Large-Format Printers

Troubleshooting

2

This Basic Guide includes three booklets.

Be sure to read " Safety Precautions" in the fi rst

booklet, Printer Operations.

Basic Guide

Printer Operations

Safety Precautions ........................................2

Types of manuals .............................................5

Documentation Conventions ............................6

Parts .................................................................8

Attaching the Roll Holder to Rolls ...................12

Loading Rolls in the Printer ............................14

Removing the Roll from the Printer ................16

Loading Sheets in the Printer .........................18

Removing Sheets ...........................................20

Consumables..................................................21

Replacing Ink Tanks .......................................22

Replacing the Maintenance Cartridge ............26

Replacing the Printhead .................................30

Menu Map.......................................................35

Troubleshooting

Troubleshooting ................................................2

If Roll Paper Jams ..........................................18

If a Sheet Jams...............................................21

If Paper is Soiled ............................................23

If Printing is Faint ............................................25

If Vertical Lines are Warped or Colors are

Misaligned ..................................................26

If Banding Occurs ...........................................28

If Line Length Does Not Match .......................30

Error Messages ..............................................32

1

2

Printer Relocation

Preparing to Transfer the Printer ......................2

Reinstalling the Printer .....................................6

Printer Driver Installation

Installing the Printer Driver (Windows) .............9

Installing the Printer Driver (Mac OS X) .........11

Convenient Printer Driver Features ................13

Read this manual before attempting to operate the printer.

Keep this manual in a handy location for future referencing.

3

ENG

Troubleshooting

This section gives troubleshooting tips in case of problems.

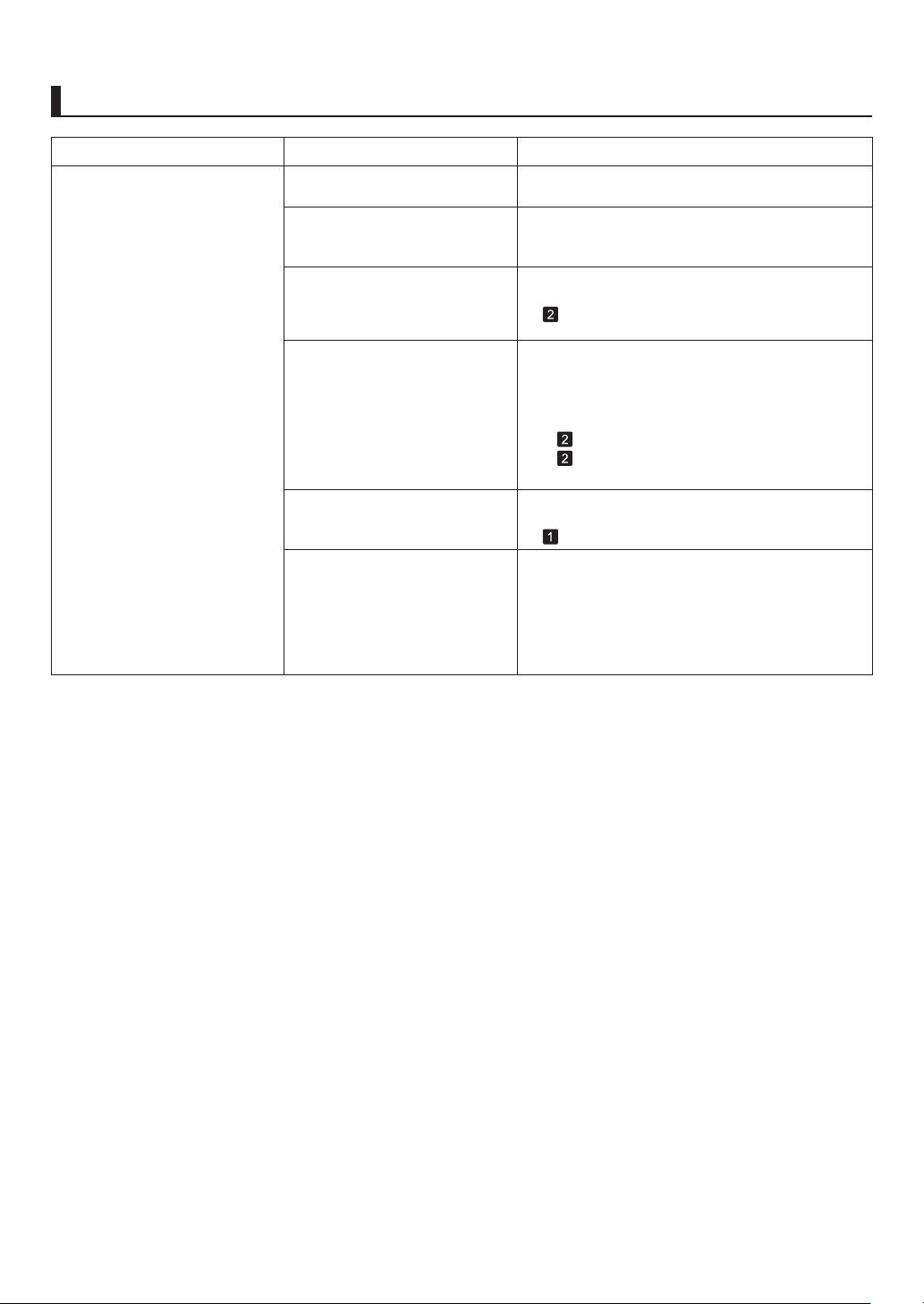

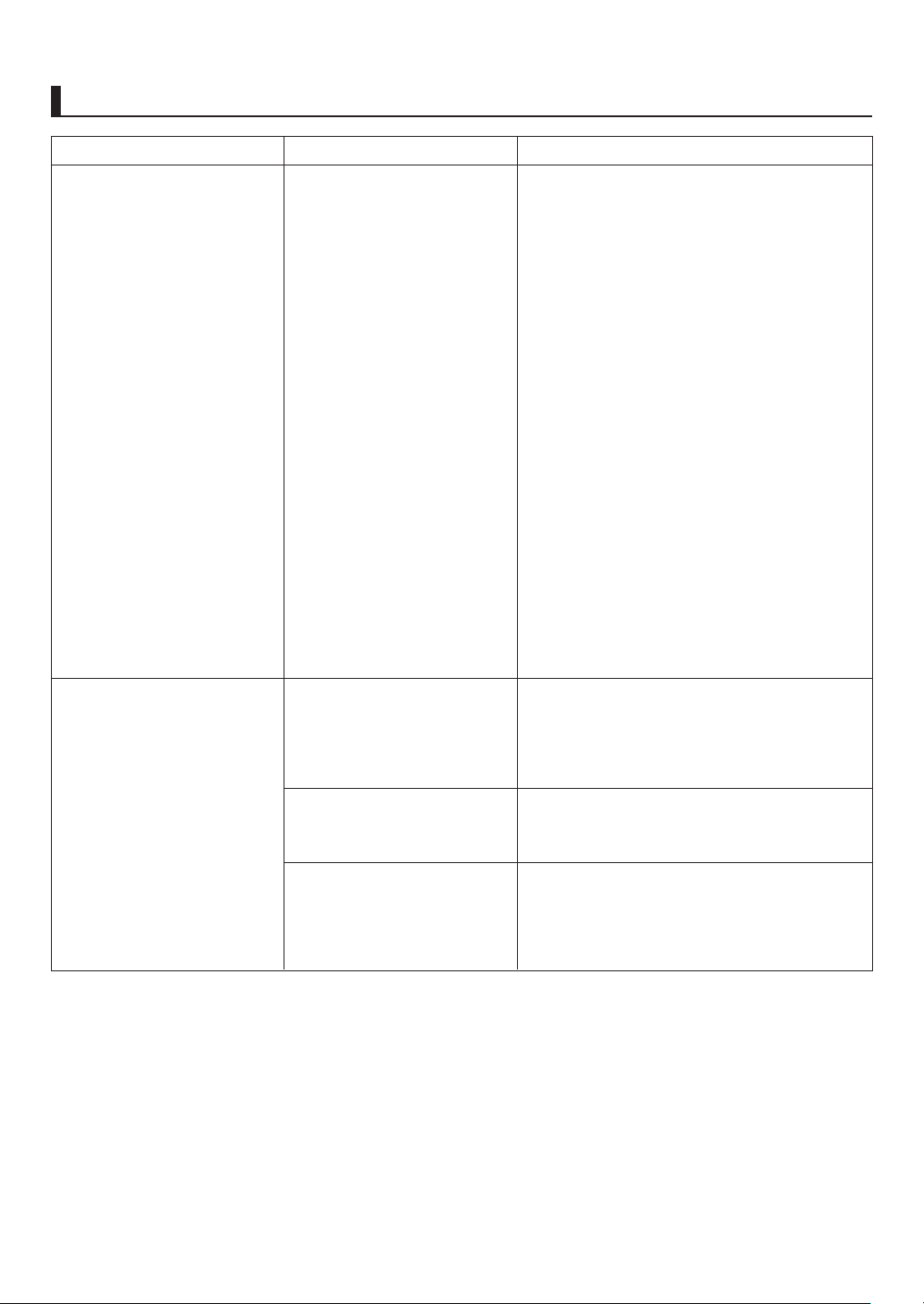

Paper Problems

Phenomenon

Roll Paper Cannot be Inserted into

the Paper Feed Slot

Cannot load sheets Press the Load button and select the paper source.The paper source selection is

Paper is not cut straight The paper is bent or curled at the

Paper is not cut In the printer driver, No or Print

A depression is left on the leading

edge

The size of clear film cannot be

detected

Roll Paper is Continuously Ejected Although sheets are selected

Cause Corrective Action

The roll paper is warped. Straighten out curls and reload the roll.

