Page 1

DOT MATRIX PRINTER

MODEL CBM920II

User’s Manual

PAPER

FEED

Page 2

WEEE MARK

,I\RXZDQWWRGLVSRVHWKLVSURGXFWGRQRWPL[ZLWKJHQHUDOKRXVHKROGZDVWH7KHUHLVD

En

VHSDUDWHFROOHFWLRQV\VWHPVIRUXVHGHOHFWURQLFVSURGXFWVLQDFFRUGDQFHZLWKOHJLVODWLRQXQGHU

WKH:((('LUHFWLYH'LUHFWLYH(&DQGLVHIIHFWLYHRQO\ZLWKLQ(XURSHDQ8QLRQ

:HQQ6LHGLHVHV3URGXNWHQWVRUJHQZROOHQGDQQWXQ6LHGLHVELWWHQLFKW]XVDPPHQPLWGHP

Ge

+DXVKDOWVPOO(VJLEWLP5DKPHQGHU:((('LUHNWLYHLQQHUKDOEGHU(XURSlLVFKHQ8QLRQ

'LUHNWLYH(&JHVHW]OLFKH%HVWLPPXQJHQIUVHSDUDWH6DPPHOV\VWHPHIUJHEUDXFKWH

HOHNWURQLVFKH*HUlWHXQG3URGXNWH

6LYRXVVRXKDLWH]YRXVGpEDUUDVVHUGHFHWDSSDUHLOQHOHPHWWH]SDVjODSRXEHOOHDYHFYRV

Fr

RUGXUHVPpQDJqUHV,OH[LVWHXQV\VWqPHGHUpFXSpUDWLRQGLVWLQFWSRXUOHVYLHX[DSSDUHLOV

pOHFWURQLTXHVFRQIRUPpPHQW jODOpJLVODWLRQ :(((VXU OHUHF\FODJHGHV GpFKHWVGHV

pTXLSHPHQWVpOHFWULTXHVHWpOHFWURQLTXHV'LUHFWLYH(&TXLHVWXQLTXHPHQWYDODEOH

GDQVOHVSD\VGHO¶8QLRQHXURSpHQQH

/HVDSSDUHLOVHWOHVPDFKLQHVpOHFWULTXHVHWpOHFWURQLTXHVFRQWLHQQHQWVRXYHQWGHVPDWLqUHV

GDQJHUHXVHVSRXUO¶KRPPHHWO¶HQYLURQQHPHQWVLYRXVOHVXWLOLVH]HWYRXVYRXVHQGpEDUUDVVH]

GHIDoRQLQDSSURSULpH

6LGHVHDGHVKDFHUVHGHHVWHSURGXFWRQRORPH]FOHFRQUHVLGXRV GRPpVWLFRVGHFDUiFWHU

Sp

JHQHUDO([LVWHXQVLVWHPDGHUHFRJLGDVHOHFWLYDGHDSDUDWRVHOHFWUyQLFRVXVDGRVVHJ~Q

HVWDEOHFHODOHJLVODFLyQSUHYLVWDSRUOD'LUHFWLYD&(VREUHUHVLGXRVGHDSDUDWRV

HOpFWULFRV\HOHFWUyQLFRV5$((YLJHQWH~QLFDPHQWHHQOD8QLyQ(XURSHD

6HGHVLGHUDWHJHWWDUHYLDTXHVWRSURGRWWRQRQPHVFRODWHORDLULILXWLJHQHULFLGLFDVD(VLVWH

It

XQVLVWHPDGLUDFFROWDVHSDUDWRSHULSURGRWWLHOHWWURQLFLXVDWLLQFRQIRUPLWjDOODOHJLVOD]LRQH

5$(('LUHWWLYD&(YDOLGDVRORDOO¶LQWHUQRGHOO¶8QLRQH(XURSHD

'HSRQHHUGLWSURGXFWQLHWELMKHWJHZRQHKXLVKRXGHOLMNDIYDOZDQQHHUXKHWZLOWYHUZLMGHUHQ(U

Du

EHVWDDWLQJHYROJHGH:(((ULFKWOLMQ5LFKWOLMQ(*HHQVSHFLDDOZHWWHOLMN

YRRUJHVFKUHYHQYHU]DPHOV\VWHHPYRRUJHEUXLNWHHOHNWURQLVFKHSURGXFWHQZHONDOOHHQJHOGW

ELQQHQGH(XURSHVH8QLH

+YLVGXYLOVNLOOHGLJDIPHGGHWWHSURGXNWPnGXLNNHVPLGHGHWXGVDPPHQPHGGLWDOPLQGHOLJH

Da

KXVKROGQLQJVDIIDOG'HUILQGHVHWVHSDUDWLQGVDPOLQJVV\VWHPIRUXGWMHQWHHOHNWURQLVNHSURGXNWHU

LRYHUHQVVWHPPHOVHPHGORYJLYQLQJHQXQGHU:(((GLUHNWLYHWGLUHNWLY(&VRP

NXQHUJOGHQGHLGHQ(XURSLVNH8QLRQ

6HTXLVHUGHLWDUIRUDHVWHSURGXWRQmRRPLVWXUHFRPROL[RFRPXP'HDFRUGRFRPDOHJLVODomR

Por

TXHGHFRUUHGD'LUHFWLYD5(((±5HVtGXRVGH(TXLSDPHQWRV(OpFWULFRVH(OHFWUyQLFRV

&(H[LVWHXPVLVWHPDGHUHFROKDVHSDUDGRSDUDRVHTXLSDPHQWRVHOHFWUyQLFRVIRUDGH

XVRHPYLJRUDSHQDVQD8QLmR(XURSHLD

-HĪHOL]DPLHU]DV]SR]E\üVLĊWHJRSURGXNWXQLHZ\U]XFDMJRUD]HP]H]Z\Ná\PL

Pol

GRPRZ\PLRGSDGNDPL:HGáXJG\UHNW\Z\:((('\UHNW\ZD(&

RERZLą]XMąFHMZ8QLL(XURSHMVNLHMGODXĪ\ZDQ\FKSURGXNWyZHOHNWURQLF]Q\FK

QDOHĪ\VWRVRZDüRGG]LHOQHVSRVRE\XW\OL]DFML

Page 3

Declaration of Conformity

This printer conforms to the following Standards:

Low Voltage Directive 73/23/EEC, 93/68/EEC and the EMC Directive 89/336/EEC,

92/31/EEC, 93/68/EEC.

LVD:EN60950-1

EMC : EN55022 Class A

EN61000-3-2

EN61000-3-3

EN55024

This declaration is applied only for 230V model.

IMPORTANT: This equipment generates, uses, and can radiate radio frequency energy

and if not installed and used in accordance with the instruction manual, may cause

interference to radio communications. It has been tested and found to comply with

the limits for a Class A computing device pursuant to Subpart J of Part 15 of FCC

Rules, which are designed to provide reasonable protection against such interference

when operated in a commercial environment. Operation of this equipment in a

residential area is likely to cause interference, in which case the user at his own

expense will be required to take whatever measures may be necessary to correct

the interference.

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Gerät angebracht und

leicht zugänglich sein.

For Uses in Canada

This Class A digital apparatus complies with Canadian ICES-003.

This digital apparatus does not exceed the class A limits for radio noise emissions

from digital apparatus, as set out in the radio interference regulations of the Canadian

department of communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les émissions

de bruit radio émanant d’appareils numériques, tel que prévu dans les réglements

sur l’interférence radio du départment Canadien des communications.

— 1 —

Page 4

GENERAL PRECAUTIONS

● Before using this product, be sure to read through this manual. After having read

this manual, keep it in a safe, readily accessible place for future reference.

● The information contained herein is subject to change without prior notice.

● Reproduction or transfer of part or all of this document in any means is prohibited

without permission from Citizen Systems.

● Note that Citizen Systems is not responsible for any operation results regardless

of missing, error, or misprinting in this manual.

● Note that Citizen Systems is not responsible for any trouble caused as a result of

using options or consumables that are not specified in this manual.

● Except explained elsewhere in this manual, do not attempt to service, disassemble,

or repair this product.

● Note that Citizen Systems is not responsible for any damage attributable to

incorrect operation/handling or improper operating environments that are not

specified in this manual.

● Data is basically for temporary use and not stored for an extended period of time

or permanently. Please note that Citizen Systems is not responsible for damage

or lost profit resulting from the loss of data caused by accidents, repairs, tests or

other occurrence.

● If you find loss of information, error, or uncertain matter, please contact your

Citizen Systems dealer.

● If you find any disordered or missing page(s), contact your Citizen Systems dealer

for replacement.

CITIZEN is registered trade mark of CITIZEN WATCH CO., LTD., Japan

CITIZEN es una marca registrada de CITIZEN WATCH CO., LTD., Japón

— 1 —

Page 5

SAFETY PRECAUTIONS

In order to prevent injury hazard to operators, third parties or damage to property, special warning

symbols are used in this user’s manual to indicate important items to be strictly observed.

Please be familiar with the following precautions before reading this manual.

● The following describes the degree of hazard and damage that could occur if the printer is

improperly operated by ignoring the instructions indicated by the warning symbols.

-WHICH SHOULD BE STRICTLY OBSERVED

Warning

Caution

This symbol is used to alert your attention to important items.

Neglecting precautions indicated by this symbol may

result in fatal or serious injury.

Neglecting precautions indicated by this symbol may

result in injury or damage to properties.

ORDINARYMAINTENANCE

● Make sure to maintain the equipment after switching OFF the power .

● When cleaning the platen of printer mechanism, wipe out the dirty portion by a cotton

pad dipped intoethyl alcohol.

● When cleaning the surface of the main unit case, use soft cloth. In case the dirty

portion can not becleared out by the soft cloth, use wet cloth squeezed tightly.

Absolutely do not use thinners, truculence,benzene or ketene group solvents, or

chemical-impregnated cleaning cloths.

● At least, leave cleaning of the inside of this equipment to your sales shop once a

year. Using thisequipment keeping dirty without cleaning the insidemay cause a fire

or breakage of the equipment.

— 2 —

Page 6

WARNING

● Never handle the printer in the manners described below; otherwise, it may be

damaged, get out of order or overheated, possibly causing smoke, fire or electric

shock.

If the printer is damaged or breaks down, be sure to turn off the power, disconnect

the power plug from the wall outlet, and contact your CITIZEN SYSTEMS dealer.

• Do not allow the printer to be subjected to any strong impact or shock, such as

stamping, hitting, dropping, and the like.

• Install the printer in a well-ventilated place. Do not use the printer in such a manner

that its ventilation slots are blocked.

• Do not install the printer in a place like a laboratory where chemical reactions are

expected, or in a place where saltish gases are present in the atmosphere.

• Use the printer only on the specified voltage and frequency.

• Do not connect/disconnect the power cord or data cable by holding the cable. Do

not pull or carry the printer in such a manner that undesirable force is applied to

the cables.

• Do not drop or insert any foreign substances, such as paper clips or pins, into the

printer.

•Avoid using excessively long power cord or data cable or multiple connections.

• Do not use power cord or data cable with a scratch or crack or with poor connection.

• Do not spill any liquid on or spray any chemical-containing liquid over the printer.

If any liquid is spilled on the printer, turn it off, disconnect the power cord from the

wall outlet, and contact your CITIZEN SYSTEMS dealer.

• Do not disassemble or modify the printer in any manner; otherwise, a fire or electric

shock may result.

● The plastic bag the printer came in must be disposed of properly or kept away from

children. Wearing it over the head may lead to suffocation.

— 3 —

Page 7

PRECAUTIONS FOR INSTALLATION

● Do not use or store the printer in a place exposed to heat of fire, moisture or direct

sunlight, or in a place where the prescribed operating temperature and humidity are

not met, or in a place exposed to oily mist, iron powder or dust; otherwise, the printer

may get out of order, emit smoke or catch fire.

● Do not install the printer in a place like a laboratory where chemical reactions are

expected, or in a place where saltish gases are present in the atmosphere; otherwise,

there may occur a danger of fire or electric shock.

● Fix the printer to the vertical panel of a sturdy mount in a place with good ventilation

and free from any vibration.

● Avoid installing and using the printer where its operation may be discouraged.

● Do not put any object on the printer, or this may cause a trouble.

● Fix the printer using the bracket and screws supplied with the printer. Tighten the

screws firmly and appropriately. Excessive tightening may result in the malfunction

or breakage of the printer.

● Do not use the printer near a radio or television receiver. Avoid sharing an electrical

outlet with a radio or television receiver, or this may cause a reception problem.

● Use the printer only on the specified voltage and current capacity. Be sure the + pole and

grounding are not connected reversely. Otherwise, the printer may emit smoke or fire.

● Confirm that the wall outlet used for printer connection has sufficient electrical capacity.

● Avoid sharing a single electrical outlet with other devices or using excessively

extended power cord; otherwise, the electrical capacity may be exceeded, causing

the power cord to emit smoke or fire or the power supply to be shut down. Also, do

not stamp on the power cord or put any object on it. Do not use the printer with

excessive stress (tension, load, etc.) applied on the power cord.

● Never connect the grounding cable to a gas pipe, or this may lead to a danger of

explosion. Before connecting or disconnecting the grounding cable, be sure to

disconnect the power plug from the wall outlet.

● Be sure to turn off the power of the printer and the host computer connected before

connecting or disconnecting the cables; always hold both plug and cable. Do not

pull or carry the printer in such a manner that an undesirable load is applied to the

cables.

● Connect the connector cables correctly and securely. Especially, if a connection is

made with the polarity reversed, internal elements inside the printer may be damaged

or the host computer connected may be adversely affected.

● Do not use excessive extension of signal wires or connection to the equipment that

is likely to generate much noise to prevent data from being affected by noise.

● Install and use the printer in a place provided with a suitable wall outlet nearby so

that you can immediately disconnect the power plug to shut off the power to the

printer if an abnormal condition occurs.

● Before transporting the printer, remove the ink ribbon and the paper roll from the

printer.

— 4 —

Page 8

PRECAUTIONS FOR HANDLING

Do not handle the equipment in the following manners, because problems may result.

● Do not print when there is no recording paper or ink ribbon set in the printer.

Otherwise, print head may be damaged.

● Be careful not to drop foreign substances, such as clips, pins, and screws, into the

equipment.

● Do not spill any liquid or spray any chemical-containing liquid over the equipment.

● Do not stamp on, drop, hit, or give a strong shock to the equipment.

● Never use a pointed object, such as a pen, to operate the operation panel.

