Bosch HMV01.1E-W0030, HMV01.1E-W0075, HMV01.1R-W0065, HMV01.1R-W0018, HMV01.1E-W0120 Project Planning Manual

...

Industrial

Hydraulics

Electric Drives

and Controls

Linear Motion and

Assembly Technologies Pneumatics

Rexroth IndraDrive

Supply Units

Project Planning Manual

Service

Automation

Mobile

Hydraulics

R911299229

Edition 01

About this Documentation Rexroth IndraDrive

Title

Type of Documentation

Document Typecode

Internal File Reference

Record of Revisions

Copyright

Rexroth IndraDrive

Supply Units

Project Planning Manual

DOK-INDRV*-HMV-*******-PR01-EN-P

Document number 120-2400-B312-01/EN

Description Release

Notes

Date

DOK-INDRV*-HMV-*******-PR01-EN-P 01.2004 Project Planning Manual;

first edition

2004 Bosch Rexroth AG

Copying this document, giving it to others and the use or com munication

of the contents thereof without express authority, are forbidden. Offenders

are liable for the payment of damages. All rights are reserved in the event

of the grant of a patent or the registration of a utility model or design

(DIN 34-1).

Validity

Published by

Note

The specified data is for product description pur poses only and may not

be deemed to be guaranteed unless expres sly confirmed in the contract.

All rights are reserved with respect to the content of this docum entation

and the availability of the product.

Bosch Rexroth AG

Bgm.-Dr.-Nebel-Str. 2 • D-97816 Lohr a. Main

Telephone +49 (0)93 52/40-0 • Tx 68 94 21 • Fax +49 (0)93 52/40-48 85

http://www.boschrexroth.de/

Dept. EDC1/EDY1 (EH/US)

This document has been printed on chlorine-free bleached paper.

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Contents I

Contents

1 Introduction 1-1

1.1 About this Documentation.............................................................................................................1-1

Purpose of Documentation ...................................................................................................... 1-1

1.2 Introducing the Devices.................................................................................................................1-1

Features and Fields of Application ..........................................................................................1-1

Main Features..........................................................................................................................1-1

Basic Structure .........................................................................................................................1-2

Drive System............................................................................................................................1-3

Tests and Certifications ...........................................................................................................1-4

2 Important Directions for Use 2-1

2.1 Appropriate Use ............................................................................................................................2-1

Introduction ..............................................................................................................................2-1

Areas of Use and Application...................................................................................................2-2

2.2 Inappropriate Use..........................................................................................................................2-2

3 Safety Instructions for Electric Drives and Controls 3-1

3.1 Introduction ...................................................................................................................................3-1

3.2 Explanations.................................................................................................................................. 3-1

3.3 Hazards by Improper Use .............................................................................................................3-2

3.4 General Information ......................................................................................................................3-3

3.5 Protection Against Contact with Electr ical Par ts...........................................................................3-5

3.6 Protection Against Electric Shock by Protective Low Voltage (PELV) .........................................3-6

3.7 Protection Against Dangerous Movements ..................................................................................3-7

3.8 Protection Against Magnetic and Electromagnetic Fields During Operation and

Mounting .......................................................................................................................................3-9

3.9 Protection Against Contact with Hot Parts..................................................................................3-10

3.10 Protection During Handling and Mounting ..................................................................................3-10

3.11 Battery Safety.............................................................................................................................. 3-11

3.12 Protection Against Pressurized Systems....................................................................................3-11

4 Identifying and Checking the Delivered Components 4-1

4.1 Delivery of Components................................................................................................................4-1

Packaging ................................................................................................................................4-1

Accompanying Documents ......................................................................................................4-1

4.2 Scope of Delivery..........................................................................................................................4-1

Overview..................................................................................................................................4-1

Checking the Delivered Components ...................................................................................... 4-1

4.3 Component Designation................................................................................................................ 4-2

DOK-INDRV*-HMV-*******-PR01-EN-P

II Contents Rexroth IndraDrive

Type Plates on the Unit............................................................................................................4-2

4.4 Device Types ................................................................................................................................4-3

Type Code................................................................................................................................4-3

5 Transport and Storage 5-1

5.1 Transporting the Devices .............................................................................................................. 5-1

Conditions................................................................................................................................5-1

5.2 Storing the Devices.......................................................................................................................5-1

Conditions................................................................................................................................5-1

In Case of Long Storage Periods.............................................................................................5-1

6 Mechanical Mounting 6-1

6.1 Mounting Conditions .....................................................................................................................6-1

Ambient and Operating Conditions..........................................................................................6-1

Duty Capacity........................................................................................................................... 6-3

6.2 Mechanical Technical Data...........................................................................................................6-4

Dimensions ..............................................................................................................................6-4

Installation Orientation.............................................................................................................6-5

Arrangement of Components in the Control Cabinet...............................................................6-5

6.3 Cooling and Cooling Units ............................................................................................................6-7

Power Dissipation ....................................................................................................................6-7

Mounting Cooling Units............................................................................................................6-8

7 Electrical Installation 7-1

7.1 General Information ......................................................................................................................7-1

7.2 Interference Elimination and EMC ................................................................................................ 7-2

Interference Elimination...........................................................................................................7-2

10 Rules for EMC-Correct Installation of Drives......................................................................7-3

Optimal EMC Installation .........................................................................................................7-5

7.3 Electrical Data...............................................................................................................................7-7

HMV01.1E-W0030, -W0075, -W0120...................................................................................... 7-7

HMV01.1R-W0018, -W0045, -W0065 .....................................................................................7-8

Control Voltage ........................................................................................................................7-9

7.4 Complete Connection Diagram...................................................................................................7-10

7.5 Connecting Cables and Rails...................................................................................................... 7-11

Connections (Power Section) ................................................................................................7-11

Control Voltage (+24 V, 0 V)..................................................................................................7-15

DC Bus (L+, L-)......................................................................................................................7-17

PE Connection of Power Supply............................................................................................7-19

PE Connection, Power Supply Unit and Neighboring Device................................................ 7-20

X1, Bus Module......................................................................................................................7-21

X2, RS232..............................................................................................................................7-22

X3, Mains Connection............................................................................................................7-23

X31, Connection for Messages.............................................................................................. 7-25

X32, Mains Contactor Control, DC Bus Short Circuit, Braking Resistor Threshold...............7-27

X33, Acknowledge Messages of Internal Ma ins Contac tor ...................................................7-29

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Contents III

X14, Mains Voltage Synchronization.....................................................................................7-30

7.6 Touch Guard ............................................................................................................................... 7-31

Cutouts...................................................................................................................................7-31

Mounting ................................................................................................................................7-32

8 Determination of Appropriate Power Supply Units 8-1

8.1 Introduction ...................................................................................................................................8-1

8.2 DC Bus Continuous Power...........................................................................................................8-1

8.3 DC Bus Peak Power .....................................................................................................................8-4

8.4 Regenerated Energy.....................................................................................................................8-5

8.5 Continuous Regenerated Power...................................................................................................8-6

8.6 Peak Regenerated Power.............................................................................................................8-7

8.7 Connected Load of the Supply Unit .............................................................................................. 8-8

9 Control Mains Contactor 9-1

9.1 Control Possibilities....................................................................................................................... 9-1

Shutdowns with Faulty Drive Electronics.................................................................................9-1

