red/black) : IR-31RB

Lifetime Single color specification, color (purple) : approx. 4 million characters

Two color specification, colors (red/black):

red approx. 750,000 characters/black approx. 1.5 million characters

Be sure to use a recommended ribbon cassette in order to maintain printing quality and

stabilize printer operation.

46

color (black) : IR-31B

color (black) : approx. 3 million characters

Paper

Use the following printing paper in order to maintain printing quality and stabilize paper

feeding.

Roll paper Paper width: 76.2±0.7mm (3±1/36 inch)

Roll diameter: φ30mm to φ83mm

Core diameter: Interior diameter φ10 mm, exterior diameter φ27mm or less

Paper thickness: 0.06 to 0.085mm

Weight: 52.3 to 64.0 g/m

Recommended paper: Register paper (Oji Paper Co., Ltd.) or equivalent

Pressure sensitive

paper

Non-carbon 2P/3P paper, 1 original + 1 copy /2 copies

Paper width: 76.2±0.7mm (3±1/36 inch)

Roll diameter: φ30mm to φ83mm

Core diameter: Interior diameter φ10 mm, exterior diameter φ27mm or less

Paper thickness: 0.05 to 0.20mm

Recommended paper: 2P NCR Super (Mitsubishi Paper Mills Limited) (prints in blue)

69.5±0.6mm (3±1/36 inch)

57.5±0.5mm (2.26±0.02inch)

+2

–0

2

(45 to 55kg/1,000 sheets/788mm x 1,091mm)

69.5±0.6mm (3±1/36 inch)

57.5±0.5mm (2.26±0.02 inch)

But the total thickness that can be cut is from 0.05 to 0.14mm.

or equivalent

(JIS P8124)

+2

–0

Cautions concerning the roll paper

Starting to wind the roll paper (interior end) processing (with center core)

It must not be folded and its internal diameter must be even.

It must not be rolled back.

There must be no glue on its center core.

It must be wound with its printing side facing outwards.

When it is 2P paper, there must be no glue between the top and bottom sheets.

In the case of 3P paper, there must be no glue on the top, middle, or bottom papers.

Use pressure sensitive paper with total thickness no greater than 0.20mm and remember

that the printer will not cut paper with total thickness greater than 0.14mm.

If you use pressure sensitive paper with total thickness greater than 0.14mm, either do

not use the cutter or else rewind the bottom paper with the rewinder to reduce the

total thickness (top paper + middle paper) to 0.14mm or less.

Appendixes

47

Chapter5

Appendixes

Interface

Serial (RS232C) interface

Pin assignment

PIN No. Signal Name Direction Function

1 Frame ground

2 TXD

3 RXD Input Data reception

4 RTS Output Same as DTR (20pin)

6 DSR Input Host reception enabled status HIGH-READY/LOW-NOT READY

7 Signal ground

20 DTR Output Printer READY/BUSY status HIGH-READY/LOW-BUSY

25 INIT Input Printer RESET (1ms or more is higher)

FG

SG

–

Output

–

Data transmission

[During DTR/RTS control]

The printer transmits data after it is confirmed that DSR is high.

(But transmission by DLE EOT, GS a)

[During XON/XOFF control]

Printer does not confirm DSR.

[During DTR/RTS control]

When the printer is in reception enabled status, it is READY, when it is

reception disabled, it is BUSY.

Printer status

1) BUSY until completion of initial settings when the power is turned on

2) BUSY in normal OFFLINE status

3) BUSY in OFFLINE status during PE

4) BUSY in OFFLINE status when other errors occur

5) BUSY when the reception buffer is full

6) BUSY during Self-Print

[During XON/XOFF control]

Always HIGH-READY except under the following conditions

1) Until completion of initial settings when the power is turned on

2) During Self-Print

Buffer Full Control

Reception buffer 40/4K

XON XOFF

Overrun/Buffer size: 16/512 bytes

XOFF cancel size: 8/1536 bytes

48

Connection with HOST

Printer D-Sub25P

1FG

2 TxD

3 RxD

20 DTR

6 DSR

16/512 bytes8/1536 bytes

4 RTS

5 CTS

7SG

25 RESET

Host D-Sub9P

1 DCD

3 TxD

2 RxD

4 DTR

6 DSR

7 RTS

8 CTS

5GD

9 RI/RESET

Parallel (IEEE1284) Interface

Pin assignment

PIN No. Direction

Compatibility Mode

1 Input *Strobe HostCLK HostCLK

2 Input/Output Data0 Data0 Data0

3 Input/Output Data1 Data1 Data1

4 Input/Output Data2 Data2 Data2

5 Input/Output Data3 Data3 Data3

6 Input/Output Data4 Data4 Data4

7 Input/Output Data5 Data5 Data5

8 Input/Output Data6 Data6 Data6

9 Input/Output Data7 Data7 Data7

10 Output *ACK PtrCLK PtrCLK

11 Output BUSY PtrBUSY/Data3,7 PtrBUSY

12 Output PE AckDataReq/Data2,6 AckDataReq

13 Output SELECT Xflag/Data1,5 Xflag

14 Input *AutoFeed HostBUSY HostBUSY

15 – (NC) (ND) (ND)

