Bosch WTVC Repair Instruction

W

W

W

T

T

T

V

V

V

C

C

C

G

G

G

A

A

A

S

S

S

D

D

D

R

R

R

Y

Y

Y

E

E

E

R

R

R

R

R

R

E

E

E

P

P

P

A

A

A

I

I

I

R

R

R

I

I

I

N

N

N

S

S

S

T

T

T

R

R

R

U

U

U

C

C

C

T

T

T

I

I

I

O

O

O

N

N

N

1 SAFETY ........................................................ 2

2 INSTALLATION............................................ 3

2.1 Basic installation ................................................................ 3

2.2 Exhaust vents...................................................................... 3

2.3 Feet (leveling legs).............................................................. 3

2.4 AQUASTOP® (aqua secure)................................................ 4

2.5 General installation warnings ............................................ 4

3 OPERATION................................................. 5

3.1 Controls ............................................................................... 5

4 COMPONENTS............................................. 6

4.1 WTVC Gas Dryer Components .......................................... 6

4.2 Operation ........................................................................... 14

5 REPAIR.......................................................15

5.1 Disassembly / Reassembly .............................................. 15

5.2 Kit Installation ................................................................... 25

5.3 Diagnosing (troubleshooting)..........................................26

5.4 Dryer noise ........................................................................ 27

5.5 Customer diagnosing ....................................................... 27

5.6 Maintenance ...................................................................... 28

6 FAULT DIAGNOSTICS............................... 29

6.1 Overheating fault codes ................................................... 32

7 TECHNICAL SPECIFICATIONS ................ 33

7.1 Dryer ratings ..................................................................... 33

702_58300000143767_ara_en_a Page 1 of 33

1 SAFETY

c Danger of electric shock.

h Danger of fire or explosion from gas.

h WARNING Modern appliances are very powerful and use high

technology devices to safely control that power. Failure to use

the correct procedures and the approved parts can create

serious hazards for the person servicing the appliance and for

the user of an appliance with a bad repair. If you do not know

how to service the appliance, do not attempt to do so!

To avoid the risk of serious injury or death while servicing these

appliances:

h Be certain that all power is removed from the appliance before

beginning service.

h Carefully follow all servicing instructions. Verify the instructions

if there are any that you don't fully understand.

h Read and heed all Cautions and Warnings on the appliance

and those with the replacement parts.

h Use caution and proper protective gear when handling chassis

panels. Some of the edges that are not normally exposed may

be very sharp.

To avoid risk of serious injury or death to the users of the appliances:

h Carefully follow all service instructions.

h Use only parts authorized for the application.

h Know the testing requirements needed to verify the safety of

the service action.

h Use proper, calibrated test equipment.

h Do all indicated safety tests and record results.

702_58300000143767_ara_en_a Page 2 of 33

2 INSTALLATION

2.1 Basic installation

Dryers shall be installed according to national and local codes.

