Page 1

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

C1120

S5 to II/O-Lightbus Interface

Technical Documentation

VERSION 2.1

Date 27.06.97 Version 2.1 Page 1 of 52

Page 2

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Table of contents

1 FUNCTIONAL DESCRIPTION OF HARDWARE..................................................................................... 3

2 FUNCTIONAL DESCRIPTION OF SOFTWARE...................................................................................... 4

2.1 Installation of Software ..................................................................................................................................... 4

2.2 Main menu......................................................................................................................................................... 5

2.3 Master Setup...................................................................................................................................................... 7

C1120 Configuration......................................................................................................................................... 9

C1120 I/O Memory Map List.......................................................................................................................... 13

Timer and Interrupts........................................................................................................................................ 19

C1100 to C1120 Project Conversion............................................................................................................... 21

Online Menu....................................................................................................................................................22

Debug Menu.................................................................................................................................................... 24

How to get started - setting up an I/O list........................................................................................................ 25

Status register S5 / C1120................................................................................................................................26

Parallel Communication Channel .................................................................................................................... 27

Table of error numbers:................................................................................................................................... 31

Service Routines in STEP 5 language.............................................................................................................. 32

Status LEDs..................................................................................................................................................... 33

2.4 Slave Setup......................................................................................................................................................34

Edit Inputs ....................................................................................................................................................... 36

Edit Outputs..................................................................................................................................................... 37

Edit Configuration........................................................................................................................................... 38

Online Menu....................................................................................................................................................40

2.5 Project Manager .............................................................................................................................................. 42

2.6 System Configuration...................................................................................................................................... 44

System Entry....................................................................................................................................................44

System ............................................................................................................................................................. 45

Language ......................................................................................................................................................... 46

Log File ........................................................................................................................................................... 47

Program Parameter.......................................................................................................................................... 48

3 C1120 INTERFACE: TECHNICAL DATA................................................................................................49

4 INSTALLATION REMARKS......................................................................................................................50

4.1 Assembly to the S5-PLC rack.......................................................................................................................... 50

4.2 Connecting to a PC.......................................................................................................................................... 50

System requirements........................................................................................................................................50

Interface ports for connection with a PC ......................................................................................................... 51

5 C1120 SERIAL PORT PINOUT.................................................................................................................. 52

Page 2 of 52 Version 2.1 Date 27.06.97

Page 3

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

1 Functional description of Hardware

C1120

General

The interface card C1120 is an intelligent interface between the BECKHOFF II/O-Lightbus

System and a SIEMENS SIMATIC S5 PLC. The SIEMENS PLC program is enabled to

access binary and analog inputs and outputs of the II/O-Lightbus System via a Dual Ported

RAM of the interface card. The I/O addresses of the II/O-Lightbus System are mapped to the

S5 I/O address memory map with a configuration program running on a personal computer.

The interface card C1120 is placed in a PLC slot for ‘intelligent peripherial devices’.

Date 27.06.97 Version 2.1 Page 3 of 52

Page 4

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

2 Functional description of Software

For further documentation it is assumed that the interface card C1120 is connected to a PC

running DOS with a serial interface cable to COMx.

2.1 Installation of Software

First step: Backup copy of installation disc

Do not forget to backup your installation disc and use the backup copy instead of the original

software disc.

- switch on your PC

- Use DISCCOPY to backup your installation disc

- Use your backup disc for the installation.

Installation to hard disc

1. switch on your PC

2. (generate and) change to your destination directory

3. insert the installation disc copy to floppy drive A:.

4. change to drive A:;

4. type: ’INSTALL C: <RETURN>’

The installation routine will copy all files to your destination directory of disc C: (or equiv.).

Start of program

start the C1120 setup program with ’PROGRAM <RETURN>’ from your

destination directory of your PC.

