Page 1

Page 2

Page 3

N500 rev. 3.1 Contents

Chapter 1

Chapter 2

- General description

¾ Standard accessories ……………………………… 1 - 1

¾ Optional accessories ……………………………… 1 - 2

¾ Connections ……………………………………… 1 - 2

¾ Battery ……………………………………………... 1 - 3

¾ General advice ……………………………………… 1 - 4

- General layout

¾ Keys/buttons on the control panel ………...…...……... 2 - 1

¾ General purpose functions …………….…..…… 2 - 4

- Functions associated with measuring phase………. 2 - 4

- Function "Other functions …" ………….…... 2 - 5

- Functions operating on graphs ………….…... 2 - 5

- To save measurements ……………………... 2 - 9

- To capture and save displayed images ………….… 2 - 10

Chapter 3

Chapter 4

Chapter 5

Chapter 6

- Home screen (menu)

- Setup mode

¾ Sensor setup …………………………………..…. 4 - 1

¾ General setup ………………………………..……. 4 - 3

- Vibrometer mode

¾ Vibrometer setup ……………………………….….…. 5 - 1

¾ Vibrometer – Measurement screen…………………….. 5 - 3

¾ Monitoring in time .……………………….……. 5 - 4

¾ Monitoring in speed ……………………….…….. 5 - 5

- FFT (Fast Fourier Transform) analyzer mode

¾ FFT Setup ……………………………………..………. 6 - 1

¾ Spectrum analysis (FFT) ……………………..………. 6 - 4

¾ Waveform function ……………………..………. 6 - 6

¾ Trigger Setup …………………………..…………. 6 - 6

Contents 1

Page 4

Chapter 7

- Balancer mode

¾ Selection of the balancing program ………...……. 7 - 2

¾ Calibration sequence ……………………..………. 7 - 6

¾ Execution of measurement…………………….………. 7 - 8

¾ Unbalance measurement and calculation of the correction 7 - 10

¾ Splitting of correction weight ……………………… 7 - 13

¾ Saving of a balancing program ……………………… 7 - 14

Chapter 8

Chapter 9

- Data manager mode

¾ Archive management ……..…………….………… 8 - 1

¾ Copying /shifting archive on USB key….…….….….… 8 - 2

¾ Sending archive to PC ……..…………….………… 8 - 4

¾ Display of measurements present in the archive ……… 8 - 5

- CEMB PoInTer (optional)

¾ System requirements ………………………...…… 9 - 1

¾ Installation and registration ………………..……. 9 - 2

¾ Measuring points archive ……………………..….…… 9 - 3

- Data manager ……………………..….…… 9 - 3

- Data protection – Password ………...….… 9 - 5

¾ List of measurements …………………………...… 9 - 5

¾ Reading measurements saved on the N500 instrument ... 9 - 6

- Loading of new measurements in archive …...… 9 - 7

- Selection and elimination of measurements …..… 9 - 8

¾ List of measurements to represent on a graph …....… 9 - 8

¾ Display of graphs ………………………..…………..… 9 - 9

- Cursor ………………………..………….… 9 - 10

- Zoom ………………………..……….…… 9 - 10

- Shifting of graphs in window ….…..………. 9 - 11

- Separate/Combine graphs ……………..………. 9 - 11

¾ Creation and printing of certificates and reports ….…... 9 - 12

Appendix A

Appendix B

Appendix C

Appendix D

- Specification

- Evaluation criteria

- A rapid guide to interpreting a spectrum

- Codes that can be used in models for certificates obtained

using the CEMB PoInTer program

Attachment:

2 Contents

Balancing accuracy for rigid rotors

Page 5

Chapter 1

General description

The N500 instrument is supplied, together with its accessories, in a special case. It is

advisable, each time the instrument is used, to place back it in its case in order to avoid risk

of damage during transit.

Standard accessories:

- Two velocity transducers dia. 40

- Two cables for connecting the transducers

- Two magnetic bases

- Two probes

- photocell 18,000 RPM complete with stand and magnetic base

- battery charger

- roll of reflecting paper

- case

- user manual

General description 1 - 1

Page 6

Optional accessories:

- acceleration transducer type TA-18/S complete with connection cable and

magnetic base

- proximity sensor complete with stand, cable and magnetic base

- optical fibre photocell (60,000 RPM) complete with stand and magnetic base

- extension cable, length 10 metres, for transducers

- extension cable, length 10 metres, for photocell

- portable printer for direct printing of certificates on standard thermal or

adhesive paper

- software CEMB PoInTer for data filing, management and printing.

N.B.:

After connecting the printer to the RS232 port, wait for about 5 seconds to allow

completion of the automatic recognition and initialization procedure. Only at this

point will it be possible to make a print-out by pressing relative key

Connections

7654321

1 – battery charger

2 – VGA output 15-pin (only for CEMB Technical Service)

3 – serial port RS232 (connecting of optional portable printer)

4 – 2 USB ports type A (master)

5 – keyboard input PS2

6 – photocell input

7 – 2 inputs, measuring channels

To connect the sensors and photocell, merely plug the connector in the corresponding

socket, pushing it until it clicks into place; make sure that the safety connection is correctly

aligned as shown in the figure.

1 - 2 General description

Page 7

Instead, to extract the connector, press its end part (blue or yellow) and at the same time

pull the main body (grey), in order to release it.

Caution:

Avoid pulling the connector with force before releasing it as described above,

otherwise there would be risk of damaging it.

Battery

The N500 instrument is provided with a built-in rechargeable lithium battery, which allows

autonomy of more than eight hours under normal operating conditions of the instrument.

The battery status is indicated by an icon in the upper right hand corner of the screen.

-

- battery partly charged

- battery almost flat (battery life remaining when this appears is approx.

one hour)

– battery flat: recharge within 5 minutes

If the battery is flat and the instrument is not recharged within 5 minutes, a message will be

displayed

and the instrument will then switch off.

battery fully charged

This would interrupt any active measurements not yet saved.

General description 1 - 3

Page 8

Caution:

It is strongly recommended to recharge the battery with the instrument switched

off: as recharging is completed within less than five hours such precaution prevents

the battery charger from being connected for an excessively long period of time

(max. 12 hours).

Caution:

The lithium battery is able to withstand the recharging-discharging cycles, even on

a daily basis, without problems but it could become damaged if allowed to be fully

discharged. For this reason it is advisable to recharge the battery at least once every

three months, even in the case of extended idle period.

N.B

:

As the greater consumption is due to the back lighting of the LCD display, the

latter is switched off automatically after two minutes if no button is pressed. The

pressing of any button (except for and those of the alphanumeric keypad) is

sufficient to switch the back lighting on again.

Caution:

If the N500 instrument is provided with battery charger Accord, when plugging the

adapter in the socket on the instrument make sure of the correct polarity, by

keeping the + symbol on the same side as the wording TIP, as shown in the

following image. If not, there is risk of damaging the instrument.

General advice

Keep and use the instrument far from sources of heat and strong electromagnetic fields

(inverters and high-power electric motors).

Measurement accuracy could be impaired by the connection cable between the transducer

and instrument, therefore it is recommended to:

- not allow such cable to have sections in common with power cables;

- prefer a perpendicular arrangement when overlapping power cables;

- always use the shortest possible length of cable; in fact floating lines would act as

active or passive antennae.

1 - 4 General description

Page 9

Chapter 2

General layout

Keys/buttons on the control panel

The control panel of the CEMB N500 instrument incorporates a keypad where the various

keys or buttons can be subdivided by function:

- on / off button

Press this button to switch the instrument on;

hold it down for at least 3 seconds to switch it off , then release the button.

N.B.

After pressing , the instrument is ready for use only at the end of the switching

on procedure, signalled by the appearance of the home screen (see Chap. 3).

Note:

After the insrument has been switched off, about 30 seconds must pass before it

can be switched back on again.

General layout 2 - 1

Page 10

- buttons for navigating between the pages

When this button is pressed in the setup screen, it confirms the settings selected

and allows going onto the next screen.

Instead, in the Measurement screen, it has the function of starting/stopping the

actual measurement (see 2-4 Start / Stop the acquisition).

N.B.

To facilitate use of the instrument also with the left hand, the button

is located on both sides of the display.

When this button is pressed, it causes quitting of the current screen with return to

the previous one, without taking into account any changes (or saves) in the settings.

Used for returning to the Main page, from any other page.

- function keys

Each function key is linked to different functions in the various screens. Such

functions are indicated in each individual case by the buttons shown at the bottom

of the display: each function is activated by pressing the function key under it.

In the setup screens they are used for setting the various parameters, each one

being indicated by a number corresponding to that of the function key to be

pressed to modify it.

- tab key

This key can only be used when two graphs are plotted on the same page; when

pressed, it changes the active graph to which the selected functions will be applied.

The active graph can be identified by the symbol located on the right side.

2 - 2 General layout

Page 11

- arrow keys

When a graph is displayed, these keys increase or decrease respectively the

minimum or max. value of the x axis ( , , ) or the y axis ( , ).

Instead, when inputting a value for a parameter, they either shift the cursor to the

left or right ( , ) and increase or decrease the value in question ( , ).

- alphanumeric keypad

This keypad serves for entering alphanumeric characters in the fields which do not

allow just default selections. Where it is possible to enter just numbers, it acts like a

normal numeric keypad.

To enter a character, press a key repeatedly to scroll the characters assigned to it

(e.g. M N O 6) until the required one is displayed.

The cursor passes on automatically to the next position after a pause of one second,

or else after pressing another key.

With it is possible to delete the character to the left of the cursor.

For example, suppose we wish to enter the word “TUR-1” press:

N.B.

An icon indicates whether the UPPER CASE style (selectable with ) or

lower case (selectable with ) is enabled for the letters.

- image capture key

Pressing of this key has the function of capturing the image present on the display

and opening a screen which allows it to be saved (see 2-10 capture and saving of

displayed images).

General layout 2 - 3

Page 12

General purpose functions

In addition to many functions, specific for each different purpose and described in relative

sections, there are certain general purpose functions which are described below.

- Functions associated with the measuring phase

Start / Stop acquisition:

In all the Measurement screens, acquisition is started by pressing , and is

subsequently stopped by again pressing . .

The active acquisition status is easily to recognize (except in the balancing function)

by the presence of a bar indicating level of the input signal to each of the activated

channels.

Instead, in the Balancing functions, this status is signalled by an indication of the

quality of the measurement in progress (see 7-8 Execution of measurement).

