Carrier 30GX125, 30GX080, 30GX115, 30GX150, 30GX136 Controls, Start-up, Operation, Service, And Troubleshooting

...

ECOLOGIC™ Air-Cooled and Fluid Cooled Chillers

Controls Start-Up, Operation,

Service, and Troubleshooting

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components, and

equipment location (roof, elevated structures, etc.). Only

trained, qualified installers and service mechanics should install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature, and on tags, stickers, and labels attached to the

equipment, and any other safety precautions that apply. Follow

all safety codes. W ear safety glasses and work gloves. Use care

in handling, rigging, and setting this equipment, and in handling all electrical components.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation and service. There may be more than one disconnect switch. Tag

all disconnect locations to alert others not to restore power

until work is completed.

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out components, or to bypass or otherwise depart from recommended procedures. Any short-to-ground of the control

board or accompanying wiring may destroy the electronic

modules or electrical components.

To prevent potential damage to heat exchanger tubes

always run fluid through heat exchangers when adding or

removing refrigerant charge. Use appropriate brine solutions in cooler and condenser fluid loops to prevent the

freezing of heat exchangers when the equipment is exposed

to temperatures below 32 F (0° C).

DO NOT VENT refrigerant relief valves within a building. Outlet from relief valves must be vented outdoors in

accordance with the latest edition of ANSI/ASHRAE

(American National Standards Institute/Ame rican Society

of Heating, Refrigeration and Air Conditioning Engineers)

15 (Safety Code for Mechanical Refrigeration). The accumulation of refrigerant in an enclosed space can displace

oxygen and cause asphyxiation. Provide adequate ventilation in enclosed or low overhead areas. Inhalation of high

concentrations of vapor is harmful and may cause heart irregularities, unconsciousness or death. Misuse can be fatal.

Vapor is heavier than air and reduces the amount of oxygen

available for breathing. Product causes eye and skin irritation. Decomposition products are hazardous.

30GX080-350

30HXA,HXC076-271

50/60 Hz

Series 3

DO NOT attempt to unbraze factory joints when servicing

this equipment. Compressor oil is flammable and there is

no way to detect how much oil may be in any of the refrigerant lines. Cut lines with a tubing cutter as required when

performing service. Use a pan to catch any oil that may

come out of the lines and as a gage for how much oil to add

to system. DO NOT re-use compressor oil.

CONTENTS

SAFETY CONSIDERATIONS

GENERAL

MAJOR SYSTEM COMPONENTS

Processor Module (PSIO-1)

DSIO-HV Relay Module

Electronic Expansion Device Module

Compressor Protection Module (CPM)

PSIO-2 (8052) Module

Keypad and Display Module

(Also Called HSIO-II)

Control (LOR) Switch

OPERATION D ATA

Electronic Expansion Device (EXD)

• EXV OPERATION

• ECONOMIZER OPERATION

Oil Pumps

Motor Cooling

Back Pressure Valve (30GX and 30HXA only)

Sensors

Compressor Protection Module (CPM)

• OUTPUTS

• INPUTS

Wye-Delta vs Across-the-Line (XL)

Starting Option

Capacity Control

• MINUTES LEFT FOR START

• MINUTES OFF TIME

• LOADING SEQUENCE

• CLOSE CONTROL

• LEAD/LAG DETERMINATION

• CAPACITY SEQUENCE DETERMINATION

• MINIMUM LOAD VALVE

• CAPACITY CONTROL OVERRIDES

Head Pressure Control

• GENERAL

• AIR-COOLED UNITS (30GX)

• WATER-COOLED UNITS (30HXC)

• CONDENSERLESS UNITS (30HXA)

• 09DK CONDENSING UNITS

• ADJUSTING PID ROUTINES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . 3

. . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . 3

. . . . . 4

. . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Page

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 533-095 Printed in U.S.A. Form 30G,H-5T Pg 1 8-99 Replaces: 30G,H-4T

CONTENTS (cont)

Page

Cooler and Condenser (30HXC)

Pump Control

• COOLER PUMP CONTROL

• CONDENSER PUMP CONTROL

Cooler Heater Control

Oil Heater Control

Keypad and Display Module

(Also Called HSIO-II)

• ACCESSING FUNCTIONS

AND SUBFUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . 15

• AUTOMATIC DEFAULT DISPLAY . . . . . . . . . . . . . . 15

• STATUS FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . 19

• TEST FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

• HISTORY FUNCTION. . . . . . . . . . . . . . . . . . . . . . . . . 27

• SET POINT FUNCTION . . . . . . . . . . . . . . . . . . . . . . . 27

• SERVICE FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . 32

• SCHEDULE FUNCTION. . . . . . . . . . . . . . . . . . . . . . . 39

Temperature Reset

• EXTERNAL TEMPERATURE RESET

• EXTERNALLY POWERED RESET

• RETURN FLUID TEMPERATURE RESET

Demand Limit

• DEMAND LIMIT (Switch Controlled, 30GX Only)

• EXTERNALLY POWERED DEMAND LIMIT

• DEMAND LIMIT (CCN Loadshed Controlled)

TROUBLESHOOTING

Checking Display Codes

Unit Shutoff

Complete Unit Stoppage

Single Circuit Stoppage

Restart Procedure

• POWER FAILURE EXTERNAL TO THE UNIT

Alarms and Alerts

Compressor Alarm/Alert Circuit

EXD Troubleshooting Procedure

• INSPECTING/OPENING ELECTRONIC

EXPANSION VALVES

• INSPECTING/OPENING ECONOMIZERS

SERVICE

Servicing Coolers and Condensers

• TUBE PLUGGING

• RETUBING

• TIGHTENING COOLER/CONDENSER

HEAD BOLTS

Inspecting/Cleaning Heat Exchangers

•COOLERS

• CONDENSERS (30HX Only)

Water Treatment

Condenser Coils (30GX Only)

• COIL CLEANING

Condenser Fans (30GX Only)

Refrigerant Charging/Adding Charge

Oil Charging/Low Oil Recharging

Oil Filter Maintenance

• REPLACING THE EXTERNAL OIL FILTER

• REPLACING THE INTERNAL OIL FILTER

Compressor Changeout Sequence

• BURNOUT CLEAN-UP PROCEDURE

Moisture-Liquid Indicator

Filter Drier

Liquid Line Service Valve

Thermistors

•LOCATION

• THERMISTOR REPLACEMENT

Pressure Transducers

• PRESSURE TRANSDUCER CALIBRATION

• TROUBLESHOOTING

Safety Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . 45-54

. . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . 52

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54-68

. . . . . . . . . . . . . . 54

. . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . 58

. . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . 60

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . 61

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• COMPRESSOR PROTECTION

• OIL SEPARATOR HEATERS (30GX)

• COOLER PROTECTION

Relief Devices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

• PRESSURE RELIEF VALVES

Control Modules

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

• PROCESSOR MODULE (PSIO-1), COMPRESSOR

PROTECTION MODULE (CPM), HIGH VOLTAGE

RELAY MODULE (DSIO-HV), AND EXV DRIVER

MODULE (DSIO-EXV), 12/6 MODULE (PSIO-2)

• RED LED

• GREEN LED

• CONTROL MODULE BATTERY REPLACEMENT

Carrier Comfort Network (CCN) Interface

. . . . . . . . 66

• PROCESSOR MODULE (PSIO-1)

• HIGH VOLTAGE RELAY MODULE (DSIO-HV)

Replacing Defective Processor Module

Winter Shutdown Preparation

PRE-START-UP PROCEDURE

System Check

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

START-UP AND OPERATION

Actual Start-up

Operating Sequence

FIELD WIRING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-75

. . . . . . . . . . . . . . . . . . . 68

. . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . . . . . . . . . . . . 69

. . . . . . . . . . 68

APPENDIX A

(Compressor Must Trip Amps)

. . . . . . . . . . . . . 76-80

APPENDIX B

(Capacity Loading Sequence)

APPENDIX C (Available Accessories)

APPENDIX D (Building Interface)

. . . . . . . . . . . . . . 81-85

. . . . . . . . . 86,87

. . . . . . . . . . . . . 88-92

APPENDIX E (Cooler and

Condenser Pressure Drop)

. . . . . . . . . . . . . . . . . 93-96

APPENDIX F

(Typical System Components)

INDEX

START-UP CHECKLIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . .CL-1 to CL-8

. . . . . . . . . . . . . 97,98

GENERAL

IMPORTANT: The 30GX,HX units use refrigerant

R-134a. Compressor oil used with R-134a is Polyolester

oil.

This publication contains Start-Up, Service, Controls, Operation and Troubleshooting data for the 30GX080-350 and

30HXA,C076-271 screw chillers.

Circuits are identified as circuits A and B, and compressors

are identified as A1 or A2 in circuit A, and B1 or B2 in

circuit B.

The 30GX,HX Series chillers feature microprocessor-based

electronic controls and electronic expansion devices (EXD) in

each refrigeration circuit.

The control system cycles compressor loaders and/or compressors to mai ntain the se lected lea ving fluid te mperature s et

point. The system automatically positions the EXD to maintain

the specified refrigerant level in the cooler. The system also has

capabilities to control a condenser water valve to maintain suitable leaving-water temperature for the 30HXC unit. Safeties

are continuously monitored to prevent the unit from operating

under unsafe conditions. A scheduling function can be programmed by the user to control the unit’s occupied and unoccupied schedules. The control also operates a test function and

a manual control function that allows the operator to check output signals and ensure components are operable.

The control system consists of a processor module

(PSIO-1), an EXD driver module (DSIO-EXV), a high voltage

relay module on 30GX units (DSIO-HV), 2 six-pack relay

boards, a keypad and display module (also called HSIO-II),

2 electronic expansion devices (EXDs), 1 compressor protection module (CPM) per pair of compressors, a PSIO-2 module,

2

6 thermistors, and up to 10 transducers. A remote enhanced

display is available as an accessory.

MAJOR SYSTEM COMPONENTS

Processor Module (PSIO-1) —

upgrade to the original PSIO (8088) module, with superior

electrical noise immunity capability. It contains the operating

software and controls the operation of the machine. It has 12

input channels and 6 output channels.

The PSIO-1 continuously monitors input/output channel information received from all the modules and controls all output

signals for all output channels. It also controls the relays on the

six-pack relay board. The processor module also controls the

EXD driver module, commanding it to open or close each

EXD in order to maintain the proper cooler level. Information

is transmitted between the processor module, CPM modules,

the EXD driver module, and the HSIO-II standard display

module through a 3-wire communications bus called COMM3.

The remote enhanced display (accessory) is connected to the

PSIO-1 module through a 3-wire communications bus, but

uses a different communication bus called COMM1. The

COMM1 bus is also used to communicate to other CCN

(Carrier Comfort Network) devices when the unit is installed in

a network application.

DSIO-HV Relay Module —

4 inputs and 8 outputs and is installed on 30GX units only. The

module communicates the status of the inputs with the PSIO-1

module and operates the oil heater, outdoor fan, and minimum

load control outputs.

Electronic Expansion Device Module —

electronic expansion device module has 4 inputs and 2 outputs.

It receives signals from the PSIO-1 module and operates the

electronic expansion devices. The electronic expansion device

module also sends the PSIO-1 module the status of its 4 input

channels.

Compressor Protection Module (CPM) —

compressor protection module monitors the high pressure

switch status, running current, and motor temperature for each

compressor. Each CPM controls up to 2 compressors. The

CPM also controls the motor cooling solenoid, oil solenoid,

and contactor outputs. A pre-punched configuration header for

each compressor determines the must trip amps setting. Each

CPM sends the PSIO-1 each compressor’s motor temperature,

relay status, and running current as a percentage of the must

trip amps value. The CPM als o communic ates any al arm conditions as the feedback value.

PSIO-2 (8052) Module —

put/output module only, as there is no unit software loaded in

the module. This module has 12 input channels and 6 output

channels.

This module is an

The DSIO-HV module has

The

The

This module is used as an in-

Keypad and Display Module (Also Called

HSIO-II) —

keys, 4 operative keys, 12 numeric keys, and a 2-line

24-character alphanumeric LCD (liquid crystal display). Key

usage is explained in the Accessing Functions and Subfunctions section on page 15.

Control (LOR) Switch —

fined by the position of the LOCAL/OFF/REMOTE (LOR)

switch. This is a 3-positi on manual swit ch th at allow s th e chiller to be put under the control of its own controls (LOCAL ),

manually stopped (OFF), or controlled through a set of remote

contacts (REMOTE). This switch i s different than the switch

This device consists of a keypad with 8 function

Control of the chiller is de-

that is used in the Flotronic™ II controls configuration. The

CCN control is enabled through the H SIO-II. The switch allows unit operation as shown in T able 1.

In the LOCAL position, the c hiller i s allowed to ope rate and

respond to the scheduling configuration, CCN configuration,

and set point data. In the remote position, the unit operates similarly to the LOCAL position, except the remote contacts must

be closed for the unit to operate.

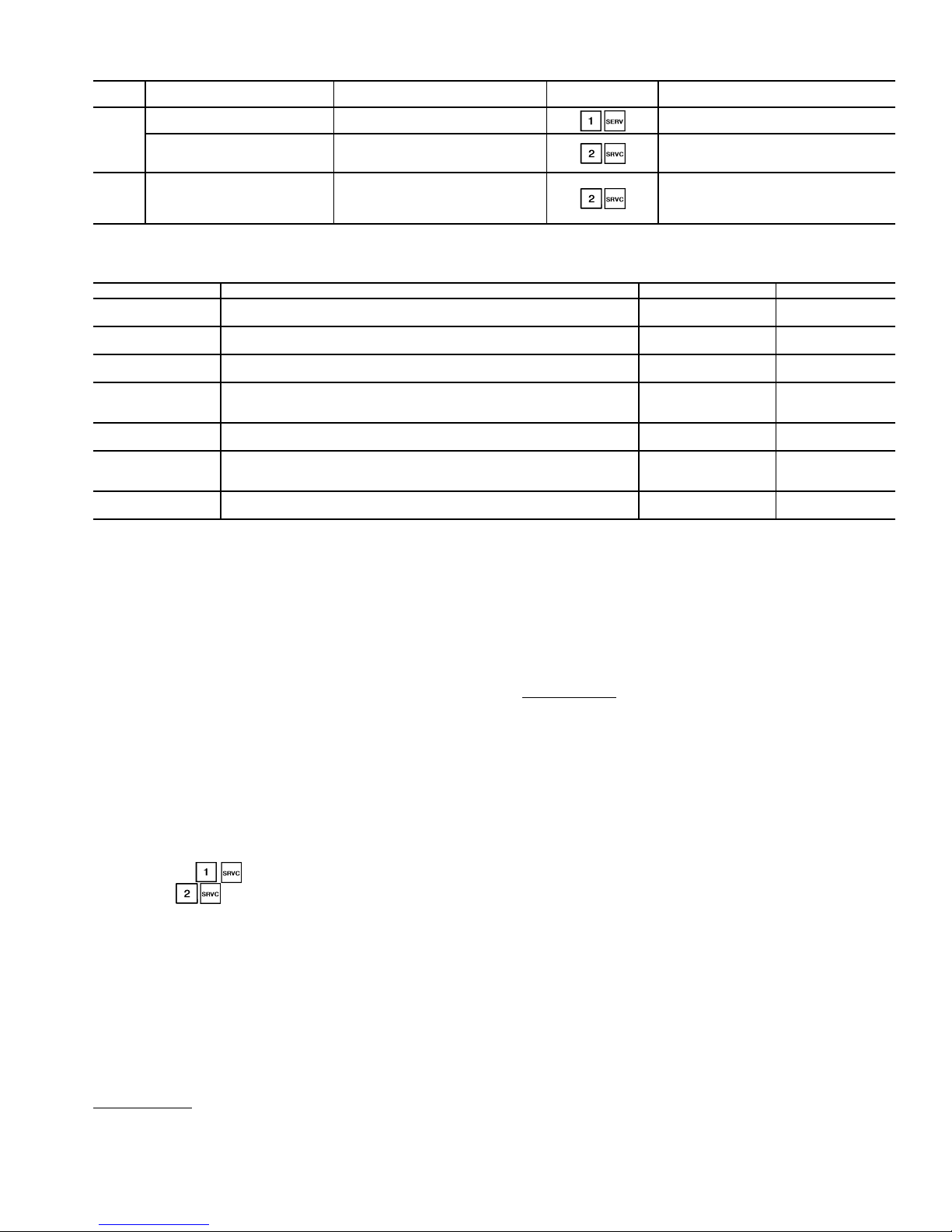

Table 1 — Unit Mode from LOR Switch

and CCN State

SWITCH

POSITION

LOCAL

OFF

REMOTE

CCN —

NR —

NOTE: If the unit is configured for a clock, then the unit is under clock control if it is in an

ON mode.

REMOTE

CONTACTS

NR

NR NR NR LOCAL OFF

OPEN NR NR LOCAL OFF

CLOSED

LEGEND

Carrier Comfort Network

Input Not Read by Processor

CCN

CONFIGURATION

DISABLE NR LOCAL ON

ENABLE

DISABLE NR LOCAL ON

ENABLE

CCN

STATE

RUN CCN ON

STOP CCN OFF

RUN CCN ON

STOP CCN OFF

UNIT

MODE

OPERATION DATA

Electronic Expansion Devi ce (EXD) —

processor controls the EXD through the EXD driver module .

The EXD will either be an EXV (electronic expansion valve) or

an economizer. Inside both these devices is a linear actuator stepper motor.

EXV OPERATION — High-pressure liquid refrigerant enters the valve through the bottom. A series of calibrated slots

are located inside t he orifice assembly. As refrigerant passes

through the orifice, the pressure drops and the refrigerant

changes to a 2-phase condition (liquid and vapor). To control

refrigerant flow for different operating conditions, the sleeve

moves up and down over the orifice, thereby changing orifice

size. The sleeve is moved by a linear stepper motor. The stepper motor moves in increments and is controlled directly by the

processor module. As the stepper motor rotates, motion is

transferred into linear movement by the lead screw. Through

the stepper motor and lead screw, 1500 discrete steps of motion

are obtained. The large number of steps and long stroke result

in very accurate control of refrigerant flow.

Each circuit has a liquid level sensor mounted vertically in

the top of the cooler shell. The level sensor consists of a small

electric resistance heater and 3 thermi stors wire d in s eries , positioned at different heights inside the body of the well. The

heater is designed so that the thermistors read approximately

200 F (93.3 C) in dry air . As the refrigerant level ris es (falls) in

the cooler, the resistance of the closes t thermistor(s) will increase (decrease) as it is cooled by the rising liquid refrigerant

(heated by the heater). This large resistance difference allows

the control to accurate ly maint ain a spe cified le vel.

The level sensor monitors the refrigerant liquid level in the

cooler and sends this infor mation to the PSIO-1. At initia l startup, the EXV position is at zero. After that, the microprocessor

keeps accurate track of the valve position in order to use this information as input for the other control functions. The processor does this by initializing the EXVs at start-up. The processor

sends out enough closing pulses to the valve to move it from

fully open to fully closed, then resets the position counter to zero. From this point on, until the next initialization, the processor counts the total number of open and closed steps it has sent

to each valve.

The micro-

3

ECONOMIZER OPERATION — Economizers are factory

installed on 30GX105-350 units and 30HXA,C161-271 units.

All other sizes use standard EXVs. The economizer improves

both the chiller capacity and efficiency as well as providing

compressor motor cooling. Inside the economizer are both a

linear stepper motor (same as standard EXV motor) and a float

valve. The stepper motor is controlled by the processor to

maintain the desired liquid level in the cooler (as is done for

chillers without economizers). The float valve maintains a liquid level in the bottom of the economizer.

Liquid refrigerant is supplied from the condenser through

the end to the bottom of the economizer. A bubbler tube supplies a small amount of discharge gas to ensure that the float

will be able to work properly. As the refrigerant passes through

the EXD, its pr essure is reduced to an inter mediate level of

about 75 psig (517 kPag). This pressure is maintained inside

the economizer shell. Next, the refrigerant flows through the

float valve where its pressure is further reduced to slightly

above the pressure in the cooler.

The increase in performance is achieved when some of the

refrigerant passing through the EXD flashes to vapor, further

subcooling the liquid that is maintained at the bottom of the

economizer. This increase in subcooling provides additional

capacity. Also, since the additional power required to accomplish this is minimal, the efficiency of the m achine improves.

The vapor that flashes rises to the top of the economizer where

it passes to the compressor and is used to provide motor cooling. After passing over the motor windings, the refrigerant

reenters the cycle at an intermediate port i n the compression

cycle.

Oil Pumps —

nally mounted prelubricating oil pump per circuit. This pump

is operated as part of the start-up sequence. On 30GX units, the

pumps are mounted to the base rails on the oil separator side of

the unit. The pumps are mounted to a bracket on the condensers of 30HXC units and to the oil separator on 30HXA units.