Page 4 of 52 Version 2.1 Date 27.06.97

Page 5

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

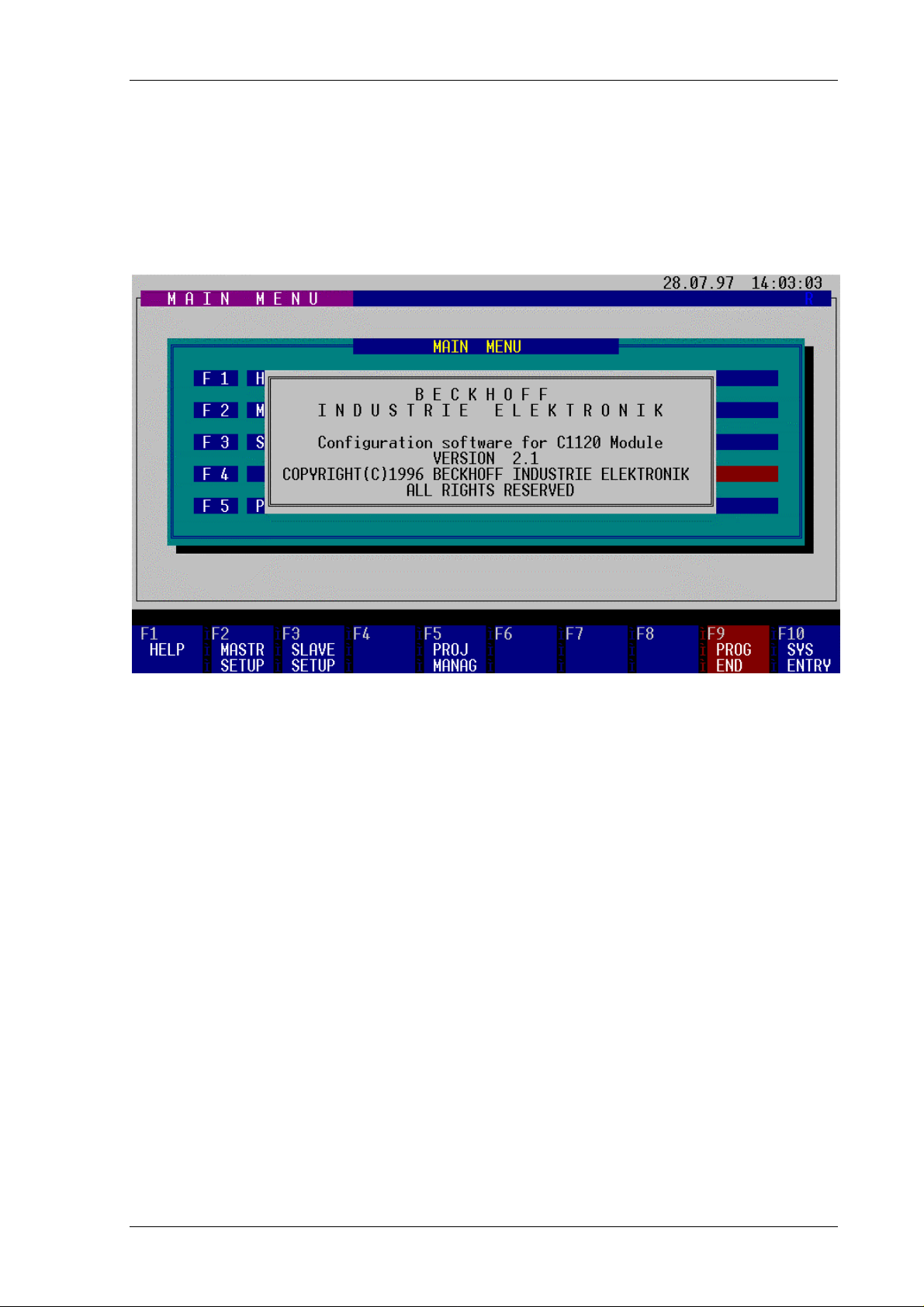

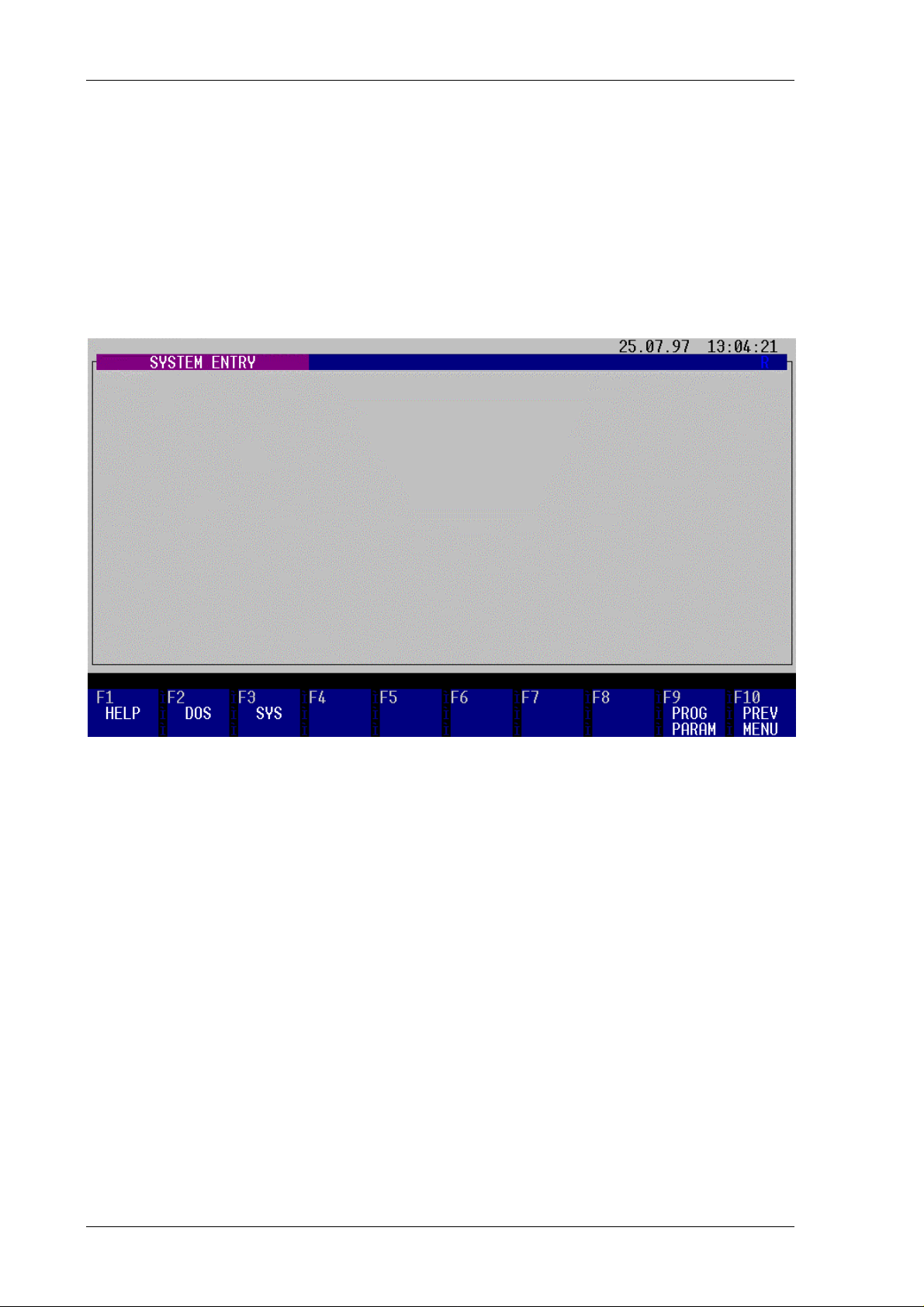

2.2 Main menu

First screen after the start of program shows:

All actions are taken with the function keys F1 to F10. Some actions are provided with

security questions. If the desired action is valid, type ‘J’ or ‘Y’ to activate, ‘N’ or ESC to quit.

By choosing the key ESC you are able to return to the higher menu levels.

Function keys

F1 HELP

Shows a help text for the equivalent menu and function keys.

F2 MASTER SETUP

changes to the master setup menu to map the II/O Lightbus System addresses to

the I/O addresses of the SIEMENS PLC.

F3 SLAVE SETUP

changes to slave setup

F5 PROJECT MANAGER

changes to the project manager menu to choose the working project from a list of

(setup) projects.

Date 27.06.97 Version 2.1 Page 5 of 52

Page 6

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

F9 PROGRAM END

returns to DOS after closing the application.

F10 SYSTEM ENTRY

changes to the setup menu of the running program.

Page 6 of 52 Version 2.1 Date 27.06.97

Page 7

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

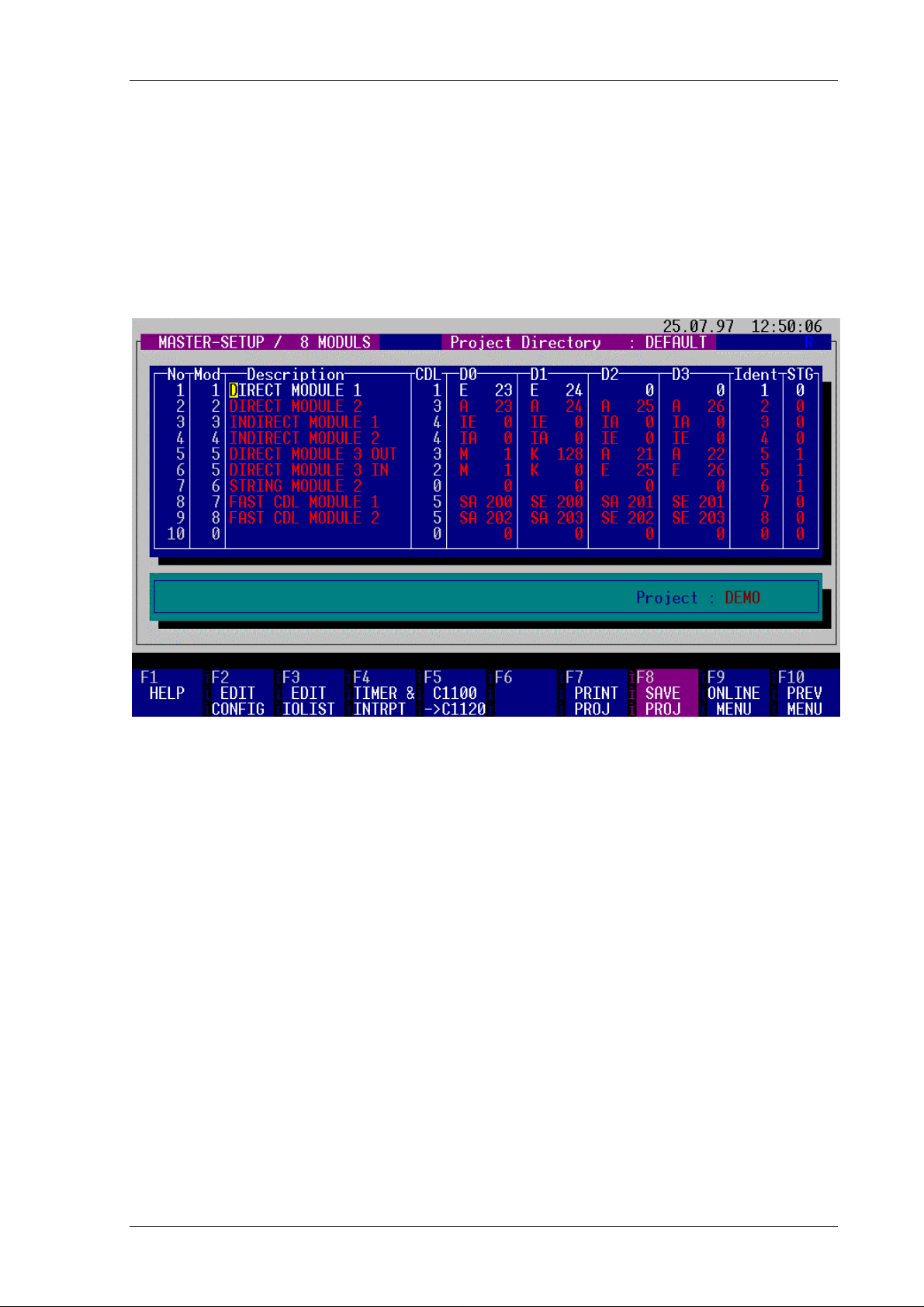

2.3 Master Setup

The master setup menu is accessed by pressing F2 key from the main menu. With this menu,

the address mapping between the II/O-Lightbus system and the SIEMENS PLC is displayed

and can be edited, saved under a project name and transfered from and to the C1120 card.

The screen shows different fields for input, status line and function key setup.

Function keys:

F1 HELP

Shows a help text for the equivalent menu and function keys.

F2 EDIT CONFIGURATION

with this menu you can change the C1120 configuration.

F3 EDIT I/O LIST

with this menu you can modify the I/O address map list.

F4 TIMER & INTERRUPTS

with this menu you can configure the four fast fieldbus interrupts of the Beckhoff

II/O Lightbus System.

Date 27.06.97 Version 2.1 Page 7 of 52

Page 8

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

F5 C1100 -> C1120

with this menu projects of the Beckhoff C1100 card are converted to C1120

projects.

F7 PRINT I/O LIST

prints the I/O map to your printer on LPT1:.

F8 SAVE PROJECT

stores the setup of C1120 under a project name - if first time used you are asked

for a project name. At further store commands, a <RETURN> stores under

existing project name.

F9 ONLINE MENU

changes to the communication menu to exchange data with the C1120 card.

F10 PREVIOUS MENU

returns to the previous menu.

