Page 1

Bio-Rad® Nuvia™ IMAC

Resin

Instruction Manual

Catalog numbers

780-0800

780-0801

780-0802

Please read these instructions prior to using Bio-Rad Nuvia IMAC

resins. If you have any questions or comments regarding these

instructions, contact your Bio-Rad Laboratories representative.

Page 2

Page 3

Table of Contents

Section 1 Introduction ............................................................ 1

Section 2 Product Description ............................................... 2

Nuvia™ IMAC Resins and

UNOsphere™ Technology .......................................... 2

Chemical Interactions ............................................... 3

Resin Characteristics ................................................ 4

Chemical Compatibilities ........................................... 5

Section 3 General IMAC Procedures ..................................... 7

Protein Binding ......................................................... 7

Washes .................................................................... 8

Elution ...................................................................... 8

Purification under Denaturing Conditions .................. 9

Imidazole Concentrations ........................................10

Section 4 Column Packing — Medium-Pressure

Columns .................................................................11

Slurry Packing an IMAC Column...............................11

Recommended Columns..........................................11

Materials ..................................................................11

Resin Preparation ....................................................12

Method ................................................................... 12

Section 5 Column Packing — Sample Preparation–Sized

Columns ................................................................ 14

Materials ................................................................. 14

Resin Preparation ................................................... 14

Method ...................................................................15

Section 6 Immobilizing Metal Ions ........................................16

Section 7 Medium-Pressure Column Purification of

Histidine-Tagged Proteins....................................17

Materials .................................................................17

Method ...................................................................18

Materials and Method for On-Column

Renaturation ........................................................... 20

Page 4

Section 8 Medium-Pressure Column Purification — Using

an Imidazole Gradient to Determine Optimal

Purification of Histidine-Tagged Proteins ........... 21

Materials ................................................................. 21

Method ................................................................... 22

Section 9 Sample Preparation–Sized Spin-Column

Purification of Histidine-Tagged Proteins ........... 25

Materials .................................................................25

Method ...................................................................26

Section 10 Regenerating, Cleaning, Sanitizing,

and Storage ..........................................................28

Regenerating the Medium .......................................28

Cleaning in Place ...................................................28

Sanitization..............................................................30

Storage .................................................................. 30

Section 11 Troubleshooting Guide ......................................... 31

Section 12 Ordering Information ........................................... 34

Section 13 References ........................................................... 34

Section 14 Legal Notices ...................................................... 34

Page 5

Section 1

Introduction

Immobilized metal affinity chromatography (IMAC) is a powerful

purification technique that relies on a molecule’s affinity for certain

metals immobilized onto a chelating surface. The chelating

ligand, nitrilotriacetic acid (NTA) in this case, may be charged with

transition metals such as Cu2+, Ni2+, Co2+, or Zn2+. This results in

high selectivity for proteins with clustered histidine residues to be

strongly retained on a porous chromatographic support.

The use of IMAC to separate an expressed recombinant protein

fused with a hexahistidine peptide tag was demonstrated

by Hochuli (1988) to yield a highly purified protein in a single

chromatographic step under both denaturing and native

conditions. The strong affinity of a histidine-tagged molecule for

metal ions often makes extensive optimization unnecessary while

also allowing chromatography under conditions that denature

proteins. For this reason, expression and IMAC purification of

histidine-tagged proteins is frequently used for structural and

functional studies of proteins.

Nuvia IMAC Ni-Charged Resin 1

Page 6

Section 2

Product Information

Nuvia™ IMAC Resins and UNOsphere™ Technology

Nuvia IMAC resin, a unique affinity support, is based on Bio-Rad’s

innovative UNOsphere beads, which use proprietary polymerization

and derivatization technologies.* The UNOsphere technology

enables the polymeric high-capacity IMAC resin to exhibit excellent

flow properties without compromising protein binding, recovery, or

purity.

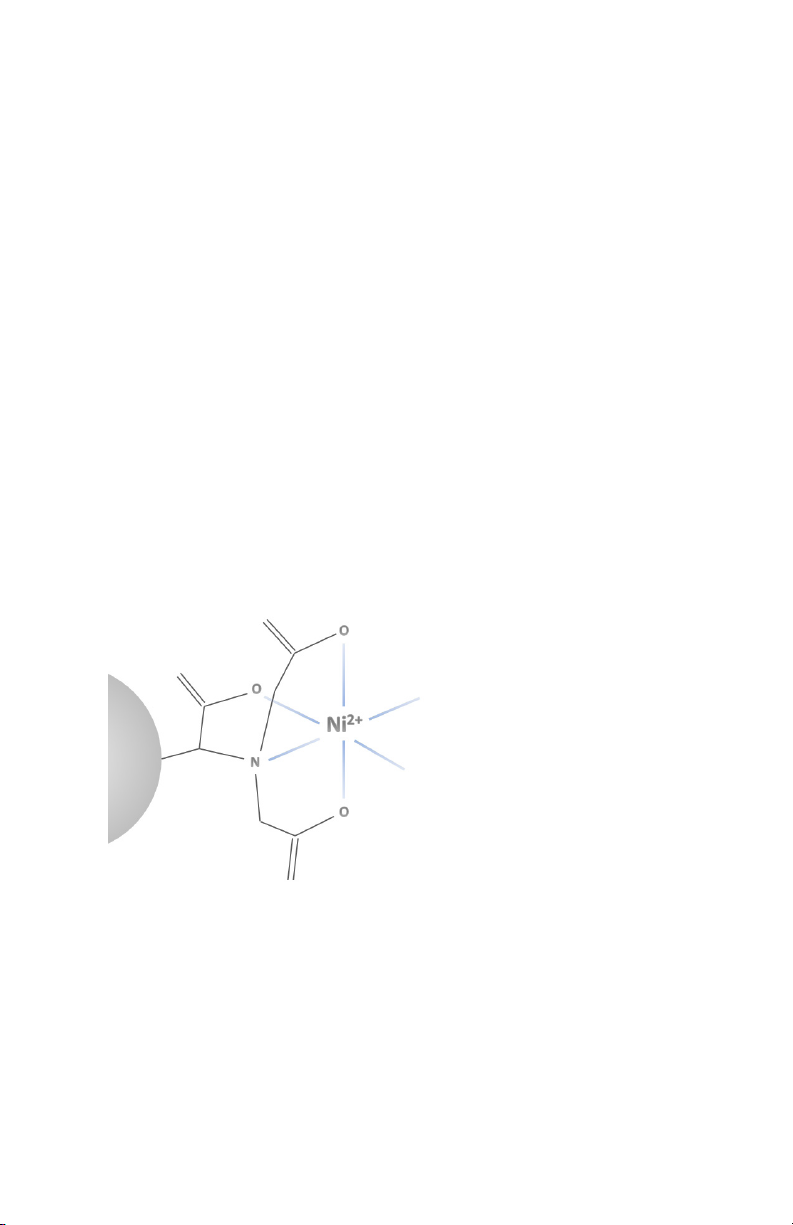

Nuvia IMAC uses NTA as its functional ligand. The tertiary amine

and carboxylic acid side chains of NTA serve as the chelating

ligands for divalent metal ions. The structure offers selective

binding of recombinant histidine-tagged proteins when this resin is

charged with Ni2+ or other transition metals. As a result, the desired

proteins can often be purified close to homogeneity in a single

step.

Structural characteristics such as the polymeric nature, optimized

ligand density, and open-pore structure of Nuvia IMAC beads

result in superb mechanical strength with high stringency, low

nonspecific effects, and the ability to provide separations at fast

flow rates. These unique features of the UNOsphere base matrix

lend a number of performance benefits to the Nuvia IMAC resin.

Nuvia IMAC is also stable across a wide pH range (2–14) and

is compatible with most reagents commonly used in protein

purifications, such as denaturants, detergents, and reducing

agents. It is amenable to separations under native or denaturing

conditions using liquid chromatography instrumentation, gravity

flow columns, or sample-preparation spin columns.

