BERTAZZONI

INSTALLATION AND USER MANUAL

BUILT-IN GAS HOBS

MODEL P93V (METAL)

MODEL P94GV (GLASS)

INSTRUCTIONS D’INSTALLATION ET D’UTILISATION

PLAQUES DE CUISSON ENCASTRABLES AU GAZ

TYPE P93V (MÉTAL)

TYPE P94GV (VERRE)

EN

FR

3100419

WWW.BERTAZZONI.COM

/ Contents

CONTENTS

EN

INTRODUCTION AND WARNINGS _________________________________________________

MANUFACTURER LIABILITY ____________________________________________________

ENVIRONMENTAL PROTECTION _________________________________________________

GENERAL SAFETY INSTRUCTIONS_______________________________________________

USAGE INSTRUCTIONS ________________________________________________________

APPLIANCE DATA PLATE ______________________________________________________

PLASTIC PACKAGING _________________________________________________________

TECHNICAL INSTALLATION INSTRUCTIONS_________________________________________

HOB INSTALLATION __________________________________________________________

IMPORTANT INFORMATION

INSTALLING THE HOB ABOVE AN OVEN _________________________________________

INSTALLING THE HOB ABOVE A CUPBOARD OR DRAWERS _________________________

HOB FASTENING________________________________________________________________

ROOM VENTILATION ___________________________________________________________

LOCATION AND VENTILATION____________________________________________________

CONNECTING THE APPLIANCE TO THE GAS SUPPLY_______________________________

PRECAUTIONS WHEN USING THE PRODUCT WITH LPG (BUTANE/PROPANE)

GAS CONVERSION ____________________________________________________________

ELECTRICAL CONNECTION ______________________________________________________

MAINTENANCE ________________________________________________________________

REPLACING COMPONENTS ____________________________________________________

______________________________________________________

___________

4

4

4

5

5

5

5

6

6

6

7

7

8

8

9

9

10

11

12

12

12

HOB DESCRIPTION _____________________________________________________________

USING THE APPLIANCE _________________________________________________________

BURNERS AND GRATES ________________________________________________________

USING THE BURNERS _________________________________________________________

SAFETY SYSTEM ______________________________________________________________

MANUAL IGNITION _____________________________________________________________

ACCESSORIES ________________________________________________________________

CLEANING THE APPLIANCE_____________________________________________________

TROUBLESHOOTING___________________________________________________________

13

14

14

14

15

15

15

15

16

2

/ From the desk of our president

FROM THE DESK OF OUR PRESIDENT

Dear new owner of a Bertazzoni appliance,

I want to thank you for choosing one of our beautiful products for your home.

My family started manufacturing kitchen appliances in Italy in 1882, building a

reputation for quality of engineering and passion for good food.

EN

Today, our products stand out because of their unique blend of authentic Italian

design and superior appliance technology. It is our mission to make products

that function perfectly and bring joy to their owners.

By making beautiful products we respond to our customers’ fl air for good design.

By making them versatile and easy-to-use, cooking with Bertazzoni becomes a

real pleasure.

This manual will help you learn to use and care for your Bertazzoni appliance in

the safest and most eff ective way, so that it can give you the highest satisfaction

for years to come.

Enjoy!

Paolo Bertazzoni

President

3

/ Introduction

INTRODUCTION

EN

READ THESE INSTRUCTIONS CAREFULLY

BEFORE INSTALLING AND USING THE

APPLIANCE.

These instructions are valid only for the countries

whose identifying symbols are shown on the

appliance label.

The manufacturer shall not be held liable for

property damage or personal injury resulting

from incorrect installation or improper use of the

appliance.

The manufacturer shall also not be held liable for

any imprecisions due to printing or transcription

errors in this booklet.

The appearance of the fi gures included herein is

only for guidance.

The manufacturer reserves the right to make

modifi cations to its products when it considers this

necessary or benefi cial, however the essential

safety and performance characters shall not be

aff ected.

THIS APPLIANCE IS DESIGNED FOR NONPROFESSIONAL, DOMESTIC USE.

This user manual is an integral part of the appliance

and must therefore be kept in its entirety in a place

accessible to the user for the entire lifetime of the

appliance.

Read this manual before using the appliance.

MANUFACTURER LIABILITY

The manufacturer shall bear no liability for

property damage or personal injury due to:

• Use of the appliance other than that specifi ed

• Failure to comply with the instructions in the

user manual

• Tampering with/unauthorised modifi cations to

any part of the appliance

• The use of non-original spare parts.

• This appliance is intended for cooking food in

the home environment. Any other use shall be

considered improper.

• The appliance is not designed to operate

with external timers or with remote-control

systems.

ENVIRONMENTAL PROTECTION

Please think of the environment

when disposing of the packaging.

This appliance is marked in accordance with

European Community Directive 2012/19/EU

on waste electrical and electronic equipment

(WEEE).

This directive defi nes the standards for the

collection and recycling of waste electrical and

electronic equipment applicable throughout the

European Union.

The packaging of this appliance is composed of

the elements strictly necessary to ensure suffi cient

protection during transport. The packaging

materials are completely recyclable, thus reducing

their environmental impact. Please help to protect

the environment by taking the following tips into

consideration:

• Sort the packaging materials for recycling

• Render the old appliance unusable before

taking it to the collection facility Ask the

competent local authorities for details of the

nearest recycling centre you can take the old

appliance to.

• Do not dispose of used oil down the drain.

Keep it in a closed container and take it to a

recycling centre; if this is not possible, dispose

of it in mixed waste (in this manner it will be

disposed of at a monitored facility – although

this is not the best solution, it at least prevents

contamination of the sewage/water systems).

WARNING: The

a declaration, under the manufacturer’s full

responsibility, that the product complies with

all European health, safety and environmental

requirements laid out in the legislation covering

this product type.

4

marking on this product is

INTRODUCTION

/ Introduction

GENERAL SAFETY INSTRUCTIONS

• During use, the appliance and its accessible

parts become very hot.

• Never touch the heating elements during use.

• Keep children under the age of eight at a

safe distance unless they are constantly

supervised.

• Children must not play with the appliance.

• This appliance may only be used by children

over the age of eight, and by people with

reduced physical, sensory or mental capacity,

or lacking in experience in the use of electrical

appliances, provided that they are supervised

or instructed by adults who are responsible for

their safety.

• Never rest metal objects on the appliance

during use, as these could become red hot.

• Switch off the appliance after use.

• Never try to put out a fi re or fl ames with water:

Turn off the appliance and smother the fl ames

with a fi re blanket or other appropriate cover.

• Cleaning and maintenance must not be carried

out by children without adequate supervision.

• Ensure that hot surfaces are allowed to cool

before proceeding to clean the appliance.

• Have installation and servicing carried out

by qualifi ed personnel in compliance with

applicable standards and legislation. Do not

try to repair the appliance yourself or without

the assistance of a qualifi ed technician.

• Do not modify this appliance.

• Do not insert anything in the slots.

• Do not obstruct ventilation openings and heat

dispersal slots.

• If the power supply cable is damaged, contact

technical support immediately and they will

arrange for it to be replaced.

• Do not use abrasive or corrosive detergents

(e.g. scouring powders, stain removers and

metallic sponges) on glass parts.

• Do not sit on the appliance.

• Do not use steam jets to clean the appliance.

• Never leave objects on the cooking surface.

• Do not use the appliance as a space heater

for any reason.

• In the event of breakage or cracking of the

glass, shut off all burners immediately and

isolate the hob's gas and electricity supplies.

Contact technical support.

• Sudden and extreme changes in temperature

can cause the glass to break – never pour

cold liquids onto the hob.

• Damaged or unsuitably sized cookware which

overhangs the edges of the hob or is poorly

positioned can cause serious injury.

• Using the hob generates heat, moisture and

combustion products – keep the area well

ventilated during operation.

INSTRUCTIONS FOR USE

• Use fl at-based cookware.

• Position pans before lighting the burners.

• Never leave the hob when cooking foods with

oil and grease, as they can fl ash over and

ignite easily.

• Do not use aerosols in the vicinity of this

appliance while it is in use.

• Adjust the fl ame so that it does not protrude

beyond the edge of the pan base, as this could

damage the handles.

• Do not place pans directly on the burners.

• Ensure that the pan is centred over the burner.

APPLIANCE DATA PLATE

The data plate bears the technical data, serial

number and brand name of the appliance. The

appliance data plate is located on the lower

casing, and must not be removed at any time. A

copy is provided in this manual for reference.

PLASTIC PACKAGING

Danger of suff ocation

• Do not leave the packaging or any part thereof

unattended.

• Do not let children play with the plastic bags.

EN

5

/ Installation

T

S

TECHNICAL INSTALLATION INSTRUCTIONS

ECHNICAL INSTALLATION INSTRUCTION

EN

The installation, adjustments, transformations and

maintenance listed in this section must only be

performed by qualifi ed technicians (in accordance

with applicable legislation). Incorrect installation

can cause property damage and injury to people

or pets; the manufacturer shall not be held liable

in this event. The appliance’s automatic regulation

or safety devices may only be modifi ed by the

manufacturer or a duly authorised supplier during

the appliance’s lifetime.

Ensure all necessary PPE is used when

carrying out the installation

INSTALLING THE HOB

Ensure that the hob is fully present and undamaged

after removing all loose parts from their inner and

outer packaging. In the event of any uncertainty,

do not use the appliance and contact technical

support.

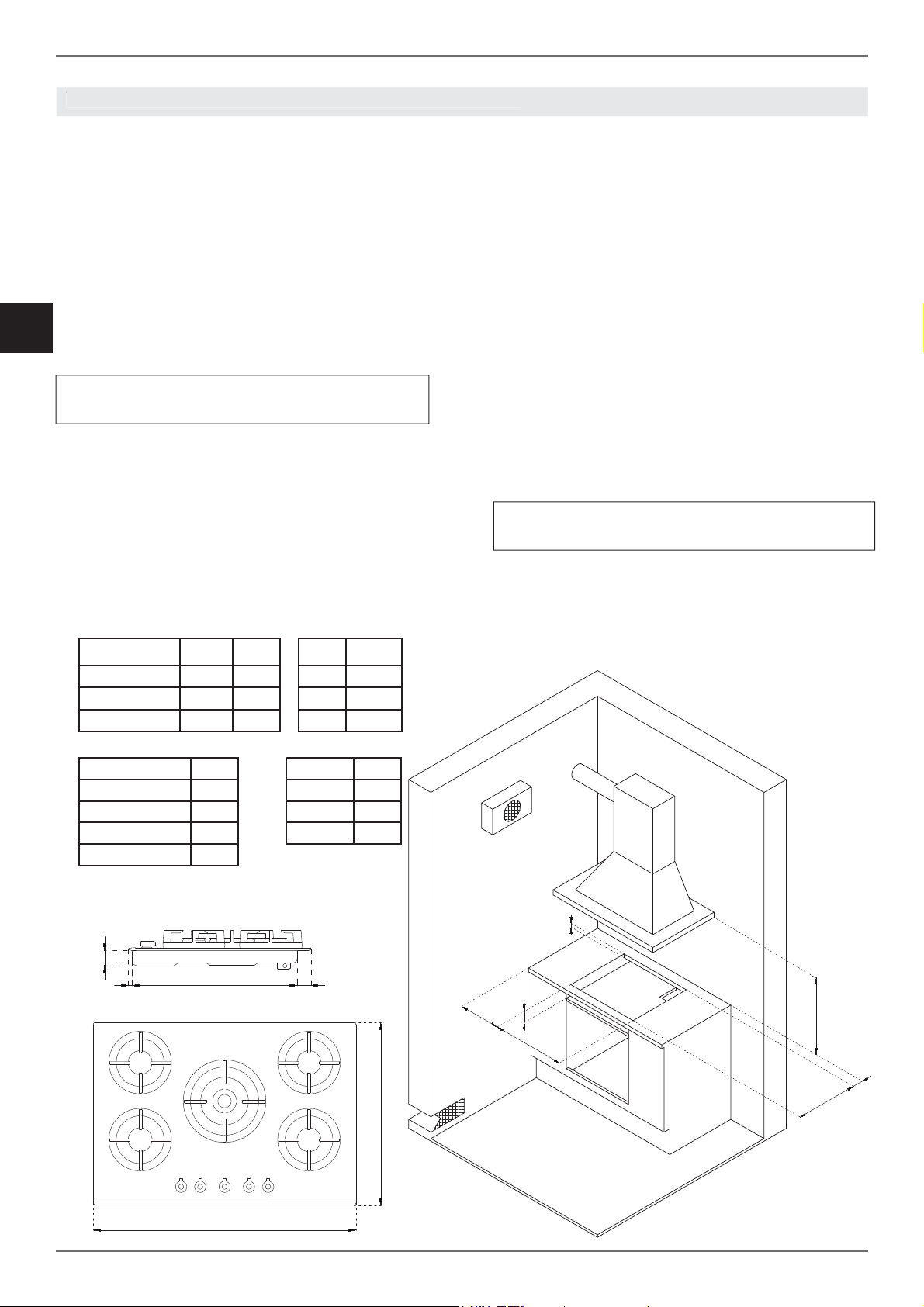

Make a cut-out in the worktop (see fi gure) in

accordance with the appliance dimensions given

in the table.

IMPORTANT INFORMATION

The hob may be installed between kitchen cabinets

or between a cabinet and a (masonry) wall. The

rear wall and surrounding surfaces must be able to

withstand temperatures of up to 90°C. To prevent

peeling of the melamine laminate typically used

on kitchen carcases, the glue bonding it must be

able to withstand temperatures of at least 150°C.

Installation of the appliance must be performed

in accordance with the provisions of applicable

legislation.

This domestic appliance is not connected to an

extraction device for combustion products. It

must therefore be connected in accordance with

the above-mentioned installation rules. Particular

attention must be paid to room ventilation

requirements.

