CBM-272

— 1 —

Declaration of Conformity

Manufacturer’s Name : Japan CBM Corporation

Manufacturer’s Address : CBM Bldg., 5-68-10, Nakano, Nakano-ku

Tokyo, 164-0001, Japan

Declare the Product

Product Name Line Thermal Printer

Model Number(s) CBM-272 Series

(CBM-272R, CBM-272P)

(S.No.0190001 ~ )

Conform to the following Standards

LVD : EN60950 :

EMC : EN55022 :

: EN61000-3-2 :

: EN61000-3-3 :

: EN55024 :

: EN61000-4-2 :

: EN61000-4-3 :

: EN61000-4-4 :

: EN61000-4-5 :

: EN61000-4-6 :

: EN61000-4-8 :

:

EN61000-4-11: 1994 0%, 5000ms/70%, 500ms/0%, 10ms

Supplementary Information

“The product complies with the requirements of the Low Voltage Directive 73/

23/EEC, 93/68/EEC and the EMC Directive 89/336/EEC, 92/31/EEC, 93/68/EEC”

A4: 1997, A11: 1997

1998 Class A

1995 +A1:1998+A2:1998

1995

1998

1995 ±4KV CD, ±8 KV AD

1996

4.5 V/m, 80 MHz-1000 MHz AM 1 KHz 80 %

1995

±1.0 KV (AC Mains), ±0.5 KV (Signal Lines)

1995

±1 KV (Normal mode), ±2 KV (Common mode)

1996 3 V, 0.15 MHz-80 MHz AM 1 KHz 80 %

1993 50 Hz, 3 A/m

Place Tokyo, Japan Signature

Date August 2001

Full Name : Mikio Moriya

Position : General Manager

R & D Department

European Contact :

Norco Declaration AB

Box 7146 S-250 07 Helsingborg Sweden

Warning : This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

This declaration is applied only for 230 V model.

— i —

IMPORTANT SAFETY INSTRUCTIONS

• Read all of these instructions and save them for future reference.

• Follow all warnings and instructions marked on the product.

• Unplug the product from the wall outlet before cleaning. Do not use liquid or aerosol

cleaners. Use a damp cloth for cleaning.

• Do not use the product near water.

• Do not place the product on an unstable cart, stand or table. The product may fall,

causing serious damage to the product.

• Slots and openings on the back or bottom of the case are provided for ventilation. To

ensure reliable operation of the product and to protect it from overheating, do not

block or cover these openings. The openings should never be blocked by placing the

product on a bed, sofa, rug of other similar surface. The product should never be

placed near or over a radiator or heater. The product should not be placed in a built-in

installation unless proper ventilation is provided.

• The product should be operated from the type of power source indicated on the

marking label. If you are not sure of the type of power available, consult your dealer

or local power company.

• Do not allow anything to rest on the power cord. Do not place the product where the

cord will be walked on.

• If an extension cord is used with the product, make sure that the total of the ampere

ratings of the products plugged into the extension cord does not exceed the extension

cord ampere rating. Also, make sure that the total of all products plugged into the wall

outlet does not exceed 15 amperes.

• Never push objects of any kind into the product through cabinet slots as they may

touch dangerous voltage points or short out parts that could result in a risk of fire or

electric shock. Never spill liquid of any kind on the product.

• Except as explained elsewhere in this manual, do not attempt to service the product by

yourself. Opening and removing the covers that are marked "Do Not Remove" may

expose you to dangerous voltage points or other risks. Refer all servicing on those

compartments to service personnel.

• Unplug the product from the wall outlet and refer servicing to qualified service

personnel under the following conditions:

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the product.

C. If the product has been exposed to rain or water.

D. If the product does not operate normally when the operating instructions are

followed. Adjust only those controls that are covered be the operating instructions

since improper adjustment of other controls may result in damage and will often

require extensive work by a qualified technician to restore the product to normal

operation.

E. If the product has been dropped or the cabinet has been damaged.

F. If the product exhibits a distinct change in performance, indicating a need for

service.

• Please keep the poly bag which the printer is packed in away from children or throw it

away to prevent children from putting it on. Putting it on may cause suffocation.

— ii —

WICHTIGE SICHERHEITSANWEISUNGEN

• Lesen Sie die nachfolgenden Anweisungen sorgfältig durch und bewahren Sie sie auf.

• Befolgen Sie alle auf dem Drucker vermerkten Hinweise und Anweisungen. Vor dem

Reinigen grundsätzlich Stecker aus der Steckdose ziehen. Keine Flüssigkeiten oder

Aerosolreiniger benutzen. Nut mit einem feuchten Tuch abwischen.

• Der Drucker darf nicht in der Nähe von Wasser aufgestellt werden.

• Drucker nicht auf einem unstabilen Wagen, Stand oder Tisch aufstellen. Der Drucker

könnte herunterfallen und dabel beschädigt werden.

• Schlitze und Öffnungen im Gehäuse, in der Rückwand und im Boden dienen der

Belüftung. Sie dürfen keinesfalls zugedeckt oder blockiert werden, da sich der Drucker

sonst überhitzt. Drucker nicht auf ein Bett, Sofa, Teppich oder dergleichen stellen.

Drucker nicht in der Nähe eines Heizkörpers aufstellen. Drucker darf nicht eingebaut

werden, falls nicht für ausreichende Beluftüng gesorgt ist.

• Drucker nur mit der auf dem Typschild angegebenen Spannung betreiben. Wenn Sie

sich nicht sicher sind, fragen Sie ihren Händler oder ihr zuständiges Elektrizitätswerk.

• Nichts auf das Stromanschlußkabel stellen. Kabel muß so verlegt werden, daß man

nicht darauftreten kann.

• Ein etwaiges Verlängerungskabel muß der Stromstärke aller daran angeschlossenen

Geräte entsprechen.

• Keine Gegenstände in die Gehäuseschlitze schieben.

• Drucker darf nur da gewartet werden, wo im Handbuch angegeben, Öffnen und.

Abnehmen von Abdeckungen, die mit "Do not remove" gekennzeichenet sind, könnte

gefährliche spannungführende Stellen oder sonstige Gefahrenpunkte freilegen. Die

Wartung solcher Stellen darf grundsätzlich nur von besonders ausgebildetem

Fachpersonal vorgenommen werden.

A. Wenn das Stromanschlußkabel oder der Stecker beschädigt oder durch-gescheuert

ist.

B. Wenn Flüssigkeit auf dem Drucker verschüttet wurde.

C. Wenn der Drucker im Regen gestanden hat oder Wasser darauf verschüttet wurde.

D. Wenn der Drucker trotz genauer Befolgung der Betriebsvorschriften nicht richtig

arbeitet. Nur die in der Bedienungsanleitung angegebenen Einstellungen

vornehmen. Ein Verstellen anderer Bedienungselemente könnte den Drucker

beschädigen und macht umständliche Arbeiten eines qualifizierten Technikers

erforderlich, um den Drucker Wieder auf den normalen Betrieb einzustellen.

E. Wenn der Drucker heruntergefallen ist oder das Gehäuse beschädigt wurde.

F. Wenn der Drucker in seiner Leistung nachläßt.

• Bitte halten Sie den Kunststoffbeutel, in den der Drucker verpackt ist, von Kindern

entfernt oder entsorgen Sie ihn, damit er nicht in die Hände von Kindern gerät. Das

Überstulpen des Beutels kann zum Ersticken führen.

Lärmemission kleiner 70dBA

— iii —

IMPORTANT: This equipment generates, uses, and can radiate radio frequency

energy and if not installed and used in accordance with the instruction manual,

may cause interference to radio communications. It has been tested and found to

comply with the limits for a Class A computing device pursuant to Subpart J of

Part 15 off FCC Rules, which are designed to provide reasonable protection against

such interference when operated in a commercial environment. Operation of this

equipment in a residential area is likely to cause interference, in which case the

user at his own expense will be required to take whatever measures may be

necessary to correct the interference.

CAUTION: Use shielded cable for this equipment.

Sicherheitshinweis

Die Steckdose zum Anschluß dieses Druckers muß nahe dem Grät angebracht und

leicht zugänglich sein.

For Uses in Canada

This digital apparatus does not exceed the class A limits for radio noise emissions

from digital, apparatus, as set out in the radio interference regulations of the

Canadian department of communications.

Pour L’utilisateurs Canadiens

Cet appareil numérique ne dépasse pas les limites de carégorie a pour les

émissions de bruit radio émanant d’appareils numériques, tel que prévu dans les

réglements sur l’interférence radio du départment Canadien des communications.

— iv —

<CAUTIONS>

• Prior to using the printer, be sure to read this User's Manual thoroughly. Please

keep it handy for reference whenever it may be needed.

• The information contained herein may be changed without prior notice.

• Reproduction of part or all of this User's Manual without permission is strictly

prohibited.

• Never service, disassemble, or repair parts that are not mentioned in this User's

Manual.

• Note that we will not be responsible for damages attributable to a user's incorrect

operation/ handling or an improper operating environment.

• Operate the printer only as described in this User's Manual; otherwise accidents

or problems may result.

• Data are basically temporary; they cannot be stored or saved permanently or for

a long time. Please note that we will not be responsible for damages or losses of

profit resulting from losses of the data attributable to accidents, repairs, tests,

and so on.

• If you have any questions or notice any clerical errors or omissions regarding the

information in this manual, please contact our office.

• Please note that, notwithstanding Item 8 above, we will not be responsible for

any effects resulting from operation of the printer.

— v —

SAFETY PRECAUTIONS — BE SURE TO OBSERVE

In order to prevent hazards to an operator or other persons and damage to

property, be sure to observe the following precautions.

• The following describes the degrees of hazard and damages that can occur if the

given instructions are neglected or the printer is incorrectly operated.

WARNING

Negligence of this precaution may result in death or serious injury.

CAUTION

Negligence of this precaution may result in injury or damage to property.

This is an illustration mark used to alert your attention.

This is an illustration mark used to indicate such information as an

i

instruction or the like.

