Page 1

Documentation

BK9055 and BK9105

Bus Coupler for Ethernet/IP

Version:

Date:

2.0.0

2019-04-12

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

1.3 Documentation issue status ..............................................................................................................7

2 Product overview.......................................................................................................................................8

2.1 BK9055 - Introduction........................................................................................................................8

2.2 BK9105 - Introduction........................................................................................................................9

2.3 Technical data .................................................................................................................................10

2.4 The Beckhoff Bus Terminal system.................................................................................................10

2.5 Ethernet ...........................................................................................................................................12

3 Mounting and wiring................................................................................................................................14

3.1 Dimensions......................................................................................................................................14

3.2 Installation on mounting rails ...........................................................................................................15

3.3 Power supply, potential groups .......................................................................................................16

3.4 ATEX - Special conditions (standard temperature range) ...............................................................18

3.5 ATEX - Special conditions (extended temperature range) ..............................................................19

3.6 ATEX Documentation ......................................................................................................................20

4 Parametrization and commissioning.....................................................................................................21

4.1 Start-up behaviour of the Bus Coupler ............................................................................................21

4.2 Parameterization of the Bus Coupler using DIP Switches* .............................................................21

4.3 Network classes ..............................................................................................................................22

4.4 IP address .......................................................................................................................................23

4.4.1 Configuration with KS2000 .............................................................................................. 23

4.4.2 Address Configuration via ARP ....................................................................................... 24

4.4.3 Address configuration via BootP server........................................................................... 25

4.4.4 Setting the address using a DHCP server ....................................................................... 29

4.4.5 Subnet mask.................................................................................................................... 29

4.4.6 Testing the IP address..................................................................................................... 30

4.4.7 Reading the MAC-ID........................................................................................................ 30

4.5 Configuration ...................................................................................................................................31

4.5.1 Mapping ........................................................................................................................... 31

4.5.2 EthernetIP Tag Wizard .................................................................................................... 33

4.5.3 Export to Rockwell ........................................................................................................... 44

5 Error handling and diagnosis.................................................................................................................50

5.1 Diagnostic LEDs ..............................................................................................................................50

6 Appendix ..................................................................................................................................................54

6.1 First Steps........................................................................................................................................54

6.2 First Steps - Example ......................................................................................................................58

6.3 General operating conditions...........................................................................................................64

6.4 Test Standards for Device Testing ..................................................................................................66

6.5 Bibliography.....................................................................................................................................66

6.6 List of Abbreviations ........................................................................................................................66

6.7 Support and Service USA................................................................................................................67

BK9055 and BK9105 3Version: 2.0.0

Page 4

Table of contents

6.8 Support and Service ........................................................................................................................68

BK9055 and BK91054 Version: 2.0.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning these components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCATP®, SafetyoverEtherCAT®, TwinSAFE®, XFC® and XTS® are

registered trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

BK9055 and BK9105 5Version: 2.0.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of instructions

In this documentation the following instructions are used.

These instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow this safety instruction directly endangers the life and health of persons.

WARNING

Risk of injury!

Failure to follow this safety instruction endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow this safety instruction can lead to injuries to persons.

NOTE

Damage to environment/equipment or data loss

Failure to follow this instruction can lead to environmental damage, equipment damage or data loss.

Tip or pointer

This symbol indicates information that contributes to better understanding.

BK9055 and BK91056 Version: 2.0.0

Page 7

1.3 Documentation issue status

Version Modifications

2.0.0 Migration

Update Technical data

ATEX notes added

Update chapter Addressing via Beckhoff BootP Server

Update chapter Error handling and diagnosis

Update structure

1.3.0 BK9055 added

1.2.3

1.2.2

1.2.1

1.2.0 • configuration chapter updated

1.1.0 internal version

1.0.0 HTML documentation; valid as from firmware B3

New: EthernetIP Tag Wizard [}44]

New: Update from the mapping calculator and export to Rockwell software [}44]

Note about data types added to chapters first steps [}54] and mapping calculator [}33]

• mapping calculator added

Foreword

Firmware notes

BK9105

Determine which firmware was fitted when the Bus Coupler left the factory by checking the adhesive label

underneath the bus coupler (see the fifth and sixth figures of the production number).

Example:

3200B2020000

The firmware in this example is B2.

In order to update your firmware, you require the KS2000 configuration software and the serial cable

included with that software. You will find the firmware under www.beckhoff.com.

Firmware Description

B5

B3

B2 First release

DIP-Switch Settings [}21]

New: K-Bus Counter [}31]

BK9055 and BK9105 7Version: 2.0.0

Page 8

Product overview

2 Product overview

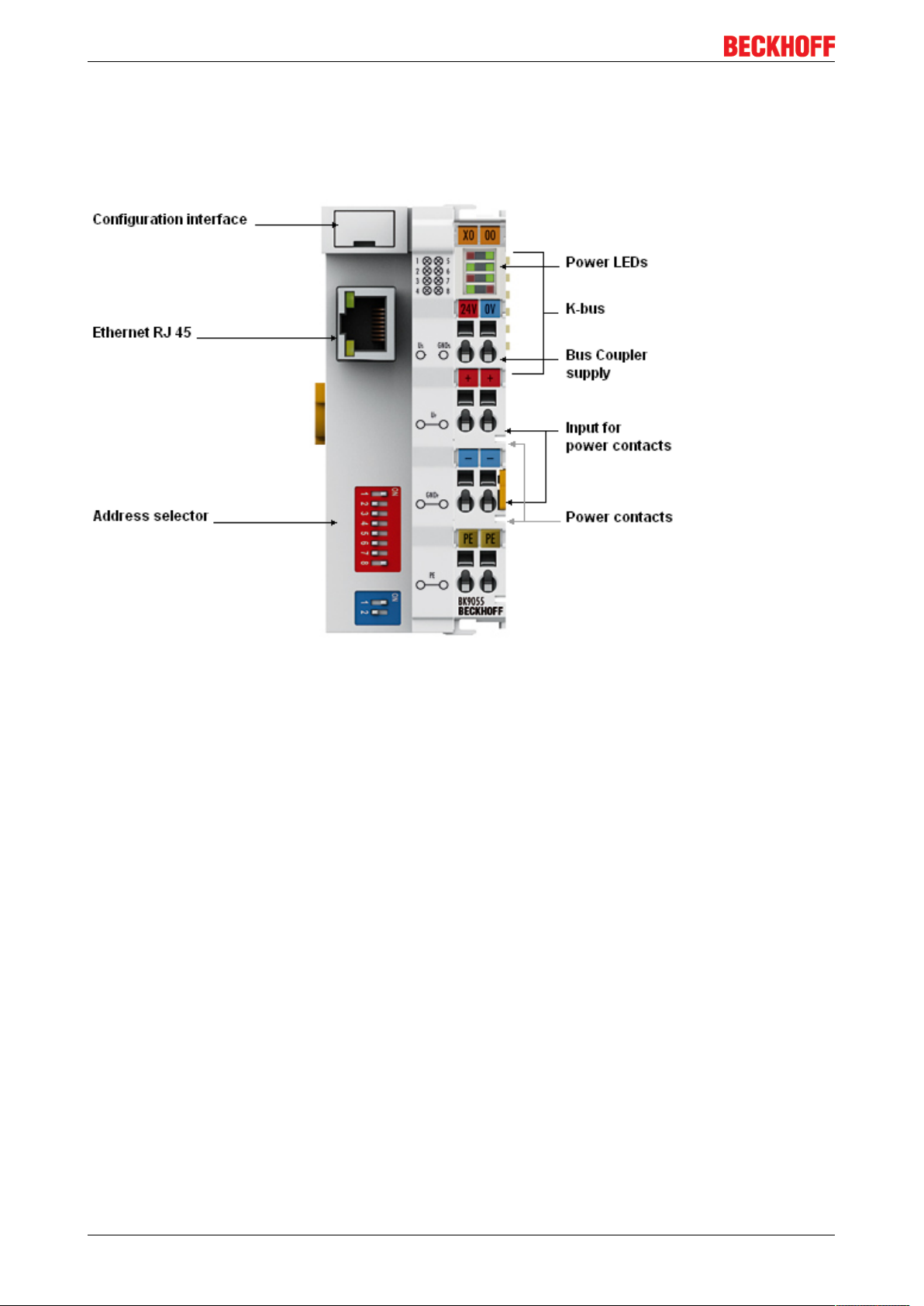

2.1 BK9055 - Introduction

Fig.1: BK9055

The Compact BK9055 Bus Coupler connects EtherNet/IP with the modular, extendable electronic terminal

blocks. One unit consists of one Bus Coupler, any number from 1to 64 terminals (255 with K-bus extension)

and one end terminal.

The Bus Coupler recognizes the terminals to which it is connected, and performs the assignment of the

inputs and outputs to the words of the process image automatically. The BK9055 Bus Coupler supports

10Mbit/s and 100Mbit/s Ethernet. Connection is through normal RJ45 connectors. The IP address is set on

the DIP switch (offset to a freely selectable start address). In networks with DHCP (a service for the

allocation of the logical IP address to the physical node address [MAC-ID]) the Bus Coupler obtains its IP

address from the DHCP server.

Ethernet/IP is the Industrial Ethernet standard of ODVA (Open DeviceNet Vendor Association). Ethernet/IP

is based on Ethernet TCP/IP and UDP/IP – IP stands for Industrial Protocol. Essentially, the CIP (Common

Industrial Protocol) used in ControlNet and DeviceNet was ported to Ethernet TCP/IP and UDP/IP.

Complex signal processing for analog I/Os, position measurement …

The BK9000 and BK9050 Bus Couplers support the operation of all Bus Terminal types.

The analog and multi-functional Bus Terminals can be adapted to each specific application using the

KS2000 configuration set. Depending on the type, the analog Bus Terminals' registers contain temperature

ranges, gain values and linearization characteristics. With the KS2000, the required parameters can be set

on a PC. The Bus Terminals store settings permanently and in a fail-safe manner.

Optionally, the Bus Terminals can also be controlled by the control system. Via function blocks (FBs), the

programmable logic controller (PLC) or the Industrial PC (IPC) handles configuration of the complete

periphery during the start-up phase. If required, the controller can upload the decentrally created

configuration data in order to centrally manage and store this data. Therefore, new adjustments are not

necessary in the event of replacement of a Bus Terminal. The controller carries out the desired setting

automatically after switching on.