The worktop must be able to withstand a maximum

temperature of 90°C (120°C for the 75cm version)

A (cm) B(cm) H(cm) L(cm)

60cm hob 56 48 60,5 52,5

75cm hob 56 48 75,5 52,5

90cm hob 85 48 89,3 52,5

C min (cm) 8,5 M (cm) 4,4

D min (cm) 3 N (cm) 1,1

E min (cm) 18 P (cm) 47,4

F min (cm) 70 Q (cm) 4

G min (cm) 8,5

M

NPQ

'

*

(

$

L

)

&

%

H

6

TECHNICAL INSTALLATION INSTRUCTIONS

T

S

ECHNICAL INSTALLATION INSTRUCTION

/ Installation

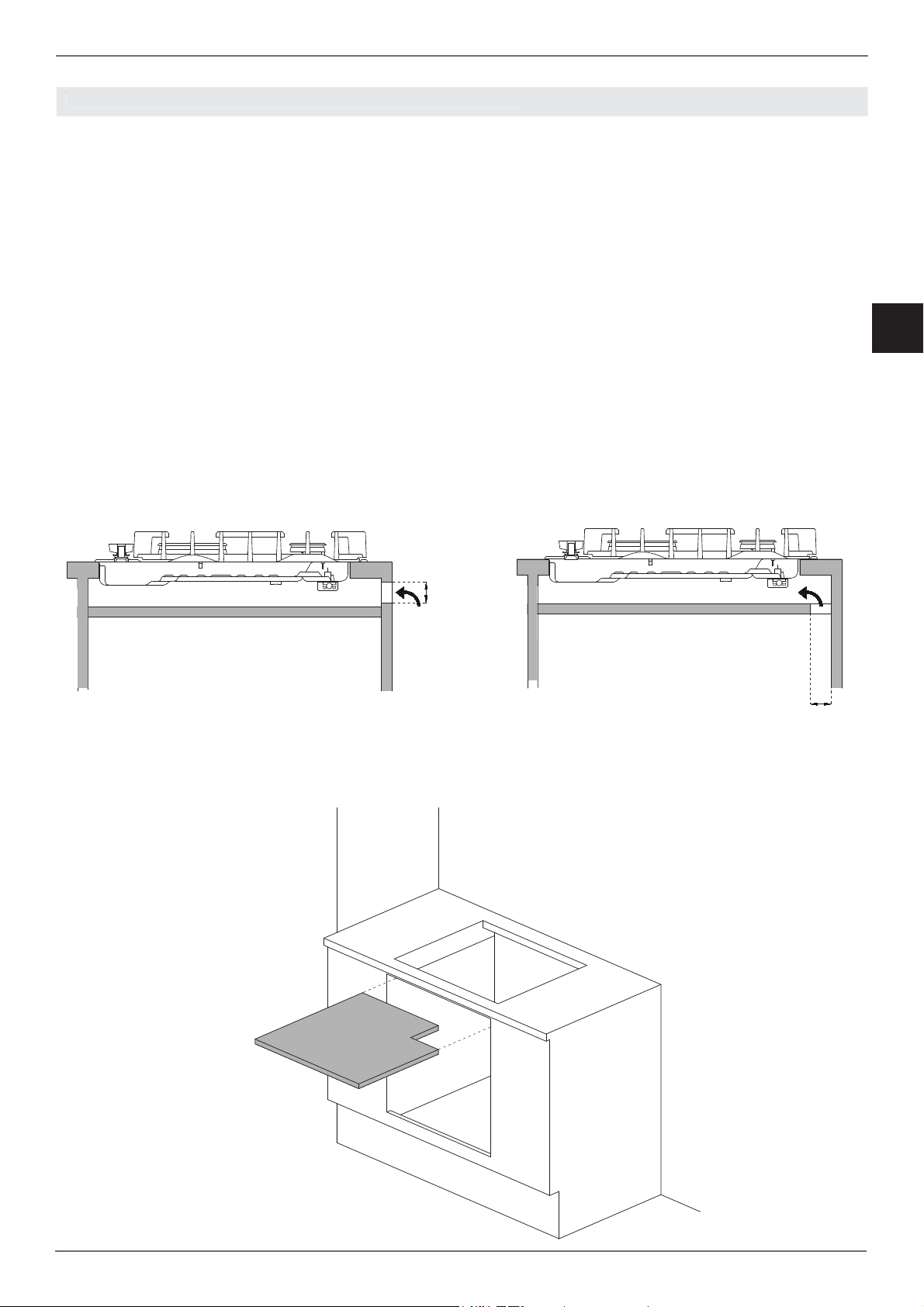

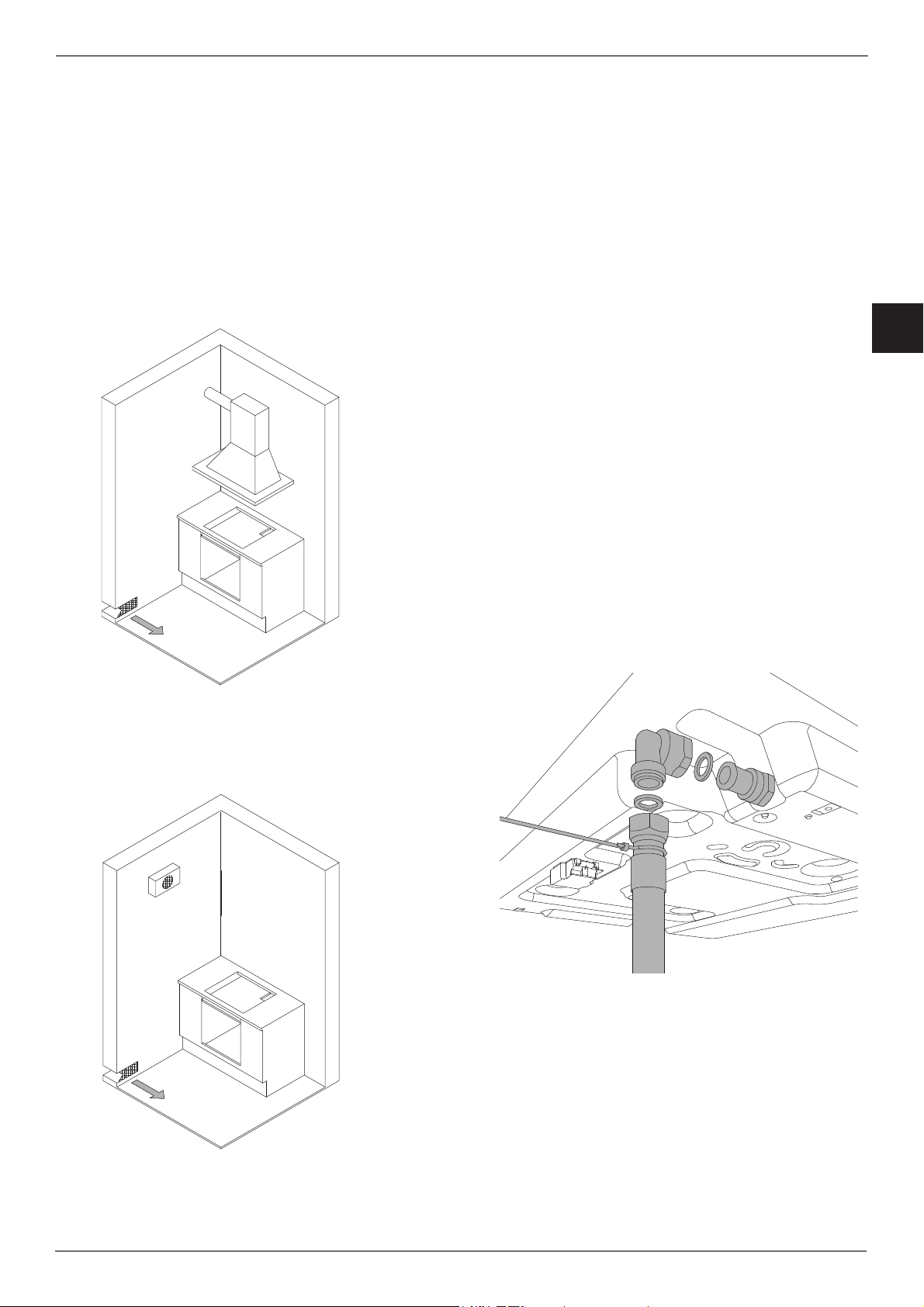

INSTALLING THE HOB ABOVE AN OVEN

The clearance between the hob and the

kitchen furniture or other installed appliances

must be enough to ensure suffi cient ventilation

and air discharge.

If installed above an oven, space must be

left between the bottom of the hob and the

top of the product installed below to allow for

ventilation of the entire compartment (see

fi gure).

The oven must be equipped with a cooling

device. The manufacturer shall bear no

liability in the event of the hob being installed

in combination with an oven from another

manufacturer.

40

INSTALLING THE HOB ABOVE A CUPBOARD

OR DRAWERS

The clearance between the hob and the

kitchen units must be enough to ensure

suffi cient ventilation and air discharge. If there

are other units/furniture (side walls, drawers,

etc.), dishwashers or fridges under the hob, a

double-layer wooden base must be installed

at least 20 mm from the bottom of the hob

to avoid any accidental contact. It must only

be possible to remove the double-layer base

using special tools.

EN

40

7

/ Installation / Ventilation

EN

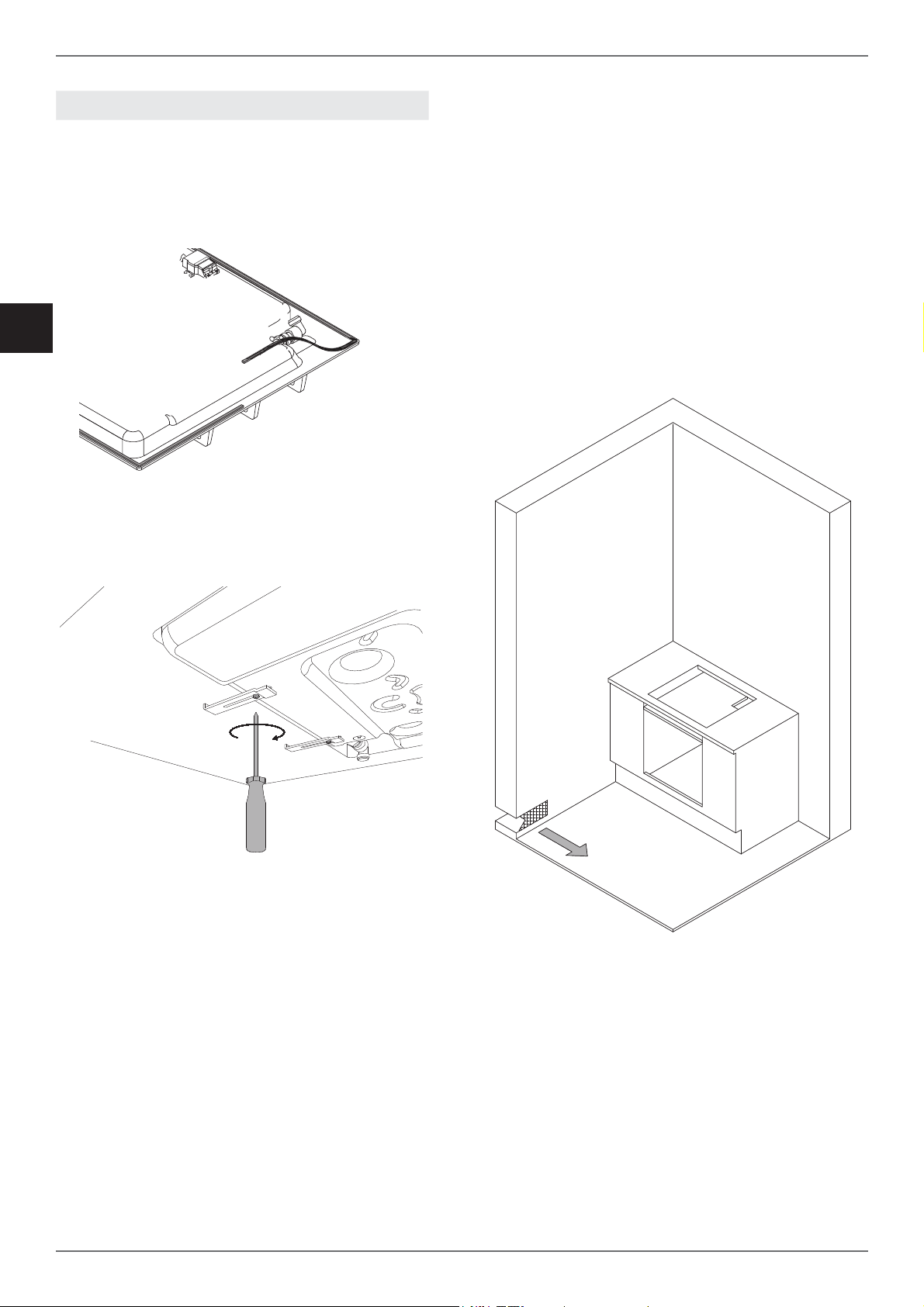

HOB FASTENING

In order to prevent accidental water ingress into

the unit below, the appliance is fi tted with a special

gasket.

1) Lay the sealing gasket out along the lower

edge of the built-in hob after cleaning the mating

surface.

2) Place the hob into the worktop cut-out.

3) To fasten the hob to the worktop, use a

screwdriver to install the four plates using the

corresponding screw in the bottom of the hob.

ROOM VENTILATION

In order to allow for correct appliance operation,

the room in which it is installed must have

continuous ventilation. The volume of the room

must be no less than 25 m³, and the quantity of

air required must be based on regular combustion

of the gas and the room ventilation. The natural

air fl ow must occur through permanent openings

in the wall of the room requiring ventilation; these

openings must lead directly outdoors, and must

have a minimum area of 100 cm².

Indirect ventilation via air taken from rooms

adjoining the one to be ventilated is also permitted,

as long as all applicable legislation is satisfi ed.

8

/ Ventilation / GAS

LOCATION AND VENTILATION

Gas cooking appliances must always have the

corresponding combustion products extracted

via cooker hoods connected to a fl ue or directly

to the outside (see Figure A). If it is not possible

to install a cooker hood, the use of an extractor

fan installed in a window or ducted directly outside

is permissible; this must be connected so as to

come on when the appliance is operational (see

Figure B), and all ventilation requirements laid out

in applicable legislation must be met.

CONNECTING THE APPLIANCE TO THE GAS

SUPPLY

Before connecting the appliance to the gas

supply, check that the data on the product

identifi cation label is compatible with the gas

supply specifi cations.

When the gas is supplied from the mains, the

appliance must be connected to the gas supply

with rigid copper tube or via a steel hose, in

accordance with applicable legislation.

When the gas is supplied from a cylinder, via a

compliant pressure regulator with continuouswall stainless-steel hose, it is advisable to install

a special after-market adapter on the hose to

facilitate connection with the hose barb of the

pressure regulator installed on the cylinder.

The hose must not pass through compartments

which may be fi lled, and must not come into

contact with moving components such as drawers.

On completing installation, check for any leaks

with a soapy solution, never with a fl ame.

EN

Figure A

WARNING: Remember that the appliance’s gas

inlet is a male 1/2” BSPP fi tting to ISO 228-1.

Figure B

9

EN

/ Gas

PRECAUTIONS WHEN USING THE PRODUCT

WITH LPG (BUTANE/PROPANE)

The gas taps installed on the hob must operate

with liquefi ed gas of controlled quality, supplied at

the correct nominal pressure.

This pressure must be guaranteed by a certifi ed

dedicated pressure regulator (not supplied with

the product).

The use of gas from uncertifi ed refi lls and/

or improper use of LPG cylinders, as well as

the corresponding regulator, can invalidate the

product warranty.

In particular, you must avoid all situations where

the gas could be polluted with residues and

impurities which, when they enter the gas circuit,

could

irreparably damage the control components such

as the taps and thermostats.

We therefore recommend:

• Using only LPG cylinders from offi cial resellers

authorised by the various manufacturers

• Using the cylinders until they are empty but

without tilting or overturning them

• Regularly cleaning the fi lter at the inlet to the

pressure regulator

Regulating the appliance for various gas types

Burner Gas type Pressure Nozzle

diameter

mbar 1/100mm g/h l/h kW kcal/h kW kcal/h 1/100mm

Town gas G110 8 145 - 227 1.00 860 0.3 258 27 reg

Auxiliary

Semirapid

Rapid

Natural gas G20 20 77 - 95 1.00 860 0.3 258 27 reg

Butane G30 30 50 73 - 1.00 860 0.3 258 27

Propane G31 37 50 71 - 1.00 860 0.3 258 27

Town gas G110 8 192 - 397 1.75 1505 0.44 378 31 reg

Natural gas G20 20 101 - 167 1.75 1505 0.44 378 31 reg

Butane G30 30 66 127 - 1.75 1505 0.44 378 31

Propane G31 37 66 125 - 1.75 1505 0.44 378 31

Town gas G110 8 280 - 681 3 2580 0.75 645 42 reg

Natural gas G20 20 129 - 286 3 2580 0.75 645 42 reg

Butane G30 30 87 218 - 3 2580 0.75 645 42

Propane G31 37 87 214 - 3 2580 0.75 645 42

Town gas G110 8 350 - 907 4 3440 1.5 1250 65 reg

Nominal fl ow rate Flow rate

Reduced

Bypass

diameter

Crown

Dual

Wok

10

Natural gas G20 20 145 - 381 4 3440 1.5 1290 65 reg

Butane G30 30 101 290 - 4 3440 1.5 1290 65

Propane G31 37 101 286 - 4 3440 1.5 1290 65

Town gas G110 8

Natural gas G20 20

Butane G30 30

Propane G31 37

ext 2x250

- 953 4.2 3612 0.48 413

int 130 int 34 reg

ext 2x110

- 476 5.0 4300 0.48 413

int 70 int 34 reg

ext 2x69

334 - 4.6 4300 0.48 413

int 46 int 34

ext 2x69

328 - 4.6 3956 0.48 413

int 46 int 34

ext 65 reg

ext 65 reg

ext 65

ext 65

GAS CONVERSION

WARNING!