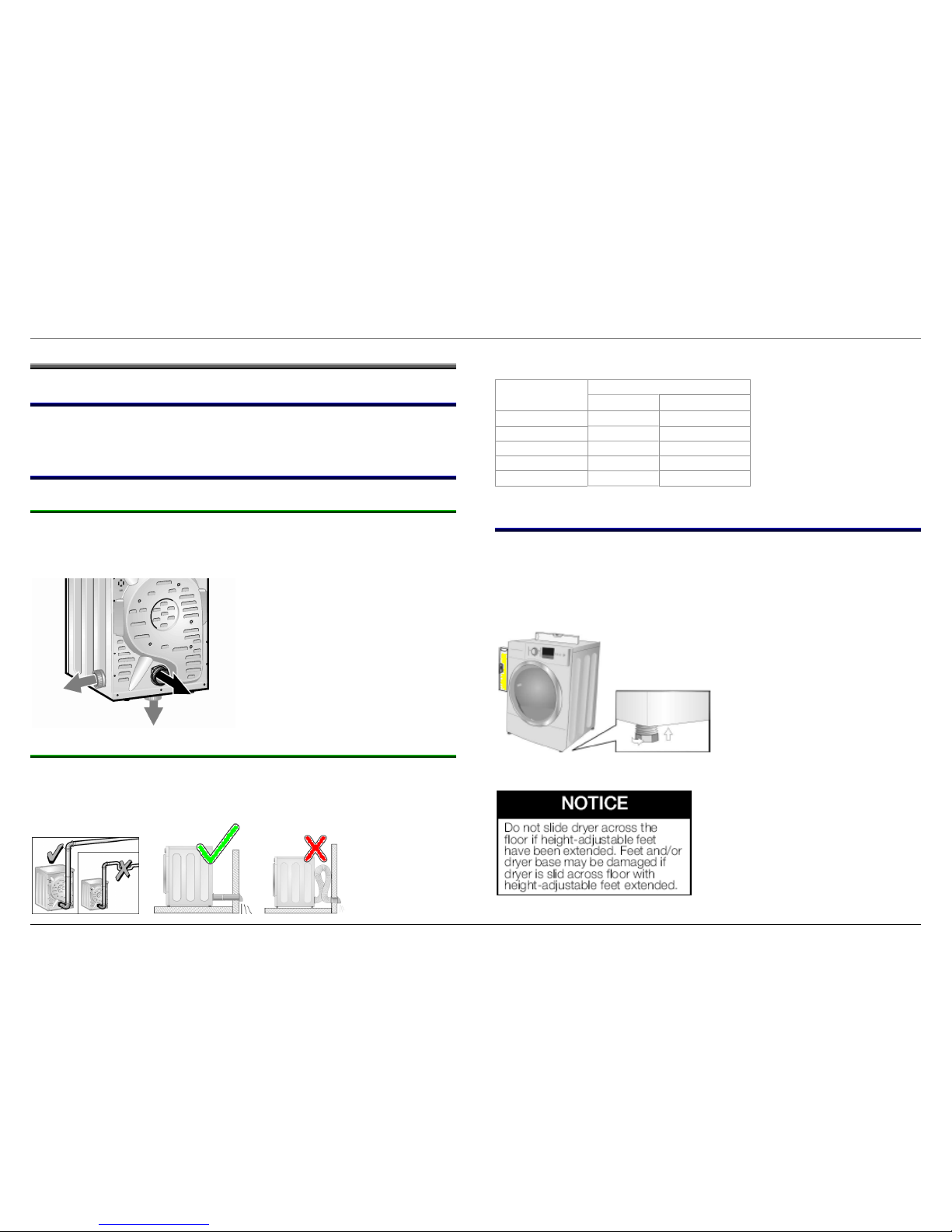

2.2 Exhaust vents

2.2.1 Locating exhaust vent

Vent is factory installed to the rear of dryers. Rear factory vent can be

changed to the bottom or right side using kits (sales accessories).

2.2.2 Installing vent ducts

For best drying, use shortest possible duct length and fewest # of

elbows.

Use the table below when selecting ducting.

# 90º Turns / Maximum Length

Elbows Rigid Duct Flexible Duct

0 20 m 14 m

1 17 m 11 m

2 14.5 m 9 m

3 12 m 7 m

4 9 m 5 m

2.3 Feet (leveling legs)

Using a level front to back and side to side, adjust feet (leveling legs)

until dryer is level. When moving dryers, screw in feet completely

before moving dryers to avoid damage.

To adjust feet (leveling

legs), rotate left to right to

lower dryer.

