Carrier 30GTN040, 30GTN060, 30GTN045, 30GTN050, 30GTN070 Operation And Service Manual

...

Controls Start-Up, Operation,

Service, and Troubleshooting

SAFETY CONSIDERATIONS

Installing, starting up, and servicing this equipment can be

hazardous due to system pressures, electrical components, and

equipment location (roof, elevated structures, etc.). Only

trained, qualified installers and service mechanics should install, start up, and service this equipment.

When working on this equipment, observe precautions in

the literature, and on tags, stickers, a nd labels attached to the

equipment, and any other safety precautions that apply. Follow

all safety codes. Wear safety glasses and work gloves. Use care

in handling, rigging, and setting this equipment, and in handling all electrical components.

Electrical shock can cause personal injury and death. Shut

off all power to this equipment during installation and service. There may be more than one disconnect switch. Tag

all disconnect locations to alert others not to restore power

until work is completed.

This unit uses a microprocessor-based electronic control

system. Do not use jumpers or other tools to short out components, or to bypass or otherwise depart from recommended procedures. Any short-to-ground of the control

board or accompanying wiring may destroy the electronic

modules or electrical components.

To prevent potential damage to heat exchanger tubes

always run fluid through heat exchangers when adding or

removing refrigerant charge. Use appropriate brine solutions in cooler fluid loops to prevent the freezing of heat

exchangers when the equipment is exposed to temperatures

below 32 F (0° C).

DO NOT VENT refrigerant relief valves within a building.

Outlet from relief valves must be vented outdoors in accordance with the latest edition of ANSI/ASHRAE (American

National Standards Institute/American Society of Heat ing,

Refrigeration and Air Conditioning Engineers) 15 (Safety

Code for Mechanical Refrigeration). The a ccumulation of

refrigerant in an enclosed space can displace oxygen and

cause asphyxiation. Provide adequate ventilation in

enclosed or low overhead areas. Inhalation of high concentrations of vapor is harmful and may cause heart irregularities, unconsciousness or death. Misuse can be fatal. Vapor

is heavier than air and reduces the amount of oxygen available for breathing. Product causes eye and skin irritation.

Decomposition products are hazardous.

30GTN,GTR040-420

30GUN,GUR040-420

Air-Cooled Reciprocating Liquid Chillers

with

Comfort

Link™ Controls

50/60 Hz

DO NOT attempt to unbraze factory joints w hen servicing

this equipment. Compressor oil is flammable and there is

no way to detect how much oil may be in any of the refrigerant lines. Cut lines with a tubing cutter as required when

performing service. Use a pan to catch any oil that may

come out of the lines and as a gage for how much oil to add

to system. DO NOT re-use compressor oil.

CONTENTS

Page

SAFETY CONSIDERATIONS

GENERAL

INTRODUCTION

MAJOR SYSTEM COMPONENTS

General

Main Base Board (MBB)

Expansion Valve (EXV) Board

Compressor Expansion Board (CXB)

Scrolling Marquee Display

Energy Management Module (EMM)

Enable/Off/Remote Contact Switch

Emergency On/Off Switch

Reset Button

Board Addresses

Control Module Communication

Carrier Comfort Network Interface

OPERATING DATA

Sensors

• T1 — COOLER LEAVING FLUID SENSOR

• T2 — COOLER ENTERING FLUID SENSOR

• T3,T4 — SATURATED CONDENSING

TEMPERATURE SENSORS

• T5,T6 — COOLER SUCTION TEMPERATURE

SENSORS

• T7,T8 — COMPRESSOR SUCTION GAS

TEMPERATURE SENSORS

• T9 — OUTDOOR-AIR TEMPERA TURE SENSOR

• T10 — REMOTE SPACE TEMPERATURE SENSOR

Thermostatic Expansion Valves (TXV)

Compressor Protection Control System

(CPCS) or Control Relay (CR)

Compressor Ground Current Protection Board

(CGF) and Control Relay (CR)

Electronic Expansion Valve (EXV)

Energy Management Module

Capacity Control

• ADDING ADDITIONAL UNLOADERS

• MINUTES LEFT FOR START

• MINUTES OFF TIME

• LOADING SEQUENCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2,3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . 3-10

. . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . 4

. . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . 16

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 2

Ta b 5 c

PC 903 Catalog No. 563-025 Printed in U.S.A. Form 30GTN-3T Pg 1 3-00 Replaces: 30GTN-2T

CONTENTS (cont)

• LEAD/LAG DETERMINATION

• CAPACITY SEQUENCE DETERMINATION

• CAPACITY CONTROL OVERRIDES

Head Pressure Control

• COMFORTLINK™ UNITS (With EXV)

• UNITS WITH TXV

Pumpout

• EXV UNITS

• TXV UNITS

Marquee Display Usage

Service Test

Configuring and Operating Dual Chiller

Control

Temperature Reset

Cooling Set Point (4 to 20 mA)

Demand Limit

• DEMAND LIMIT (2-Stage Switch Controlled)

• EXTERNALLY POWERED DEMAND LIMIT

(4 to 20 mA Controlled)

• DEMAND LIMIT (CCN Loadshed Controlled)

TROUBLESHOOTING

Compressor Protection Control System

(CPCS) Board

Compressor Ground Current (CGF) Board

(30GTN,R and 30GUN,R130-210, 230A-315A,

and 330A/B-420A/B)

EXV Troubleshooting

• STEP 1 — CHECK PROCESSOR EXV OUTPUTS

• STEP 2 — CHECK EXV WIRING

• STEP 3 — CHECK RESISTANCE OF EXV MOTOR

WINDINGS

• STEP 4 — CHECK THERMISTORS THAT

CONTROL EXV

• STEP 5 — CHECK OPERATION OF THE EXV

Alarms and Alerts

SERVICE

Electronic Components

Compressors

• COMPRESSOR REMOV AL

• OIL CHARGE

Cooler

•COOLER REMOVAL

• REPLACING COOLER

• SERVICING THE COOLER

Condenser Coils

Condenser Fans

Refrigerant Feed Components

• ELECTRONIC EXPANSION VALVE (EXV)

• MOISTURE-LIQUID INDICATOR

• FILTER DRIER

• LIQUID LINE SOLENOID VALVE

• LIQUID LINE SERVICE VALVE

Thermistors

•LOCATION

• REPLACING THERMISTOR T2

• REPLACING THERMISTORS T1,T5,T6,T7, AND T8

• THERMISTORS T3 AND T4

• THERMISTOR/TEMPERATURE SENSOR CHECK

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. . . . . . . . . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . 45

. . . . . . . . . . . . . . . . . . . . . . . . . 47-52

. . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

. . . . . . . . . . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

. . . . . . . . . . . . . . . . . . . 58

Page

Page

Safety Devices

• COMPRESSOR PROTECTION

• LOW OIL PRESSURE PROTECTION

• CRANKCASE HEATERS

• COOLER PROTECTION

Relief Devices

• HIGH-SIDE PROTECTION

• LOW-SIDE PROTECTION

• PRESSURE RELIEF VALV ES

Other Safeties

PRE-START-UP

System Check

START-UP AND OPERATION

Actual Start-Up

Operating Limitations

• TEMPERATURES

• VOLTAGE

• MINIMUM FLUID LOOP VOLUME

• FLOW RATE REQUIREMENTS

Operation Sequence

Refrigerant Circuit

FIELD WIRING

APPENDIX A — CCN TABLES

APPENDIX B — FLUID PRESSURE DROP

CURVES

START-UP CHECKLIST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . 66,67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67-70

. . . . . . . . . . . . . . . . 71-79

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80-87

. . . . . . . . . . . . . . . . .CL-1 to CL-8

GENERAL

The model 30GTN,R chillers are air-cooled chillers uti lizing refrigerant R-22. The model 30GUN,R chillers are aircooled chillers utilizing refrigerant R-134a.

Unit sizes 230-420 are modular units which are shipped as

separate sections (modules A and B). Installation instructions

specific to these units are shipped inside the individual modules. See T ables 1A and 1B for a listing of unit si zes and modular combinations. For modules 230B-315B, follow all general

instructions as noted for unit sizes 080-110. For all remaining

modules, follow instructions for unit sizes 130-210.

INTRODUCTION

This publication contains Start-Up, Service, Controls, Operation, and Troubleshooting information for the 30GTN,R040420 and 30GUN,R040-420 liquid chillers with ComfortLink

controls.

The 30GTN,R and 30GUN,R040-420 chillers are equipped

with electronic expansion valves (EXVs) or, on size 040-110

FIOP (factory-installed option) units, conventional thermostatic expansion valves (TXVs). The size 040-110 FIOP chillers

are also equipped with liquid line solenoid valves (LLSV).

NOTE: TXVs are not available on modular units.

Differences in operations and controls between standard

and 040-110 FIOP units are noted in appropriate sections in

this publication. Refer to the Installation Instructions and the

Wiring Diagrams for the appropriate unit for further details.

2

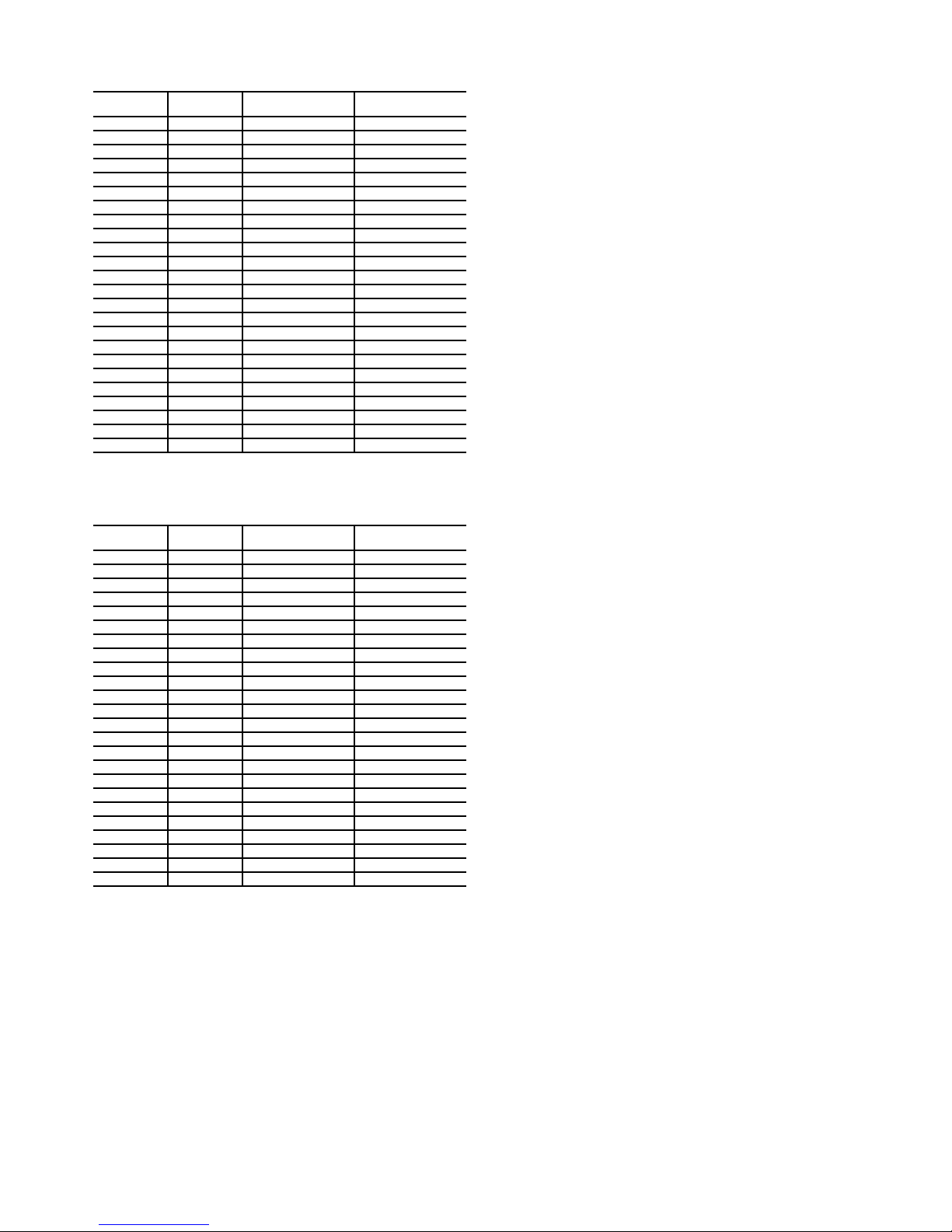

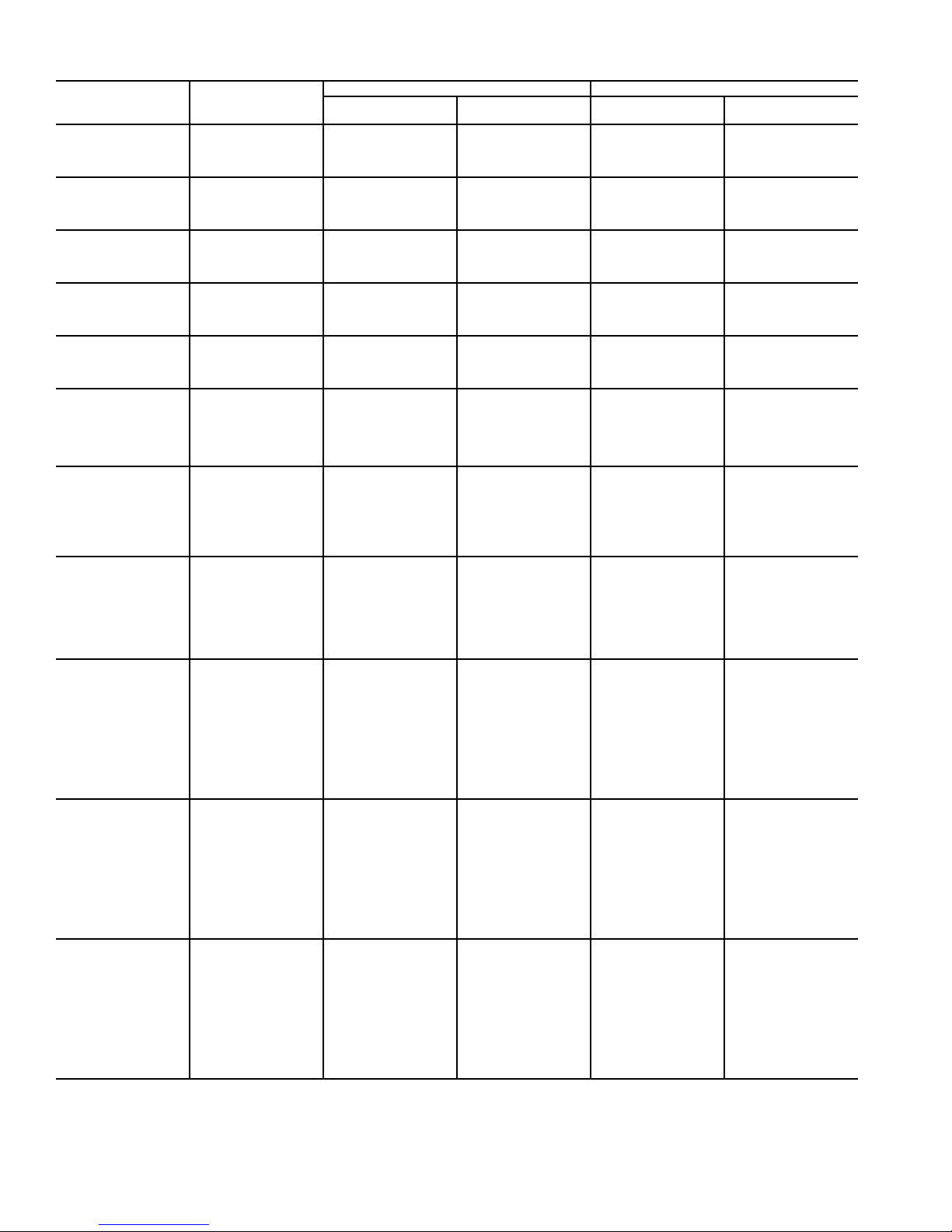

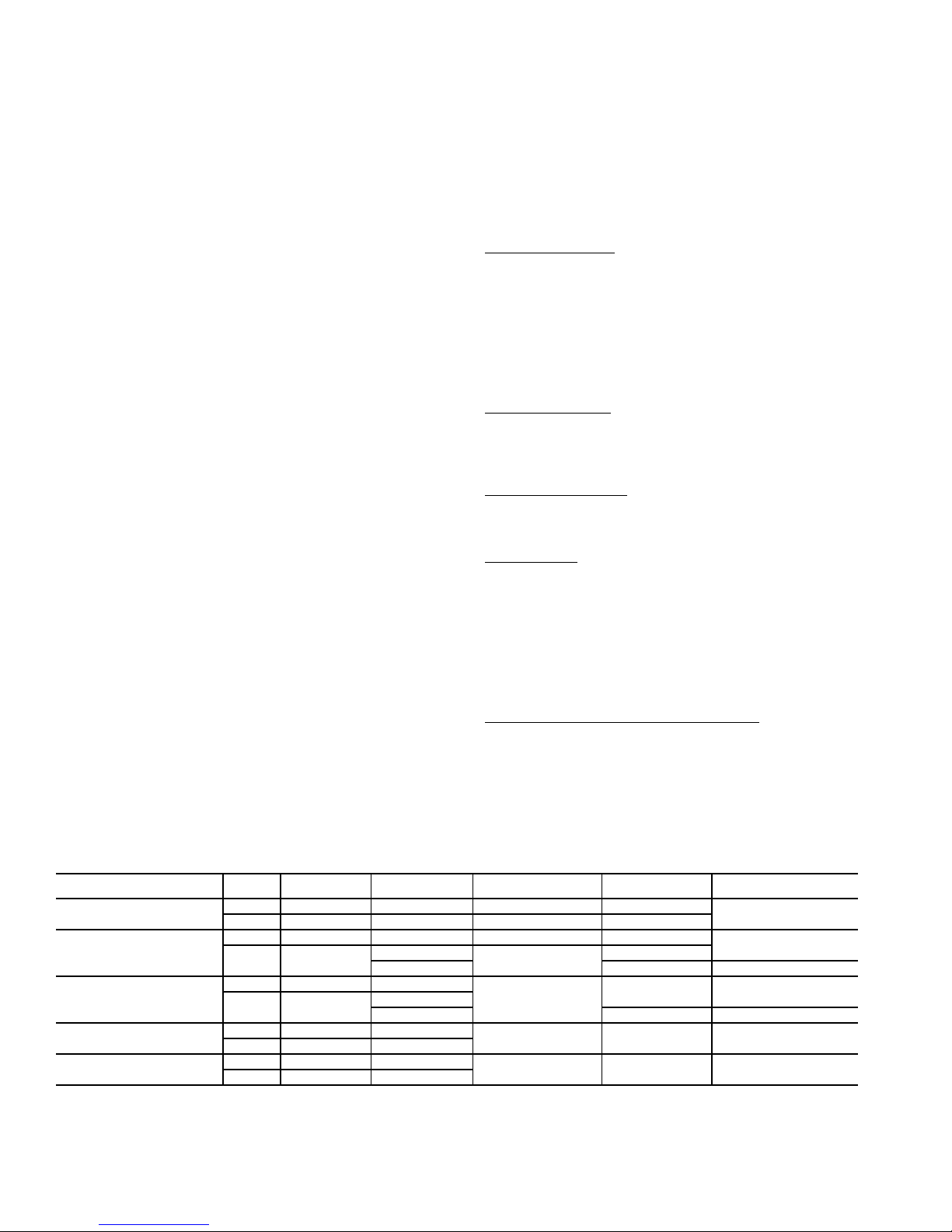

Table 1A — Unit Sizes and Modular Combinations

(30GTN,R)

UNIT

30GTN,R

040

045 45 — —

050 50 — —

060 60 — —

070 70 — —

080 80 — —

090 90 — —

100 100 — —

110 110 — —

130 125 — —

150 145 — —

170 160 — —

190 180 — —

210 200 — —

230 220 150 080

245 230 150 090

255 240 150 100

270 260 170 100

290 280 190 110

315 300 210 110

330 325 170 170

360 350 190 190/170*

390 380 210 190

420 400 210 210

*60 Hz units/50 Hz units.

NOMINAL

TONS

40 — —

SECTION A

UNIT 30GTN,R

SECTION B

UNIT 30GTN,R

Table 1B — Unit Sizes and Modular Combinations

(30GUN,R)

UNIT

30GUN,R

040 26 — —

045 28 — —

050 34 — —

060 42 — —

070 48 — —

080 55 — —

090 59 — —

100 66 — —

110 72 — —

130 84 — —

150 99 — —

170 110 — —

190 122 — —

210 134 — —

230 154 150 080

245 158 150 090

255 165 150 100

270 176 170 100

290 193 190 110

315 206 210 110

330 219 170 170

360 243 190 190/170*

390 256 210 190

420 268 210 210

*60 Hz units/50 Hz units.