Note: UNOsphere media, from which Nuvia IMAC is derived,

was designed to achieve the highest productivity (grams of

drug or target per operational hour per liter of support) possible.

UNOsphere media may be run at the highest rates and loading

capacities and will stay within the pressure limits of the column and

chromatography system.

* U.S. patent 6,423,666.

2 Nuvia IMAC Ni-Charged Resin

Page 7

Under optimized conditions, the binding capacity for 6x histidinetagged proteins is >40 mg/ml resin (see Table 1). The product is

a 50% (v/v) slurry of resin, which is suspended in a 20% ethanol

solution. Nuvia IMAC resin is amenable to process and laboratoryscale use and is available precharged with Ni2+ in bottles as well

as prepacked into columns. Table 1 lists key characteristics of the

resin, while Table 2 lists a variety of compounds compatible with

Nuvia IMAC support.

Chemical Interactions

Nuvia IMAC resin is composed of NTA groups coupled to

a UNOsphere base matrix via a proprietary polymerization

derivatization technology. It is well-suited to recombinant histidinetagged purifications and results in high binding capacity and

specificity for the target molecule.

Although the most commonly used metal ion for histidine-tagged

purifications is Ni2+, other metals may be used to increase efficacy

of purification. Therefore, choosing another type of immobilized

metal ion can change the selectivity of an IMAC resin.

Fig. 1. Partial structure of Nuvia Ni-charged IMAC resin. Image illustrates UNOsphere base

bead with coupled NTA functional ligand.

Nuvia IMAC Ni-Charged Resin 3

Page 8

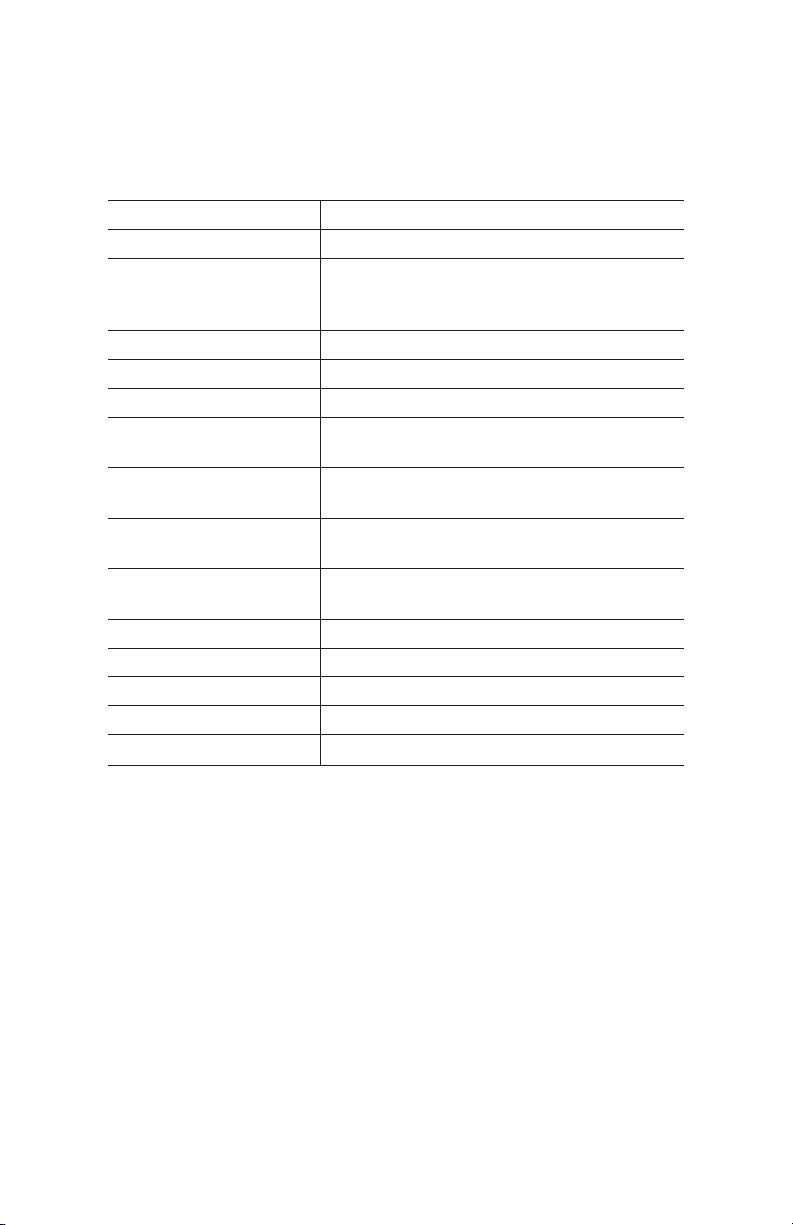

Resin Characteristics

The characteristics of Nuvia IMAC resin are detailed in Table 1.

Table 1. Characteristics of Bio-Rad Nuvia IMAC Resin.

Functional ligand Nitrilotriacetic acid (NTA)

Base bead UNOsphere base matrix

Form 50% suspension in 20% ethanol or pre-

packed into columns; comes precharged

2+

with Ni

Particle size 38–53 µm

Mean particle size 50 µm

Metal ion capacity ≥18 µmol Cu2+/ml Nuvia IMAC resin

Dynamic binding

capacity*

Recommended linear

flow rate

Maximum operating

pressure

pH stability, short-term/

cleaning

Chemical compatibility See Table 2

Storage 4°C to ambient temperature

Shelf life in 20% ethanol ≥3 year at ambient temperature

Operational temperature 4–40°C

Autoclaving conditions 0.1 M sodium acetate at 120°C for 30 min

≥40 mg/ml resin

<500 cm/hr at 25°C

45 psi

2–14

* Dynamic binding capacity conditions (Q10% determination):

Column volume: 1 ml, 5.6 mm x 4 cm (ID x H)

Sample: 1.0 mg/ml 6x histidine-tagged pure protein (40 kD)

Note: Dynamic binding capacity will vary from protein to protein.

