Canon iP90 Service Manual

PIXMA iP90

SER VICE

MANUAL

Canon

Copyright 2005, Canon U.S.A. This technical publication is the proprietary and confidential information of Canon U.S.A. which

shall be retained for reference purposes by Authorized Service Facilities of Canon U.S.A. Its unauthorized use is prohibited.

I. TABLE OF CONTENTS

Part 1 MAINTENANCE ......................................................................... 3

1. MAINTENANCE ...................................................................................................................3

1.1 Adjustment, Periodic Maintenance, Periodic Parts Replacement, and Consumables

Replacement, by Service Engineer.................................................................................3

1.2 Product Life.....................................................................................................................3

2. LIST OF ERROR DISPLAY / INDICATION...........................................................................4

2.1 Operator Call Errors (LED Blinks in Orange) ..................................................................4

3. REPAIR ................................................................................................................................5

3-1. Notes on Service Part Replacement (Disassembling/Reassembling)............................5

3-2. Special Notes on Repair Servicing.................................................................................5

3-3. Adjustment / Settings.....................................................................................................7

Part 2 TECHNICAL REFERENCE........................................................ 9

1. New technology....................................................................................................................9

2. Cleaning Mode and Amount of Ink Purged.........................................................................11

3. PRINT MODE.....................................................................................................................12

4. FAQ (Specific Problems and Solution)................................................................................16

2

Part 1 MAINTENANCE

1. MAINTENANCE

1.1 Adjustment, Periodic Maintenance, Periodic Parts Replacement, and

Consumables Replacement, by Service Engineer

(1) Adjustment (changes from the i70/PIXUS 50i base model)

Adjustment Timing Purpose Tool

Waste ink counter

resetting

At replacement of

- Drain pack ass'y

(QL2-0194: main waste ink

absorber)

or

- Ink absorbers

(QC1-5831/1211/1212:

platen waste ink absorbers)

Three items are to be

replaced at the same time.

To reset the waste ink

counter.

Note:

It is possible to reset the

main waste ink counter

and the platen waste ink

counter respectively.

In the i70 / PIXUS 50i and

i80 / PIXUS 80i, the waste

ink counters are reset at

the same time.

1.2 Product Life

(1) Ink tank

Note: The color red indicates the changes from the i70 / PIXUS 50i base model.

BCI-15 Black: 200 pages (JEIDA standard pattern J1, standard mode, plain paper)

185 pages (1,500-character pattern, standard mode, plain paper)

450 pages (JIS-SCID No. 5, standard mode, plain paper)

BCI-16 Color: 100 pages (JIS-SCID No. 5, standard mode, plain paper)

Approx.

time

None. 1 min.

3

2. LIST OF ERROR DISPLAY / INDICATION

Errors are indicated by the LED, and warnings are displayed on the monitor of the computer

connected to the printer.

2.1 Operator Call Errors (LED Blinks in Orange)

Note: The color red indicates changes from the i70 / PIXUS 50i base model.

LED

blinking in

orange

2 times No paper. Set paper, and press the

3 times Paper jam. Remove the jammed paper, and press

4 times Either black or color ink

tank (or both ink tanks) is

not installed, or not

installed properly.

5 times The print head is not

installed properly or the

print head has problems.

8 times Warning: The waste

ink absorber is almost

full (approx. 95% of the

maximum capacity).

9 times Communication with the

digital camera has been

failed./

The connected digital

camera or digital video

camera is not supported

by the PIXMA iP90 /

PIXUS iP90.

12 times Low battery. Put the battery on charge or print with

* For the PIXMA iP90 / PIXUS iP90, it is possible to reset ‘main waste ink counter’ and ‘platen waste

ink counter’ respectively.

For the i70 / PIXUS 50i and i80 / PIXUS 80i, they are reset at the same time.

Error Solution Remarks

Resume/Cancel button.

the Resume/Cancel button.

Install both black and color ink tanks.

When the ink tanks have been already

installed, re-install them.

- Install the print head (when the print

head has been already installed,

re-install it), and close the print head

cover.

- With the print head installed, turn the

printer off and on.

Pressing the Resume/Cancel button

cancels the error and resumes printing.

In repair servicing, replace the following

items and reset the appropriate waste

ink counter.*

- Main waste ink absorber:

Drain pack ass’y (QL2-0194)

- Platen waste ink absorber:

Ink absorber

(QC1-5831/1211/1212,

Three items are to be replaced at

the same time.)

Disconnect the cable from, both the

digital camera and the printer, and

press the Resume/Cancel button.

Reconnect them and try again.

the AC adapter.

If the error

persists, the ink

tank sensor may

have problems.

The service call

error, indicati ng

the waste ink

absorber is full, is

likely to occur

soon.

