Page 1

User’s Manual

DOT MATRIX PRINTER MECHANICAL

CONTROL LSI FOR DP910 SERIES

MODEL

Rev.1.00 Newly issued Sep.30th,2000

CBM-909PC SERIES

Page 2

REVISION

Rev.No. Date Content

1.00 Sep. 30, 2000 Newly issued

i

Page 3

CBM-909PC Series User’sManual

CONTENTS

1. General Specifications .................................................................................................................................................... 1

1.1 LSI Package.............................................................................................................................................................. 1

1.2 LSI Type ................................................................................................................................................................... 1

1.3 Printing functions ..................................................................................................................................................... 1

1.4 Control functions...................................................................................................................................................... 2

1.5 Operating voltage ..................................................................................................................................................... 2

1.6 Oscillation frequency ............................................................................................................................................... 2

2. Electrical Characteristics ............................................................................................................................................... 3

2.1 Absolute maximum ratings ...................................................................................................................................... 3

2.2 Operating range ........................................................................................................................................................ 3

2.3 Characteristics of LSI............................................................................................................................................... 4

2.4 Pin configurations .................................................................................................................................................... 5

3. Description of signals ...................................................................................................................................................... 8

3.1 Description of control signals .................................................................................................................................. 8

3.2 Description of communication signals .................................................................................................................. 14

3.3 Description of printer control signals .................................................................................................................... 17

3.4 Description of control functions ............................................................................................................................ 18

4. Control commands ........................................................................................................................................................ 19

4.1 Print command ....................................................................................................................................................... 19

4.2 Cancel command .................................................................................................................................................... 19

4.3 Enlarged character.................................................................................................................................................. 19

4.4 Power down control ............................................................................................................................................... 19

4.5 ESC control ............................................................................................................................................................ 23

5. Character code table ..................................................................................................................................................... 24

5.1 International character codes ................................................................................................................................. 24

5.2 Japanese character codes........................................................................................................................................ 26

ii

Page 4

CBM-909PC Series User’sManual

The CBM-909PC Series Control LSI is intended for driving the mechanism of DP910 series printer.

TYPE

CBM – 909PC – 2 D

Model name

Control LSI

Column capacity

2: 24 Columns

4: 40 Columns

Type of package

D: DIP type

F: Flat type

iii

Page 5

1. GENERAL SPECIFICATIONS

1.1 LSI Package

1) D type: 42 pin plastic Shrink DIP

2) F type: 44 pin plastic QFP

1.2 LSI Type

C-MOS LSI

1.3 Printing Functions

Mechanism of the DP-910 series

1) Printing system: Mechanical dot matrix

2) Printer specifications:

Model Digits Printing Speed Control Board

MD-910 24 2.5 l/S CBM-909-2XX

MD-911 40 1.8 l/S CBM-909-4XX

CBM-909PC Series User’sManual

3) Types of characters

Japanese International 24 Digits 40 Digits

JIS 128 CH. V 5 x 8 dots 7 x 8 dots

ASCII (C) 64 CH. V 5 x 8 dots 7 x 8 dots

ASCII ($) 32 CH. VV5 x 8 dots 7 x 8 dots

Graphic 32 CH. VV6 x 8 dots 7 x 8 dots

Ext. char. registration

8 CH VV6 x 8 dots 7 x 8 dots

* Half dot included.

4) Line space: 2 dots, 1/36 inch (at initial setting)

5) Printing direction: L-type/R-type selectable

L-type=From the left to the right, R-type=From the right to the left

6) Bit image printing: The data subsequent to a bit image command is printed in the bit image mode.

*

1

Page 6

1.4 Control functions

1) Paper feed function

2) Self printing function

3) Buffer-full automatic printing function

4) Emergency stop function

5) Control codes

Print command: CR or LF

Input data cancel: CAN

Enlarged character printing: Double (transverse direction)

International character printing: 32 characters

Bit image printing: ESC + K + n1 + n2 + n3

CBM-909PC Series User’sManual

External character registration function: 8 characters at maximum

Line space seetting: Even number of lines out of 4 to 255 dot lines

Power-down function: DC2, DC3

Paper feed command: (ESC + B + n, 4 ≤ n ≤ 255)

1.5 Operating Voltage

1) Voltage: VDD=4.5 to 6.0 V DC at operating

VDD=3.5 to 6.0 V DC at low speed mode.*1

*1 The LSI is operated at low speed mode for first 60 ms after resetting the system.

2) Current:

VDD=5.0 V

At operating : 2.5 mA (typ.)

At power-down : DC2 0.5 mA (typ.)

At power-down : DC3 0.5 uA (typ.)

1.6 Oscillation frequency

4.19 MHz ±0.5%

2

Page 7

2. Electrical Characteristics

2.1 Absolute maximum ratings (Ta=25°C)

Item Symbol Test condition Ratings Unit

Power Supply VDD Ta = 25˚C –0.3~7.0 V

Input Voltage *1 Vi Ta = 25˚C –0.3~VDD+0.3 V

Storage temperature Tstg. — –65~150 ˚C

2.2 Operating Range

Item Symbol Test condition Ratings Unit

Power Supply VDD Operating 4.5~6.0 V

CBM-909PC Series User’sManual

low speed mode 3.5~6.0 *2 V

Operating temperature Top — –40~85 ˚C

Note)

*1. If the input voltage exceeds a rated value, malfunctioning results, and in the worst case, the IC may be destroyed.

At power-on time, do not apply an input signal prior to VDD.

*2 Under regular operations it will operate in the high speed mode between the range of 4.5-6.0 V

Before moving on to the normal operations after the power down or power on function, it will operate in low

speed between the 60 ms and operates between 3.5 and 6.0 V.