— vi —

WARNING

● Never handle the printer in the following manners, as it may break, become out

of order, or overheat causing smoke and resulting in fire or electric shock. If

the printer is used in an abnormal condition, such as when broken, then

problems, smoke emission, abnormal odor/noise, and fire can result. If an

abnormal condition exists, be sure to disconnect the power plug from a plug

socket, and contact our dealer. Never repair the printer on your own - it is very

dangerous.

• Do not allow the printer to receive a strong impact or shock, such as kicking,

stomping, hitting, dropping, and the like.

• Install the printer in a well-ventilated place. Do not use it in such a manner

that its ventilation port will be blocked.

• Do not install the printer in a place like a laboratory where chemical reactions

are expected, or in a place where salt or gases are contained in the air.

• Do not connect/disconnect a power cord or a data cable, while holding the

cable. Do not pull, install, use, or carry the printer in such a manner that force

will be applied to the cables.

• Do not drop or insert any foreign substances, such as clips or pins, into the

printer.

• Do not spill any liquid or spray any chemical-containing liquid over the printer.

If any liquid is spilled on it, turn off the power, disconnect the power cable and

power cord from the plug socket, and so on, and contact our dealer.

• Never disassemble or remodel the printer. Negligence of this may cause fire

or electric shock.

• Use the printer only with the specified commercial power supply and AC

adapter. Negligence of this may result in fire, electric shock, or problems.

• If you drop or break the AC adapter, or if water or the like gets inside it, unplug

it immediately from the socket and contact your dealer.

• Do not damage, break, process, bend/pull by force, twist, or printing head an

AC adapter cord. Also, do not put a heavy substance on it or heat it. The AC

adapter cord could be broken, resulting in fire, electric shock, or trouble. If the

AC adapter cord is damaged, contact our dealer.

• Do not connect/disconnect the AC adapter with wet hands.

• Do not overload a single electrical outlet, using a table tap or a current tap

socket.

The printer packing bag must be discarded or kept away from children. A child

●

can suffocate if the bag is placed over the printing head.

— vii —

PRECAUTIONS FOR INSTALLATION

• Do not use or store the printer in a place exposed to fire, moisture, or direct

sunshine, or in a place near a heater or thermal device where the prescribed

operating temperature and humidity are not met, or in a place exposed to much oil,

iron powder, or dust. The printer may become out of order, emit smoke, or catch

fire.

• Do not install or use the printer in a place like a laboratory where chemical

reactions are expected, or in a place where salt or gases are contained in the air.

There is a danger of fire or electric shock.

• Install the printer on a flat, stable desk or table that is free from vibration, in a wellventilated place.

• Do not install the printer at a location where its operation could be hindered.

• Do not place anything on the printer or leave small objects, like a clip or pin, around

it. A foreign object could cause trouble if it gets inside.

• Do not use any sharp-pointed object, such as a pen, for example, to touch the

operation panel of the printer. It could cause trouble.

• Do not use the printer near a radio or TV receiver. Do not share the power from a

plug socket a radio or TV receiver is connected to. It may cause a reception

problem.

• Use the printer only at the specified power supply, voltage and frequency.

Otherwise, it may emit smoke and catch fire or cause other problems.

• Connect only the specified power source. Use of an unspecified power source

could cause trouble or smoke/fire.

• Confirm that a plug socket used for connection has sufficient capacity.

• Avoid connecting a power cable to a plug socket shared by other devices or

extending the wiring too far. It may result in the cable catching fire or a power

outage. Also, do not step on or apply an excessive force (Pull, load) to the cable,

and do not use the printer with such a force applied to it.

• Never connect a grounding cable (Frame ground) to a gas pipe. There is a danger

of explosion. When connecting or disconnecting the grounding cable, be sure to

disconnect the power cable and the power plug from the plug socket.

• When connecting/disconnecting the cables, be sure to turn off the power first,

including the connected side, and then connect/disconnect them, holding a plug

and a connector. Pulling the cable itself could cause it to snap or become

damaged.

• Connect a power cable or a connector cable securely. Avoid reversing the polarity

when connecting as internal elements may be broken or a mating device may be

adversely affected.

• Use a shielding wire or twisted pair wire for a signal line, in order to minimize noise

effect. Do not route the cable too long or connect it to a noisy device. Connection

to a noisy device could cause erroneous printing due to corrupt data, and so on.

• Use the printer in an environment where there is a plug socket near the main body

and you can easily disconnect the power plug from it, to shut off the power.

• When the printer will not be used for a long period of time, unplug it and remove

the paper roll from it.

• When transporting the printer, remove the paper roll from the paper holder.

— viii —

PRECAUTIONS FOR HANDLING

Do not handle the printer in the following manners, because problems may result.

• Do not use any other power source besides the accessory AC adapter. Also, do

not use the AC adapter for other purposes.

• Do not print without paper.

• Do not drop or put any foreign object, such as a clip, pin, or the like, inside the

printer.

• Do not spill any liquid or spray any chemical-containing liquid over the printer.

• Never use a pointed object, such as a pen, to operate the operation panel.

• Do not use Scotch tape to fasten paper together for continuous use. It could

damage the printing head.

• Never pull the set paper forcibly. When opening/closing the printer cover, take

care that the paper will not be caught. It could cause the paper to jam.

• Be sure to use the specified paper. Use of paper other than the recommended

type may damage the printing head or lower the printing quality.

To Prevent Injury and Spreading of Damage

• Never touch the printing head, motors, or paper cutter. Your finger may be cut.

• Avoid physical contact with any movable part (e.g. printer mechanism or gears)

or electrical component within the printer while printing or immediately after.

They may be very hot and can burn your hand/finger.

• Be careful to avoid bodily injure or damaging other objects with an edge of sheet

metal.

• Should any error occur while operating the printer, stop it immediately and

disconnect the power plug from the plug socket.

• Only a qualified serviceman is allowed to disassemble or repair the printer.

• Should a problem occur, leave solving it to our serviceman. Do not disassemble

the printer on your own.

• When opening/closing the printer cover, and so on, be careful not to catch your

hand or finger on the printer.

• Each time you finish using, turn off the power switch and unplug the power plug

from the wall outlet.

— ix —

i

DAILY MAINTENANCE

• At the time of maintenance, be sure to turn off the power switch of the printer

and unplug it from the socket.

• Use a dry soft cloth to wipe off stains and dust from the surfaces of the main

body case. For severe soiling, dip the cloth in water and wring it, for wiping off

the soil. Never use organic solvents, such as alcohol, thinner, trichlene, benzene,

ketone, or chemical dusters.

• If the printer is contaminated with paper powder, use a soft brush to clean it. Be

careful not to damage the printing head.

CAUTION:

The printing head and motor are very hot. Be careful not to touch them

immediately after printing. Do not touch the heating surface of the printing

head with a bare hand or metal.

• Cleaning the Printing Head

1. Referring to "4.9 Eliminating the Paper Jam," detach the platen roller unit.

2. Moisten gauze slightly with alcohol, and clean the heating surface of the

printing head with it.

3. Reattach the platen roller unit.

CAUTION:

The printing head and motor are very hot. Be careful not to touch them

immediately after printing. Do not touch the heating surface of the printing

head with a bare hand or metal. When detaching or reattaching the platen roller

unit, be sure to raise up the printing head; otherwise, they could be damaged.

Handle the detached platen roller unit carefully so as not to damage it.

— x —

SAFETY CAUTIONS ON THE BATTERY PACK

This printer can operate on a rechargeable battery pack (nickel-hydrogen batteries).

To ensure maximum safety, observe the following safety precautions:

DANGER

● To prevent electrolyte leakage, heat build-up, or bursting:

• Do not throw battery packs into fire or expose to any heat source.

• Do not immerse the battery pack in water or get it wet as it will cause damage

to the battery pack.

• Do not short the positive (+) or negative (–) terminal with a wire, chain, metallic

accessory or any other conductive material as it will cause damage to the

battery pack or a skin burn from overheat.

• Do not attempt to disassemble or modify the battery pack as this may cause

overheating, fire or the electrolyte to burst.

• The battery pack has positive (+) and negative (–) electrodes. If you have

difficulty in connecting, check the orientation.

• Do not attempt to directly connect the battery pack in a wall outlet or a car

cigarette lighter socket.

If electrolyte gets into the eyes, do not rub. Rinse thoroughly with fresh water

●

and then call a doctor.

Do not attempt to modify the built-in battery charger in the printer. It should

●

only be used for charging the supplied battery pack. To prevent the battery

pack from bulging, heat build-up or bursting, only charge with the supplied

battery pack charger.

Charge the battery pack from the dedicated built-in charger and within the

●

specified charging time.

• Running the battery pack through repeated partial charge and drain cycles may

cause a gradual reduction of return power called “memory effect” that

shortens battery life.

Use the battery pack within the specified operating temperature range and

●

environmental conditions.

• Battery pack performance may deteriorate if used outside specified operating

conditions.

If the battery pack requires replacement, take it to your dealer for servicing.

●

• Replacing with a battery pack outside of the specified ratings may damage the

printer.

— xi —

WARNINGS

● If the printer or its internal battery pack shows any sign of electrolyte leakage,

discoloration, deformation, or odd smell, immediately stop using the printer.

Then call your dealer.

If a charging cycle does not complete within the specified time, stop charging

●

at that point. This will help prevent electrolyte leakage, heat build-up, or

bursting.

Never remove the battery pack from the printer or use it for driving any other

●

device. Such a practice may cause damage to the battery pack or the target

device.

To prevent electrolyte leakage or heat build-up, do not attempt to remove the

●

outer jacket from the battery pack.

The battery pack has a limited life. If charging cycle time is significantly

●

shortened although the specified charging requirements are satisfied, it is most

likely that the battery life has expired. Replace it with a fresh one.

To prevent possible heat build-up or terminal corrosion, do not soak the battery

●

pack in tap water or seawater, or wet its terminals.

If electrolyte comes into contact with the skin or clothing, rinse it off

●

immediately with fresh water.

To prevent the battery pack from lowered performance or low voltage, do not

●

leave the printer power on for a long time period.

Do not attempt to charge the battery pack when not connected to the printer.

●

— xii —

CAUTIONS

● Do not give the battery pack a severe jolt or drop it on a hard surface.

