Page 1

ProteinChip®

SEND ID Array

Instruction Manual

Catalog #C57-30081

For Technical Support, contact your

local Bio-Rad office, or in the U.S.,

call 1-800-4BIORAD (1-800-424-6723).

Page 2

Use

n

Peptide analysis

Introduction

Fundamental to most applications of laser desorption/ionization

mass spectrometry (LDI-MS) is the addition of matrix to the

analyte. Matrix signals interfere in the low molecular weight (MW)

range of the spectra, rendering matrix-assisted laser desorption/

ionization (MALDI)-MS and surface-enhanced laser desorption/

ionization (SELDI)-MS techniques problematic for peptide

analysis. Surface-enhanced neat desorption (SEND) technology

is unique in that the matrix is integral to the ProteinChip array

surface. The chemical noise in the spectra from the matrix is

significantly reduced when compared to addition of matrix

on-spot (particularly in the region 600 to 1,500 Da). This allows

the use of SELDI for lower MW species analysis with a reduced

amount of interfering peaks in the spectra.

The ProteinChip SEND ID array has C-18 as a functional group,

allowing the use of the array for on-chip cleanup, removing salt

and denaturant (such as urea) prior to analysis by SELDI.

The primary application of the ProteinChip SEND ID array is

peptide analysis. Successful mass determination of molecules

lower than 600 Da will be determined by how well these

molecules are ionized, desorbed, and detected by the mass

spectrometer. If laser intensity has to be increased above a

certain level to detect the molecule, the background peaks below

the 600 Da range may interfere with detection of analyte peaks.

1 © 2007 Bio-Rad Laboratories, Inc.

Page 3

Storage and Packaging

Store ProteinChip SEND ID arrays at room temperature. They

should be stored in the foil pouch in which they are supplied to

limit their exposure to light.

ProteinChip SEND ID arrays are packaged in a 12-array

ProteinChip cassette. A bioprocessor reservoir is included in the

package to protect the arrays during shipment (see Figure 1).

The spare ProteinChip cassette included to separate the

reservoirs from the arrays should be removed before use in

the ProteinChip cassette-compatible bioprocessor (catalog

#C50-30011). As the recommended protocols are rarely done

with more than a few microliters of sample, this reservoir is not

needed and should be discarded.

The arrays can be used in the cassette, or individual arrays can be

removed for processing. Take care to avoid touching the arrays.

A pair of ProteinChip array forceps (catalog #C20-10002) helps to

remove the arrays from the cassette (see Figure 2).

Fig. 1. ProteinChip cassette

and reservoir.

2 © 2007 Bio-Rad Laboratories, Inc.

Fig. 2. Removal of ProteinChip

arrays from the cassette using

array forceps.

Page 4

Technical Considerations

n

If your sample has salt or urea contamination, proceed directly

to Protocol 2. Otherwise, perform Protocol 1 first. If there is

insufficient signal after reading the arrays, a cleanup step is

recommended: Add 5 µl of 0.1% trifluoroacetic acid (TFA) to

the spot; do not agitate; remove the 0.1% TFA droplet after

30 sec; and add 5 µl 25% acetonitrile (ACN) and 0.1% TFA to

the spot. Allow to dry, and read the arrays again

n

With ProteinChip SEND ID arrays, it is essential that you mix

your sample with a solution of 50% ACN and 0.2% TFA at a

1:1 (v/v) ratio before adding to the spot

n

Ideally, the final concentration of ACN after dilution is 25%;

a final concentration of greater than 40% ACN is not compatible

with the ProteinChip SEND ID array

Factors That Can Result in Weak Signal

n

We do not recommend washing on-spot (by pipetting the

sample up and down) because this can reduce signal

n

Weak signal can be improved by adding ACN to your sample

as described in Protocol 1

n

A predominant peak at mass-to-charge ratio (m/z) 211

indicates sodium contamination, and you should perform

sample cleanup as described in Protocol 2, step 5. This

contamination can suppress sample peaks and result in

weak signal

3 © 2007 Bio-Rad Laboratories, Inc.