● Do not use Scotch tape to fasten paper together for continuous use.

● Never pull the set paper forcibly or pull the paper in the direction reverse to the

paper feed direction.

● Replace the ink ribbon before it is broken by overuse. Do not refill the ink ribbon.

● Remove the ribbon cassette when the printer is left unused for a long time.

● Leaving the printer unused for a long time with a ribbon cassette loaded may cause

smudged printing. Continuous printing at low temperature may cause thin printing

due to the characteristic of ink.

● Do not deliver the printer with a ribbon cassette and roll paper loaded.

To Prevent Injury and Spreading of Damage

● Do not touch the printing part of the print head.

● While the equipment power is on, do not touch the moving parts, such as a cutter

and gear, or electric parts inside the equipment.

● Please place neither hand nor the finger when you open and shut the panel.

● Be careful to avoid bodily injure or damaging other objects with an edge of sheet

metal.

● Should any error occur while operating the equipment, stop using it immediately,

disconnect the power plug from the plug socket, and then contact your CITIZEN

SYSTEMS dealer.

● In case of a failure, do not attempt to disassemble the printer. Refer the repair service

to your nearest CITIZEN SYSTEMS dealer or service personnel.

— 5 —

Page 9

THE TABLE OF CONTENTS

1. INTRODUCTION .................................................................................. 8

1.1 Features .................................................................................................... 8

1.2 Accessories ............................................................................................... 8

2. TYPE CLASSIFICATIONS .................................................................... 9

2.1 Type ........................................................................................................... 9

2.2 Power supply ............................................................................................ 9

2.3 Specifications ......................................................................................... 10

3. EXTERNAL APPEARANCE AND PART DESCRIPTIONS................... 11

3.1 External Appearance .............................................................................. 11

3.2 Part Descriptions .................................................................................... 12

4. OPERATIONS ..................................................................................... 13

4.1 Rack Mounting ....................................................................................... 13

4.2 I/F Cable Connection .............................................................................. 14

4.3 Panel Opening/Closing .......................................................................... 15

4.4 Paper Feeding ......................................................................................... 16

4.5 Setting Ribbon Cassette ........................................................................ 16

4.6 Setting Paper .......................................................................................... 17

4.7 Auto Loading Function .......................................................................... 19

4.8 Self-printing Function, Hexadecimal Printing Function ...................... 20

4.9 Memory Switch Setting ......................................................................... 21

4.10 PNE, PE, Other errors ........................................................................... 25

4.11 Clearing Lamp Status, I/F signal status, error, etc. ............................26

4.12 Special Functions ................................................................................. 27

5. PARALLEL INTERFACE ...................................................................... 28

5.1 Specifications ......................................................................................... 28

5.2 Connector Pin Assignment .................................................................... 28

5.3 Description of Input/Output Signals ..................................................... 29

5.4 Electrical Characteristics ........................................................................ 30

6. SERIAL INTERFACE ........................................................................... 31

6.1 Specifications ......................................................................................... 32

6.2 Connector Pin Assignment .................................................................... 31

6.3 Description of Input/Output Signal ....................................................... 32

6.4 Electrical Characteristics ........................................................................ 32

6.5 Error Detection ....................................................................................... 33

— 6 —

Page 10

7. DIP SWITCH (SW1) SETTING ........................................................... 34

7.1 DIP Switch Position ................................................................................ 34

7.2 Parallel Interface Type............................................................................ 34

7.3 Serial Interface Type .............................................................................. 35

8. PRINT CONTROL FUNCTION ........................................................... 36

8.1 List of Control Codes ............................................................................. 36

8.2 Control Code Details .............................................................................. 37

9. CHARACTER CODE TABLE ............................................................... 49

9.1 Code page table ..................................................................................... 49

9.2 International Character Code Table ...................................................... 53

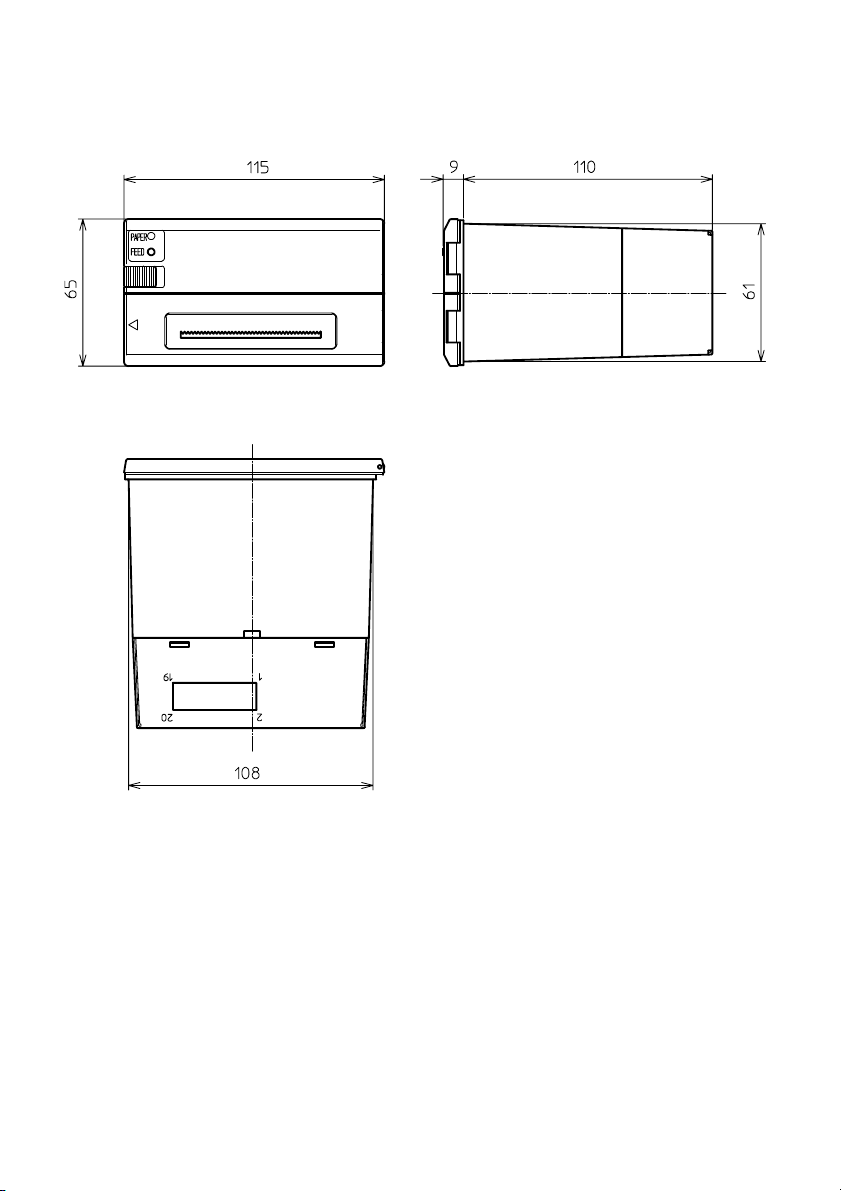

10. EXTERNAL DIMENSIONS ............................................................... 54

— 7 —

Page 11

1. INTRODUCTION

The CBM-920II is a dot-impact printer widely usable with various data communication

terminals, POS terminal and measurement terminals.THE CBM-920II, a compact type

printer with rated into a rack.

This printer, being compact and equipped with extensive functions, is suitable to a

wide range of applications.

Read this manual thoroughly to understand the product before use.

1.1 Features

1. Compact desk-top dot matrix printer

2. Light weight

3. Paper-near-end detecting function

4. Autoloading function

5. Conformity to RS-232C and Centronics.

6. 40 digit 24 print digit number digits/type is prepared.

7. Low price

8. Abundant initialization functions with external switch and internal memory switch

9. CBM-920 emulation

10. CBM-920, iDP3110 emulation selectable

1.2 Accessories

Confirm that the printer is supplied together with the following accessories.

Paper roll (1 roll)

Ribbon cassette (1 unit)

I/F cable (1)

Rack Including mounting brackets (1 unit)

Installation metal fittings fixation screw (2)

Wire clamping (1)

User’s manual (1 booklet)

— 8 —

Page 12

2. TYPE CLASSIFICATIONS

2.1 Type

The product is categorized according to the naming plan indicated below.

CBM-920II

-

24

40

R

P

J

-XXX

F

CBM-920II - 24 R J -XXX

Model Name

OEM spec.

Number of columns

24: 24 columns/144 dots

(MD-910 mechanism use)

40: 40 columns/180 dots

(MD-911 mechanism use)

Interface

R: Serial (RS-232C)

P: Parallel (Conformity to Centronics)

Character set

J: Japan

F: International

2.2 Power supply

Prepare stable power supply having voltage of DC +5V ±5% and current capacity of 2.5A

or more and a peak current of 4 A or more.

NOTE

The power supply of this printer is internally separated in two: one is for control circuit and the

other is for driving mechanism. The supply voltage may be lowered even if the rating of the

power used is sufficient depending on the current consumption during printing or on the length

of the power cord.

In such a case, reconfirming the wiring or power supply used or separating the power supply

for control system and driving mechanism from each other is recommended.

Control power supply (Vcc) DC+5V± 5% 0.2A or more

Driving power supply (Vp) DC+5V±10% 2.5A or more (Peak current 4A or more)

— 9 —

Page 13

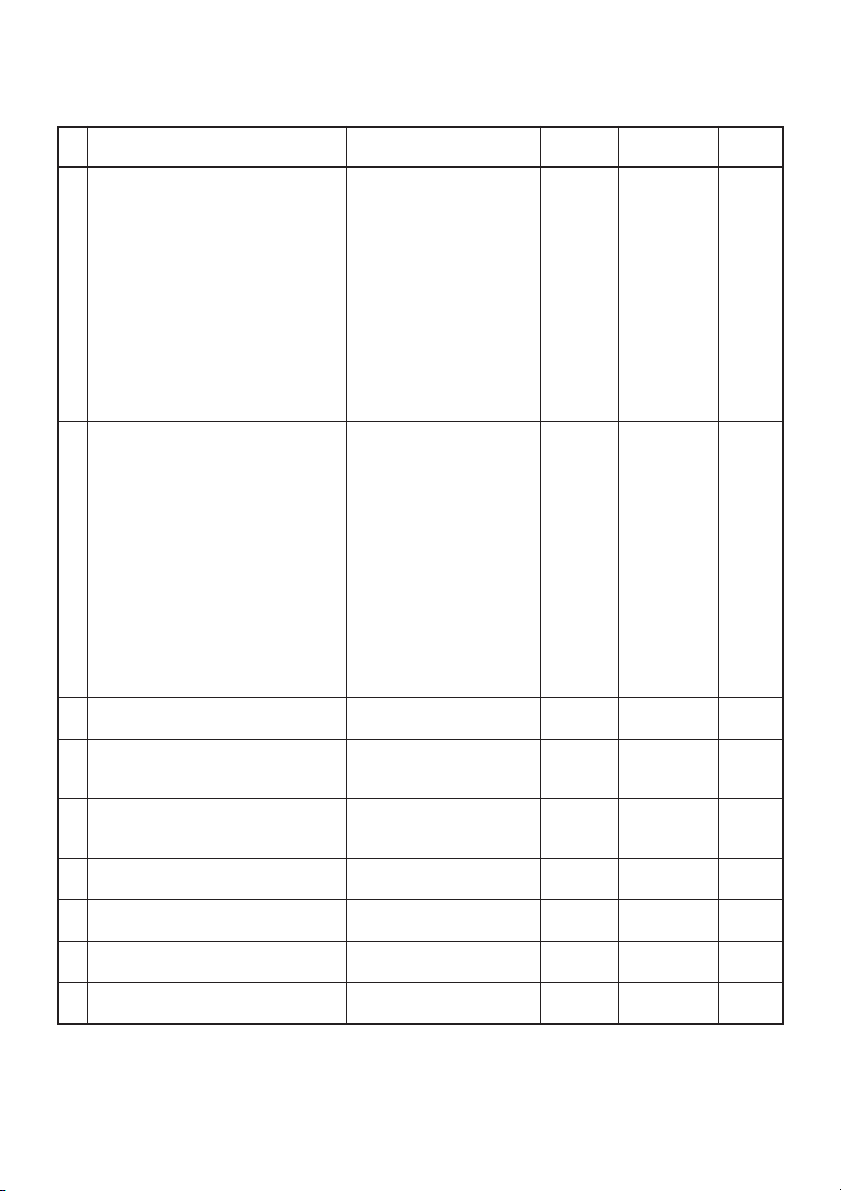

2.3 Specifications

Item CBM-920II-24** CBM-920II-40**

1 Printing method Dot matrix

2 Printing direction One-way printing (normal character, inverted character)

3 Character configuration (W × H) (5 + 1) × 8 (4 + 0.5) × 8

4 Character size (W × H) 1.62 × 2.4 mm 1.08 × 2.4 mm

5 Number of columns per line 24 columns: 144 dots/line 40 columns: 180 dots/line

6 Printing speed Approx. 2.5 lines/sec. Approx. 1.8 lines/sec.

7 Character spacing 1.98 mm 1.19 mm

8 Line pitch 3.52 mm

9 Paper feed speed Approx. 5 lines/s Approx. 3.6 lines/s

10 Paper Single sheet (Thickness: 0.09 mm or less)

11 Interface Serial Interface (RS-232C) or Parallel Interface (Conformity to

12 Input buffer 2k bytes/72 bytes (Selectable by memory SW)

13 Emulation CBM-920 emulation and IDP3110 emulation

14 Code page CP437, 852, 857, 858, 860, 863,865, 866, 869, WPC1252,

15 International character Character of 14 countries is available.

16 Special mode Hexadecimal dump printing, Memory SW setting

17 Paper-near-end detection Detected when printing paper gets scarce.

18 Paper-end detection Printing suspended when printing paper is lost.

19 Autoloading function Feeds paper by a specified amount when printing paper is set.

20 Error detection Mechanical lock error, Memory check error, Low voltage/High

21 Ink ribbon Black (Dedicated ribbon cassette)

22 Voltage Control system: DC5V ±5% (0.2A)

23 Power consumption Printing: Approx. 7 VA (Duty: 12%)

24 Weight Approx. 500 g (Including mounting brackets, ribbon cassette)

25 Reliability MCBF: Approx. 1.5 million lines MCBF: Approx. 1 million lines

26 Dimension 115 (W) × 65 (H) × 119( D) mm

27 Panel installation hole size 109 (W) × 62 (H) +0 mm, -0.5mm

28 Operating temperature and 0 to 40°C, 35 to 85% RH (without condensation)

humidity

29 Storage temperature and –20 to 60°C, 10 to 90% RH (without condensation)

humidity

30 Safety standard UL (RU), TUV-TUV, CE-Marking

Paper roll: 57.5 ±0.5 (W) × φ50 mm

Core ID: φ12 ±1 mm Core OD: φ18 ±1 mm

Centronics)

(selectable with memory SW)

Katakana, CBM-920 emulation (Japan, International), Blank page

voltage error

Service life: Approx. 200,000 letters

Driving system: DC5V ±10% (Approx. 2.5A, Approx. 4A peak)

* The user is requested to prepare external power supply.