To prevent electrolyte leakage or lowered battery performance, do not use or

●

leave the battery pack exposed under direct sunlight, in a hot car compartment,

or in the path of hot airflow from a heater.

When recharging the battery pack, follow the instructions in the relevant

●

sections of the User's Manual.

Charging efficiency depends significantly on the ambient temperature. The

●

most efficient temperature range is from 10°C to 30°C. It is recommended you

charge the battery pack within this optimum range.

To prevent possible electrolyte leakage, do not leave the battery pack

●

connected to the printer for a long time period. Also be sure to turn the printer

power off after every use.

Be sure to recharge the battery pack before using the printer 1) for the first

●

time after purchase or 2) again after remaining idle for more than 3 months.

The battery pack will also self-discharge during extended periods of storage. It

is recommended you recharge the battery pack every 3 to 6 months.

If the battery pack is recharged after the printer is left unused for more than 3

●

months, the charging cycle may terminate before the battery pack is fully

charged up. In such a case, repeat the charging/discharging cycle several times.

To prevent lowered performance from self-discharging or electrolyte leakage

●

during long-term storage (more than 6 months and less than 2 years), store the

battery pack from –20°C to +35°C (optimally from 10°C to 30°C).

After the battery pack is taken out of low-temperature (0°C or below) or high-

●

temperature (40°C or above) storage, do not use it until its temperature falls

within the operating range and stabilizes. Otherwise, you may encounter

problems with low voltage or lowered performance.

Soiled terminals may result in power interruptions or failure to charge. Always

●

keep the battery pack terminals clean. Use a soft, dry cloth for cleaning.

Keep the printer and the battery pack out of the reach of children. While

●

charging or operating, keep children away from the printer so they cannot take

the battery pack out of the printer.

Do not allow children access to the printer and the battery pack.

●

— xiii —

BATTERY PACK LIFE

• The battery pack is designed to have life span of more than 300 recharging cycles

or 3 to 5 years (at room temperature), provided that it is properly used without

overcharging or over-discharging (charging capacity is lowered to 60% or more).

It should be noted, however, that actual battery life could be less depending on

cycle frequency or operating conditions.

• Due to its electrochemical nature, battery pack performance gradually degrades

as a result of long-term storage and repeated use.

• Due to memory effect, the battery pack may not fully charge when plenty of

energy still remains in it. Fully discharge the battery by printing before recharging

again.

• If the battery pack only provides very short operating performance, its battery life

has most likely expired.

• Have your dealer replace the battery pack with a fresh one.

DISCARDING THE BATTERY PACK

• The way of discarding used battery packs differs from one country/region to

another. Discard them in compliance with local environmental regulations, laws,

ordinances and recycling systems.

• The battery pack contains recyclable rare metal material, including nickel.

Recycling serves to reduce waste and preserve the environment. Do not throw

away used battery packs. Take them to your local dealer.

For more information, contact your dealer.

— xiv —

CONTENTS

1. OUTLINE ..................................................................................... 1

1.1 Features ..................................................................................................... 1

1.2 Unpacking .................................................................................................. 2

2. BASIC SPECIFICATIONS ............................................................ 3

2.1 Model Classifications ................................................................................ 3

2.2 Basic Specifications .................................................................................. 4

2.3 Paper Specifications ................................................................................. 6

2.3.1 Recommended Paper ....................................................................... 6

2.3.2 Printing Position ................................................................................ 7

2.3.3 Printing Head and Paper Cutter Layout...........................................7

3. OUTER APPEARANCE AND COMPONENT PARTS .................. 8

4. OPERATION .............................................................................. 10

4.1 Connecting AC Adapter ..........................................................................10

4.2 Replacing the Battery Pack ..................................................................... 11

4.2.1 Removing the Battery Pack ............................................................ 11

4.2.2 Installing the Battery Pack ..............................................................12

4.3 Charging the Battery Pack ......................................................................13

4.3.1 Non-Floating Charging ................................................................... 13

4.3.2 Floating Charging............................................................................13

4.3.3 Battery-Powered Operation............................................................14

4.3.4 Battery Voltage Check ..................................................................... 15

4.4 Reset.........................................................................................................17

4.4.1 Reset during a Printing Task........................................................... 17

4.4.2 Voltage Drop....................................................................................17

4.5 Power Save and Auto Power Off ........................................................... 18

4.6 Connecting Interface Cable .................................................................... 19

4.7 Inserting the Paper .................................................................................. 20

4.8 How to Remove Remaining Paper Roll .................................................22

4.9 Eliminating the Paper Jam .....................................................................23

4.10 FEED Switch Function........................................................................... 24

4.10.1 When Thermal Paper is Used ...................................................... 24

4.10.2 When the Macro is Executed ....................................................... 24

— xv —

4.11 Paper End Function ............................................................................... 24

4.12 Paper Near End Function...................................................................... 25

4.13 Auto-Loading Function .........................................................................27

4.14 Self-Print Function ................................................................................ 27

4.15 Operation Panel and Display of Error.................................................. 28

4.16 Red/Black Print (Precautions for Use).................................................. 30

5. DIP SWITCH SETTING.............................................................. 31

5.1 Location of DIP Switch............................................................................ 31

5.2 DIP Switch Function ................................................................................ 31

5.3 Jumper Wire Function ............................................................................34

6. PARALLEL INTERFACE ............................................................. 35

6.1 Specifications .......................................................................................... 35

6.2 Connector's Pin Configuration ............................................................... 35

6.3 Input and Output Signals ....................................................................... 36

6.3.1 Input and Output Signals ............................................................... 36

6.3.2 Electrical Characteristics.................................................................36

6.3.3 Timing Chart...................................................................................37

6.3.4 Data Receiving Control ...................................................................37

6.3.5 Buffering ..........................................................................................37

7. SERIAL INTERFACE .................................................................. 38

7.1 Specifications .......................................................................................... 38

7.2 Connector's Pin Configuration ............................................................... 38

7.3 Input and Output Signals ....................................................................... 39

7.3.1 Input and Output Signals ............................................................... 39

7.3.2 Data Configuration .......................................................................... 40

7.3.3 Error Detection ................................................................................ 40

7.3.4 Data Receiving Control ...................................................................41

7.3.5 Buffering ..........................................................................................41

7.3.6 Electrical Characteristics.................................................................41

8. POWER CONNECTOR .............................................................. 42

9. MAINTENANCE AND SERVICE ............................................... 43

— xvi —

10. PRINT CONTROL FUNCTIONS .............................................. 44

10.1 Command List ....................................................................................... 44

10.2 Command Details.................................................................................. 46

10.2.1 Descriptions of Each Items ........................................................... 46

10.2.2 Command Details..........................................................................47

11. CHARACTER CODES TABLE.................................................. 95

11.1 International .......................................................................................... 95

11.2 Code Page Katakana (Japanese).......................................................... 96

11.3 International Character Codes Table ................................................... 97

APPENDIX 1. BLOCK DIAGRAM.................................................. 98

APPENDIX 2. OUTLINE DRAWING.............................................. 99

APPENDIX 3. WALL MOUNTING HOLES LAYOUT

DRAWING ............................................................ 100

— xvii —

<<<German>>>

4. BETRIEB .................................................................................. 112

4.1 Anschließen des Netzteils .................................................................... 112

4.2 Auswechseln des Akkus ....................................................................... 113

4.2.1 Entnehmen des Akkus ..................................................................113

4.2.2 Einsetzen des Akkus......................................................................114

4.3 Laden des Akkus ................................................................................... 115

4.3.1 Ungepuffertes Laden ....................................................................115

4.3.2 Gepuffertes Laden.........................................................................115

4.3.3 Akkugespeister Betrieb ................................................................. 116

4.3.4 Prüfen der Akkuspannung ............................................................ 117

4.4 Rückstellungen ......................................................................................119

4.4.1 Rückstellungen bei laufendem Druckbetrieb .............................. 119

4.4.2 Spannungsabfall ...........................................................................119

4.5 Stromsparmodus und automatische Abschaltung ............................ 120

4.6 Anschließen des Schnittstellenkabels ................................................. 121

4.7 Einsetzen des Papiers ........................................................................... 122

4.8 Entnehmen der eingesetzten Papierrolle ............................................124

4.9 Beseitigen von Papierstau .................................................................... 125

4.10 FEED-Schalterfunktion ........................................................................ 126

4.10.1 Bei Verwendung von Thermalpapier.........................................126

4.10.2 Bei Ausführung eines Makros .................................................... 126

4.11 Papierende-Funktion ........................................................................... 126

4.12 Papiermangel-Funktion ...................................................................... 127

4.13 Autoladefunktion.................................................................................129

4.14 Selbstdruckfunktion ............................................................................129

4.15 Bedienfeld und Fehleranzeigen ......................................................... 130

4.16 Rot/Schwarz-Druck (Vorsichtsmaßregeln) ........................................ 132

5. DIP-SCHALTEREINSTELLUNG ............................................... 133

5.1 Lage der DIP-Schalter ........................................................................... 133

5.2 DIP-Schalterfunktion .............................................................................133

5.3 Jumperdraht-Funktion .......................................................................... 136

9. WARTUNG UND DIENST....................................................... 137

— xviii —

1. OUTLINE

This compact battery-powered line thermal printer is designed for use with data

terminals and instrumentation equipment. Its abundant built-in features allow you

to widely use this printer for different applications. Prior to using it, read and

understand this manual thoroughly.

1.1 Features

1. Can be powered by battery

2. Small, lightweight, and installable in a narrow area

3. High speed and low noise, owing to line thermal print

4. Long-life printing head and high reliability, owing to the simple mechanism

5. Easy paper-loading, owing to the auto-loading function

6. Built-in input buffer

7. Capable of printing a bar code (Special command)

8. Capable of printing in two colors (when special paper is used)

9. External characters registration function (94 kanji characters, 95 ANK

characters)

— 1 —

1.2 Unpacking

When unpacking the package, confirm that the following parts are provided:

• Printer body (including battery pack) 1 unit

• Sample paper roll 1 roll

• AC adapter 1 piece

• AC cord 1 piece

• User's manual 1 copy

CAUTION

• Install the printer body on a flat and stable desk or mount it onto the wall, etc.,

using a hook, etc.