Page 5

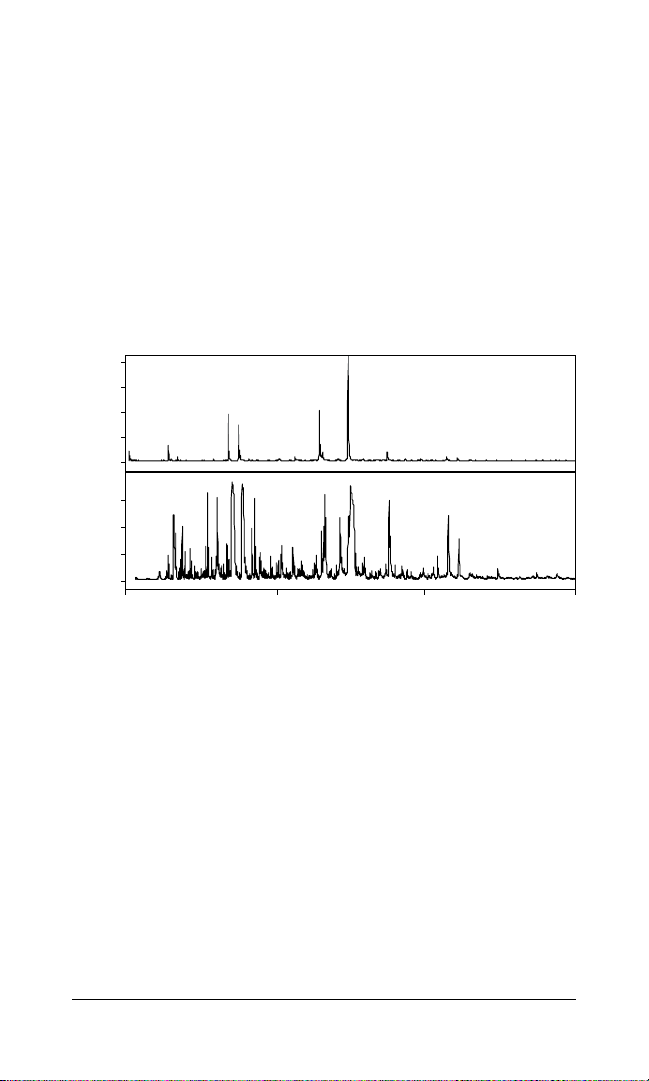

Chemical Noise

Because ProteinChip alpha-cyano-4-hydroxycinnamic acid

(CHCA) matrix is integral to the array surface, chemical noise

from matrix peaks are significantly reduced with the ProteinChip

SEND ID array when compared to standard MALDI or SELDI

analysis. Some chemical noise will be seen; the amount seen is

affected by two main factors (Figure 3):

n

Increased laser intensity will increase chemical noise

n

The higher the concentration of sample, the lower the intensity

of chemical noise peaks

A

20

15

10

Intensity

5

0

B

75

50

Intensity

25

0

0 250 500 750

171.0+H

189.0+H

Fig. 3. Comparison of chemical noise peaks due to variation in sample

concentration and laser intensity. A, minimal chemical noise is seen when

concentration of sample is high and laser intensity is low (1 pmol of sample applied

directly to the array); B, increased chemical noise is seen below 600 Da when sample

concentration is decreased to 50 fmol and increased laser intensity is necessary.

m/z, mass-to-charge ratio.

378.0+H

m/z

4 © 2007 Bio-Rad Laboratories, Inc.

Page 6

Protocol 1

The following method can be used to apply a sample directly to

the ProteinChip SEND ID array for peptide analysis.

1. Mix your sample 1:1 (v/v) with 50% ACN (v/v) and 0.2% TFA

in deionized (DI) water.

2. Add 1–2 µl of sample to each spot on the ProteinChip

SEND ID array.