4 Nuvia IMAC Ni-Charged Resin

Page 9

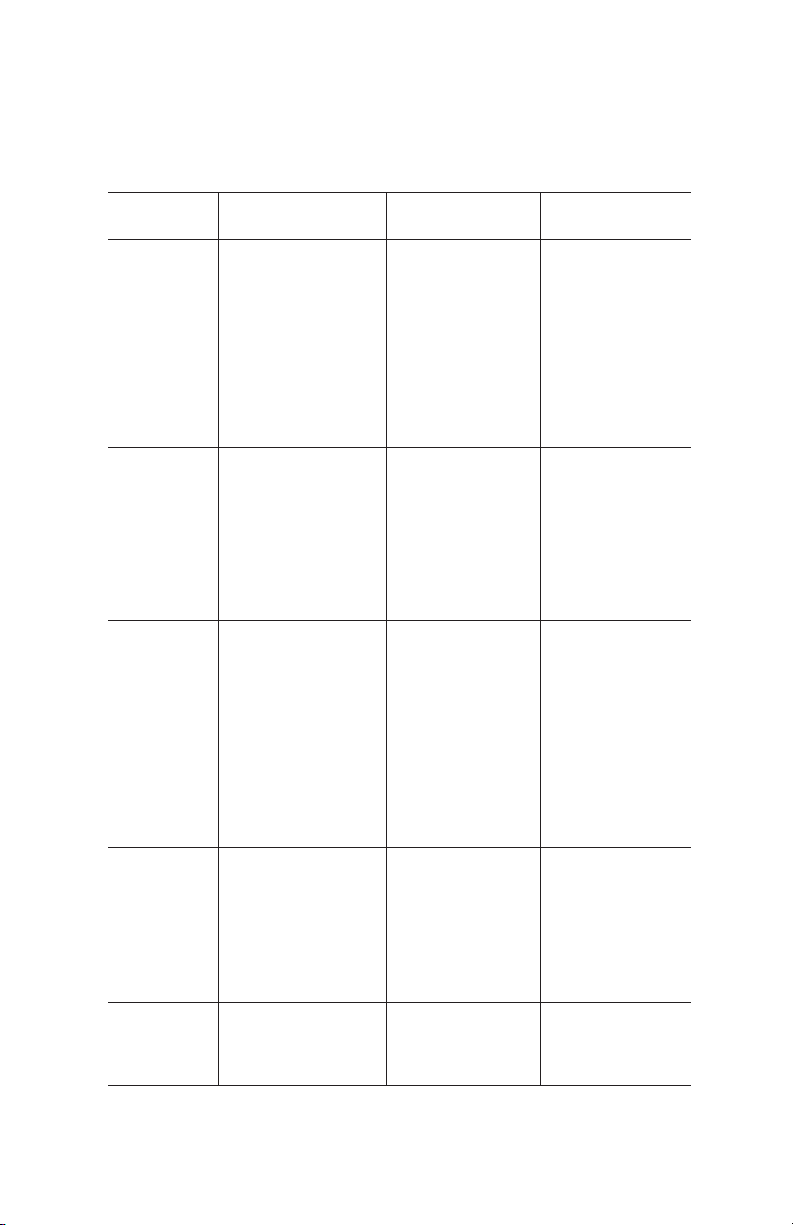

Chemical Compatibilities

The chemical characteristics of Nuvia IMAC resin are detailed in Table 2.

Table 2. Chemical Compatibilities for Nuvia IMAC Resins.

Reagent

Group

Buffer

reagents

Chelating

reagents

Sulfhydryl

reagents

Reagent Comments Stability

Tris, HEPES,

MOPS

Sodium or

potassium

phosphate

EDTA, EGTA Strips nickel ions

β-Mercaptoethanol

Used with

proteins more

stable in

nonphosphate

buffers

from the resin

Reduces random

disulfide bonds

preventing

protein

aggregation

during purification

≤50 mM

secondary and

tertiary amines

50 mM sodium

or potassium

phosphate are

recommended

as starting

buffers

≤0.1 mM

successfully

used to remove

trace metal

contaminants

>1 mM can

cause significant

reduction in

binding capacity

≤20 mM

DTT, TCEP

Detergents Nonionic

detergents (Triton,

Tween)

Zwitterionic

detergents

(CHAPS, CHAPSO)

Denaturants Guanidine HCl

(GuHCl)

Urea

Transition metals

at the center of

IMAC resin (Ni2+)

are susceptible to

reduction

Removes

background

proteins

and nucleic acids

Solubilizes

membrane

proteins

Solubilizes

proteins

Nuvia IMAC Ni-Charged Resin 5

≤10 mM DTT

and 20 mM

TCEP

≤2%

≤1%

≤6 M

≤8 M

Page 10

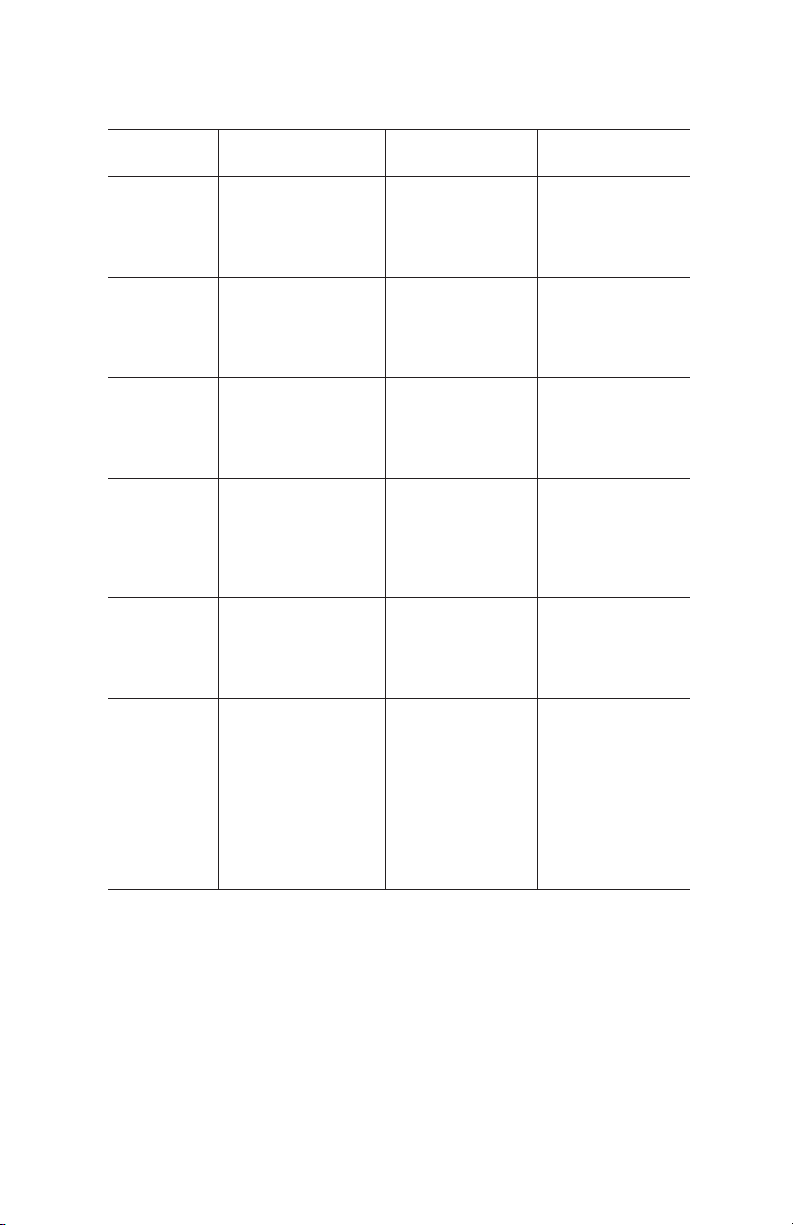

Table 2. Chemical Compatibilities for Nuvia IMAC Resins, Continued.

Reagent

Reagent Comments Stability

Group

Other

additives

NaCl Deters

nonspecific

protein binding

due to ionic

interactions

MgCl

2

Essential

component for

purification of

Ca2+ binding

proteins

CaCl

2

Essential

metal cofactor for

nucleases

≤2 M (at least

300 mM NaCl

should be

included in

buffers)

≤100 mM

(HEPES or Tris

buffers should be

used to prevent

precipitation)

≤5 mM (HEPES

or Tris buffers

should be used

to prevent

precipitation)

Glycerol Included

to prevent

hydrophobic

interactions

between proteins

≤20%

(backpressure

may increase

significantly,

slower flow rates

may be required)

Ethanol Included

≤20%

to prevent

hydrophobic

interactions

between proteins

Imidazole Competes for

binding sites with

histidine-tagged

residues by

interaction

with the metal

residues

May be

used in low

concentrations

in the wash

buffer (<30 mM)

to limit binding

of undesired

proteins; for

elution, ≤500 mM

may be used

6 Nuvia IMAC Ni-Charged Resin

Page 11

Section 3

General IMAC Procedures

Protein Binding

Protein adsorption to immobilized ions is performed around

neutral to slightly alkaline pH conditions (pH 7.0–8.0). To reduce

nonspecific ionic effects, concentrations of up to 1 M NaCl may

be added to the binding solution. Recombinant 6x histidine tags,

located at either the amino or carboxyl terminus of the protein, can

bind with high affinity to the matrix even when the 6x histidine tag

isn’t completely accessible. In general, the fewer the number of

accessible histidine residues, the weaker the protein binding is to

the affinity matrix. Untagged proteins that have naturally occurring

and noncontiguous histidine residues also bind to IMAC resins, but

with much lower affinity.

Batch mode binding is a good alternative if proteins are expressed

at low levels or if the overall concentration of the recombinant

6x histidine tag is low. In this case, proteins are bound to the

Nuvia™ IMAC resin in solution prior to packing the protein-resin

complex into a liquid chromatography column for wash and elution

steps. Altering the imidazole concentration of the lysis buffer may

also optimize binding. Low concentrations (0–15 mM imidazole)

are recommended and will aid in reducing nonspecific binding of

weakly interacting proteins.

