Page 1

Type 8694

Positioner Top Control Basic

Electropneumatic position controller

Operating Instructions

Page 2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

Sous réserve de modifications techniques.

© Bürkert Werke GmbH & Co. KG, 2008 - 2019

Operating Instructions 1909/10_EN-EN_00805886 / Original DE

Page 3

Type 8694

Positioner Type 8694

Table of ConTenTs

1 OPERATING INSTRUCTIONS ........................................................................................................................................................7

1.1 Symbols

Definition of term / abbreviation ...................................................................................................................................7

1.2

AUTHORIZED USE .............................................................................................................................................................................8

2

2.1 Restrictions

BASIC SAFETY INSTRUCTIONS .................................................................................................................................................9

3

GENERAL INFORMATION .............................................................................................................................................................10

4

Contact address ..................................................................................................................................................................10

4.1

4.2 Warranty

4.3 Trademarks

Information on the internet ............................................................................................................................................10

4.4

SYSTEM DESCRIPTION ................................................................................................................................................................11

5

Intended application area ...............................................................................................................................................11

5.1

Function of the positioner and combination with valve types ....................................................................11

5.2

......................................................................................................................................................................................7

...............................................................................................................................................................................8

...................................................................................................................................................................................10

............................................................................................................................................................................10

Features of the valve types ...........................................................................................................................................12

5.3

Structure of the positioner ............................................................................................................................................13

5.4

5.4.1 Representation ....................................................................................................................................13

5.4.2 Features ................................................................................................................................................14

5.4.3 Function diagram of the positioner with single-acting actuator .............................................. 15

Type 8694 positioner (position controller) ............................................................................................................16

5.5

5.5.1 Schematic representation of the position control Type 8694 ..................................................16

5.5.2 Functions of the position controller software ............................................................................... 17

Interfaces of the positioner ..........................................................................................................................................19

5.6

TECHNICAL DATA .............................................................................................................................................................................20

6

6.1 Conformity

6.2 Standards

6.3 Licenses

Operating conditions ........................................................................................................................................................20

6.4

..............................................................................................................................................................................20

................................................................................................................................................................................20

...................................................................................................................................................................................20

3

english

Page 4

Type 8694

6.5 Mechanical data ...................................................................................................................................................................20

Pneumatic data ....................................................................................................................................................................21

6.6

Type labels ..............................................................................................................................................................................21

6.7

6.7.1 Type label standard ............................................................................................................................21

6.7.2 UL type label ........................................................................................................................................22

6.7.3 UL additional label ..............................................................................................................................22

Electrical data .......................................................................................................................................................................22

6.8

6.8.1 Electrical data without bus control 24 V DC ...............................................................................22

6.8.2 Electrical data with AS-Interface bus control ..............................................................................23

Factory settings of the positioner ..............................................................................................................................24

6.9

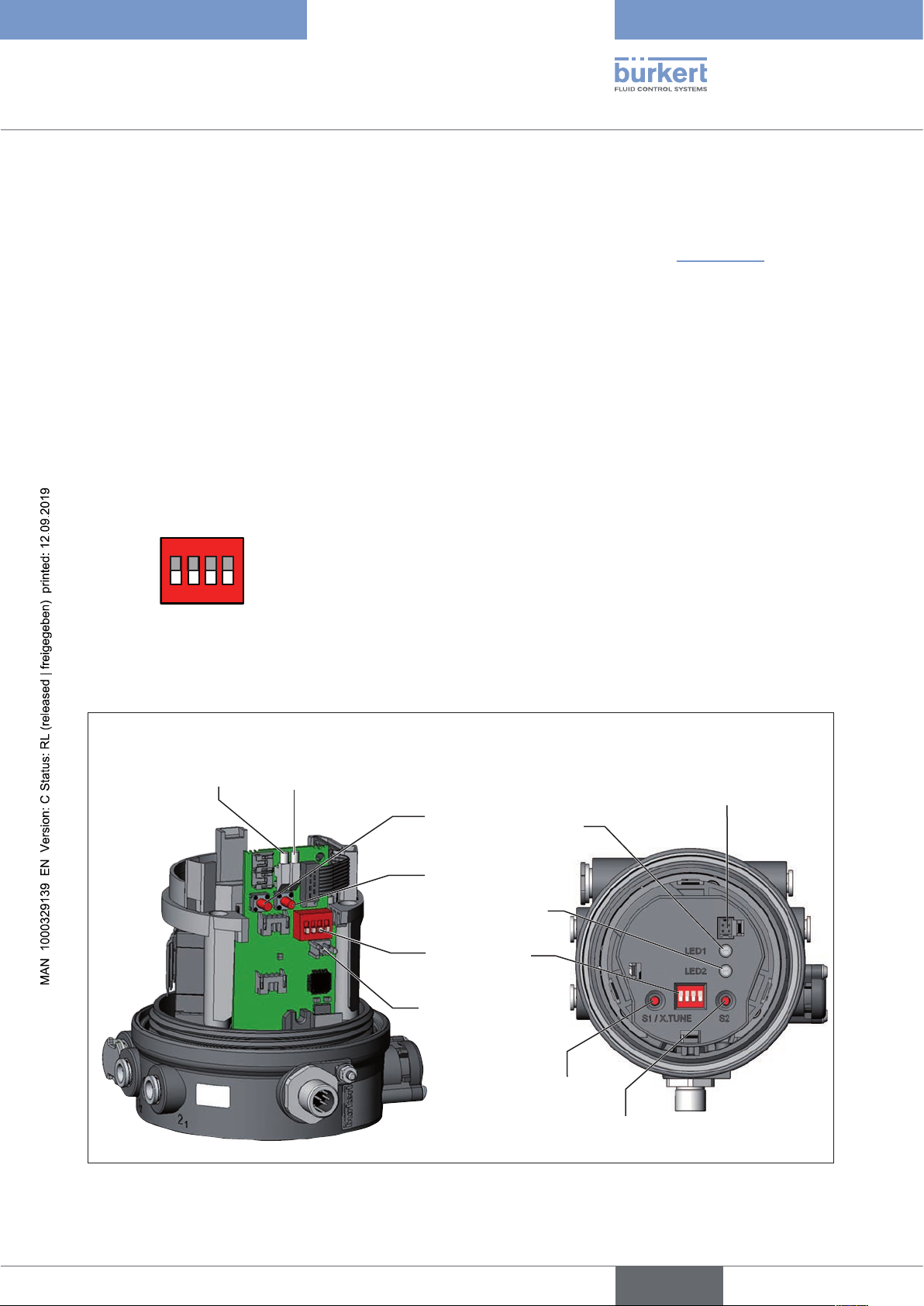

CONTROL AND DISPLAY ELEMENTS ...................................................................................................................................25

7

Operating status ...................................................................................................................................................................... 25

7.1

Control and display elements of the positioner .................................................................................................25

7.2

Configuration of the keys ................................................................................................................................................... 27

7.3

Function of the DIP switches ........................................................................................................................................... 29

7.4

Display of the LEDs ............................................................................................................................................................... 31

7.5

Error messages ....................................................................................................................................................................... 32

7.6

7.6.1 Error messages in MANUAL and AUTOMATIC operating statuses .........................................32

7.6.2 Error messages while the X.TUNE function is running ..............................................................32

8 INSTALLATION

Safety instructions .............................................................................................................................................................33

8.1

Installation of the positioner Type 8694 on process valves of series 2103, 2300 and 2301 .....33

8.2

Installing the positioner Type 8694 on process valves belonging to series 26xx and 27xx .......... 36

8.3

Rotating the actuator module ......................................................................................................................................40

8.4

Rotating the positioner for process valves belonging to series 26xx and 27xx ...............................42

8.5

...................................................................................................................................................................................33

PNEUMATIC INSTALLATION .......................................................................................................................................................43

9

Manual actuation of the actuator via pilot valves ..............................................................................................44

9.1

9.1.1 Single-acting actuators (control function A and B) ....................................................................44

ELECTRICAL INSTALLATION 24 V DC ...................................................................................................................................46

10

Safety instructions .............................................................................................................................................................46

10.1

4

english

Page 5

Type 8694

10.2 Electrical installation with circular plug-in connector .....................................................................................46

10.2.1 Designation of the contacts Type 8694 ........................................................................................ 46

10.2.2 Connection of the positioner Type 8694 ......................................................................................47

Electrical installation with cable gland ....................................................................................................................48

10.3

AS-INTERFACE INSTALLATION ................................................................................................................................................51

11

AS-Interface connection .................................................................................................................................................51

11.1

Maximum length of the bus line .................................................................................................................................51

11.2

Technical data for AS-Interface PCBs .....................................................................................................................51

11.3

Programming data ..............................................................................................................................................................52

11.4

Communication sequence for the version S-7.A.5 profile ..........................................................................53

11.5

LED status display ..............................................................................................................................................................54

11.6

Electrical installation AS-interface ............................................................................................................................55

11.7

11.7.1 Safety instructions ..............................................................................................................................55

11.7.2 Connection with circular plug-in connector M12 x 1, 4-pole, male .......................................56

11.7.3 Connection with multi-pole cable and ribbon cable terminal ...................................................56

12 START-UP

12.1

12.2

.............................................................................................................................................................................................58

Safety instructions .............................................................................................................................................................58

Specifying the standard settings ................................................................................................................................58

12.2.1 Running the automatic adjustment X.TUNE .........................................................................58

OPERATION AND FUNCTION ....................................................................................................................................................61

13

Basic functions ........................................................................................................................................................................ 61

13.1

13.1.1 DIR.CMD -

Effective direction of the positioner set-point value ...................................................................62

13.1.2 CUTOFF -

Sealing function for the positioner .................................................................................................63

13.1.3 CHARACT -

Select the transfer characteristic between input signal (position set-point value) and

stroke ..................................................................................................................................................... 64

13.1.4 INPUT -

Enter the input signal .........................................................................................................................66

13.1.5 RESET -

Reset to factory settings ...................................................................................................................67

13.1.6 X.TUNE -

Automatic adjustment of the positioner to the relevant operating conditions ......................67

5

english

Page 6

Type 8694

13.2 Auxiliary functions .................................................................................................................................................................. 68

13.2.1 DIR.ACTUATOR -

Effective direction of the actuator ................................................................................................... 68

13.2.2 SPLITRANGE -

Signal split range ................................................................................................................................69

13.2.3 X.LIMIT -

Limiting the mechanical stroke range ............................................................................................70

13.2.4 X.TIME -

Limiting the control speed ................................................................................................................71

13.2.5 X.CONTROL -

Parameterization of the positioner .................................................................................................. 72

13.2.6 SAFE POSITION -

Definition of the safe position .......................................................................................................... 72

13.2.7 SIGNAL ERROR -

Configuration of signal level fault detection ................................................................................. 73

13.2.8 BINARY INPUT -

Activation of the binary input ........................................................................................................... 73

13.2.9 OUTPUT (optional) -

Configuration of the analog output ................................................................................................ 74

SAFETY END POSITIONS ............................................................................................................................................................75

14

Safety end positions after failure of the electrical or pneumatic auxiliary power ...........................75

14.1

15 MAINTENANCE

Safety instructions .............................................................................................................................................................76

15.1

Service at the air intake filter .......................................................................................................................................77

15.2

16 ACCESSORIES

Communications software .............................................................................................................................................78

16.1

..................................................................................................................................................................................76

..................................................................................................................................................................................78

16.1.1 USB interface ......................................................................................................................................78

16.1.2 Download ............................................................................................................................................. 78

17 DISASSEMBLY

...................................................................................................................................................................................79

Safety instructions .............................................................................................................................................................79

17.1

Disassembly the positioner ...........................................................................................................................................79

17.2

PACKAGING AND TRANSPORT ...............................................................................................................................................81

18

19 STORAGE

20 DISPOSAL

6

..............................................................................................................................................................................................81

............................................................................................................................................................................................81

english

Page 7

Type 8694

Operating instructions

1 OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which is

easily accessible to every user, and make these instructions available to every new owner of the device.