NOMINAL

TONS

SECTION A

UNIT 30GUN,R

SECTION B

UNIT 30GUN,R

MAJOR SYSTEM COMPONENTS

General —

rocating chillers contain the ComfortLink™ electronic control

system that controls and monitors all operations of the chiller.

The control system is composed of several components as

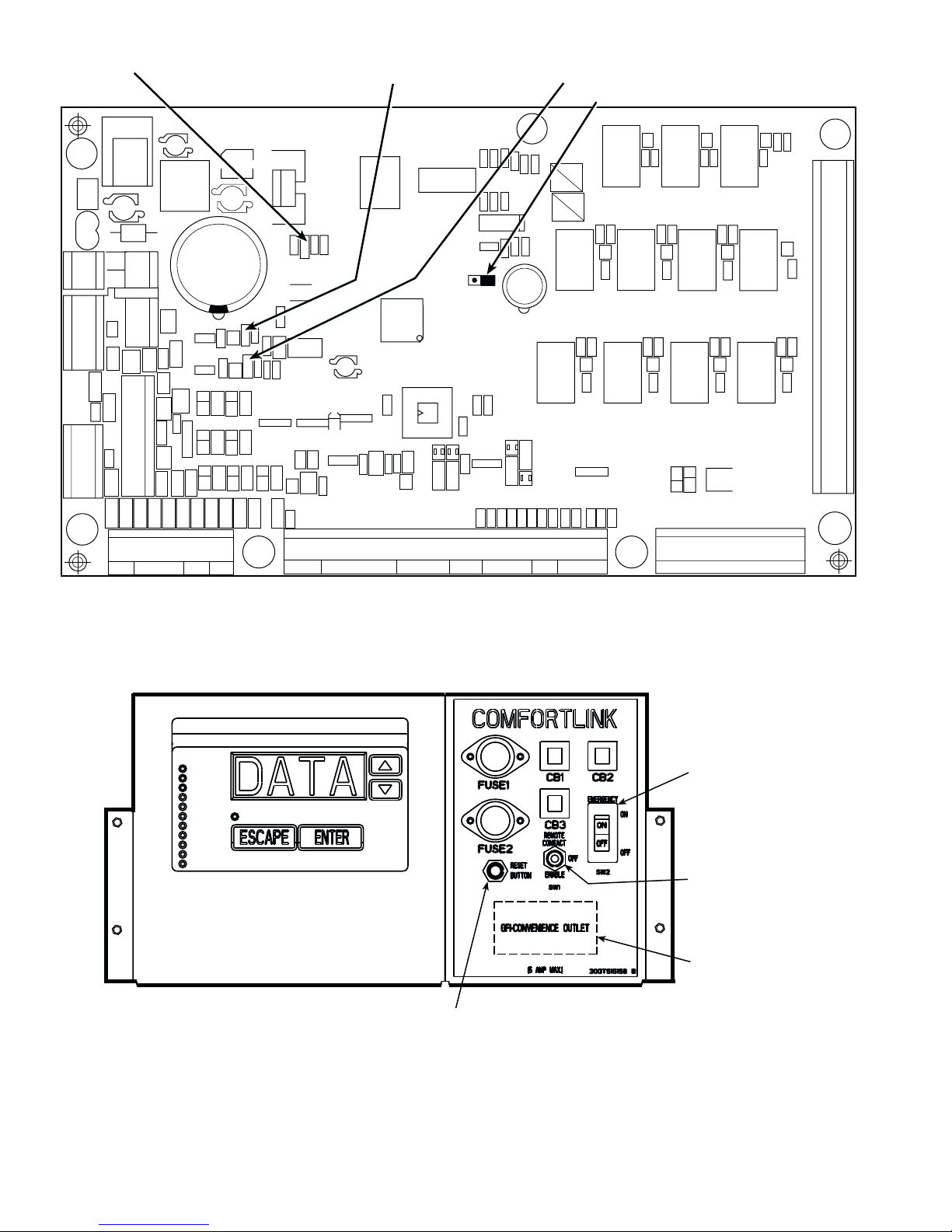

listed in the sections below. See Fig. 1 for typical control box

drawing. See Fig. 2-4 for control schematics.

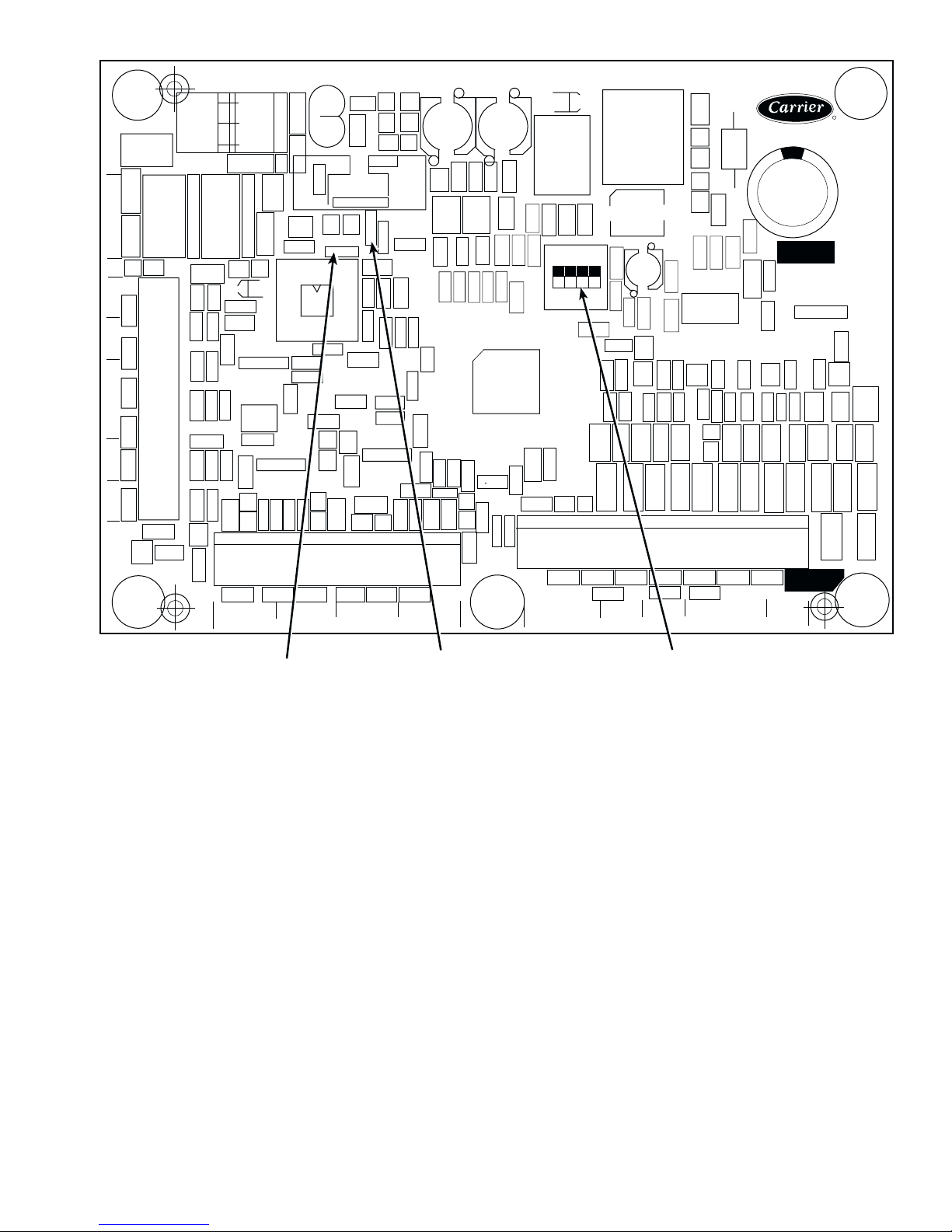

Main Base Board (MBB) —

the heart of the ComfortLink control system. It contains the

major portion of operating software and controls the ope ration

of the machine. The MBB continuously monitors input/output

channel information received from its inputs and from all other

modules. The MBB receives inputs from thermistors T1-T6,

T9, and T10. See Table 2. The MBB also receives the feedback

The 30GTN,R and 30GUN,R air-cooled recip-

See Fig. 5. The MBB is

inputs from compressors A1, A2, B1 and B2, and other status

switches. See Table 3. The MBB also controls several outputs.

Relay outputs controlled by the MBB are shown in Table 4.

Information is transmitted between modules via a 3-wire communication bus or LEN (Local Equipment Network). The

CCN (Carrier Comfort Network) bus is also supported. Connections to both LEN and CCN buses are made at TB3. See

Fig. 5.

Expansion Valve (EXV) Board —

The electronic expansion valve (EXV) board receives inputs from thermistors

T7 and T8. See Table 2. The EXV board communicates with

the MBB and directly controls the expansion valves to maintain the correct compressor superheat.

Compressor Expansion Board (CXB) —

The

CXB is included as standard on sizes 150-210 (60 Hz) and 130

(50 Hz) and associated modular units. The compressor expansion board (CXB) receives the feedback inputs from compressors A3, B3 and A4. See Table 3. The CXB board communicates the status to the MBB and controls the outputs for these

compressors. An additional CXB is required for unit sizes 040110, 130 (60 Hz), 230B-315B with additional unloaders.

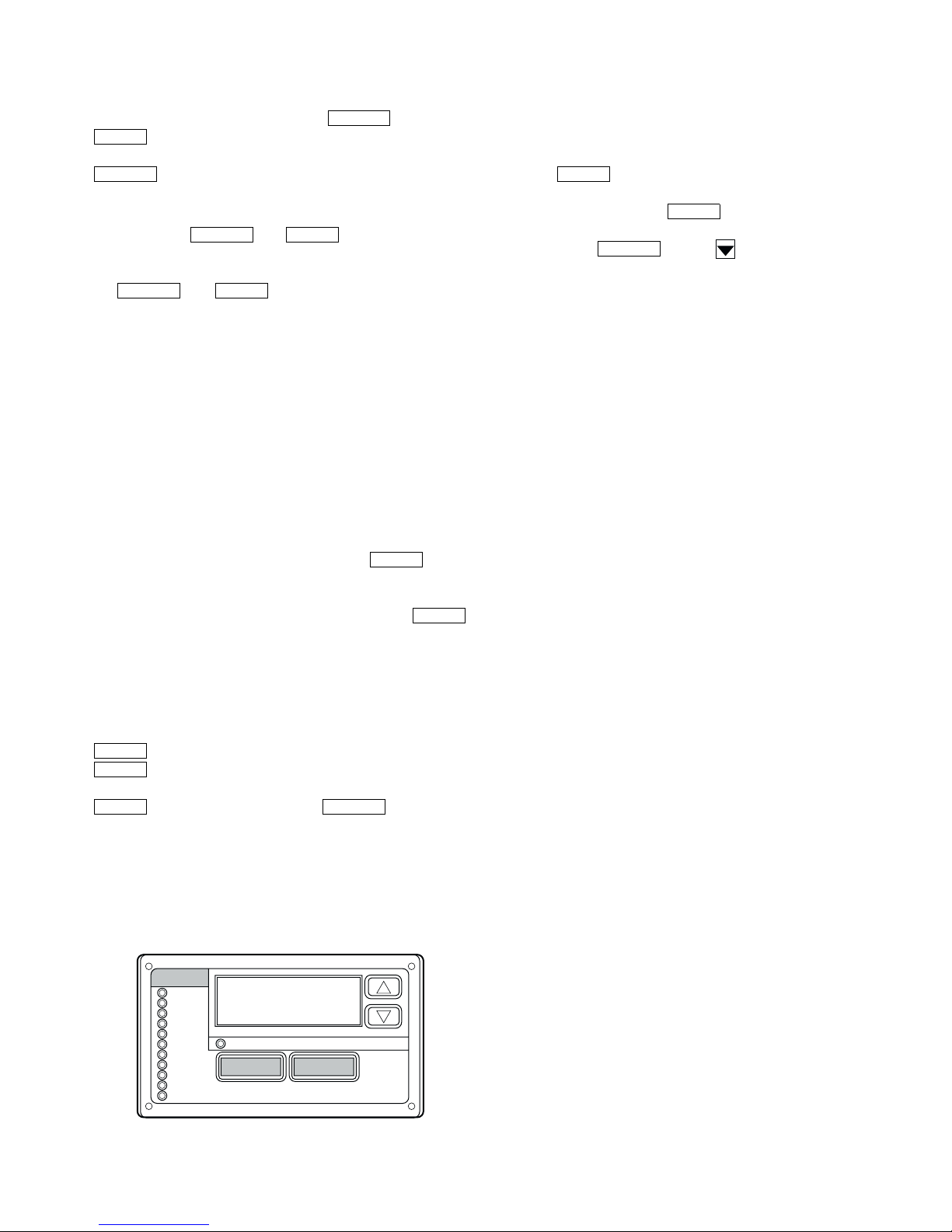

Scrolling Marquee Display —

This device is the keypad interface used for accessing chiller information, reading

sensor values, and testing the chiller. The marquee display is a

4-key, 4-character, 16-segment LED (light-emitting diode) display. Eleven mode LEDs are located on the display as well as

an Alarm Status LED. See Marquee Disp lay Us age section on

page 29 for further details.

Energy Management Module (EMM) —

The

EMM module is available as a factory-installed option or as a

field-installed accessory. The EMM module receives 4 to

20 mA inputs for the temperature reset, cooling set point reset

and demand limit functions. The EMM module also receives

the switch inputs for the field-installed 2-stage demand limit

and ice done functions. The EMM module communicates the

status of all inputs with the MBB, and the MBB adjusts the

control point, capacity limit, and other functions according to

the inputs received.

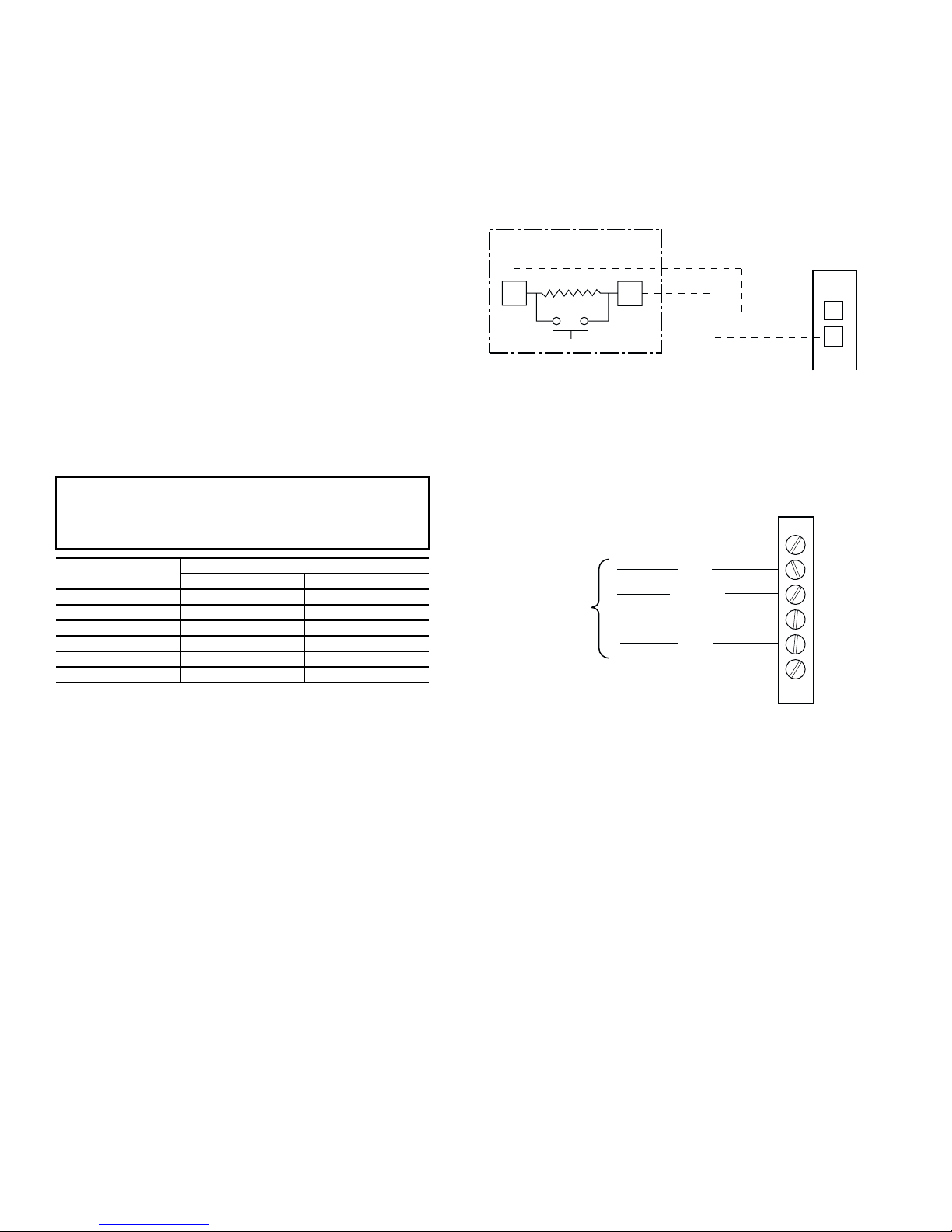

Enable/Off/Remote Contact Switch —

The

Enable/Off/Remote Contact switch is a 3-position switch used

to control t h e c h il le r. When switched to th e E na b le position the

chiller is under its own control. Move the switch to the Off position to shut the chiller down. Move the switch to the Remote

Contact position and a field installed dry contact can be used to

start the chiller. The contacts must be rated for dry circuit application capable of handling a 24 vac load. In the Enable and Remote Contact (dr y contacts clo sed) position s, the chiller is allowed to operate and respond to the scheduling configuration,

CCN configuration and set point data. See Fig. 6.

Emergency On/Off Switch —

The Emergency On/

Off switch should only be used when it is required to shut the

chiller off immediately. Power to the MBB, EMM, CXB, and

marquee display is interrupted when this switch is off and all

outputs from these modules will be turned off. The EXV board

is powered separately, but expansion valves will be closed as a

result of the loss of communication with the MBB. There is no

pumpout cycle when this switch is used. See Fig. 6.

Reset Button —

A reset button is located on the fuse/

circuit breaker panel for unit sizes 130-210 and associated

modules. The reset button must be pressed to reset either

Circuit Ground Fault board in the event of a trip.

Board Addresses —

The Main Base Board (MBB) has

a 3-position Instance jumper that must be set to ‘1.’ All other

boards have 4-position DIP switches. All switches are set to

‘On’ for all boards.

3

Control Module Communication

RED LED — Proper operation of the control boards can be

visually checked by looking at the red status LEDs (lightemitting diodes). When operating correctly, the red status

LEDs should be blinking in unison at a rate of once every

2 seconds. If the red LEDs are not blinking in unison, verify

that correct power is being supplied to all modules. Be sure that

the Main Base Board (MBB) is supplied with the current software. If necessary, reload current software. If the problem still

persists, replace the MBB. A red LED that is lit continuously or

blinking at a rate of once per second or faster indicates that the

board should be replaced.

GREE N LED — The MBB has one green LED. The Local

Equipment Network (LEN) LED should always be blinking

whenever power is on. All other boards have a LEN LED

which should be blinking whenever power is on. Check LEN

connections for potential communication errors at the board J3

and/or J4 connectors. Communication between modules is accomplished by a 3-wire sensor bus. These 3 wires run in parallel from module to module. The J4 connector on the MBB provides both power and communication directly to the marquee

display only .

YELLOW LED — The MBB has one yellow LED. The

Carrier Comfort Network (CCN) LED will blink during times

of network communication.

Carrier Comfort Network (CCN) Interface —

The 30GTN,R chiller units can be connected to the CCN if

desired. The communication bus wiring is a shielded,

3-conductor cable with drain wire and is supplied and installed

in the field. The system elements are connected to the communication bus in a daisy chain arrangement. The positive pin of

each system element communication connector must be wired

to the positive pins of the system elements on either side of it.

This is also required for the negative and signal ground pins of

each system element. Wiring connections for CCN should be

made at TB3. Consult the CCN Contractor ’s Manual for further information.

NOTE: Conductors and drain wire must be 20 AWG (American Wire Gage) minimum stranded, tinned copper. Individual

conductors must be insulated with PVC, PVC/nylon, vinyl,

Teflon, or polyethylene. An aluminum/polyester 100% foil

shield and an outer jacket of PVC, PVC/nylon, chrome vinyl,

or Teflon with a minimum operating temperature range of

–20 C to 60 C is required. Wire manufactured by Alpha (2413

or 5463), American (A22503), Belden (8772), or Columbia

(02525) meets the above mentioned requirements.