When a circuit is required to start, the controls energize the

oil pump first and read the oil pressure transducer reading. The

pump is operated for a period of 20 seconds, after which the oil

solenoid is energized to open the oil inlet valve at the compressor. The control again reads the pressure from the oil pressure

transducer. If the pump has built up sufficient oil pressure, the

compressor is allowed to start.

Once the compressor has started, the oil pump is turned off

within 10 seconds. If the pump is not able to build up enough

oil pressure, the pump is turned off. Within 3 seconds, the

pump is re-energized and makes one additio nal attempt to build

oil pressure. The control generates an alarm if the second attempt fails.

The oil pump is also used to supplement system pressure

under certain operating conditions. The oil flow requirements

of the compressor vary based on pressure differential across the

compressor. The oi l pump is designed to provi de differential oil

pressure during low pressure differential conditions. It is not

designed to overcome high pressure drop across filters during

high pressure differential conditions.

If the differential oil pressure (oil pressure – economizer

pressure) for a compressor is less than 13 psi then the oil pump

will be started. Just before the oil pump is started the control

measures the pressure differential between the discharge pressure and oil pressure (oil system pressure drop). The oil system

pressure drop is saved and used to determine when the oil

pump should be shut off.

When the oil pump is operating, it is capable of increasing

oil pressure from 0 psi to 50 psi depending on the oil flow

The 30GX,HX screw chillers use one exter-

requirements of the compressor. For example, if the compressor needs 2 gpm (high pressure differential condition) and the

oil pump is capable of 1.2 gpm, there is no pressure rise and the

oil flow will bypass the check valve and supply the 2 gpm to

the compressor. If the compressor requires .75 gpm, the oil

pump will increase pressure to satisfy the oil pressure requirement.

The pump will continue to operate until the discharge pressure minus economizer pressure is greater then 17 psi plus the

oil system pressure drop.

Example:

Discharge pressure 80 psi

Oil pressure 65 psi

Oil system pressure drop80 –65 = 15 psi

Economizer pressure 55 psi

Suction pressure 42 psi

Based on the above conditions the oil pump will be started

because differential oil pressure equals 10 psi.

The oil pump will continue to operate until the discharge

pressure minus economizer pressure (which equals 25) is

greater than 17 plus 15 (oil system loss before pump was started). The only way this can be satisfied is if the discharge pressure increases or the compressor unloads at which point the oil

pump will be shut off.

Motor Cooling —

tures are controlled to a set point of 200 F (93.3 C). The control

accomplishes this by cycling the motor cooling solenoid valve

to allow liquid refrigerant to flow across the motor windings as

needed. On units equipped with economizers, flash gas leaves

the top of the economizer and continually flows to the motor

windings. All refrigerant used for motor cooling re-enters the

rotors through a port located midway along the compression

cycle and is compressed to discharge pressure.

Compressor motor winding tempera-

Back Pressure Valve (30GX and 30HXA

only) —

30GX units and mounted on the oil separator shell of 30HXA

units. The valve’s function is to ensure that there is sufficient

system differential pressure to allow for oil to be driven back to

the compressor. A small copper line (economizer pressure) is

connected to the top of the valve, which contains an internal

spring that closes a piston if the pressure in the oil separator is

not at least 15 psig greater than the economizer pressure.

Sensors —

Flotronic™ II chiller control system) gathers information from

sensors to control the operation of the chiller. The units use up

to 10 standard pressure transducers, up to 8 standard thermistors (including 4 motor temperature thermistors), and 2 liquid level thermistors to monitor and control system operation.

The sensors are listed in Table 2.

Compressor Protection Module (CPM) —

CPM controls up to 2 compressors. The CPM provides the following functions:

• compressor main contactor control|

• Wye-Delta contactor transition

• compressor ground current protection

• motor temperature reading

• high-pressure protection

• reverse rotation protection

• current imbalance protection

• compressor oil solenoid control

• motor cooling solenoid contro l

• sensor bus communications

• starting and running overcurrent protection

This valve is located on the oil separator outlet on

The 30GX,HX control system (based on the

One

4

The CPM has the following 4 output relays and 4 inputs:

OUTPUTS:

• compressor contactor

• compressor oil solenoid

• compressor motor cooling soleno id

• Wye-Delta transition relay

INPUTS:

• motor temperature

• three-phase current

• high-pressure switch

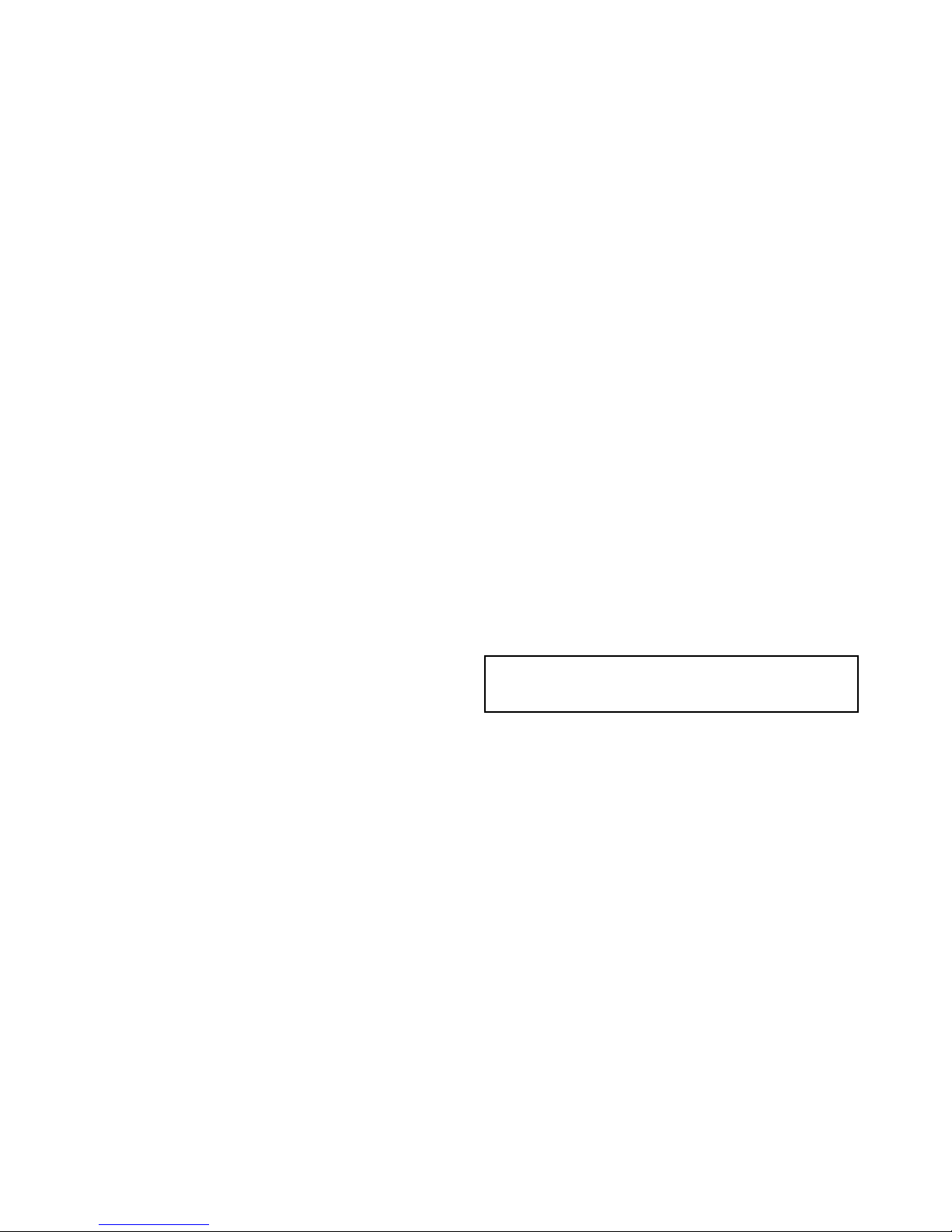

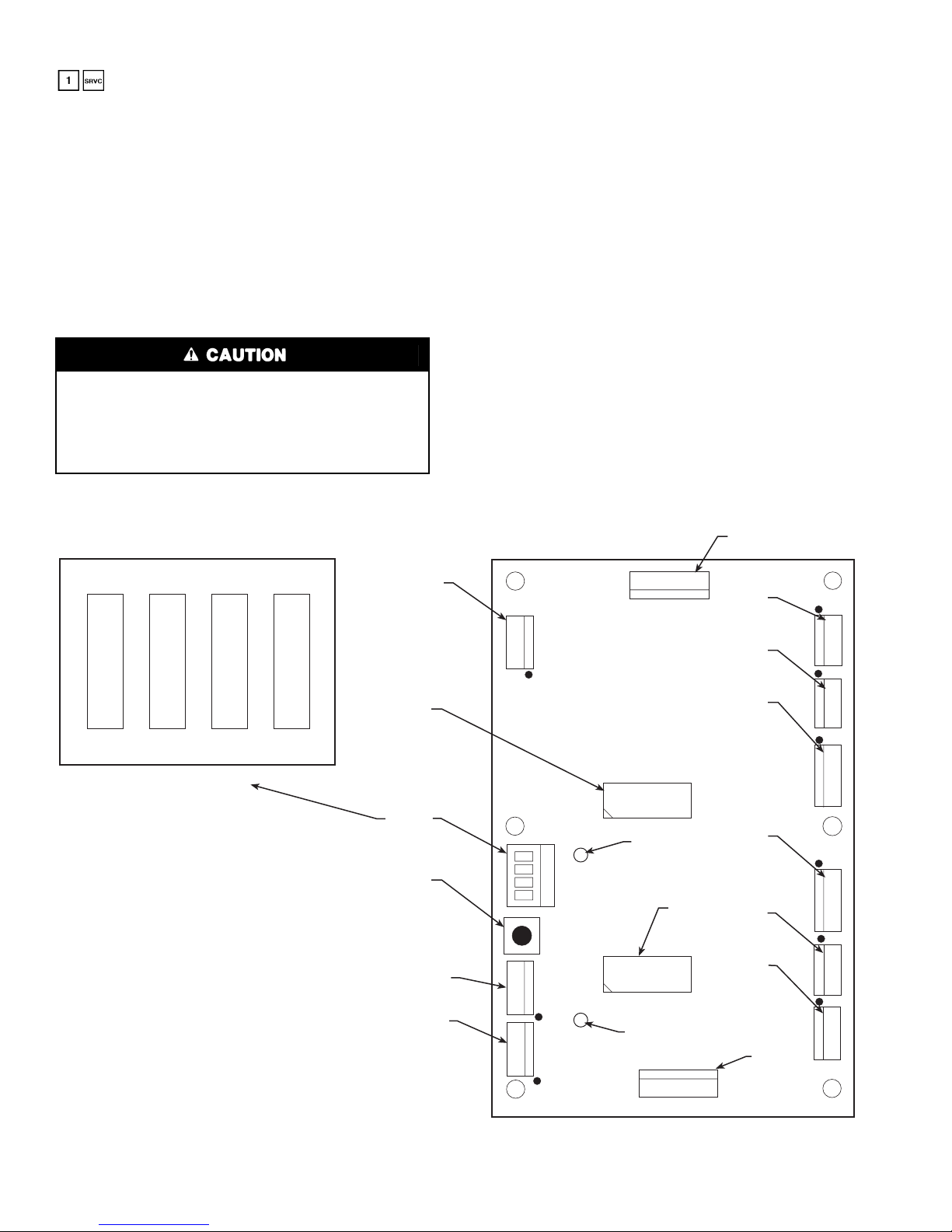

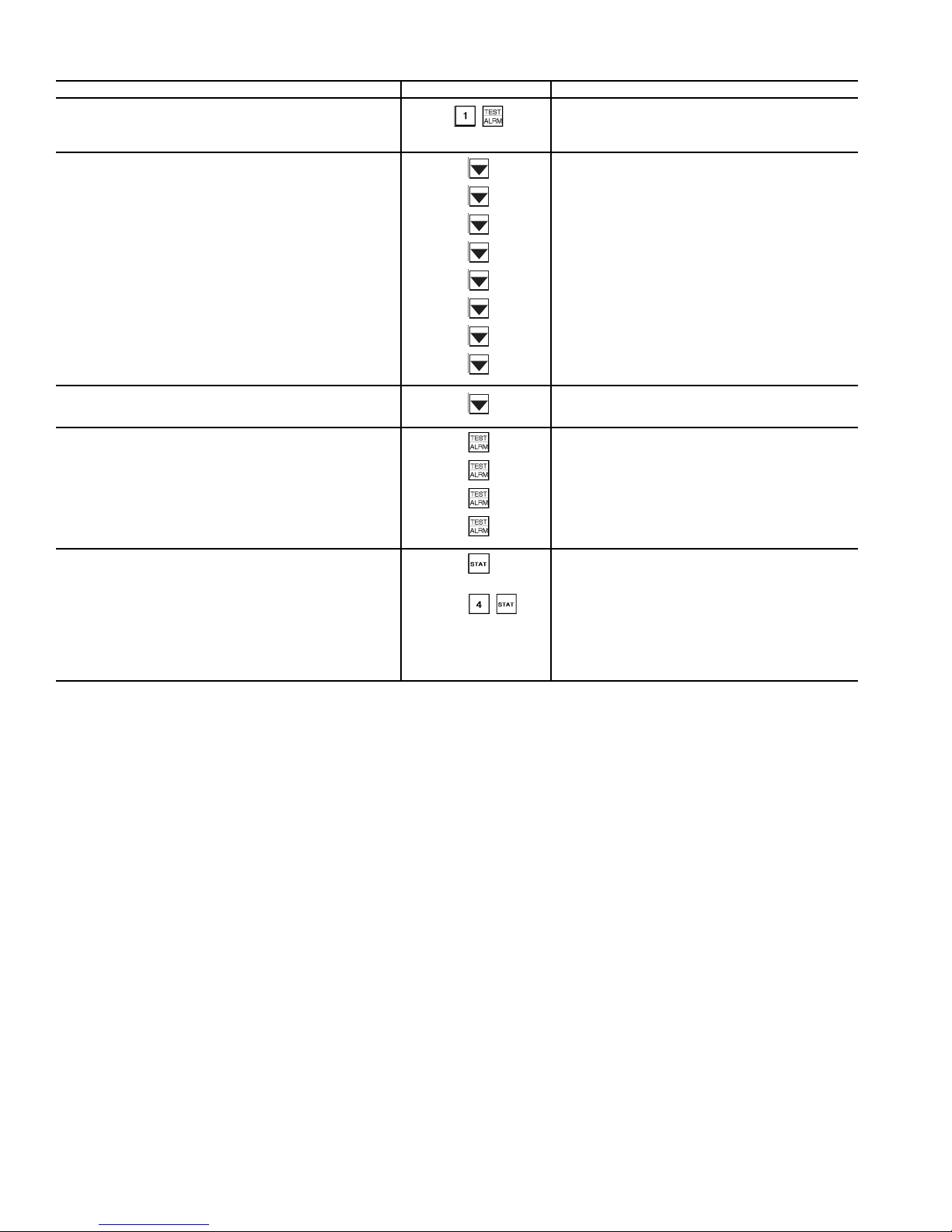

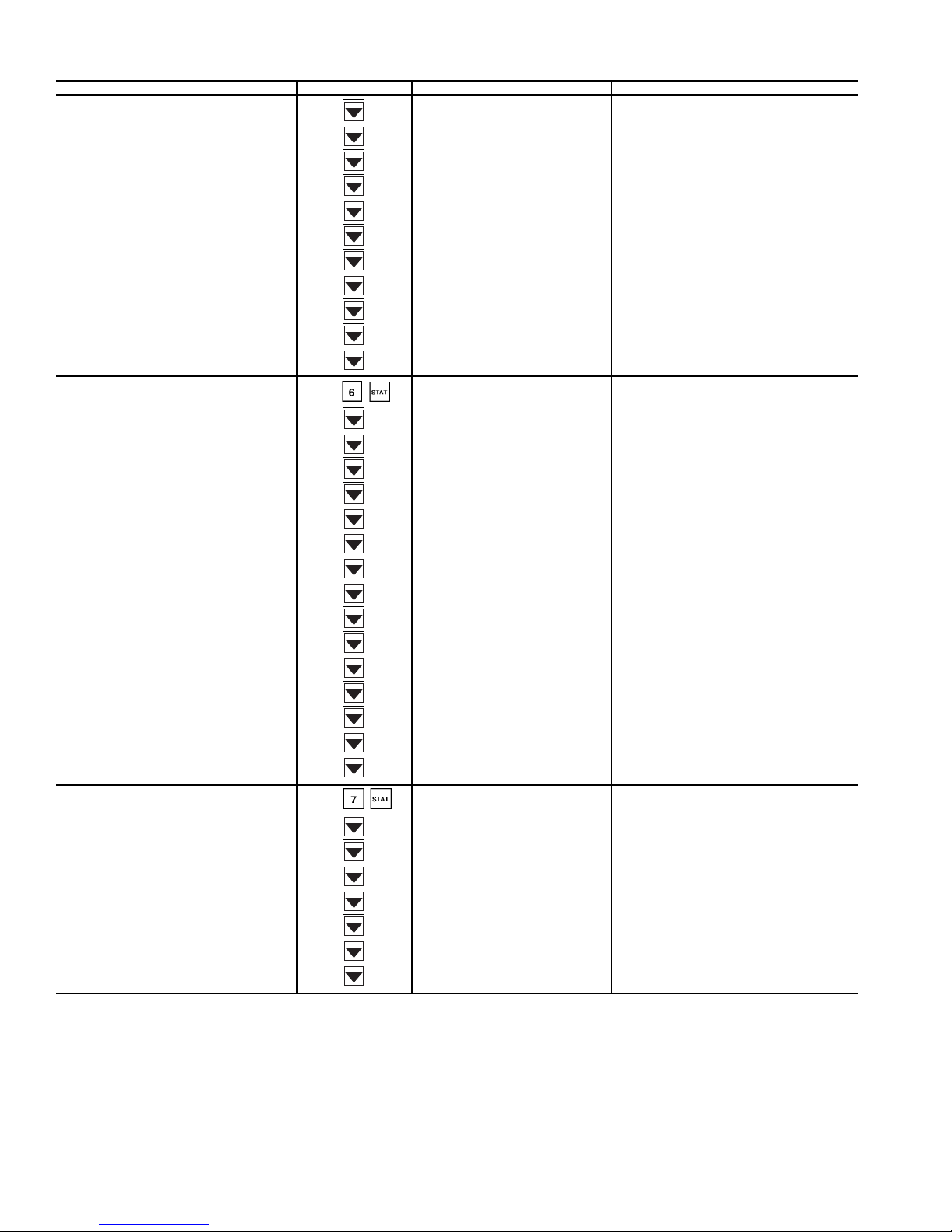

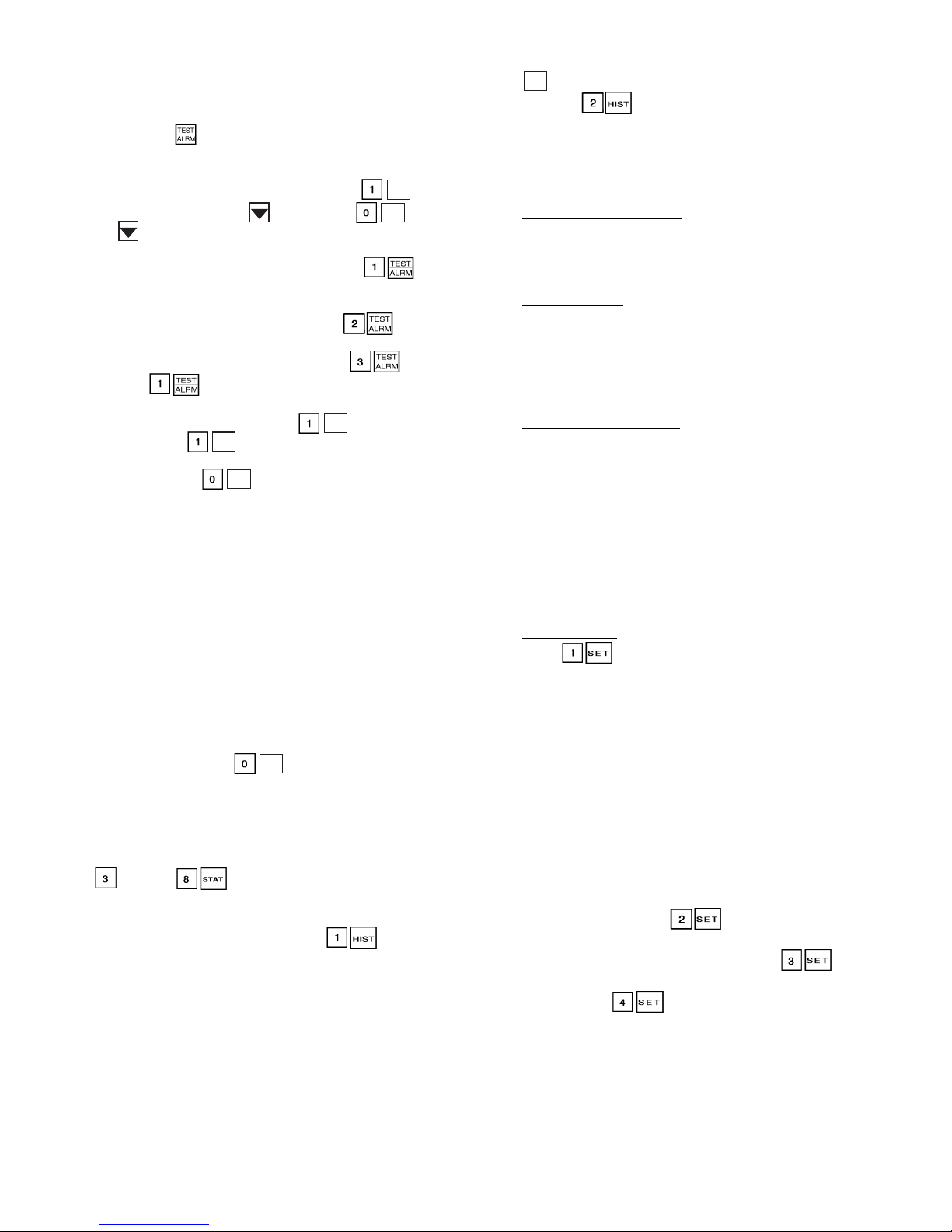

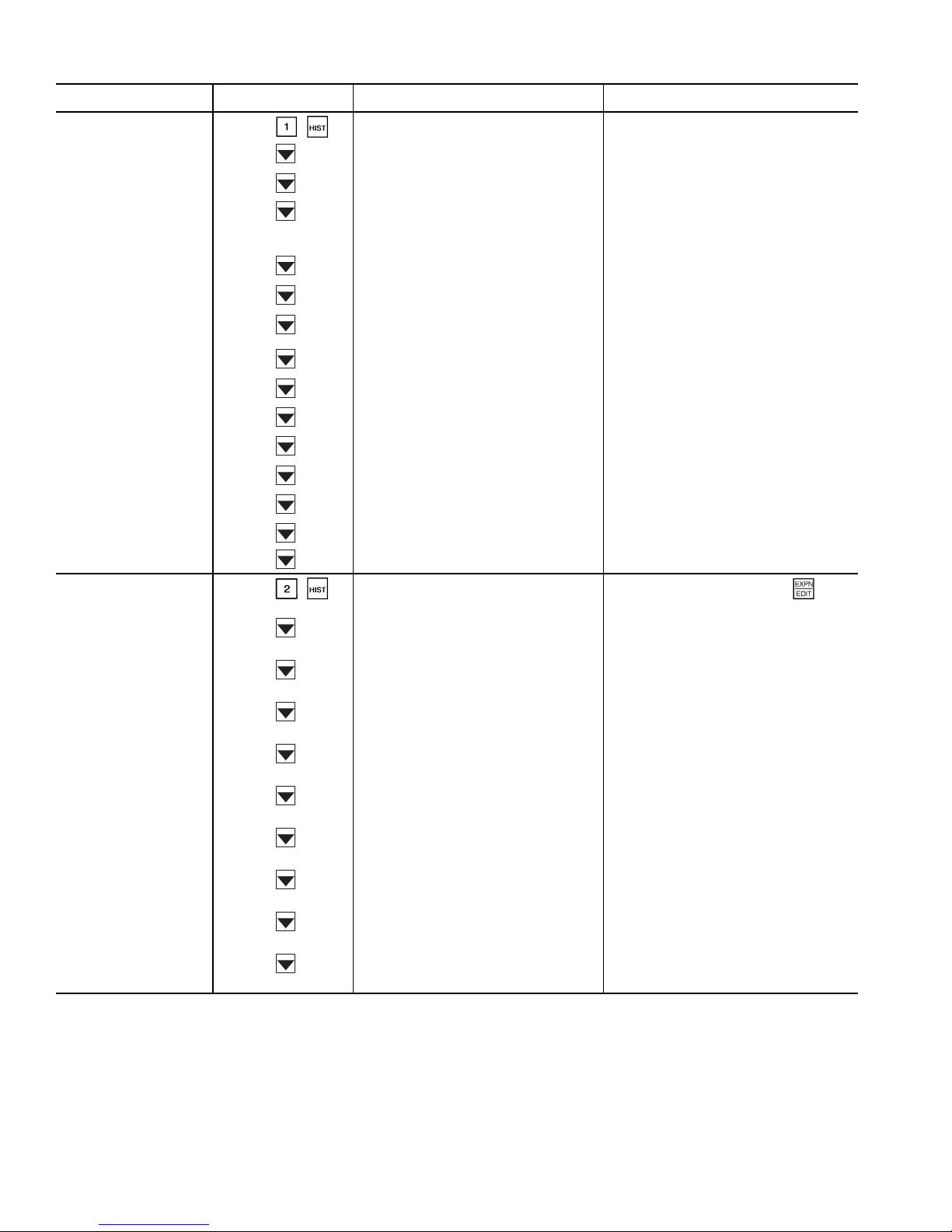

A diagram of the CPM board is (HN67LM101) shown in

Fig. 1. One CPM board is installed on 30GX080-176 and

30HXA,C076-186 units, and 2 CPM boards are installed on

30GX205-350 and 30HXA,C206-271 units. The address for

switches 3 and 4. For CPM1 (compressors A1 and B1), both

DIP switches should be set to 0. For CPM2 (compressor A2,

for 30GX205-265 and 30HXA,C206-271 units only and compressors A2 and B2 for 30GX281-350 only), both switches

should be set to 1. See Table 3 for CPM board connections.

The CPM has a reset button located between the DIP switch

and the J10 connector. Pressing the reset button on the CPM

will clear any current CPM alarms, but will not turn off any

outputs from the CPM. Pressing the reset button on the CPM

will NOT cause the board to go through initialization. Initialization period only occurs during power-up and lasts for approximately 2 minutes. Each compressor’s MTA (must trip

amps) setting is communicated to the PSIO-1 during the initialization period. Switches 1 and 2 should be set to 0. See Table 4

for DIP switch settings.

each CPM board is set using DIP (dual in-line package)

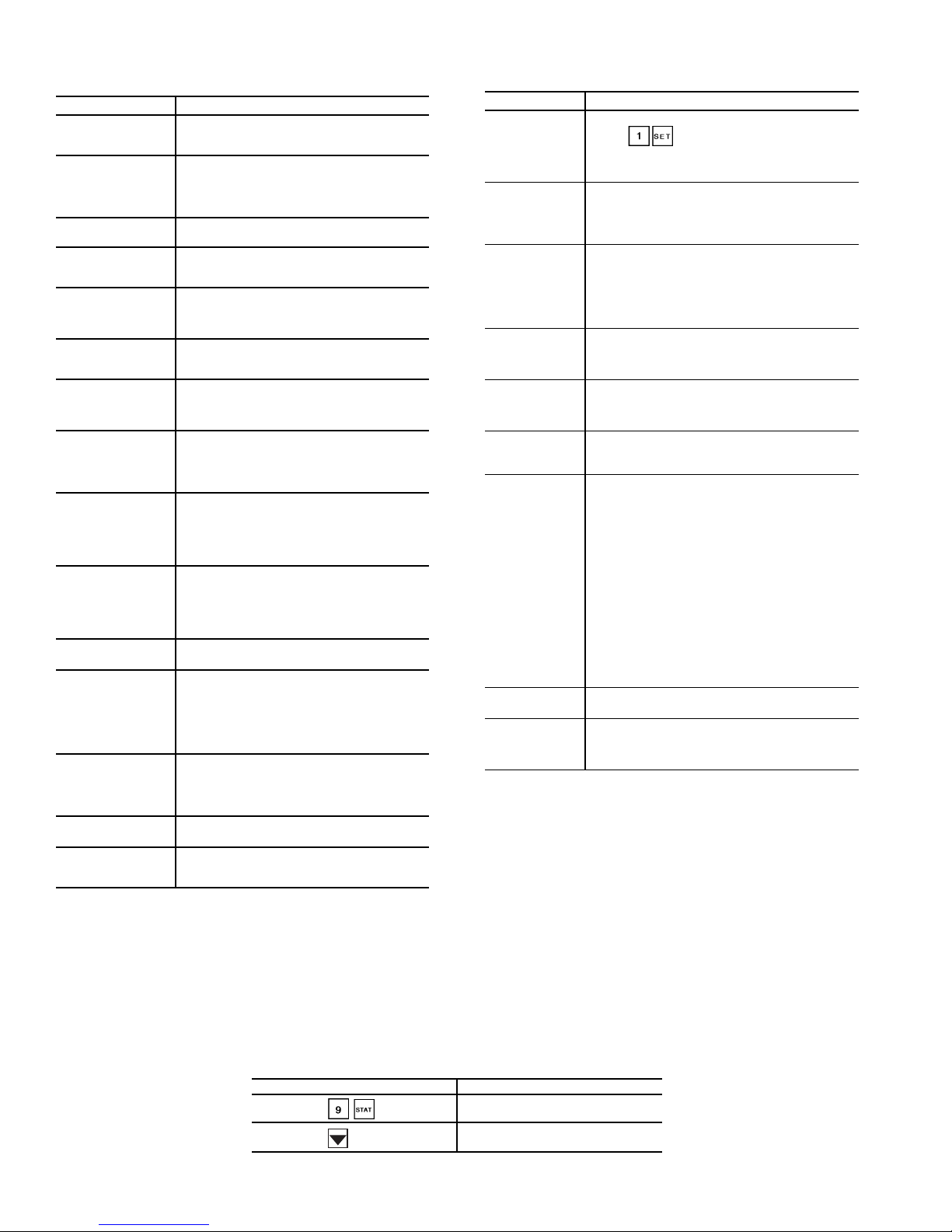

Table 2 — Thermistor and Transducer Locations

Sensor Description Location Connection Terminals

T1

T2

Motor Temp A1

Motor Temp A2*

Motor Temp B1

Motor Temp B2†

T5

T6

LL-A (T3)

LL-B (T4)

T7 (optiona l)* *

STP (optional)**

T8 (optiona l)* *

T9 (optiona l)* *

Sensor Description Location Connection Terminals

DPT-A

SPT-A

EPT-A

OPT-A1

OPT-A2*

DPT-B

SPT-B

EPT-B

OPT-B1

OPT-B2†

*30HX206-271 and 30GX205-265 only.

†Sensors are available as accessories for field installation.

Cooler Leaving Fluid Temp Cooler Head Leaving Fluid Side PSIO-2, J7 pins 2,3

Cooler Entering Fluid Temp Cooler Head Entering Fluid Side PSIO-2, J7 pins 5,6

Motor Temperature A1 Compressor A1 Junction Box CPM1, plug J5

Motor Temperature A2 Compressor A2 Junction Box CPM2, plug J5

Motor Temperature B1 Compressor B1 Junction Box CPM1, plug J9

Motor Temperature B2 Compressor B2 Junction Box CPM1, plug J9

Discharge Gas Temp A Top of Oil Separator Circuit A PSIO-2, J7 pins 8,9

Discharge Gas Temp B Top of Oil Separator Circuit B PSIO-2, J7 pins 11,12

Liquid Level Circuit A Top of Cooler Circuit A PSIO-1, J7 pins 5,6

Liquid Level Circuit B Top of Cooler Circuit B PSIO-1, J7 pins 8,9

Outdoor Air Thermistor Outside Air Stream PSIO-2, J7 pins 20,21

Space Temperature Conditioned Space PSIO-2, J7 pins 23,24

Condenser Entering Water Thermistor Condenser Entering Fluid Line PSIO-2, J7 pins 14,15

Condenser Leaving Water Thermistor Condenser Leaving Fluid Line PSIO-2, J7 pins 17,18

Discharge Pressure Circuit A Top of Condenser Separator Circuit A PSIO-1, J7 pin 22

Suction Pressure Circuit A Top of Cooler Circuit A PSIO-1, J7 pin 19

Economizer Pressure Circuit A Economizer Line Entering Comp A PSIO-1, J7 pin 10

Oil Pressure Compressor A1 Compres sor A1 Oil Connection PS IO-1, J7 pin 25

Oil Pressure Compressor A2 Compres sor A2 Oil Connection PS IO-1, J7 pin 1

Discharge Pressure Circuit B Top of Oil Separator Circuit B PSIO-1, J7 pin 16

Suction Pressure Circuit B Top of Cooler Circuit B PSIO-1, J7 pin 31

Economizer Pressure Circuit B Economizer Line Entering Comp B PSIO-1, J7 pin 13

Oil Pressure Compressor B1 Compres sor B1 Oil Connection PS IO-1, J7 pin 28

Oil Pressure Compressor B2 Compres sor B1 Oil Connection PS IO-1, J7 pin 16

THERMISTORS

PRESSURE TRANSDUCERS

Table 3 — Compressor Protection Module

(CPM) Plug Connections

CPM PLUG DESCRIPTION

J1

J2, J6

J3, J7

J4, J8

J5, J9

J10, J11

NOTE: Plugs J2-J5 are for compressors A1 (CPM1) or A2 (CPM2).

Plugs J6-J9 are for compressor B1 (CPM1) or B2 (CPM2).

24-vac Power Input

Compressor Contactor(s)

High Pressure Switch, Oil and Motor Cooling

Solenoids

Current Sensor Input

Compressor Motor Temperature Input

Communication Connections

30GX080-176

30HXA076-186

30HXC076-186

30GX205-350

30HXA206-271

30HXC206-271

5

Table 4 — CPM Address DIP Switch Settings:

UNIT

CPM1 CPM2

1234 1 2 3 4

0000————

0000 0 0 1 1

To verify proper must trip amps header configuration, press

and use the up arrow key on the HSIO to locate the

must trip amp values. Press the reset button on the control panel to update these values. See Appendix A. If the values do not

match those in Appendix A, verify that the configuration headers have been properly punched out.

The CPM communicates on the COMM3 communic ation

bus to the PSIO-1 module. Proper operation of the CPM board

can be verified by observing the 2 LEDs (light-emitting diodes)

located on the board. The red LED blinks at a rate of once every 1 to 2 seconds. This indicates that the module is powered

and operating correctly. The green LED blinks when the module is satisfactorily communicating with the PSIO-1 module.

The CPM communicates the status of its inputs and outputs,

and reports 15 different alarm conditions to the PSIO-1. The

alarms are listed in Table 5.

The CPM module has many features that are specifically

designed to protect the compressor, including reverse rotation protection. Do not attempt to bypass or alter any of the

factory wiring. Any compressor operation in the reverse

direction will result in a compressor failure that will require

compressor replacement.

The PSIO-1 will generate an alert when it receives an alarm

input from the CPM. The alert will be generated in a y.xx format, where “y” refers to the compre ssor and “xx” to the alarm

value in Table 5 (decimal point removed). For example, the

HSIO might display Alarm 1.75 for a contactor failure occurring on compressor A1. Similarly, the display would read 5.85

for a motor overtemperature condition on compressor B1.

Alerts for compressors A2 and B2 (if present) would be generated as “2.xx” and “6.xx,” respectively. Alarm codes 3 and 4

would not be used. Ending zeros are not displayed.

The high-pressure switch is wired in series with the relay

coils of the 8 relays on the CPM. If this switch opens during

operation, all relays on the CPM are deenergized and the compressor is stopped. The failure is reported to the PSIO-1 and the

processor module locks off the compressor from restarting until the alarm is manually reset.

1

0

SW1

LEGEND

LED —

MTA —

NOTES:

1. The red LED blinks continuously when the module

is operating properly.

2. The green LED blinks continuously when communicating properly with PSIO-1.

3. On all plugs, pin 1 is identified by a “●.’’

1

0

SW2

Light-Emitting Diode

Must Trip Amps

1

00

SW3 SW4

1

COMP 2

MTA

HEADER

DIP

SWITCH

RESET

BUTTON

J1

J10

J11

3

2

1

3

2

1

3

2

1

1

2

3

4

8

8

GREEN LED

12

3

RED LED

5

4

5

4

1

COMP 1

MTA

HEADER

1

2

3

1

J7

J6

1

J9

J8

J4

J5

J2

J3

2

3

1

2

3

1

2

3

4

1

2

3

4

1

2

3

1

2

3

Fig. 1 — Compressor Protection Module (HN67LM101)