Important safety information.

Read the operating instruction carefully and thoroughly. Study in particular the chapters entitled “Basic safety

instructions” and “Authorized use”.

▶ The operating instructions must be read and understood.

1.1 Symbols

DANGER!

Warns of an immediate danger.

▶ Failure to observe the warning will result in a fatal or serious injury.

WARNING!

Warns of a potentially dangerous situation.

▶ Failure to observe the warning may result in serious injuries or death.

CAUTION!

Warns of a possible danger.

▶ Failure to observe this warning may result in a moderate or minor injury.

NOTE!

Warns of damage to property.

• Failure to observe the warning may result in damage to the device or the equipment.

Indicates important additional information, tips and recommendations.

refers to information in these operating instructions or in other documentation.

▶ Designates an instruction to prevent risks.

→ Designates a procedure which you must carry out.

1.2 Definition of term / abbreviation

The term “device” used in these instructions always stands for the positioner Type 8694.

In these instructions, the abbreviation “Ex” always refers to “potentially explosive”.

english

7

Page 8

Type 8694

Authorized use

2 AUTHORIZED USE

Non-authorized use of the positioner Type 8694 may be a hazard to people, nearby equipment and the

environment.

The device is designed to be mounted on pneumatic actuators of process valves for the control of media.

▶ Do not expose the device to direct sunlight.

▶ Use according to the authorized data, operating conditions and conditions of use specified in the contract

documents and operating instructions. These are described in the chapter entitled “6 Technical data”.

▶ The device may be used only in conjunction with third-party devices and components recommended and

authorized by Bürkert.

▶ In view of the large number of options for use, before installation, it is essential to study and if necessary to

test whether the positioner is suitable for the actual use planned.

▶ Correct transportation, correct storage and installation and careful use and maintenance are essential for reli-

able and faultless operation.

▶ Use the positioner Type 8694 only as intended.

2.1 Restrictions

If exporting the system/device, observe any existing restrictions.

8

english

Page 9

Type 8694

Basic safety instructions

3 BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

• contingencies and events which may arise during the installation, operation and maintenance of the devices.

• local safety regulations – the operator is responsible for observing these regulations, also with reference to the

installation personnel.

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

General hazardous situations.

To prevent injury, ensure:

▶ In the potentially explosion-risk area the positioner Type 8694 may be used only according to the specification

on the separate approval sticker. For use observe the additional instructions enclosed with the device together

with safety instructions for the explosion-risk area.

▶ Devices without a separate approval sticker may not be used in a potentially explosive area.

▶ That the system cannot be activated unintentionally.

▶ Installation and repair work may be carried out by authorized technicians only and with the appropriate tools.

▶ After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a defined

or controlled manner.

▶ The device may be operated only when in perfect condition and in consideration of the operating instructions.

▶ The general rules of technology apply to application planning and operation of the device.

To prevent damage to property on the device, ensure:

▶ Do not feed any aggressive or flammable media into the pilot air port.

▶ Do not feed any liquids into the pilot air port.

▶ When unscrewing and screwing in the body casing or the transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing of Type 8694.

▶ Do not put any loads on the housing (e.g. by placing objects on it or standing on it).

▶ Do not make any external modifications to the device bodies. Do not paint the housing parts or screws.

english

9

Page 10

Type 8694

Basic safety instructions

NOTE!

Electrostatic sensitive components / modules.

The device contains electronic components, which react sensitively to electrostatic discharge (ESD). Contact

with electrostatically charged persons or objects is hazardous to these components. In the worst case scenario,

they will be destroyed immediately or will fail after start-up.

▶ Observe the requirements in accordance with EN 100 015 - 1 and to minimize or avoid the possibility of damage

caused by sudden electrostatic discharge.

▶ Also ensure that you do not touch electronic components when the power supply is on.

4 GENERAL INFORMATION

4.1 Contact address

Germany

Bürkert Fluid Control System

Sales Center

Chr.-Bürkert-Str. 13-17

D-74653 Ingelfingen

Tel. + 49 (0) 7940 - 10 91 111

Fax + 49 (0) 7940 - 10 91 448

E-mail: info@burkert.com

International

Contact addresses can be found on the final pages of the printed operating instructions.

And also on the Internet at:

www.burkert.com

4.2 Warranty

The warranty is only valid if the positioner Type 8694 is used as intended in accordance with the specified application conditions.

4.3 Trademarks

10

Brands and trademarks listed below are trademarks of the corresponding companies / associations / organizations

Loctite Henkel Loctite Deutschland GmbH

4.4 Information on the internet

The operating instructions and data sheets for Type 8694 can be found on the Internet at:

www.burkert.com

english

Page 11

Type 8694

System description

5 SYSTEM DESCRIPTION

5.1 Intended application area

The positioner Type 8694 is designed to be mounted on pneumatic actuators of process valves for the control of

media.

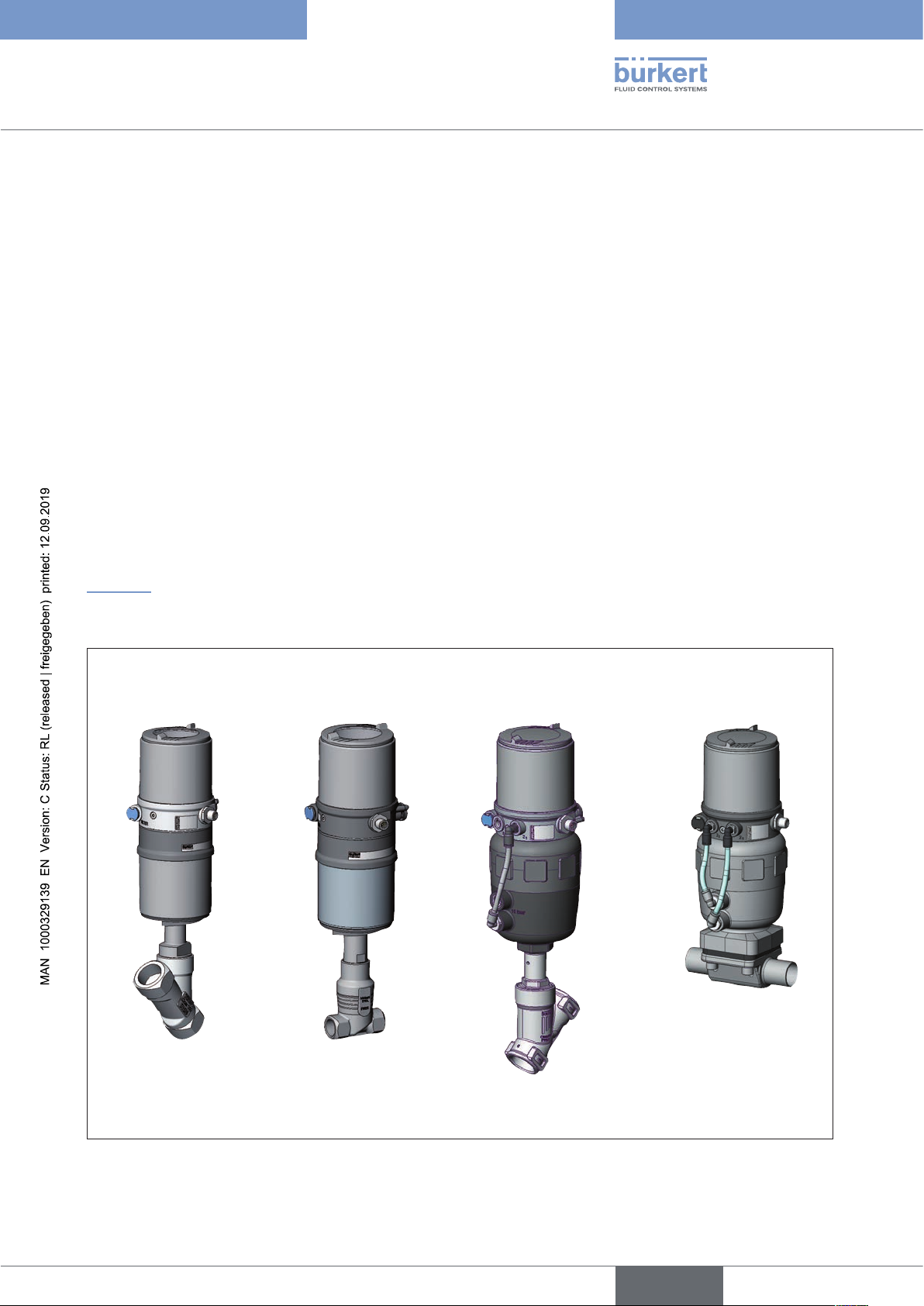

5.2 Function of the positioner and combination with

valve types

Positioner Type 8694 is an electropneumatic position controller for pneumatically actuated control valves with

single-acting actuators.

Together with the pneumatic actuator, the positioner forms a functional unit.

The control valve systems can be used for a wide range of control tasks in fluid technology and, depending on the

application conditions, different process valves belonging to series 2103, 2300, 2301, 26xx or 27xx from the Bürkert

range can be combined with the positioner. Angle-seat valves, diaphragm valves or ball valves fitted with a control

cone are suitable.

“Figure 1” shows an overview of the possible combinations of positioner and different pneumatically actuated valves.

Different actuator sizes and valve nominal widths, not illustrated here, are available for each type. More precise

specifications can be found on the respective data sheets. The product range is being continuously expanded.

Positioner Type 8694

with diaphragm

valve

with angle seat valve

Type 2300

Figure 1: Overview of possible combinations

with straight seat valve

Type 2301

Type 2730

with angle seat valve

Type 2702

11

english

Page 12

Type 8694

System description

The position of the actuator is regulated according to the position set-point value. The position set-point value is

specified by an external standard signal.

Pneumatically actuated piston actuators and rotary actuators can be used as an actuator. Single-acting actuators

are offered in combination with the positioner.

For single-acting actuators, only one chamber is aerated and deaerated in the actuator. The generated pressure works

against a spring. The piston moves until there is an equilibrium of forces between compressive force and spring force.