Many additives can be used without affecting the binding of

histidine-tagged proteins to IMAC resins. For example, urea,

GuHCl, nonionic detergents, and organic solvents (refer to

Section 2, Table 2) are all valid options. Chelating agents, such as

EDTA or citrate, should not be included. Reducing agents such as

β-mercaptoethanol and DTT may be used at low concentrations.

Potassium phosphate or sodium phosphate buffers are

recommended solutions for equilibration and binding.

Recommended binding buffer:

• 20–50 mM sodium or potassium phosphate, containing up to

1.0 M NaCl.

Begin with: 50 mM sodium phosphate, 0.3 M NaCl, pH 8.0

Nuvia IMAC Ni-Charged Resin 7

Page 12

Washes

Stringency of 6x histidine-tag binding can be effectively increased

by 1) including low concentrations of imidazole in the binding and

wash solutions, or 2) reducing the pH. Generally, highly expressed

proteins, such as those from a bacterial expression system, have

fewer contaminant proteins that copurify along with the protein of

interest. Endogenous protein contaminants are more abundant

in eukaryotic expression systems and tend to bind to the IMAC

adsorbent more weakly. In these instances, nonspecific binding

of proteins containing neighboring histidine residues becomes

a problem. These endogenous species may be washed from

the resin by either lowering the pH to 6.3 or adding imidazole to

binding and wash solutions in concentrations of 5–30 mM. The

optimal pH and/or imidazole concentration used in wash buffers

is always protein dependent and should always be determined

experimentally.

Recommended wash buffer:

• 5–30 mM imidazole; for example, 50 mM sodium phosphate,

0.3 M NaCl.

Begin with: 5 mM imidazole, 50 mM sodium phosphate,

0.3 M NaCl, pH 8.0

Elution

Desorption of the histidine-tagged protein may be accomplished in

one of three ways: introduction of a competitor ligand, reduction of

the pH, or stripping of the immobilized metal.

In competitive elution, a step or gradient elution with ligands such

as imidazole, histidine, histamine, or glycine may be carried out.

When using a gradient elution with imidazole, it is important to preequilibrate the column with low concentrations of imidazole (1 mM)

and include the same concentration in the sample. This prevents

adsorption of imidazole onto the resin from triggering a drop in pH,

which might prematurely elute bound histidine-tagged proteins.

Lowering the pH of the elution buffer (pH 4.5–5.3) also releases

bound histidine-tagged proteins. In this case, the histidine residues

become protonated and are unable to bind to the immobilized ion.

Protein sensitivity to low pH ranges, however, must be taken into

consideration.

8 Nuvia IMAC Ni-Charged Resin

Page 13

If lower pH is used to elute bound proteins, tubes filled with a

strong neutralizing buffer such as 1 M Tris-HCl, pH 8.0 may be

used to collect acidic eluates (100–200 µl eluate/ml neutralizing

buffer). The recommended range is pH 3–5 with acetate buffers

being a preferred choice. Weakly bound contaminants may be

washed off in an intermediate wash at around pH 5.5–6.5.

Strong chelating agents such as EDTA and EGTA strip immobilized

ions from the column and cause the bound histidine-tagged

protein to elute as a protein-metal complex. This results in metal

ions appearing in the protein fractions.

Recommended elution buffer for Nuvia IMAC resin

Though a number of conditions can be used to elute the target

protein from the Nuvia resin, adjusting the concentration of

imidazole is recommended.

Recommended elution buffer:

• 20–500 mM imidazole; for example, 50 mM sodium

phosphate, 0.3 M NaCl.

Begin with: 0.5 M imidazole, 50 mM sodium phosphate,

0.3 M NaCl, pH 8.0

Purification under Denaturing Conditions

When overexpressed in E. coli, some proteins may aggregate,

forming what are known as inclusion bodies. These inclusion

bodies need to be solubilized in strong denaturants such as

6 M guanidine HCl or 8 M urea in order to purify the histidinetagged protein. Usually proteins expressed as inclusion bodies

are not in their native conformation, so high concentrations of

denaturants may be used during lysate preparation and protein

purification.

In order to restore the native conformation and activity of the

protein, the denaturant must be removed by dilution, dialysis, or

size exclusion chromatography. Renaturation of the protein while it

is still bound to the IMAC column is a good alternative and offers

several advantages. Aggregation may be kept to a minimum if the

protein refolds on the column when the denaturant is removed.

Higher concentrations of the refolded protein may therefore be

collected.

Nuvia IMAC Ni-Charged Resin 9

Page 14

Finally, the use of a liquid chromatography system ensures that

the adjustment of denaturants, detergents, salts, and pH will be

effectively controlled.

Imidazole Concentrations

For optimal protein purification results, it is crucial that the

imidazole concentrations in lysis, binding, and wash buffers, as

well as elution buffers, be empirically established. Determine

optimized conditions using a small amount of sample. These

conditions may then be used to design the purification protocol

for larger samples on the same column or on a larger column. As

each protein behaves differently, it is helpful to keep the following

points in mind during lysate preparation and purification:

• Low concentrations of imidazole (1–30 mM) in lysis, binding,

and wash buffers are recommended if the potential for

background contaminants exists. The ability for nontagged

contaminating proteins to bind to the resin is generally higher

under nondenaturing conditions than under denaturing

conditions

• Low concentrations of imidazole (1–30 mM) help minimize

nonspecific binding of proteins containing noncontiguous

histidine residues by competing with them for available binding

sites on the transition metal. Competition occurs because

the imidazole ring is also found in the histidine-containing

compound

• If the recombinant histidine-tagged protein does not bind

under higher concentrations, the imidazole concentration can

be reduced for binding and wash steps

• A gradient elution test may be used to determine

concentrations of imidazole for wash and elution steps. Once

the imidazole concentration to elute the protein is established,

large samples and/or columns may be used

10 Nuvia IMAC Ni-Charged Resin

Page 15

Section 4

Column Packing — Medium-Pressure Columns

Slurry Packing an IMAC Column

Slurry packing is preferred for small columns. This method

describes packing a Nuvia™ IMAC resin with aid from a pump. For

best results, use 5–50 mm ID columns and a bed height of

5–30 cm.

Recommended Columns

Bio-Rad’s Bio-Scale™ MT high-resolution columns may be used

for the following column-packing procedure. These columns are

empty and may be packed with the support of choice.

Bio-Scale MT columns are convenient to use with Bio-Rad’s

NGC™ chromatography system or any medium- or high-pressure

system:

• Bio-Scale MT2 column (7 x 52 mm) for bed volumes

up to 2 ml

• Bio-Scale MT5 column (10 x 64 mm) for bed volumes

up to 5 ml

• Bio-Scale MT10 column (12 x 88 mm) for bed volumes

up to 10 ml

• Bio-Scale MT20 column (15 x 113 mm) for bed volumes

up to 20 ml

Materials

• Empty column (1–5 cm ID x 30 cm) with flow adaptors, inlet

and outlet ports

• Glass filter

• Nuvia IMAC Ni-charged resin

• Packing reservoir

• Pump

Nuvia IMAC Ni-Charged Resin 11

Page 16

Resin Preparation

Nuvia IMAC Ni-charged resins come in a 20% ethanol solution,

supplied for resin storage. The column can be slurry packed in

this solution; simply resuspend the resin in the ethanol solution

provided. Before applying sample, ensure that all ethanol is

removed during the equilibration step.

Method

1. Eliminate air from the column dead spaces. Attach the inlet

of a peristaltic or other pump to the outlet of the MT column.

Fill the column with distilled water to about 10% of its volume.

Flush end pieces with distilled water to ensure that the bottom

of the bed support is fully saturated and free of air bubbles.

Allow a few centimeters of distilled water to remain when

closing the outlet valve.

2. Suspend the 50% v/v slurry by gently swirling or stirring with a

glass or plastic rod.

