ATL Ultramark 4 Service manual

P/N 4730-0001-06 Rev C

Ultramark 4

ULTRASOUND SYSTEM

field service manual

Service Manual 4730-0001-06 Rev B consists of:

UM-4 Service Manual P/N 4720-0001-06 (9/6/94)

with the following manual changes inserted:

4725-0001-10 (9/6/94)

4725-0001-11 (4/14/95)

September, 1999

A detailed Table of Contents and List of Effective Pages begins on Page i. It includes the latest

change date for each page in the manual. Original pages will not have any date in the Contents and

List of Effective Pages or at the bottom of the page. A change bar (

) located in the outside margin

of a page denotes the specific part of a page that was changed at that date. A pointing hand (

) indicates the portion of a figure that has been revised.

Advanced Technology Laboratories, Inc.

P.O. Box 3003

Bothell, WA 98041-3003

COPYRIGHTE1992 BY ADVANCED TECHNOLOGY LABORATORIES, INC.

ALL RIGHTS RESERVED

PRINTED IN USA

“Access”, “CAD”, “Cineloop”, and “Ultramark” are registered trademarks of Advanced Technology Laboratories, Inc.

“HDI”, “Open Line Access”, and “Advanced Technology Laboratories” are trademark of Advanced Technology Laboratories, Inc.

“Matrix” is a trademark of Matrix Corporation.

“Polaroid”, “AutoFilm” and “FreezeFrame” are trademarks of Polaroid Corporation.

“Okidata” and “Microline” are registered trademarks of Oki America Inc.

Introduction

Introduction

This manual provides only information

most often needed in the field.

Experienced personnel will be able to use

accompanying performance testing, and

preventive maintenance checklists.

Organization

The manual contains major tab divisions

for diagrams, procedures, adjustments,

fault isolation, configuration supplement,

Operating Notes, Service Bulletins, reference, and parts.

ACTIVE DOCUMENT LIST: lists all active

documents pertaining to the Ultramarkr4

Ultrasound System. Listed are active service bulletins, service manuals, operation

manuals and operating notes.

OPERATING NOTES: contains operating

information not incorporated into the

operation manual.

SERVICE BULLETINS: copies of all

active service bulletins are included. “Hot

Tips” may be added as they are received

by the CSR.

REFERENCE: for information regarding

interconnecting cables and connectors

used in the Ultramarkr4, as well as other

miscellaneous information.

REPLACEABLE PARTS: illustrated parts

listings of parts commonly replaced in the

field.

REFERENCE: included are connector

pinouts, difficult removal/install instructions and other material not suited for inclusion in other manual sections.

DIAGRAMS: includes diagrams of system/

data paths, power distribution, and cabling.

PROCEDURES: contains information on

installation, performance testing, and preventive maintenance.

ADJUSTMENTS: procedures for field

authorized adjustments, including adjustment parameters and location diagrams.

FAULTISOLATION: fault isolation information in tabular format.

CONFIGURATION: hardware and software compatibility information for specific

system configurations.

Ultramark 4 Field Service Manual

Manual Usage and Update Information

The Table of Contents and List of Effective

Pages have been combined for this

manual. There is no List of Illustrations or

List of Tables. This will facilitate frequent

updating of the manual and allow TSRs to

easily determine the effective date of referenced information.

The contents of manual change packages

should be inserted as indicated on the

cover sheet attached to the package.

Changed or added pages can be identified

by the change date at the bottom of the

effected page. No change date indicates

the page is an original page. Change bars

xiii

Introduction

located in the outside margin of the page

denotes the specific part of apage that was

changed at that date. A pointing hand indicates the portion of the figure that has been

changed.

Page numbers are divided into three parts.

The prefix indicates the system. The

middle portion indicates the section within

the major tab. The suffix indicates the

actual page number.

Safety and Precautions

This section provides biological, procedural, environmental, electrical and

mechanical safety information.

WARNING statements identify conditions

or practices that could result in personal

injury or death.

CAUTION statements identify conditions

or practices that could result in equipment

damage.

Biological Safety

CAUTION:

Scanheads must be connected

and selected before turning a system on.

Do not disconnect scanheads while systems are on. Disconnect with power on

only if image has been frozen or if scanhead has been deselected.

CAUTION:

Do not sterilize scanheads with

heat, liquid, gas, or solvents. Do not autoclave or expose to temperatures exceeding 50_C (131_F). Permanent damage

may result.

WARNING:

scanheads prior to cleaning.

WARNING:

ing, and cable before using the instrument. Do

not use damaged transducers.

WARNING:

ment is classified ClassI, TypeB as defined in

IEC Standard 601-1 Safety of Medical Electrical Equipment. Electrical shock protection is

provided byconnecting theinstrument chassis

to safety ground using the 3-wire power cable

provided. This cable must be connected to a

properly grounded receptacle. Do not defeat

the grounding integrity of the equipment.

Disconnect power source and

Inspect the transducer face,hous-

Equipment grounding: This equip-

The assessment of the biological effects of

diagnostic ultrasound on humans is not

complete. Diagnostic ultrasound procedures should be used only for valid reasons, for the shortest period of time, and at

the lowest power settings necessary to

produce diagnostically acceptable

images.

Procedural Safety

WARNING:

unless another person capable of rendering

first aid is present.

xiv

Do not service or adjust a system

WARNING:

is not properly grounded. The system must be

plugged into a hospital-grade outlet.

WARNING:

power connected. Under certain conditions,

dangerous voltages may exist with power

removed. Disconnect power and discharge

circuits before touching.

WARNING:

qualified service personnel only.Avoid electric

shock and fire hazard by using proper fuses.

CAUTION:

Shock hazards exist if the system

Do not replace components with

Fusereplacement is tobedone by

Verify the system is set to

proper power source voltage and the cart

Ultramark 4 Field Service Manual

Introduction

C

C

power plug mates with the power receptacle.

WARNING:

introduced by using substituted parts or modified instruments.

WARNING:

mended by ATLmay cause electrical shock or

other unsafe conditions.

CAUTION:

Additional hazards may be

Using accessories not recom-

Verify circuit boards and components are dry before applying power to

the system.

Electro-Static Precautions

CAUTION:

This equipment contains compoents which are electro-static sensitive.

Proper static procedures, protection and

equipment must be used prior to opening,

and during handling of of this equipment.

Failure to use proper ESD procedures will

causedamagetothese components.Such

damage to components is not covered by

ATL warranties. Refer to General Field

Service Manual, (P/N 4720-0219-01) for

details.

Environmental Safety

WARNING:

presence of flammable gases or anesthetics

or in an oxygen enriched environment (i.e., in

an explosive atmosphere). An explosioncould

result.

Do not operate a system in the

can cause it to become mechanically

unstable.

CAUTION:

Do not use esters or ketone

solutions to clean parts. Discoloration (or

worse) will result.

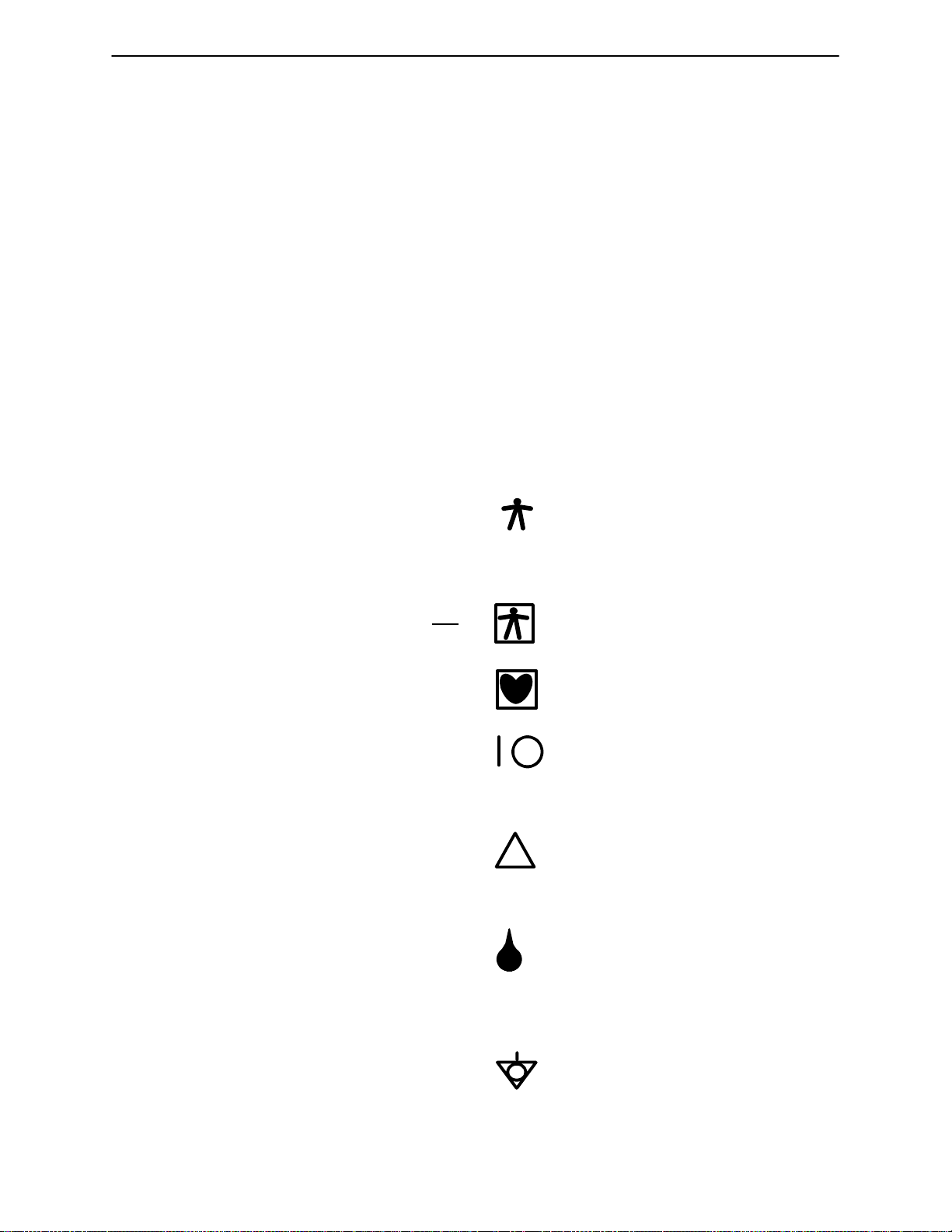

System Safety Symbology

Document IEC601-1, International Electrotechnical Commission: Safety of Medical Electrical Equipment, classifies patient

connections according to whether the

outer enclosure is grounded or floating

(non-conducting). The classifications are

shown below.

Grounded chassis. Protection

against electrical shock is provided

by connection of chassis to the

safety ground (IEC601-1 Type B).

Isolated patient connection (IE

601-1 Type BF).

Isolated patient connection (IE

601-1 Type CF).

I and O on circuit breaker and

power switch represents ON and

OFF, respectively.

This symbol identifies safety note.

!

Be sure you understand the function of this control before using it.

Drip-proof hand-held appliance

Mechanical Safety

CAUTION:

Use caution when transporting

the system over uneven surfaces, including entry to or exit from elevators.

WARNING:

equipment specified by ATL, on the system.

Ultramark 4 Field Service Manual

Stacking equipment, other than

(trans-ducer assembly). This

instrument may be safely handled

with wet hands.

Identifies protective earth ground

(located next to ground stud on the

rear panel).

xv

Introduction

The following are internal symbols (for reference only):

Identifies the point where the system safety ground is fastened to

the chassis.

Identifies high voltage components operating above 1000 Vac

or 1500 Vdc.

xvi

Ultramark 4 Field Service Manual

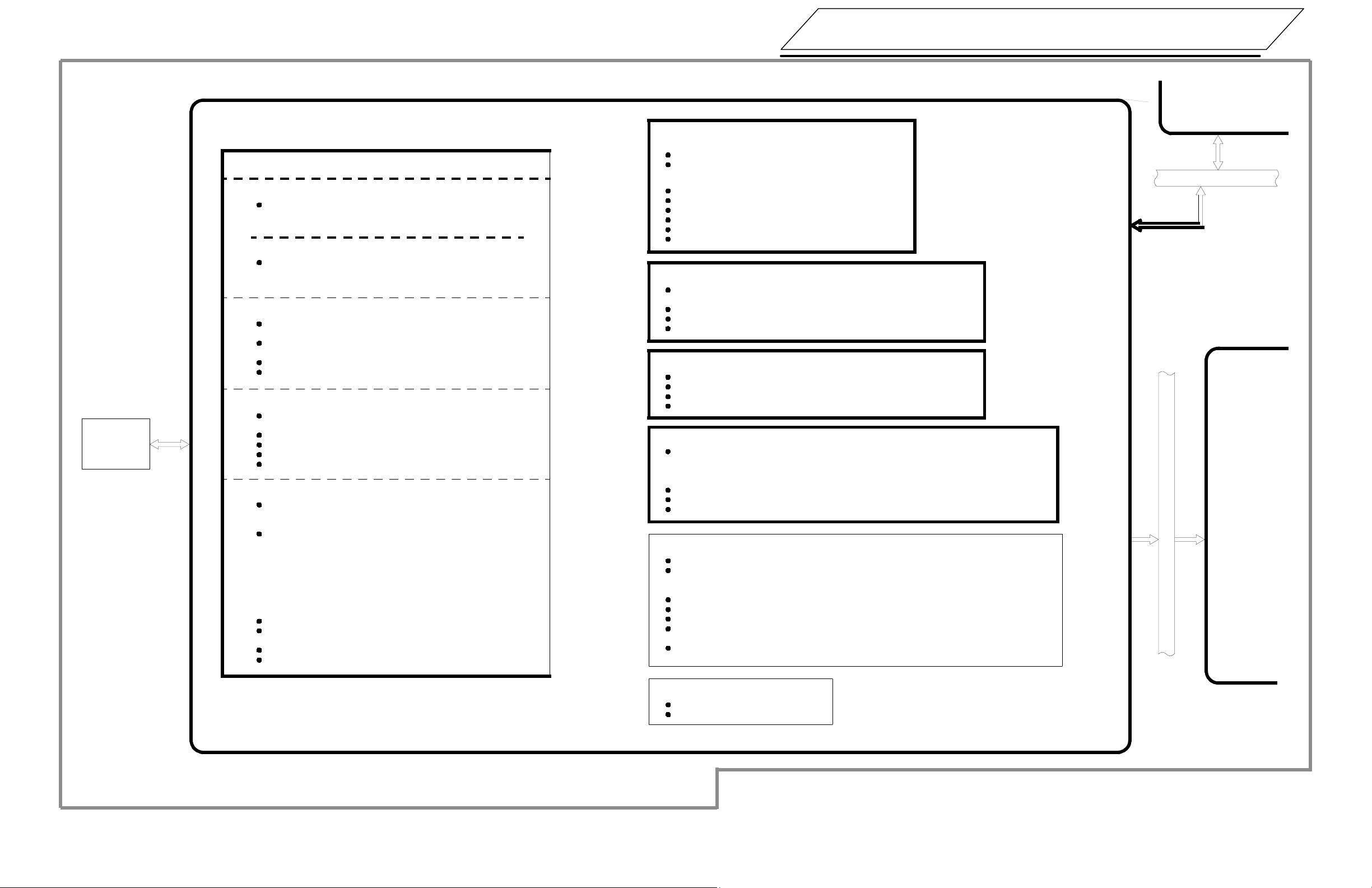

SCANHEADS

ACQUISITION GROUP

(A1-A4) BEAMFORMER

A1 RF Select PCB (S1)