Stand-by: Approx. 0.5 VA

VCCI Class A, FCC Class A

— 10 —

Page 14

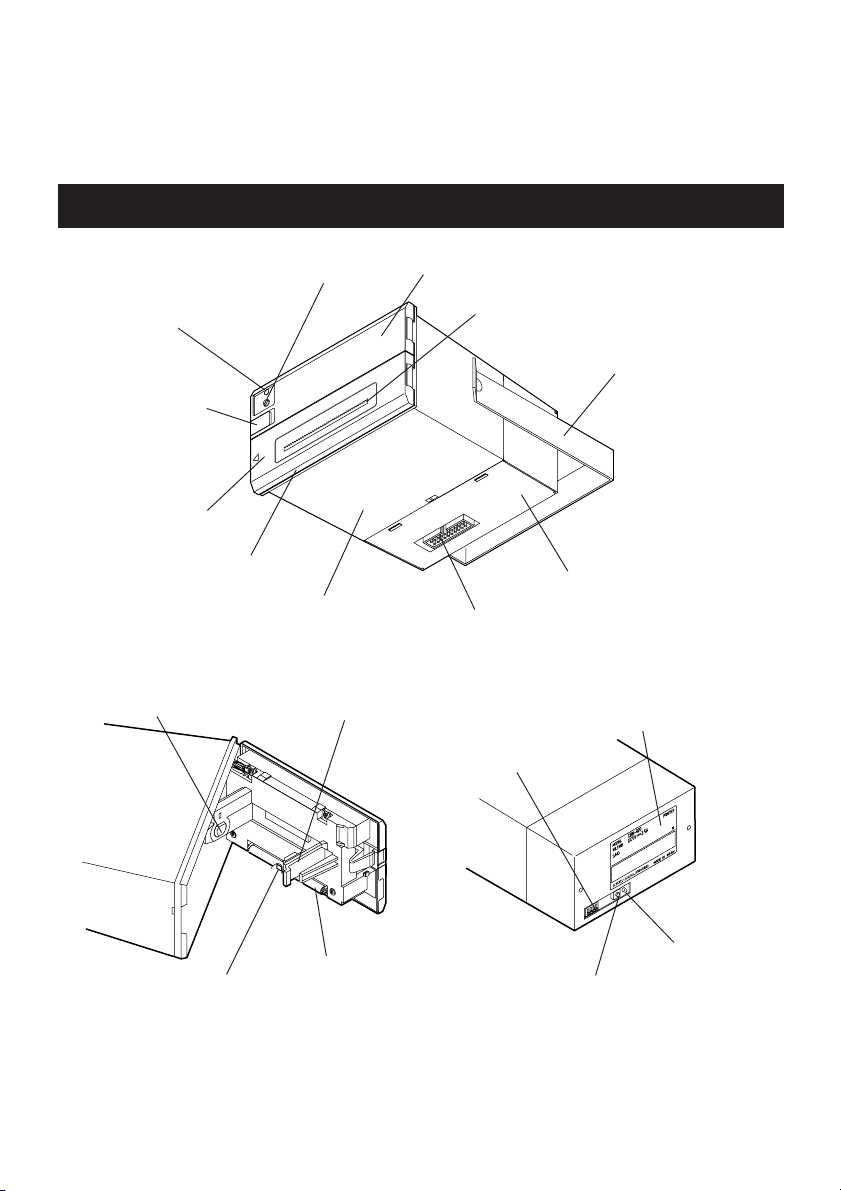

3. EXTERNAL APPEARANCE AND

PART DESCRIPTIONS

3.1 External Appearance

(3) Paper lamp

(4) Knob

(5) Ribbon cover

(8) PNE sensor

(2) FEED switch

E

P

A

P

D

E

E

F

Fixed axis

R

Case

(6) Paper holder

Front cover

Paper cutting part

(12) Mounting bracket

Rear cover

(1) I/F connector

Ratings seal

(9) DIP switch (SW1)

(7) PE sensor

Roller

(11) POWER lamp

(10) Back switch

— 11 —

Page 15

3.2 Part Descriptions

(1) I/F connector Printer can be connected to the signal line of various kinds

Interface connector

(

(2) FEED switch Paper is fed while this switch is pressed and held.

(3) Power lamp Lights/blinks when the paper has become scarce or run out.

(4) Knob Used to set paper or to open the front cover when setting

(5) Ribbon cover Opened/closed when replacing the ink ribbon cassette. Can

(6) Paper holder Printing paper is set and fixed here.

(7) PE sensor Detects no paper condition.

of host via a cable. Please ensure that both the printer and

)

the host are turned off before connecting or disconnecting.

This connector also has a power input.

Connect the FG terminal to the earth.

Cable connected differs with the interface.

Turning the printer power on while pressing and holding

this switch causes self-printing to start.

In the memory switch setting mode, various kinds of setting

are available by pressing this switch.

The lighting status depends on the memory switch setting.

Blinks when mechanism error or the like occurs depending

on the condition of memory switch setting.

or replacing paper.

open when you pull the left side of the front face toward

you.

Insert the print paper into the paper inlet and then set the

paper.

(8) PNE sensor Detects paper-low condition.

This function is enabled or disabled depending on the mode

or memory switch setting.

(9) DIP switch (SW1) This switch allows basic initial setting.

(10) Back switch Press this switch to use special function.

(11) POWER lamp Lighted when power is turned ON. Blinks at the occurrence

(12) Mounting bracket A bracket to hold the printer body.

Use this switch before turning on the printer.

This switch is not used in normal operation.

of error or during memory switch setting.

Hold the printer to the panel or the like by using the two

screws supplied.

— 12 —

Page 16

4. OPERATIONS

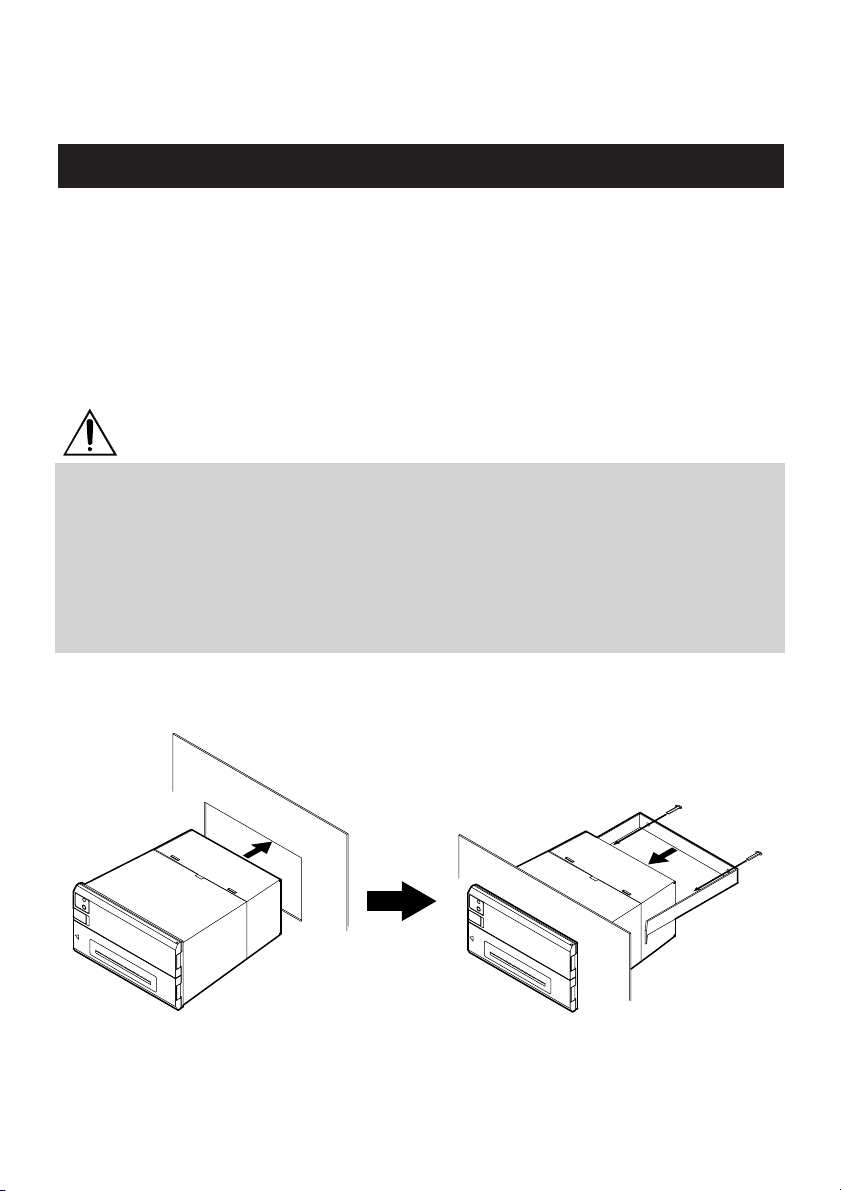

4.1 Rack Mounting

(1) As in the following drawing, insert themain body into the rack.

(2) Inserting the main body on the rear side with mounting bracket, fasten thema in

body with the screws.

Pay attention not to tighten screws excessively.

(3) After fixing, confirm opening/closing of the front panel, etc..

NOTE

The mount (rack, etc.) shall be about 1 to 3 mm in thick.

Use the material that is free from deformation for the mount when the printer is placed to the

mount.

Tighten the screws taking not to give deformation to the printer, bracket, or mount. Excessive

tightening of screw not only provides stress on the printer but also causes failure in the printer.

Recommended mounting hole dimensions

109 (W) x 62 (H) mm

To lerance:+0 mm, -0.5 mm

— 13 —

Page 17

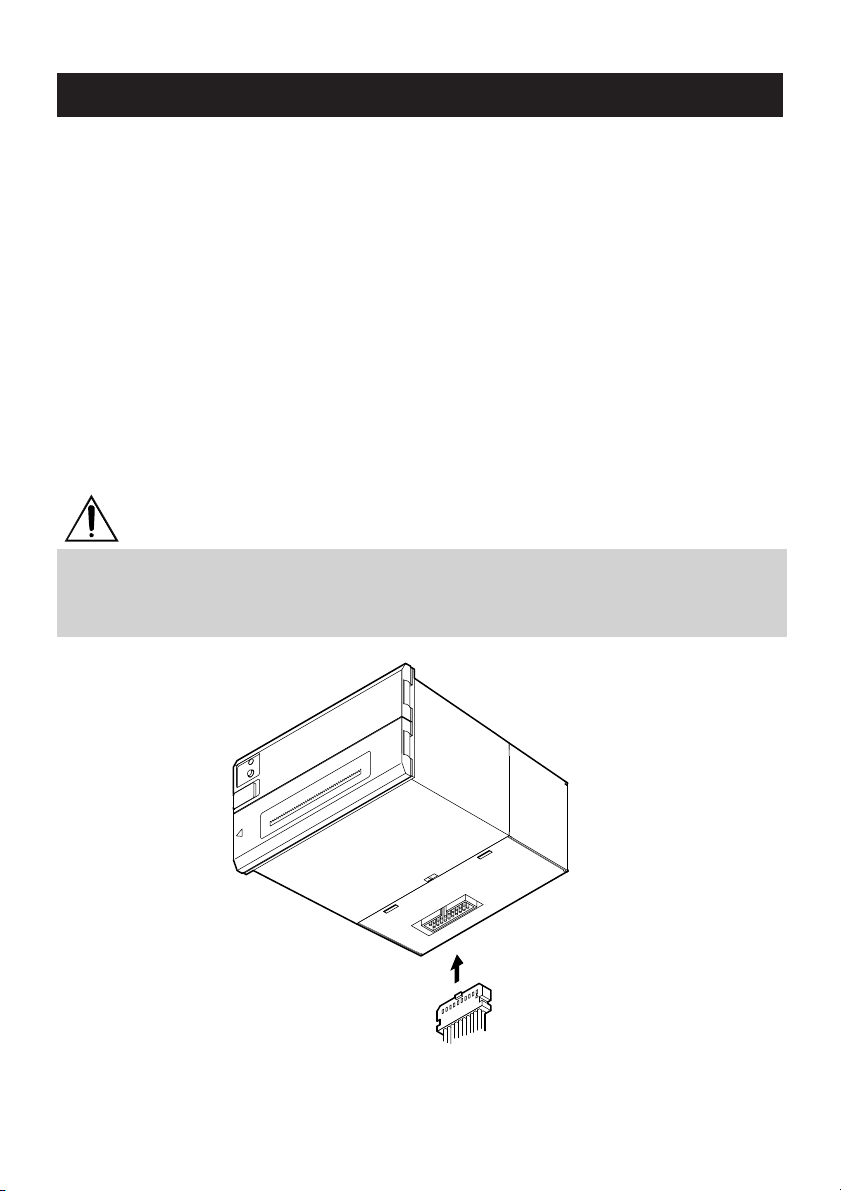

4.2 I/F Cable Connection

(1) Hold the protruding section at the rear of the printer cover and lift in the direction

indicated.

(1) Confirm that themain power supply, etc. are OFF.

(2) Prepare power supply satisfying the power voltage and current capacity having

been specified in the specifications.

(3) Firmly connect, in appropriate direction, the power supply and the main body

through using the attached cable. The connector is at the bottom of the main

body as shown in the drawing. This cable is integrated with the communication

cable. The power cable is larger than the communication cable, which is colored

in red and in orange for +5V use and in black for GND.

(4) Connect a power supply cable to the power supply. Pay attention not to connect

power supply cable in reverse polar.

NOTE

Be sure to connect power cord and interface cable in correct polarity.

Connecting cable in reverse polarity may cause damage not only to the printer but also to the

host.

Hold the connector when connecting or disconnecting the power cord of interface cable.