Isolate the appliance’s gas and electricity supplies

before performing any maintenance.

The gas conversion procedure involves two steps:

• Replacing the nozzles

• Burner minimum adjustment

/ Gas conversion

WARNING: After performing the above-mentioned

procedures, the technician must apply the label

corresponding to the new gas regulation to replace

the old one. This label is contained in the bag of

spare nozzles.

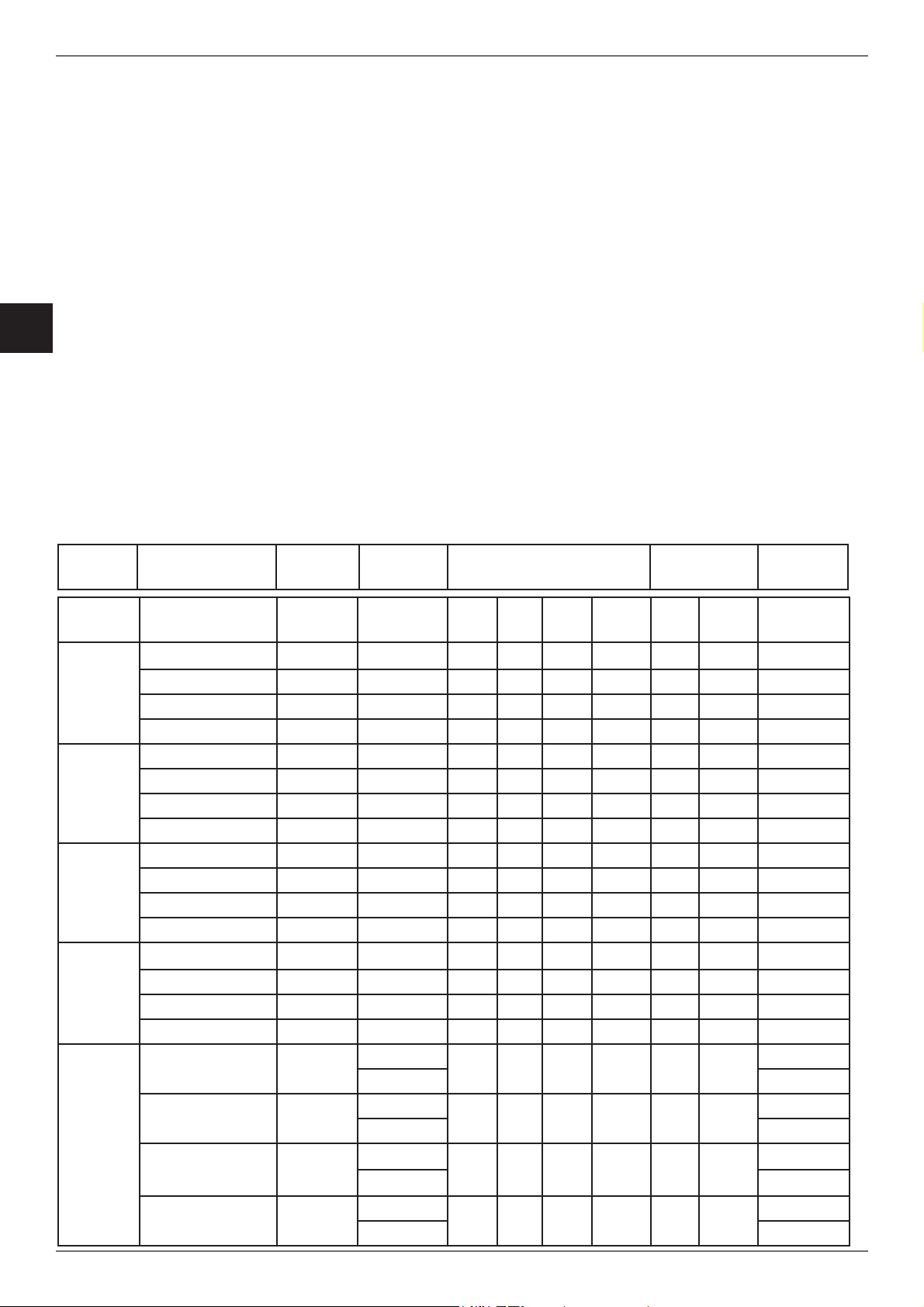

Step 1: Replacing the nozzles

Proceed as follows to change the burner nozzles:

lift the fl ame spreaders and unscrew the nozzles

using a 7 mm spanner, then replace them with

those required for new gas in accordance with the

TABLE (each nozzle has the number indicating its

diameter stamped on its body).

Keep the old nozzles in case they are required in

future.

EN

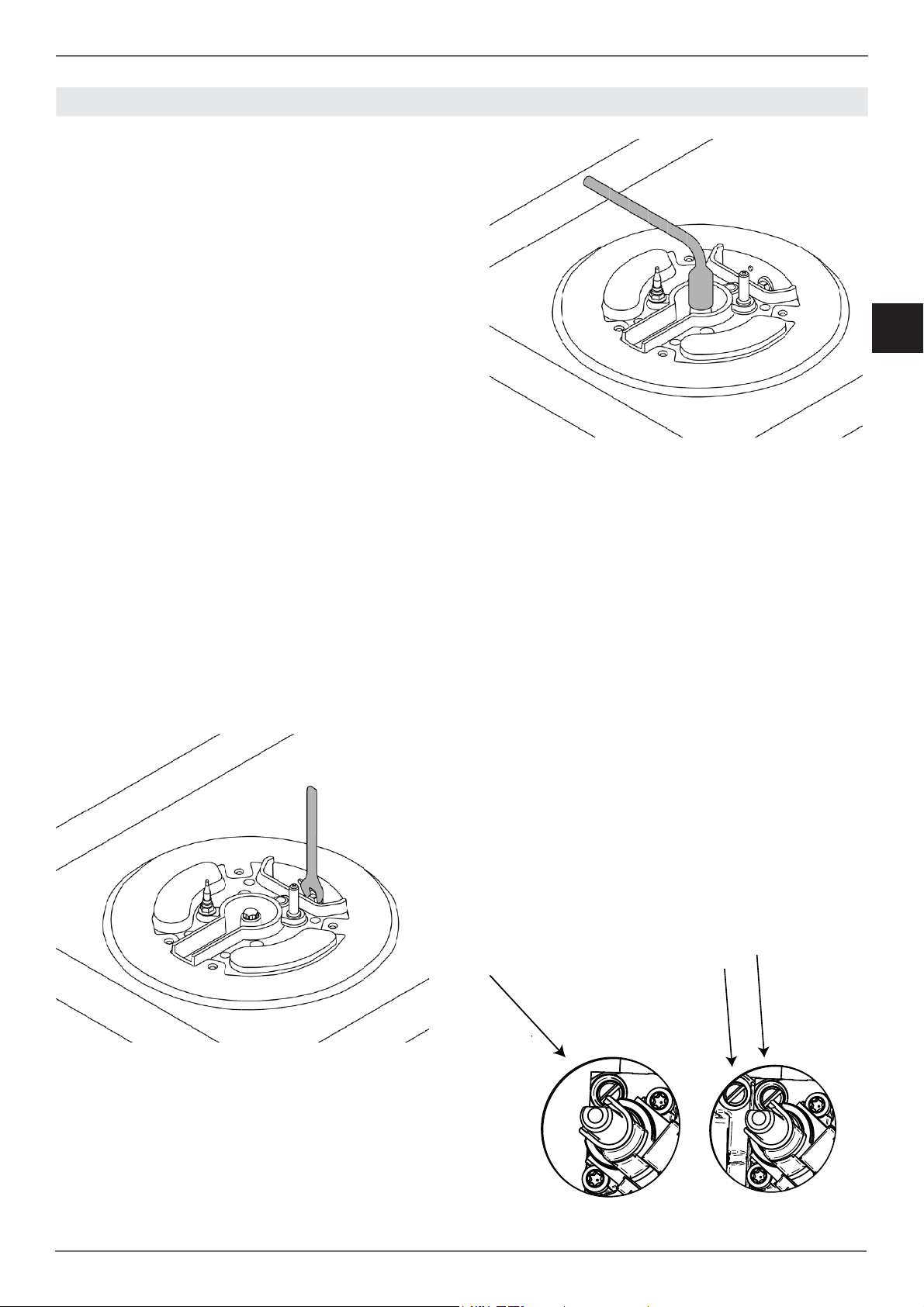

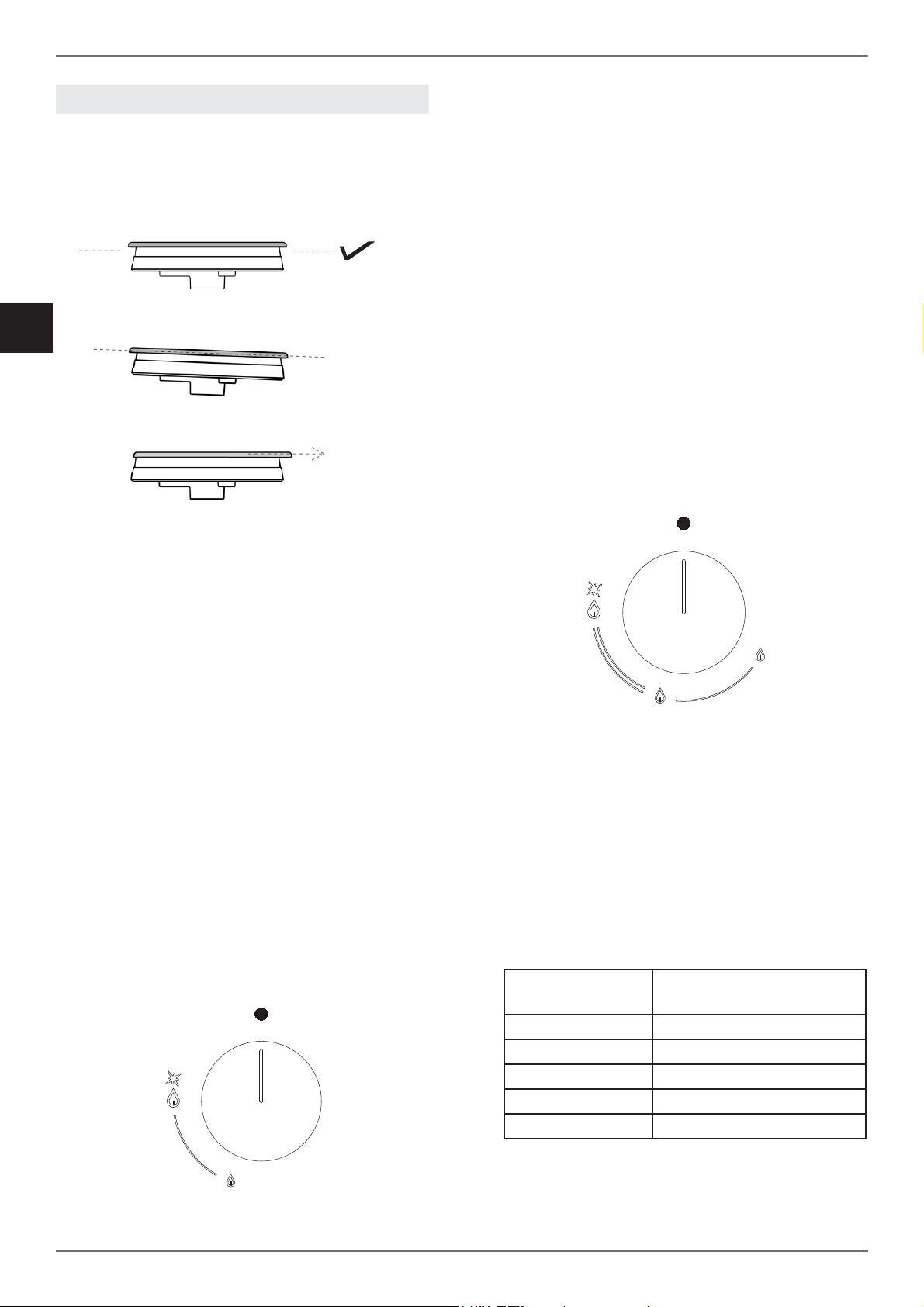

Step 2: Burner minimum adjustment

Light the nozzle and turn the knob to the MINIMUM

position (small fl ame).

2) Remove the knob, which is simply friction fi tted

to the spindle.

3) Use a small screwdriver on the gold screw next

to the knob shank (see fi gure) and turn the fl ow

control screw to the left or right until the burner

fl ame is suitably regulated to the MINIMUM

setting.