It is important when connecting to a CCN communication

bus that a color coding scheme be used for the entire network

to simplify the installation. It is recommended that red be used

for the signal positive, black for the signal negative, and white

for the signal ground. Use a similar scheme for cables containing different colored wires.

At each system element, the shields of its communic ation

bus cables must be tied together. If the communication bus is

entirely within one building, the resulting continuous shield

must be connected to a ground at one point only. If the communication bus cable exits from one building and enters another,

the shields must be connected to grounds at the lightning suppressor in each building where the cable enters or exits the

building (one point per building only). To connect the unit to

the network:

1. Turn off power to the control box.

2. Cut the CCN wire and strip the ends of the red (+), white

(ground), and black (–) conductors. (Substitute appropriate colors for different colored cables.)

3. Connect the red wire to (+) terminal on TB3 of the plug,

the white wire to COM terminal, and the black wire to the

(–) terminal.

4. The RJ14 CCN connector on TB3 can also be used, but is

only intended for temporary connection (for example, a

laptop computer running Service Tool).

IMPORTANT: A shorted CCN bus cable will prevent

some routines from running and may prevent the unit

from starting. If abnormal conditions occur, unplug the

connector. If conditions return to normal, check the

CCN connector and cable. Run new cable if necessary.

A short in one section of the bus can cause probl ems

with all sys tem elem en ts on th e bu s.

Table 2 — Thermistor Designations

THERMISTOR

NO.

T1 J8-13,14 (MBB) Cooler Leaving Fluid

T2 J8-11,12 (MBB) Cooler Entering Fluid

T3

T4

T5

T6

T7

T8

T9

T10

EXV — Electronic Expansion Valve

MBB — Main Base Board

LEGEND

PIN

CONNECTION

POINT

J8-21,22 (MBB) Saturated Condensing

J8-15,16 (MBB) Saturated Condensing

J8-24,25 (MBB) Cooler Suction Temperature,

J8-18,19 (MBB) Cooler Suction Temperature,

J5-11,12 (EXV) Compressor Suction Gas

J5-9,10 (EXV) Compressor Suction Gas

J8-7,8 (MBB) Outdoor-Air Temperature

J8-5,6 (MBB) Remote Space Temperature

THERMISTOR INPUT

Te m p e ra tu r e, C kt A

Te m p e ra tu r e, C kt B

Ckt A (EXV Only)

Ckt B (EXV Only)

Temperature, Ckt A (EXV Only)

Temperature, Ckt B (EXV Only)

Sensor or Dual Chiller LWT

Sensors (Accessory)

Sensor (Accessory)

4

STATUS SWITCH

Oil Pressure, Ckt B

Oil Pressure, Ckt A

Remote On/Off

Compressor Fault

Signal, B3

Compressor Fault

Signal, B2

Compressor Fault

Signal, B1

Compressor Fault

Signal, A4

Compressor Fault

Signal, A3

Compressor Fault

Signal, A2

Compressor Fault

Signal, A1

CPCS —

CR —

CXB —

MBB —

OPS —

Compressor Protection Control System

Control Relay

Compressor Expansion Board

Main Base Board

Oil Pressure Switch, Circuit A or B

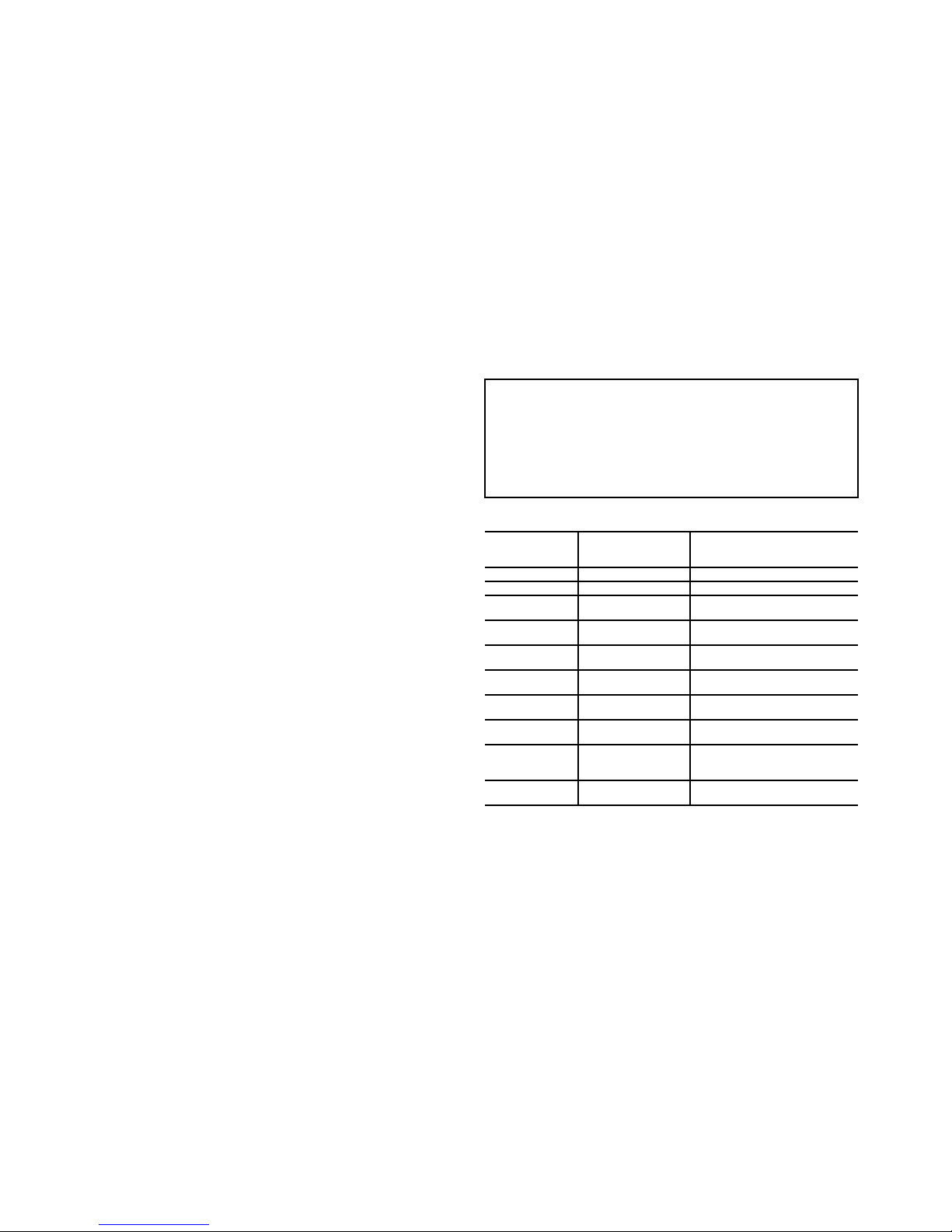

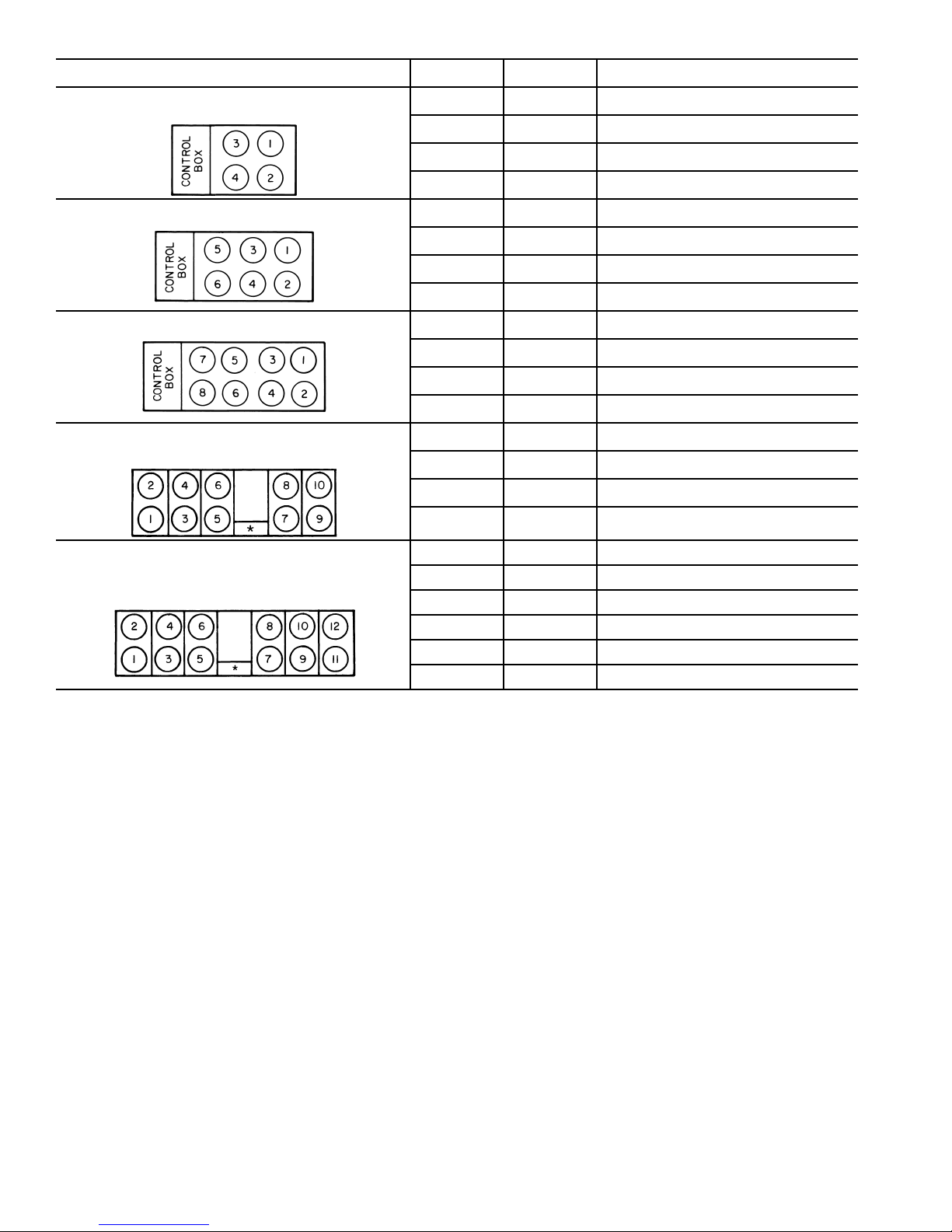

Table 3 — Status Switches

PIN

CONNECTION

POINT

J7-1, 2 (MBB) Not Used* OPSB OPSB OPSB OPSB OPSB OPSB

J7-3, 4 (MBB) Not Used* OPSA OPSA OPSA OPSA OPSA OPSA

TB5-13, 14 Field-Installed Relay Closure

J5-8, 12 (CXB) Not Used Not Used Not Used Not Used Not Used CR-B3 CR-B3

J9-2, 12 (MBB) Not Used Not Used CPCS-B2 CR-B2 CR-B2 CR-B2 CR-B2

J9-8, 12 (MBB) CR/CPCS-B1† CPCS-B1 CPCS-B1 CR-B1 CR-B1 CR-B1 CR-B1

J5-5, 12 (CXB) Not Used Not Used Not Used Not Used Not Used Not Used CR-A4

J5-11, 12 (CXB) Not Used Not Used Not Used Not Used CR-A3 CR-A3 CR-A3

J9-5, 12 (MBB) Not Used CPCS-A2 CPCS-A2 CR-A2 CR-A2 CR-A2 CR-A2

J9-11, 12 (MBB) CR/CPCS-A1† CPCS-A1 CPCS-A1 CR-A1 CR-A1 CR-A1 CR-A1

LEGEND *The OPS can also be added as an accessory.

040-060 (50 Hz)

040-070 (60 Hz)

070

(50 Hz)

080, 230B

090-110,

245B-315B

†The CPCS can be added as an accessory.

130

(60 Hz)

130 (50 Hz)

150, 230A-

255A

170,190,

270A,290A,

330A/B,

360A/B, 390B

210, 315A,

390A,

420A/B

Table 4 — Output Relay

RELAY

NO.

K1(MBB)

K2 (MBB)

K3 (MBB)

K4 (MBB)

K5 (MBB)

K6 (MBB)

K7 (MBB)

K8 (MBB)

K9 (MBB)

K10 (MBB)

K11 (MBB)

K1 (CXB)

K2 (CXB)

K3 (CXB)

K4 (CXB)

K5 (CXB)

K6 (CXB)

OFM —

*And associated modular units.

†Field-installed accessory unloader.

Energize Compressor A1 and OFM1 (040-110*)

Energize Liquid Line Solenoid Valve for Ckt A (if used)

(040-110*)

Energize Compressor A1, OFM5, and OFM7 (130-210*)

Energize Compressor B1 and OFM2 (040-110*)

Energize Liquid Line Solenoid Valve for Ckt B (if used)

(040-110*)

Energize Compressor B1, OFM6, and OFM8 (130-210*)

Energize Unloader A1 (040-170*)

No Action (190-210*)

Energize Unloader B1 (040-070†, 080-170*)

No Action (190,210*)

No Action (040-060, 50 Hz; 040-070, 60 Hz)

Energize Compressor A2 (070, 50 Hz; 080-210*)

No Action (040-080*)

Energize Compressor B2 (090-210*)

Alarm

Cooler Pump

Energize First Stage of Condenser Fans:

040-050 —OFM3

060-110* — OFM3, OFM4

130 (60 Hz) — OFM1,OFM2

Energize First Stage of Ckt A Condenser Fans:

130 (50 Hz), 150,170* — OFM1

190,210* —OFM1,OFM11

Energize Second Stage of Condenser Fans:

040-050 — OFM4

060-090* — OFM5, OFM6

100,110* — OFM5,OFM6,OFM7,OFM8

130 (60 Hz) — OFM3,OFM4,OFM9,OFM10

Energize First Stage of Ckt B Condenser Fans:

130 (50 Hz), 150,170* — OFM2

190,210* — OFM2,OFM12

Hot Gas Bypass

No Action (040-110*; 130, 60 Hz)

Energize Compressor A3 (130, 50 Hz; 150-210*)

No Action (040-150*)

Energize Compressor B3 (170-210*)

Energize Compressor A4 (210*)

Energize Accessory Unloader A2 (080-110*)

Energize Accessory Unloader B2 (080-110*)

Energize Second Stage of Ckt A Condenser Fans:

130 (50 Hz), 150-210* — OFM3,OFM9

Energize Second Stage of Ckt B Condenser Fans:

130 (50 Hz), 150-210* — OFM4,OFM10

LEGEND

Outdoor-Fan Motor

DESCRIPTION

LEGEND FOR FIG. 1-4

C—

CB —

CCN —

CGF —

CHT —

CKT —

CLHR —

CPCS —

CWFS —

CWPI —

CR —

CXB —

EQUIP GND —

FB —

FC —

FCB —

FIOP —

EMM —

EXV —

FCB —

HPS —

LCS —

LEN —

MBB —

NEC —

OAT —

OPS —

PL —

PW —

SN —

SPT —

TRAN —

SW —

TB —

TDR —

TXV —

UL —

XL —

Compressor Contactor

Circuit Breaker

Carrier Comfort Network

Compressor Ground Fault

Cooler Heater Thermostat

Circuit

Cooler Heater Relay

Compressor Protection and Control System

Chilled Water Flow Switch

Chilled Water Pump Interlock

Control Relay

Compressor Expansion Board

Equipment Ground

Fuse Block

Fan Contactor

Fan Circuit Breaker

Factory-Installed Option Package

Energy Management Module

Electronic Expansion Valve

Fan Circuit Breaker

High-Pressure Switch

Loss-of-Charge Switch

Local Equipment Network

Main Base Board

National Electrical Code

Outdoor-Air Temperature

Oil Pressure Switch

Plug

Par t Wind

Sensor (Toroid)

Space Temperature

Transformer

Switch

Terminal Block

Time Delay Relay

Thermostatic Expansion Valve

Unloader

Across-the-Line

5

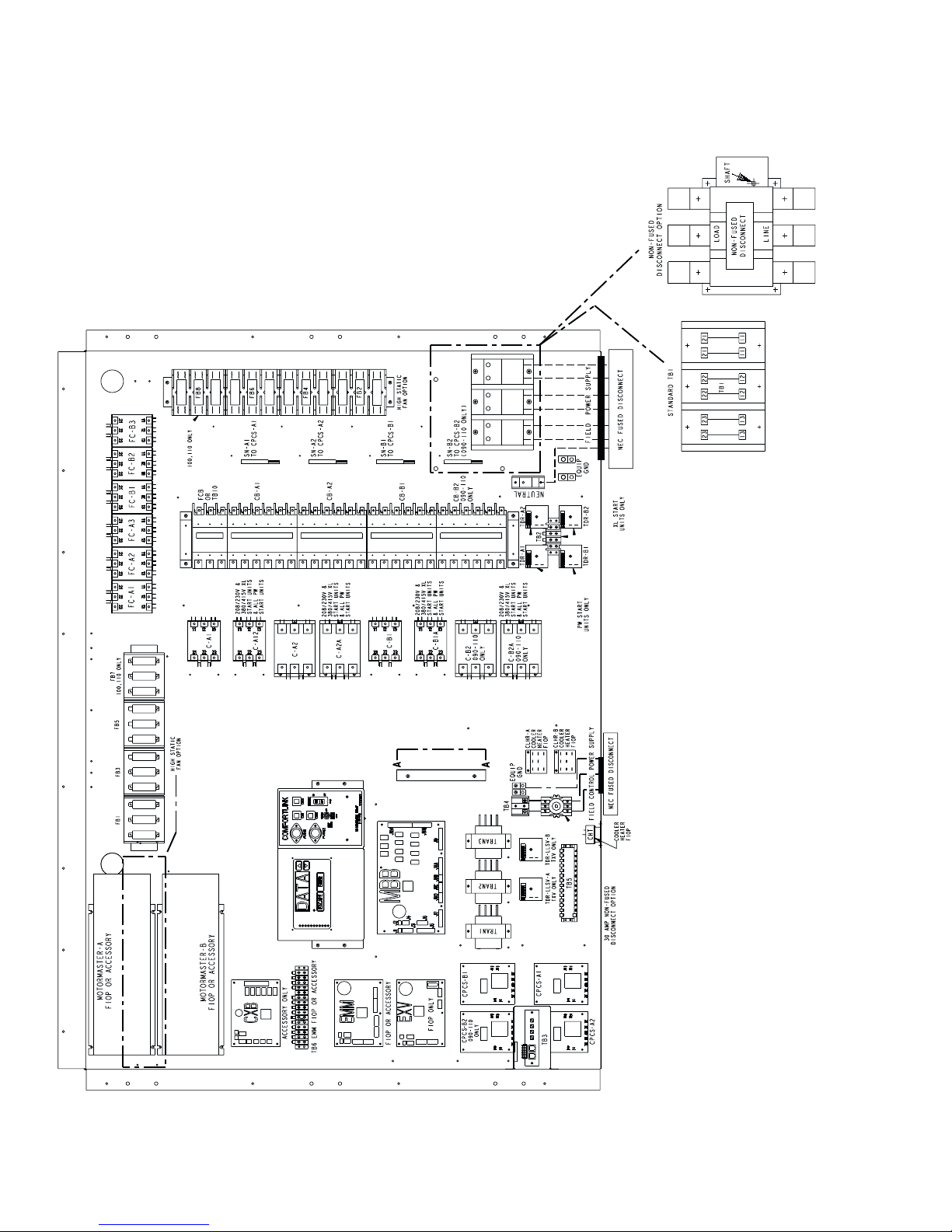

Fig. 1 — Typical Control Box (080-110 and Associated Modular Units Shown)