Paper is jammed by the paper feed

slot.

incorrect.

cut position.

position before it is cut.

You are using paper that cannot be

cut with the Cutter Unit .

Cut Guideline is specified in Auto

Cut .

In the Control Panel menu,

Cutting Mode is set to Eject or

Manual .

Keeping a roll in the printer for a

long time without printing on it may

leave a depression on the leading

edge.

The Platen is soiled with ink or

other substances.

as the paper source, a roll was

advanced.

Remove the jammed paper.

, If Roll Paper Jams)

(→

(→

, If a Sheet Jams)

Straighten out any curling by the edges of the paper.

Reload the paper correctly.Paper rises by the ends of the cut

Specify Manual in Cutting Mode in the Control

Panel menu and use scissors or a cutting tool to cut

the roll after printing.

(→"Specifying the Cutting Method for Rolls," User

Manual)

Specify Yes in Auto Cut in the printer driver.

If the Cutting Mode is Eject , press the Cut button to

cut the paper.

If the Cutting Mode is Manual , cut rolls with scissors

or the like.

When printing quality is most important, we

recommend setting TrimEdge Reload to On or

Automatic so that the paper edge is automatically cut

before printing.

(→ , Menu Map)

Open the Top Cover and clean the entire Platen .

, If Paper is Soiled)

(→

After roll ejection stops, follow these steps to reload

the roll.

Push the Release Lever back.1.

Open the Roll Cover .2.

Using both hands, rotate the Roll Holder toward

3.

the back to rewind the roll. At this time, ensure that

both ends of the roll are rewound evenly.

Pull the Release Lever forward.4.

Load the roll. At this time, be sure to press the Load

5.

button and select Load Roll Paper .

(→

, Loading Rolls in the Printer)