Braking with Emergenc y Stop or Power Failure ...................................................................... 9-1

9.2 Controlling the Supply Unit with Emergency Stop Relays ............................................................9-1

With DC Bus Dynamic Brake...................................................................................................9-1

Without DC Bus Dynamic Brake..............................................................................................9-4

9.3 Control via NC Controller .............................................................................................................. 9-6

10 Troubleshooting 10-1

10.1 General........................................................................................................................................10-1

10.2 Fault Diagnostics and Resetting Faults ......................................................................................10-1

10.3 Checking and Repairing the Unit ................................................................................................10-2

10.4 Replacing the Unit....................................................................................................................... 10-3

10.5 Diagnostic Display.......................................................................................................................10-4

11 Disposal and Environmental Protection 11-1

11.1 Disposal ......................................................................................................................................11-1

Products.................................................................................................................................11-1

Packaging Materials ............................................................................................................... 11-1

11.2 Environmental Protection............................................................................................................11-1

No Release of Hazardous Substances..................................................................................11-1

Materials Contained in the Produc ts......................................................................................11- 1

Recycling................................................................................................................................11-2

12 Service & Support 12-1

12.1 Helpdesk ..................................................................................................................................... 12-1

12.2 Service-Hotline............................................................................................................................ 12-1

12.3 Internet........................................................................................................................................12-1

12.4 Vor der Kontaktaufnahme... - Before contacting us....................................................................12-1

12.5 Kundenbetreuungsstellen - Sales & Service Facilities ...............................................................12-2

DOK-INDRV*-HMV-*******-PR01-EN-P

IV Contents Rexroth IndraDrive

13 Appendix 13-1

13.1 Connection of Supply Unit by Wires ...........................................................................................13-1

Supply Unit to the Left of the Drive Controller .......................................................................13-1

Supply Unit to the Right of the Drive Controller.....................................................................13-2

13.2 Stacked Devices .........................................................................................................................13-3

Counterclockwise Cable Routing........................................................................................... 13-3

Clockwise Cable Routing....................................................................................................... 13-4

13.3 Mains Connection .......................................................................................................................13-5

General ..................................................................................................................................13-5

Mains Supply Requirements.................................................................................................. 13-6

HMV01.1E..............................................................................................................................13-7

HMV01.1R..............................................................................................................................13-9

Fusing with Direct Mains Supply..........................................................................................13-13

13.4 Grounding the Power Supply System.......................................................................................13-13

13.5 Fault Current Protective Device................................................................................................13-14

13.6 Earth Leakage Monitor..............................................................................................................13-14

13.7 Chronological Sequence when Switching ON and OFF...........................................................13-15

When Switching On .............................................................................................................13-15

When Switching Off .............................................................................................................13-16

13.8 Auxiliary Components ............................................................................................................... 13-17

Mains Choke........................................................................................................................13-17

Mains Filter HFD..................................................................................................................13-19

14 Index 14-1

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Introduction 1-1

1 Introduction

1.1 About this Documentation

Purpose of Documentation

This documentation describes

• planning the mechanical control cabinet construction

• planning the electrical control cabinet construction

• logistical handling of the equipment

1.2 Introducing the Devices

Features and Fields of Application

The supply unit …

• supplies IndraDrive M drive controllers with the required DC bus

voltage

• loops the 24 V control voltage of an external 24 V power supply

through to the drive controllers

• communicates with the drive controllers via a module bus

The supply units can be used for realizing a multitude of drive task s in

most diverse applications. F or these pur pos es ther e ar e 2 dif f er ent devic e

types (regenerative, non-regenerative) with graduated supply power

available.

Main Features

• design with regeneration back to the mains (HMV01.1R-Wxxxx)

and without regeneration back to the mains (HMV01.1E-Wxxxx)

• external 24 V supply required (signal processing not supplied from

DC bus)

• 3-phase mains connection (380V... 480V, +-10% 50Hz-60Hz)

• integrated mains contactor for E-Stop

• integrated braking resistor (bleeder) for feeding supply units

(HMV01.1E-Wxxxx)

• integrated emergency braking resistor for regenerative supply units

(HMV01.1R-Wxxxx)