702_58300000143767_ara_en_a Page 3 of 33

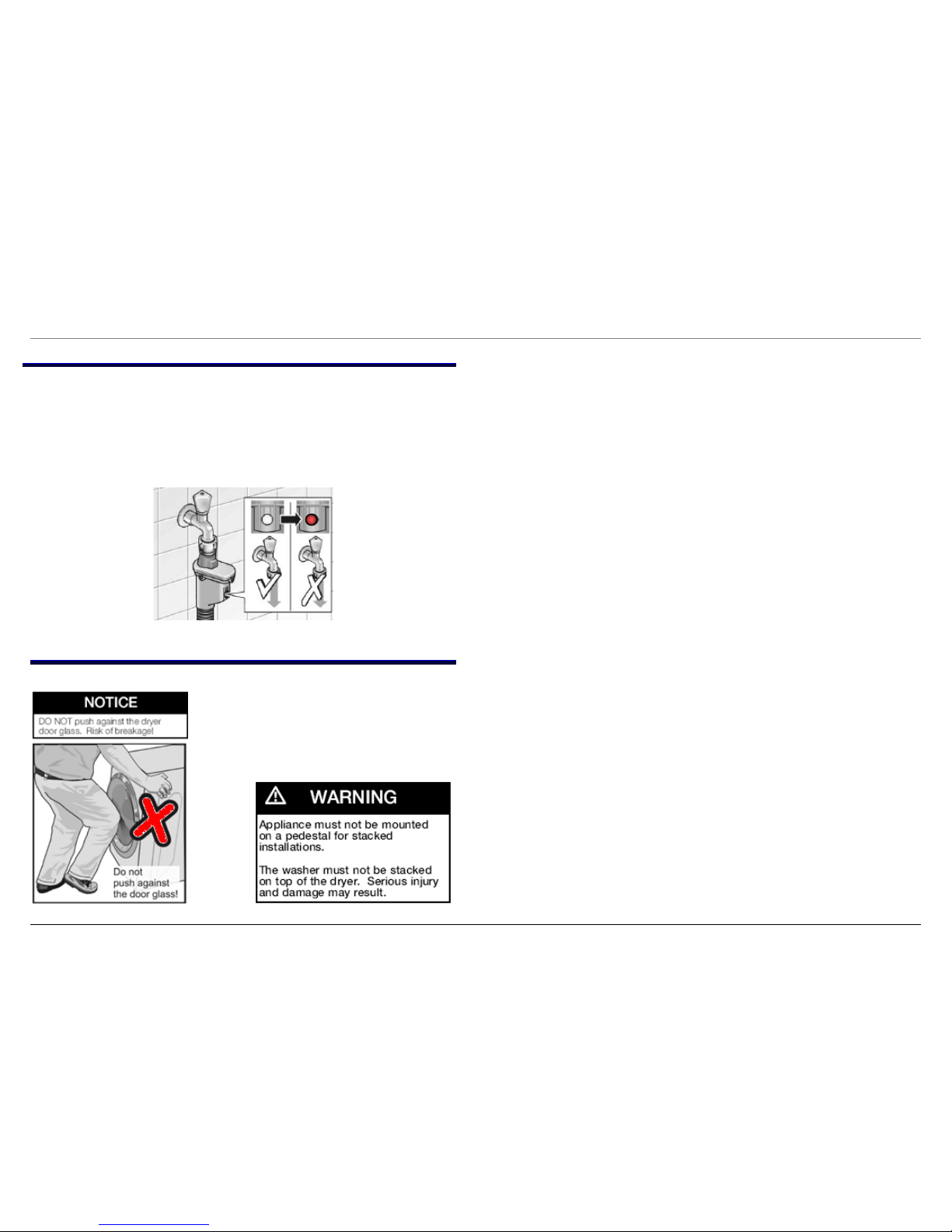

2.4 AQUASTOP® (aqua secure)

AQUASTOP® water inlet hoses prevent water from leaking. They

connect like standard hoses with no special installation needed. If an

inner hose ever should leak, the hose shuts off and it’s indicator

shows red. Hoses are one-time and must be replaced when

indicators are red.

2.5 General installation warnings

702_58300000143767_ara_en_a Page 4 of 33

3 OPERATION

3.1 Controls

Controls are shown below. Rotate the knob to the desired drying

program and push the Start/Pause button.

There are option buttons for delicate fabrics and saving energy. Dryer

status is shown in LED’s at the left of the display.

702_58300000143767_ara_en_a Page 5 of 33

4 COMPONENTS

4.1 WTVC Gas Dryer Components

Basic components are control module, gas burner, gas igniter, flame

sensor, drive motor with fan, two NTC temperature sensors, two hilimit temperature protectors, moisture sensor and broken belt switch.

Gas dryers are set up for natural gas and can be converted to LP

using a kit (WTZ1280).

4.1.1 Gas burner assembly

Burner assemblies include an NTC temperature sensor and a

manually resettable hi-limit temperature protector. The NTC is

mounted at the rear of the assembly near where it attaches to the

vent.