6

CCN

LEN

DATA

COMMUNICATION

PORT

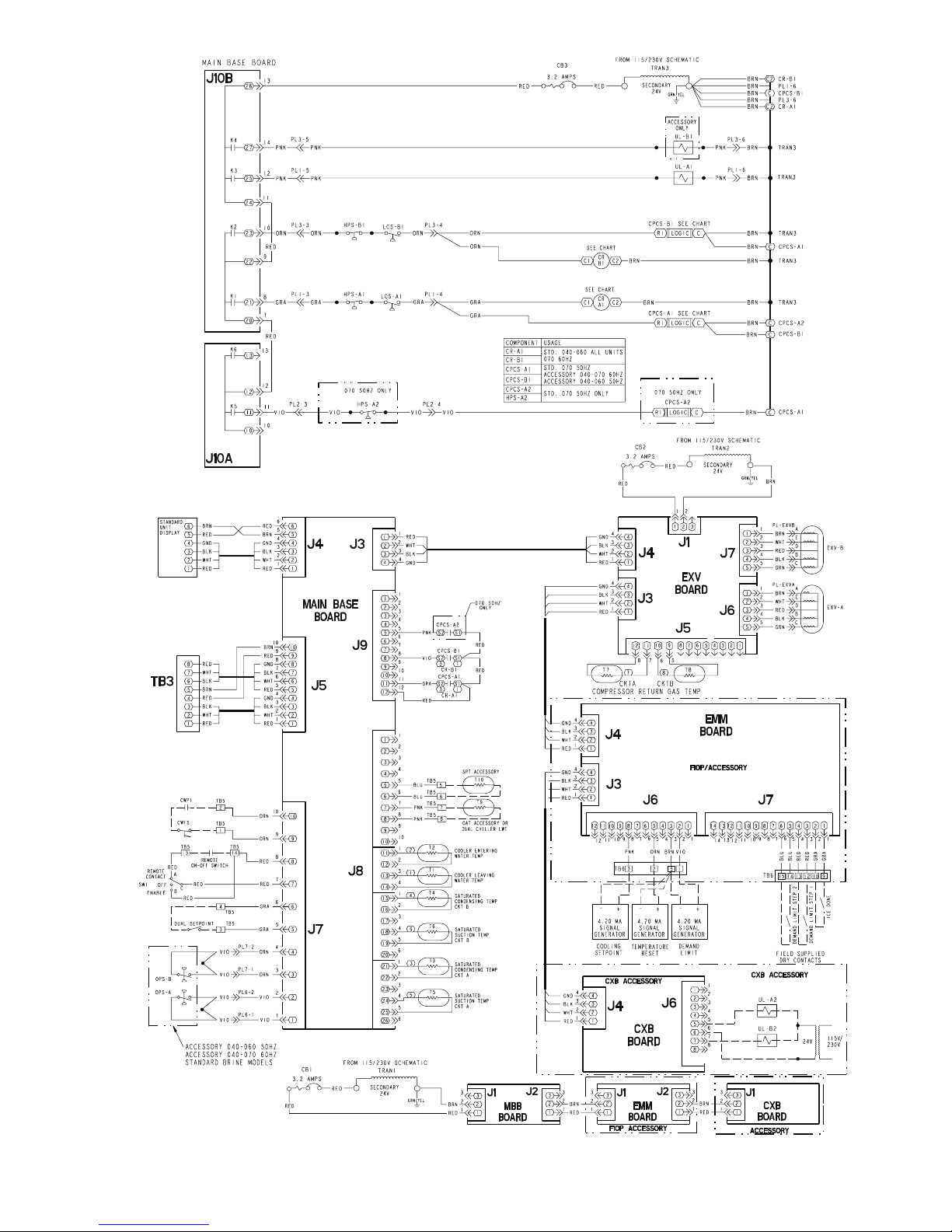

Fig. 2 — 24 V Control Schematic, Unit Sizes 040-070

7

CCN

LEN

DATA

COMMUNICATION

PORT

/

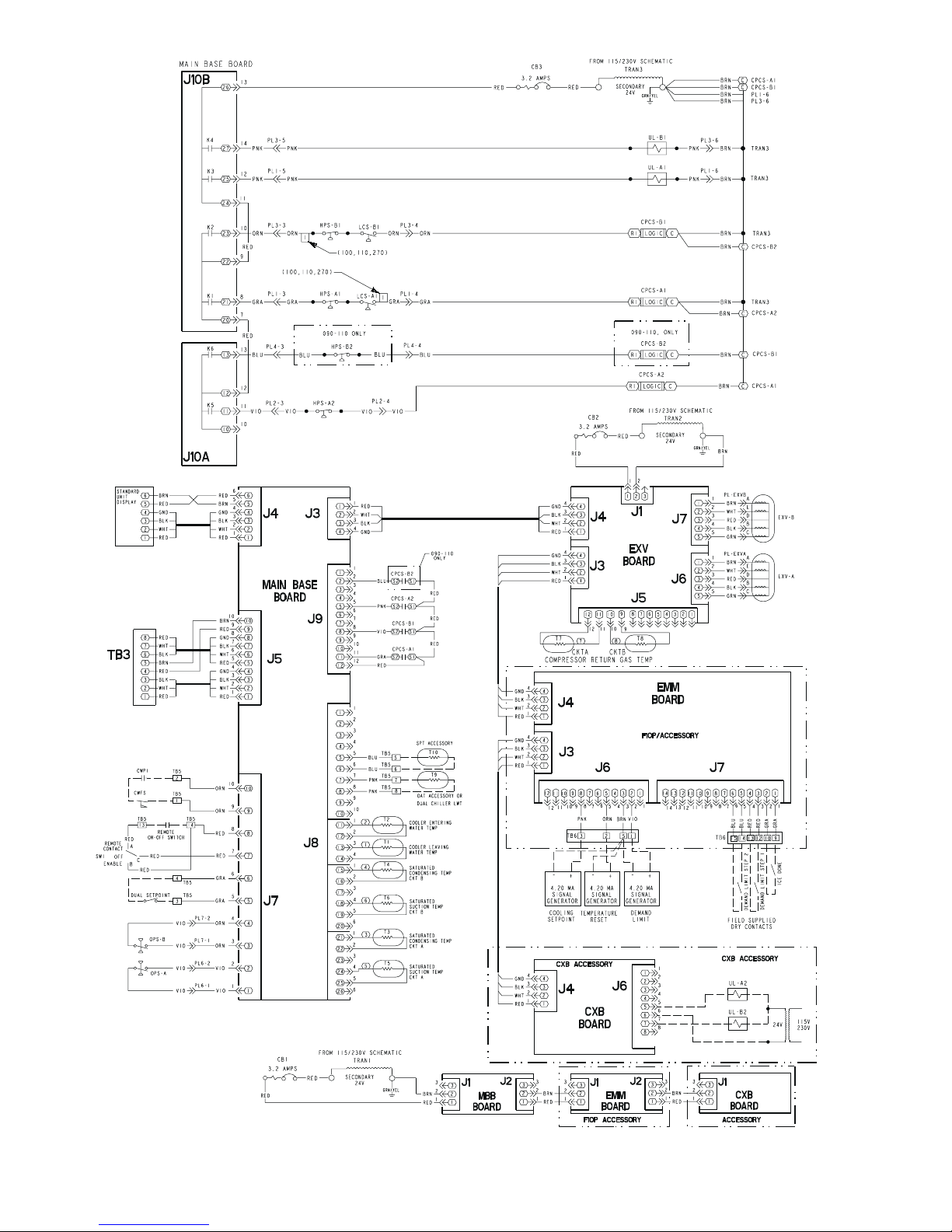

Fig. 3 — 24 V Control Schematic, Unit Sizes 080-110, 230B-315B

Fig. 3 — 24 V Control Schematic, Unit Sizes 080-110, 230B-315B

8

CCN

LEN

DATA

COMMUNICATION

PORT

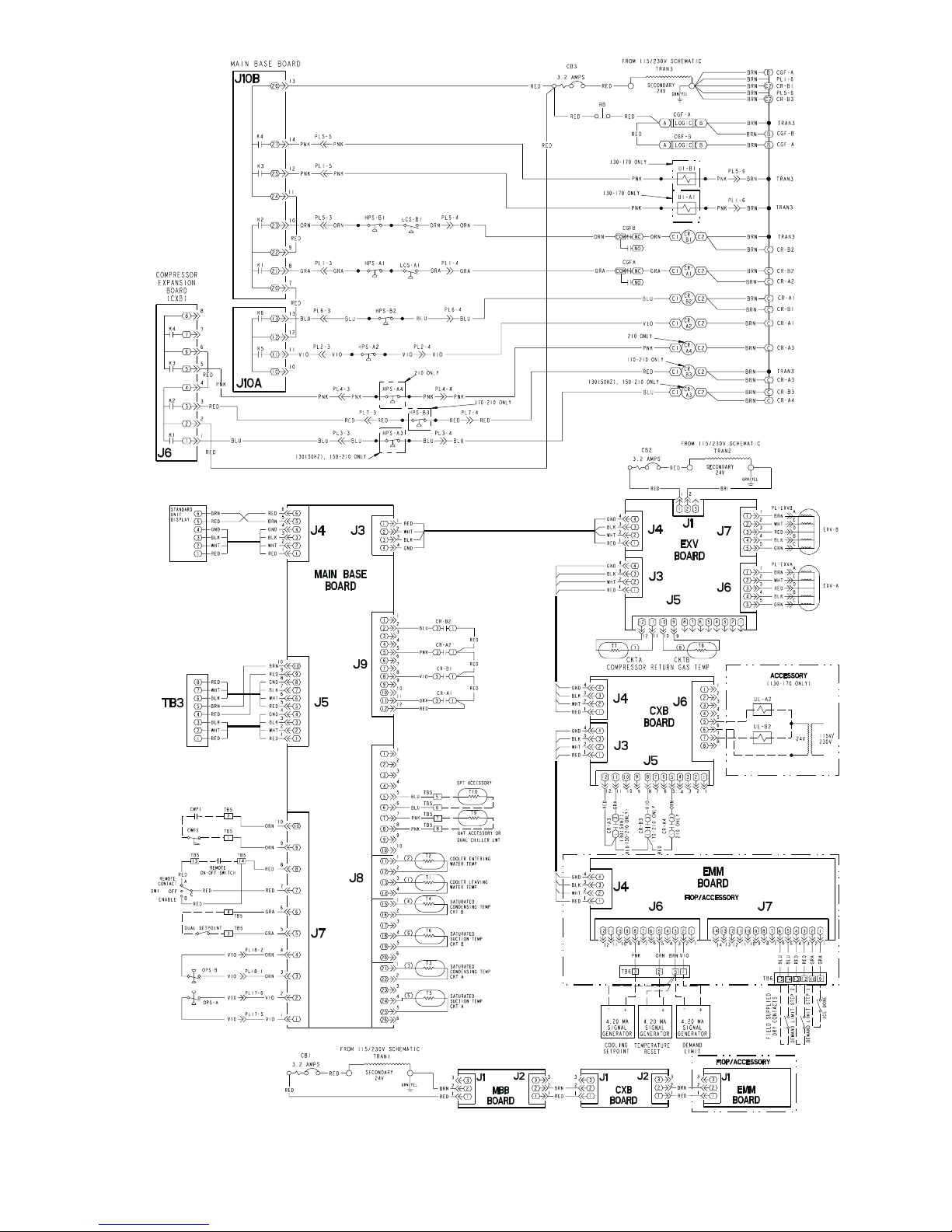

Fig. 4 — 24 V Control Schematic, Unit Sizes 130-210, 230A-315A, 330A/B-420A/B

9

RED LED - STATUS GREEN LED -

LEN (LOCAL EQUIPMENT NETWORK)

CEPL130346-01

YELLOW LED CCN (CARRIER COMFORT NETWORK)

INSTANCE JUMPER

J1

J4

J6

J5

J2

J3

J7

LEN

CCN

STATUS

J8

Fig. 5 — Main Base Board

J10

J9

Fig. 6 — Enable/Off/Remote Contact Switch, Emergency On/Off Switch,

RESET BUTTON

(SIZES 130-210 AND

ASSOCIATED MODULES ONLY)

and Reset Button Locations

10

EMERGENCY ON/OFF

SWITCH

ENABLE/OFF/REMOTE

CONTACT SWITCH

GFI-CONVENIENCE

OUTLET ACCESSORY

ON 208/230V 460 AND

575V ONLY

OPERATING DATA

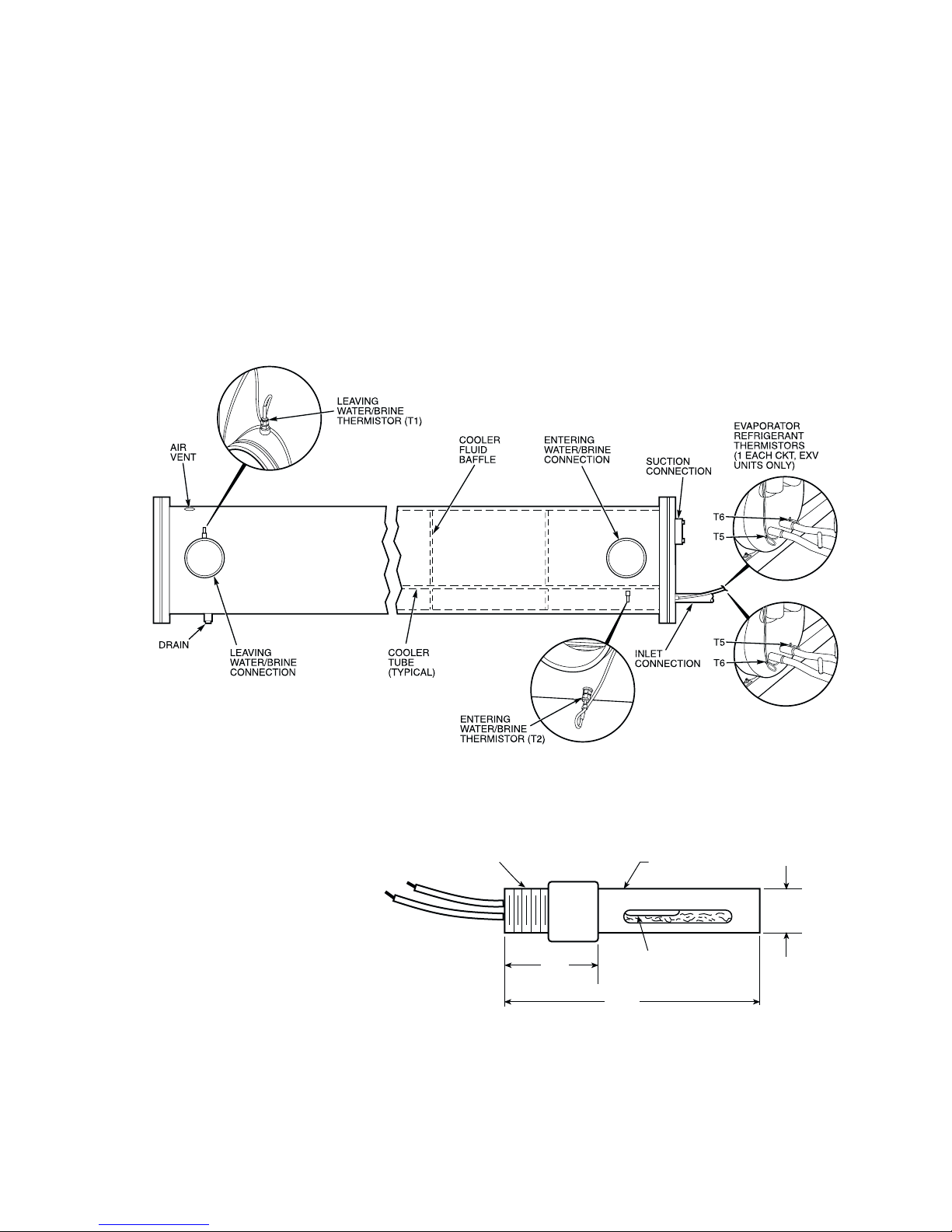

Sensors —

to sense temperatures for controlling chiller operation. See

Table 2. These sensors are outlined below. See Fig. 7-10 for

thermistor locations. Thermistors T1-T9 are 5 kΩ at 77 F

(25 C). Thermistors T1, T2, T3-T6 and T7-T 9 have different

temperature versus resistance and voltage drop performance.

Thermistor T10 is 10 kΩ at 77 F (25 C) and has a different temperature vs resistance and voltage drop performance. See Thermistors section on page 59 for temperature-resistance-voltage

drop characteristics.

T1 — COOLER LEAVING FLUID SENSOR — This thermistor is located in the leaving fluid nozzle. The thermistor

probe is inserted into a friction-fit well.

T2 — COOLER ENTERING FLUID SENSOR — This

thermistor is located in the cool er shel l in th e first ba ffle spac e

in close proximity to the cooler tube bundle.

The electronic control uses 4 to 10 thermistors

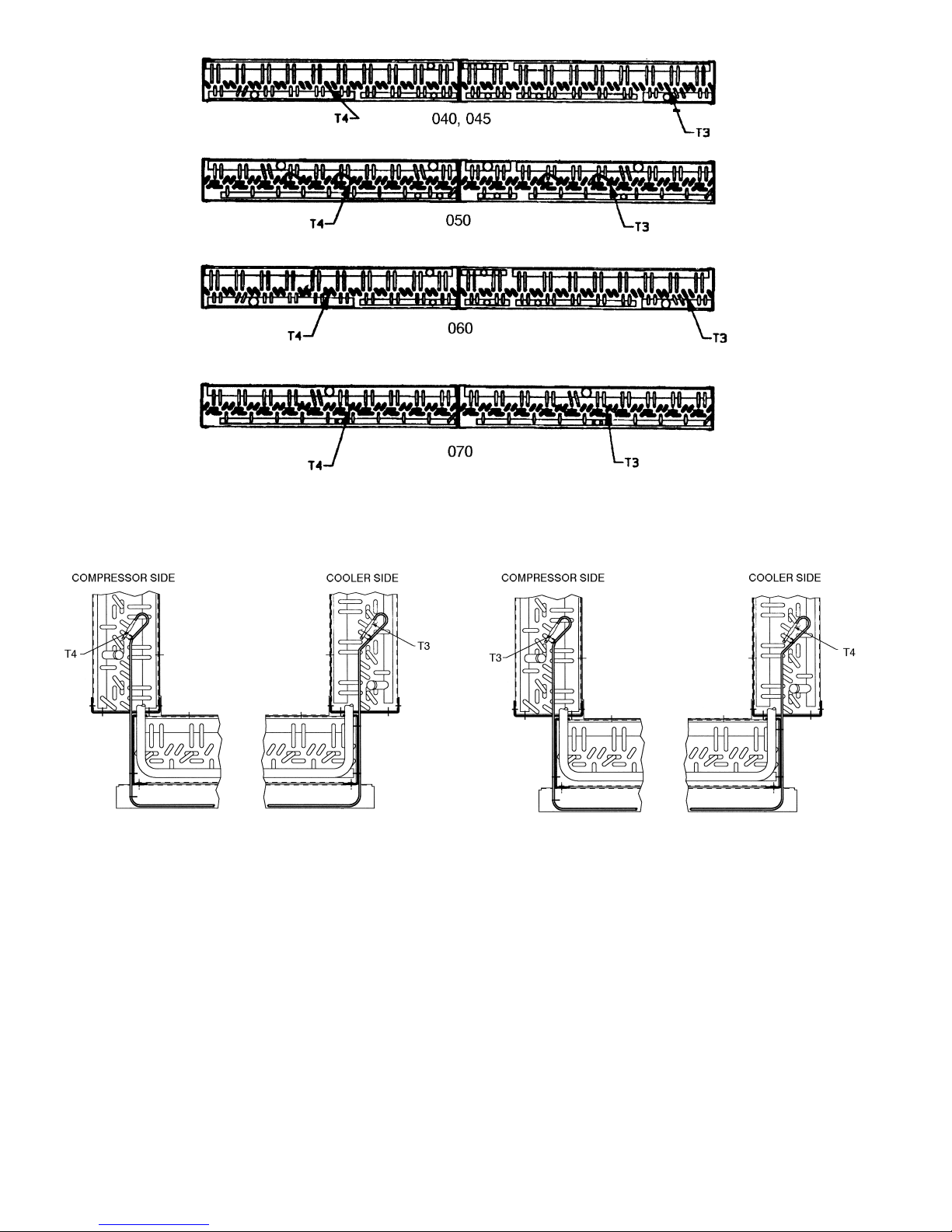

T3, T4 — SATURATED CONDENSING TEMPERATURE

SENS O RS — These 2 thermistors are clamped to the outside

of a return bend of the condenser coils.

T5, T6 — COOLER SUCTION TEMPERATURE SENSORS — These thermistors are located next to the refrigerant

inlet in the cooler head, and are insert ed into a friction-fit well.

The sensor well is located directly in the refrigerant path. These

thermistors are not used on units with TXVs.