BK9055 and BK91058 Version: 2.0.0

Page 9

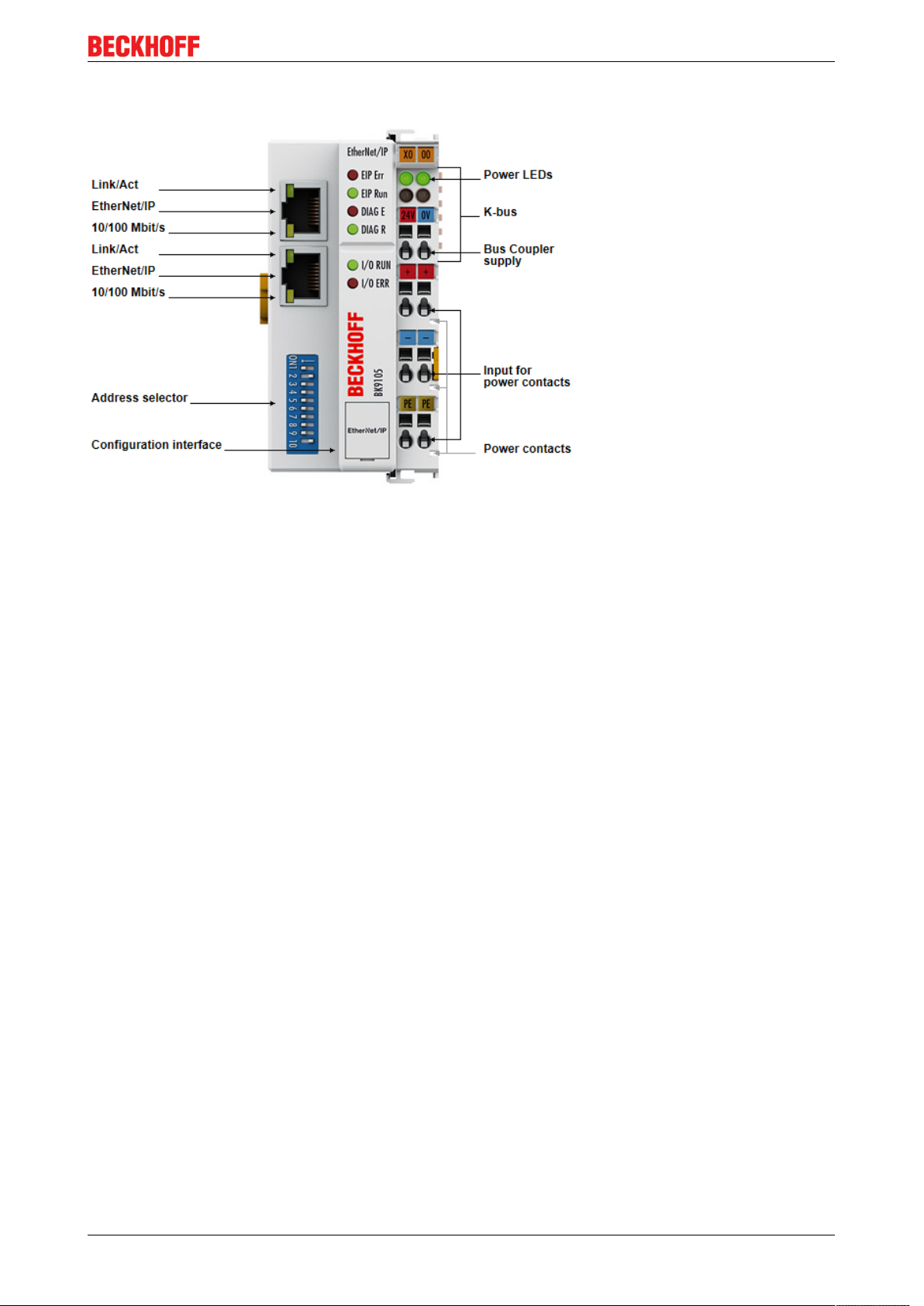

2.2 BK9105 - Introduction

Product overview

Fig.2: BK9105

The BK9105 Bus Coupler connects EtherNet/IP with the modular, extendable electronic terminal blocks. One

unit consists of one Bus Coupler, any number from 1 to 64 terminals (255 with K-bus extension) and one end

terminal.

The Bus Coupler recognizes the terminals to which it is connected, and performs the assignment of the

inputs and outputs to the words of the process image automatically. The BK9105 Bus Coupler supports

10Mbit/s and 100Mbit/s Ethernet. Connection is through normal RJ 45 connectors. The IP address is set on

the DIP switch (offset to a freely selectable start address). In networks with DHCP (a service for the

allocation of the logical IP address to the physical node address [MAC-ID]) the Bus Coupler obtains its IP

address from the DHCP server.

The BK9105 contains a 3-port switch. Two ports operate external on RJ 45 connectors and can be utilized.

The I/O stations can thus be configured with a line topology, instead of the classic star topology. In many

applications this significantly reduces the wiring effort and the cabling costs. The maximum distance between

two couplers is 100m. Up to 20 BK9105 Bus Couplers are cascadable, so that a maximum line length of

2km can be achieved.

Ethernet/IP is the Industrial Ethernet standard of ODVA (Open DeviceNet Vendor Association). Ethernet/IP

is based on Ethernet TCP/IP and UDP/IP – IP stands for Industrial Protocol. Essentially, the CIP (Common

Industrial Protocol) used in ControlNet and DeviceNet was ported to Ethernet TCP/IP and UDP/IP.

Complex signal processing for analog I/Os, position measurement …

The BK9105 Bus Coupler supports the operation of all Bus Terminal types.

The analog and multi-functional Bus Terminals can be adapted to each specific application using the

KS2000 configuration set. Depending on the type, the analog Bus Terminals' registers contain temperature

ranges, gain values and linearization characteristics. With the KS2000, the required parameters can be set

on a PC. The Bus Terminals store settings permanently and in a fail-safe manner.

Optionally, the Bus Terminals can also be controlled by the control system. Via function blocks (FBs), the

programmable logic controller (PLC) or the Industrial PC (IPC) handle configuration of the complete

periphery during the start-up phase. If required, the controller can upload the decentrally created

configuration data in order to centrally manage and store this data. Therefore, new adjustments are not

necessary in the event of replacement of a Bus Terminal. The controller carries out the desired setting

automatically after switching on.

BK9055 and BK9105 9Version: 2.0.0

Page 10

Product overview

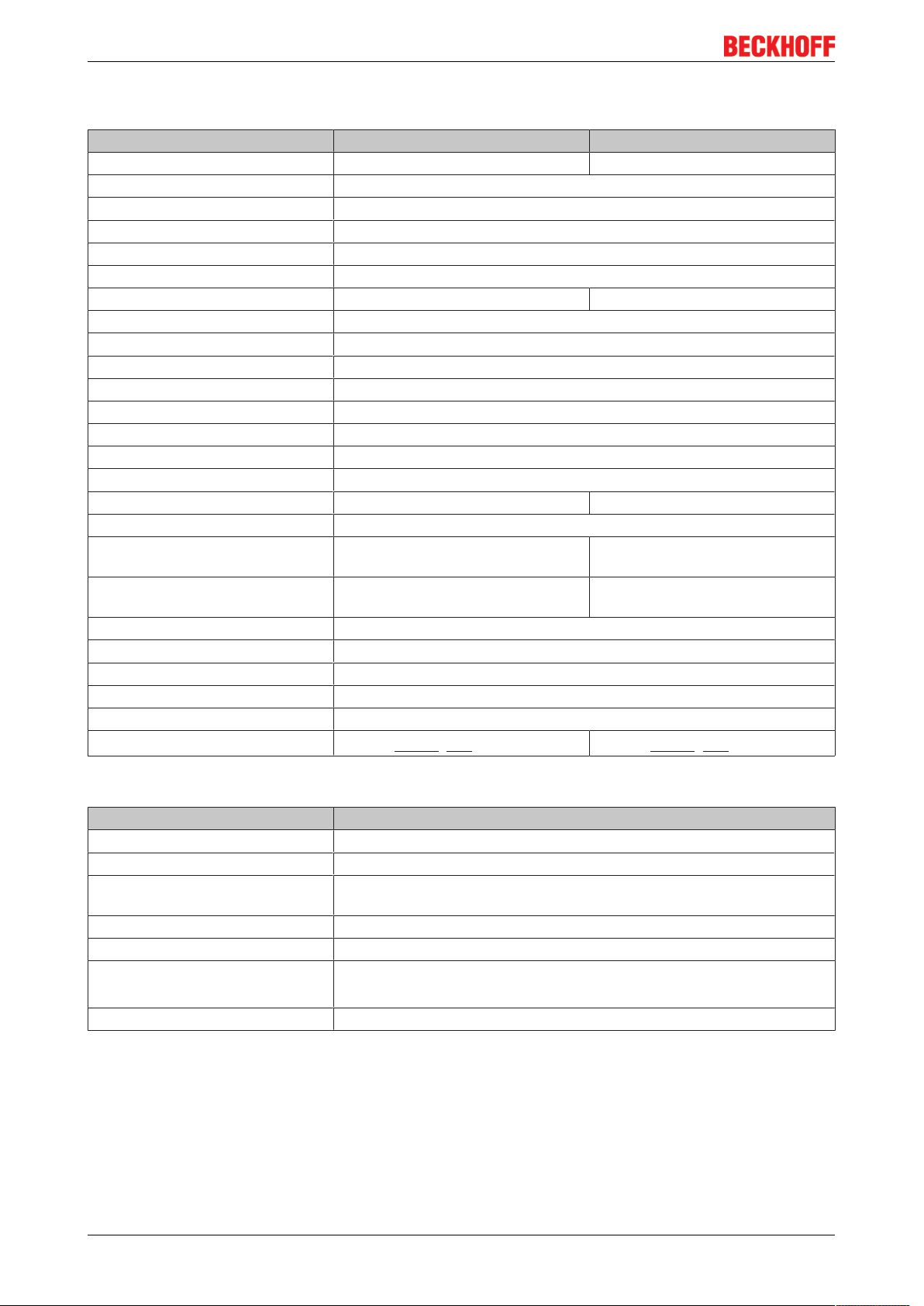

2.3 Technical data

Technical data BK9055 BK9105

Number of Bus Terminals 64 (255 with K-Bus extension) 64

Digital peripheral signals 3,936 Inputs/Outputs

Analog peripheral signals 122 Inputs/Outputs

Protocol EtherNet/IP

Configuration possibility Via the KS2000 configuration software or the controller (TwinCAT)

Maximum number of bytes 492bytes of input and 492bytes of output data

Bus connection 1 x RJ45 2 x RJ45 (2 Port Switch)

Power supply 24VDC (-15%/+20%)

Input current 70mA + (total K-Bus current)/4, 500mA max.