R

E

P

A

P

D

E

E

F

1

19

2

20

— 14 —

Page 18

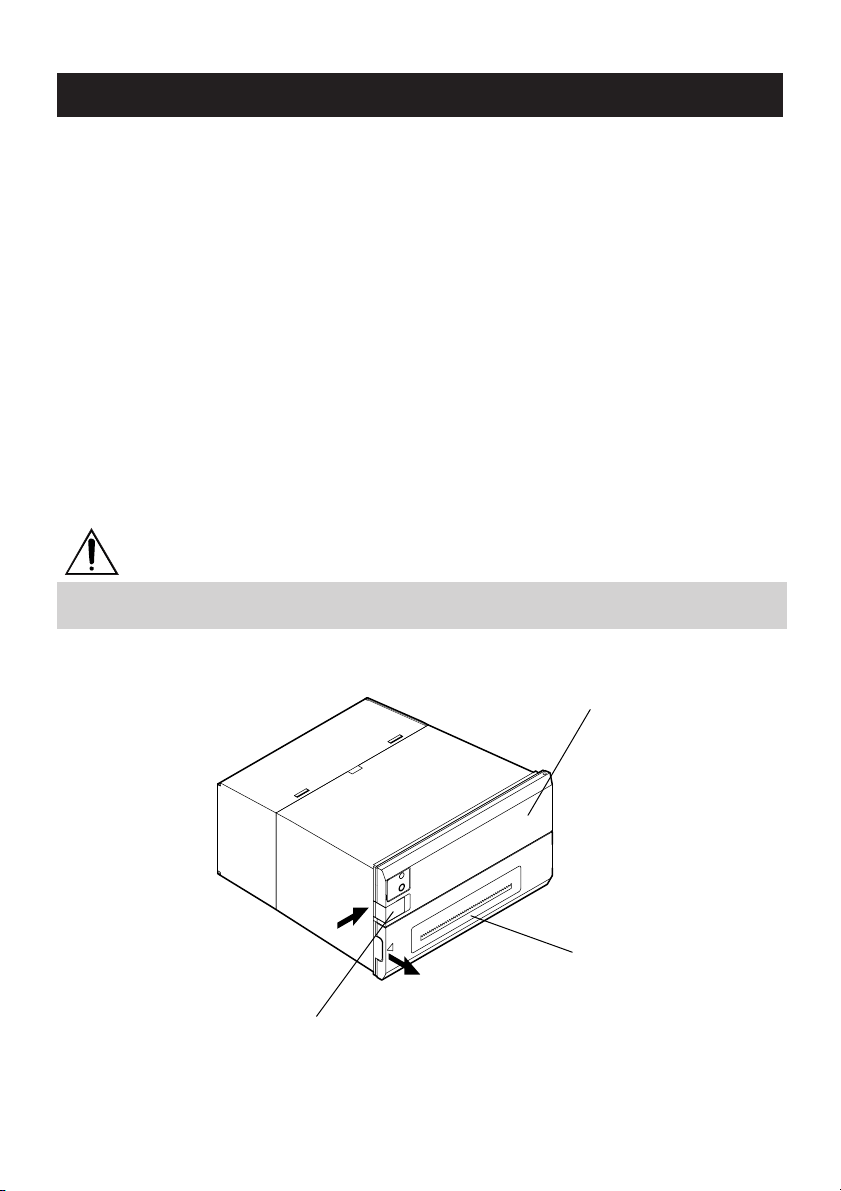

4.3 Panel Opening/Closing

4.3.1 Opening/Closing of Front Panel

(1) Applying your finger on the projection on the left side of the front panel,

pull it forward when the lock is released. It opens by about 180° centering

around the fixed axis.

(2) For closing, pressing the front panel, tightly close it until click sound is heard.

Also, confirm, on closing, that paper is free of slackening.

4.3.2 Opening/Closing of Ribbon Cover

(1) When paper is out of the front cover, cut it off.

(2) Applying your finger on the dent on the left side of the ribbon cover, pull it

forward.

It opens by about 180° centering around the fixed axis.

(3) For closing, pressing the ribbon cover, close it tightly.

NOTE

When closing the front cover, be sure not to catch paper. Otherwise, printing fault or printer

malfunction may occur.

Knob

R

E

P

A

P

D

E

E

F

— 15 —

Front cover

Ribbon cover

Page 19

4.4 Paper Feeding

With the FEED switch pressed once, paper is fed by one line.

Paper is fed while it is continuously pressed.

To feed paper, do not pull it forcibly. Use the FEED switch.

During pressing the FEED switch, the data can not be received.

Printing does not start while the switch is pressed. Pressing this switch during printing

does not feed paper.

NOTE

Do not use a pointed object, such as a pen, to press the FEED switch.

Never apply excessive force to the FEED switch.

4.5 Setting Ribbon Cassette

(1) Open the ribbon cover. Be sure to turn off power before opening it.

(2) In case the paper is out from front

cover, cut the paper or remove this

PAPER

FEED

paper.

(3) Confirming the correct direction of a

new ribbon cassette, insert ribbon

between the printing head and the

platen and press cassette down from

the knob side.

PULL

(4) Turning the ribbon cassette knob in the

arrowed direction, remove slack.

(5) On replacing a ribbon cassette, pull it out as holding the "PULL" part.

NOTE

• Leaving the printer for a long time with a ribbon cassette loaded may cause smudged printing.

Continuous printing at low temperature may cause thin printing due to the characteristic of

ink.

• Do not print without ribbon cassette loaded. Otherwise, print head may be damaged.

• Replace the ink ribbon before it is broken by overuse. Do not refill the ink ribbon.

• When setting or removing the ribbon cassette, do not apply excessive force to the ribbon

cassette or printer. Otherwise, printer malfunction may occur.

• Use the specified ink ribbon.

— 16 —

Page 20

4.6 Setting Paper

(1) Open the front panel.

(2) Use the paper with its end cut straight at right angle or obliquely as shown in the

figure.

(3) Set the roll paper while turning the paper holder in the arrow direction and putting

paper roll core onto the holder.

(4) Insert the end of print paper into the paper insertion slot of the printer.

When auto loading function is enabled, paper is loaded automatically.

When auto loading function is disabled, insert the paper into the insertion slot

while pressing and holding the FEED button. Keep the FEED switch held until

paper appears from the paper exit.

(5) Eliminating slack on the printing paper, close the front panel. Be sure not to

catch paper.

(6) When replacing printing paper, remove the core with the paper holder turned in

the arrow direction. Press the FEED switch to remove the paper remained. Do

not pull the paper forcibly when removing paper.

(7) When setting print paper is completed, press the FEED switch once. The printer

returns to data ready and print ready state.

Note that if “Auto clear after paper setting”is set, completing paper setting

operation automatically enters the data ready and print ready state.

OK OK NG NG NG

— 17 —

Page 21

NOTE

• Set the print paper in the correct direction.

• When closing the front panel, be sure not to catch paper. Otherwise, paper jam, etc. may

occur.

• Do not start printing without print paper properly held in the paper holder; otherwise, paper

jam or the like may occur.

• While replacing the paper, do not send data from the host.

• Do not pull the paper in reverse direction of paper feed. This may cause abnormality of print

head.

• In case the paper is set at as skew angle, paper jam may occur. If paper jam occurs, turn off the

power switch and pull out the jammed paper slowly straightforward in the paper feed direction.

• Note that if “Auto clear after paper setting”is set and data is present in the print buffer, print

operation starts automatically after print paper is set.

• Do not use roll paper of φ50 mm or more. Otherwise, paper jam or the like may occur.

NOTES ON PAPER

Shape:

Use the roll paper with the beginning of winding (innermost end of the paper roll)

treated as follows:

(1) No fold and well aligned to inside diameter.

(2) No flap

(3) Not pasted to the paper core (if any).

(4) No colored part facing PNE sensor (Otherwise, variations in PNE sensor

detection may occur.)

Recommended paper:

One-ply paper..... 45 to 55kg / 1,000 sheets / 1091 x 788 mm

Paper roll diameter

(1) With core

Use paper core of f12 mm inner diameter and f18 mm outer diameter.

Using paper core of greater than f18 mm or cone type may have effect on

the PNE sensor.

(2) Without core

Start winding for printing at the position of f12 mm or more. The PNE

sensor starts detection of PNE (Paper Near End) around f20 mm. If you use

a roll paper without core, keep the paper remainder in mind.

If the start of winding is f12 mm or more, print paper may flip flop in the

printer and may affect PNE sensor detection.

— 18 —

Page 22

4.7 Auto Loading Function

This printer is equipped with a function to automatically load paper.

When print paper is inserted into the insertion slot in accordance with “Setting Printing

Paper” causes paper to be fed automatically by a specified amount.

If print paper is skewed or fed abnormally, remove it gently and insert the paper again.

If you do not want to use this function, set this function disabled by using a memory

switch. (Paper insertion is available with the FEED switch.)

If “Auto clear after paper setting” is set, the printer enters the data ready and print

ready state after completing paper setting. Note that printing starts automatically if

print data is present in the receiving buffer.

If “Clear with FEED switch after paper setting” is set, press the FEED switch once after

completing auto loading.

If paper removal is attempted or paper is not inserted correctly during auto loading,

paper feed operation stops. Insert the print paper again.

NOTE

• Do not pull the print paper during auto loading.

• If print paper is not fed by auto loading, remove the print paper and then insert it again.

• Note the direction of the print paper setting.

— 19 —

Page 23

4.8

Turning the printer power on while pressing and holding the FEED switch causes the

following state.

Before operating the FEED switch, confirm that the DIP switch (SW1) No. 4 at the back

of the printer is set to OFF.

• Self-printing function

• Hexadecimal printing function

(1) Self-printing function

(2) Hexadecimal printing function

Self-printing Function, Hexadecimal Printing Function

Prints model name, version, initial setting state, etc.

Prints all data sent from the host in hexadecimal code.

This mode lasts till the printer is turned off.

Turn the printer power on with the FEED switch pressed and held.

Release the FEED switch in 3 seconds after printer power on, and self-printing

starts. After self-printing, normal printing state is restored.

Turn the printer power on with the FEED switch pressed and held for approx. 6

seconds and then release the FEED switch. The printer prints “Hexadecimal

Dump” and then stops.

The printer prints data sent from the host by converting it to hexadecimal code.

If the data received last is less than one line, press the FEED switch to print the

received data. Print data for one line differs depending on the specification

(number of digits).

Example of Self-print:

Example of Hexadecimal print:

— 20 —

Page 24

4.9 Memory Switch Setting

<Memory Switch Initial Setting>

NO. Item Japan (920JPN) International (920Intl)

0 International character selection Japanese U.S.A

1 Code page selection 920 emulation (Japan) 920 emulation (International)

2 Emulation selection CBM920 emulation

3 Ack timing *2 After clearing BUSY (After)

Communication error data processing

4 Paper-near-end selection Valid

5 Power ON state Online

6 Busy signal clear timing *1 CBM-920

7 Input buffer size 2k bytes

8 PE output at PNE *2 Valid

Communication data bit length selection

9 I/F, LED state at PNE I/F+LED

A BUSY at FEED switch ON Invalid

B Auto loading Valid (short)

C Clear after auto loading FEED SW

D Supply voltage check Only at power ON

E Paper lamp CBM920 emulation

*1: Effective only for parallel I/F (P model).

*2: Applicable to parallel I/F (P model).

*3: Applicable to serial I/F (R model).

*3 Replace with 7Fh (7Fh)

*3 8 bits

Memory switch setting can be changed by a command or by manual operation.

a) Change by command

Memory switch can be changed by a command. For details, refer to “8.

Print Control Function”.

When the printer receives the command, it outputs a BUSY signal and enters

memory setting mode. After writing into memory switch, software resetting

is carried out and the receive buffer/print buffer are cleared causing each

set value to return to the initial value and then the contents of the memory

switch(es) are reloaded.

Commands are set one by one. Use care when changing two or more set

values.

— 21 —

Page 25

b) Change by manual operation

Set the DIP switch (SW1) No. 4 at the back of the printer to ON. Turn the

printer power on while pressing and holding the FEED switch.

The printer prints the information on the current memory switch setting

and then enters the Change Setting mode.

In this case, the PAPER lamp and the POWER lamp blink alternatively at 1second intervals and the BUSY signal is outputted.

Using the FEED switch, choose one of the options for each setting item.

Changing setting item

A total of 15 setting items are available.

The printer prints the contents of setting items and current set values on

print paper.

Pressing the FEED switch short causes the setting item to move.

When all the setting items are changed, the re-setting state or writing

(registering) to memory switch state is reached.

To change the value of setting item, press and hold the FEED switch for

more than 1 second. Current set value is printed with a mark “?”.

Changing options

When item to be selected in the setting items is specified, current option is

printer with a mark “?”.

When selecting an option, press the FEED switch short. Specified options

are printed one by one. When the last option is reached, selection is returned

to the first.

To decide the selection, press and hold the FEED switch for more than 1

second.

Setting options is restored to changing setting items.

Writing the setting items to memory switch (registration)

When the last setting item is selected after setting the options of necessary

setting items, the following is printed.

"Short:Retry Long:Write"

Press the FEED switch for more than 1 second. The printer prints the setting

status and writes the status of setting to the memory switch (registration).

After completion of writing, the printer prints a message and then stops.

After memory switch setting, return the DIP switch No. 4 to OFF.

NOTE

Before turning the printer power on again, return the DIP switch No. 4 to OFF. If the printer is

operated normally with that switch set to ON, the printer prints the message.

When you press the FEED switch for more than 1 second, the PAPER lamp changes from blinking

to lighting condition.

Even when transferring to memory setting mode, the printer detects paper end condition or

the like. However, before transferring to this mode, be sure sufficient paper is present in the

printer.

— 22 —

Page 26

<Contents of Memory Switch Setting>

NO. Setting items Options Value*1 Printout of Factory

(Printout in the lower) option setting

0 International character selection U.S.A 0 USA ● *2

country France 1 FRANCE

For international character set,

refer to International Character

Code Table.

1 Code page selection Code page 437 0 CP-437

Codepage katakana 1 Katakana

For code page, refer to Character

Code Table.