* NO ACTIVE CIRCUITRY, JUST ROUTES SCANHEAD SIGNALS

TO FRONT END PCB (VIA CHABIN CABLES TO RF SELECT PCB

TO CENTER SECTION OF 3-PIECE MB)

A1 Doppler Pulser PCB (S2)

* VARIABLE AMPLIFIER FOR EXCITATION XMT PULSES FROM

PULSE PROCESSOR FOR MECHANICAL SCANHEADS IN CW AND

PULSED DOPPLER MODES

A2 Beamformer Front End PCB

* T/R SWITCHS BLOCK PULSERS FROM REACHING TGC

AMPLIFIERS AND BEAMFORMER FOCUS PCB

* HIGH VOLTAGE MUX SWITCHES (HV16'S). ROUTE PULSERS

TO FORM CORRECT APERTURE

* TGC AMPLIFICATION OF INCOMING RF SIGNALS

* SENDS RECEIVED RF TO BEAMFORMER FOCUS PCB

A3 Beamformer Focus PCB

* CROSSPOINT SWITCHES DEROTATE (RESTORES SEQUENCIAL

ORDER OF INDIVIDUAL CH ANNELS)

* REMOVES DELAYS FROM INDIVIDUAL INCOMING RF SIGNALS

* DEPTH OF FOCUS CONTROL

* DEMULTIPEXES (COMBINES) AND AMPLIFIES RF SIGNALS

* SENDS LINEAR RF TO PULSE PROCESSOR

A4 Beamformer Controller PCB

* DOWNLOADS OPERATING PARAMETERS (DEPTH, MODE,

S/H TYPE, ETC) FROM SYSTEM CONTROLLER TO

PROGRAMMABLE PULSE WIDTH GENERATOR

* CONTROLS BEAMFORMING

- PHASES APERTURE (CREATES PARABOLIC BEAM; OUTER

ELEMENTS FIRE FIRST; CENTER ELEMENTS FIRE LAST;

VIA MECHANICAL/ANALOG DELAY LINES)

- VARIES TRANSMIT FOCUS BY ZONE (VARIES DELAY RATIOS

OF PARABOLIC BEAM CURVE)

- SHIFTS APERTURE VIA HV MUX SWITCHES ON FRONT END

PCB (ELEM 1-32 -->2-33, ETC)

- SHIFTS DELAYS TO MAINTAIN SYMMETRY (ROTATION)

* SENDS PULSERS TO BEAMFORMER FRONT END PCB

* CONTROLS BEAMFORMER FOCUS PCB DEROTATION (REMOVING

APERTURE PHASING)

* ID'S LINEAR SCANHEADS, INCL AA

* SENDS LINEAR XDR FIRE TO PULSE PROCESSOR

Section 1A System/Data Path

A5 PULSE PROCESSOR PCB

S1

* SYSTEM RECEIVER FUNCTIONS

* OTHER FUNCTIONS SAME AS S2 PULSE PROCESSOR

S2

* GENERATES 2D XMT PULSES FOR ALL SCANHEADS

* CONTROLS POWER OUTPUT

* GENERATES TGC FOR SYS RCVR AND BMFMR FRONT

END PCB (A2)

* CONVERTS ANALOG RF INTO DIGITIZED ECHO DATA

* EDGE ENHANCEMENT/DYNAMIC RANGE

A6 DOPPLER ACQUISITION PCB

* PROCESSES CW AND PULSED DOPPLER SIGNALS FROM SYSTEM RECEIVER

TO GENERATE FORWARD AND REVERSE FLOW SIGNALS

* WALL, THUMP AND NOISE FILTERING

* A-TO-D CONVERSION

* GENERATES FORWARD AND REVERSE AUDIO SIGNALS

A7 DOPPLER PROCESSOR PCB

* GENERATES CW AND PULSED DOPPLER XMT PULSES FOR ALL SCANHEADS

* FFT OF DIGITIZED DOPPLER SIGNALS

* GRAYSCALE MAPPING

* TIMING SIGNALS FOR DOPPLER PCB'S

A8 MOTOR CONTROLLER PCB

* POSITIONAL CONTROL FOR MECHANICAL SCANHEADS

- END-FIRE (WOBBLERS)

- ACCESS (ROTARY, INCL DPLX CW) AND MERCURY

- ANNULAR ARRAY

* SENDS XDCR FIRE TO PULSE PROCESSOR PCB (A5) FOR ALL MECHANICAL S/Hs, INCL AA

* REPORTS TRANSDUCER ANGLE TO SCAN CONVERTER

* I.D.'S MECHANICAL SCANHEADS

SYSTEM RECEIVER (S2 ONLY)

* RF RELAYS; T/R SWITCHING; B.P. FILTERS, AMPS

* RCV FRONT END FOR STATIC PROBES, AND ALL MECHANICAL SCANHEADS, INCL DUPLEX CW

- XMT & RCV FRONT END FOR SECTOR 2D IMAGING (INCL DUPLEX CW; NOT AA)

- RECEIVE FRONT END FOR STATIC CW AND PULSED DOPPLER

* RF FILTERING AND NOISE SUPPRESSION

* APPLIES TGC FROM PULSE PROCESSOR TO 2D SIGNAL

* SWITCHES TO PULSE PROC FOR 2D PULSER OR TO DOP PULSE

* SWITCHES RF SIGNAL TO PULSE PROCESSOR FOR ACCESS

AND EFT 2D OR TO DOPPLER ACQUISITION FOR MECH DOP

* 7500-0511-XX SWITCHES 2D & PULSE DOPPLER BETWEEN EFT, ACCESS AND DUPLEX

CW SCANHEADS; SWITCHES CW BETWEEN STATIC PROBES AND DUPLEX CW SCANHEADS

CONTROL GROUP

(SHEET 2)

SERIAL BUS

A

C

Q

U

I

S

I

T

I

O

N

B

U

S

DISPLAY

GROUP

(SHEET 2)

ECG MODULE

* PATIENT/SYSTEM ECG ISOLATION

* ECG SIGNAL AMPLIFICATION

Ultramark 4 Field Service Manual

01 ES01-B01 01

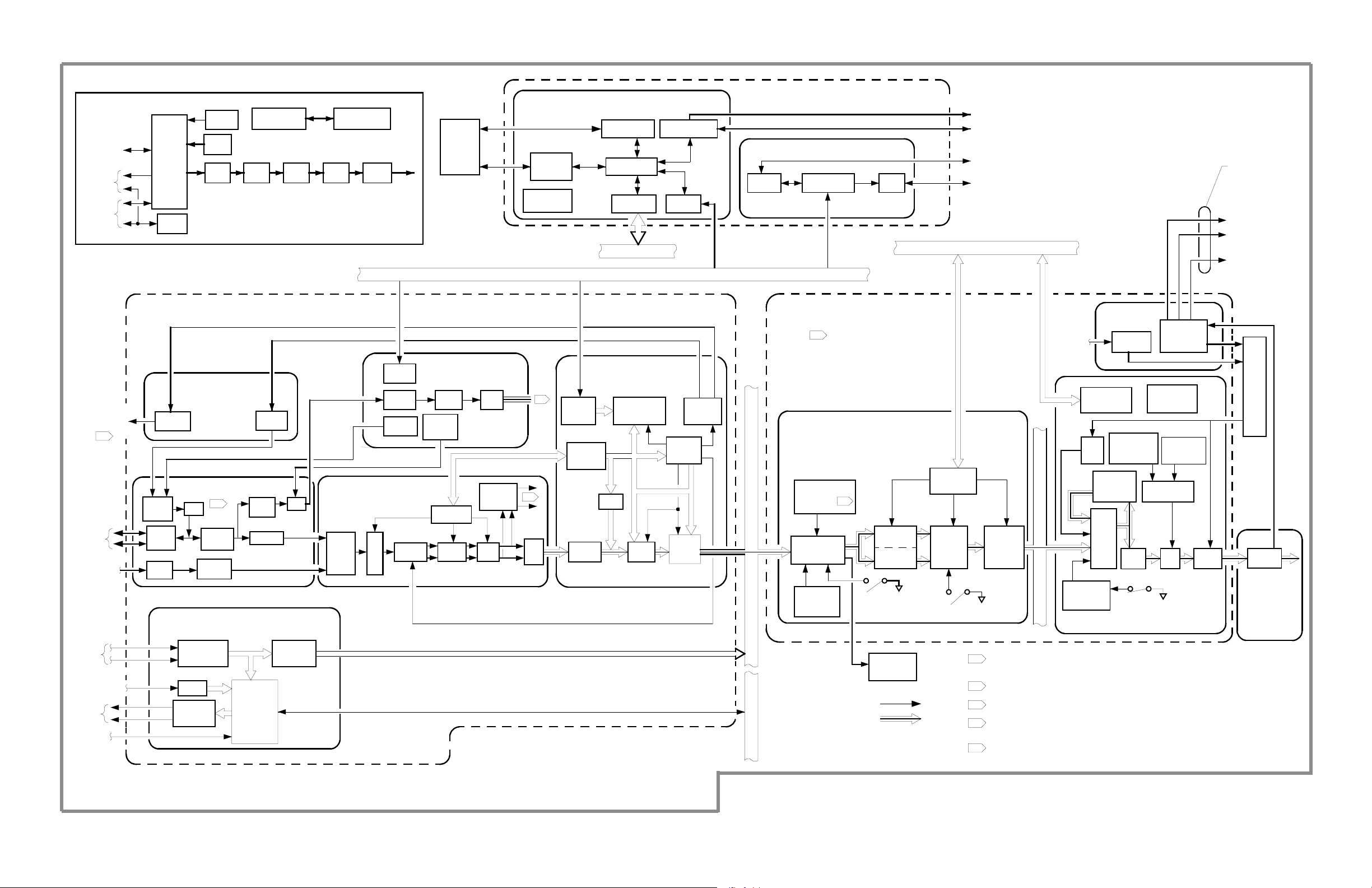

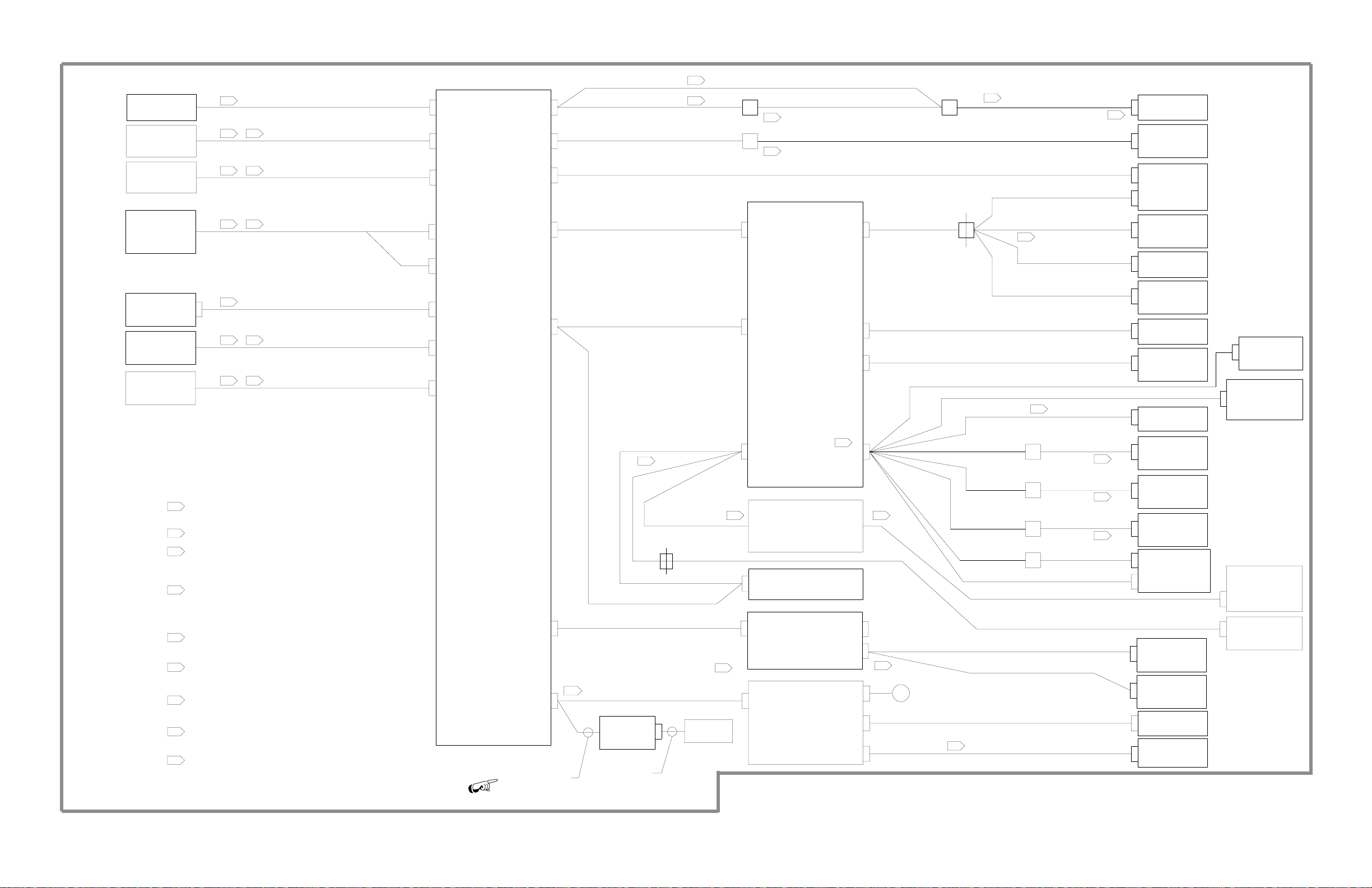

Figure 1A-1. UM-4 PCB Functions (Sheet 1 of 2)