Ensure that an input signal is not input before the VDD when turning on the power. If the input signal should

come first, then add an electric current limited resistance (1k-ohm) in the series with the input ports.

3

Page 8

2.3 Characteristics of LSI

Item Sym. Test condition MIN Typ MAX Unit

“H” Input Voltage VIH

“L” Input Voltage VIL

“H” Output Voltage VOH

“L” Output Voltage VOL

Port

VDD =

4.5

~

6.0 V

CBM-909PC Series User’sManual

(Ta=–40~85°C, VDD=3.5~6.0 V)

Port 0.8 VDD VDD

V

x1, x2 VDD –0.5 VDD

Port 0 0.2 VDD

V

x1, x2 0 0.4

IOH = –1 mA VDD –1.0

V

IOH = –100 µA VDD –0.5

IOL = 1.6 mA 0.4

V

IOL = 400 µA 0.5

“H” Input Leakage Current

“L” Input Leakage Current

“H” Output Leakage Current

“H” Output Leakage Current

Built-in pull-up Resistance *2

Current

ILIH Port. VIN = VDD 3 µA

ILIL Port. VIN = 0 V –3 µA

ILOH Port. VOUT = VDD 3 µA

ILOL Port. VOUT = 0 V –3 µA

RL

IDD

*1

VDD = 5.0V

± 10%

Port

VDD = 3.0V

± 10%

f = 4.19 MHz

VDD = 5.0V ± 10%

At operating

Halt mode

VDD = 5.0V ± 10%

Stop mode

15 40 80

kΩ

30 300

2.5 8.0 mA

500 1500 µA

0.5 20 µA

Note)

*1. The IDD current is not included the current through the built-in pull-up resistance.

*2. At operating, the pull-up resistance in ports P10~P13, P20~P23, P30~P33, P60~P63, P70~P73 and P80~P81, will be

set.

At power-down mode, the pull-up resistance in ports P20~P23, P30~P33, P60~P63 and P70~P73 will be set.

Ports P40~P43, and P50~P53 are not built in pull-up resistance.