Page 8 of 52 Version 2.1 Date 27.06.97

Page 9

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

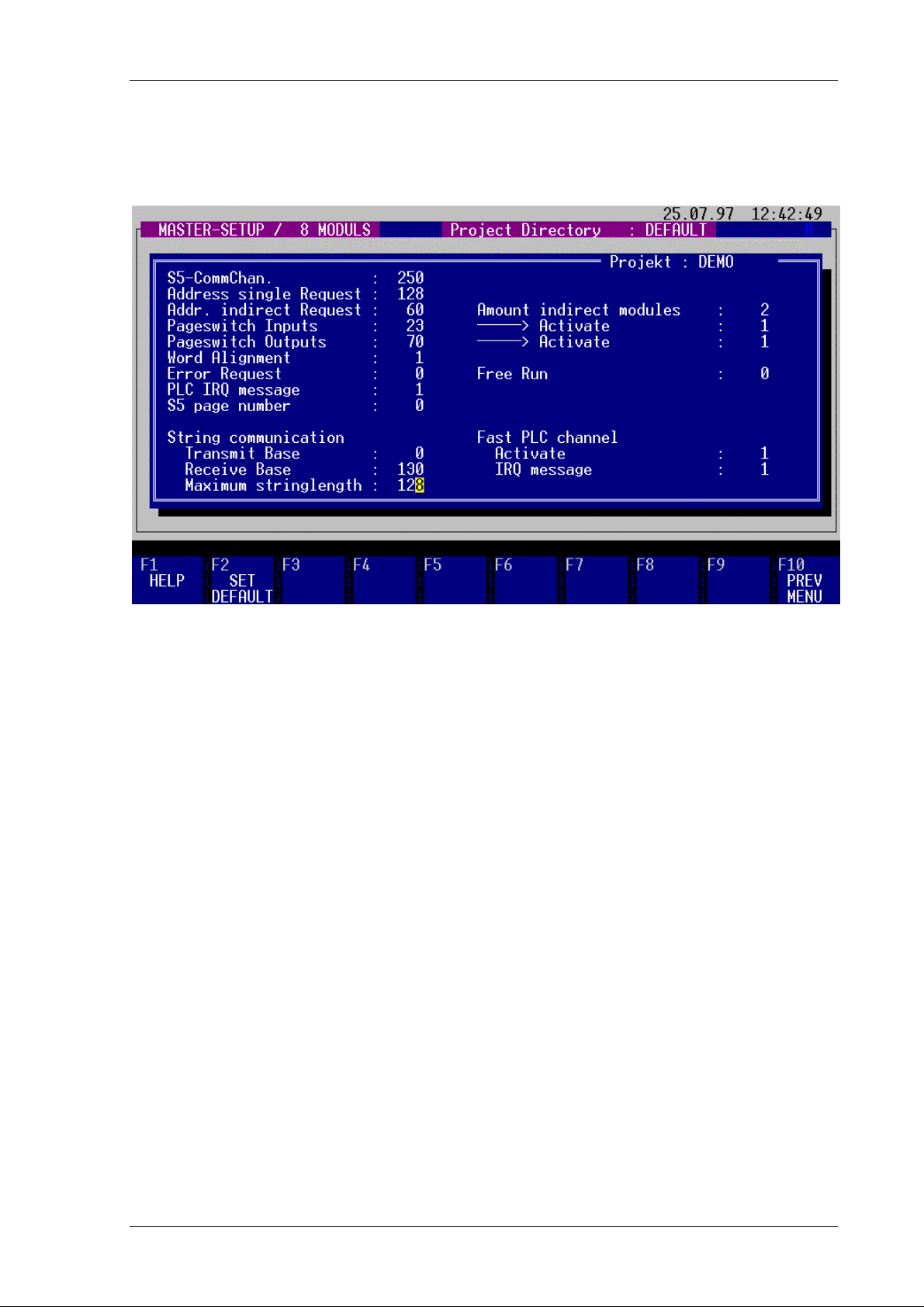

C1120 Configuration

with this menu you can change the C1120 configuration to setup all necessary parameters for

the C1120 interface.

The field "S5-CommChannnel" describes the base address for the parallel channel functions

(see chapter "parallel channel" ). For use of more than one C1120 cards in one PLC the base

address default of 250 for the communication channel can be changed to an other address (

from address 128 - 250, length 6 Byte ). The address for status register will automatically

change to input value +4 and the address for interrupt request will change to input value +5.

A single request is able to access an II/O Lightbus module directly without synchronized

exchange with the process image (between read of input process image and output process

image write)*, by use of the STEP 5 commands "Load I/O process peripherials" e.g. "

Transfer I/O process peripherials ". Therefore, the base address "Address single request" of

an address block for the single request is to be defined between 128 and 250. By setting a "0"

for the base address "Address single request" the single request is disabled.

________________

* the PLC updates the Transfer Pr oc ess Image automatically

Date 27.06.97 Version 2.1 Page 9 of 52

Page 10

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

To enlarge the I/O address space, the use of "indirect modules" is available - a list of module

data fields is stored in the C1120 RAM memory. The base address to exchange data with the

Process image of the PLC is defined here (see equiv. chapter).

To obtain correct data for the PLC process image, the process image memory of the C1120 is

divided in pages, which each by each are switched towards the PLC and towards the II/O

Lightbus to refresh data contents. The pageswitch mechanism changes the memory pages to

and from the PLC. The pageswitch inputs are defined as lowest address, the pageswitch

outputs are defined as highest address by default.

By writing a "1" to the field "word alignment", the PLC is enabled to access the process

image by word commands (16 bit - wise) The necessary selects are generated automatically.

For use of more than one C1120, the word alignement can be disabled by overwriting a "0".

The default setup value of "0" in the field "Error request" enables the C1120 to stop the PLC

with a timeout status of the C1120 in case errors occur on the II/O-Lightbus System, the

C1120 interface deletes the I/O addresses in the Dual Ported RAM mapped to the PLC in case

of error. By programming OB 23 and OB 28 the timeout can be managed by PLC software.

By setting the field value "Error request" to "1", the I/O addresses are not deleted in case of

errors. The latest input data values are held in place, the writing of outputs data is confirmed,

but writing is not executed, the error flag in the status byte is set.

IMPORTANT REMARK:

By use of option "1" the user has to achieve the check of the status byte error

flag in every PLC cycle to branch into a error routine, if the error flag is set.

After occurance of the error flag the fault number and number of modules can

be read via the parallel communication channel. After return from the fault

situation (repair of fiber optic media) a start of the II/O-Lightbus System can be

forced by resetting the C1120 by software from the PLC.

In case of no success of the reset function, the error flag is set again, and as a

return value of the function RESET-LWL the value of the init- error is returned

(refer to chapter "Parellel communication channel").

Page 10 of 52 Version 2.1 Date 27.06.97

Page 11

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

By setting the "Free Run" option to "1" in the equivalent mask, the inputs of the II/O-Lightbus

System are read asyncronously to the PLC- process image at maximum II/O Lightbus

communication refresh rate. The pageswitch mechanism displayes the newest process image

memory page to the PLC.

Entering a “1” in the field PLC IRQ Frame causes the C1120 to send an extra control and

interrupt message frame for triggering a local process image cycle on the intelligent peripheral

modules. Those message frames are appended to the process data message frames.

The current page address of the C1120 is entered in the Page Number field.

String communication is used for communicating with intelligent peripheral modules. It can

be used, among other things, for configuring the modules. The data packages (strings) are

transmitted to the C1120 by way of the page frame.

The field Transmit Basis is for entering the page frame offset for the strings being sent. It

should be noted that starting from the offset, 2 bytes are reserved for the handshake between

PLC and C11220. The actual string is entered starting at the offset + 2.

The field Receive Basis is for entering the page frame offset for the st rings being received. It

should be noted that starting from the offset, 2 bytes are reserved for the handshake between

PLC and C11220. The actual string is entered starting at the offset + 2.

The field Maximum String Length is for entering the maximum permissible length of the

strings.

The purpose of the fast communications channel is for improved process synchronisation

during multi-processor operation (see also “Fast Communications Channel”).

Entering a “1” in the Activate field enables the fast communications channel (see also “Fast

Communications Channel”).

Entering a “1” in the field IRQ Frame causes the C1120 to send an extra control and

interrupt message frame for triggering a local process image cycle on the intelligent peripheral

modules assigned to the process channel. Those message frames are appended to the process

data message frames.

Date 27.06.97 Version 2.1 Page 11 of 52

Page 12

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

function keys

F1 HELP

displays help text.

F2 SET DEFAULT

sets configuration parameters to default.

F10 PREVIOUS MENU

returns to the master setup menu.

IMPORTANT REMARK regarding the page number:

The page number for data exchange with the PLC is configurable, beginning with

interface version numbers above V 1.51. Up to Version 1.51, the page number for

data exchange is 0 by default.

