ATL Ultramark 9HDI Service Manual

P/N 4730-0013-04 Rev B

£

9

Field Service Manual

Service Manual 4730-0013-04 Rev A consists of:

4720--0013--04 Rev A (2/96)

HDI

August, 1999

A detailed Table of Contents and List of Effective Pages are contained in

Page i. Changed or added pages, from the initial manual release, can be

identified by the change date located at the bottom of each page. No

changedateindicatesthatthispageistheoriginalrelease and has notbeen

changed. A change bar ( ), located in the outside margin of a page,

denotesthespecificpart ofapage thatwaschangedatthatdate.Apointing

hand ( ) indicates the portion of a figure that has been revised.

For a list of current documents, refer to the latest revision of the Active

Documents List -- Ultramark 9 HDI System, P/N 4768-0013-01.

ATL

P.O. Box 3003

Bothell, WA 98041-3003

COPYRIGHTE1996 BY ATL

ALL RIGHTS RESERVED

PRINTEDINUSA

“ATL” , “Advanced Technology Laboratories”, ”Cineloop” , “HDI”, and “Ultramark” are registered trademark of ATL

“Color Power Angio”, “High Definition”, “High Q”, “Power Motion”, and “Tissue Specific” are trademarks of ATL.

Non-ATL product names may be trademarks or registered trademarks of their respective owners.

Introduction

Organization

Introduction

This manual provides only information most often needed in the field.

Experienced personnel will be able to use accompanying performance testing, and preventive maintenance checklists.

The manual contains major tab divisions for diagrams, procedures,

adjustments, fault isolation, configuration supplement, Operating

Notes, Service Bulletins, reference, and parts.

ACTIVE DOCUMENT LIST: lists all active documents pertaining to

the Ultramarkr9 HDI Ultrasound System. Listed are active service

bulletins, service manuals, operation manuals, translated operation

manuals and operating notes.

HDI--i

DIAGRAMS: includes diagrams of system/data paths, power distribution, and cabling.

PROCEDURES: contains information on pre-installation requirements, installation, performance testing, and preventive maintenance.

ADJUSTMENTS: procedures for field authorized adjustments,

including adjustment parameters and location diagrams.

FAULT ISOLATION: system self-diagnostics and fault isolation

information organized by PCB. Also includes minimum configuration

information.

CONFIGURATION: hardware and software compatibility information

for specific system configurations.

OPERATING NOTES: contains operating infor-mation not incorporated into the operation manual.

HDI--ii

SERVICE BULLETINS: includes copies of all active service bulletins. “Hot Tips” may be added as they are received by the CSR.

REPLACEABLE PARTS: contains illustrated parts listings of parts

commonly replaced in the field.

REFERENCE: for information regarding interconnecting cables and

connectors used in the Ultramark 9 HDI as well as other miscellaneous information. This section is currently empty.

Manual Usage and Update Information

The Table of Contents and List of Effective Pages have been combined for this manual. There is no List of Illustrations or List of Tables.

This will facilitate frequent updating of the manual and allow CSRs to

easily determine the effective date of referenced information.

The contents of a manual change package should be inserted as

indicated on the cover sheet attached to the package. Changed or

added pages can be identified by the change date at the bottom of

the affected page. No change date indicates the page is an original

HDI--iii

page. Change bars located in the outside margin of the page denote

the specific part of a page that was changed at that date. A pointing

hand indicates the portion of the figure that has been changed.

Page numbers are divided into three parts. The prefix identifies the

system covered by the manual. The middle portion identifies the section of the manual. The suffix indicates the actual page number.

Safety and Precautions

This section provides biological, procedural, environmental, electrical

and mechanical safety information.

WARNING statements identify conditions or practices that could

result in personal injury or death.

CAUTION statements identify conditions or practices that could result

in equipment damage.

HDI--iv

Biological Safety

The assessment of the biological effects of diagnostic ultrasound on

humans is not complete. Diagnostic ultrasound procedures should be

used only for valid reasons, for the shortest period of time, and at the

lowest power settings necessary to produce diagnostically acceptable images.

Procedural Safety

W ARNING

Do not service or adjust a system unless another

person capable of rendering first aid is present.

CAUTION

Do not sterilize scanheads with heat, liquid, gas, or

solvents. Do not autoclave or expose to temperatures exceeding 50_C(131_F). Permanent damage

may result.

HDI--v

W ARNING

Disconnect power source and scanheads prior to

cleaning.

W ARNING

Inspect the transducer face, housing, and cable

before using the instrument. Do not use damaged

transducers.

W ARNING

Equipment grounding: This equipment is classified

Class I, Type B as defined in IEC Standard 601-1

Safety of Medical Electrical Equipment. Electrical

shock protection is provided by connecting the

instrument chassis to safety ground using the

3-wire power cable provided. This cable must be

connected to a properly grounded receptacle. Do

not defeat the grounding integrity of the equipment.

HDI--vi

W ARNING

Shock hazards exist if the system is not properly

grounded. The system must be plugged into a hospital-grade outlet.

W ARNING

Do not replace components with power connected.

Under certain conditions, dangerous voltages may

exist with power removed. Disconnect power and

discharge circuits before touching.

W ARNING

Fuse replacement is to be done by qualified service

personnel only. Avoid electric shock and fire hazard

by using proper fuses.

CAUTION

Verify the system is set to proper power source

voltage and the cart power plug mates with the

power receptacle.

HDI--vii

W ARNING

Additional hazards may be introduced by using

substituted parts or modified instruments.

W ARNING

Using accessories not recommended by ATL may

cause electrical shock or other unsafe conditions.

CAUTION

Verify circuit boards and components are dry

before applying system power.

CAUTION

This equipment contains components which are

electro-static sensitive. Proper static procedures,

protection and equipment must be used prior to

opening and during handling of this equipment.

Failure to use ESD procedures will cause damage

to these components. Such damage to components

is not covered by ATL warranties.

HDI--viii

Environmental Safety

Do not operate a system in the presence of flammable gases or anesthetics or in an oxygen

enriched environment (i.e., in an explosive atmosphere). An explosion could result.

Mechanical Safety

Use caution when transporting the system over

uneven surfaces, including entry to or exit from elevators.

Stacking equipment on the system, other than ATL

specified equipment, can cause it to become

mechanically unstable.

W ARNING

CAUTION

W ARNING

HDI--ix

Do not use esters or ketone solutions to clean

parts. Discoloration (or worse) will result.

System Safety Symbology

Document IEC601-1, International Electrotechnical Commission:

Safety of Medical Electrical Equipment, classifies patient connections

according to whether the outer enclosure is grounded or floating

(non-conducting). The classifications are shown below.

Grounded chassis. Protection against electrical shock is provided by

connection of chassis to the safety ground (IEC601-1 Type B).

Isolated patient connection (IEC 601-1 Type BF).

Isolated patient connection (IEC 601-1 Type CF).

CAUTION

I and O on circuit breaker and power switch represents ON and OFF,

respectively.

HDI--x

!

IPX--1

This symbol identifies safety note. Be sure you understand the function of this control before using it.

Drip-proof hand-held appliance (transducer assembly). This instrument may be safely handled with wet hands.

Identifies protective earth ground (located next to ground stud on

the rear panel).

Identifies the point where the system safety ground is fastened to the

chassis.

The following a re internal symbols (for reference only):