4

Page 9

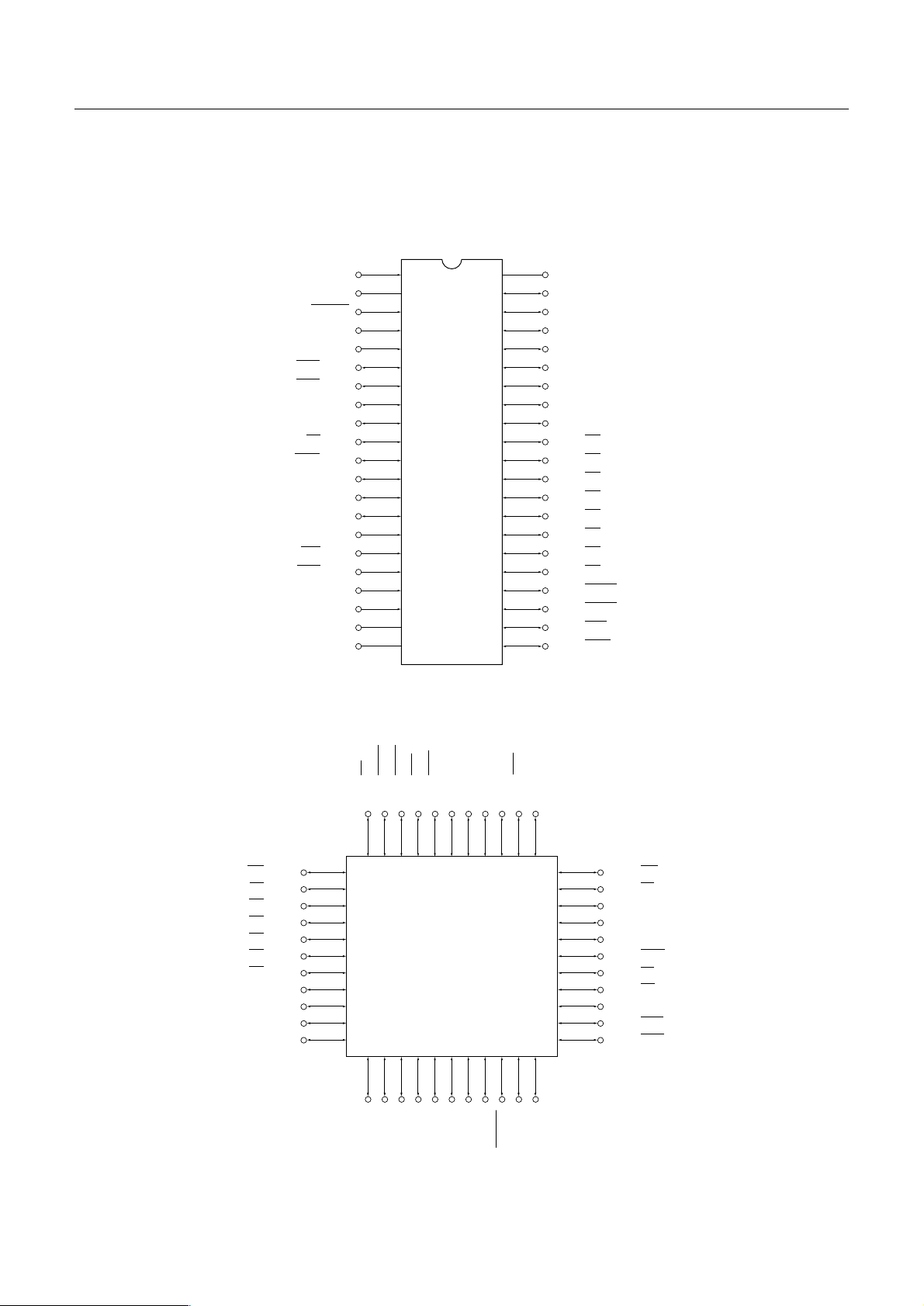

2.4 Pin configurations (Top View)

a) 42 Pin plastic shrink DIP

CBM-909PC Series User’sManual

b) 44 Pin plastic QFP

RDY

ACK

S3

RP

PF

SLIN

PXD

S2

S1

ES

INT

STB

RXD

DP

XT1

XT2

RESET

X1

X2

P33

P32

P31

P30

P81

P80

P03

P02

P01

P00

P13

P12

P11

P10

NC

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

DD

21

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

Vss

P40

P41

P42

P43

P50

P51

P52

P53

P60

P61

P62

P63

P70

P71

P72

P73

P20

P21

P22

P23

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

HA

HB

HC

HD

HE

HF

HG

HH

MSTR

MSTP

PFS

PWC

HG

HF

HE

HD

HC

HB

HA

DB7

DB6

DB5

DB4

P72

P71

P70

P63

P62

P61

P60

P53

P52

P51

P50

10

11

HH

MSTR

MSTP

PWC

PFS

P73

P20

P21

P23

P22

1

2

3

4

5

6

7

8

9

NC

P43

P42

P40

P41

DB3

DB2

DB0

DB1

DP

RXD

STB

DD

V

NC

P10

P11

P12

NC

3435363738394041424344

33

32

31

30

29

28

27

26

25

24

23

2221201918171615141312

SS

V

XT1

XT2

X1

RESET

X2

P13

P00

P01

P02

P03

P80

P81

P30

P31

P32

P33

INT

ES

S1

S2

RXD

SLIN

PF

RP

S3

ACK

RDY

5

Page 10

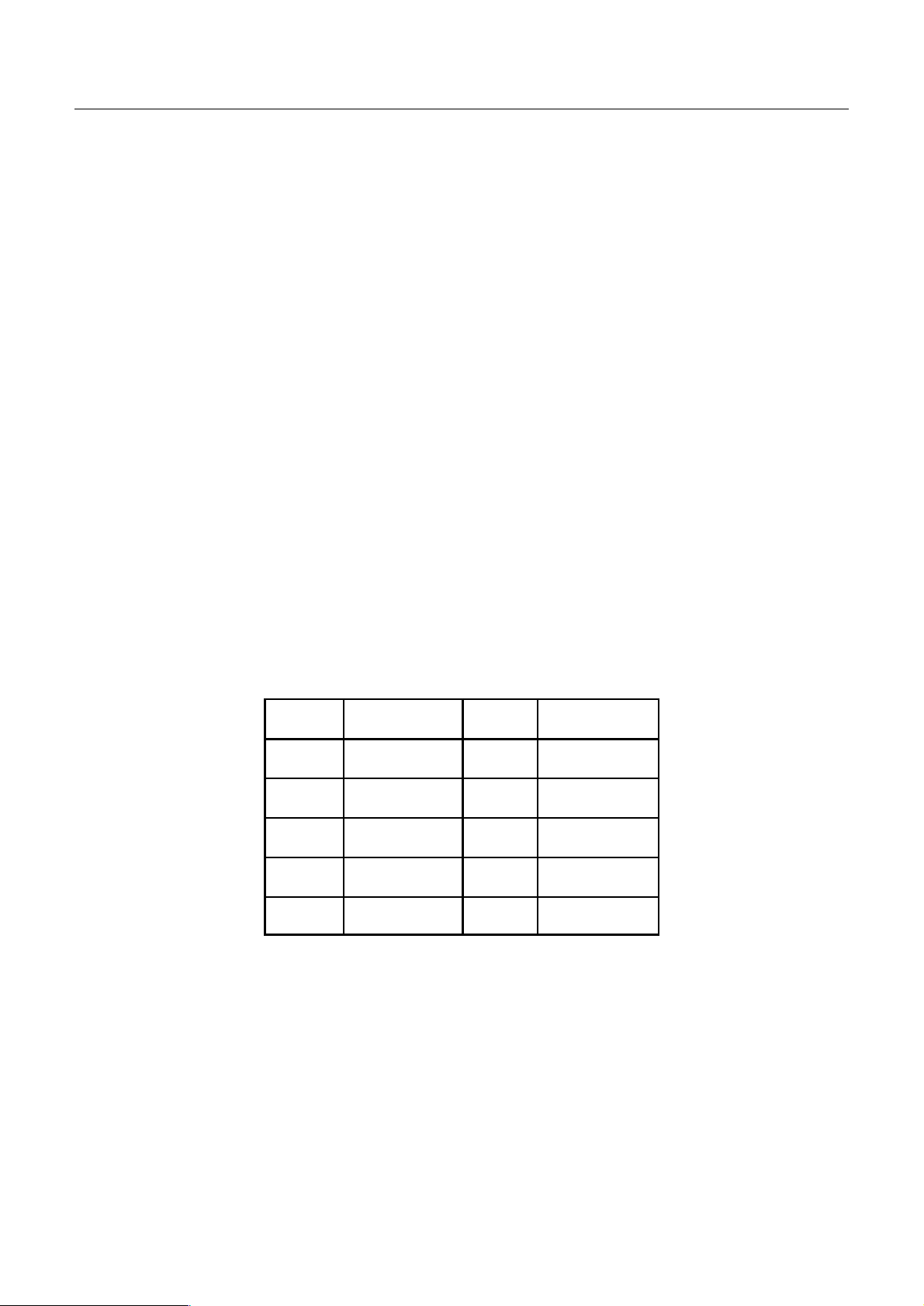

c) Pin Assignment

Pin No. Symbol Signal

QFP DIP IN OUT

CBM-909PC Series User’sManual

Function

18 1 XT1

19 2 XT2

20 3 Reset V

21 4 X1 V

22 5 X2 V

23 6 RDY V

24 7 ACK V

25 8 S3 V

26 9 RP V

27 10 RF V

Connect to VDD or VSS.