4

3. REPAIR

3-1. Notes on Service Part Re placement (Disassembling/Reassembling)

It is possible to replace the main ink absorber and platen ink absorber respectively.

Other service part replacement is the same as the i70 / PIXUS 50i.

Service part Notes on replacement Adjustment / settings Operation check

Drain pack ass’y

(QL2-0194)

Ink absorber

(QC1-5831/1211/1212)

Reset the main waste ink

counter.

Replace

QC1-5831/1211/1212 at

the same time.

Reset the platen waste ink

counter.

- Service test print

- EEPROM

information print

- Service test print

- EEPROM

information print

3-2. Special Notes on Repair Servicing

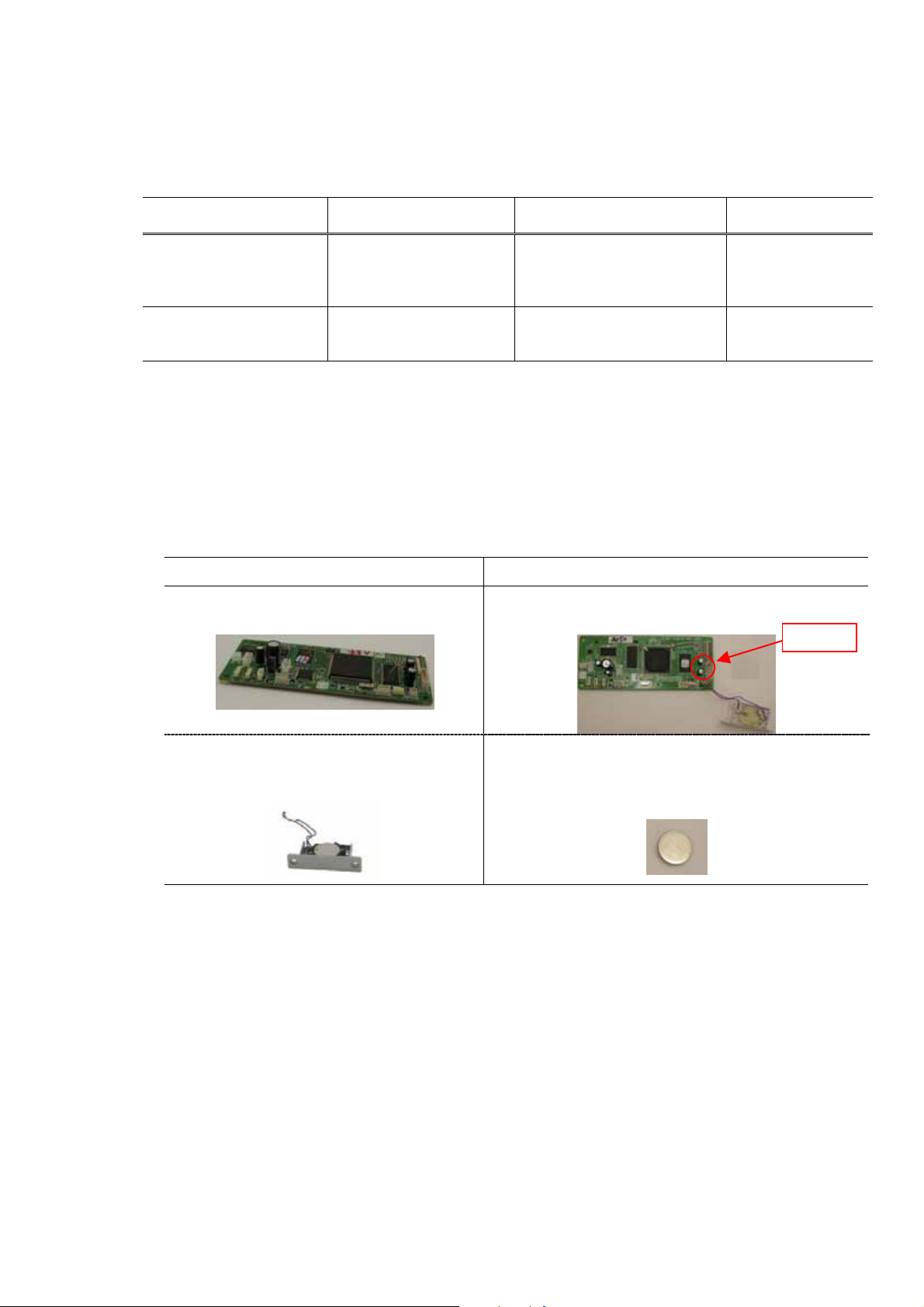

(1) Elimination of connectors (cable soldering to board)

In order to reduce costs, some connectors on the boards listed below are eliminated, and the

applicable cables are soldered to the boards. Accordingly, a set of board and cable is to be replaced

in repair servicing of them.