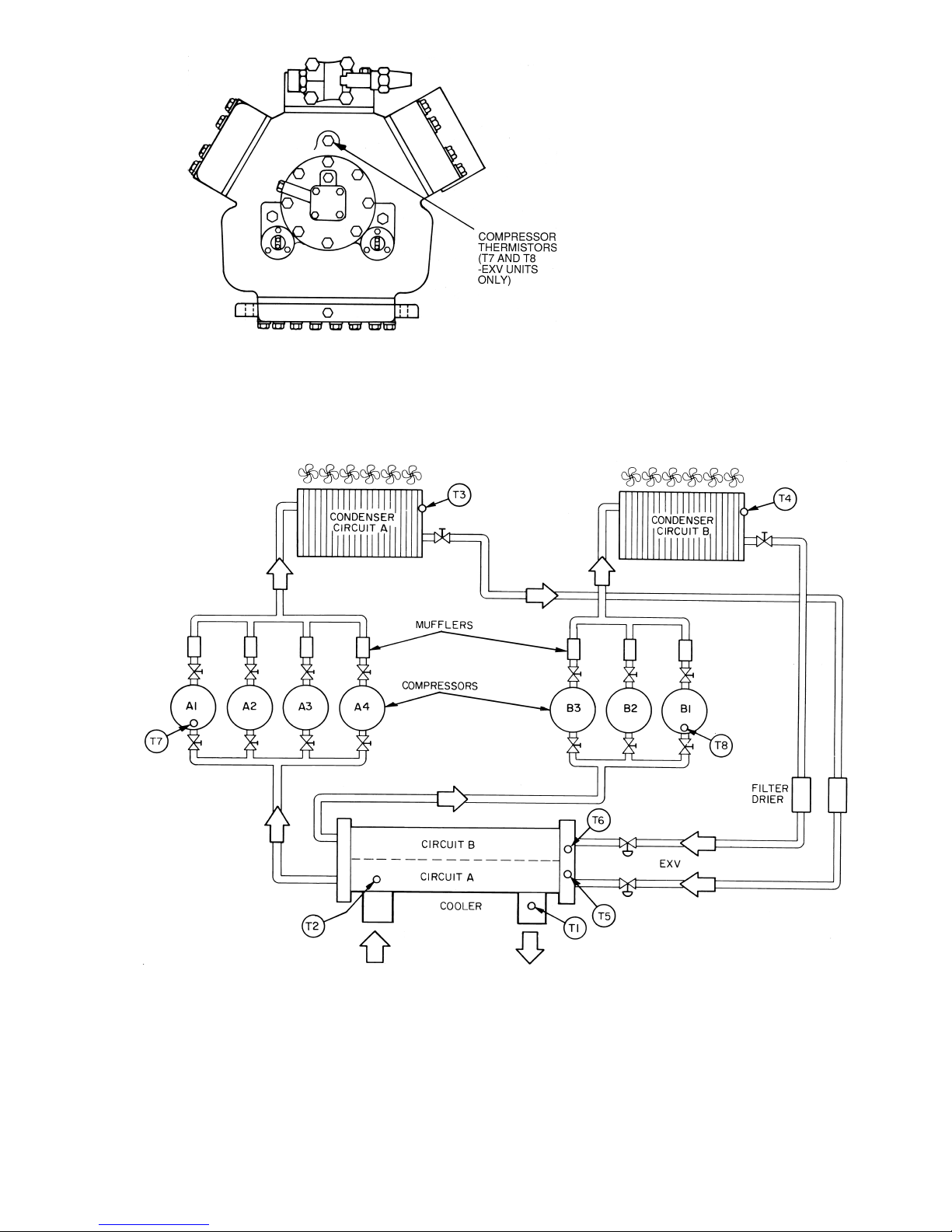

T7, T8 — COMPRESSOR SUCTION GAS TEMPERATURE SENSORS — These thermistors are located in the lead

compressor in each circuit in a suction passage aft er the refrigerant has passed over the motor and is about to enter the cylinders. These thermistors are ins erted into frict ion-fit wells. T he

sensor wells are located directly in the refrigerant path. These

thermistors are not used on units with TXVs.

T9 — OUTDOOR-AIR TEMPERATURE SENSOR —

Sensor T9 is an accessory sensor that is remotely mounted and

used for outdoor-air temperature reset.

MIN. 6” OF 22 AWG WIRES

WITH ENDS STRIPPED BACK

.25” ±1/8”

1/2 NPT MALE

THREADED ADAPTER

REF.

1.81

(46.0)

1/2” PVC SHIELD

3/16” DIA.

THERMOWELL (S.S.)

REF.

5.75

(146.1

040-110*

130-210*

REF.

.83 D

(21.1)

LEGEND

AWG —

EXV —

*And associated modular units.

American Wire Gage

Electronic Wire Gage

Fig. 7 — Cooler Thermistor Locations and Accessory Outdoor-Air Temperature Sensor Detail

11

040-070

080-110 AND ASSOCIATED MODULAR UNITS* 130-210 AND ASSOCIATED MODULAR UNITS*

*When thermistor is viewed from perspective where the compressor is on the left and the cooler is on the right.

Fig. 8 — Thermistor T3 and T4 Locations

12

Electronic Expansion Valve

EXV —

Fig. 9 — Compressor Thermistor Locations (T7 and T8)

LEGEND

Fig. 10 — Typical Thermistor Location (30GTN,R and 30GUN,R 210, 315A, 390A, 420A/B Shown)

13

T10 — REMOTE SPACE TEMPERA TURE SENSOR —

Fig. 11 — Typical Space Temperature

Sensor Wiring

Fig. 12 — CCN Communications Bus Wiring

to Optional Space Sensor RJ11 Connector

Sensor T10 (part no. HH51BX006) is an accessory sensor that

is remotely mounted in the controlled space and used for space

temperature reset. The sensor should be installed as a

wall-mounted thermostat would be (in the conditioned space

where it will not be subjected to either a cooling or heating

source or direct exposure to sunlight, and 4 to 5 ft above the

floor). The push button override button is not supported by the

ComfortLink™ Controls.

Space temperature sensor wires are t o be connected to terminals in the unit main control box. The space temperature

sensor includes a terminal block (SEN) and a RJ11 female connector. The RJ1 1 connector is used to tap into the Carrier Comfort Network (CCN) at the sensor.

T o connect the space temperature sensor (Fig. 11):

1. Using a 20 AWG (American Wire Gage) twisted pair

conductor cable rated for the application, connect 1

wire of the twisted pair to one SEN terminal and connect the other wire to the other SEN terminal located

under the cover of the space temperature sensor.

2. Connect the other ends of the wires to terminals 5 a nd 6

on TB5 located in the unit control box.

Units on the CCN can be monitored from the space at the

sensor through the RJ11 connector, if desired. To wire the RJ11

connector into the CCN (Fig. 12):

2. Insert and secure the red (+) wire to terminal 5 of the

space temperature sensor terminal block.

3. Insert and secure the white (ground) wire to terminal 4 of

the space temperature sensor.

4. Insert and secure the black (–) wire to terminal 2 of the

space temperature sensor.

5. Connect the other end of the communication bus cable to

the remainder of the CCN communication bus.

SPT (T10) PART NO. HH51BX006

SENSOR

SEN

SEN

TB5

5

6

IMPORTANT: The cable selected for the RJ11 connector wiring MUST be identical to the CCN communication bus wire used for the entire network. Refer to table

below for acceptable wiring.

MANUFACTURER

Alpha

American

Belden

Columbia

Manhattan

Quabik

Regular Wiring Plenum Wiring

1895 —

A21451 A48301

8205 884421

D6451 —

M13402 M64430

6130 —

PART NO.

1. Cut the CCN wire and strip ends of the red (+), white

(ground), and black (–) conductors. (If another wire

color scheme is used, strip ends of appropriate wires.)

TO CCN

TERMINALS

ON TB3

AT UNIT

CCN+

CCN GND

CCN-

T-55 SPACE

SENSOR

6

5

4

3

2

1

14

Thermostatic Expansion Valves (TXV) —

Fig. 13 — Compressor Protection Control

System Module — Sizes 040-110

Fig. 14 — Compressor Ground Fault Module

— Sizes 130-210

30GTN,R and 30GUN,R 040-110 units are available from the

factory with conventional TXVs with liquid line solenoids. The

liquid line solenoid valves are not intended to be a mechanical

shut-off. When service is required, use the liquid line service

valve to pump down the system.

NOTE: This option is not available for modular units.

The TXV is set at the factory to maintain approximately 8 to

12° F (4.4 to 6.7° C) suction superheat leaving the cooler by

metering the proper amount of refrigerant into the cooler. All

TXVs are adjustable, but should not be adjusted unless abso-

lutely necessary. When TXV is used, thermistors T5, T 6, T7,

and T8 are not required.

The TXV is designed to limit the cooler saturated suctio n

temperature to 55 F (12.8 C). This makes it possible for unit to

start at high cooler fluid temperatures without overloading the

compressor.

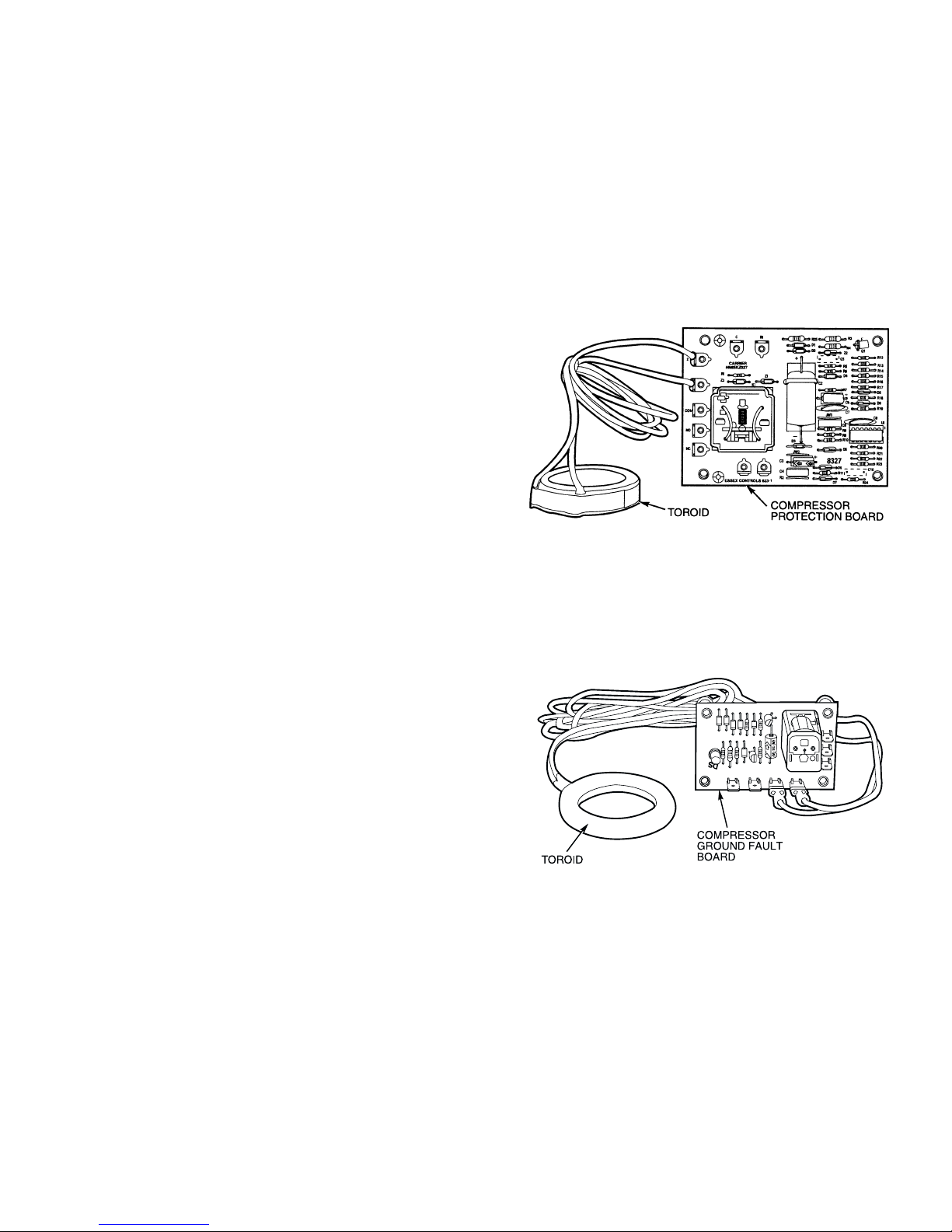

Compressor Protection Control System (CPCS

[CPCS — Standard on Sizes 080-110 and

Optional on Sizes 040-070]) or Control Relay

(CR) — 30GTN,R and 30GUN,R 040-110 —

compressor has its own CPCS module or CR. See Fig. 13 for

CPCS module. The CPCS or CR is used to control and protect

the compressors and crankcase heaters. The CPCS and CR provide the following functions:

• compressor contactor control/crankcase heater

• crankcase heater control

• compressor ground current protection (CPCS only)

• status communication to processo r board

• high-pressure protection

One large relay is located on the CPCS board. This relay

controls the crankcase heater and compressor contactor, and

also provides a set of signal contacts that the microprocessor

monitors to determine the operating status of the compressor. If

the processor board determines that the compressor is not operating properly through the signal contacts, it will lock the compressor off by deenergizing the proper 24-v control relay on the

relay board. The CPCS board contains logic that can detect if

the current-to-ground of any compressor winding exceeds

2.5 amps. If this condition occurs, the CPCS shuts down the

compressor.

A high-pressure switch is wired in series between the MBB

and the CR or CPCS. On compressor A1 and B1 a loss-ofcharge switch is also wired in series with the high-pressure

switch. If the high-pressure switch opens during operation of a

compressor, the compressor will be stopped, the failure will be

detected through the signal contacts, and the compressor will

be locked off. If the le ad compressor in eithe r circuit is shut

down by the high-pressure switch, loss-of-charge switch,

ground current protector, or oil safety switch, all compressors

in that circuit are shut down.

NOTE: The CR operates the same as the CPCS, except the

ground current circuit protection is not provided.

Compressor Ground Current Protection

Board (CGF) and Control Relay (CR) —

30GTN,R and 30GUN,R 130-210, and associated modular

units (see T a ble 1) contain one compressor ground current protection board (CGF) (see Fig. 14) for each refrigeration circuit.

The CGF contains logic that can detect if the current-to-ground

Model

Each

The

of any compressor winding exceeds 2.5 amps. If this occurs,

the lead compressor in that circuit is shut down along with other compressors in that circuit.

A high-pressure switch is wired in series between the MBB

and the CR. On compressor A1 and B1 a loss-of-charge switch

is also wired in series with the high-pressure swit ch. The lead

compressor in each circuit also has the CGF contacts described

above. If any of these switches open during operation of a compressor, the CR relay is deenergized, stopping the compressor

and signaling the processor at the MBB-J9 inputs to lock out

the compressor. If the lead compressor in either circuit is shut

down by high-pressure switch, compressor ground fault, oil

pressure switch, or the loss-of-charge switch, all compressors

in that circuit are also shut down.

15

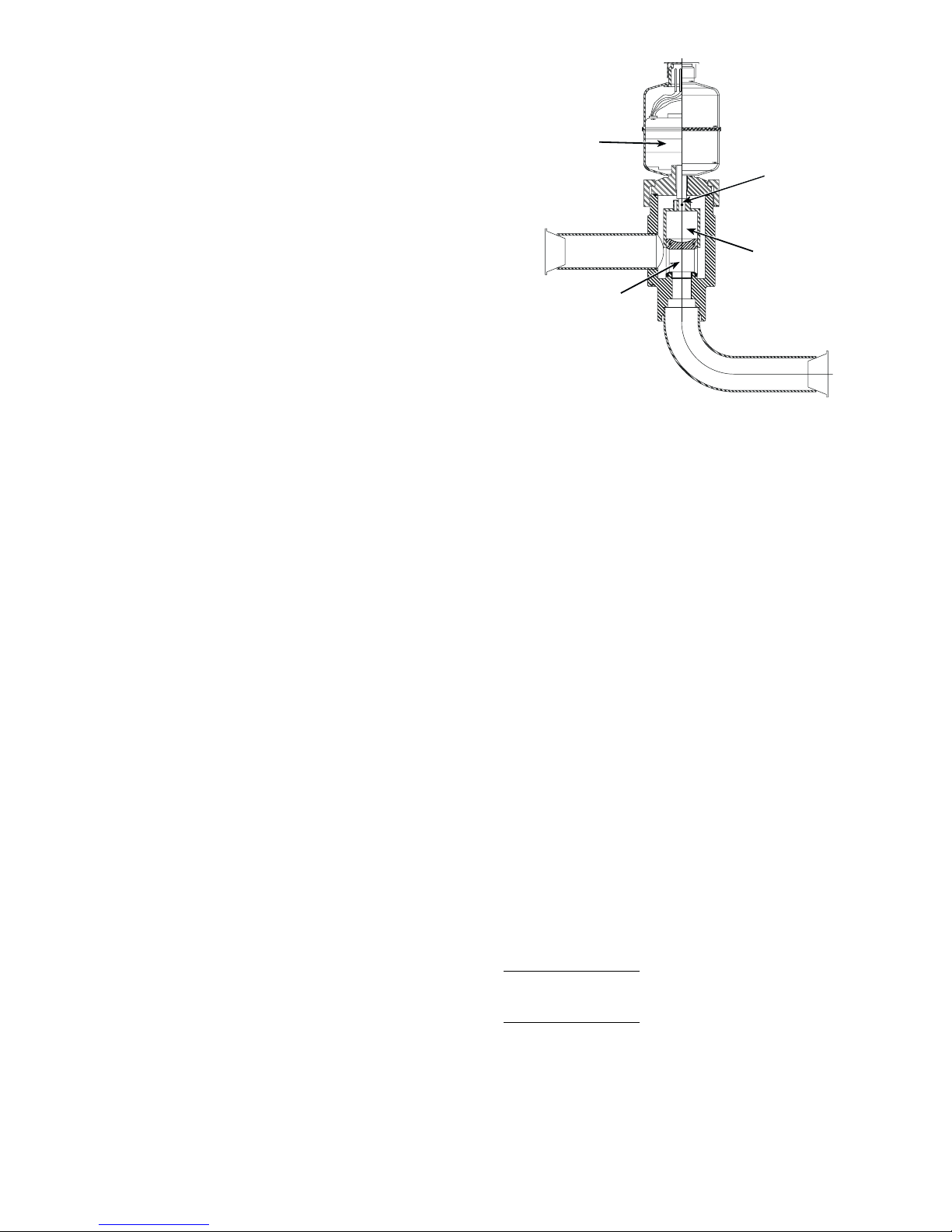

Electronic Expansion Valve (EXV) (See

Fig. 15 — Electronic Expansion Valve (EXV)

Fig. 15) —

EXV. This device eliminates the use of the liquid line solenoid

pumpdown at unit shutdown. An O-ring has been added t o bottom of orifice a ssem bly to com plete a se al i n the v alve on s hutdown. This is not a mechanical shut-off. When service is

required, use the liquid line service val ve to pump down the

system.

High pressure refrigerant enters bottom of val ve where it

passes through a group of machined slots in side of orifice assembly. As refrigerant passes through the orifice, it drops in

pressure. To control flow of refrigerant, the sleeve slides up and

down along orifice assembly, modulating the size of orifice.

The sleeve is moved by a linear stepper motor that moves in increments controlled directly by the processor. As stepper motor

rotates, the moti on is translated into li near movement of lead

screw. There are 1500 discrete steps with this combination. The

valve orifice begins to be exposed at 320 steps. Since there is

not a tight seal with the orifice and the sleeve, the minimum position for operation is 120 steps.

Two thermistors are used to determine suction superheat .

One thermistor is located in the cooler and the othe r is locat ed

in the cylinder end of the compressor after refrigerant has

passed over the motor. The difference between the 2 thermistors is the suction superheat. These machines are set up to

provide approximately 5 to 7 F (2.8 to 3.9 C) superheat leaving

the cooler. Motor cooling accounts for approximately 22 F

(12.2 C) on 30GTN,R units and 16 F (8.9 C) on 30GUN,R

units, resulting in a superheat entering compressor cylinders of

approximately 29 F (16.1 C) for 30GTN,R units and 23 F

(12.8 C) for 30GUN,R units.

Because the valves are controlled by the EXV module, it is

possible to track the position of the valve. Valve position can be

used to control head pressure and system refrigerant charge.

During initial start-up, the EXV module will drive each

valve fully closed. After initialization period, valve position is

controlled by the EXV module and the MBB.

The EXV is used to limit the maximum cooler saturated

suction temperature to 55 F (12.8 C). This makes it possible for

the chiller to start at high cooler fluid temperatures without

overloading the compressor.

Energy Management Module (Fig. 16) —

factory-installed option or field-installed accessory is used for

the following types of temperature reset, demand limit, and/or

ice featu res :

• 4 to 20 mA leaving fluid temperature reset (requires

field-supplied 4 to 20 mA generator)

• 4 to 20 mA cooling set point reset (requires field-

supplied 4 to 20 mA generator)

• Discrete inputs for 2-step demand limit (requires field-

supplied dry contacts capable of handling a 5 vdc, 1 to

20 mA load)

• 4 to 20 mA demand limit (requires field-supplied 4 to

20 mA gener ator)

• Discrete input for Ice Done switch (requires field-

supplied dry contacts capable of handling a 5 vdc, 1 to

20 mA load)

See Demand Limit and Temperature Reset sections on

pages 46 and 43 for further details.