UM4-01A-1

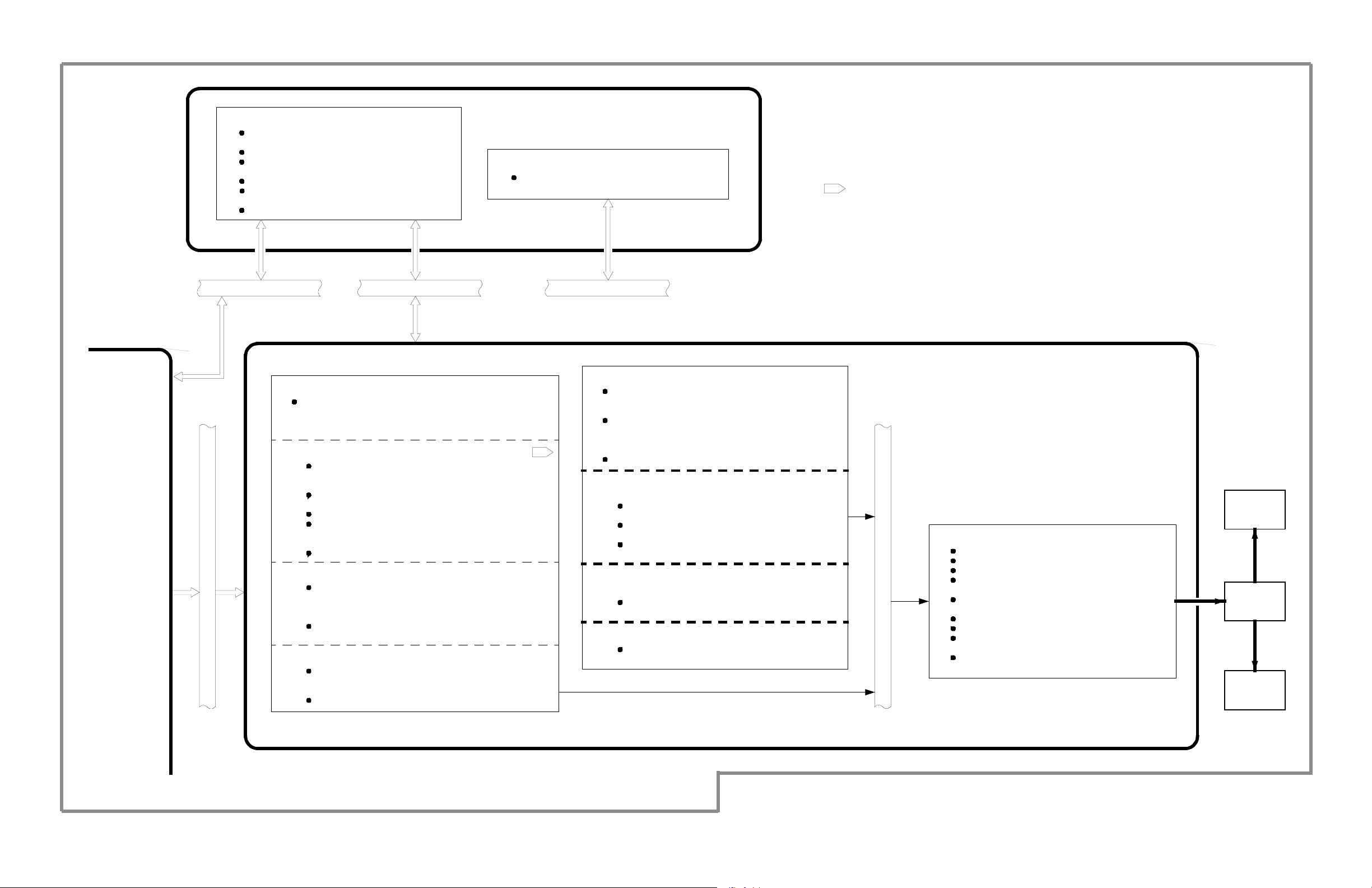

A15 SYSTEM CONTROLLER PCB

* RECEIVES USER COMMANDS FROM CONTROL MODULE

AND FOOTSWITCH

* CONTROLS SYSTEM PCB'S AND PERIPHERALS

* PROVIDES SYSTEM INTERFACE TO DATA COMM

MODULE OR SERIAL PORT

* CONTROLS DATA COMM DISC DRIVES

* PERFORMS ALL MEASUREMENT AND ANALYSIS

FUNCTIONS

* GENERATES REPORTS AND DRIVES PRINTER

CONTROL GROUP

KEYBOARD CONTROLLER

* PROVIDES USER INTERFACE BETWEEN CONTROL

MODULE CONTROLS AND SYSTEM CONTROLLER

1

COMBO AND CINE PCBs COMBINE FUNCTIONS OF A9

S.C. INTERFACE AND A10 S.C. BUFFER PCBs.

CINE PCB HAS EXPANDED MEMORY FOR CINELOOP.

ACQUISITION

GROUP

(Sheet 1)

A

C

Q

U

I

S

I

T

I

O

N

B

U

S

SERIAL BUS

(A9-A11) 2D SCAN CONVERTER

* FORMATS 2D ULTRASOUND DATA, EITHER POLAR

(SECTOR) OR RECTANGULAR (LINEAR) INTO

RECTANGULAR COORDINATES WITH RASTER TV

TIMING

A9 S.C. INTERFACE, COMBO OR CINE PCB

* RECEIVES CONTROL, ACQUISITION AND ADDRESS DATA

FROM BEAMFORMER, PULSE PROCESSOR, AND MOTOR

AND SYSTEM CONTROLLERS

* ACQUISITION CONTROL OF 2D AND TM-MODE SCAN

CONVERTER GROUPS VIA ACQ AND SAMPLE CLOCKS

* FRAME AVERAGING (SMOOTHING)

* INTERPOLATES SECTOR COORDINATES TO

RECTANGULAR COORDINATES (ROW AND COLUMN)

FOR DISPLAY

* MEMORY READ/WRITE CONTROL

A10 SCAN CONVERTER BUFFER PCB

* 2D SCAN CONVERSION: SHIFTS A LINE OF VIDEO IN AT

ULTRASOUND SCAN RATE (1-10 KHZ), SHIFTS OUT AT

TV HORIZONTAL SWEEP RATE (15,750 HZ, EIA; 16.625

HZ, CCIR)

* STORES 2D IMAGES FOR FREEZE FRAME AND "IMAGE

STORE" FUNCTION

A11 S. C. OUTPUT ADDRESS GENERATOR

* MANIPULATES DISPLAY ADDRESSES TO PRODUCE

PAN/ZOOM MAGNIFICATION, IMAGE BOUNDARY LIMITS ,

AND OTHER DISPLAY FEATURES

* GENERATES FRAME RATE

SERIAL BUSPARALLEL BUS

(A12-A13) TM-MODE 2D SCAN CONVERTER

* FORMATS M-MODE AND DOPPLER ULTRASOUND DATA,

INTO SCROLLING RECTANGULAR COORDINATES WITH

RASTER TV TIMING

* M-MODE AND DOPPLER SCAN CONVERSION: SHIFTS A

LINE OF DATA IN AT ULTRASOUND SCAN RATE (1-10

KHZ), SHIFTS OUT AT TV HORIZONTAL SWEEP RATE

1

(15.750 KHZ, EIA; 16.625 HZ, CC IR)

* FORMATS ECG SIGNAL ONTO DISPLAY AREA

DISPLAY GROUP

A12 TM-MODE PCB

(-OO PCB IS S1 ONLY, NO DOPPLER)

* STORES M-MODE AND DOPPLER VIDEO FOR F REEZE

FRAME

* PROCESSES AND FORMATS M-MODE, DOPPLER AND

ECG DATA

* SENDS M-MODE, DOPPLER AND ECG VIDEO TO

HARDCOPY STRIPCHART PERIPHERAL

A13 TM-AUXILIARY PCB

(REQUIRES -02 OR HIGHER TM-MODE PCB)

* GENERATES ANNOTATIONS AND MARKERS FOR

SCROLLING M-MODE AND DOPPLER DISPLAYS

A12 TM-COMBO PCB

* EQUIVALENT OF COMBINED TM-MODE AND TM-AUX

PCBS

A14 DISPLAY CONTROLLER PCB

V

I

D

E

O

B

U

S

* GENERATES ALL TV TIMING SIGNALS

* GENERATES COMPOSITE VIDEO

* GENERATES ALPHANUMBERICS AND GRAPHICS

* PROVIDES VIDEO MULTIPLEXING IN 2D/M-MODE

DISPLAY

* ACQUIRES AND STORES VIDEO FRAMES FOR DUAL

IMAGE AND IMAGE-TO-DISC FUNCTIONS

* FRAME GRABBER MEMORY FOR VCR PLAYBACK

* POST PROCESSING FOR IMAGE ENHANCEMENT

* SENDS VIDEO TO MONITOR, AND THROUGH A/V

MODULE TO AUX MONITOR AND PERIPHERALS

* SWITCHES VIDEO OUTPUT BETWEEN REAL-TIME AND

VCR PLAYBACK

VIDEO

MONITOR

AUDIO/

VIDEO

MODULE

PERIPHERALS

AND

AUXILIARY

MONITOR

UM4-01A-2

01 ES01-B02 02

Figure 1A-1. UM-4 PCB Functions (Sheet 2 of 2)

Ultramark 4 Field Service Manual

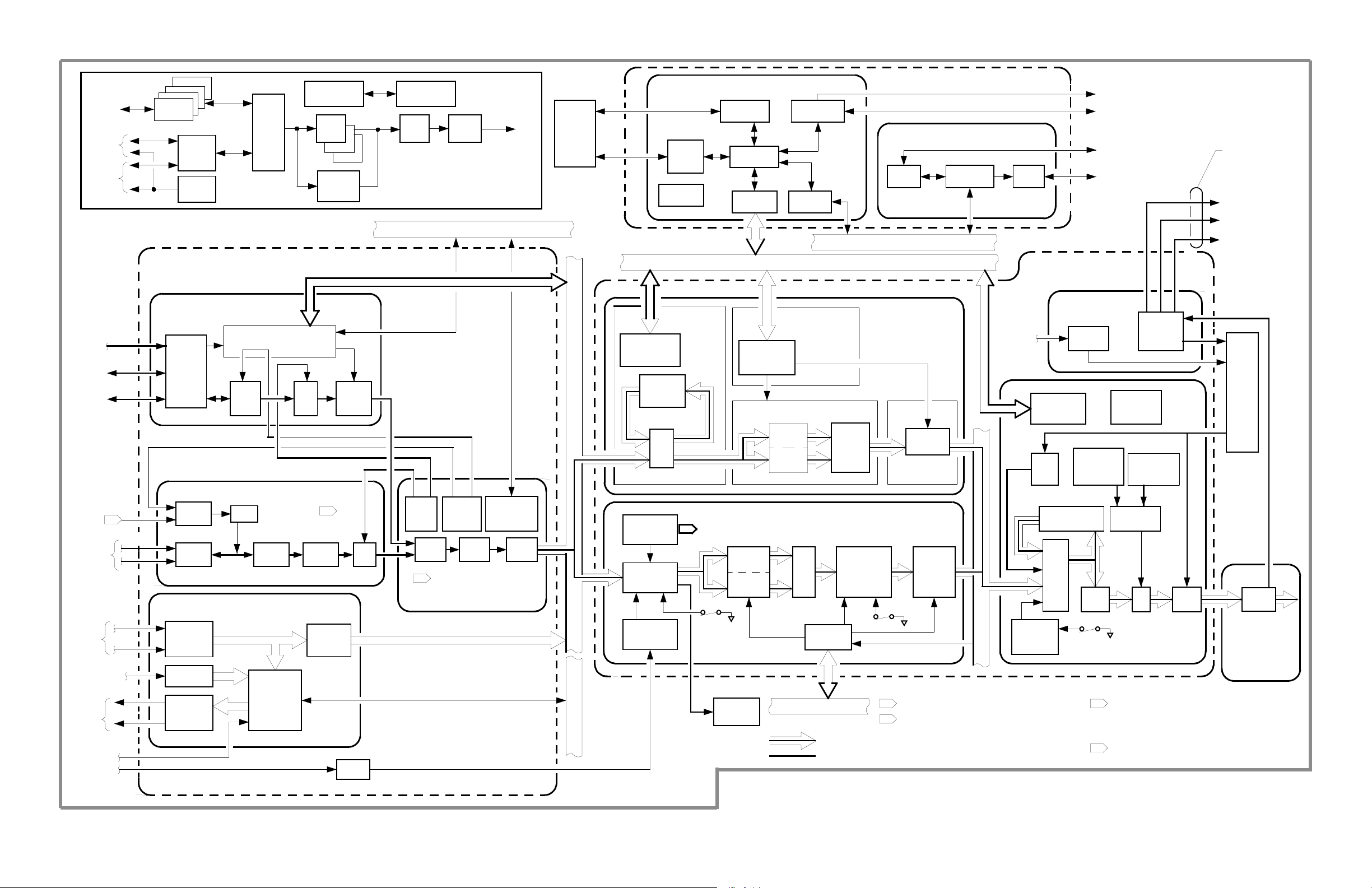

DFT

ACCESS

EFT

BEAM-

FORMER

PULSE

PROC

SYSTEM

REC

MOTOR

CONT

ACQUISITION GROUP

SYSTEM

CONTROLLER

2-D

SC

T-M

MODE

SC

KEYBOARD

CONTROLLER

DISP

CONT

VIDEO

DR

COMP

OUT

SIMPLIFIED IMAGING

DATA PATH

SERIAL BUS

DATA

COMM

MODULE

SYSTEM CONTROLLER

(A15)

FLOPPY

DISK

CONT

CLOCK

CALENDER

DATA COM M

INTERFACE

MICRO-

PROCESSOR

PARALLEL

PORTS

PARALLEL BUS

PERIPHERAL

PORTS

SERIAL

PORTS

CONTROL GROUP

KEYBOARD CONTROLLER

BUFFER

SERIAL BUS

MICRO-

PROCESSOR

UART

DISPLAY GROUP

VCR CONTRO L

HARDCOPY

DEVICES/

FOOTSWITCHES

CONTROL PANEL

ALPHANUMERIC

KEYBOARD

REAR PANEL PCB

AUX MONITOR

PHOTO MODULE

LINESCAN REC

PAGE PRINTER OR

MATRIX CAM ERA

XDR ID

DFT

ANNULAR

ARRAY

724B

ACCESS

EFT

724B

ACCESS

EFT

ANALOG

CONTROL

SIGNALS-EFT

ACCESS/724B

724B

ACCESS

EFT

XDR ID

ECG LEADS

BEAMFORMER (A1-A4)

RF

SELECT

(S1)

DOPPLER

PULSER

(S2)

(A1)

FRONT

END

(A2)

CONTROL

(A4)

TGC

(A2)

FOCUS

(A3)

A

C

Q

U

I

S

I

T

I

O

N

B

U

S

ACQUISITION

ADDRESSING

& CONTROL

FRAME

AVERAGER

MEMORY

MUX

INTERFACE

(A9)

OUTPUT

ADDRESSING

& CONTROL

BUFFER MEMORY (A10)

MEMORY

PAGE 0

MEMORY

PAGE 1

OUTPUT

ADDRESS

GENERATOR

(A11)

OUTPUT

MUX

2D SCAN

CONVERTER

INTER-

POLATOR

INTERFACE

VCR

CONTROL

(A9)

A/V

MODULE

MICRO-

PROCESSOR

A/D

VCR

DECODER

ALPHA-

NUMERIC

GENERATOR

VIDEO

TIMING

CIRCUITS

GRAPHICS

VIDEO

SPLITTER

VCR

GEN

SYSTEM RECEIVER

RF

1

RELAY

RF

RELAY

ISO

T/R

SWITCH

BUFFER

2

TGC

MOTOR CONTROLLER (A8)

POSITION

QUANTI-

TIZERS

A/D

MOTOR

DRIVERS

(3)

SERVO

CONTROL

CIRCUITS

(CPU)

LINE

COUNT/

STATUS

ECG

TGC

RF

RELAY

3

PULSER

PROC

RAMP

GEN

PULSE PROCESSOR (A5)

RF

MICRO-

PROCESSOR

A/D

MARKERS

& ANNO-

TATION

GAMMA

CORRECTION

& FILTER

ECG

PRO-

CESSING

S

E

R

I

A

L

B

U

S

4

T2

LINESCAN

RECORDER

T-M MODE SCAN CONVERTER (A12)

MEMORY

A

MEMORY

B

MUX

PARALLEL BUS

DECIMATION

AND

MUX

SCROLL

CONTROL

DATA PATH

DISPLAY

MEMORY

V

T1

SEE DOPPLER DATA PATH BLOCK DIAGRAM.