DOK-INDRV*-HMV-*******-PR01-EN-P

1-2 Introduction Rexroth IndraDrive

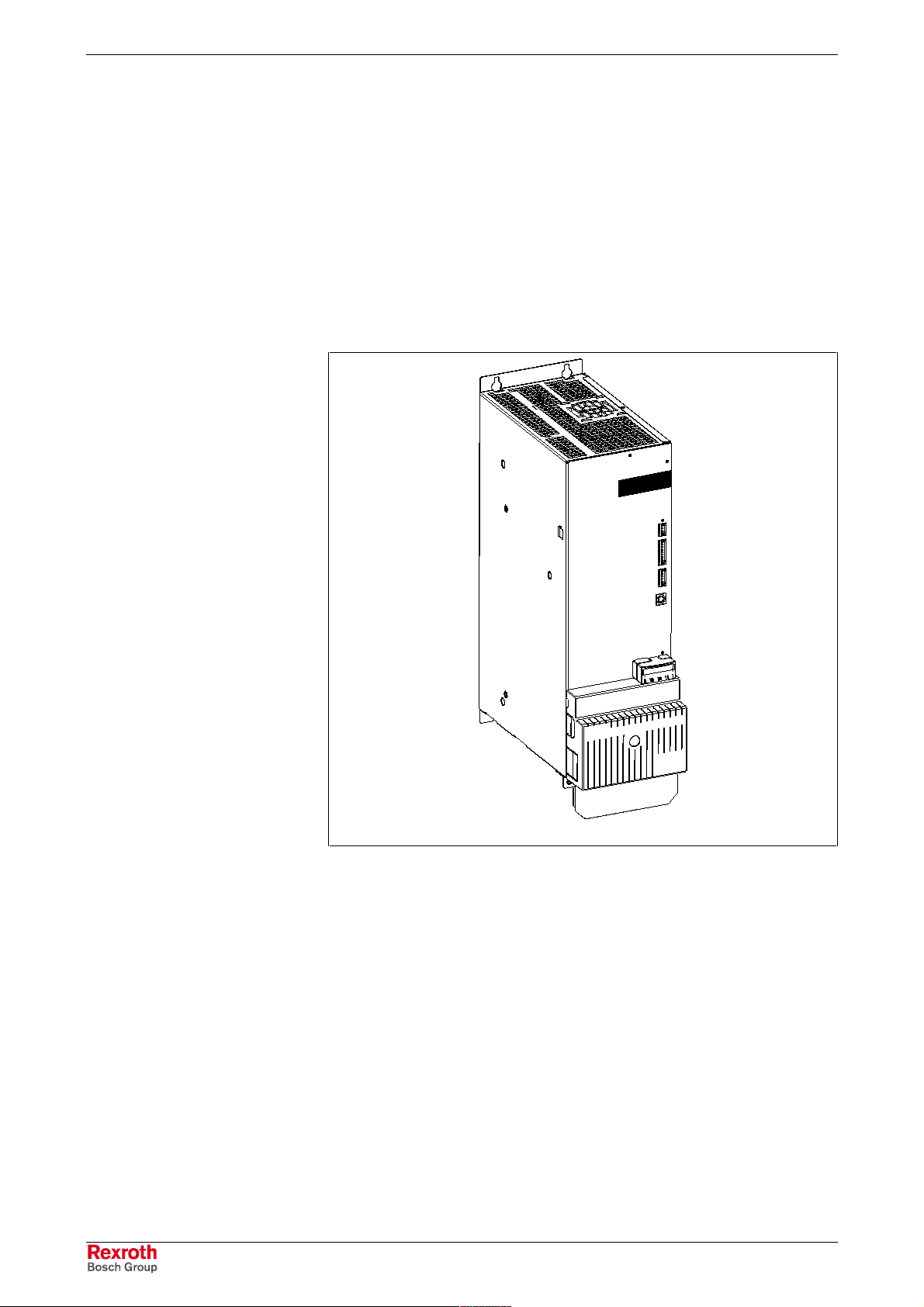

Basic Structure

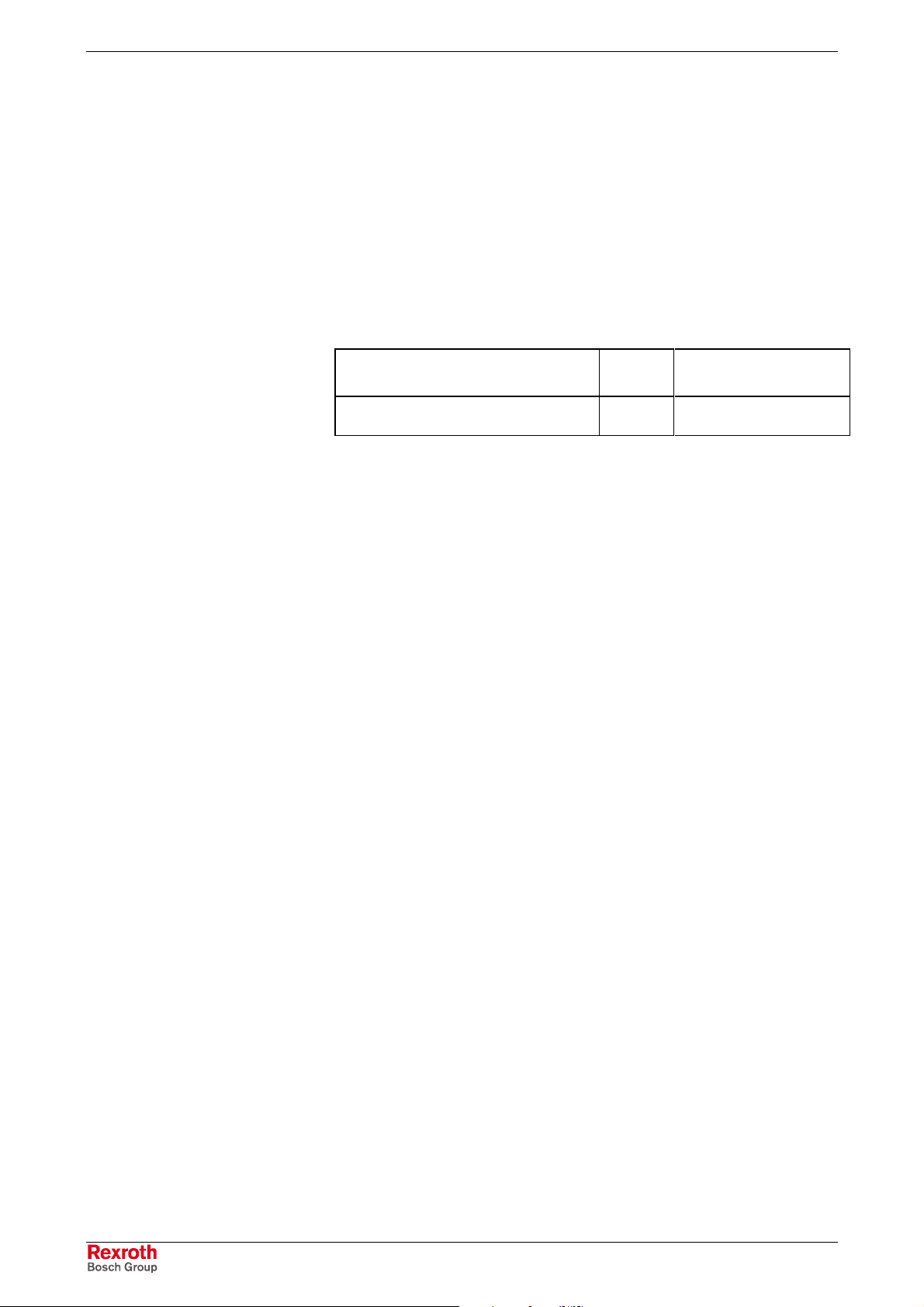

Supply Unit

1

2

3

hmv_aufbau.fh7

1: Signal processing

2: Control panel (Display)