Identifies high voltage components operating above 1000 VDC or

1500 VAC.

HDI--xi

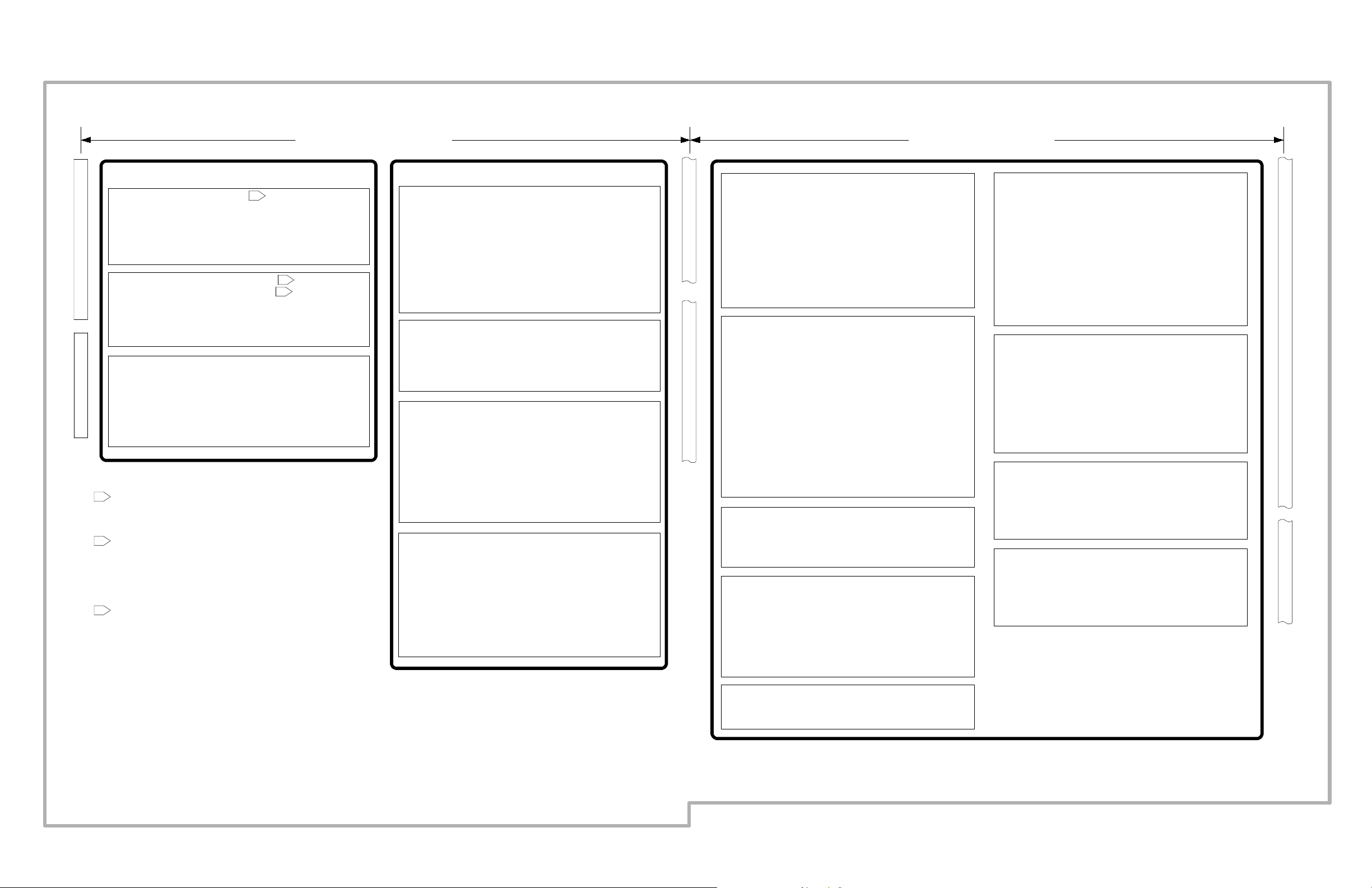

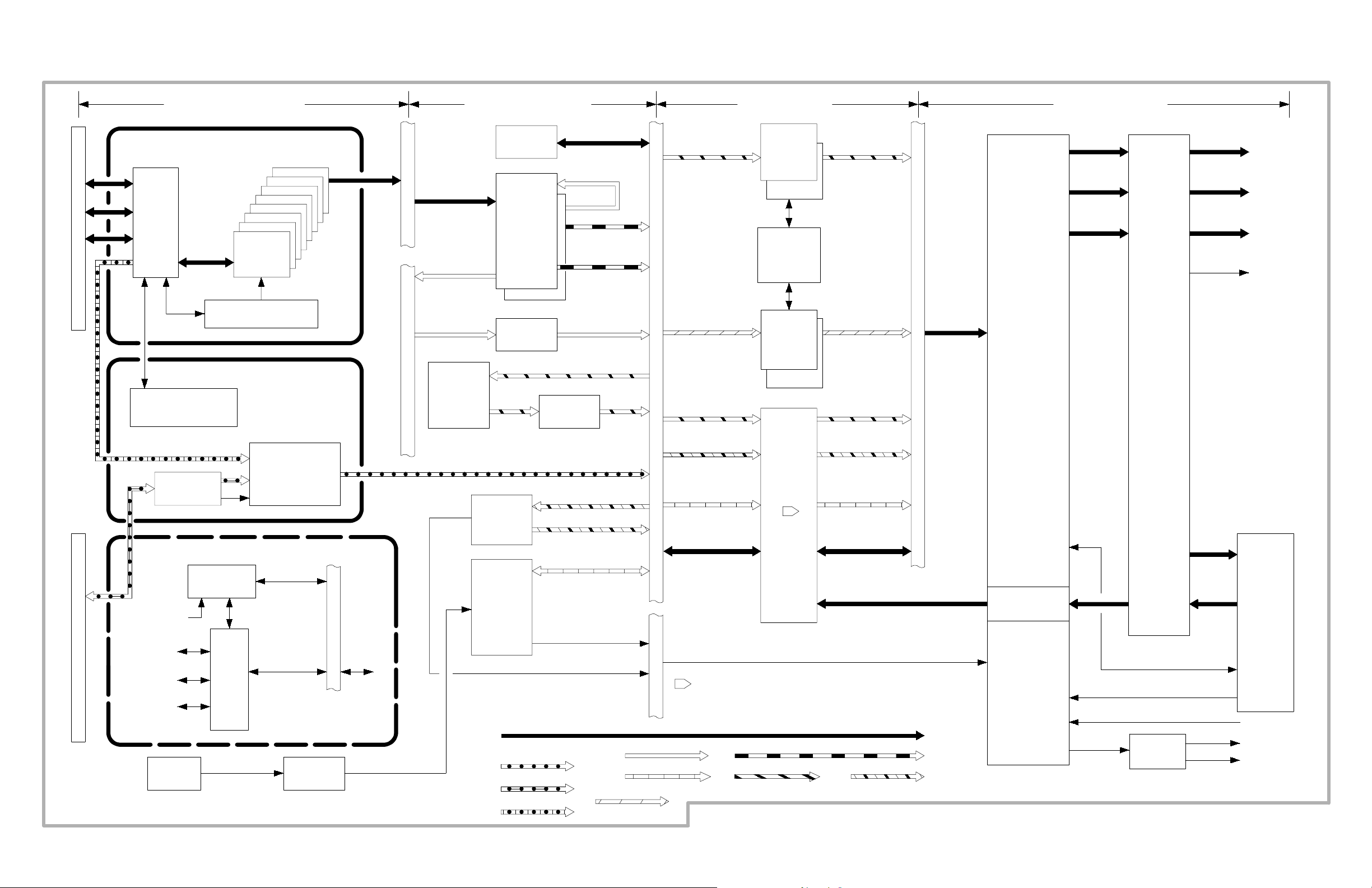

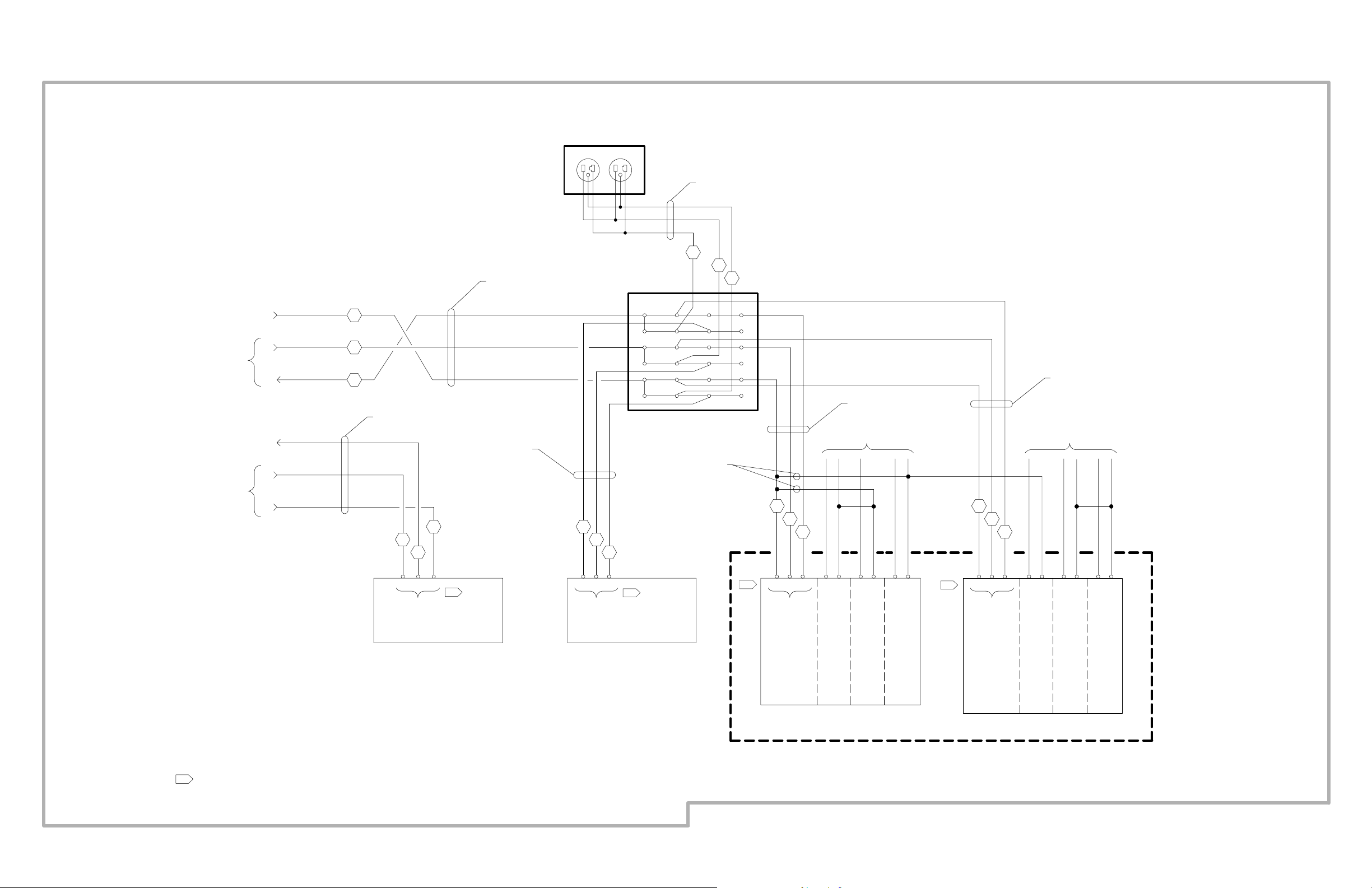

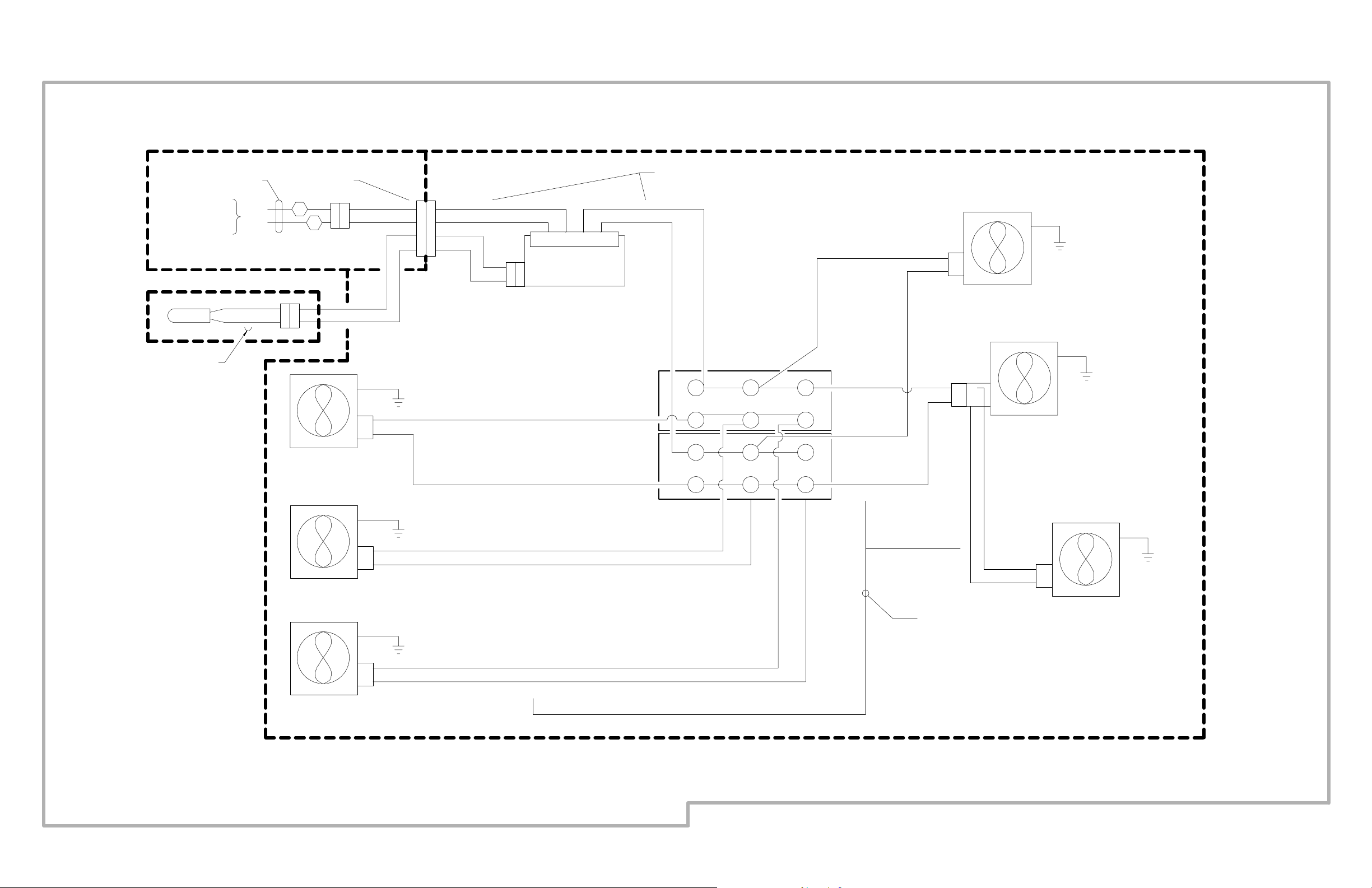

1A Block Diagrams

NOTE:

NOTE:

The block diagrams in this section include PCBs for all

options available for each PCB configuration. Refer to the

following notes as appropriate.

The Doppler Acquisition PCB is installed only if the sys-

D

tem has steered CW or TCD.

The Motor Controller PCB is installed only if the system

D

has A6--3 scanhead capabilities.

Dual IFOM PCBs are installed only on ESP systems. A

D

single IFOM PCB is installed in A16 for Non-ESP systems.

Many PCBs used in Ultramark 9 HDI systems now have

mu ltip le re fere nce designators. Re fer to

PCB slot locations.

Section 5 C

for

HDI-- 1 A--1

)

ACQUISITION GROUP

PROCESSOR GROUP

A

R

R

A

Y

S

C

A

N

H

E

A

D

S

C

W

P

R

O

B

E

S

MECHANICAL

MOTOR CONTROLLER 7500--0617

* Provides WAM motor drive

* Decodes transducer position

* Generates column request to front end

to initiate transmit burst

* SCIP bus interface

* 4 independent power amplifiers with auto--shutdown

if preset power limits are exceeded

2D ACQUISITION, (MFE1) 7500--0655

* Generates 120 MHz system clock

* Part of static CW Doppler transmit andreceive

preamp

* General I/Q reference clock

* Static TCD pulser and preamp

DOPPLER ACQUISITION, (MFE2) 7500--0615

* Required for steered CW, T CD, and static CW

* Receives RF signals from beamformer or MFE1

* Filters and amplifies the RF signal

* Mixes RF down to basebandfrequency

* Low and highpass filtering of baseband frequency

* Audio amplification

* A/D conversion

* Digital control of filtering and amplification

Refer to Tables 5C--1and 5C--2for PCB slot locations.

1

2

Generates 120 MHz clock on ST CW systems

and on Non--steered CW systems with the

7500--0570 FEC. On newer systems without

ST CW/CW, the 2DAcquisition will not be

installed. In this case, the 120 MHz clock

originates from the 7500--0754 FEC.

3

The MFE1 is not in thesteered CW data path.

It generates static CW/TCD transmit pulses

and is in receive data path for static CW/TCD.

For steered CW, the system uses more thanone

element for TX and RX. Steered CW transmit and

receive signals must be routed thru thebeamformer

to provide summation.

1

3

2

ARRAY

FRONT--END CONTROLLER, 7500--0570

* Generates SCIP Bus master clock

for ADDA, IFO, MMC, FEC, and CPU PCB’s

* TGC generation

* Header generation

* High PRF

* PRI sequencing

* Generates transmit and receive delays

* Provides all control and PRI timing functions

for various front ends

* Provides all system backplane clocks

* The 7500--0754 PCB has 120 MHz system clock

when used in non--steered CW only

SCANHEAD SELECT, 7500--0629

* Scanhead interface: linear and phased

Array path via relay to Channel PCB’s

* Scanhead personality interface

* TGC Summation Bus

* CW Summation Bus

* Steered CW path via coax to MFE2

SCANHEAD SELECT DAUGHTER 7500--0636

* Decodes control signals from FEC to Scanhead

Select PCB and pulser power supplies

* Monitors high voltage and +12V on Scanhead

Select PCB

* Interface decoded scanhead personality data from

Scanhead Select PCB back to FEC PCB

* Decodes control data from FEC to HV Mux

ICs in L10--5 scanhead

* Decodes control data from FEC to relays in

Scanhead Select PCB

* S/H temperature monitor

* TGC voltage monitor

CHANNEL, 7500--0544

* 128 transmit pulser elements (16/Channel PCB)

* 128 channel receive apertures

* Echo Summation

* Summed Steered CW toScanhead Select Interface

* TGC waveform generation

* All Channel PCB’s required for scanhead

operation but not required for scanhead ID.