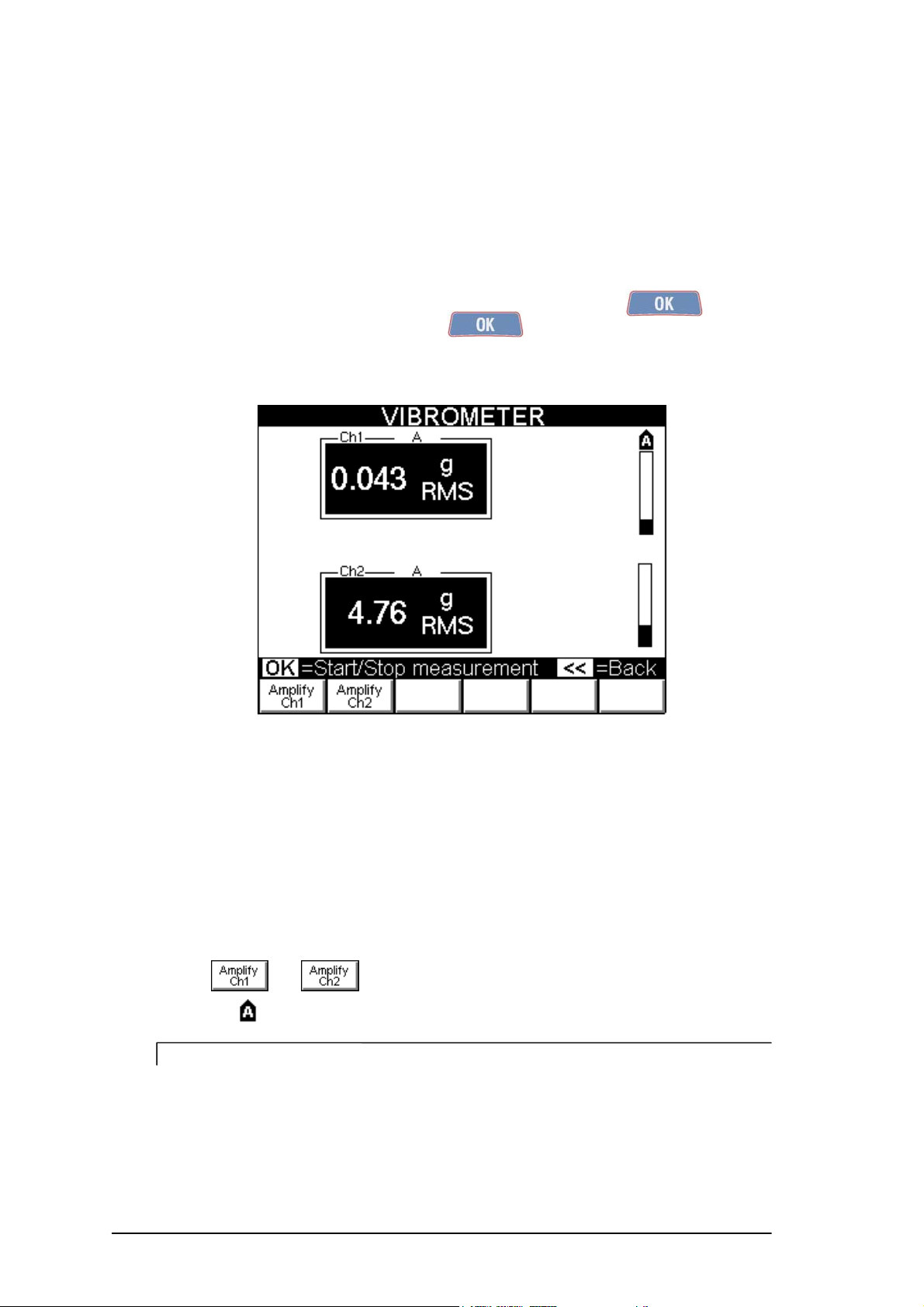

To modify amplification of the channels:

When the measurement is activated (apart from the Balancing functions where this

would be counter-productive), the analog amplification can be enabled or disabled

separately for each of the channels activated: this is possible by selecting

either or . The activated amplification condition is signalled

by symbol placed immediately above the corresponding signal level bar.

N.B.

In order to obtain a good measurement, always start with the amplification

disabled. Start the acquisition and observe the level bar for each activated channel:

enable amplification if the signal is small. Again check the level of the signal: if far

from full scale (saturation zone), maintain the amplification, otherwise disable it

again and perform the measurement with the non amplified channel.

2 - 4 General layout

Page 13

Caution:

After changing the amplification, wait for a few seconds until the measurement

becomes steady.

- Function “Other functions...”

When there are more than six functions accessible from a certain screen, there are not

enough function keys to correspond to them; in such cases the key is associated

with

Pressing of this key causes substitution of the functions corresponding to ...

with another five. The original correspondence can be reset by again pressing

- Functions operating on the graphs

Scale setting:

allows selecting the function for modification of the minimum and

maximum values of the axes in a graph; in this way it is possible to display just the

zone of greater interest. When activated, the following sub-functions are made

available:

: : quit the Scale Setting function

: preset minimum value of the x axis

: preset maximum value of the x axis

: preset minimum value of the y axis

: preset maximum value of the y axis

: sets the axis limits to be coherent with the graph data

The value of the limit selected (x

min

, x

max

, Y

or else Y

min

, displayed by white

max

wording on black background), can be increased or decreased by pressing

. or for x axis and or for the y axis.

N.B.

Measurement can be started with also while Set scale is activated but

it would automatically cause exit from this function.

N.B.

When two graphs are shown both at the same time on the same screen, the

scale functions operate on the active graph (identified by symbol ).

To change the active graph, proceed to press the key

General layout 2 - 5

Page 14

Use of the cursor

For easier reading and interpretation of the displayed data, it is possible to introduce

a cursor in any graph, provided the visible region is not blank:

this can be done with . A window at the top right corner of the graph

contains the co-ordinates of the point where the cursor lies.

The cursor can be shifted by one step to the right or to the left by using the

following keys or respectively .

For quick reaching of points from the current position, hold down

or . With the cursor is removed.

N.B.

Measurement can started with also while the cursor is visible; at

the end of the measurement, the cursor remains visible.

N.B.

When two graphs are represented on the same screen simultaneously, it is possible

to display the cursor on both in order to have easier comparisons and assessments.

However, pressing of the function keys will only have effect on that of the

currently activated graph (identified by the symbol ).

To change the activated graph, proceed to press the key .

2 - 6 General layout

Page 15

Change of display channel:

If both measuring channels are enabled, various types of display are possible, namely:

- just graph of channel Ch1

- just graph of channel Ch2

- graphs of channels Ch1 and Ch2 simultaneously

The passing in sequence between the various possibilities is obtained by repeatedly

pressing . This corresponds in each case to these options

or .

General layout 2 - 7

Page 16

List of peaks

When this function is selected, a table appears with the 10 peaks of highest value present in

the zone of the spectrum displayed, and associated with the corresponding frequencies.

Their value is calculated by applying an interpolation algorithm to the FFT graph; this also

allows identifying peaks not situated in correspondence to one of the lines of the spectrum.

When is pressed, the system quits this function and again displays the graph (or

graphs).

N.B.

The 10 highest peaks are determined in relation to the highest value present in the

spectrum; hence in certain cases the list could contain less than 10 peaks.

N.B.

If graphs of both channels are displayed, the list of peaks should be calculated for

the active one (identifiable by the symbol ).

2 - 8 General layout

Page 17

- to save measurements

The N500 instrument allows easy saving of the acquired data; for such purpose, four

different archives are available for the four different types of acquisition possible:

- waveform

- spectra (FFT)

- monitoring in time

- monitoring in speed

Pressing of allows displaying the archive corresponding to the measurement

made. All 50 overall positions (marked respectively with M001 … M050) are listed; the

blank ones can be recognized by the symbol -----, the other positions give the name, date

and time of saving their contents.

To select the position where to save the measurement made, use the arrow keys and

, then merely press

name, as explained in 2-3 – Alphanumeric keyboard.

If a two-channel acquisition has been performed, data save is performed automatically for

both channels in the same file.

To delete a measurement and to clear the corresponding position in the archive, press

button. Instead with it is possible to fully clear the measurements archive.

to display a pop-up in which to enter the required

N.B.

Keys and , which either increase or decrease by 10 respectively the

position selected, can be used for quick scrolling of the archive.

N.B.

As the spectrum is the type of measurement of greater interest, the N500

instrument allows memorization of up to 500 FFTs.

General layout 2 - 9

Page 18

- to capture and save displayed images

In all screens of the N500 instrument, the image visible on the display can be captured

with then saved in png format in an appropriate archive. This image can be used

subsequently if required to accompany documentation produced by the operator.

Selection of the position where to save can be done with the arrow keys and ,

then merely press to display a pop-up where to enter the required name, as

explained in 2-3 – Alphanumeric keypad.

To delete an image, and clear the corresponding position in the archive, merely press the

button . Instead with it is possible to fully clear the image file.

N.B.

Keys and , which either increase or decrease by 10 respectively the

position selected, can be used for quick scrolling of the archive.

2 - 10 General layout

Page 19

Chapter 3

Home screen (menu)

After fully switching on the N500 instrument, it shows its Home screen

which, besides showing a set of information:

– Manufacturer logo and name of the instrument

– Serial number (S/N) of the instrument

– Current program version

– Battery state:

- fully charged

- partly charged

- almost flat

- flat

– instrument being charged (connection to socket via the battery charger

supplied) as a normal menu, it also proposes and allows selection of the available

modes, namely:

1. Vibrometer mode

- Measurement of the total value and synchronous measurement of vibration

- Measurement and memorization of the trend in vibration against variation in time or

rotor speed

Home screen 3 - 1

Page 20

2. FFT analyzer mode

- Splitting of the vibration into its component frequencies

- Display of waveform of the vibration

3. Balancer mode

- Balancing of rotors

4. Setup mode

- Setting of the characteristics of sensors connected to the instrument

- Setting of the general operating parameters of the instrument

5. Data manager mode

- Data management (change of the name or delete the data saved on instrument

N500)

- Copying or shifting data to USB key.

N.B.

It is possible to return to this screen from any other by pressing

3 - 2 Home screen

Page 21

Chapter 4

Setup mode

Sensor setup

The N500 instrument can be used with different types and models of sensors. Therefore in

order to ensure correct measurement, it is necessary to preset exactly the type of sensitivity

of the sensors actually connected.

N.B.

Although the instrument can operate correctly with any combination of sensors, it

is advisable to connect sensors of the same type and model to the two channels.

1. Type of sensor:

Any one of the following possibilities can be selected:

– OFF : sensor not present (or else channel to be kept switched off)

– ACCEL : accelerometer

– VELOC : velocity sensor

– DISPLC : proximity sensor (non-contact)

N.B.

It is not possible to set both channels to OFF; at least one of the two channels

should be activated.

Setup mode 4 - 1

Page 22

N.B.

Although the required unit of measurement can differ from the natural one of the

sensor, these are the only combinations are possible.

TYPE OF SENSOR REQUIRED MEASUREMENT

ACCEL acceleration, speed, displacement

VELOC speed, displacement

DISPLC displacement

N.B.

The N500 instrument is able to determine automatically whether there is no sensor

connected to an enabled channel (i.e. not set to OFF Sensors Setup) and it signals

this by showing the symbol in the vicinity of the signal bar of the

corresponding channel (only during measurement).

To avoid displaying this symbol, it is advisable to disable the channel when not

used, by setting to OFF.

Caution:

The appearance of this symbol for a channel where a sensor is really connected,

could indicate a possible malfunction of the sensor or else a problem in connection

(e.g. the cable could have been sheared).

In such case it is advisable to carry out a few tests by connecting a sensor (which is

known to be operating properly) to the channel in question; if the indication

persists, contact CEMB Technical Service.

2. Sensitivity of the sensor

This is the number of volts per unit produced by the sensor: it is expressed for the various

types in:

TYPE OF SENSOR SENSITIVITY TYPICAL VALUE

ACCEL mV/g 100

VELOC mV/(mm/s) 21.2

DISPLC mV/µm

0,25

Caution:

Different models can have sensitivity differing from the typical values; pay attention

when taking the correct value from the sensor documentation and preset it .

4 - 2 Setup mode

Page 23

General Setup

N.B.

When the key is pressed, the SYSTEM INFO pop-up appears, containing

full information concerning the system. Strike any key to close this window.

The parameters for general use of the instrument should be preset in this page.

1. Date

Use the alphanumeric keypad to enter the date in the format DD/MM/YYYY.

2. Time

Use the alphanumeric keypad to enter the date in the format HH:MM:SS.

3. Language

Select one of the possible languages:

- ITALIANO

- ENGLISH

- DEUTSCH

- FRANÇAIS

- ESPAÑOL

4. Measurement system

The units of measure for the acceleration, speed and displacement values can be the

following respectively:

- g; mm/s; µm : metric units

- g; inc/s; mils : imperial units

6. Updating of firmware

Pressing of key does not set any parameter, but it does allow updating the

program (firmware) inside the instrument, if this proves necessary. Each new firmware

version consists of a file with the extension fmw, which should be copied in the main

directory on the USB key supplied. Merely insert the pendrive in one of the USB ports of

Setup mode 4 - 3

Page 24

the instrument, then press to start the automatic updating procedure, at the

end of which the pop-up

signals successful transfer of the file and requests switching the instrument off, then on

again to complete the operation.

Caution:

Updating of the firmware is a delicate operation, which could last a few minutes. It

should be carried out by paying careful attention to the instructions supplied in

order not to cause malfunctions or data loss; for this reason, a confirmation is

requested before activating this procedure.

Only the firmware obtained directly from CEMB Technical Service should be used. It is

advisable to remove the USB key before rebooting the instrument.