Starting current app. 2.5 x continuous current

Recommended fuse ≤ 10A

K-Bus power supply up to 1750mA

Power contact voltage max. 24V

Power contact current load max. 10A

Dielectric strength 500V (power contact / supply voltage / fieldbus)

Weight app. 100g app. 170g

Assembly on 35mm mounting rail according to EN 60715

Permissible ambient temperature

(operation)

Permissible ambient temperature

(storage)

Permissible relative humidity 95%, no condensation

Vibration / shock resistance conforms to EN60068-2-6/ EN60068-2-27

EMC resistance burst / ESD conforms to EN61000-6-2/ EN61000-6-4

Installation position variable

Protection class IP20

Approvals

0°C ... +55°C -25°C ... +60°C

-25 °C ... +85°C -40 °C ... +85°C

CE, UL, ATEX [}18] CE, UL, ATEX [}19], GL

DC

System

System data EtherNet/IP

Number of I/O modules only limited by the IP address space

Number of I/O points depending on the controller

Data transfer medium twisted pair copper cable, 4 x 2, shielded, category 5 (100Mbit/s),

category 3 (10Mbit/s)

Distance between modules 100m

Data transfer rate 10/100Mbit/s

Topology BK9055: star wiring

BK9105: line or star wiring

Cascading up to 20 BK9105 or max. line length 2km

2.4 The Beckhoff Bus Terminal system

Up to 256 Bus Terminals, with 1 to 16I/O channels per signal form

The Bus Terminal system is the universal interface between a fieldbus system and the sensor / actuator

level. A unit consists of a Bus Coupler as the head station, and up to 64 electronic series terminals, the last

one being an end terminal. Up to 255 Bus Terminals can be connected via the K-bus extension. For each

BK9055 and BK910510 Version: 2.0.0

Page 11

Product overview

technical signal form, terminals are available with one, two, four or eight I/O channels, which can be mixed

as required. All the terminal types have the same mechanical construction, so that difficulties of planning and

design are minimized. The height and depth match the dimensions of compact terminal boxes.

Decentralised wiring of each I/O level

Fieldbus technology allows more compact forms of controller to be used. The I/O level does not have to be

brought to the controller. The sensors and actuators can be wired decentrally, using minimum cable lengths.

The controller can be installed at any location within the plant.

Industrial PCs as controllers

The use of an Industrial PC as the controller means that the operating and observing element can be

implemented in the controller's hardware. The controller can therefore be located at an operating panel, in a

control room, or at some similar place. The Bus Terminals form the decentralised input/output level of the

controller in the control cabinet and the subsidiary terminal boxes. The power sector of the plant is also

controlled over the bus system in addition to the sensor/actuator level. The Bus Terminal replaces the

conventional series terminal as the wiring level in the control cabinet. The control cabinet can have smaller

dimensions.

Bus Couplers for all usual bus systems

The Beckhoff Bus Terminal system unites the advantages of a bus system with the possibilities of the

compact series terminal. Bus Terminals can be driven within all the usual bus systems, thus reducing the

controller parts count. The Bus Terminals then behave like conventional connections for that bus system. All

the performance features of the particular bus system are supported.

Mounting on standardized mounting rails

The installation is standardized thanks to the simple and space-saving mounting on a standardized mounting

rail (EN60715, 35mm) and the direct wiring of actuators and sensors, without cross connections between

the terminals. The consistent labelling scheme also contributes.

The small physical size and the great flexibility of the Bus Terminal system allow it to be used wherever a

series terminal is also used. Every type of connection, such as analog, digital, serial or the direct connection

of sensors can be implemented.

Modularity

The modular assembly of the terminal strip with Bus Terminals of various functions limits the number of

unused channels to a maximum of one per function. The presence of two channels in one terminal is the

optimum compromise of unused channels and the cost of each channel. The possibility of electrical isolation

through potential feed terminals also helps to keep the number of unused channels low.

Display of the channel state

The integrated LEDs show the state of the channel at a location close to the sensors and actuators.

K-bus

The K-bus is the data path within a terminal strip. The K-bus is led through from the Bus Coupler through all

the terminals via six contacts on the terminals' side walls. The end terminal terminates the K-bus. The user

does not have to learn anything about the function of the K-bus or about the internal workings of the

terminals and the Bus Coupler. Many software tools that can be supplied make project planning,

configuration and operation easy.

Potential feed terminals for isolated groups

The operating voltage is passed on to following terminals via three power contacts. You can divide the

terminal strip into arbitrary isolated groups by means of potential feed terminals. The potential feed terminals

play no part in the control of the terminals, and can be inserted at any locations within the terminal strip.

BK9055 and BK9105 11Version: 2.0.0

Page 12

Product overview

Up to 64Bus Terminals can be used in a terminal block, with optional K-bus extension for up to 256Bus

Terminals. This count does include potential feed terminals, but not the end terminal.

Bus Couplers for various fieldbus systems

Various Bus Couplers can be used to couple the electronic terminal strip quickly and easily to different

fieldbus systems. It is also possible to convert to another fieldbus system at a later time. The Bus Coupler

performs all the monitoring and control tasks that are necessary for operation of the connected Bus

Terminals. The operation and configuration of the Bus Terminals is carried out exclusively by the Bus

Coupler. Nevertheless, the parameters that have been set are stored in each Bus Terminal, and are retained

in the event of voltage drop-out. Fieldbus, K-bus and I/O level are electrically isolated.

If the exchange of data over the fieldbus is prone to errors or fails for a period of time, register contents (such

as counter states) are retained, digital outputs are cleared, and analog outputs take a value that can be

configured for each output when commissioning. The default setting for analog outputs is 0 V or 0 mA. Digital

outputs return in the inactive state. The timeout periods for the Bus Couplers correspond to the usual

settings for the fieldbus system. When converting to a different bus system it is necessary to bear in mind the

need to change the timeout periods if the bus cycle time is longer.

The interfaces

A Bus Coupler has six different methods of connection. These interfaces are designed as plug connectors

and as spring-loaded terminals.

2.5 Ethernet

Ethernet was originally developed by DEC, Intel and XEROX (as the "DIX" standard) for passing data

between office devices. The term nowadays generally refers to the IEEE802.3 CSMA/CD specification,

published in 1985. Because of the high acceptance around the world this technology is available everywhere

and is very economical. This means that it is easy to make connections to existing networks.

There are now a number of quite different transmission media: coaxial cable (10Base5), optical fiber

(10BaseF) or twisted pairs (10BaseT) with screen (STP) or without screen (UTP). Using Ethernet, different

topologies can be built such as ring, line or star.

Ethernet transmits Ethernet packets from a sender to one or more receivers. This transmission takes place

without acknowledgement, and without the repetition of lost packets. To achieve reliable data

communication, there are protocols, such as TCP/IP, that can run on top of Ethernet.

Basic principles

The Internet Protocol (IP)

The internet protocol (IP) forms the basis of this data communication. IP transports data packets from one

device to another; the devices can be in the same network, or in different networks. IP here looks after the

address management (finding and assigning MAC-IDs), segmentation and routing. Like the Ethernet

protocol, IP does not guarantee that the data is transported - data packets can be lost, or their sequence can

be changed.

TCP/IP was developed to provide standardised, reliable data exchange between any numbers of different

networks. TCP/IP was developed to provide standardised, reliable data exchange between any numbers of

different networks. Although the term is often used as if it were a single concept, a number of protocols are

layered together: e.g. IP, TCP, UDP, ARP and ICMP.

Transmission Control Protocol (TCP)

The Transmission Control Protocol (TCP) which runs on top of IP is a connection-oriented transport protocol.

It includes error detection and handling mechanisms. Lost telegrams are repeated.

BK9055 and BK910512 Version: 2.0.0

Page 13

Product overview

User Datagram Protocol (UDP)

UDP is connectionless transport protocol. It provides no control mechanism when exchanging data between

sender and receiver. This results in a higher processing speed than, for example, TCP. Checking whether or

not the telegram has arrived must be carried out by the higher-level protocol.

Internet Control Message Protocol (ICMP)

It is used by end devices, to exchange information about the current status of the internet protocol.

Address Resolution Protocol (ARP)

Performs conversion between the IP addresses and MAC addresses.

BootP

The BootP protocol allows the TCP/IP address to be set or altered, by addressing the network device with its

MAC-ID.

BK9055 and BK9105 13Version: 2.0.0

Page 14

Mounting and wiring

3 Mounting and wiring

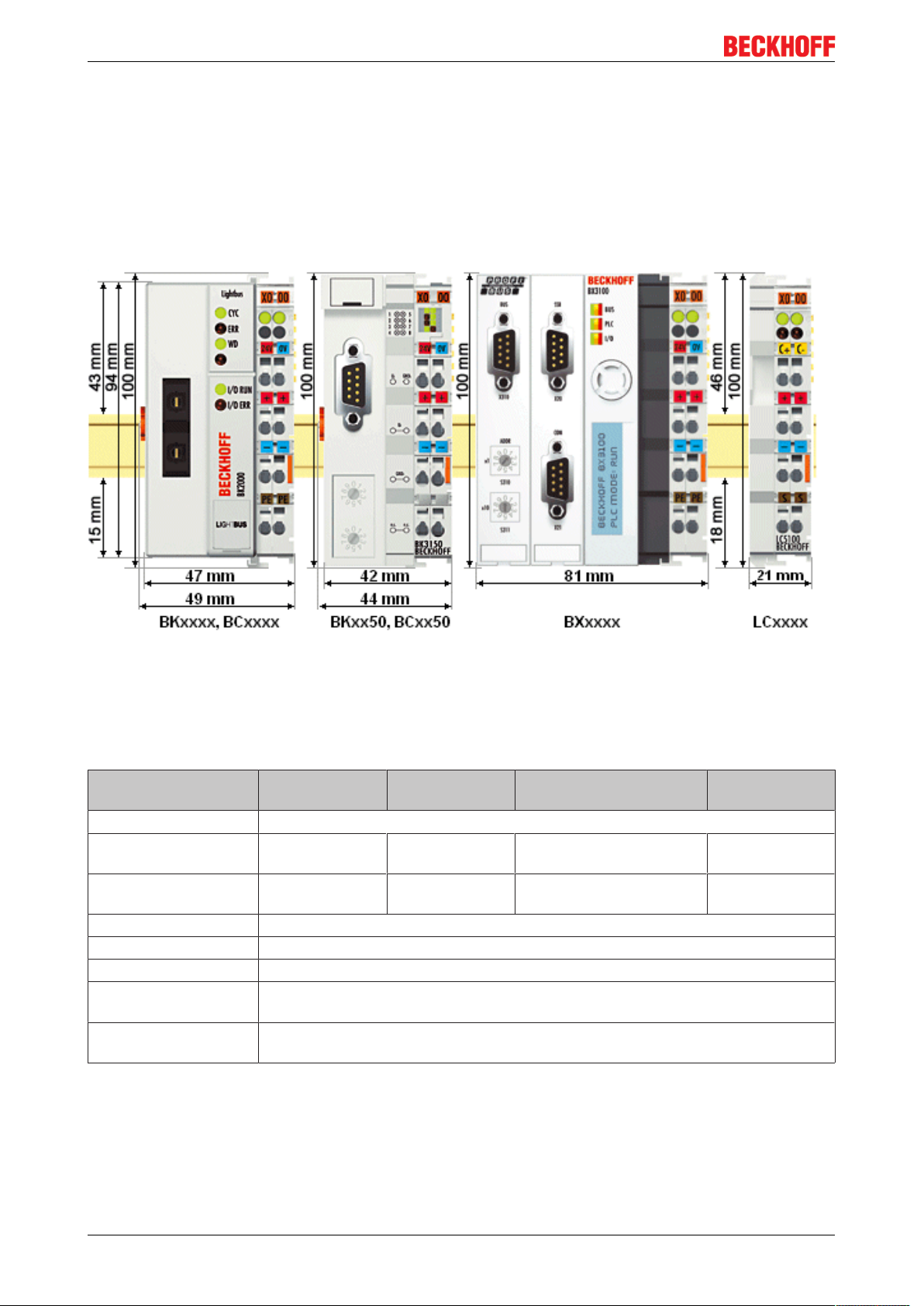

3.1 Dimensions

The system of the Beckhoff Bus Terminals is characterized by low physical volume and high modularity.