16 – GND GND GND

17 – F G F G F G

18 Output Logic-H Logic-H Logic-H

19–30 – GND GND GND

31 Input *INIT *INIT *INIT

32 Output *FAULT *DataAvail/Data0,4 *DataAvail

33 – GND (ND) (ND)

34 Output DK_STATUS (ND) (ND)

35 Output +5V (ND) (ND)

36 Input *Select-in 1284-Active 1284-Active

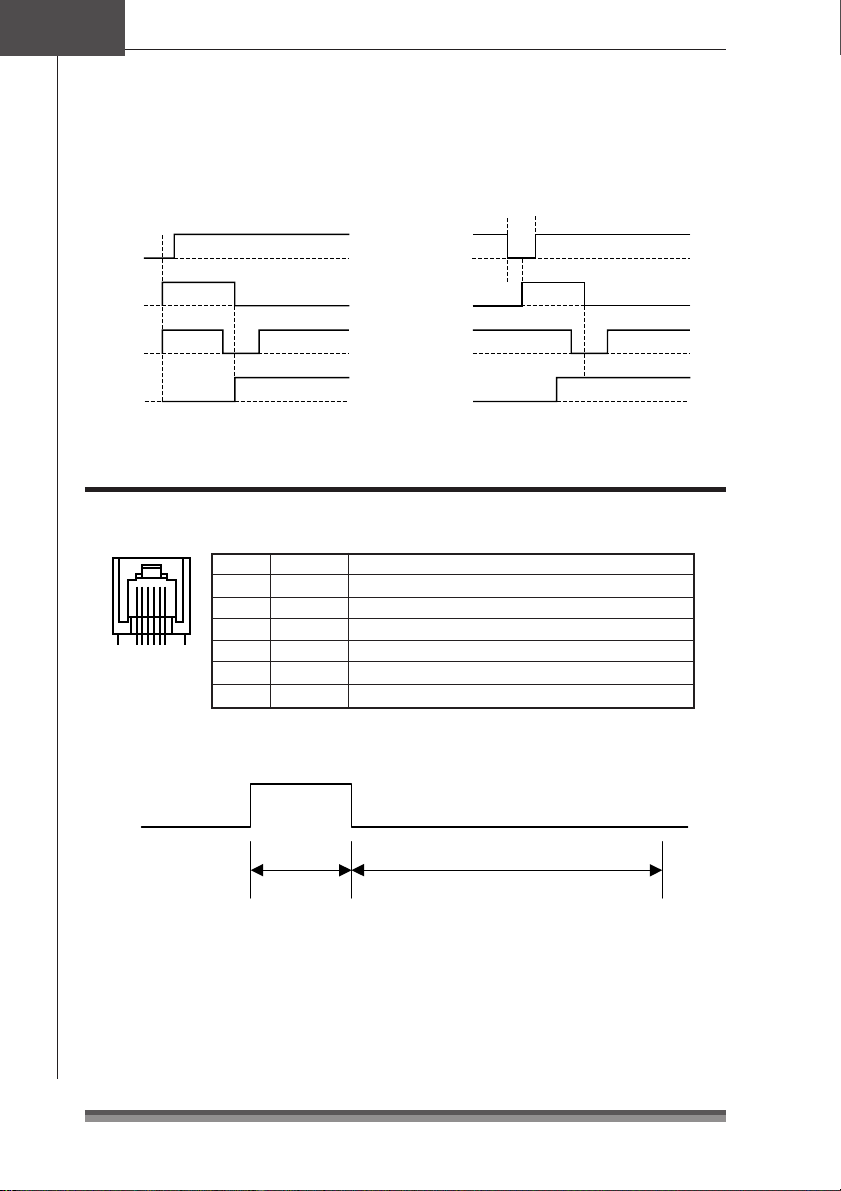

Data Reception Timing

Function

Nibble Mode Byte Mode

(*: Active Low)

Appendixes

Data 1–8

∗STROBE

BUSY

∗ACK

A

C

B

D

EF

A : MIN. 1µs

B : MIN. 1µs

C : MIN. 1µs

D : MAX. 1µs

E : Approx. 3.2µs

F : Approx. 3.2µs

49

Chapter5

Appendixes

Parallel (IEEE1284) Interface

Timing when power is on INIT signal timing

∗RESET

BUSY

∗INT

BUSY

A : More than 16µs

A

B : Less than 200µs

B

∗ACK

SELECT

∗ACK

∗FAULT

Drawer Kick-Out Interface

Pin assignment

PIN No. Direction Function

1 – Frame GND

2 Output Drawer Kick-out Signal 1

3 Input Drawer Open/Close

61

The ESC pm t1 t2 commands select either Drawer Kick-out Signal 1 or 2 to set the

pulse time.

Note:

• T2 (when OFF) ≥ T1 (when ON) Ω4 is satisfied.

• The maximum amperage at +24V is up to 1A. When connected to one that exceeds

1A, the printer and connected equipment may be damaged.

4 – +24V

5 Output Drawer Kick-out Signal 2

6 – Signal GND

T1 x 2ms

When ON

T2 x 2ms

When OFF

50

6-1-12, Tanashi-cho, Nishi-Tokyo-shi, Tokyo 188-8511, JAPAN

Tel: +81-424-68-4608 Fax: +81-424-68-4997

NJ74902-51F Printed in China

Loading...

Loading...