6

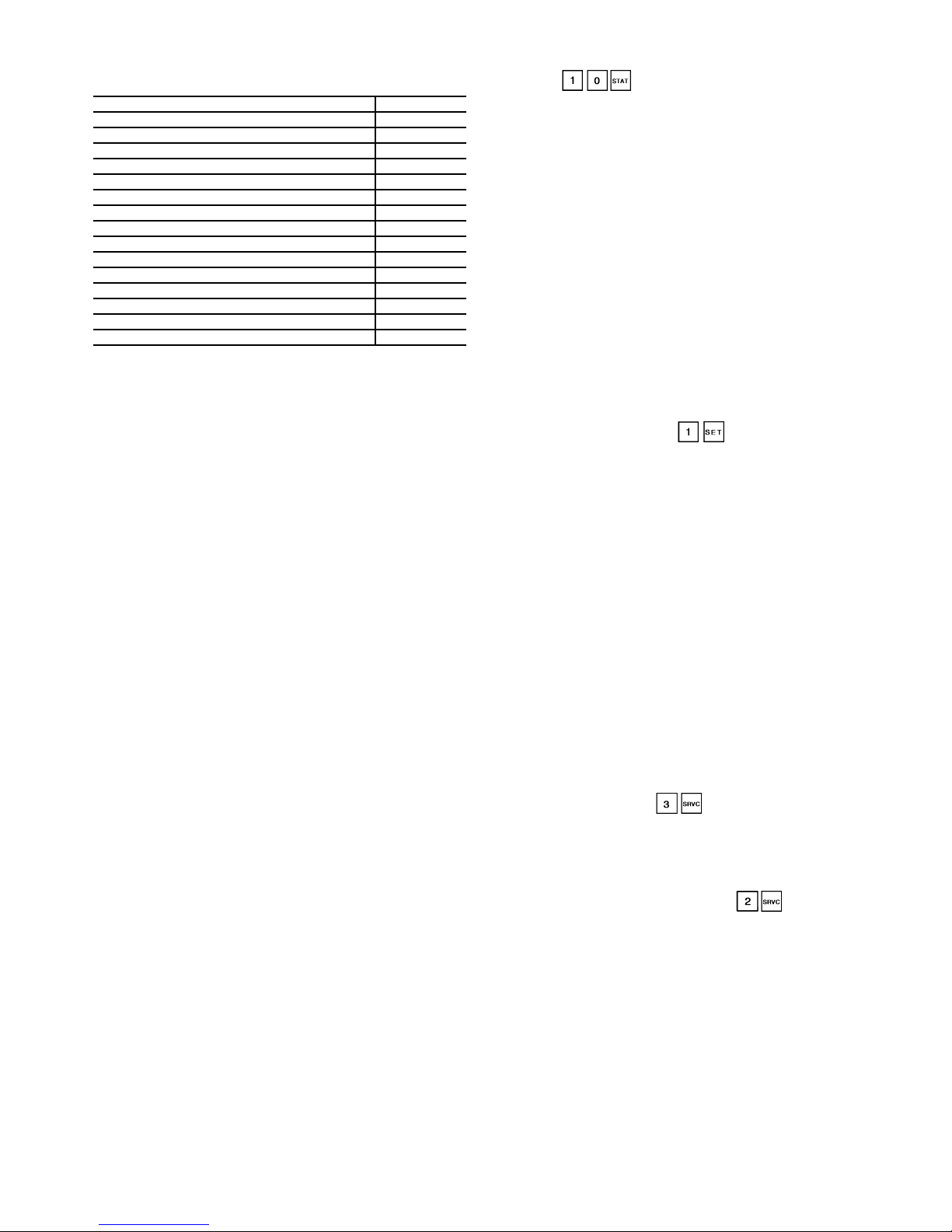

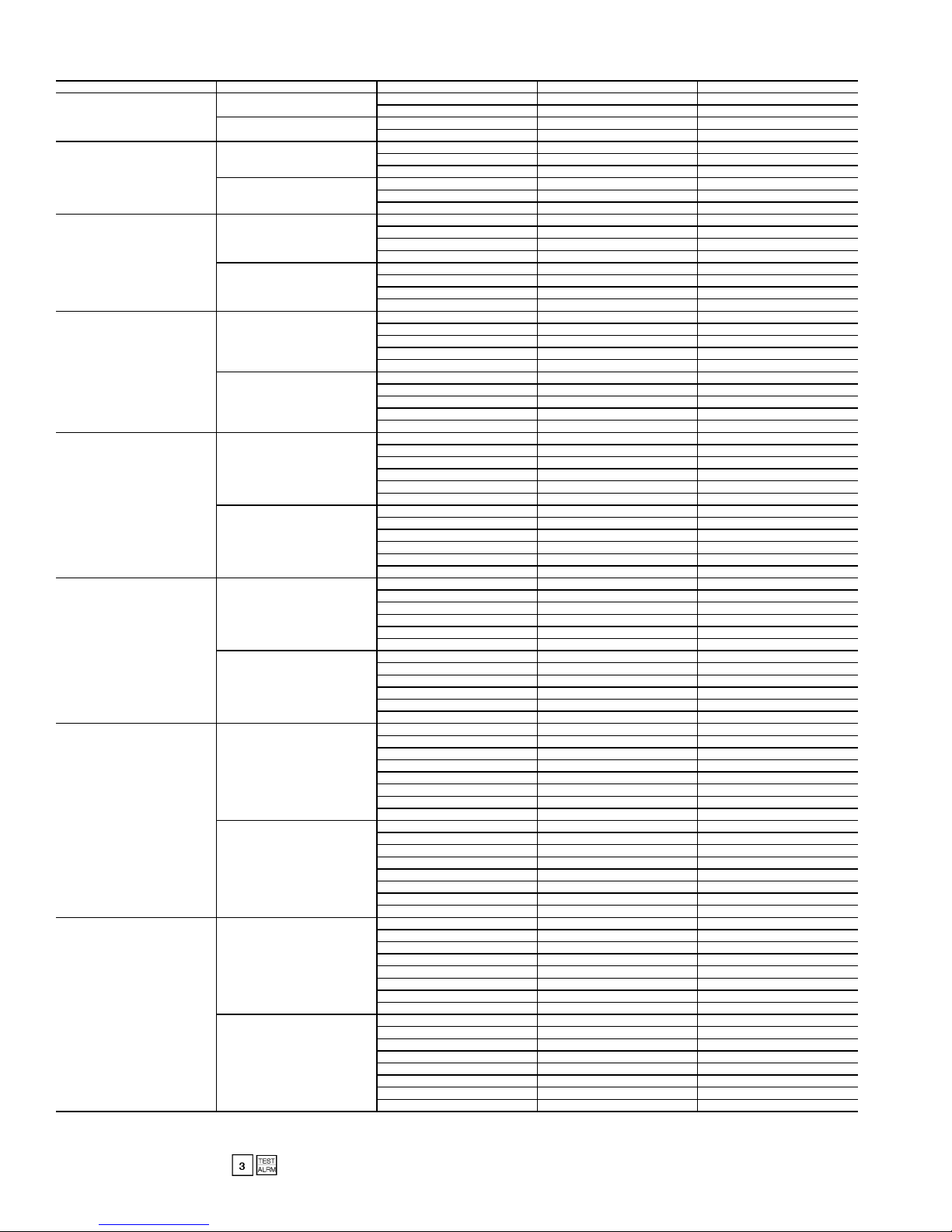

Table 5 — Compressor Protection Module

Feedback Codes

High Pressure Switch Trip 1.0

No Motor Current 2.0

Current Imbalance Alarm 10% 2.5

Current Imbalance Warning 10% 2.7

Current Imbalance 25% 3.0

Single Phase Current Loss 3.5

High Motor Current 4.0

Ground Fault 5.0

Contactor Failure 7.5

Current Phase Reversal 8.0

Motor Overtemperature 8.5

Open Thermistor 9.0

Configuration Header Fault 9.5

Shorted Thermistor 10.0

No Error 0

ALARM CONDITION VALUE

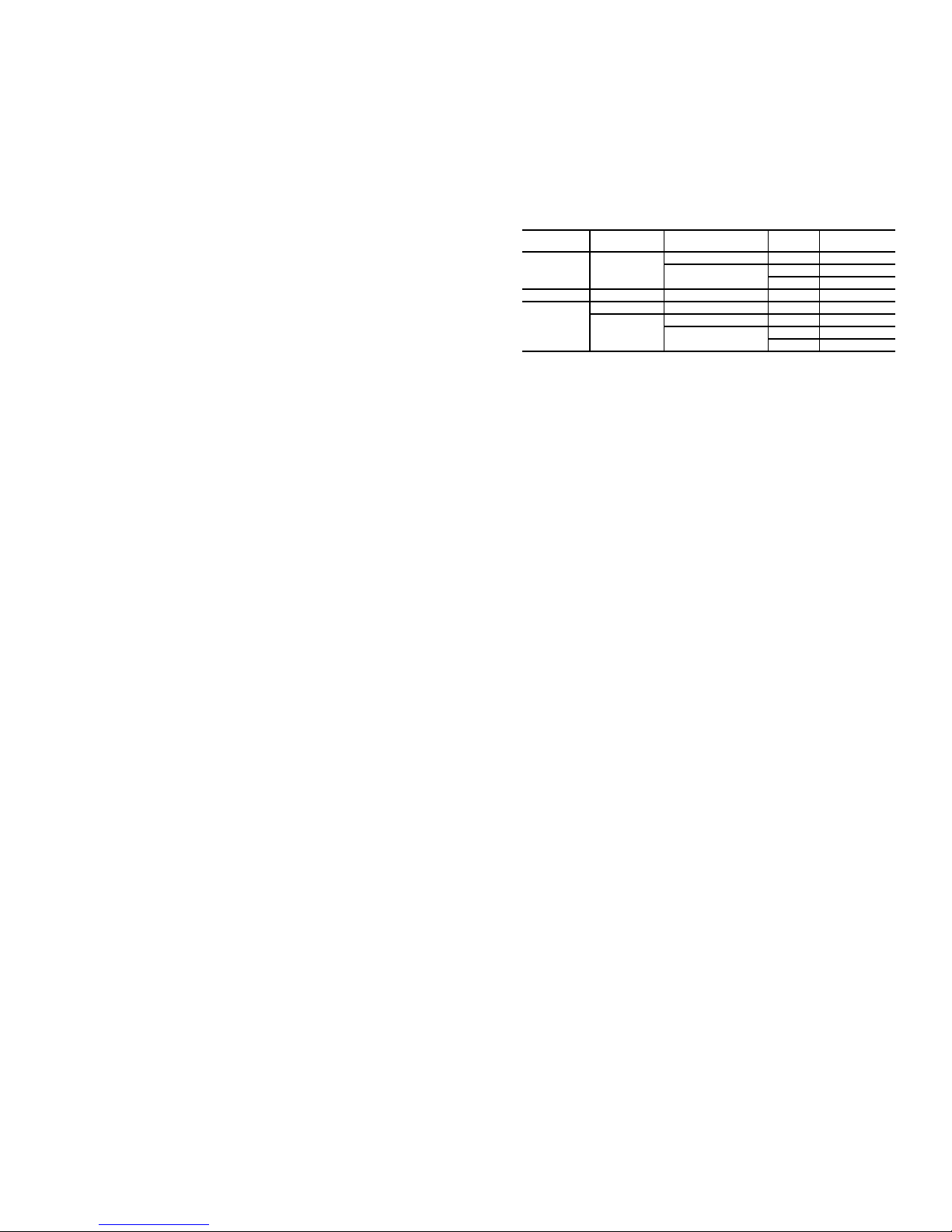

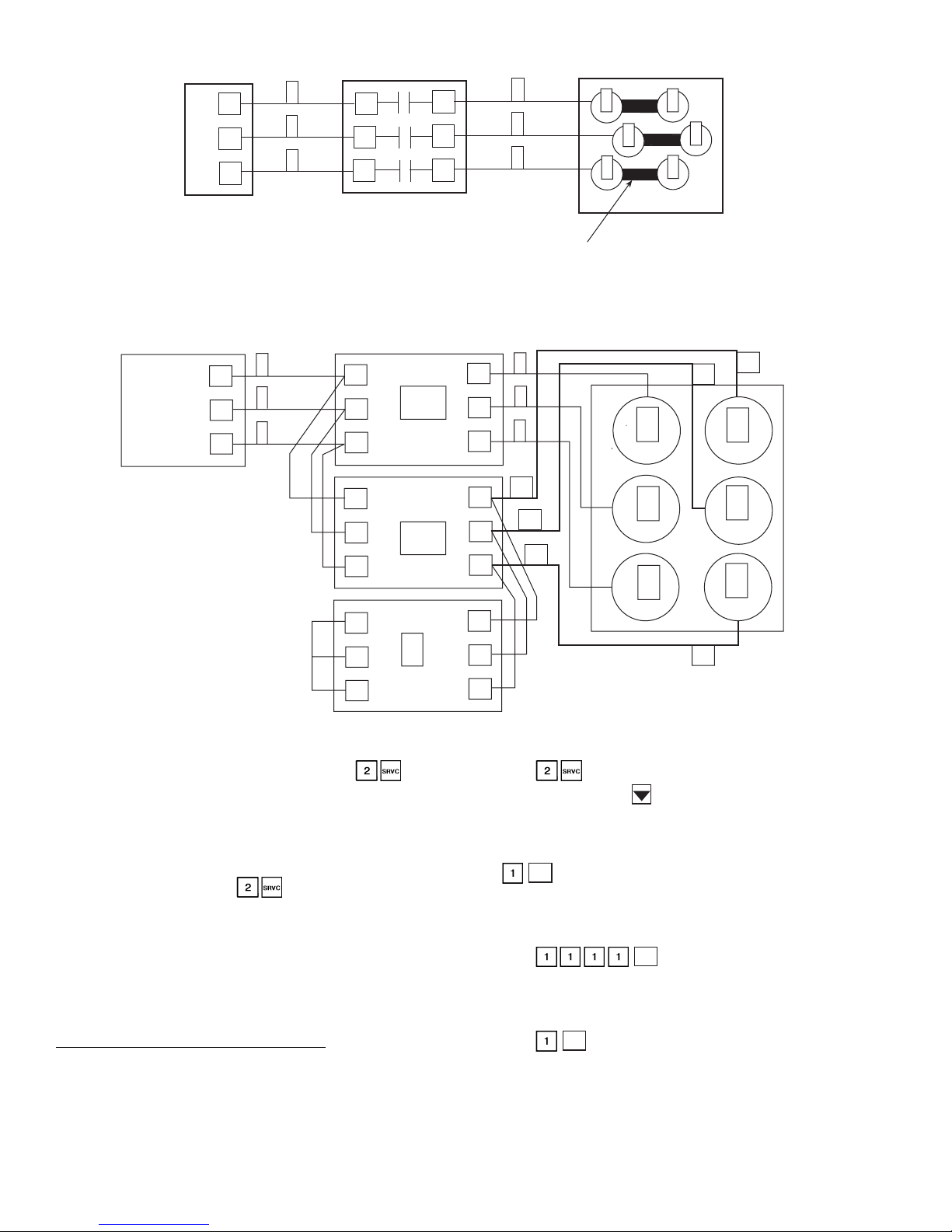

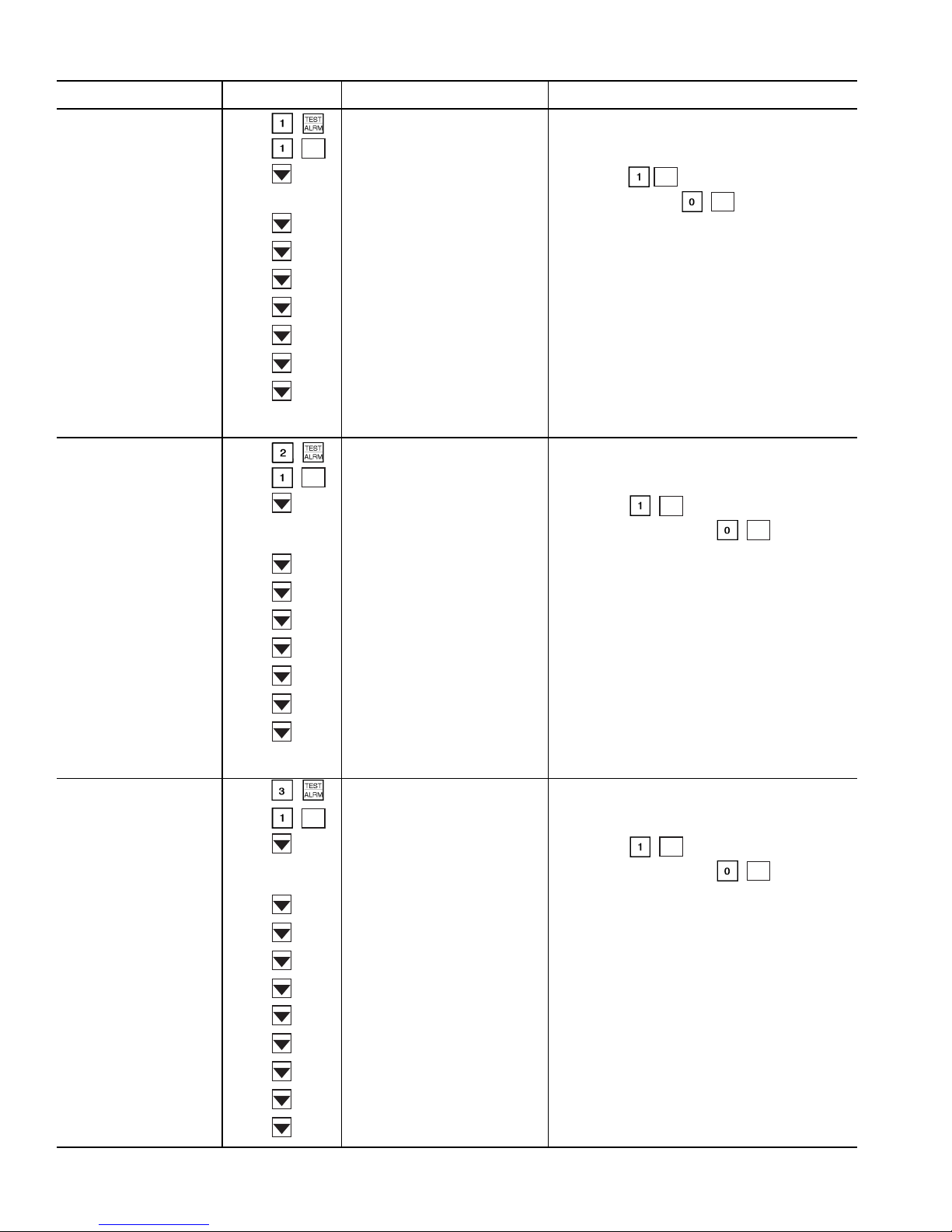

Wye-Delta vs Across-the-Line (XL) Starting

Option —

208/230-3-60 or 230-3-50 (5 or 8 at Position 12 in model number) are supplied with factory installed Wye-Delta starters. All

other voltage options can be ordered with either Wye-Delta or

XL starting options. The XL starting method is the most cost

effective and simply starts the compressor motor in a Delta

configuration (the motors are designed for continuous operation in this configuration) using a single contactor. See Fig. 2.

This is the simplest starting method to use and is ideal where

starting current does not require limiting.

Where current limitations exist, the Wye-Delta option may

be used. See Fig. 3. This option uses a factory-installed starter

assembly for each compressor, which consists of 3 contactors

labelled 1M, 2M, and S. As the compressor is started, the CPM

module energizes contactors 1M and S, which connects and

energizes the motor windings in a Wye configuration. The

starting current required will be approximately 60% less than

that required for an XL start due to the higher impedance of the

motor windings when W ye connected. The compressor will attain about 100% of its normal operating speed (approximately

3 to 5 seconds) before the CPM module deenergizes the S contactor and energizes the 2M contactor, switching the compressor windings to a Delta wiring configuration. The S and 2M

contactors in the starter assembly are both mechanic ally and

electrically interlocked so that they will not both be energized

at the same time.

Do not alter the factory-installed power wiring from the

control box terminal block to the compressor junction block.

Doing so will cause permanent damage t o the compress or and

will require that the compressor be replaced.

Capacity Control —

pressors, loaders, and minimum load control valves to maintain

the user-configured leaving chilled fluid temperature set point.

Entering fluid temperature is used by the microprocessor to determine the temperature drop across the cooler and is used in

determining the optimum time to add or subtract capacity stages. The chilled fluid temperature set point can be automatically

reset by the return temperature reset or space and outdoor-air

temperature reset features. It can also be reset from an ext ernal

4 to 20 mA signal (requires field-supplied 500-ohm,

sistor), or from a network signal.

The capacity control algorithm runs every 30 seconds. The

algorithm attempts to maint a in the Control Point at the desired

set point. Each time it runs, the control reads the e ntering and

leaving fluid temperatures. The control determines the rate at

which conditions are changing and calculates 2 variables based

All 30GX,HX chillers operating at voltages of

The control system cycles com-

1

/2 watt re-

on these conditions. Next, a capacity ratio (Load/Unload Factor

under ) is calculated using the 2 variables to determine whether or not to make any changes to the current stages

of capacity. This ratio value ranges from –100 to + 100%. If the

next stage of capacity is a compressor, the control start s (stops)

a compressor when the ratio reaches + 100% (–100%). If the

next stage of capacity is a loader, the control energizes (deenergizes) a loader when the ratio reaches + 60% (–60%). Loaders

are allowed to cycle faster than com pressors, to minimize the

number of starts and stops on each compressor. A delay of

90 seconds occurs after each capacity step change.

MINUTES LEFT FOR START — This value is displayed in

the Status subfunction and represents the amount of time to

elapse before the unit is started. This value can be zero without

the machine running in many situations. This can include

being unoccupied, LOR switch in the OFF position, CCN not

allowing unit to start, Demand Limit in effect, no call for cooling due to no load, and alarm or alert conditions present. If the

machine should be running and none of the above are true, a

minimum off time may be in effect. The machine should start

normally once the time limit has expired.

MINUTES OFF TIME ( ) — This user configurable

time period is used by the control to determine how long unit

operation is delayed after power is applied/restored to the unit.

It is also used to delay compressor restarts after the unit has

shut off its lowest stage of capacity. Typically, this time period

is configured when multiple machines are located on a single

site. For example, this gives the user the ability t o prevent all

the units from restarting at once afte r a power fa ilure. A val ue

of zero for this variable does not mean that the unit should be

running.

LOADING SEQUENCE — The 30GX,HX compressor efficiency is greatest at full load. Therefore, the following

sequence list applies to capacity control.

1. The next compressor is not started until all others are running at 100%.

2. The second unloading stage is only used during initial

capacity staging of the unit at start-up.

3. Whenever a compressor is started i n a c ircuit , th e loaders in

the circuit are deenergized for 15 seconds before the compressor is started. The loaders are energized 90 seconds after

the compressor is started.

CLOSE CONTROL ( ) — When configured for Close

Control, the control is allowed to use any loading/capacity control devices required to maintain better leaving fluid temperature regulation. All stages of unloading are available. See

Appendix B for an example.

LEAD/LAG DETERMINATION ( ) — This is a configurable choice and is factory set to be automatic. The value

can be changed to Circuit A or Circuit B leading, as desired.

Set at automatic, the control will sum the current number of

logged circuit starts and one-quarter of the current operating

hours for each circuit. The circuit with the lowest sum is

started first. Changes to which circuit is the lead circuit and

which is the lag are made when shutting off compressors.

On 30HX206-271 and 30GX205-350 units set for staged

loading, the control fully loads the lead circuit before starting

the lag circuit and unloads the lag circuit first. When these units

are set for equal loading, the control maintains nearly equal

capacities in each circuit when the chiller is loading and

unloading.

7

TERMINAL BLOCK

21

22

23

COMPRESSOR CONTACTOR

1

2

3

L1

L2

L3

T1

1

2

T1

3

T3

JUMPER BARS

COMPRESSOR JUNCTION BOX

1

2

3

Fig. 2 — Across-the Line (XL) Compressor Wiring

6

4

5

TERMINAL BLOCK

21

22

23

1

2

3

COMPRESSOR STARTER ASSEMBLY

L1

L2

L3

L1

L2

L3

L1

L2

L3

1M

2M

S

Fig. 3 — Wye-Delta Compressor Wiring

CAPACITY SEQUENCE DETERMINATION ( ) —

This is configurable as equal circuit loading or staged circuit

loading with the default set at staged. The control determines

the order in which the steps of capacity for each circuit are

changed. This control choice does NOT have any impact on

machines with only 2 compressors.

MINIMUM LOAD VALVE ( ) — When this option is

installed and configured, the first stage of capacity is altered by

energizing the Minimum Load valve relay. Once the control

requires more capacity, the minimum load valve is deenergized

and normal capacity staging resumes with loaders and compressors. Similarly, the Minimum Load valve relay will be

energized for the last stage of capacity to be used before t he

circuit is shut down.

Configure Unit for Minimum Load Control

— The chiller

must be configured for minimum load control operation. This

may be done using the unit keypad (HSIO-2). Set the LOCAL/

OFF/REMOTE (LOR) switch in the OFF position.