1

FOR SYSTEMS WITHOUT RESOLUTION PLUS,

2

SYSTEM RECEIVER FUNCTIONS ARE

PROVIDED BY CIRCUITRY ON THE PULSE

PROCESSOR PCB (7500-0313).

I

D

E

O

B

U

S

FRAME BUFFER

MEMORY

DIS-

PLAY

MUX

GRAY BAR

GEN-

ERATOR

OVERWRITE

MUX

POST

PROC

T1

D/A

VIDEO

RELAY

DISPLAY

CONTROLLER (A14)

FOR RESOLUTION PLUS SYSTEMS, PULSE

3

PROCESSOR PCB IS PART NUMBER 7500-0370

FOR SYSTEMS WITHOUT RESOLUTION PLUS.

PULSE PROCESSOR PCB IS 7500-0313.

MAY BE ON TM MODE PCB OR ON TM

4

AUXILLARY PCB.

VIDEO

DRIVER

MON-

ITOR

REAR

PANEL

PCB

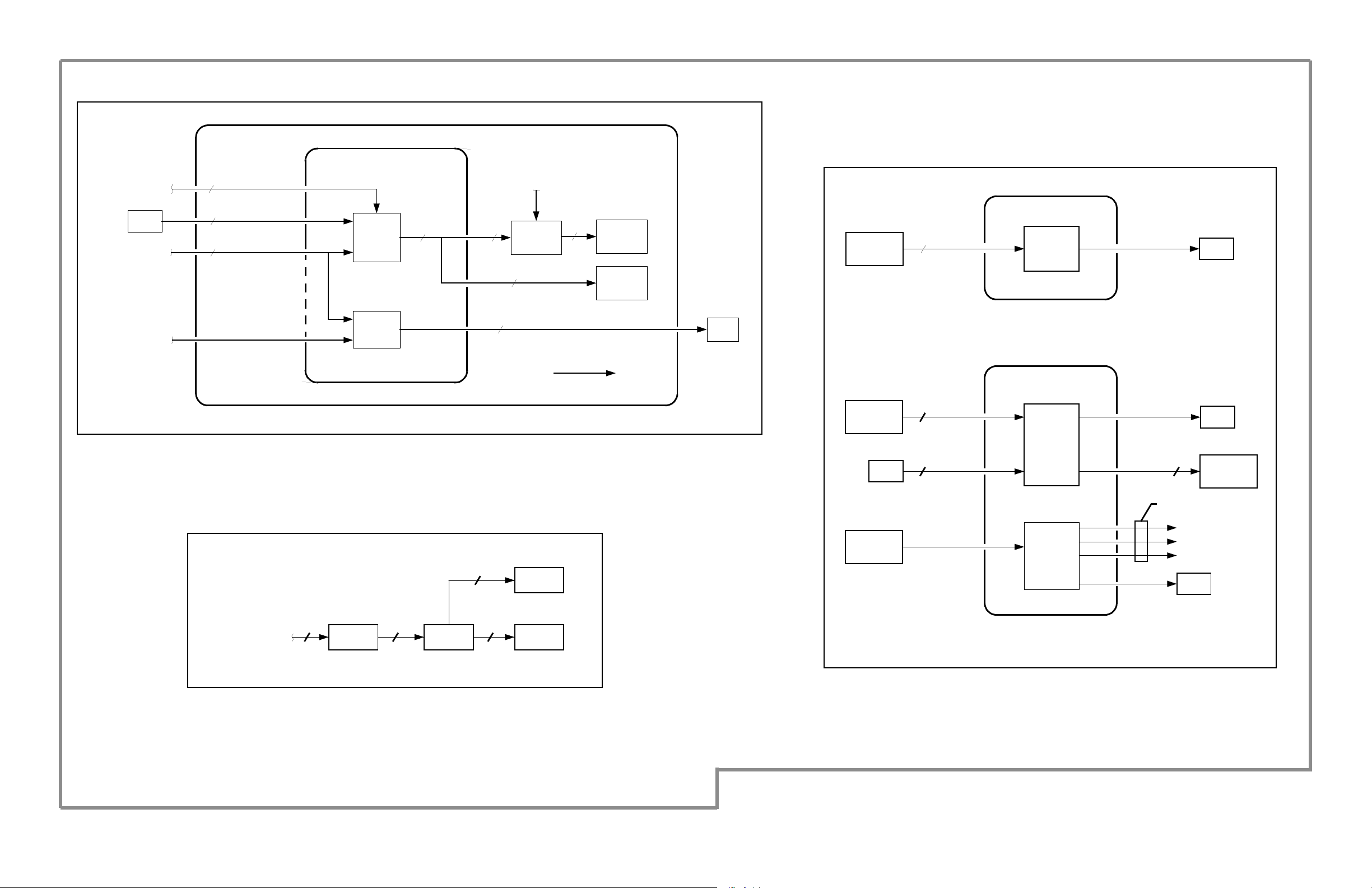

Figure 1A-2. Imaging/M-Mode Data Path Block Diagram

01 ES01-B03 01

Ultramark 4 Field Service Manual

UM4-01A-3

STATIC

XDCR

(CW)

ACCESS

EFT

SYSTEM

REC

MOTOR

CONT

DOP

PULSR

PULSE

PROC

DOP

ACQ

SYSTEM

CONTROLL ER

DOP

PROC

TM

SC

KEYBOARD

CONTROLL ER

DISP

CONT

SIMPLIFIED DOPPLER DATA PATH

VIDEO

DR

COMP

OUT

DATA

COMM

MODULE

SYSTEM CONTROLLER

DATA COMM

INTERFACE

FLOPPY

DISK

CONT

CLOCK

CALENDER

MICRO-

PROCESSOR

PARALLEL

PORTS

PARALLEL BUS

(A15)

PERIPHERAL

PORTS

SERIAL

PORTS

CONTROL GROUP

KEYBOARD CONTROLLER

BUFFER

SERIAL BUS

MICRO-

PROCESSOR

UART

VCR CONTROL

HARDCOPY

DEVICES/

FOOTSWITCHES

CONTROL PANEL

ALPHANUMERIC

KEYBOARD

PARALLEL BUS

REAR PANEL PCB

AUX MONITOR

PHOTO MODULE

LINESCAN REC

PAGE PRINTER OR

MATRIX CAMERA

STATIC

TRANSDUCER

5

ACCESS

EFT

STATIC

TRANSDUCER

ACCESS

EFT

ANALOG

CONTROL

SIGNALS-EFT

ACCESS

ACCESS

EFT

XDR ID

ACQUISITION GROUP

CW PULS

DOPPLER

PULSER (A1)

CW

BUFFER

2D PULS

SYSTEM RECEIVER

ISO

POSITION

QUANTI-

TIZERS

A/D

MOTOR

(3)

5

T/R

SWITCH

B.P.

FILTER

CONTROL

CIRCUITS

RF

RELAY

RF

RELAY

AMP

MOTOR CONTROLLER (A8)

DRIVERS

BUFFER

BUFFER

SERVO

(CPU)

PULSE

AMP

PD PULS

TGC

LINE

COUNT/

STATUS

MICRO

PROC

RF

RELAY

PULSER

DOPPLER

ACQUISITION (A6)

A

RF

RELAY

T

MIXERS

T

E

N

PULSE

PROCESSOR (A5)

RF

PROC

TGC

RAMP

GEN

CONTROL

FILT

PROC

A/D

PHASE

SHIFT &

SUMMING

GAIN

2

MUX

&

A/D

DISPLAY GROUP

4

VCR

CONTROL

A/V

MODULE

VCR

DECODER

VIDEO

SPLITTER

DOPPLER

PROCESSOR (A7)

1

SERIAL

BUS

INT

DOPPLER

ACQ

INT

FFT

INPUT

PROCESSOR

TEST

MICRO-

& MEMORY

FFT

CLOCK

ACQ

BUS

INT

CW

PULSER

INTFC

A

C

Q

U

I

S

I

T

I

O

N

B

U

S

T-M MODE

SCAN CONVERTER (A12)

MARKERS

& ANNO-

TATION

GAMMA

CORRECTION

& FILTER

CESSING

ECG

PRO-

3

MEMORY

A

MEMORY

B

T2

SCROLL

CONTROL

DECI-

MATION

AND

MUX

V

I

D

E

O

B

U

S

DISPLAY

MEMORY

T1

MICRO-

PROCESSOR

A/D

GRAY BAR

GEN-

ERATOR

FRAME

BUFFER

MEMORY

DIS-

PLAY

MUX

ALPHA-

NUMERIC

GENERATOR

POST

PROC

VIDEO

TIMING

CIRCUITS

GRAPHICS

OVERWRITE

MUX

D/A

T1

GEN

VIDEO

RELAY

DISPLAY

CONTROLLER (A14)