2

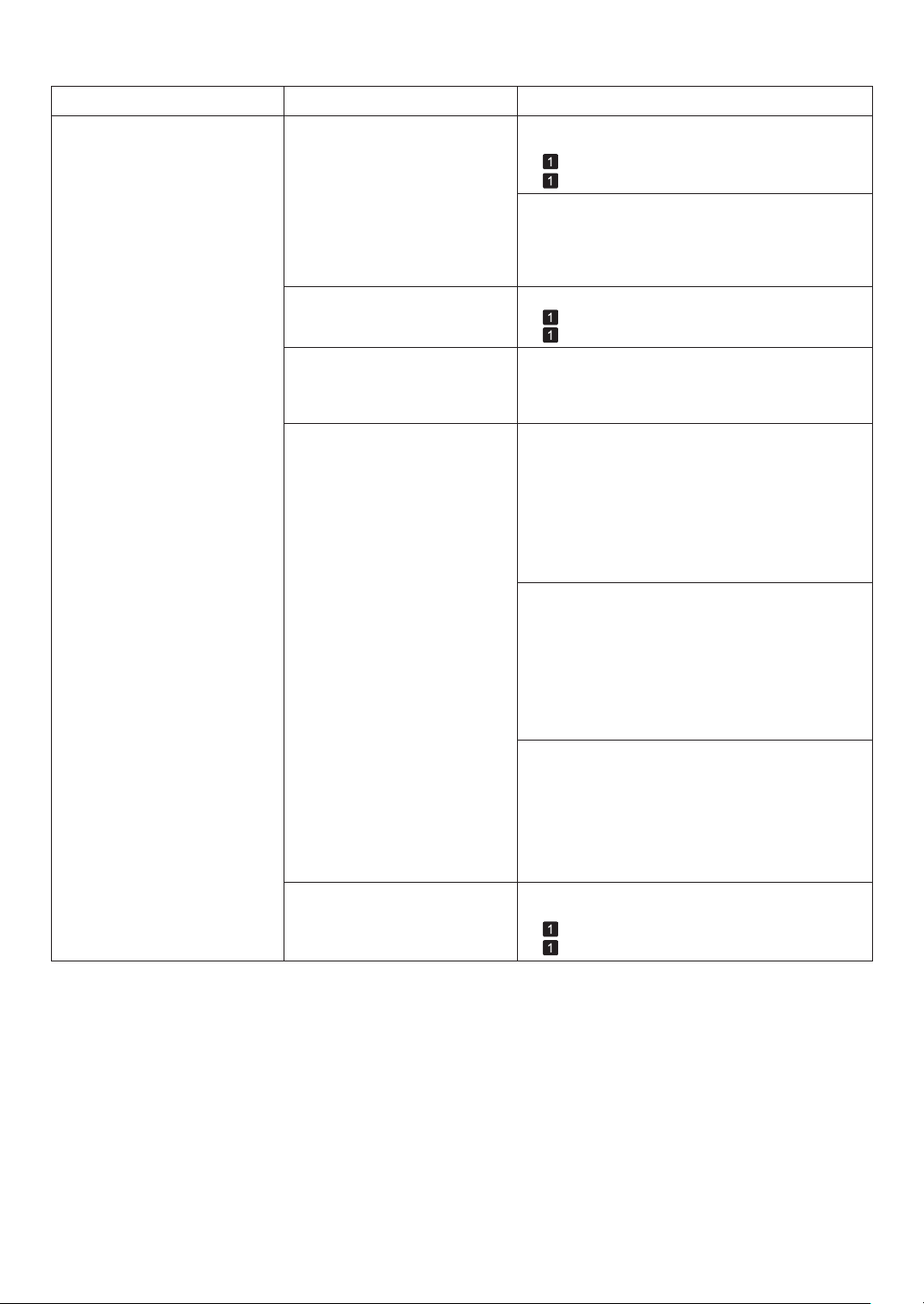

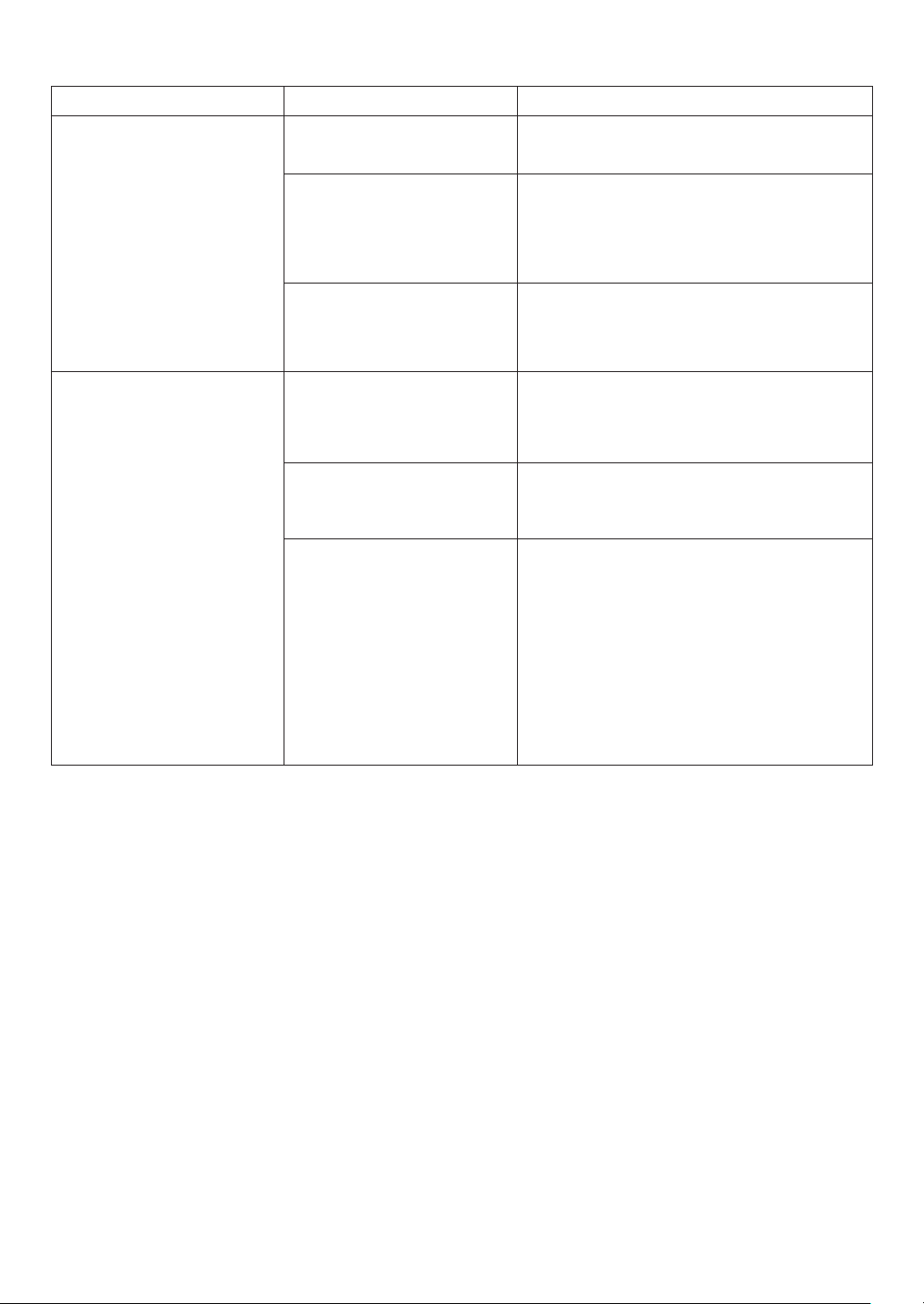

Printing Does Not Start

Troubleshooting

Phenomenon

The Data Lamp on the control

panel does not light up

The printer does not respond even

if print jobs are sent

Ink Filling.. is displayed

The display screen indicates

Agitating

Cause Corrective Action

The printer is not on.

The printer is not selected in the

printer driver. (The printer is in

Sleep mode.)

The print job is paused. (The

printer is in Sleep mode.)

In the Control Panel menu, Pause

Print is On .

You have selected Save in mail

box in Output Method on the

printer.

Print jobs are pending. Manage the jobs on hold and print as needed.

The printer was forced off during

operation.

Make sure the power cord is securely plugged in, all

the way. Press the Power button to turn on the printer.

In Windows, select the printer by clicking Select

Printer or Printer in the printing dialog box and try

printing again.

In Mac OS X, select the printer by clicking Printer

Setup Utility (or Print Center ) and try printing again.

In Windows, restart the print job as follows.

Select the printer icon in the Printers and Faxes

1.

(or Printers ) window.

Clear Pause Printing in the File menu to restart the

2.

print job.

In Mac OS X, restart the print job as follows.

Click Print & Fax . (This is identified as Printer

1.

Setup Utility in some versions of Mac OS X.)

Select the printer, and then Start Jobs in the

2.

Printers menu to restart the print job.

Set Pause Print to Off .

(→"Pausing Printing," User Manual)

Print the job saved on the printer's hard disk.

(→"Printing Saved Jobs," User Manual)

(→"Managing Pending Jobs (Printing or Deleting Jobs

on Hold)," User Manual)

Wait until the system has been filled with ink. This

process may take about seven and a half minutes.

Please wait until ink agitation is finished.Ink agitation is in progress.

The time for agitation varies depending on how long

the printer has been off. (Between about 30 seconds

and two minutes.)

3

Troubleshooting

The printer stops during a print job

Phenomenon

An error message is shown on the

Display Screen

The printer ejects blank, unprinted

paper

Status Corrective Action

An error message is displayed

during printing.

The last portion of roll paper was

used during a print job, and paper

could not be advanced because

the trailing edge is taped to the roll.

The leading edge of the roll paper

was cut to straighten it.

The Printhead nozzles are

clogged.

A print job was received from an

incompatible printer driver.

The printer has received print data

that includes HP RTL commands

when Auto Rotate is On in the

Control Panel menu.

The printer is damaged.

Check the error message and take action as

necessary.

(→ , Error Messages)

Remove the used roll and insert a new roll.

, Removing the Roll from the Printer)

(→

(→"Removing the Roll Holder from Rolls," User

Manual)

(→"Loading and Printing on Rolls," User Manual)

The leading edge of rolls may be cut to straighten

it if you have selected Trim Edge First > On or

Automatic in the Control Panel menu.

(→"Cutting the Leading Edge of Roll Paper

Automatically," User Manual)

Print a test pattern to check the nozzles and make

sure the Printhead is in good condition for printing.

(→"Checking for Nozzle Clogging," User Manual)

Use the correct imagePROGRAF printer driver for the

printer and try printing again.

In the Control Panel , set Auto Rotate to Off and

print again.

(→

, Menu Map)

Contact your Canon dealer for assistance.