• Do not install the printer near a heater or in a place exposed to the direct sunshine.

• Do not use the printer in a high-temperature, high-humidity, or contaminated

environment.

• Do not allow dew condensation to form on the printer. If such condensation should

form, do not turn on the power until it has completely gone away.

• Use only the accessory AC adapter. Do not use it for any other purpose.

• If you do not use the printer for a long period, disconnect the power cable from the

socket.

• Keep this manual carefully at hand for ready reference.

— 2 —

2. BASIC SPECIFICATIONS

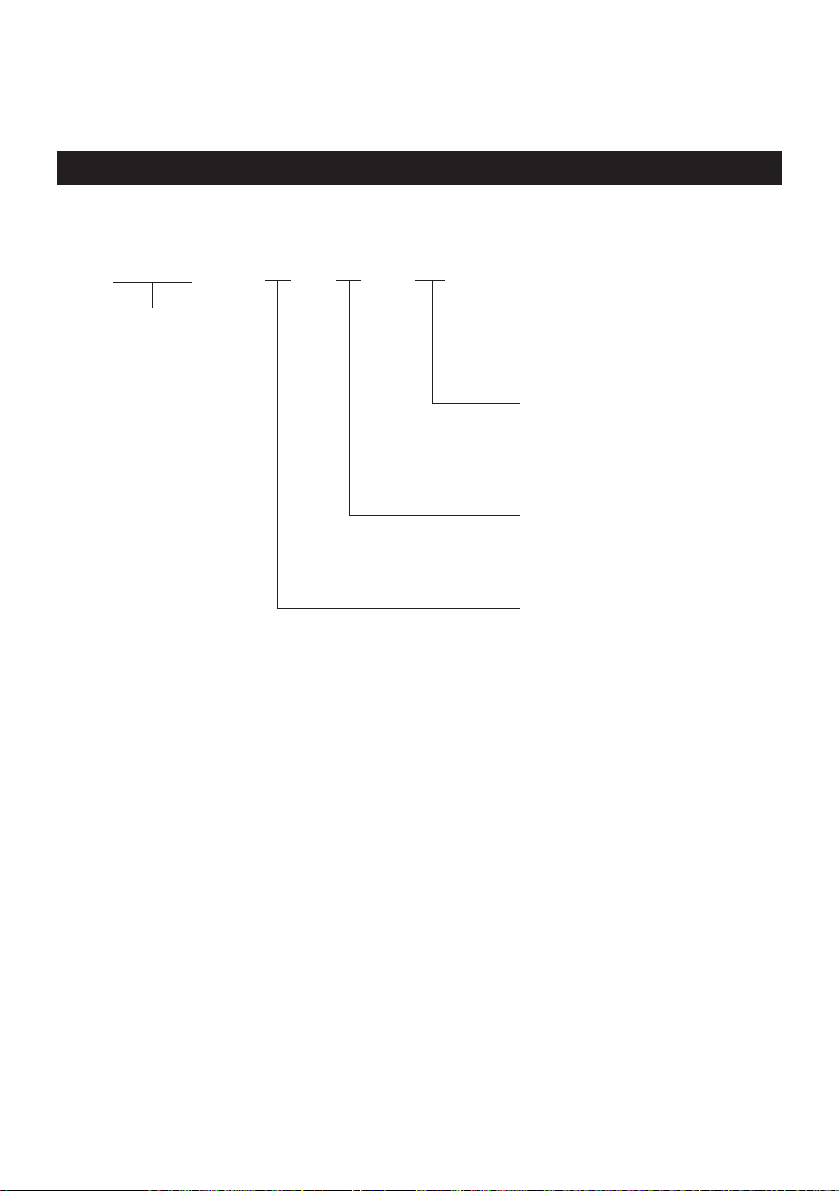

2.1 Model Classifications

The models are classified by the following designation method:

CBM-272 - R F 120

Model Name CBM-272:

Battery-powered model

AC Power Cord

International Characters

Interface

120: 120 V AC

230: 230 V AC

F: International

R: Serial (RS-232C)

P: Parallel

(CENTRONICS Compliant)

*Special Switching Power Source and Power Cord

Switching power source :27 AD (Input: 100 to 240 V AC)

Power cord :100 V AC --- 2-core cord

120 V AC --- 2-core cord

230 V AC --- 2-core cord

Cord length :Power cord (For AC Input) --- Approx. 1.8 m

Secondary side (For DC Output) --- Approx. 1.8 m

— 3 —

2.2 Basic Specifications

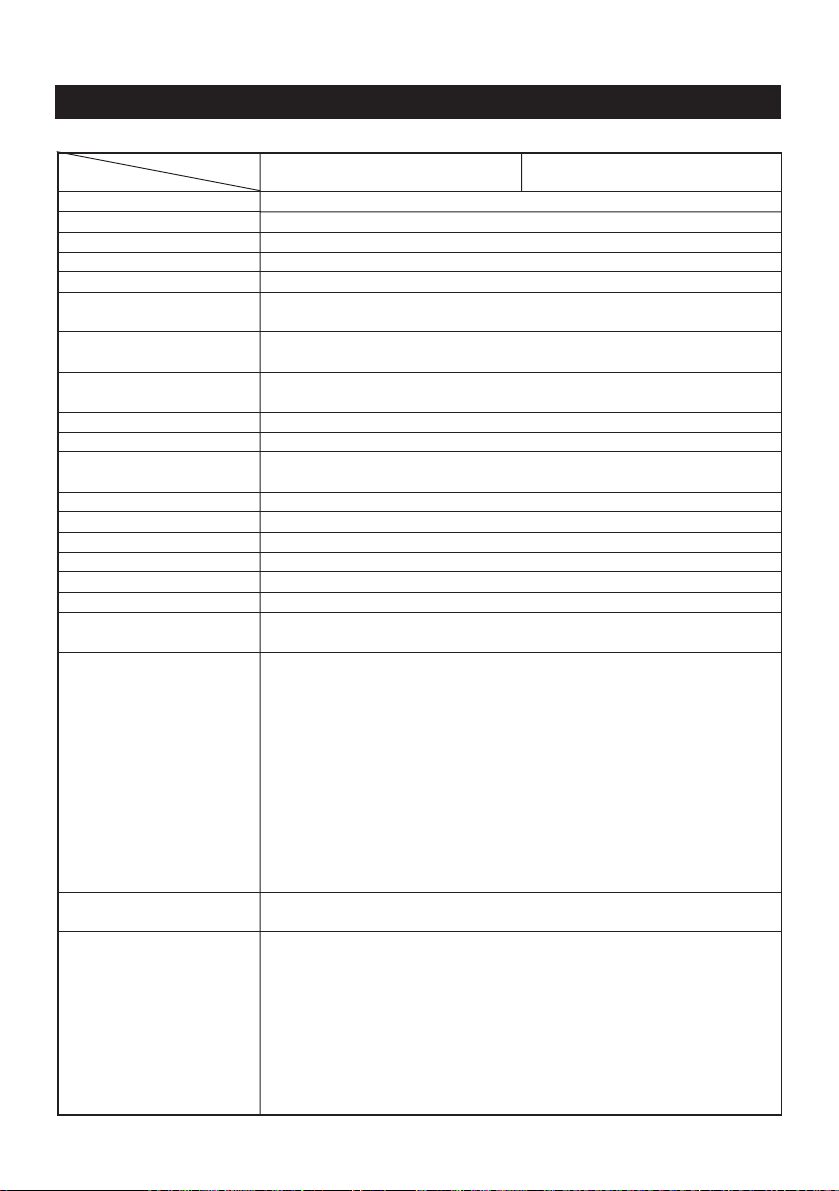

Item

Model

Printing system

Printing width

Dot density

Paper feed pitch

Printing speed

Printing columns and

character size

Line interval

Character types

Character code

Bar code type

Paper

(See Paper Specifications)

Interface

Input buffer

Download characters

Auto-loading

Paper end function

Paper near end function

Printing color

Battery

No. of printable lines

Power save and auto

power off

CBM-272-RF120

CBM-272-PF120

Line thermal dot printing

48 mm (384 dots/line)

8 dots/mm (Width, Length)

0.125 mm

Approx. 11 lines/sec. (At maximum)

32 columns (12 x 24 Font A) 1.25 x 3.00 mm

42 columns (9 x 24 Font B) 0.88 x 3.00 mm

Initial value: 4.23 mm (1/6 inch)

Can be set with a command (1/360 inch at minimum)

Alphanumeric characters, symbols, international characters

(Choose from 10 countries)

Domestic characters, IBM characters #2 (Choose either)

UPC-A/E, JAN (EAN) 13-/8-column, ITF, CODE 39, CODE 128, CODABAR

Thermal paper roll : 58 + 0/- 1 mm x ø83 (max.) mm, 60~75µm thick

Serial (RS-232C), Parallel (CENTRONICS compliant)

2 KB

Font A, B: 95 characters each

Provided (Can be enabled/disabled with the DIP switch)

Provided

Provided (Can be enabled/disabled with the DIP switch)

Capable of printing in two colors (red/black) with the special thermal

paper.

Battery pack: 6HR-AAU-CBM (7.2 VDC, 1650 mA/h)

Ni-MH (pack of 6 AA dry cells, connectable to charger circuit via

connector)

Charging time: Approx. 5.5 hours (to full charge)

Charging monitor: POWER lamp (Red) lit in charging, goes off when

fully charged.

Recharging cycles: Over 300 cycles (at room temperature)

Charger: Built in the CBM-272 Printer.

Charger power supply: Power adapter (27AD)

The printer can be powered while the batteries are charging (floating).

Discharge control: Low voltage alarm=5.9 V, discharge termination

voltage=5.6 V, monitored by signal output and POWER lamp (Green).

Approx. 30,000 lines and more (continuous sliding print of ANK,

standard print density, at room temperature)

To save battery consumption, the printer automatically enters the power

save mode if it receives no print data, or not operated, for approx. 10

minutes. If the same inactive state continues for another 10 minutes, the

auto power off feature automatically turns the printer off. (The timer

intervals can be set with a DIP switch.)