Caution:

If the automatic updating operation is not performed successfully, contact CEMB

Technical Service, citing the type of error signalled.

4 - 4 Setup mode

Page 25

Chapter 5

Vibrometer mode

One of the simplest, but at the same time most significant information in vibration analysis,

is the overall value of the actual vibration. In fact, this is very often the first parameter to be

considered when evaluating the operating conditions of a motor, fan, pump, machine

tool...

Appropriate tables allow discrimination between an optimum state and a good state, or

from an allowable, tolerable, non-permissible or even a dangerous one. (see Appendix B

– Evaluation criteria).

In certain situations instead, it could be interesting to know the values of modulus and

phase of the synchronous vibration (1xRPM), i.e. corresponding to the speed of rotation of

the rotor.

The vibrometer mode is designed to make this type of measure and also makes available

two monitoring functions, for observing the trend of vibration plotted against time or

against variation in rotor speed.

Vibrometer setup

Settings required for correct measurement of the overall value are selected in the

VIBROMETER SETUP page.

1. Unit of measurement

Select the unit of measurement in which to supply the vibration; possibilities are as follows:

– acceleration (g)

– speed (mm/s or inch/s)

– displacement (µm or mils)

Vibrometer mode 5 - 1

Page 26

2. Type of measurement

As with all physical quantities, vibration has a value which can vary from instant to instant:

mathematically it may be described as a function of time. Hence its overall value can be

calculated according to three different types:

– RMS (Root Mean Square):

This is the average value of the vibration previously squared;

This is the typically used value, above all, for acceleration or speed measurements.

– PK (Peak):

This is the maximum value reached by the vibration in a certain interval of time.

– PP (Peak-to-Peak):

This is the difference between maximum value and minimum value reached by the

vibration in a certain period of time;

It is normally used for measuring displacement.

3. Frequency range

The overall value of vibration normally originates from the sum of various contributory

factors, caused by several phenomena, and therefore they occur associated with different

frequencies. Depending on the case, it could be of interest to take into account, in the

overall value, only those corresponding to a certain frequency band, namely:

– 3-300 Hz if the range of interest is limited to phenomena with low frequencies

– 10-1000 Hz to meet conditions of ISO 10816-1 standard (typical)

– 10-10000 Hz to take into account a wide band

A CUSTOM frequency range is available for expert users (and for very particular

conditions). This range allows setting as required both the sampling frequency f

number of samples N

. In fact the overall value is calculated with digital techniques starting

s

and the

s

from the signal spectrum; therefore, the sampling parameters determine the band limits

according to the following relationships:

min

=f 2

f

s

N

s

max

=f

f

s

2.56

5 - 2 Vibrometer mode

Page 27

N.B.

Use of the CUSTOM frequency band is only recommended for expert users who

have sound knowledge of the basic concepts in digital signal processing. In fact, an

incorrect choice of sampling parameters could lead to unsatisfactory results. For

example, with too low a f

information; on the other hand, with too high a frequency, the resolution could be

insufficient to distinguish the two peaks.

, there is risk of losing important high frequency

max

4. Average N°

This is the number of value which should be calculated and averaged between each other

to increase stability of the measurement. Four averages are more than sufficient for normal

vibration measurements on rotating machines.

After making the required settings, press to access the VIBROMETER

Measurement screen.

Vibrometer – Measurement screen

The Measurement page supplies a series of information, organized as shown in the figure:

1

3

8

4

5

1. channel measured

2. measurement information: indicates unit of the sensor (A, V or D) and any

conversion made to supply the overall value (e.g. AÆV means that the measurement

is made with an accelerometer, but the vibration is supplied in speed)

3. overall value of the vibration

4. unit of measurement

5. type of measurement

6. value of the synchronous vibration

7. phase of the synchronous vibration

8. speed rotation of rotor

9. signal level bar

2

6

7

9

10

Vibrometer mode 5 - 3

Page 28

10. amplification status of the channel

N.B.

The values obtained in this mode can be reused to evaluate the operating status of

the instrument by using, for example, the tables and graphs given in Appendix B

of this manual.

The default measurement is that of the total vibration value, but by pressing it is

possible to switch to measurement of the synchronous value: in this mode, information

appears concerning the modulus, phase and speed of rotation. Pressing of allows

return to measurement of the overall. value. N.B. To perform a synchronous measurement,

it is necessary to connect the photocell and make sure that it is positioned correctly (see

Speed monitoring 5-6).

Direct printing of the vibration value (optional).

By connecting the portable printer supplied (optional) then pressing it is possible

to print directly in field the vibration values displayed in the VIBROMETER PAGE

Monitoring in time

The monitoring in time function allows observing (and memorizing if necessary) of the

trend of the overall vibration value plotted against time. For such purpose, it is necessary to

preset a value which is adequate for the parameter by selecting from the following

possibilities:

– 1'' - one second

– 10'' - ten seconds

– 1' - one minute

– 15' – fifteen minutes

After pressing a measurement is made of the overall value, indicated by a

point on the graph; such measurement is automatically repeated according to the preset

time step, and a new point is represented in the graph. Availability of a new measurement is

signalled by momentarily displaying the time step in white on black background

(under the icon with metronome ).

When the number of measurements made exceeds forty, just the most recent forty

measurements are shown in the graph.

Monitoring is stopped by a further pressing of and the typical control

functions of the graphs become available (see 2-5 Functions operating on the graphs).

- Set scale (with which it is also possible display all the measurements made)

- Show cursor

- Change of channel displayed

- List of peaks

5 - 4 Vibrometer mode

Page 29

When and then is selected, the entire monitoring can be saved in a file

for subsequent analysis.

When the acquisition is enabled for both channels, the data save is performed automatically

for both channels in the same file.

N.B.

As access to the Monitoring in time function is gained from the

VIBROMETER screen, the settings used for calculation of the overall value are

the ones selected in the VIBROMETER SETUP screen.

N.B.

The memory allotted for a single monitoring, allows memorizing a maximum of

1024 values per channel: when the limit is reached, the acquisition is stopped

automatically without data loss. For this reason, it is important to use the most

suitable frequency according to the duration of the phenomenon concerned.

Vibrometer mode 5 - 5

Page 30

Monitoring in speed

In many situations it could prove useful to associate the vibration value with that of the

speed of rotation of a shaft; in this way it could be possible to investigate, for example,

how the overall or the synchronous component varies during machine starting or stop

phase, with identification of any critical zones or zones with risk of resonance, which are

best to avoid.

In order to be able to use this function, it is essential to have the tachometric signal;

therefore it is necessary

- to apply a reflecting label on the rotor as reference mark (0°). Starting from this

position, proceed to measure the angles in direction opposite to that of the shaft

rotation.

– connect the photocell and position it correctly (50 – 400 mm), so that the led

located behind it lights up once for each rev. when the reference mark is

illuminated by the light beam. If the operation is not regular, either retract or

approach the photocell, or else incline it with the respect to the workpiece surface.

Speed monitoring can be performed according to two different modes, namely:

- monitoring of overall vibration (overall)

- monitoring of modulus and phase of the vibration synchronous with the speed

of rotation (1xRPM)

An icon on the top part of the page indicates which mode is currently selected; this mode

can be changed by pressing .

Two graphs are always displayed simultaneously in a synchronous monitoring. Such graphs

can be:

– modulus and phase of the vibration of channel 1

– modulus and phase of the vibration of channel 2

– modulus of the vibration for both channels

To switch between the various modes, press

After pressing a vibration measurement is made and a speed reading taken,

these are then plotted by a point on the graph; such measurements are repeated

automatically, with a new point added each time to the graph.

For the sake of convenience, the current rotor speed, expressed in RPM, is displayed at the

top right, alongside the symbol

5 - 6 Vibrometer mode

Page 31

Monitoring is stopped by a further pressing of and the typical graph control

functions become available (see 2-5 Functions operating on the graphs).

- Set scale

- Show cursor

- Change of channel displayed

- List of peaks

When is pressed, the entire monitoring can be saved in a file for subsequent

analysis.

When the acquisition is enabled for both channels, the data save is performed automatically

for both channels in the same file.

N.B.:

The memory allotted for a single monitoring, allows memorizing a maximum of

1024 values per channel: when the limit is reached, the acquisition is stopped

automatically without data loss. For this reason, it is important to use the most

suitable frequency according to the duration of the phenomenon concerned.

Vibrometer mode 5 - 7

Page 32

Page 33

Chapter 6

FFT (Fast Fourier Transform) analyzer mode

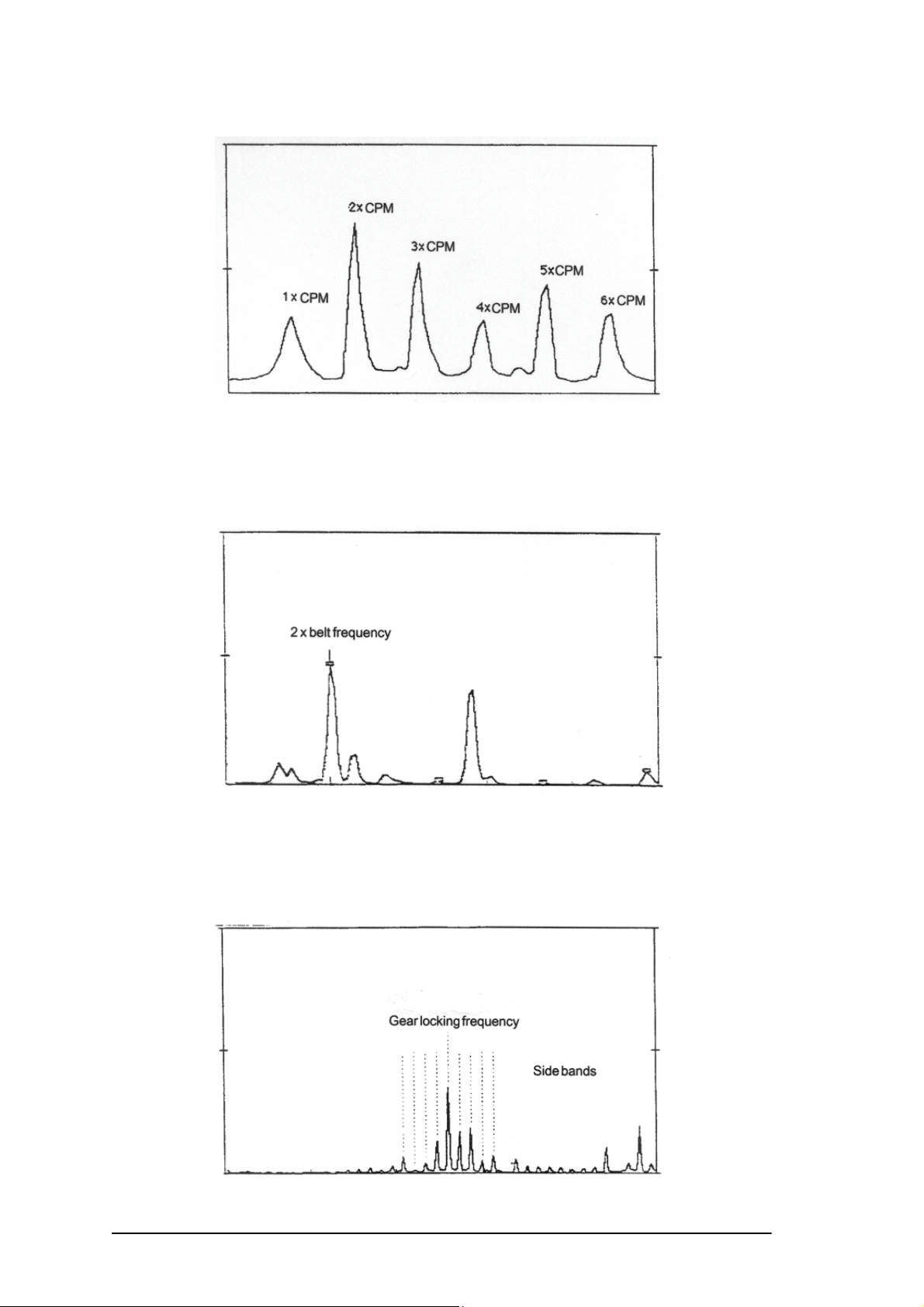

A complete analysis of the vibration cannot fail to take into account the study of the

various factors contributing towards forming its overall value. Hence it is essential to be

able to carry out spectrum analysis with FFT (Fast Fourier Transform) algorithm.