(a) Main board ----- Cable to the coin battery

The service part settings are as follows:

i70 / PIXUS 50i, i80 / PIXUS 80i PIXMA iP90 / PIXUS iP90

Main board

Main board (including the coin battery holder)

Soldered

Coin battery unit (including the coin battery)

Coin battery (commercially available, not designated

as a service part)

Maxell CR2032

Notes on main board replacement: Remove the coin battery from the original main board, and

install it in the battery holder of the replaced main board.

5

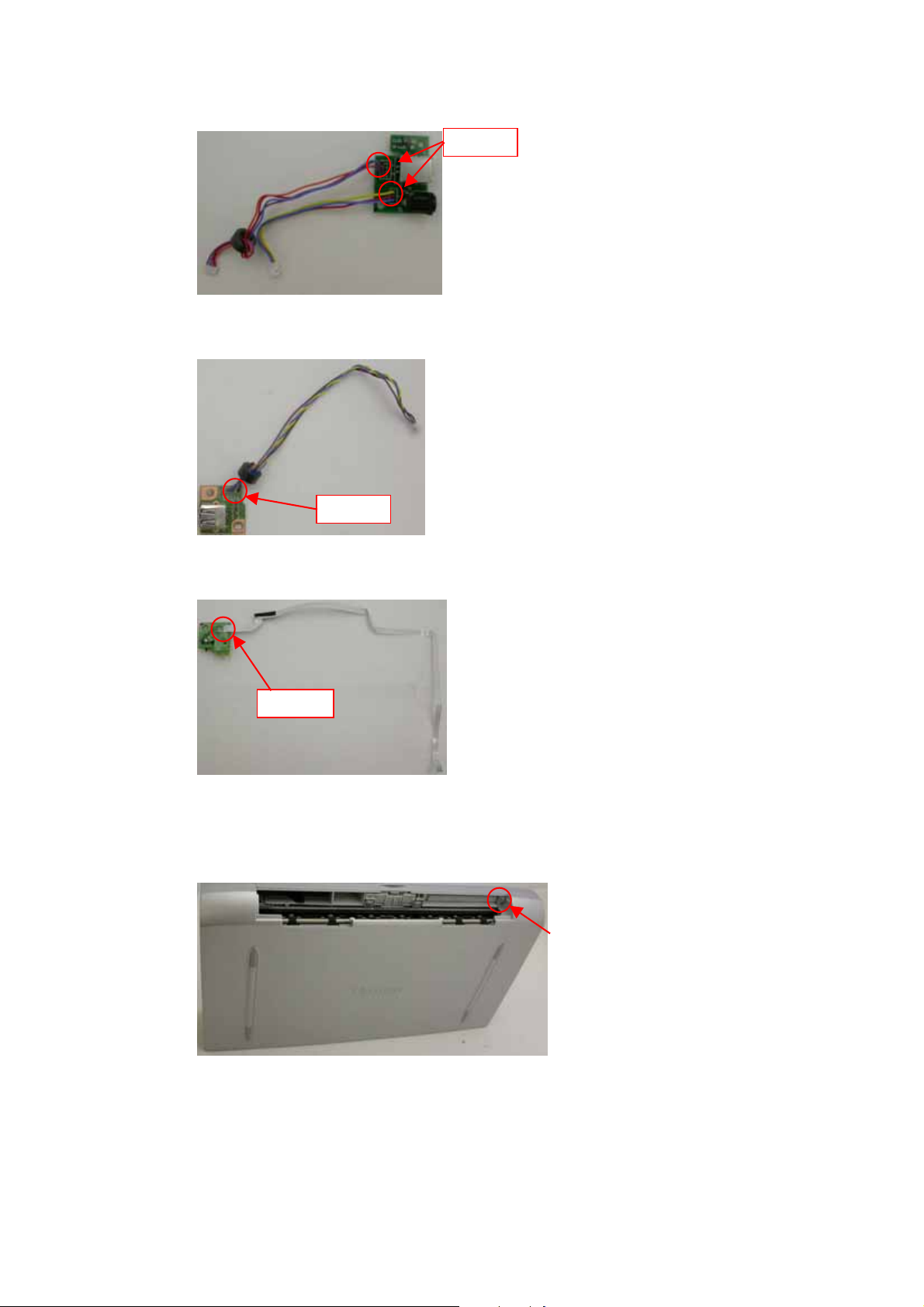

(b) USB board ----- Cables to the main and DC-DC boards

Soldered

(c) DC-D board ----- Cables to the main board

Soldered

(d) Door sensor board ----- Flexible cable to the main board

Soldered

(2) Tapping Screw

The tapping screw is used in the main case unit at the location indicated below. As no metal sheet is

inserted between the screw and the main case unit, be careful not to fasten the screw too tight.

6

Loading...

Loading...