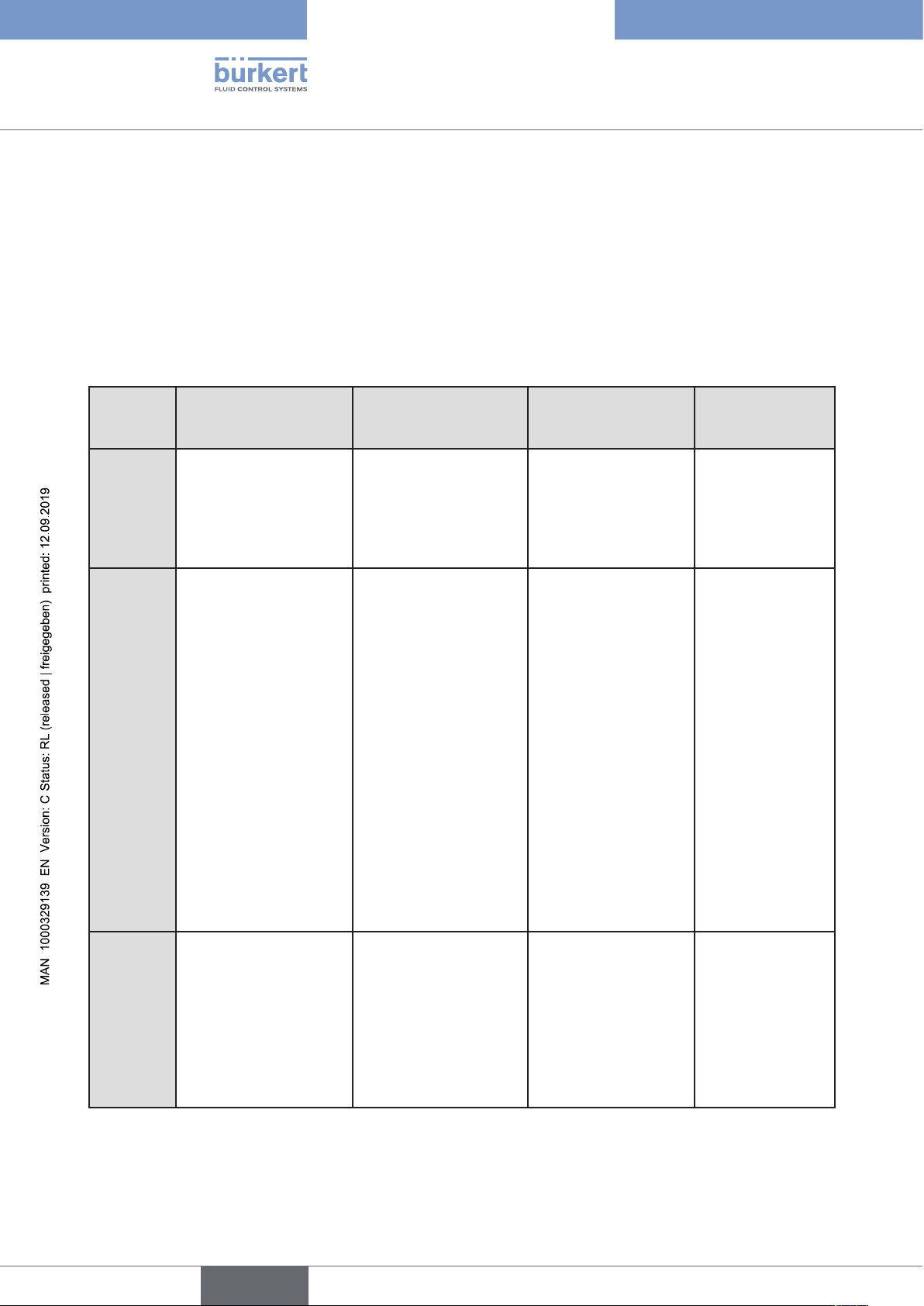

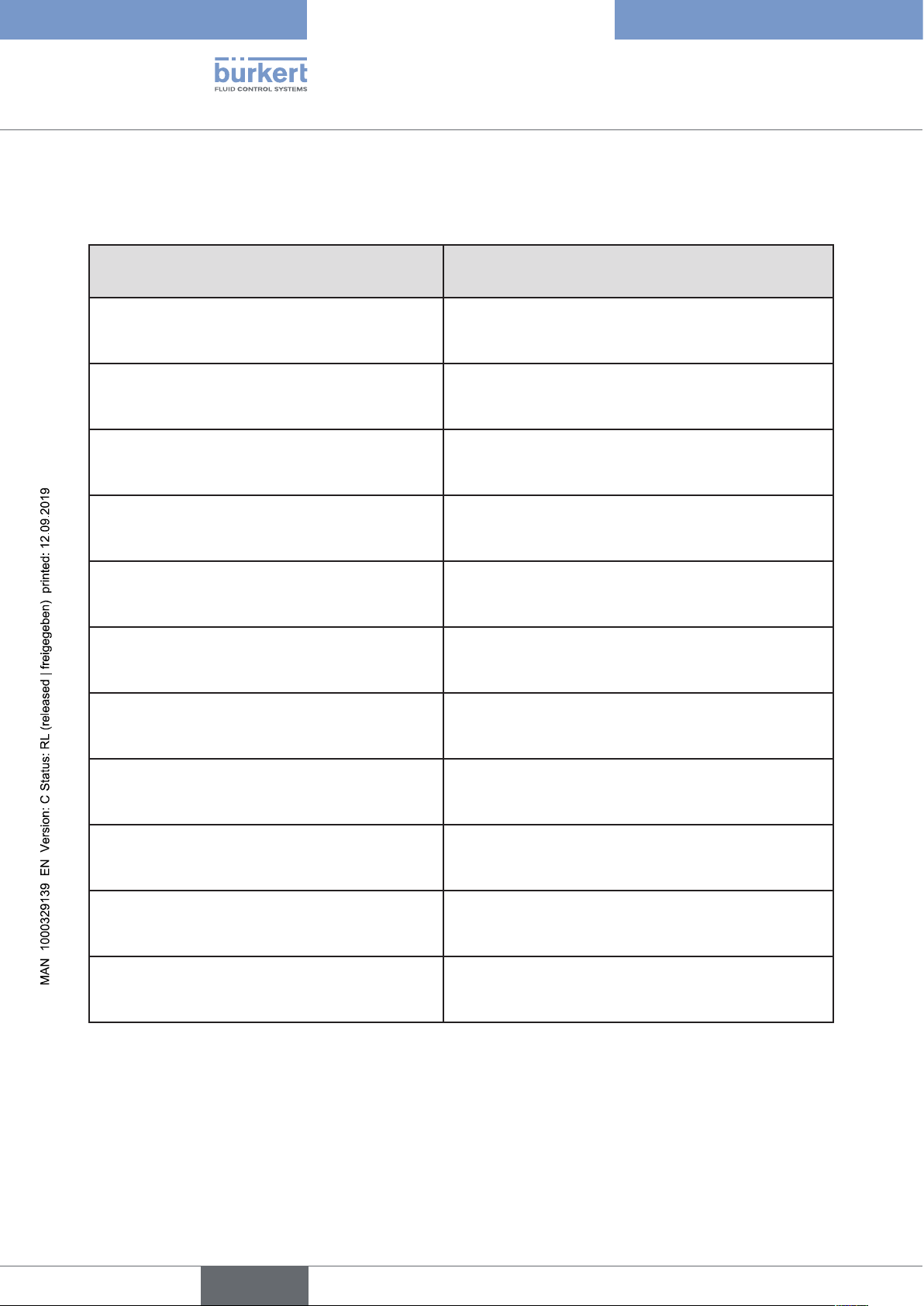

5.3 Features of the valve types

Types

Features

Angle seat control

valves / straight seat

control valves

• 2300

• 2301

• 2702

• 2712

• incoming flow under

seat

• no closing impact

• straight flow path of

the medium

• self-adjusting

stuffing box for high

leak-tightness

Diaphragm valves Ball valves Flap valves

• 2103

• 2730

• 2731

• medium is hermetically separated from

the actuator and

environment

• cavity-free and selfdraining body design

• any flow direction with

low-turbulence flow

• steam-sterilizable

• CIP-compliant

• no closing impact

• 2652

• 2655

• 2658

• scrapable

• minimum dead space

• unaffected by

contamination

• little pressure loss

compared to other

valve types

• seat and seal can

be exchanged in the

three-piece ball valve

when installed

• 2672

• 2675

• unaffected by

contamination

• little pressure

loss compared to

other valve types

• inexpensive

• low construction

volume

12

Typical

media

Table 1: Features of the valve types

• water, steam and

gases

• alcohols, oils, propellants, hydraulic fluids

• salt solutions, lyes

(organic)

• solvents

english

• actuator and diaphragm can be

removed when the

body is installed

• neutral gases and

liquids

• contaminated,

abrasive and

aggressive media

• media of higher

viscosity

Note

can be used as

process controller only

• neutral gases and

liquids

• clean water

• slightly aggressive

media

• neutral gases

and liquids

• slightly

aggressive media

Page 13

Type 8694

System description

5.4 Structure of the positioner

The positioner Type 8694 consists of the micro-processor controlled electronics, the position measuring system

and the control system. The device is designed using three-wire technology. The positioner is operated via 2 keys

and a 4-pole DIP switch. The pneumatic control system for single-acting actuators consists of 2 solenoid valves.

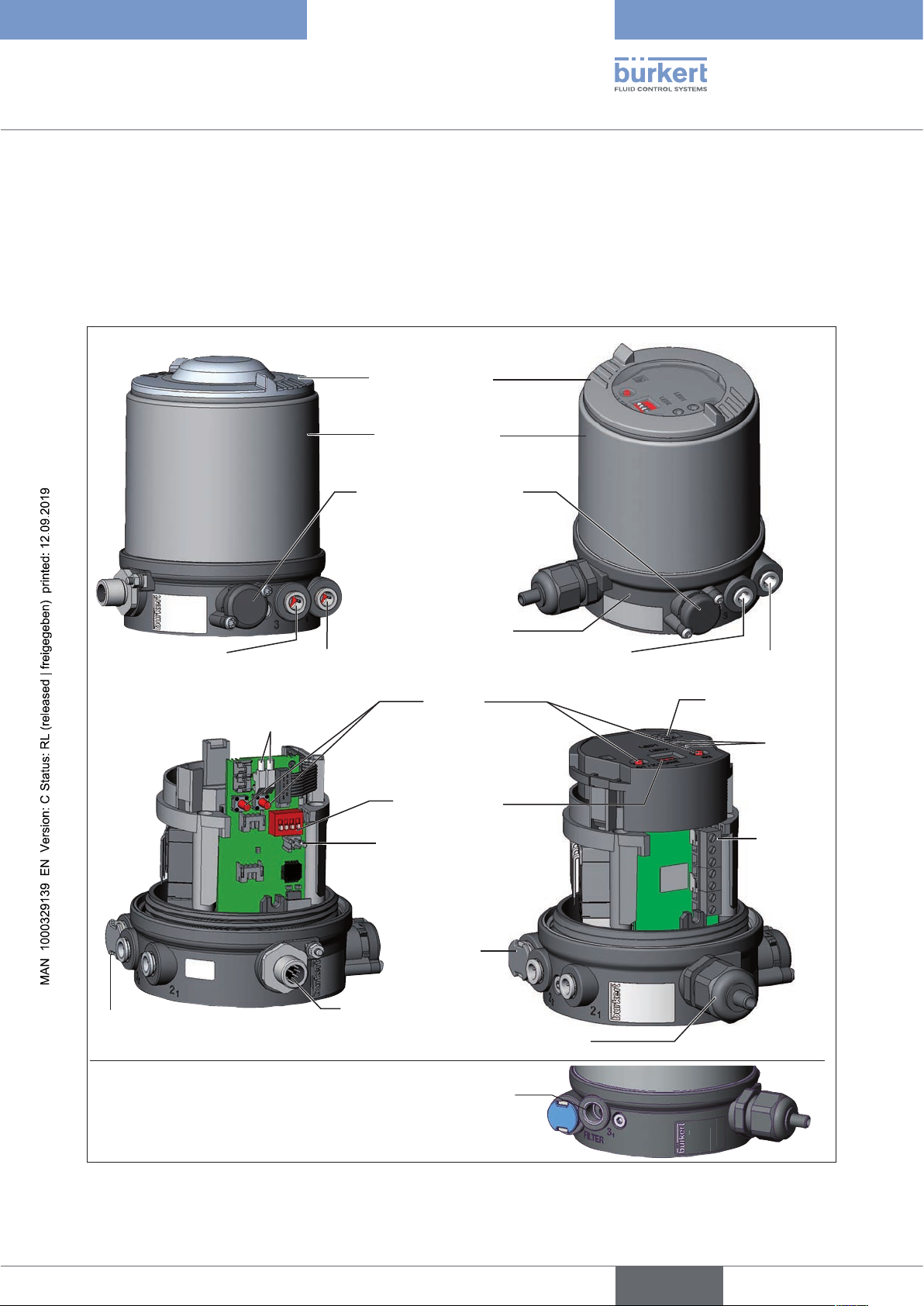

5.4.1 Representation

Version 1

Exhaust air connection (label: 3)