* Applies transmit and receive delays

* Applies TGC to Echo RF data

7500--0755

7500--0772

7500--0754

A

E

C

H

O

B

U

S

B

E

C

H

O

B

U

S

IMAGE BUS MEMORY, 7500--0405

* 256 pages of system memory for 7500--0405 and

7500--0722 PCB’s

* 1024 pages of system memory for 7500--0569PCB

* Stores 2D Cineloop, Doppler,and Doppler

data review

* Manages transfer of Doppler,Color,M--Mode,

and ECG data toImage Bus

* Generates timing signals for memory

* Determines priority of PCB’s requesting

memory time

* Refresh timing

* Image Bus control

IF OUTPUT,7500--0592 (Stand--alone)

* Color samples from RF Data

* Demodulation and bandwidth limiting

* Array sample volume generation

* Doppler Cineloop Limits,Reset, and

Frame Number

* Line density

* Echo detection and compression

* 2D dynamic range

* Self--test capability

* Transfers color and Pulsed Doppler to

Image Memory

* CW Doppler memory addressing

* Participates in 2D depth scaling

* Receives beamformed RF data and performs

demodulation and bandpass filtering to produce

in--phase and quadrature complex data samples

* Creates Image Bus addresses for a color flow

test pattern

IF OUTPUT MASTER/SLAVE, 7500--0783

* Same functions as 7500--0592 IFOM

* Doubles through--put

* Used only on systems with ESP capability

ECHO INPUT MODULE, 7500--0692

* Final 2D and M--Mode depth scaling

* Cineloop memory addressing

* M--Mode enhance

* Receives detected echo data from array front

end, processes data, and writes processed

data to image memory

* Needed for generation oftiming signals sent

through M--Mode/Physio to the Scrolling

Graphics Display

7500--0722

7500--0783 (Stand--alone)

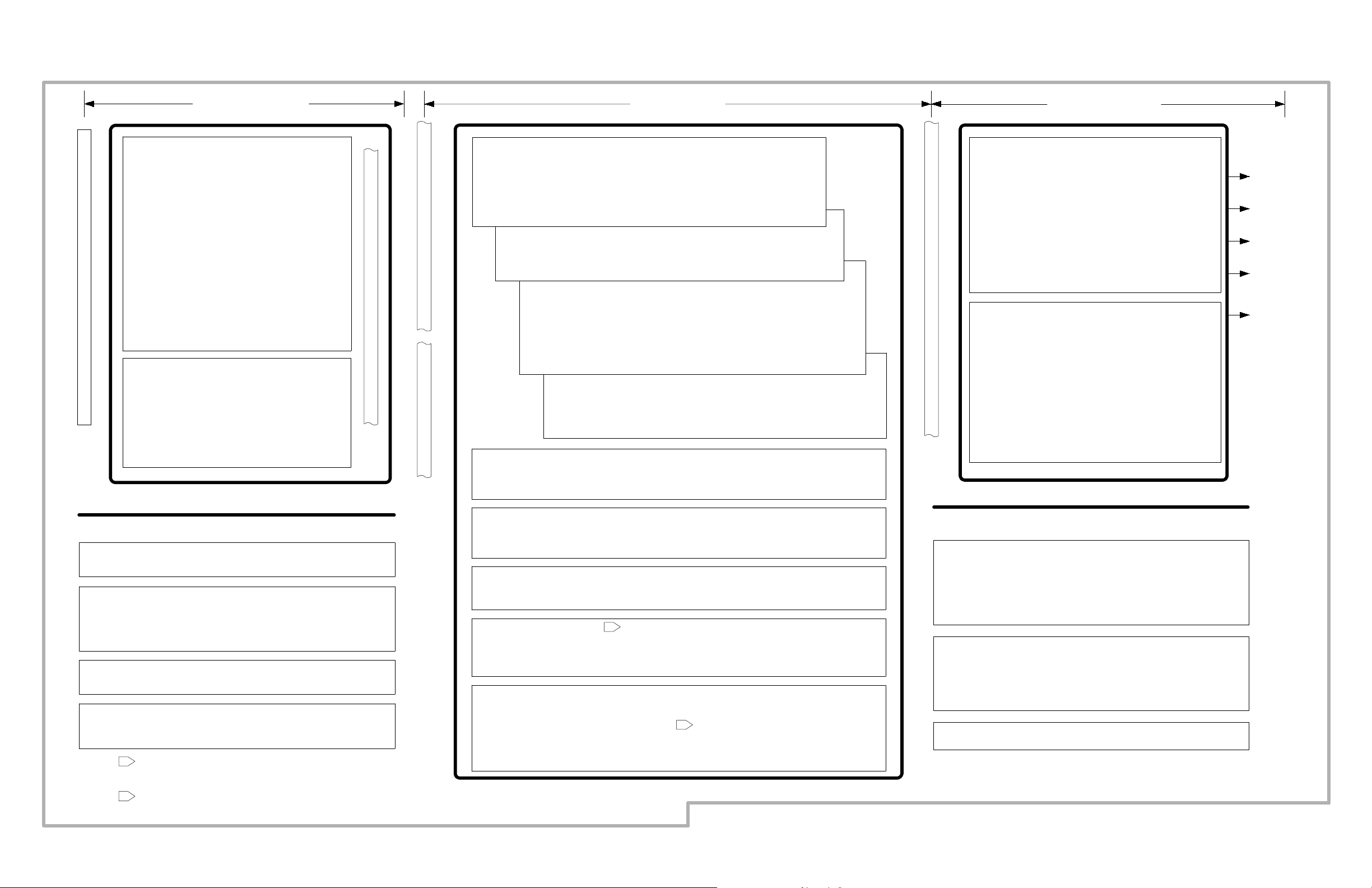

ADVANCED DIGITAL DATA ANALYZER, 7500--0603

* FFT processing

* Array Pulsed Doppler wall filters

* Doppler audio

* Color capture

* Doppler audio synthesis and output

* Doppler signal optimization

* Overall supervision and control of Doppler

processing

* Image memory processing tasks

(edge detection, Doppler history reconstruction,

and color capture)

* Spectral estimation and display processing

* Color Persistence

* ADDA is the only PCB touse Image Bus for

checksum

M--MODE/PHYSIO PROCESSOR, 112--25337

* M--Mode Zoom

* Physio processing: ECG, pulse,

phono displays

* Acquires M--Modedata and performs temporal

averaging to produce visible M--Mode sweep

rates

* Digitizes physiological information from

ECG Isolation PCB, attaches it to processed

M--Mode and sends it to Image Memory

* Generates timing signals for Color M--Mode

and sends them toScrolling Graphics Display

COLOR DATAPROCESSOR, 7500--0602

* Array color wall filter

* Dynamic Motion Differentiation

* Spectral Estimator interface

* Removes Doppler signals coming from stationary

or slow moving structures

* Eliminates high amplitude, low frequency echoes

SPECTRAL ESTIMATOR, 7500--0382

* Generates Color Flow display parameters

* Stores color data in Image Memory

* Estimates frequency, velocity, andstrength

of the returned signal

* Interface with the CDP

* Sends color frame interrupt to system CPU

7500--0671

7500--0829

I

M

A

G

E

B

U

S

A

U

D

I

O

B

U

S

ECG ISOLATION, 3500--1319

* ECG receiver and preamp

* Pulse and phono receiver and preamp

Figure 1A--1. UM--9 HDI PCB Functions (1 of 2

10 ES01--B01 19

HDI-1A-2

)

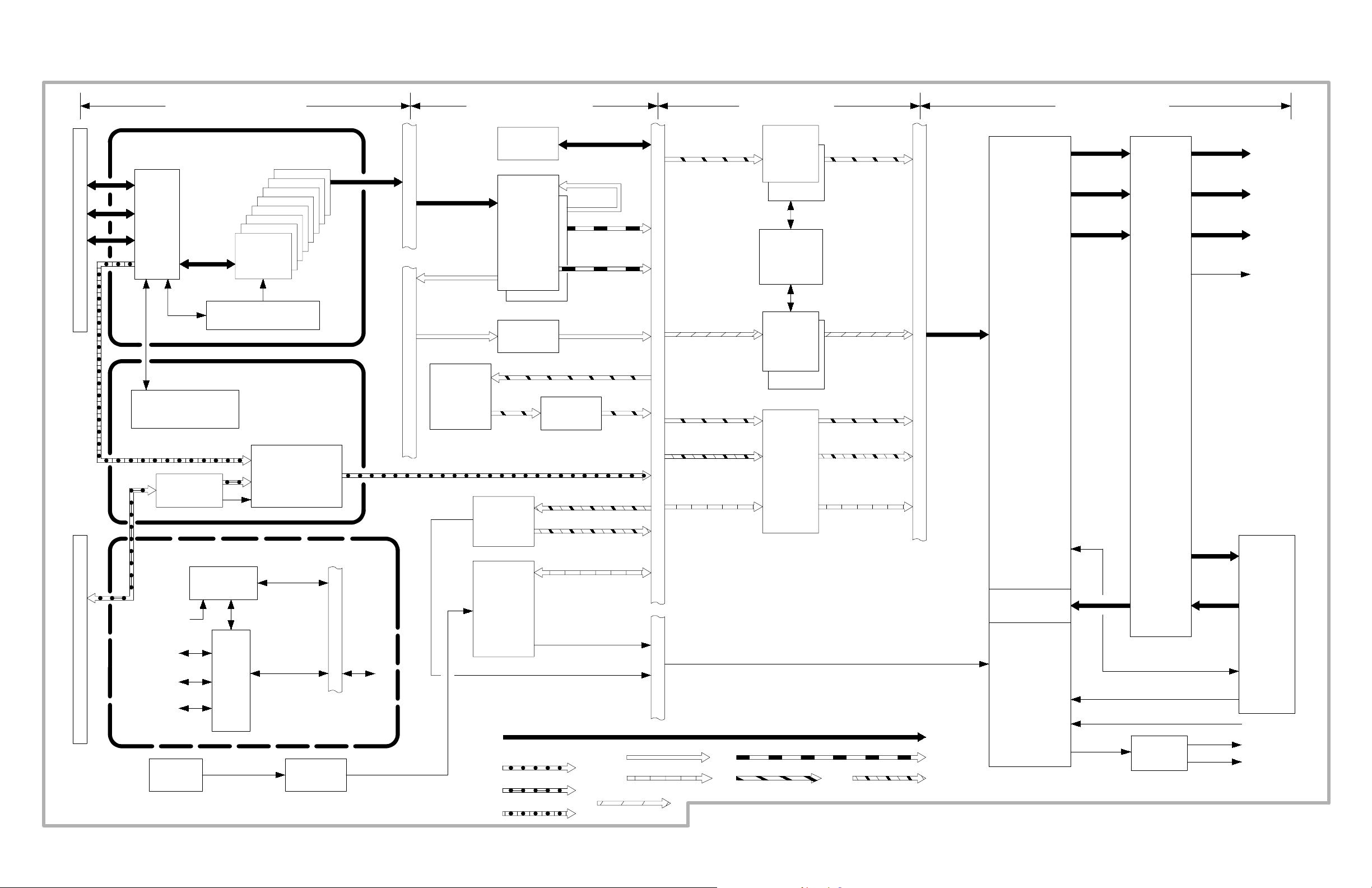

CONTROL GROUP

IMAGE GROUP

DISPLAY GROUP

CONTROL INTERFACE, 7500--0528

* LED Function

* Interface between front panel controls

and system CPU

* I/O port for MIC

* Self test feature

* Soft click audio output

P

H

Y

S

I

O

S

E

N

S

O

R

S

Mode Switch PCB, 7500--0441

Footswitch PCB

* Controls footswitch operation

TactSwitch PCB, 7500--0436

* Front panel pushbuttons, status LED’s,

control panel speaker, rotary controls,

encoder controls

* Switch daughterboard PCB provides

encoder controls (2D, DOPPLER, and

COLORGAINcontrol)

Trackball Switch PCB, 7500--0442

* S1 (Enter), S2 (Set), Trackball

SYSTEM CPU, 7500--0573

* Hard disk control

* Floppy disk control

* System controller (32--bit microprocessor)

* System clock

* Measurement and Analysis

* RS--232 interface

* Monitors critical analog voltages

* Real--time clock and backup

* Stores user defaults

7500--0749

7500--0757

I

M

A

G

E

C

O

N

T

R

O

L

B

U

S

B

U

S

A

U

D

I

O

B

U

S

2D SCAN CONVERTER

*5PCBset

* Formats ultrasound input data into sector or linear rectangular--

coordinate output synchronized to TV raster timing

* Frame averaging (Dynamic Contrast Enhancement)

* 2D pan zoom

* Image orientation (reversal and inversion)