When planning a project it must be assumed that at least one Bus Coupler and a number of Bus Terminals

will be used. The mechanical dimensions of the Bus Couplers are independent of the fieldbus system.

Fig.3: Dimensions

The total width in practical cases is composed of the width of the Bus Coupler, the KL9010 Bus End

Terminal and the width of the bus terminals in use. Depending on function, the Bus Terminals are 12 or

24mm wide. The front wiring increases the total height of 68 mm by about 5 to 10mm, depending on the

wire thickness.

Mechanical data BKxxxx

BCxxxx

Design form compact terminal housing with signal LED

Material Polyamide

(PA 6.6)

Dimensions (W x H x D) 49 x 100 x 68mm 44 x 100 x 68mm 81 (BX8000 61) x 100 x

Mounting on 35 mm C-rail in accordance with EN 60715 with latching

Stackable by Double groove-tongue connection

Labelling Standard terminal block labelling

Vibration/shock

resistance

EMC immunity/

emission

conforms to EN 60068-2-6 / EN 60068-2-27

conforms to EN 61000-6-2 / EN 61000-6-4

BKxx50

BCxx50

Polyamide

(PA 6.6)

BXxxxx LCxxxx

Polycarbonate Polyamide

(PA 6.6)

21 x 100 x 68mm

89mm

BK9055 and BK910514 Version: 2.0.0

Page 15

Mounting and wiring

Connection technology BKxxxx

BCxxxx

Wiring Cage Clamp® spring-loaded system

Connection cross-section 0.08mm² ... 2.5 mm², stranded, solid wire, 28-14 AWG

Fieldbus connection depending on fieldbus spring-loaded terminals

Power contacts 3 spring contacts

Current loading IMAXX 10 A (125 A short circuit)

Rated voltage 24V

DC

BKxx50

BCxx50

BXxxxx LCxxxx

3.2 Installation on mounting rails

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting, disassembly or

wiring of the Bus Terminals.

Mounting

The Bus Couplers and Bus Terminals are attached to commercially available 35mm mounting rails (DIN rail

according to EN60715) by applying slight pressure:

1. First attach the Fieldbus Coupler to the mounting rail.

2. The Bus Terminals are now attached on the right-hand side of the fieldbus Coupler. Join the components with slot and key and push the terminals against the mounting rail, until the lock clicks onto the

mounting rail.

If the terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting rail. At

the installation, the locking mechanism of the components must not come into conflict with the fixing

bolts of the mounting rail. To mount the mounting rails with a height of 7.5mm under the terminals

and couplers, you should use flat mounting connections (e.g. countersunk screws or blind rivets).

Disassembly

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

1. Carefully pull the orange-colored lug approximately 1cm out of the terminal to be disassembled, until

it protrudes loosely. The lock with the mounting rail is now released for this terminal, and the terminal

can be pulled from the mounting rail without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal away from the mounting rail.

Connections within a Bus Terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the Bus Terminal block. The power contacts are supplied via terminals on the Bus Coupler.

BK9055 and BK9105 15Version: 2.0.0

Page 16

Mounting and wiring

Power contacts

During the design of a Bus Terminal block, the pin assignment of the individual Bus Terminals must

be taken account of, since some types (e.g. analog Bus Terminals or digital 4-channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed Terminals (KL91xx, KL92xx

and EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labelled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

NOTE

Risk of damage to the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively coupled to the

mounting rail. This may lead to incorrect results during insulation testing or to damage on the terminal (e.g.

disruptive discharge to the PE line during insulation testing of a consumer with a nominal voltage of 230V).

For insulation testing, disconnect the PE supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further feed points for testing, these Power Feed Terminals can be released and pulled at

least 10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

Wiring

Up to eight connections enable the connection of solid or finely stranded cables to the Bus Terminals. The

terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square opening

above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire safely and permanently.

Shielding

Analog sensors and actuators should always be connected with shielded, pair-wise twisted cables.

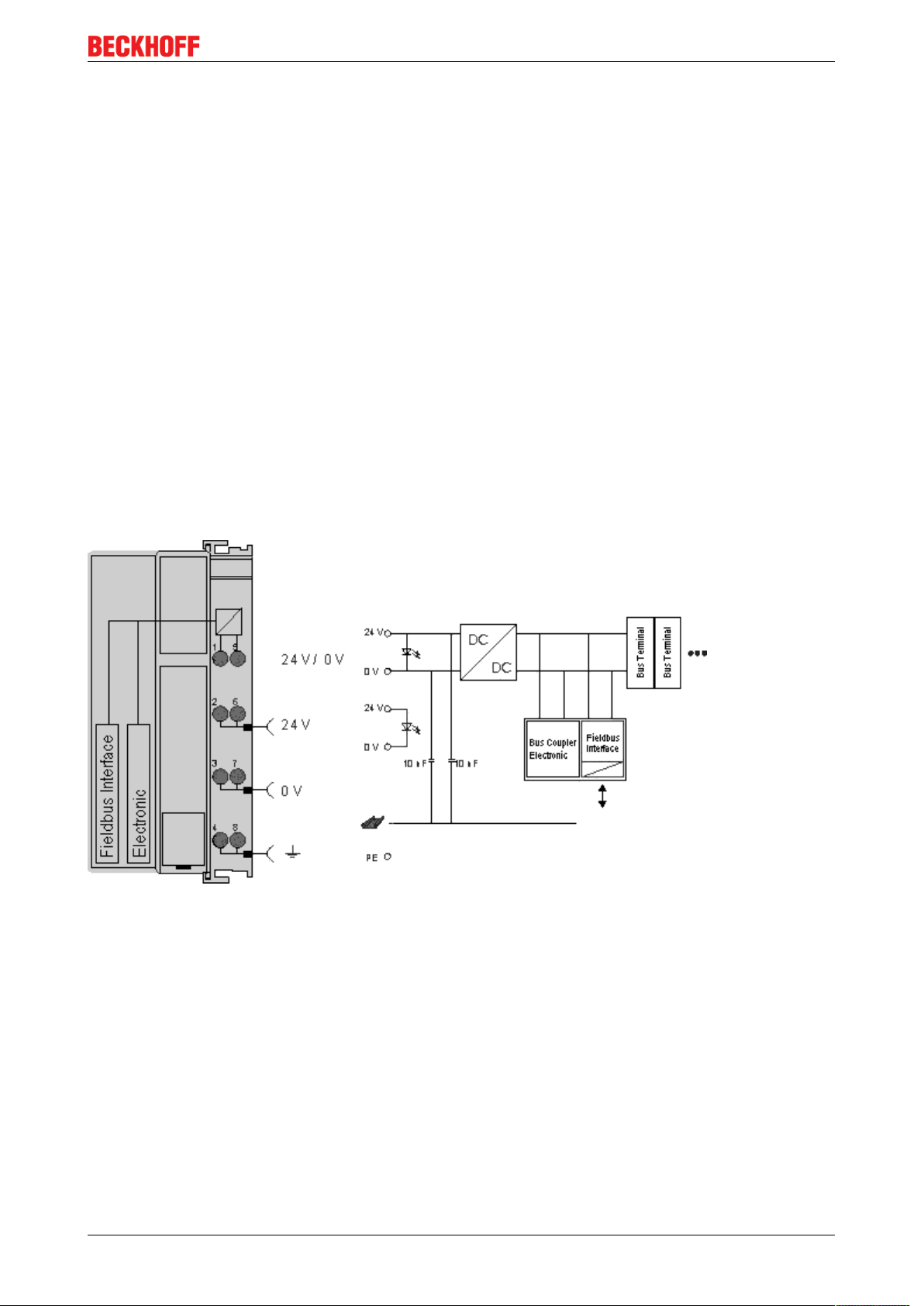

3.3 Power supply, potential groups

Power supply for the Bus Coupler

The Bus Couplers require a 24 VDC supply for their operation. The connection is made by means of the upper

spring-loaded terminals labelled 24V and 0V. The supply voltage feeds the Bus Coupler electronics and,

over the K-Bus/E-Bus, the Bus Terminals. The power supply for the Bus Coupler electronics and that of the

K-Bus/E-Bus are electrically separated from the potential of the field level.

Power supply for the power contacts

The bottom six connections with spring-loaded terminals can be used to feed the supply for the peripherals.

The spring-loaded terminals are joined in pairs to a power contact. The feed for the power contacts has no

connection to the voltage supply for the Bus Coupler. The design of the feed permits voltages of up to 24V.

The assignment in pairs and the electrical connection between feed terminal contacts allows the connection

wires to be looped through to various terminal points. The current drawn from the power contacts must not

exceed 10A for long periods. The current carrying capacity between two spring-loaded terminals is identical

to that of the connecting wires.

BK9055 and BK910516 Version: 2.0.0

Page 17

Mounting and wiring

Power contacts

On the right hand face of the Bus Coupler there are three spring contacts for the power contact connections.

The spring contacts are hidden in slots so that they cannot be accidentally touched. By attaching a Bus

Terminal the blade contacts on the left hand side of the Bus Terminal are connected to the spring contacts.

The tongue and groove guides on the top and bottom of the Bus Coupler and of the Bus Terminals

guarantees that the power contacts mate securely.

Configuration interface (not for BK1250, EK1x00)

The standard Bus Couplers have an RS232 interface at the bottom of the front face. The miniature connector

can be joined to a PC with the aid of a connecting cable and the KS2000 configuration software. The

interface permits the Bus Terminals to be configured, for example adjusting the amplification factors of the

analog channels. The interface can also be used to change the assignments of the bus terminal data to the

process image in the Bus Coupler. The functionality of the configuration interface can also be reached via

the fieldbus using string communication facility.

Electrical isolation

The bus couplers operate by means of three independent potential groups. The supply voltage feeds the KBus/E-Bus electronics in the Bus Coupler and the K-Bus/E-Bus itself in an electrically isolated manner. The

supply voltage is also used to generate the operating voltage for the fieldbus.