Body casing removed:

Transparent cap

Body casing

Pressure limiting valve

(for protection against too

high internal pressure in

case of error)

Connection housing

Pressure supply connection

(label: 1)

LED

Buttons

Version 2

Exhaust air connection (label: 3)

Pressure supply

connection (label: 1)

Communications

interface

LED

Air intake filter

(exchangeable)

with pilot-operated control system for high air flow rate

Figure 2: Structure

DIP Switches

Communications

interface

Air intake

filter

(exchangeable)

Electrical connection

(cable gland M16 x 1.5

or circular plug-in connector M12 x 1)

Additional exhaust air port (label: 3.1)

only for Type 23xx and 2103

(actuator size ø 130)

Screwtype

terminals

13

english

Page 14

Type 8694

System description

5.4.2 Features

• Models

for single-acting valve actuators.

• Position measuring system

Contactless and therefore wear-free position measuring system.

• Microprocessor-controlled electronics

for signal processing, control and valve control.

• Control module

The device is controlled via 2 buttons and a 4-pole DIP switch. 2x 2-colored LEDs indicate different statuses of

the device.

• Control system

The control system consists of 2 solenoid valves. One valve is used to aerate and another to deaerate the

pneumatic actuator. The solenoid valves operate according to the rocker principle and are controlled with a

PWM voltage via the controller. Doing so achieves a higher flexibility with regard to actuator volume and final

control speed. The direct-action model has an orifice of DN 0.6. In larger pneumatic actuators the solenoid

valves feature diaphragm amplifiers to increase the maximum flow and therefore to improve the dynamics (DN

2.5).

• Position feedback (optional)

The position of the valve can be transmitted to the PLC via an analog 0/4-20 mA output.

• Binary input

If a voltage > 10 V is applied, SAFE POSITION is activated, i.e. the valve is moved to the safety position

(factory setting, can be changed with communications software).

• Pneumatic interfaces

1/4“ connections with different thread forms

(G, NPT)

hose plug-in connection

• Electrical interfaces

Circular plug-in connector or cable gland

Pneumatic interface

14

Electrical interface

• Body

The body of the positioner is protected from excessively high internal pressure, e.g. due to leaks, by a pressure

limiting valve.

• Communications interface

For configuration and parameterization.

english

Page 15

Type 8694

System description

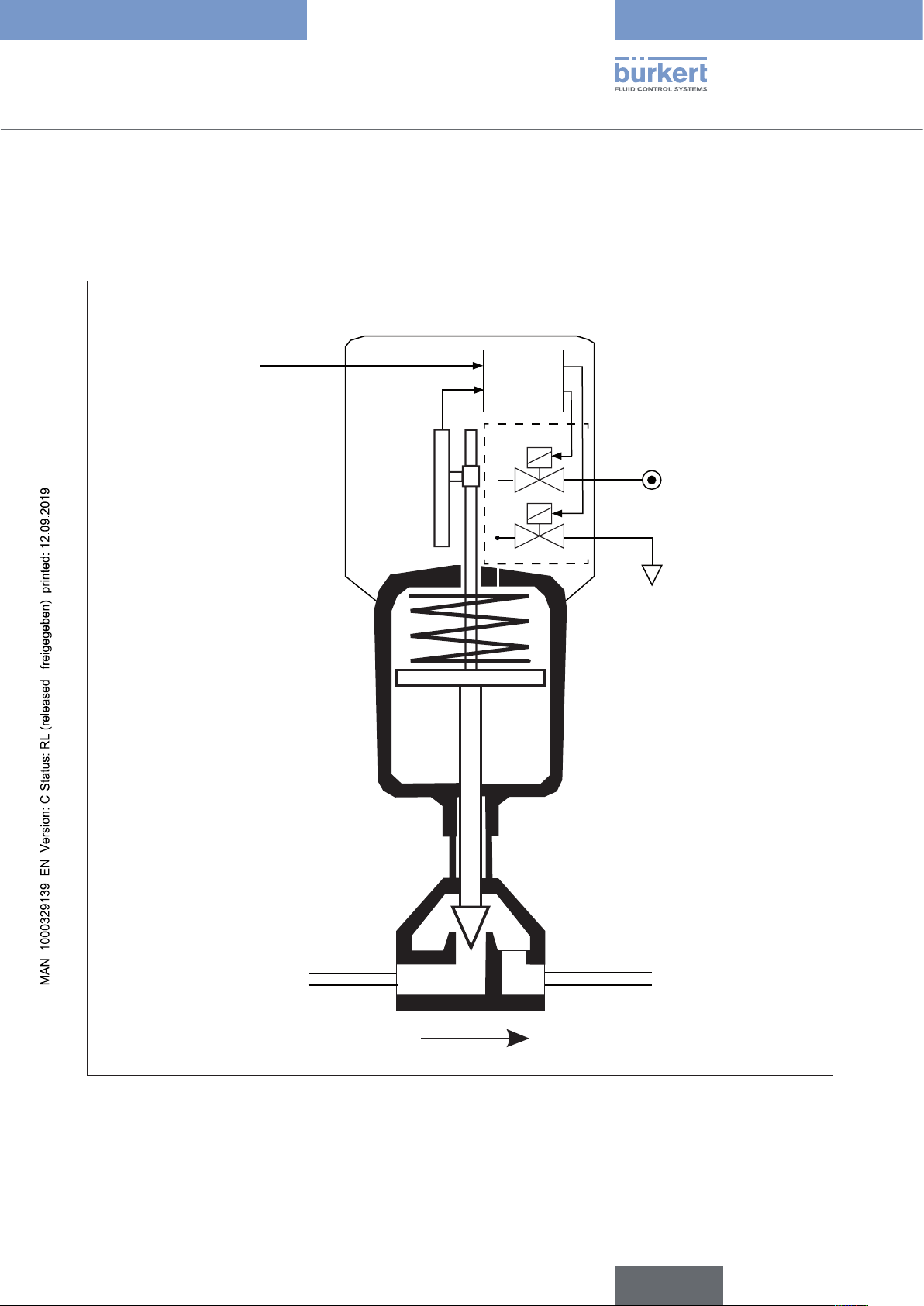

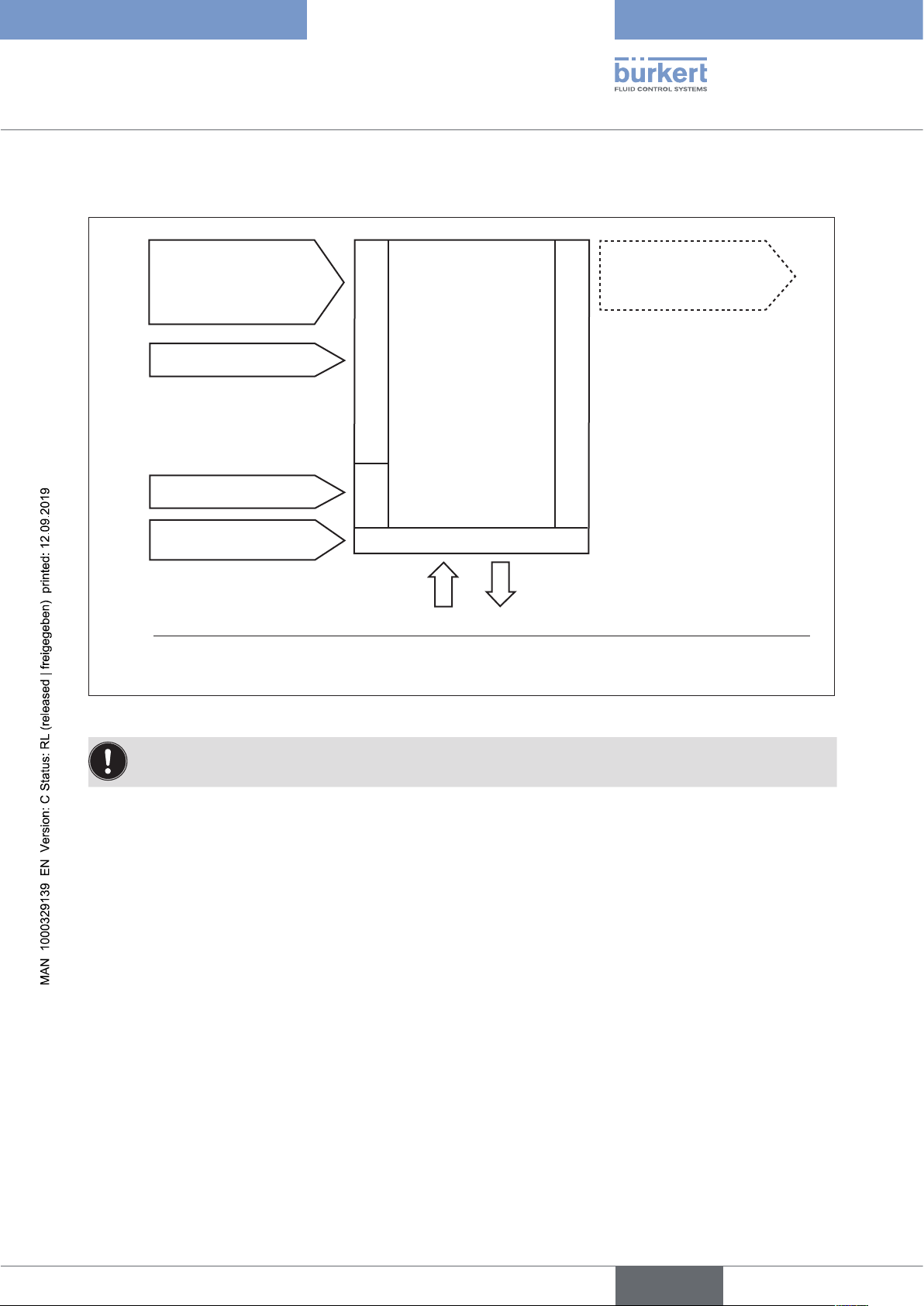

5.4.3 Function diagram of the positioner with single-acting actuator

The illustrated function diagram describes the function of the positioner (Type 8694).