Such technique allows splitting and memorizing a measured signal into its component

frequencies in a certain period of time, thus making it easier to discover their causes.

Analysis of the highest peaks in the spectrum, together with analysis of the frequencies to

which they correspond allows determining which are the principle sources of vibration and,

therefore, the aspects on which to act in order to reduce them.

Although a spectrum contains a series of very significant information, its interpretation

requires a certain amount of experience and attention; for this purpose, the material given

in Appendix C – A rapid guide to interpreting a spectrum could be useful.

FFT Setup

The choice of correct settings is vital in order to highlight the significant information in the

spectrum thus separating it from the inevitable background noise.

1. Unit of measurement

Select the unit of measurement in which the vibration is to be supplied; possibilities are as

follows:

– acceleration (g) – enhances the higher frequencies and attenuates the lower ones

– speed (mm/s or inch/s)

– displacement (µm or mils) – enhances the lower frequencies and attenuates the

higher ones.

FFT analyzer mode 6 - 1

Page 34

2. Type of measurement

This is the mode in which each component (line) of the spectrum is applied; it can be:

– RMS (Root Mean Square):

This is the one most typically used, as it is associated with the overall RMS value.

– PK (Peak):

This is the maximum value reached by the component in question in a certain

interval of time;

it is rarely used because it does not provide information about the overall PK value;

line by line it is simply equal to the RMS value multiplied by 1.41.

– PP (Peak-to-Peak):

This is the difference between maximum value and minimum value reached by the

vibration in a certain interval of time;

it is rarely used because it does not provide information about the overall PP value;

line by line it is simply equal to the RMS value multiplied by 2.82.

3. Unit of frequency

It can be chosen from:

- Hz – cycles (revs) per second

– RPM – revs. per minute

N.B.

Obviously the relationship 1 Hz = 60 RPM holds good between the two units

4. Max frequency

This is the maximum frequency of interest in the phenomenon; in practice, it is the

maximum frequency which can be shown in the spectrum. It can be chosen from the

following default values 25, 100, 500, 1000, 2500, 5000, 10000 and 15000 Hz, on the basis

of which the N500 instrument will choose the appropriate frequency for data acquisition.

N.B.

The typical choice, suitable for most situations, is 1000 Hz (60,000 RPM),

coherently with the requirements of ISO 10816-1.

N.B.

One practical consideration normally adopted is that of making sure that the max.

frequency preset is at least 20-30 times that of the frequency of rotation of the shaft

being examined. This allows including in the spectrum also the high frequency zone

where problems relating to the bearings usually occur.

N.B.

With other conditions remaining the same, the choice of a maximum low frequency

(less than 1000 Hz) would cause an appreciable increase in the times required for

acquisition and measurement.

6 - 2 FFT analyzer mode

Page 35

5. N° of lines

Such parameter defines the number of lines used in the FFT algorithm, in practice

associated with the resolution in frequency in the spectrum. This determines how close can

be the frequency of two peaks so that they still remain distinct in the FFT graph. Such

resolution is equal to

f

max

N

linee

therefore to maintain it constant, when the max. frequency is increased, likewise the

number of lines should be increased.

It is useful to remember that the time required for acquisition of the correct number of

samples is exactly equal to the inverse of the resolution; then the time required for data

processing should be added to this time. An example of the relation between resolutionacquisition time may be derived from the following table:

N.B.

The use of an excessively high number of lines is not recommended unless in

situations where an extreme resolution is essential. In fact, such choice would lead

to an increase in calculation times and space required for data saving, often without

adding particular information.

A reasonable choice would be 200, 400 or max. 800 lines, being careful to set a

max. frequency coherent with the situation in question.

6. Average N°

Resolution [Hz] t

5 0.2

2.5 0.4

1.25 0.8

0.625 1.6

0.3125 3.2

acquisition

[sec]

This is the number of spectra which should be calculated and averaged between each other

to increase stability of the measurement. Four averages are more than sufficient for normal

vibration measurements on rotating machines.

Press to access the SPECTRUM ANALYSIS (FFT) measurement screen.

FFT analyzer mode 6 - 3

Page 36

Spectrum analysis (FFT)

The so-called FFT algorithm is applied to the signals acquired with due respect for the

settings made; in accordance with the recommendations deriving from the mathematical

treatment from which it has been taken, such numeric processing is preceded by

application of a Hanning window to the acquired signal. This allows attenuating the edge

effects due to digitizing as well as reducing phenomena of leakage in the spectrum.

The Measurement page appears like the one shown in the figure. It is organized so as to

maximize as much as possible the area dedicated for representation of the FFT graph.

A box Ovrll is located on the left side giving the overall value of the signal for the channel

displayed; it has the same units of measurement as those of the FFT. Such information

allows monitoring the total vibration, also during the analysis of its single components.

Beside the usual graphic control functions (see 2-5 Functions operating on graphs),

namely:

- Set scale

- Show cursor

- Change of displayed channel

- List of peaks in order to display the list of highest peaks in the spectrum (see 2-8

List of peaks).

the following are available:

– Waveform (see 6-6 Waveform function).

– Trigger Setup to set a trigger to be used for starting the acquisition

(see 6-6 Trigger Setup).

6 - 4 FFT analyzer mode

Page 37

Harmonic cursor

When the cursor is displayed on an FFT graph (see. 2-6 Use of the cursor), it means that

a special mode known as harmonic cursor is available.

The frequency at which the cursor is currently positioned when is pressed, is

considered as the fundamental frequency of the signal under examination, and on the graph

all the harmonics of higher order (2nd, 3rd, 4th, …) are marked

Shifting of the cursor, which varies the frequency considered as fundamental, causes the

automatic updating of the position of all the multiple ones.

Use of the harmonic cursor allows easy recognition in the spectrum of families of peaks in

correspondence of frequencies, which are multiples between each other, and typically

indicative of special defects (see Appendix C).

FFT analyzer mode 6 - 5

Page 38

Waveform function

In the second series of functions (accessed by pressing ) is present

which allows access to a page where the vibration signals are shown in relation to time.

In this mode, the N500 instrument can be used as an actual oscilloscope, and further

enhances the variety of information which can be deduced from the vibration signals.

This mode also contains all the typical graph control functions (see 2-5 Functions

operating on graphs).

It is possible to return to SPECTRUM ANALYSIS by selecting then .

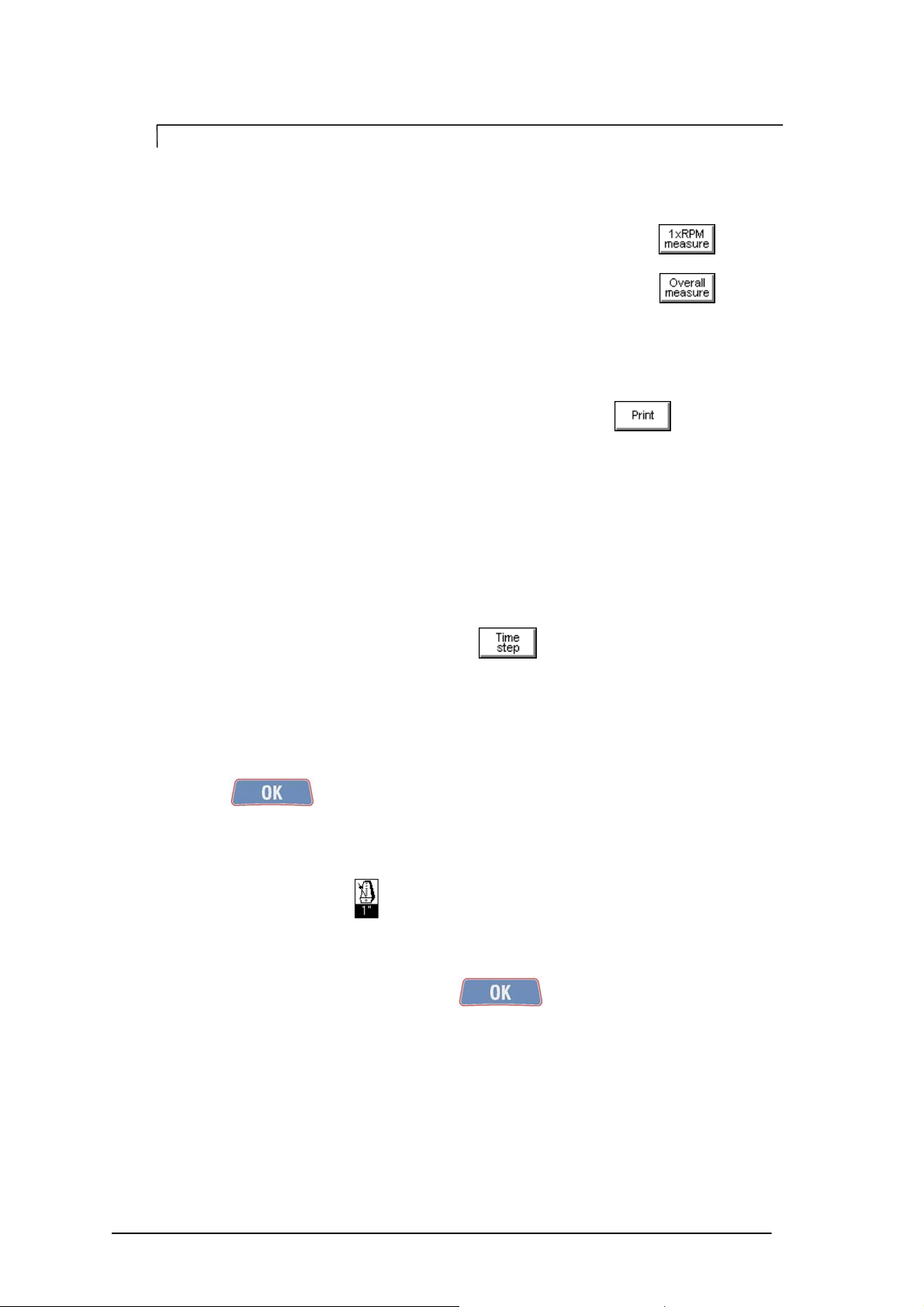

Trigger Setup

In certain cases, it could be useful for acquisition not to start with the pressing of

by the operator, rather with a certain condition associated with the phenomenon being

observed; this is possible by enabling the so-called trigger. In this way, the measurement

does not started immediately after pressing , but only when the signal of the

trigger channel exceeds a preset threshold.

Operation of a trigger can be enabled in two distinct modes, namely:

– Cont. (continuous mode)

– Single (single measurement)

and requires presetting of

– a channel

– a threshold

6 - 6 FFT analyzer mode

Page 39

One of the most frequent uses is the so-called Impact test: A hammer is used to stress a

structure and to cause it to vibrate in order to determine its natural frequencies. For such

purpose, a sensor should be placed in the zone to be examined and a threshold value

chosen, which is higher than the background noise read, but lower than that produced by

the hammering with which the structure is stressed.

N.B.

After enabling the trigger and selecting the required settings, press

to return to the Measurement page in which the mode selected for the trigger is

specified by a specific icon:

– continuous mode

– "single measurement" mode

Now merely press , and wait for the trigger threshold to be exceeded.

If it is required to stop the procedure manually (before or after exceeding the threshold),

just press again.

1. Modes

This is the parameter which indicates whether the trigger is:

– OFF (disabled) :

the measurement is started and stopped manually by the operator on pressing

– Cont. (enabled in continuous mode) :

acquisition is started when the signal exceeds the trigger threshold, and continues

until the operator stops it manually (by pressing )

– Single (enabled in “single measurement” mode) :

When the signal exceeds the trigger threshold, a single measurement is made (duly

observing the parameters set for the FFT), then the acquisition is stopped

automatically; this is the most frequently used mode because it allows analyzing

phenomena of transitory type; by suitably presetting the FFT parameters, it is

possible to obtain an acquisition time sufficiently long for containing all the

important information.

