CANON MP130, MP110 Service Manual

PIXMA MP110/130

SERVICE

MANUAL

REVISION 0

HY8-13A2-000

COPYRIGHT©2004 CANON INC. CANON PIXMAMP110/130 NOVEMBER 2004

Scope

This manual has been issued by Canon Inc., to provide the service technicians of this product with the

information necessary for qualified persons to learn technical theory, installation, maintenance, and repair

of products. The manual covers information applicable in all regions where the product is sold. For this

reason, it may contain information that is not applicable to your region.

Revision

This manual could include technical inaccuracies or typographical errors due to improvements or changes

made to the product. When changes are made to the contents of the manual, Canon will release technical

information when necessary. When substantial changes are made to the contents of the manual, Canon will

issue a revised edition.

The following do not apply if they do not conform to the laws and regulations of the region where the

manual or product is used:

Trademarks

Product and brand names appearing in this manual are registered trademarks or trademarks of the

respective holders.

Copyright

All rights reserved. No parts of this manual may be reproduced in any form or by any means or translated

into another language without the written permission of Canon Inc., except in the case of internal business

use.

Copyright © 2004 by Canon Inc.

CANON INC.

Inkjet MFP Quality Assurance Div.

5-1 Hakusan 7-Chome, Toride-city, Ibaraki 302-8501, Japan

I. MANUAL OUTLINE

This manual consists of the following three parts to provide information necessary to service the PIXMA

MP110/MP130:

Part 1: Maintenance

Information on maintenance and troubleshooting of the PIXMA MP110/MP130

Part 2: Technical Reference

New technology and technical information such as FAQ's (Frequently Asked Questions) of the PIXMA

MP110/MP130

Part 3: Appendix

Block diagrams PIXMA MP110/MP130

Reference:

This manual does not provide sufficient information for disassembly and reassembly procedures. Refer

to the graphics in the separate Parts Catalog.

II. TABLE OF CONTENTS

Page Part 1: MAINTENANCE

1-1 1. MAINTENANCE

1-1 1-1. Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement

Consumables by Service Engineer

1-2 1-2. Customer Maintenance

1-3 1-3. Product Life

1-3 1-4. Special Tools for Service

1-4 1-5. Serial Number Location

1-5 2. LIST OF ERROR DISPLAY / INDICATION

1-5 2-1. Users Error Messeges

1-8 2-2. User Error Codes

1-8 2-3. Service Error Codes

1-8 2-4. New Error Codes and Recovery Methods

1-8 2-5. Warnings

1-9 2-6. Troubleshooting by Symptom

1-12 3. REPAIR

1-12 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling)

1-14 3-2. Special Notes on Repair Servicing

(1)

Flexible cable and harness wiring, connection

(2) Notes on disassembly

1-16 3-3. Adjustment / Settings

(1) Paper feed motor adjustment

(2) Grease application

(3) Waste ink counter setting

1-19 3-4. User Data Flow

1-21 3-5. Service Switches

(1) Hardware switches

(2) Service data overview

(3) Service data registration / setting method

(4) Service data menu

(5) New service data added to this model

1-25 3-6. Test Mode

(1) User test print Functions

(2) Test mode overview

(3) Test mode Menu

1-29 3-7. Flash ROM Version Upgrade

1-30 4. CLEANING YOUR MACHINE

1-30 4-1 Exterior

1-30 4-2 Scanning Unit

1-31 5. PRINTER TRANSPORTATION

Page Part 2: TECHNICAL REFERENCE

2-1 1. NEW TECHNOLOGIES

2-1 2. CLEANING MODE AND AMOUNT OF INK PURGED

2-2 3. PRINT MODE

2-6 4. FAQ (Problems Specific to the PIXMA MP110/ MP130 and Corrective Actions)