BBuurrnneerr

cchhaammbbeerr

Gas

valve

BBuurrnneerr

((vveennttuurrii))

FFllaammee

sseennssoorr

IIggnniitteerr

HHii--lliimmiitt

BBuurrnneerr

cchhaammbbe

e

r

r

BBrrookkeenn bbeelltt

sswwiittcch

h

FFrroonntt ((bbeeaarriinngg))

sshhiieelld

d

MMootto

o

r

r

Fan

Gas

valve

Push

button to

reset Hi-limit

red

Hi-

limit

p

rotector.

702_58300000143767_ara_en_a Page 6 of 33

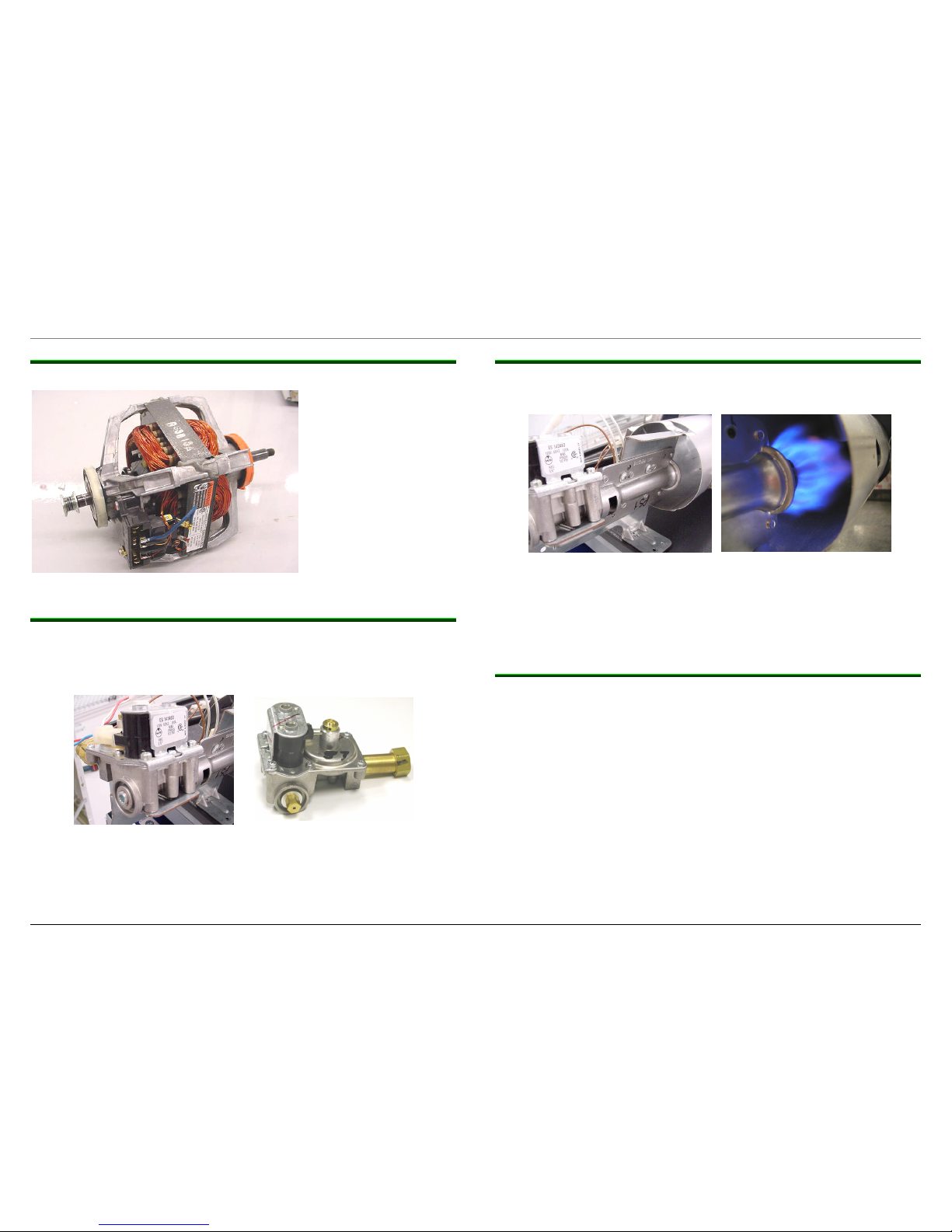

4.1.2 Drive motor

4.1.3 Gas valve

The gas valve, whether natural gas or LP, includes the appropriate

regulator and jet (orifice).