COMPRESSOR JUNCTION BOX

T2

T3

T1

T3

T1

T1

T2

T3

T2

1

2

3

21

1

2

22

23

3

6

4

6

4

5

5

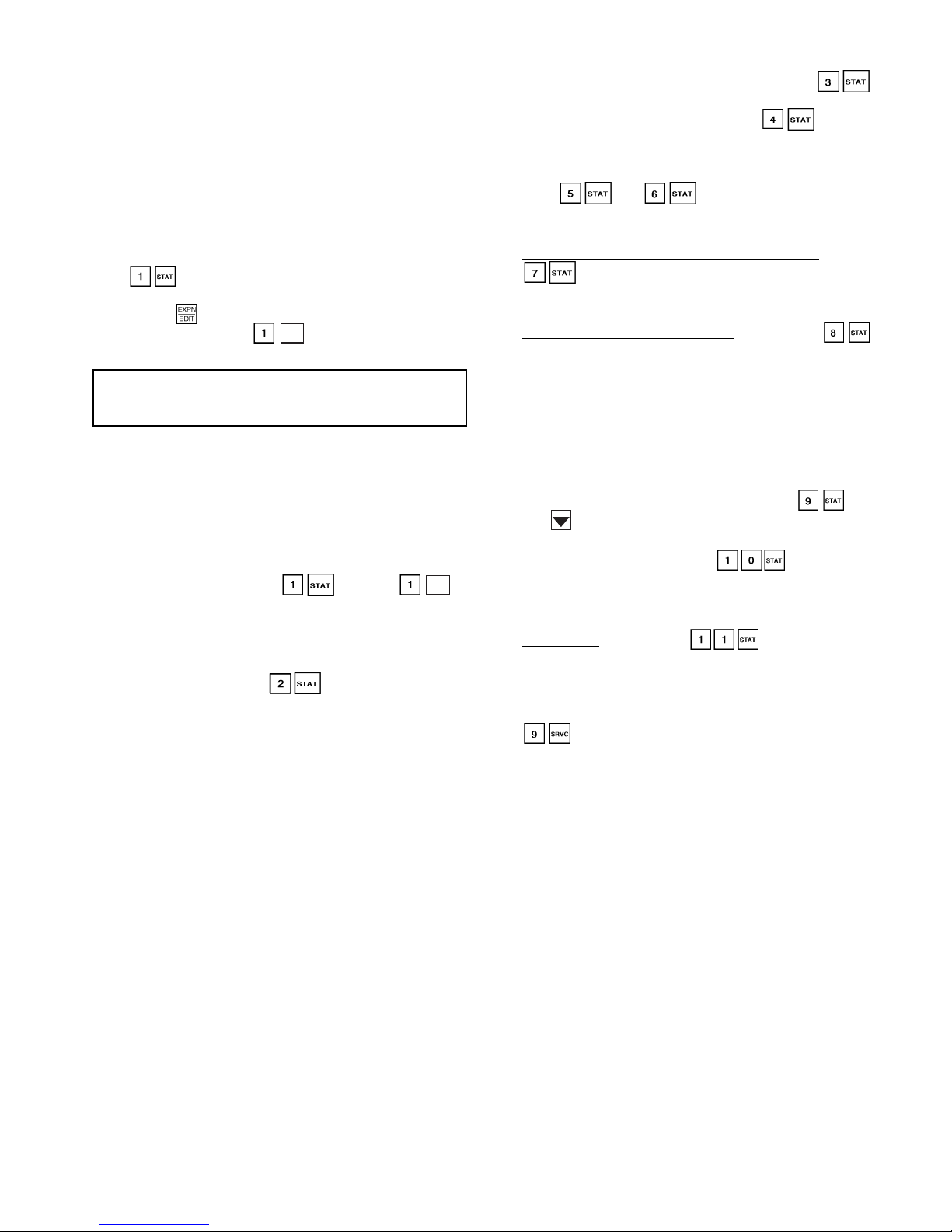

1. Press on the keypad.

2. Press the down arrow until the display reads:

MIN. LOAD V AL V E SELECT

DISABLE

3. T o enable the minimum load valve feature, press

ENTER

.

4. The display may read as follows. (If not, skip to Step 7.)

P ASSWORD PROTECTED FUNCTION

ENTER P ASSWORD

5. Press .

ENTER

6. The HSIO-2 again displays the following:

MIN. LOAD V AL V E SELECT

DISABLE

7. Press . The display changes to:

ENTER

MIN. LOAD V AL V E SELECT

ENABLE

8

The chiller is now configured for minimum load valve

control.

Test Minimum Load Relay Outputs

— After the unit is reconfigured, test the operation of the relay and solenoid valve

using the Quick Test software function. Test Circuit A as follows (the LOCAL/OFF/REMOTE (LOR) switch must be in

the OFF position):

1. Press on the HSIO-2 keypad.

2. Press the down arrow until the display reads:

MIN. LOAD V AL VE A

RELA Y IS OFF

3. Press .

ENTER

4. The display may read as follows. (If not, skip to Step 7.)

P ASSWORD PROTECTED FUNCTION

ENTER P ASSWORD

5. Press .

ENTER

6. The HSIO-2 again displays the following:

MIN. LOAD V AL VE A

RELA Y IS OFF

7. Press to energize the relay. The display reads:

ENTER

MIN. LOAD V AL VE A

RELA Y IS ON

An audible click will be heard. Verify that the solenoid valve

for Circuit A is energized.

8. Press to turn off the minimum load valve relay for

ENTER

Circuit A.

To check the operation of the solenoid valve on Circuit B,

follow the same procedure as the preceding, but enter

in Step 1, instead of . The display screens will be fo r

Circuit B instead of A.

Adjust Setting of Minimum Load Ball Valve

— The minimum load ball valve must be adjusted to suit the application.

Calibrate one circuit at a time as follows:

1. Adjust the ball valve so that it is approximately half open.

2. Operate the chiller in Manual Control mode, with one circuit

operating, and all compressor loaders deenergized. See Manual Control Mode section on page 32 for further information.

3. Record the cooler ∆T (the difference between cooler enter-

ing fluid temperature and cooler leaving fluid temperature)

at this fully unloaded condition.

4. Use the Manual Control feature to enable the minimum load

valve for the circuit that is operating.

5. Observe and record the cooler ∆T with the minimum load

valve energized.

6. Adjust the minimum load ball valve until the cooler temper-

ature difference reading from Step 5 is equal to half of the

temperature difference reading from Step 3.

7. Open the ball valve to decrease the temperature difference or

close the ball valve to increase the temperature difference

(∆T). When the valve is adjusted correctly, the difference

between cooler entering and leaving fluid temperatures

when the minimum load control is energized must be at least

half of the temperature difference when the minimum load

control is deenergized. For example, if the difference

between the cooler entering and leaving water temperature is

3° F with the valve deenergized, then the difference between

cooler entering and leaving water temperature must be at

least 1.5° F with the valve energized.

Once the outputs have been tested and the ball valve adjusted, the installation is complete. Disable manual control and

return chiller to desired operational status.

CAPACITY CONTROL OVERRIDES — The following

overrides will modify the normal operation of the routine.

Deadband Multiplier

— The user configurable Deadband

Multiplier ( ) has a default value of 1.0. The range is

from 1.0 to 4.0. When set to other than 1.0, this factor is applied to the capacity Load/Unload Factor. The larger this value

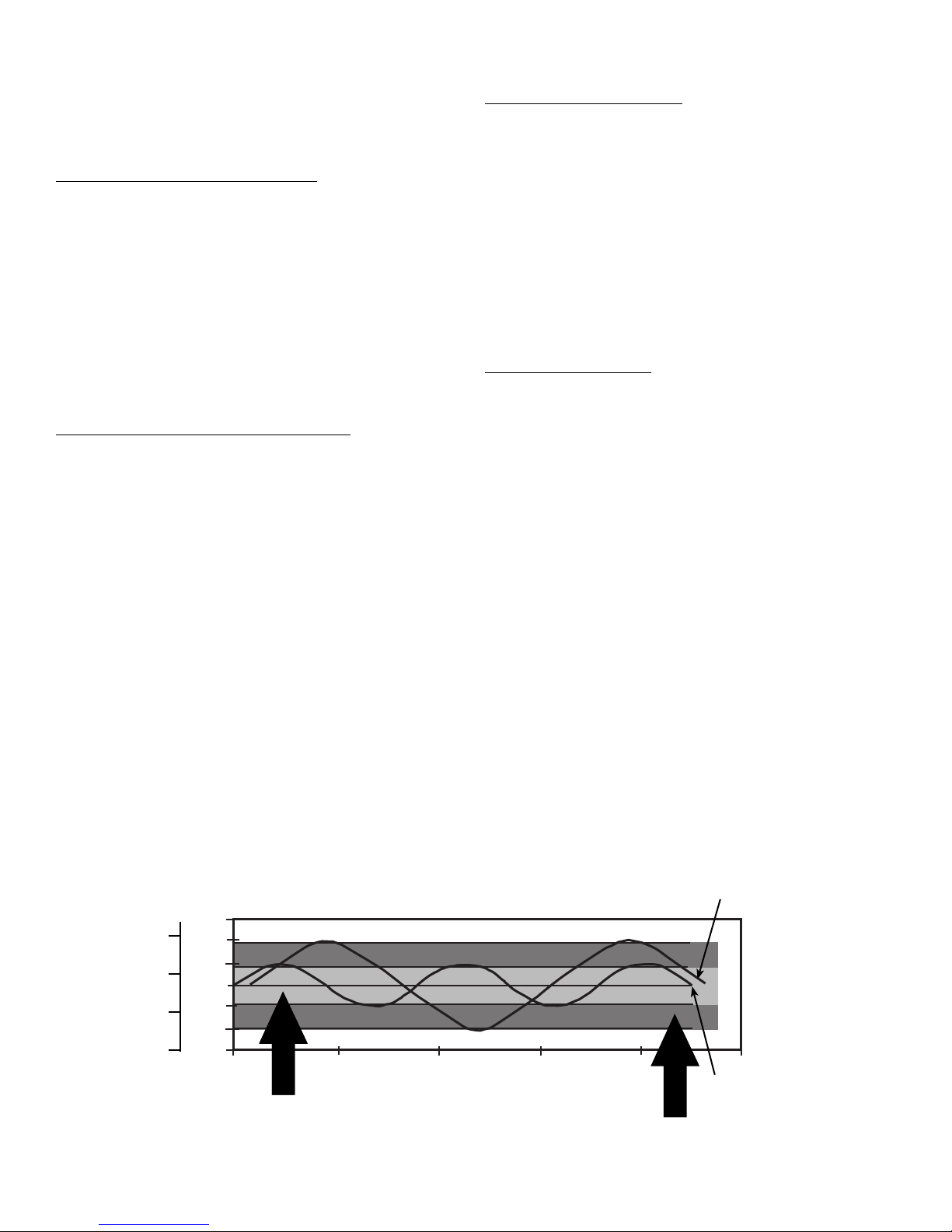

is set, the longer the control will delay between adding or removing stages of capacity. Figure 4 shows how compressor

starts can be reduced over time if the leaving water temperature

is allowed to drift a larger amount above and below the set

point. This value should be set in the range of 3.0 to 4.0 for systems with small loop volumes.

First Stage Override

— If the current capacity stage is zero,

the control will modify the routine with a 1.2 factor on adding

the first stage to reduce cycling. This factor is also applied

when the control is attempting to remove the last stage of

capacity.

Slow Change Override

— The control prevents the capacity

stages from being changed when the leaving fluid temperature

is close to the set point (within an adjustable deadband) and

moving towards the set point.

Ramp Loading

( ) — Limits the rate of change of leaving fluid temperature. If the unit is in a Cooling mode and configured for Ramp Loading, the control makes 2 comparisons

before deciding to change stages of capacity. The control calculates a temperature difference betw een the control point and

leaving fluid temperature. If the difference is greater tha n 4° F

(2.2° C) and the rate of change (°F or °C per minute) is more

than the configured Cooling Ramp Loading value ( ),

the control does not allow any changes to the current stage of

capacity.

Low Entering Fluid Temperature Unloading

— When the

entering fluid temperature is below the control point, the control will attempt to remove 25% of the current stages being

used. If exactly 25% cannot be removed, the control removes

an amount greater than 25%, but no more than necessary. The

lowest stage will not be removed.

Low Discharge Superheat

— If a circuit’s discharge superheat

is less than 15° F (8.3° C), the control does not increase the current capacity stage. If the discharge superheat is le ss than 5° F

(2.8° C) and decreasing, the circuit is unloaded every 30 seconds until the superheat is greater than 5° F (2.8° C). The final

capacity stage is not unloaded unless an alarm condition exists.

This override is ignored for the first 3 minutes after a compressor is started.

Low Saturated Suction Temperature

— To avoid freezing the

cooler, the control will compare the cir cuit Saturated Suction

temperature with a pre determined freeze point. If the cooler

fluid selected is water, the freeze point is 28 F (–2.2 C). If the

cooler fluid selected is bri ne, the freeze poi nt is 8° F (4.4 ° C)

below the cooling set point (lower of 2 cooling set points for

dual configuration). If the saturated suction temperature is

below the freeze point, the unit capacity is not allowed to

increase.

For brine applications, the freeze point (Brine Freeze Point)

can be entered by pressing and scrolling 12 items

down. The cont rol will use the B rine Freeze Point va lue less

6° F (3.3° C) as the freeze point to compare with the Saturated

Suction temperature. The default for t he Brine Freez e Point is

34 F (1.1 C) which means the control will use 28 F (–2.2 C) as

the freeze point. The brine freeze point is adjustable from –15 F

to 34 F (–26.1 to 1.1 C).

9

For water [brine] circuits, if t he Sat urat ed Suct ion tempera ture falls below 34 F (1.1 C) [th e Brine F reeze Poi nt], the unit

capacity will not increase. If the Saturated Suction temperature

falls below 28 F (–2.2 C), [the Brine Freeze Point minus 6° F

(3.3° C)], for 90 seconds, all loaders in the circuit are turned

off. If this condition continues for a total of 3 minutes, the circuit will alarm and shut down.

High Condensing Temperature Unloading

— Every 10 seconds the control checks for the conditions below. Loaders will

be cycled as needed to control the saturated condensing temperature below the configured maximum condensing temperature. Configured maximums are 154 F (67.8 C) for 30GX,

152 F (66.7 C) for 30HXA, and 122 F (50 C) for 30HXC units.

If a circuit’s saturated condensing temperature is more than

12° F (6.7° C) below the maximum condensing temperature,

the circuit capacity is not allowed to increase. If the saturated

condensing temperature is more than 2° F (1.1° C) above the

maximum condensing temperature for 60 seconds, a loader is

turned off. If the saturated condensing temperature rises to

more than 5° F (2.8° C) above the maximum condensing temperature during the 60 seconds, a loader is turned off immediately. If all the loaders were already off, the compressor is shut

down and an alarm is generated.

MOP (Maximum Operating Pressure) Override

— The control monitors saturated condensing and suction temperature for

each circuit as well as differential oil pressure. Based on a configurable maximum operating set point (saturated suction temperature), set maximum condensing temperature, and minimum differential oil pressure, the control may reduce the number of capacity stages being used and/or may lower the EXD

position when system pressures approach the set parameters.

Head Pressure Control

GENERAL — The microprocessor controls the condenser

fans (30GX) or water val v e (30HX C ) to maintain the saturated

condensing temperature to a configurable set point. The

30HXA condenserless units with a 09DK condenser use a

combination of factory-supplied fan cycling pressure switches

(shipped in the 30HXA control box), temperature switches,

and an accessory Motormaster

50DJ902811) or Motormaster III (part no. 30GT910-079) control to control head pressure independent of 30HXA unit control. The fans are staged or speed varied (30GX) or water valve

controlled (30HXC) based on each circuit’s saturated condensing temperature and compressor status. Water cooled units

(30HXC) operating at less than 70 F (21.1 C) for entering condenser water require the use of head pressure control.

The chiller must be field configured for the options shown

in T able 6. Fan stage settings are shown in Table 7.