Capacity Control —

pressors, unloaders, and hot gas bypass solenoids to maintain

the user-configured leaving chilled fluid temperature set point.

Entering fluid temperature is used by the Main Base Board

(MBB) to determine the temperature drop across the cooler and

is used in determining the optimum time to add or subtract capacity stages. The chilled fluid temperature set point can be automatically reset by the return tem perature reset or space and

outdoor-air temperature reset features. It can also be reset from

Standard units are equipped with a bottom seal

This

The control system cycles com-

STEPPER

MOTOR (12 VDC)

LEAD SCREW

PISTON SLEEVE

ORIFICE ASSEMBLY

(INSIDE PISTON SLEEVE)

an external 4 to 20 mA signal (requires Energy Management

Module FIOP/accessory).

With the automatic lead-lag feature i n the unit, the control

determines which circuit will start first, A or B. At the first call

for cooling, the lead compressor crankcase heater will be deenergized, a condenser fan will start, and the compressor will start

unloaded.

NOTE: The automatic lead-lag feature is only operative when

an even number of unloaders is present. The 040-070 units

require an accessory unloader to be installed on the B1 compressor for the lead-lag feature to be in effect.

If the circuit has been off for 15 minutes, and the unit is a

TXV unit, liquid line solenoid will remain closed during startup of each circuit for 15 seconds while the cooler and suction

lines are purged of any liquid refrigerant. For units with EXVs,

the lead compressor will be signaled to start. The EXV will remain at minimum position for 10 seconds before it is allowed

to modulate.

After the purge period, the EXV will begin to meter the refrigerant, or the liquid line solenoid will open allowing the

TXV to meter the refrigerant to the cooler. If the off-time is less

than 15 minutes, the EXV will be opened as soon as the compressor starts.

The EXVs will open gradually to provide a controlled startup to prevent liquid flood-back to the compressor. During startup, the oil pressure switch is bypassed for 2 minutes to allow

for the transient changes during start-up. As additional stages

of compression are required, the processor control will add

them. See Tables 5A and 5B.

If a circuit is to be stopped, the control will first start to close

the EXV or close the liquid line solenoid valve.

For units with TXVs

, the lag compressor(s) will be shut

down and the lead compressor will continue to operate for

10 seconds to purge the cooler of any refrigerant.

For units with EXVs

, the lag compressor(s) will be shut

down and the lead compressor will continue to run. After t he

lag compressor(s) has shut down, the EXV is signaled to close.

The lead compressor will remain on for 10 seconds after the

EXV is closed.

During both algorithms (TXV and EXV), all diagnostic

conditions will be honored. If a safety trip or alarm condition is

detected before pumpdown is complete, the circuit will be shut

down.

16

CEBD430351-0396-01C

PWR

J1

J2

J4 J3

J5

RED LED - STATUS

LEN

STATUS

J6

GREEN LED LEN (LOCAL EQUIPMENT NETWORK)

Fig. 16 — Energy Management Module

J7

ADDRESS

DIP SWITCH

TEST 1

CEPL130351-01

TEST 2

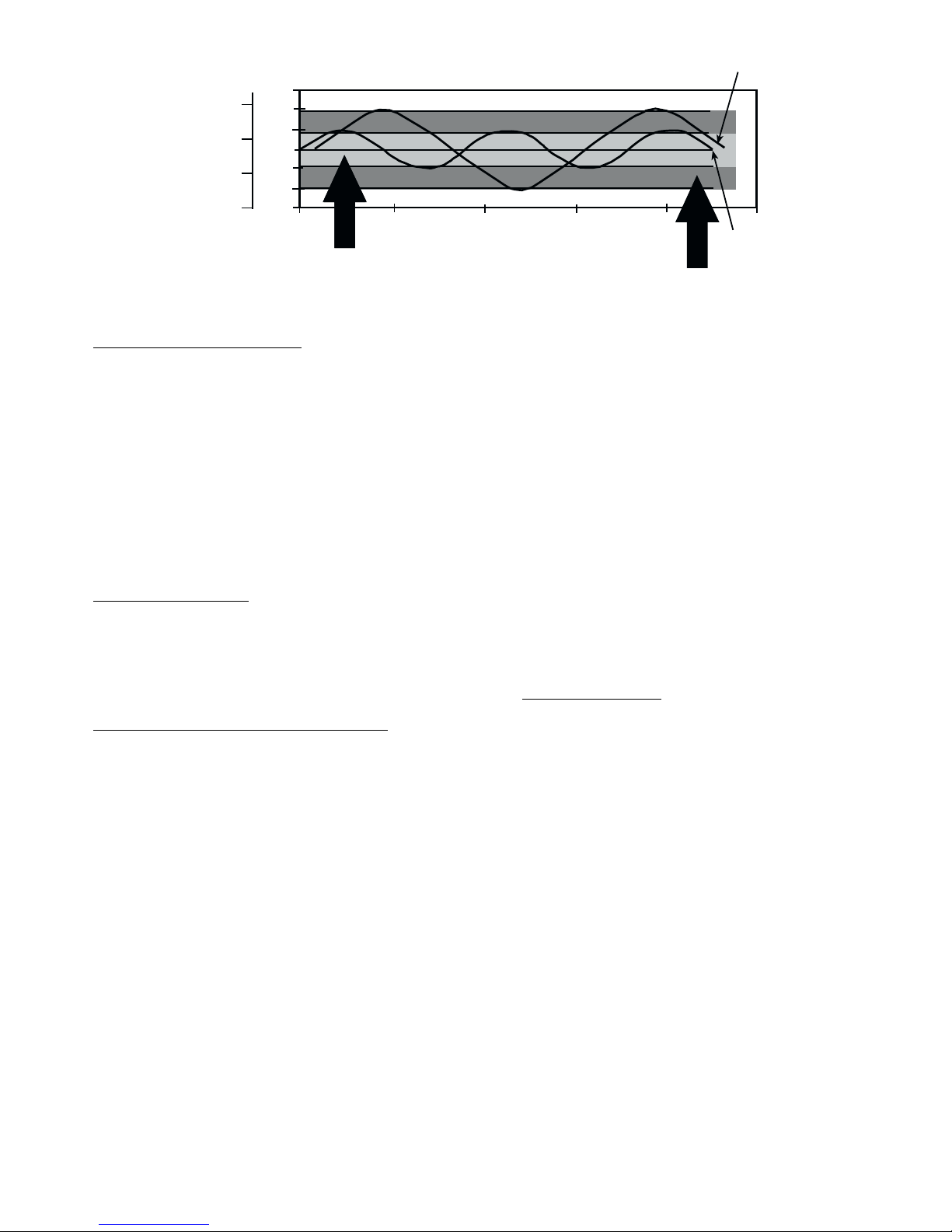

The capacity control algorithm runs every 30 seconds. The

algorithm attempts to maintain the leaving chilled water temperature at the control point. Each time it runs, the control reads

the entering and leaving fluid temperatures. The control determines the rate at which conditions are changing and calculates

2 variables based on these conditions. Next, a capacity ratio is

calculated using the 2 variables to determine whether or not to

make any changes to the current stages of capacity. This ratio

value ranges from –100 to + 100%. If the next stage of capacity

is a compressor, the control starts (stops) a compressor when

the ratio reaches +100% (–100%). If the next stage of capacity

is an unloader, the control deenergizes (energizes) an unloader

when the ratio reaches +60% (–60%). Unloaders are allowed to

cycle faster than compressors, to minimize the number of starts

and stops on each compressor. A delay of 90 seconds occurs after each capacity step change.

17

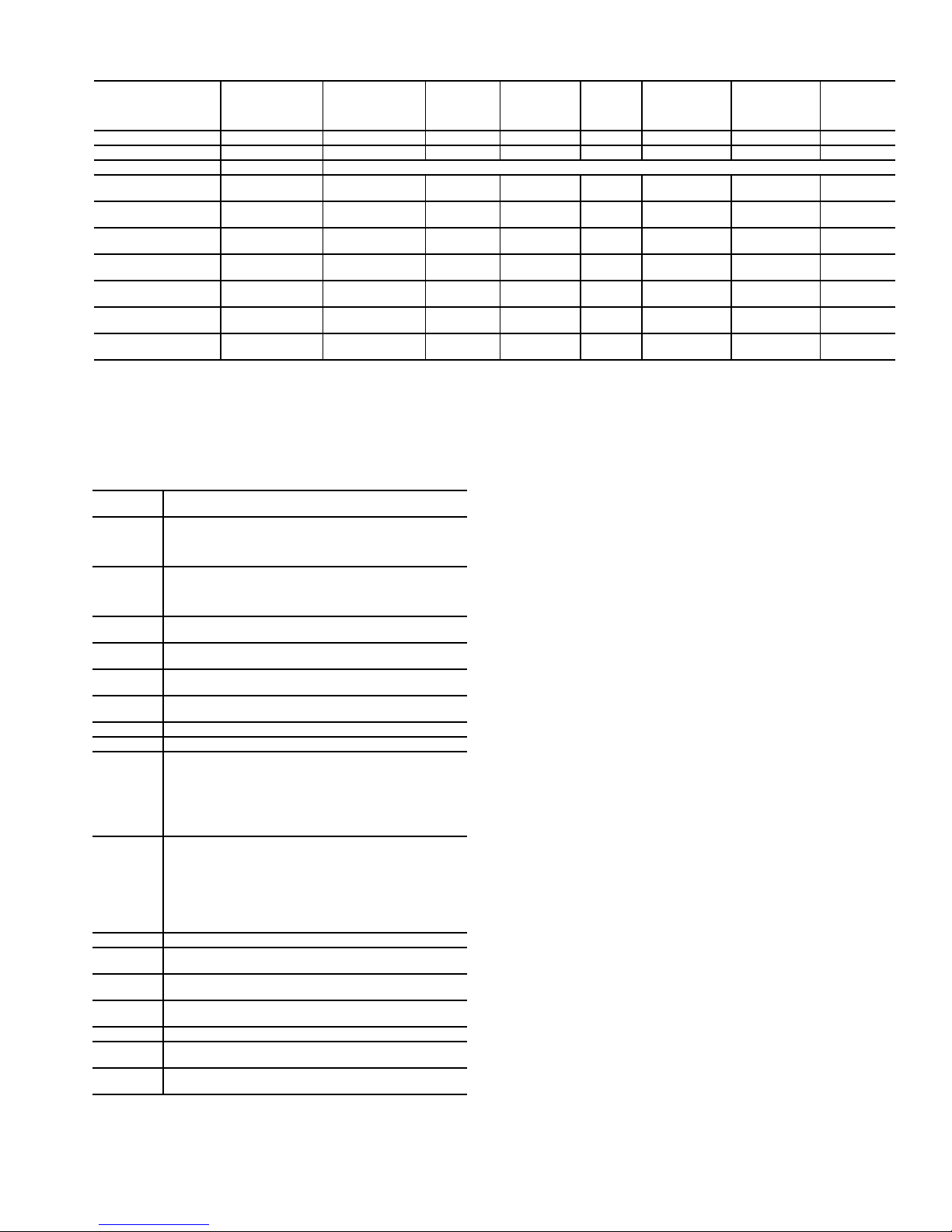

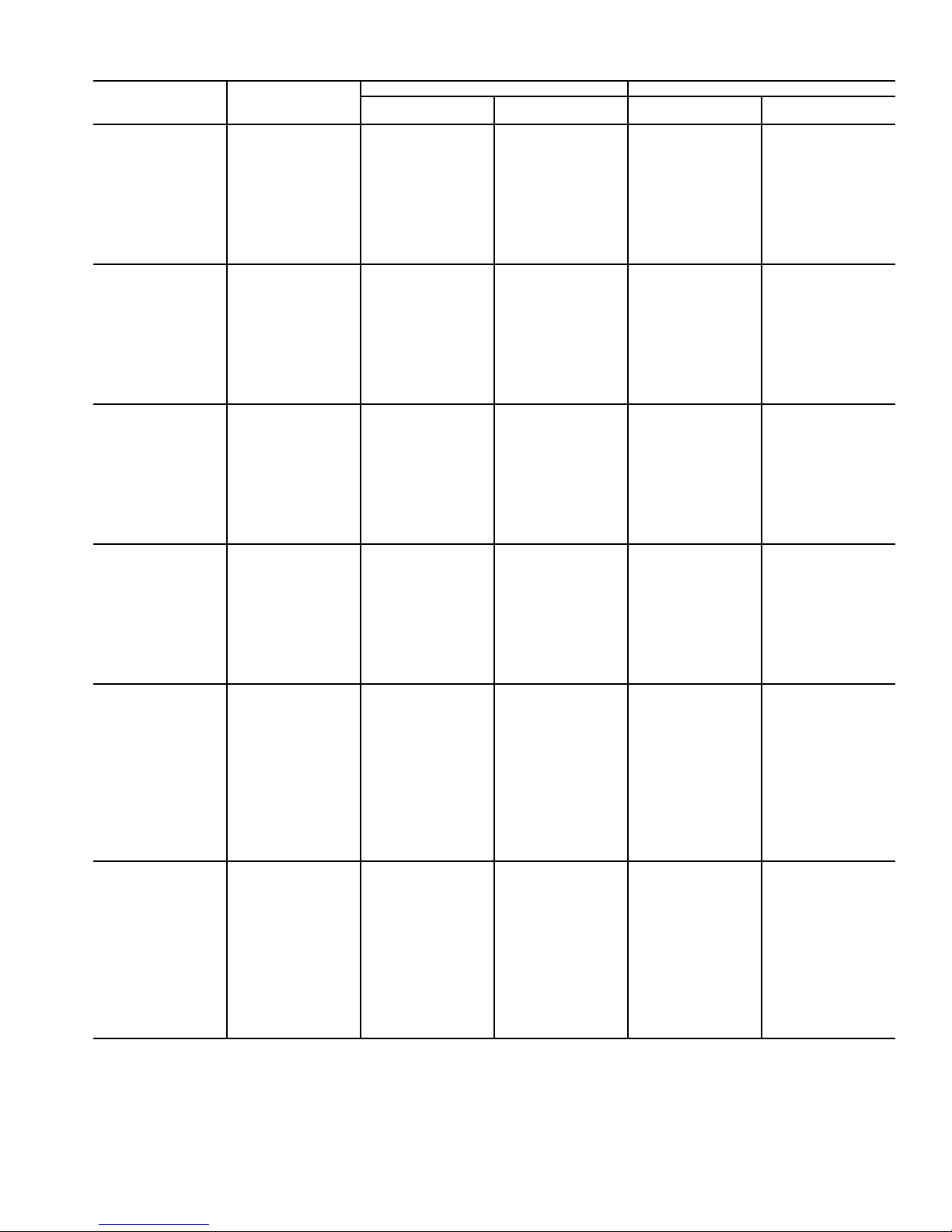

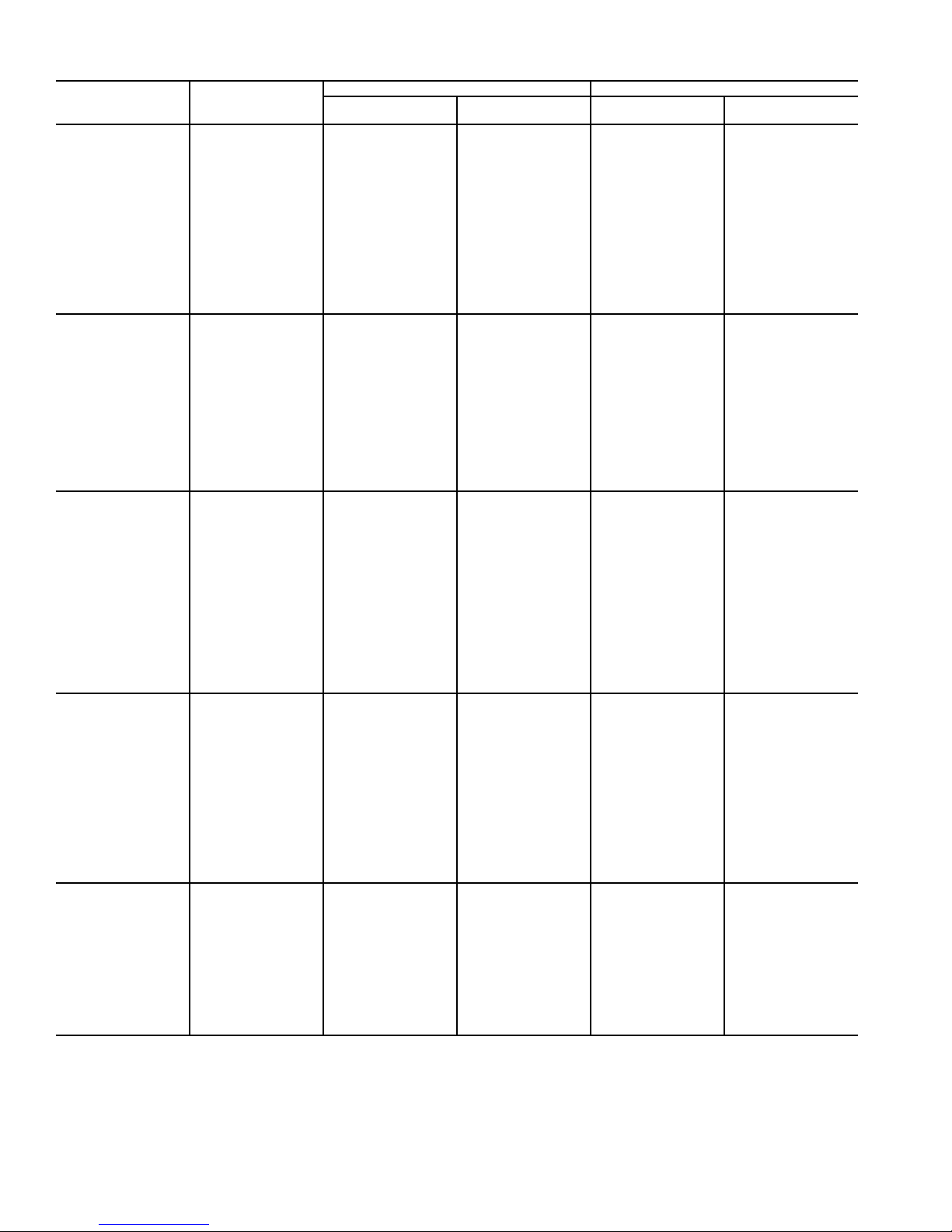

Table 5A — Part Load Data Percent Displacement, Standard Units

UNIT

30GTN,R

30GUN,R

040 (60 Hz)

040 (50 Hz)

045 (60 Hz)

045 (50 Hz)

050 (60 Hz)

050 (50 Hz)

060 (60 Hz)

060 (50 Hz)

070 (60 Hz)

070 (50 Hz)

080, 230B (60 Hz)

080, 230B (50 Hz)

090, 245B (60 Hz)

090, 245B (50 Hz)

100, 255B,

270B (60 Hz)

*Unloaded compressor.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

125A1*——

250A1——

375A1*, B1——

4 100 A1,B1 ——

124A1*——

247A1——

376A1*,B1——

4 100 A1,B1 ——

131A1*——

244A1——

387A1*,B1——

4 100 A1,B1 ——

128A1*——

242A1——

387A1*,B1——

4 100 A1,B1 ——

133A1*——

250A1——

383A1*,B1——

4 100 A1,B1 ——

119A1*——

227A1——

365A1*,B1——

473A1,B1——

5 92 A1*,A2,B1 ——

6 100 A1,A2,B1 ——

1 22 A1* 30 B1*

234A144B1

3 52 A1*,B1* 52 A1*,B1*

4 67 A1*,B1 63 A1,B1*

5 78 A1,B1 78 A1,B1

6 89 A1*,A2,B1 85 A1,A2,B1*

7 100 A1,A2,B1 100 A1,A2,B1

1 17 A1* 25 B1*

225A138B1

3 42 A1*,B1* 42 A1*,B1*

4 54 A1*,B1 50 A1, B1*

5 62 A1,B1 62 A1,B1

6 79 A1*,A2,B1* 79 A1*,A2,B1*

7 92 A1*,A2,B1 88 A1,A2,B1*

8 100 A1,A2,B1 100 A1,A2,B1

1 18 A1* 18 B1*

227A127B1

3 35 A1*,B1* 35 A1*,B1*

4 44 A1*,B1 44 A1,B1

5 53 A1,B1 53 A1,B1

6 56 A1*,A2,B1* 62 A1*,B1*,B2

7 65 A1*,A2,B1 71 A1,B1*,B2

8 74 A1,A2,B1 80 A1,B1,B2

9 82 A1*,A2,B1*,B2 82 A1*,A2,B1*,B2

10 91 A1*,A2,B1,B2 91 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

114A114B1*

221A121B1

3 29 A1*,B1* 29 A1*,B1*

4 36 A1*,B1 36 A1,B1*

5 43 A1,B1 43 A1,B1

6 61 A1*,A2,B1* 53 A1*,B1*,B2

7 68 A1*,A2,B1 60 A1,B1*,B2

8 75 A1,A2,B1 67 A1,B1,B2

9 86 A1*,A2,B1*,B2 86 A1*,A2,B1*,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 16 A1* 16 A1*