2 Emulation selection CBM920 Emulation 0 CBM-920 ●

Emulation iDP3110 Emulation 1 iDP3110

3 ACK Timing Before clearing BUSY 0 Before

ACK Timing *4

3

Communication error data processing

Comm Error

4

Paper-near-end selection Valid 0 Enable ●

PNE Sensor Invalid 1 Disable

5 Power ON state Online 0 Select ●

P-ON Sel *6 Offine 1 Deselect

6 Busy signal clear timing Standard 0 Standard

Busy *7 CBM-920 1 CBM-920 ●

7 Input buffer size 2k bytes 0 2Kbytes ●

Buffer 72bytes 1 72bytes

*5 Replaced with 3Fh 1 3Fh

Germany 2 GERMANY

England 3 U.K.

Denmark 4 DENMARK

Sweden 5 SWEDEN

Italy 6 ITALY

Spain 7 SPAIN

Japan 8 JAPAN ●*3

Norway 9 NORWAY

Denmark 2 10(A) DENMARK2

Spain 11(B) SPAIN2

Latin America 12(C) Ltn.Ame

Korea 13(D) KOREA

Code page 858 2 CP-858

Code page 860 3 CP-860

Code page 863 4 CP-863

Code page 865 5 CP-865

Code page 852 6 CP-852

Code page 866 7 CP-866

Code page 857 8 CP-857

WPC1252 9 Windows

Code page 864 10(A) CP-864

Code page 869 11(B) CP-869

920 Japan 253(C) 920Jpn ●*3

920 International 254(D) 920Intl ●*2

Blank code page 255(E) Space

Before and after clearing BUSY

After clearing BUSY 2 After ●

Ignored 0 Ignore

Replaced with 7Fh 2 7Fh ●

1 Center

— 23 —

Page 27

NO. Setting items Options Value*1 Printout of Factory

(Printout in the lower) option setting

8 PE output at PNE Valid 0 Enable ●

PNE Peout Invalid 1 Disable

8

Communication data bit length selection

Bit Length 7 bits 1 7 bits

9 I/F, LED state at PNE I/F and LED 0 I/F+LED ●

PNE Signal *8 I/F only 1 I/F only

A BUSY at FEED switch ON Invalid 0 Disable ●

FEED SW Busy valid 1 Enable

B Auto loading Short (Few lines) 0 Short ●

AutoLoad Long (Approx 2 times) 1 Long

C Clear after auto loading FEED SW 0 FEED SW ●

AL recover Auto 1 Auto

D Supply voltage check At Power ON 0 PowerON ●

Power Check Always 1 Always

E Paper lamp CBM-920 Emulation 0 CBM-920 ●

Paper LED CBM-920II 1 CBM-920II

*1: Value in () is the one printed as the initial setting items in self-printing.

*2: Initial setting value of overseas specification (F model)

*3: Initial setting value of domestic specification (J model)

*4: Setting item of parallel I/F (P model)

*5: Setting item of serial I/F (R model)

*6: In the offline state, pressing the FEED switch once with power ON sets the online state.

*7: Only parallel I/F (P mode) functions

Standard: Clear after confirming the start of STB signal.

CBM-920: Clear after completion of storing data to the input buffer.

*8: Indicates that I/F outputs BUSY at the detection of PNE. LED indicates PAPER lamp.

8 bits 0 8 bits ●

LED only 2 LED only

Invalid 2 Disable

For the setting of DIP switches, refer to “7. Setting DIP Switches”.

— 24 —

Page 28

4.10

(1) Paper-near-end (PNE)

When the print paper becomes scarce, the printer detects paper-near-end.

This error occurs when the PNE sensor detects paper-near-end consecutively for

approx. 2 seconds. When the printer detects enough paper for more than 1 second,

the paper-near-end is cleared automatically. The indication and signal status

varies in accordance with the setting status of memory switches 5, 8 and 9.

(2) Paper-end (PE)

If the print paper runs out of paper, the printer detects paper-end. If the printer

detects PE during printing, it stops printing. PE is cleared when new paper is set.

The PAPER lamp lights (blinks) and issues BUSY and PE signals to the host.

(3) Mechanism error (Mechanism alarm)

This alarm is issued when the printer mechanism is locked by paper jam or the

like during printing or paper feeding.

The printer outputs the BUSY and FAULT signals to the host. The PAPER lamp

blinks depending in accordance with the status of memory switch setting.

After removing the error state, press the FEED switch to restore.

If the error state cannot be cleared, turn the printer power off and verify the error

status.

(4) Memory error (RAM error)

This error is issued when error occurs in the memory built in the printer at the

time of printer power on.

The PAPER lamp blinks and outputs BUSY and FAULT to the host.

Turn the printer power off and then turn the printer on. If error still occurs with

the printer power on, this is an unrecoverable error. Contact your nearest CITIZEN

SYSTEMS dealer.

PNE, PE, Other errors

(5) Memory switch error

This error is developed when any abnormality is detected in the setting of memory

switch when the printer is powered on. This error is recovered by resetting the

memory setting and turning the printer power on again.

If the error cannot be recovered even by resetting, turn the printer power off and

contact your nearest CITIZEN SYSTEMS dealer.

(6) Voltage error

This error occurs when the printer detects abnormal supply voltage in mechanism

driving system when the printer power is turned on or during printer operation.

The PAPER lamp blinks and outputs BUSY and FAULT to the host. This is an

unrecoverable error. Turn off the printer immediately.

This error occurs when the fuse for mechanism driving is blown.

For details of the lamp state and interface signal state at the occurrence of error, refer

to the next page.

For serial interface model, read the BUSY signal as DTR signal.

— 25 —

Page 29

4.11

Clearing Lamp Status, I/F signal status, error, etc.

Lamp status and I/F signal status in various states of the printer are as shown below.

Error state may vary a little depending on the printer mode.

Note that the some indication and output status may vary depending on the setting of

memory switch.

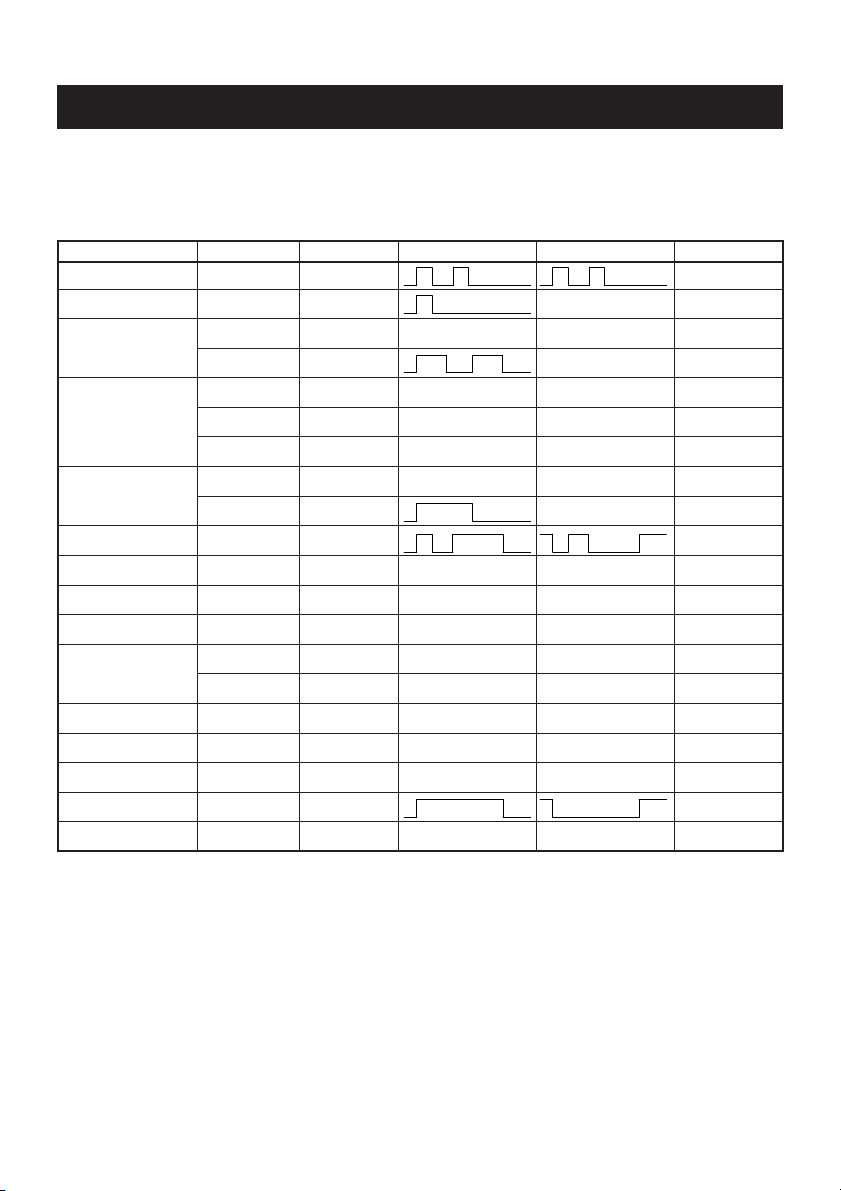

State

RAM error — — — Impossibility BUSY, FAULT

Memory switch error

Mechanism error MSW-E:0 FEED switch Turning off Lights BUSY, FAULT

PNE detection*2 MSW-9:0 PNE clear Lights Lights BUSY, PE *1

PE detection MSW-E:0 PE clear Lights Lights BUSY, PE

Voltage error — — — Impossibility BUSY, FAULT

In auto loading — — — — — — Lights Lights BUSY, PE

PE clear MSW-C:0 FEED switch Lights Lights BUSY

Pressing FEED switch

At power ON MSW-5:1 FEED switch Slow blinking Lights BUSY

Hexadecimal dump setting

Memory switch setting

*Item selection — — — — — — Lights Lights BUSY

*1: Subject to memory switch No.8 setting.

*2: PNE does not function when memory switch No. 4 is disabled.

Memory switch

— — — — — — Lights None

MSW-E:1 FEED switch Lights BUSY, FAULT

MSW-9:1 PNE clear Turning off Lights PE *1

MSW-9:2 PNE clear Lights Lights None

MSW-E:1 PE clear Lights BUSY, PE

MSW-A:0 — — — Turning off Lights None

MSW-A:1 — — — Turning off Lights BUSY

— — — — — — Lights Lights BUSY

— — — — — — BUSY

Return PAPER lamp POWER lamp I/F signal line

— 26 —

Page 30

4.12 Special Functions

This printer allows following printing and setting by using “Back switch” located on

the back of the printer.

(1) In case of normal printing operation

When the printer is ready for printing in normal operation, press and hold this

switch for more than 3 seconds (PAPER lamp lights) and then release it. The

printer prints the detailed status of memory switches currently set.

When pressing and holding this switch for more than 6 seconds and then releasing

it (PAPER lamp goes off), the printer starts self-printing.

(2) In case of memory switch setting

When the printer is ready for selecting items in the state of transferring to memory

switch setting mode, pressing and holding this switch for approx. 3 seconds or

more and then releasing it results in transfer to the last item selection state (state

of re-setting or selecting memory switch writing).

If this switch is pressed for approx. 6 seconds or more and then released, the

memory switch is restored to the initial state. As the initial state is only set in the

setting mode, writing to memory switch is necessary. If the FEED switch is kept

pressed when this switch is released, the printer is initialized to domestic setting.

If the FEED switch is not pressed, the printer is initialized to overseas setting.

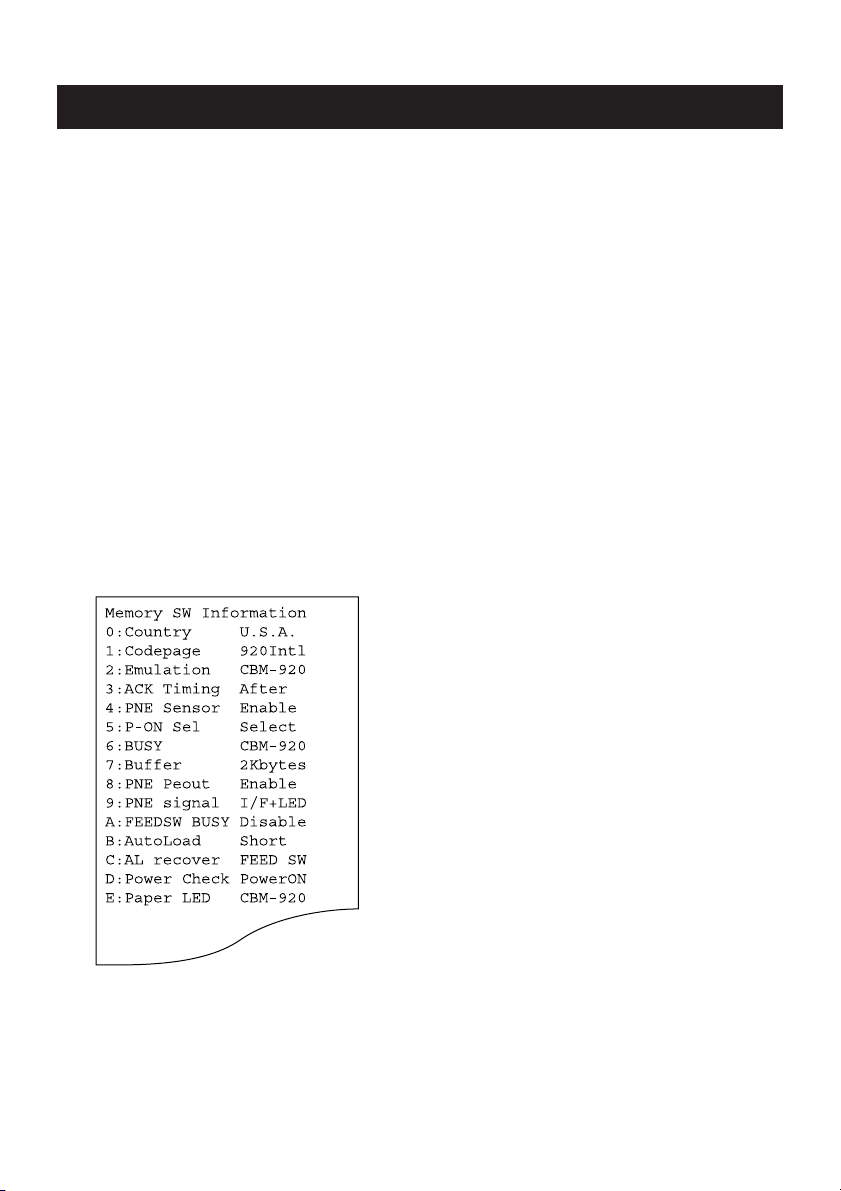

[Printout of memory switch domestic setting]