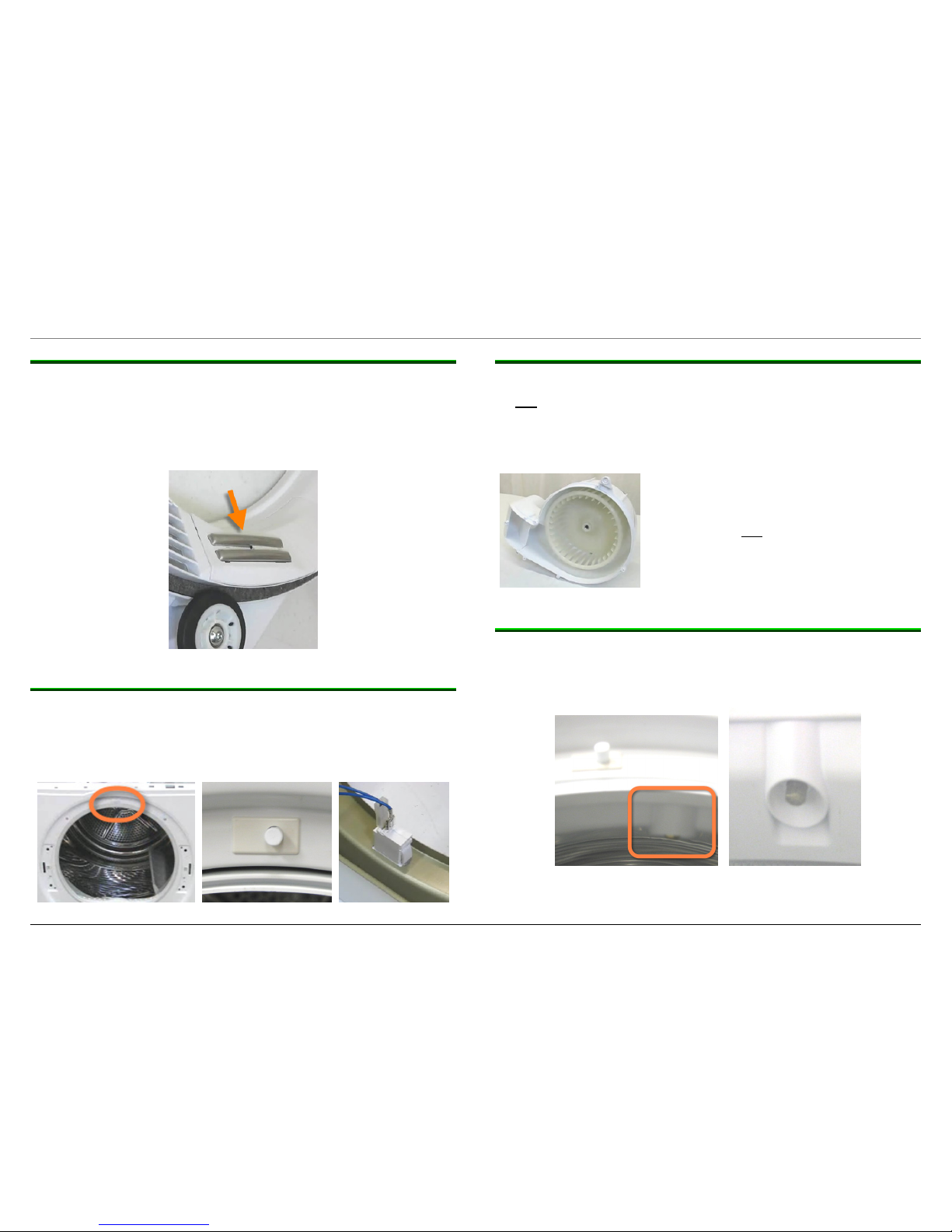

4.1.4 Burner

The burner mounts next to the gas valve jet (orifice). A burner ring is

used for natural gas dryers to optimize performance.