To turn the printer on again, temporarily set the POWER switch to OFF,

then set it back to ON. All data will initialize when the printer repowers.

The power save and auto power off features are left disabled when the

printer is powered from the AC adapter.

CBM-272-RF230

CBM-272-PF230

— 4 —

Item

Model

AC adapter

Type

AC cord

Supply voltage

Power consumption

Weight

Outer dimensions

Operating temperature and

humidity

Storage temperature and

humidity

Reliability

EMI *1

Applicable standard

(Main body) *1

Applicable standard

(Power source)

Rated input : 100 ~ 240 V, 50/60 Hz, 40 VA

Rated output : 7.2 V DC, 2 A

27 AD

2-core cord (Depends on the destination)

120 V AC +/– 10%, 60 Hz 230 V AC +/– 10%, 50/60 Hz

At non-printing: Approx. 2 W

At printing: Approx. 15 W (approx. 20 W at maximum)

Main body: Approx. 750 g (Paper roll excluded)

AC adapter: Approx. 350 g

106 (W) x 183 (D) x 126 (H) mm

5 ~ 40°C, 35 ~ 85 % RH (No dew condensation)

–20 ~ 60°C, 10 ~ 90% RH (No dew condensation)

Printing head life: (25°C)

FCC Class-A EN55022 Class-A

UL, C-UL GS, CE Marking

UL, C-UL GS

CBM-272-RF120

CBM-272-PF120

Pulse resistance : 50 million pulses or more (Print rate 12.5%)

Wear resistance : 50 km or more (With recommended thermal paper

at normal temperature and humidity)

*1 indicates the standard satisfied when the AC adapter 27AD is used.

CBM-272-RF230

CBM-272-PF230

— 5 —

2.3 Paper Specifications

2.3.1 Recommended Paper

• Type : Thermal paper

• Paper width : 58 + 0/– 1 mm

• Paper thickness : 60~75µm

• Roll diameter : ø83 mm or less

• Printing surface : Outside of the roll (Surface)

• Recommended paper : TF50KS-E2C (Monochrome) made by NIPPON PAPER or

its equivalent 735 FA (2-color, Black based) made by

RICOH or its equivalent PB670 (2-color, Red based)

made by MITSUBISHI PAPER or its equivalent

• Core : ø12 mm (Inner dia.), (18 mm øOuter dia.)

CAUTION:

• Use of non-specified paper may cause irregularity of print density. If this is the case,

use the DIP switch to reset print density. (See 5. DIP SWITCH SETTING)

• Do not paste the paper to the core.

• If the paper comes in contact with a chemical or oil, it may discolor or lose a record.

• Do not rub the paper surface strongly with a nail or hard metal. It may discolor.

• Discoloring starts at about 70°C. Watch out for effects of heat, humidity, light, and

so on.

— 6 —

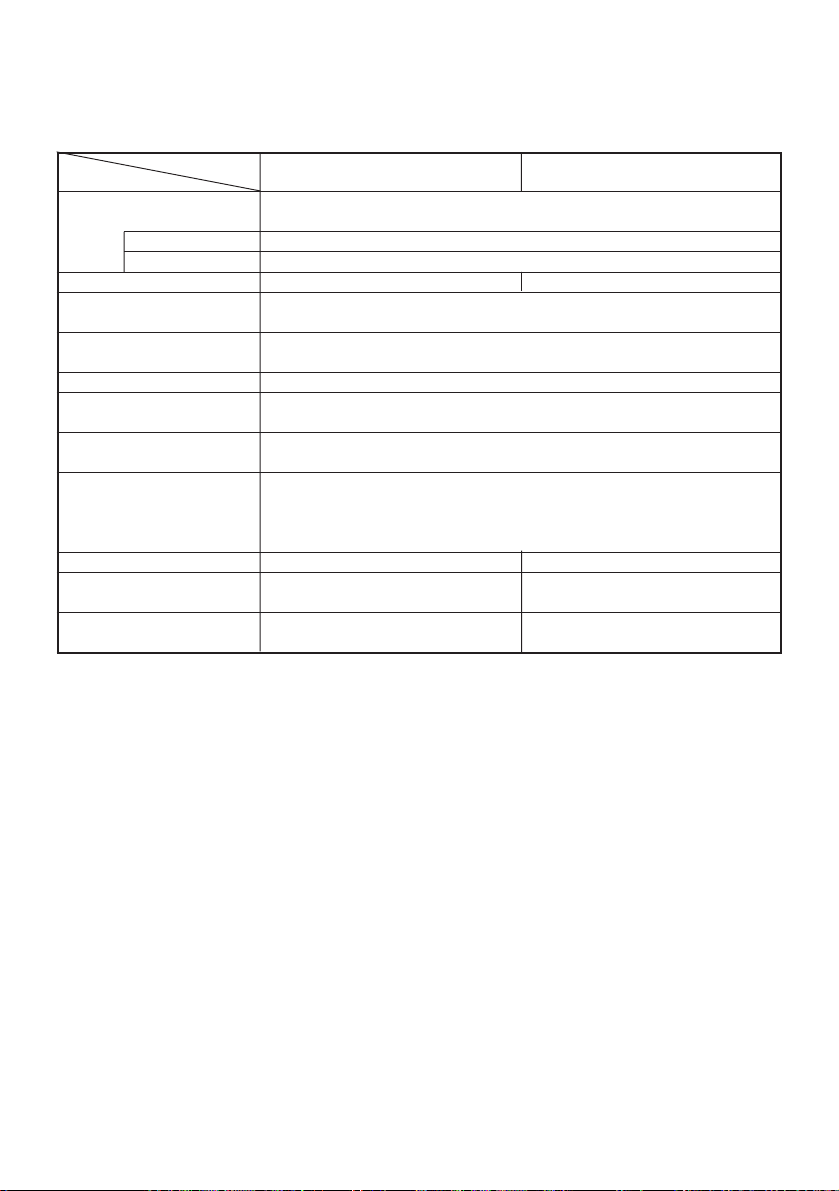

2.3.2 Printing Position

Thermal paper

Paper Width: 58 mm

About 4 mm About 6 mm

Printing Area: 48 mm

2.3.3 Printing Head and Paper Cutter Layout

Paper Cutter Position

About 13.5 mm

Head Position

Paper Feed

Direction

— 7 —

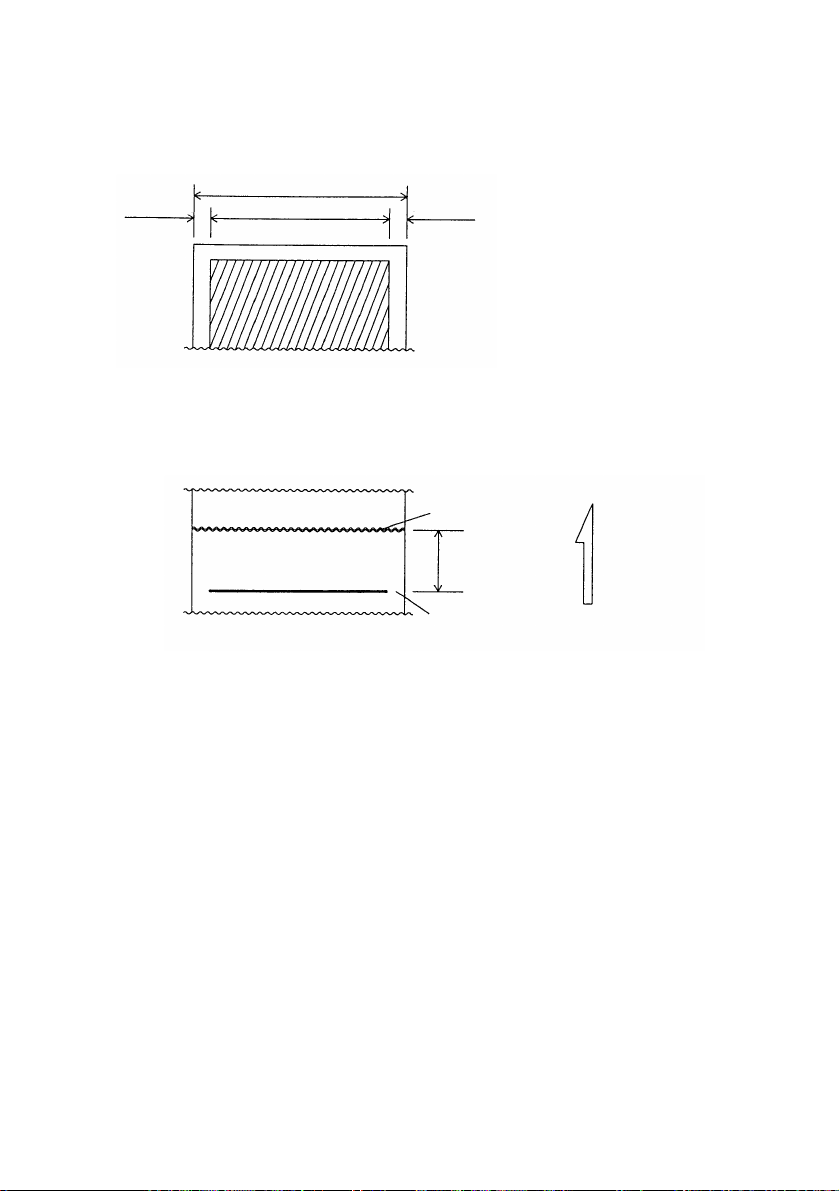

3. OUTER APPEARANCE AND COMPONENT PARTS

(14) Printer Cover

Upper Cover

Bottom Cover

(1) POWER Switch

(2) POWER Lamp

(3) ERROR Lamp

(4) PAPER lamp

(5) FEED Switch

Printer Mechanism

(11) Paper Cutter

(13) Interface Connector

(12) Power Connector

(7) PNE Sensor

(8) DIP Switch

(6) Paper Holder

(10) Head-up Lever

(9) Platen Roller Unit

— 8 —

(1) POWER switch

Turns on/off the power for the printer body.