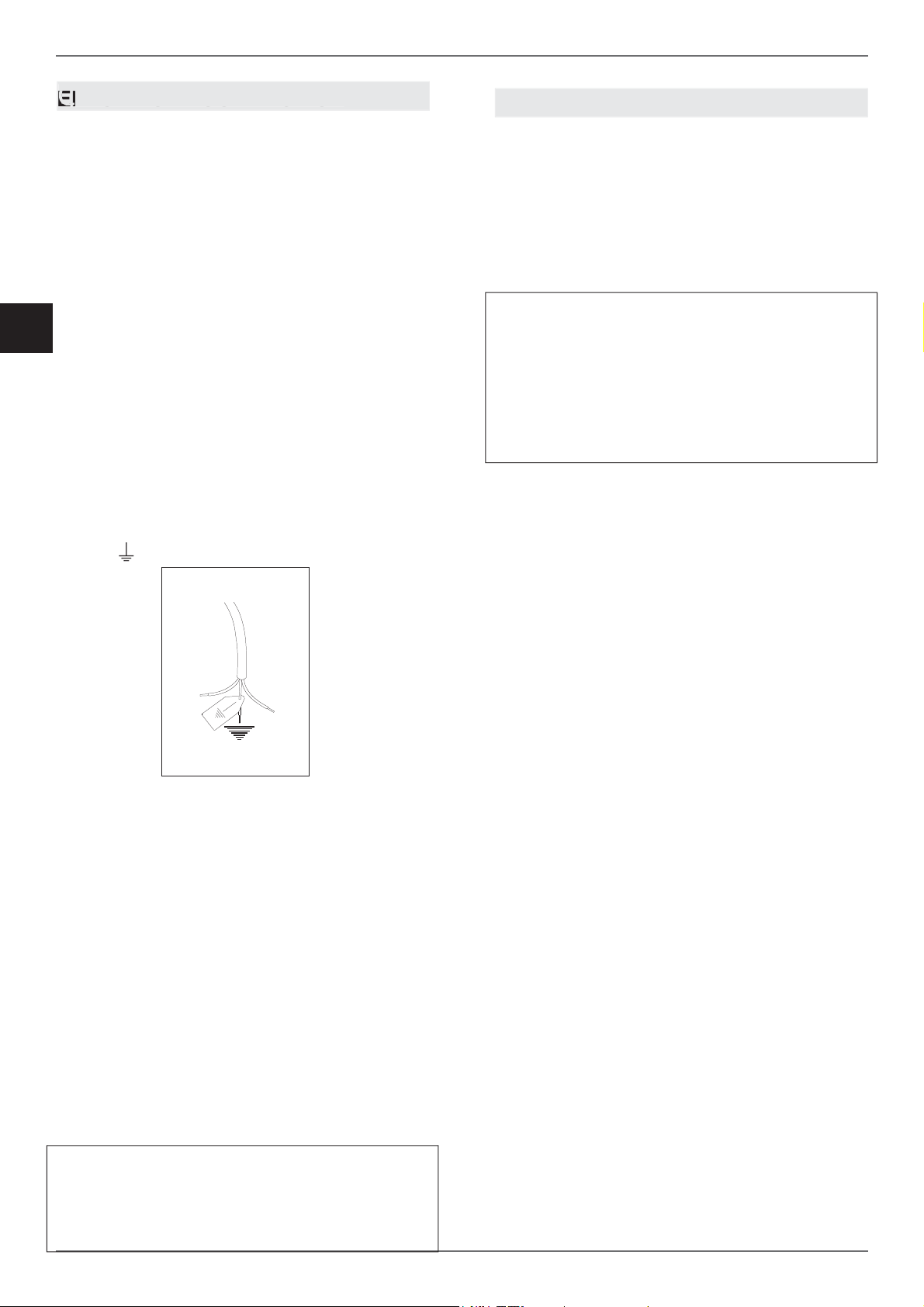

For dual burner knobs there are two fl ow control

screws: screw A to adjust the inner ring, and screw

B to adjust the outer ring.

4) Ensure that, when moving from the MAXIMUM

to the MINIMUM position, the fl ame does not go

out.

WARNING: The above-mentioned regulation

must only be performed for burners running on

natural gas (methane): when using LPG (butane

or propane), the screw must be locked all the way

to the right.

A

B

11

/ Electrical connection / Maintenance

EN

ELECTRICAL CONNECTION

The electrical connection must be made in

accordance with applicable standards and

legislation.

Before connecting up the appliance, check that:

• The mains electricity supply matches the

characteristics indicated on the appliance

data plate.

• The circuit wiring and outlet are equipped with

a compliant earth connection.

When the oven is connected to the mains power

supply via a socket:

• Wire a plug onto the power cable which

must comply with applicable standards in the

country of use; the plug (and its fuse, where

applicable) must be suitable for the rated load

specifi ed on the appliance data plate. Connect

the cores of the cable in accordance with the

fi gure, ensuring you follow the harmonised

wiring colour scheme:

L (live/hot/phase) = brown wire

N (neutral) = blue wire

earth ”

” symbol = yellow/green wire

MAINTENANCE

REPLACING COMPONENTS

Isolate the appliance’s gas and electricity supplies

before performing any maintenance.

Contact an authorised service centre if functional

components such as burners, taps and electrical

components require replacement.

WARNING:

If the power cable requires replacement, the

installer/maintenance technician must use

H05VV-F 3x0.75 mm

conductor around 2 cm longer than the live

and neutral wires. They must also comply with

the instructions given for the initial electrical

connection.

2

cable and leave the earth

L

N

• The power cable must be positioned in such

a way that it does not reach a temperature of

90°C at any point.

• Do not use adapters, extension leads, gang

sockets etc. as these could cause loose

contacts and overheat.

When the appliance is to be hard-wired to the

mains circuit:

• The circuit must be fi tted with a omnipolar

circuit breaker of suitable capacity for the

appliance's rated load.

• The earth conductor must not be switched

by the breaker and must be connected to the

earthing system.

• As an alternative, an RCBO may also be used,

or RCD protection in addition to or instead of

a fuse or MCB, depending on the applicable

electrical code.

WARNING: The appliance complies with the

requirements of 2016/426/EU (Gas Appliances

Regulation), 2014/35/EU (Low Voltage

Directive) on electrical safety, and 2014/30/EU

(Electromagnetic Compatibility Directive).

12

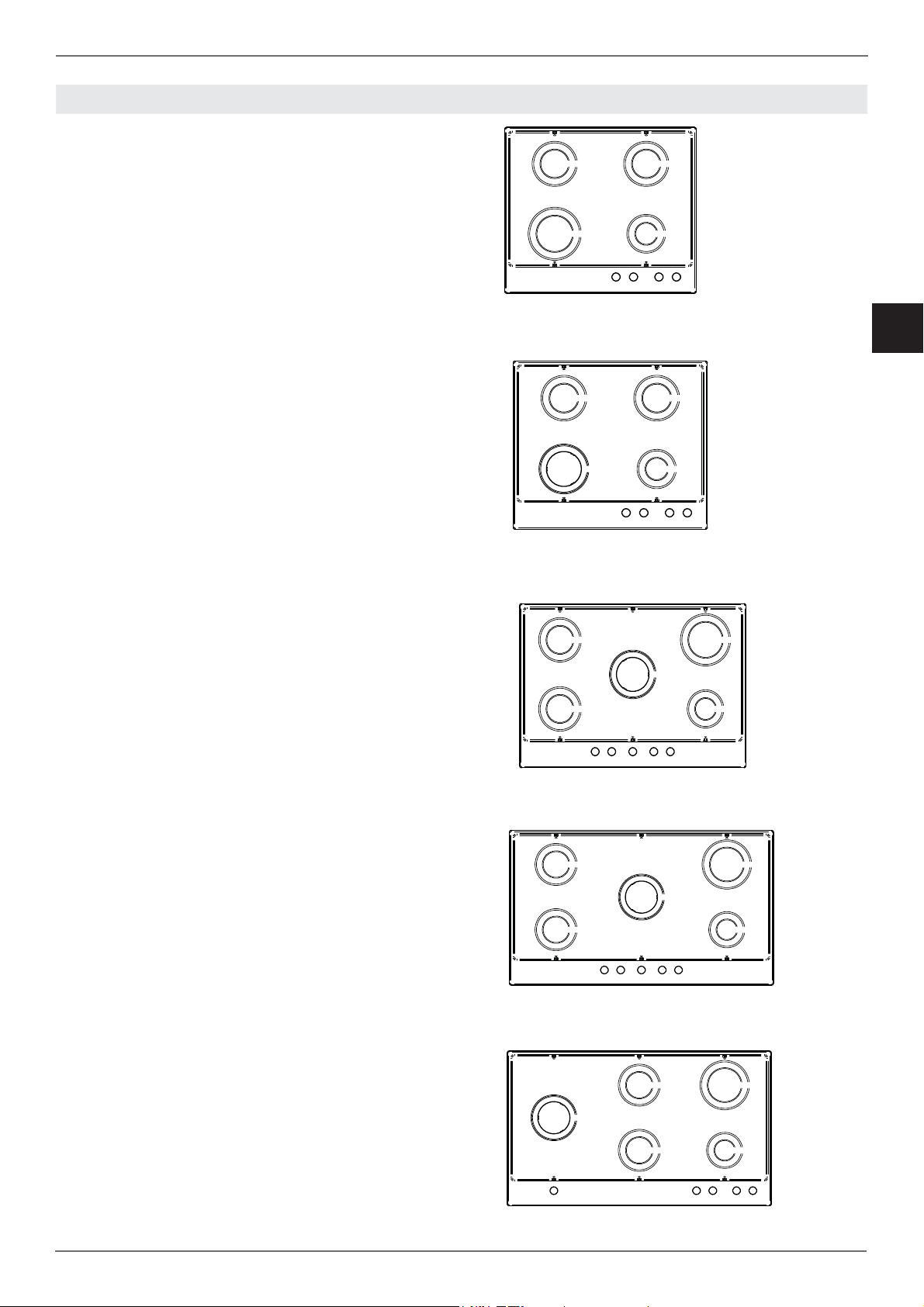

DESCRIPTION OF HOBS

/ Description of Hobs

CONTROLS / BURNERS

1 Front right auxiliary burner

2 Rear right semi-rapid burner

3 Rear left semi-rapid burner

4 Front left rapid burner

CONTROLS / BURNERS

1 Front right auxiliary burner

2 Rear right semi-rapid burner

3 Rear left semi-rapid burner

4 Front left crown burner

EN

CONTROLS / BURNERS

1 Front right auxiliary burner

2 Rear right rapid burner

3 Central crown burner

4 Rear left semi-rapid burner

5 Front left semi-rapid burner

CONTROLS / BURNERS

1 Front right auxiliary burner

2 Rear right rapid burner

3 Central dual burner or crown burner

4 Rear left semi-rapid burner

5 Front left semi-rapid burner

CONTROLS / BURNERS

4

5

3

5 4 3 2 1

3

2

1

2

1 Front right auxiliary burner

2 Rear right rapid burner

3 Rear central semi-rapid burner

4 Front central semi-rapid burner

5 Left side dual burner or crown burner

5

4

5 4 3 2 1

1

13

/ Use

EN

USE

BURNERS AND GRATES

The fl ame spreaders and burner caps must be

correctly positioned in order for the hob to operate

properly.

X

X

USING DUAL BURNERS (where applicable)

Dual burners off er greater fl exibility, as it is

possible to light both rings or just the inner ring.

Turn the corresponding knob to the left to the

MAXIMUM position (1).

Press the knob to start the gas fl ow and ignite the

burner.

When the burner lights, keep the knob held down

for around ten seconds, then release.

If the burner goes out after releasing the knob,

repeat the entire operation.

In position 2 the outer ring is at the minimum

setting and the ring crown is at the maximum.

In position 3 the inner ring is at the maximum

setting and the outer ring is off .

In position 4 the inner ring is at the minimum

setting and the outer ring is off .

Incorrect positioning of the fl ame spreaders and

caps can lead to burner damage.

The grids must be positioned in their seats inside

the hob.

USING THE BURNERS

Next to each knob is an indication of which burner

it operates.

Turn the knob corresponding to the selected

burner to the left to the MAXIMUM position (large

fl ame).

Press the knob to start the gas fl ow and ignite the

burner.

When the burner lights, keep the knob held down

for around ten seconds, then release.

If the burner goes out after releasing the knob,

repeat the entire operation.

To shut off the burner, turn the knob to the right to

the zero position.

Tips for optimum burner use:

• Use appropriate pans for each burner (see

table).

• When the pan boils, move the knob to the

MINIMUM position.

• Always use pans with lids.

BURNER PAN DIAMETER

(RECOMMENDED) cm

Auxiliary 12 - 14

Semi-rapid 14 - 26

Rapid 18 - 26

Crown 22 - 26

Dual 22 -26

14

/ Use / Cleaning

E

SAFETY SYSTEMS

A fl ame sensor (thermocouple) is installed on

each burner to prevent gas from coming out if the

fl ame is accidentally extinguished.

If there is a blackout of the electricity supply, the

hob will keep working without any danger.

MANUAL IGNITION

In the event of a power failure, the burners can be

ignited manually.

Turn the knob corresponding to the selected

burner to the left to the MAXIMUM position (large

fl ame).

Press down on the knob to start the fl ow of gas,

then bring a lighter or fl ame up to the burner.

When the burner lights, keep the knob held down

for around ten seconds, then release.

ACCESSORIES

Wok Adapter

Supplementary grid to be used on crown burners

with concave-bottom cookware.

Coff ee Pot Reducer

Supplementary grid to be used on the auxiliary

burner for coff ee pots or cookware with a diameter

below 12 cm.

CLEANING THE APPLIANCECLEANING THE APPLIANC

Before performing any cleaning operation, wait

for all parts to cool down and isolate the hob’s

electricity and gas supply.

Cleaning the hob:

The burner heads, enamelled steel grids,

enamelled caps and fl ame spreaders must be

regularly cleaned with warm soapy water then

rinsed and dried thoroughly.

Any liquid which should overfl ow from the

cookware must always be removed with a cloth.

If it is diffi cult to open or close one of the gas taps,

do not force it! Request urgent assistance from

the technical support network.

Cleaning Enamelled Parts:

To maintain the characteristics of the enamelled

components, they should be cleaned frequently

with soapy water. Never use scouring powders.

Do not leave acidic or basic substances (vinegar,

lemon juice, salt, tomato juice etc.) sitting on

enamelled parts, and do not wash enamelled

parts when they are still hot.

Cleaning Stainless-Steel Parts

Clean the components with soapy water and

then dry them with a soft cloth. The shine can be

maintained by periodic use of commonly available

products. Never use scouring powders or pads.

Cleaning the Burner Flame Spreaders:

As they are simply resting in position, they can

be cleaned simply by removing them from their

seats and washing them with soapy water. Do not

immerse in water or wash them under running

water. After drying them thoroughly and checking

that the holes are not blocked, return them to their

correct position.

Cleaning Glass Hobs:

To degrease, use washing-up liquid and vinegar,

then rinse; otherwise, clean with washing-up

liquid, rinse, then pass over with a moist cloth

before drying.

To remove encrusted food, soak with soapy water

or washing-up liquid for a few minutes. After a few

minutes, rinse and wash the hob.

Avoid anti-limescale, abrasive and multi-purpose

products, as they will aff ect the look of the glass

after a while.

Cleaning the Hob Grids:

Do not wash the grids in the dishwasher.

White residue on the grids is due to normal contact

with cookware, and not indicative or defects or

abrasions in the enamel.

EN

15

EN

/ Troubleshooting

TROUBLESHOOTING

In some cases operational faults can be easily

resolved.

Read the following tips before contacting technical

support.

The burner does not light.

Check that there is no food residue between the

igniter and burner.

Check that the gas and electricity supplies are

present.

Check that the burners are correctly located and

are not wet.

The igniter is still not working.

Water has probably entered the hob during

cleaning. Isolate the electricity supply and wait a

few hours to allow it to dry thoroughly.

The igniter does not work

Check that the electrical isolation switch or circuit

breaker is in the on position, and that there are no

problems with the electricity supply.

The burner fl ame is not even.

The burner is not correctly positioned.

The burner holes are dirty or blocked by water.

The knob will not stay in place.

The knob clip is broken: call customer service for

a replacement.

There is no gas fl ow.

Check that the gas isolation tap is not closed/the

cylinder is not empty.