Note: All Bus Terminals are electrically isolated from the K-Bus/E-bus. The K-Bus/E-bus is therefore

completely electrically isolated.

Fig.4: Electrical isolation

BK9055 and BK9105 17Version: 2.0.0

Page 18

Mounting and wiring

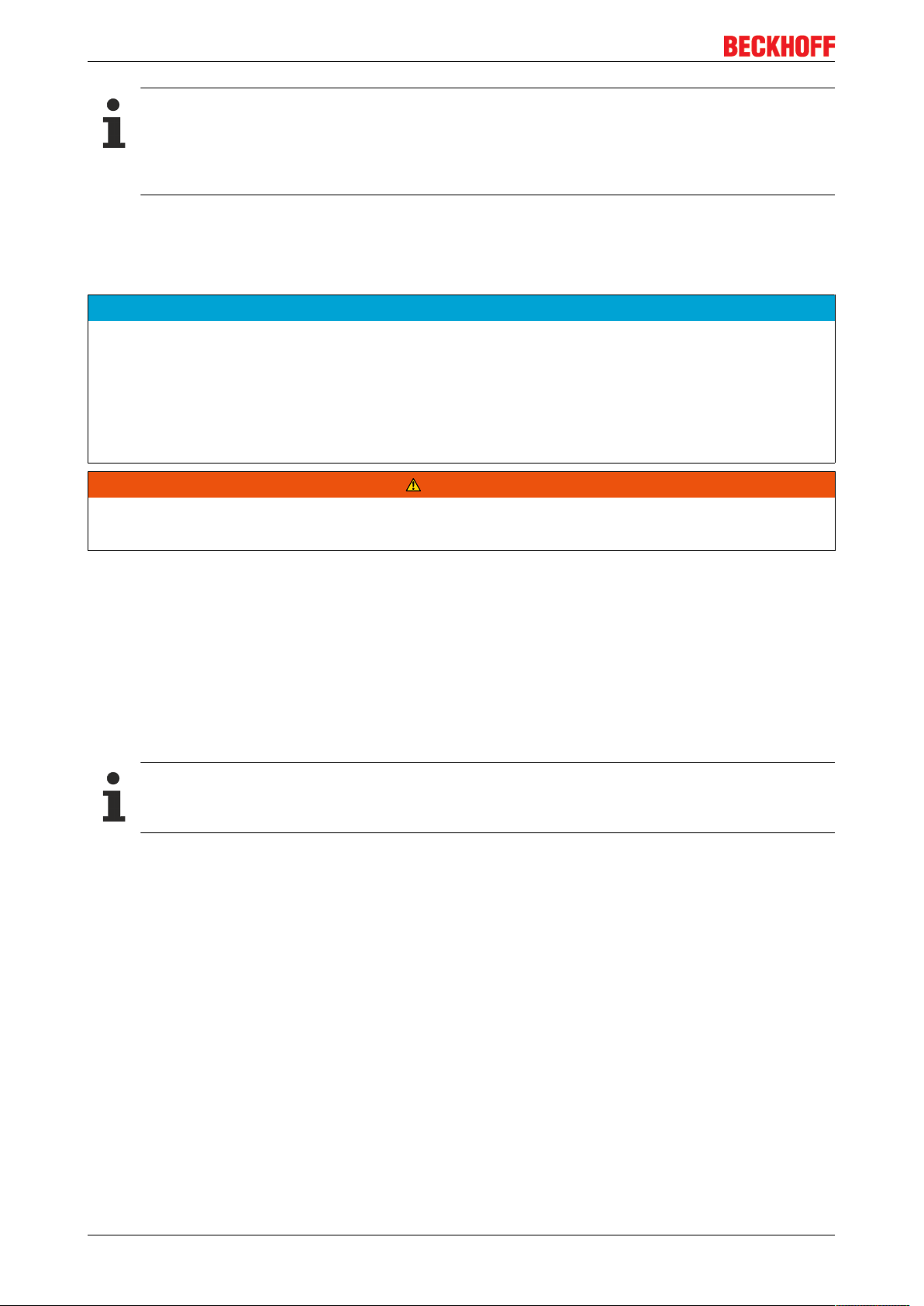

3.4 ATEX - Special conditions (standard temperature range)

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus components with

standard temperature range in potentially explosive areas (directive 94/9/EU)!

• The certified components are to be installed in a suitable housing that guarantees a protection class of at

least IP54 in accordance with EN 60529! The environmental conditions during use are thereby to be

taken into account!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observe the permissible ambient temperature range of 0 to 55°C for the use of Beckhoff fieldbus components standard temperature range in potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The individual terminals may only be unplugged or removed from the Bus Terminal system if the supply

voltage has been switched off or if a non-explosive atmosphere is ensured!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

• The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the supply voltage has

been switched off or if a non-explosive atmosphere is ensured!

• Address selectors and ID switches may only be adjusted if the supply voltage has been switched off or if

a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0:2012+A11:2013

• EN 60079-15:2010

Marking

The Beckhoff fieldbus components with standard temperature range certified for potentially explosive areas

bear one of the following markings:

II 3GKEMA 10ATEX0075 X Ex nA IIC T4 GcTa: 0…55°C

or

II 3GKEMA 10ATEX0075 X Ex nC IIC T4 GcTa: 0…55°C

BK9055 and BK910518 Version: 2.0.0

Page 19

Mounting and wiring

3.5 ATEX - Special conditions (extended temperature range)

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus components with

extended temperature range (ET) in potentially explosive areas (directive 94/9/EU)!

• The certified components are to be installed in a suitable housing that guarantees a protection class of at

least IP54 in accordance with EN 60529! The environmental conditions during use are thereby to be

taken into account!

• If the temperatures during rated operation are higher than 70°C at the feed-in points of cables, lines or

pipes, or higher than 80°C at the wire branching points, then cables must be selected whose temperature data correspond to the actual measured temperature values!

• Observe the permissible ambient temperature range of -25 to 60°C for the use of Beckhoff fieldbus components with extended temperature range (ET) in potentially explosive areas!

• Measures must be taken to protect against the rated operating voltage being exceeded by more than

40% due to short-term interference voltages!

• The individual terminals may only be unplugged or removed from the Bus Terminal system if the supply

voltage has been switched off or if a non-explosive atmosphere is ensured!

• The connections of the certified components may only be connected or disconnected if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

• The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the supply voltage has

been switched off or if a non-explosive atmosphere is ensured!

• Address selectors and ID switches may only be adjusted if the supply voltage has been switched off or if

a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0:2012+A11:2013

• EN 60079-15:2010

Marking

The Beckhoff fieldbus components with extended temperature range (ET) certified for potentially explosive

areas bear the following marking:

II 3GKEMA 10ATEX0075 X Ex nA IIC T4 GcTa: -25…60°C

or

II 3GKEMA 10ATEX0075 X Ex nC IIC T4 GcTa: -25…60°C

BK9055 and BK9105 19Version: 2.0.0

Page 20

Mounting and wiring

3.6 ATEX Documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

Pay also attention to the continuative documentation

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

that is available in the download area of the Beckhoff homepage http:\\www.beckhoff.com!

BK9055 and BK910520 Version: 2.0.0

Page 21

Parametrization and commissioning

4 Parametrization and commissioning

4.1 Start-up behaviour of the Bus Coupler

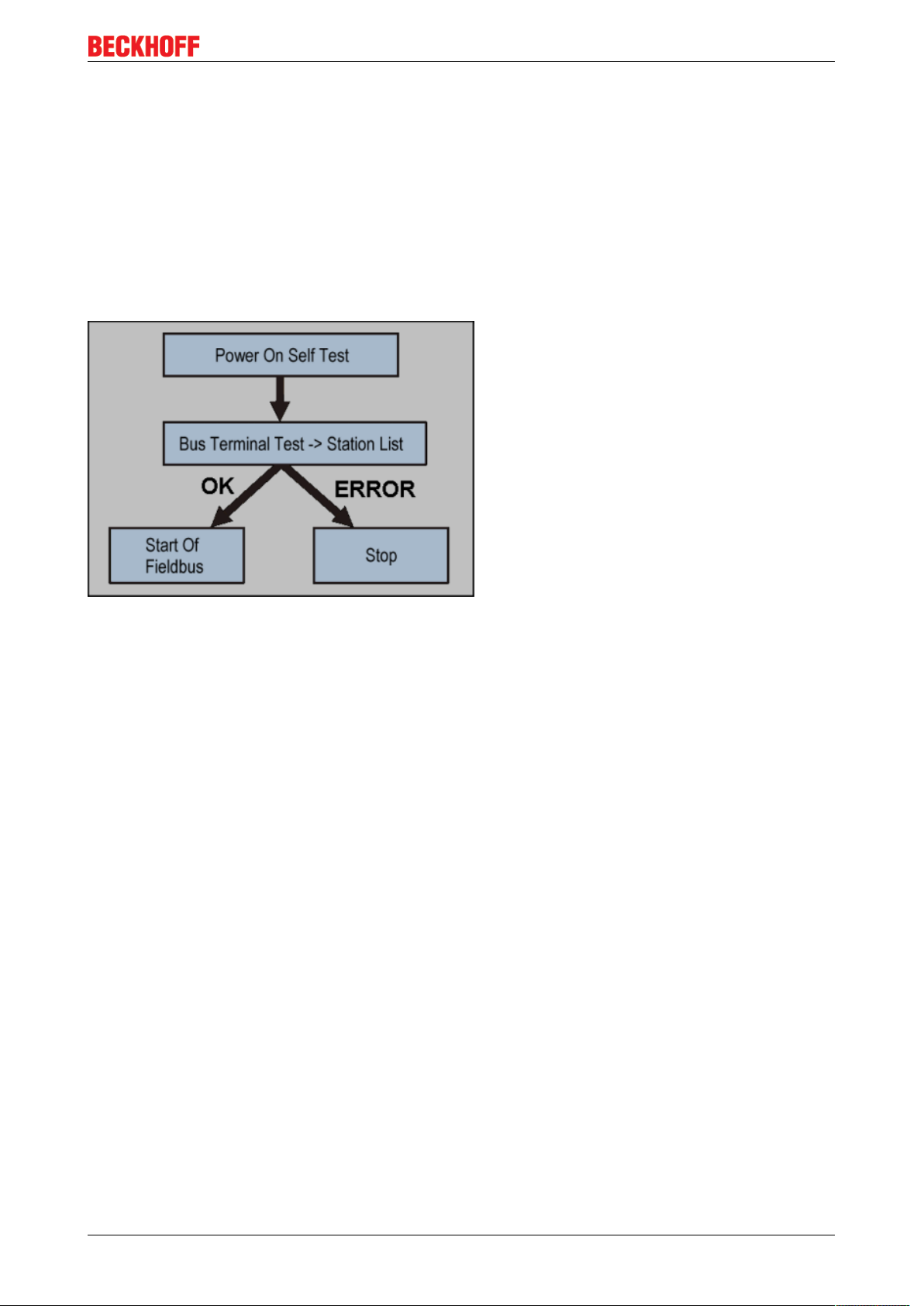

Immediately after being switched on, the Bus Coupler checks, in the course of a self-test, all the functions of

its components and the communication on the K-bus/E-bus. The red I/O LED blinks while this is happening.