223A123A1

3 31 A1*,B1* 31 A1*,B1*

4 39 A1*,B1 39 A1*,B1

5 46 A1,B1 46 A1,B1

6 58 A1*,A2,B1* 58 A1*,A2,B1*

7 66 A1*,A2,B1 66 A1*,A2,B1

8 73 A1,A2,B1 73 A1,A2,B1

9 85 A1*,A2,B1*,B2 85 A1*,A2,B1*,B2

10 92 A1*,A2,B1,B2 92 A1*,A2,B1,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

% Displacement

(Approx)

Compressors

% Displacement

(Approx)

Compressors

18

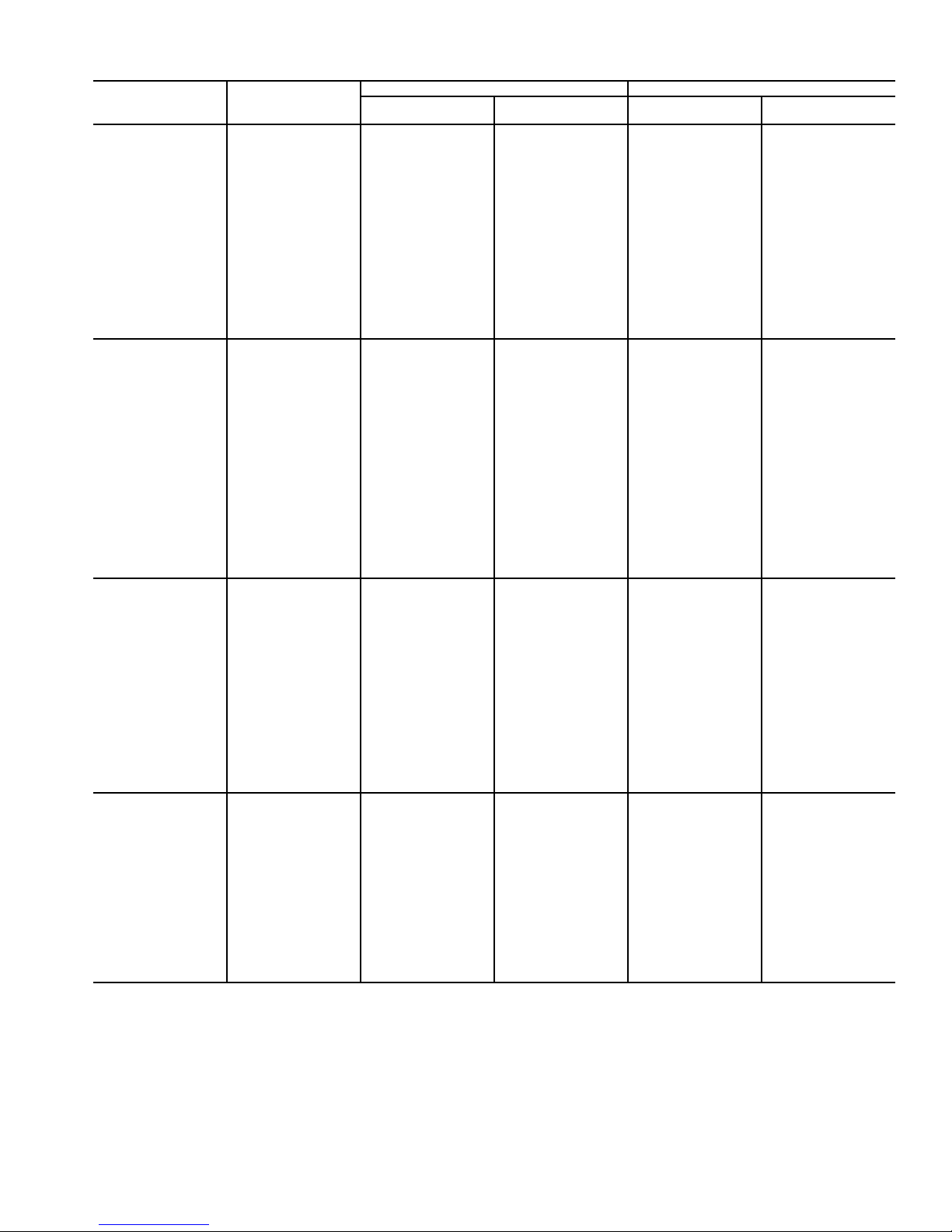

Table 5A — Part Load Data Percent Displacement, Standard Units (cont)

UNIT

30GTN,R

30GUN,R

100, 255B

270B (50 Hz)

110, 290B,

315B (60 Hz)

110, 290B,

315B (50 Hz)

130 (60 Hz)

130 (50 Hz)

150, 230A, 245A,

255A (60 Hz)

*Unloaded compressor.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

1 13 A1* 13 B1*

220A120B1

3 26 A1*,B1* 26 A1*,B1*

4 33 A1,B1 33 A1,B1

5 40 A1,B1 40 A1,B1

6 57 A1*,A2,B1* 57 A1*,B1*,B2

7 63 A1*,A2,B1 63 A1,B1*,B2

8 70 A1,A2,B1 70 A1,B1,B2

9 87 A1*,A2,B1*,B2 87 A1*,A2,B1*,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 14 A1* 14 B1*

221A121B1

3 29 A1*,B1* 29 A1*,B1*

4 36 A1*,B1 36 A1,B1*

5 43 A1,B 43 A1,B1

6 61 A1*,A2,B1* 53 A1*,B1*,B2

7 68 A1*,A2,B1 60 A1,B1*,B2

8 75 A1,A2,B1 67 A1,B1,B2

9 86 A1*,A2,B1*,B2 86 A1*,A2,B1*,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 17 A1* 17 B1*

225A125B1

3 33 A1*,B1* 33 A1*,B1*

4 42 A1*,B1 42 A1,B1*

5 50 A1,B1 50 A1,B1

6 58 A1*,A2,B1* 58 A1*,B1*,B2

7 67 A1*,A2,B1 67 A1,B1*,B2

8 75 A1,A2,B1 75 A1,B1,B2

9 83 A1*,A2,B1*,B2 83 A1*,A2,B1*,B2

10 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 14 A1* 14 B1*

221A121B1

3 28 A1*,B1* 28 A1*,B1*

4 35 A1*,B1 35 A1,B1*

5 42 A1,B1 42 B1,B1

6 58 A1*,A2,B1* 58 A1*,B1*,B2

7 64 A1*,A2,B1 64 A1,B1*,B2

8 71 A1,A2,B1 71 A1,G1,B2

9 87 A1*,A2,B1*,B2 87 A1*,A2,B1*,B2

10 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

11 100 A1,A2,B1,B2 100 A1,A2,B1,B2

1 10 A1* 16 B1*

214A125B1

3 26 A1*,B1* 26 A1*,B1*

4 35 A1*,B1 31 A1,B1*

5 39 A1,B1 39 A1,B1

6 44 A1*,A2,B1* 51 A1*,B1*,B2

7 53 A1*,A2,B1 56 A1,B1*,B2

8 57 A1,A2,B1 64 A1,B1,B2

9 69 A1*,A2,B1*,B2 69 A1*,A2,B1*,B2

10 78 A1*,A2,B1,B2 75 A1,A2,B1*,B2

11 82 A1,A2,B1,B2 82 A1,A2,B1,B2

12 87 A1*,A2,A3,B1*,B2 87 A1*,A2,A3,B1*,B2

13 96 A1*,A2,A3,B1,B2 91 A1,A2,A3,B1*,B2

14 100 A1,A2,A3,B1,B2 100 A1,A2,A3,B1,B2

1 11 A1* 18 B1*

215A127B1

3 29 A1*,B1* 29 A1*,B1*

4 38 A1*,B1 33 A1,B1*

5 42 A1,B1 42 A1,B1

6 44 A1*,A2,B1* 55 A1*,B1*,B2

7 53 A1*,A2,B1 60 A1,B1*,B2

8 58 A1,A2,B1 69 A1,B1,B2

9 71 A1*,A2,B1*,B2 71 A1*,A2,B1*,B2

10 80 A1*,A2,B1,B2 75 A1,A2,B1*,B2

11 85 A1,A2,B1,B2 85 A1,A2,B1,B2

12 86 A1*,A2,A3,B1*,B2 86 A1*,A2,A3,1*,B2

13 95 A1*,A2,A3,B1,B2 91 A1,A2,A3,B1*,B2

14 100 A1,A2,A3,B1,B2 100 A1,A2,A3,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

% Displacement

(Approx)

Compressors

% Displacement

(Approx)

Compressors

19

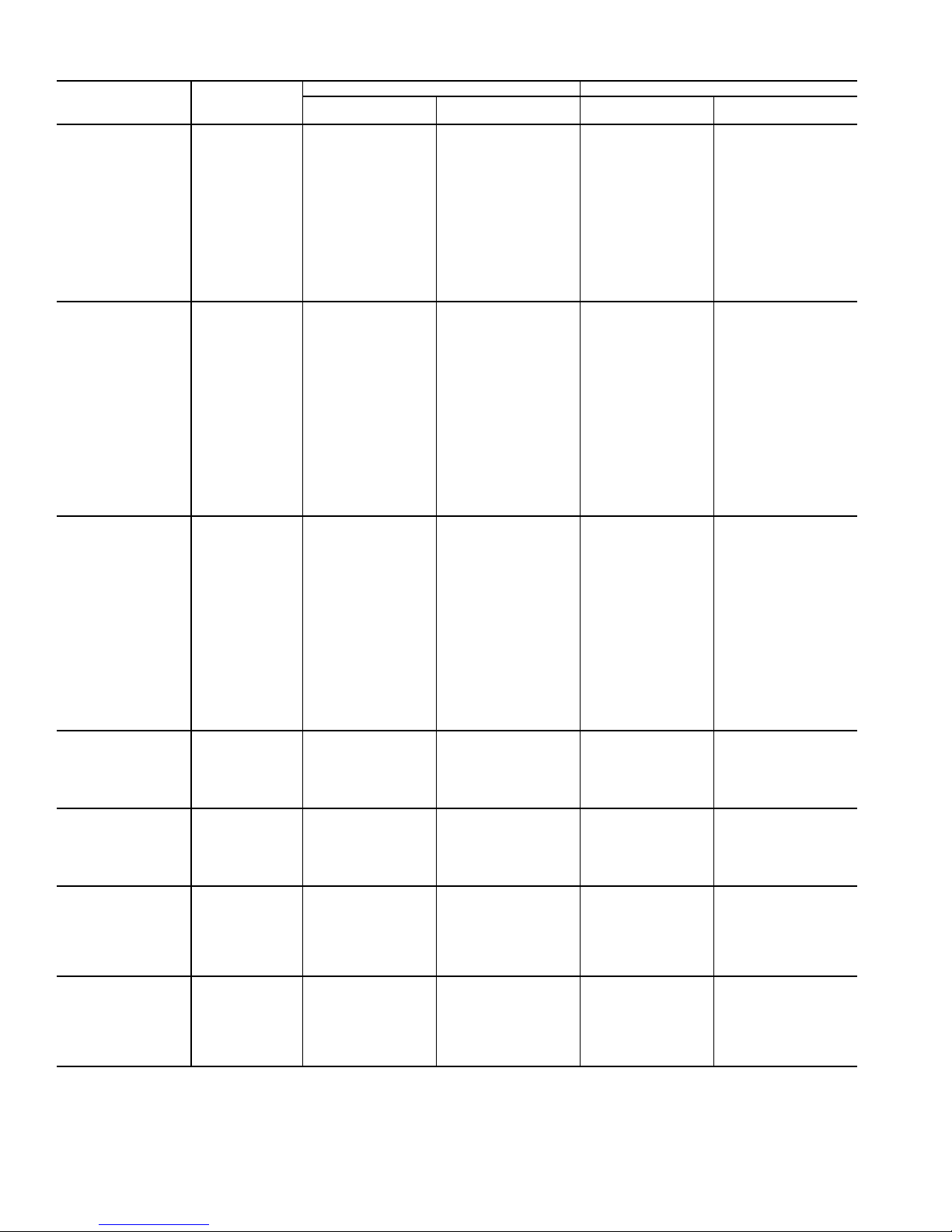

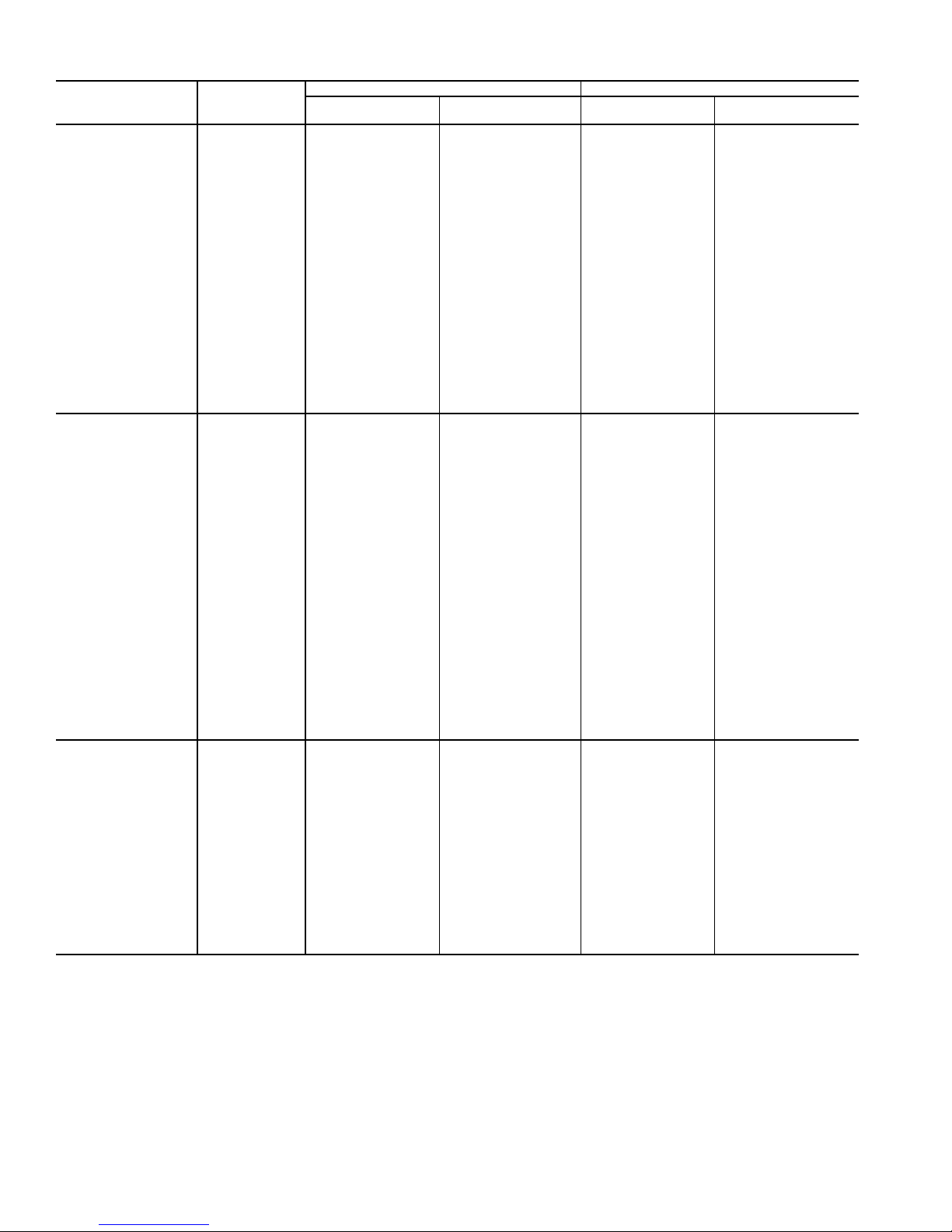

Table 5A — Part Load Data Percent Displacement, Standard Units (cont)

UNITT

30GTN,R

30GUN,R

150, 230A, 245A,

255A (50 Hz)

170, 270A,

330A/B (60 Hz)

170, 270A,

330A/B,

360B (50 Hz)

190, 290A, 360A/B,

390B (60 Hz)

190, 290A, 360A,

390B (50 Hz)

210, 315A, 390A,

420A/B (60 Hz)

210, 315A, 390A,

420A/B (50 Hz)

*Unloaded compressor.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

7

1

2

3

4

5

6

7

% Displacement

LOADING SEQUENCE A LOADING SEQUENCE B

(Approx)

13

20

26

33

40

46

53

60

66

73

80

86

93

100

11

17

23

28

33

39

45

50

56

61

67

73

78

83

89

95

100

9

14

19

23

28

33

37

42

52

57

61

72

76

81

91

96

100

13

25

41

56

78

100

17

33

50

67

83

100

11

25

36

56

67

86

100

9

26

35

51

67

84

100

Compressors

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

A1,B1

A1,A2,B1

A1,A2,B1,B2

A1,A2,A3,B1,B2

A1,A2,A3,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

A1*

A1

A1*

A1

A1*

A1

A1

A1

A1

A1

% Displacement

(Approx)

13

20

26

33

40

46

53

60

66

73

80

86

93

100

11

17

23

28

33

39

45

50

56

61

67

73

78

83

89

95

100

9

14

19

23

28

38

43

47

52

57

61

72

76

81

91

96

100

13

25

41

56

78

100

17

33

50

67

83

100

14

25

44

56

75

86

100

16

26

42

51

67

84

100

Compressors

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

B1

A1,B1

A1,B1,B2

A1,A2,B1,B2

A1,A2,B1,B2,B3

20

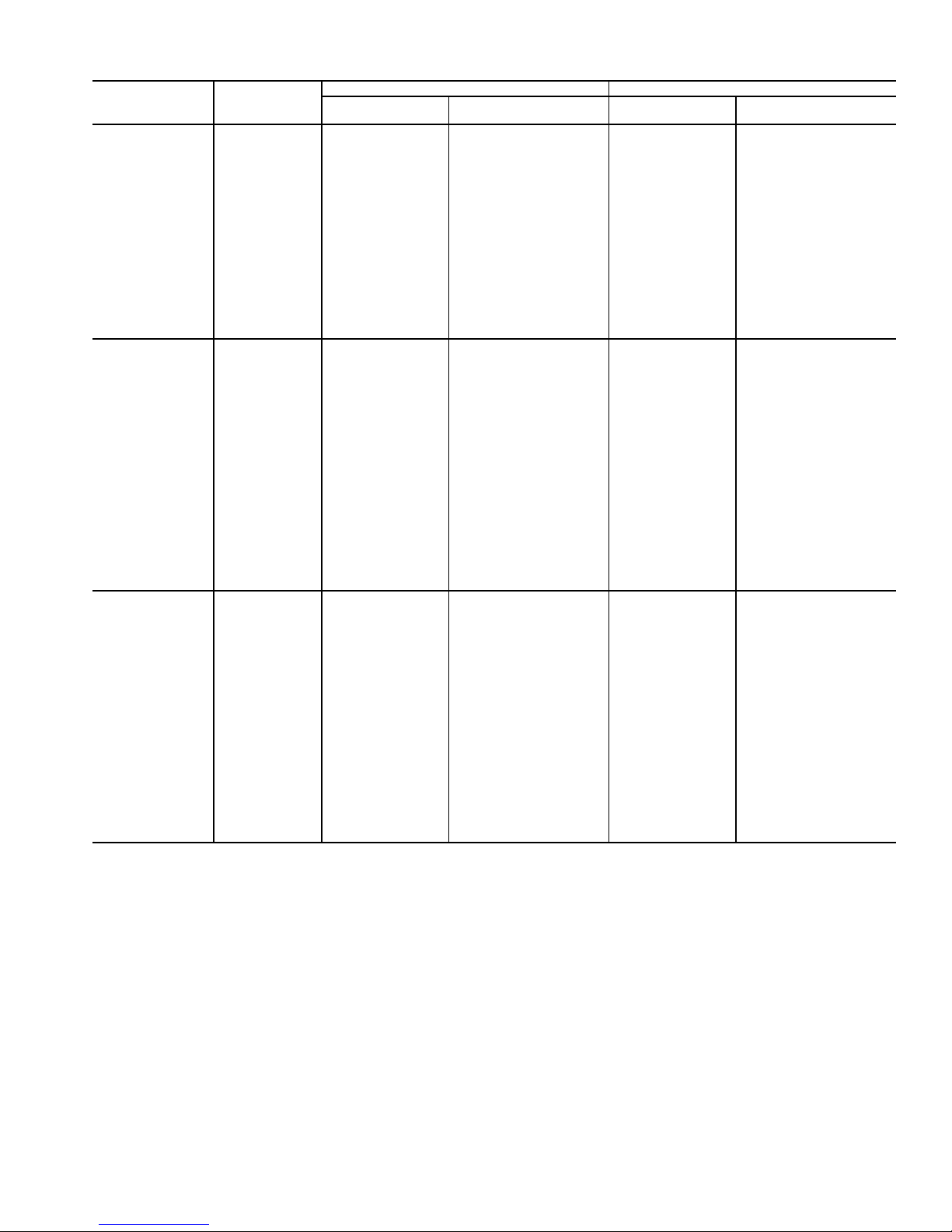

Table 5B — Part Load Data Percent Displacement, With Accessory Unloaders

UNIT

30GTN,R

30GUN,R

040 (60 Hz)

040 (50 Hz)

045 (60 Hz)

045 (50 Hz)

050 (60 Hz)

050 (50 Hz)

060 (60 Hz)

060 (50 Hz)

070 (60 Hz)

070 (50 Hz)

080, 230B (60 Hz)

080, 230B (50 Hz)

090, 245B (60 Hz)

*Unloaded compressor.