WARRANTY AND CUSTOMER SERVICE:

WWW.BERTAZZONI.COM

16

INSTRUCTIONS D’INSTALLATION ET D’UTILISATION

PLAQUES DE CUISSON ENCASTRABLES AU GAZ

TYPE P93V (MÉTAL)

TYPE P94GV (VERRE)

FR

3100419

WWW.BERTAZZONI.COM

/ Table des matières

TABLE DES MATIÈRES

FR

AVERTISSEMENTS _____________________________________________________________

RESPONSABILITÉ DU FABRICANT _______________________________________________

PROTECTION DE L’ENVIRONNEMENT ____________________________________________

CONSIGNES GÉNÉRALES DE SÉCURITÉ _________________________________________

AVERTISSEMENTS D’UTILISATION ______________________________________________

PLAQUE D’IDENTIFICATION ____________________________________________________

EMBALLAGES EN PLASTIQUE __________________________________________________

MANUEL TECHNIQUE POUR L’INSTALLATEUR ______________________________________

INTÉGRATION DE LA PLAQUE DE CUISSON ______________________________________

AVERTISSEMENTS IMPORTANTS _______________________________________________

INSTALLATION AU-DESSUS D’UN FOUR ENCASTRÉ _______________________________

INSTALLATION AU-DESSUS D’UN LOGEMENT OU DE TIROIRS _______________________

FIXATION DE LA PLAQUE DE CUISSON ____________________________________________

VENTILATION AMBIANTE _______________________________________________________

EMPLACEMENT ET AÉRATION __________________________________________________

RACCORDEMENT DE LA PLAQUE À L’ALIMENTATION EN GAZ _______________________

PRÉCAUTIONS D’UTILISATION DU PRODUIT AVEC DU GAZ GPL ______________________

CONVERSION DU GAZ _________________________________________________________

BRANCHEMENT ÉLECTRIQUE ___________________________________________________

ENTRETIEN ___________________________________________________________________

REMPLACEMENT DES COMPOSANTS ____________________________________________

4

4

4

5

5

5

5

6

6

6

7

7

8

8

9

9

10

11

12

12

12

DESCRIPTION DES PLAQUES DE CUISSON _________________________________________

UTILISATION __________________________________________________________________

BRÛLEURS ET GRILLES ________________________________________________________

UTILISATION DES BRÛLEURS ___________________________________________________

SYSTÈME DE SÉCURITÉ ________________________________________________________

ALLUMAGE MANUEL ___________________________________________________________

ACCESSOIRES ________________________________________________________________

NETTOYAGE DE L’APPAREIL _____________________________________________________

DYSFONCTIONNEMENT _________________________________________________________

13

14

14

14

15

15

15

15

16

2

/ Message du Président

MESSAGE DU PRÉSIDENT

Cher nouveau propriétaire d’un produit Bertazzoni,

Je tiens à vous remercier d’avoir choisi l’un de nos magnifi ques produits pour

votre habitation.

Ma famille s’est lancée dans la fabrication d’équipements de cuisine en Italie

en 1882, se bâtissant ainsi une solide réputation en termes de qualité de

conception ainsi qu’une véritable passion pour la gastronomie.

Aujourd’hui, nos produits se distinguent de leurs concurrents puisqu’ils

représentent l’incroyable union d’un design purement italien et d’une

technologie d’avant-garde. Notre mission est de réaliser des produits qui

fonctionnent parfaitement et procurent du plaisir à leurs utilisateurs.

En réalisant des produits à l’esthétique sans pareille, nous répondons aux

attentes de nos clients en matière de design irréprochable. En réalisant des

produits polyvalents et simples à utiliser, cuisiner avec Bertazzoni devient un

vrai plaisir.

Le présent manuel vous aidera à utiliser et à entretenir de la manière la plus

sûre et effi cace le produit Bertazzoni dont vous avez fait l’achat, de sorte qu’il

puisse vous apporter la plus grande satisfaction lors des années à venir.

Nous vous souhaitons de profi ter pleinement de toutes ses possibilités !

Paolo Bertazzoni

Président

FR

3

/ Avertissements

AVERTISSEMENTS

FR

VEILLER À LIRE LES PRÉSENTES

INSTRUCTIONS AVANT D’INSTALLER ET

D’UTILISER L’APPAREIL.

Les présentes instructions sont valables

uniquement dans les pays auxquels elles sont

destinées, dont les symboles d’identifi cation

fi gurent sur l’étiquette d’identifi cation de l’appareil.

Le fabricant ne saurait être tenu pour responsable

des éventuels dommages matériels et/ou

corporels causés par une mauvaise installation

ou par une mauvaise utilisation de l’appareil.

Le fabricant décline toute responsabilité en cas

d’inexactitudes dues à des erreurs d’impression

ou de transcription présentes dans le présent

manuel. La représentation des fi gures présentes

dans le manuel est purement indicative. Le

fabricant se réserve la faculté d’apporter à ses

produits les modifi cations jugées nécessaires ou

utiles sans que les caractéristiques essentielles

de sécurité et de fonctionnement ne soient

aucunement altérées.

L’APPAREIL OBJET DU PRÉSENT MANUEL

N’A PAS ÉTÉ CONÇU POUR UN USAGE

PROFESSIONNEL MAIS POUR UN USAGE

DOMESTIQUE.

Le présent manuel d’utilisation fait partie intégrante

de l’appareil, il doit être conservé intact et doit

rester à portée de main de l’utilisateur pendant

tout le cycle de vie de l’appareil. Avant d’utiliser

l’appareil, veiller à lire le présent manuel.

RESPONSABILITÉ DU FABRICANT

Le fabricant décline toute responsabilité en cas de

dommages corporels et/ou matériels causés par :

• une utilisation de l’appareil autre que celle

prévue ;

• le non-respect des prescriptions fi gurant dans

le présent manuel d’utilisation ;

• la modifi cation de toute partie de l’appareil

quelle qu’elle soit ;

• l’utilisation de pièces détachées non d’origine.

• L’appareil objet du présent manuel est destiné

à la cuisson d’aliments dans un environnement

domestique. Toute autre utilisation doit être

considérée comme impropre.

• L’appareil n’est pas conçu pour fonctionner

en étant relié à des timers externes ni à des

systèmes de commande à distance.

PROTECTION DE L’ENVIRONNEMENT

Veiller à éliminer les emballages

dans le respect de l’environnement.

L’appareil objet du présent manuel est marqué

conformément à la directive européenne 2012/19/

UE en matière de déchets d’équipements

électriques et électroniques (DEEE).

Cette directive défi nit les normes de collecte et

de recyclage des équipements hors d’usage

applicables dans toute l’Union européenne.

L’emballage de l’appareil est constitué des

éléments strictement nécessaires afi n de garantir

une protection effi cace pendant son transport.

Les matériaux d’emballage sont entièrement

recyclables, aussi leur impact sur l’environnement

est minime. Le fabricant invite à contribuer à la

protection de l’environnement en respectant entre

autres les conseils suivants :

• éliminer les éléments et matériaux d’emballage

dans les conteneurs de tri prévus à cet eff et ;

• avant de remettre l’appareil à éliminer à

un centre de collecte, veiller à le rendre

inutilisable ; s’informer auprès des services

locaux compétents afi n de connaître le centre

de collecte des matériaux recyclables le plus

proche auquel l’appareil peut être remis ;

• ne pas éliminer les huiles usées dans un

lavabo ; les conserver dans un récipient fermé

et les remettre à un centre de collecte ou,

en cas d’impossibilité, les éliminer avec les

ordures ménagères (de sorte qu’elles soient

éliminées dans une décharge contrôlée ; bien

qu’il ne s’agisse pas de la meilleure solution,

cela permet de prévenir la contamination des

eaux).

ATTENTION : en apposant le marquage

le produit objet du présent manuel, le fabricant

certifi e, en engageant sa seule responsabilité,

la conformité de l’appareil à toutes les normes

européennes de sécurité, de santé et de protection

de l’environnement.

4

sur

AVERTISSEMENTS

/ Avertissements

CONSIGNES GÉNÉRALES DE SÉCURITÉ

• L’appareil et ses parties accessibles

deviennent très chauds pendant l’utilisation.

• Ne pas toucher les éléments chauff ants

pendant l’utilisation.

• Ne pas laisser d’enfants de moins de 8 ans à

proximité de l’appareil à moins qu’ils ne soient

constamment surveillés.

• Les enfants ne doivent pas jouer avec

l’appareil.

• L’appareil peut être utilisé par des enfants à

partir de 8 ans et par des personnes à capacités

physiques, sensorielles ou mentales réduites

ou bien ne possédant pas l’expérience ni les

connaissances nécessaires, à condition que

ce soit sous surveillance ou d’avoir reçu les

instructions nécessaires de personnes adultes

et responsables de leur sécurité.

• Pendant l’utilisation, ne pas poser d’objets

métalliques sur l’appareil : ils pourraient

devenir incandescents.

• Après utilisation, éteindre l’appareil.

• Ne pas tenter d’éteindre une fl amme/un

incendie avec de l’eau : éteindre l’appareil et

recouvrir la fl amme à l’aide d’un couvercle ou

d’une couverture ignifuge.

• Les opérations de nettoyage et d’entretien ne

doivent pas être confi ées à des enfants sans

surveillance.

• S’assurer que les surfaces aient refroidi avant

de procéder au nettoyage de l’appareil.

• Confi er l’installation et les interventions

d’assistance à un personnel qualifi é

conformément aux normes en vigueur. Ne

jamais tenter de réparer soi-même l’appareil

ou sans l’assistance d’un technicien qualifi é.

• Ne pas modifi er l’appareil.

• Ne pas introduire d’objets dans les fentes.

• Ne pas obstruer les ouvertures ni les orifi ces

de ventilation et de dissipation de la chaleur.

• Dans le cas où le câble d’alimentation

électrique serait endommagé, contacter

aussitôt le service d’assistance technique

pour en eff ectuer le remplacement.

• Sur les parties en verre, ne pas utiliser de

détergents abrasifs ou corrosifs (par exemple

des produits en poudre, des détachants et des

éponges métalliques).

• Ne pas s’asseoir sur l’appareil.

• Ne pas utiliser de vapeur pour nettoyer

l’appareil.

• Ne pas laisser d’objets sur les surfaces de

cuisson.

• N’utiliser en aucun cas l’appareil comme

source de chauff age ambiant.

• En cas de rupture, de fêlure et/ou de fi ssure de

la plaque en verre, éteindre immédiatement

tous les brûleurs et débrancher la plaque

de cuisson de l’alimentation en gaz et en

électricité. S’adresser au service d’assistance.

• Les brusques variations de température

peuvent provoquer la rupture du verre ; aussi,

ne pas verser de liquides froids sur la plaque

de cuisson pendant son utilisation.

• Les récipients endommagés, de dimensions

inadaptées, dépassant des bords de la plaque

de cuisson ou mal positionnés peuvent causer

de graves blessures.

• L’utilisation de la plaque de cuisson à gaz

génère de la chaleur, de l’humidité et des

produits de combustion ; veiller à bien ventiler

la pièce pendant le fonctionnement.

AVERTISSEMENTS D’UTILISATION

• Utiliser des récipients de cuisson à fond plat.

• Positionner les casseroles avant d’allumer le

feu.

• Ne pas s’éloigner pendant la cuisson des

aliments eff ectuée avec de l’huile ou autres

matières grasses : celles-ci peuvent facilement

s’enfl ammer.

• Ne pas utiliser de sprays à proximité de la

plaque lorsqu’elle est allumée.

• Régler la fl amme de sorte qu’elle ne dépasse

pas des limites de la casserole pour ne pas en

endommager les poignées.

• Ne pas poser de casseroles directement sur

les brûleurs.

• S’assurer que la casserole est centrée par

rapport au brûleur.

PLAQUE D’IDENTIFICATION

Sur la plaque d’identifi cation fi gurent les données

techniques, le numéro de série et le marquage.

La plaque d’identifi cation se trouve sur le carter

inférieur et ne doit en aucun cas être retirée (une

copie de cette plaque fi gure dans le manuel).

EMBALLAGES EN PLASTIQUE

Risque d’étouff ement

• Ne pas laisser les emballages ou parties de

ceux-ci sans surveillance.

• Ne pas laisser d’enfants jouer avec les sachets

en plastique de l’emballage.

FR

5

/ Installation

MANUEL TECHNIQUE POUR L’INSTALLATEUR

ANUEL TECHNIQUE POUR L’INSTALLATEUR

FR

L’installation, tous les réglages, les modifi cations

et les interventions d’entretien indiqués dans

la présente section doivent être exclusivement

confi és à un personnel qualifi é (conformément

aux normes en vigueur). Une mauvaise

installation peut causer des dommages corporels

(aux personnes et aux animaux) ainsi que des

dommages matériels dont le fabricant ne saurait

être tenu pour responsable. Pendant le cycle de

vie de l’équipement, les dispositifs de sécurité ou

de réglage automatique des appareils peuvent

être modifi és uniquement par le fabricant ou par

le fournisseur dument autorisé à cet eff et.

Procéder à l’installation uniquement après

s’être muni des équipements de protection

individuelle.

INTÉGRATION DE LA PLAQUE DE CUISSON

Après avoir retiré les diff érentes parties mobiles

de leur emballage interne et externe, s’assurer

que la plaque de cuisson est intacte. Au moindre

doute, ne pas utiliser le four et contacter le centre

d’assistance. Compte tenu des dimensions

critiques de l’appareil (voir tableaux), réaliser une

ouverture dans le plan du meuble (voir fi gure)

en respectant les dimensions fi gurant dans le

tableau.

A (cm) B (cm) H (cm) L (cm)

Plaque de 60 cm 56 48 60,5 52,5

Plaque de 75 cm 56 48 75,5 52,5

Plaque de 90 cm 85 48 89,3 52,5

AVERTISSEMENTS IMPORTANTS

La plaque de cuisson peut être insérée entre

des meubles de cuisine ou entre un meuble et

la paroi en dur. La paroi arrière et les surfaces

environnantes doivent résister à une température

de 90 °C. Pour éviter que le plastique laminé qui

recouvre le meuble ne se décolle, la colle utilisée

doit résister à une température d’au moins 150 °C.

L’installation de l’appareil doit être eff ectuée

conformément aux prescriptions des normes en

vigueur.

L’appareil n’est pas relié à des dispositifs

d’expulsion des produits de combustion. Il doit

donc être raccordé conformément aux règles

d’installation susmentionnées. Il est notamment

nécessaire de veiller à bien respecter les

prescriptions en matière d’aération et de ventilation

de l’espace.

Le plan du meuble doit être en mesure de

supporter une température maximale de

90 °C (120 °C pour la version de 75 cm)

C min. (cm) 8,5 M (cm) 4,4

D min. (cm) 3 N (cm) 1,1

E min. (cm) 18 P (cm) 47,4

F min. (cm) 70 Q (cm) 4

G min. (cm) 8,5

M

NPQ

H

'

*

(

$

L

)

&

%

6

MANUEL TECHNIQUE POUR L’INSTALLATEUR

ANUEL TECHNIQUE POUR L’INSTALLATEUR

/ Installation

INSTALLATION AU-DESSUS D’UN FOUR

ENCASTRÉ

La distance entre la plaque de cuisson et les

meubles de cuisine ou les appareils encastrés

doit garantir une ventilation et une évacuation

de l’air suffi santes.

En cas d’installation au-dessus d’un four, il

est nécessaire de maintenir un espace entre

le dessous de la plaque de cuisson et la partie

supérieure de l’appareil installé au-dessous

ainsi que de garantir la ventilation de tout le

logement (comme indiqué sur la fi gure).

Le four doit être doté d’un système de

refroidissement. Le fabricant décline toute

responsabilité en cas d’installation sur un four

d’une autre marque.

INSTALLATION AU-DESSUS D’UN LOGEMENT

OU DE TIROIRS

La distance entre la plaque de cuisson et les

meubles de cuisine doit garantir une ventilation

et une évacuation de l’air suffi santes. En

présence d’autres meubles (parois latérales,

tiroirs, etc.), lave-vaisselle ou réfrigérateur,

sous la plaque de cuisson, il est nécessaire

d’installer un double fond en bois à une

distance d’au moins 20 mm du dessous de

la plaque de cuisson pour éviter tout contact

accidentel. Le retrait du double fond doit être

possible uniquement à l’aide d’outils prévus à

cet eff et.