1

LINESCAN

S

E

R

I

A

L

B

U

S

RECORDER

DATA PATH

TO 2D SCAN CONVERTER

SEE IMAGING DATA PATH BLOCK DIAGRAM

2 SEE AUDIO DATA PATH BLOCK DIAGRAM

3 MAY BE ON TM MODE, ON TM AUXILIARY PCB, OR TM MODE COMBO PCB

4

5

ALTHOUGH NOT PART OF THE DOPPLER DATA PATH, THE

2D SCAN CONVERTER IS REQUIRED FOR DOPPLER OPERATION

REFER TO FIGURE 1A-5 FOR 3500-10 16-XX

RECEIVER AND DUPLEX CW PATH

VCR

VIDEO

DRIVER

REAR

PANEL

PCB

01 ESO1-B04 01

MONITOR

Figure 1A-3. Doppler Data Path Block Diagram

UM4-01A-4

Ultramark 4 Field Service Manual

FROM SYSTEM

CONTROLLER PCB

VCR

FROM DOPPLER

ACQUISITION PCB

2

2

2

RT/VCR

L/R PLYBK

AUDIO

L/R DOPPLER

AUDIO

A/V MODULE

AUDIO

SOURCE

SWITCH

VOLUME CONTROL

L/R AUDIO

22

AUDIO

AMPS

2

AUDIO GROUP

2

SPEAKERS

HEAD

PHONES

SYSTEM

CONTROLLER

5

VCR

CONTROL

A/V MODULE

PARALLEL

TO

SERIAL

VCR

MICROPHONE

FROM DOPPLER

ACQUISITION PCB

AUDIO

MIXER

UM-4 HFC AUDIO DATA PATH

2

VCR

AUDIO

AMPS

2

222

L/R AUDIO

VCR

DATA PATHS

SYSTEM

CONTROLLER

VCR

DISPLAY

CONTROLLER

VCR

HEAD-

PHONES

SPEAKERS

- A/V MODULE WITHOUT VCR STATUS -

A/V MODULE

VCR

7

5

CONTROL

VCR

STATUS

MICRO-

PROCESSOR

SWITCH

VIDEO

SPLITTER

CONTROL

STATUS

- A/V MODULE WITH VCR STATUS (SMART A/V) -

2

REAR PANEL

LSR

MIC

PHOTO MAP

VCR

VCR

SYSTEM

CONTROLLER

UM-4A, PV, AND CV AUDIO DATA PATH

Figure 1A-4. UM-4 Audio Data Paths and VCR Status

Ultramark 4 Field Service Manual

VCR CONTROL AND STATUS DATA PATH

01 ES01-B05 01

UM4-01A-5

UM4--01A--6

1A System/Data Path

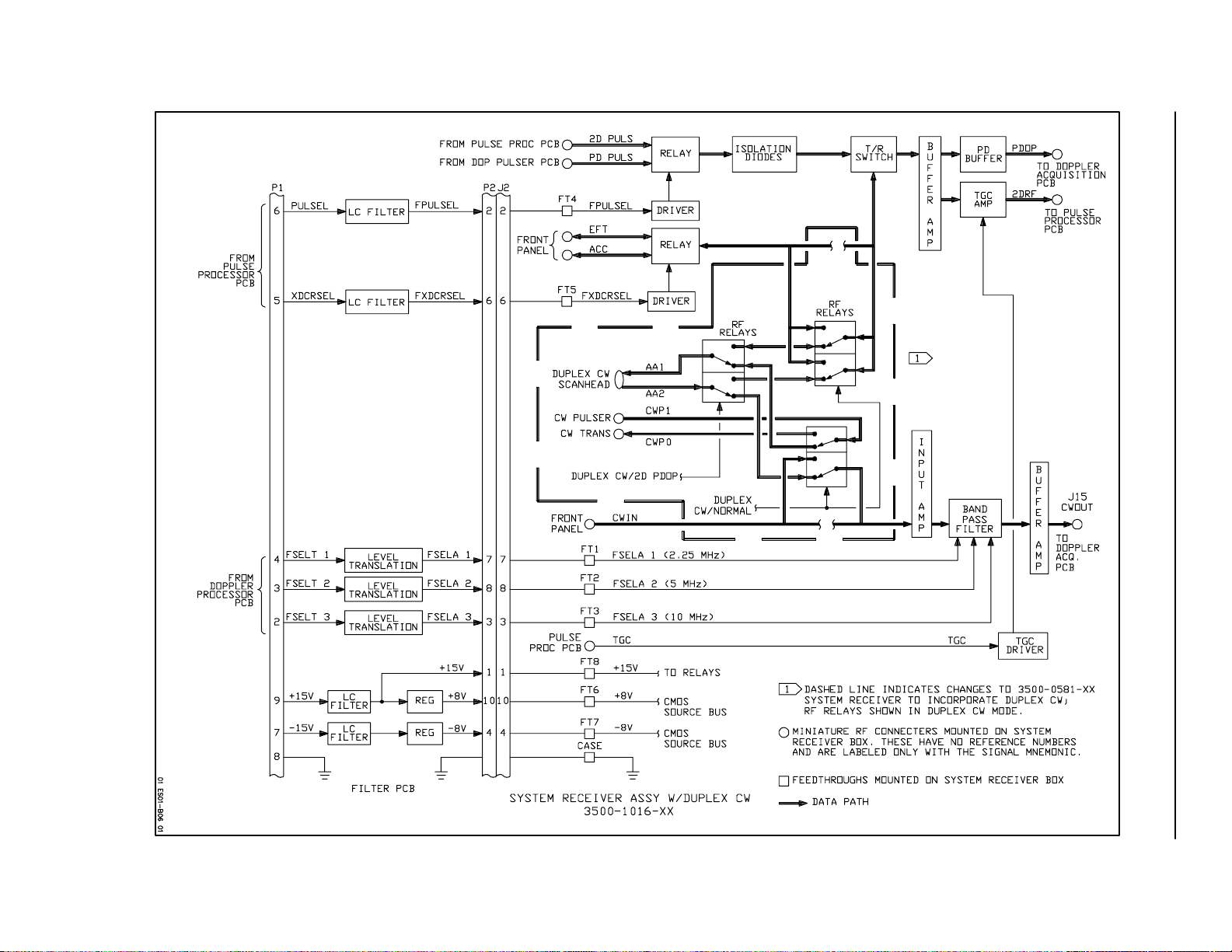

Figure 1A--5. Duplex CW System Receiver Block Diagram

Ultramark 4 Field Service Manual

1ASystem/Data Path

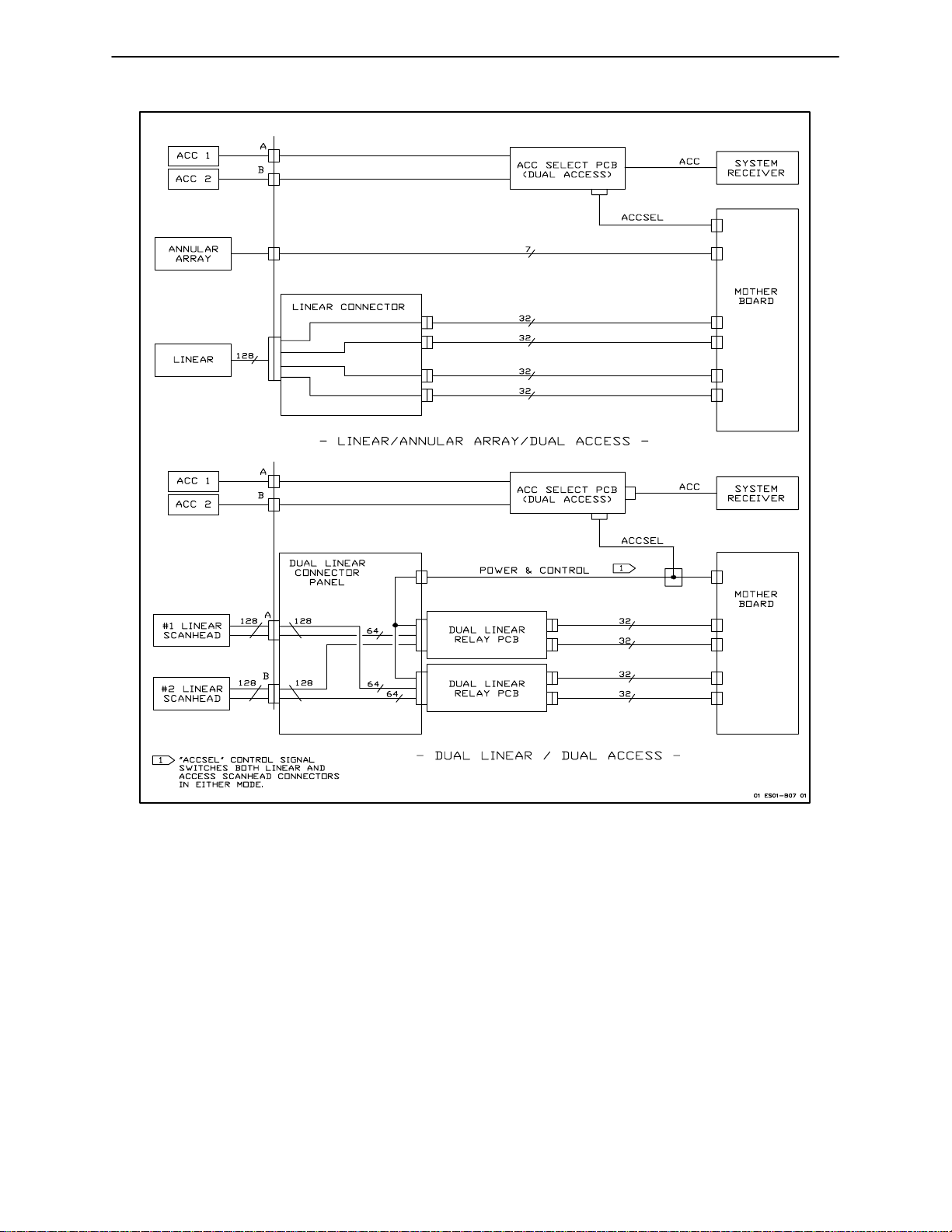

Figure 1A--6. Dual Access and Dual Linear Circuit Details

Ultramark 4 Field Service Manual

UM4--01A--7

UM4--01A--8

1A System/Data Path

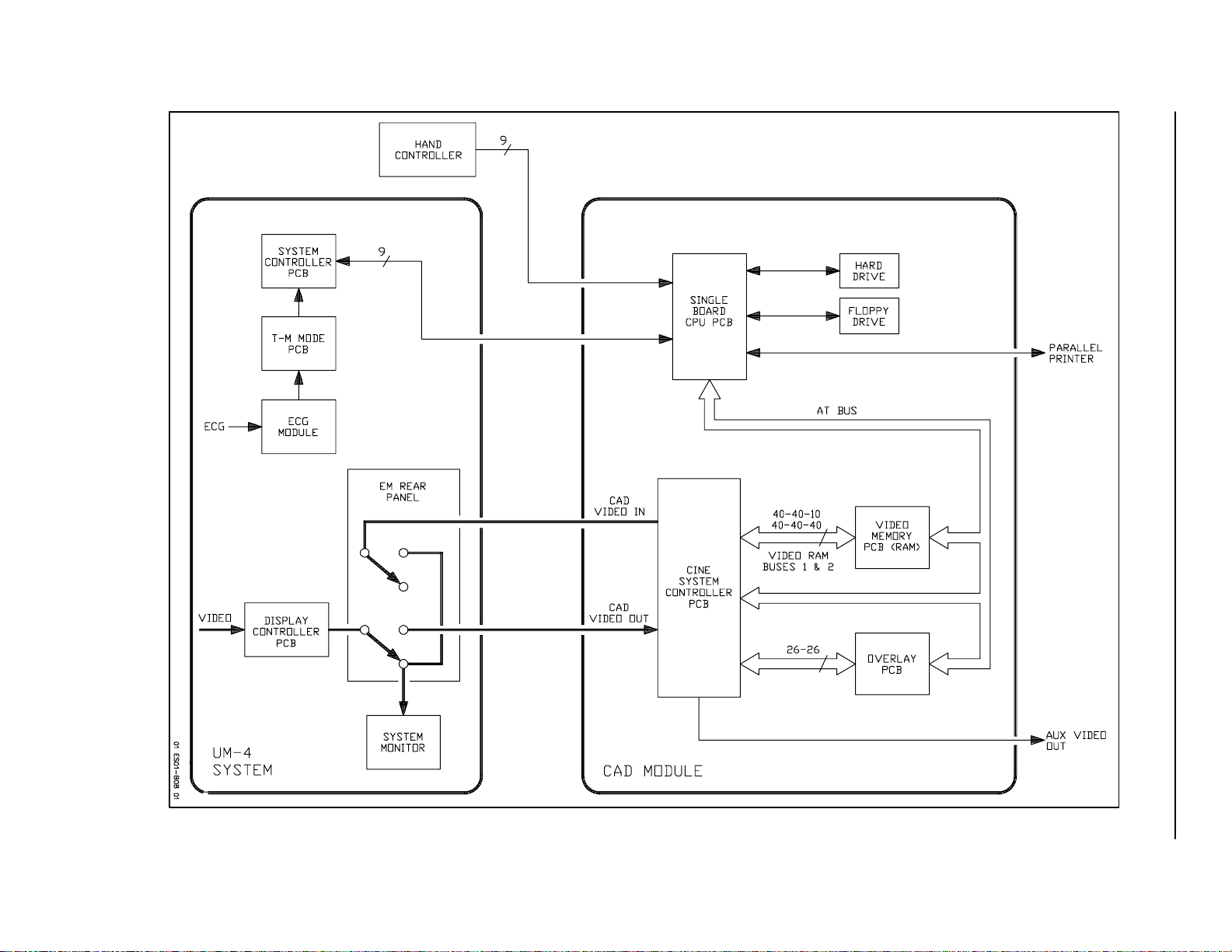

Figure 1A--7. UM-4 CAD Block Diagram

Ultramark 4 Field Service Manual

Ultramark 4 Field Service Manual

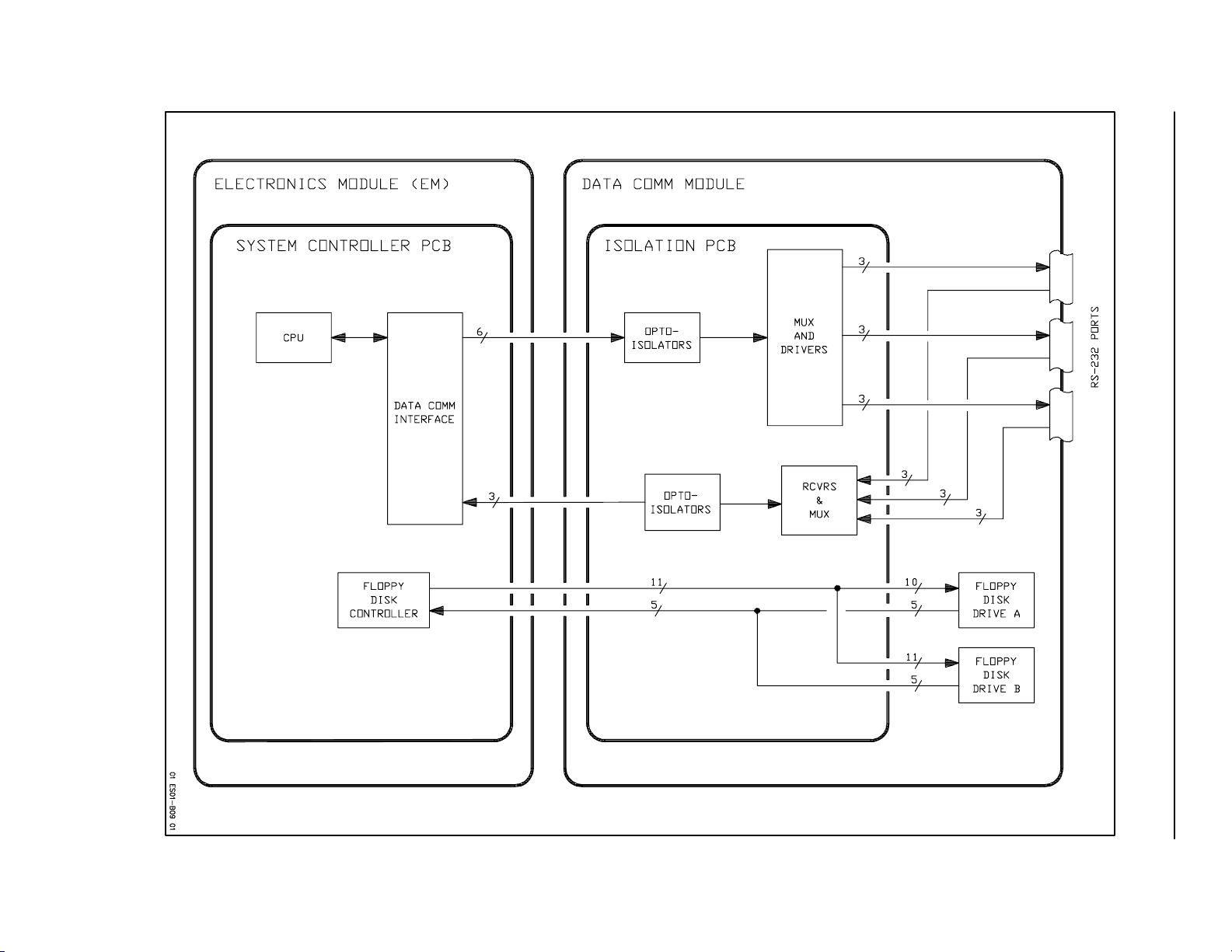

Figure 1A--8. Data Comm Block Diagram

UM4--01A--9

1ASystem/Data Path

INTERNAL

FAN

UNREGULATED +15V (MC)