®

(part no. 50DJ902801 or

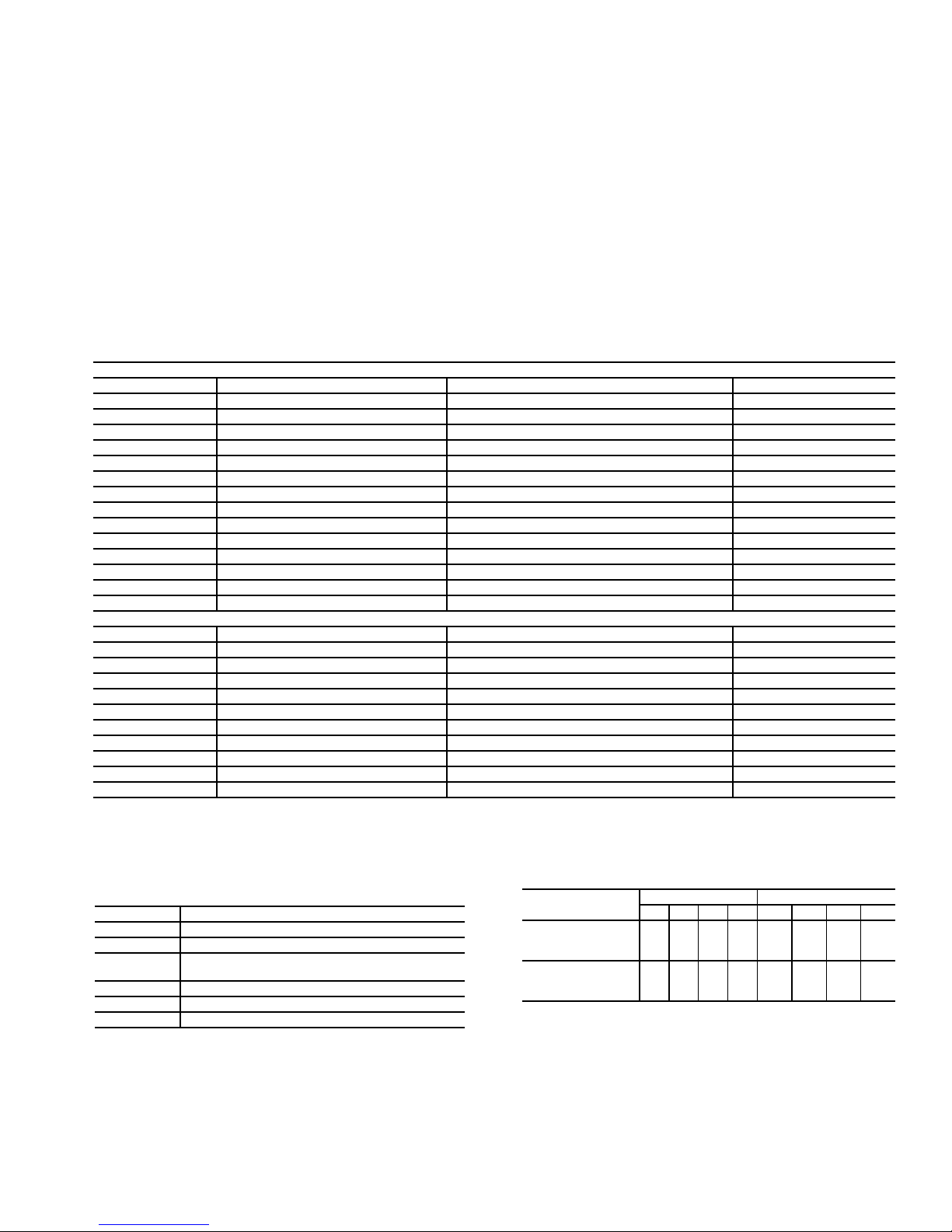

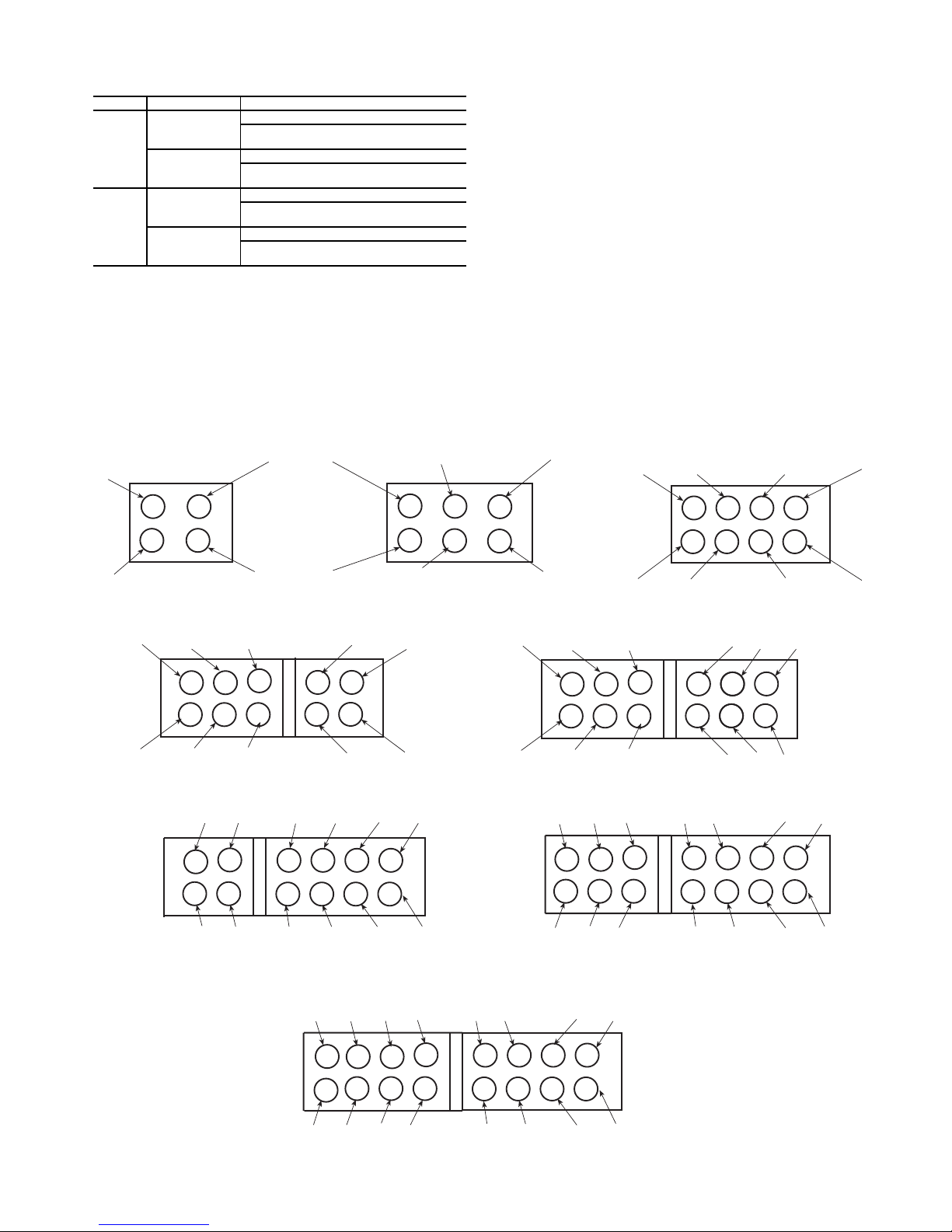

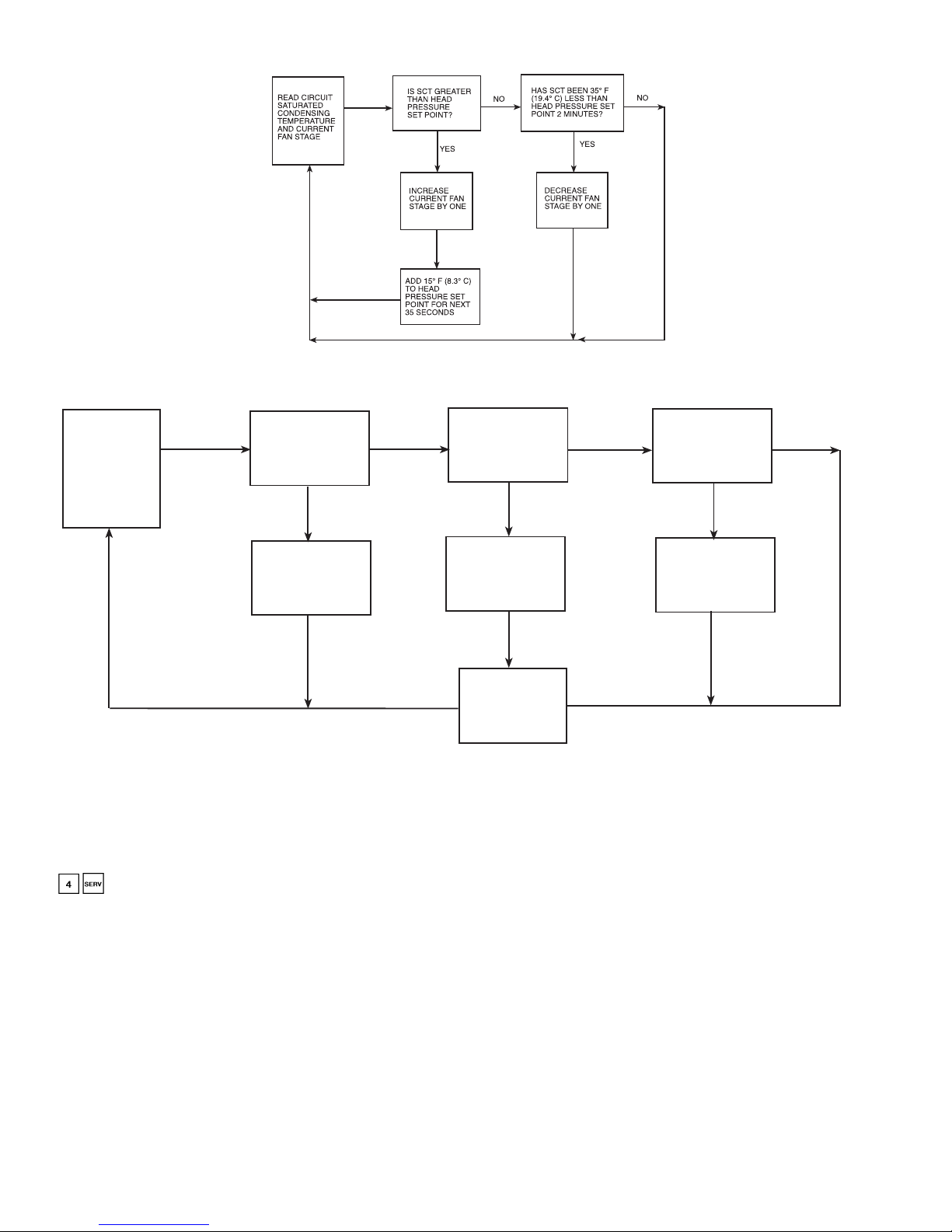

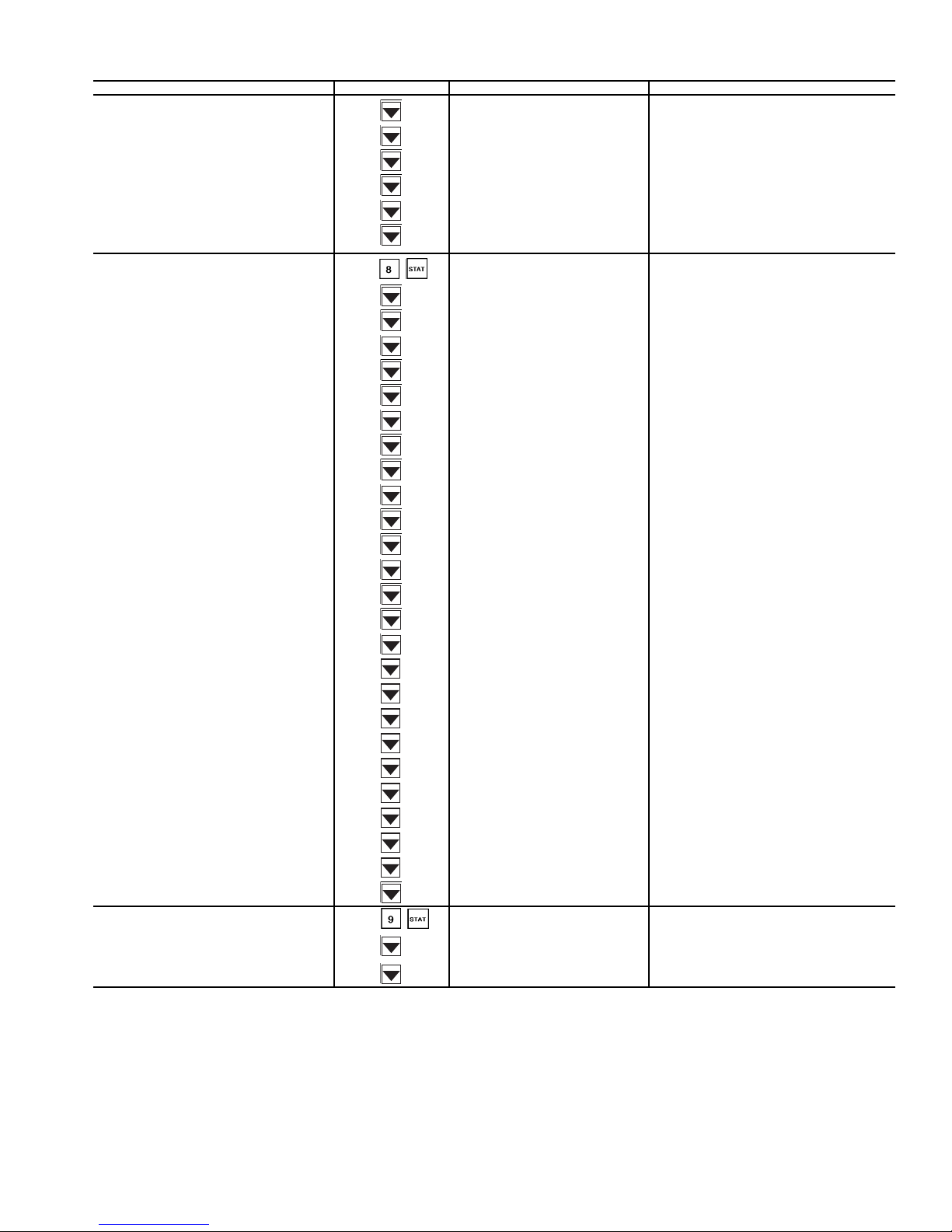

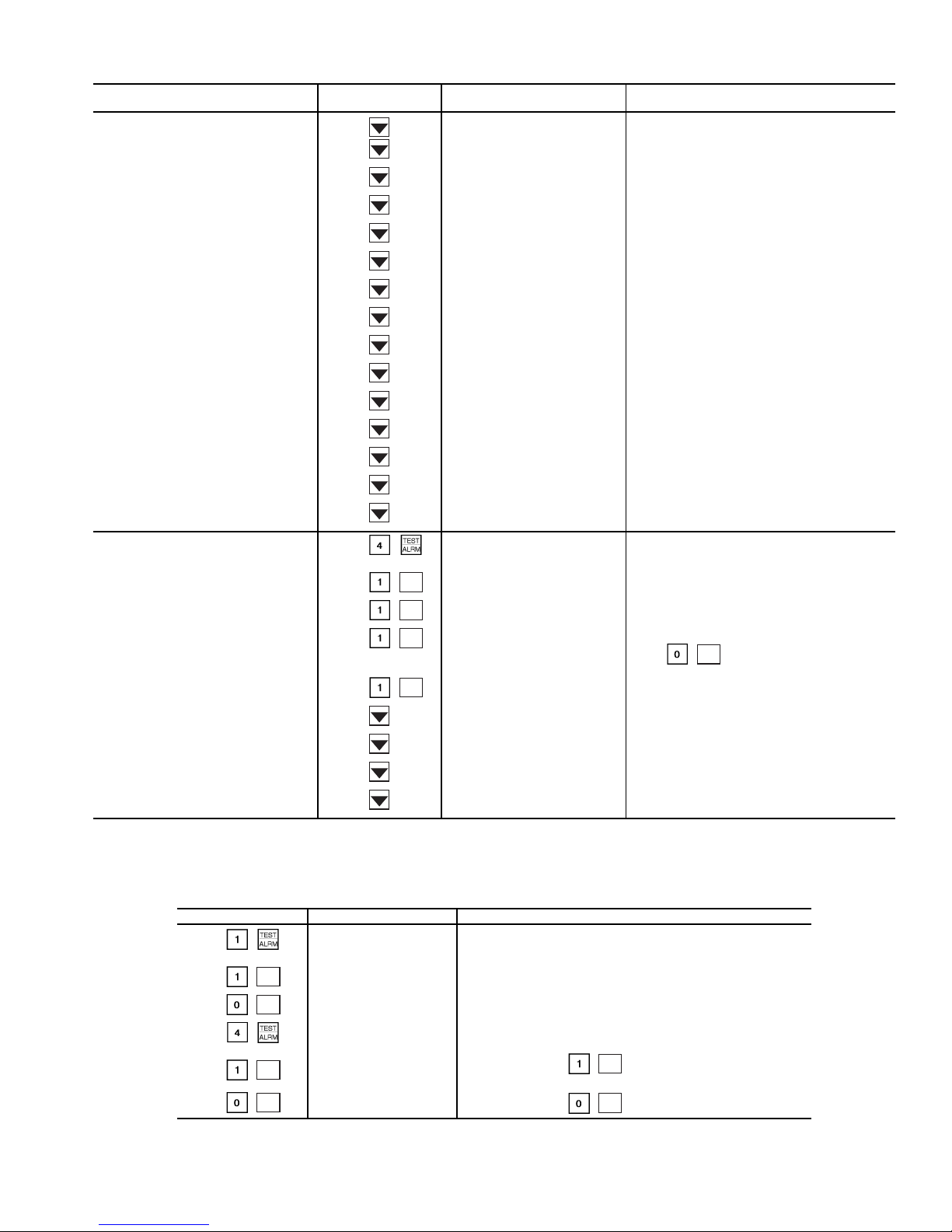

AIR-COOLED UNITS (30GX) — See Fig. 5 for condenser

fan locations.

Without Motormaster® Control

— The first stage of fans are

turned on based on compressor status or a Head Pressure Set

Point based on Saturated Condensing Temperature (SCT).

Additional fan stages are added when the SCT exceeds the

Head Pressure Set Point. The Head Pressure Se t Point is configurable in the Set Point subfunction. The default is 113 F

(45 C). Once a fan stage has been added, the software temporarily modifies the head pressure set point by adding 15° F

(8.3° C) for 35 seconds. A fan stage will be removed when the

Saturated Condensing Temperature has been less than the

Head Pressure Set Point minus 35 F (19.4 C) for 2 minutes.

The control uses the higher of the 2 Saturated Condensing

Temperature values for 30GX080-150 and 160 units. For the

30GX151 and 161-350 units, each circuit’s fan stages are independently controlled based on the circuit Saturated Condensing Temperature. Refer to Table 7 for condenser fan control

information. See Fig. 6A.

With Motormaster Control

— For low-ambient operation, the

lead fan in each circuit can be equipped with the optional or

accessory Motormaster III head pressure controller. If factory

installed, the controller will be configured for 4 to 20 mA control. With the Motormaster III option enabled, the PSIO-1

module calculates the required output based on Saturated Condensing temperature, Head Pressure set point, and a PID (proportional integral derivative) loop calculation. This 4 to 20 mA

output is driven through the PSIO-2 module. Proportional,

Integral, and Derivative gain parameters for air cooled controls

are adjustable and can be found in the Service subfunction.

Checkout and adjustment of the PID loop should only be

performed by certified Carrier Comfort Network technicians.

To obtain this accessory for field installation, order by part

number 30GX-900---012 for a single controller package

(30GX080-150 and 160). Order part number 30GX-900---014

for a dual controller package (30GX151 and 161-350). These

packages contain all the hardware required to install the accessory . See Fig. 6B.

The control will use the higher of the 2 Saturated Condensing Temperature values for 30GX080-150 and 160 units. For

the 30GX151 and 161-350 units, each circuit’s fan stages are

independently controlled based on the circuit Saturated Condensing Temperature. Refer to Table 8 for condenser fan staging information.

47

8

7

LWT (C)

6

5

LEGEND

LWT —

Leaving Water

Temperature

46

45

44

43

LWT (F)

42

41

0 200 400 600 800 1000

STANDARD

DEADBAND

DEADBAND EXAMPLE

TIME (SECONDS)

Fig. 4 — Deadband Multiplier

10

2 STARTS

3 STARTS

MODIFIED

DEADBAND

Table 6 — Field Configured Chiller Options

UNIT CONFIGURATION OPTION DESCRIPTION HSIO LOCATION FACTORY CONFIGURED?

Fan Staging Select Air cooled staging method Yes. See Table 7

30GX

30HXC

Motormaster® Control Select Applies to air cooled units only

Water Valve Type Applies to water cooled unit only

Set to 1 to enable (Motormaster only)

Set to 1 = 4 to 20 mA, 2 = 2 to 10 V,

Yes. 0 = None

Yes. 0 = None

3 = 20 to 4 mA, 4 = 10 to 2 V

Table 7 — Fan Staging Settings for Air Cooled (30GX) Units

UNIT 30GX DESCRIPTION OPTION NUMBER HSIO DISPLAY

080-105

106-125

136, 150, 160

151, 161, 175,

205, 225

176

206, 226, 250

251-350

LEGEND

SCT —

Saturated Condensing Temperature

1st stage compressor status and SCT set point

2nd stage common control based on highest SCT

1st stage compressor status and SCT set point

2nd and 3rd stage common control based on highest SCT

1st stage compressor status and SCT set point

2nd through 4th stage common control based on highest SCT

1st stage each circuit, compressor status

2nd stage Circuit B independent

2nd and 3rd stage Circuit A independent

1st stage each circuit, compressor status

2nd and 3rd stage each circuit independent

1st stage each circuit, compressor status

2nd stage Circuit B independent

2nd, 3rd and 4th stage Circuit A independent

1st stage each circuit, compressor status

2nd, 3rd and 4th stage each circuit independent

12 Com_1cmp

14 Com_2cmp

16 Com_3cmp

7 A2B1_stg

3 Ind_2stg

9 A3B2_cmp

5 Ind_3stg

WATER-COOLED UNITS (30HXC) — The 30HXC chillers

can be configured to control direct or reverse-acting water

valves that are controlled by a 4 to 20 mA signal. A 2 to10 vdc

signal can be used by installing a 500-ohm

1

/2 watt resistor

across the 2 output terminals of the 4 to 20 mA signal. The 4 to

20 mA control scheme reads the saturated condensing temperature and uses a PID (proportional integral deriative) loop to

control the head pressure. Proportional, Integral and Derivative

gain parameters for the water cooled controls are adjustable

and can be found in the Service subfunction. Checkout and

adjustment of the PID loop should only be performed by certified Carrier Comfort Network technicians.

CONDENSERLESS UNITS (30HXA) — The remote condenser fans are controlled by 2 relays with the 30HXA control

box. See Field Wiring section on page 73 for wiring details.

The 30HXA control must be configured to turn the 09DK fans

on and/or off. To set the 30HXA control for this configuration

Unit T ype under must be changed to 3 (Split System).

Next, under , Head Pressure Control Type must be

changed to 1 (Air Cooled), and Condenser Pump control must

be set to 0 (Not Controlled).

The 30HXA control does not support a 4 to 20 mA or a 2 to

10 vdc output for fan speed control. Instead, head pressure control is accomplished with fan cycling pressure switches

(09DK054-094), temperature switches (09DK044, 074-094)

and Motormaster control. Motormaster and Motormaster III

control is used with temperature sensor input to control condenser fan speed. See accessory installation instructions for

further information.

09DK CONDENSING UNITS

09DK044 Units

— The 09DK044 units have accessory provision for fully automatic intermediate-season head pressure

control through condenser fan cycling. Fan number 2 and 3

cycling is controlled by outdoor-air temperature through air

temperature switches (ATS) 1 and 2.

The air temperature switches are located in the low er divider panel underneath the coil header. The sensing element is exposed to air entering the no. 1 fan compartment through a hole

in the panel. Fan no. 1 is non-cycling.

The air temperature switch controls the fans as shown in

Table 9.

09DK054-094

— The capacity of an air-cooled condenser increases with increased temperature difference (defined as saturated condenser temperature minus entering outdoor-air temperature) and decreases with decreased temperature difference.

A drop in entering outdoor-air temperature results in a lower

saturated condensing temperature. When outdoor-air temperature drops below the minimum temperature for standard units,

additional head pressure control is required.

Model 09DK units have fully automatic intermediateseason head pressure control through condenser fan cycling

using electromechanical fan cycling controls. Standard head

pressure controls regulate the 100 and 50/50% condenser

capacity applications. Head pressure can also be controlled

by fan cycling controls supplemented by the accessory

Motormaster III solid-state head pressure control. See Motormaster

III installation instructions for more information.

In the standard control scheme, fans 1 and 2 are on when

there is a call for cooling from the respective coil circuits. Fans

1 and 2 are non-cycling. On 054 and 064 units, fans 3 and 4 are

controlled by using a fan cycling pressure switch on each of the

primary coil circuits in response to condensing pressure. On

074-094 units, fans 3 and 4 are controlled using a fan cycling

pressure switch in each of the primary coil circuits in response

to condensing pressure. Fans 5 and 6 are controlled by using

two air temperature switches, which respond to the outdoor

ambient temperature. The air temperature swit ches are locat ed

on the control box shelf.

11

Table 8 — 30GX080-350 Condenser Fan Staging (PSIO-1 Controlled)

30GX UNIT SIZE FAN TYPE FAN CONTACTOR FANS CONTROLLED FAN RELAY NO.*

080-105

106-125

136, 150, 160

151, 161, 175, 205, 225

176

206, 226, 250

251, 265

281-350

LEGEND

Comp. —

FC —

*Fan Relay number displayed when using

Compressor

Fan Contactor

Standard

High Static

Standard

High Static

Standard

High Static

Standard

High Static

Standard

High Static

Standard

High Static

Standard

High Static

Standard

High Static

to test fans.