3: Power connections and control voltage connection

Fig. 1-1: Basic structure

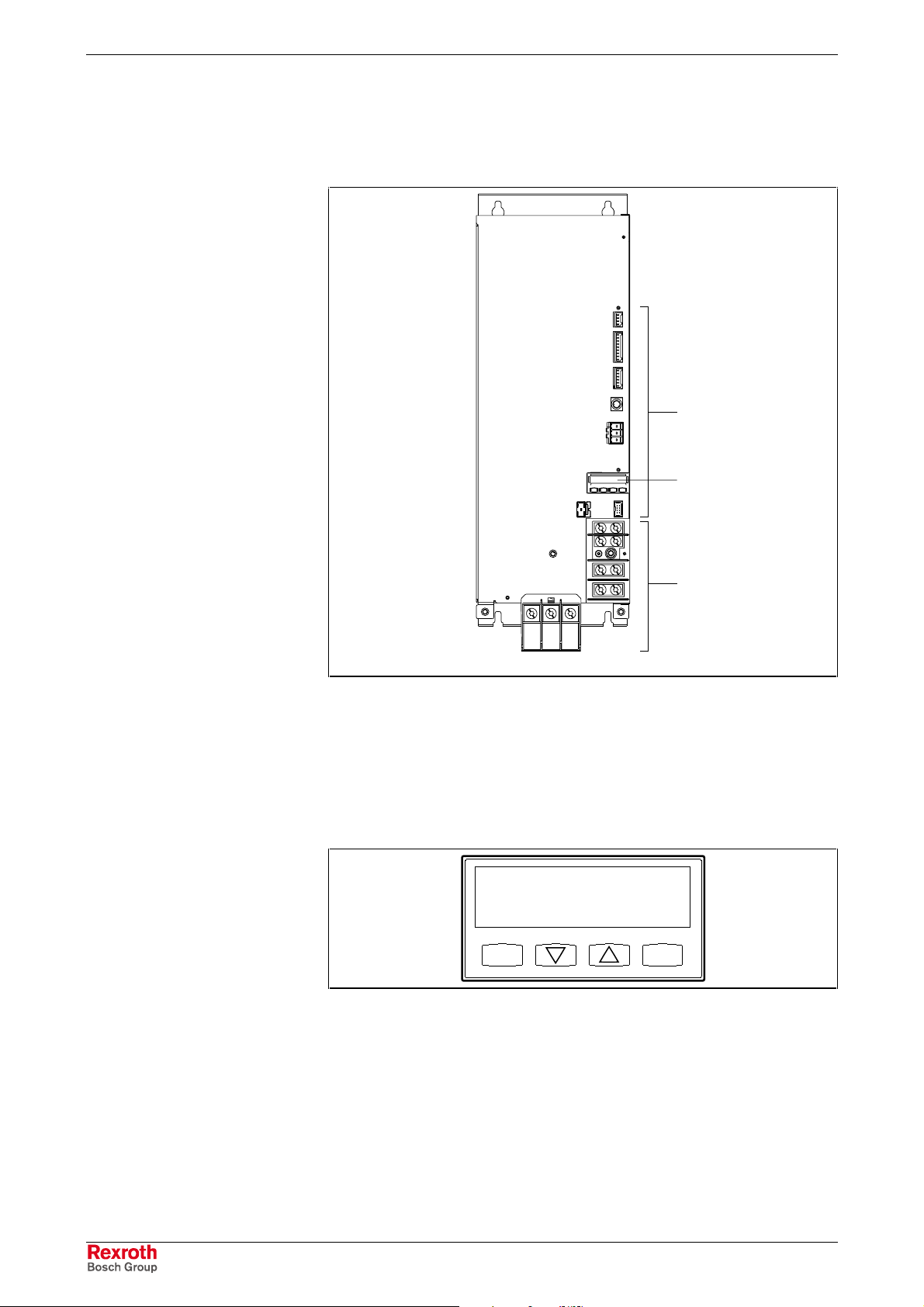

Control Panel

The control panel is a separate part which is plugged on the supply unit.

The supply unit is supplied ex works complete with control panel.

01.F4002

Esc

Fig. 1-2: Standard control panel with sample display and control elements

• Operating status, command and error diagnoses, and warnings for

problems requiring attention are shown in the display.

• Using the four buttons, the commissioning operator or service

engineer can opt, in addition to master communication using the

commissioning tool or NC control, to display further error diagnoses.

Enter

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Introduction 1-3

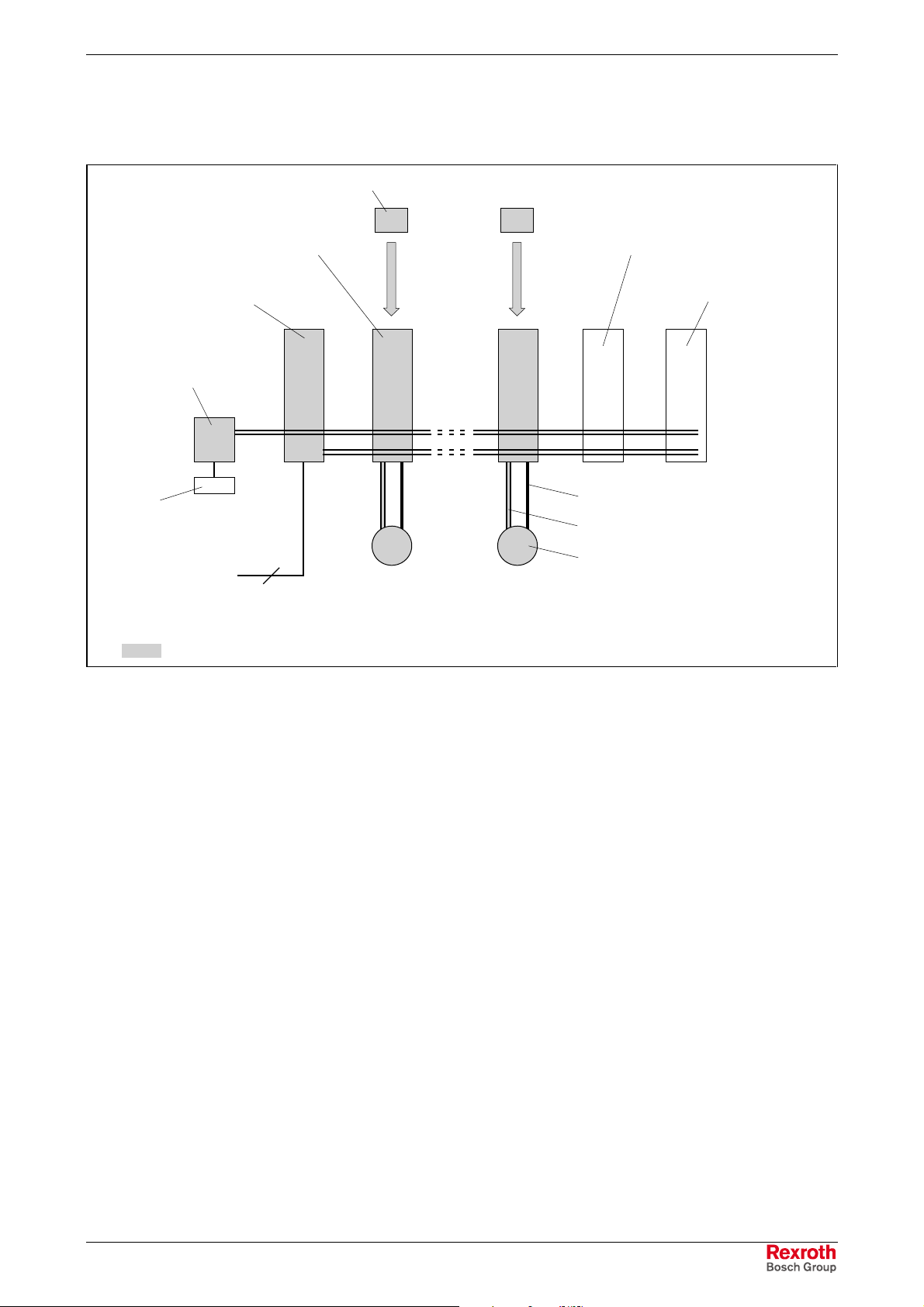

Drive System

The following figure shows the components of the drive system.

firmware

24 V supply unit

battery

components shown in gray are absolutely necessary

drive controller

supply unit

mains supply

DC bus resistor unit

DC bus capacitor unit

RKS - ready-made encoder cable

RKG - ready-made power cable

3

Fig. 1-3: Drive system

motor

Fa5147f1.fh7

DOK-INDRV*-HMV-*******-PR01-EN-P

1-4 Introduction Rexroth IndraDrive

Tests and Certifications

CE Mark

C-UL-US Listing

Tests

CEf1.fh7

Fig. 1-4: CE mark

In preparation

Insulation-high-voltage test in

accordance with EN50178

Separation between control and

power voltage circuits

Air gaps and leakage distances In accordance with EN50178

Fig. 1-5: Tests

Routine testing with DC 2230 V, 1 min

resp.

Routine testing with AC 1575 V, 1 min;

Power supply with 0,1 A short-circuit

current

Safe separation in accordance with

EN50178

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Important Directions for Use 2-1

2 Important Directions for Use

2.1 Appropriate Use

Introduction

Rexroth products represent state-of-the-art developments and

manufacturing. They are tested prior to delivery to ensure operating safety

and reliability.

The products may only be used in the manner that is defined as

appropriate. If they are used in an inappropriate manner, then situations

can develop that may lead to property damage or injury to personnel.

Note: Rexroth, as manufacturer, is not liable for any damages

resulting from inappropriate us e. In such cases , the guarantee

and the right to payment of damages resulting from

inappropriate use are forfeited. The user alone carries all

responsibility of the risks.