— 27 —

Page 31

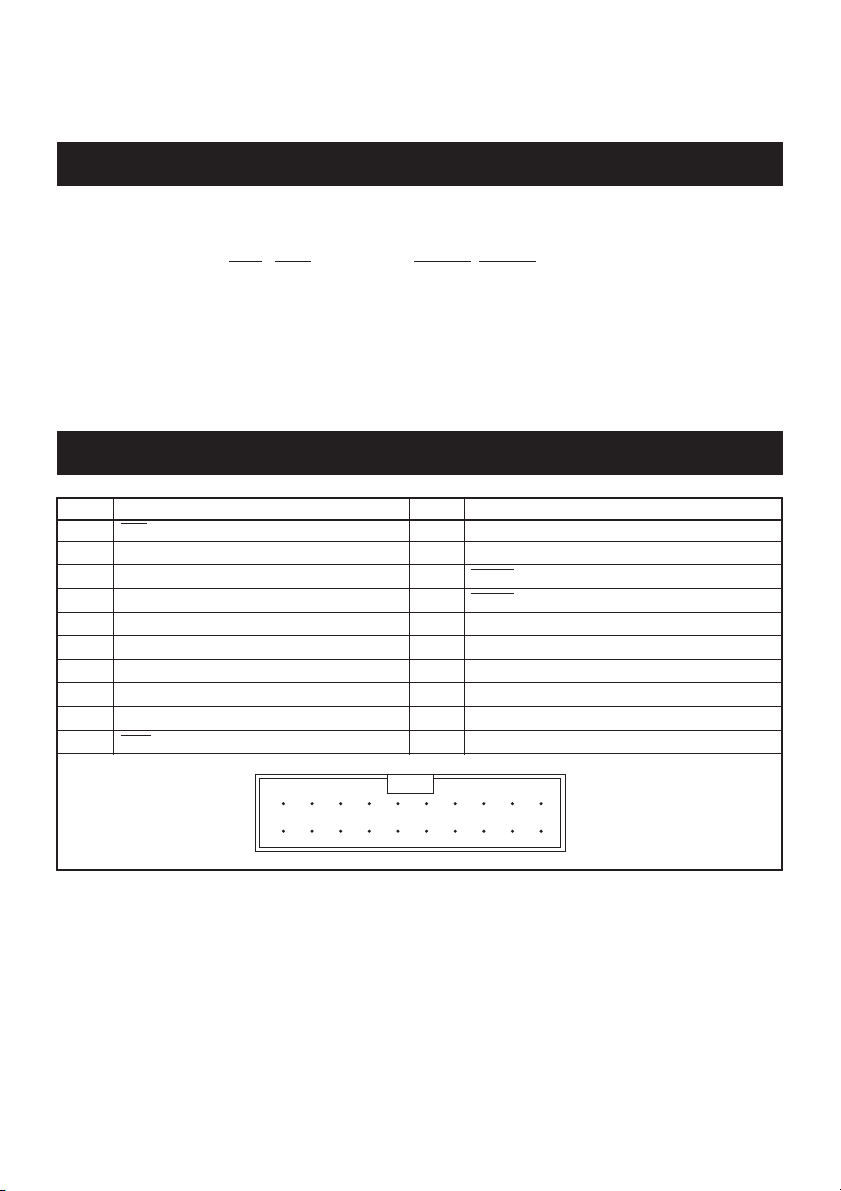

5. PARALLEL INTERFACE

5.1 Specifications

(1) Data input system: 8 bit parallel (DATA 1-8).

(2) Control signal: ACK, STB, BUSY, PE, RESET, FAULT

(3) Power cable: +5V, GND and FG

(4) Compatible connector:

HIF3F-20PA-2.54DS(71) (Hirose Electric compatible)

HIF3C-20D-2.54C (Hirose Electric compatible)

5.2 Connector Pin Assignment

Pin Signal Name Pin Signal Name

1 STB 11 BUSY

2DATA 1 12PE

3DATA 2 13FAULT

4DATA 3 14 RESET

5DATA 4 15 GND (For interface)

6DATA 5 16 FRAME GND (FG)

7DATA 6 17 +5V (For circuit control)

8DATA 7 18 GND (For circuit control)

9DATA 8 19 +5V (For mechanism drive)

10 ACK 20 GND (For mechanism drive)

19

20

1

2

— 28 —

Page 32

5.3 Description of Input/Output Signals

(1) Input signal

•DATA 1 to DATA 8 . . . 8 bit parallel signal (positive logic)

• STB . . . Strobe signal for reading out data (negative logic)

• RESET . . . Signal for resetting the entire unit (negative logic 4 ms or more)

(2) Output signal

•ACK . . . 8 bit data signal for requesting data. ACK is issued at the end of the

• BUSY . . . Signal indicating the printer is busy. Input new data when the signal

• PE . . .Signal that shows form cutting (positive logic)

•FAULT. . . . Signal that shows that trouble like mechanism alarm etc. occurred

(3) Other

• GND . . . Ground commonly used in the circuit

• FRAME GND . . . Frame ground (case ground)

(4) Timing chart

Busy signal timing: Clear timing can be selected by the memory switch.

ACK signal timing: The following kinds of timing can be selected by the memory

switch setting.

BUSY signal (negative logic)

is in “LOW” condition (positive logic)

POWER

DATA

STB

T2

BUSY

ACK

DATA DATA DATA

T1

T3

T1: 2.0us MIN

T2: 500ms MIN

T3: 5us TYP

Busy signal timing: Clear timing can be selected by the memory switch.

ACK signal timing: The following kinds of timing can be selected by the memory

switch setting.

Before

Center

After

BUSY

ACK

BUSY

ACK

BUSY

ACK

T5

— 29 —

T4

T4: 5us TYP

T5: 5us TYP

Page 33

5.4 Electrical Characteristics

(1) Input signal level

The input except RESET are CMOS signal levels. As the input side is pulled up

with a resistance of 10 kΩ, it can be used at TTL level.

CMOS Level TTL Level

“HIGH” level: 4.0 V MIN “HIGH” level: 2.4 V MIN

“LOW” level: 1.0 V MAX “LOW” level: 0.4 V MAX

(2) Output signal level

All inputs are TTL level. As the input side is pulled up with a resistance of 10 kΩ,

it can be used at TTL level.

“HIGH” level: 2.4 V MIN

“LOW” level: 0.4 V MAX

(3) I/O conditions

< HOST SIDE > < PRINTER SIDE >

DATA

STB

RESET

ACK, BUSY, PE, FAULT

10k

10k

330

102 102

5k

104

10k

(HC573 or equivalent)

(HC04 or equivalent)

(7406 or equivalent)

(HC05 or equivalent)

— 30 —

Page 34

6. SERIAL INTERFACE

6.1 Specifications

(1) Synchronization: Asynchronous

(2) Baud rate

1200, 2400, 4800, 9600, 19200 Baud/sec (User selection)

(3) Word configuration

• Start bit: 1 bit

• Data bit: 7 bits or 8 bits (User selection)

• Parity bit: odd, even, no parity (User selection)

• Stop bit: 1 bit or more

(4) Data I/O signal

RxD, TxD (RE-232C)

(5) Control signal

DTR, PE, RESET, FAULT

(6) Signal polarity

RS-232C TTL , CMOS

• Mark = Logic “1” (−3 V to −12V) • H level = Logic “1”

• Space = Logic “0” (+3 V to +12 V) • L level = Logic “0”

(7) Power cable

+5V, GND and FG

(8) Compatible connector:

HIF3F-20PA-2.54DS(71) (Hirose Electric compatible)

HIF3C-20D-2.54C (Hirose Electric compatible)

6.2 Connector Pin Assignment

Pin Signal Name Pin Signal Name

1 to 8 N.C (Unconnection) 15 GND (For interface)

9 RxD 16 FRAME GND (FG)

10 TxD 17 +5V (For circuit control)

11 DTR 18 GND (For circuit control)

12 PE 19 +5V (For mechanism drive)

13 FAULT 20 GND (For mechanism drive)

14 RESET

19

20

— 31 —

1

2

Page 35

6.3 Description of Input/Output Signal

(1) Signal input to printer (RS-232C)

RxD(RECEIVE DATA) . . . Serial receive data signal

(2) Signal input to printer (TTL,CMOS)

RESET. . . Signal for resetting the whole printer (negative logic) 4 ms or more

(3) Signal output from printer (RS-232C)

TxD(TRANSMIT DATA). . .Serial transmit data signal

DTR(DATA TERMINAL READY)

When this signal is Ready (Space), send data or command from the host. If

transmission is made when this signal is Busy (Mark), overrun error occurs.

If the signal is ready even if the printer is in printing operation, data can be

sent to the input buffer.

At the time of printer power on, test printing, reset occurrence, and memory

switch setting, this signal is Busy.

(4) Signal output from printer (TTL,CMOS)

PE. . . Signal indicating end of paper (positive logic)

FAULT. . . Signal indicating occurrence of failure such as mechanism alarm

(negative logic)

(5) Data configuration

One data frame

Mark

t

Space

(1) (2) (4)(3)

b0, b1, b2, ...

6.4 Electrical Characteristics

(1) RS-232C I/O signals (RxD/TxD/DTR)

•Input (RxD), Output (TxD)

Mark = (−8 V): Stop bit

Space = (+8 V): Start bit

• Output (DTR)

Mark = (−8 V): For Busy

Space = (+8 V): For Ready

< printer side > < host side >

(MAX232E compatible) (MAX232E compatible)

— 32 —

(1) Start bit (1 bit)

(2) Data bit (7/8 bits)

(3) Parity bit (0/1 bit)

(4) Stop bit (more than 1 bit)

* Parity bit may or may not be present.

RxD

TxD

DTR

Page 36

(2) TTL circuit (PE/RESET/FAULT)

Input (RESET)

The input signal level is TTL level.

“HIGH” level: 2.4 V MIN

“LOW” level: 0.4 V MAX

RESET

5K

104

(7406 compatible)

Output (RE/FAULT)

The output signal level is TTL level.

“HIGH” level: 2.4 V MIN

“LOW” level: 0.4 V MAX

PE/FAULT

10K

(HC05 compatible)

6.5 Error Detection

This printer detects the following communication errors in the data communication

of serial interface. When any error occurs, the printer converts (or may ignore in

some case) the data at the occurrence of the error to the characters set by the memory

switch and then prints the characters.

• Parity error

Parity error occurs when parity check is specified and parity is not observed in

the even and odd parity checks.

• Framing error

When space state detected on detection of stop bit.

• Overrun error

This error occurs when next data is transferred to receiving buffer though input

buffer is full of data.

RECEIVING CONTROL AND BUFFERING

This equipment controls, on receipt of print data, receiving (DTR Control) in one-word

unit. If the host disregards DTR and carries out data transmission at this time, overrun of receiving data may be resulted. This state should be avoided on the host’s

responsibility. (The data discharging type host cannot follow this.)

— 33 —

Page 37

7. DIP SWITCH (SW1) SETTING

7.1 DIP Switch Position

DIP switch (SW1) is located at the back of the printer as shown in the figure below.

The polarity and part of the function of the switch differs depending on the interface.

For memory switch setting, refer to “4.9 Setting Memory Switches”.

NOTE

Before setting, turn the printer power off.

Do not use edged object, such as a pen, to change the switch.

Serial

1ON2 3 4 5 6 7 8

Parallel

1ON2 3 4

7.2 Parallel Interface Type

Switch No. Function OFF ON Factory Setting

1 Character direction Normal Inverted OFF

2 (920)* CR command Ignore CR CR + LF OFF

2 (3110)* CR command CR LF OFF

3 RESET in Disable Enable ON

4 Memory switch Disable Setting Enable Setting OFF

*: Difference may occur in accordance with the emulation set by the memory switch.

After setting DIP switch No. 4 to ON, turning the printer power on with the SEL switch

pressed and held causes the printer enter the Manual memory switch setting mode.

After manual setting mode, be sure to set this switch to OFF.

— 34 —

Page 38

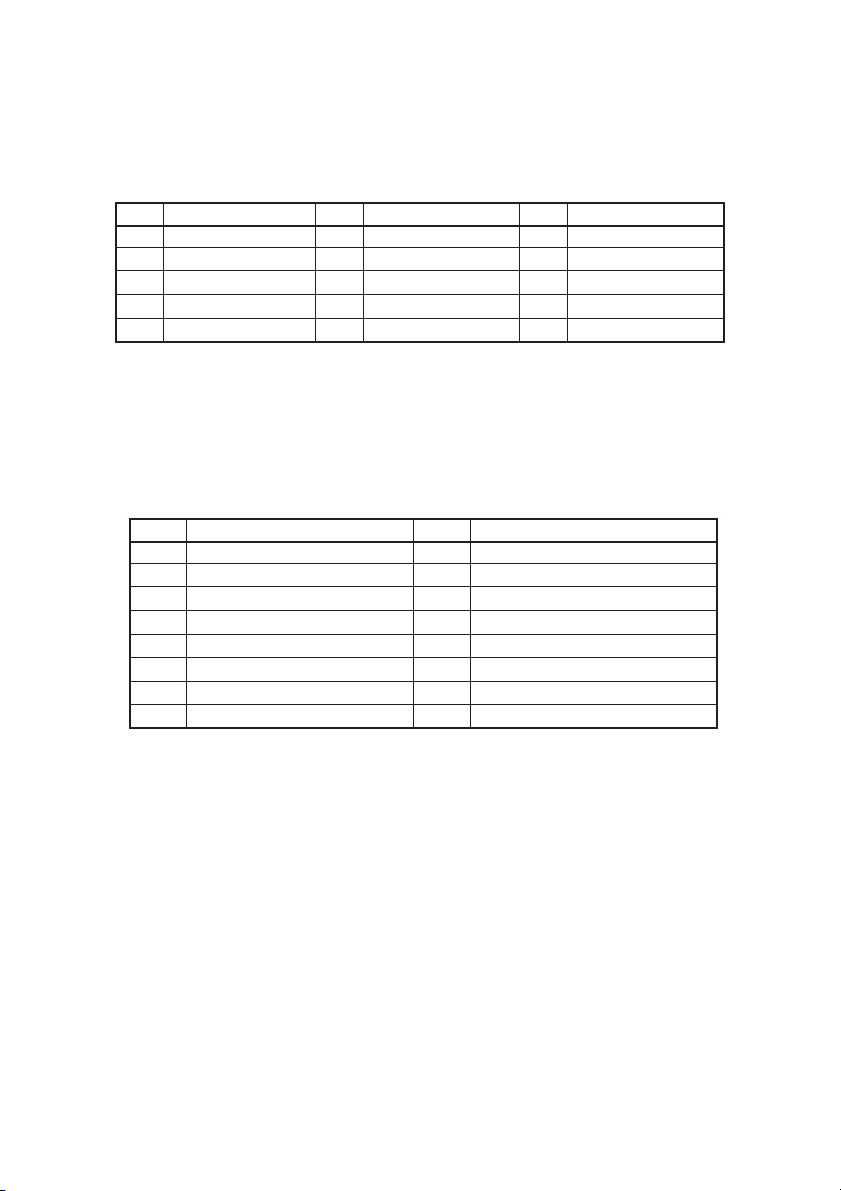

7.3 Serial Interface Type

Switch No. Function OFF ON Factory Setting

1 Character direction Normal Inverted OFF

2 (920)* CR command Ignore CR CR + LF OFF

2 (3110) CR command — — OFF

3 Reset in Disable Enable ON

4 Memory switch Disable Setting Enable Setting OFF

5 OFF

6 OFF

7 OFF

8 OFF

* Difference may occur in accordance with the emulation set by the memory switch.