3. Carefully transfer about a third of the slurry down the side into

the column using a glass or plastic rod to avoid introducing air

bubbles.

4. Start the pump at a low flow rate (eg. 0.5 ml/min). The resin

will begin to pack in the column. As the liquid level in the

column drops, continue to transfer the rest of the slurry until

the packed bed reaches 1 cm from the top. Stop or slow the

pump flow rate as necessary.

Gently add more distilled water down the side of the column

to make sure the liquid does not fall below the resin level.

Continue adding distilled water until the bed seems to have

stabilized. Then gently fill the column to the top with distilled

water.

5. Stop the pump and prepare to insert the top adapter.

6. Insert the top flow adaptor. Use care to avoid introducing any

air bubbles. Insert the adaptor into the column at an angle.

Make sure the exit tubing is open so that distilled water can

flow out the top adaptor along with any air.

12 Nuvia IMAC Ni-Charged Resin

Page 17

7. Adjust the adaptor to sit directly on top of the resin bed.

Open the column outlet and pump distilled buffer through the

column at a) a packing flow rate of ~400–600 cm/hr for 5 to

10 min, or b) the maximum pressure allowed by the column

hardware and resin. The resin bed will compress while packing

at high flow rates. Mark the compression level with a pen.

Stop the flow. At this point, the resin bed height may readjust

and rise. If this happens, adjust the flow adaptor to compress

the bed another 0.1–0.5 cm past the level marked with the

pen.

8. Reconnect the pump and equilibrate. Pass eluent (distilled

water) through the column at the packing flow rate. During

equilibration, the bed may compress even further. When a

constant bed height is reached, mark the compression level at

this flow rate. Again, adjust the adaptor to compress the bed

an additional 0.1–0.5 cm past the level marked.

Note: Chromatographic steps during purification should not be

run at greater than 75% of the packing flow rate.

Nuvia IMAC Ni-Charged Resin 13

Page 18

Section 5

Column Packing — Sample Preparation–Sized

Columns

Use this method for packing Nuvia™ IMAC resin into sample

preparation micro spin columns.

Materials

1. Reagents

• 0.1 M NiSO4 (or other suitable metal salt solution)

Note: Charging Nuvia IMAC nickel-charged resin (Ni-charged

resin) is not required for initial use. For subsequent uses it is

recommended that the resin be cleaned of all contaminants,

stripped of metal ions, and recharged with proper metal ions

prior to loading sample.

If needed, the procedure to charge Nuvia IMAC (uncharged)

resin is explained in Section 6, Immobilizing Metal Ions.

2. Equipment

• Sample preparation–sized columns (for example,

Micro Bio-Spin™ columns, catalog #732-6204)

• Plasticware, 2 ml capped and 2 ml capless tubes

• Nuvia IMAC Ni-charged resin

• Tabletop centrifuge

• 1 ml pipet with wide-bore pipet tips

Resin Preparation

Nuvia IMAC Ni-charged resins come in a 20% ethanol solution,

supplied for resin storage. The column can be packed in this slurry

or decanted into distilled water and packed.

14 Nuvia IMAC Ni-Charged Resin

Page 19

Method

1. Thoroughly suspend Nuvia IMAC resin.

2. Place the column into an appropriate collection vessel; for

example, a 2 ml capless collection tube.

3. Using a pipet, transfer the appropriate amount of Ni-charged

Nuvia IMAC resin to a microcentrifuge tube. If using a Micro

Bio-Spin column, transfer 0.2 ml slurried Ni-charged Nuvia

IMAC resin to the column. This is equivalent to ~100 µl of a

packed resin bed.

4. Remove storage solution by centrifugation. Centrifuge at

1,000 x g for 15 sec to pack resin.

5. Wash column with at least 5 column volumes (or ~500 µl) of

distilled water. Centrifuge at 1,000 x g for 15 sec to pack resin.

6. If using Ni-charged resin, equilibrate the column with at least

5 column volumes of binding buffer. The column is now ready

for separation.

Nuvia IMAC Ni-Charged Resin 15

Page 20

Section 6

Immobilizing Metal Ions

Efficacy of protein binding by IMAC depends on two factors: the

number of available histidine, cysteine, and tryptophan residues

on a protein’s surface, and the number of coordination sites on

the immobilized ion that are not occupied by the chelating ligand

and thus available to bind amino acid residues. Nuvia™ IMAC resin

uses a quadridentate ligand (NTA), which leaves two of the six

coordination sites on the nickel ion accessible to the protein of

interest.

Although the most commonly used ion is Ni2+, protein selectivity

may be increased through the choice of metal ion used,

understanding of the structure of the metal-chelate complex

and its interaction with the protein, knowledge of the protein’s

expression level, and the ligand density of the IMAC adsorbent.

While high ligand density usually means higher binding capacity, it

can also translate into lower target protein selectivity. Nuvia IMAC

resin, based on the polymeric UNOsphere™ technology, has been

specifically formulated with an optimal number of chelating ligands

on the resin’s surface and pores to deliver both good capacity and

excellent protein purity.

1. Equilibrate the column with 5 column volumes of 50 mM

sodium acetate, 0.3 M NaCl, pH 4.0.

2. After slurry packing is complete (see Sections 4 and/or 5), the

column is ready for the removal or addition of metal ions.

3. If necessary, strip any metal ions by washing with 10 column

volumes of 50 mM sodium phosphate, 0.3 M NaCl, and

0.05–0.5 M EDTA, pH 7.5.

4. Make a 0.1–0.3 M solution of the metal ion of choice. For best

results, the pH of the solution should be <7 (neutral to weakly

acidic).

5. Apply 3–5 column volumes of the metal ion solution.

6. Wash with 5 column volumes of 50 mM sodium acetate, 0.3 M

NaCl, pH 4.0. Remove excess ions by washing.

7. Wash with 10 column volumes of deionized water.

8. Equilibrate with at least 5 column volumes of starting buffer; for

example, 50 mM sodium phosphate, 0.3 M NaCl, pH 7–8. The

column is now ready for separation.

16 Nuvia IMAC Ni-Charged Resin

Page 21

Section 7

Medium-Pressure Column Purification

of Histidine-Tagged Proteins

For this guideline, the sample is applied to a packed column and

the proteins are eluted using a high concentration of imidazole.

The guideline does not optimize the imidazole concentration, but

instead provides for fast capture of the target protein that may be

used as a quick check for protein expression levels. Higher levels

of purity are achievable by optimizing imidazole concentrations,

which improves protein separation. See Section 8, MediumColumn Purification – Using an Imidazole Gradient to Determine

Optimal Purification of Histidine-Tagged Proteins.

Materials

1. Reagents

Binding buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• Low concentrations imidazole* (0–15 mM)

• Adjust to pH 8.0

Wash buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• Low concentrations of imidazole* (0–30 mM)

• Adjust to pH 8.0

Elution buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• Higher concentrations of imidazole* (250–500 mM)

• Adjust to pH 8.0

* For optimal protein purification results, it is crucial that the

imidazole concentrations in lysis, binding, and wash buffers, as

well as elution buffers, be empirically established. Determine

optimized conditions using a small amount of sample.

Nuvia IMAC Ni-Charged Resin 17

Page 22

2. Equipment

• IMAC column (as prepared in Section 4)

3. Biological Sample

• Clarified lysate

The binding capacity of the Nuvia™ IMAC resin is ~40 mg

histidine-tagged protein per ml resin. Larger amounts of

protein will require use of a larger column.

4. Additional Materials

• Medium-pressure chromatography system (such as

Bio-Rad’s BioLogic™ or NGC™ system)

• Equipment for determining total protein concentration

within the lysate

Method

1. Equilibrate the column with at least 5 column volumes of

binding buffer.

2. Add or dilute sample in binding buffer and load onto the

column using a desired flow rate.

The choice of binding buffer will vary based on the properties

of the sample to be purified. Sodium or potassium phosphate

is recommended as a general starting buffer; for example,

50 mM sodium phosphate, 300 mM NaCl, 5 mM imidazole,

pH 8.0. Binding of histidine-tagged protein on the Nuvia IMAC

resin is optimal in the pH range of 7–8.