Before using Rexroth products, mak e sure that all the pre-requisites for

an appropriate use of the products are satisfied:

• Personnel that in any way, shape or form uses our products m ust first

read and understand the relevant safety instructions and be familiar

with appropriate use.

• If the product takes the form of hardware, then they must remain in

their original state, in other words, no structural changes are permitted.

It is not permitted to decompile software products or alter source

codes.

• Do not mount damaged or faulty products or use them in operation.

• Make sure that the products have been installed in the manner

described in the relevant documentation.

DOK-INDRV*-HMV-*******-PR01-EN-P

2-2 Important Directions for Use Rexroth IndraDrive

Areas of Use and Application

Supply units of Rexroth are designed to supply the Rexroth IndraDrive M

drive controllers.

Control and monitoring of the motors may require additional sensor s and

actors.

Note: The supply units may only be used with the accessories and

parts specified in this docum ent. If a com ponent has not been

specifically named, then it may not be either mounted or

connected. The same applies to cables and lines.

Operation is only permitted in the s pecified conf igurations and

combinations of com ponents using the software and f irmware

as specified in the relevant function descriptions.

The supply units may only be operated under the assembly, installation

and ambient conditions as described here (temperature, system of

protection, humidity, EMC requirements, etc.) and in the position

specified.

2.2 Inappropriate Use

Using the supply units outside of the above-referenced areas of

application or under operating conditions other than described in the

document and the technical data specified is defined as “inappropriate

use".

Supply units may not be used if

• they are subject to operating conditions that do not meet the above

• Rexroth has not specifically released them for that intended purpos e.

specified ambient conditions. This includes, for example, operation

under water, in the case of extreme temperature fluctuations or

extremely high maximum temperatures or if

Please note the specifications outlined in the general safety

instructions!

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-1

3 Safety Instructions for Electric Drives and Controls

3.1 Introduction

Read these instructions before the initial startup of the equipment in order

to eliminate the risk of bodily harm or material damage. Follow these

safety instructions at all times.

Do not attempt to install or start up this equipm ent without first r eading all

documentation provided with the product. Read and understand these

safety instructions and all user docum entation of the equipment prior to

working with the equipment at any time. If you do not have the user

documentation for your equipment, contact your local Rexroth

representative to send this documentation immediately to the person or

persons responsible for the safe operation of this equipment.

If the equipment is resold, rented or transferred or passed on to others,

then these safety instructions must be delivered with the equipment.

Improper use of this equipment, failure to follow

the safety instructions in this document or

tampering with the product , i ncluding disabling

WARNING

of safety devices, may result in material

damage, bodily harm, electric shock or even

death!

3.2 Explanations

The safety instructions describe the following degrees of hazard

seriousness in compliance with ANSI Z535. The degree of hazard

seriousness informs about the consequences resulting from noncompliance with the safety instructions.

Warning symbol with signal

word

DANGER

WARNING

CAUTION

Degree of hazard seriousness according

to ANSI

Death or severe bodily harm will occur.

Death or severe bodily harm may occur.

Bodily harm or material damage may occur.

DOK-INDRV*-HMV-*******-PR01-EN-P

Fig. 3-1: Hazard classification (according to ANSI Z535)

3-2 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

3.3 Hazards by Improper Use

High voltage and high discharge current!

Danger to life or severe bodily harm by electric

shock!

DANGER

Dangerous movements! Danger to life, severe

bodily harm or material damage by

unintentional motor movements!

DANGER

High electrical voltage due to wrong

connections! Danger to life or bodily harm by

electric shock!

WARNING

WARNING

CAUTION

CAUTION

Health hazard for persons with heart

pacemakers, metal implants and hearing aids in

proximity to electrical equipment!

Surface of machine housing could be extremely

hot! Danger of injury! Danger of burns!

Risk of injury due to improper handling! Bodily

harm caused by crushing, shearing, cutting and

mechanical shock or incorrect handling of

pressurized systems!

CAUTION

Risk of injury due to incorrect handling of

batteries!

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-3

3.4 General Information

• Bosch Rexroth AG is not liable for damages resulting from failure to

observe the warnings provided in this documentation.

• Read the operating, maintenance and safety instructions in your

language before starting up the machine. If you find that you cannot

completely understand the documentation for your product, please ask

your supplier to clarify.

• Proper and correct transport, storage, assembly and installation as

well as care in operation and maintenance are prerequisites for

optimal and safe operation of this equipment.

• O nly persons who are trained and qualified for the use and operation

of the equipment may work on this equipment or within its proximity.

• The persons are qualified if they have sufficient k nowledge of the

assembly, installation and operation of the equipm ent as well as an

understanding of all warnings and precautionary measures noted in

these instructions.

• Furthermore, they must be trained, instructed and qualified to

switch electrical circuits and equipment on and off in accordance

with technical safety regulations, to ground them and to mark them

according to the requirements of safe work practices. They must

have adequate safety equipment and be trained in first aid.

• Only use spare parts and accessories approved by the manufacturer.

• Follow all safety regulations and requirements for the specific

application as practiced in the country of use.

• The equipment is designed for installation in industrial machinery.

• The ambient conditions given in the product documentation must be

observed.

• Use only safety features and applications that are clearly and explicitly

approved in the Project Planning Manual.

For example, the following areas of use are not permitted: construction

cranes, elevators used for people or freight, devices and vehicles to

transport people, medical applications, refinery plants, transport of

hazardous goods, nuclear applications, applications sensitive to high

frequency, mining, food processing, control of protection equipment

(also in a machine).

• The information given in the documentation of the product with r egard

to the use of the delivered components contains only examples of

applications and suggestions.

The machine and installation manufacturer must

• make sure that the delivered components are suited for his

individual application and check the information given in this

documentation with regard to the use of the components,

• mak e sure that his application complies with the applicable safety

regulations and standards and carry out the required measures,

modifications and complements.

• Startup of the delivered components is only permitted once it is sure

that the machine or installation in which they are installed complies

with the national regulations, safety specifications and standards of the

application.

DOK-INDRV*-HMV-*******-PR01-EN-P

3-4 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

• Operation is only permitted if the national EMC regulations for the

application are met.

The instructions for installation in accordance with EMC requirements

can be found in the documentation "EMC in Drive and Control

Systems".

The machine or installation manufacturer is responsible for

compliance with the limiting values as prescribed in the national

regulations.

• Technical data, connections and operational conditions are specified in

the product documentation and must be followed at all times.

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-5

3.5 Protection Against Contact with Electrical Parts

Note: This section refers to equipment and drive components with

voltages above 50 Volts.

Touching live parts with voltages of 50 Volts and more with bar e hands or

conductive tools or touching ungrounded housings can be dangerous and

cause electric shock. In order to operate electrical equipment, certain

parts must unavoidably have dangerous voltages applied to them.

High electrical voltage! Danger to life, severe

bodily harm by electric shock!

DANGER

⇒ Only those trained and qualified to work with or on

electrical equipment are perm itted to operate, maintain

or repair this equipment.

⇒ Follow general construction and safety regulations when

working on high voltage installations.

⇒ Before switching on power the ground wire must be

permanently connected to all electrical units according

to the connection diagram.

⇒ Do not operate electrical equipment at any time, even

for brief measurements or tests, if the ground wire is not

permanently connected to the points of the com ponents

provided for this purpose.

⇒ Before work ing with electrical parts with voltage higher

than 50 V, the equipment must be disconnected from

the mains voltage or power supply. Make sure the

equipment cannot be switched on again unintended.