Page 12 of 52 Version 2.1 Date 27.06.97

Page 13

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

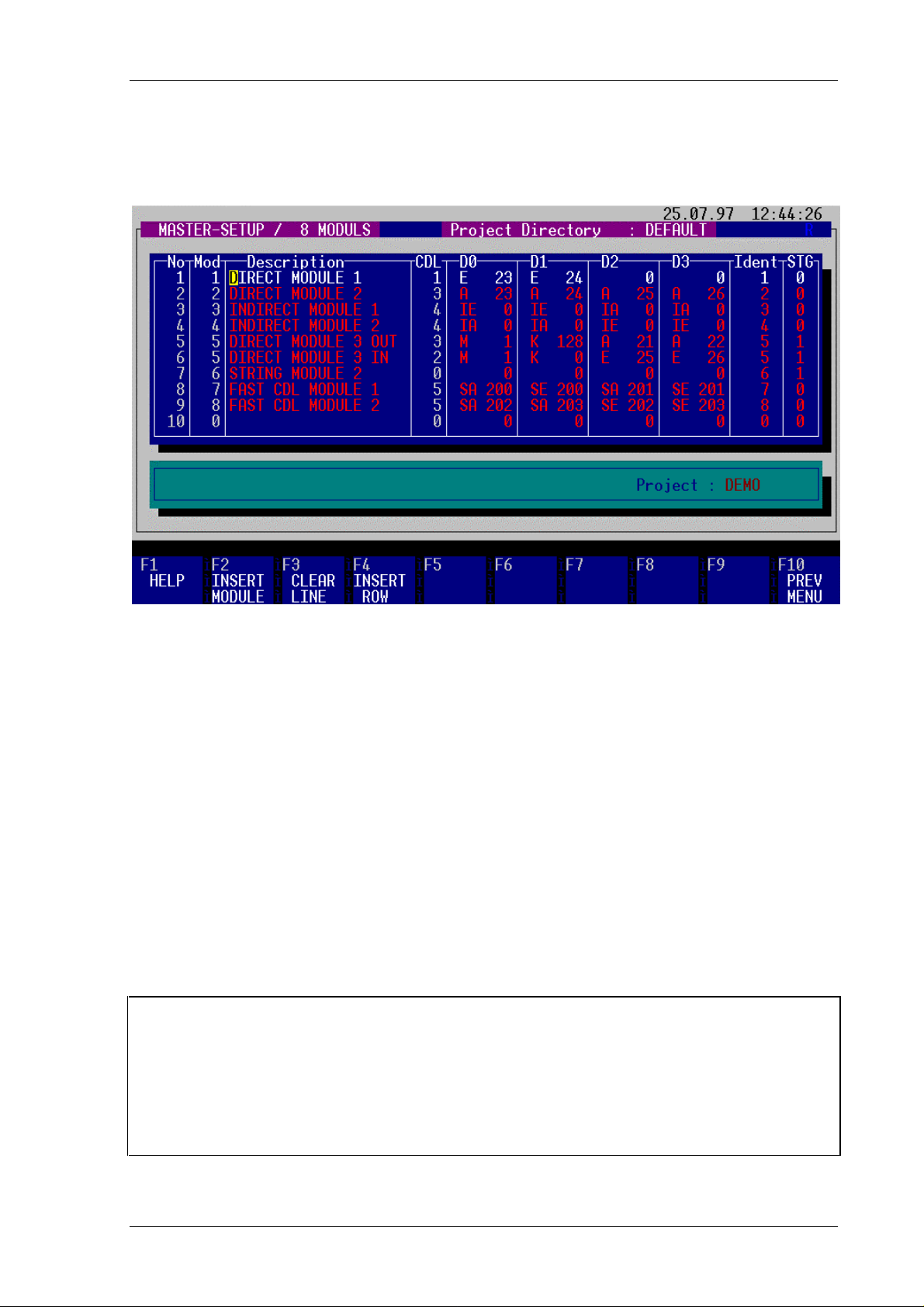

C1120 I/O Memory Map List

All used II/O-Lightbus modules must be listed in the I/O list. The order of modules in the I/O

list must reflect their physical position in the II/O-Lightbus System ring.

First step is to edit the I/O list:

Each new module is to be introduced to the list by pressing "F2": "Insert module". No actions

take place during editing without adding a module as described. Addresses of existing

modules can be edited and overwritten easily, modules can be deleted by pressing "F3". If a

module is deleted, it has to be removed from the II/O-Lightbus System ring.

The coloumn "No" holds the actual line number. The coloumn "Mod" holds the corresponding

module address. The coloumn "Msg" is without further use. The coloumn "Description" keeps

a 20 character user description of the module name or function. The "CDL" - coloumn is used

internally.

The address name of the SIEMENS PLC process image is entered in the fields "D0" to "D3".

You can use any order or use addresses twice etc.

The coloumn "Ident" maps the indirect modules to their physical II/O-Lightbus address.

In the column “STG”, those modules that are to be processed as part of the string

communication are identified by a “1”. Those modules are similarly assigned to their

physical module addresses by means of the Ident number.

Warning ! The interface card C1120 is not able to identify modules. If the I/O list and

physical order of modules are different, or the inputs and outputs are set up

incorrectly by DIP switches, I/O data is transferred erroneous from the PLC

program to the modules without recognition.

Date 27.06.97 Version 2.1 Page 13 of 52

Page 14

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Function keys

F1 HELP

displays help text.

F2 INSERT MODULE

by pressing "F2" a new module is inserted at the current cursor position. The

address is set to the equivalent line number. Following module addresses are

incremented. After inserting a new module, description, I/O addresses and ident

no. can be edited. Every line of the I/O list, containing a module number and I/O

addresses, generates one telegram for II/O-Lightbus per PLC cycle.

F3 CLEAR MODULE

by pressing "F3" a line of the II/O setup is deleted. A confirmation is necessary

for that action to take place.

Warning ! In case of deleting a module from the I/O list, it is definitively

necessary to remove the equivalent module from the II/OLightbus ring. Otherwise the II/O-Lightbus ring is incorrectly

configured and is not ready to work.

F4 INSERT ROW

If it is necessary to serve a module with more than one telegram per cycle,

additional telegrams are generated by inserting a line to an existing module entry.

In this case, the inserted line holds the same module number as the line before.

F10 PREVIOUS MENU

returns to the master setup menu.

Page 14 of 52 Version 2.1 Date 27.06.97

Page 15

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Modules can be set up in the configuration list as:

- direct module or

- indirect module,

depending on the necessity of access in every PLC cycle. This is supplied to enlarge the

address space of the PLC above 128 bytes process image.

Direct modules

Direct modules are mapped directly to the PLC process image. The PLC process image

addresses are edited in the I/O byte addresses D0 to D3 of every telegram frame belonging to

the module - each line in the setup screen belongs to a dedicated II/O-Lightbus telegram frame

to the addressed module. The address names (e.g. O 10) of the PLC programm are used for

reference.

Example given: the modules 1 and 2 are mapped as direct modules. The STEP5 program

accesses the I/O addresses 23 to 26, the C1120 maps the I/O data to the modules 1 and 2:

IB 23, IB 24 from module 1

OB 23, OB 24, OB 25, OB 26 to module 2

The inputs and outputs can be addressed bit-, byte-, or wordwise:

I 23.0 ... I 23.7, oder IW 23 = IB 23 & IB 24

are handled as usual.

All direct mapped modules are refreshed synchronously and cyclic with the PLC cycle and

process image refresh. The direct mapped modules can be accessed directly from the PLC

program at any time.

The modules 7 and 8 are also direct modules. However, they are assigned to the fast

communications channel by means of their identification codes “SA” and “SE” respectively.

If intelligent modules are to be addressed during the PLC cycle (e.g. terminal bus coupler) the

first two data bytes (D0, D1) can be assigned constants. Those constants are entered with the

identification codes “M” (for memory) and “C” (for constant).

In the example, D0 on module 5 is assigned the fixed value 1 (“M”) and D1 the fixed value

128 (“C”).

Date 27.06.97 Version 2.1 Page 15 of 52

Page 16

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Indirect modules

To enlarge the address space of the PLC system, modules can be mapped "indirectly":

they are accessed via a list of "indirect" communications, being addressed by a dedicat ed base

address. These communications are processed in every PLC cycle. They can be used to

enlarge the address space of 128 I/O Bytes of the PLC by placing the base address of the

indirect communication list above 128. Another option is to change the contents of the I/O list

cycle by cycle: a part of the II/O-Lightbus modules are mapped in a round robin way to the

indirect I/O list to fit the to tal number of II/O Lightbus I/O bytes to the I/O address space of

the PLC, with the effect, that those modules are being served only at occurence in the indirect

communications list. One or more modules can be mapped to the indirect communications

list. A single address block consists of the module address (IDENT number) and four bytes of

I/O data. The reservation of memory space is done with the menu "Edit configuration": After

definition of the base address of the indirect I/O list it is necessary to allocate 5 x (number of

modules) Bytes list size: First byte contains the address number, following four bytes

containing the I/O data. The list ends with a "0" found in an address byte location. These

addresses are not available for standard I/O via PLC process image transfer. Address conflicts

have to be avoided by the PLC programmer.

Arbitration of indirect modules

Indirect modules are listed in the I/O setup list, coloumn "D0 .. D3" with IE or IA, with

address number 0. The choice of IE or IA is without use for the communication and only

indicates the configuration of the II/O-Lightbus modules for input (IE) or output (EA).

By use of the indirect communications list every module in the II/O Lightbus System can be

accessed, even the direct configured: Their IDENT- number has to be placed in the first

address block address location, following four bytes keep I/O data. By this, the module is

accessed via the indirect communication mechanism. By replacing the IDENT number in the

first location of the address block with "0", the indirect communication is skipped. If the

programmer decides to address a direct module via indirect communication, the module is

addressed twice by the II/O-Lightbus System.

Important! If inputs are read via indirect communication, the programmer has to regard

that input informations are valid one cycle after the following. Outputs are

written during the following cycle . This effect can be managed by using the

statusbyte of the PLC (PB/PY 254): Bit 1 acts as life bit and changes status

every cycle. By reading the life bit the programmer can recognize and count

cycles (refer also to chapter "status register S5/C1120).