Not use

System reset signal. If this signal is set to the Low level, the inside of the

LSI is initialized.

Oscillator terminals. 4.19 MHz ± 0.5%

If receivable at data transfer time, this signal is set to the Low level.

If data read is completed at parallel data receive time, the Low pulse is

output.

Function selection S3.

RP Signal from the printer.

Paper feed signal. Effective only in the off-line mode.

28 11 SLIN V

29 12 RXD V

30 13 S2 VV

31 14 S1 VV

32 15 ES V

33 16 INT V

35 17 STB V

36 18 RXD V

On-line setting signal. When this signal is at the Low level, the on-line

mode is selected to enable data transfer. When this signal is at the High

level, the off-line mode is selected to disable data transfer.

Serial transfer. Serial data input pin.

Function selection S2 * 1

Function selection S1 * 1

Power-down command signal. If this signal is set to the Low level, control

is interrupted and oscillation stops, resulting in the power-down mode.

Power-down reset signal. If this signal is set to the Low level, the powerdown mode is reset.

Strobe pulse input

Negative logic

“Low”=8-bit data read

DIP type: Connect to 12 PIN

QFP type: Connect to 29 PIN

37 19 DP V

DP signal from the printer

6

Page 11

Pin No. Symbol Signal

QFP DIP IN OUT

CBM-909PC Series User’sManual

Function

38 20

39 21 VDD

40 22 PWC V

41 23 PFS V

42 24 MSTP V

43 25 MSTR V

44 26 HH V

127 HG V

228 HF V

329 HE V

430 HD V

531 HC V

NC

Power

The DC-DC converter control signal.

PF Solenoid signal.

Motor brake signal.

Motor drive signal.

Print solenoid drive signals.

632 HB V

733 HA V

8 34 DB7 V

9 35 DB6 V

10 36 DB5 V

11 37 DB4 V

13 38 DB3 V

14 39 DB2 V

15 40 DB1 V

16 41 DB0 V

17 42 VSS

12

Parallel data (8 bits)

Positive logic

“High”=“1”

”Low”=“0”

GND

NC

34

7

Page 12

3. Description of signals

3.1 Description of control signals

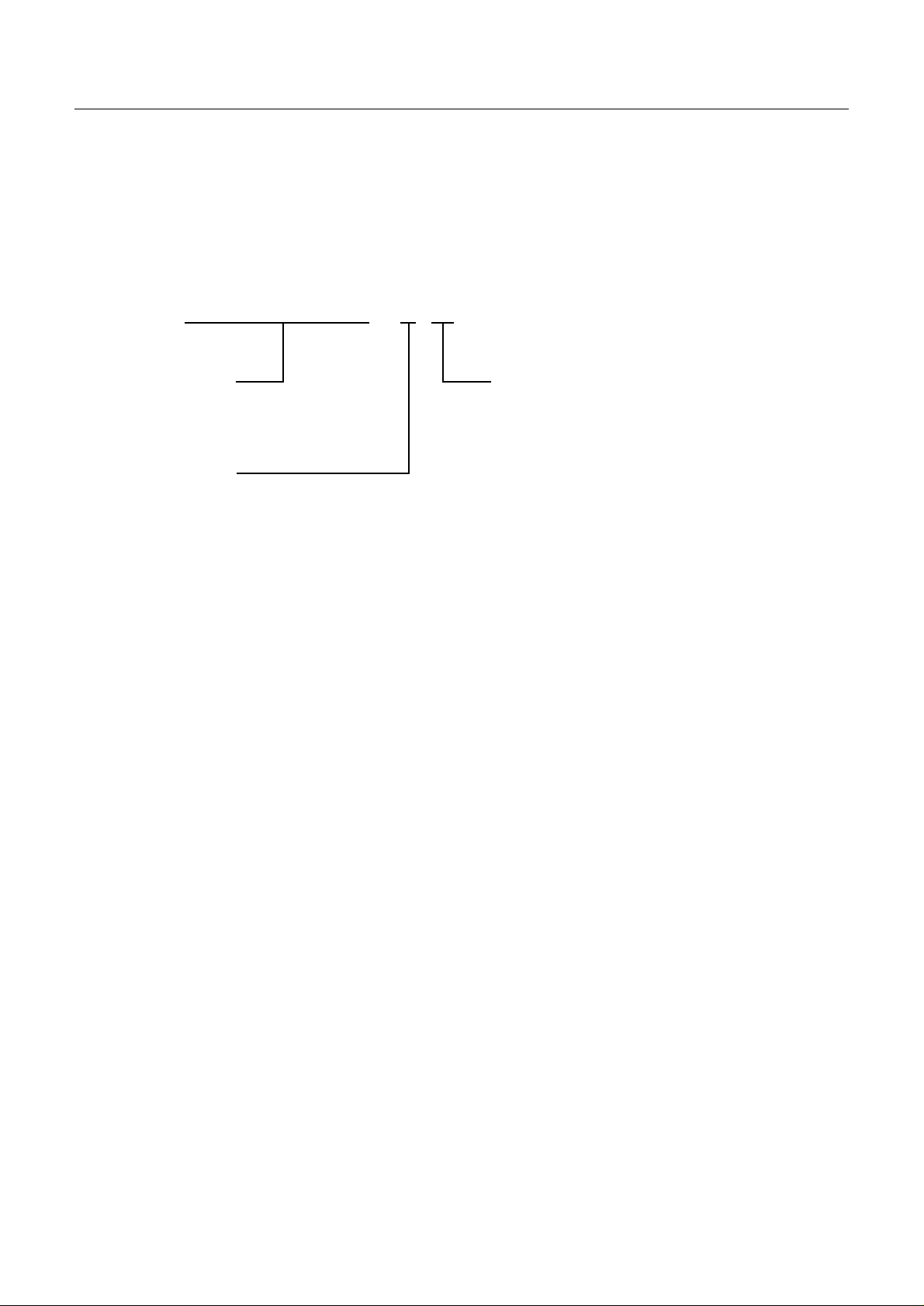

1. RESET

The LSI is initialized by setting the reset pin at the low level. The reset pulse is required to be 10 µS or more,

while the LSI is operating. When the power is switched on, if using the ceramic oscillator, send the low level

signal for 4 ms through the reset pin.