Set DIP switch No. 4 to ON. Then turn the printer power on while pressing and holding

the FEED switch. The printer enters the manual memory switch setting mode. After

manual setting mode, be sure to set this switch to Off.

Baud rate and parity selection

87 65

OFF OFF OFF OFF 4800 None O

OFF OFF OFF ON 1200 None —

OFF OFF ON OFF 2400 None —

OFF OFF ON ON 4800 None —

OFF ON OFF OFF 9600 None —

OFF ON OFF ON 19200 None —

OFF ON ON OFF 1200 Odd —

OFF ON ON ON 2400 Odd —

ON OFF OFF OFF 4800 Odd —

ON OFF OFF ON 9600 Odd —

ON OFF ON OFF 19200 Odd —

ON OFF ON ON 1200 Even —

ON ON OFF OFF 2400 Even —

ON ON OFF ON 4800 Even —

ON ON ON OFF 9600 Even —

ON ON ON ON 19200 Even —

Transmission rate

and parity

Switch No.

The following reference

Baud Rate

(bps)

Parity Factory Setting

— 35 —

Page 39

8. PRINT CONTROL FUNCTION

8.1 List of Control Codes

Symbol Function No.

LF 0A Line feed after print O*1 O*1 1

CR 0D Carriage return and line feed O*1 O*1 1

SI 0F Normal size character O O 2

SO 0E Double width character O O 2

RS 1E Double width character O — 2

US 1F Normal size character O — 2

CAN 18 Cancel data O — 3

DC2 12 Inverted character O — 4

DC1 11 Initialize O — 5

ESC + “B” 1B, 42 Feed paper continuously O O 6

ESC + “R” 1B, 52 Select international character O O 7

ESC + “t” 1B, 74 Select code page O O 8

ESC + “/” 1B, 2F Register sentence O — 9

ESC + “! ” 1B, 21 Print registered characters O — 10

ESC + “%” 1B, 25 Enable/Disable registered characters O*2 O*2 11

ESC + “&” 1B, 26 Register user-defined character O*3 O*3 12

ESC + “K” 1B, 4B Print bit image O O 13

FS + “W” 1C, 57, 1 Double height and width character / clear O — 14

ESC + “A” 1B, 41 Set line spacing — O 15

DC4 14 Clear double width character — O 2

DC3 13 Power down function O*4 O*4 16

DC2 12 Power down function — O 16

ESC + “) ” 1B, 29, Change memory switch O O 17

*1: Invalid in some case. Refer to the descriptions for “LF” and “CR”

*2: Invalid in some case. Refer to the descriptions for “Enable/Disable registered characters”.

*3: Function differs by the number of printable columns (specification). Refer to the descriptions for

“Register user-defined character”.

*4: Different in function. Refer to the descriptions for “Power down function”.

Code

(Hexadecimal) CBM920 iDP3110

Emulation

— 36 —

Page 40

8.2 Control Code Details

(1) Command for Line Feed After Printing (CR/LF)

By entering CR (0DH)/LF (0AH) codes, data in the print buffer is printed followed

by a line feed. Without data in the print buffer, only a line feed is performed.

This command is ignored just after buffer full in case of 920 emulation.

CR and LF are valid in the following conditions.

CBM-920 Emulation

Serial LF only CR and LF

Parallel LF only CR and LF

iDP3110 Emulation

Serial CR only LF only

Parallel LF only CR only

SW1 Switch No.1

OFF ON

SW2 Switch No.2

OFF ON

(2) Specify/Clear double-width character (SI, SO, US, RS, and DC4) command

SI/SO codes function in the same manner as US/RS as long as 8-bit data are

assigned (serial communication data bit length), which, however, are divided,

under 7-bit assignment, into SI (20H~7FH characters) print assignment and SO

(A0H~FFH characters) print assignment functions.

1. Standard letter assignment (SO/RS) command:

With SI (0FH)/US (1FH) codes input, lateral enlargement is cancelled and

the data following are printed in standard letters. This command can cancel

only lateral enlargement, which dose not apply to ×4 enlargement.

2. Laterally enlarged letter assignment (SO/RS) command:

With SO (0EH)/RS (1EH) codes input in any columns, the data following are

printed in prints enlarged double in width.

Although standard and enlarged letters can be mixed within one line,

automatic (buffer-full) printing takes place when the number of columns

reaches 24 (or 40) counted in standard letters. With 920 emulation, laterally

enlarged letter assignment is cleared by printing after line feed, followed

by SI, US, and DC1. With 3110 emulation, it is cleared by printing after line

feed by LF and CR, followed by SI, US, and DC4.

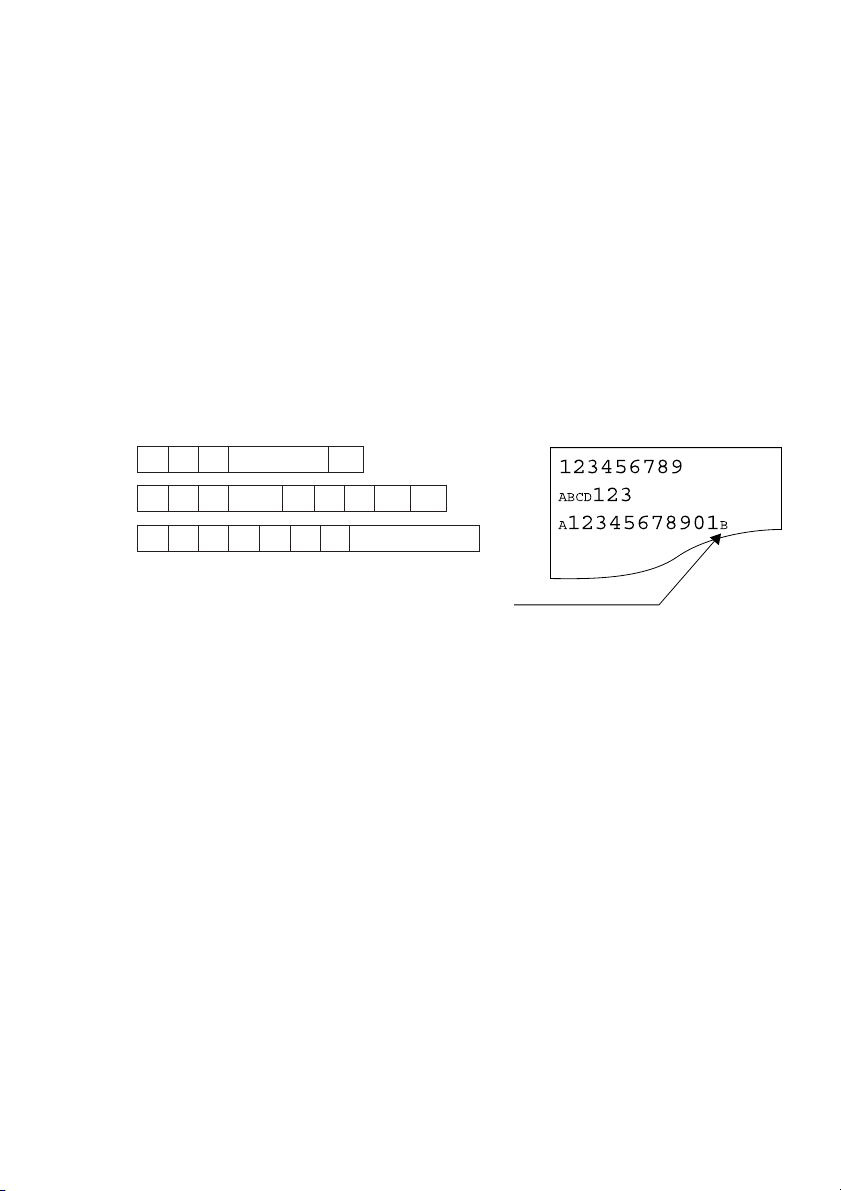

[Example of receive data

(For 24-column model)]

SO

1234567890

SO 123 SI

CR

ABCD CR

SO 123 SI ABCD

SO SO

12345678901B

[Results of Printing]

SO 12 CR

— 37 —

Page 41

(3) Data Cancel (CAN) Command

With CAN (18H) code input, print data held within the line before input of the

CAN code are all cancelled.

[Results of Printing][Example of print data]

CAN ABC CRSO 123456

* As data “123456” are cancelled without the command “SO” cancelled, “ABC”

is printed in lateral enlargement.

(4) Inverted Letter Assignment (DC2) Command

When data are input with DC2 (12H) attached at the beginning of a line (invalid

when attached to any other place), data following are all printed in inverted letters.

To cancel this, input either DC2 again or DC1 (initial setting.)

(5) Initial Setting (DC1) Command

With DC1 (11H) input, various conditions set after power supply are cancelled

and the state as at supply of power is restored.

Content of the input buffer, however, is held unchanged.

(6) Continuous Paper Feed Assignment (ESC + “B”) Command

With ESC (1BH) +“B” (42H) + n code input, continuous paper feed at n-dot line is

executed.

However, n allows continuous paper feed to be executed at even-numbered dot

line in the range of 4 ≤ n ≤ 255. If n is specified otherwise, this command is

cancelled.

When this command is entered, print data, if any, in the input buffer is printed.

Print line (10-dot line) is included in the amount of line feed “n”; therefore, 4 ≤ n

≤ 9 provides a line space of “0”.

ABC

— 38 —

Page 42

(7) International Character Select (ESC + “R”) Command

By entering the code ESC (1BH) + “R” (52H) + n, characters input hereafter are set

to the characters for the following countries.

With n other than those specified, the set value for the U.S. is assigned.

n Country n Country n Country

0 U.S.A. (USA) 5 Sweden (SWE) 10 Denmark 2 (DEM 2)

1 France (FRA) 6 Italy (ITA) 11 Spain 2 (SPN 2)

2 Germany (GER) 7 Spain (SPA) 12 Latin America ( )

3 U.K. (U.K) 8 Japan (JPN) 13 Korea (KOR)

4 Denmark (DEM) 9 Norway (NOR)

Note : International character set at printer power on and after reset signal input

differs depending on the status of memory switch setting.

(8) Codepage Select (ESC + “t”) Command

By the entry of ESC (1BH) + ”t” (74H) + n code, the follwing character code table

can be selected. When n is other than specified, it is set to code page CP437.

n Character Code Table n Character Code Table

0 CP437 (USA,Std-Europe) 8 CP857 (Turkish)

1 Katakana 9 WPC1252 (Win. Latin1)

2 CP858 (Multilingual) 10 CP864 (Arabic)

3 CP860 (Portuguese) 11 CP869 (Greek)

4 CP863 (Canadian-French)

5 CP865 (Nordic) 253 CBM-920 Emulation (Japan)

6 CP852 (Eastern Europe) 254 CBM-920 Emulation (International)

7 CP866 (Russian) 255 Blank page

Note : Code page at printer power on and after reset signal input differs depending

on the status of memory switch setting.

Factory setting for “F” model of character set in model category is CBM920 overseas compatible and that for “J” model is CBM-920 domestic

compatible.

— 39 —

Page 43

(9) Sentence Registration (ESC + “/”) Command

With input of ESC (1BH) + “/” (2FH) + n + ‘registered’ + CR (0DH) / LF (0AH) code,

24 (40)-bytes data following n are registered. Set a numeral of 1~8 to n.

With any other numeral having been set, data following is regarded as print data,

where no registration takes place and printing conducted.

Data cannot exceed one line and must be ended with CR (0DH) or LF (0AH).

To r egister a statement exceeding one line, the statement up to 24 (40) bytes is

registered and the data following is printed out as print data.

The ESC command cannot be registered.

The registered data is cleared when the printer is turned off.

(10) Registered Sentence Printing (ESC + “!” ) Command

With ESC (1BH) + “!” (21H) + n code input, the statement already registered in

the numeral assigned to n is printed.

Assign, to n, a numeral of 1 to 8. With any other numeral having been set, no

execution takes place.

Note 1: As much as 24 (40) bytes of data can be registered. In case that 24 (40)

columns are exceeded on printing (because of enlarged or ×4 letters

having been assigned, etc.), printing is conducted up to 24 (40)th column

and the columns overflowed are printed in the next line. Be sure to

make registration in consideration of printing results.

Note 2: When double height and width character printing or inverted character

printing is executed in registered sentence printing, this setting is active

even after returning to normal printing unless that setting is cancelled.

[Application Example] [Registered State]

CR

CR

CR

Itisapen1

2

3

4

5

6

7

8

ESC / 1

This is a pen

Registered in 1.

ESC / 9

It this a pen ?

No registration made with 9.

ESC / 1

Is this a pen

Overwritten on sentence registered initially in 1.

ESC ! 1

Printing of sentence registered in 1.

[Printing Result]

(Printed without registration)

(Printed with ESC+!+1)

— 40 —

Page 44

(11) Registered Letter Valid/Invalid (ESC + “%”) Command

Whether a registered pattern is valid or invalid is set with ESC (1BH) + ”%” (25H)

+ n code being input.

n = 1 (01H): Registered pattern to be made valid.

(Addresses for which no registration change has been conducted are taken as

inside fixed characters.)

n = 0 (00H): Registered pattern to be made invalid.

(Taken as inside fixed character sets.)

With CBM-920 emulation 40-digit version, to use the registered characters, it is

necessary to set the registered characters to be valid using this command. With

iDP3110 emulation and CBM-920 emulation 24-digit version, the registered

characters are valid at the registration of the user-defined characters without

setting the registered characters to be valid.