⇒ The following should be observed with electrical drive

and filter components:

⇒ W ait five (5) minutes af ter switching off power to allow

capacitors to discharge before beginning to work.

Measure the voltage on the capacitors before beginning

to work to make sure that the equipment is safe to

touch.

⇒ Never touch the electrical connection points of a

component while power is turned on.

⇒ Install the covers and guards provided with the

equipment properly before switching the equipment on.

Prevent contact with live parts at any time.

⇒ A residual-current-operated protective device (RCD)

must not be used on electric drives! Indirect contact

must be prevented by other means, for example, by an

overcurrent protective device.

⇒ Electrical components with exposed live parts and

uncovered high voltage terminals must be installed in a

protective housing, for example, in a control cabinet.

DOK-INDRV*-HMV-*******-PR01-EN-P

3-6 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

To be observed with electrical drive and filter components:

High electrical voltage on the housing!

High leakage current! Danger to life, danger of

injury by electric shock!

DANGER

⇒ Connect the electrical equipment, the housings of all

electrical units and motors permanently with the safety

conductor at the ground points before power is

switched on. Look at the connection diagram. This is

even necessary for brief tests.

⇒ Connect the safety conductor of the electrical

equipment always permanently and firmly to the

supply mains. Leakage current exceeds 3.5 mA in

normal operation.

⇒ Use a copper conductor with at least 10 mm² cross

section over its entire cour se for this saf ety conductor

connection! The cross section must not be smaller

than the cross section of a phase of the mains suppy

wire.

⇒ Prior to startups , even for brief tests, always connect

the protective conductor or connect with ground wire.

Otherwise, high voltages can occur on the housing

that lead to electric shock.

3.6 Protection Against Electric Shock by Protective Low Voltage (PELV)

All connections and terminals with voltages between 0 and 50 Volts on

Rexroth products are protective low voltages designed in accordance with

international standards on electrical safety.

High electrical voltage due to wrong

connections! Danger to life, bodily harm by

electric shock!

WARNING

⇒ Only connect equipment, electrical components and

cables of the protective low voltage type (PELV =

Protective Extra Low Voltage) to all terminals and

clamps with voltages of 0 to 50 Volts.

⇒ Only electrical circuits may be connected which are

safely isolated against high voltage circuits. Safe

isolation is achieved, for example, with an isolating

transformer, an opto-electronic coupler or when

battery-operated.

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-7

3.7 Protection Against Dangerous Movements

Dangerous movements can be caused by faulty control of the connected

motors. Some common examples are:

• improper or wrong wiring of cable connections

• incorrect operation of the equipment components

• wrong input of parameters before operation

• malfunction of sensors, encoders and monitoring devices

• defective components

• software or firmware errors

Dangerous movements can occur immediately after equipment is

switched on or even after an unspecified time of trouble-free operation.

The monitoring in the drive components will normally be sufficient to avoid

faulty operation in the connected drives. Regarding personal safety,

especially the danger of bodily injury and material damage, this alone

cannot be relied upon to ensure complete safety. Until the integrated

monitoring functions becom e effective, it must be assum ed in any case

that faulty drive movements will occur. The extent of faulty drive

movements depends upon the type of control and the state of operation.

DOK-INDRV*-HMV-*******-PR01-EN-P

3-8 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

Dangerous movements! Danger to life, risk of

injury, severe bodily harm or material damage!

DANGER

⇒ Ensure personal safety by means of qualified and

tested higher-level monitoring devices or measures

integrated in the installation. Unintended machine

motion is possible if monitoring devices are disabled,

bypassed or not activated.

⇒ Pay attention to unintended machine m otion or other

malfunction in any mode of operation.

⇒ Keep f ree and clear of the m achine’s range of m otion

and moving parts. Possible measures to prevent

people from accidentally entering the machine’s r ange

of motion:

- use safety fences

- use safety guards

- use protective coverings

- install light curtains or light barriers

⇒ Fences and coverings must be strong enough to

resist maximum possible momentum, especially if

there is a possibility of loose parts flying off.

⇒ Mount the emergency stop switch in the immediate

reach of the operator. Verify that the emer gency stop

works before startup. Don’t operate the m achine if the

emergency stop is not working.

⇒ Isolate the drive power connection by means of an

emergency stop circuit or use a starting lockout to

prevent unintentional start.

⇒ Make sure that the drives are brought to a safe

standstill before accessing or entering the danger

zone. Safe standstill can be achieved by switching off

the power supply contactor or by safe mechanical

locking of moving parts.

⇒ Secure vertical axes against falling or dropping after

switching off the motor power by, for example:

- mechanically securing the vertical axes

- adding an external braking/ arrester/ clamping

mechanism

- ensuring sufficient equilibration of the vertical axes

The standard equipment m otor brake or an external

brake controlled directly by the drive controller are

not sufficient to guarantee personal safety!

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-9

⇒ Dis connect electrical power to the equipment using a

master switch and secure the switch against

reconnection for:

- maintenance and repair work

- cleaning of equipment

- long periods of discontinued equipment use

⇒ Prevent the operation of high-frequency, remote

control and radio equipment near electronics circuits

and supply leads. If the use of such equipment cannot

be avoided, verify the system and the installation for

possible malfunctions in all possible positions of

normal use before initial startup. If neces sary, perform

a special electromagnetic c ompatibility (EMC) test on

the installation.

3.8 Protection Against Magnetic and Electromagnetic Fields During Operation and Mounting

Magnetic and electromagnetic fields generated near current-carrying

conductors and permanent m agnets in m otors represent a ser ious health

hazard to persons with heart pacemakers, metal implants and hearing

aids.

WARNING

Health hazard for persons with heart

pacemakers, metal implants and hearing aids in

proximity to electrical equipment!

⇒ Persons with heart pacemakers, hearing aids and

metal implants are not perm itted to enter the following

areas:

- Areas in which electrical equipm ent and parts are

mounted, being operated or started up.

- Areas in which parts of motors with permanent

magnets are being stored, operated, repaired or

mounted.

⇒ If it is necess ary for a person with a heart pacemak er

to enter such an area, then a doctor must be

consulted prior to doing so. Heart pacemakers that

are already implanted or will be implanted in the

future, have a considerable variation in their electric al

noise immunity. Therefore there are no rules with

general validity.

⇒ Persons with hearing aids, metal implants or metal

pieces must consult a doctor before they enter the

areas described above. Otherwise, health hazards will

occur.

DOK-INDRV*-HMV-*******-PR01-EN-P

3-10 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

3.9 Protection Against Contact with Hot Parts

Housing surfaces could be extremely hot!

Danger of injury! Danger of burns!

⇒ Do not touch housing surfaces near sources of heat!

CAUTION

Danger of burns!

⇒ After switching the equipment off, wait at least ten (10)

minutes to allow it to cool down before touching it.

⇒ Do not touch hot parts of the equipment, such as

housings with integrated heat sinks and resistors.

Danger of burns!

3.10 Protection During Handling and Mounting

Under certain conditions, incorrect handling and mounting of parts and

components may cause injuries.

CAUTION

Risk of injury by incorrect handling! Bodily

harm caused by crushing, shearing, cutting and

mechanical shock!

⇒ Observe general installation and safety instructions

with regard to handling and mounting.