Example:

In above shown setup screen the modules 3 and 4 are mapped indirect. The base address for

indirect communications list is set up to 60, number of indirect modules is 2. By this, 10

Bytes of address block space are available for the programmer: By te 60 contains the IDENTnumber of module 3 (3), the bytes 61 to 64 are I/O data for module 3. Address 65 keeps the

IDENT number of module 4 (4), bytes 66 to 69 are I/O data for module 4. Byte 70 is available

for standard or direct I/O.

Page 16 of 52 Version 2.1 Date 27.06.97

Page 17

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Arbitration of a single load /transfer of peripherial bytes

As used with the indirect communications list every module in the II/O Lightbus System can

be accessed immediately via a single communication list: The IDENT- number of a dedicated

module has to be placed in the first address block address location, following four bytes keep

the I/O data.

For handshake purposes two bits in the Status Byte of the PLC can be used: PB/PY254 and

PB/PY 255 Bit 0:

First, IDENT number and I/O data are written to the single communication list. Then, bit 0 of

PB/PY 254 is set (strobe bit) by the PLC. After this, a transfer to PB PY 255 with any data

forces an interrupt and II/O Lightbus communication with the C1120 interface.

The C1120 interface card responds with setting the bit 0 of PB/PY 254 (ACK bit): the data

byte contents are valid and can be read by the PLC with L PB. The PLC handshakes with

resetting the bit 0 of PB/PY 254 (strobe bit). The C1120 ends the handshake cycle by resetting

the ACK bit 0 of PB/PY 254.

By setting "address single communication" to 0 in the setup screen, this option is not

supported during the use with this setup.

Example :

The value of the single communication address is set to 128.

S5 C1120

1.) Transfer identnumber for dedicated

II/O-Lightbus module address to

PB/PY 128

2.) Transfer transmit data from memory

flags or equiv. to PB/PY 129,130, 131,

132

3.) Set strobebit

LKB 1

T PB/PY 254

4.) Force interrupt on C1120: transfer

something to PB/PY255

L KH AFFE

T PY 255

5.) Polling of ack- bit in statusregister II/O-Lightbus communication doing

transfer to and from the module

6.) Set of Ack.- bit in statusregister

7.) Load of valid data from the single

communication list to destination

LPW

TDW

TMW

8.) Reset strobebit

Polling of ack- bit in statusregister

9.) Reset of Ack.- bit in statusregister

Date 27.06.97 Version 2.1 Page 17 of 52

Page 18

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Fast Communications Channel

If the S5 is run in multi-processor mode, one CPU can be assigned the fast communications

channel in order to improve process image synchronisation.

The fast communications channel works only with a selection of peripheral modules which

are given the identification codes “SA” or “SE” on the IO List. The range of values for the

entries is from 128 to 255. The priority for fast communication is lower than for single box

mode and higher than for cyclical operation.

To activate the channel, you must enter the option “ 1” in the Activate field in the menu

option Edit Configuration.

Handling of Fast Communications Channel

The fast communications channel is operated with a handshake procedure.

The sequence for the individual steps is described below.

S5 C1120

1.) Writes a 1 to the cell

Page + 1023 (Interrupt)

2.) Polls the cell Page + 1022 while cell

equals 0

3.)

-”-

4.) Writes a 0 to the cell

Page + 1023 (Interrupt)

5.) Polls the cell Page + 1022 while cell

equals 1

Process image for fast

communications channel is updated

Process image is updated,

Acknowledged by writing a 1 to the

cell Page + 1022

Writes a 0 to the cell

Page + 1022

Page 18 of 52 Version 2.1 Date 27.06.97

Page 19

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Timer and Interrupts

With this menu the four fast interrupts of the Beckhoff II/O-Lightbus System can be

configured:

It is possible to connect the interrupts with a free running timer. To select the timer period,

enter the timer period in the equivalent field. Valid values are 0 ms (meaning "timer

disabled") up to 1677 ms.

Interrupts can be counted: The field "count address" holds the base address of the counters of

the four interrupts. Each counter is two bytes long, therefore 8 bytes are reserved. To enable a

counter, the field "Count" should hold a "1".

The fast interrupts are configured by moving the cursor the the equivalent line and interrupt

field, pressing key "F6" repetitively to choose the characteristic from "not activated", "rising

edge", "negative edge", "toggle".

The fast interrupts are configured by positioning the cursor on the relevant interrupt field and

pressing the function key F6 to select the desired characteristic. Pressing the F6 key toggles

between the options “ Not Activated” , “ Positive Edge” , “ Negative Edge” and “ Change of

Edge” .

If the relevant interrupt channel is activated by a “ 1” in the column “ S5 IRQ” , when the

interrupt event occurs, an interrupt is triggered on the S5.

An interrupt request is reset by reading a specific cell in the Dual Port RAM. The base address

entered in the field S5 IRQ Address indicates the address offset. In the example, accessing

the address 190 would reset interrupt request 0, and accessing address 192 would reset

interrupt request 2.

Date 27.06.97 Version 2.1 Page 19 of 52

Page 20

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

It is possible to count the number of interrupt events occurring within a specific time interval.

The time interval can be entered in the field “Timer Period” and must be in the range 0 ms

(timer disabled) to 1677 ms.

The relevant interrupt channel must be activated by entering a “1” in the field “Count”.

The start address from which the count results are to be stored is entered in the field “Count

Address”.

The count results are in the form of a 16-bit value so that 2 bytes are reserved for each

counter. In the example, the count result from interrupt channel 1 would be stored starting at

address 182, and the count result from interrupt channel 2 starting from address 184.

Function keys:

F1 HELP

displays help text.

F6 IRQ CONFIGURATION

chooses the interrupt characteristic (see above).

F10 PREVIOUS MENU

returns to master setup menu.

Page 20 of 52 Version 2.1 Date 27.06.97

Page 21

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

C1100 to C1120 Project Conversion

This menu helps to convert setups saved under a specific project name for the C1100 interface

to a C1120 interface project:

To start conversion, the path, directory name and project name have to be entered in the

equivalent lines (e.g. " C:\C1100\SYS\").

The projectname of the C1120 project to be generated is entered in the field C1120 project

name. Path and directory of the C1120 project can be changed in the menu "Project Manager"

To start conversion, press "F2".

Parameters of the C1100 which are no longer needed are discarded, others set to default

values (see menu "Edit Coniguration").

Function keys:

F1 HELP

displays help text.

F2 CONVERT

The conversion is started with this menu.

F10 PREVIOUS MENU

returns to master setup menu.

Date 27.06.97 Version 2.1 Page 21 of 52

Page 22

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

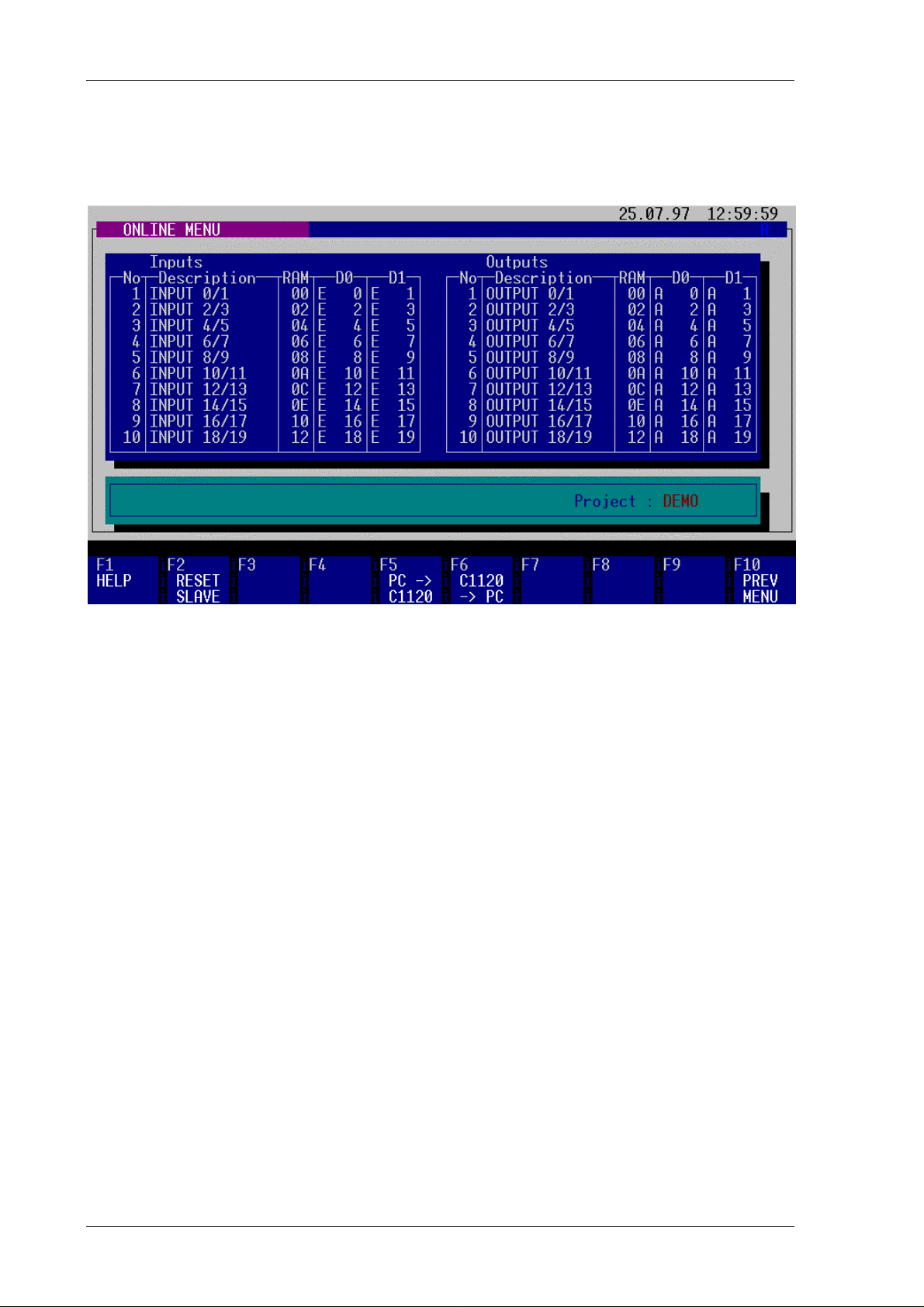

Online Menu

For transfer of setups from a PC to the C1120 interface and back, the online menu helps to

control communication actions, saving and printing of project setups:

If a communication timeout occurs during or at start of a transfer, first action to be taken

should be to check the RS232 interface cable and the serial interface parameters in the menu

"Program Parameters".

Function keys:

F1 HELP

displays help text.

F2 RESET C1120

Generates a software reset of the C1120 interface. The interface boots and runs

through following steps:

- self test of the C1120 interface,

- the configuration saved in the EEPROM memory is loaded and activated,

- the II/O-Lightbus ring is reset.

The status of the C1120 is displayed after completion of the reset in the status

line. This function can be activated only while the PLC is in STOP mode.

Page 22 of 52 Version 2.1 Date 27.06.97

Page 23

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

F3 FRACT TEST

This menu command tests the II/O-Lightbus ring and reports the number of

integrated modules or - in case of errors - the location of a ring interruption.

F4 TRANSMIT CONTROL

With this test it is possible to take the II/O-Lightbus ring under observation, e.g. to

find a ring fault: After start of this test, all modules from the C1120 interface to

the ring interruption show the "CYCLE" LED. After the ring interruption, the

"CYCLE" LED of modules is off, possibly showing the red "ERROR" LED.

Switching back to standard mode is done with a RESET.

During the TRANSMIT CONTROL, the PLC must reside in STOP mode.

F5 PC -> C1120

Transmits the contents of the I/O list to the C1120 interface. The interface will

work properly only after completion of this download, followed by a RESET or

cold boot. During download, the PLC must reside in STOP mode.

F6 C1120 -> PC

Reads the actual I/O configuration from a C1120 interface.

F9 DEBUG MENU

Changes to the debug menu. Occuring II/O-Lightbus errors are reported here.

F10 PREVIOUS MENU

returns to master setup menu.

Date 27.06.97 Version 2.1 Page 23 of 52

Page 24

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Debug Menu

The debug menu helps to analyze the status and quality of the II/O-Lightbus ring. Two tables

show the parity error and status information:

The parity error table allows to analyze and identify the location of parity error sources. To

use this option, II/O-Lightbus modules must be configured with SPROMS of type "132".

The II/O error status table shows an overview of all occured I/O errors.

Function keys:

F1 HELP

displays help text.

F6 IIO ERRORS

The display is refreshed to actual status by pressing "F6".

F10 PREVIOUS MENU

returns to master setup menu.

Page 24 of 52 Version 2.1 Date 27.06.97

Page 25

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

How to get started - setting up an I/O list

- Connect PC with the C1120 interface with the interface cable.

- Power on PLC and PC: PLC must reside in STOP mode, II/O-Lightbus ring has to

be closed before Power on.

- Start PC program for C1120 configuration.

- Check the setup of the serial port with the help of the setup menu.

- Change to the master setup menu.

- Edit the I/O-list: Enter the modules in the order of occurence in the II/O-Lightbus

ring. Enter the PLC-I/O-addresses.

- Save the configuration in a file with the name of the field "filename". ( At first

installation and at start of the program, this file is named DEFAULT.IOL).

- Change to the online menu.

- Force a download to transfer the I/O-list to the C1120-interface.

- Reset the C1120 interface to start with the new configuration.

- set S5-PLC to run mode: force the S5 -PLC to read the I/O configuration at start.

The C1120- configuration is recognized by the PLC.

Date 27.06.97 Version 2.1 Page 25 of 52

Page 26

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Status register S5 / C1120

The C1120 interface occupies the addresses PB/PY 250 to PB/PY 255 by default. This setup

is configurable. By generating a single transfer to peripherial byte PB/PY 255 (T PB 255) the

C1120 interface is interrupted for a single request. The peripherial byte PB/PY 254 is the

status register C1120.

S5 input status (readable with the command L PB 254)

Bit 0 : ACKN : acknowlege "single request II/O-Lightbus cycle finished"

Bit 1 : LIFE : This status bit toggles before transmission of I/O data to and from the

modules on the I/O list. By monitoring the LIFE bit in the STEP 5 program

it is possible to supervise the transmission of information to the indirect

modules, especially in case of short PLC cycle times.

Bit 2 : LWL-ERROR : This bit is set, if an error occurs in the II/O-Lightbus

System. Depending on the configuration of the field "error request" the PLC

reacts with a change to STOP mode ("error request" = "0") or not ("error

request" = "1").

Bit 3 : Local error on BK2000 module

Bit 4 : INPUT-VALID : indicates the input data to be valid after reset or program

start. The bit is set after complete initialization of the II/O-Lightbus System

and stays to be logic "1" afterwards.

S5 Output status (writeable with the command T PB 254)

Bit 0: Strobe bit for a single request.

Bit 1: Cycle mode ON ("0") or OFF ("1").

By setting this bit to "1", the cycle mode transmissions are stopped. Inputs

and Outputs are accessible only by single requests, until the cycle mode is

enabled again.

Bit 2: Free running mode (bit processing only)

The free running mode disables the cycle mode. Information is transmitted

in an asynchronous way on the II/O Lightbus ring. Data bytes, which belong

together, have to be transmitted via the single request. The life bit is passive

in this mode.

Page 26 of 52 Version 2.1 Date 27.06.97

Page 27

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Parallel Communication Channel

The parallel channel is used to start service functions of the C1120 interface. The channel

occupies the addresses 250 to 253 by default. This setup can be changed to any address

between 128 and 255.

The following information structure is available (shown for PB/PY default):

PB/PY 253 = parallel channel handshake

PB/PY 252 = parallel channel function number

PB/PY 251 = parallel channel argument 1

PB/PY 250 = parallel channel argument 2

The handshake is carried out with the peripherial address PB/PY 253 or equivalent. Following

control bits represent status information to both sides ( S5 --> C1120 and C1120 --> S5 ):

Bit 253.7: strobebit for parallel handshake

Bit 253.6: acknowlege bit for parallel handshake

The PLC is always the master of the communication via the parallel channel: the function call

is handed to the C1120 interface. The C1120 responds with data belonging to the function

call.

Date 27.06.97 Version 2.1 Page 27 of 52

Page 28

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

How to program a parallel channel communication:

a.) Request of the Siemens PLC to the C1120 interface (master is transmitter)

1. Write function number to PB/PY 252

2. Write argument 1 to PB/PY 251

3. Write argument 2 to PB/PY 250

4. Set strobe bit PB/PY 253.7

5. Wait for C1120 acknowlege bit PB/PY 253.6 to be "1" (function is started by

C1120 interface)

6. Reset strobe bit PB/PY 253.7

7. Wait for C1120 acknowlege bit PB/PY 253.6 to be "0" (end of handshake cycle).

b.) Answer of the C1120-interface to the Siemens PLC (master is receiver)

1. C1120 sets strobe bit PB/PY 253.7 after receiption of a function call as described

under a): Valid data bytes are ready to be read.

2. Read data: The function number is represented in PB/PY 252,

argument 1 is represented in PB/PY 251,

Argument 2 is represented in PB/PY 250.

3. Set acknowlege bit PB/PY 253.6 at end of data read.

4. C1120 interface resets strobe bit PB/PY 253.7.

5. End handshake cycle by resetting acknowlege bit PB/PY 253.6.

All steps of the handshake have to take place in the above described order. All function calls

are carried out with full handshake.