FR

40

40

7

/ Installation / Ventilation

FR

FIXATION DE LA PLAQUE DE CUISSON

Pour prévenir les infi ltrations accidentelles

de liquides dans le meuble situé au-dessous,

l’appareil est doté d’un joint spécifi que.

1) Appliquer le joint d’étanchéité le long du bord

inférieur du plan d’encastrement après en avoir

nettoyé la surface.

2) Introduire la plaque dans l’ouverture du meuble.

3) Pour fi xer la plaque au plan, visser les 4 pattes

sur la partie inférieure de la plaque au moyen d’un

tournevis et des vis prévues à cet eff et.

VENTILATION AMBIANTE

Pour garantir le bon fonctionnement de l’appareil,

il est nécessaire que la pièce dans laquelle il est

installé soit constamment ventilée. Le volume de

la pièce ne doit pas être inférieur à 25 m³ et la

quantité d’air doit être fonction de la combustion

régulière du gaz et de la ventilation de la pièce.

Le fl ux d’air naturel doit être garanti par des

ouvertures permanentes réalisées sur les murs

de la pièce à ventiler : ces ouvertures doivent

donner sur l’extérieur et leur section doit être au

minimum de 100 cm².

La ventilation indirecte est également admise, par

prélèvement d’air dans les pièces mitoyennes à la

pièce à ventiler, en veillant dans ce cas à respecter

scrupuleusement les normes en vigueur.

8

/ Ventilation / GAZ

EMPLACEMENT ET AÉRATION

Les produits de combustion des appareils de

cuisson à gaz doivent toujours être expulsés au

moyen de hottes reliées à une cheminée, à un

conduit ou bien directement à l’extérieur (voir

fi gure A). Dans le cas où l’utilisation d’une hotte

s’avérerait impossible, il est possible d’utiliser un

ventilateur installé sur une fenêtre ou donnant

directement sur l’extérieur, à mettre en marche

lorsque l’appareil est utilisé (voir fi gure B), à

condition de respecter scrupuleusement les

dispositions relatives à la ventilation des normes

en vigueur.

RACCORDEMENT DE LA PLAQUE À

L’ALIMENTATION EN GAZ

Avant de raccorder l’appareil à l’alimentation

en gaz, s’assurer que les données fi gurant sur

l’étiquette d’identifi cation sont compatibles avec

celles du réseau de distribution de gaz.

Lorsque le gaz est distribué au moyen de

conduites, l’appareil doit être raccordé au

circuit d’adduction de gaz au moyen d’un tuyau

métallique rigide en cuivre ou d’un tuyau fl exible

en acier conformément aux normes en vigueur.

Lorsque le gaz provient d’une bonbonne, l’appareil

doit être alimenté au moyen d’un régulateur de

pression conforme aux normes en vigueur et

de tuyaux fl exibles en acier inoxydable à paroi

continue. Sur le tuyau fl exible, il est recommandé

d’installer un adaptateur spécial, disponible dans

le commerce, afi n de faciliter la jonction avec le

raccord du régulateur de pression monté sur la

bonbonne.

FR

Le tuyau ne doit pas traverser d’espaces pouvant

être encombrés et ne doit en aucun cas se trouver

au contact de parties mobiles, comme des tiroirs.

Une fois l’installation terminée, s’assurer de

l’absence de fuites au moyen d’une solution

savonneuse et en aucun cas à l’aide d’une

fl amme.

Figure A

ATTENTION : il est rappelé que le raccord

d’arrivée de gaz de l’appareil est pourvu d’un

fi letage 1/2 gaz cylindrique mâle conforme aux

normes UNI-ISO 228-1.

Figure B

9

/ Gaz

FR

PRÉCAUTIONS D’UTILISATION DU PRODUIT

AVEC DU GAZ GPL

Les robinets de gaz montés sur la plaque de

cuisson doivent fonctionner avec du gaz liquide à

qualité contrôlée, distribué à la pression nominale

prévue.

Cette pression doit être garantie au moyen d’un

régulateur de pression certifi é (non fourni avec le

produit).

L’utilisation de gaz provenant de recharges non

certifi ées et/ou l’utilisation inappropriée de la

bonbonne de GPL et du régulateur correspondant

peuvent invalider la garantie du produit.

Il est en particulier nécessaire d’éviter toutes les

situations susceptibles de polluer le gaz avec des

résidus et des impuretés qui, introduits dans le

circuit de gaz, peuvent

endommager irréparablement les éléments de

contrôle tels que les robinets et les thermostats.

Adaptation aux diff érents types de gaz

Brûleur Type de gaz Pression Diamètre

de la buse

Aussi, il est recommandé :

• d’utiliser uniquement des bonbonnes de GPL

provenant de revendeurs offi ciels et agréés par

les fabricants.

• d’utiliser les bonbonnes jusqu’à ce qu’elles soient

vides, sans jamais les incliner ni les retourner.

• de nettoyer régulièrement le fi ltre présent à

hauteur de l’arrivée du régulateur de pression.

Débit nominal Débit

réduit

Diamètre

bypass

mbar 1/100 mm g/h l/h kW kcal/h kW kcal/h 1/100 mm

Gaz de ville G110 8 145 - 227 1,00 860 0,3 258 27 reg.

Auxiliaire

Semirapide

Rapide

Couronne

Dual Wok

Naturel G20 20 77 - 95 1,00 860 0,3 258 27 reg.

Butane G30 30 50 73 - 1,00 860 0,3 258 27

Propane G31 37 50 71 - 1,00 860 0,3 258 27

Gaz de ville G110 8 192 - 397 1,75 1505 0,44 378 31 reg.

Naturel G20 20 101 - 167 1,75 1505 0,44 378 31 reg.

Butane G30 30 66 127 - 1,75 1505 0,44 378 31

Propane G31 37 66 125 - 1,75 1505 0,44 378 31

Gaz de ville G110 8 280 - 681 3 2580 0,75 645 42 reg.

Naturel G20 20 129 - 286 3 2580 0,75 645 42 reg.

Butane G30 30 87 218 - 3 2580 0,75 645 42

Propane G31 37 87 214 - 3 2580 0,75 645 42

Gaz de ville G110 8 350 - 907 4 3440 1,5 1290 65 reg.

Naturel G20 20 145 - 381 4 3440 1,5 1290 65 reg.

Butane G30 30 101 290 - 4 3440 1,5 1290 65

Propane G31 37 101 286 - 4 3440 1,5 1290 65

ext. 2 x 250

Gaz de ville G110 8

ext. 2 x 110

Naturel G20 20

Butane G30 30

int. 130 int. 34 reg.

- 953 4,2 3612 0,48 413

- 476 5,0 4300 0,48 413

int. 70 int. 34 reg.

ext. 2 x 69

334 - 4,6 4300 0,48 413

int. 46 int. 34

ext. 65 reg.

ext. 65 reg.

ext. 65

10

Propane G31 37

ext. 2 x 69

328 - 4,6 3956 0,48 413

int. 46 int. 34

ext. 65

CONVERSION DU GAZ

ATTENTION !

Avant d’eff ectuer toute opération d’entretien,

veiller à débrancher l’appareil de l’alimentation en

gaz et de l’alimentation électrique.

La procédure de conversion du gaz prévoit

2 étapes :

• remplacement des buses

• réglage du minimum des brûleurs

ATTENTION : après avoir eff ectué les opérations

de remplacement susmentionnées, à la place de

l’étiquette d’origine, le technicien doit appliquer sur

l’appareil l’étiquette correspondant au nouveau

réglage de gaz. Cette étiquette est présente dans

le sachet des buses de rechange.

Étape 1 : remplacement des buses

Pour remplacer les buses des brûleurs, procéder

comme suit : soulever les couronnes et dévisser

les buses à l’aide d’une clé anglaise de 7 mm, puis

les remplacer par celles prévues pour le nouveau

gaz, conformément aux indications du TABLEAU

(chaque buse est marquée d’un numéro indiquant

le diamètre, imprimé sur le corps).

Conserver les buses démontées pour une

éventuelle utilisation future.

/ Conversion du gaz

Étape 2 : réglage du minimum des brûleurs

1) Allumer le brûleur et placer le bouton sur la

position MINIMUM (petite fl amme).

2) Retirer le bouton du robinet (fi xée par simple

pression sur la tige du robinet).

3) Utiliser un petit tournevis, près de la tige du

robinet du plan de travail au niveau de la vis

(dorée) présente sur la partie inférieure du robinet

(voir fi gure ci-contre), et la tourner à droite ou à

gauche jusqu’à ce que la fl amme du brûleur soit

correctement réglée sur le MINIMUM.

Sur le robinet Dual, deux vis de réglage sont

présentes : la vis A pour régler la couronne interne

et la vis B pour régler la couronne externe.

4) En passant rapidement de la position MAXIMUM

à la position MINIMUM, s’assurer que la fl amme

ne s’éteint pas.

ATTENTION : le réglage ci-dessus doit être

eff ectué uniquement avec des brûleurs alimentés

au gaz méthane ; avec les brûleurs alimentés au

gaz liquide, la vis doit être bloquée à fond dans le

sens horaire.

FR

A

B

11

/ Branchement électrique / Entretien

FR

BRANCHEMENT ÉLECTRIQUE

Le branchement électrique doit être eff ectué en

conformité aux normes et aux dispositions légales

en vigueur.

Avant d’eff ectuer le branchement, s’assurer que :

• Les caractéristiques du secteur d’alimentation

électrique sont adaptées aux données fi gurant

sur l’étiquette d’identifi cation.

• La prise et l’installation sont reliées à la terre

conformément aux normes en vigueur.

Quand le branchement au secteur d’alimentation

est eff ectué par l’intermédiaire d’une prise :

• Appliquer au câble d’alimentation une fi che

aux normes adaptée à la charge indiquée sur

l’étiquette d’identifi cation. Brancher les fi ls

conducteurs en faisant référence au schéma

de la fi gure et en veillant à respecter les

correspondances ci-dessous :

lettre L (phase) = conducteur marron ;

lettre N (neutre) = conducteur bleu ;

symbole ” ” terre = conducteur jaune-vert ;

ENTRETIEN

REMPLACEMENT DES COMPOSANTS

Avant d’eff ectuer toute opération d’entretien,

veiller à débrancher l’appareil de l’alimentation en

gaz et de l’alimentation électrique.

Pour le remplacement de composants

fonctionnels, tels que les brûleurs, les robinets

et les composants électriques, s’adresser à un

centre d’assistance agréé.

ATTENTION : en cas de remplacement du

câble d’alimentation, l’installateur / technicien

doit utiliser un câble H05VV-F 3 x 0,75 mm

veiller à ce que le conducteur de terre soit plus

long que les conducteurs de phase (d’environ

2 cm). Il est également nécessaire de respecter

les avertissements relatifs au branchement

électrique.

2

et

L

N

• Le câble d’alimentation doit être positionné de

sorte qu’il n’atteigne à hauteur d’aucun point

une température de 90 °C.

• Pour le branchement, ne pas utiliser de

réductions, d’adaptateurs ni de dérivateurs

susceptibles de provoquer des faux contacts

et des surchauff es dangereuses qui en

résulteraient.

Si le branchement est eff ectué directement au

secteur d’alimentation électrique :

• Entre l’appareil et le secteur d’alimentation

électrique, intercaler un interrupteur

omnipolaire dimensionné en fonction de la

charge de l’appareil.

• Le câble de terre ne doit pas être interrompu

par l’interrupteur et doit être relié à la terre.

• Diff éremment, le branchement électrique peut

également être protégé par un interrupteur

diff érentiel.

ATTENTION : l’appareil est conforme aux

prescriptions des règlements 2016/426/EU (GAR),

relatif aux appareils à gaz à usage domestique et

similaire, 2014/35/EU (« basse tension »), relatif

à la sécurité électrique, et 2014/30/EU (directive

CEM), relatif à la compatibilité électromagnétique.

12

DESCRIPTION DES PLAQUES DE CUISSON

/ Description des plaques de cuisson

COMMANDES / ÉLÉMENTS CHAUFFANTS

1 Brûleur auxiliaire avant droit

2 Brûleur semi-rapide arrière droit

3 Brûleur semi-rapide arrière gauche

4 Brûleur rapide avant gauche

COMMANDES / ÉLÉMENTS CHAUFFANTS

1 Brûleur auxiliaire avant droit

2 Brûleur semi-rapide arrière droit

3 Brûleur semi-rapide arrière gauche

4 Brûleur couronne avant gauche

COMMANDES / ÉLÉMENTS CHAUFFANTS

FR

1 Brûleur auxiliaire avant droit

2 Brûleur rapide arrière droit

3 Brûleur couronne centrale

4 Brûleur semi-rapide arrière gauche

5 Brûleur semi-rapide avant gauche

COMMANDES / ÉLÉMENTS CHAUFFANTS

1 Brûleur auxiliaire avant droit

2 Brûleur rapide arrière droit

3 Brûleur Dual ou couronne centrale

4 Brûleur semi-rapide arrière gauche

5 Brûleur semi-rapide avant gauche

COMMANDES / ÉLÉMENTS CHAUFFANTS

1 Brûleur auxiliaire avant droit

2 Brûleur rapide arrière droit

3 Brûleur semi-rapide arrière central

4 Brûleur semi-rapide avant central

5 Brûleur Dual ou couronne latérale gauche

4

5

5

3

5 4 3 2 1

3

4

2

1

2

1

5 4 3 2 1

13

/ Utilisation

FR

UTILISATION

BRÛLEURS ET GRILLES

Les couronnes et les chapeaux doivent être

correctement positionnés, de sorte que la plaque

de cuisson fonctionne correctement.

X

X

Le mauvais positionnement de la couronne et du

chapeau peut endommager le brûleur.

UTILISATION DU BRÛLEUR DUAL (si prévu)

Pour plus de fonctionnalité, le brûleur Dual peut

fonctionner entièrement allumé ou bien avec la

seule couronne interne allumée.

Tourner le bouton correspondant dans le sens

antihoraire et l’amener à hauteur de la position

MAXIMUM 1.

Appuyer sur le bouton pour ouvrir le gaz et

commander l’allumage.

Une fois l’allumage survenu, maintenir le bouton

enfoncé pendant environ 10 secondes puis le

relâcher.

Dans le cas où le brûleur s’éteindrait après avoir

relâché le bouton, répéter toute l’opération.

En position 2, la couronne externe est au

minimum et la couronne interne au maximum de

la puissance de la fl amme.

En position 3, la couronne interne est au maximum

et la couronne externe est éteinte.

En position 4, la couronne interne est au minimum

et la couronne externe est éteinte.

Les grilles doivent être placées dans leur logement

sur la plaque de cuisson.

UTILISATION DES BRÛLEURS

Sur le panneau de commande, chaque bouton est

accompagné de l’indication du brûleur auquel il

correspond.

Tourner dans le sens antihoraire le bouton

correspondant au brûleur sélectionné et l’amener

à hauteur de la position MAXIMUM (grande

fl amme).

Appuyer sur le bouton pour ouvrir le gaz et

commander l’allumage.

Une fois l’allumage survenu, maintenir le bouton

enfoncé pendant environ 10 secondes puis le

relâcher.

Dans le cas où le brûleur s’éteindrait après avoir

relâché le bouton, répéter toute l’opération.

Pour éteindre le brûleur, tourner le bouton dans le

sens horaire jusqu’à la position 0.