The gas dryer burner circuit runs through the motor & Hi-limit. The

connection through the motor cuts out the burner if the motor isn’t

running.

Motor is rated 120

VAC, 60 Hz, 1/3 HP

(248.5 W), 5.0 A,

1725 RPM, 40ºC

ambient, class B

insulation. It drives

the fan (in front) and

drum (in rear, using

pulley shown).

Drum

belt

pulley

Fan

wheel

shaft

Burner

GGaass vvaallvvee

4.1.5 Gas leak testing (using soapy water)

Whenever gas connections are changed or disturbed, they should be

checked for leaks using a soapy water solution.

1. Reconnect all gas connections and turn on the gas supply to

the dryer, using household gas inlet pressure.

2. Apply soapy water solution with a spray bottle. Spray union

and brass connections completely.

3. Watch connections carefully for about two minutes. If there is a

leak, bubbles will form in the area of the leak. Soapy water will

not stay on connections long, so spray more solution on them

when soapy water isn’t visible.

4. If bubbles form around the union, tighten the connection and

repeat steps 3 and 4 until no bubbles form.

702_58300000143767_ara_en_a Page 7 of 33

5. If bubbles form around the brass connector or on the gas valve

itself, replace the leaking valve with a new one and repeat

steps 3, 4 and 6.

6. Clean all soapy water solution with a rag or paper towel.

7. Never use a flame to check for gas leaks!

4.1.6 Igniter

Igniters glow after

4.1.7 Flame sensor

Flame sensors detect flame out in 30 – 60 seconds and direct the

igniter to reignite flames.

4.1.8 Lint screen sensors

The front (bearing) shield contains two sensors – accessible after the

lint screen is removed. Along with the heater NTC and hi-limit

protector, the lint screen NTC and hi-limit protector provide

temperature regulation and safety.

30 seconds, reliably igniting gas flames.

Igniters can be damaged if not handled with care.

Hi-limit NTC

Hi-limit

NTC

702_58300000143767_ara_en_a Page 8 of 33

4.1.9 Broken belt switch

The broken belt switch prevents the dryer from running if the belt has

broken or been left disconnected. It must be manually reset (by

pushing the left plunger in (viewing rear of dryer) – the dryer will not

run if the switch hasn’t been reset.

4.1.10 Air exhaust duct

Air exhaust duct connects to the fan and allows exhausting through

the rear of dryers. Using kits (sales accessories), dryers can be

vented out the bottom or right side.

Fan

Vent

Push left plunger (toward

right) to reset broken belt

switch whenever drum or

belt has been removed for

any repair.

4.1.11 Fascia (control) panel

Fascia panel includes the knob, which is factory built into the panel

and cannot be obtained separately. Buttons can be obtained

separately.

702_58300000143767_ara_en_a Page 9 of 33

4.1.12 Moisture sensor

Moisture sensor consists of two electrodes (located just left of the lint

screen on the front bearing shield). Moisture from clothes completes

the circuit between the two sensors, showing clothes aren’t dry.

Placing the moisture sensor on the front shield eliminates sensors

inside drums and conductance brushes outside drums.

4.1.13 Door switch

Door switch engages the door, turning the light on and off and

notifying the dryer the door is closed for drying. To remove it, push

the two latches inward and slide the switch toward the front of the

dryer.

4.1.14 Fan wheel replacement

Even though WTVC and WTMC dryers use the same fan motor, they

do not use the same fan. Due to differing front bearing shield and lint

screen dimensions, air flows differently through the two dryers. Dryer

control software for each dryer is carefully matched to each fan to

provide the same drying results.

WTMC fan 491640 hasn’t been tested in

WTVC dryers and WTVC fan 648683

hasn’t been tested in WTMC dryers.

Fans must not be interchanged because

it will void the warranty, will affect the UL

certification, will affect drying and may

generate error codes.

4.1.15 Mist care (on selected dryers)

Mist care (on selected dryers) sprays a mist of water into dryers to

refresh clothing and relax any wrinkles. Water sprays occasionally as

needed, determined by the control.

702_58300000143767_ara_en_a Page 10 of 33

Loading...

Loading...