†Two unloaders, both unloaded.

NOTE: Some control steps will be skipped if they do not increase chiller capacity when staging up or decrease chiller capacity when staging down.

CONTROL

STEPS

1 25 A1* 25 B1*

250A150B1

3 75 A1*,B1 75 A1,B1*

4 100 A1,B1 100 A1,B1

1 24 A1* 21 B1†

247A137B1*

345A1*,B1† 53 B1

4 61 A1*,B1* 45 A1*,B1†

5 84 A1,B1* 61 A1*,B1*

6 100 A1,B1 84 A1,B1*

7 ——100 A1,B1

118A1† 20 B1†

2 31 A1* 38 B1*

344A156B1

438A1†,B1† 38 A1†,B1†

551A1*,B1† 51 A1*,B1†

6 69 A1*,B1* 69 A1*,B1*

7 82 A1,B1* 82 A1,B1*

8 100 A1,B1 100 A1,B1

115A1† 18 B1†

2 28 A1* 38 B1*

342A158B1

433A1†,B1† 33 A1†,B1†

547A1*,B1† 47 A1*,B1†

6 67 A1*,B1* 67 A1*,B1*

7 80 A1,B1* 80 A1,B1*

8 100 A1,B1 100 A1,B1

116A1† 16 B1†

2 33 A1* 33 B1*

350A150B1

431A1†,B1† 31 A1†,B1†

549A1*,B1† 49 A1*,B1†

6 66 A1*,B1* 66 A1*,B1*

7 83 A1,B1* 83 A1,B1*

8 100 A1,B1 100 A1,B1

111A1† 15 B1†

2 19 A1* 31 B1*

327A147B1

425A1†,B1† 25 A1†,B1†

533A1*,B1† 33 A1*,B1†

6 49 A1*,B1* 49 A1*,B1*

7 57 A1,B1* 57 A1,B1*

8 73 A1,B1 73 A1,B1

984A1†,A2,B1 68 A1,A2,B1†

10 92 A1*,A2,B1 84 A1,A2,B1*

11 100 A1,A2,B1 100 A1,A2,B1

111A1† 15 B1†

2 22 A1* 30 B1*

334A144B1

441A1†,B1* 48 A1,B1†

555A1†,B1 63 A1,B1*

6 67 A1*,B1 78 A1,B1

7 78 A1,B1 85 A1,A2,B1*

8 89 A1*,A2,B1 100 A1,A2,B1

9 100 A1,A2,B1 ——

18A1† 13 B1†

2 17 A1* 25 B1*

325A138B1

433A1†,B1* 50 A1,B1*

546A1†,B1 62 A1,B1

6 54 A1*,B1 67 A1*,A2,B1†

7 62 A1,B1 75 A1,A2,B1†

871A1†,A2,B1* 88 A1,A2,B1*

984A1†,A2,B1 100 A1,A2,B1

10 92 A1*,A2,B1 ——

11 100 A1,A2,B1 ——

19A1† 9B1†

2 18 A1* 18 B1*

327A127B1

435A1†,B1 35 A1,B1†

5 44 A1*,B1 44 A1,B1*

6 53 A1,B1 53 A1,B1

756A1†,A2,B1 62 A1,B1†,B2

8 65 A1*,A2,B1 71 A1,B1*,B2

9 74 A1,A2,B1 80 A1,B1,B2

10 82 A1†,A2,B1,B2 82 A1,A2,B1†,B2

11 91 A1*,A2,B1,B2 91 A1,A2,B1*,B2

12 100 A1,A2,B1,B2 100 A1,A2,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

% Displacement

(Approx)

Compressors

% Displacement

(Approx)

Compressors

21

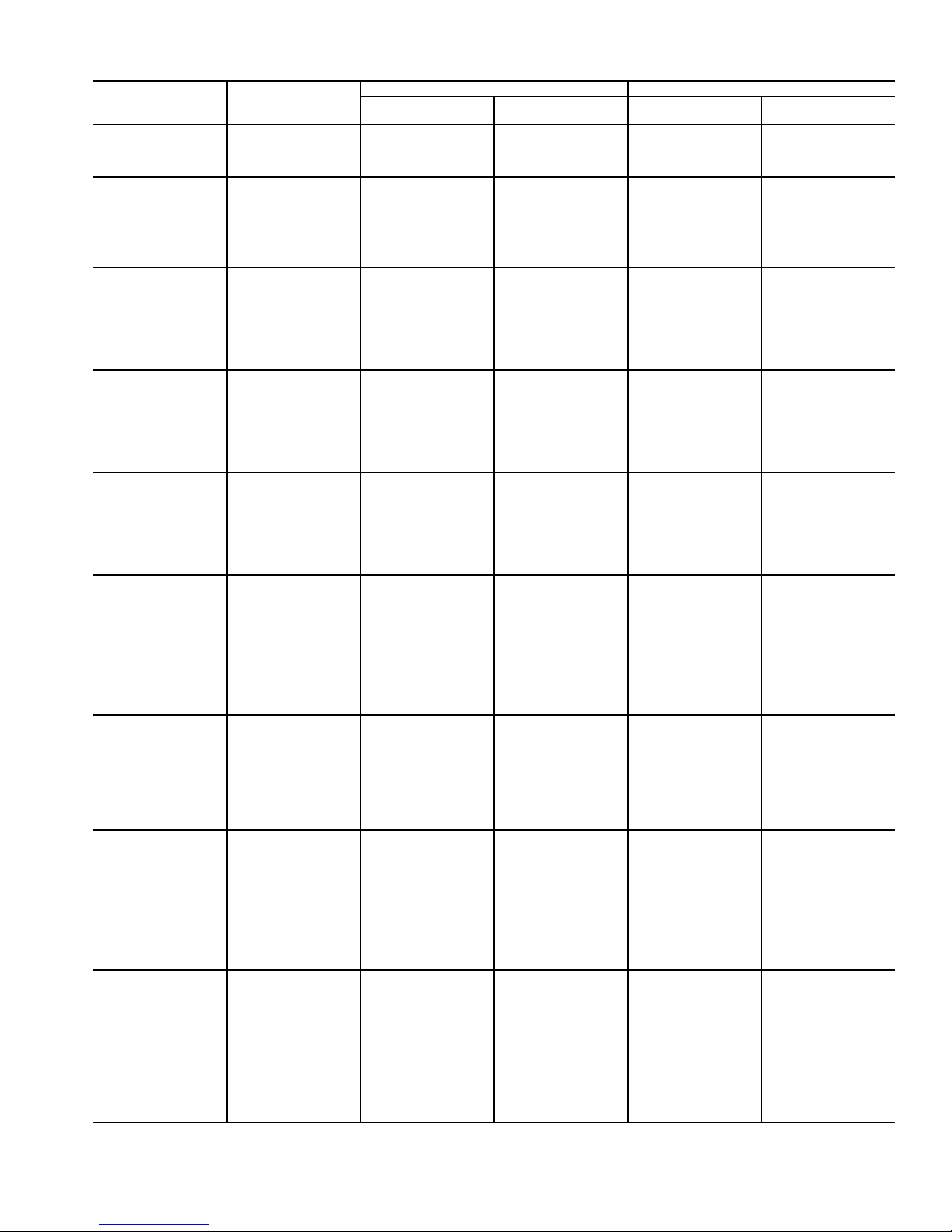

Table 5B — Part Load Data Percent Displacement, With Accessory Unloaders (cont)

UNIT

30GTN,R

30GUN,R

090, 245B (50 Hz)

100, 255B,

270B (60 Hz)

100, 255B,

270B (50 Hz)

110, 290B,

315B (60 Hz)

110, 290B,

315B (50 Hz)

*Unloaded compressor.

†Two unloaders, both unloaded.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

17A1† 7B1†

2 14 A1* 14 B1*

321A121B1

429A1†,B1 29 A1,B1†

5 36 A1*,B1 36 A1,B1*

6 43 A1,B1 43 A1,B1

749A1†,A2,B1† 46 A1*,B1†,B2

854A1†,A2,B1* 53 A1,B1†,B2

961A1†,A2,B1 60 A1,B1*,B2

10 68 A1*,A2,B1 67 A1,B1,B2

11 75 A1,A2,B1 72 A1†,A2,B1†,B2

12 79 A1†,A2,B1*,B2 79 A1*,A2,B1†,B2

13 86 A1†,A2,B1,B2 86 A1,A2,B1†,B2

14 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

15 100 A1,A2,B1,B2 100 A1,A2,B1,B2

18A1† 8B1†

2 16 A1* 16 B1*

323A123B1

431A1†,B1 31 A1,B1†

5 39 A1*,B1 39 A1,B1*

6 46 A1,B1 46 A1,B1

750A1†,A2,B1* 50 A1*,B1†,B2

858A1†,A2,B1 58 A1,B1†,B2

9 66 A1*,A2,B1 66 A1,B1*,B2

10 73 A1,A2,B1 73 A1,B1,B2

11 77 A1†,A2,B1*,B2 77 A1*,A2,B1†,B2

12 85 A1†,A2,B1,B2 85 A1,A2,B1†,B2

13 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

14 100 A1,A2,B1,B2 100 A1,A2,B1,B2

17A1† 7B1†

2 13 A1* 13 B1*

320A120B1

426A1†,B1 26 A1,B1†

5 33 A1*,B1 33 A1,B1*

6 40 A1,B1 40 A1,B1

743A1†,A2,B1† 43 A1†,B1†,B2

850A1†,A2,B1* 50 A1*,B1†,B2

957A1†,A2,B1 57 A1,B1†,B2

10 63 A1*,A2,B1 63 A1,B1*,B2

11 70 A1,A2,B1 70 A1,B1,B2

12 74 A1†,A2,B1†,B2 74 A1†,A2,B1†,B2

13 80 A1†,A2,B1*,B2 80 A1*,A2,B1†,B2

14 89 A1†,A2,B1,B2 87 A1,A2,B1†,B2

15 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

16 100 A1,A2,B1,B2 100 A1,A2,B1,B2

17A1† 7B1†

2 14 A1* 14 B1*

321A121B1

429A1†,B1 29 A1,B1†

5 36 A1*,B1 36 A1,B1*

6 43 A1,B1 43 A1,B1

747A1†,A2,B1† 46 A1*,B1†,B2

854A1†A2,B1* 53 A1,B1†,B2

961A1†,A2,B1 60 A1,B1*,B2

10 68 A1*,A2,B1 67 A1,B1,B2

11 75 A1,A2,B1 72 A1†,A2,B1†,B2

12 79 A1†,A2,B1*,B2 79 A1*,A2,B1†,B2

13 86 A1†,A2,B1,B2 86 A1,A2,B1†,B2

14 93 A1*,A2,B1,B2 93 A1,A2,B1*,B2

15 100 A1,A2,B1,B2 100 A1,A2,B1,B2

18A1† 8B1†

2 17 A1* 17 B1*

325A125B1

433A1†,B1 33 A1,B1†

5 42 A1*,B1 42 A1,B1*

6 50 A1,B1 50 A1,B1

758A1†,A2,B1 58 A1,B1†,B2

8 67 A1*,A2,B1 67 A1,B1*,B2

9 75 A1,A2,B1 75 A1,B1,B2

10 83 A1†,A2,B1,B2 83 A1,A2,B1†,B2

11 92 A1*,A2,B1,B2 92 A1,A2,B1*,B2

12 100 A1,A2,B1,B2 100 A1,A2,B1,B2

LOADING SEQUENCE A LOADING SEQUENCE B

% Displacement

(Approx)

Compressors

% Displacement

(Approx)

Compressors

22

Table 5B — Part Load Data Percent Displacement, with Accessory Unloaders (cont)

UNIT

30GTN,R

30GUN,R

130 (60 Hz)

130 (50 Hz)

150, 230A, 245A,

255A (60 Hz)

150, 230A, 245A,

255A (50 Hz)

*Unloaded compressor.

Two unloaders, both unloaded.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

LOADING SEQUENCE A LOADING SEQUENCE B

% Displacement

(Approx)

8

14

21

22

28

35

42

44

51

58

64

71

73

80

87

93

100

6

10

14

22

31

35

39

40

49

53

57

65

74

78

82

83

91

96

100

6

11

15

24

33

38

42

49

53

58

66

75

80

85

91

95

100

6

13

20

26

33

40

46

53

60

66

73

80

86

93

100

Compressors

A1†,A2,B1†

A1†,A2,B1*

A1†,A2,B1†,B2

A1†,A2,B1*,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†,A2,B1*

A1†,A2,B1*,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†,A2,A3,B1*,B2

A1†,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1†,A2,B1*,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1†

A1*

A1

A1†,B1*

A1†,B1

A1*,B1

A1,B1

A1†,A2,B1

A1,A2,B1

A1,A2,B1†

A1†

A1*

A1

A1†,B1*

A1†,B1

A1*,B1

A1,B1

A1†,A2,B1

A1*,A2,B1

A1,A2,B1

A1†

A1*

A1

A1†,B1*

A1†,B1

A1*,B1

A1,B1

A1†,A2,B1

A1*,A2,B1

A1,A2,B1

A1†

A1*

A1

A1†,B1

A1*,B1

A1,B1

A1†,A2,B1

A1*,A2,B1

A1,A2,B1

% Displacement

(Approx)

8

14

21

22

28

35

42

44

51

58

64

71

73

80

87

93

100

8

16

25

31

39

43

47

56

64

65

74

82

83

91

100

—

—

—

—

9

18

27

33

42

46

51

60

69

75

86

91

100

—

—

—

—

6

13

20

26

33

40

46

53

60

66

73

80

86

93

100

Compressors

B1†

B1*

B1

A1*,B1†

A1,B1†

A1,B1*

A1,B1

A1†,B1†,B2

A1*,B1†,B2

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1†,A2,B1†,B2

A1*,A2,B1†,B2

A1,A2,B1†,B2

A1,A2,B1*,B2

A1,A2,B1,B2

B1†

B1*

B1

A1,B1*

A1,B1

A1*,B1†,B2

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1†,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1†,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

—

—

—

—

B1†

B1*

B1

A1,B1*

A1,B1

A1*,B1†,B2

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

—

—

—

—

B1†

B1*

B1

A1,B1†

A1,B1*

A1,B1

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1,A2,B1†,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1,A2,A3,B1†,B2

A1,A2,A3,B1*,B2

A1,A2,A3,B1,B2

23

Table 5B — Part Load Data Percent Displacement, With Accessory Unloaders (cont)

UNIT

30GTN,R

30GUN,R

170, 270A,

330A/B (60 Hz)

170, 270A,

330A/B, 360B (50 Hz)

190, 290A, 360A/B,

390B (60 Hz)

*Unloaded compressor.

†Two unloaders, both unloaded.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

% Displacement

LOADING SEQUENCE A LOADING SEQUENCE B

(Approx)

6

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

5

9

14

14

19

23

28

28

33

37

42

43

48

52

57

61

63

67

72

76

81

82

87

91

96

100

9

13

18

21

25

33

37

41

49

53

56

71

74

78

93

96

100

Compressors

A1†,B1*

A1†,B1

A1*,B1

A1,B1

A1†,A2,B1*

A1†,A2,B1

A1*,A2,B1

A1,A2,B1

A1†,A2,B1*,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†,A2,A3,B1*,B2

A1†,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1†,A2,A3,B1*,B2,B3

A1†,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1†,B1*

A1†B1

A1*,B1

A1,B1

A1†,A2,B1*

A1†,A2,B1

A1*,A2,B1

A1,A2,B1

A1†,A2,B1†,B2

A1†,A2,B1*,B2

A1†,A2,B1,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1†A2,A3,B1†,B2

A1†,A2,A3,B1*,B2

A1†,A2,A3,B1,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1†,A2,A3,B1†,B2,B3

A1†,A2,A3,B1*,B2,B3

A1†,A2,A3,B1,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1†

A1*

A1

A1†

A1*

A1

A1*

A1

% Displacement

(Approx)

6

11

17

17

23

28

33

34

39

45

50

51

56

61

67

67

73

78

83

84

89

95

100

5

9

14

14

19

23

28

29

34

38

43

47

48

52

57

61

63

67

72

76

81

82

87

91

96

100

9

13

18

21

25

33

37

41

49

53

56

71

74

78

93

96

100

Compressors

B1†

B1*

B1

A1*,B1†

A1,B1†

A1,B1*

A1,B1

A1*,B1†,B2

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1†,B2

A1,A2,B1†,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1†,B2,B3

A1,A2,B1†,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1†,B2,B3

A1,A2,A3,B1†,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

B1†

B1*

B1

A1*,B1†

A1,B1†

A1,B1*

A1,B1

A1†,B1†,B2

A1*,B1†,B2

A1,B1†,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1†,B2

A1,A2,B1†,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1†,A2,B1†,B2,B3

A1*,A2,B1†,B2,B3

A1,A2,B1†,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1†,A2,A3,B1†,B2,B3

A1*,A2,A3,B1†,B2,B3

A1,A2,A3,B1†,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B3,B3

B1*

B1

A1*,B1*

A1,B1*

A1,B1

A1*,B1*,B2

A1,B1*,B2

A1,B1,B2

A1*,A2,B1*,B2

A1,A2,B1*,B2

A1,A2,B1,B2

A1*,A2,B1*,B2,B3

A1,A2,B1*,B2,B3

A1,A2,B1,B2,B3

A1*,A2,A3,B1*,B2,B3

A1,A2,A3,B1*,B2,B3

A1,A2,A3,B1,B2,B3

24

Table 5B — Part Load Data Percent Displacement, With Accessory Unloaders (cont)

UNIT

30GTN,R

30GUN,R

190, 290A, 360A,

390B (50 Hz)

210, 315A, 390A,

420A/B (60 Hz)

210, 315A, 390A,

420A/B (50 Hz)

*Unloaded compressor.

†Two unloaders, both unloaded.

NOTE: These capacity control steps may vary due to lag compressor sequencing.

CONTROL

STEPS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

% Displacement

LOADING SEQUENCE A LOADING SEQUENCE B

(Approx)

11

11

22

28

33

39

44

50

55

61

67

72

78

83

89

94

100

8

11

17

22

25

28

33

36

48

52

56

59

63

67

78

83

86

92

97

100

7

9

17

23

26

27

32

35

43

48

51

59

65

67

75

81

84

92

97

100

Compressors

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*,A2,A3,A4,B1*,B2,B3

A1*,A2,A3,A4,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

A1*

A1

A1*,B1*

A1*,B1

A1,B1

A1*,A2,B1*

A1*,A2,B1

A1,A2,B1

A1*,A2,B1*,B2

A1*,A2,B1,B2

A1,A2,B1,B2

A1*,A2,A3,B1*,B2

A1*,A2,A3,B1,B2

A1,A2,A3,B1,B2

A1*,A2,A3,B1*,B2,B3

A1*,A2,A3,B1,B2,B3

A1,A2,A3,B1,B2,B3

A1*,A2,A3,A4,B1*,B2,B3

A1*,A2,A3,A4,B1,B2,B3

A1,A2,A3,A4,B1,B2,B3

% Displacement

(Approx)

11

17

22

28

33

39

44

50

55

61

67

72

78

83

89

94

100

9

14

17

21

25

37

40

44

48

51

56