After completion of the self-test, the Bus Coupler starts to test the attached Bus Terminals (the "Bus

Terminal Test"), and reads in the configuration. The Bus Terminal configuration is used to generate an

internal structure list, which is not accessible from outside. In case of an error, the Bus Coupler enters the

Stop state. Once the start-up has completed without error, the Bus Coupler enters the fieldbus start state.

Fig.5: Start-up behaviour of the Bus Coupler

The Bus Coupler can be made to enter the normal operating state by switching it on again once the fault has

been rectified.

4.2 Parameterization of the Bus Coupler using DIP Switches*

*) Firmware version B5 or higher

The following parameterizations can be carried out without using configuration software, with the aid of the

DIP switches and the end terminal (KL9010).

This parameterization mode is only active if only one end terminal (KL9010) is inserted. Otherwise, the

normal settings apply.

Restoring the manufacturer's settings

• Switch off the Bus Coupler, and plug in just the end terminal (KL9010).

• Set all the DIP switches to ON, and switch the Bus Coupler on again.

• Once the default parameters have successfully been set, the Error LED lights, and the I/O Run and I/O

Error LEDs flash alternately.

• You can then switch the Bus Coupler off, connect the Bus Terminals, and continue as usual.

Setting the Ethernet parameters

• Switch off the Bus Coupler, and plug in just the end terminal (KL9010).

• Set all the DIP switches to OFF, and switch the Bus Coupler on again.

• The I/O RUN and I/O Error LEDs light steadily.

• Make the desired setting in accordance with the following table.

BK9055 and BK9105 21Version: 2.0.0

Page 22

Parametrization and commissioning

DIP switch Parameters Selection Setting Comment

1 Baud Rate 10 MBaud OFF (0)

100 MBaud ON (1) Default

2 Auto-Baud-Rate Disable OFF (0)

Enable ON (1) Default

3 Transmission type Half duplex OFF (0)

Full duplex ON (1) Default

• To accept the values, set DIP switch 10 to ON.

By flashing the I/O RUN and I/O ERR LEDs the Bus Coupler indicates that it has accepted the

parameters.

• You can then switch the Bus Coupler off, connect the Bus Terminals, and continue as usual.

4.3 Network classes

Three different network classes are distinguished. They determine how many address bits are reserved for

the network ID and how many for the node number (e.g. for PCs or Bus Couplers). The difference is located

in the first three bits of the IP address.

Network

class

A 7 126 24 16777214

B 14 16382 16 65536

C 21 2097150 8 254

Number of bits for

the network ID

Enables no. of

networks

No. of bits for the

node address

Enables no. of nodes per

network

Unique IP address

An IP address must be unique within the entire connected network!

Fig.6: Network classes

Identical network class

In a communication with another Ethernet devices, the IP address set must have the same network

class. Sample: Your PC has the address 172.16.17.55, which means the coupler must have the address 172.16.xxx.xxx (xxx stands for a number between 0 and 255.0 is usually used by the router/

switch and should therefore remain reserved).

In order to see the PC's own address, the command ipconfig can be entered into a DOS window under

Windows NT/2000/XP.

BK9055 and BK910522 Version: 2.0.0

Page 23

Parametrization and commissioning

4.4 IP address

The IP address can be set using four different procedures, and these will be described in more detail below.

Procedure Explanation Necessary components

KS2000 Addressing using the KS2000 configuration

software and DIP switches

ARP

BootP

Addressing via the ARP table [}24]

Addressing via BootP server [}25]

DHCP Addressing via DHCP server DHCP server

4.4.1 Configuration with KS2000

The KS2000 configuration software (from version 3.2.8) can be used to set the TCP/IP address in a dialog

box, or it can be written directly into the registers. DIP switches 9 and 10 (for BK9050 DIP switches 1 and 2

in blue) should both be OFF (0) before switching on.

Table 100

Register High-Byte Low-Byte

0 IP-Byte 2 IP-Byte 1

1 Not used IP-Byte 3

KS2000 configuration software and KS2000

cable

PC with network

BootP server

Default

Byte Default value (hex) Default value (dec)

1 0xAC 172

2 0x10 16

3 0x11 17

4 (DIP switch) (0 to 255

dec

dec

dec

dec

)

Sample

Fig.7: DIP switch

Switch no. 1 2 3 4 5 6 7 8 9 10

Valence 1 2 4 8 16 32 64 128 - -

In this example ON OFF OFF ON OFF OFF ON ON OFF OFF

Value 1 0 0 8 0 0 64 128 - - Total=201

Software reset

A software reset is required to save changes in the Bus Coupler tables. A hardware reset (power

on/off) is not sufficient!

BK9055 and BK9105 23Version: 2.0.0

Page 24

Parametrization and commissioning

4.4.2 Address Configuration via ARP

An easy method of modifying the IP address is to set the address using the DOS window. It is, however, only

possible to alter addresses within the same network class. The new IP address that has been set remains

stored even after the Bus Coupler has been switched off.

Procedure

• Set DIP switches 9 and 10 to OFF. DIP switches 1-8 then no longer have any address function.

• Open a DOS box on your PC.

• Enter the command "ping <OLD IP address>" to create an entry in the ARP table.

• Read the table with the command "ARP -a".

• Enter "ARP -d <OLD IP address>" to remove the Bus Coupler from the table.

• Use "ARP -s <NEW IP address> <MAC-ID> [}30]" to make an entry manually.

• With "ping -l 123 <NEW IP address>" the new IP address becomes valid.

A short flash from the ERROR LED at the moment of switching on indicates that the Bus Coupler is being

addressed by ARP, and that DIP switches 1-8 give no indication of the address that is set.

Changing the IP address

When the IP address is changed, all the dynamic ARP entries should be cleared. To change the IP

address it is one ping with the length of 123 bytes is permitted for reconfiguration of the IP address

(<ping -l "IP address>) necessary.

Example

1. C:>ping 172.16.17.255

2. C:>arp -a

172.16.17.25500-01-05-00-11-22

3. C:>arp -d 172.16.17.255

4. C:>arp -s 172.16.44.44 00-01-05-00-11-22

5. C:>ping -l 123 172.16.44.44

BK9055 and BK910524 Version: 2.0.0

Page 25

Parametrization and commissioning

4.4.3 Address configuration via BootP server

4.4.3.1 Addressing via Beckhoff BootP Server

BootP Server

Disable all other Ethernet adapter in your “network connections” before you start the BootP Server.

You have then only one Ethernet adapter which you can use for BootP.

Connecting to the BootP Server

BootP server: ftp://ftp.beckhoff.de/software/TwinCAT/TwinCAT2/Unsupported_Utilities/TcBootP_Server/

How to use the BootP server

Use the BootP server with the BK9105 in one of two ways:

1. Statically store an IP address by switching all the dip switches 1-9 to the on position

Fig.8: Beckhoff BootP Server - DIP switch settings for statically stored IP address

When choosing this mode, power cycling the BK9105 with the dip switches set to ON 1-9 will keep the IP

address set by the BootP server. The BootP server does not need to be present after this point.

2. Dynamically set an IP address that is assigned by the BootP by turning on only dip switch 9

Fig.9: Beckhoff BootP Server - DIP switch settings for dynamically set IP address

Be sure to configure the BootP server with the Mac ID of the BK9105 and the desired IP address.

BK9055 and BK9105 25Version: 2.0.0

Page 26

Parametrization and commissioning

Fig.10: Beckhoff BootP server configuration - Start

Then, start the server and reboot the BK9105. After a connection and an IP address are established, the

following time stamp appears:

BK9055 and BK910526 Version: 2.0.0

Page 27

Parametrization and commissioning

Fig.11: Beckhoff BootP server configuration - Time Stamp

Regard dip switch 9 for dynamically set IP address

It is not possible to change dip switches 1 to 9 for a static IP address. They must remain on. If using

the BootP server to assign the address every time the BK9105 is powered on, make sure dip switch

9 is on.

4.4.3.2 Addressing via Rockwell BOOTP/DHCP Server 2.3

IP address save modes

DIP switches 1 to 8 in the ON position

The address assigned by the BootP server is stored, and the BootP service will not be restarted after the

next cold start.

The address can be cleared again by reactivating the manufacturers' settings (using the KS2000 software or

with the DIP switch and end terminal [}27]).

DIP switches 1 to 8 in the OFF position

The IP address assigned by the BootP server is only valid until the Bus Coupler is switched off. The BootP

server must assign a new IP address to the Bus Coupler at the next cold start.

The address is, however, retained through a software reset of the Bus Coupler

Switch the DIP Switch 1 to 8 ON or OFF and DIP 9-10 ON.

BK9055 and BK9105 27Version: 2.0.0

Page 28

Parametrization and commissioning

Take note that the dip switches 1 to 8 no longer hold any addressing capabilities.

The MAC Address begins with 00-01-05-xx-xx-xx (see under the BK9105 to find the MAC address).

Fig.12: Rockwell BOOTP/DHCP Server 2.3 - MAC address

After a successful addressing you can disable the BOOTP addressing.

BK9055 and BK910528 Version: 2.0.0

Page 29

Parametrization and commissioning

Fig.13: Rockwell BOOTP/DHCP Server 2.3 - successful addressing

4.4.4 Setting the address using a DHCP server

To set the address by means of a DHCP server, set DIP switch 9 to OFF (0) and DIP switch 10 to ON (1).

In this state the DHCP service is switched on, and the Bus Coupler is assigned an IP address by the DHCP

server.

The DHCP server must know the MAC ID of the Bus Coupler and should assign the same IP address to this

MAC ID on each startup.

The TCP/IP error LED flashes while the address is being allocated.

4.4.5 Subnet mask

The subnet mask is subject to the control of the network administrator, and specifies the structure of the

subnet.

Small networks without a router do not require a subnet mask. The same is true if you do not use registered

IP numbers. A subnet mask can be used to subdivide the network with the aid of the mask instead of using a

large number of network numbers.

The subnet mask is a 32-bit number:

• Ones in the mask indicate the subnet part of an address space.

• Zeros indicate that part of the address space which is available for the host IDs.