The column may be run at flow rates up to 500 cm/hr. Higher

binding of histidine-tagged proteins will be achieved at lower

flow rates. Average binding capacity of the Nuvia IMAC resin is

approximately 40 mg histidine-tagged protein/ml resin.

3. Collect fractions.

These fractions represent unbound proteins.

4. Wash the resin with at least 5 column volumes of wash buffer

to remove unbound sample.

Wash out remaining unbound solutes. Repeat wash steps as

necessary for the A

to be at or near baseline.

280

18 Nuvia IMAC Ni-Charged Resin

Page 23

5. Collect fractions from wash steps.

Pool recovered unbound proteins with fractions collected in

step 3.

6. Elute bound proteins with 5 column volumes of elution buffer.

Collect 2 ml fractions, or approximately 0.2 column volumes

each.

The choice of elution buffer will vary depending on the

procedure used. For example, a range of imidazole

concentrations (100–500 mM) may be used to elute bound

protein from the Nuvia IMAC resin.

7. Repeat elution steps 2 to 4 more times.

Save the eluates for further analysis (A

, SDS-PAGE, ELISA,

280

etc.).

IMAC Purification under Denaturing Conditions

In some cases it may be necessary to use denaturants such as

urea to solubilize inclusion bodies, which are not generally in their

native conformation. To perform this, up to 8 M urea (or 6 M

guanidine HCl) may be used in the binding, wash, and elution

buffers listed above. Elution is still achieved by increasing the

imidazole concentration.

Note: If using guanidine HCl (GuHCl), it must be removed from

purified samples prior to loading onto SDS-PAGE gels to prevent

precipitation. Proteins that have been lysed and adsorbed onto

the column with guanidine HCl may be washed and eluted with a

urea-based buffer.

Often the protein can be restored to its native form. To do this, the

denaturant used to lyse and purify the sample must be removed

using dilution, dialysis, or size exclusion chromatography.

Renaturation of the protein while it is still bound to the IMAC

column is a good alternative and offers several advantages.

Aggregation may be kept to a minimum if the protein refolds on the

column when the denaturant is removed. Higher concentrations of

the refolded protein may therefore be collected. Guidelines for

on-column renaturation are suggested on the following page.

Nuvia IMAC Ni-Charged Resin 19

Page 24

Materials for On-Column Renaturation

1. Reagents

Refolding buffer

• 20 mM sodium phosphate (NaH2PO4) (pH 8.0)

• 20 mM imidazole

• 300 mM NaCl

• 1 mM β-mercaptoethanol

Urea binding buffer (refolding buffer with 8 M urea)

Phosphate elution buffer (with high imidazole)

• 20 mM sodium phosphate (NaH2PO4) (pH 8.0)

• 500 mM imidazole

• 300 mM NaCl

• 1 mM β-mercaptoethanol

Note: The β-mercaptoethanol should be added to solutions

only immediately before use.

Method for On-Column Renaturation

1. Wash the column containing the bound protein with 10 column

volumes of urea binding buffer.

2. Apply a linear gradient from 100% urea-binding buffer to 100%

refolding buffer over 60 min at 0.5 ml/min. Refolding is initiated

by a descending gradient from 8 to 0 M urea.

3. Apply a linear gradient from 100% refolding buffer to 100%

phosphate elution buffer with high imidazole.

4. If necessary, add another chromatography step.

Size exclusion chromatography may be a good choice

because aggregates of unrefolded protein can be removed

and the buffer composition of the purified material can be

changed simultaneously.

20 Nuvia IMAC Ni-Charged Resin

Page 25

Section 8

Medium-Pressure Column Purification — Using

an Imidazole Gradient to Determine Optimal

Purification of Histidine-Tagged Proteins

Gradient elution tests are useful because they do not require

optimization of imidazole concentrations, but instead may be

used to determine suitable imidazole concentrations for wash and

elution steps. Once a suitable concentration has been determined

using a gradient elution such as the one outlined below, often an

easier protocol using step elution may be used for subsequent

purification of larger sample volumes.

With step elution, the protein can be collected in smaller

volumes and at higher concentrations. Using this protocol, the

concentration of imidazole that elutes the target protein may be

calculated and used for a step protocol.

This protocol requires the use of a gradient mixer coupled to a

chromatography system such as Bio-Rad’s NGC™ system to

establish a linear gradient.

Materials

1. Reagents

Binding buffer

• 20 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• 20 mM imidazole

• Adjust to pH 8.0

Elution buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• 500 mM imidazole

• Adjust to pH 8.0

2. Equipment

• Chromatography system with dual pump and gradient

capability

• Fraction collector

• IMAC column (as prepared in Section 4)

Nuvia IMAC Ni-Charged Resin 21

Page 26

3. Biological Sample

• Clarified lysate

Note: Keep the sample as small as possible during

optimization of binding and elution conditions.

4. Additional Materials

• Equipment for assessing protein purity and recovering of

the histidine-tagged protein

Method

Part 1: Optimizing the Imidazole Concentration

1. Purge the entire flow path of the chromatography system with

water according to the manufacturer’s instructions.

Connect the column and wash it with 10 column volumes

of water. Disconnect the column either by valve switching

or manually. Purge the flow path before the column with

elution buffer from inlet B and, with the column offline, then

with binding buffer from inlet A. Purge the entire system with

binding buffer. Reconnect the column to the system.

2. Equilibrate the column with 10 column volumes of binding

buffer (0%B).

3. Begin collecting fractions of 1 column volume.

If a 1 ml IMAC column is used, 1 ml fractions are

recommended. For larger columns, reduce the fractions

collected to amounts from 0.2 to 0.5 column volumes.

4. Load sample and collect the flowthrough in fractions

appropriate to the size of the column (as recommended

above).

Note: Monitor the backpressure while sample is being applied.

If the sample is insufficiently clarified, backpressure will

increase.

5. Wash the unbound material with 10 column volumes of

binding buffer (0%B).

6. Elute the sample with a linear gradient of 0–50% elution buffer.

7. Wash the column with 100% of the elution buffer for 5 column

volumes.

22 Nuvia IMAC Ni-Charged Resin

Page 27

8. Equilibrate the column with 10 column volumes of binding

buffer (0%B). Stop collecting fractions.

9. Identify the fractions that contain the histidine-tagged protein

using an activity assay (such as one of Bio-Rad’s protein assay

kits), UV absorbance, SDS-PAGE, or western blot analysis

with antihistidine antibodies or antibodies specific to the target

protein.

10. Calculate the concentration of imidazole that corresponds to

the elution peak of the histidine-tagged protein.

Note: The delay due to column volume and the tubing in

the chromatography system need to be considered when

comparing the actual gradient trace to the programmed

gradient.

11. Based on calculated imidazole concentration, a stepwise

experiment may now be designed.

The following tips are useful to keep in mind when designing the

experiment:

• Maintain the concentration of imidazole in the binding

(also called equilibration) buffer at 20 mM. If large amounts

of contaminants are also adsorbed onto the resin, the

concentration of imidazole in the sample and equilibration

buffer may be increased. This may reduce the overall amount

of target protein bound and should be carried out with care.

However, it will also increase the column’s binding capacity

for the target protein due to the reduction in contaminating

proteins

• Include a wash step with an imidazole concentration slightly

lower than the concentration necessary to elute the target

protein. This will increase purity by removing unbound

contaminants without eluting the bound histidine-tagged

protein. The optimized wash step should include 50 mM

sodium phosphate, 0.3 M NaCl, and an appropriate

concentration of imidazole

• The elution buffer should contain a concentration of imidazole

greater than the calculated concentration corresponding to the

eluted peak of target protein

• Perform a trial run

Nuvia IMAC Ni-Charged Resin 23

Page 28

Part 2: Using an Optimized Imidazole Concentration for

Purification

1. Prepare 500 ml binding buffer and 500 ml elution buffer for a 5

ml column.