Subsequent acquisitions would only succeed in capturing noise, therefore they

would be counter-productive.

FFT analyzer mode 6 - 7

Page 40

When the trigger is enabled, the following settings become visible in the TRIGGER

SETUP page:

– Channel

– Threshold

2. Channel

This indicates on which channel (Ch1 or Ch2) to make the comparison between the signal

value and the threshold value in order to activate the acquisition.

N.B.

If just one of the two measuring channels is enabled, obviously choice of the trigger

channel is obligatory, hence it is forced automatically.

3. Threshold

This is the level which the signal must exceed (in a leading edge of the waveform) in order

for the acquisition to be started automatically. The selection of a suitable value is normally

one of the most delicate operations, but by using the N500 instrument it is considerably

simplified. The graph at the bottom of the page shows in real time the signal of the trigger

channel (in continuous line) and the current threshold (broken line). Hence the effect of

different values can be assessed immediately, thus making it easier to make a rapid choice

of the value considered most appropriate.

6 - 8 FFT analyzer mode

Page 41

After pressing the threshold value can be preset in two ways, namely:

– By typing, using the numeric keyboard (only after pressing , it is possible

to shift the broken line in the graph);

– by using and to increase or decrease the value of a single digit,

which can be selected with and (the broken line in the graph is shifted

immediately, however at the end, pressing of is always necessary in order

to confirm).

N.B.

The trigger threshold should always be set in the unit of natural measurement of

the sensor. However, in the Measurement page, it is possible to supply the vibration

in other units even if this is not recommended when making measurements with

the trigger enabled.

FFT analyzer mode 6 - 9

Page 42

6 - 10 FFT analyzer mode

Page 43

Chapter 7

Balancer mode

One of the causes of vibration most frequently encountered in actual practice, is the

unbalance of a rotating part (lack of uniformity of the mass about its axis of rotation); such

unbalance can be corrected with a balancing procedure.

The N500 instrument allows balancing any rotor under service conditions in one or two

planes, by using one or two vibration pick-ups and a photocell.

Ad hoc procedures have been drawn up for the most frequent situations (balancing on one

plane with just one sensor and balancing on two planes with two sensors). These

procedures guide the operator step-by-step through the sequence of operations. A general

guided procedure is available for all the other cases (rarely used).

Some rules to be observed in order to perform correct balancing are as follows:

- place the sensors as close as possible to the supports of the rotor to be balanced, by

using the magnetic base or by fastening via a tapped hole to ensure good

repeatability;

- apply a reflecting label on the rotor as reference mark (0°). The angles are measured,

starting from this position, in direction opposite to that of shaft rotation.

– Connect the photocell and place it in correct position (50 – 400 mm), so that the led

at the back of the photocell lights up only just once per rev. when the light beam

illuminates the reference mark. If operation is incorrect, either retract or approach

the photocell or else incline it with respect to the workpiece surface.

For further consideration, see attached brochure Balancing accuracy for rigid rotors.

The balancing procedure consists of two parts, namely:

– calibration: a series of spins allows determining the parameters required for balancing

in the case of a given rotor

– measurement of the unbalance and calculation of the correction.

Balancer mode 7 - 1

Page 44

As the calibration is normally a laborious procedure, the parameters derived should be

memorized, then called in the case of subsequent maintenance work on the same machine.

This is possible via the balancing programs: a program is defined with a series of settings in

order to work on a particular rotor and it contains all the information and data acquired

regarding such rotor. It is possible to save the current program at any moment in a special

archive so that it is available at later dates.

N.B.

If it is required to use data and parameters of a previously stored program, it is

essential to mount the transducer in exactly the same position on the rotor.

Selection of the balancing program

When the balancing function is selected, a page is presented to the operator in which to

select the balancing program to be used, choosing between the following options:

– New program

– Loading of program from archive

– Use of current program (only available if a program has been previously created or

loaded)

7 - 2 Balancer mode

Page 45

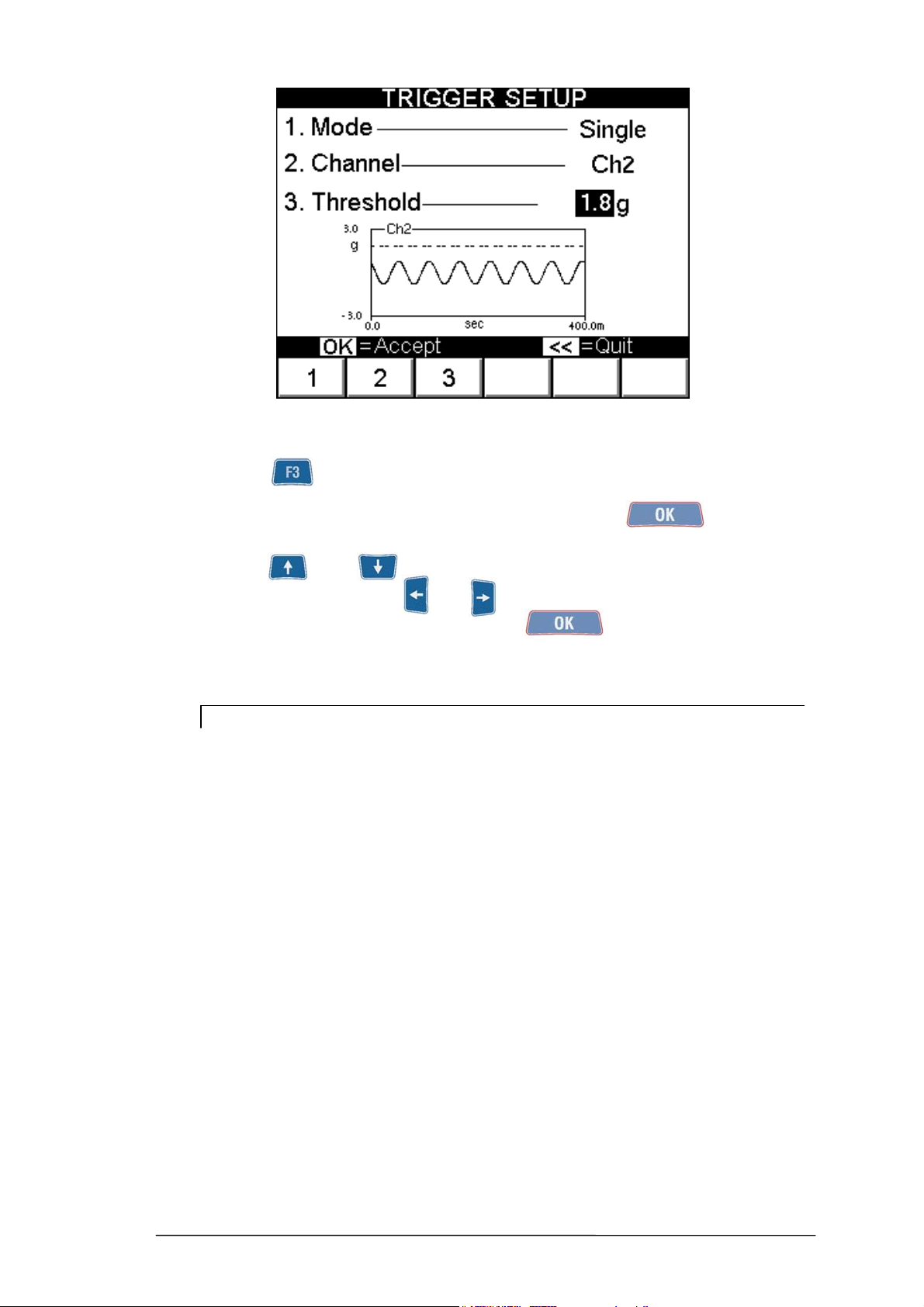

1. New program – BALANCING SETUP

The creation of a new program entails setting of a series of parameters. This is done in the

BALANCING SETUP screen.

1. Number of planes

This is the number of planes on which to act to correct the unbalance of the

rotor. The number can be 1 or 2.

2. Filter accuracy

Balancing under not particularly stable signal conditions is certainly critical and

needs acquisition for longer times in order to obtain a satisfactory quality of the

value measured. This can be achieved by acting on the filter accuracy:

acquisition made with a broad filter: faster, but only suitable for

particularly stable signal conditions (high unbalance values).

acquisition made with a narrow filter: suitable in most conditions.

acquisition made with a very narrow filter: suitable for

particularly critical signal conditions (low unbalance values);

requires longer times

N.B.:

Depending on the accuracy selected for the filter, the instrument automatically

determines the number of revs. necessary for each acquisition. As it could be

necessary to have up to some hundred revs. in certain situations, the time required

for each measurement could likewise be equal to some tens of a second. Taking

into account that a certain number of consecutive acquisitions is necessary so that

the quality of the measurement can reach acceptable levels, the time required for an

acquisition could also entail several minutes in the case of slow rotors.

Balancer mode 7 - 3

Page 46

For example, for a rotor with speed of rotation 600 RPM, it could be necessary to

wait up to 10 seconds before being able to view the first result of the measurement.

3. Unit of measurement of the vibration

This is the unit of measurement in which to supply the vibration to the sensors:

– acceleration (g (acc))

– speed (mm/s, inc/s)

– displacement (µm or mils)

N.B.

In order to avoid possible confusion with grams (often used for expressing the

unbalance in the metric system), in the Balancing functions, the symbol

g (1 g = 9.81 m/s2) is accompanied by the explicit indication acc (acceleration)

given alongside between brackets.

4. Type of vibration measurement

The vibration measured by the sensors can be expressed in three different types:

- RMS (Root Mean Square):

This is the average value of the vibration previously squared;

It is the one typically used, especially for measurements of acceleration or

speed.

- PK (Peak):

This is the maximum value reached by the vibration in a certain interval of

time.

- PP (Peak-to-Peak):

This is the difference between maximum value and minimum value reached

by the vibration in a certain interval of time;

It is normally used for measuring displacement..

Confirmation of the settings made (with ) creates a new balancing program

not associated with any name, seeing as though it is directly accessible as current program.

Only when saving in the archive, will there be a request to the operator to enter a special

name which will characterize it from that moment on.