However, unless oscillation is stabilized, it is necessary to set the reset pin to the low level. After oscillation

is stabilized, set the reset pin to the high level.

VDD

PWC

CBM-909PC Series User’sManual

Reset

Oscillation

Low speed

1 Wait mode

Approx. 31.3 ms Approx. 60 ms

It is necessary to secure an oscillation stabilization time (4 ms or more).

1

mode

High speed

operation

8

Page 13

Resetting the stop mode

DC3 code

CBM-909PC Series User’sManual

Reset

PWC

Operating

Oscillation

*2) At low speed mode, power source range of 3.5~6.0 V, activate the DC-DC converter with the PWC signal

and supply the LSI with a voltage between 4.5~6.0 V.

As a result, you will obtain the operation voltage range between 3.5~6.0 V.

Resetting the halt mode

1

2

HALT HALT

Stop mode Wait mode Low speed mode

Approx. 31.3 ms Approx. 60 ms

Operating High

speed mode

RESET

PWC

Operating

Oscillation

DC2 code

HALT mode Wait mode

Low speed mode High speed mode

Approx. 31.3 ms Approx. 60 ms

9

Page 14

CBM-909PC Series User’sManual

2. PWC

This terminal will be in the “LOW” level under the low-speed operation mode (60 ms) and normal operation

mode. It will be in the “HIGH” level during power down.

By controlling (Refer to the circuitry diagram on p. XX, item XX) the DC-DC converter with the PWC signal, an

operation voltage range between 3.5-6.0 V can be obtained.

3. SLIN

Setting the SLIN pin to the Low level places this system in the on-line mode and causes it to be ready to receive

the data.

When this SLIN is at the High level, the system is placed in the off-line mode and can not receive the data. At this

time, it receives the signal PF (paper feed).

This system samples the SLIN signal in the following cases.

• After completing a system reset

• After resetting the power-down mode

• While the data is ready

• While the paper is being fed

V When the SLIN signal is set to Low during paper feed by the PF signal, the system is placed in the on-line

mode after ocmpleting that feed.

V When the SLIN signal is set to High during the text mode, the system is placed in the off-line mode after

printing the data in the print buffer.

V When the SLIN signal is set to High during the bit image mode, the data in the print buffer is cleared and the

bit image mode is also reset.

4. PF

This is a manual paper feed pin and doubles as a self test printing pin.

This pin accepts a signal only when the system is in the off-line mode, except the power-down mode.

Line feed is performed while this pin is held at the Low level (30 ms or more). To conduct a self printing test, set

the PF pin to the Low level and turn on the power or input the RESET signal.

5. INT

This is used to reset the power-down mode by the DC2 and DC3 command.

V Resetting the power-down mode by the DC2 command.

This is done by setting the INT pin to the Low level for 10 µs or more.

V Resetting the power-down mode by the DC3 command.

This is done by holding the INT pin at the Low level until XTAL oscillation is stabilized, and then, by setting

the pin to the High level.

6. ES

Setting this pin to the Low level interrupts system control and stops oscillation, resulting in the power-down

mode.

Resetting the power-down mode by the ES signal. This is done by holding the ES pin at the high level and

inputting the RESET signal.