4

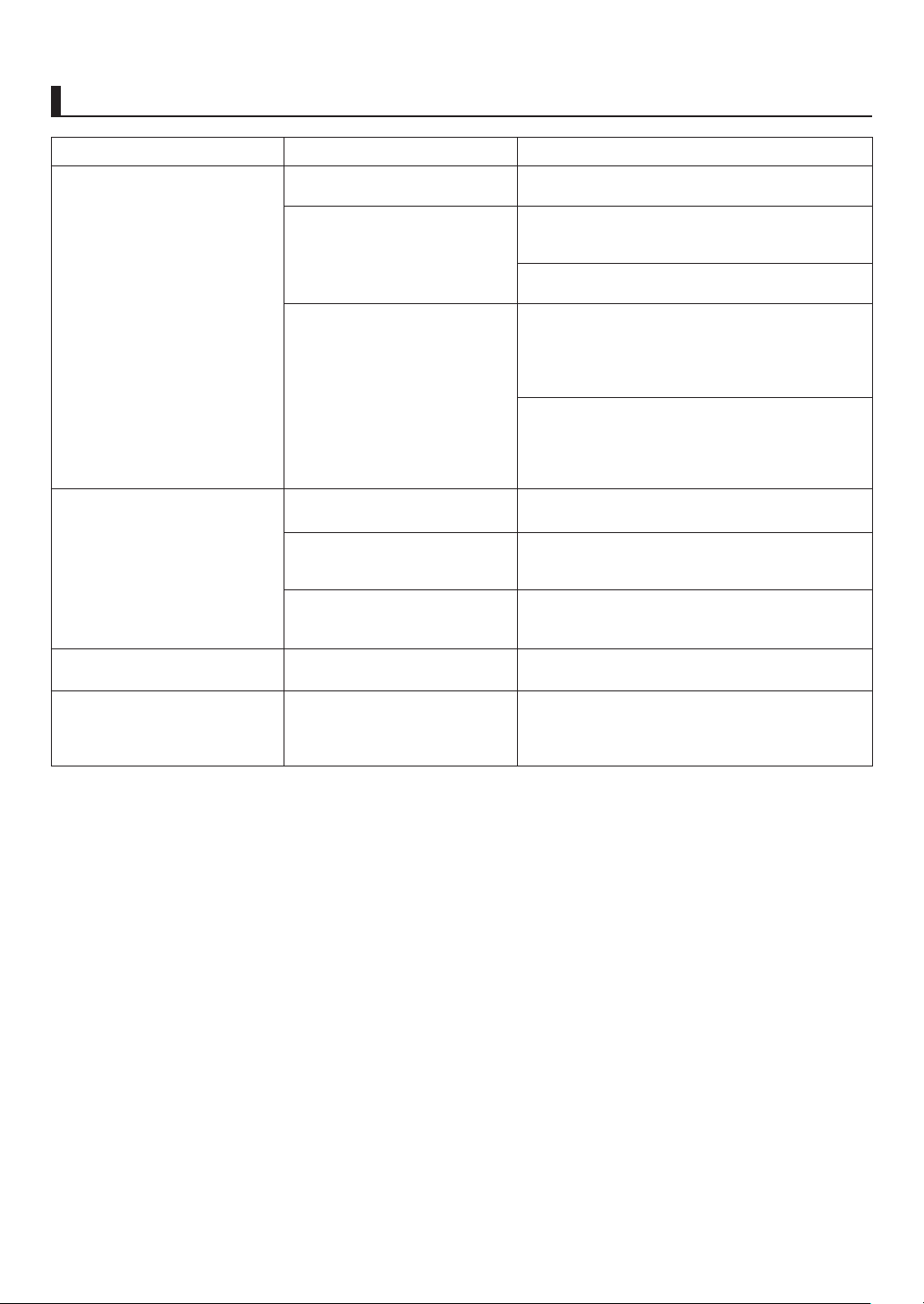

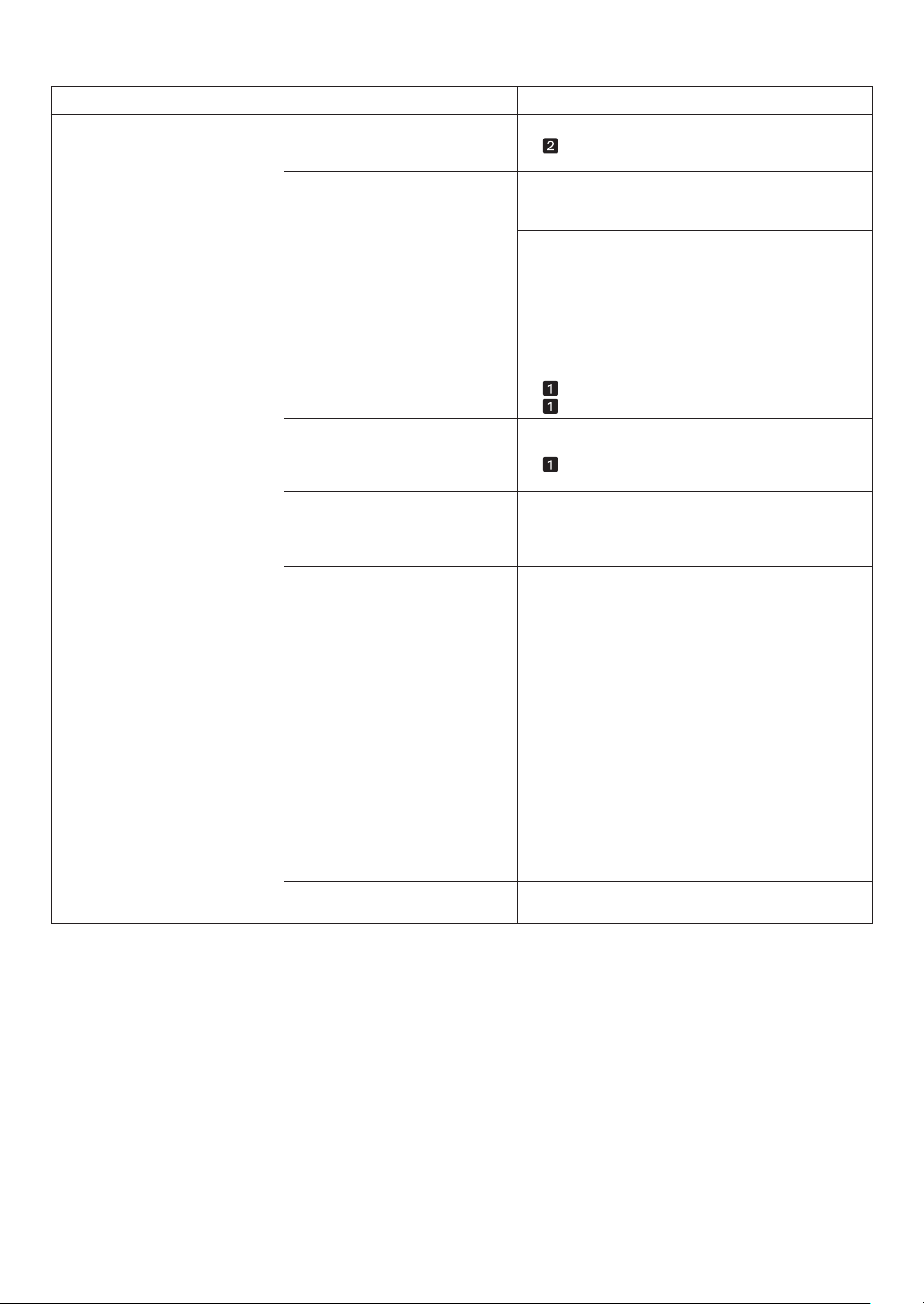

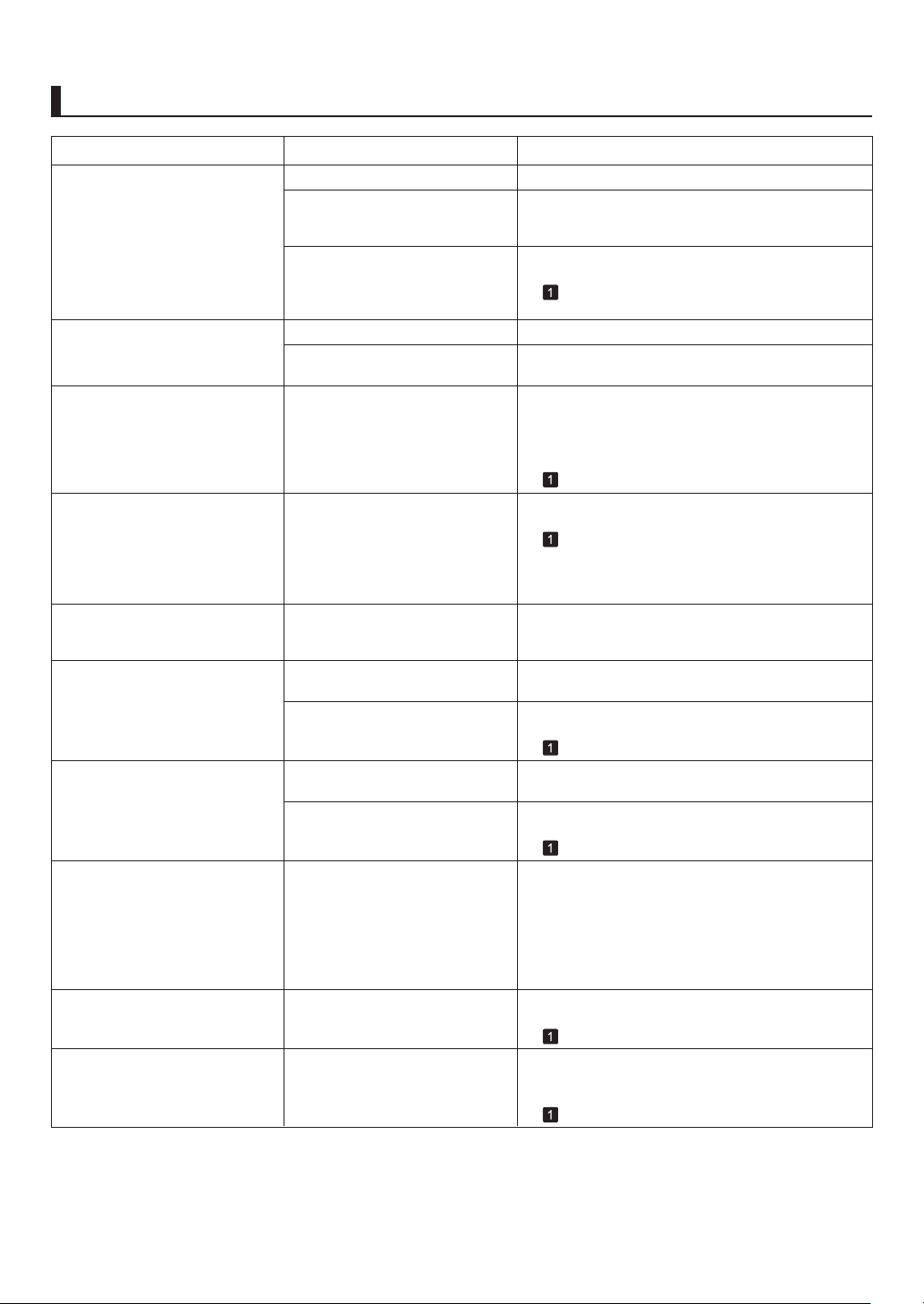

Problems with the Printing Quality

Troubleshooting

Phenomenon

Printing is faint

Cause Corrective Action

You may be printing on the wrong

side of the paper.