Page Part 3: APPENDIX

3-1 1. BLOCK DIAGRAM

3-2 2. PIXMA MP110/ MP130 SPECIFICATIONS

Part 1

Maintenance

1. MAINTENANCE

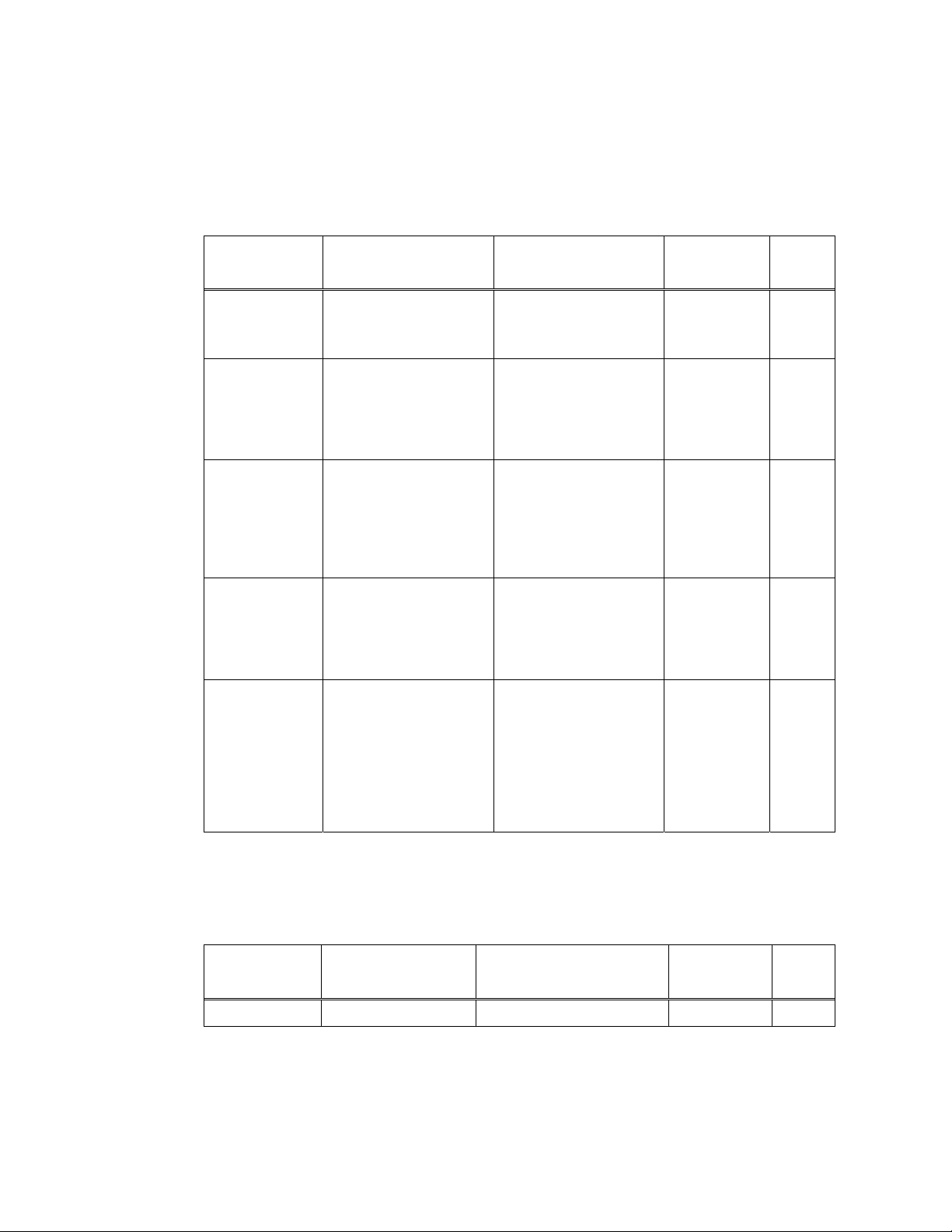

1-1 Adjustment, Periodic Maintenance, Periodic Replacement Parts, and Replacement

Consumables by Service Engineer

(1) Adjustment

Item Timing Purpose Tool

Country setting

(Service Mode)

Registration of

waste ink

absorption

amount at the

waste ink counter

(Service Mode)

Print head

alignment

Paper feed motor

installation

adjustment *1

Grease

application

*1: Caution for the paper feed motor installation adjustment

The screws securing the paper feed motor may be loosened only at replacement of the paper feed motor unit.