(2) POWER lamp (Green/Red)

Comes on in green when the POWER switch is set to ON.

This light is lit in red while the battery is charging, and goes off when it is fully

charged up.

(3) ERROR lamp (Red)

Illuminated at the time of a head-up mechanical error, and blinks at the time of

starting a macro.

(4) PAPER lamp (Red)

Illuminated when the paper is running out (when there is little paper left), and

blinks when a label paper cut is specified.

(5) FEED switch

Feeds the paper. It is fed continuously while the switch is held down.

(6) Paper holder

Set the paper roll in this holder.

(7) PNE sensor

Detects that the paper is running out.

(8) DIP switch

Initially sets the printer at power-on and sets the functions.

(9) Platen roller unit

Detach this unit when the paper is jamming or when you clean the head.

(10) Head-up lever

Used when replacing the paper or detaching/reattaching the platen roller unit.

(11) Paper cutter

Cuts the printed paper.

(12) Power connector

Connects to the accessory AC adapter (27AD).

(13) Interface connector

Connects to a communication interface cable. There are two types, for serial

and parallel interfaces.

(14) Printer cover

Detach this cover when replacing the paper.

— 9 —

4. OPERATION

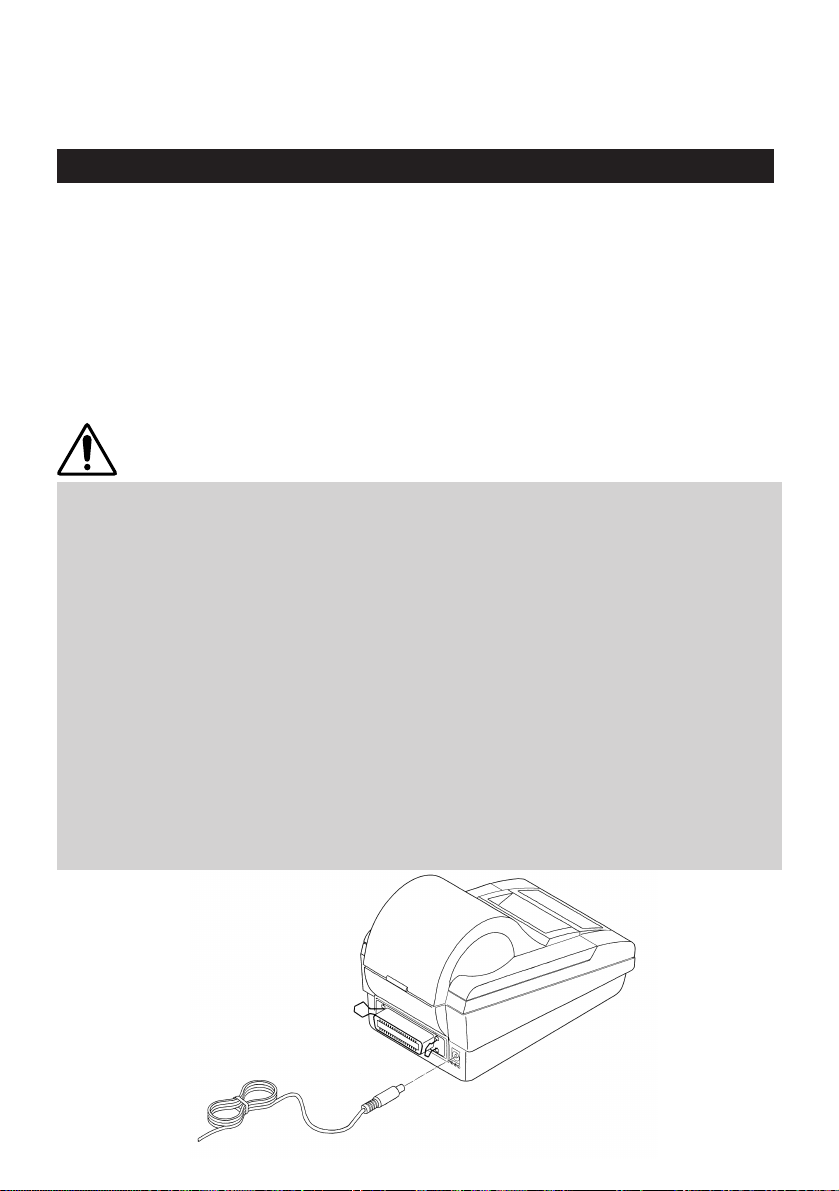

4.1 Connecting AC Adapter

Turn off the power.

1

Connect the cable connector of the AC adapter to the power connector located on

the back of the printer.

2

Connect the AC power cord of the AC adapter, and plug it into a socket.

(For the details of printer status, see “Operation Panel and Display of Error” in

3

Section 4.15.)

CAUTION:

• Use only the specified AC adapter.

• When disconnecting/reconnecting the cable connector of the AC adapter, be sure to

hold the connector.

• Separate the AC adapter from other noise-generating devices.

• Pulling the AC power cord may damage it, resulting in a fire, electric shock, or

snapping.

• If a thunder/lightning storm is nearby, disconnect the AC adapter from the socket

and do not use the printer, because a fire or electric shock may occur.

• Do not put the AC power cord close to a heating device. Its coating can melt and

cause a fire or electric shock.

• Install the printer in a well-ventilated place, because the AC adapter generates heat

when it is used.

• Use the specified AC power source. Connect to a power source with sufficient

capacity. If the capacity is insufficient, a fire may result from heat generation.

• After using the printer or when not using it for a long period of time, be sure to

unplug the AC adapter from a plug socket for your safety.

• Before connectiong the AC adapter be sure to set the POWER switch to OFF.

— 10 —

— 10 —

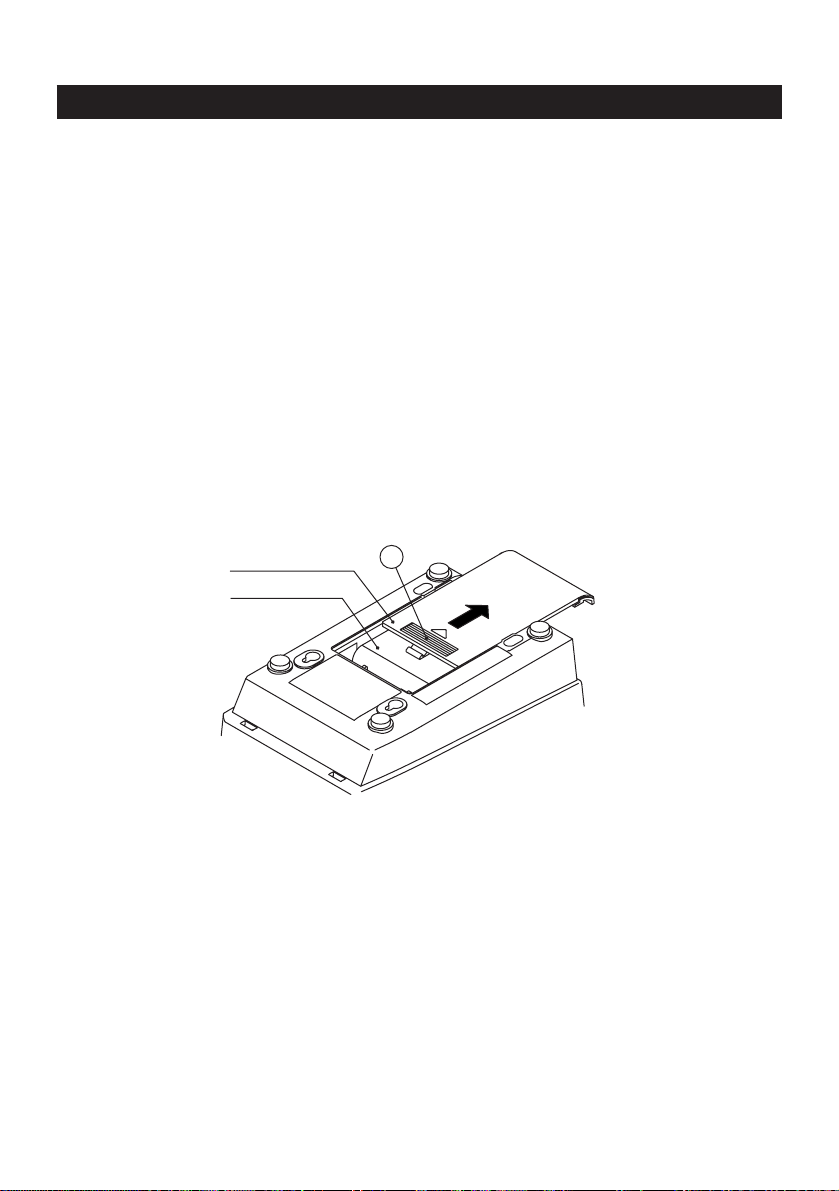

4.2 Replacing the Battery Pack

4.2.1 Removing the Battery Pack

Unplug the AC cord from the wall outlet.

1

Set POWER switch to OFF.

2

Remove the battery cover.

3

(While pressing down section A, slide the battery cover in the direction of the

arrow.)

Remove battery pack from compartment and disconnect its connecter.

4

Battery cover

Battery pack

A

— 11 —

4.2.2 Installing the Battery Pack

With the labeled side of battery pack facing up, connect the battery

connecter.

1

Insert the battery pack into the battery compartment.

(Tuck the battery connecter tidily in the extra space of the compartment.)

2

Place the battery cover back over the compartment by sliding it from the

back of the printer. (Exercise care not to bite the battery leads.)

3

Be sure to install the battery cover after the battery pack is replaced.

4

Label

Battery pack

Battery connecter

CAUTION:

• When connecting or disconnecting the battery connecter, be sure to hold the

connector shells. Never pull the battery leads.

• Do not give the battery pack a severe jolt or drop on a hard surface.

• To prevent the battery pack from bulging, heat build-up, or bursting, never use any

battery pack other than the supplied battery pack.

• Never remove the battery pack from the printer and use it for driving any other

device. Such a practice may cause damage to the battery pack or the target device.

• Be sure to install the battery cover after the battery pack is replaced.