⇒ Use appropriate mounting and transport equipment.

⇒ Take precautions to avoid pinching and crushing.

⇒ Use only appropriate tools. If specified by the product

documentation, special tools must be used.

⇒ Use lifting devices and tools correctly and safely.

⇒ For safe protection wear appropriate protective

clothing, e.g. safety glasses, safety shoes and saf ety

gloves.

⇒ Never stand under suspended loads.

⇒ Clean up liquids from the floor imm ediately to prevent

slipping.

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Safety Instructions for Electric Drives and Controls 3-11

3.11 Battery Safety

Batteries contain reactive chemicals in a solid housing. Inappropriate

handling may result in injuries or material damage.

Risk of injury by incorrect handling!

⇒ Do not attempt to reactivate discharged batteries by

heating or other methods (danger of explosion and

CAUTION

Note: Be aware of environmental protection and disposal! The

batteries contained in the product should be considered as

hazardous material for land, air and sea trans port in the sense

of the legal requirements (danger of explosion). Dispose

batteries separately from other waste. Observe the legal

requirements in the country of installation.

cauterization).

⇒ Never charge non-chargeable batteries (danger of

leakage and explosion).

⇒ Never throw batteries into a fire.

⇒ Do not dismantle batteries.

⇒ Do not damage electrical com ponents installed in the

equipment.

3.12 Protection Against Pressurized Systems

Certain motors and drive controllers, corr esponding to the information in

the respective Project Planning Manual, must be provided with

pressurized media, such as compressed air, hydraulic oil, cooling fluid

and cooling lubricant supplied by external systems. Incor rect handling of

the supply and connections of pressurized systems can lead to injuries or

accidents. In these cases, improper handling of external supply systems,

supply lines or connections can cause injuries or material damage.

Danger of injury by incorrect handling of

pressurized systems!

⇒ Do not attempt to disassemble, to open or to cut a

CAUTION

pressurized system (danger of explosion).

⇒ Observe the operation instructions of the respective

manufacturer.

⇒ Before disassembling pressurized systems, release

pressure and drain off the fluid or gas.

⇒ Use suitable protective clothing (for example safety

glasses, safety shoes and safety gloves)

⇒ Remove any fluid that has leaked out onto the floor

immediately.

DOK-INDRV*-HMV-*******-PR01-EN-P

Note: Environmental protection and disposal! T he m edia used in the

operation of the pressurized system equipment may not be

environmentally compatible. Media that are damaging the

environment must be dis posed separately from norm al waste.

Observe the legal requirements in the country of installation.

3-12 Safety Instructions for Electric Drives and Controls Rexroth IndraDrive

Notes

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Identifying and Checking the Delivered Components 4-1

4 Identifying and Checking the Delivered

Components

4.1 Delivery of Components

Packaging

Packaging Units

Packaging Labels

Disposal of Packaging Material

The components are supplied in separate packaging units.

The content of the packed components and the order number may be

identified using the adhesive barcode label on the packaging.

See chapter 11 "Disposal and Environmental Protection".

Accompanying Documents

A delivery note in duplicate can be found in an envelope on one of the

packages supplied. No other accompanying documents are provided.

The total number of c ontainers supplied is recorded on the delivery note

or consignment note.

4.2 Scope of Delivery

Overview

as standard optional

touch guard rails for connecting the DC bus

grounding bracket rails for connecting the control voltage

connector X31, X32, X33

safety instructions (brochure; DOK-

GENERAL-DRIVE******-SVSx-MS-P)

Fig. 4-1: Scope of delivery

Checking the Delivered Components

Please immediately check whether the delivered components are:

• complete

• correct

• intact

DOK-INDRV*-HMV-*******-PR01-EN-P

4-2 Identifying and Checking the Delivered Components Rexroth IndraDrive

4.3 Component Designation

Each drive component is identified by a type designation.

A type plate is attached to all units, including the motor.

A label (cable marker) is wrapped round the ready-made cable. The type

designation and length are indicated on this label. (The designation for the

cable itself, without connector, is printed on the cable sheath.)

The identification of acc essories packed in bags is either printed on the

bag or indicated in an accompanying note.

Type Plates on the Unit

Fig. 4-2: Type plate arrangement

hmv_typenschild.fh7

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Identifying and Checking the Delivered Components 4-3

4.4 Device Types

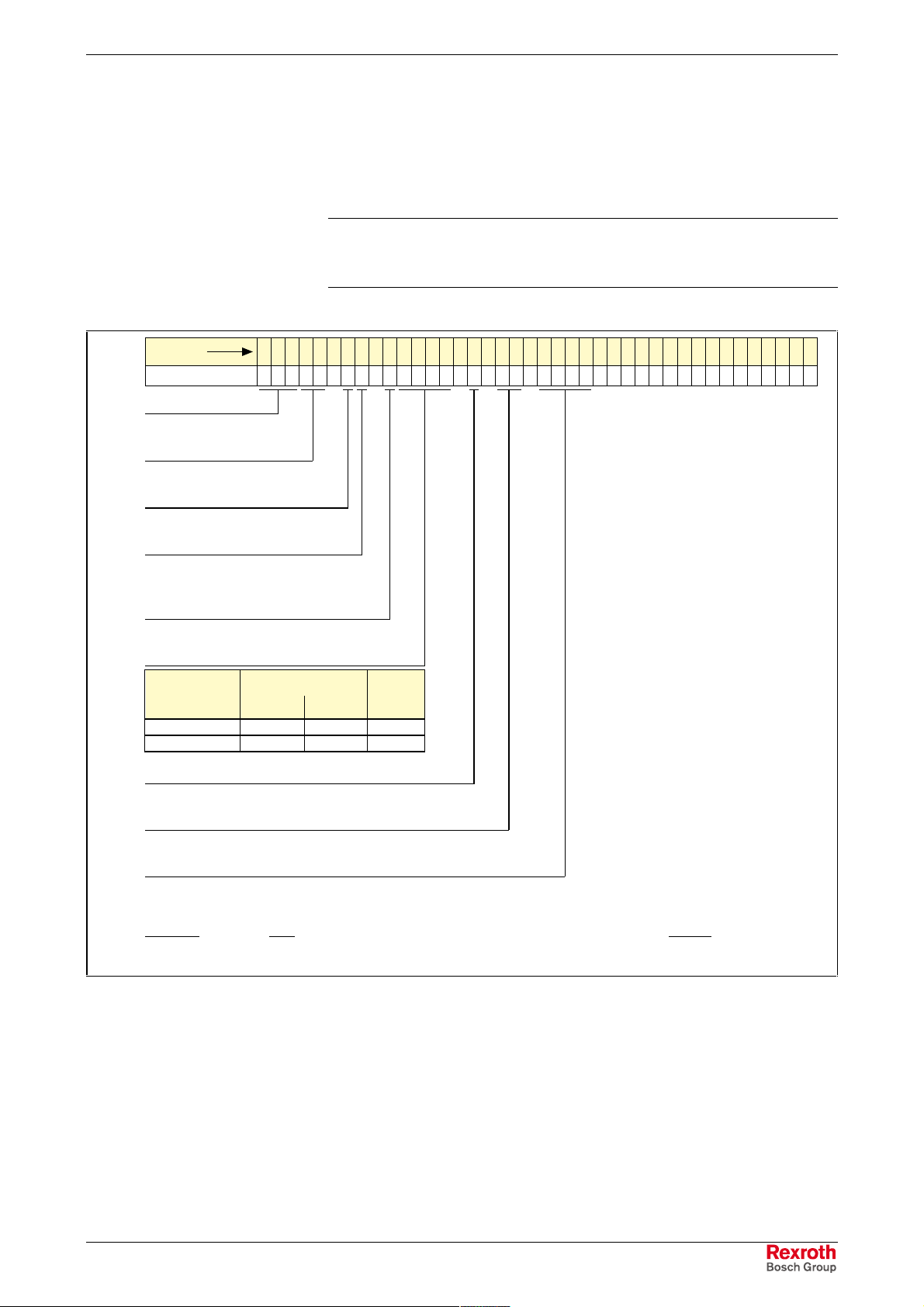

Type Code

Note: The following figure illustrates the bas ic structure of the type

code. Your sales representative will help with the current

status of available versions.