- At MAIN BOARD

ASS’Y replacement

- At MAIN BOARD

ASS’Y replacement

- At INK ABSORBER

(HY7-2819/2820)

replacement

- At print head

replacement

- At MAIN BOARD

ASS’Y replacement

-At PAPER FEED

MOTOR UNIT

replacement

-At CARRIAGE UNIT

replacement

-At MAIN UNIT

replacement

To set the country. None

(Service Mode

MARKET

MODEL-JPN)

To register the waste ink

absorption amount at the

waste ink counter.

To compensate the print

head landing-in position

error.

To adjust the belt tension.

(Install the paper feed

motor unit by moving in

the direction to stretch the

belt tightly with proper

tension.)

-To apply grease to the

carriage sliding portion

and the carriage rail

portion.

- To apply grease to the

blade.

- To apply grease to the

Eject Roller sliding

portion.

None

(Service Mode

COUNTER

ACSESS)

None

- Main body

buttons

- Computer

settings via

the printer

driver

None 2 min.

-FLOIL

KG-107A

(QY9-0057)

-MOLYKOTE

PG641

(CK-0562)

Approx.

time

1 min.

1 min.

2 min.

2 min.

(2) Periodic maintenance

Item Timing Purpose Tool Approx.

time

None

1-1

(3) Periodic replacement parts

Item Timing Purpose Tool Approx.

None

(4) Replacement consumables

Item Timing Purpose Tool Approx.

None

time

time

1-2 Customer Maintenance

Item Timing Purpose Tool

Print head

alignment

Print head cleaning When print quality is

Print head

refreshing

Ink tank

replacement

Paper feed roller

cleaning

At print head

replacement.

not satisfying.

When print quality is

not satisfying (and not

improved by print head

cleaning).

When an ink tank

becomes empty. (At No

Ink error)

When paper cannot be

fed properly.

To compensate the print

head landing-in position

error.

To improve nozzle

conditions.

To improve nozzle

conditions.

- -

To clean the paper feed

rollers.

- Main body

buttons

- Computer

performed by

the automatic

settings via the

printer driver

- Main body

buttons

- Computer

settings via the

printer driver

- Main body

buttons

- Computer

setting via the

printer driver

Main body

buttons

Approx.

time

3 min.

30 sec. 1 min.

1 min. 1 min.

and half

2 min.

2 min.

1-2

1-3 Product Life

(1) Main body

At any of the following (I) to (II), whichever comes first.

(I) Print Volume: 4,000 pages

BK: 2,000 pages (in printing A4, Black 1,500 character standard document pattern)

CL: 1,200 pages (in printing A4, 7.5 % duty per color pattern)

120 pages (in printing A4, photo, borderless)

80 pages (in printing L-size, photo, borderless)

600 pages (in printing Postcard, photo, borderless)

The figures of Print Volume shown above indicate an assumed breakdown when an average user prints 4,000

pages.

(II) Years of use:

3 years of use

(2) Print head

(3) Ink tanks

BCI-24Black: approx. 300 pages (JEIDA standard patternJ1, plain paper, standard mode)

approx. 520 pages (ISO JIS-SCID No. 5 pattern, plain paper, standard mode)

BCI-24Color: approx. 170 pages (ISO JIS-SCID No. 5 pattern, plain paper, standard mode)