10

Page 15

CBM-909PC Series User’sManual

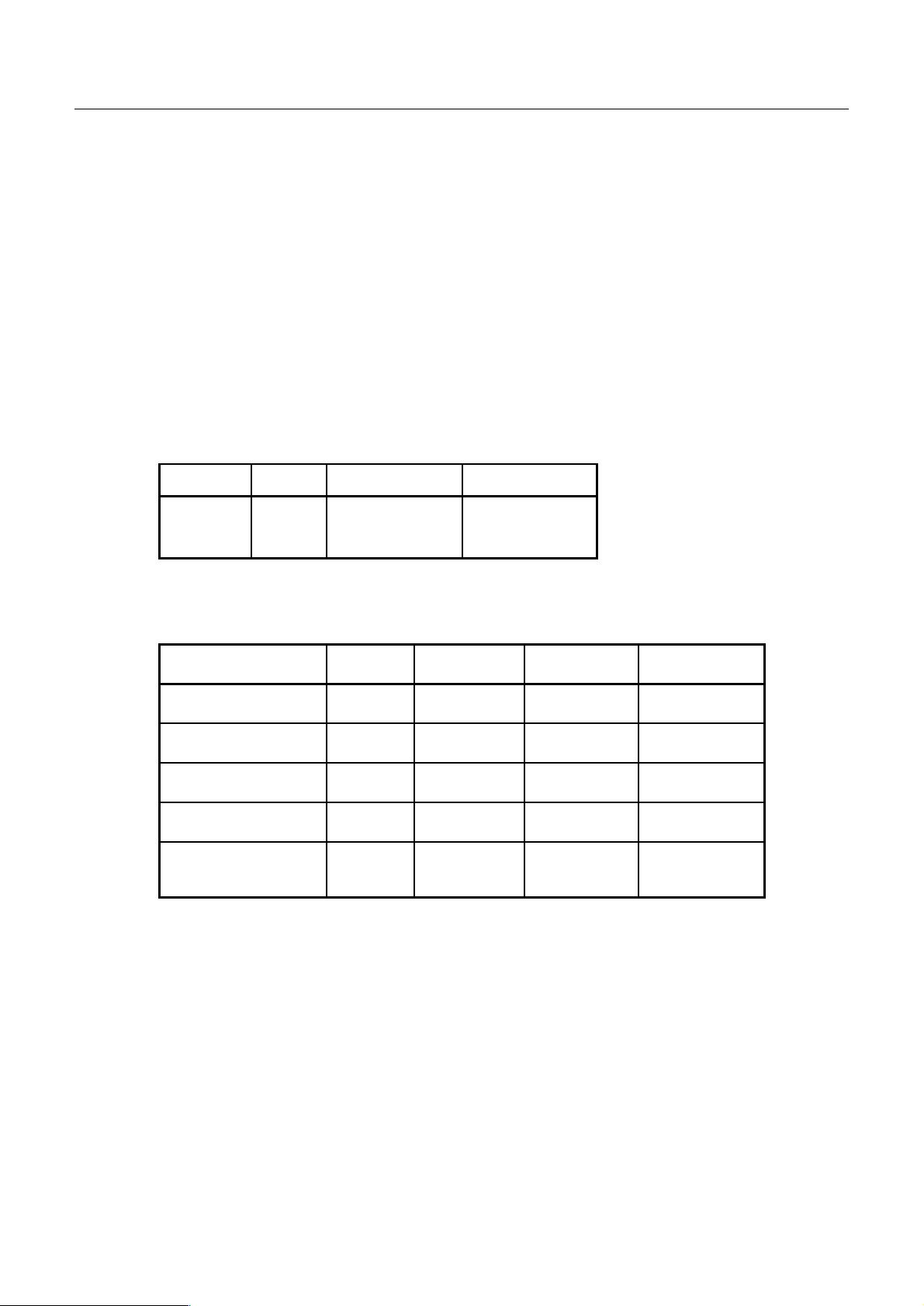

7. S1, S2, S3

Function Setting DIP switch.

Symbol Function OFF ON

S1 Data transfer method Serial Parallel

S2 Printing method L-type R-type

Print command at parallel CR LF

S3

Baud rate at serial 9,600 bps 4,800 bps

1) The S1 and S2 terminals will be used as an input-port at initializing and an output-port at normally operating.

Therefore add a resistance (10 kΩ~47 kΩ) between the S1, S2 terminals and the DIP switch, and then add a

pull-up resistance (100 kΩ~150 kΩ) as shown below.

22

LS1

P23

S1

S2

S3

PWC

P01

P02

P03

14

13

3

R21

R20

47K x 2

150K x 2

VDD

DSW1

1

2

3

11

Page 16

2) Printing method

Printing method is specified by setting DIP switch S2.

For bit image printing, inverted printing is not performed even if R-TYPE is specified.

L–TYPE R–TYPE

CITIZEN

CITIZEN

CBM-909PC Series User’sManual

Paper

advance

123

123456

CBM

Paper

advance

CITIZEN

CITIZEN

CBM

123456

123

Printing direction Printing direction

12

Page 17

8. X1, X2

Use a ceramic oscillator for the clock of this LSI.

The oscillation frequency must be range 4.19 MHz ± 0.5%.

Recommended oscillator parts are the following.

CBM-909PC Series User’sManual

Maker Type f

MURATA

M.F.G

CSA 4.19 MGU

4.19 MHz ± 0.5%

CSA 4.19 MG

C1

C2

Capacitor

C1 C2

Operating

Voltage

30PF 30PF 2.7 ~ 6.0 V

30PF 30PF 3.0 ~ 6.0 V

X1

X2

CSA4.19MG

4.19MHz

9. Others

XT1 and XT2 are the input terminals when using an external clock. However, this LSI is set to use X1 and X2.

Please refrain from using terminal XT2 and connect terminal XT1 to Vss (GND).

The connect terminal NC is not connected to the inside of the LSI.

13

Page 18

3.2 Description of communication signals

1. DB0~DB7

These are parallel 8 bit data receive pins. For more details on the timing of the parallel data reception, refer to

the time chart 3.2-6.

When the SLIN is setting the low level and the RDY outputs low level, the 8 bit data is latched by the STB

signal (low level).

However, until the ACK pulse is output, hold the STB to low level.

2. RXD

This is the input pin to receive the serial data.

Refer to the timing chart 3.2-7.

When the RDY terminal is in the “LOW” level during the on-line status, the serial data from the host

computer can be received via this terminal.

This incorporates a data buffer for one line.

CBM-909PC Series User’sManual

Every time a line is printed the motor will stop, however when data transmission of the next line is finished

while the printing head is returning it can undergo continuous printing without stopping the motor.

3. RDY

This terminal is used for parallel and serial data receptions.

The signals received when the RDY signal is on-line notifies the host that the LSI data can be received.

When Using With a Parallel Interface

After verifying that the RDY signal of the host is in the ”LOW” level, there is a need to output data DB0DB7 and output the STB terminal in “LOW” level.

This LSI will maintain the RDY signal at the “HIGH” level after verifying that the STB terminal is in

“LOW” level.

However, the data read-in is not completed at this time. The data read-in of the LSI is completed only when

an ACK pulse is output.

When Using With a Serial Interface

After verifying that the RDY signal of the host side is in “LOW” level, there is a need to put the RXD signals

in the “LOW” level to perform data communication immediately after.

The RDY terminal is in the “HIGH” level under the following conditions.

a) during power down

b) during off-line

c) during data read-in

d) during printing

What is more, the RDY terminal during system reset will be in the floating status.