Abbrev.

Column

Example:

1. Product

1.1 HMV . . . . . . . . . = HMV

2. Line

2.1 1 . . . . . . . . . . . . . . . . . . . = 01

1234 6789105 1234 6789205 1234 6789305 1234 6789405

HMV01 . 1E -W0030 -A- 07-NNNN

3. Design

3.1 1 . . . . . . . . . . . . . . . . . . . . . . . . . = 1

4. Power supply

4.1 feeded . . . . . . . . . . . . . . . . . . . . . . = E

4.2 regenerative. . . . . . . . . . . . . . . . . . . = R

5. Cooling mode

5.1

Air, internal (through integrated blower)

6. Rated output

Rated output Power supply Code

[ KW ] E R

with choke

30 X - 0030

45 - X 0045

7. Protection mode

7.1 IP 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = A

8. DC-bus nominal voltage

8.1 DC 700V. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .= 07

9. Other design

9.1 none . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . = NNNN

10. Standard reference

Standard Titel Edition

DIN EN 60529 Degrees of protection provided by enclosures (IP-Code) 2000-09

= W

DOK-INDRV*-HMV-*******-PR01-EN-P

Fig. 4-3: Type code

4-4 Identifying and Checking the Delivered Components Rexroth IndraDrive

Notes

DOK-INDRV*-HMV-*******-PR01-EN-P

Rexroth IndraDrive Transport and Storage 5-1

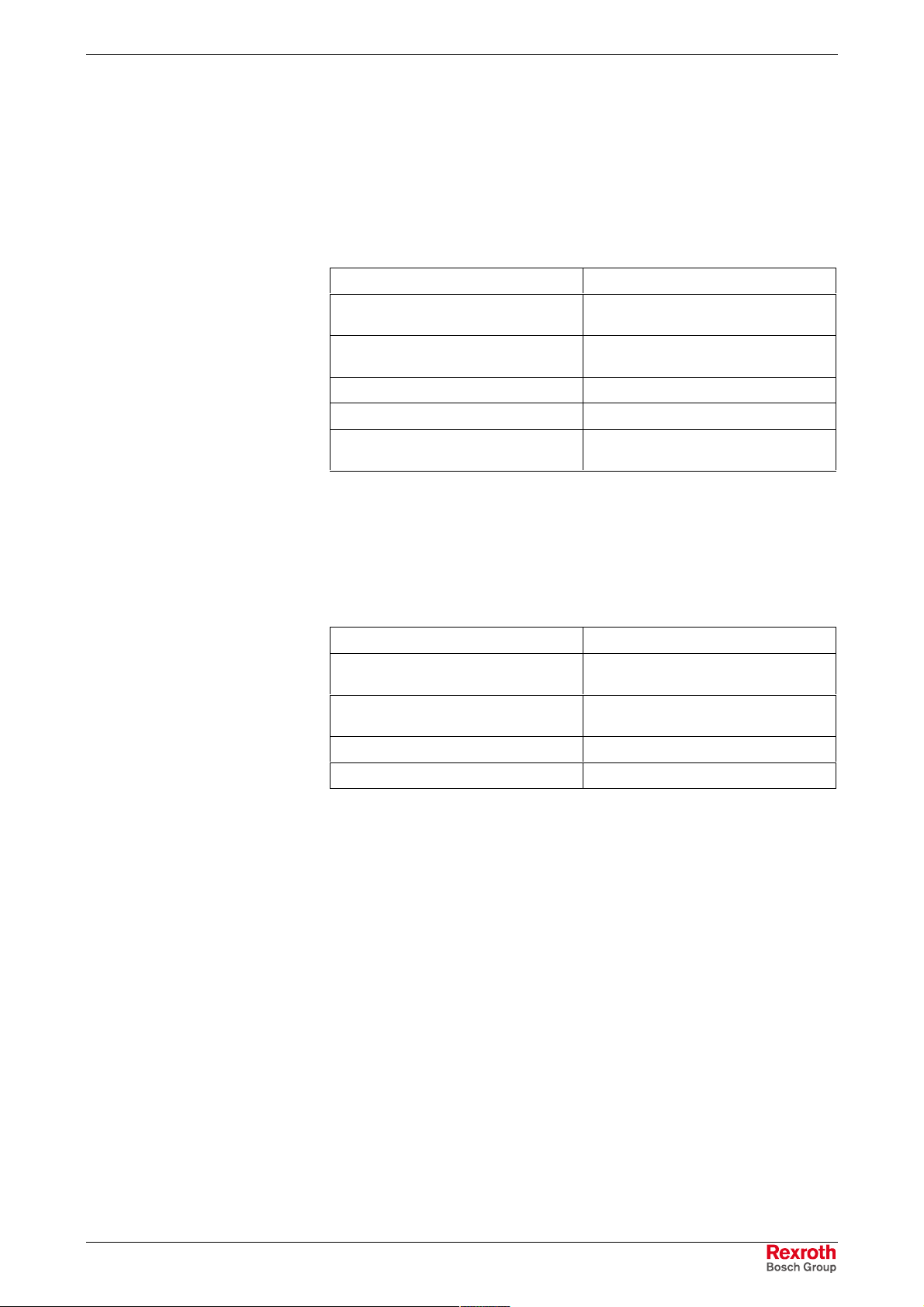

5 Transport and Storage

5.1 Transporting the Devices

Conditions

temperature -25 ... 70 °C

relative humidity 5 ... 95%;

climatic category 2K3

absolute humidity 1 ... 60 g/m

climatic category 2K3

moisture condensation not allowed

icing not allowed

Shock check not in operation

according to EN 60068-2-27

Fig. 5-1: Conditions for transport

Halve sine in 3 axis:

10g / 11ms

3

5.2 Storing the Devices

Conditions

temperature -25 ... 55 °C

relative humidity 5 ... 95%;

absolute humidity 1 ... 29 g/m

moisture condensation not allowed

icing not allowed

Fig. 5-2: Conditions for storage

In Case of Long Storage Periods

The power supply units contain sensitive electrolytic capacitors.

Therefore, in the case of long storage periods, operate the power supply

units once a year for at least 1 hour with power on (DC bus voltage mus t

be applied).

climatic category 1K3

3

climatic category 1K3

DOK-INDRV*-HMV-*******-PR01-EN-P

5-2 Transport and Storage Rexroth IndraDrive

Notes

DOK-INDRV*-HMV-*******-PR01-EN-P

Loading...

Loading...