external

position

set-point value

Position

controller

Control system

1

2

Control system

1: Aeration valve

2: Bleed valve

Pressure

supply

Positioner

Actual

position

Position

measuring

system

Pneumatic actuator

(single-acting)

Valve

(actuator)

Exhaust air

Figure 3: Function diagram

15

english

Page 16

Type 8694

System description

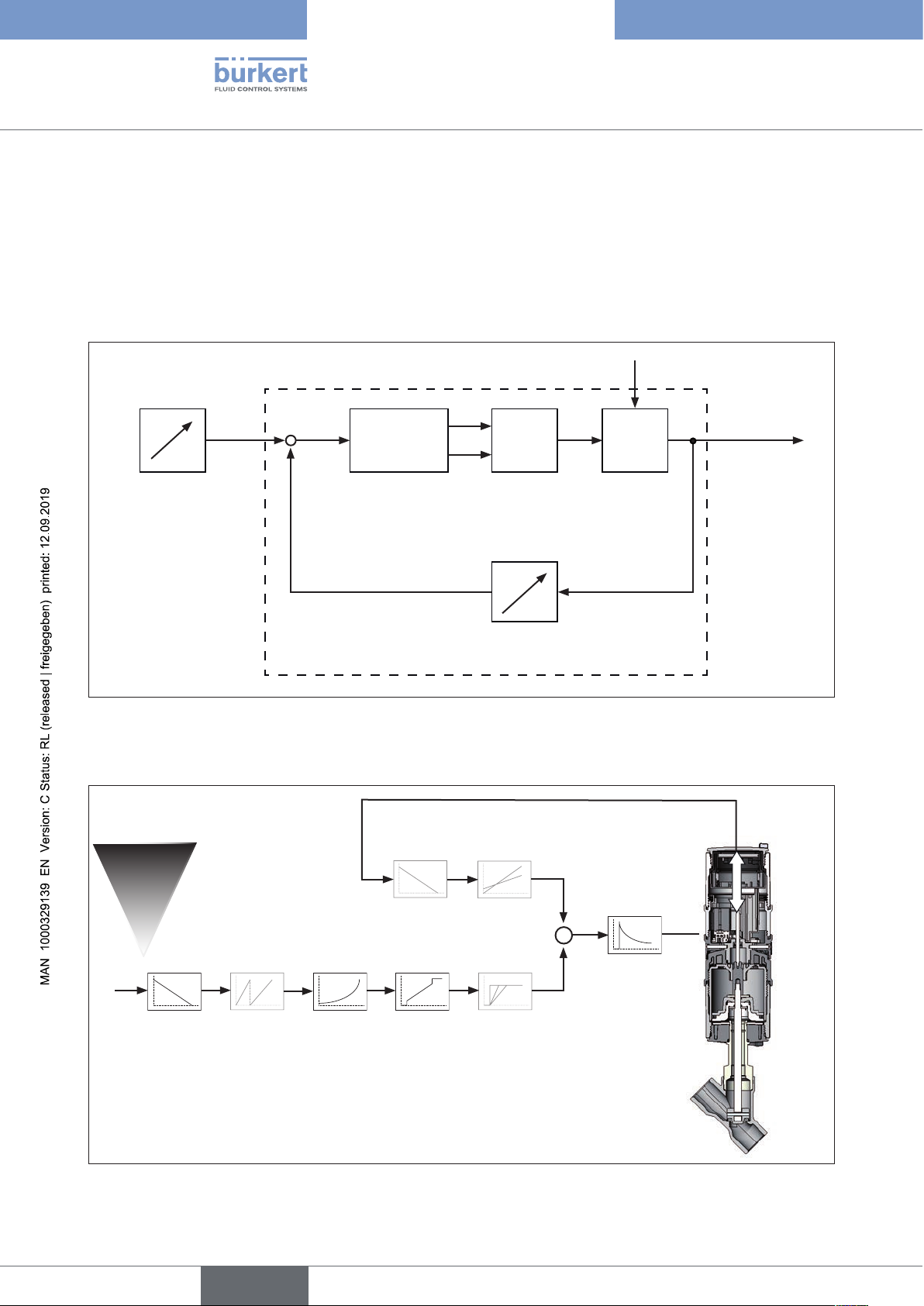

5.5 Type 8694 positioner (position controller)

The position measuring system records the current position (POS) of the pneumatic actuator. The position controller

compares this actual position value with the set-point value (CMD) which is definable as standard signal. In case

of a control deviation (Xd1), a pulse-width modulated voltage signal is sent to the control system as a manipulated variable. If there is a positive control difference in single-acting actuators, the air inlet valve is controlled via

output B1. If the control difference is negative, the bleed valve is controlled via output E1. In this way the position

of the actuator is changed until control difference is 0. Z1 represents a disturbance variable.

Z1

B1

Position

set-point

CMD Xd1

+

-

Position

controller

E1

Solenoid valves

P

K

Valve opening

Control valveControl system

value

POS

Position control

circuit

Position measuring system

Figure 4: Signal flow plan of position controller

5.5.1 Schematic representation of the position control Type 8694

16

4 ... 20 mA1)

0 ... 20 mA

DIR.ACT

INP

DIR.CMD

1) Default setting

2) Can only be activated with communications software

Figure 5: Schematic representation of position control

SPLTRNG

2)

CHARACT

CUTOFF

english

2)

X.LIMIT

X.TIME

POS

2)

CMD

2)

POS

CMD

X.CONTROL

DBND

Page 17

Type 8694

System description

5.5.2 Functions of the position controller software

Functions I

• Activation via DIP switches

• Parameter setting via communications software

Additional function Effect

Sealing function

CUTOFF

Correction line to adjust the operating characteristic

CHARACT

Effective direction of the controller set-point value

DIR.CMD

Table 2: Functions I

Valve closes tight outside the control range. Specification

of the value (as %), from which the actuator is completely

deaerated (when 0 %) or aerated (when 100 %)

(see chapter “7.4 Function of the DIP switches”).

Linearization of the operating characteristic can be implemented (see chapter “7.4 Function of the DIP switches”).

Reversal of the effective direction of the set-point value

(see chapter “7.4 Function of the DIP switches”).

english

17

Page 18

Functions II

• Activation and parameter setting via communications software

Additional function Effect

Type 8694

System description

Standard signal for set-point value

INPUT

Effective direction of the actuator

DIR.ACTUATOR

Signal split range

SPLITRANGE

Mechanical stroke range limit

X.LIMIT

Opening and closing time

X.TIME

Position controller

X.CONTROL

Safety position

SAFE POSITION

Select set-point value standard signal

Assignment of the aeration status of the actuator

chamber to the actual position.

Standard signal as % for which the valve runs through

the entire mechanical stroke range.

Limit the mechanical stroke range

Limit the control speed

Parameterize the position controller

Definition of the safety position

18

Signal level fault detection

Configuration of signal level fault detection

SIGNAL ERROR

Binary input

Configuration of the binary input

BINARY INPUT

Analog output

Configuration of the analog output (optional)

OUTPUT

Reset

Reset to factory settings

RESET

Table 3: Functions II

english

Page 19

Type 8694

System description

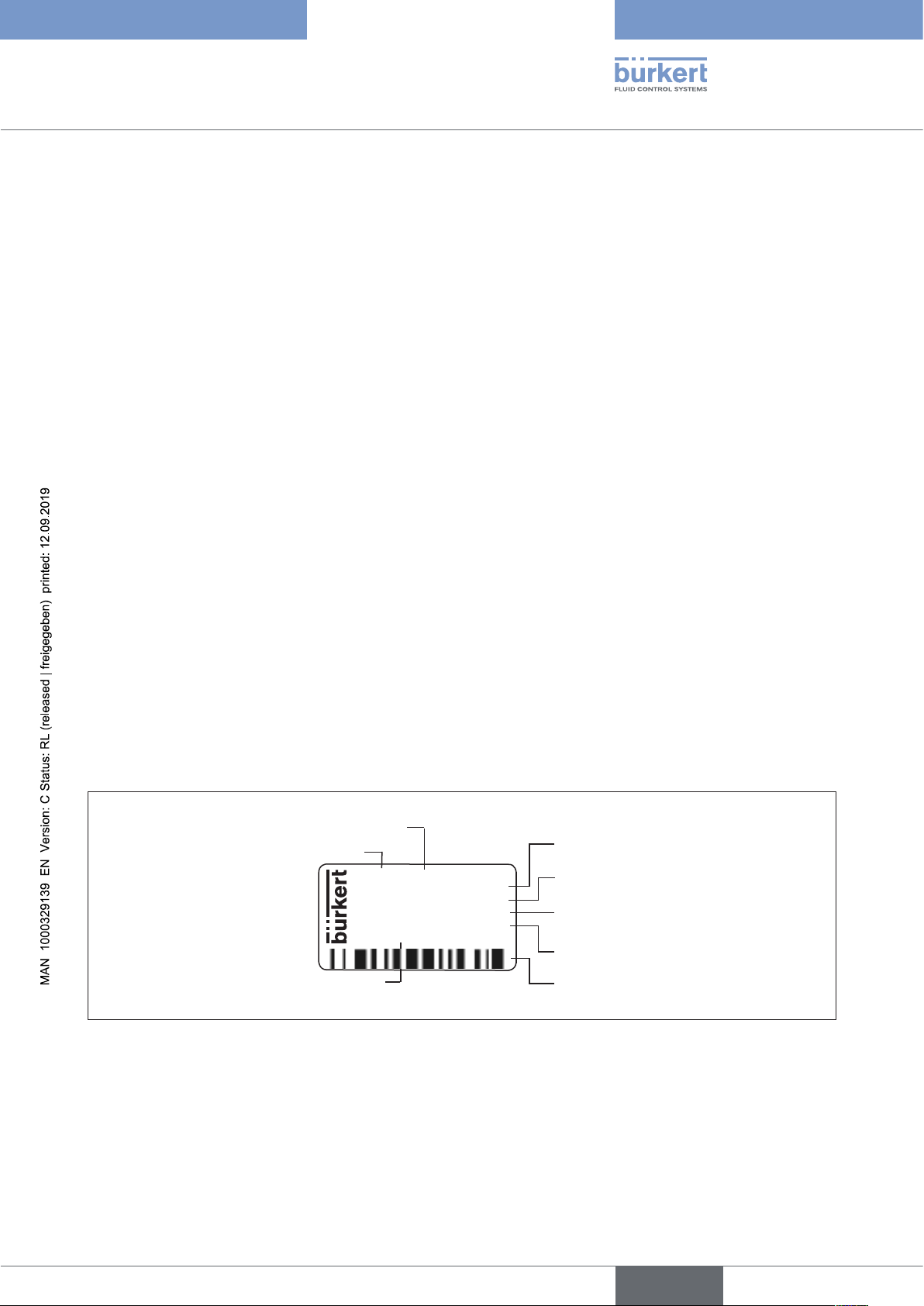

5.6 Interfaces of the positioner

Input for position

set-point value3)

4 – 20 mA4)

0 – 20 mA

Binary input

24 V DC

Communications

interface

3) Or optional bus connection AS interface

4) Default setting

Inputs

Power

Positioner

Operation

Analog

position feedback

(optional)

Outputs

Figure 6: Interfaces

The positioner Type 8694 is a 3-wire device, i.e. the power (24 V DC) is supplied separately from the setpoint value signal.