Conseils pour une utilisation optimale des

brûleurs :

• Pour chaque brûleur, utiliser des casseroles

appropriées (voir tableau).

• Une fois l’ébullition atteinte, placer le bouton

du brûleur sur la position MINIMUM.

• Veiller à toujours utiliser des casseroles

munies de couvercle.

BRÛLEUR DIAMÈTRES

CONSEILLÉS DES

CASSEROLES EN cm

Auxiliaire 12 - 14

Semi-rapide 14 - 26

Rapide 18 - 26

Couronne 22 - 26

Dual 22 -26

14

/ Utilisation / Nettoyage

SYSTÈME DE SÉCURITÉ

Un capteur de présence de fl amme (thermocouple)

est installé sur chaque brûleur pour couper le gaz

en cas d’extinction accidentelle de la fl amme.

En cas de coupure de courant, la plaque de

cuisson continue de fonctionner correctement,

sans danger.

ALLUMAGE MANUEL

En cas d’absence d’alimentation électrique, les

brûleurs peuvent être allumés manuellement :

Tourner dans le sens antihoraire le bouton

correspondant au brûleur sélectionné et l’amener

à hauteur de la position MAXIMUM (grande

fl amme).

Appuyer sur le bouton pour ouvrir le gaz et

approcher un allumeur ou une fl amme du brûleur.

Une fois l’allumage survenu, maintenir le bouton

enfoncé pendant environ 10 secondes puis le

relâcher.

ACCESSOIRES

Adaptateur Wok

Grille supplémentaire à utiliser sur les brûleurs à

couronne avec des récipients de cuisson à fond

concave.

Réduction pour cafetière

Grille supplémentaire à utiliser sur le brûleur

auxiliaire, pour les récipients de cuisson de

diamètre inférieur à 12 cm.

NETTOYAGE DE L’APPAREILNETTOYAGE DE L’APPAREIL

Avant d’eff ectuer toute opération de nettoyage,

attendre que toutes les parties aient refroidi et

débrancher la plaque de l’alimentation en gaz et

en électricité.

Nettoyage du plan de travail :

À intervalles réguliers, les têtes des brûleurs, les

grilles en acier émaillé, les chapeaux émaillés

et les couronnes doivent être nettoyés à l’eau

tiède et savonneuse, rincés et bien essuyés. Les

liquides ayant débordé des casseroles doivent

être éliminés à l’aide d’un torchon. Dans le cas où

l’ouverture ou la fermeture d’un robinet s’avérerait

diffi cile, ne pas forcer mais demander aussitôt

l’intervention de l’assistance technique.

Nettoyage des parties émaillées :

Pour conserver les caractéristiques des parties

émaillées, il est nécessaire de procéder à un

nettoyage fréquent à l’eau savonneuse. Ne jamais

utiliser de poudres abrasives. Éviter de laisser

des substances acides ou alcalines (vinaigre, jus

de citron, sel, sauce tomate, etc.) sur les parties

émaillées et de les laver lorsqu’elles sont encore

chaudes.

Nettoyage des parties en acier inox :

Nettoyer les parties en acier inox à l’aide d’eau

savonneuse et les essuyer avec un chiff on doux.

Le brillant peut être entretenu en appliquant à

intervalles réguliers des produits prévus à cet

eff et vendus dans le commerce. Ne jamais utiliser

de poudres ni d’éponges abrasives.

Nettoyage des couronnes des brûleurs :

Étant simplement posées, pour leur nettoyage, il

suffi t de les retirer de leur logement et de les laver

à l’eau savonneuse. Ne pas les plonger dans l’eau

ni les laver sous un jet d’eau courante. Après les

avoir bien essuyées et s’être assuré que les trous

ne sont pas bouchés, les remettre correctement

en place.

Nettoyage du plan en verre :

Pour dégraisser le verre, utiliser du liquide

vaisselle et du vinaigre puis rincer ou bien nettoyer

avec du liquide vaisselle, rincer, passer un chiff on

humide et essuyer. Pour retirer les incrustations,

les mouiller avec de l’eau savonneuse ou du

liquide vaisselle. Au bout de quelques minutes,

rincer et laver la plaque de cuisson. Éviter les

produits anticalcaire, les produits abrasifs et

autres produits multifonctions qui, avec le temps,

endommagent le verre.

Nettoyage des grilles :

Ne pas laver les grilles au lave-vaisselle.

Les traces blanches sur les grilles sont dues au

frottement des casseroles et non pas à un défaut

ou à l’abrasion de l’émail.

FR

15

FR

/ Dysfonctionnement

DYSFONCTIONNEMENT

Dans certains cas, les éventuels dysfonctionnement

sont faciles à résoudre.

Avant de s’adresser au service d’assistance

technique, eff ectuer les contrôles ci-dessous.

Le brûleur ne s’allume pas.

S’assurer de l’absence de résidus alimentaires

entre la bougie et le brûleur.

Contrôler l’alimentation en gaz et l’alimentation

électrique.

S’assurer que les brûleurs ne sont pas mouillés et

qu’ils sont correctement positionnés.

L’allumeur reste activé.

De l’eau s’est probablement infi ltrée dans la plaque

à l’occasion du nettoyage. Couper l’alimentation

électrique et attendre quelques heures, le temps

que la plaque sèche.

L’allumeur ne fonctionne pas.

S’assurer que l’interrupteur de l’alimentation

électrique est allumé et que cette dernière ne

présente aucun problème d’approvisionnement.

La fl amme du brûleur n’est pas uniforme.

Le brûleur est mal positionné.

Les trous du brûleur sont sales ou obstrués par

de l’eau.

Le bouton ne reste pas en position.

Le clip du bouton est cassé : contacter le service

d’assistance pour le remplacer.

Le gaz n’arrive pas.

S’assurer que le robinet de gaz n’est pas fermé ou

vérifi er si la bonbonne n’est pas vide.

GARANTIE ET SERVICE CLIENTS :