The Printhead nozzles are

clogged.

Because the printer was left

without ink tanks installed for some

time, ink has become clogged in

the ink supply system.

Paper is jammed inside the Top

Cover .

The ink was not dry when paper

was cut.

Printing may be faint if Print

Quality in Advanced Settings

in the printer driver is set to

Standard or Draft .

Print on the printing surface.

Print a test pattern to check the nozzles and see if

they are clogged.

(→"Checking for Nozzle Clogging," User Manual)

After the ink tanks have been installed for 24 hours,

run Head Cleaning B from the Control Panel .

, If Printing is Faint)

(→

Follow the steps below to remove the jammed piece

of paper inside the Top Cover .

Open the Top Cover and make sure the Carriage

1.

is not over the Platen .

Remove any scraps of paper inside the Top Cover .

2.

, If Roll Paper Jams)

(→

, If a Sheet Jams)

(→

Close the Top Cover .

3.

Specify a longer drying period in the Control Panel

menu, in Paper Details > Roll DryingTime .

, Menu Map)

(→

In Advanced Settings of the printer driver, choose

Highest or High in Print Quality .

Printing in Draft or Standard mode is faster and

consumes less ink than in Highest or High modes,

but the printing quality is lower.

(→"Giving Priority to Particular Graphic Elements and

Colors for Printing," User Manual)

5

Troubleshooting

Phenomenon

Paper rubs against the printhead

Cause Corrective Action

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

Paper has been loaded incorrectly,

causing it to wrinkle.

The Printhead is set too low in the

Control Panel menu.

You are printing on heavyweight

paper or paper that curls or

wrinkles easily after absorbing ink.

When you have loaded paper, the

paper you have loaded does not

match the type selected on the

Control Panel .

Load paper of the same type as you have specified in

the printer driver.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

1.

Press the Stop button and stop printing.

2.

Change the type of paper in the printer driver and

try printing again.

Reload the paper.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

In the Control Panel menu, set Head Height to

Automatic .

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

When printing on Heavyweight Coated Paper or

other paper-based media, choose a VacuumStrngth

setting of Strong or Strongest in the Control Panel

menu. If the paper still rubs, set Head Height to

Highest in the Control Panel menu.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

When printing on CAD Tracing Paper or other film-

based media, choose a VacuumStrngth setting of

Standard , Strong , or Strongest in the Control Panel

menu. If the paper still rubs, set Head Height to

Highest in the Control Panel menu.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

When printing on paper 0.1 mm (0.004 in) thick or

less, choose a VacuumStrngth setting of Weakest

in the Control Panel menu. If the paper still rubs, set

Head Height to Highest in the Control Panel menu.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

Be sure to select the correct type of paper in the

Control Panel menu when loading paper.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