7 - 4 Balancer mode

Page 47

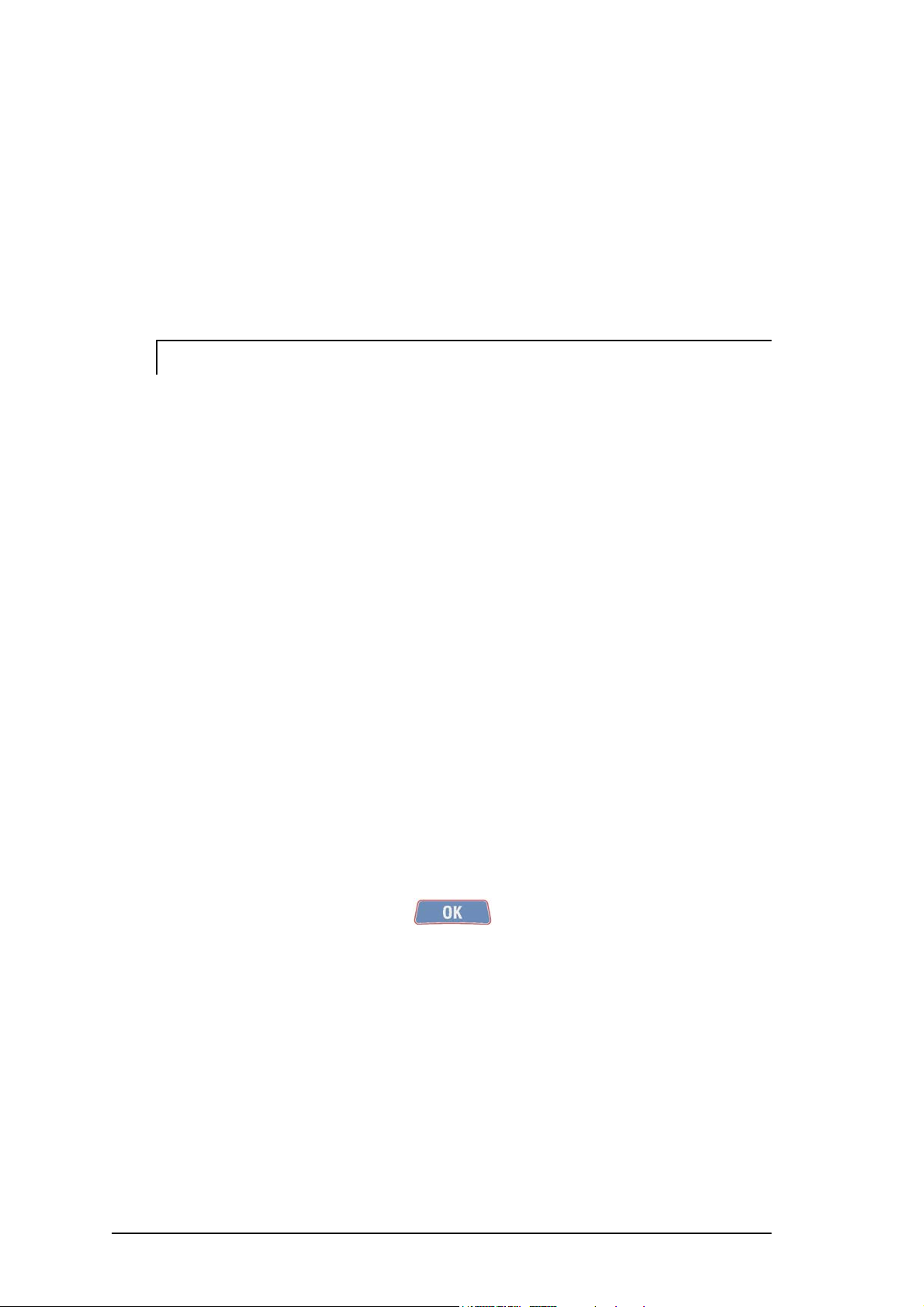

2. Load program from archive

When this option is selected, access is gained to the program archive.

Arrow keys and allows scrolling the 10 available positions, thus selecting the

required program (visible in negative, i.e. with white writing on black background); the

program can then be loaded by pressing .

If it is not possible to carry out the operation correctly (e.g. attempt made to load a

program from an empty position, indicated by the symbol -----), an error message appears

in the black band in the bottom area of the page.

After loading, the following is displayed:

– the measurement and unbalance correction screen, if the calibration procedure has

already been completed;

– the calibration screen, if not.

3. Use current program

This option allows resuming the last program used (new or loaded), exactly from the point

where it had been abandoned.

Caution

:

When the instrument is switched off, this causes loss of unsaved data (and

therefore of the current program); hence this option is not initially available when

the instrument is switched on again; it becomes available only after a program has

been created or loaded from the archive.

Balancer mode 7 - 5

Page 48

Calibration sequence

The calibration operation, necessary for assessing the unbalance of a rotor, is normally a

procedure consisting of various steps. Above all, for the most common two cases, it

consists of:

- Calibration for balancing on one plane:

1) first spin without test weight

2) second spin with test weight on the balancing plane

- Calibration for balancing on two planes:

1) first spin without test weight

2) second spin with test weight only on the first balancing plane

3) third spin with test weight only on the second balancing plane

For the two configurations

– correction on one plane with one sensor

– correction on two planes with two sensors

The calibration sequence screen on the N500 instrument is organized as in the figures.

1

2

3

5

4

7

6

8

9

10

1

2

3

5

4

6

7

8

9

10

7 - 6 Balancer mode

Page 49

1 - number and name of the balancing program (if loaded from the archive),

or else ----

2 - current speed of rotation, in RPM

3 - layout of the position of the sensors and correction planes on the rotor; indication

of the plane on which to apply the test weight

N.B.

This representation is approximate only; the sensors and correction planes can be

chosen in any position relative to each other (external sensors or sensors inside

planes, ... ) since the calibration serves especially for determining correct

parameters for balancing in any configuration.

4 - value and angular position of any test weight

5 - indication of the vibration component synchronous with the rotation (unbalance) in

value and phase for every measuring channel

6 - average speed of rotation and filter accuracy with which the vibration has been

measured

N.B.

The average speed value is highly important because the calibration procedure can

only be considered as properly performed if between one step and the other, such

speed does not exhibit differences exceeding 5%. It is up to the operator to check

for this condition.

7 - indication of the number of calibration step selected

8 - indication of the status of the calibration steps

completed

to be done

9 - instructions for the current calibration step

10 - functions for selecting the calibration step

: go the previous step

: go to next step (if the current step is the last step of the sequence,

this function, which is indicated by , ends the calibration and

loads the unbalance measuring page).

N.B.

When each already completed step is selected, the available data appear on the

monitor (vibration, average measuring speed, ... ). Such information is useful, also at

a later date, to decide whether to repeat or not to repeat the measurement.

N.B.

Although it is advisable to perform the calibration steps in the order in which they

appear, it is perfectly possible to select a different order according to your

particular requirements.

Balancer mode 7 - 7

Page 50

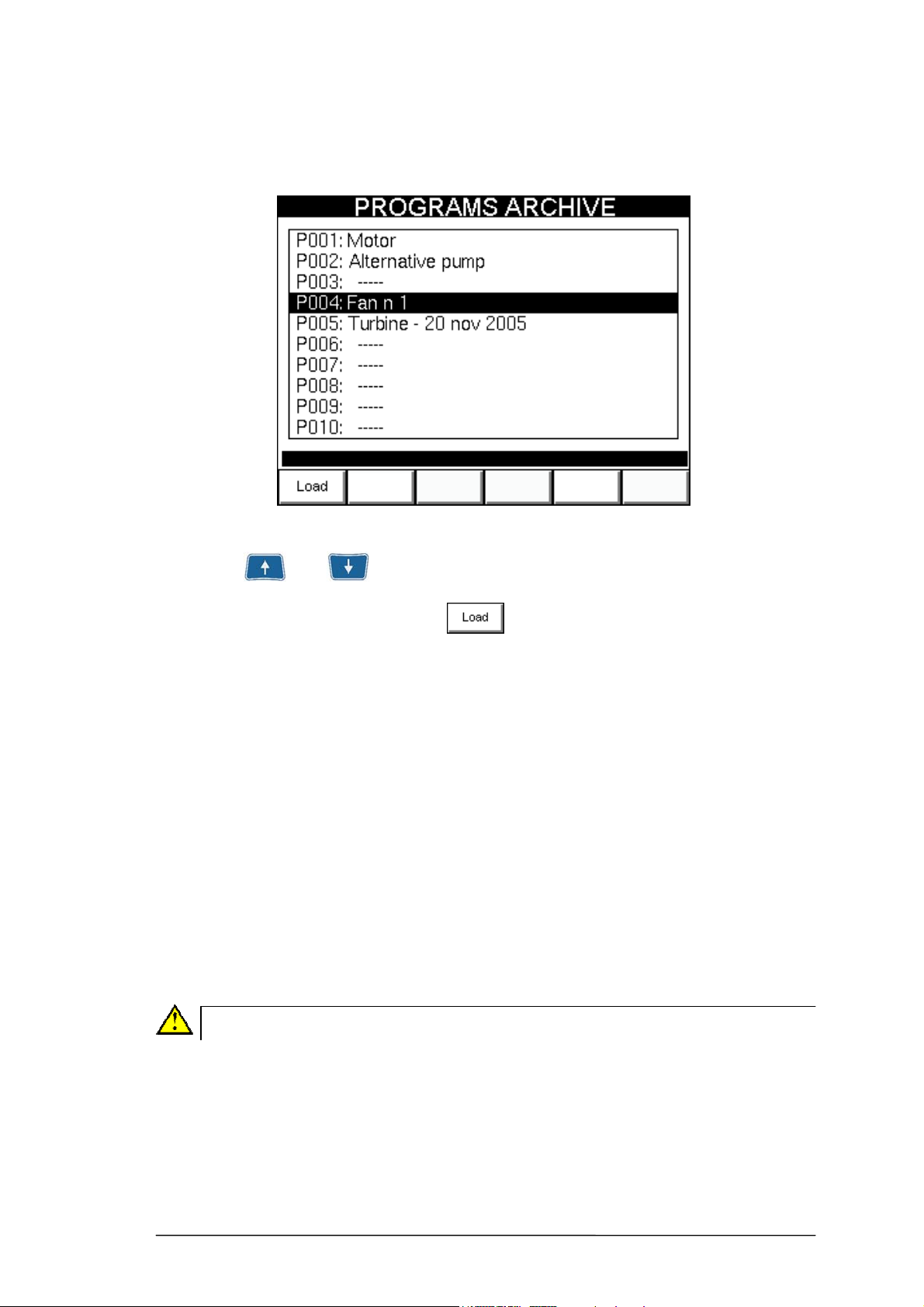

Execution of measurement

To start the measurement in any of these steps, press ; a pop-up panel appears

showing, in real time, the quality of the current measurement (for each channel).

The higher is the level of the bars, the better will be the quality of the measurement (which

is averaged over time). After reaching the required level, stop the measurement again by

pressing .

If the operator decides to accept the value, then he must press corresponding to

the option , which flashes in order to warn the operator the importance of

pressing it.

When the measurement is accepted, the corresponding calibration step is indicated as

complete .

N.B.

Unstable signals produce measurements whose quality is unable to reach acceptable

levels; under these conditions, it is advisable to increase filter accuracy

(see 7-3 Filter accuracy) and consequently repeat the entire procedure.

N.B.

If the quality of a particular measurement has been altered by a special event (e.g.

an impact), the time required to go back to it could be excessively long; to speed it

up, the measurement can be reset manually by pressing .

7 - 8 Balancer mode

Page 51

Test weight

Calibration requires the use of a test weight, to be applied in succession on the various

correction planes. These two parameters should be preset, with the appropriate

functions and by typing the appropriate values with the numeric

keypad, and confirming with .

To cover the various operational requirements when balancing on two planes, it is

possible to specify a different test weight (value and angular position) on plane 1 and on

plane 2.

N.B.

The value of the test weight should be indicated in general units U. The operator

can decide independently to make these U correspond to the physical units

preferred by him, bearing in mind that also the unbalance and necessary

correction will be indicated in the same units U.

Caution

Correct choice has been made of the test weight if it produces, in each of the spins,

a sufficient variation in the vibration compared to that of the initial spin.