* Interpolates image display data

* Sets display boundaries

S.C. Output Address Generator PCB (B/W and Color) 7500--0499

* Uses CPU timing and control data from the system CPU and the

respective Interface PCB (B/W or Color) to create row and

column display addresses

S.C. Interface PCB (B/W or Color) 7500--0557

* Transfers control messages from the Image Bus to the respective

Output Address Generator PCB and theDual Buffer Memory PCB

* Transfers image data from ImageMemory to the Dual Buffer

* Receives and interpolates display data from the Dual Buffer

Memory PCB and transfers it tothe Video Bus

* Performs frame averaging function (Dynamic Contrast Enhancement)

Dual Buffer Memory PCB 7500--0558

* Provides image data storage for the 2Dscan converter module

* Modifies the display address from the OutputAddress Generator

PCB, and uses thataddress to select the correct data from

the memory array for transfer to theInterface PCB

DISPLAY GRAPHICS, 7500--0514 COLOR

* Scrolling spectral display

* Color M--Mode display

* Doppler ECG display

ADVANCED VIDEO PROCESSOR, 3500--1200 (NTSC)

* All non--scrolling general purpose

graphics

* Grayscale/color mapping

* Generates RGB signals

* Image processing curves

* Doppler grayscale curves

* All system video timing

V

I

D

E

O

B

U

S

* Graybar/Colorbar generator

* VCR remote control and framegrab sync

* Audio preamplification

* Hidden digital overlay for tape directory

* Audio buffer mute control

* Color vs. echo overwrite

REAR PANEL,

3500--1257(NTSC)

3500--1256(PAL)

3500--1511(NTSC/PAL)

* Video switch matrix

* Video sync distribution

* RS--232/422 port

* PAL/NTSC generation

* Video Format Converter PCB, or Video Encoder/

Decoder PCB used as daughter boards

(NTSC or PAL) 7500--0506/0758

* Video output buffer

* Volume control interface (12V)

* Receives 3 different RGB video signals

* Accepts, buffers and distributes

video signals

* Provides DC restored video to theAVP

for frame grabbing

3500--1201 (PAL)

3500--1444 (PAL)

VIDEO

MONITORS

EXTERIOR

VIDEO

MONITOR

HARDCOPY

FRAME

SYNC

VCR

LAMBDA POWER SUPPLY

* Generates +/--48 volts to pulser

PULSER POWER SUPPLY, 3500--1131

* Generates pulser voltage

* Receives +/--48V and converts to transducer pulser voltage

which is variable to +/-- 105V, depending on the scanhead

type, system type, and mode ofoperation

DIGITAL POWER SUPPLY (L.H. RESEARCH)

* Converts 120 VACinto +5 VDC, --5.2 VDC, and +/-- 12 VDC

ANALOG POWER SUPPLY

* Six discrete power supplies which convert 120 VAC

to +6V,--6V, +15V, --15V, +16.5V, --16.5V

1

Frame Grabber functional only on systems

with 17.X software andup.

2

Frame Grabber functions of the Advanced

Frame Grabber PCB functional only on

systems with 17.X software and up.

MASTER SCROLLING GRAPHICS, 7500--0515

* 2D ECG display

* Scrolling M- -Modedisplay

* M--mode ECG display

SCROLLING GRAPHICS DISPLAY, 7500--0864

* Combines all functions of Display Graphics (7500--0514) and Master Scrolling

Graphics (7500--0515)

FRAME GRABBER, 7500--0556

* 4 on 1Save--Recall Format (only on systems without Advanced Frame Grabber)

* VCR Freeze Frame

* Patient Directory

* Hidden Digital

ADVANCED FRAME GRABBER, 7500--0554

* Combines all functions of Display Graphics (7500--0514) and Master Scrolling

Graphics (7500--0515) and Frame Grabber (7500--0556) Refer to PCB functions

listed above for each of thesePCB’s. 2

* Grabs video data and stores in ImageMemory

* Retrieves video data from Image Memory for display

* Scrolling graphics for M--Mode,Doppler, ECG and Physio

* Retrieves Hidden Digital information from VCR playback signal

Refer to PCB functions listed above for each of these PCB’s.