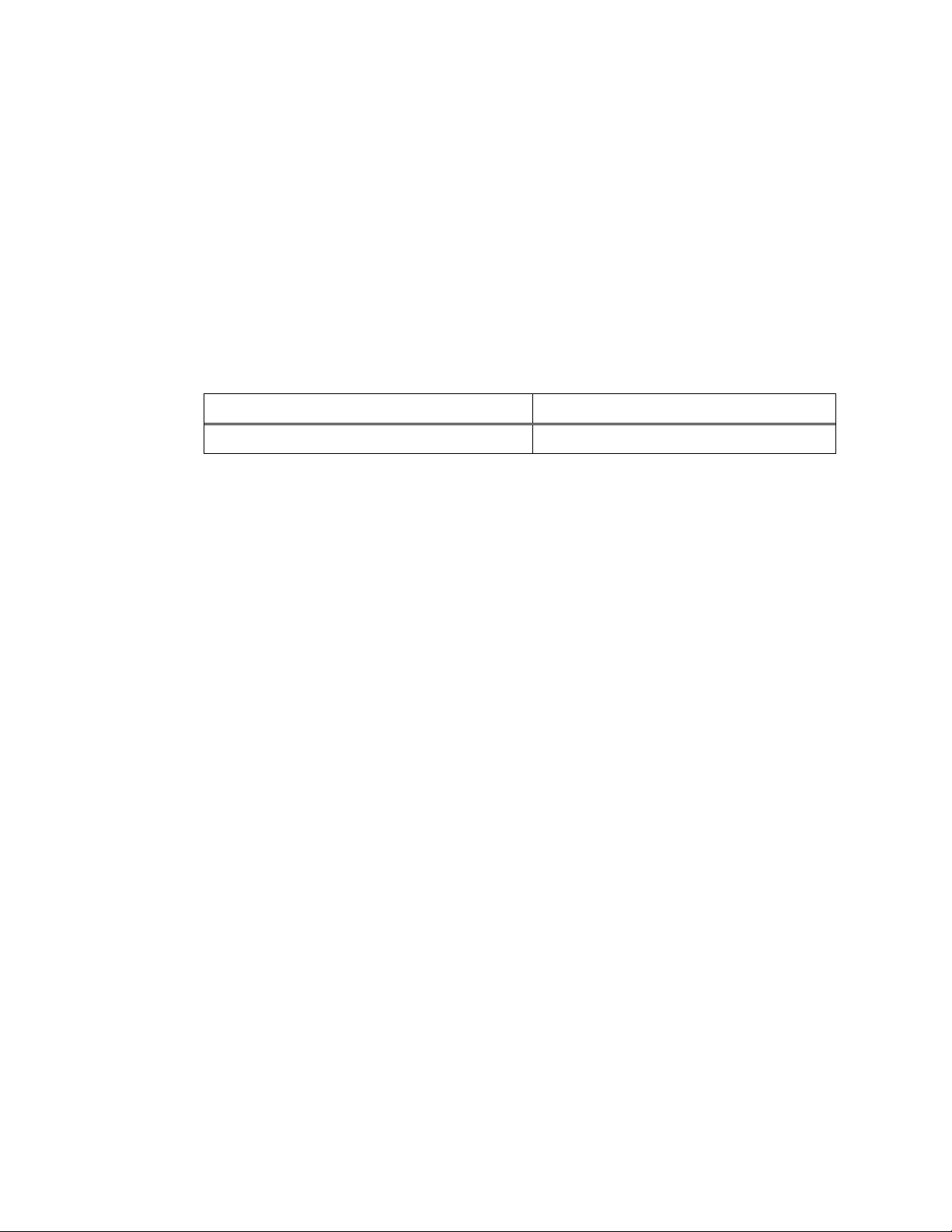

Item Details

Structure 4 color integrated head (Detachable ink tanks)

Print head Bk: 320 nozzles, 2-column vertical array

C/M/Y: 128 nozzles/color, 2-column vertical array/color

Droplet: Bk 30pl, Col 5pl/2pl

Ink colors Bk (pigment), Col: C, M, Y (high coloration)

Ink tanks BCI-24Black, BCI-24Color

Weight Approx. 58 g (ink tanks are not included)

Form of supply Service parts (ink tanks are not included)

Service parts number: QY6-0054

Product life 4,000 pages (the same as the main body)