• Input for position set-point value (4 – 20 mA corresponds to 0 – 100 %

(depending on position of DIP switch 1)).

• Binary input

If a voltage > 10 V is applied, SAFE POSITION is activated, i.e. the valve is moved to the safety position

(factory setting, can be changed with communications software).

• Analog position feedback (optional)

The position of the valve can be transmitted via an analog 4 – 20 mA output to the PLC

(4 – 20 mA corresponds to 0 – 100 %).

english

19

Page 20

Type 8694

Technical data

6 TECHNICAL DATA

6.1 Conformity

In accordance with the EU Declaration of conformity, the positioner Type 8694 is compliant with the EU Directives.

6.2 Standards

The applied standards on the basis of which compliance with the EU Directives is confirmed are listed in the EU

type examination certificate and/or the EU Declaration of Conformity.

6.3 Licenses

The product is approved for use in zone 2 and 22 in accordance with ATEX directive 2014/34/EU category 3GD.

Observe instructions on operation in an explosion-risk (Ex) area.

Observe the ATEX additional instructions.

The product is cULus approved. Instructions for use in the UL area see chapter “6.8 Electrical data”.

6.4 Operating conditions

WARNING!

Solar radiation and temperature fluctuations may cause malfunctions or leaks.

▶ If the device is used outdoors, do not expose it unprotected to the weather conditions.

▶ Ensure that the permitted ambient temperature does not exceed the maximum value or drop below the mini-

mum value.

Ambient temperature see type label

Degree of protection

Evaluated by the manufacturer: Evaluated by UL:

IP65 / IP67 according to EN 60529 * UL Type 4x Rating *

Operating altitude up to 2000 m above sea level

20

* Only if cables, plugs and sockets have been connected correctly and in compliance with the exhaust air concept see chapter

“9 Pneumatic installation”.

6.5 Mechanical data

Dimensions See data sheet

Body material exterior: PPS, PC, VA,

interior: PA 6; ABS

Sealing material EPDM / (NBR)

Stroke range of valve spindle: 2 – 45 mm

english

Page 21

Type 8694

Technical data

6.6 Pneumatic data

Control medium neutral gases, air

Quality classes in accordance with ISO 8573-1

Dust content Quality class 7 max. particle size 40 µm, max. particle density 10 mg/m³

Water content Quality class 3 max. pressure dew point

- 20 °C or min. 10 °C below the lowest operating temperature

Oil content Quality class X max. 25 mg/m³

Temperature range

of the control medium -10 – +50 °C

Pressure range

of the control medium 3 – 7 bar

Air output of pilot valve 7 lN / min (for aeration and deaeration)

(QNn - value according to definition for pressure drop from 7 to 6 bar

absolute)

optional: 130 lN / min (for aeration and deaeration)

(only single-acting)

Connections Plug-in hose connector Ø6 mm / 1/4"

Socket connection G1/8

6.7 Type labels

6.7.1 Type label standard

Example:

Supply voltage / Control

Type

8694 24 V DC

single act Pilot 0,6

Pmax 7bar

Tamb 0°C - +60°C

S/N 001000

00185134

D-74653 Ingelfingen

Identification number

W14UN

CE

Control function - Pilot valve

Max. operating pressure

Max. ambient temperature

Serial number - CE mark

Bar-code

Figure 7: Example of type label

21

english

Page 22

6.7.2 UL type label

Example:

Type; Features of the type code applicable to UL and ATEX

8694 -E3-...-0 PU02

Single act Pilot 3.0 24V

Pmax 7 bar

Tamb -10 - +55 °C

S/N 1001

00123456

D-74653 Ingelfingen

Figure 8: UL type label (example)

CE

W15MA

Type 8694

Technical data

Control function; pilot valve;

Supply voltage pilot valve

Max. operating pressure

Max. ambient temperature

Serial number; CE mark

Identification number; Date of manufacture (encoded)

Bar code

6.7.3 UL additional label

Example:

Degree of protection

Circuit with limited power

Supply voltage device

Figure 9: UL additional label (example)

Type 4X enclosure

NEC Class 2 only

Supply voltage: 24V

6.8 Electrical data

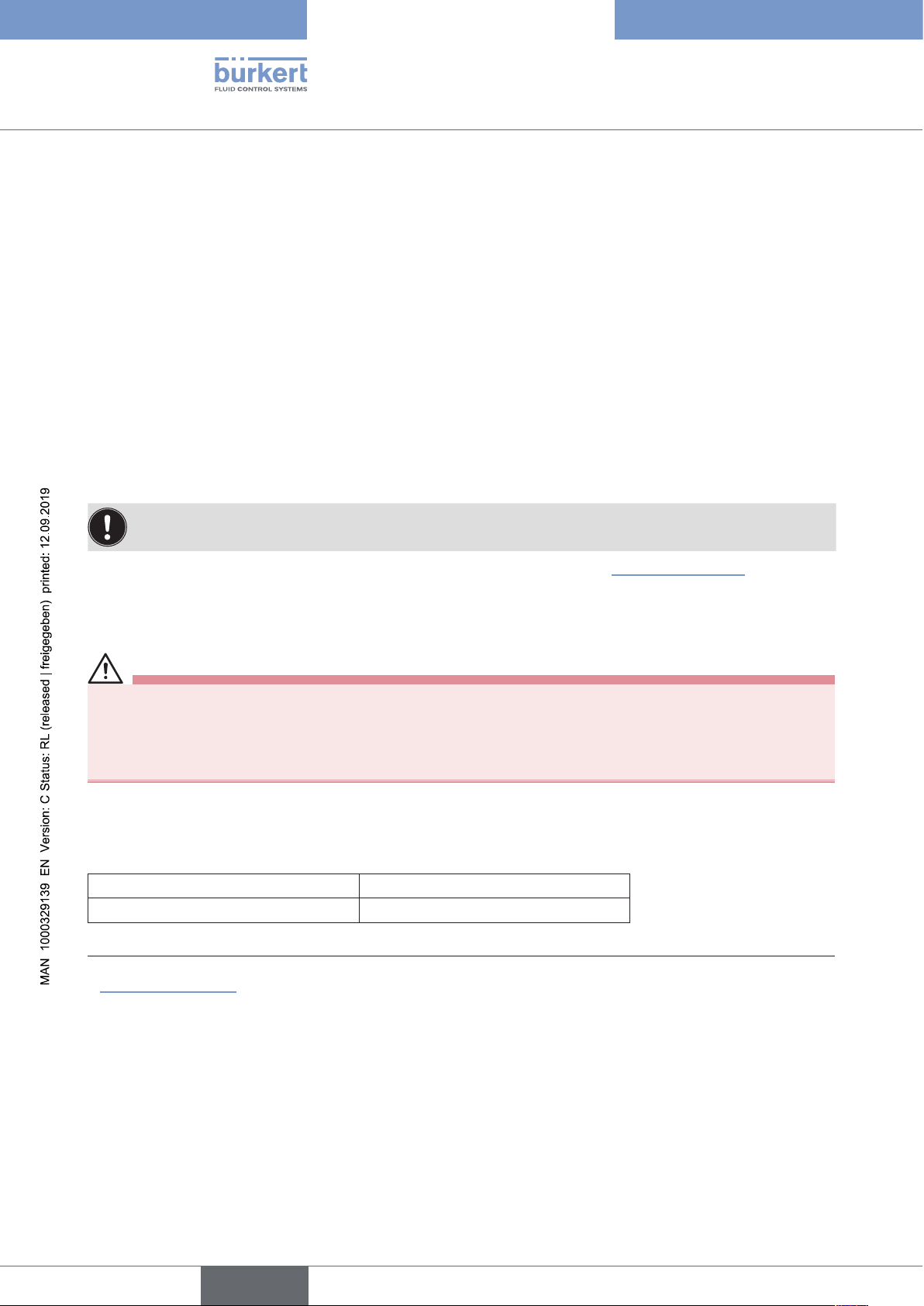

WARNING!

Only circuits with limited power may be used for UL approved components according to “NEC Class 2”.

6.8.1 Electrical data without bus control 24 V DC

22

Protection class 3 as per DIN EN 61140 (VDE 0140-1)

Connections Cable gland M16 x 1.5, wrench size 22 (clamping area 5 – 10 mm)

with screw-type terminals for cable cross-sections 0.14 – 1.5 mm²

Circular plug-in connector (M12 x 1, 8-pole)

Control valve

Operating voltage 24 V DC ± 10% - max. residual ripple 10 %

Power input ≤ 3.5 W

Input resistance

for set-point value signal 75 Ω at 0/4 - 20 mA / 12 bit resolution

english

Page 23

Type 8694

Technical data

Analogue position feedback

max. load

for current output 0/4 – 20 mA 560 Ω

Binary input 0 – 5 V = log “0”, 12 - 30 V = log “1”

inverted input in reverse order

Communications interface Direct connection to PC via USB adapter with integrated interface driver,

communication with communications software, see “Table 34: Accessories”.

6.8.2 Electrical data with AS-Interface bus control

Protection class 3 as per DIN EN 61140 (VDE 0140-1)

Connections Circular plug-in connector (M12 x 1, 4-pole)

Electrical supply voltage 29.5 V – 31.6 V DC (according to specification)

Devices without external supply voltage:

Max. power consumption 150 mA

Devices with external supply voltage:

External supply voltage 24 V ± 10 %

The power supply unit must

include a secure disconnection in

accordance with IEC 364-4-41

(PELV or SELV)

Max. power consumption 100 mA

Max. power consumption

from AS-Interface 50 mA

english

23

Page 24

6.9 Factory settings of the positioner

Functions can be activated via DIP switches:

Function Parameter Value

Type 8694

Technical data

CUTOFF

CHARACT

DIR.CMD

Table 4: Factory settings - Functions I

Sealing function below

Sealing function above

2 %

98 %

Select characteristic FREE

Effective direction set-point value rise

Functions can be activated via communications software:

Function Parameter Value

INPUT

DIR.ACTUATOR

SPLITRANGE

Function deactivated

X.LIMIT

Function deactivated

Set-point value input 4 ... 20 mA

Effective direction actual value rise

Signal split range below

Signal split range above

Stroke limit below

Stroke limit above

0 %

100 %

0 %

100 %

5)

24

X.TIME

Function deactivated

Actuating time Open

Actuating time Closed

(1 s) values determined by X.TUNE

(1 s) values determined by X.TUNE

After implementation of RESET: 1 s

X.CONTROL

Deadband

Open amplification factor

Close amplification factor

1,0 %

(1) values determined by X.TUNE

(1) values determined by X.TUNE

After implementation of RESET: 1

SAFE POSITION

SIGNAL ERROR

Safety position 0 %

Sensor break detection set-point value OFF

Function deactivated

BINARY INPUT

OUTPUT

(optional)

Table 5: Factory settings Functions II

5) Without change to the settings via the communications software a linear characteristic is stored in FREE.