FC-1 1, 2 5

FC-2 3, 4 1

FC-1, 1A 1, 2 5

FC-2, 2A 3, 4 1

FC-1 1, 2 5

FC-2 3, 4 1

FC-3 5, 6 2

FC-1, 1A 1, 2 5

FC-2, 2A 3, 4 1

FC-3, 3A 5, 6 2

FC-1 1, 2 5

FC-2 3, 4 1

FC-3 5, 6 2

FC-4 7, 8 2

FC-1, 1A 1, 2 5

FC-2, 2A 3, 4 1

FC-3, 3A 5, 6 2

FC-4, 4A 7, 8 2

FC-1 1, 2 Comp. B1 contactor†

FC-2 3, 4 3

FC-3 5, 6 2

FC-4 7, 8 Comp. A1/A2 contactor†

FC-5 9, 10 1

FC-1, 1A 1, 2 Comp. B1 contactor†

FC-2, 2A 3, 4 3

FC-3, 3A 5, 6 2

FC-4, 4A 7, 8 Comp. A1/A2 contactor†

FC-5, 5A 9, 10 1

FC-1 1, 2 Comp. B1 contactor†

FC-2 3, 4 3

FC-3 5, 6 4

FC-4 7, 8 Comp. A1 contactor†

FC-5 9, 10 1

FC-6 11, 12 2

FC-1, 1A 1, 2 Comp. B1 contactor†

FC-2, 2A 3, 4 3

FC-3, 3A 5, 6 4

FC-4, 4A 7, 8 Comp. A1 contactor†

FC-5, 5A 9, 10 1

FC-6, 6A 11, 12 2

FC-1 1, 2 Comp. B1 contactor†

FC-2 3, 4 3

FC-3 5, 6 1

FC-4 7, 8 Comp. A1/A2 contactor†

FC-5 9, 10 2

FC-6 11, 12 2

FC-1, 1A 1, 2 Comp. B1 contactor†

FC-2, 2A 3, 4 3

FC-3, 3A 5, 6 1

FC-4, 4A 7, 8 Comp. A1/A2 contactor†

FC-5, 5A 9, 10 2

FC-6, 6A 11, 12 2

FC-1 2, 4 1

FC-2 6, 8 2

FC-3 1 Comp. B1 contactor†

FC-4 3 3

FC-5 5, 7 4

FC-6 9, 10 Comp. A1/A2 contactor†

FC-7 11, 12 2

FC-8 13, 14 2

FC-1, 1A 2, 4 1

FC-2, 2A 6, 8 2

FC-3 1 Comp. B1 contactor†

FC-4 3 3

FC-5, 5A 5, 7 4

FC-6, 6A 9, 10 Comp. A1/A2 contactor†

FC-7, 7A 11, 12 2

FC-8, 8A 13, 14 2

FC-1 1, 2 Comp. B1/B2 contactor†

FC-2 3, 4 3

FC-3 5, 6 4

FC-4 7, 8 4

FC-5 9, 10 1

FC-6 11, 12 Comp. A1/A2 contactor†

FC-7 13, 14 2

FC-8 15, 16 2

FC-1, 1A 1, 2 Comp. B1/B2 contactor†

FC-2, 2A 3, 4 3

FC-3, 3A 5, 6 4

FC-4, 4A 7, 8 4

FC-5, 5A 9, 10 1

FC-6, 6A 11, 12 Comp. A1/A2 contactor†

FC-7, 7A 13, 14 2

FC-8, 8A 15, 16 2

†Proper rotation of these fans to be checked when compressor(s) is running. See Fig. 5 for

condenser fan locations when viewing from the control box end.

NOTE: For 30GX151, 161-350 units, fan relays 1 and 2 energize Circuit A fans. Fan relays

3 and 4 energize Circuit B fans.

12

Table 9 — Air Temperature Switch Control

(09DK044 Units)

FAN FAN SWITCH TEMPERATURE

ON

FAN 2

OFF

ON

FAN 3

OFF

Above 65 ± 3 F (18.3 ± 1.7 C)

Between 55 and 65 F (12.8 and 18.3 C)

and temperature falling

Below 55 ± 3 F (12.8 ± 1.7 C)

Between 55 and 65 F (12.8 and 18.3 C)

and temperature rising

Above 80 ± 3 F (26.7 ± 1.7 C)

Between 70 and 80 F (21.1 and 26.7 C)

and temperature falling

Below 70 ± 3 F (21.1 ± 1.7 C)

Between 70 and 80 F (21.1 and 26.7 C)

and temperature rising

The fan cycling pressure switch controls the fans as follows:

Fans 3 and 4 are on above 185 ± 10 psig (1276 ± 69 kPa) and

off below 97 ± 10 psig (669 ± 69 kPa). If pressure is rising between 97 psig (669 kPa) and 185 psig (1276 kPa), fans 3 and 4

are off. If pressure is falling from 185 psig (1276 kPa) to

97 psig (669 kPa) fans 3 and 4 are on.

30GX080-105 30GX106-125 30GX136,150,160

4

2

CONTROL

BOX

END

2

4

The 09DK054-094 condensers are supplied with fan cycling pressure switches suitable for use with R-22 refrigerant.

Fan cycling pressure switches that are compatible with R-134a

refrigerant pressures are shipped with the 30HXA chillers.

These fan cycling pressure switches must be installed in place

of the 09DK factory-installed switches before charging to ensure proper head pressure control.

The air temperature switch controls th e fans as foll ows: On

the 074-094 condensers, below 70

±

3 F (21.1 ± 1.7 C) outdoor

ambient, fans 5 and 6 are off; above 80 ± 3 F (26.7 ± 1.7 C) fans

5 and 6 are on. Between 70 F (21.1 C) and 80 F (26.7 C),

whether fans 5 and 6 are on or off depends on whether temperature is rising or falling. If the temperature is rising from 70 F

(21.1 C) to 80 F (26.7 C), fans 5 and 6 are off. If the temperature is falling from 80 F (26.7 C) to 70 F (21.1 C), fans 5 and 6

are on.

6

CONTROL

BOX

END

24 6 8

CONTROL

BOX

END

1

10

9

CONTROL

BOX

END

3

1

3

5

13 5 7

30GX151,161,175,205,225 30GX176

8

7

6

5

4

3

2

CONTROL

BOX

END

1

12

7911

30GX206,226,250 30GX251,265

10

3

1

2

4

5

7

8

6

11

9

12

10

12

14

13

9

11

30GX281-350

10

16

12

14

8

6

4

2

6810

4

2

CONTROL

BOX

END

3

5

8

6

5

7

1

4

2

CONTROL

BOX

END

1

3

15

13

9

11

5

7

1

3

Fig. 5 — 30GX Condenser Fan Locations

13

CONTROL

BOX

END

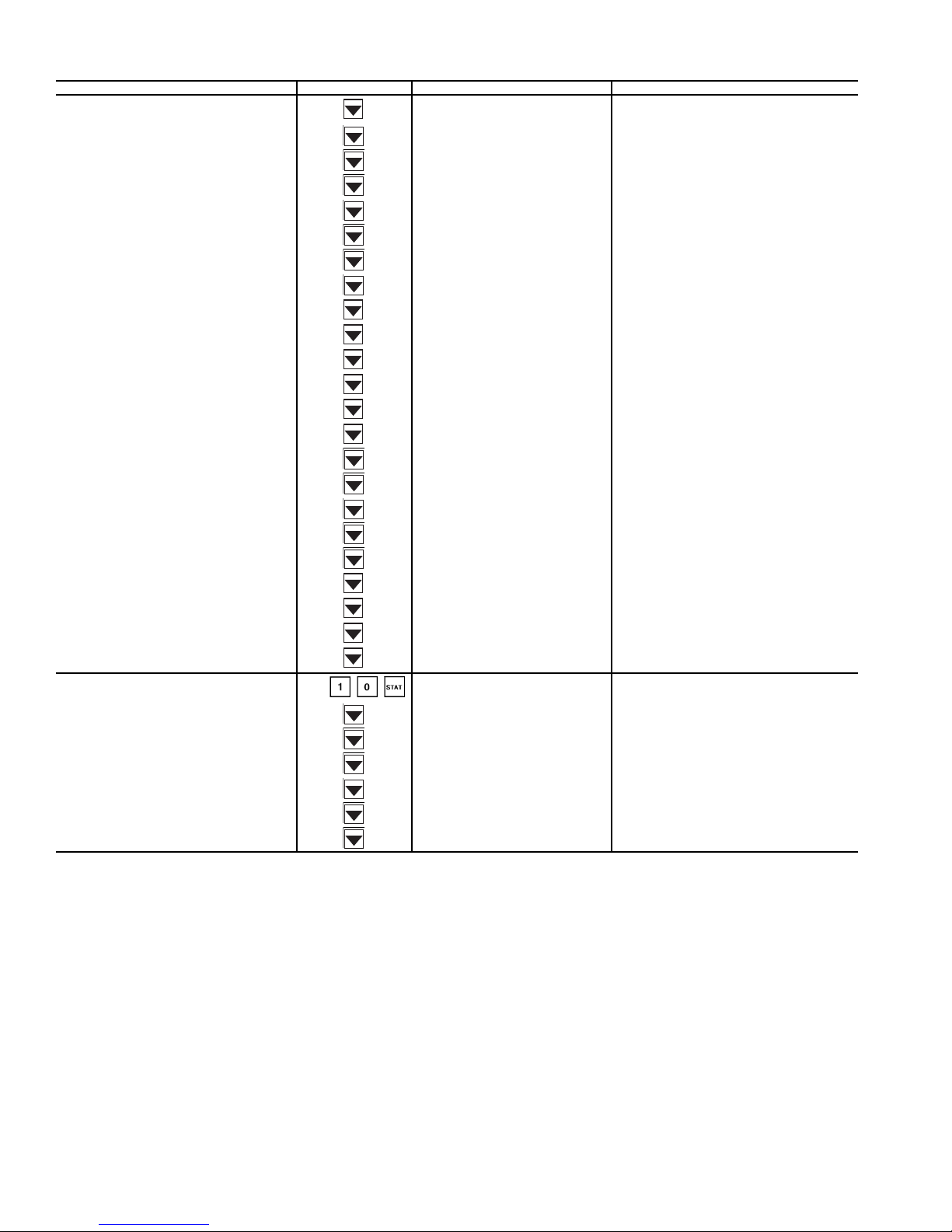

30GX UNITS — MOTORMASTER III CONTROL NOT INSTALLED

LEGEND

Saturated Condensing Temper ature

SCT —

Fig. 6A — 30GX Head Pressure Control Without Motormaster

30GX UNITS — MOTORMASTER III CONTROL INSTALLED

READ CIRCUIT

SATURATED

CONDENSING

TEMPERATURE

AND CURRENT

FAN STAGE

IS SCT GREATER

THAN HEAD

PRESSURE SET

POINT PLUS 15°F

(8.3°C)?

YES

INCREASE

CURRENT FAN

STAGE BY ONE

NO

Fig. 6B — 30GX Head Pressure Control Without Motormaster III Control

ADJUSTING PID ROUTINES — The 30GX and 30HXC

head pressure control routines use PID (proportional integral

derivative) loops to maintain a user-configurable head pressure

set point. Gain defaul t values are located in the Service function. See page 32. The current values can be read under

from the HSIO. The control calculates a new fan

speed (30GX) or water valve position (30HXC) every 5 seconds based on these gain values and an error term equal to saturated condensing temperature minus head pressure set point.

If the control routine is not responding fast enough to large

changes (circuit starting, for example), increase the proportional term.

When the routine is making too great a change to valve position or fan speed, decrease the proportional term. To minimize hunting, keep the integral term positive and as low as possible. This value is used to control “droop,” which is common

in master/submaster control schemes. The default for the derivative term is zero. The value should not need to be changed.

Cooler and Condenser (30HXC) Pump Control —

cooler and condenser (30HXC) pump control. Inputs for a

The 30GX and 30HX chillers can be configured for

®

III Control

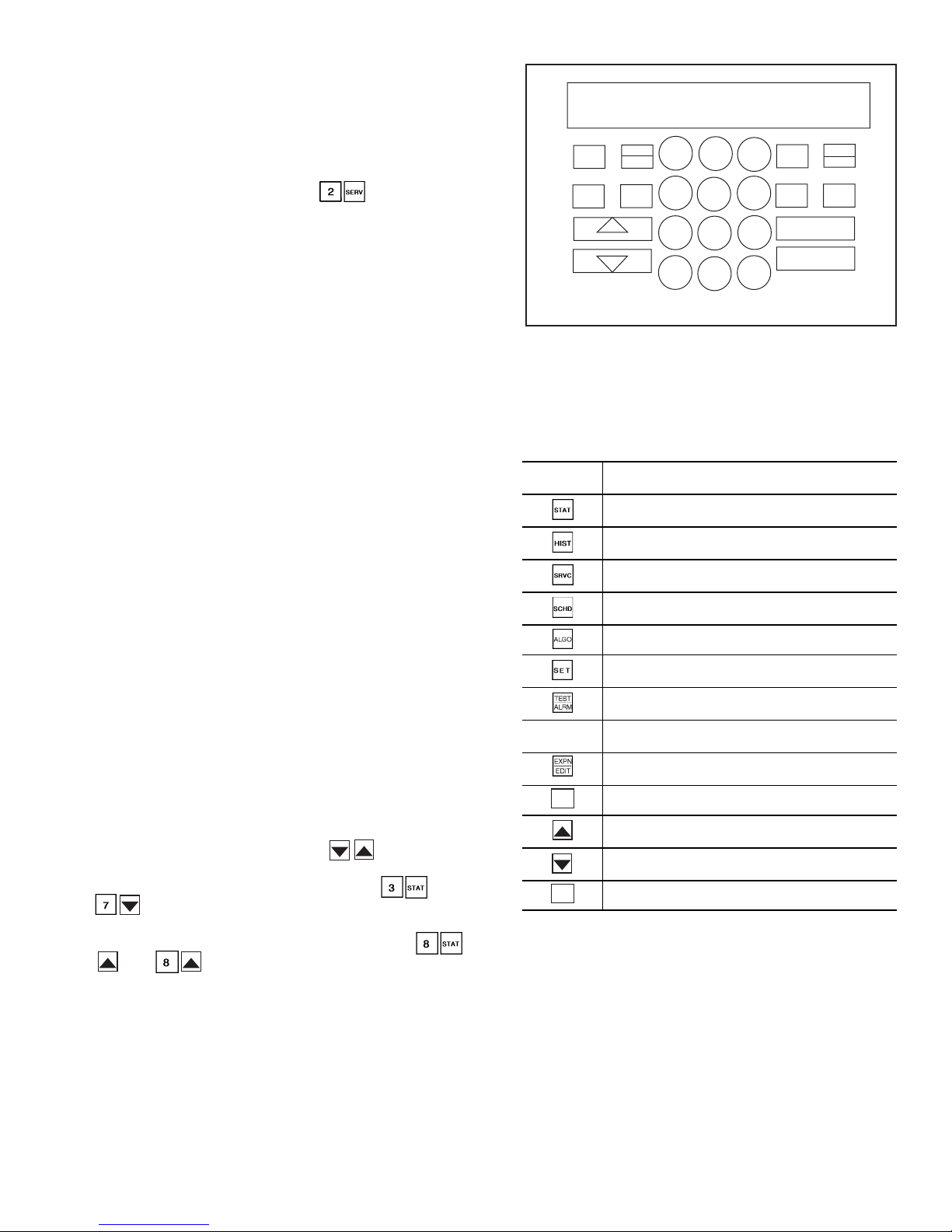

CALCULATE NEW

PID VALUE. DOES

OUTPUT REQUIRE

MORE FANS?

YES

INCREASE

CURRENT FAN

STAGE BY ONE

OUTPUT NEW mA

SIGNAL TO

CONTROLLER

NO

DOES PID OUTPUT

REQUIRE LESS

FANS?

YES

DECREASE

CURRENT FAN

STAGE BY ONE

NO

cooler flow switch or interlock and condenser flow switch are

also provided.

COOLER PUMP CONTROL — Proper configuration of the

cooler pump control and cooler pump interlock is required to

prevent possible cooler freeze-up. The cooler pump interlock

should always be enabled. This prevents the chiller from operating unless chilled water flow is detected. See page 73 of the

Field Wiring section for proper connection of the chilled water

flow switch and cooler pump interlock.

The factory default setting for cooler pump control is “0”

(not controlled). It is recommended for 30GX packaged aircooled chillers that the cooler pump control be utilized unless

the chilled water pump runs continuously or the chilled water

system contains a suitable anti-freeze solution. The cooler

pump relay is energized when the chiller enters an occupied

mode. In the event a freeze protection alarm is generated t he

cooler pump relay is also energized. If the cooler heater is

being used and has been on for more than 15 minutes during

saturated suction freeze protection, the cooler pump relay is

energized.

When the cooler pump control is set to “0” and the cooler

pump interlock is set to “1” an alarm 53 will be generated if

flow is not proven within one minute after the unit is enabled

and in an occupied mode.

14

When the cooler pump control is set to “1” and the cooler

CLEAR

ENTER

1

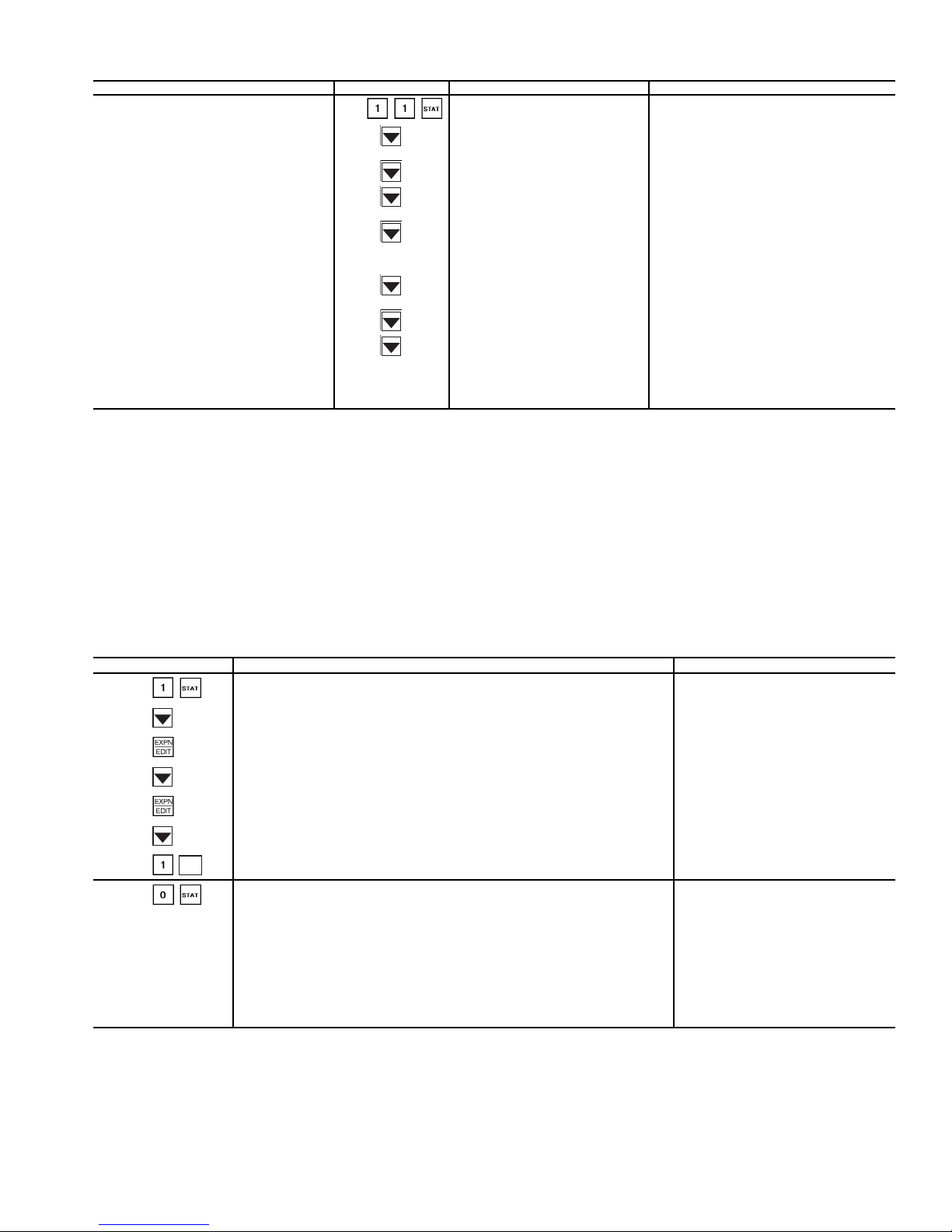

2

3

4

5

6

7

8

9

0

.