1

AUDIO BUFFER, 7500--0433

* Volume control

* Headphone audio amplifier

* Speaker audio amplifier

* Real time right and left Doppler audio

* VCR playback of right and leftchannel Doppler audio,

and right channel microphone audio

BACKPLANE MOTHERBOARD, 7500--0588

* Signal distribution

* Structural support

* Power distribution

* Ground plane

* Multi--layer PCB

FAN SPEED CONTROLLER, 2100--0679

7500--0677

Figure 1A--1. UM--9 HDI PCB Functions (2 of 2

10 ES01--B02 15

HDI--1A--3

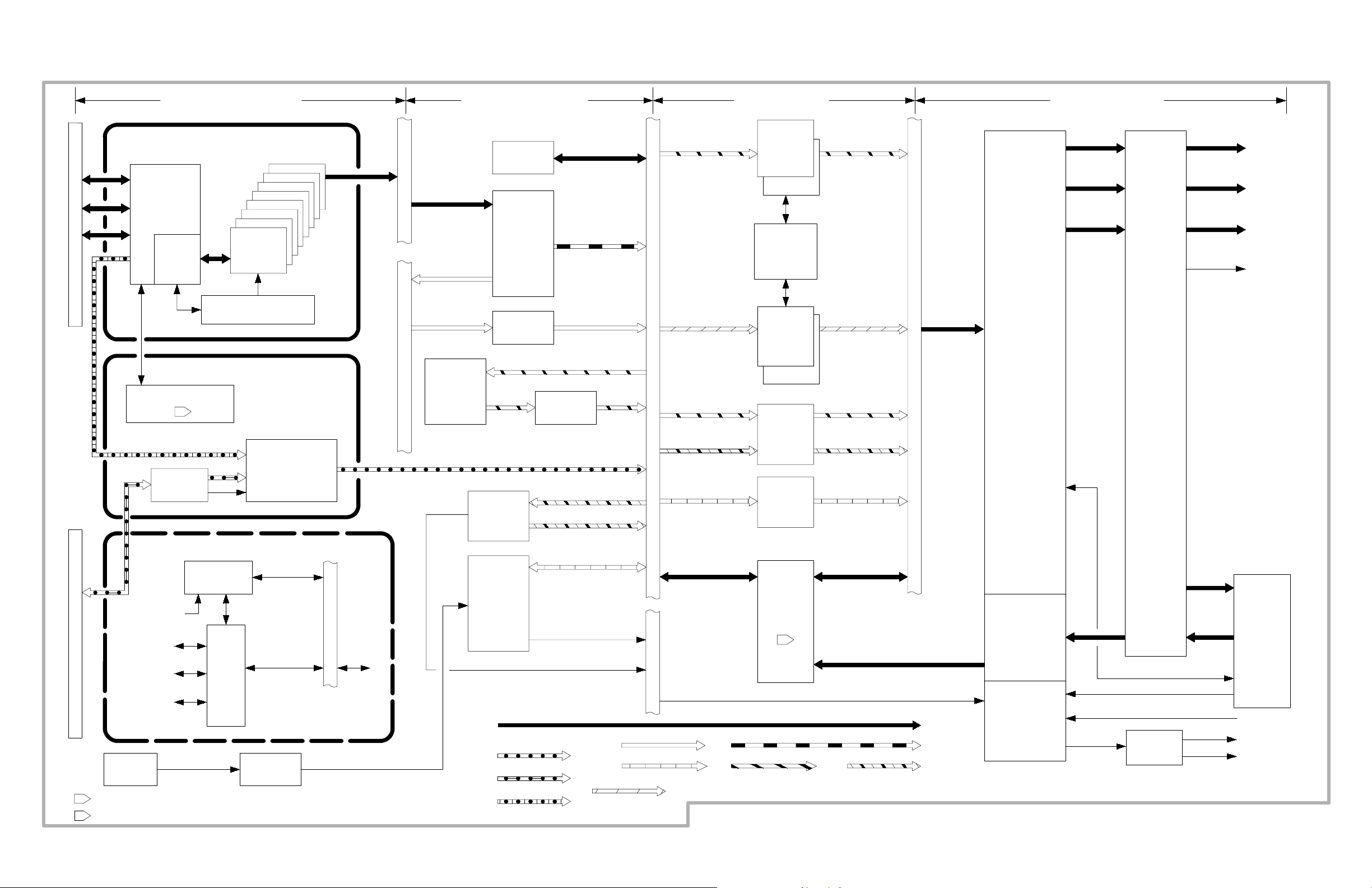

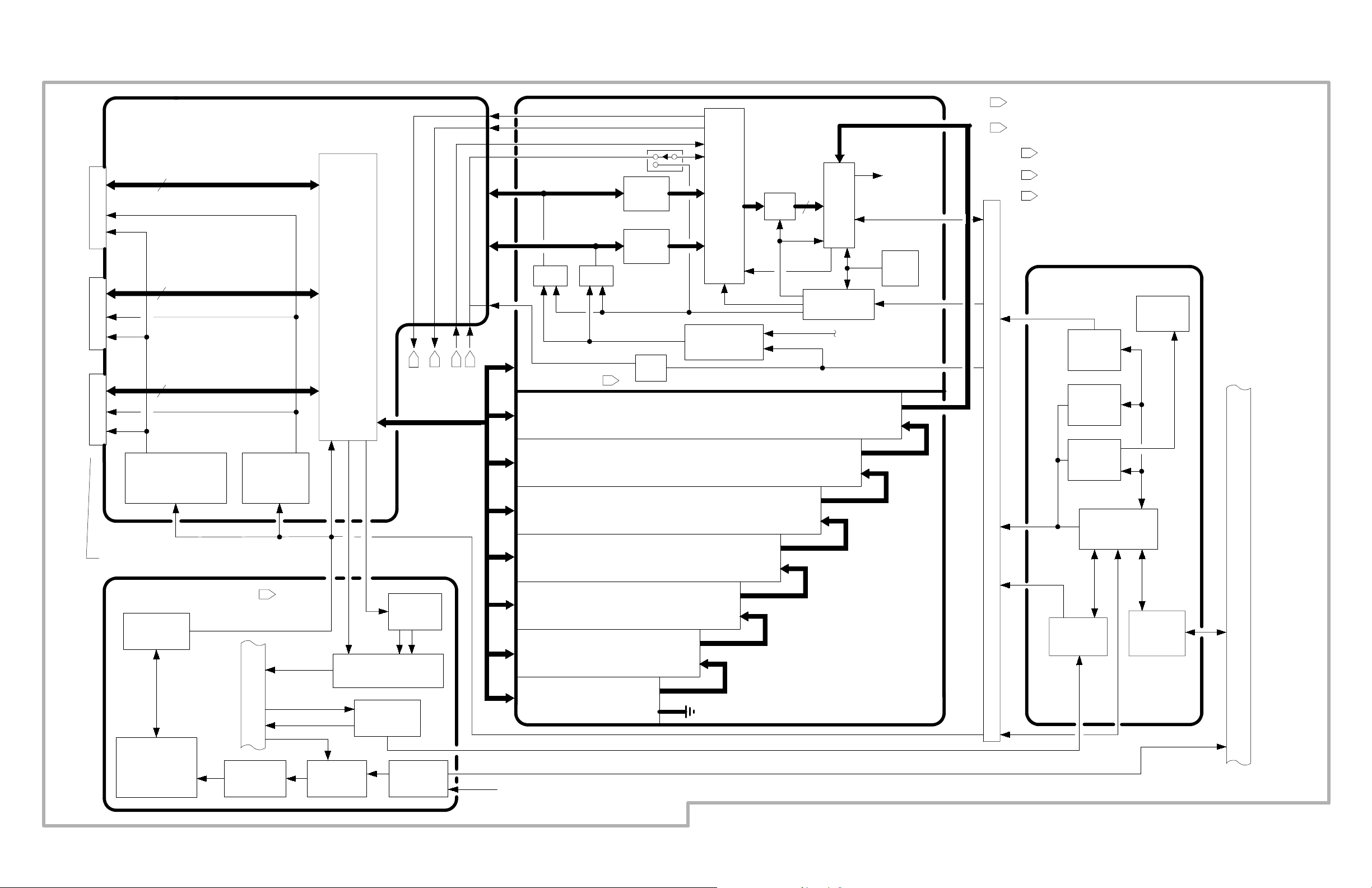

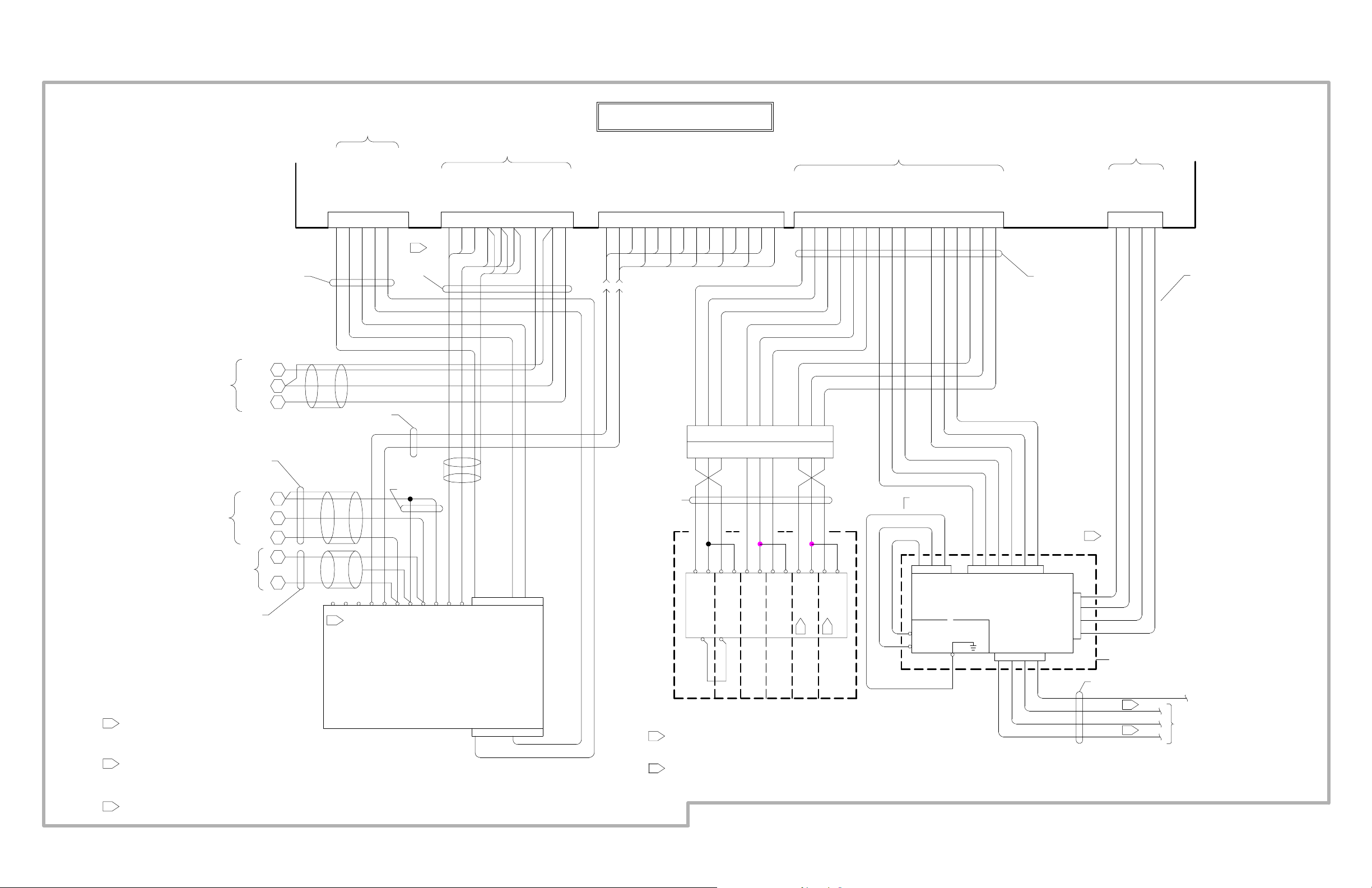

ACQUISITION GROUP PROCESSOR GROUP IMAGE GROUP DISPLAYGROUP

ARRAY FRONT--END

A

R

R

A

Y

S

C

A

N

H

E

A

D

S

RF

SCANHEAD

SELECT

SCANHEAD

SELECT

DAUGHTER

BOARD

MOTOR CONTROLLER

1

CHANNEL

PCB

FRONT--END

CONTROLLER

MECHANICAL

FRONT--END

A

E

C

H

O

B

U

S

GRAYSCALE 2D/

GRAYSCALE 2D/

B

E

C

H

O

B

U

S

ALL

DATATYPES

16 BITS

M--MODE ECHO

8BITS

M--MODE ECHO

COLOR

DATA

PROCESSOR

IMAGE

MEMORY

IF OUTPUT

MODULE

ECHO INPUT

MODULE

ALL DATA TYPES

SPECTRAL, COLOR

DOPPLER

64 BITS

ECHO

COLOR DOPPLER

SPECTRAL

ESTIMATOR

I

M

A

G

E

B

U

S

SPECTRAL/PHYSIO

2D ECH0 2D ECHO

COLOR M--MODE

COLOR

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

SCAN

CONVERTER

DUAL BUFFER

MEMORY

B/W

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

DISPLAY

GRAPHICS

2D COLOR2D COLOR

COLOR M--MODE

SPECTRAL/PHYSIO

V

I

D

E

O

B

U

S

ALL

DATATYPES

ADVANCED

VIDEO

PROCESSOR

VIDEO

”A”

VIDEO

”B”

VIDEO

”C”

VIDEO

MONITORS

EXTERIOR

VIDEO

MONITOR

HARDCOPY

FRAME

SYNC

REAR

PANEL

DOPPLER

ACQUISITION

2D ACQ

(MFE1)

S

T

A

T

I

C

C

W

/

T

C

D

P

R

O

B

E

S

1 Refer to Tables 5C--1and 5C--2 for PCB slot locations.

2

FLOPPY DISK

PHYSIO ECG/PHYSIO

SENSORS

Frame Grabber functions of the Advanced Frame Grabber PCB functional only on systems with 17.X software and up.

INTERFACE

HARD DISK

REPORT

PRINTER

USER

SCS1

RS--232

PHYSIO PHYSIO

I/Q

CONTROL

INTERFACE

CPU

(MFE2)

CONTROL

CONTROL

PREAMP PCB

CONTROL GROUP

C

O

N

T

R

O

L

TO ALL

B

MODULES

U

S

ADVANCED

DIGITAL

DATA

ANALYZER

M--MODE/

PHYSIO

PROCESSOR

(STEERED CW,STATIC CW,STATIC TCD)

STATICCW/STATIC TCD

STEERED CW

PULSED/CW DOPPLER

SPECTRAL DOPPLER

M--MODE ECHO

PHONO AUDIO

DOPPLER AUDIO

2D ECHO

FRAME--GRAB DATA

A

U

D

I

O

B

U

S

ECHO

M--MODE ECHO

M--MODE/PHYSIO M--MODE/PHYSIO

ALL DATA TYPES

MASTER

SCROLLING

GRAPHICS

FRAME

GRABBER

2

COLOR

FRAME--GRAB DATA

VCR VIDEO

AUDIO

DOPPLER

PULSED/CW/SPECTRAL

V

I

D

E

O

B

U

S

VCR

PATH

INTERNAL VCR CONTROL

VCR AUDIO

AUDIO

PATH

AUDIO

BUFFER

PCB

VCR

VIDEO

VCR

VIDEO

PLAYBACK

VCR

MICROPHONE

SPEAKER

PHONES

10 ES01--B03 15

Figure 1A--2. System Signal Path Diagram

(Systems with 7500--0588 or 7500--0677 Motherboards)

HDI-1A-4

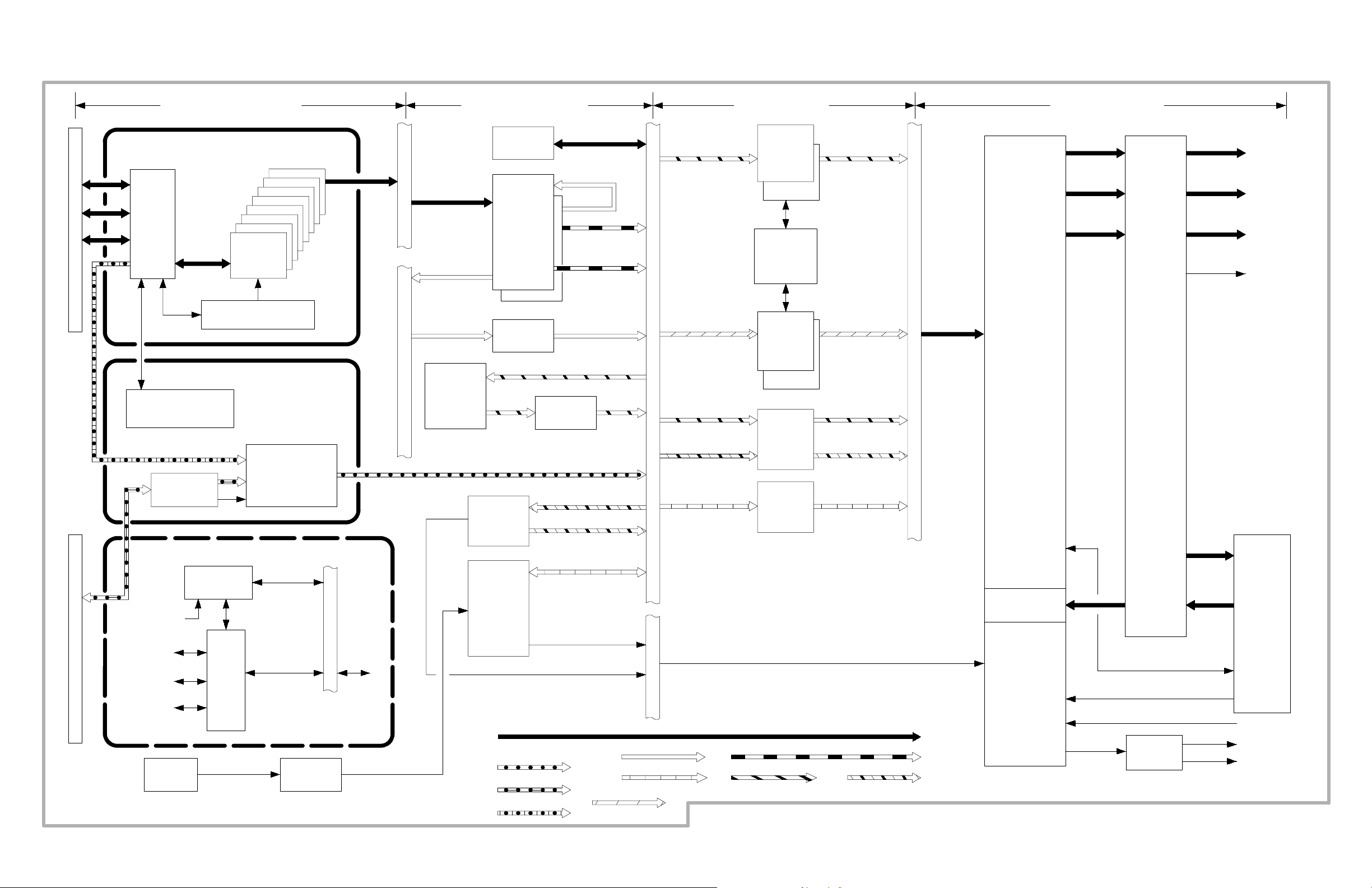

ACQUISITION GROUP PROCESSOR GROUP IMAGE GROUP DISPLAYGROUP

ARRAY FRONT--END

A

R

R

A

Y

S

C

A

N

H

E

A

D

S

RF

SCANHEAD

SELECT

MOTOR CONTROLLER

CHANNEL

PCB

FRONT--END

CONTROLLER

MECHANICAL

FRONT--END

A

E

C

H

O

B

U

S

GRAYSCALE 2D/

GRAYSCALE 2D/

B

E

C

H

O

B

U

S

ALL

DATATYPES

16 BITS

M--MODE ECHO

8BITS

M--MODE ECHO

COLOR

DATA

PROCESSOR

IMAGE

MEMORY

IF OUTPUT

MODULE

MASTER

SLAVE

ECHO INPUT

MODULE

COLOR DOPPLER

ALL DATA TYPES

SPECTRAL, COLOR

SPECTRAL

ESTIMATOR

8BITS

DOPPLER

ECHO

64 BITS

I

M

A

G

E

B

U

S

SPECTRAL/PHYSIO

2D ECH0 2D ECHO

COLOR M--MODE

COLOR

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

SCAN

CONVERTER

DUAL BUFFER

MEMORY

B/W

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

DISPLAY

GRAPHICS

2D COLOR2D COLOR

COLOR M--MODE

SPECTRAL/PHYSIO

V

I

D

E

O

B

U

S

ALL

DATATYPES

ADVANCED

VIDEO

PROCESSOR

A10

VIDEO

”A”

VIDEO

”B”

VIDEO

”C”

VIDEO

MONITORS

EXTERIOR

VIDEO

MONITOR

HARDCOPY

FRAME

SYNC

REAR

PANEL

DOPPLER

ACQUISITION

2D ACQ

(MFE1)

S

T

A

T

I

C

C

W

/

T

C

D

P

R

O

B

E

S

FLOPPY DISK

USER

INTERFACE

HARD DISK

REPORT

PRINTER

SCS1

RS--232

PHYSIO ECG/PHYSIO

SENSORS

I/Q

CONTROL

INTERFACE

CPU

PHYSIO PHYSIO

(MFE2)

CONTROL GROUP

CONTROL

CONTROL

PREAMP PCB

C

O

N

T

R

O

L

B

U

S

TO ALL

MODULES

ADVANCED

DIGITAL

DATA

ANALYZER

M--MODE/

PHYSIO

PROCESSOR

(STEERED CW,STATIC CW,STATIC TCD)