Purge the pumps with the fresh buffers. Adjust buffer volumes

for larger scale purifications.

2. Equilibrate the column with 10 column volumes of

equilibration/binding buffer.

3. Begin collecting fractions.

If a 1 ml IMAC column is used, 1 ml fractions are

recommended. For larger columns, reduce the fractions

collected to amounts ranging from 0.2 to 0.5 column volumes.

4. Load sample and collect the flowthrough in fractions

appropriate to the size of the column, as recommended

above.

Note: Monitor the backpressure while the sample is

being applied. If the sample is insufficiently clarified, the

backpressure will increase.

5. Wash the column with a minimum of 5 column volumes of

binding buffer to remove unbound contaminants.

6. Wash the column with a minimum of 5 column volumes of

binding or starting buffer that contains imidazole in a quantity

that will not elute the target protein.

7. Elute the histidine-tagged protein with 5 column volumes of

elution buffer with an optimized imidazole concentration.

8. Wash the column with 5 column volumes of elution buffer.

Stop collecting fractions.

9. Re-equilibrate the column with 10 column volumes of

equilibration (binding) buffer.

10. Assess the purity and recovery of the target protein using an

activity assay (such as one of Bio-Rad’s protein assay kits),

UV absorbance, SDS-PAGE, or western blot analysis with

antihistidine antibodies or antibodies specific to the target

protein.

24 Nuvia IMAC Ni-Charged Resin

Page 29

Section 9

Sample Preparation–Sized Spin-Column Purification

of Histidine-Tagged Proteins

Materials

1. Reagents

Binding/wash buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• 5 mM imidazole

• Adjust to pH 8.0

Optimized wash buffer with imidazole (optional, see Section 8)

• A wash buffer containing slightly less imidazole than

necessary to elute the target protein may be used

to increase the stringency of the wash step. Refer to

Section 8, Medium-Pressure Column Purification —

Using an Imidazole Gradient to Determine Optimal

Purification of Histidine-Tagged Proteins

• Once the concentration of imidazole in the wash

step is determined using medium-pressure column

chromatography, a stepwise elution step may be

carried out as indicated in this protocol

Elution buffer

• 50 mM sodium phosphate (NaH2PO4)

• 300 mM NaCl

• 500 mM imidazole

• Adjust to pH 8.0

Note: If necessary, up to 8 M urea may be added to these

buffers in order to solubilize proteins in inclusion bodies. See

Section 7 for more information.

2. Equipment

• Sample preparation–sized IMAC spin column (as prepared

in Section 5) (for example, Micro Bio-Spin™ columns, cat.

#732-6204)

• Plasticware, 2 ml capped and 2 ml capless tubes

Nuvia IMAC Ni-Charged Resin 25

Page 30

3. Biological Sample

• Clarified lysate

The binding capacity of Nuvia™ IMAC resin is ≥40 mg histidinetagged protein per ml resin. Larger amounts of protein will

require a larger column

4. Additional Materials

• Equipment for assessing protein purity and recovery of the

histidine-tagged protein

Method

Reserve a small amount of lysate prior to loading sample onto

the column. This will serve as sample for the lysate lane for later

analysis with, for example, SDS-PAGE.

Part 1: Binding the Sample

1. Start with a prepacked spin column, charged with the metal

ion of choice.

See Section 5, Column Packing — Sample Preparation–Sized

Columns for protocol.

2. Place prepacked spin column in an appropriate spin collection

tube.

3. Pre-equilibrate the spin column with 5 column volumes of

binding buffer.

The choice of binding buffer will vary based on the properties

of the sample to be purified. Potassium phosphate and

sodium phosphate are recommended as general starting

buffers; for example, 50 mM sodium or potassium phosphate,

300 mM NaCl, pH 8.0. Binding of histidine-tagged protein on

the Nuvia™ IMAC resin is optimal in the pH range of 7–8.

4. Add an appropriate amount of lysate (≤0.5 ml) to the micro

spin column.

5. Mix by pipetting up and down 5 times.

Incubate for up to 5 min in micro spin column.

6. Centrifuge at 1,000 x g for 1 min.

Remove the unbound proteins by centrifuging.

26 Nuvia IMAC Ni-Charged Resin

Page 31

Part 2: Washing the Resin

1. Insert micro spin column into new collection vessel.

2. Wash the resin with at least 5 column volumes of binding

buffer containing imidazole.

Pipet up and down at least 5 times.

Note: If previously determined, you may use an optimized

concentration of imidazole that is slightly less than the

concentration necessary to elute the target protein. See

Section 8.

3. Centrifuge at 1,000 x g for 1 min.

Remove remaining unbound proteins by centrifuging. The

wash step can be repeated if necessary.

Part 3: Eluting the Histidine-Tagged Protein

1. Insert micro spin column into a new, clean collection vessel.

2. Elute bound proteins with 5 column volumes of elution buffer.

Pipet up and down at least 5 times and incubate for up to

5 min.

The choice of elution buffer will vary depending on the

procedure used. For example, a range of imidazole

concentrations (150–500 mM) may be used to elute bound

protein from the Nuvia IMAC resin.

3. Analyze fractions from above steps by A

, SDS-PAGE,

280

ELISA, etc.

Nuvia IMAC Ni-Charged Resin 27

Page 32

Section 10

Regenerating, Cleaning, Sanitizing, and Storage

Nuvia™ IMAC columns are well-suited for reuse. The polymeric

nature and open pore structure of the resin allow the column to be

run at high flow rates during regeneration, cleaning, and sanitizing

steps. Protein separations are unaffected, even after numerous

cycles, as reproducibility is extremely high.

Unless otherwise stated, the following steps may be carried out at

2 ml/min.

Regenerating the Medium

Regeneration cleans the medium adequately to start the next

cycle. In general, IMAC columns may be used a number of

times before they need to be recharged with metal ions. When it

becomes necessary, regenerate metal-charged Nuvia IMAC resins

by first stripping with an EDTA solution. Wash the column with 10

column volumes of 20 mM sodium phosphate, up to 1 M NaCl,

and 0.2 M EDTA, pH 7.4. Ensure that residual EDTA is completely

removed from the column by washing it with 3–5 column volumes

of binding buffer followed by 3–5 column volumes of distilled water.

Recharge the IMAC resin as recommended in Section 6,

Immobilizing Metal Ions, or proceed with cleaning-in-place

measures (below).

Cleaning in Place

A column used to purify protein from cell extract usually contains

some soluble substances and cell debris that are nonspecifically

adsorbed onto the matrix. Cleaning in place eliminates material

not removed by regeneration and prevents progressive buildup of

contaminants. If the column is to be reused, these contaminants

should be cleaned from the column if they were not completely

removed during the sample clarification steps.

The following steps may be followed to clean IMAC columns. This

protocol also includes a regeneration step. For optimal results, the

column can be run at 2–5 ml/min.

28 Nuvia IMAC Ni-Charged Resin

Page 33

1. Strip metal ions.

Wash with 10 column volumes of 50 mM sodium phosphate,

0.3 M NaCl, and 0.05–0.5 M EDTA, pH 7.5.

2. Wash the column with one of the following solutions at

2 ml/min:

a. 1% acetic acid

• This solution may be used as a cleaning, sanitizing,

and storage solution with Nuvia IMAC resins

• 10–15 min exposure time

• Rinse with 10 column volumes of distilled water

b. 2 M NaCl (removes ionic contaminants)

• 10–15 min exposure time

• Rinse with 10 column volumes of distilled water

c. 1 M NaOH up to 3 hr (removes precipitated, hydrophobic,

and lipoproteins)

• Exposure time is usually 1–3 hr

• Rinse with 10 column volumes of distilled water

d. 70% ethanol or 30% isopropyl alcohol (removes

precipitated, hydrophobic, and lipoproteins)

• 15–20 min exposure time

• Alternatively, use 0–30% gradient isopropyl alcohol

over 5 column volumes, followed by 2 column

volumes 30% isopropyl alcohol

• Rinse with 10 column volumes of distilled water

3. Remove cleaning solution(s) from column by rinsing with 10

column volumes of binding buffer.