-

STAT

SET

SCHD

EXPN

EDIT

SRVC

HIST

ALGO

TEST

ALRM

TWENTY-FOUR CHARACTER

TWO-LINE LCD DISPLAY

LEGEND

LCD —

Liquid Crystal Display

Fig. 7 — Keypad and Display Module

pump interlock is set to “1” an alarm 53 will be generated if

flow is not proven within one minute after the cooler pump relay is energized. An alarm 55 will be generated if the interlock

contacts remain closed when the cooler pump relay is off. In either cooler pump control configuration, alarm 54 will be generated whenever the cooler pump interlock is open for at least

5 seconds during operation.

CONDENSER PUMP CONTROL ( ) — Factory defaults for both condenser pump control and condenser flow

switch are set to “Not Controlled” and “Disabled,” respectively. The condenser pump can be controlled in one of two

ways: In the first method, the pump can be controlled like the

cooler pump — it is turned on whenever the machine is in the

on state and turned off otherwise (set to “1” using the Service

function). The second method of control is to turn the pump on

when the fir st compresso r is started and off when the last compressor is turned off (set to “2” using the Service function).

With the flow switched enabled, the control checks the status

of the input one minute after starting the pump. An alarm 49 is

generated if the flow switch input is not closed.

Cooler Heater Control —

Accessory cooler heaters

can be ordered for the 30GX chillers. If installed and e nabled,

these heaters are turned on only when the machine is in the off

state and the chiller is in a saturated suction temperature freeze

condition.

Oil Heater Control —

Standard feature that controls oil

temperature based on Saturated Condensing Temperature

(SCT). Heaters turn on at <105 F (40.6 C) SCT, and turn off at

>110 F (43.3 C) SCT.

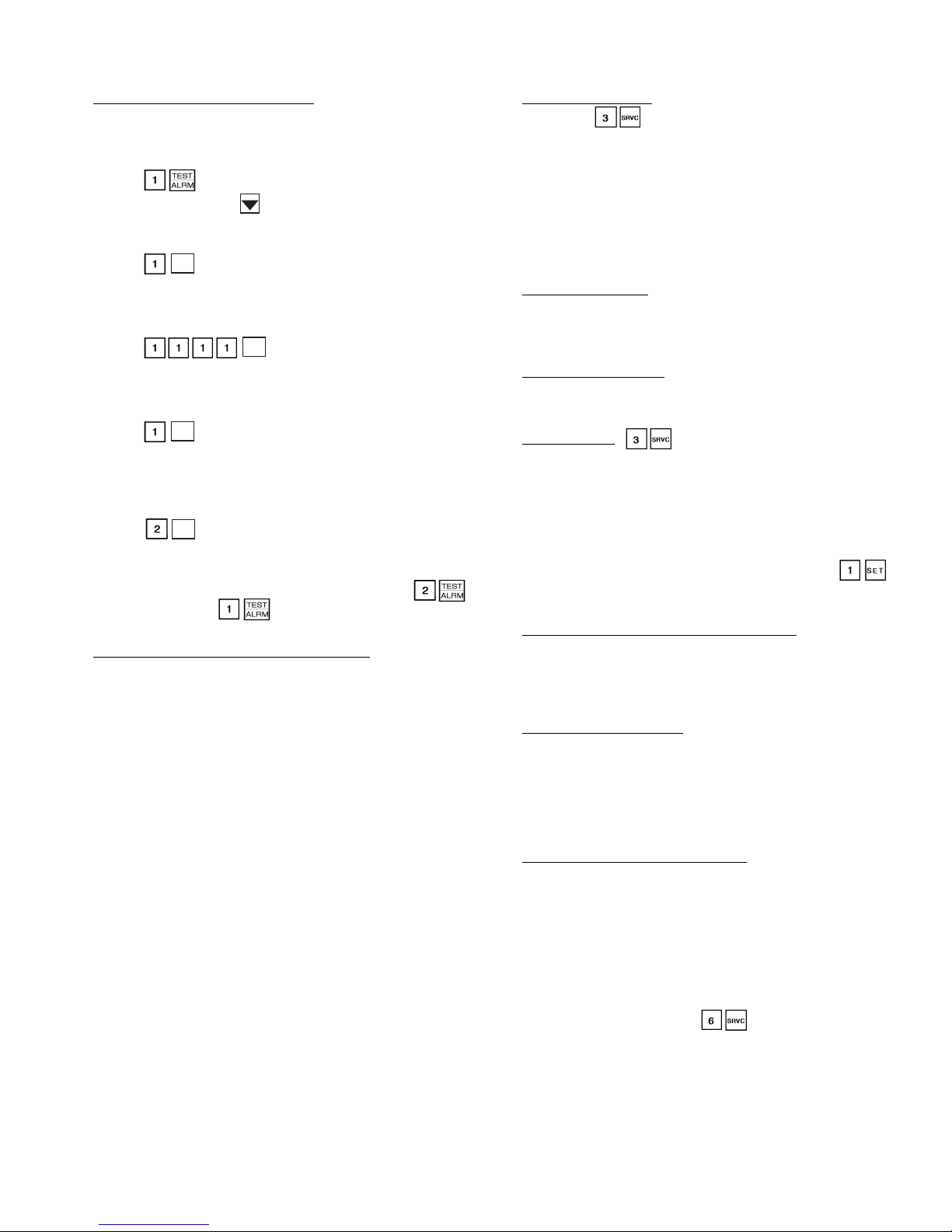

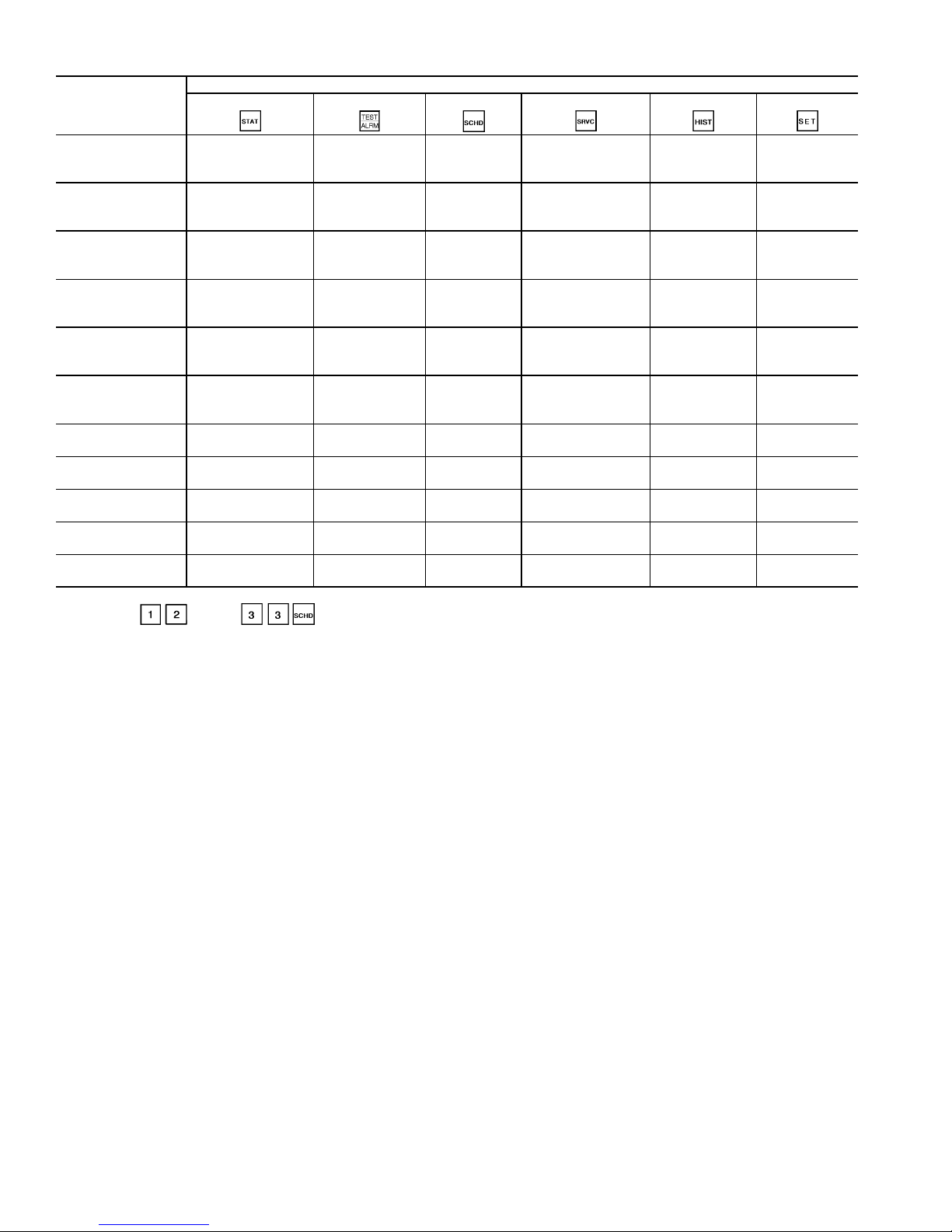

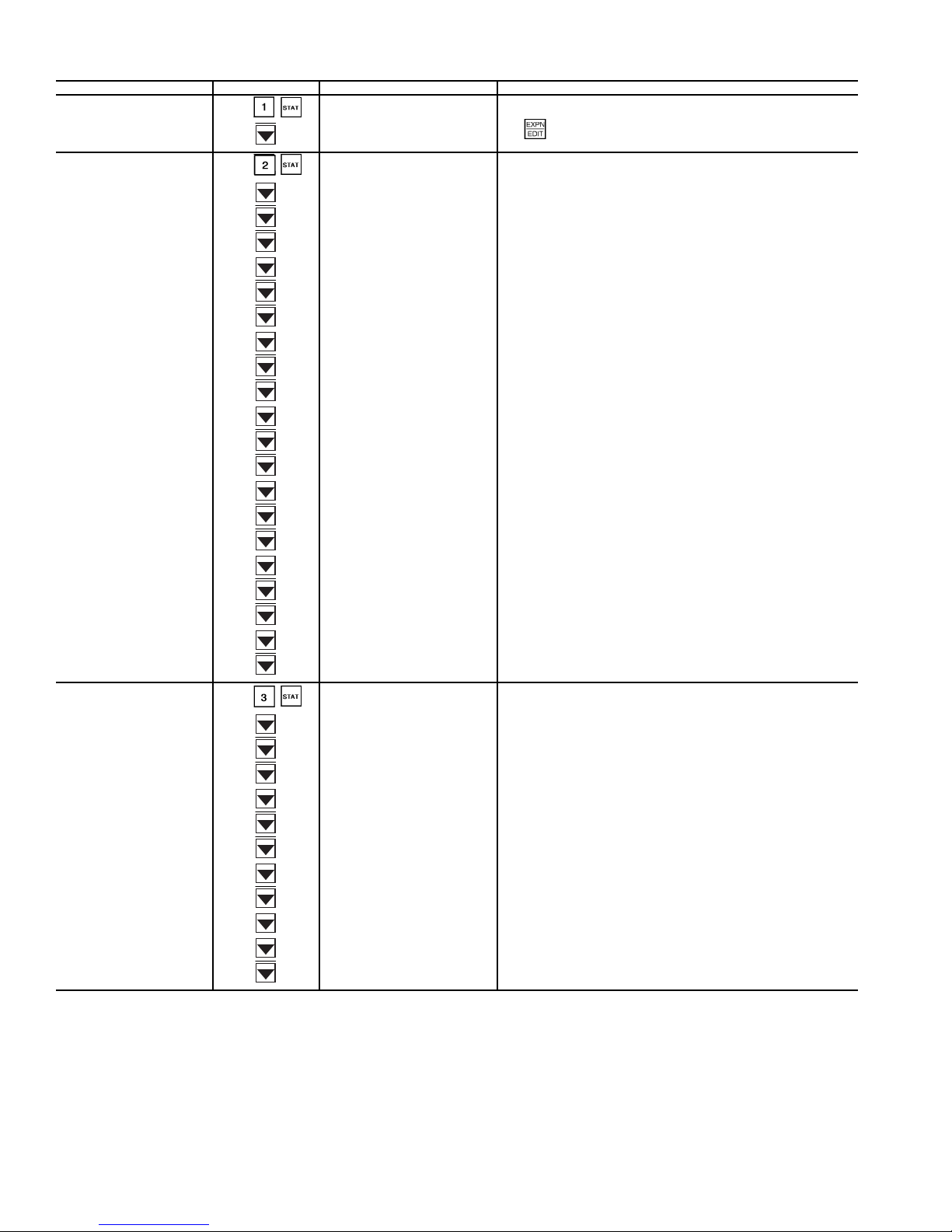

Keypad and Display Module (Also Called

HSIO-II) —

cate with the processor. It is used to enter configurations and

set points and to read data, perform tests, and set schedules.

The device consists of a keypad with 7 function keys, 5 operative keys, 12 numeric keys (0 to 9, •, and -), and a 2-line,

24-character alphanumeric liquid crystal display . See Fig. 7.

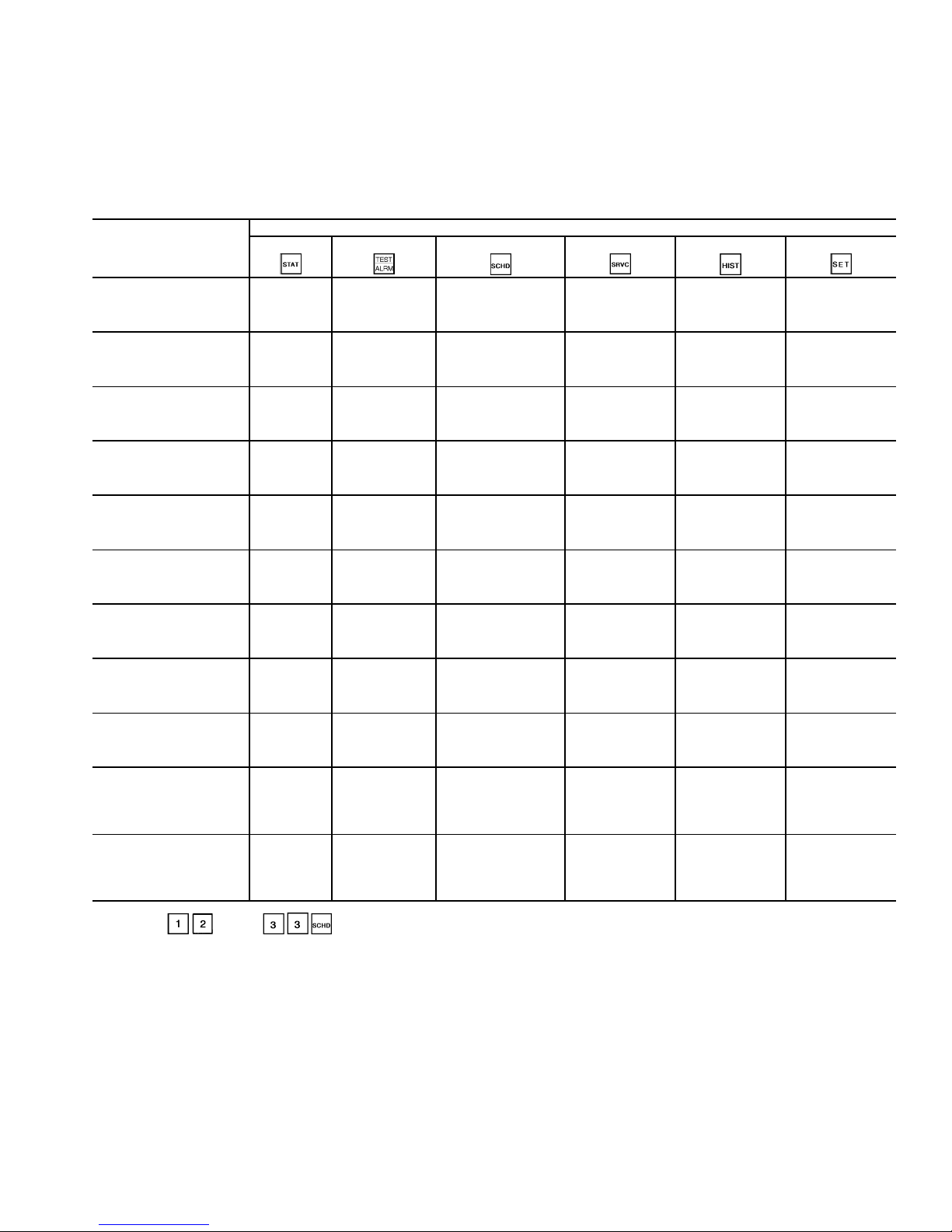

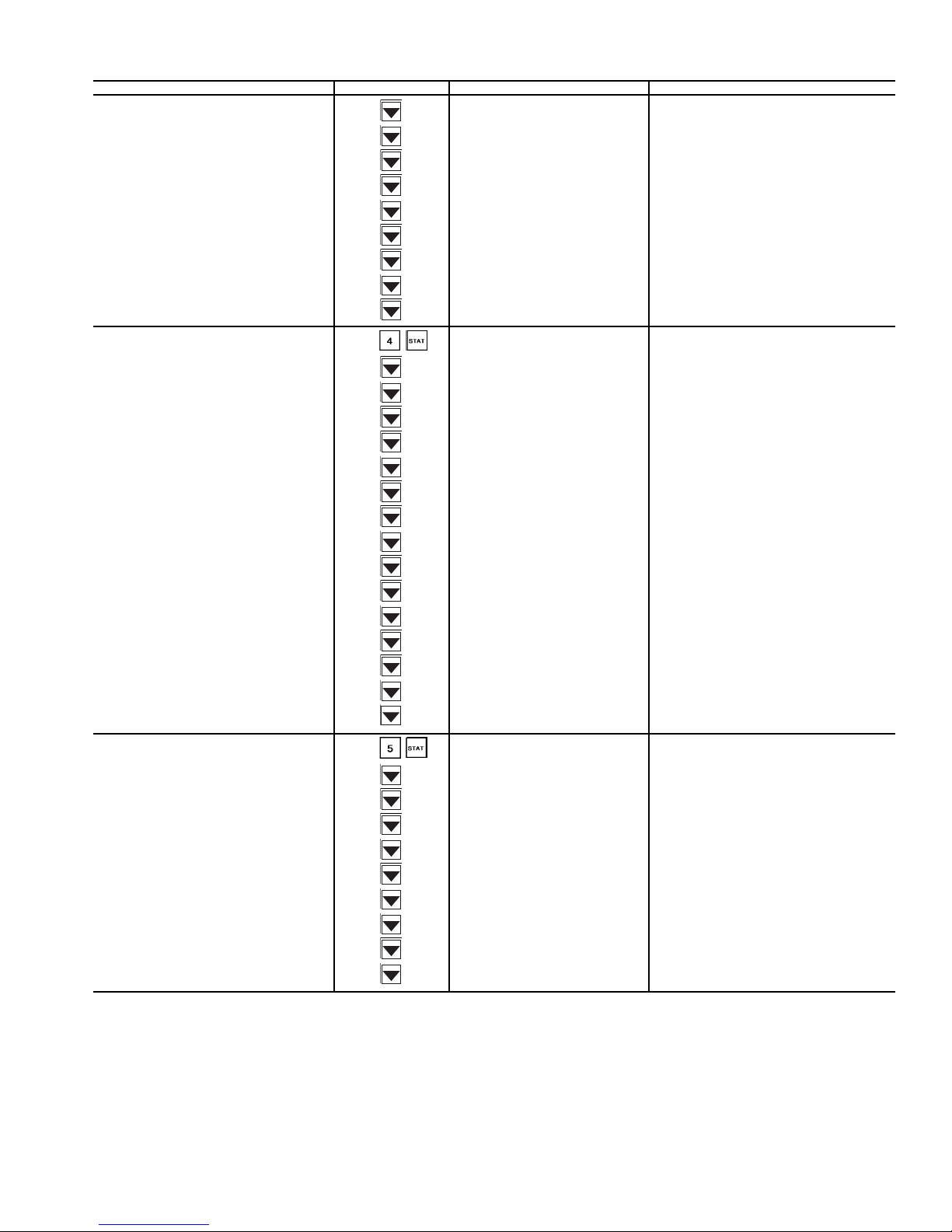

ACCESSING FUNCTIONS AND SUBFUNCTIONS —

Table 10 shows a brief description of the keypad buttons.

Table 11A shows the 6 functions (identified by name) and the

subfunctions (identified by number). Table 11B shows the

6 functions (identified by name) and the subfunctions (identified by number) when using the optional remote enhanced display controller. Table 12 shows a brief example on how to

access subfunctions.

NOTE: It is not necessary to use the through every

item in a subfunction. For example, if you wanted to read the

oil pressure for the A1 compressor, press , then

procedure to view an item near the bottom of a subfunction. To

view Condenser Pump Flow Switch status, press ,

, and . This procedure is available in all functions

except the TEST function.

AUTOMATIC DEF AULT DISPLAY — When the keypad has

not been used for 10 minutes, the display automatically