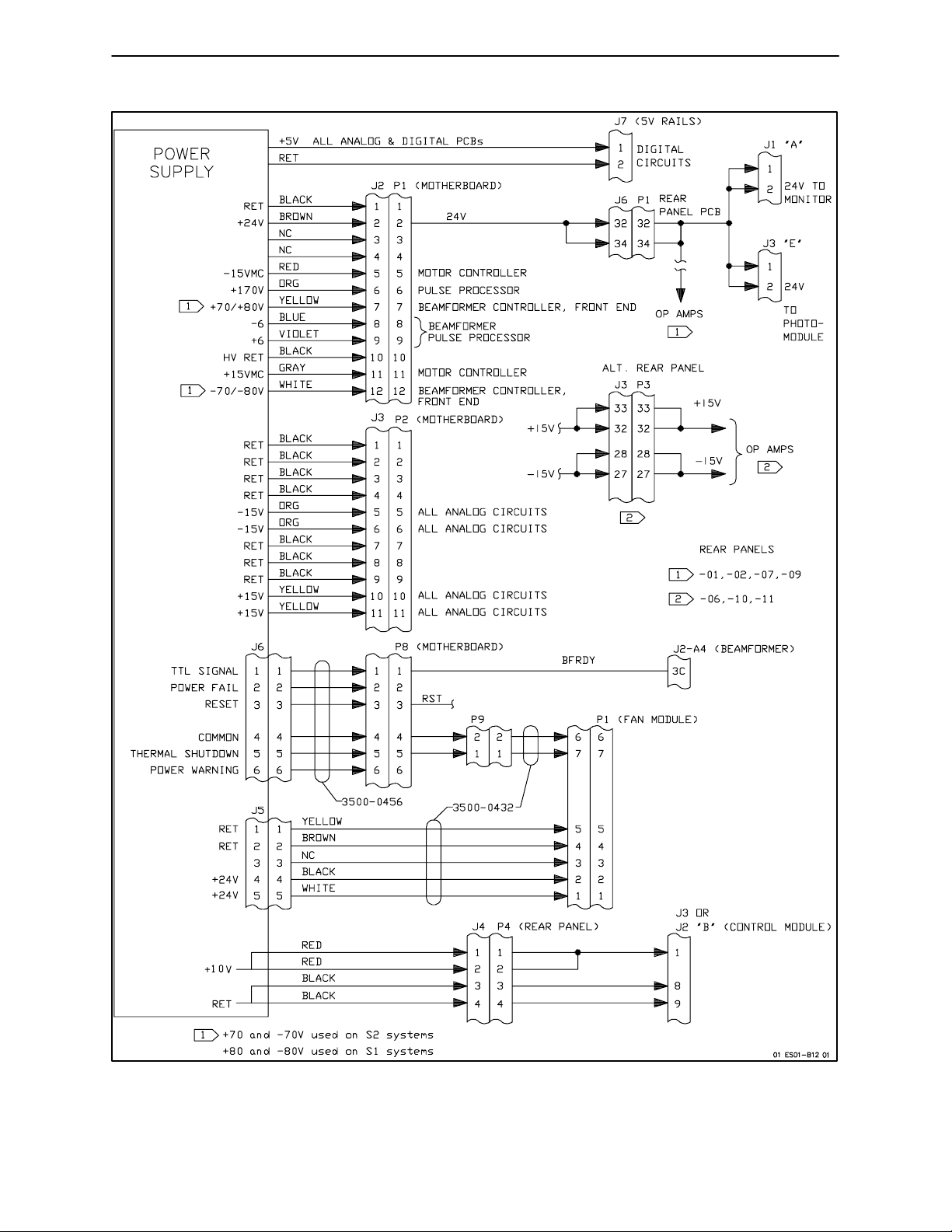

Section 1B Power Distribution

J4

+9V

9V RTN

3

4

1

2

CONTROL

MODULE

AC

+15V MC

-15V MC

+5V

-5V RTN

+15V AN

-15 AN

115/230VAC

FROM POWER

DISTRIBUTION

ASSEMBLY

J1

SYSTEM

POWER SWITCH

PRIMARY PCB

LINE

CONDITIONING

AND

VOLTAGE

CONFIG.

STRAPPING

RECTIFIER

AND

FILTER

CONTROL

AND PULSE

WIDTH

MODULATOR

10V

CHANNEL

TRNSFMR

5V

CHANNEL

TRNSFMR

RECTIFIERS

AND

FILTERS

RECTIFIERS

AND

FILTERS

15V MC RTN

REGULATORS

+15V AN

-15V AN

- UM-4 -

15V AN RTN

~

F1/F2

POWER DISTRIBUTION ASSY

SYSTEM

POWER SWITCH

EM (J1)

A/V MODULE

DATA COM M

OR CAD

VIDEO PRINTER

+6V

-6V

+170V

1

1

+70V/+80V

-70V/-80V

CURRENT

SENSING

HIGH

VOLTAGE

CONTROL

6V RTN

1

1

+6V

-6V

+170V

+70V/+80V

-70V/-80V

HV RTN

J2

5

MOTOR

CONTROLLER

11

J7

(5V RAIL)

1

SYSTEM

2

PCBs

J3

1

2

10

11

5

SYSTEM

PCBs

6

3

4

9

7

8

J2

9

BEAMFORMER

PULSE PROCESSOR

8

6

PULSE PROCESSOR

7

12

BEAMFORMER

10

AC

- UM-4A -

~

BEAMFORMER

FAN MODUL E

F1/F2

POWER DISTRIBUTION ASSY

J6

BF READY

1

THERMAL SHUTDOWN

5

F3

1

+70V AND -70V USED ON S2 SYSTEMS

+80V AND -80V USED ON S1 SYSTEMS

2

T1

EM (J1)

AC

OUTLETS

2

1:1 EXCEPT FOR 35 00-1096-XX

WHICH IS 2:1 (240V IN / 120V OUT)

SHUTDOWN CONTROL LINE

HIGH TEMP

SENSE

15V AN

SECONDARY PCB

THERMAL CUTOUT

+5V

OVER-VOLTAGE

OVER-CURRENT

CONTROL

CONTROL

LOGIC

Ultramark 4 Field Service Manual

+24V

HIGH CURRENT

DETECT

24V RTN

HIGH VOLTAGE CONTROL

LOGIC COMMMON

Figure 1B-1. Power Module Block Diagram

24V RTN

+24V

POWER FAIL

RESET

+24V

2

SYSTEM MONITOR

PHOTO MODULE

1

J5

4

5

FAN MODUL E

1

2

J6

2

SYSTEM

3

PCBs

6

01 ES01-B10 01

UM4-01B-1

120/240

VAC

FPC

VCR

120/240

VAC

SCR OR

PAGE PRINTER

OR

MATRIX CAMERA

ELECTRONICS MODULE

+5 VOLTS

RETURN

SYSTEM

POWER

MODULE

1-7

8-18

AUDIO/VIDEO MODULE

P7

24

20,21

22 22

22-25 VOLT UNREG DC

+12 VOLTS

P8

18

16

2

20

3,6

1-2

9-15

P3 (D)

AC

SOCKET

A/V

MODULE

PWR

SUPPLY

+5 VOLTS

+5 VOLT

RRTN

P9

1

2-4

11

-12 VOLTS

+5 VOLTS

+5 VOLT

RETURN

12 VOLT

RETURN

D

120/240

VOLTS AC

P1

24

20,21

P2

18

16

2

20

3,6

VCR

DIGITAL

INTERFACE

VCR

STEREO

INTERFACE

1,3

2,4

1,2

14,15

P6 (I)

AUX

MONITOR

P10 (J)

AUDIO

AMPLIFIERS

P4 (H)

VCR

RETURN

1-2

9-15

E

1-2

9-15

P2 (EO1)

+24 VOLTS

+24 VOLT RETURN

1,2

9

P1 (EO2)

PHOTO

MODULE

01 ES01-B11 01

Figure 1B-2. A/V Module Power Distribution

UM4-01B-2

Ultramark 6 Field Service Manual

1BPower Distribution

Ultramark 4 Field Service Manual

Figure 1B--3. UM-4 Power Distribution

UM4--01B--3

1B Power Distribution

Table 1B--1. Power Distribution

POWER SUPPLY

TTL Control Signal J6-1

Power Fail

Reset

Thermal Shutdown J6-5

MOTHERBOARD

+5 Volts +5 Volt Rail

5VoltReturn

+170 Volts

+80 Volts, S1;

+70 Volts, S2

--80 Volts,S1;

--70 Volts,S2

HV Return

--15MC Volts

+15 MC Volts

15 MCV Return

+15 Volts

--15 Volts

Analog Ground

+6 Volts

--6Volts

+24 Volts

24 Volt Return

XDR Ground

SYSTEM RECEIVER

+15 Volts (analog) P1-9

- -15 Volts (analog)

Ground

DOPPLER PULSER (A1)

+5 Volts P3-4A ,4B,4C,5A,5B,5C,6A,

Digital Ground P3-1A ,1B,1C,2A,2B,2C,3A,

+15 Volts (analog)

- -15 Volts (analog)

Ground

J6-2

J6-3

5VoltReturnRail

J2-6

J2-7

J2-12

J2-10

J2-5

J2-11

J3-1,2

J3-10,11

J3-5,6

J3-3,4,7,8,9

J2-9

J2-8

J2-2

J2-1

5VoltReturnRail

P1-7

P1-8

6B,6C

3B,3C

P3-25A,25B,25C

P3-27A,27B,27C

P2-2A ,2B,4A,4B,4C,5A,6A

P3-26A,26B,26C,31A,31B,

31C

BEAMFORMER FRONT END (A2)

+80 Volts, S1; J4-1,2

+70 Volts, S2

--80 Volts,S1;

--70 Volts,S2

Return

+15 Volts

--15 Volts

Analog Ground

+6 Volts

--6Volts

BEAMFORMER FOCUS (A3)

+15 Volts

--15 Volts

Analog Ground

+6 Volts

--6Volts

BEAMFORMER CONTROLLER (A4)

Return J4-3,4

+80 Volts, S1;

+70 Volts, S2

--70 Volts,S2

TTL Control

Reset

+5 Volts

Return

+80 Volts, S1;

+70 Volts, S2

--80 Volts,S1;

--70 Volts,S2

HV Return

+15 Volts

--15 Volts

Analog Ground

J4-5,6

J4-3,4,7,8,10,12,14,16,18

J3-25A,25B,25C

J3-27A,27B,27C

J3-26A,26B,26C,32B

J3-32A

J3--32C

J3-25A,25B,25C

J3-27A,27B,27C

J1-8A,8B,8C,9A,9B,9C,10A,

J4-5,6

J4-1,2--80 Volts,S1;

J2-3C

J3-18B

J3-4A,4B,4C,5A,5B,5C,6A,

6B,6C

J3--1A,1B,1C,2A,2B,2C,3A,

3B,3C,7B,8B,9B,10B,11B,

19A,19B,19C

J3-23C

J3-23B

J3-24A,24B,24C

J3--25A,25B,25C

J3-27A,27B,27C

J3-26A,26B,26C

10B,10C,12A,12B,12C,

13C,14A,14B,14C,16A,

16B,17B,17C,23A,23B,

23C,24B,25B,25C,26B,

26C,28A,28B,28C

J3-32A

J3-32C

UM4--01B--4

Ultramark 4 Field Service Manual

Table 1B--1. Power Distribution (Cont’d)

1BPower Distribution

PULSE PROCESSOR (A5)

Reset

+5 Volts

Return

+170 Volts

HV Return

+15 Volts

--15 Volts

+6 Volts

--6Volts

DOPPLER ACQUISITION (A6)

+5 Volts

Digital Ground

+15 Volts (analog)

- -15 Volts (analog)

DOPPLER PROCESSOR (A7)

+5 Volts

Digital Ground

+6 Volts

--6Volts

J3-18B

J3-4A,4B,4C,5A,5B,6A,

6B,6C

J3-1A,1B,1C,2A,2B,2C,

3A,3B,3C

J3-23A

J3-24A,24B,24C

J3-25A,25B,25C

J3--27A,27B,27C

J2-9-20A,9-27B,9-30CAnalog Ground

J3-26A,26B,26C,31A,31B,

31C

J3-32A

J3-32C

P3-4A ,4B,4C,5A,5B,5C,

6A,6B,6C

P3-1A ,1B,1C,2A,2B,2C,

3A,3B,3C

P3-25A,25B,25C

P3-27A,27B,27C

P3-26A,26b,26C,31A,31B,Ground

31C

P3-4A ,4B,4C,5A,5B,5C,

6A,6B,6C

P3-1A ,1B,1C,2A,2B,2C,

3A,3B,3C

P3-32A

P3-32C

P2-2A ,2B,4A,4B,4C,5A,Analog Ground

6A

P3-26A,26B,26C,31A,31B,

31C

ECG ISOLATION

+15 Volts J2-9

--15 Volts

Analog Ground

SCAN CONVERTER INTERFACE (A9)

+5 Volts J3-4A,4B,4C,5A,5B,5C,

Digital Ground J1-1A,4A,6B,6C,7A,

SCANCONVERTERBUFFER(A10)

+5 Volts J3-4A,4B,4C,5A,5B,5C,

Digital Ground

J2-7

J2-1,2,3,4,6,8,10

6A,6B,6C

10A,13A,15C,16A,

19A,21B,23C,28B,

29B,30B,31B,32B

J2-3B,6B,8B,9A,9C,

12B,15B,16A,16C

17B,18B,19A,19C,

22B,26B,27A,27C

31B,32B,32C

6A,6B,6C

J1-1A,4A,6B,6C,7A,10A,

13A,15C,16A,19A,21B,

23C,28B,29B,30B,31B,

32B

J2-3B,6B,8B,9A ,9C,12B,

15B,16A,16C,17B,18B,

19B,19C,22B,26B,27A,

27C,31B,32A,32C

J3-1A,1B,1C,2A,2B,2C,

3A,3B,3C,7B,8B,9B,

10B,11B,14B,19A,19B

19C

MOTOR CONTROLLER (A8)

Power Fail J3-16A

Reset

10.00 Volts

+5 Volts

Return

--15 VoltMotor

Control J3-20A,20B,20C

+15 volt Motor

Control J3-22A,22B,22C

Return J3-21A,21B,21C

Ultramark 4 Field Service Manual

J3-18B

J1-29A

J3-4A,4B,4C,5A,5B,5C,

6A,6B,6C,16A,16B,16C

J3-1A,1B,1C,2A,2B,2C,

3A,3B,7B,8B,9B,10B,

11B,14B,15A,15B,15C,

19A,19B,19C,21C

SCAN CONVERTER OUTPUT ADDRESS GEN. (A11)

+5 Volts J3-4A,4B,4C,5A,5B,5C,6A,

6B,6C

Return J1-1A,4A,6B,6C,7A,10A,13A,

15C,16A,19A,21B,23C,

28B,29B,30B,31B,32B

J2-3B,6B,8B,9A ,9C,12B,15B,

16A,16C,17B,18B,19A,

19C,22B,26B,27A,27C,

31B,32A,32C

J3-1A,1B,1C,2A,2B,2C,3A,

3B,3C

UM4--01B--5

1B Power Distribution

Table 1B--1. Power Distribution (Cont’d)

TM-MODE (A12)

+5 Volts J3-4A,4B,4C,5A,5B,5C,6A,

Return

+15 Volts J3-25A,25B,25C

--15 Volts

Analog Ground

Reset

+15 Volts

--15 Volts

Analog Ground P4-1,2,6,8,10

TM AUXILIARY (A13)

+5 Volts P3-4A ,4B,4C,5A,5B,5C,6A,

Digital Ground

DISPLAY CONTROLLER (A14)

+5 Volts J3-4A,4B,4C,5A,5B,5C,6A,

Return

+15 Volts

--15 Volts

Analog Ground

SYSTEM CONTROLLER (A15)