STATICCW/STATIC TCD

STEERED CW

PULSED/CW DOPPLER

SPECTRAL DOPPLER

M--MODE ECHO

PHONO AUDIO

DOPPLER AUDIO

2D ECHO

A

U

D

I

O

B

U

S

ECHO

M--MODE ECHO

M--MODE/PHYSIO M--MODE/PHYSIO

ALL DATA TYPES

MASTER

SCROLLING

GRAPHICS

COLOR

AUDIO

DOPPLER

PULSED/CW/SPECTRAL

VCR

PATH

AUDIO

PATH

INTERNAL VCR CONTROL

VCR AUDIO

AUDIO

BUFFER

PCB

VCR

VIDEO

VCR

VIDEO

PLAYBACK

VCR

MICROPHONE

SPEAKER

PHONES

10 ES01--B14 07

Figure 1A--3. System Signal Diagram (Systems with 7500--0677

Motherboard and Scrolling Graphics Cards only)

HDI--1A--5

ACQUISITION GROUP PROCESSOR GROUP IMAGE GROUP DISPLAY GROUP

ARRAY FRONT--END

A

R

R

A

Y

S

C

A

N

H

E

A

D

S

RF

SCANHEAD

SELECT

MOTOR CONTROLLER

CHANNEL

PCB

FRONT--END

CONTROLLER

MECHANICAL

FRONT--END

A

E

C

H

O

B

U

S

GRAYSCALE 2D/

GRAYSCALE 2D/

B

E

C

H

O

B

U

S

ALL

DATATYPES

16 BITS

M--MODE ECHO

8BITS

M--MODE ECHO

COLOR

DATA

PROCESSOR

IMAGE

MEMORY

IF OUTPUT

MODULE

MASTER

SLAVE

ECHO INPUT

MODULE

COLOR DOPPLER

ALL DATA TYPES

SPECTRAL, COLOR

SPECTRAL

ESTIMATOR

8BITS

DOPPLER

ECHO

64 BITS

I

M

A

G

E

B

U

S

SPECTRAL/PHYSIO

2D ECH0 2D ECHO

COLOR M--MODE

COLOR

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

SCAN

CONVERTER

DUAL BUFFER

MEMORY

B/W

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

2D COLOR2D COLOR

COLOR M--MODE

SPECTRAL/PHYSIO

V

I

D

E

O

B

U

S

ALL

DATATYPES

ADVANCED

VIDEO

PROCESSOR

A10

VIDEO

”A”

VIDEO

”B”

VIDEO

”C”

VIDEO

MONITORS

EXTERIOR

VIDEO

MONITOR

HARDCOPY

FRAME

SYNC

REAR

PANEL

DOPPLER

ACQUISITION

2D ACQ

(MFE1)

S

T

A

T

I

C

C

W

/

T

C

D

P

R

O

B

E

S

FLOPPY DISK

USER

INTERFACE

HARD DISK

REPORT

PRINTER

SCS1

RS--232

PHYSIO ECG/PHYSIO

SENSORS

I/Q

CONTROL

INTERFACE

CPU

PHYSIO PHYSIO

(MFE2)

CONTROL GROUP

CONTROL

CONTROL

PREAMP PCB

C

O

N

T

R

O

L

B

U

S

TO ALL

MODULES

ADVANCED

DIGITAL

DATA

ANALYZER

M--MODE/

PHYSIO

PROCESSOR

(STEERED CW,STATIC CW,STATIC TCD)

STATICCW/STATIC TCD

STEERED CW

PULSED/CW DOPPLER

SPECTRAL DOPPLER

M--MODE ECHO

PHONO AUDIO

DOPPLER AUDIO

2D ECHO

A

U

D

I

O

1

B

U

S

ECHO

M--MODE ECHO

M--MODE/PHYSIO M--MODE/PHYSIO

FRAME--GRAB FRAME--GRAB

DATA

Frame Grabber functions of the Advanced Frame Grabber

PCB functional only on systems with 17.X software and up.

ALL DATA TYPES

ADVANCED

FRAME

GRABBER

COLOR

1

VCR

VIDEO

VCR

VIDEO

PLAYBACK

VCR

MICROPHONE

SPEAKER

PHONES

10 ES01--B15 06

AUDIO

DOPPLER

DATA

VCR VIDEO

PULSED/CW/SPECTRAL

VCR

PATH

AUDIO

PATH

INTERNAL VCR CONTROL

VCR AUDIO

AUDIO

BUFFER

PCB

Figure 1A--4. System Signal Path Diagram (Systems with 7500--0677

Motherboard and Advanced Frame Grabber)

HDI-1A-6

ACQUISITION GROUP PROCESSOR GROUP IMAGE GROUP DISPLAY GROUP

ARRAY FRONT--END

A

R

R

A

Y

S

C

A

N

H

E

A

D

S

RF

S

T

A

T

I

C

C

W

/

T

C

D

P

R

O

B

E

S

SCANHEAD

SELECT

CHANNEL

PCB

FRONT--END

CONTROLLER

MOTOR CONTROLLER

2D ACQ

(MFE1)

USER

INTERFACE

HARD DISK

FLOPPY DISK

REPORT

PRINTER

SCS1

RS--232

PHYSIO ECG/PHYSIO

SENSORS

I/Q

CONTROL

INTERFACE

CPU

PHYSIO PHYSIO

MECHANICAL

FRONT--END

DOPPLER

ACQUISITION

(MFE2)

CONTROL GROUP

CONTROL

CONTROL

PREAMP PCB

C

O

N

T

R

O

L

B

U

S

TO ALL

MODULES

A

E

C

H

O

B

U

S

GRAYSCALE 2D/

GRAYSCALE 2D/

B

E

C

H

O

B

U

S

ALL

DATATYPES

16 BITS

M--MODE ECHO

8BITS

M--MODE ECHO

COLOR

DATA

PROCESSOR

PROCESSOR

(STEERED CW,STATIC CW,STATIC TCD)

IMAGE

MEMORY

IF OUTPUT

MODULE

MASTER

SLAVE

ECHO INPUT

MODULE

COLOR DOPPLER

ADVANCED

DIGITAL

DATA

ANALYZER

M--MODE/

PHYSIO

STATICCW/STATIC TCD

STEERED CW

ALL DATA TYPES

8BITS

SPECTRAL, COLOR

DOPPLER

64 BITS

ECHO

SPECTRAL

ESTIMATOR

PULSED/CW DOPPLER

SPECTRAL DOPPLER

M--MODE ECHO

PHONO AUDIO

DOPPLER AUDIO

2D ECHO

I

M

A

G

E

B

U

S

SPECTRAL/PHYSIO

A

U

D

I

O

B

U

S

ECHO

M--MODE ECHO

2D ECH0 2D ECHO

COLOR M--MODE

M--MODE/PHYSIO M--MODE/PHYSIO

ALL DATA TYPES

COLOR

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

SCAN

CONVERTER

DUAL BUFFER

MEMORY

B/W

2D SCAN

CONVERTER

ADDRESS

GENERATOR

INTERFACE

SCROLLING

GRAPHICS

DISPLAY

COLOR

COLOR M--MODE

SPECTRAL/PHYSIO

AUDIO

DOPPLER

2D COLOR2D COLOR

PULSED/CW/SPECTRAL

V

I

D

E

O

B

U

S

ALL

DATATYPES

ADVANCED

VIDEO

PROCESSOR

A10

VCR

PATH

AUDIO

PATH

VIDEO

”A”

VIDEO

”B”

VIDEO

”C”

INTERNAL VCR CONTROL

REAR

PANEL

VCR AUDIO

AUDIO

BUFFER

PCB

VIDEO

MONITORS

EXTERIOR

VIDEO

MONITOR

HARDCOPY

FRAME

SYNC

VCR

VIDEO

VCR

VIDEO

PLAYBACK

VCR

MICROPHONE

SPEAKER

PHONES

10 ES01--B16 05

Figure 1A--5. System Signal Path Diagram (Systems with 7500--0677

Motherboard and Scrolling Display only)

HDI--1A--7

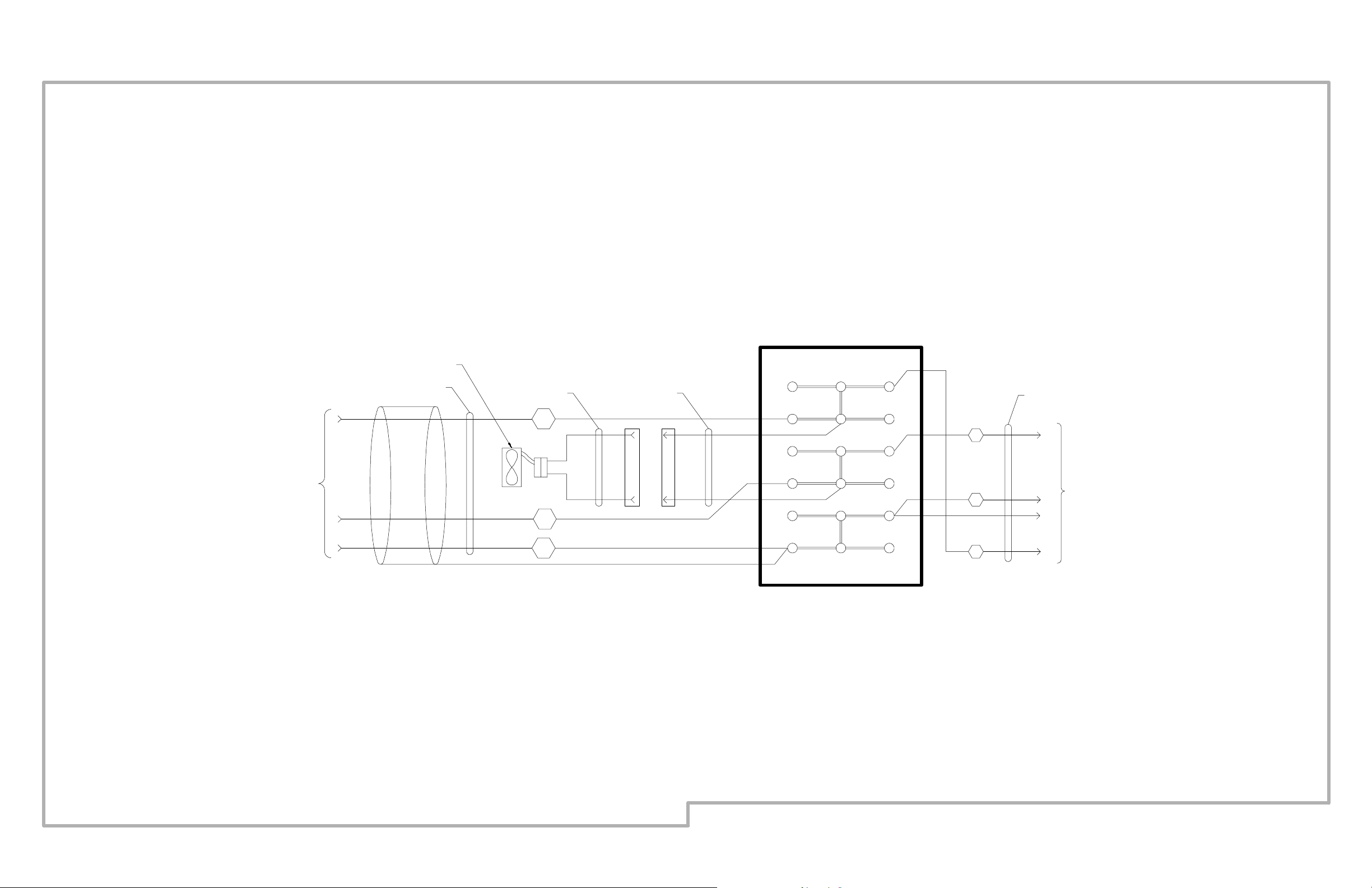

SCANHEAD SELECT PCB

64/128 ELEMENTS

(LINEAR, CURVED, PHASED)

7 ELEMENTS (ANNULAR)

A

64/128 ELEMENTS

(LINEAR, CURVED, PHASED)

B

C

PERSONALITY

INTERFACE

(ON DAUGHTER BOARD)

FRONT PANEL SCANHEAD CONNECTORS

7 ELEMENTS (ANNULAR)

64/128 ELEMENTS

(LINEAR, CURVED, PHASED)

7 ELEMENTS (ANNULAR)

DATA

MOTOR CONTROLLER PCB

POWER

AMPLIFIER

(4X)

ANALOG FILTER

(PROGRAMMABLE

PROBE

COMPENSATION)

16.5V MOTOR DRIVE

ELEMENT

INTERFACE

(HV MUX)

(IN SCANHEAD)

2

P

O

S

I

T

I

O

N

B

U

S

D/A

CONVERSION

192--

RELAYS

SUBTRACTOR

COMMAND

REGISTER

ENCA

ENCB

ENCZ

POSITION

COUNTER

ANGLE

DETECTOR

CONTROLLER

3

8 CHANNELS

16 ELEMENTS

FOR EACH PCB

ENCODER

PHASE A

PHASE B

MOTOR

CPU

STEERED CW SUMMATION BUS

A23--A29 circuitry is similar to that shown in A22.