To reset to the state where inside fixed characters are usable while registered

characters are valid, it is necessary to disable the registered characters. Command

for setting to invalid operates regardless of the emulation or number of digits.

Registered Characters Enable/Disable Command Set to Valid Set to Invalid

CBM-920 Emulation (40 digits) O O

CBM-920 Emulation (24 digits) × O

iDP3110 Emulation (40 digits) × O

iDP3110 Emulation (24 digits) × O

O: Operation enabled by the Valid/Invalid command of registered characters.

×: As the registered characters are valid by the Register User-defined Character

command, it is not necessary to set the registered characters to be valid.

(12) Character Registration (ESC + “&”) Command

1. For 24-column model (ESC + “&” + A1 + A2)

Individual patterns can be registered by entering the code ESC (1BH) + ”&”

(26H) + A1 + A2, then entering the pattern data.

A maximum of 224 characters can be registered, and any address in the

range of 20H to FFH can be used for the registration. However, if a new

pattern is registered in an address already in use, existing data is cleared

and the newly entered data becomes valid.

[Address setting]

Specified address is matched to the character code and can be accessed

likewise to the stored fixed character record. If a fixed character is defined

in the specified address, the fixed character becomes invalid.

A1 signifies the starting address for the registrations, A2 is the ending

address. When A1<A2 or (A2-A1)>7 is specified, no registration occurs and

data following is treated as print data.

— 41 —

Page 45

[Method of data transmission]

1) Single character registration

Select the address to be defined (character code) from among 20H to

FFH and designate is as A1. When registering a single character,

starting and ending addresses match each other. That is, A1=A2.

<Example>

A 6 × 6 dot matrix full dot pattern is to be registered in address 41H

(code for the fixed character “A”. (Numerals are hexadecimal.)

ESC + “&” + A1 + A2 + “Pattern data (6 bytes)”

1B 36 41 41 FF FF FF FF FF FF

In the successive controls, a 6 × 8 dot matrix full dot is output whenever the

character code 41H is specified. (Character “A” cannot be accessed.)

2) Multiple character registration

By repeating the single character registration, a maximum of 8

characters can be registered. When defining multiple characters in a

successive address (character code), register pattern data for a

maximum of 8 characters by designation A1 as the starting address

and A2 as the ending address.

((A1-A2)+1)x6 bytes are required for pattern data.

Note: A1 < A2, A2 – A1 ≤ 7

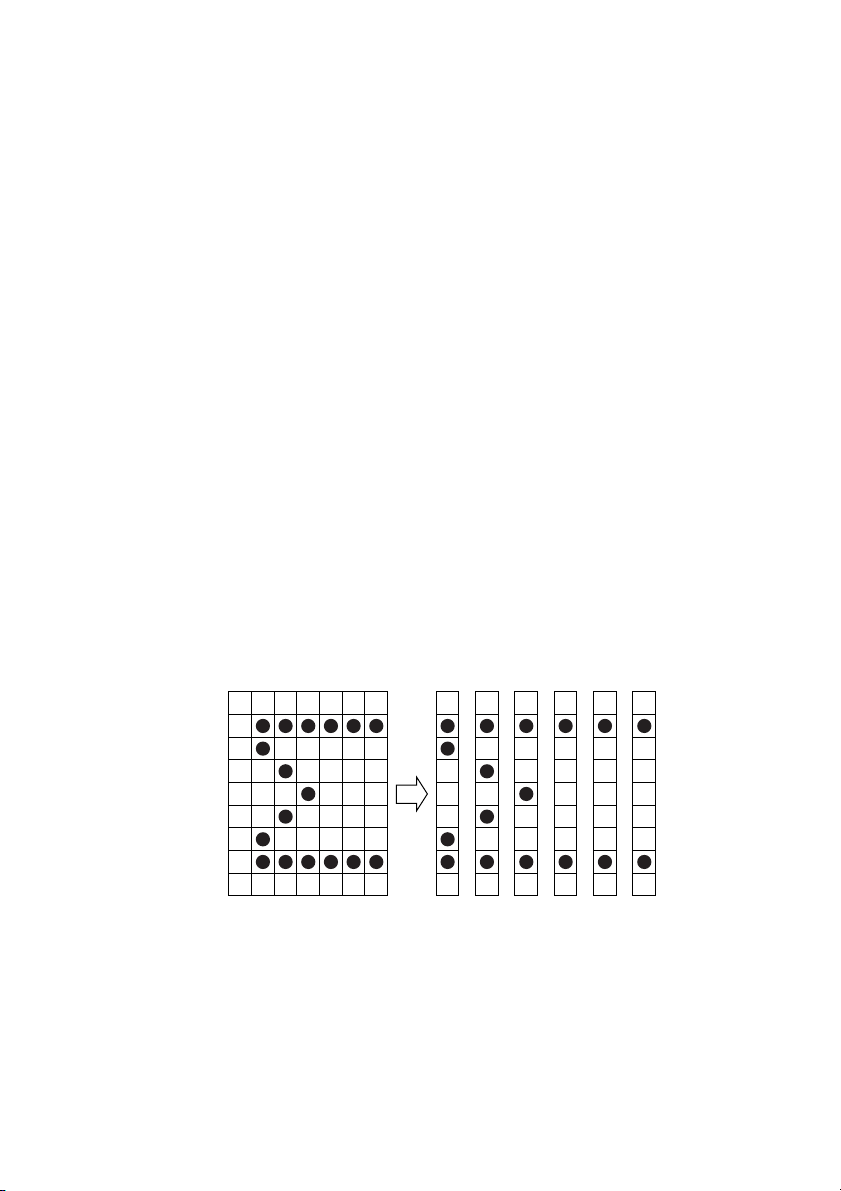

[Pattern data configuration]

Pattern data to be registered must consist of 6 bytes per character. That is,

pattern data configured by a 6 × 8 dot matrix is broken up into 6 vertically

positioned units each of which is represented by 1 byte of data. All together,

6 bytes of data are transmitted.

<Example> When transmitting the following data:

321 654

0

1

2

3

4

5

6

7

1 2 3 4 5 6

[Printing of registered letters]

To print registered character, in the same manner as printing other fixed

characters, use the commands (CR, LF, ESC + B + n).

— 42 —

Page 46

2. For 40-column model

In CBM-920 emulation (ESC + “&” + C1 + A1 + A2)

In iDP3110 emulation (ESC + “&” + A1 + A2)

With ESC (1BH) + ”&” (26H) + {C1} + A1 + A2 code and the pattern data

following input, a pattern is registered. Only CBM-920 emulation is specified

for { }. Up to 224 characters can be registered into addresses from 20H to

FFH. When the same pattern data is registered in the same address, data

registered before is cleared and the new data becomes valid.

[Recognition of use of upper most bit]

For recognition of use or non-use of the uppermost bit by a character to be

registered, set data to Parameter C1.

C1=0 (00H): Uppermost bit not used.

Other than C1=0: Uppermost bit used.

If 0 is set to this parameter regardless of whether most significant bit is

specified, character as imaged cannot be registered.

[Setting of addresses]

A1 : Registration starting address (20H~FFH)

A2 : Registration ending address (20H~FFH)

[Pattern data configuration]

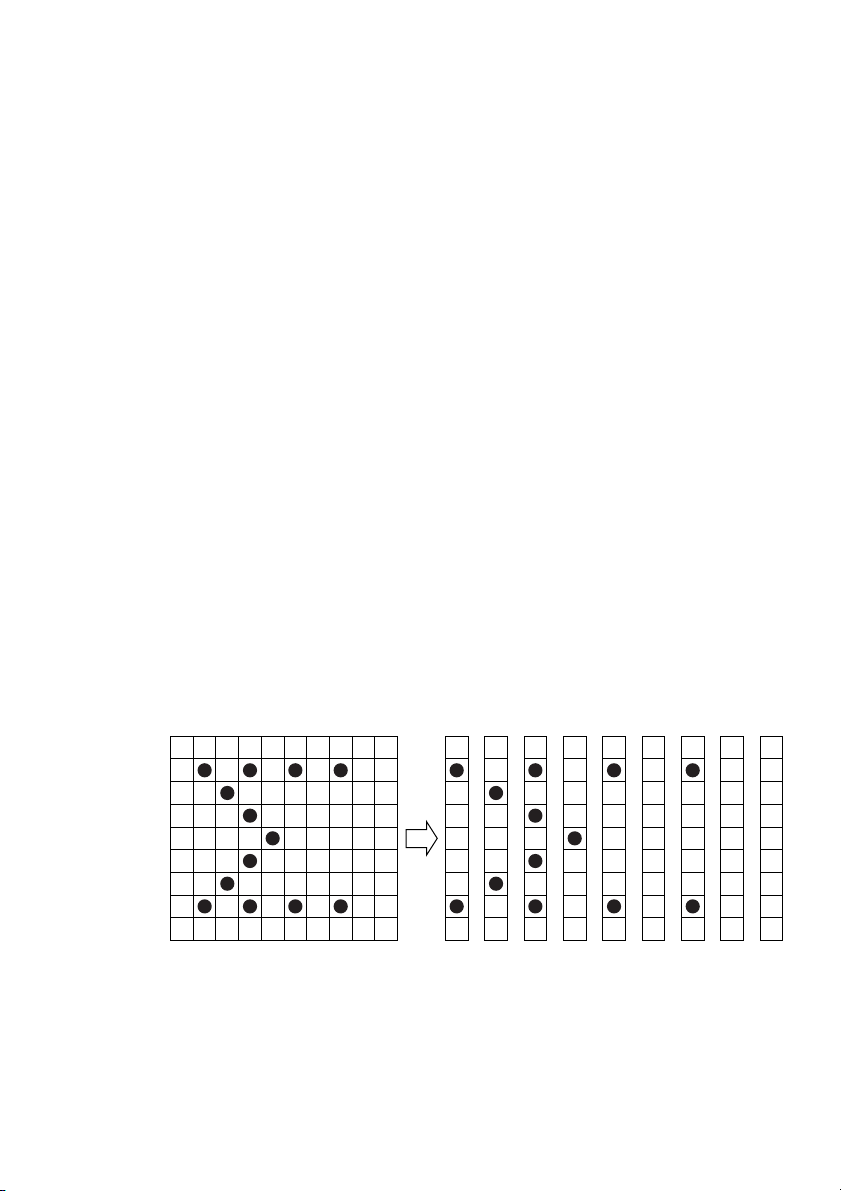

Pattern data to be registered must consist of 9 bytes per character. That is,

pattern data configured by 9 × 8 dot matrix is broken up into 9 vertically

each of which is represented by 1 byte of data. All together, 9 bytes of data

are transmitted.

In case of iDP3110 emulation, blank data is automatically assigned to the

8th and 9th lines and pattern data consisting of 7 bytes is transferred.

<Example> When transmitting the following pattern data:

In CBM-920 emulation

321 654

0

1

2

3

4

5

6

7

— 43 —

1 2 3 4 5 6 7 8 987 9

*

*

*

*

*

*

*

*

41H 22H 55H 08H 41H 00H 41H 00H 00H

*

*

*

*

*

Page 47

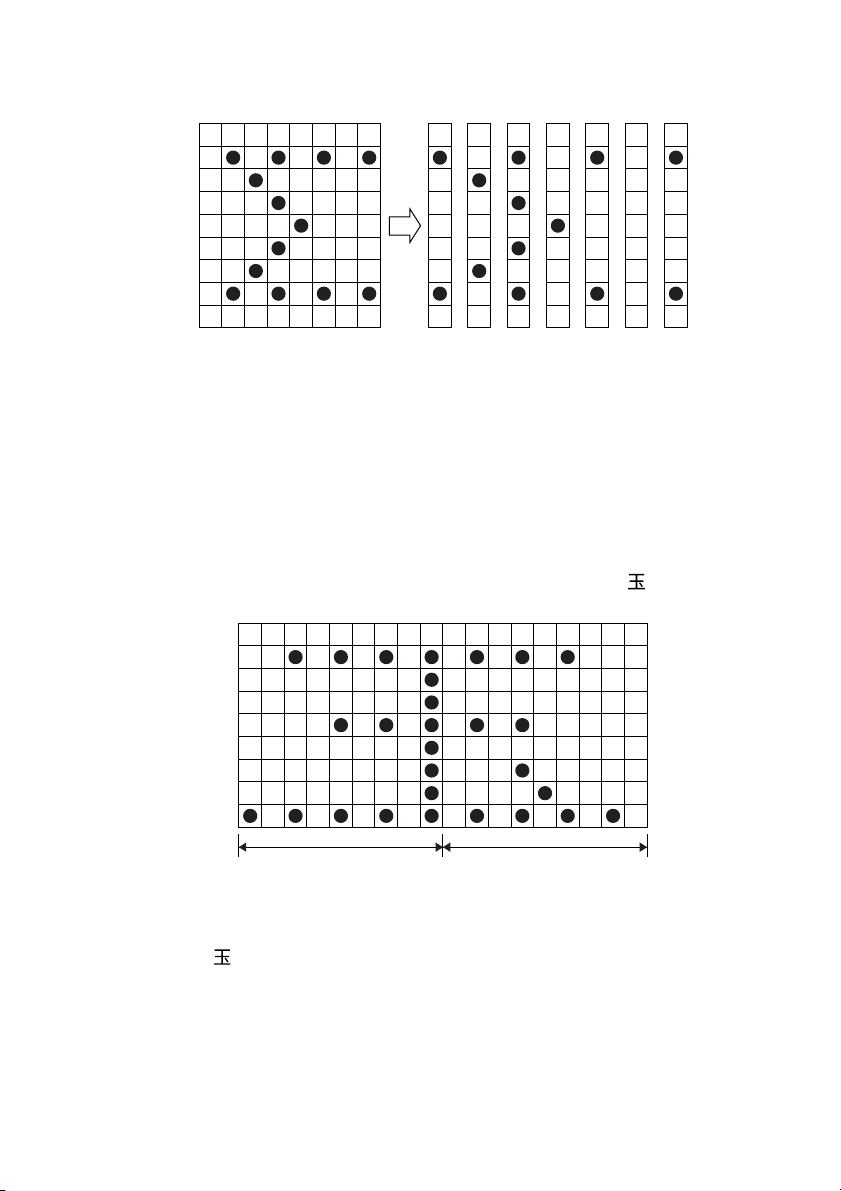

In iDP3110 emulation