BK9055 and BK9105 29Version: 2.0.0

Page 30

Parametrization and commissioning

Description Binary representation Decimal representation

IP address 10101100.00010000.00010001.11001000 172.16.17.200

Subnet mask 11111111.11111111.00010100.00000000 255.255.20.0

Network ID 10101100.00010000.00010000.00000000 172.16.16.0

Host ID 00000000.00000000.00000001.11001000 0.0.1.200

Standard subnet mask

Address class Standard subnet mask (decimal) Standard subnet mask (hex)

A 255.0.0.0 FF.00.00.00

B 255.255.0.0 FF.FF.00.00

C 255.255.255.0 FF.FF.FF.00

Subnets and host number

Neither subnet 0 nor the subnet consisting only of ones may be used. Neither host number 0 nor

the host number consisting only of ones may be used!

If the IP address is set using the KS2000 configuration software, it is necessary for the subnet mask

also to be changed with the KS2000 configuration software.

If ARP addressing is used, the associated standard subnet mask, based on the IP address, is entered.

Under BootP or DHCP the subnet mask is transmitted also by the server.

4.4.6 Testing the IP address

To test the IP address you can use the Ping command in a Windows prompt.

Fig.14: Testing the IP address using the Ping command

4.4.7 Reading the MAC-ID

Proceed as follows to read the MAC-ID.

• Change the IP address on your PC to 172.16.x.x and the Subnet mask to 255.255.0.0

The IP address when supplied by the manufacturer on the BC9000 and BK9000 is 172.16.17.255 (DIP

switches 1 to 8 are set to ON).

The IP address of the IP67 Fieldbus Boxes are set to 172.16.18.(rotary switch setting).

• Start the DOS Window

• Send a Ping to IP address 172.16.17.xxx

• Read the MAC-ID with arp -a.

BK9055 and BK910530 Version: 2.0.0

Page 31

Parametrization and commissioning

4.5 Configuration

4.5.1 Mapping

Type: ETHERNET-MODULE Generic Ethernet Module

Comm Format: SINT, INT or DINT

Assembly Instance:

• Input: 101Size: 4 x SINT (BYTE) + terminals (2 x INT + terminals or 1 x DINT + terminals)

• Output: 102Size: 4 x SINT (BYTE) + terminals (2 x INT + terminals or 1 x DINT + terminals)

• Configuration: 100Size 0

Mapping rules

Complex terminals* (see documentation terminals)

• Word Alignment

• complex mapping

Comm Format: SINT

Offset Inputs Outputs

0 Status Byte0 Control Byte0

1 Status Byte1 Control Byte1

2 Status Byte2 Control Byte2

3 Status Byte3 Control Byte3

4...x complex terminals* complex terminals*

x...y digital terminals** digital terminals**

*) complex terminals, example KL15xx, KL25xx, KL3xxx, Kl4xxx, KL5xxx, KL6xxx, KL8xxx

**) digital terminals, example KL1xxx, KL2xxx, KM1xxx, KM2xxx

Comm Format: INT

Offset Inputs Outputs

0 Status Word0 Control Word0

1 Status Word1 Control Word1

2...x complex terminals* complex terminals*

x...y digital terminals** digital terminals**

*) complex terminals, example KL15xx, KL25xx, KL3xxx, Kl4xxx, KL5xxx, KL6xxx, KL8xxx

**) digital terminals, example KL1xxx, KL2xxx, KM1xxx, KM2xxx

Comm Format: DINT

Offset Inputs Outputs

0 Status DWord 0 Control DWord 0

1...x complex terminals* complex terminals*

x...y digital terminals** digital terminals**

*) complex terminals, example KL15xx, KL25xx, KL3xxx, Kl4xxx, KL5xxx, KL6xxx, KL8xxx

**) digital terminals, example KL1xxx, KL2xxx, KM1xxx, KM2xxx

BK9055 and BK9105 31Version: 2.0.0

Page 32

Parametrization and commissioning

Mapping terminals

Example 1: (only digital terminals)

Comm Format INT

Size: 3 x Input, 3 x Output

1 x BK9105

2 x KL1002

2 x KL2012

1 x KL9010

Offset Name Inputs Outputs

0 Control/Status Word 0 DeviceName:I.data[0] DeviceName:O.data[0]

1 Control/Status Word 1 DeviceName:I.data[1] DeviceName:O.data[1]

2 digital terminals DeviceName:I.data[2]

(Bit 0..3, 4..15 unused)

Example 2:

Comm Format INT

Size: 7 x Input, 7 x Output

1 x BK9105

1 x KL1408

2 x KL2012

1 x KL3312

1 x KL9010

DeviceName:O.data[2]

(Bit 0..3, 4..15 unused)

Offset Name Inputs Outputs

0 Control/Status Word 0 DeviceName:I.data[0] DeviceName:O.data[0]

1 Control/Status Word 1 DeviceName:I.data[1] DeviceName:O.data[1]

2 KL3312 Channel 0

Control/Status

3 KL3312 Channel 0 DeviceName:I.data[3] (Bit 0..15) DeviceName:O.data[3] (Bit 0..15)

4 KL3312 Channel 1

Control/Status

5 KL3312 Channel 1 DeviceName:I.data[5] (Bit 0..15) DeviceName:O.data[5] (Bit 0..15)

6 digital terminals DeviceName:I.data[6]

BK9105 Control and Status

Status Bits 0 to 31

0 1 2* 3* 4 5 6 7 8 to 15* 16 to 23 24 to 31

K1 - L1 L2 - - - - K-Bus Counter K-Bus Error Code K-Bus Error argument

K1 - if K1 = TRUE, K-Bus error, Error Code bit 16-31 (see K-Bus Error LED [}50])

L1 or L2 active

* Firmware version B3 increment if a K-Bus cycle is ready

DeviceName:I.data[2]

(Bit 0..7, 8..15 unused)

DeviceName:I.data[4]

(Bit 0..7, 8..15 unused)

(Bit 0..7, 8..15 unused)

DeviceName:O.data[2]

(Bit 0..7, 8..15 unused)

DeviceName:O.data[4]

(Bit 0..7, 8..15 unused)

DeviceName:O.data[6]

(Bit 0..3, 4..15 unused)

Control Bits 0 to 31

0 1 2* 3* 4 5 6 7 8 9 10 11 12 13 14 15 16 to 23 24 to 31

K1 R1 L1 L2 - - - - - - - - - - - - - -

K1 - 0->1 rising Trig K-Bus Reset

R1 - 1->0 falling Trig Reboot BK9105

L1 - 1-> Outputs are frozen

L2 - 1-> Leave K-Bus Cycle, if L1 and L2 TRUE then is only L2 active

*) Firmware version B3 necessary

BK9055 and BK910532 Version: 2.0.0

Page 33

Parametrization and commissioning

4.5.2 EthernetIP Tag Wizard

Mapping

The BK9105 can be mapped as short integer (byte), integer (word), or double integer (double word).

In the following description it is mapped as double integer!

Installation

• Download the file EIPTOOL.zip from this CHM-File click on the following Link (https://

infosys.beckhoff.com/content/1033/bk9055_bk9105/Resources/zip/4524990475.zip)

• Extract all the contained files from the ZIP file into a folder (e.g. BK9105helper) on your PC

• Start the EtherNetIPConfigTool.exe

Overview

This application note covers how to use the EthernetIP Tag Wizard. After reading this note you will be able to

build a rack of Beckhoff IO and automatically import it into RSLogix 5000. Not only will the nodes be

automatically created, but the IO will have an exact description in the IO map.

Supporting Documents and References

Put link to BK9105 here, as well as the link to the EIP tool.

Key Concepts

With this tool a user will be able to create the Beckhoff IO Rack, save the IO mapping configuration and

Import that configuration into RSLogix 5000. RSLogix 5000 does not need to be installed on the PC you

have the Tag Wizard on, however it will be convenient.

Procedure

To get started we have to have an RSLogix configuration with a minimum of a processor and Ethernet IP

Master. If you are simply adding a rack to an existing configuration, this process will be the same.

BK9055 and BK9105 33Version: 2.0.0

Page 34

Parametrization and commissioning

Fig.15: EthernetIP Tag Wizard

All one has to do is simply save this configuration as an .L5K file to the desired location. In this example, all

files are saved to the root directory of the Tag Wizard.

BK9055 and BK910534 Version: 2.0.0

Page 35

Parametrization and commissioning

Fig.16: EthernetIP Tag Wizard - Save as type

Once the RSLogix 5000 configuration is saved please minimize and open up the folder where the tag wizard

is stored. In this folder you will find a couple reference files. The EthernetIPMaster.txt is very important. This

is a text file that stores the name that Rockwell gives its scanners. If your scanner is NOT in the list, please

feel free to add it. It is VERY important that the scanner is added just as it appers in your .L5K file.

Fig.17: EthernetIP Tag Wizard - EthernetIPMaster.txt

At this point all one has to do is double click on EtherNetIPConfigTool.exe and it will open. Once open, add

your BK9105 or IL230x-B905 to the configuration.

BK9055 and BK9105 35Version: 2.0.0

Page 36

Parametrization and commissioning

Fig.18: EthernetIP Tag Wizard - EtherNetIPConfigTool

When adding your coupler you will be prompted to enter the correct IP address.

Fig.19: EthernetIP Tag Wizard - Enter IP address

If you select the Field Bus Box IL230X-B905 you will be prompted additionally with the following.

Fig.20: EthernetIP Tag Wizard - Automatic adding Local IO

The software automatically is adding the 230x combo box to your configuration.

At this point you simply add the IO to your configuration in the order that they are left to right on the coupler,

by simply double clicking on the correct terminal.

BK9055 and BK910536 Version: 2.0.0

Page 37

Parametrization and commissioning

Fig.21: EthernetIP Tag Wizard - Adding the IO to cour configuration

Once you have all the IO added in the correct order, you have a couple different selections as to how to save

review or export this data. To review, all one has to do is simply select the coupler you want to review and

then Report>Coupler (Or network [If network is selected only the first coupler will show graphically but the

mapping below is correct])

Fig.22: EthernetIP Tag Wizard - selections

BK9055 and BK9105 37Version: 2.0.0

Page 38

Parametrization and commissioning

Fig.23: EthernetIP Tag Wizard - Mapping

All one has to do at this point to save or export the data is File>Save XML (this saves the configuration to a

XML file, File>Save Network Report (saves so as you can print it for machine documentation)

Save>Configuration (If you want to add to this configuration in the future) and File>Save To L5K file.

Fig.24: EthernetIP Tag Wizard - Save To L5K file

When saving to a L5K file you are prompted to select the correct Ethernet IP master (This list is read from

the text file mentioned earlier).

BK9055 and BK910538 Version: 2.0.0

Page 39

Fig.25: EthernetIP Tag Wizard - choose the correct Ethernet IP master

Parametrization and commissioning

Fig.26: EthernetIP Tag Wizard select the correct Ethernet IP master

Once we have the master selected, then choose OK.

Next you will be prompted to select the correct path to the stored .L5K file, and select Open. Once opened

you will notice an AB.L5K file in the same directory you saved the original L5K file.