— 12 —

4.3 Charging the Battery Pack

The battery pack can be charged in either non-floating or floating modes. In

floating mode, the battery pack can be charged while the printer is operating.

4.3.1 Non-Floating Charging

Turn off the power.

1

Plug the cable connector of the AC adapter into the power connector at the

2

back of printer.

Connect the AC cord of the AC adapter, and plug the other end to a wall

outlet.

3

(1) The POWER lamp comes on in red, indicating that charging has started.

(2) Charging completes in approx. 6 hours when the POWER lamp goes off.

(Trickle charging continues until the AC cord is unplugged from the wall

outlet.)

(3) Disconnect the AC cord of the AC adapter from the wall outlet.

(4) Set the printer's POWER switch to ON. The POWER lamp will come on in

green, indicating that the printer is ready.

4.3.2 Floating Charging

Turn off the power.

1

Connect AC cord of the AC adapter, and plug the other end to a wall outlet.

2

Set printer's POWER switch to ON. The POWER lamp will light in green. Now

you can use the printer while charging the battery pack. (Charging conditions

3

are identical to those in non-floating mode.)

— 13 —

4.3.3 Battery-Powered Operation

The printer is powered only from the battery pack if the AC adapter is left

disconnected. The printer is ready to be run by the battery when its POWER

switch is pressed ON (POWER lamp lit in green). Be sure to press the POWER

switch OFF (POWER lamp goes off) after every use.

Protecting the Battery Pack

(1) If the battery voltage drops to around 5.9 V, the POWER lamp starts blinking in

green to indicate low voltage. The printer can deliver a low voltage alarm to

an external device (by setting DIP switch1-5).

(2) If the battery voltage drops further to around 5.6 V, the printer is automatically

turned off.

(3) If the printer is powered up again, the POWER lamp will either come on or

start blinking in green (in Standby mode). If printing resumes, the printer will

shut down soon again due to low battery voltage.

* In the case of (1) or (2) above, the battery pack requires recharging.

Low Voltage Signal

If the battery voltage drops to 5.9 V while in battery-powered operation, the printer

can deliver a low voltage signal.

(1) Serial interface → Sends a DTR indicating low voltage.

DIP switch1-5

OFF = Send no DTR.

ON = Send DTR.

(2) Parallel interface → Sends a SELECT (L) indicating low voltage.

DIP switch1-5

OFF = Send no SELECT.

ON = Send SELECT.

Power Save and Auto Power Off Features

(1) If the printer receives no print data from the host, or not operated, for a set

time period, it enters power save mode to reduce unnecessary battery

consumption. (The timer is set to 10 minutes by default. It can be set with a

DIP switch.)

POWER lamp’s luminance in green is reduced to a half, indicating that the

printer is in power save mode.

(2) If the power save mode continues for another 10 minutes, the auto power off

feature automatically turns the printer off.

(3) The printer can be repowered by cycling the POWER switch.

— 14 —

4.3.4 Battery Voltage Check

If the battery voltage drops below 5.6 V, the voltage check feature automatically

shuts off the printer (POWER switch is left at ON). While the printer may be

repowered by cycling the POWER switch, the battery pack will require recharging

at this point.

The voltage check feature is more likely to activate in print mode than standby

mode. It activates the battery pack protection circuit and shuts off battery power

supply.

CAUTION:

• While the battery pack is charging, the battery cover will become slightly hot. This

will cause no problem.

• If the battery cover becomes too hot (50°C or above) while charging, immediately

unplug the AC cord from the outlet and call your dealer.

• Charging efficiency depends significantly on the ambient temperature. The most

efficient temperature range is from 10°C to 30°C. It is recommended you charge the

battery pack within this optimum range.

• To prevent possible electrolyte leakage, do not leave the battery pack connected to

the printer for a long time period. Also be sure to turn the printer power off after

every use.

• Be sure to recharge the battery pack before using the printer 1) for the first time after

purchase or 2) again after remaining idle for more than 3 months. The battery pack

will also self-discharge during extended periods of storage. It is recommended you

recharge the battery pack every 3 to 6 months.

• If the battery pack is recharged after the printer is left unused for more than 3

months, the charging cycle may terminate before the battery pack is fully charged

up. In such a case, repeat the charging/discharging cycle several times.

• After the battery pack is taken out of low-temperature (0°C or below) or hightemperature (40°C or above) storage, do not use it until its temperature falls within

the operating range and stabilizes. Otherwise, you may encounter problems with low

voltage or lowered performance.

• Do not attempt to modify the built-in battery charger in the printer. It should only be

used for charging the supplied battery pack. To prevent the battery pack from

bulging, heat build-up or bursting, only charge with the supplied battery pack

charger.

• Charge the battery pack with the dedicated built-in charger and within the specified

charging time.

Running the battery pack through repeated partial charge and drain cycles may cause

a gradual reduction of return power called “memory effect” that shortens battery

life.

• If the printer or its internal battery pack shows any sign of electrolyte leakage,

discoloration, deformation, or odd smell, immediately stop using the printer. Then

call your dealer.

— 15 —

CAUTION:

• If a charging cycle does not complete within the specified time, stop charging at that

point. This will help prevent electrolyte leakage, heat build-up, or bursting.

• The battery pack has a limited life. If charging cycle time is significantly shortened

although the specified charging requirements are satisfied, it is most likely that the

battery life has expired. Replace it with a fresh one.

• To prevent the battery pack from lowered performance or low voltage, do not leave

the printer power turned on for a long time period.

• Do not attempt to charge the battery pack when not connected to the printer.

• Due to its electrochemical nature, battery pack performance gradually degrades as

a result of long-term storage and repeated use.

• Due to memory effect, the battery pack may not fully charge when plenty of energy

still remains in it. Fully discharge the battery by printing before recharging again.

• If the battery pack only provides very short operating performance, its battery life

has most likely expired.

— 16 —

4.4 Reset

4.4.1 Reset during a Printing Task

The printer, when operating on battery power, may reset (POWER lamp goes off)

while it is printing dense patterns or images. This is because the battery voltage

drops below 5.6 V due to dense pattern, tripping the battery protection circuit. This

phenomenon is more likely to occur after the battery voltage starts dropping. If the

printer resets too frequently despite this action, recharge the battery pack.

4.4.2 Voltage Drop

Battery voltage drop increases with the number of simultaneously active dots,

which makes the printer more likely reset. This phenomenon is likely to occur in

battery-powered operation.

Increased print density may be another cause of frequent reset because it extends

strobe length although the number of active dots is not affected. (default print

density is at standard level). In particular, reset can occur when printing under low

temperature conditions.

— 17 —

4.5 Power Save and Auto Power Off

To save unnecessary battery consumption, the printer automatically enters the

power save mode if it receives no print data, or is not operated, for approx. 10

1

minutes. If the same inactive state continues for another 10 minutes, the auto

power off feature automatically turns the printer off. (The timer intervals can be set

with a DIP switch.)

No data, no operation (variable)↓Power Save (fixed to 10 min.)

↓

↑

Auto Power Off

• Can be set with a DIP switch.

• The auto power off feature is inactive when the head-up lever is pulled up or, PE/

PNE feature is active.

(1) Serial interface

DS2

5

OFF

ON

OFF

ON

6

No data, no operation

OFF

OFF

ON

ON

10 min.

20 min.

30 min.

Power Save

No time limit

↑

10 min.

↑

↑

Auto Power Off

NO

YES

No data, no operation for 10 min.

↑

No data, no operation for 20 min.

↑

No data, no operation for 30 min.

Remarks

Auto Power Off is inactive.

• By default, DS2-5 and DS2-6 are set to ON and OFF, respectively.

• “No data“ means that no print data is being sent from the host to the printer.

• “No operation“ means that neither the FEED switch nor the head up lever on the

printer is operated.

• The printer enters the normal mode from the power save mode when its FEED

switch or head up lever is operated or power is applied from the AC adapter to

the printer's DC IN port.

(2) Parallel interface

DIP switches DS2-1 and DS2-2 are used for parallel interface.

To repower the printer after it is turned off by auto power off, temporarily set its

POWER switch to OFF, then set it back to ON. At this time all data will initialize.

2

The power save or auto power off feature is disabled when the printer is powered

from the AC adapter.

3

— 18 —

4.6 Connecting Interface Cable

Turn off the power. (Mating side included)

1

Check the top and bottom of cable terminals, and connect to the interface

connector.

2

Fix the cable terminals. Serial interface : Tighten screws, to fix it.

3

Connect the cable to the host computer.

Parallel interface : Turn a stopper, to fix it.

4

CAUTION:

• Referring to "6. PARALLEL INTERFACE" and "7. SERIAL INTERFACE," check the pin

configuration of the interface connector and cable. Wrong wiring could cause

trouble or malfunctioning to not only the printer body but also the host computer.

• When disconnecting/reconnecting the interface cable, be sure to hold the connector.

Pulling the cable itself may snap the internal wires.

• Connect the interface cable securely. Otherwise, communications may not be

obtained due to a connection failure.

— 19 —

4.7 Inserting the Paper

CAUTION:

• Be sure to use the specified paper roll.

• Use of non-specified paper may not guarantee the print quality, printing head life,

and so on.

Hold the convexity on the rear of the printer cover, and raise it upward.

1

Cut the front end of the paper roll almost at a right angle.

2

CAUTION:

• The printer cover is not stationary (Opening/Closing). After detaching it, be careful

not to lose or break it.

• Do not insert a ragged or dog-eared end of the paper roll, because it could result in a

paper jam or insertion error.

Good Good Good No Good No Good No Good

Make sure that the power is turned on.

3

Pull the head-up lever to this side to raise up the printing head.

4

If there is still some paper remaining after a paper-out indication, eliminate the

paper roll according to “4.8 How to Remove Remaining Paper Roll.”

5

Insert the front end of the paper roll straight into a paper insertion slot.

6

Set the paper roll firmly in the paper holder.

7

— 20 —

Put back the head-up lever. The paper roll is automatically pulled in by the platen

roller to feed a constant amount of paper. (When auto-loading is enabled.)

8

Put back the printer cover.