+5 Volts J3-4A,4B,4C,5A,5B,5C,6A

Return J1-10A,10B,13A,13B,21A,

4.8V Battery

Reset

Power Fail

6B,6C

J2-3B,9A,9C,19A,19C,26B,

27A,27C,32A,32C

J3-1A,1B,1C,2A,2B,2C,3A,

3B,3C

J3-27A,27B,27C

J3-26A,26B,26B

J3--18B

P4-9

P4-7

6B,6C

P3-1A ,1B,1C,2A,2B,2C,3A,

3B,3C

6B,6C

J3-1A,1B,1C,2A,2B,2C,3A,

3B,3C

J3-25A,25B,25C

J3-27A,27B,27C

J1-30A,30B,30C,31A,31B

32A,32B

J3-26A,26B,26C

6B,6C

21B,21C,23A,24B,24C,

25A,25C,26A,27A,30A,

31B

J2-19A,19C,22B

J3-15B

J3-18B

J3-16A

FAN MODULE

+24 Volts P1-1,2

Return

LINESCAN RECORDER, PAGE PRINTER, VGR

+5 Volts J4(C)-12

Return J4(C)-14-23,25

+24 Volts J1(A)-1,3

Return J1(A)-2,5

+24 Volts

Return

+5 Volts

Return

+10 Volts J2(B)-1

Return

REAR PANEL (7500-0318-01, -02)

+5 Volts P1-21,23

Return

+24 Volts

Return

+10 Volts

Return

REAR PANEL (7500-0318-03, above)