Fig.27: EthernetIP Tag Wizard - select the correct path to the stored .L5K file

BK9055 and BK9105 39Version: 2.0.0

Page 40

Parametrization and commissioning

Fig.28: EthernetIP Tag Wizard - ABL5k.L5K

Go back to RSLogix 5000, File>Open>

Fig.29: EthernetIP Tag Wizard - open the L5K file

Select the NEW .L5K file then Import

BK9055 and BK910540 Version: 2.0.0

Page 41

Parametrization and commissioning

Fig.30: EthernetIP Tag Wizard - Safe the Imported Project

Now to check out all of the new IO

BK9055 and BK9105 41Version: 2.0.0

Page 42

Parametrization and commissioning

Fig.31: EthernetIP Tag Wizard - check out all of the new IO

Please note to look in the Controller tags for not only did the software create new module defined tags, it

labeled them accordingly in the Logical order, NOT the physical order.

BK9055 and BK910542 Version: 2.0.0

Page 43

Parametrization and commissioning

Fig.32: EthernetIP Tag Wizard - Controller tags

Coupler Status and Coupler Control

After the import is successful, please see that the Coupler Status and Coupler Control is described

at the bit level. Also the status and control for each complex channel is defined with the HBYTE>Empty LBYTE Status or Ctrl as the upper byte is padded.

BK9055 and BK9105 43Version: 2.0.0

Page 44

Parametrization and commissioning

4.5.3 Export to Rockwell

Create a master Ethernet IP (limitation only master, not Multimaster support)

Fig.33: Export to Rockwell - Create a master Ethernet IP

Save as the project as .L5k format

Fig.34: Export to Rockwell - Save as the project as .L5k format, step 1

BK9055 and BK910544 Version: 2.0.0

Page 45

Parametrization and commissioning

Fig.35: Export to Rockwell - Save as the project as .L5k format, step 2

Create the project with the configurator and export with the push button AB CSV

Fig.36: Export to Rockwell - export with the push button AB CSV

Select the file L5k, which you have generated

BK9055 and BK9105 45Version: 2.0.0

Page 46

Parametrization and commissioning

Fig.37: Export to Rockwell - Select the created file L5k

Open AB's tool, and select open

Fig.38: Export to Rockwell - open the ABL5K.L5K

Select the file ABL5K.L5K (fixed name!)

BK9055 and BK910546 Version: 2.0.0

Page 47

Parametrization and commissioning

Fig.39: Export to Rockwell - Select the file ABL5K.L5K

Save the project as ACD

Fig.40: Export to Rockwell - Save the project as ACD

Read the import configuration, with the comments

BK9055 and BK9105 47Version: 2.0.0

Page 48

Parametrization and commissioning

Fig.41: Export to Rockwell - Read the import configuration

BK9055 and BK910548 Version: 2.0.0

Page 49

Parametrization and commissioning

Fig.42: Export to Rockwell - Read the import configuration with comments

BK9055 and BK9105 49Version: 2.0.0

Page 50

Error handling and diagnosis

5 Error handling and diagnosis

5.1 Diagnostic LEDs

After switching on, the Bus Coupler immediately checks the connected configuration. Error-free start-up is

indicated when the red I/O ERR LED goes out. If the I/O ERR LED blinks, an error in the area of the

terminals is indicated. The error code can be determined from the frequency and number of blinks. This

permits rapid rectification of the error.

The Bus Coupler has two groups of LEDs for the display of status. The upper group with four LEDs indicates

the status of the respective fieldbus. The significance of the fieldbus status LEDs is explained in the

appropriate sections of this manual. It corresponds to the usual fieldbus display.

On the upper right hand side of the Bus Couplers are two more green LEDs that indicate the supply voltage.

The left hand LED indicates the presence of the 24V supply for the Bus Coupler. The right hand LED

indicates the presence of the supply to the power contacts.

Fig.43: BK9105 Diagnostic LEDs

BK9055 and BK910550 Version: 2.0.0

Page 51

Fig.44: BK9055, BK9105 - LEDs

Error handling and diagnosis

LEDs for power supply diagnosis

LED Meaning

LED Us off The power supply voltage Us is not present

on The power supply voltage Us is present

LED Up off The power supply voltage Up (for Power Contacts) is not present

on The power supply voltage Up (for Power Contacts) is present

LEDs at RJ45

LED Meaning

LED Link/Act off No physical connection present

on Physical connection present

flashes Communication available

LED 10/100 Mbit/s

(BK9105 only)

off 10 Mbit/s (if LED Link/Act is shining or flashing)

on 100 Mbit/s

BK9055 and BK9105 51Version: 2.0.0

Page 52

Error handling and diagnosis

LEDs for fieldbus diagnosis

EtherNet/IP Diagnosis EIP E (red) EIP R (green) DIAG E (red) DIAG R (green)

IP Address OK off 0,5s x x

No IP Address (Dip Switch 8,9 -> on) off off x x

Online off on x x

Offline PLC Stop off 0,1s x x

TimeOut 0,5s off x x

IP Address conflict on off x x

Configuration Diagnosis EIP E (red) EIP R (green) DIAG E (red) DIAG R (green)

OK x x off on

In data too less x x Flashing* 1

In data too big x x Flashing* 2

Out data too less x x Flashing* 3

Out data too big x x Flashing* 4

Wrong Assembly Instance x x Flashing* 5

Second Master x x Flashing* 6

*) Bytes are too less (missing) or to big

X: The status of the LED is not relevant for this diagnosis.

Example:

Data Length In too big 5Bytes…

• Start Error Code: Red LED is quickly flashing, green LED is Off

• Red LED is ON, green LED show you the Error Code flashing 2 times (1 Sec)

• Red LED OFF, green LED off

• Red LED flashing 5 times (1 Sec), error argument, green LED off

Fig.45: Example for Error Code and Error Argument

BK9055 and BK910552 Version: 2.0.0

Page 53

LEDs for K-Bus diagnosis

Error handling and diagnosis

Error code Error

Argument

Persistent,

continuous

blinking

1 pulse 0 EEPROM checksum error Set manufacturer’s setting with the KS2000

1 Code buffer overflow Insert fewer Bus Terminals. The programmed

2 Unknown data type Software update required for the Bus Coupler

2 pulses 0 Programmed configuration has

n (n > 0) Table comparison (Bus

3 pulses 0 K-Bus command error • No Bus Terminal inserted

4 pulses 0 K-Bus data error, break behind

n Break behind Bus Terminal n Check whether the Bus End Terminal KL9010 is

5 pulses n K-Bus error in register

6 pulses 0 Error at initialization Exchange Bus Coupler

1 Internal data error Perform a hardware reset on the Bus Coupler

2 DIP switch changed after a

4 DIP switch incorrect for BootP

8 Internal data error Perform a hardware reset on the Bus Coupler

16 Error in IP socket Perform a hardware reset on the Bus Coupler

14 pulses n nth Bus Terminal has the wrong

15 pulses n Number of Bus Terminals is no

16 pulses n Length of the K-Bus data is no

Description Remedy

EMC problems • Check power supply for overvoltage or

undervoltage peaks

• Implement EMC measures

• If a K-Bus error is present, it can be localized by

a restart of the coupler (by switching it off and

then on again)

configuration software

configuration has too many entries in the table

Check programmed configuration for correctness

an incorrect table entry

Incorrect table entry

Terminal n)

• One of the Bus Terminals is defective; halve the

number of Bus Terminals attached and check

whether the error is still present with the

remaining Bus Terminals. Repeat until the

defective Bus Terminal is located.

Check whether the n+1 Bus Terminal is correctly

the Bus Coupler

communication with Bus

Terminal n

software reset

format

longer correct

longer correct

connected; replace if necessary.

connected.

Exchange the nth bus terminal

(switch off and on again)

Perform a hardware reset on the Bus Coupler

(switch off and on again)

Set 1-8 to on or off, see BootP [}25]

(switch off and on again)

(switch off and on again)

Start the Bus Coupler again, and if the error

occurs again then exchange the Bus Terminal

Start the Bus Coupler again. If the error occurs

again, restore the manufacturers setting using the

KS2000 configuration software

Start the Bus Coupler again. If the error occurs

again, restore the manufacturers setting using the

KS2000 configuration software

BK9055 and BK9105 53Version: 2.0.0

Page 54

Appendix

6 Appendix

6.1 First Steps

Mapping

The BK9105 can be mapped as short integer (byte), integer (word), or double integer (double word).

In the following description it is mapped as double integer!

Addressing with the BOOTP/DHCP Server 2.3

Switch the DIP Switch 1 to 8 OFF and DIP 9 to 10 ON.

The MAC Address begins with 00-01-05-xx-xx-xx (see under the BK9105, here you find the MAC address).

Fig.46: First Steps - Addressing - Step 1

After a successful addressing you can disable the BOOTP addressing.

BK9055 and BK910554 Version: 2.0.0

Page 55

Appendix

Fig.47: First Steps - Addressing - Step 2

Open RSLogix 5000 and create a new PLC project

When creating a new project make sure to select the correct controller type and controller settings. In this

example we are using a SoftLogix Virtual Chasis, with the BK9105 (Beckhoff EthernetIP Bus coupler)

Fig.48: First Steps - Create a new PLC project

BK9055 and BK9105 55Version: 2.0.0

Page 56

Appendix

Add Ethernet IP Module

Now you need to add your main communications module. Make sure you know the IP address of the card

that is setup as the EtherNet IP card, that address will have to be set in the module settings along with the

slot the card is in.

Fig.49: First Steps - Add Ethernet IP Module

Add Ethernet IP Box

When adding the BK9105 box you must select the "ETHERNET-MODULE" as it is a generic Ethernet/IP

device and we will configure it to work with our BK9105.

Fig.50: First Steps - Add Ethernet IP Box

Configuring the BK9105 in RSLogix

For the example here we used two KL1012 terminals and two KL2032. With these cards that gave us 2

words total of input and output data. On the properties dialog you will need to change some of the box

settings, please read below for recommendations on settings.

BK9055 and BK910556 Version: 2.0.0

Page 57

• IP Address (Refer to IP Address section of documentation)

• The Assembly Instances will be as follows

◦ Input: 101

◦ Output: 102

◦ Configuration: 100

• Things to keep in mind when entering the data size for I/O

◦ There will always be 4bytes of input and 4bytes of output data that is used for

◦ Digital IO each channel will consume 1bit of process data.

◦ Complex IO please refer to terminal documentation for consumed data size.

Appendix

Fig.51: First Steps - Configure the BK9105 in RSLogix

Working with IO data

Download the code to the controller unit, once you go online you will be able to toggle IO. Keep in mind that

the first DINT is the Status for both the input and output data. At this point if you have the controller in RUN

mode you will be able to toggle inputs and see the value in "bk9105:I.Data[1]" change and you should be

able to update the values in "bk9105:O.Data[1]" and see the outputs change.

Fig.52: First Steps - Work with IO data

BK9055 and BK9105 57Version: 2.0.0

Page 58