Page 28 of 52 Version 2.1 Date 27.06.97

Page 29

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Several special functions are available for the PLC via the parallel communication channel:

Function-nr 48 = 30H

II/O-Lightbus Error status request

Request from PLC Argument 1 Argument 2

---- ----

Reply from C1120 Interface Argument 1 Argument 2

Error number *)

Function-nr 53 = 35H

Reset II/O-Lightbus

Request from PLC Argument 1 Argument 2

---- ----

Reply from C1120 Interface Argument 1 Argument 2

Error number *) Module number

Function-nr 54 = 36H

II/O-Lightbus Transmit test

Request from PLC Argument 1 Argument 2

---- ----

Reply from C1120 Interface Argument 1 Argument 2

---- ----

Function-nr 55 = 37H

II/O-Lightbus Interrupt location test

Request from PLC Argument 1 Argument 2

---- ----

Reply from C1120 Interface Argument 1 Argument 2

Error number *) Module number

Date 27.06.97 Version 2.1 Page 29 of 52

Page 30

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Function-nr 56 = 38H

II/O-Lightbus Loss test

Request from PLC Argument 1 Argument 2

---- ----

Reply from C1120 Interface Argument 1 Argument 2

Error number *) Module number

Function No. 59 = 3BH

Reset String Slaves

Request from PLC Argument 1 Argument 2

Adress of string

slave

Response from C1120 Argument 1 Argument 2

Error number *) ----

*) Error number see table

----

Page 30 of 52 Version 2.1 Date 27.06.97

Page 31

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

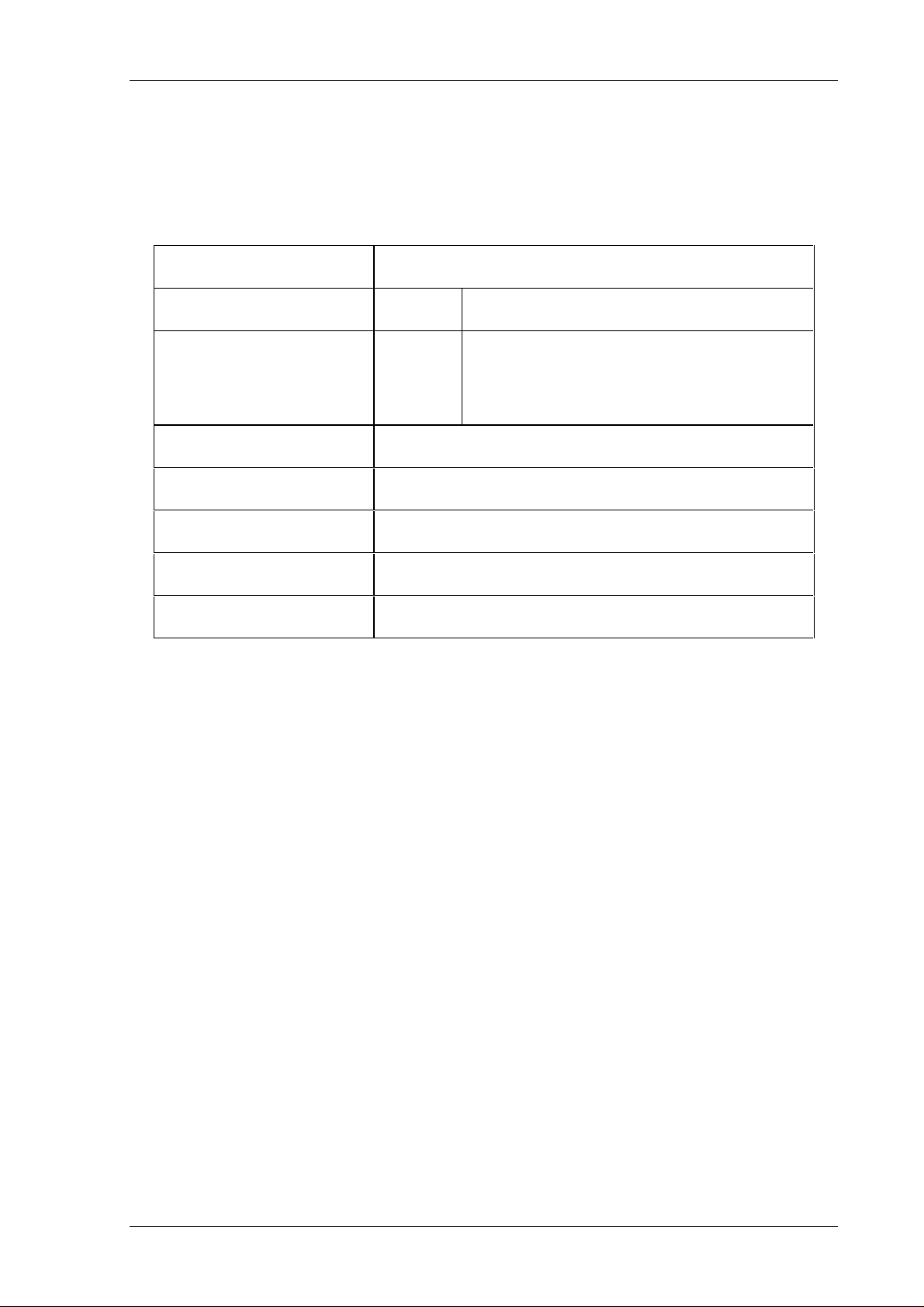

Table of error numbers:

Error number Error cause

1

2 - 9 Intensity test not successful

10 - 12

13

14 - 16

17 No receiption of II/O-Lightbus signals

20 - 21

22 - 23

24

25 Error at address test

26

27 General fault during II/O-Lightbus initialisation

28

29

30 Not allowed ident number was found

31

32

33

34 Number of modules in I /O list does not match number of modules

in II/O-Lightbus ring

35

36

37 Transmission interrupt in the II/O-Lightbus ring

(module number = location of interrupt) *)

38

39

40

41 free running mode disa bled after timeout of PLC (PLC in STOP

mode)

42 general II/O-Lightbus error

43 adress check error

50 timeout at reset of a string slave

51 slave is not registered as string slave

60

61

62

63

...

98 Download successfully ended

99 Transmission test processing

*) Modules are counted from end of ring. If n is answer to function, n modules from end of ring receive valid

II/O-Lightbus telegra m frames.

Date 27.06.97 Version 2.1 Page 31 of 52

Page 32

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Service Routines in STEP 5 language

Following described service routines are available at the moment of issue:

1. Function block for single request

2. Function block for error status request / reset of II/O-Lightbus System

3. Function block for quick process channel

Page 32 of 52 Version 2.1 Date 27.06.97

Page 33

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Status LEDs

3 Status LEDs are shown on the front panel of the C1120 interface:

1. RUN : If this LED shows the C1120 interface is ready to work.

2. CPU-ERR : Intermitting light indicates mismatch of number of modules in

the configuration and II/O-Lightbus ring. Possibly the

EEPROM memory is defect.

Uninterrupted light indicates a general interface error. A cold

start is recommended prior to change of the interface.

3. II/O-ERR : Intermitting light indicates a general II/O-Lightbus error, which

can be analyzed in details or serviced by the special functions.

Date 27.06.97 Version 2.1 Page 33 of 52

Page 34

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

2.4 Slave Setup

The C1120 interface is able to interface to a PLC behaving as a slave to a Master PLC with

C1120 interface. In this configuration, the slave C1120 interface is driven by a (standard)

master system, which supervises the II/O-Lightbus. I/O-data transmission and other

interesting applications are available in this configuration. Configuring an interface as a slave

is done with the help of this menu:

The menu offers two tables, a status line and the usual function keys:

Function keys:

F1 HELP

displays help text.

F2 EDIT INPUTS

changes to the menu to edit the input data table.

F3 EDIT OUTPUTS

changes to the menu to edit the output data table.

F4 EDIT CONFIGURATION

changes to the menu to edit the slave configuration.

Page 34 of 52 Version 2.1 Date 27.06.97

Page 35

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

F6 PROJECT MANAGER

the slave project manager is under development.

F7 PRINT (SLAVE) PROJECT

the print function is under development.

F8 SAVE PROJECT

saves the configuration to the hard disc.

F9 ONLINE MENU

changes to the online menu.

F10 PREVIOUS MENU

changes to the main menu.

Date 27.06.97 Version 2.1 Page 35 of 52

Page 36

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Edit Inputs

This menu helps editing the input data for the PLC. Output data are edited with a special

menu. The field "No" shows the line number of the table, "description" shows a text edited by

the user. The field "RAM" shows the offset address of the slave receive buffer. The fields

"D0", "D1" hold the PLC input addresses for the data in the RAM offset addresses of the

slave receive buffer.

Before inserting a new line with key "F4", no line can be edited.

Function keys:

F1 HELP

displays help text.

F4 INSERT LINE

inserts a new line at the actual cursor position. Following line numbers are

incremented.

F5 DELETE LINE

deletes a line at the actual cursor position. Following line numbers are

decremented.

F10 PREVIOUS MENU

changes to the main menu.

Page 36 of 52 Version 2.1 Date 27.06.97

Page 37

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Edit Outputs

This menu helps editing the output data for the PLC. Output data are edited with a special

menu. The field "No" shows the line number of the table, "description" shows a text edited by

the user. The field "RAM" shows the offset address of the slave transmit buffer. The fields

"D0", "D1" hold the PLC output addresses for the data in the RAM offset addresses of the

slave transmit buffer.

Before inserting a new line with key "F4", no line can be edited.

Function keys:

F1 HELP

displays help text.

F4 INSERT LINE

inserts a new line at the actual cursor position. Following line numbers are

incremented.

F5 DELETE LINE

deletes a line at the actual cursor position. Following line numbers are

decremented.

F10 PREVIOUS MENU

changes to the main menu.

Date 27.06.97 Version 2.1 Page 37 of 52

Page 38

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Edit Configuration

This menu is used to edit the configuration data of the C1120 interface.