This may be considered satisfactory if we have at least one from the following:

- variation in module of at least 30%

- variation in phase of at least 30°

:

Balancer mode 7 - 9

Page 52

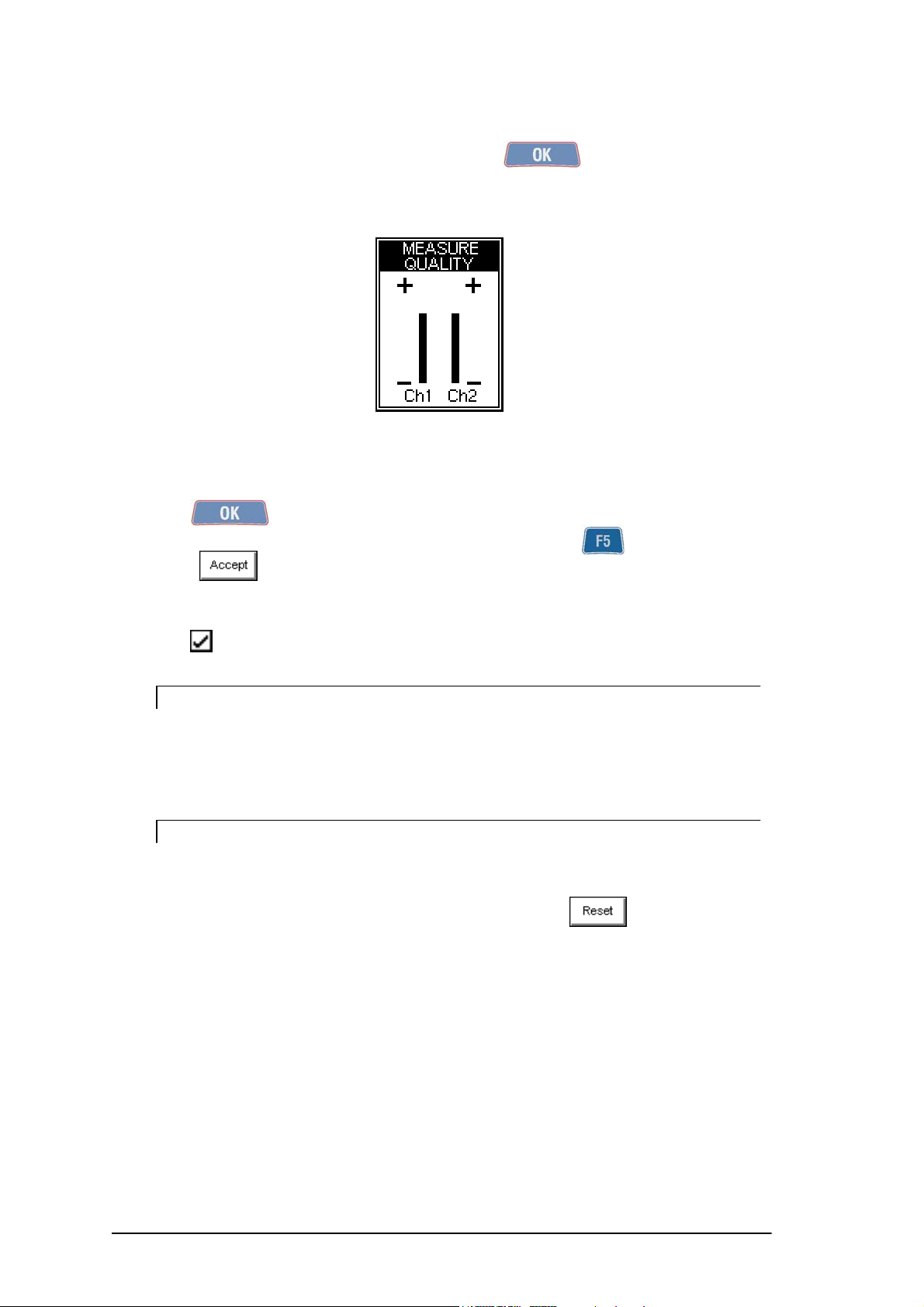

Unbalance measurement and calculation of the correction

In appearance the UNBALANCE MEASUREMENT page is very similar to the calibration

page:

1

2

3

4

6

7

2

3

6

7

5

8

1

4

5

8

and the following information is given:

1 – number and name of the balancing program (when loaded from the archive),

otherwise ----

2 – current speed of rotation, in RPM

3 – layout of the position of the sensors and correction planes on the rotor

N.B.

This representation is approximate only; the sensors and correction planes can be

chosen in any position relative to each other (external sensors or sensors inside the

planes, ... ) since the calibration serves especially for determining correct

parameters for balancing in any configuration..

7 - 10 Balancer mode

Page 53

4 – indication of the correction weight, in value and position on every plane.

N.B.

The module is indicated in general units U, corresponding to those used in setting

the test weight. As the program makes use of correction through addition of

material, the position indicated is the one where to add the correction weight.

When it is required to proceed by removal of material, act in a position

diametrically opposite (add 180° to the displayed phase)

5 – average speed of rotation and filter accuracy with which the unbalance has been

measured

Caution:

The average speed value is important because it allows checking whether the

measurement has been made at a speed not too different from that used in the

calibration spins (differences less than 5%). Owing to small amounts of non

linearity always preset in actual practice, it is not advisable to proceed to calculate

the correction at a speed too widely different from the calibration speed. Checking

of this condition is up to the operator.

6 – value and phase of the vibration synchronous with the rotation (1xRPM) and total

value(Overall) vibration measured via the sensors

N.B.

This information is considerably important as indicator of the reliability of the

balancing: what concerns us in actual practice is to reduce the vibration to under a

certain value considered as tolerable (see Appendix B). However reduction of the

unbalance only has effect on the 1xRPM component. A low value of this

component, accompanied by a high Overall indicates problems differing from those

of unbalance, which, therefore, cannot be corrected by balancing.

7 – instructions for unbalance measurement and calculation of the correction

8 – functions available

: calibration procedure

N.B.

If the calibration procedure has not been completed, this button starts flashing, to

warn the operator to return to the calibration procedure before being able to make

unbalance measurements. If not, indication is already given of the correction

weights and positions where to act, deduced from the calibration spins.

Balancer mode 7 - 11

Page 54

: direct printing of a balancing certificate by using the portable printer

provided (optional). The certificate gives the unbalances on the

correction planes (in units U), as well as the values of vibration (overall

and synchronous) of these planes. The following is an example of this

certificate:

: function involving splitting of the correction weight on two presettable

angles (see 7-13 Splitting of correction weight. )

: : shows the program archive (to allow saving or eliminating a program)

As in calibration, to start or stop measurement, press ; while the

measurement is active a pop-up appears to indicate the quality of measurement of each

channel.

After making the corrections indicated, the measurement-correction procedure can be

repeated until the required conditions are met (typically vibration measured by the

sensors lower than a certain value).

7 - 12 Balancer mode

Page 55

Splitting of correction weight

In this page it is possible to select between the correction modes:

- by addition of material

- by removal of material

By pressing push buttons and respectively.

In certain practical situations it is not possible to correct in the position calculated

theoretically as optimum position: in the case of a fan, for example, such position could fall

in the gap between two blades, where obviously it is not possible to add or remove

material. However, it is often the case also for uniform rotors, to prefer to correct where

holes are already present, or else to avoid acting in particular zones.

The split function of the N500 function calculates the weights to be applied or to remove

corresponding to any two positions α1 and α2, so that their effects are equivalent to those

of the correction calculated by the balancing algorithm.

When or is pressed, the user can assign the most appropriate value to

these two positions, by selecting from those effectively available in practice for that

particular rotor. By pressing the two corresponding correction weights are

automatically calculated and displayed.

Such operation can be performed separately on each of the planes, after selecting the

required one by pressing .

Balancer mode 7 - 13

Page 56

Caution:

Whatever the value of α1 and α2, the angle of

revolution is subdivided into two parts, one part

convex (<180°) and the other concave (>180°).

In order to carry out the splitting, angles α1 and α2

should be chosen so that the correction position

calculated during balancing, lies within the convex

zone.

If not, such splitting would be impossible, and the

N500 instrument would indicate zero as correction

weight for both positions α1 and α2.

N.B.:

It is useful to observe that the more the α1 and α2 positions are further apart from

the position calculated in balancing, the higher must be the values of the

corresponding weights. Hence it is advisable to select α1 and α2 as close as possible

to the correction angle obtained by the balancing operation, or at least to make sure

that they differ by less than 150°.

Saving of a balancing program

After displaying the program archive, proceed to select (with and the

position in which to save the current program.

When is pressed, a pop-up appears in which to enter the program name, as

explained in 2-3 Alphanumeric keypad..

Instead, when is pressed, the selected program can be eliminated, provided it is

not the current one .

Instead with it is possible to eliminate all the balancing programs contained in the

archive.

7 - 14 Balancer mode

Page 57

Chapter 8

Data manager mode

The N500 instrument allows saving the measurements made (FFT, waveforms and

monitoring) in special archives, which can be managed through this special function

directly accessible from the home screen.

Upon pressing a MEASUREMENT ARCHIVE screen appears where it is

possible to select between the following possibilities:

– Data management (i.e. rename or eliminate the data present);

– Copy the data on the USB key (pen drive) supplied, leaving a copy of the data on the

N500 instrument;

– Shift the data on the USB key (pen drive) supplied, thus deleting the data from the

N500 instrument;

– send archive to PC using CEMB PoInTer software

– load (display) measurements already in the archive.

Archive management

Measurements saved with the N500 instrument are subdivided by type into different

archives:

– waveforms

– FFT

– Monitoring in time

– Monitoring in speed

A fifth archive is reserved for the images in the screens,captured by pressing .

(see 2-10 - Capture and saving of displayed images).

Data manager mode 8 - 1

Page 58

When one of the archives in selected in the SELECT DATA MANAGER screen, its

contents will be displayed making distinction between empty positions (-----), and occupied

positions (name, date and time of save).

After selecting one of the items of data, the latter can be renamed or eliminated (to free

space) if it no longer serves.

To fully clear the archive, press then confirm by pressing .

N.B.

The archive can be scrolled by one position at a time with the and

keys, or more quickly with and (+10 and –10 respectively).

Copying /shifting archive on USB key

The data on the N500 instrument can be copied or shifted to the USB key supplied, and

then easily imported on to an ordinary PC with CEMB PoInTer software (see Chap. 9).

However without such software it is possible to use the images captured in the various

screens, e.g. by attaching them to any documentation produced with one of the various text

editors.

Caution

The pendrive supplied by CEMB is formatted for use on either the N500

instrument or on a standard PC with Windows or Linux operating system. Never,

under any circumstances whatsoever, proceed to a new formatting of the pendrive

otherwise it could no longer be used with the N500 instrument. In such case,

contact the CEMB Technical Service.

8 - 2 Data manager mode

Page 59

After inserting the pen drive in one of the two USB ports on the instrument

it is necessary to select which archive/archives to be transferred. These will be marked with

the symbol placed alongside its/their name.

Pressing of

causes starting of the data transfer process, indicated by the

pop-up wait message

At the end, the symbol indicates that the operation has been concluded successfully.

Instead, any errors are given in the same pop-up message alongside the symbol .

Data manager mode 8 - 3

Page 60

Caution

Never extract the USB key while the pop-up wait message is showed and before

proceeding, wait at least for its led to flash slowly. If flashing is rapid, it means that

the data transfer is still in progress and extracting the pen drive could block the

system, besides causing data loss. In such case, it could be necessary to reboot the

instrument.

The archives are copied on the pen drive inside the Db_N500 folder, in a specially created

subdirectory, whose name is the data of transfer in YYMMDD format (e.g. 051221 for 21

December 2005). In order to allow downloading of two or more archives in the same day,

there is provision for an adding a suffix “_* ” to this name where * is a letter assigned

progressively from A to Z.

Obviously it is not possible to transfer more the 26 archives on the key on the same day

before proceeding to load them on the PC, with the CEMB PoInTer software

(see 9-7 – Loading of new measurements in the archive), or manually.

Caution:

Never shift, rename or delete the folders or files downloaded on the pen drive from

the N500 instrument because this could cause malfunctions or incompatibility of

the CEMB PoInTer software.

Caution:

If the following error message appears

st

even with the pen drive inserted correctly, there could be a problem of recognition of

the key.

Try removing it, then inserting it again, switching the instrument off and on again if

necessary. If the problem persists, contact the Technical Service Department.