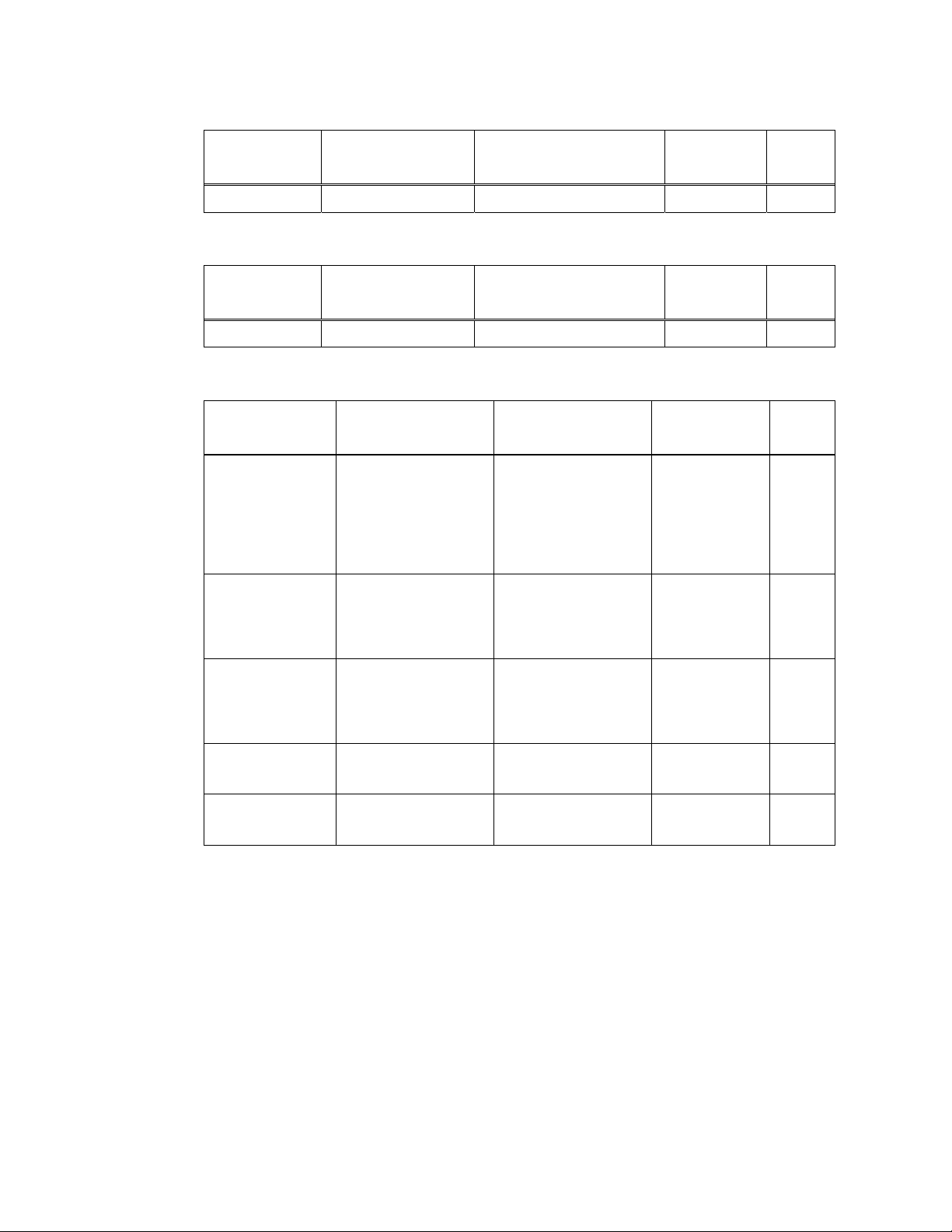

1-4 Special Tools for Service

Name Tool No. Purpose Remarks

MOLYKOTE

PG641

CK-0562-000 To be applied to the lift cam base upper

gear and the lift cam shaft sliding portion.

In common with

other models.

FLOIL KG-107A QY9-0057-000 To be applied to the carriage sliding

portion, the carriage rail portion, and the

paper guide flapper’s sliding portion.

1-3

In common with

other models.

1-5 Serial Number Label Location

The middle on the rear cover

1-4

2. LIST OF ERROR DISPLAY / INDICATION

Error Messages

Look for the applicable error message and execute the appropriate countermeasures.