Binary input function

Operating principle of binary input

Norm signal output: Parameter

Norm signal output: Type

Safety position

Normally open

Position

4 – 20 mA

english

Page 25

Type 8694

Control and display elements

7 CONTROL AND DISPLAY ELEMENTS

The following chapter describes the operating statuses as well as the control and display elements of the positioner.

Further information on the operation of the positioner can be found in the chapter entitled “12 Start-up”.

7.1 Operating status

AUTOMATIC (AUTO)

Normal controller mode is implemented and monitored in AUTOMATIC operating status.

→ LED 1 flashes green.

MANUAL

In MANUAL operating status the valve can be opened and closed manually via the keys.

→ LED 1 flashes red / green alternately.

DIP switch 4 can be used to switch between the two operating statuses AUTOMATIC and MANUAL.

ON DIP

2 3 4

1

7.2 Control and display elements of the positioner

Version 1

LED 2LED 1

Key 1

Key 2

LED 2

DIP Switches

Communications

interface

Version 2

Communications

interface

LED 1

ON DIP

1 2 3 4

Figure 10: Description of control elements

Key 1

Key 2

25

english

Page 26

Type 8694

Control and display elements

The positioner features 2 buttons, 4-pole DIP switches and 2x 2-colored LEDs as a display element.

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing or transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing.

→ To operate the buttons and DIP switches, for

Version 1: unscrew the body casing

Version 2: unscrew the transparent cap

Transparent cap

Body casing

Connection housing

Actuator

Version 1 Version 2

Figure 11: Open positioner

Body casing

Seal

body casing

Connection housing

Figure 12: Position of the seal in the body casing

→ Version 1:

Check that the seal is correctly positioned in the body casing.

26

NOTE!

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674077

6) The assembly tool (674077) is available from your Bürkert sales office.

english

6)

).

Page 27

Type 8694

Control and display elements

7.3 Configuration of the keys

The configuration of the 2 keys varies depending on the operating status (AUTOMATIC / MANUAL).

The description of the operating statuses (AUTOMATIC / MANUAL) can be found in the chapter entitled “7.1

Operating status”.

Version 1 Version 2

Key 1

Key 2

Figure 13: Description of the buttons

Key 1

Key 2

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing or transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing.

→ To operate the buttons, for

Version 1: unscrew the body casing

Version 2: unscrew the transparent cap

Transparent cap

Body casing

Connection housing

Actuator

Version 1 Version 2

Figure 14: Open positioner

27

english

Page 28

MANUAL operating status (DIP switch 4 set to ON):

Key Function

7)

1

2

Table 6: Configuration of the keys for MANUAL operating status

Aerate

(manually open / close the actuator)

Deaerate7)

(manually open / close the actuator)

8)

8)

AUTOMATIC operating status (DIP switch 4 set to OFF):

Key Function

1 Press for 5 seconds to start the X.TUNE function

2 -

Type 8694

Control and display elements

Table 7: Configuration of the keys for AUTOMATIC operating status

Body casing

Seal

body casing

Connection housing

Figure 15: Position of the seal in the body casing

→ Version 1:

Check that the seal is correctly positioned in the body casing.

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing or transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing.

28

Damage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674077

7) No function if the binary input was activated with the “Manual/Auto change-over” via the communications software

8) Depending on the operating principle of the actuator.

9) The assembly tool (674077) is available from your Bürkert sales office.

9)

).

english

Page 29

Type 8694

Control and display elements

7.4 Function of the DIP switches

ON DIP

2 3 4

1

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing or transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing.

→ To operate the DIP switches, for

Version 1: unscrew the body casing

Version 2: unscrew the transparent cap

Transparent cap

Version 1 Version 2

Figure 16: Open positioner

DIP Switches Position Function

1 ON Reversal of the effective direction of the set-point value (DIR.CMD)

(set-point value 20 – 4 mA corresponds to position 0 – 100 %), descending

OFF Normal effective direction of the set-point value

(set-point value 4 – 20 mA corresponds to position 0 – 100 %), ascending

2 ON Sealing function active. The valve completely closes below 2 %

above 98 % of the set-point value (CUTOFF)

OFF No sealing function

3 ON Correction characteristic for adjustment of the operating characteristic

(linearization of the process characteristic CHARACT)

OFF Linear characteristic

Body casing

Connection housing

Actuator

11)

10)

and opens

4 ON Operating status MANUAL (BY HAND)

OFF Operating status AUTOMATIC (AUTO)

Table 8: DIP Switches

10) Factory setting, can be changed via communications software.

11) The characteristic type can be changed via communications software.

29

english

Page 30

Type 8694

Control and display elements

Information about the communications software:

The switching position of the DIP switch has priority over the settings via the communications software.

If the values of the sealing function (CUTOFF) or the correction characteristic (CHARACT) are changed

via the communications software, the corresponding function must be active (DIP switches set to ON).

The effective direction of the set-point value (DIR.CMD) can be changed via the DIP switches only.

If the correction characteristic (CHARACT) is not changed via the communications software, a linear characteristic is saved when DIP switch 3 is set to ON.

A detailed description of the functions can be found in the chapter entitled “Basic functions”.

Body casing

Seal

body casing

Connection housing

Figure 17: Position of the seal in the body casing

→ Version 1:

Check that the seal is correctly positioned in the body casing.

NOTE!

Breakage of the pneumatic connection pieces due to rotational impact.

▶ When unscrewing and screwing in the body casing or transparent cap, do not hold the actuator of the pro-

cess valve but the connection housing.

D

amage or malfunction due to penetration of dirt and humidity.

▶ To observe degree of protection IP65 / IP67, screw the transparent cap in all the way.

→ Close the device (assembly tool: 674077

12)

).

30

12) The assembly tool (674077) is available from your Bürkert sales office.

english

Page 31

Type 8694

Control and display elements

7.5 Display of the LEDs

Version 1 Version 2

LED 1 LED 2

LED 1

(green /

red)

Display of mode

statuses

AUTO, MANUAL,

X.TUNE and FAULT

LED 2

(green /

yellow)

Display of the actuator

status

(open, closed, opens

or closes)

Figure 18: LED display

LED 1 (green / red)

LED statuses

Display

green red

on off Acceleration phase when Power ON

flashes slowly off Operating status AUTO (AUTOMATIC)

flashing flashing MANUAL operating status

alternating

flashes quickly off X.TUNE function

off on

ERROR (see chapter entitled “7.6 Error messages”)

off flashes slowly AUTO operating status for sensor break detection

Table 9: Display LED 1

LED 2 (green / yellow)

LED statuses

Display

green yellow

on off Actuator closed

off on Actuator open

flashes slowly off

off flashes slowly

remaining control deviation

(actual value > set-point value)

remaining control deviation

(actual value < set-point value)

flashes quickly off Closing in MANUAL operating status

off flashes quickly Opening in MANUAL operating status

Table 10: Display LED 2

31

english

Page 32

Type 8694

Control and display elements

7.6 Error messages

7.6.1 Error messages in MANUAL and AUTOMATIC operating statuses

Display Cause of fault Remedial action

LED 1 (red) onChecksum error in data memory

→ Data memory defective

The device automatically switches to an older

→

(possibly not current) data record.

Table 11: Error messages in the operating statuses

Not possible, device defective

7.6.2 Error messages while the X.TUNE function is running

Display Cause of fault Remedial action

LED 1 (red) onNo compressed air connected Connect compressed air

Compressed air failure while the X.TUNE

function was running

Actuator or control system deaeration side

leaking

Control system aeration side leaking Not possible, device defective

Check compressed air supply

Not possible, device defective

32

Table 12: Error messages for the X.TUNE function

english

Page 33

Type 8694

Installation

8 INSTALLATION

8.1 Safety instructions

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following assembly, ensure a controlled restart.

8.2 Installation of the positioner Type 8694 on process valves of series 2103, 2300 and 2301

NOTE!

When mounting on process valves with a welded body, follow the installation instructions in the operating instructions for the process valve.

Procedure:

1. Install switch spindle

Transparent cap

Pilot air ports

(plug-in hose connectors with collets or

threaded bushings)

Actuator

Figure 19: Installation of the switch spindle (1), series 2103, 2300 and 2301

→ Unscrew the transparent cap on the actuator and unscrew the position display (yellow cap) on the spindle

extension (if present).

english

33

Page 34

Type 8694

Installation

→ For version with plug-in hose connector, remove the collets (white nozzles) from both pilot air ports (if

present).

Puck

Switch spindle

Guide element

Groove ring

max. 1 Nm

max. 5 Nm

Actuator cover

O-ring

Spindle extension

Figure 20: Installation of the switch spindle (2), series 2103, 2300 and 2301

NOTE!

Improper installation may damage the groove ring in the guide element.

The groove ring is already be pre-assembled in the guide element and must be “locked into position” in the

undercut.

▶ When installing the switch spindle, do not damage the groove ring.

→ Push the switch spindle through the guide element.

NOTE!

Screw locking paint may contaminate the groove ring.

▶ Do not apply any screw locking paint to the switch spindle.

→ To secure the switch spindle, apply some screw locking paint (Loctite 290) in the tapped bore of the spindle

extension in the actuator.

34

→ Check that the O-ring is correctly positioned.

→ Screw the guide element to the actuator cover (maximum torque: 5 Nm).

→ Screw switch spindle onto the spindle extension. To do this, there is a slot on the upper side

(maximum torque: 1 Nm).

→ Push puck onto the switch spindle and lock into position.

english

Page 35

Type 8694

Installation

2. Install sealing rings

→ Pull the form seal onto the actuator cover (smaller diameter points upwards).

→ Check that the O-rings are correctly positioned in the pilot air ports.

When the positioner is being installed, the collets of the pilot air ports must not be fitted to the actuator.

Form seal

Pilot air port

Caution:

collets must not be

fitted !

Installation of the form

seal

Figure 21: Installation of the sealing rings, series 2103, 2300 and 2301

3. Install positioner

→ Align the puck and the positioner until

1. the puck can be inserted into the guide rail of the positioner (see “Figure 22”)

and

2. the connection pieces of the positioner can be inserted into the pilot air ports of the actuator (see also

“Figure 23”).

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

Guide rail

Puck

Figure 22: Aligning the puck

35

english

Page 36

Type 8694

Installation

→ Push the positioner, without turning it, onto the actuator until no gap is visible on the form seal.

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screws may be tightened to a maximum torque of 1.5 Nm only.

→ Attach the positioner to the actuator using the two side fastening screws. In doing so, tighten the screws only

hand-tight (max. torque: 1.5 Nm).

Fastening screws

max. 1.5 Nm

Connection pieces

Pilot air

ports

Figure 23: Installation of positioner, series 2103, 2300 and 2301

Actuator

8.3 Installing the positioner Type 8694 on process valves belonging to series 26xx and 27xx

Procedure:

1. Install switch spindle

Guide element

Spindle extension

36

Actuator

Figure 24: Installing the switch spindle (1), series 26xx and 27xx

→ Unscrew the already fitted guide element from the actuator (if present).