WWW.BERTAZZONI.COM

16

لطﻌﻟا \

لطﻌﻟا

.ﺔﻟوﮭﺳﺑ ﺔﯾﻠﯾﻐﺷﺗ لﺎطﻋأ يأ لﺣ تﻻﺎﺣﻟا ضﻌﺑ ﻲﻓ نﻛﻣﯾ

.ﻲﻧﻔﻟا مﻋدﻟا ﺔﻣدﺧﺑ ﺔﻧﺎﻌﺗﺳﻻا لﺑﻗ ﺔﯾﻟﺎﺗﻟا تارﯾذﺣﺗﻟا نﻣ ﻖﻘﺣﺗ

.لﻣﻌﺗ ﻻ ﺔﻠﻌﺷﻟا

.ﺔﻠﻌﺷﻟاو لﺎﻌﺷﻹا ةدﺣو نﯾﺑ مﺎﻌط ﺎﯾﺎﻘﺑ دوﺟو مدﻋ نﻣ دﻛﺄﺗ

ءﺎﺑرﮭﻛﻟاو زﺎﻐﻠﻟ ﺢﯾﺣﺻﻟا دادﻣﻹا نﻣ ﻖﻘﺣﺗ

ﺢﯾﺣﺻ لﻛﺷﺑ ﺎﮭﻌﺿو مﺗو ﺔﻠﻠﺑﻣ رﯾﻏ تﻼﻌﺷﻟا نأ دﻛﺄﺗ

.ﺎًطﺷﻧ لﻌﺷُﻣﻟا لظﯾ

رظﺗﻧاو ءﺎﺑرﮭﻛﻟا لﺻﻓا .فﯾظﻧﺗﻟا ءﺎﻧﺛأ دﻗوﻣﻟا لﺧاد هﺎﯾﻣ تﻠﺧد ﺎﻣﺑر

.فﯾﻔﺟﺗﻟﺎﺑ حﺎﻣﺳﻠﻟ تﺎﻋﺎﺳ ﻊﺿﺑ

لﻣﻌﯾ ﻻ لﻌﺷُﻣﻟا

.ءﺎﺑرﮭﻛﻟا دادﻣإ ﻲﻓ ﺔﻠﻛﺷﻣ كﺎﻧھ سﯾﻟو لﻣﻌﯾ ءﺎﺑرﮭﻛﻟا حﺎﺗﻔﻣ نأ دﻛﺄﺗ

.دﺣوﻣ رﯾﻏ ﺔﻠﻌﺷﻟا بﮭﻟ

.ﺔﺣﯾﺣﺻ ةروﺻﺑ ﺔﻋوﺿوﻣ رﯾﻏ ﺔﻠﻌﺷﻟا

.ءﺎﻣﻟﺎﺑ ةدودﺳﻣ وأ ﺔﺧﺳﺗﻣ ﺔﻠﻌﺷﻟا تﺎﺣﺗﻓ

.ﮫﻧﺎﻛﻣ ﻲﻓ رﻘﺗﺳﯾ ﻻ ضﺑﻘﻣﻟا

.ﮫﻟادﺑﺗﺳﻻ ﻲﻧﻔﻟا مﻋدﻟا ﺔﻣدﺧﺑ لﺻﺗا ،روﺳﻛﻣ ضﺑﻘﻣﻟا تﯾﺑﺛﺗ ﻲﻏرﺑ

.ﻖﻓدﺗﯾ ﻻ زﺎﻐﻟا

رﯾﻏ ﺔﻧاوطﺳﻷا نأ دﻛﺄﺗ وأ ﻖﻠﻐﻣ رﯾﻏ زﺎﻐﻟا ﻖﻓدﺗ ةدﺣو مﺎﻣﺻ نأ دﻛﺄﺗ

.ﺔﻏرﺎﻓ

:ءﻼﻣﻌﻟا ﺔﻣدﺧو نﺎﻣﺿﻟا

WWW.BERTAZZONI .COM

16

فﯾظﻧﺗﻟا \ مادﺧﺗﺳﻻا \

ز

ﺗ

زﺎﮭﺟﻟا فﯾظﻧﺗ

ﺎﮭﺟﻟا فﯾظﻧ

زﺎﻐﻟا ﺔﻛﺑﺷ نﻋ ﮫﻠﺻﻓاو دﻗوﻣﻟا ءازﺟأ ﻊﯾﻣﺟ درﺑﺗ ﻰﺗﺣ رظﺗﻧا

.فﯾظﻧﺗ ﺔﯾﻠﻣﻋ يﺄﺑ مﺎﯾﻘﻟا لﺑﻗ ءﺎﺑرﮭﻛﻟاو

:دﻗوﻣﻟا فﯾظﻧﺗ

ﻲﻠطﻣﻟا ذﻻوﻔﻟا نﻣ تﺎﻛﺑﺷﻟاو تﻼﻌﺷﻟا سوؤر فﯾظﻧﺗﺑ موﻘﺗ نأ بﺟﯾ

مﮭﻔطﺷو نوﺑﺎﺻو رﺗﺎﻓ ءﺎﻣﺑ ﺎًﯾرود بﮭﻠﻟا تﺎﻋزوﻣو ﺔﯾﻠطﻣﻟا ﺔﯾطﻏﻷاو

.اًدﯾﺟ مﮭﻔﯾﻔﺟﺗ مﺛ

.شﺎﻣﻘﻟا نﻣ ﺔﻌطﻗ مادﺧﺗﺳﺎﺑ ﻲﻧاوﻷا نﻣ طﻗﺎﺳﺗﻣ لﺋﺎﺳ يأ ﺔﻟازإ بﺟﯾ

ﻻ ،زﺎﻐﻟا ﻖﻓدﺗ طﺑﺿ تﺎﻣﺎﻣﺻ نﻣ يأ ﻖﻠﻏو ﺢﺗﻓ ﺔﺑوﻌﺻ ﺔﻟﺎﺣ ﻲﻓ

.روﻔﻟا ﻰﻠﻋ ﺔﯾﻧﻔﻟا ةدﻋﺎﺳﻣﻟا لﺧدﺗ بﻠطا نﻛﻟو ،فﻧﻌﺑ ﮫﺣﺗﻔﺗ

:ﺔﯾﻠطﻣﻟا ءازﺟﻷا فﯾظﻧﺗ

نوﺑﺎﺻﻟاو ءﺎﻣﻟﺎﺑ رارﻣﺗﺳﺎﺑ ﺔﯾﻠطﻣﻟا ءازﺟﻷا فﯾظﻧﺗ يرورﺿﻟا نﻣ دﻌُﯾ

بﻧﺟﺗ .ﺔطﺷﺎﻛ ﻖﯾﺣﺎﺳﻣ ﺎًﻘﻠطﻣ مدﺧﺗﺳﺗ ﻻ .ﺎﮭﺻﺋﺎﺻﺧ ﻰﻠﻋ ظﺎﻔﺣﻠﻟ

،لﺧﻟﺎﻛ) ﺔﯾﻠطﻣﻟا ءازﺟﻷا نﻣ يأ ﻰﻠﻋ ﺔﯾوﻠﻗ وأ ﺔﯾﺿﻣﺣ داوﻣ ﻊﺿو

لﺳﻏ ﺎًﺿﯾأ بﻧﺟﺗ و (ﺦﻟإ... مطﺎﻣطﻟا رﯾﺻﻋ ،ﺢﻠﻣﻟا ،نوﻣﯾﻠﻟا رﯾﺻﻋ

.ﺔﻧﺧﺎﺳ لازﺗ ﺎﻣ ﺎﻣﻧﯾﺑ ﺔﯾﻠطﻣﻟا ءازﺟﻷا

:أدﺻﻠﻟ موﺎﻘﻣﻟا ذﻻوﻔﻟا نﻣ ءازﺟﻷا فﯾظﻧﺗ

شﺎﻣﻘﻟا نﻣ ﺔﻌطﻘﺑ مﮭﻔﯾﻔﺟﺗﺑ مﻗ مﺛ نوﺑﺎﺻﻟاو ءﺎﻣﻟﺎﺑ ءازﺟﻷا هذھ فظﻧ

كﻧﻛﻣﯾ قوﺳﻟا ﻲﻓ ﺔﻟوادﺗﻣﻟا ﺔﺻﺎﺧﻟا داوﻣﻠﻟ مظﺗﻧﻣﻟا لﺎﻣﻌﺗﺳﻻﺎﺑو .لﻠﺑﻣﻟا

.طﺷﺎﻛ ﺞﻧﻔﺳإ وأ ﻖﯾﺣﺎﺳﻣ ﺎًﻘﻠطﻣ مدﺧﺗﺳﺗ ﻻ .زﺎﮭﺟﻟا ﻖﯾرﺑ ﻰﻠﻋ ظﺎﻔﺣﻟا

:بﮭﻠﻟا ﻊﯾزوﺗﺑ ﺔﺻﺎﺧﻟا تﻼﻌﺷﻟا فﯾظﻧﺗ

نوﺑﺎﺻﻟاو ءﺎﻣﻟﺎﺑ مﮭﻠﺳﻏو مﮭﻧﻛﺎﻣأ نﻣ مﮭﻋزﻧ ﻲﻔﻛﯾ ،مﮭﺑﯾﻛرﺗ ﺔﻟوﮭﺳﻟ

ءﺎﻣ تﺣﺗ ﮫﻠﺳﻐﺑ مﻘﺗ ﻻو ءﺎﻣﻟا ﻲﻓ ًﺎﻘﻠطﻣ زﺎﮭﺟﻟا رﻣﻐﺗ ﻻ .مﮭﻔﯾظﻧﺗﻟ

ﻰﻟإ مھدﻋا بوﻘﺛﻟا دادﺳﻧا مدﻋ نﻣ دﻛﺄﺗﻟاو ﺎًﻣﺎﻣﺗ مﮭﻔﯾﻔﺟﺗ دﻌﺑو .يرﺎﺟ

.ىرﺧأ ةرﻣ مﮭﻌﺿو

:ﻲﺟﺎﺟزﻟا ﺢطﺳﻟا فﯾظﻧﺗ

فظﻧ وأ ،فطﺷا مﺛ موﺣﺷﻟا ﺔﻟازﻹ لﺧﻟاو قﺎﺑطﻷا فظﻧﻣ مدﺧﺗﺳا

.فﻔﺟو ﺔﻠﻠﺑﻣ شﺎﻣﻗ ﺔﻌطﻗ ررﻣ مﺛ فطﺷاو نوﺣﺻﻟا فظﻧﻣ مادﺧﺗﺳﺎﺑ

وأ ﻲﻧوﺑﺎﺻ ءﺎﻣ ﺎﮭﻔﯾظﻧﺗ بوﻠطﻣﻟا ﺔﻘطﻧﻣﻟا ﻰﻠﻋ ﻊﺿ تﺎﺑﺳرﺗﻟا ﺔﻟازﻹ

.دﻗوﻣﻟا لﺳﻏاو ﻖﺋﺎﻗد ﻊﺿﺑ رورﻣ دﻌﺑ فطﺷا .قﺎﺑطأ فظﻧﻣ

ةددﻌﺗﻣو ﺔطﺷﺎﻛﻟا تﺎﺟﺗﻧﻣﻟاو تﺎﺑﺳرﺗﻟا ﺔﻟازإ تﺎﺟﺗﻧﻣ بﻧﺟﺗ

.تﻗوﻟا رورﻣ ﻊﻣ ﺎًﺣﯾﺑﻗ ﺢﺑﺻﯾ جﺎﺟزﻟا نﻷ تﺎﻣادﺧﺗﺳﻻا

:تﺎﻛﺑﺷﻟا فﯾظﻧﺗ

.قﺎﺑطﻷا ﺔﻟﺎﺳﻏ ﻲﻓ تﺎﻛﺑﺷﻟا لﺳﻐﺗ ﻻ

ﻲﻧاوأ ﻊﻣ يدﺎﻌﻟا كﺎﻛﺗﺣﻻا ﺔﺟﯾﺗﻧ تﺎﻛﺑﺷﻟا ﻰﻠﻋ ءﺎﺿﯾﺑﻟا ﺎﯾﺎﻘﺑﻟا ثدﺣﺗ

.ءﻼطﻟﺎﺑ شودﺧ وأ بوﯾﻋ ﻰﻟإ رﯾﺷﺗ ﻻو ﻲﮭطﻟا

نﺎﻣﻷا مﺎظﻧ

لﻛ ﻰﻠﻋ (يرارﺣ جودزﻣ) بﮭﻠﻟا دوﺟو رﺎﻌﺷﺗﺳا زﺎﮭﺟ تﯾﺑﺛﺗ مﺗﯾ

.بﮭﻠﻟ ﻲﺿرﻌﻟا ءﺎﻔطﻹا ﺔﻟﺎﺣ ﻲﻓ زﺎﻐﻟا برﺳﺗ ﻊﻧﻣﻟ ﺔﻠﻌﺷ

عﺎطﻘﻧا ﺔﻟﺎﺣ ﻲﻓ رطﺧ نود ﺢﯾﺣﺻ لﻛﺷﺑ لﻣﻌﻟا ﻲﻓ دﻗوﻣﻟا رﻣﺗﺳﯾ

.ﻲﺋﺎﺑرﮭﻛﻟا رﺎﯾﺗﻟا

يودﯾﻟا لﺎﻌﺷﻹا

:ﻲﺋﺎﺑرﮭﻛﻟا رﺎﯾﺗﻟا عﺎطﻘﻧا ﺔﻟﺎﺣ ﻲﻓ ﺎًﯾودﯾ تﻼﻌﺷﻟا لﺎﻌﺷإ نﻛﻣﯾ

ﺔﻋﺎﺳﻟا برﺎﻘﻋ هﺎﺟﺗا سﻛﻋ ﻲﻓ ﺔﺑوﻠطﻣﻟا ﺔﻠﻌﺷﻟﺎﺑ صﺎﺧﻟا حﺎﺗﻔﻣﻟا ردأ

.رﯾﺑﻛ دﯾدﺷ بﮭﻟ لﺑﺎﻘﯾ ﺎﻣﺑ ﻰﺻﻗﻷا ﻊﺿوﻟا ﻰﻠﻋ ﮫطﺑﺿاو

ّ

نﻣ بﮭﻟ وأ ﺔﺣا

ٍناوﺛ 10 ةدﻣﻟ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿﻟا ﻲﻓ رﻣﺗﺳا ﺔﻠﻌﺷﻟا لﺎﻌﺷإ دﻧﻋ

.رﻌﻘﻣ رﻌﻗ تاذ ﺔﯾﻋوأ ﻊﻣ جﺎﺗﻟا تﻼﻌﺷﻟا ﻰﻠﻋ مادﺧﺗﺳﻼﻟ ﺔﯾﻓﺎﺿإ ﺔﻛﺑﺷ

نﻋ لﻘﯾ رطﻘﺑ ﺔﯾﻋوﻸﻟ ةدﻋﺎﺳﻣﻟا ﺔﻠﻌﺷﻟا ﻰﻠﻋ مادﺧﺗﺳﻼﻟ ﺔﯾﻓﺎﺿإ ﺔﻛﺑﺷ

دﻗ بﯾرﻘﺗﺑ مﻗو زﺎﻐﻟا قﻼطﻹ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿا

.ﺔﻠﻌﺷﻟا

.هررﺣ مﺛ ﺎًﺑﯾرﻘﺗ

تﺎﻘﺣﻠﻣﻟا

ةﻼﻘﻣ ﺔﻠﻌﺷ لوﺣﻣ

ةوﮭﻘﻟا ﻖﯾرﺑﻹ ضﻔﺧ ةدﺣو

.مﺳ 12

15

مادﺧﺗﺳﻻا \

(ترﻓاوﺗ ﺎﻣﻧﯾأ) ﺔﺟودزﻣﻟا ﺔﻠﻌﺷﻟا مادﺧﺗﺳا

وأ لﻣﺎﻛﻟﺎﺑ ﺔﺟودزﻣﻟا ﺔﻠﻌﺷﻟا لﺎﻌﺷإ نﻛﻣﯾ ﺔﻧورﻣﻟا نﻣ دﯾزﻣﻟا ءﺎﻔﺿﻹ

.طﻘﻓ ﺔﯾﻠﺧادﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟا

ﺔﻋﺎﺳﻟا برﺎﻘﻋ هﺎﺟﺗا سﻛﻋ ﻲﻓ ﺔﺑوﻠطﻣﻟا ﺔﻠﻌﺷﻟﺎﺑ صﺎﺧﻟا ضﺑﻘﻣﻟا ردا

.(1 ﻰﺻﻗﻷا) ﻊﺿوﻟا ﻰﻠﻋ ﮫطﺑﺿاو

.لﺎﻌﺷﻹا لﯾﻌﻔﺗو زﺎﻐﻟا قﻼطﻹ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿا

ٍناوﺛ 10 ةدﻣﻟ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿﻟا ﻲﻓ رﻣﺗﺳا ﺔﻠﻌﺷﻟا لﺎﻌﺷإ دﻧﻋ

.هررﺣ مﺛ ﺎًﺑﯾرﻘﺗ

.لﻣﺎﻛﻟﺎﺑ تاوطﺧﻟا ررﻛ ،ضﺑﻘﻣﻟا كرﺗ دﻌﺑ ﺔﻠﻌﺷﻟا ءﺎﻔطﻧا ﺔﻟﺎﺣ ﻲﻓ

بﮭﻟ) ﺔﺟرد لﻗأ ﻰﻠﻋ 2 ﻊﺿوﻣﻟا دﻧﻋ ﺔﯾﺟرﺎﺧﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟا ﺢﺑﺻﺗ

(دﯾدﺷ بﮭﻟ) بﮭﻠﻟ ﺔﺟرد ﻰﻠﻋأ ﻰﻠﻋ ﺔﯾﻠﺧادﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟاو (ضﻔﺧﻧﻣ

بﮭﻟ) ﺔﺟرد ﻰﻠﻋأ ﻰﻠﻋ 3 ﻊﺿوﻣﻟا دﻧﻋ ﺔﯾﻠﺧادﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟا ﺢﺑﺻﺗ

ةﺄﻔطﻣ ﺔﯾﺟرﺎﺧﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟاو (دﯾدﺷ

بﮭﻟ) ﺔﺟرد لﻗأ ﻰﻠﻋ 4 ﻊﺿوﻣﻟا دﻧﻋ ﺔﯾﻠﺧادﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟا ﺢﺑﺻﺗ

.ةﺄﻔطﻣ ﺔﯾﺟرﺎﺧﻟا جﺎﺗﻟا ﺔﻠﻌﺷﻟاو (ضﻔﺧﻧﻣ

لﺎﻣﻌﺗﺳﻻا

تﺎﯾاوﺷﻟاو تﻼﻌﺷﻟا

ثﯾﺣﺑ ﺔﺣﯾﺣﺻ ةروﺻﺑ تﻼﻌﺷﻟا ﺔﯾطﻏأو بﮭﻠﻟا تﺎﻋزوﻣ ﻊﺿو بﺟﯾ

.ﺢﯾﺣﺻ لﻛﺷﺑ دﻗوﻣﻟا لﻣﻌﯾ

X

X

مﺳ (نﺳﺣﺗﺳﯾ)

:تﻼﻌﺷﻠﻟ زﺎﺗﻣﻣﻟا مادﺧﺗﺳﻼﻟ ﺢﺋﺎﺻﻧ

.(ضﻔﺧﻧﻣ بﮭﻟ)

ً

ﺎﻣﺋاد مدﺧﺗﺳا

ﺔﻠﻌﺷﻟاﻲﮭطﻟا ءﺎﻧإ رطُﻗ

ةدﻋﺎﺳﻣ14 - 12

ﺔﻌﯾرﺳ فﺻﻧ26 - 14

ﺔﻌﯾرﺳ26 - 18

جﺎﺗ ﺔﻠﻌﺷ26 - 22

ﺔﺟودزﻣ ﺔﻠﻌﺷ26 - 22

ﻰﻟإ تﻼﻌﺷﻟا ﺔﯾطﻏأو بﮭﻠﻟا تﺎﻋزوﻣﻟ ﺊطﺎﺧﻟا ﻊﺿوﻟا يدؤﯾ نأ نﻛﻣﯾ

.ﺔﻠﻌﺷﻟا فﻠﺗ

.دﻗوﻣﻟا لﺧاد ﺎﮭﻧﺎﻛﻣ ﻲﻓ تﺎﻛﺑﺷﻟا ﻊﺿو بﺟﯾ

تﻼﻌﺷﻟا مادﺧﺗﺳا

.مﻛﺣﺗﻟا ﺔﺣوﻟ ﻰﻠﻋ ضﺑﻘﻣ لﻛﺑ ﺔﻘﻠﻌﺗﻣﻟا ﺔﻠﻌﺷﻟا ﻰﻟإ رﺎﺷُﯾ

ﺔﻋﺎﺳﻟا برﺎﻘﻋ هﺎﺟﺗا سﻛﻋ ﻲﻓ ﺔﺑوﻠطﻣﻟا ﺔﻠﻌﺷﻟﺎﺑ صﺎﺧﻟا حﺎﺗﻔﻣﻟا ردأ

.رﯾﺑﻛ دﯾدﺷ بﮭﻟ لﺑﺎﻘﯾ ﺎﻣﺑ ﻰﺻﻗﻷا ﻊﺿوﻟا ﻰﻠﻋ ﮫطﺑﺿاو

.لﺎﻌﺷﻹا لﯾﻌﻔﺗو زﺎﻐﻟا قﻼطﻹ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿا

• .(لودﺟﻟا رظﻧأ) ﺔﺑﺳﺎﻧﻣﻟا ﻲﮭطﻟا ﻲﻧاوأ ﺔﻠﻌﺷ لﻛﻟ مدﺧﺗﺳا

• ﻰﻧدﻷا ﻊﺿوﻟا ﻰﻠﻋ ضﺑﻘﻣﻟا طﺑﺿا نﺎﯾﻠﻐﻟا ﺔﺟردﻟ لوﺻوﻟا دﻧﻋ

• .ءﺎطﻐﺑ ةدوزﻣ ﻲﮭط ﻲﻧاوأ

ٍناوﺛ 10 ةدﻣﻟ ضﺑﻘﻣﻟا ﻰﻠﻋ طﻐﺿﻟا ﻲﻓ رﻣﺗﺳا ﺔﻠﻌﺷﻟا لﺎﻌﺷإ دﻧﻋ

.هررﺣ مﺛ ﺎًﺑﯾرﻘﺗ

.لﻣﺎﻛﻟﺎﺑ تاوطﺧﻟا ررﻛ ،ضﺑﻘﻣﻟا كرﺗ دﻌﺑ ﺔﻠﻌﺷﻟا ءﺎﻔطﻧا ﺔﻟﺎﺣ ﻲﻓ

ﻰﺗﺣ ﺔﻋﺎﺳﻟا برﺎﻘﻋ هﺎﺟﺗا ﻲﻓ ضﺑﻘﻣﻟا رﯾودﺗﺑ مﻗ ﺔﻠﻌﺷﻟا ءﺎﻔطﻹ

رﻔﺻ ﻊﺿوﻣﻟا

14

دﻗاوﻣﻟا فﺻو \

دﻗاوﻣﻟا فﺻو

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ةدﻋﺎﺳﻣ ﺔﻠﻌﺷ 1

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 2

نﯾﺧﺳﺗﻟا رﺻﺎﻧﻋ \ مﻛﺣﺗﻟا تادﺣو

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 3

رﺎﺳﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ﺔﻌﯾرﺳ ﺔﻠﻌﺷ 4

نﯾﺧﺳﺗﻟا رﺻﺎﻧﻋ \ مﻛﺣﺗﻟا تادﺣو

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ةدﻋﺎﺳﻣ ﺔﻠﻌﺷ 1

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 2

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 3

رﺎﺳﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ جﺎﺗ ﺔﻠﻌﺷ 4

نﯾﺧﺳﺗﻟا رﺻﺎﻧﻋ \ مﻛﺣﺗﻟا تادﺣو

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ةدﻋﺎﺳﻣ ﺔﻠﻌﺷ 1

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ ﺔﻠﻌﺷ 2

ﺔﯾزﻛرﻣ جﺎﺗ ﺔﻠﻌﺷ 3

رﺎﺳﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 4

رﺎﺳﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 5

نﯾﺧﺳﺗﻟا رﺻﺎﻧﻋ \ مﻛﺣﺗﻟا تادﺣو

4

3

2

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻣﺎﻣأ ةدﻋﺎﺳﻣ ﺔﻠﻌﺷ 1

نﯾﻣﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ ﺔﻠﻌﺷ 2

ﺔﯾزﻛرﻣ جﺎﺗ وأ ﺔﺟودزﻣ ﺔﻠﻌﺷ 3

رﺎﺳﯾﻟا ﺔﮭﺟ ﺔﯾﻔﻠﺧ ﺔﻌﯾرﺳ فﺻﻧ ﺔﻠﻌﺷ 4

5