2-1 User’s error messages

Look for the applicable error message and execute the appropriate countermeasures.

“BLACK INK LOW”

Cause: The ink level in the black ink tank is low.

Solution: Make sure you have a new black ink tank ready to replace the used one when ink runs out. If the

machine stops printing when copying or photo printing, you can continue printing by pressing the

[OK] button. However, note that ink may run out. If print quality deteriorates or the print out is blank,

replace the ink tank.

“CANNOT USE CARD TURN OFF AND ON”

Cause: You have inserted a memory card incompatible with the machine or a damaged memory card into the

card slot.

Solution: Remove the memory card from the card slot, and then turn the power OFF and ON again.

“CARD READ ERROR TURN OFF AND ON”

Cause: The data on the memory card may be inaccessible.

Solution: Check the data on the memory card in your digital camera.

Check the connection between the multi-card board and the MAIN board.

Replace the multi-card board.

Replace the MAIN board.

1-5

“CARTRIDGE JAMMED”

Printing position compensation failed

Cause: Carriage movement prevented by one of the following.

Damaged or deformed carriage shaft.

Insufficient grease.

Solution: Replace the carriage shaft.

Replace the deformed parts.

Apply more grease.

Cause: Bi-directional print displacement compensation failed because the carriage motor is out of step, or

some similar reason.

Solution: Replace the carriage motor.

Home position error

Cause: Tried to stop the carriage unit that has been moving or to move the carriage unit at a pause by force.

Solution: Do not touch the carriage unit other than the carriage at the cartridge replacement position.

Cause: Foreign body in carriage section.

Solution: Open flatbed ass’y and remove the foreign body.

Cause: Loose carriage belt.

Solution: Replace the carriage unit.

Cause: Carriage motor does not work.

Solution: Switch Power OFF/ON.

Replace the carriage motor.

Cause: The position of the carriage cannot be detected (due to smears on the carriage encoder film or a MAIN

board failure).

Solution: Switch Power OFF/ON.

Wipe the carriage encoder film with a cloth moistened with alcohol.

Replace the carriage unit.

Replace the carriage encoder film.

Replace the MAIN board.

“CHECK PRINTER”

Cause: The printer’s internal unit has malfunctioned.

Solution: Clear the paper jam.

Press the [OK] button.

Reinstall the print head.

Turn the power off and on.

1-6

“COLOR INK LOW”

Cause: The ink level in the color ink tank is low.

Solution: Make sure you have a new color ink tank ready to replace the used one when ink runs out. If the

machine stops printing when copying or photo printing, you can continue printing by pressing the

[OK] button. However, note that ink may run out. If print quality deteriorates or the print out is blank,

replace the ink tank.

“COVER OPEN”

Cause: You opened the scanning unit (printer cover) during an operation.

Solution: Close the scanning unit (printer cover).

Cause: Cover sensor failure.

Solution: Replace the cover sensor.

“PUT IN CARTRIDGE”

Cause: The print head is not set in this machine.

Solution: Set the print head.

“PLEASE CLEAR PAPER JAM AND PRESS [OK]”

Cause: There is a recording paper jam.

Solution: Clear the recording paper jam and press the [OK] button.

“PLEASE L

Cause: The multi-purpose tray is empty.

Solution: Load paper in the multi-purpose tray. Make sure that the stack is below the paper limit mark. Then

“WASTE NEAR FULL”

Cause: The waste ink tank absorber (which holds the ink used for print head cleaning) is nearly full.

Solution: If the “CHECK PRINTER” message is displayed, select “COUNTER ACCESS” in the Service Mode

“WRONG CARTRIDGE”

Cause: The print head is not installed correctly.

Solution: Install the print head correctly.

Cause: The print head failure.

Solution: Replace the print head.

OAD PAPER AND PRESS [OK]”

press the [OK] button.

and input “0” at the waste ink counter. After that, replace the ink tank absorber.

1-7

2-2 User Error Codes

None.

2-3 Service Error Codes

None

2-4 New Error Code and Recovery Methods

None

2-5 Warnings

Main body no LED indications.