→ Remove intermediate ring (if present).

english

Page 37

Type 8694

Installation

Puck

Switch spindle

Guide element

O-ring

Plastic part

(Switch spindle)

Spindle (actuator)

Figure 25: Installing the switch spindle (2), series 26xx and 27xx

→ Press the O-ring downwards into the cover of the actuator.

→ Actuator size 125 and bigger with high air flow rate:

remove existing spindle extension and replace with the new one. To do this, apply some screw locking paint

(Loctite 290) in the tapped bore of the spindle extension.

→ Screw the guide element into the cover of the actuator using a face wrench

13)

(torque: 8.0 Nm).

→ To secure the switch spindle, apply some screw locking paint (Loctite 290) to the thread of the switch spindle.

→ Screw the switch spindle onto the spindle extension. To do this, there is a slot on the upper side

(maximum torque: 1 Nm).

→ Push the puck onto the switch spindle until it engages.

13) Journal Ø: 3 mm; journal gap: 23.5 mm

37

english

Page 38

Type 8694

Installation

2. Install positioner

→ Push the positioner onto the actuator. The puck must be aligned in such a way that it is inserted into the guide

rail of the positioner.

NOTE!

Damaged printed circuit board or malfunction.

▶ Ensure that the puck is situated flat on the guide rail.

Guide rail

Puck

Figure 26: Aligning the puck

→ Press the positioner all the way down as far as the actuator and turn it into the required position.

Fastening screws

max. 1.5 Nm

Figure 27: Installing the positioner

Ensure that the pneumatic connections of the positioner and those of the valve actuator are situated preferably vertically one above the other.

If they are positioned differently, longer hoses may be required other than those supplied in the accessory kit.

38

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screws may be tightened to a maximum torque of 1.5 Nm only.

→ Attach the positioner to the actuator using the two side fastening screws. In doing so, tighten the fastening

screws hand-tight only (maximum torque: 1.5 Nm).

english

Page 39

Type 8694

Installation

3. Install pneumatic connection between positioner and actuator

Pilot air outlet 2

Pilot air outlet 2

1

2

Upper pilot air port

Lower pilot air port

Example ∅ 80, CFA

Figure 28: Installing the positioner

→ Screw the plug-in hose connectors onto the positioner and the actuator.

→ Using the hoses supplied in the accessory kit, make the pneumatic connection between the positioner and

actuator with the following “Table 13: Pneumatic connection to actuator - CFA” or “Table 14: Pneumatic connection to actuator - CFB”.

NOTE!

Damage or malfunction due to ingress of dirt and moisture.

To observe degree of protection IP65 / IP67:

▶ In the case of actuator size ∅ 80, ∅ 100

connect the pilot air outlet which is not required to the free pilot air port of the actuator or seal with a plug.

▶ In the case of actuator size ∅ 125

seal the pilot air outlet 22 which is not required with a plug and feed the free pilot air port of the actuator via a

hose into a dry environment.

Control function A (CFA)

Process valve closed in rest position (by spring force)

Actuator size ∅ 80, ∅ 100

∅ 125

Pilot air outlet

2

2

2

2

2

2

1

1

Positioner

Upper pilot air port

Lower pilot air port

Actuator

Dry area

Table 13: Pneumatic connection to actuator - CFA

39

english

Page 40

Control function B (CFB)

Process valve open in rest position (by spring force)

Actuator size ∅ 80, ∅ 100

Pilot air outlet

2

2

2

1

Positioner

Upper pilot air port

Lower pilot air port

Actuator

Dry area

Table 14: Pneumatic connection to actuator - CFB

Type 8694

Installation

2

∅ 125

2

2

1

"In rest position" means that the pilot valves of the positioner Type 8694 are isolated or not actuated.

8.4 Rotating the actuator module

The actuator module (positioner and actuator) can be rotated for straight seat valves and angle seat valves

belonging to series 2300, 2301 and 27xx only.

The position of the connections can be aligned steplessly by rotating the actuator module (positioner and actuator)

through 360°.

Process valves Type 2300, 2301 and 27xx: Only the entire actuator module can be rotated. The positioner cannot be rotated contrary to the actuator.

The process valve must be in the open position for alignment of the actuator module.

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

Procedure:

40

→ Clamp valve body in a holding device (only required if the process valve has not yet been installed).

NOTE!

Damage to the seat seal or the seat contour.

▶ When removing the actuator module, ensure that the valve is in open position.

→ Control function A: Open process valve.

english

Page 41

Type 8694

Installation

Actuator

module

Key contour

Nipple

Figure 29: Rotating the actuator module

without hexagon

Hexagon

Nipple

with hexagon

→ Using a suitable open-end wrench, counter the wrench flat on the pipe.

→ Actuator module without hexagon:

Fit special key

14)

exactly in the key contour on the underside of the actuator.

→ Actuator module with hexagon:

Place suitable open-end wrench on the hexagon of the actuator.

WARNING!

Risk of injury from discharge of medium and pressure.

If the direction of rotation is wrong, the body interface may become detached.

▶ Rotate the actuator module in the specified direction only (see “Figure 30”) .

→ Actuator module without hexagon:

Rotate clockwise (as seen from below) to bring the actuator module into the required position.

→ Actuator module with hexagon:

Rotate counter-clockwise (as seen from below) to bring the actuator module into the required position.

Open-end wrench

Special key

Figure 30: Rotating with special key / open-end wrench

14) The special key (665702) is available from your Bürkert sales office.

without hexagonwith hexagon

41

english

Page 42

Type 8694

Installation

8.5 Rotating the positioner for process valves belonging to series 26xx and 27xx

If the connecting cables or hoses cannot be fitted properly following installation of the process valve, the positioner

can be rotated contrary to the actuator.

Fastening screw (2x)

Positioner

Pneumatic connection

Actuator

Figure 31: Rotating the positioner, series 26xx and 27xx

Procedure

→ Loosen the pneumatic connection between the positioner and the actuator.

→ Loosen the fastening screws (hexagon socket wrench size 2.5).

→ Rotate the positioner into the required position.

NOTE!

Too high torque when screwing in the fastening screw does not ensure degree of protection IP65 /

IP67.

▶ The fastening screw may be tightened to a maximum torque of 1.5 Nm only.

→ Tighten the fastening screws hand-tight only (maximum torque: 1.5 Nm).

→ Re-attach the pneumatic connections between the positioner and the actuator. If required, use longer hoses.

42

english

Page 43

Type 8694

Pneumatic installation

9 PNEUMATIC INSTALLATION

DANGER!

Risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure and deaerate/drain lines.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

Procedure:

→ Connect the control medium to the pilot air port (1) (3 – 7 bar; instrument air, free of oil, water and dust).

→ Attach the exhaust air line or a silencer to the exhaust air port (3)

and, if available to the exhaust air port (3.1)

Important information for the problem-free functioning of the device:

▶ The installation must not cause back pressure to build up.

▶ Select a hose for the connection with an adequate cross-section.

▶ The exhaust air line must be designed in such a way that no water or other liquid can get into the device

through the exhaust air port (3) or (3.1).

Exhaust air port

Figure 32: Pneumatic connection

(label: 3)

Pilot air port

(label: 1)

Additional exhaust air port (label: 3.1)

only for Type 23xx and 2103

with pilot-operated control system

for high air flow rate (actuator size ø 130)

43

english

Page 44

Type 8694

Pneumatic installation

Caution:(Exhaust air concept):

In compliance with degree of protection IP67, an exhaust air line must be installed in the dry area.

Keep the adjacent supply pressure always at least 0.5 – 1 bar above the pressure which is required to

move the actuator to its end position. This ensures that the control behavior is not extremely negatively

affected in the upper stroke range on account of too little pressure difference.

During operation keep the fluctuations of the pressure supply as low as possible (max. ±10 %). If fluctuations are greater, the control parameters measured with the X.TUNE function are not optimum.

9.1 Manual actuation of the actuator via pilot valves

9.1.1 Single-acting actuators (control function A and B)

The actuator can be moved without a power supply from the rest position to its end position and back again. To do

this, the pilot valves must be actuated with a screwdriver.

NOTE!

The hand lever may be damaged if it is simultaneously pressed and turned.

▶ Do not press the hand lever when turning it.

Pilot valve non activated

(normal position)

Hand lever

to the left

Pilot valve activated

Hand lever

to the right

Pilot valve

for aerate

Pilot valve

for deaerate

Type 8694 for high air flow rate

Pilot valve

for aerate

44

Pilot valve

for deaerate

Figure 33: Pilot valves for aerate and deaerate the actuator

english

Page 45

Type 8694

Pneumatic installation

Move actuator to end position

Turn the hand levers to the right using a screwdriver.

Note: - do not press the hand levers when turning them

- observe the sequence as described below

→ 1. Actuate hand lever pilot valve deaeration.

→ 2. Actuate hand lever pilot valve aeration.

Both hand levers point to the right.

The actuator moves to the end position.

Figure 34: Move actuator to end position

Move actuator back to the rest position

Turn the hand levers to the left using a screwdriver.

Note: - do not press the hand levers when turning them

- observe the sequence as described below

2.1.

Type 8694 for high air flow rate

1.2.

→ 1. Actuate hand lever pilot valve aeration.

→ 2. Actuate hand lever pilot valve deaeration.

Both hand levers point to the left (normal position).

The actuator moves by spring force to the rest position.

Figure 35: Move actuator back to the rest position

Caution:

If the pilot valves are actuated, electrical control is not possible.

▶ Move hand levers to normal position before starting up the device.

1.2.

Type 8694 for high air flow rate

2.1.

45

english

Page 46

Type 8694

Electrical installation 24 V DC

10 ELECTRICAL INSTALLATION 24 V DC

All electrical inputs and outputs of the device are not galvanically isolated from the supply voltage.

Two kinds of connections are used for the electrical bonding of the positioner:

• Cable gland

with cable gland M16 x 1.5 and screw-type terminals

• Multi-pole

with circular plug-in connector M12 x 1, 8-pole

10.1 Safety instructions

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

WARNING!

Risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only and with the appropriate tools.

Risk of injury from unintentional activation of the system and an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

10.2 Electrical installation with circular plug-in connector

DANGER!

Risk of electric shock.

▶ Before working on equipment or device, switch off the power supply and secure to prevent reactivation.

▶ Observe applicable accident prevention and safety regulations for electrical equipment.

46

10.2.1 Designation of the contacts Type 8694

View without body

casing

7

8

Figure 36: Circular plug M12 x 1, 8-pole

english

5

6

1

Circular plug

4

M12 x1, 8-pole

3

2

Page 47

Type 8694

Electrical installation 24 V DC

10.2.2 Connection of the positioner Type 8694

→ Connect the pins according to the model (options) of the positioner.

Input signals of the control center (e.g. PLC) - circular plug M12 x 1, 8-pole

Pin Wire color

1 2white

brown

grey

5

pink

6

Table 15: Pin assignment - input signals of the control center - circular plug M12 x 1, 8-pole

15)

Configuration External circuit / signal level

Set-point value + (0/4 – 20 mA)

Set-point value GND

Binary input +

Binary input GND

1

+ (0/4 ... 20 mA)

2 GND

5 + 0 ... 5 V (log. 0)

identical to Pin 3 (GND)

Output signals to the control center (e.g. PLC) - circular plug M 12 x 1, 8-pole

(required for analogue output option only)

Pin Wire color

8 7red

blue