• Rinse column with 50 mM sodium phosphate,

0.3 M NaCl, pH 8

• Ensure the eluate is ~pH 8 and the UV signal has returned

to baseline

4. Recharge the column with metal ion of choice.

• Refer to Section 6, Immobilizing Metal Ions

Nuvia IMAC Ni-Charged Resin 29

Page 34

Sanitization

Sanitization inactivates microorganisms and prevents buildup of

endotoxins. For optimal results, the column should be run at

300 cm/hr.

The column may be washed with the following solution:

• 1 M NaOH

Rinse solution from column with 3–5 column volumes of distilled

water. Re-equilibrate the column with 3–5 column volumes of

binding buffer.

Storage

Nuvia IMAC resin is stable at room temperature across a broad

pH range (2–14). The medium may also be stored in either of the

following solutions:

• 2% benzyl alcohol

• 20% ethanol

30 Nuvia IMAC Ni-Charged Resin

Page 35

Section 11

Troubleshooting Guide

Problem Possible Cause Solution

Sample is too viscous High concentration

of host nucleic acids

in lysate

Insufficient amount of

homogenization

buffer

Viscosity of extract can be reduced by

adding Benzonase nuclease (1.7 U/ml)

with 1 mM MgCl2 to fragment bacterial

DNA. Incubate on ice for 15 min

Dilute sample by adding more

homogenization buffer

Sample application

causes column

to clog

No protein is eluted Expression of target

Insufficient

clarification of sample

protein in extract is

very low and is not

found in the eluate

Target protein is

found in inclusion

bodies or possible

insufficient lysis

Target protein

is found in the

flowthrough

Prevent cell debris from clogging the

column by increasing the centrifugation

speed or filtering the sample

Check expression level of protein by

estimating the amount in the extract,

flowthrough, eluted fraction, and pellet

upon centrifugation. Use western blotting

with anti-6x histidine antibodies, target

protein-specific antibodies, ELISA, or

enzyme activity determination

Apply larger sample volume

Minimize contact with hydrophobic

surfaces (that is, polystyrene tubes).

Proteins at low concentration may bind to

the surface of the tube

Increase intensity/duration of disruption

and homogenization

If protein is insoluble, use 6 M guanidine

HCl or 8 M urea to lyse denatured proteins

(see Sections 3, and 7)

Reduce imidazole concentration in

sample, binding, and wash buffers.

An imidazole gradient may be used to

determine optimal amounts for wash and

elution conditions

Check pH levels of sample. A decrease in

pH may result during the homogenization

step or during growth of the culture

medium. Adjust pH to 7–8

The histidine tag may not be accessible.

Use denaturing conditions to purify protein

or reclone the plasmid construct with the

histidine-tagged sequence placed at the

opposite terminus

Nuvia IMAC Ni-Charged Resin 31

Page 36

Problem Possible Cause Solution

No protein is eluted

(continued from

previous page)

Protein precipitates

during purification

Poor recovery

of target protein

Histidine-tagged

protein is not pure

Target protein is found

in the flowthrough

(continued from

previous page)

Elution conditions

are too mild or

protein may be in

an aggregated or

multimer form

Temperature is too

low

Aggregate forms

Protein is found in the

flowthrough

Binding capacity of

the column has been

exceeded

Target protein was

not detected in the

flowthrough

Strong nonspecific

adsorption of the

target protein to the

matrix

Contaminants elute

with target protein

Strongly bound

contaminants elute

with protein

Association of

contaminating

proteins with target

protein via disulfide

bonds

Proteolytic cleavage during fermentation

or purification has caused the histidine tag

to be removed. Add protease inhibitors or

make a new construct with histidine tag

attached to other terminus

Elute with pH or imidazole step elution

Perform the purification at room

temperature

Add solubilization agents to samples and/

or buffers: 0.1% Triton X-100, Tween 20,

20 mM β-mercaptoethanol and ≤20%

glycerol to maintain protein solubility

See recommendations in No protein is

eluted section

Increase the column size or reduce the

sample volume application

Capillary sample loop is too small

Reduce hydrophobic adsorption by

including detergents or organic solvents,

or by increasing the concentration of NaCl

Make binding and wash steps more

stringent. Include 10–20 mM imidazole in

binding and wash buffers

Prolong the wash step containing

imidazole

Column is too large; reduce amount of

Nuvia™ IMAC resin used

Very high concentrations of imidazole

will cause strongly bound contaminants

to elute as well. Reduce the imidazole

concentration during the elution

Include ≤30 mM β-mercaptoethanol.

Exercise caution if using DTT

32 Nuvia IMAC Ni-Charged Resin

Page 37

Problem Possible Cause Solution

Histidine-tagged

protein is not pure

(continued from

previous page)

Association between

the histidine-tagged

protein and protein

contaminant

Potential degradation

of fusion protein by

proteases

Contaminants exhibit

similar affinity to target

protein

Add nonionic detergent or alcohol (that

is, ≤2% Triton X-100, 2% Tween 20, or

≤20% glycerol) to reduce hydrophobic

interactions. Concentration of NaCl may

be increased to minimize electrostatic

interactions

Include 1 mM PMSF or other protease

inhibitor in lysis buffer to reduce partial

degradation

Add a chromatography step; that is, ion

exchange, hydrophobic interaction, or

size exclusion

Nuvia IMAC Ni-Charged Resin 33

Page 38

Section 12

Ordering Information

Nuvia IMAC™ Ni-Charged Resin

Catalog # Description

780-0800 Nuvia IMAC Ni-Charged Resin, 25 ml bottle

780-0801 Nuvia IMAC Ni-Charged Resin, 100 ml bottle

780-0802 Nuvia IMAC Ni-Charged Resin, 500 ml bottle

Bio-Scale™ Mini Nuvia™ IMAC Ni-Charged Cartridges

Catalog # Description

780-0811 Bio-Scale Mini Nuvia IMAC Ni-Charged Cartridge,

1 x 5 ml column

780-0812 Bio-Scale Mini Nuvia IMAC Ni-Charged Cartridge,

5 x 5 ml columns

Section 13

References

Hochuli E (1988). Large-scale chromatography of recombinant

proteins, J Chromatogr 444, 293–302.

Porath J et al. (1975). Metal chelate affinity chromatography, a new

approach to protein fractionation. Nature 258, 598–599.

Section 14

Legal Notices

Triton is a trademark of Union Carbide. Tween is a trademark of ICI

Americas, Inc. Benzonase is a trademark of Merck KGaA Corp

34 Nuvia IMAC Ni-Charged Resin

Page 39

Page 40

Bio-Rad

Laboratories, Inc.

Life Science

Group

Web site ww w.bio-rad.com USA 800 424 6723

Australia 61 2 9914 2800 Austria 01 877 89 01 Belgium 09 385 55 11

Brazi l 55 11 3065 7550 Canada 905 364 3435 China 86 21 6169 8500

Czech Republic 420 241 430 532 Denma rk 44 52 10 00

Finland 09 804 22 00 France 01 47 95 69 65 Ger many 089 31 884 0

Greece 30 210 9532 220 Hon g Kong 852 2789 330 0

Hungary 36 1 459 6100 India 91 124 4029300 Israel 03 963 6050

Italy 39 02 2160 91 Japan 81 3 6361 7000 Kore a 82 2 347 3 4460

Mexico 52 5 55 488 7670 The Netherlands 0318 540666

New Zealand 64 9 415 2280 Norway 23 38 41 30

Poland 48 22 331 99 99 Portugal 351 21 472 7700

Russia 7 495 721 14 04 Singapore 65 6415 3188

South Africa 27 861 246 723 Spain 3 4 91 590 5200

Sweden 08 555 1270 0 Switzerland 026 674 55 05

Taiwan 88 6 2 2578 7189 Thailand 1800 88 22 88

United Kingdom 020 8328 200 0

Sig 121310044307 Rev A US/EG

Loading...

Loading...