6

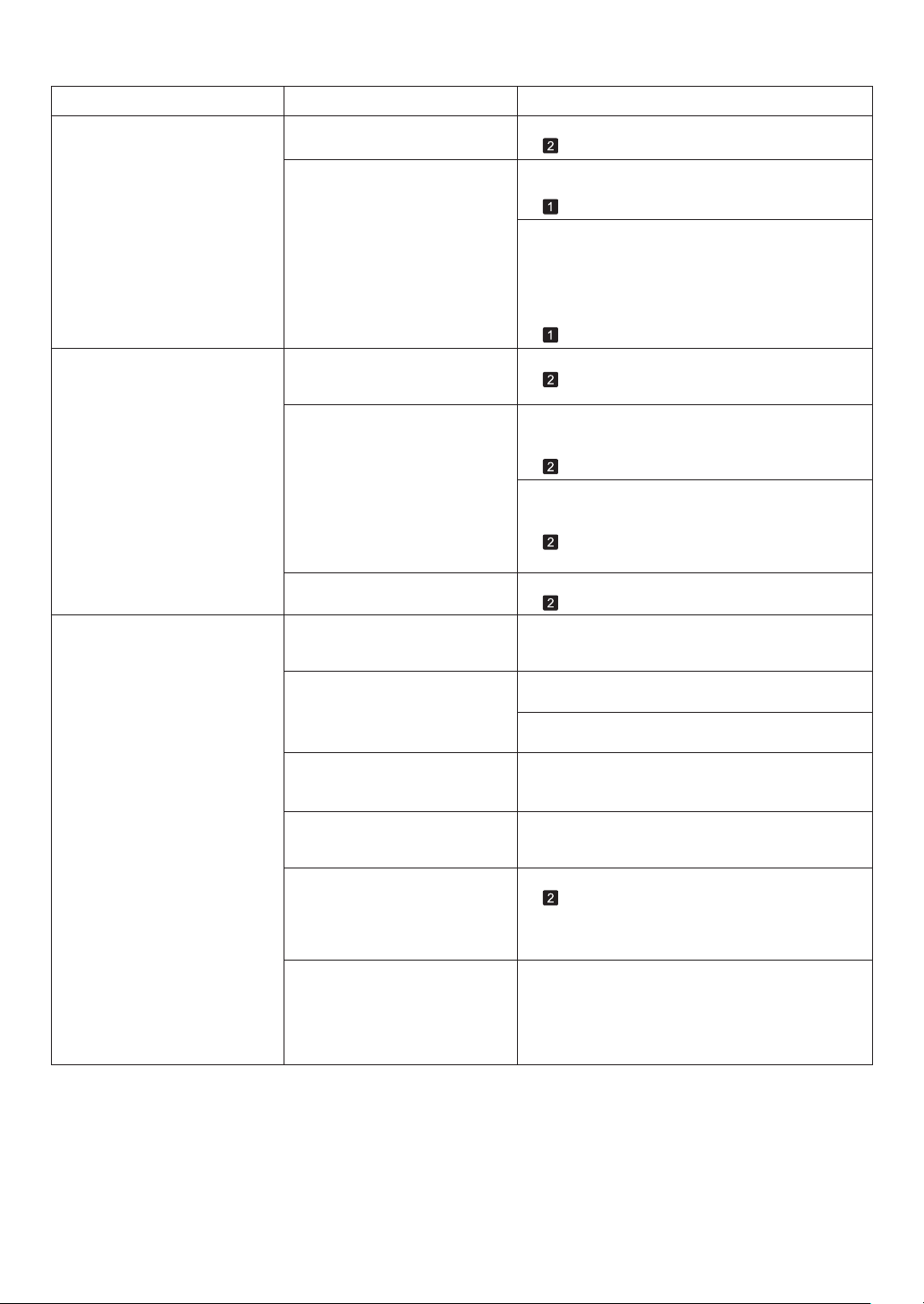

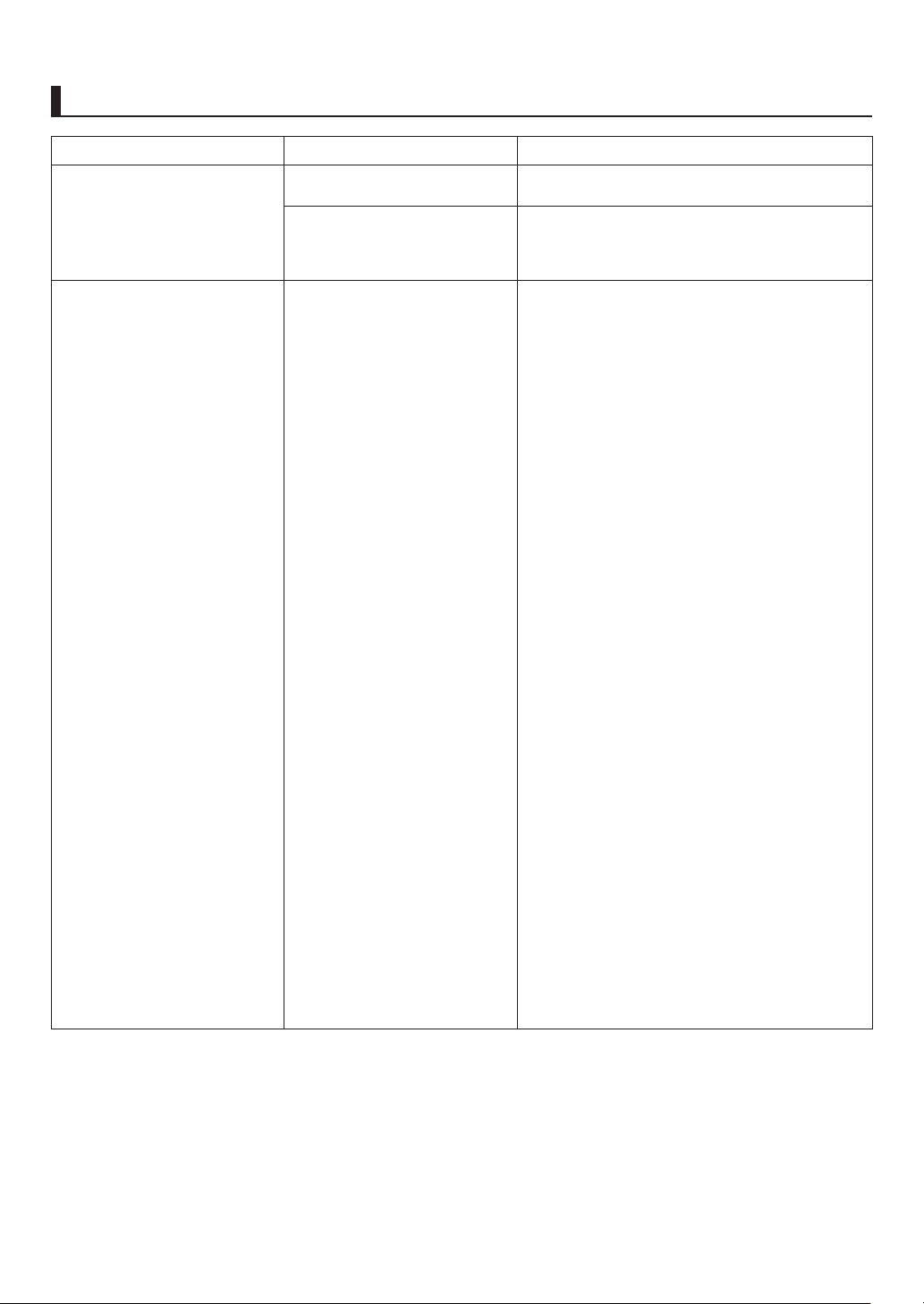

Phenomenon Cause Corrective Action

The edges of the paper are dirty Open the Top Cover and clean the Platen .The Platen has become dirty after

borderless printing or printing on

small paper.

The type of paper as specified on

the printer does not match the type

specified in the printer driver.

The paper is wrinkled or warped.

A cut line is printed because

CutDustReduct. is On in the

Control Panel menu to reduce

cutting dust.

The Printhead is set too low in the

Control Panel menu.

You are printing on heavyweight

paper or paper that curls or

wrinkles easily after absorbing ink.

The

Ejection Guide is soiled.

(→

, If Paper is Soiled)

Make sure the same type of paper is specified on the

printer as in the printer driver.

(→"Changing the Type of Paper," User Manual)

Make sure the same paper type is specified in the

printer driver as on the printer.

Press the Stop button and stop printing.

1.

Change the type of paper in the printer driver and

2.

try printing again.

Straighten out the wrinkles or curls and reload the

paper. Do not use paper that has been printed on

previously.

(→

, Loading Rolls in the Printer)

(→

, Loading Sheets in the Printer)

If this function is not needed, set CutDustReduct. to

Off in the Control Panel menu.

, Menu Map)

(→

In the Control Panel menu, set Head Height to

Automatic .

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

When printing on Heavyweight Coated Paper or

other paper-based media, choose a VacuumStrngth

setting of Strong or Strongest in the Control Panel

menu. If the paper still rubs, set Head Height to

Highest in the Control Panel menu.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

When printing on CAD Tracing Paper or other film-

based media, choose a VacuumStrngth setting of

Standard , Strong , or Strongest in the Control Panel

menu. If the paper still rubs, set Head Height to

Highest in the Control Panel menu.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

Clean the Ejection Guide .

(→"Cleaning the Printer Exterior," User Manual)

Troubleshooting

7

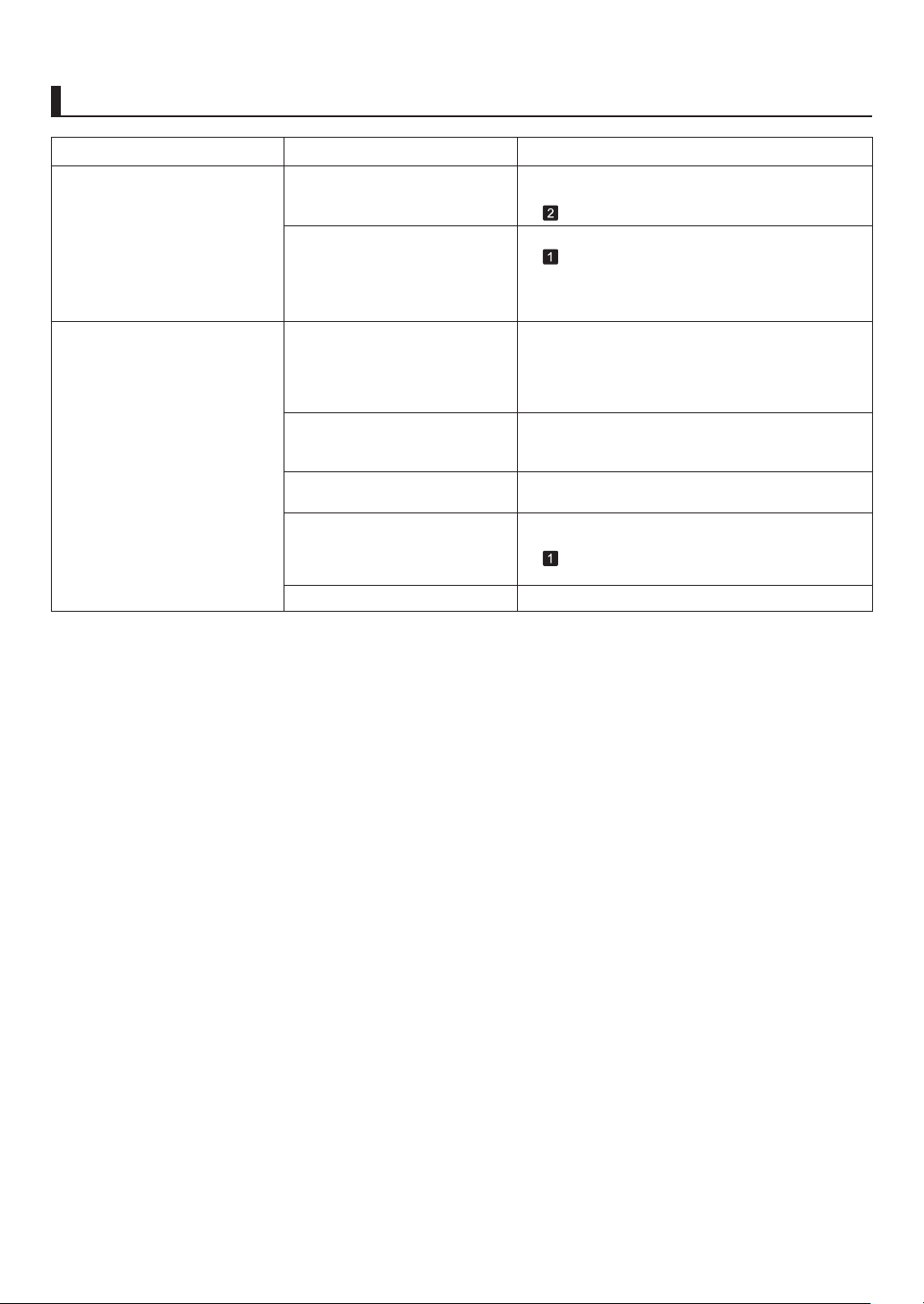

Troubleshooting

Phenomenon

The surface of the paper is dirty Clean the Paper Retainer .

The back side of the paper is dirty The Platen has become dirty after

Printed colors are inaccurate

Cause Corrective Action

The Paper Retainer is soiled.

, If Paper is Soiled)

(→

You are using a paper that does

not dry easily.

borderless printing or printing on

small paper.

The Platen has become soiled

because you have set Width

Detection to Off in the Control

Panel menu.

The Paper Retainer is soiled.

Color adjustment has not been

activated in the Advanced

Settings of the printer driver.

Colors have not been adjusted on

the computer or monitor.

The Printhead nozzles are

clogged.

In the Windows printer driver,

Application Color Matching

Priority is not selected.

Printhead characteristics gradually

change through repeated use, and

colors may change.

Color may change slightly even

on the same model of printer if

you use a different version of the

firmware or printer driver, or when

you print under different settings or

in a different printing environment.