3. Allow the spots to air-dry.

4. Read the arrays in the ProteinChip SELDI reader.

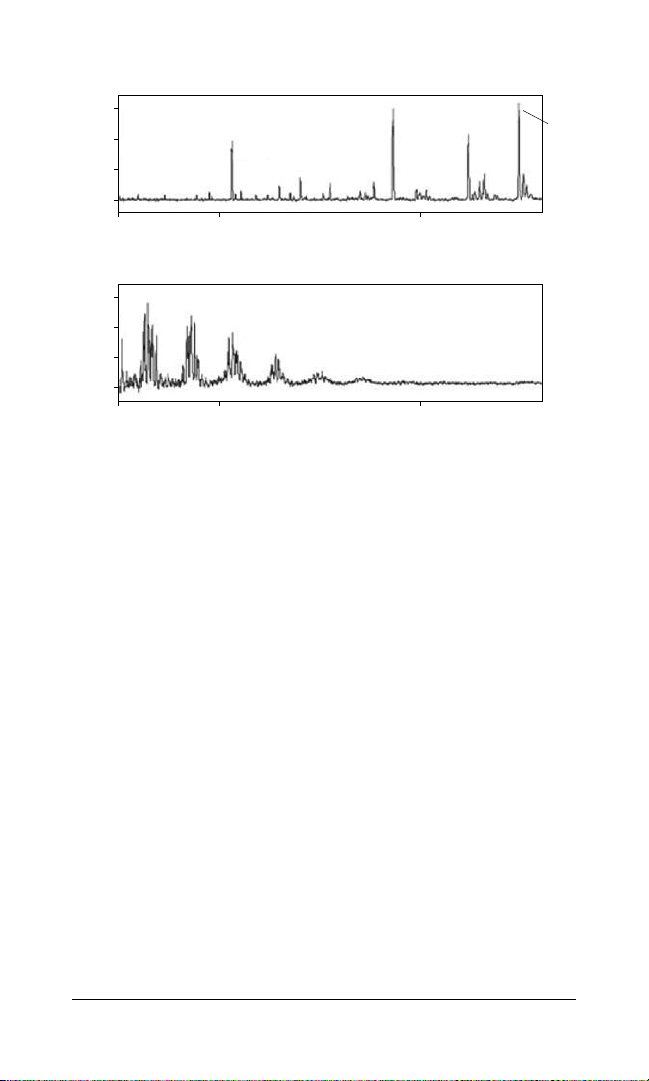

Protocol 2

The following method can be used to clean up a sample on

the ProteinChip array to remove salt and urea contamination

(see Figure 4). The C-18 chemistry on the surface selectively retains

peptides through their hydrophobic regions while impurities are

washed away.

1. Mix sample with 0.2% TFA at a 1:1 (v/v) ratio.

2. Apply 5 µl of 0.1% TFA to the ProteinChip SEND ID array.

Remove within 30 sec; do not agitate. Repeat.

3. Spot 2 µl of sample onto the array.

4. Incubate the samples for 10 min in a humidity chamber

at room temperature. Remove the samples.

5. Add 5 µl of 0.1% TFA to each spot. Remove within

30 sec; do not agitate.

6. Add 2 µl of 25% ACN (v/v) and 0.1% TFA in DI water to

each spot.

7. Allow the array to air-dry.

8. Read the array in the ProteinChip SELDI reader.

5 © 2007 Bio-Rad Laboratories, Inc.

Page 7

ProteinChip SEND ID array

30

20

10

Relative intensity

0

1,000 2,000

1,060.46

1,859.01

2,482.0

2,230.97

ProteinChip NP20 array with CHCA matrix

60

40

20

Relative intensity

0

1,000 2,000

m/z

Fig. 4. Clearly visible peptide peaks with the ProteinChip SEND ID array.

Upper panel, shown after on-chip cleanup of a bovine serum albumin (BSA) digest

contaminated with 2 M urea; bottom panel, only matrix peaks are visible when the

same sample is applied to a ProteinChip NP20 array with no cleanup and CHCA

added separately.

Ordering Information

Catalog # Description

C57-30081

C20-10002

ProteinChip SEND ID Arrays, A–H format, 12

ProteinChip Array Forceps, 1 pair

6 © 2007 Bio-Rad Laboratories, Inc.

Page 8

The SELDI process is covered by U.S. patents 5,719,060, 6,225,047, 6,579,719,

Life Science

Group

07-0780 1207 Sig 1207

10008249 US/EG Rev D

Bio-Rad

Laboratories, Inc.

Web site www.bio-rad.com USA 800 4BIORAD

Australia 61 02 9914 2800 Austria 01 877 89 01

Belgium 09 385 55 11 Brazil 55 21 3237 9400

Canada 905 364 3435 China 86 21 6426 0808

Czech Republic 420 241 430 532 Denmark 44 52 10 00

Finland 09 804 22 00 France 01 47 95 69 65

Germany 089 318 84 0 Greece 30 210 777 4396

Hong Kong 852 2789 3300 Hungary 36 1 455 8800

India 91 124 4029300 Israel 03 963 6050 Italy 39 02 216091

Japan 03 6361 7000 Korea 82 2 3473 4460

Mexico 52 555 488 7670 The Netherlands 0318 540666

New Zealand 0508 805 500 Norway 23 38 41 30

Poland 48 22 331 99 99 Portugal 351 21 472 7700

Russia 7 495 721 14 04 Singapore 65 6415 3188

South Africa 27 861 246 723 Spain 34 91 590 5200

Sweden 08 55512700 Switzerland 061 717 95 55

Taiwan 886 2 2578 7189 United Kingdom 0208328 2000

6,818,411, and other issued patents and pending applications in the U.S. and

other jurisdictions.

Loading...

Loading...