14

Page 19

CBM-909PC Series User’sManual

4. STB

This is a terminal used during parallel data reception and to input the data set signals from the host.

For the LSI to output signal level of this terminal it must be in the on-line status and the RDY signal must be in

the “LOW” level. If the STB terminal is in ”LOW” level, the LSI will consider that the data is sent from the host

via the DB0-DB7 and start reading the data after the RDY terminal is switched to the “HIGH” level.

When the LSI completes the data read-in it will output an ACK pulse.

There is a need to keep the STB terminal in the “LOW” level until the startup of the ACK signal at the host is

verified.

5. ACK

This is the data read-in signal used during parallel data reception.

During parallel data reception this terminal is in the on-line status and after outputting the RDY signal it will

verify that the STB terminal is in the “LOW” level.

Then it will output a “LOW” pulse of about 2 µs as a read-in timing signal to input the data in the terminal.

Therefore, there is a need for the data to be stable between, before and after these pulses.

6. Parallel interface timing chart

VDD

RESET

SLIN

RDY

DS0~DDS7

STB

ACK

RF

*1

*2 100 ms (Min.)

*5

*3

1us (Min.) 1us (Min.)

2.0us

90us (Min.)

50us (Min.)

30ms (Min.)

IN

*4

IN

50us (Max.)

OUT

IN

IN

OUT

IN

*1 It is necessary to secure an oscillation frequency stabilization time.

*2 Time required for the LSI to make the SLIN pin sensible after resetting the system.

*3 Since the DTR signal may rise regardless of the STB signal due to printer control, it is necessary to output

the STB signal within 200 µs after checking the DTR signal.

15

Page 20

*4 After this, paper feed is enabled via the PF pin.

*5 The ACK signal is output by 1 pulse after resetting the LSI.

7. Serial interface timing chart

CBM-909PC Series User’sManual

VCC

RESET

SLIM

DTR

RXD

SAMPLING

DATA

PF

*1

*2

*6

D0 D1 D2 D3 D4 D5 D6 D7

*3 *4

*5

*1 It is necessary to secure an oscillation frequency stabilization time.

*2 Time required for the LSI to make the SLIN pin sensible after resetting the system.

*3 The number of start bits should be 1 bit.

*4 The number of stop bits should be 1 bit or more.

IN

IN

50us (Max.)

OUT

IN

IN

30ms (Min.)

*5 After this, paper feed is enabled via the PF pin.

*6 The DTR signal may rise regardless of the RXD signal due to printer control. When transferring the data,

therefore, it is necessary to set the RXD signal to the Low level within 200 µs after checking the DTR signal,

and then, transfer the data.

16

Page 21

3.3 Description of printer control signals

1) RP

This terminal is used to input the signal that determining the printing start position. Connect it on one side of

the reset detector on the printer.

The other terminal of the reset detector is to be connected to the GND or the PWC terminal.

2) MSTR

This is the motor drive signal terminal and the motor will operate when the terminal is in the “LOW” level

status.

3) MSTP

This is the motor control signal terminal and outputs a “LOW” level of a maxinum of 60 ms immediately

after the motor is turned off.

Brake the motor when this terminal is in the “LOW” level status.

4) HA, HB, HC, HD, HE, HF, HG, HH

CBM-909PC Series User’sManual

These terminals output the drive signals of the printer solenoid and the printer solenoid is activated when

these terminals are in the “LOW” level.

5) PFS

This is the paper feed solenoid drive signal and will drive the PF solenoid when this terminal is in the

“LOW” level.

6) DP

Received the printer solenoid drive timing from the printer.

Upon onset of the printer timing, it is advised that the DP signal from the printer is shaped with a transistor,

and then put in the LSI DP terminal since it employs a photosensor.

+V

VDD

DP

P10/Pin#19

Photo-Sensor

17

Page 22

3.4 Description of control functions

1. Buffer full automatic print

When the input buffer is filled up by the character data, it starts the printing automatically.

2. Self test printing

This LSI has a built in self print function.

Take the following procedures to test.

a) Set the paper properly.

b) Turn off the power switch.

c) Turn on the power switch while keeping the PF signal to the low level, then set it to the high level.

d) To stop the printing, turn off the power switch or set RESET signal to low level.

3. Emergency Stop Function

CBM-909PC Series User’sManual

When the following abnormalities are detected during the print operation, cut off the power to the print head

solenoids and motor, and put the LSI in the power down mode.

The emergency stop can be cleared by resetting the LSI.

Printer abnormalities are as follows.

a) Motor lock.

b) Operation defect in the timing detector (DP signal)

c) Operation defect in the reset detector (RP signal)

18

Page 23

4 CONTROL COMMANDS

4.1 Print commands: CR (0DH), LF (0AH)

When the parallel interface is used, either CR or LF code can be selected by preset (S3). If the set CR or LF code

is input, the data in the print buffer is printed and line feed is performed.

When the serial interface is used, only the CR code becomes effective regardless of preset (S3).

When graphic mosaic printing is performed, line feed is not performed by the print command, and graphic mosaic

printing is allowed on the next line.

4.2 Cancel command: CAN (18H)

This code cancels all the data on the identical line in the print buffer, which was input before the code is input.

4.3 Enlarged character printing: SO (0EH)

The printing data following this code is printed with its width doubled.

This function is cleared by the print command (CR LF) or DC4 (14H).

4.4 Power-down control: DC2 (12H), DC3 (13H)

CBM-909PC Series User’sManual

There are two kinds of power-down mode, DC2 and DC3 codes, in order to reduce current consumption. If this

code is received, the power-down mode is put into effect after printing the data received before it.

a. DC2 (12H)

Inputting the DC2 code places this unit in the power-down mode.