Displayed warning Remarks

None None

1-8

2-6 Troubleshooting by symptom

Symptom Solution Remarks

General

errors

Printing

operation

errors

Printing

quality

errors

The unit does not power on.

Nothing is displayed in LCD

display.

The buttons on the

operation panel do not

work.

Paper is not fed properly.

(The Paper feed motor does

not run.)

Paper is not picked up from

the auto sheet feeder.

The carriage motor does not

run.

- Nothing is printed at all.

- Colors are not printed.

(1) Check the power cord connection.

(2) Check the connection between the

MAIN board (J5) and the power

supply unit.

(3) Replace the power supply unit.

(1) Check the connection between the

Operation panel unit and the MAIN

board (J4).

(2) Replace the SCANNER unit.

(3) Replace the MAIN board.

(1) Check the connection between the

Operation panel unit and the MAIN

board (J4).

(2) Replace the SCANNER UNIT.

(3) Replace the MAIN board.

(1) Check the connection between the

paper feed motor and the MAIN board

(J7).

(2) Replace the paper feed motor.

(3) Replace the MAIN board. *1

(1) Check whether there is any broken

part or foreign matter in the paper feed

section.

(2) Replace the SEPARATION UNIT.

(3) Replace the MAIN board. *1

(1) Check the connection between the

carriage motor and the MAIN board

(J6).

(2) Replace the carriage motor.

(3) Replace the MAIN board. *1

(1) Remove the print head and reinstall

it.

(2) Perform the cleaning on the print

head five times with the cleaning

operation and print out the nozzle

check pattern. Visually cheek the test

print for non-discharge of ink from

nozzle. (Fig. 1-1)

(3) Replace the print head. *2

(4) Replace the appropriate ink tank.

(5) Replace the purge unit.

(6) Replace the carriage unit.