DIFFERENTIAL STEERED CW ANALOG SIGNAL

ODD CHNL PCBANALOG TGC

EVEN CHNL PCB ANALOG TGC

2D

ELEMENT 0

1 CHANNEL

(2 ELEMENTS)

ELEMENT 1

ODD CHNL PCB TGC SUM BUS

EVEN CHNL PCB TGC SUM BUS

5

4

3

PULSER PULSER

DIFFERENTIAL

ANALOG TGC

CHANNEL PCB

1

TRANSMIT

RECEIVE

SWITCH

16 T/R/PCB

TRANSMIT

RECEIVE

SWITCH

D/A

CONV.

CW

LOW

2D

TGC/

STEERED

CW

MIXER

ASIC

8/PCB

LO

TRACKING

HIGH VOLTAGE

REGULATORS

(2/PCB)

A/D

8/PCB

8

CONTROL

CHANNEL PCB

CHANNEL PCB

CHANNEL PCB

CHANNEL PCB

CHANNEL PCB

CHANNEL PCB

OUT

A26

SUM

A27

SUM

A28

SUM

A25

SUM

SUM

1/2

FIFO

SUM

ASIC

4/PCB

1/2 DELAY

ASIC CONTROL

4/PCB

PULSER POWER SUPPLY

DIGITAL TGC AND PULSER

CONTROL BUS FROM FEC

BOARD 0

A24

SUM

SUMMED

CHANNELS

TO IFOM

FRONT END

CONTROL BUS

XDCR

TABLE

RAM

120 MHZ

A23

SUM

A22

SUM

FROM OTHER

CHANNEL PCB’S

CHANNEL PCB

BOARD 7

24 MHz SYSTEM CLOCK

A29

IN

1

Refer to Tables 5C--1and 5C--2for PCB slot locations.

2

Summed differential steered CW signals to MFE2

3

Channel PCB 1,3,5,7 analog TGC4

Channel PCB 0,2,4,6 analog TGC

5

FRONT END CONTROLLER PCB

TGC

SEQUENCER

F

R

O

N

T

E

N

D

B

U

S

N

E

T

W

O

R

K

GATE

ARRAY

SEQUENCER

INTER--

PRI

SEQUENCER

INTRA--

PRI

SEQUENCER

MODULE

OPERATION

PROCESSOR

HEADER

GENERATOR

SERIAL

CONTROL

INTERFACE

PROCESSOR

S

Y

S

T

E

M

C

O

N

T

R

O

L

I

N

T

TO/FROM

E

SYSTEM

R

CPU PCB

F

A

C

E

P

R

O

C

E

S

S

O

R

B

U

S

10 ES01--B06 08

Figure 1A--6. Digital Beamformer and Motor Controller Block Diagram

HDI-1A-8

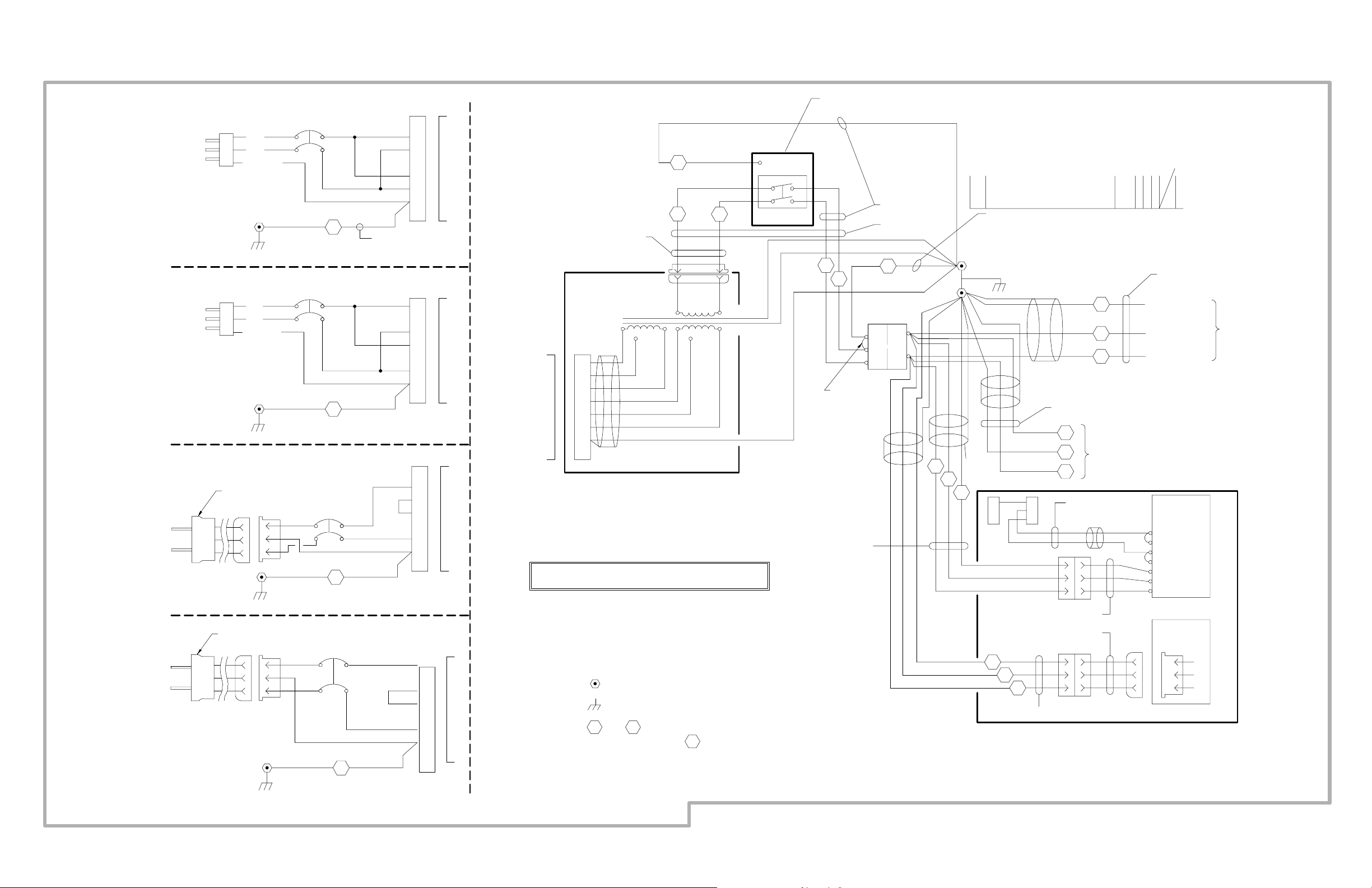

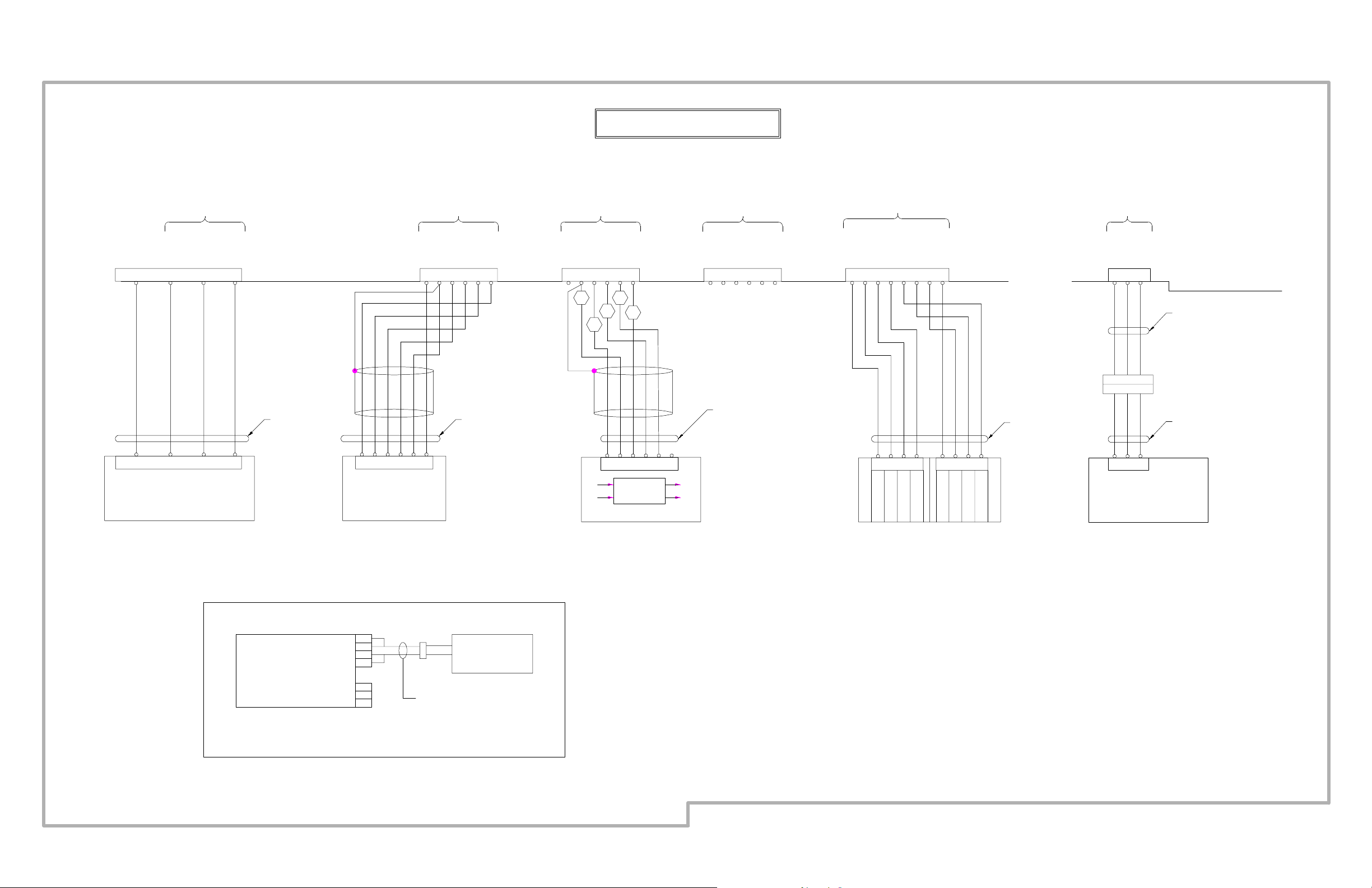

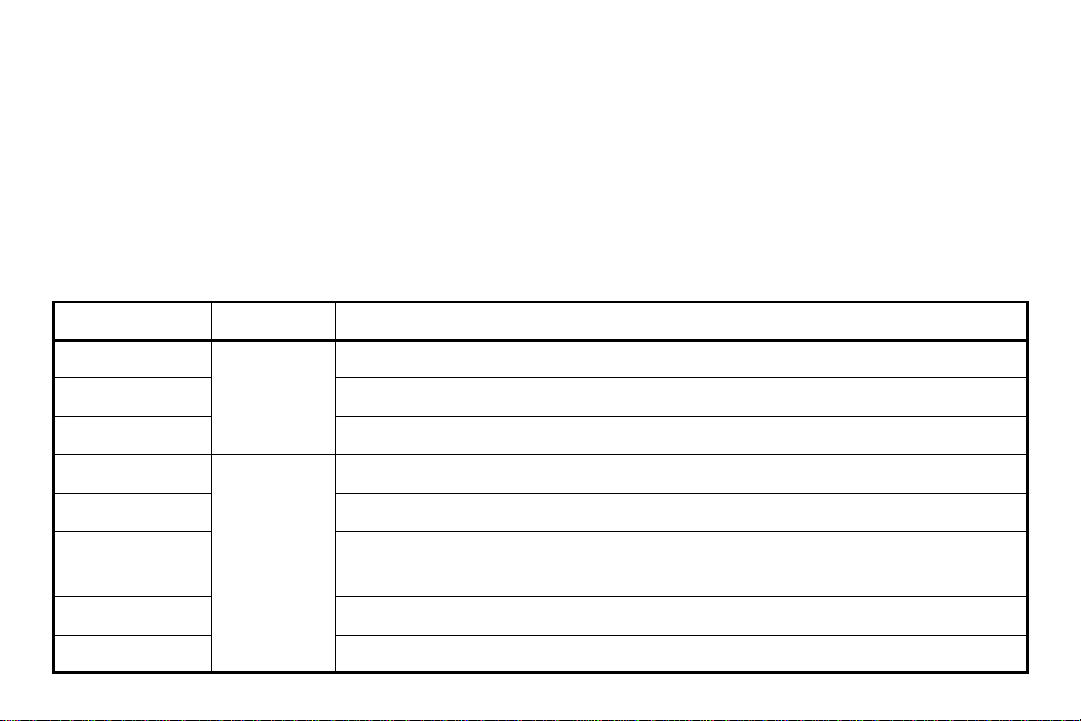

1B Power Distribution

111--24280--02

111--24280--02

POWER CORD

BRN

BLU

GRN/YEL

E4

BRN

BLU

GRN/YEL

E4

E4

MAIN CIRCUIT

BREAKER

12

3

MAIN CIRCUIT

BREAKER

34

1

2

3

1

2

3

4

206

21

206

MAIN CIRCUIT

BREAKER

3

206

MAIN CIRCUIT

BREAKER

1

3

206E4

21

4

2

4

3500--1308--XX

WHT

BLK

GRN/YEL

WHT

BLK

GRN/YEL

P1

1

2

3

4

5

6

7

8

P1

1

2

3

4

5

6

7

8

P1

1

2

3

4

5

6

7

8

P1

1

2

3

4

5

6

7

8

J1

100V

J1

120V

220V

SWITCH = 3300--0283--01

116

107 106

3500--1156--XX

WHT BLK

P1

J1

J1

1

2

3

4

5

6

7

8

(SHIELD)