At this time, oscillation of the oscillator does not stop.

[Resetting the power-down mode]

a-1) Input to INT

If the Low pulse is applied to the INT pin for 10 µs or more, the condition existing just before power-

down is restored in about 100 ms and allows you to control the printer and transfer the data.

a-2) Input to RESET

If the Low pulse is applied to the RESET pin for 4 ms or more, the power-down mode is reset and the

inside of the unit is initialized to be ready to operate in about 100 ms.

b. DC3 (13H)

Inputting the DC2 code places this unit in the power-down mode.

At this time, oscillation of the oscillator stops. Therefore, current consumption is much less than the DC2

power-down mode.

[Resetting the power-down mode]

b-1) Input to INT

If the Low level is applied to the INT pin for 10 µs, the power-down mode is reset, and about 4 ms after

oscillation is stabilized, the condition existing just before power-down is restored in about 100 ms and

allows you to control the printer and transfer the data.

19

Page 24

CBM-909PC Series User’sManual

b-2) Input to RESET

If the Low level is applied to the RESET pin for 4 ms or more, the power-down mode is reset. However,

unless oscillation is stabilized, it is necessary to set the RESET pin to the Low level. After oscillation is

stabilized, set the RESET pin to the High level.

This initializes the inside of the unit and starts it in about 100 ms.

D0 through D7 are dot points in each position:

“1” for a point, and “0” for a space.

When n1, n2, n3, are specified beyond their ranges, or when n2=n3=0 is specified, the text mode results with the

bit image mode cancelled.

Since this printer prints by 4-dot line, insufficient data is printed as a space after reading in the 4-dot line worth of

data or when the n1, n2, n3, specified data is completed.

IN the MD-910 specifications, when n1,=23 is specified, the 4 dots from the most significant dot (MSC DOT) are

invalidated. This is because there are 180 dots fro one-line printing positions.

Although the text mode has been restored after bit image printing, the line space=0 has been assumed.

Therefore, it is necessary to perform line feed before printing in the text mode.

Note)

For bit image printing, inverted printing is not performed even if R-type is specified.

c. International character setting; ESC + R + n

The ESC + R + n command specifies the following character table of each country.

n Country n Country

0 U.S.A 5 Sweden

1 France 6 Italy

2 Germany 7 Spain

3 Britain 8 Japan

4 Denmark

“n” other 0 to 8 is invalid (not changed).

n=8 (Japan) is set at power-on or after a reset.

20

Page 25

CBM-909PC Series User’sManual

d. External character registration; ESC + & + A1 + A2

Up to 8-character pattern can be registered by inputting the pattern data following the ESC + & + A1 + A2

command.

Registerable character addresses are the code table 20H through OFFH, that is 8 characters.

The character address at the start of registration is “A1”, and that at the end of registration is “A2”.

When registering one character, it should be A1=A2.

When registering multiple characters, it should be A1<A2 and A2-A1 ≤ 7.

When external character registration is done in the same character address duplicately, the pattern registered later

becames effective.

If more than 8 characters are registered, all the character patterns registered so far are cleared.

The pattern data should be as follows.

The MD-910 specifications require 6 bytes per character.

1 1

23456

LSD

MSD

63H255H349H441H541H641H

Pattern data (6 bytes)

The MD-911 specifications require 7 bytes per character.

1 1

234567

LSD

MSD

41H222H355H408H541H600H741H

Pattern data (7 bytes)

The pattern for the MD-911 specifications does not allow the dots to be consecutively arranged in the printing direction

(line direction).

Printing is not allowed at the point “*” to the right of the point “.”shown above. Even if you specify the pattern at the

point “*”, the print “*” of registration is canceled.

21

Page 26

CBM-909PC Series User’sManual

e. Continuous paper feed; ESC + B + n

The ESC + B + n command provides continuous paper feed by “n” lines.

The range of “n” is even-number dot lines within 4 ≤ n ≤ 255.

When “n” is an odd number, it is assumed to be an even number of “n-1”.

When the number within the range of “0 ≤ n ≤ 3” is specified for “n”, this command is canceled.

When there is data in the buffer, this command will be carried out n-dot line feed after printing is completed.

If the range of “n” is within 4 ≤ n ≤ 9, there is no line space.

22

Page 27

CBM-909PC Series User’sManual

4.5 ESC control

The following setting funcitons can be performed by the ASCII code subsequent to the ESC (1BH) code. If you

input other ASCII code than those defined below after the ESC code, that ASCII code and the ESC code are

invalidated. In the following commands;

“n” is an 8-bit binary number.

“+” is a separator for convenience sake.

a. Line space setting command: ESC + A + n

The command ESC + A + n allows you to set the interline space of “n” dots.

“n” should be 0 ≤ n ≤ 255. If an odd number is specified for “n”, the line space will be “n-1” dots.

Initial setting for the line space is 2 dots.

b. Bit image printing: ESC + K + n1 + n2 + n3

The command ESC + K + n1 + n2 + n3 changes over the mode from the text mode to the bit image mode.

The transfer amout of the bit image data entered subsequent to this command is specified with n1, n2, n3.

D7 D6 D5 D4 D3 D2 D1 D0

n3 x 256 + n2

Ranges of n1, n2, n3

n1

1 Byte

n 1 n 2 n 3

MD – 910 1 ~ 18 0 ~ 255 0 ~ 1

MD – 911 1 ~ 23 0 ~ 255 0 ~ 1

23

Page 28

5 CHARACTER CODE TABLE

5.1 INTERNATIONAL CHARACTER CODES

CBM-909PC Series User’sManual

24

Page 29

CBM-909PC Series User’sManual

25

Page 30

5.2 JAPANESE CHARACTER CODES

CBM-909PC Series User’sManual

26

Loading...

Loading...