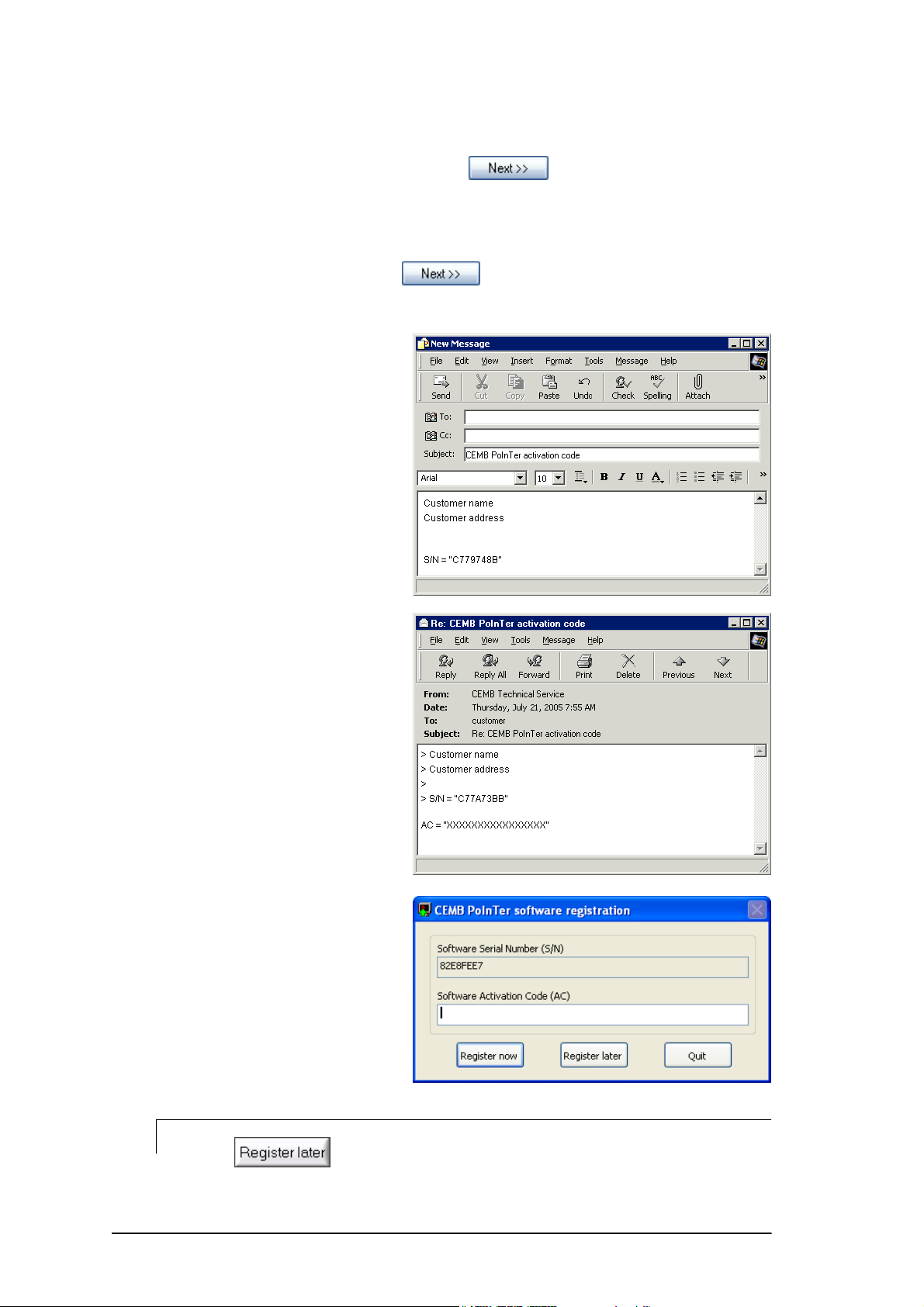

Sending archive to PC (CEMB PoInTer software required)

Data stored in the N500 instrument can be sent directly to a PC equipped with CEMB

PoInTer software, version 2.6 or greater.

To complete this operation successfully, connect the N500 instrument to the serial port

(RS232) of the PC using the cable supplied by CEMB for this purpose. After starting the

'Import data' function in the CEMB PoInTer software, wait until the communication in

progress message appears (see 9-6 - Reading measurements saved on the N500

instrument

key.

.), then select the archives to be sent on the N500 instrument and finally press

; the procedure is similar to that followed for the transfer of data using a USB

8 - 4 Data manager mode

Page 61

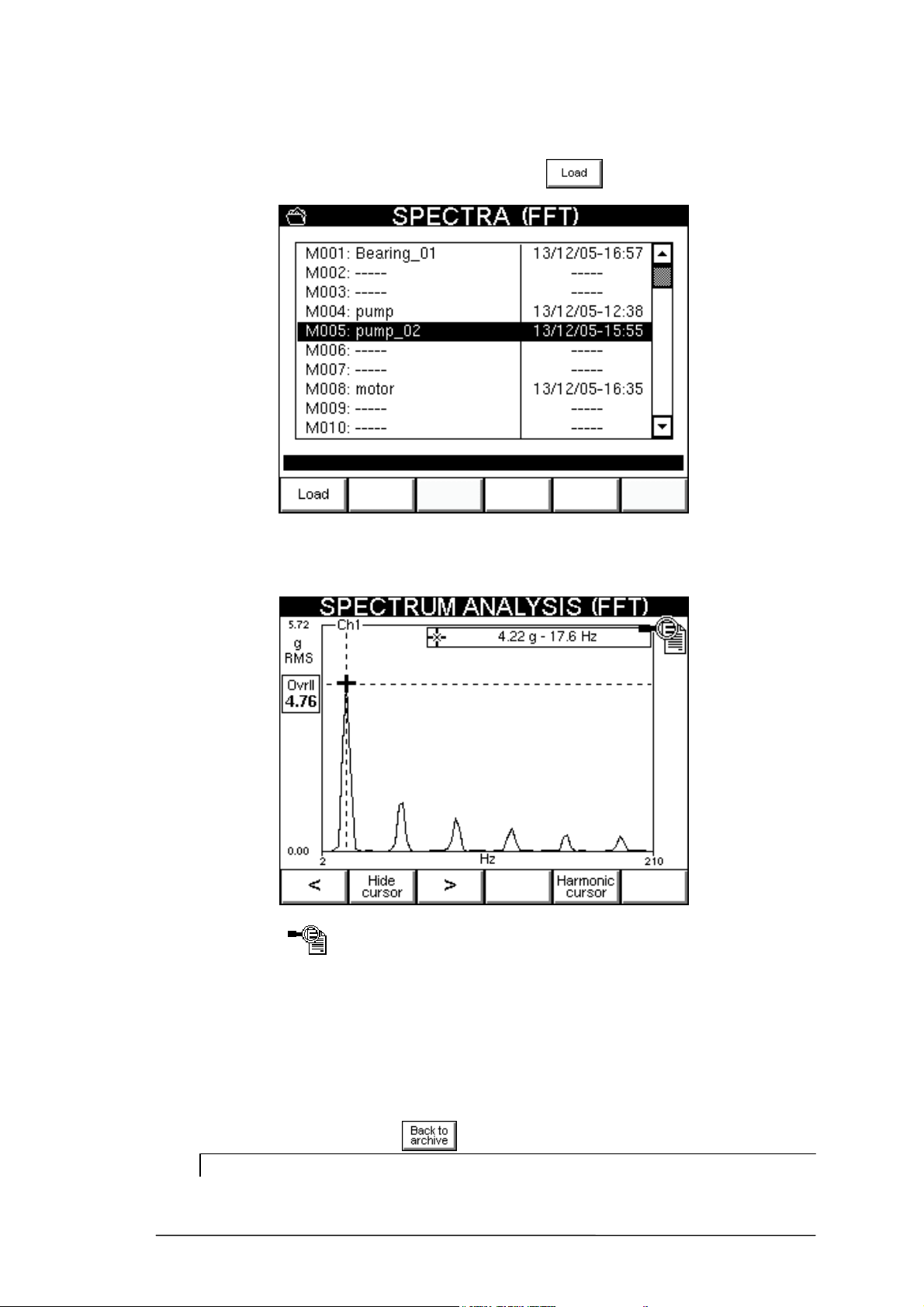

Display of measurements present in the archive

It is possible to display all the measurements and images saved in the N500 instrument by

selecting them from the relative archive and pressing

This makes it very easy to obtain comparisons and to make assessments directly "in field ".

The various data are presented in screens wholly similar to the corresponding measurement

screens.

in which the icon at the top right serves for reminding the user that being display

pages, it is not possible, for example, to start a new acquisition.

Instead, the following functions are available

- set scale

- show cursor

- change of channel displayed (only for two-channel measurement)

- list of peaks (only for FFT)

To quit the display screens, press

N.B.:

available.

Data manager mode 8 - 5

Obviously if an item from the image archive is loaded, no function is

Page 62

8 - 6 Data manager mode

Page 63

Chapter 9

CEMB PoInTer Program (optional)

The data collected and memorized with the N500 instrument can readily imported to a PC

(directly or using a USB key), and subsequently analyzed, processed, compared, printed.

Such operation is considerably facilitated by using the CEMB PoInTer (Portable

Instruments Terminal) software, available for Windows operating systems.

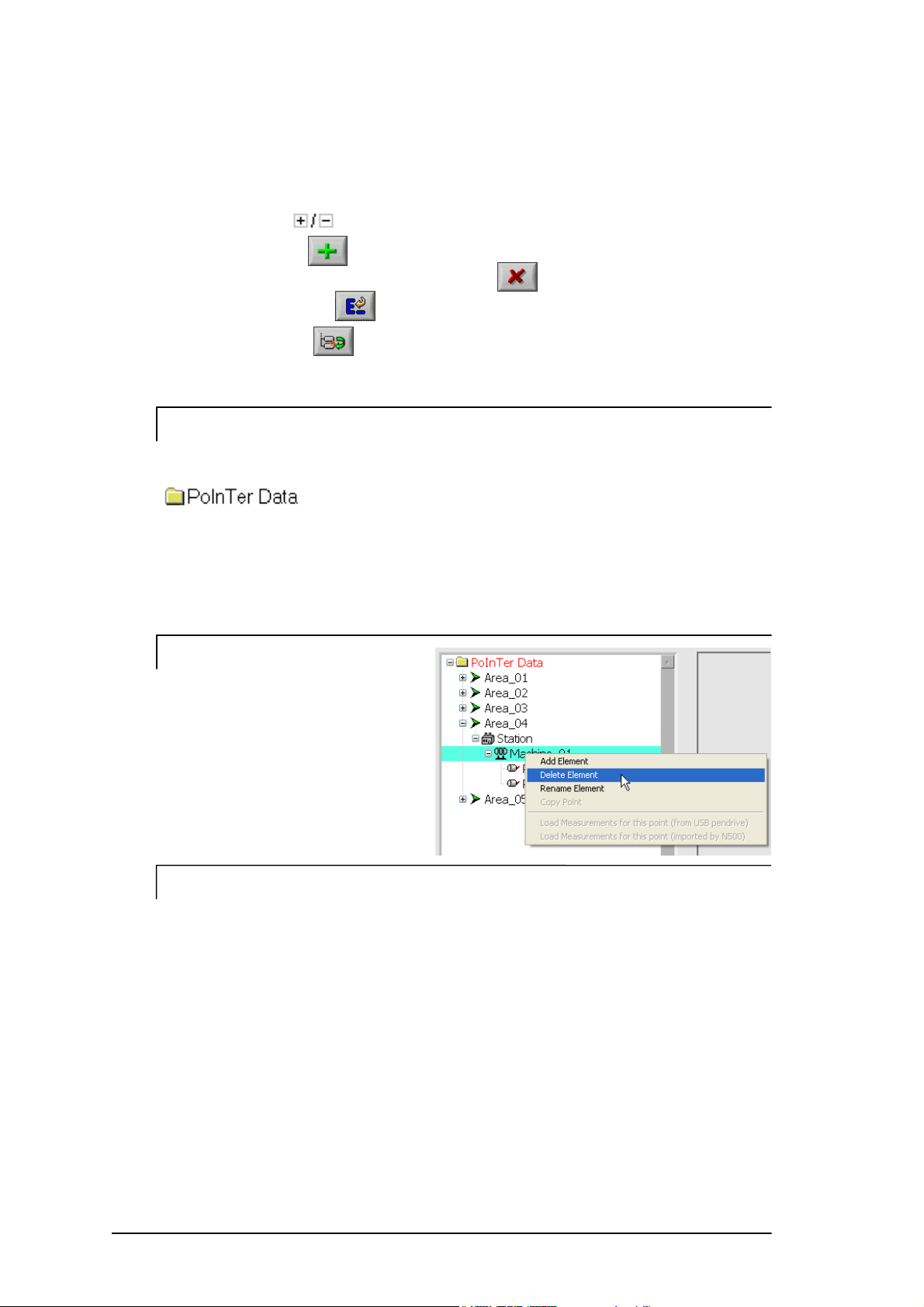

Its main page

1 2 3

can be imagined as being subdivided into three zones, which allow the following items to

be controlled respectively:

1 – archive of measuring points

2 – measurements available for the point selected

3 – list of measurements to be plotted in a graph