In the Control Panel menu, set Roll DryingTime to

at least 1 min.

, Menu Map)

(→

When paper that does not dry easily is used for

printing, it may curl during printing and touch the

output tray.

In this case, in the Control Panel menu, set Scan

Wait Time to an option other than Off .

However, note that printing will now take longer.

(→

, Menu Map)

Open the Top Cover and clean the Platen .

(→

, If Paper is Soiled)

Set Width Detection to On in the Control Panel

menu, and then open the Top Cover and clean the

Platen .

, If Paper is Soiled)

(→

Open the Top Cover and clean the Platen . After this,

manually advance the roll onto the Platen before

printing.

(→

, If Paper is Soiled)

(→"Feeding Roll Paper Manually," User Manual)

Clean the Paper Retainer .

, If Paper is Soiled)

(→

In the Advanced Settings of the printer driver, access

Color Settings in Color Mode to adjust colors.

Refer to the computer and monitor documentation to

adjust the colors.

Adjust the settings of the color management software,

referring to the software documentation as needed.

Print a test pattern to check the nozzles and see if

they are clogged.

(→"Checking for Nozzle Clogging," User Manual)

Click Special Settings on the Layout sheet of the

printer driver and select Application Color Matching

Priority in the dialog box.

Adjust the Printhead alignment.

(→

, If Vertical Lines are Warped or Colors are

Misaligned)

(→"Manual Adjustment to Straighten Lines and Colors

(Head Posi. Adj.)," User Manual)

Follow these steps to prepare the printing

environment.

Use the same version of firmware or printer driver.1.

Specify the same value for all settings items.2.

8

Phenomenon Cause Corrective Action

Banding in different colors occurs The paper feed amount is out of

adjustment.

Printing does not proceed

smoothly because print jobs are

interrupted during transmission.

In the Control Panel menu, Adj.

Priority is set to Print Length .

The Printhead is out of alignment. Adjust the Printhead alignment.

The Printhead nozzles are

clogged.

Streaks may occur if you set the

Print Quality too low.

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

Adjust the feed amount.

(→"Adjusting the Feed Amount," User Manual)

Exit other applications and cancel other print jobs.

Setting Adj. Priority to Print Quality in the Control

Panel menu and adjusting the feed amount may

improve results.

(→"Adjusting the Feed Amount," User Manual)

(→ , If Vertical Lines are Warped or Colors are

Misaligned)

Print a test pattern to check the nozzles and see if

they are clogged.

(→"Checking for Nozzle Clogging," User Manual)

Choose a higher level of Print Quality in the

Advanced Settings of the printer driver and try

printing again.

Printing in Draft or Standard mode is faster and

consumes less ink than in Highest or High modes,

but the printing quality is lower.

(→"Giving Priority to Particular Graphic Elements and

Colors for Printing," User Manual)

Load paper of the same type as you have specified in

the printer driver.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

Troubleshooting

9

Troubleshooting

Phenomenon Cause Corrective Action

Colors in printed images are

uneven

Line Drawing/Text is selected

when printing images in many solid

colors.

You are printing on paper that curls

easily.

Printed colors may be uneven if

you set the Print Quality too low.

Color may be uneven between

dark and light image areas.

When borderless printing is used,

the edge of the paper is cut during

printing. Thus, ink density may be

slightly uneven at the edges.

The Printhead is out of alignment.

Drying documents stacked on

each other may cause uneven

colors.

Density may be uneven if you use

Glossy Paper or Coated Paper .

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

In Print Priority in the Advanced Settings of the

printer driver, choose Image .

Printed colors may appear uneven on the leading

edge of paper that is susceptible to curling. Select

a stronger level in VacuumStrngth in the Control

Panel menu to increase suction against the paper, or

specify a trailing margin of 20 mm (0.79 in) or more.

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

Choose a higher level of Print Quality in the

Advanced Settings of the printer driver.

Printing in Draft or Standard mode is faster and

consumes less ink than in Highest or High modes,

but the printing quality is lower.

(→"Giving Priority to Particular Graphic Elements and

Colors for Printing," User Manual)

Select Unidirectional Printing in the Advanced

Settings of the printer driver.

Specify No in Auto Cut in the printer driver before

printing. In this case, the paper can be printed without

borders on the left and right sides only. Cut the printed

document ejected from the printer, then use scissors

to cut away the edges on the top and bottom.

Choose a higher level of Print Quality in the

Advanced Settings of the printer driver.

(→"Giving Priority to Particular Graphic Elements and

Colors for Printing," User Manual)

Adjust the Printhead alignment.

(→ , If Vertical Lines are Warped or Colors are

Misaligned)

To avoid uneven colors, we recommend drying each

sheet separately.

In Advanced Settings of the printer driver, choose

Highest or High in Print Quality .

Load paper of the same type as you have specified in

the printer driver.

(→ , Loading Rolls in the Printer)

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

10

Phenomenon Cause Corrective Action

Image edges are blurred or white

banding occurs

The contrast becomes uneven

during printing

The length of printed images is

inaccurate in the feeding direction

The Platen suction is too strong.

The Printhead is set too high in the

Control Panel menu.

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

The paper feed amount is out of

adjustment.

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

In the Control Panel menu, Adj.

Priority is set to Print Quality .

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

In the Control Panel menu, set VacuumStrngth to

Weakest .

(→"Adjusting the Vacuum Strength (VacuumStrngth),"

User Manual)

In the Control Panel menu, set Head Height to

Lowest .

(→"Troubleshooting Paper Abrasion and Blurry

Images (Head Height)," User Manual)

Load paper of the same type as you have specified in

the printer driver.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

Adjust the feed amount.

(→"Adjusting the Feed Amount," User Manual)

Load paper of the same type as you have specified in

the printer driver.

(→

, Loading Rolls in the Printer)

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

Set Adj. Priority to Print Length in the Control

Panel menu, and then execute Adjust Length .

(→"Adjusting the Feed Amount," User Manual)

Load paper of the same type as you have specified in

the printer driver.

, Loading Rolls in the Printer)

(→

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

Troubleshooting

11

Troubleshooting

Phenomenon

Images are printed crooked

Documents are printed in

monochrome

Line thickness is not uniform

Lines are misaligned The Printhead alignment is not

Cause

In the Control Panel menu, Skew

Check Lv. is set to Loose or Off .

In the Control Panel menu, Width

Detection is set to Off .

In the Advanced Settings of

the printer driver, Monochrome ,

Monochrome (BK ink) , or

Monochrome Bitmap is specified

in Color Mode .

The Printhead nozzles are

clogged.

In the Special Settings dialog box

of the Windows printer driver, Fast

Graphic Process is selected.

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

adjusted.

The type of paper specified in the

printer driver does not match the

type loaded in the printer.

Corrective Action

In the Control Panel menu, set Skew Check Lv. to

Standard .

Set Width Detection to On in the Control Panel

menu.

In the Advanced Settings of the printer driver, specify

Color in Color Mode and try printing again.

Print a test pattern to check the nozzles and see if

they are clogged.

(→"Checking for Nozzle Clogging," User Manual)

Access the printer driver Properties dialog box from

Print in the File menu of the source application, and

follow these steps to print.

1.

Clear the option Open Preview When Print Job

Starts on the Main sheet.

2.

Clear the option Page Layout on the Layout sheet.

Click the Special Settings button on the Layout

3.

sheet to display the Special Settings dialog box,

and then clear the Fast Graphic Process check

box.

Load paper of the same type as you have specified in

the printer driver.

(→

, Loading Rolls in the Printer)

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

Adjust the Printhead alignment.

(→ , If Vertical Lines are Warped or Colors are

Misaligned)

(→"Manual Adjustment to Straighten Lines and Colors

(Head Posi. Adj.)," User Manual)

(→"Adjusting Line Misalignment (Head Inc. Adj.),"

User Manual)

Load paper of the same type as you have specified in

the printer driver.

(→

, Loading Rolls in the Printer)

(→

, Loading Sheets in the Printer)

Make sure the same type of paper is specified in the

printer driver as you have loaded in the printer.

Press the Stop button and stop printing.1.

Change the type of paper in the printer driver and

2.

try printing again.

12

Cannot Print Over Network

Troubleshooting

Phenomenon

Cannot connect the printer to the

network

Cannot print over a TCP/IP

network

Cause Corrective Action

The Ethernet cable is not

connected correctly to the printer's

Ethernet port.

The printer's IP address is not

configured correctly.

The printer's TCP/IP network

settings are not configured

correctly.