ISO--XFMR

(2601--0018--01)

AC POWER DISTRIBUTION

J1

NOTES: =GROUND STUD

=

GROUND TO CART WELDMENT

101

T

AND

100

=

TWISTED PAIR WIRE NUMBERS

INSIDE ARE WIRE NUMBERS

GRN/YEL

WHT

BLK

GRN/YEL

GRN/YEL

21 22

11 12

ON/STDBY

SWITCH

GRN/YEL

102

103

9903--0355--01

3500--0767--XX

EM FILTER

5

E

N

1

L

2

(SHIELD)

3500--1156--XX

CONDUIT

110

IN OUT

N

L

ABDI

2/27/91

3500--1305--XX

E2

E3

111

3

4

(SHIELD)

(SHIELD)

3500--1159--XX

208

207

308

307

(SHIELD)

307

209

GRN

BLU

BRN

3500--0897--XX

3500--0766--XX

308

309

3500--0767--XX

309

108

109

TO DIGITAL

POWER SUPPLY

(FIGURE 1B--2)

P/O 3500--0896--XX

(SHIELD)

S. SPEISER

3500--1155--XX

TO TB1, PIN 17

TO TB1, PIN 9

TO TB1, PIN 1

--S

-+

+S

FG

N

H

1700--0016--XX

COLOR

VIDEO

MONITOR

3500--0778--XX

B/W

VIDEO

MONITOR

POWER

SUPPLY

FIGURE 1B--2

MONITOR ASSEMBLY

E = GROUND

240V

10 ES01--B10 05

Figure 1B--1. Power Conversion and Main Power Assy Wiring Diagram

HDI--1B--1

(FOR VCR AND PRINTER POWER CABLES)

3500--1155--XX

DUPLEX RECEPTACLE (115V)

3500--1161--XX

210

212

214

(FIGURE 1B--1)

FROM

LINE FILTER

(FIGURE 1B--1)

(FIGURE 1B--1)

FROM

LINE FILTER

(FIGURE 1B--1)

TO E3

TO E3

111

N

L

108

109

3500--1159--XX

12

56

9

10

13

14

17

18

22

21

TERMINAL BLOCK TB1

(LOCATED IN UPPER PORTION

3500--1123--XX

OF P.S.ASSEMBLY)

3100--1779--XX

4

3

8

7

12

11

16

15

20

19

24

23

3500--1123--XX

FIGURE 1B--3

SHEET 1

3500--1124--XX

FIGURE 1B--3

SHEET 1

2X

N

L

208

207

115V

INPUT

209

LNE

1

203

204

L

115V

INPUT

205

E

N

1

205

204

1

E

115V

INPUT INPUT

504

203

N

505

L

(--S) --6V

514

506

(+S) 6V RTN

507

509

(+S) +6V

(--S) 6V RTN

(+S) +15V

(--S) 15V RTN

218

217

1

ENL

216

510

115V

(--V) --15V

508

511

512

(--V) --16.5V

(+V) 15V RTN

515

513

(+V) +16.5V

(+V) +16.5V RTN

(--V) 16.5V RTN

1 E = GROUND

DIGITAL POWER SUPPLY

(1700--0057--XX, L.H. RESEARCH)

PULSER POWER SUPPLY ASSY

(3500--1131--XX)

1700--0050--XX

1700--0050--XX

1700--0028--XX

1700--0055--XX

1700--0054--XX

1700--0055--XX

ANALOG POWER SUPPLY

10 ES01--B11 01

Figure 1B--2. AC Distribution Wiring Diagram

HDI-1B-2

MB1J1E

MB1J1A

SYSTEM

BACKPLANE

7500--0588--XX

7500--0677--XX

MB1J11A

MB1J11B

+5V SENSE

+5V SENSE RTN

POWER FAIL

123456 10987654321 1234 5678910 10987654321 11 12 13 14 15 16 4321

301

303

304

T301

3500--1215--XX

TO TB2

314

FIGURE 1B--3

SHEET 2

FIGURE 1B--3

SHEET 2

FIGURE 1B--4

3500--1162--XX

”T” numbers indicate the

1

white wire of a twisted

wire pair.

16.5V is supplied to A16/A18 Motor Controller.

2

On systems with the 7500--0677--XX Motherboard, install the Motor Controller PCB only in slot A18

and the Doppler Acquisition PCB (MFE2) only in slot A19.

PIN 8

TO TB2

PIN 14

TO TB2

PIN 2

3500--1304--XX

TO TB2

PIN 18

TO TB2

PIN 6

TO TB2

PIN 12

315

316

350C

352C

351C

202

201

(SHIELD)

(SHIELD)

(SHIELD)

3

1700--0057--XX

L.H. RESEARCH

3500--1212--XX

(BUS BARCABLE)

ENL

DIGITAL P.S.

+5V

--5.2V SENSE

T304

+5V RTN

--5.2V SENSE RTN

N\C

3500--1306--XX

3500--1164--XX

+12V

+12V RTN

+6V

+6V RTN

--6 V

+15V

+15V RTN

--15V

509

510

HV1+

336

--5.2V

T310

1

T310--T311--T312

--12V

--5.2V

--12V RTN

T311

310--311--312

--5.2V RTN

--5.2V

--5.2V RTN

T312

301

1

--5.2V RTN

--5.2V

+5V SENSE

310

--5.2V RTN

311

312

T301

43

2

RTN

N\C

N\C

5V SENSE

303

12V RTN

N\C

314

5

PWR FAIL

--1 2 VDC

+12 VDC

E11 E12 E13

EEEEEEEEEE

316

315

3500--1151--XX

(BUS BARASSEMBLY)

123 456 789

3500--1312--XX

504

505

506

520

514

(+S) +6V

(--S)6V RTN

(+S) 6V RTN

520

1700--0050--XX

1

J1

6

N\C

(--S)--6V

1700--0050--XX

507

(+S) +15V

509

E14

506

505

504

507

Z1

987654321

Z2

510

511

512

508

(--V)--15V

(--S)15V RTN

1700--0028--XX

513

12 515

(--V)--16.5V

(+V) 15V RTN

1700--0054--XX

(+V) +16.5V

(--V) 16.5V RTN

(+V) 16.5V RTN

2

2

1700--0055--XX

1700--0055--XX

HV1 RTN

337

N\C

HV1--

338

3500--1125--XX

32

+48V

--48V RTN

HV2+

HV2 RTN

339

340

1

RTN

48VI

48VI

CHASIS

PULSER P.S.

7500--0589--XX

LAMBDA P.S.

1700--0061--XX

341

GND

HV2--

513

P1

FG

+16.5 VDC

16.5 RTN

511

512

336

337

338

123

RTN

HV +

HV

--16.5 VDC

339

456

HV +

HV --

RTN

HV --

HV

123

340

RTN

HV

HV +

3500--1183--XX

341

3500--1131--XX

PULSER

POWER

SUPPLY ASSY

J3

HV --

SYNC

HVCTRL1

HVCTRL2

DISABLE

4

P4

N\C

P2

1

2

3

4

ANALOG POWER SUPPLY

N\C

N\C

N\C

--5.2V RTN

SENSE

3456

12

J2

N\C

--5.2V SENSE

4

304

T304

HV+ and HV-- are variable from 0 to 105V and depend on the

scanhead type, system type, and mode ofoperation.

Refer to Service Bulletin HDI--30 and Table 3--1.

5

3500--1131--XXcomprises 7500--0589--XX and 1700--0061--XX.

5

3500--1234--XX

PWR SEL

HV CTRL1

3500--1131--XX

4

4

HV CTRL2

CTRL RTN

2275--0285--XX

HV ENABLE0--5V

(FROM SCANHEAD SELECT MODULE)

TO

SCANHEAD

SELECT

MODULE

10 ES01--B08 04

3

E = GROUND

Figure 1B--3. DC Distribution Wiring Diagram (1 of 3)

HDI--1B--3

2100--0538--XX

3500--1304--XX

352C

LOCATED IN UPPER PORTION OF POWER SUPPLY ASSEMBLY

12V DC TERMINAL BLOCK TB2

123

3500--1154--XX3500--1153--XX

--12V

--12V DI G

456

789

314

3500--1306--XX

FROM DIGITAL

POWER

SUPPLY

FIGURE 1B--3

SHEET 1

(SHIELD)

REAR PANEL

DC

FAN

351C

350C

+12

+12V DIG

12V RTN

101112

131415

161718

315

316

TO MB1J1A

FIGURE 1B--3

SHEET 1

10 ES01--B09 01

Figure 1B--3. DC Distribution Wiring Diagram (2 of 3)

HDI-1B-4

SYSTEM BACKPLANE

7500--0588--XX

7500--0677--XX

1--17

1--17

+12V

+12V RTN

MB1J3B

+5V RTN

+5V

+5V

+5V RTN

5678123412 536 6352 43211 4 654

1 234

+12V RTN

DISK

DRIVE

+5V

+5V RTN

+12V

FLOPPY

+12V RTN

+12V

3500--1135--XX

4321

+12V RTN

HARD

DISK

DRIVE

+5V

+5V RTN

+12V

MB1J5 MB1J1B MB1J1C J23

+12V

12V RTN

--12V

+5V

+5V RTN

+12V

ECG PREAMP

DIG GND

1918 20

--12V

2018 19

111--26423--XX

J24

REAR PANEL PCB

--5.2V

(SHIELD) (SHIELD)

3500--0844--XX

635214

--5.2V

+5V RTN

+5V

--12V

12V RTN

346

347

349

345

2536

+12V

GND

CONTROL INTERFACE PCB

348

+12V

P1B

41

+155V

DISPLAY

RETURN

MB1J1D

N\C

N\C

N\C

3500--1303--XX

N\C

N\C

N\C

--12V

12V RTN

+12V

1 23

321

J2

AUDIO BUFFER

REAR PANEL MODULE PCB

7500--0676--XX

3500--0830--XX

3500--0845--XX

B/W

VIDEO

MONITOR

POWER

SUPPLY

1700--0016--XX

+S

+

--

--S

L

H

N

P/O 3500--0896--XX

VIDEO MONITOR ASSEMBLY

+20V

+20V RTN

Figure 1B--3. DC Distribution Wiring Diagram (3 of 3)

10 ES01--B12 01

HDI--1B--5

^J

POWER SUPPLY AREA

3500--1162--XX

DIGITAL POWER

SUPPLY

FIGURE 1B--3

SHEET 1

+12V

--12V

TOP OF CARD CAGE

3500--1109--XX

(TEMP SENSOR)

3500--1221--XX

201

1

1

2

2

P2

202

P2

11

22

3500--1173--XX

P1

1

1

2

2

3443

11

22

P5

P6

+

--

P2

32 1

4

FAN

CONTROLLER

PCB

2100--0679--XX

1(+)

2(--)

P3

+

--

1

P3

4

1

P4

4

2

56

2

5

3

3

6

P4a P4b

+

--

+

--

FANASSEMBLY TRAY

TERMINAL BLOCK TB3

(PART OF 3500--1174--XX)

P7

+

--

3500--1174--XX

P8

+

--

P5

+

--

2100--0386--XX

(6X)

10 ES01--B13 01

Figure 1B--4. Fan Power (DC) Distribution Wiring Diagram

HDI-1B-6

NOTE:

In the following table captions, where there are two slot locations separated by a slash, the slot locations correspond to

the -0588 and -0677 motherboards respectively. Where

there is only one slot location, it corresponds to both motherboards.

Table 1B--1. Power Distribution: A1/A12, A3/A1, A4/A7

Voltage Jack Pins

+5 P1 31A, 31B, 31C

--5.2 30A, 30B

D--GND 27A, 29A, 29B, 29C, 30C, 32A, 32B, 32C

+12 P2 1A, 1B

--12 2A, 2B

D--GND 1C, 2C, 16A, 19C, 21A, 21B, 21C, 28A, 28B, 28C, 32A, 32B,

32C

+5 31A, 31B, 31C

--5.2 25A, 29B

HDI-- 1 B--7

Voltage PinsJack

+5 P3 31A, 31B, 31C

D--GND 32A, 32B, 32C

HDI-- 1 B--8

Loading...

Loading...