9

CAUTION:

• If the paper roll is still slack, rewind the paper to remove the slack.

• If the paper roll is tilted, raise the head-up lever to correct the paper roll position, or

pull out the paper roll and set it again.

• Do not open the printer cover while printing.

• Do not hold or press the paper roll while printing, because it could cause a paper

jam.

• After the paper is set, the printer is made ready to start printing. Note that if data is

remaining in the buffer, the printer will start printing after the paper is set.

• Do not run the printer with its cover removed, because it could cause

malfunctioning or an irregularity of the sensor.

— 21 —

4.8 How to Remove Remaining Paper Roll

Remove the printer cover.

1

Raise the head-up lever.

2

Gently pull out the paper to the near side. If the paper roll is still remaining, cut it

just before the paper insertion slot before pulling it out.

3

CAUTION:

• Do not pull out the paper roll in the opposite direction.

• Never take out paper with the head-up lever lowered, because it could damage the

printing head.

• The printer mechanism may be very hot just after printing, so be duly careful.

— 22 —

4.9 Eliminating the Paper Jam

Turn off the power.

1

Detach the printer cover.

2

Cut the paper roll near the paper insertion slot.

3

Raise the head-up lever.

4

Raise the blue levers located on both sides of the platen roller unit, to gently

detach the unit. The platen roller unit can be detached by manually raising the

5

blue levers.

Remove the remaining paper roll completely from the paper passage.

6

Confirming the direction of the platen roller unit, reattach it to the mechanism.

7

Shift down the blue levers on both sides, to fix the unit.

Lower the head-up lever.

8

— 23 —

CAUTION:

• Do not carry out this work just after printing because the printing head is very hot.

• Be sure to turn off the power when detaching the platen roller unit.

• When eliminating remaining paper, do not touch the heating surface of the head with

a bare hand or metal piece.

• Do not detach the platen roller unit unless necessary, such as for a paper jam.

• When putting back the platen roller unit, be sure to confirm that it is correctly

reattached.

• Never detach or reattach the platen roller unit with the head-up lever lowered.

4.10 FEED Switch Function

4.10.1 When Thermal Paper is Used

Pressing the switch, feed the paper by 1 line. If the switch is held down, the paper

will be fed continuously.

4.10.2 When the Macro is Executed

If the ERROR lamp is blinking while waiting for execution of a macro, press the

FEED switch. The waiting state continues until the switch is pressed.

4.11 Paper End Function

If the printing paper runs out, the parallel interface will output BUSY, FAULT, and

PE to the host, and the serial interface will output DTR to stop printing,

respectively. If some data are still remaining in the buffer, printing will be resumed

after replacing the paper. Replace the paper according to “4.7 Inserting the Paper.”

After replacing the paper, cancel BUSY (DTR), FAULT, and PE outputs. For details,

see “4.12 Paper Near End Function.”

— 24 —

4.12 Paper Near End Function

If the paper is running out, the PNE sensor informs the host computer that the

paper is running out, by means of a signal output or the PAPER lamp on the panel.

The PAPER lamp is illuminated unconditionally.

If the PNE sensor detects that the paper is running out, the PAPER lamp will be

illuminated.

1

If PNE is enabled, the parallel interface will output PE. (At initial setting)

2

Printing is allowed up to about 1.5 m. (Initial value) After printing or feeding the

paper by a specified amount, the parallel interface will output BUSY and FAULT,

3

and serial interface will output DTR to stop printing, respectively.

Replace the paper according to the procedure in “4.7 Inserting the Paper.”

4

After replacing the paper, cancel the BUSY (DTR), FAULT, and PE outputs.

5

(1) The following lists the outputs made by the near paper end function and the

paper end function. The output state can be changed by the DIP switch or a

command.

DS1-1

State

OFF

*Mark : Default setting

PNE : Paper Near End

PE : Paper End

ON

PNE

Function

Disabled

Enabled

PE Signal Output Setting

When PE is selected*

When PNE is selected

When PE is selected

When PNE is selected*

by Command

PE Output

When PE is detected*

When PNE is detected

When PE is detected

When PNE is detected*

— 25 —

BUSY (DTR)/

FAULT Output

When PE is detected*

When PE is detected

When printing stops

due to PNE*

When printing stops

due to PNE

PAPER

Lamp

At PNE*

At PNE

At PNE

At PNE*

(2) Print amount after detecting PNE

When PNE is enabled, a printable amount after PNE detection can be adjusted.

PNE is detected when the remaining amount of the paper roll is about 2~3 m.

(It depends on the paper quality used, paper thickness, and operating

environment.)

An initial value is 1.5 m. Up to 1.5 m can be printed after detecting PNE. At

this time, with the approx. 70µm-thick recommended paper, the remaining

amount of the paper will be about 0.5~1.5 m when printing stops.

It can be adjusted between 0 and 2.55 m with a command. Adjust it

depending on the operating environment and paper quality.

Depending on an adjustment value, paper end may be detected (Printing stop)

first.

If PNE is detected at power-on, a set amount of printing will be done from that

point. (The default is 1.5 m)

— 26 —

4.13 Auto-Loading Function

This printer has a function to automatically set the paper. If the paper end sensor,

near paper end sensor, and head-up lever are cancelled, the paper will be

automatically fed by a constant amount in about 1 second.

In order to smooth operation, cancel the head-up mechanism last.

Also, you can use the DIP switch to enable/disable the function. If disabled, autoloading will not be performed.

CAUTION:

• When auto-loading is being activated, do not touch the paper roll, because it could

result in a paper feed failure or cause the paper to be one-sided.

• Be sure to set the paper until it comes into contact with the platen roller; otherwise,

the paper cannot be fed and the printing head could be damaged.

4.14 Self-Print Function

This printer has a function to perform preset printing. Turn on the power with the

FEED switch held down. It will print the ROM version, DIP switch state, characters

used, kanji, etc. After self-printing is completed, the printer restores its normal

operating conditions.

CAUTION:

• Do not use this function when the paper roll is running out.

• Data communication cannot be done during self-printing.

— 27 —

4.15 Operation Panel and Display of Error

1. POWER lamp (Green/Red)

The POWER lamp indicates printer status with 2 colors.

(1) When powered by AC adapter (battery pack is charged in floating mode)

Item

Charging

battery pack

Floating

charging

Status

Charging

Fully charged

Printing

Charging

Fully charged

POWER

Switch

OFF

OFF

ON

ON

POWER

Lamp

(Green)

Off

Off

Lighting

Lighting

POWER

Lamp

(Red)

Lighting

Off

Off

Off

(2) When powered by battery pack (AC adapter disconnected)

Item

Battery

powered

Power Save

or Auto

Power Off

Status

Non-

operation

Printing

Below 6.5 V

Below 6.0 V

No data, no

operation

Power Save

Auto Power

Off

POWER

Switch

OFF

ON

ON

ON

ON

ON

ON

POWER

Lamp

(Green)

Off

Lighting

Blinking

Off

Lighting

Lighting at

half

luminance

Off

POWER

Lamp

(Red)

Off

Off

Off

Off

Off

Off

Off

Timer set with DIP switch

Timer fixed to 10 min, and

POWER lamp (Green)

lights at half luminance.

*If the printer turns off with auto power off, it can be repowered by cycling the

POWER switch.

Remarks

Trickle charging

Remarks

Low Voltage signal

(10/20/30 min.)

— 28 —

2. ERROR lamp (Red), PAPER lamp (Red)

Indicates an error by illuminating or blinking the lamps.

Error

ERROR Lamp

Display

PAPER Lamp

Reset

Memory check error

Head-up

Head overheat

Paper near end

Paper end

Macro execution wait

Quick blinking

ON

Blinking

OFF

OFF

Slow blinking

OFF

OFF

OFF

ON

ON

OFF

Cannot be reset

Lower the head-up lever.

Automatically reset by a

temperature drop

Set a new paper roll after a

print stop.

Set a new paper roll.

Press the FEED switch.

<Error Details>

Head-up ----- Occurs when the head-up lever is raised. The printer cannot

feed the paper or print. The parallel interface outputs BUSY

and FAULT, and serial interface DTR, respectively.

Head overheat ----- If the temperature of the printing head rises (About 65°C or

more), in order to protect it against overheating, a printing

head temperature sensor will be activated to stop printing.

The parallel interface outputs BUSY and FAULT, and serial

interface DTR, respectively. If the temperature drops (About

60°C), printing will be automatically resumed.

Paper near end ----- If the diameter of the paper roll decreases, the paper near

end sensor will react to inform you that the paper roll is

running out. See “4.12 Paper Near End Function”.

Paper end ----- If the paper roll runs out, the paper sensor near the printing

head will react to stop printing. See “4.11 Paper End

Function”.

— 29 —

4.16 Red/Black Print (Precautions for Use)

(1) Types of paper

The red and black two-color thermal paper changes its colors by controlling

the energy applied to the thermal head. It is largely divided into two types,

depending on the color development order. Select either of them to suit your

application.

1. Red-based two-color thermal paper (PB670: MITSUBISHI PAPER)

Red print (low energy) → Black print (high energy)

2. Black-based two-color thermal paper (735FA: RICOH)

Black print (low energy) → Red print (high energy)

(2) High-energy printing rate

High-energy print (black print on red-based paper, or red print on black-based

paper) required the application of high energy to the thermal head. To protect

the service life of the thermal head, use the following printing ratio as a

guideline. Also use the default printing rate.

1. Continuous print of high-energy print only : 6 % or less

2. Mixed continuous print of low-energy and high-energy print

: 30 % or less of the

standard printing rate of

12.5 %

3. Printing rate per dot line : 50 % or less

(3) Minimum dots for high-energy print

When high-energy print is used, the recommended minimum area is 3 dots

(length) x 3 dots (width) or more. Depending on the set printing density, the

paper used, or the printing characters, a sufficient change of color tone may

not be obtained even by high-energy print.

(Characters such as [, !, ', (, i, -, font B with small dot matrix)

It is recommended to use in such printing patterns as double-width characters,

double-height characters, double-width and -height characters.

CAUTIONS

• If high-energy print is continuously carried out at a high operating ambient