The computer you are trying

to print from is not configured

correctly.

1.2.Make sure the printer is connected to the network

with the correct Ethernet cable, and then turn the

printer on. For instructions on connecting the cable,

refer to the Setup Guide .

Make sure the Link indicator is lit.

The bottom indicator is green if the printer is

connected via 1000BASE-T, while the top indicator

is orange if connected via 100BASE-TX and the top

indicator is green if connected via 10BASE-T.

If the Link indicator is not lit, check the following

points.

Make sure the hub is on.•

Make sure the end of the Ethernet cable is

•

connected correctly.

Insert the Ethernet cable until it clicks and locks

in place.

Make sure there is no problem with the Ethernet

•

cable.

If there is any problem, replace the Ethernet

cable.

Check the communication mode with the hub.•

Although the printer normally detects the hub

communication mode and transmission rate

automatically (in auto negotiation mode),

sometimes the hub settings cannot be detected.

In this case, confi gure the connection method

manually, specifying the communication mode in

use.

(→"Confi guring the Communication Mode

Manually," User Manual)

Make sure the printer's IP address is configured

correctly.

(→"Configuring the IP Address Using

imagePROGRAF Device Setup Utility," User Manual)

(→"Configuring the IP Address Using the Printer

Control Panel," User Manual)

Make sure the printer's TCP/IP network settings are

configured correctly.

(→"Configuring the Printer's TCP/IP Network

Settings," User Manual)

Make sure the computer's TCP/IP network settings

are configured correctly.

(→"Configuring the Printer Driver Destination

(Windows)," User Manual)

(→"Configuring the Destination in TCP/IP Networks

(Macintosh)," User Manual)

13

Troubleshooting

Phenomenon Cause Corrective Action

Cannot print over AppleTalk or

Bonjour networks

Cannot print over a NetWare

network

The AppleTalk protocol is not

enabled on the printer.

The computer you are trying

to print from is not configured

correctly.

The computer and printer are not

on the same network.

The printer's NetWare settings are

not configured correctly.

The computer you are trying

to print from is not configured

correctly.

The NetWare server and services

are not configured correctly.

Activate AppleTalk on the printer.

(→"Configuring the Printer's AppleTalk Network

Settings," User Manual)

Make sure the computer's AppleTalk settings are

configured correctly.

(→"Configuring the Destination for AppleTalk

Networks (Macintosh)," User Manual)

(→"Configuring the Destination for Bonjour Network

(Macintosh)," User Manual)

Due to the nature of Bonjour, you cannot print if the

printer is on another network behind a router. Make

sure the computer and printer are on the same

network. For information about network settings, ask

your network administrator.

Make sure the printer's NetWare settings are

configured correctly. In particular, make sure a valid

frame type is selected.

(→"Configuring the Printer's NetWare Network

Settings," User Manual)

Make sure the computer's NetWare settings are

configured correctly.

(→"Configuring NetWare Network Settings," User

Manual)

Check the following points.

1.

Make sure the NetWare file server is running.

2.

Make sure there is enough free disk space on the

NetWare file server. Insufficient disk space may

prevent you from processing large print jobs.

3.

Start NWADMIN or PCONSOLE and confirm that

the print service is configured correctly and the print

queue is available.

4.

If data transmission to a printer on another subnet

fails, deactivate NCP burst mode in that printer's

network protocol settings.

If the printer is used in queue server mode, specify

5.

" Other/Unknown " as the printer type.

14

HP-GL/2 Problems

Troubleshooting

Phenomenon

Lines or images are incomplete in

printed HP-GL/2 jobs.

With HP-GL/2, printing is

misaligned

Lines are printed too thick or thin in

HP-GL/2 print jobs

HP-GL/2 jobs are printed in

monochrome (or color)

Printed colors of lines are

inaccurate during HP-GL/2 printing

HP-GL/2 printing takes a long time Please wait a while until printing is finished.Large print jobs with a lot of data

The printer stops when printing an

HP-GL/2 job (the carriage stops

moving)

Replotting with HP-GL/2 jobs is not

possible.

HP-GL/2 jobs are printed 6 mm

larger than specified

HP-GL/2 jobs are printed at

maximum size, even if a standard

size is specified

Cause Corrective Action

The memory is full.

An HP-GL/2 command not

supported by this printer was

received.

The printer has received print data

that includes HP RTL commands

when Auto Rotate is On in the

Control Panel menu.

The plotter origin is incorrect.

The Margin setting in the Control

Panel menu is incorrect.

The Width setting in the Control

Panel menu is incorrect.

The Color Mode setting in the

Control Panel menu is incorrect.

AdjustFaintLines is On in the

Control Panel menu.

take longer to print.

A job was printed when Input

Resolution in the Control Panel

menu was set to 600dpi .

The printer is analyzing the print

job.

A job was printed when Input

Resolution in the Control Panel

menu was set to 600dpi .

The data was lost because of

replotting.

The page size of the HP-GL/2

print job, as created in the source

application, is incorrect.

The page size of the HP-GL/2

print job, as created in the source

application, is incorrect.

Check the size of the data in the print job.

Check the print job and settings.

In the Control Panel , set Auto Rotate to Off and

print again.

(→

, Menu Map)

Check the printing commands.

Adjust the Margin setting values in the Control Panel

menu.

Check the Width setting value specified for Pen no.

in the palette ( Palette A or Palette B ) selected in the

Control Panel menu. If fine lines are printed faintly,

setting ThickenFineLines to On will print the lines

more distinctly.

(→

, Menu Map)

Check the Color Mode setting in the Control Panel

menu.

, Menu Map)

(→

However, for optimal Printhead performance, the

printer consumes trace amounts of color ink even

when Monochrome is selected as Color Mode .

Setting AdjustFaintLines to Off in the Control

Panel menu may help produce the expected results.

However, lines in some colors may appear broken.

In the Control Panel menu, set Input Resolution to

300dpi and print again.

(→ , Menu Map)

Please wait a while until printing is finished.

In the Control Panel menu, set Input Resolution to

300dpi and print again.

, Menu Map)

(→

Data for replotting is lost after the following

operations. In this case, send the print job again.

The memory buffer was cleared from the Control

1.

Panel .

The printer was turned off.2.

The printer received a new HP-GL/2 print job.3.

Printing has been canceled4.

In the Control Panel menu, set PageSizeProcess1

to On .

, Menu Map)

(→

In MAIN MENU , set PageSizeProcess2 or Conserve

Paper to On .

The layout will be changed to the optimal layout.

(→

, Menu Map)

15

Troubleshooting

Other Problems

Phenomenon

The printer does not go on Plug the power cord into the outlet, and then turn on

If the Printer Makes a Strange

Sound

Cause Corrective Action

The printer is unplugged.

The specified voltage is not

supplied.

The printer makes a sound during

operation.

the printer.

Check the voltage of the outlet and breaker.

Use a power source that conforms to the printer

specifications.

(→"Specifications," User Manual)

The following sounds do not indicate a problem with

the printer.

There is a sound of suction from the Platen •

To prevent paper from rising, paper is held against

the Platen by suction from Vacuum holes under it.

There is a sound when a different size of paper is

•

used and when the Carriage goes from side to side

When paper of a different size is used, a valve is

automatically activated to switch the area for paper

suction, which may make a sound. This mechanism

prevents suction from Vacuum holes where there is

no paper.

In addition, ink is ejected in sync with the movement

of the Carriage back and forth to ensure optimal ink

fl ow. At this time, the valve automatically switches

the area for paper suction, which may make a

sound.

Roll paper makes a fl uttering sound during printing•

There may be a fl uttering sound when large paper is

advanced.

You suddenly hear the tone for cleaning operations•

At regular intervals, for printer maintenance,

cleaning operations will begin automatically, even if

the printer is in Sleep mode.

You suddenly hear the tone for ink agitation•

At regular intervals, to ensure optimal printing

quality, the ink is agitated automatically, even if the

printer is in Sleep mode. Ink agitation takes about

30 seconds.

The ink is also agitated automatically under the

following conditions. Note that other operations are

not possible while Agitating is displayed on the

control panel.

After the printer is turned on. (The time for

•

agitation varies depending on how long the

printer was off—between about 30 seconds and

two minutes.)

After data transmission. (After about a minute

•

and a half, printing operations begin. However,

printing may start later after data reception,

depending on the size of print data.)

After ink tank replacement. (Ink agitation takes

•

about three and a half minutes.)

In other cases, contact your Canon dealer.

16

Loading...

Loading...