The pageswitch mechanism provides a consistent process image to the PLC at any time of

processing: While one process image is switched to the PLC, I/O communication is done with

a second process image. The fields "Pageswitch inputs" and "Pageswitch outputs" represent

the memory addresses of the I/O bytes which cause a pageswitch when they are accessed, the

lowest input and highest output byte by default. Different PLC CPU´s scan the process image

either from the lowest or from the highest addresses. The first memory access of the scan

should cause a pageswitch for the inputs, the last for the outputs. The default setting is

prepared to serve CPU´s, which scan the process image beginning with the lowest address.

The field "Status address" contains the address of the status byte. Following information is

reported to the PLC:

Statusbyte.0 : not used

Statusbyte.1 : not used

Statusbyte.2 : II/O-Lightbus Timeout error flag

Statusbyte.3 : not used

Statusbyte.4 : Inputs valid flag

Statusbyte.5 : not used

Statusbyte.6 : not used

Statusbyte.7 : not used

The indication of an II/O-Lightbus timeout can be configured with the help of the

configuration field "watchdog time". If during the choosen time interval no valid Lightbus

telegram is being received, an error status event is reported equivalent to the setup fiel d "S5

error request". By setting the field "watchdog time" to value "0", the watchdog is disabled.

Page 38 of 52 Version 2.1 Date 27.06.97

Page 39

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Setting the field "S5 error request" to value "0" (default) results in switching the PLC to

STOP mode with an acknowlege delay by deleting the addresses of the I/O bytes in the dual

port memory of the C1120 interface. The acknowlege delay event can be managed by the PLC

by programming the OB 23 and 28.

Setting the field "S5 error request" to value "1" results in leaving the I/O addresses undeleted.

A static display of the last I/O status remains in the process image unchanged. The status byte

reports an error by setting the error flag, anyway.

Function keys:

F1 HELP

displays help text.

F2 SET DEFAULT

sets the configuration to default values.

F10 PREVIOUS MENU

changes to the main menu.

IMPORTANT REMARK regarding the page number:

The page number for data exchange with the PLC is configurable, beginning with

interface version numbers above V 1.51. Up to Version 1.51, the page number for

data exchange is 0 by default.

Date 27.06.97 Version 2.1 Page 39 of 52

Page 40

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Online Menu

This menu is used to communicate between the configuration PC and the C1120 interface:

Upload and download of setups is managed.

Function keys:

F1 HELP

displays help text.

F2 RESET SLAVE

Resets the C1120 interface, processing following steps:

- self test of the C1120 interface,

- activation of the configuration stored in the EEPROM memory.

The status of the C1120 interface is displayed in the status line after the reset. This

function only takes place, if the PLC is residing in STOP mode.

F5 PC -> C1120

Transmits the configuration data to the C1120 interface. The interface is able to

process propperly under following circumstances: A correct configuration is

transmitted, afterwards a reset or cold start is forced. During this procedure, the

PLC has to reside in STOP mode.

Page 40 of 52 Version 2.1 Date 27.06.97

Page 41

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

F6 C1120 -> PC

Reads the actual configuration from the C1120 interface to the PC.

F10 PREVIOUS MENU

changes to the main menu.

Date 27.06.97 Version 2.1 Page 41 of 52

Page 42

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

2.5 Project Manager

With the help of this menu, different setups can be managed under the name of projects:

Function keys:

F1 HELP

displays help text.

F2 SET PATH

changes to new drive path for project file.

F3 CHANGE DIRECTORY

changes to new directory in a path for project file.

F4 MAKE DIRECTORY

generates a new directory in a path for project file.

F5 DELETE DIRECTORY

deletes an empty directory.

Page 42 of 52 Version 2.1 Date 27.06.97

Page 43

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

F6 OPEN PROJECT

Loads a project from the actual directory.

F7 MAKE PROJECT

generates a new project in the actual directory.

F8 DELETE PROJECT

deletes a project from the actual directory.

F9 COPY PROJECT

Copies a project from the actual directory to any path and/or directory.

F10 PREVIOUS MENU

returns to master setup menu.

Date 27.06.97 Version 2.1 Page 43 of 52

Page 44

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

2.6 System Configuration

System Entry

Pressing F10 from the main menu leads to the system entry menu, from here the user can

choose the menus DOS, SYSTEM and PROGRAM PARAMETER.

Function keys:

F1 HELP

displays help text.

F2 DOS

Opens a DOS shell.

F3 SYSTEM

offers the submenus language and logfile.

F9 PROGRAM PARAMETER

contains the configuration parameters of the configuration software.

F10 PREVIOUS MENU

returns to master setup menu.

Page 44 of 52 Version 2.1 Date 27.06.97

Page 45

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

System

This menu offers the submenus LANGUAGE and LOGFILE.

Function keys:

F1 HELP

displays help text.

F3 LANGUAGE

offers the submenu LANGUAGE to choose different language options.

F4 LOG FILE

offers the submenu LOG FILE containing status history information.

F10 PREVIOUS MENU

returns to master setup menu.

Date 27.06.97 Version 2.1 Page 45 of 52

Page 46

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Language

This menu is used to change the actual menu language during program execution:

Function keys:

F1 HELP

displays help text.

F2 GERMAN

switches to german language menu.

F3 ENGLISH

switches to english language menu.

F10 PREVIOUS MENU

returns to master setup menu.

Page 46 of 52 Version 2.1 Date 27.06.97

Page 47

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Log File

With the help of this menu the logfile can be displayed to review the event history:

Function keys:

F1 HELP

displays help text.

F5 COPY LOGFILE

Copies the file ’PROGRAM.LOG’ to the drive set in the menu "Programm

Parameter" (floppy, etc.).

F10 PREVIOUS MENU

returns to master setup menu.

Date 27.06.97 Version 2.1 Page 47 of 52

Page 48

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

Program Parameter

The configuration for the configuration program for the C1120 interface is set and stored with

the help of this menu:

It is possible to move the cursor through the mask to access and change parameters of the

program.

The field "Language" is used to set the default language to german ("0") or english ("1").

The parallel and serial port is configured by changing the port number in the equivalent fields.

A "1" in the field "LCD-Display" sets a display color set for LCD requirements.

The fields "Harddisc" and "Floppy" show the actual active drives.

Function keys:

F1 HELP

displays help text.

F9 SAVE PAGE

saves the setting to the configuration file.

F10 PREVIOUS MENU

returns to master setup menu.

Page 48 of 52 Version 2.1 Date 27.06.97

Page 49

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

3 C1120 Interface: Technical Data

CPU

memory

Ports

Field bus

Transmission rate

Power supply

Current consumption

Housing

80C166 Communication processor

COM1 serial port

eqiv. RS232 C or 20 mA current loop

occupied by the configuration pr ogram

Beckhoff II/O-L i ghtbus System

2,5 MBaud, 32 Bit user data in 25 µs

5V from S5-PLC Bus

1,5 A from S5-PLC Bus

S5 Adaption capsule for intelligent peripherials

Date 27.06.97 Version 2.1 Page 49 of 52

Page 50

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

4 Installation Remarks

4.1 Assembly to the S5-PLC rack

1. Switch off PLC and external power supplies

2. The C1120 interface should be mounted in a slot for intelligent peripherials or

communication processors (slot 0) of the S5- rack CR700-1.

3. Pull off the blind plug and place the C1120 interface in the slot like any other

interface.

No external power supply is necessary for the C1120 interface, it is driven directly from the

S5 PLC Bus. The powero n of the interface follows the power on of the PLC. At this time, all

fiber optic connections of the Beckhoff Lightbus ring have to be connected to maintain a

proper initialization.

4.2 Connecting to a PC

System requirements

For configuration and address initialization of the C1120 interface following equipment is

required:

- An IBM PC/AT or compatible PC with at least 640 kByte memory,

- a serial port,

- optional a parallel port,

- a monochrom- or color monitor and a hercules, EGA- or VGA- compatible

graphic adapter,

- a 5¼" or a 3½" floppy disc,

- DOS 3.3 or higher or a compatible operating system,

- a standard serial RS232- cable with 9-pin connector (pinout see annex).

Page 50 of 52 Version 2.1 Date 27.06.97

Page 51

C1120 S5 to II/O Lightbus Interface Beckhoff II/O-Lightbus System

Interface ports for connection with a PC

The interfacing is realized with a standard serial RS232- cable with 9-pin connector (pinout

see annex) for the port connector of the C1120 interface.

Date 27.06.97 Version 2.1 Page 51 of 52

Page 52

C1120 S5 to II/O-Lightbus Interface Beckhoff II/O-Lightbus System

5 C1120 Serial Port Pinout

Pinout of RS232 C / current loop port

(9-pin SUB-D connector on front of C1120)

Pin Signal Port

1

2

3

4

5

6

7

8

9

TXD RS232 C COM2:

TXD RS232 C COM1:

RXD RS232 C COM1:

RXD RS232 C COM2:

Signal

GND

TXD 20mA+ COM1:

TXD 20mA- COM1:

RXD 20mA+ COM1:

RXD 20mA- COM1:

-

Page 52 of 52 Version 2.1 Date 27.06.97

Loading...

Loading...