(7) Replace the MAIN board. *1

1-9

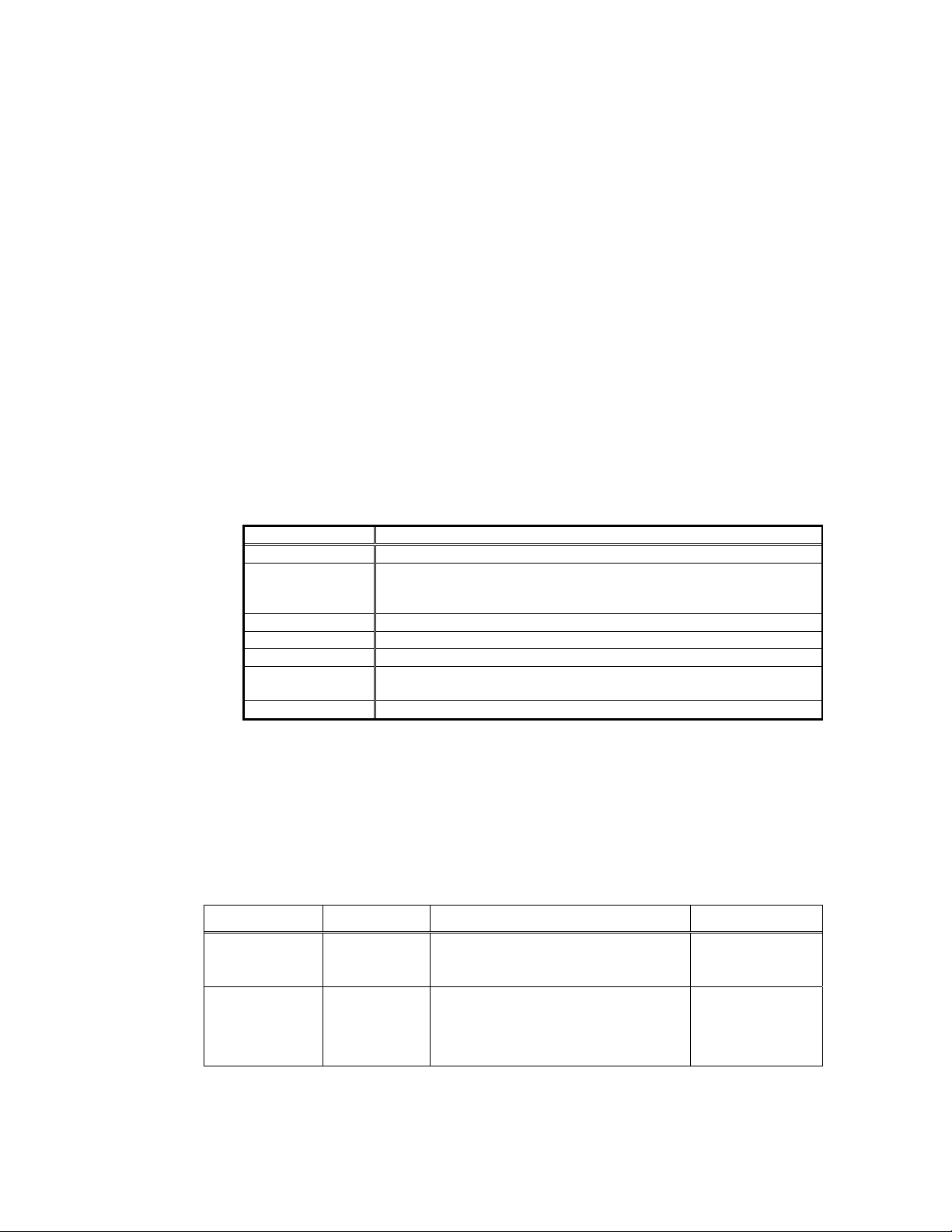

Symptom Solution Remarks

Printing

quality

error

Scanning

errors

*1 The absorption amount of the waste ink absorber is set based upon the amount that the BJ cartridge has

ejected. The settings of the waste ink capacity are stored in EEPROM of MAIN board. When replacing the MAIN

board, check the waste ink capacity before the replacement, and input the waste ink capacity at the new MAIN

Blotches or blank ink appears

after cleaning the print head.

Lines that the printing data

does not contain are printed.

Soiled paper

Pictures or characters are

extended in print results.

The Contact Sensor drive

motor does not run.

The Scanned images are

abnormal

The image has vertical stripes.

The colors or the brightness of

the image is abnormal.

.

(1) Remove the print head and reinstall

it.

(2) Perform the cleaning on the print

head five times with the cleaning

operation and print out the nozzle

check pattern. Visually check the

test print for non-discharge of ink

from nozzle. (Fig. 1-1)

(3) Replace the print head. *2

(4) Replace the appropriate ink tank.

(5) Replace the purge unit.

(6) Replace the carriage unit.

(7) Replace the MAIN board. *1

(8) Replace the MAIN board.

(1) Feed a few sheets of paper through

the machine.

(2) Clean the paper feed section with a

clean cloth or a clean cotton bud.

<Carriage scanning direction>

(1) Check whether grease is applied to

the carriage encoder film.

(2) Carefully and gently wipe the

carriage encoder film using lint-free

paper moistened with

Do not scratch the surface of the

carriage encoder film.

(3) Replace the carriage encoder film.

(4) Replace the carriage unit.

<Paper feeding direction>

(1) Check whether grease is applied to

the paper feed encoder film.

(2) Carefully and gently wipe the paper

feed encoder film using lint-free

paper moistened with

Do not scratch the surface of the

paper feed encoder film.

(3) Replace the paper feed encoder

film.

(4) Replace the timing sensor unit.

(1) Check the connection between the

contact sensor drive motor and the

MAIN board (J8).

(2) Replace the scanner unit.

(3) Replace the MAIN board.

(1) Check the connection between the

contact sensor and the MAIN board

(J8).

(2) Replace the scanner unit.

(3) Replace the MAIN board.

(1) Clean the document glass.

(2) Check the connection between the

contact sensor and the MAIN board

(J8).

(3) Replace the scanner unit.

(4) Replace the MAIN board.

alcohol.

alcohol.

1-10

Loading...

Loading...