+5 Volts P3-21,22

+15 Volts

--15 Volts

+24 Volts

Return

+10 Volts

Return P4-3,4

P1-4,5

SYSTEM MONITOR

PHOTO MODULE

J3(E)-1,2

J3(E)-9-15

DATA COMM MODULE

J6(F)-34

J6(F)-20,23,28,30,35-37

CONTROL MODULE

J2(B)-8,9

P2-9,11

P1-1,3

P1-9,11

P4-1,2

P4-3,4

P3-32,33

P3-27,28

P3-1,3

P3-9,11

P4-1,2

UM4--01B--6

Ultramark 4 Field Service Manual

1BPower Distribution

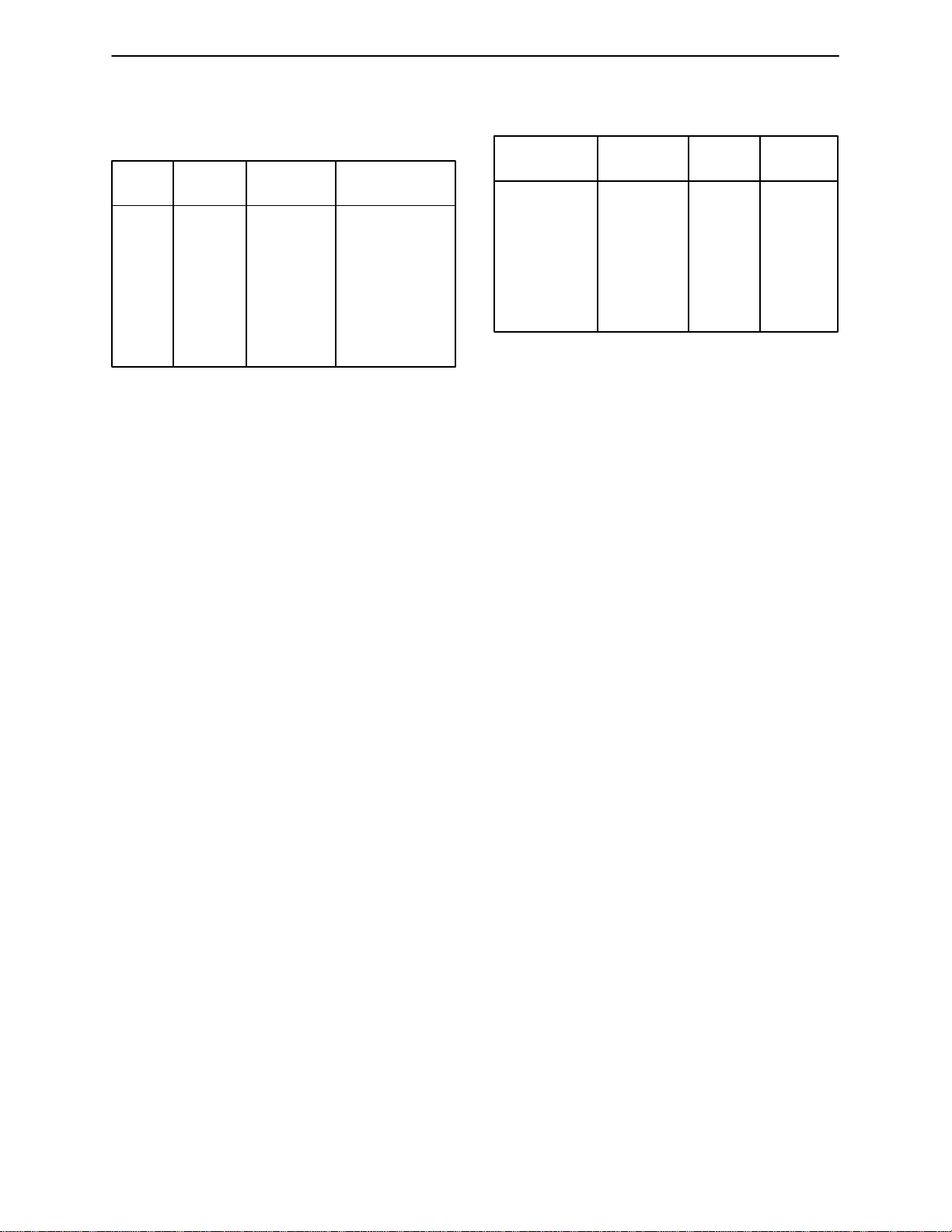

Table 1B--2. Power Module Connections

Power Mother- Rear Panel

Supply board PCB Other

J2 P1

J3 P2

J4 P4

J4 P2

J5 P3

J6 P1

J7 Footswitch cable

J8 *

J9 J8

*Hardwired in U318-01, -02

Table 1B--3. Power Supply Fuses

Power Supply ATL Part

Part Number Fuse Value Number

1700-0009-02

1700-0002-04,

-09, -11 F201, F202 15A,125V 2700-0072

1700-0009-01

1700-0002-05,

06, -10, -12 F201, F202 8A,250V 2700-0045

1700-0009-01

1700-0002-01 F300 2.5A N/A

Ultramark 4 Field Service Manual

UM4--01B--7

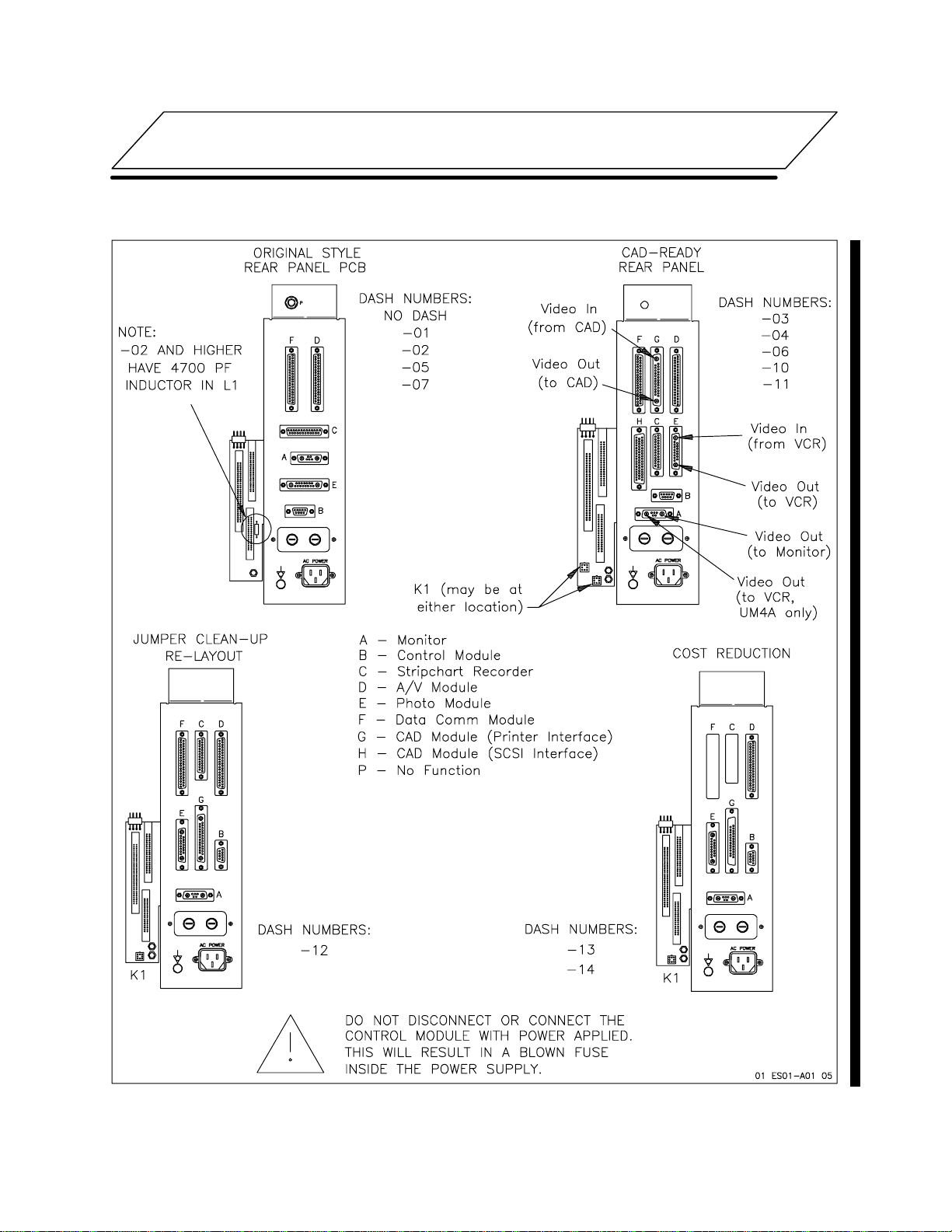

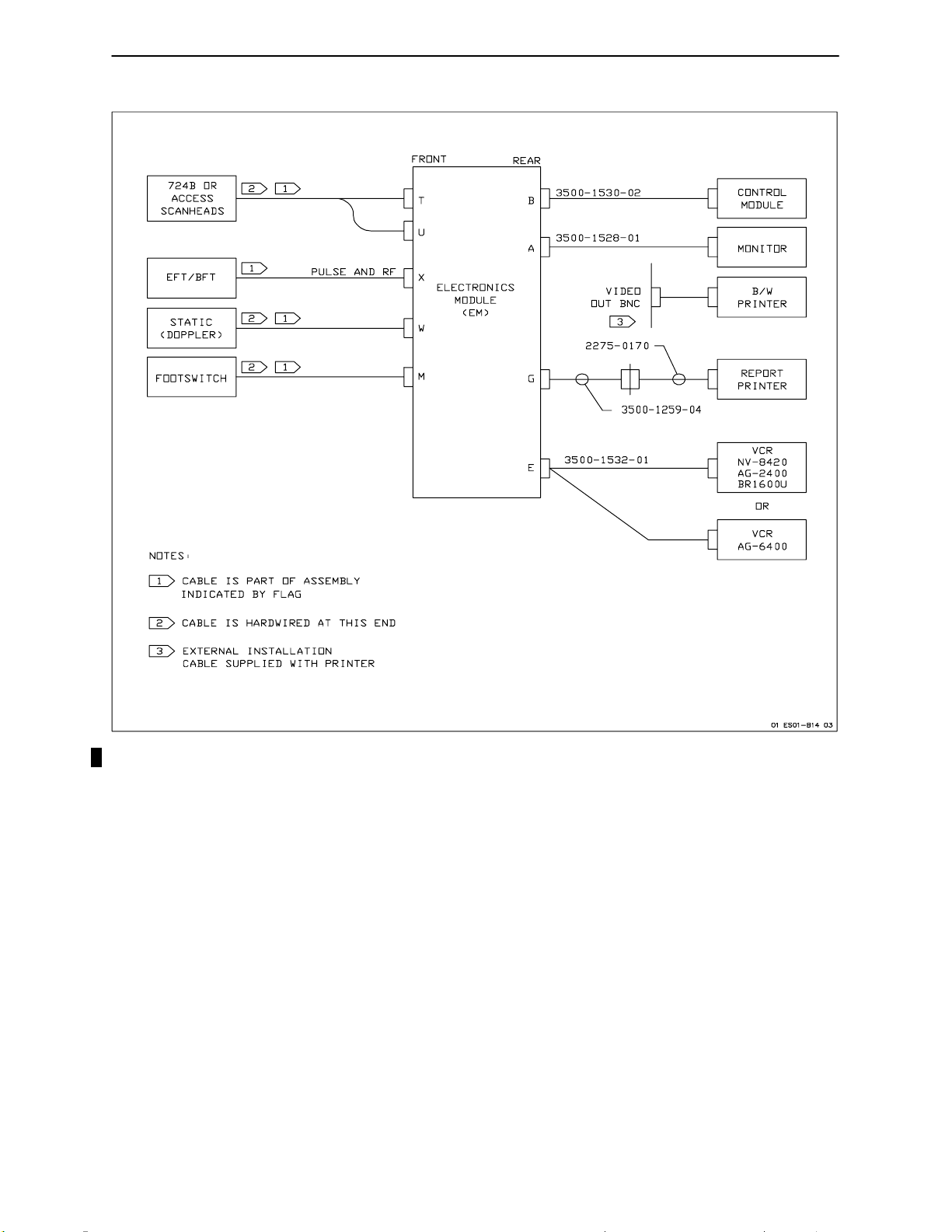

Section 1C Cabling

Figure 1C--1. EM Rear Panel Connections

Ultramark 4 Field Service Manual

UM4--01C--1

1C Cabling

UM4--01C--2

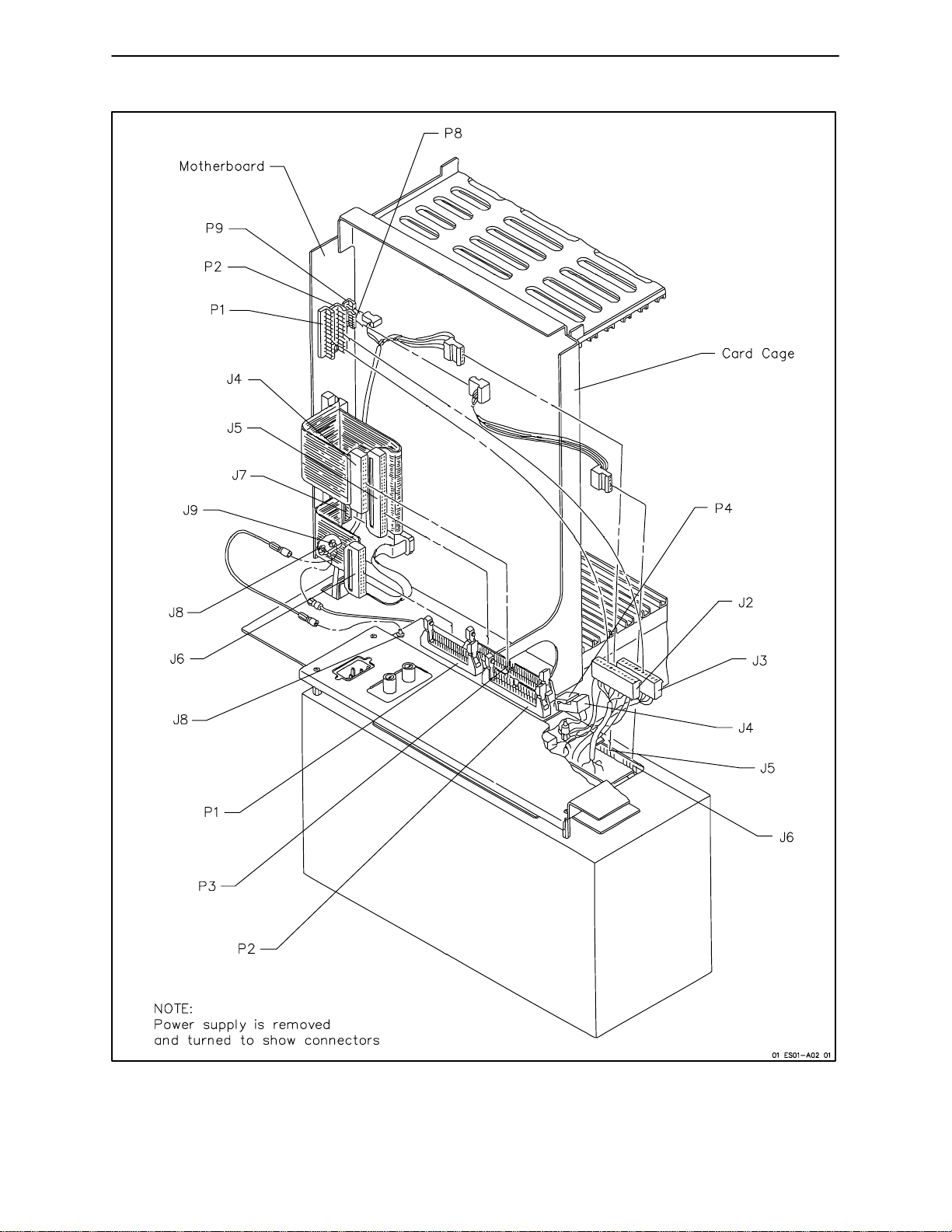

Figure 1C--2. Power Module Connections

Ultramark 4 Field Service Manual

ECG LEADS

LINEAR

DFT

ANNULAR

ARRAY

FRONT

1

2

1

2

1

N

R

S

REAR

A

B

C

2275-0064

2251-0004

2275-0057

8

3

4

4

2275-0102-00

BULKHEAD

1

2275-0101

2251-0003

2275-0057

2275-0122

2

MONITOR

CONTROL

MODULE

LS-8

LINESCAN

RECORDER

724B OR

ACCESS

SCANHEADS

EFT/BFT

STATIC

(DOPPLER)

FOOTSWITCH

NOTES:

1

2

3

4

5

6

7

8

9

2

1

1

2

1

12

CABLE IS PART OF ASSEMBLY

INDICATED BY FLAG

CABLE IS HARDWIRED AT THIS FLAG

ONLY ONE OF THE CABLES

SHOWN MAY BE CONNECTED

TO THIS CONNECTOR

TWO CABLES ARE CONNECTED IN

OEM TO ALLOW SEPARATION OF

NEWER HUMAN FACTORS

MODULE FROM EM

ATTENUATOR CABLE REQUIRED

WITH -04 AND -05 A/V MODULE

PART NUMBER SPECIFIES PANEL

AND CABLE

EITHER DATA COMM OR CAD;

EITHER PHOTO MODULE OR CAD

CABLE SELECTION DEPENDS ON

HF MODULE DASH LEVEL

SEE PARTS, TABLE 8-11

PULSE AND RF

T

U

X

W

M

ELECTRONICS

MODULE

(EM)

D

E

F

G

3500-1259-04

2275-0103

3

2275-0106

2275-0090

3500-0465-01

3500-0915-01

PRINTER

INTERFACE

2275-0092

3

RS232

3500-4036-01

BULKHEAD

AUX VIDEO

PRINTER

2275-0126

D

AUDIO

EO1

EO2

E

F

7

VIDEO

(A/V)

MODULE

VIDEO COPY

INTERFACE

3500-0944-01

PHOTO

MODULE

DATA

COMM

MODULE

CAD

MODULE

G

I

J

2275-0228-01

2275-0088

3

H

22

K

L

3

AUX VIDEO

9

2275-0173

3500-0515

3500-0610

3500-0700-02

3

6

3500-0700-02

3500-4037-01

2275-0176

2275-0129

2275-0170

(ALT 3500-059 2)

2275-0222-02

2275-0109

2275-0121

3500-0623-01

3500-0613

2275-0125

3500-0491

2250-0223

5

2250-0222

5

2250-0223

5

3500-0723-02

VGR 4000

PAGE

PRINTER

MATRIX

1010

LENZAR 2100

MULTI-IMAGE

CAMERA

VIDEO

OUTPUT

DOPPLER

SPEAKERS AND

AMPS

GENERIC

VCR PANEL

MONO DOM

VCR

NV-8420

STEREO DOM

VCR

VR 40A

MONO INTL

VCR

(NV-180 EG)

STEREO VCR,DOM

AG6400,

AG-7400

SMALL

PRINTER

(TP-10)

LARGE

PRINTER

(182 or 320)

PAR. PRINTER

(182 or 320)

HAND

CONTROLLER

VCR

AG 2400

STEREO VCR

(INT)

AG 6200 (INT)

AG 6300 (DOM)

VIDEO GRAPHICS

PRINTER

YP-1810/UP- 850

UP860/UP870

VIDEO COPY

PROCESSOR

P60U

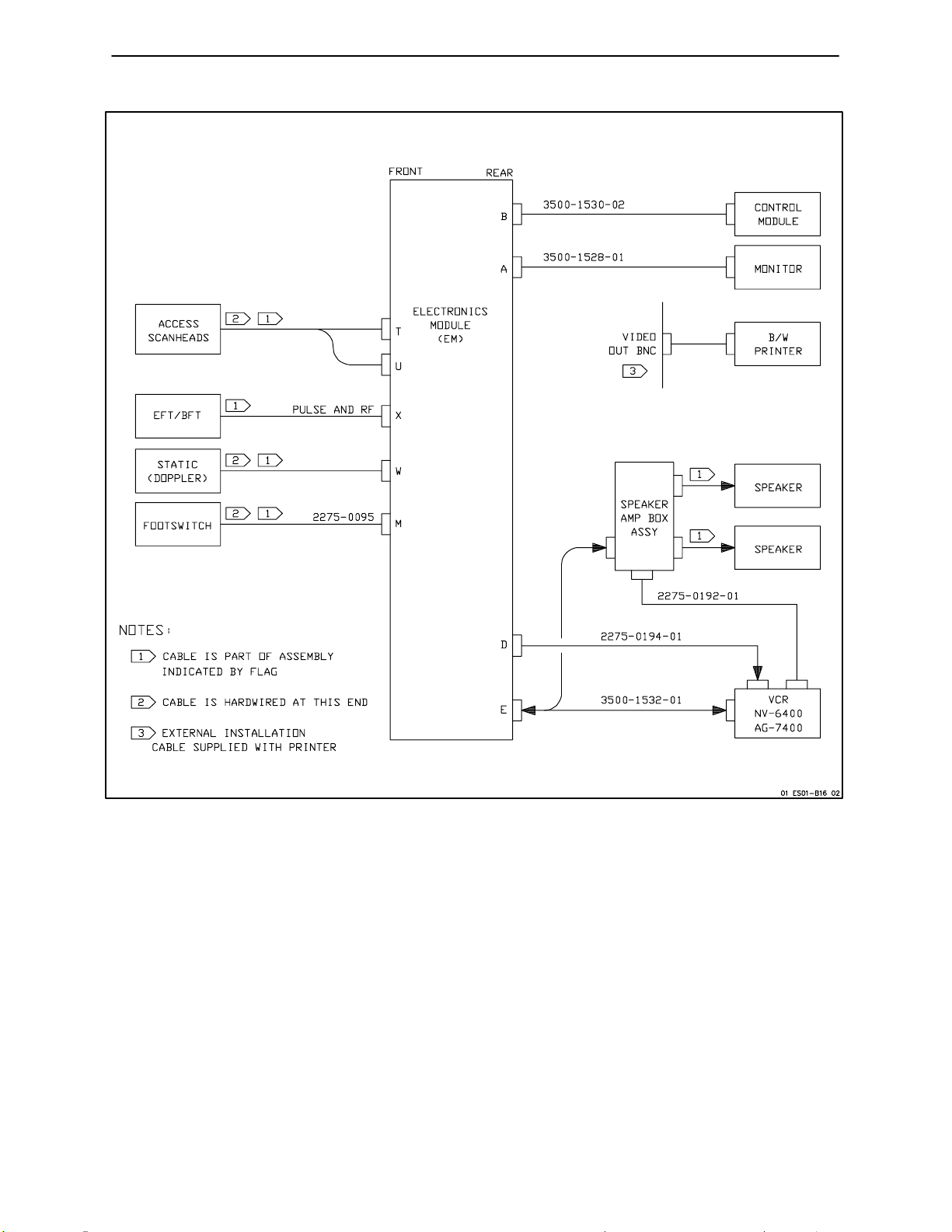

01 ES01-B13 04

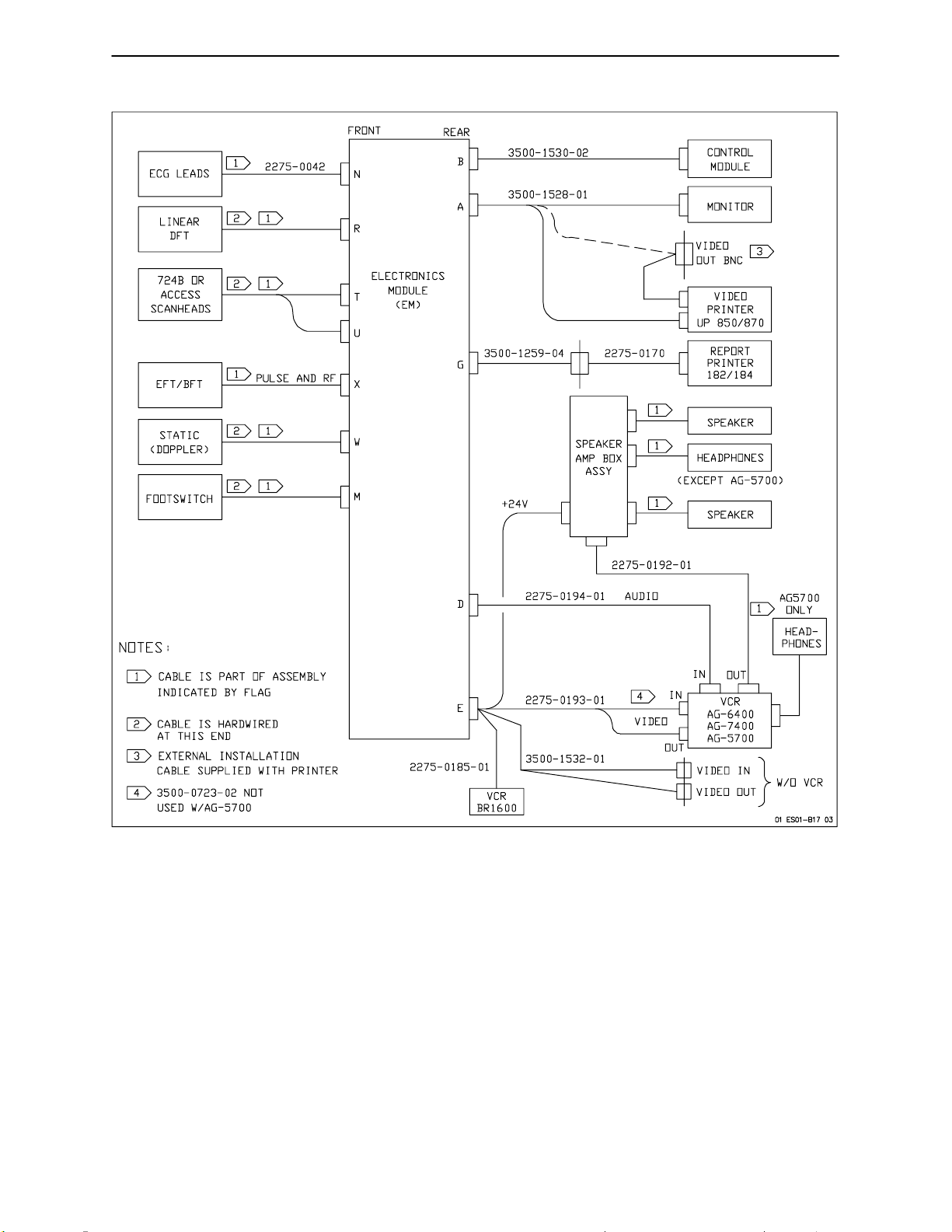

Figure 1C-3. UM-4 Human Factors Cart (HFC) Cabling Diagram

Ultramark 4 Field Service Manual UM4-01C-3Ultramark 4 Field Service Manual

1C Cabling

UM4--01C--4

Figure 1C--4. UM-4A (OB) Cabling Diagram

Ultramark 4 Field Service Manual

1CCabling

Ultramark 4 Field Service Manual

Figure 1C--5. UM-4CV Cabling Diagram

UM4--01C--5

1C Cabling

UM4--01C--6

Figure 1C--6. UM-4PV Cabling Diagram

Ultramark 4 Field Service Manual

1CCabling

Figure 1C--7. UM-4A (Full Feature) and 4A

Ultramark 4 Field Service Manual

PLUS

Cabling Diagram

UM4--01C--7

Section 2A Pre-Installation Requirements

2A--1 Introduction

The purpose of this evaluation is to ensure

a trouble-free installation and to assist the

customer in providing an environment that

supports the reliable performance o f an

ATL ultrasound system. This document is

intended to guide you through a comprehensive inspection that ensures all physical, electrical and environmental

conditions are appropriate for optimum

system operation.

NOTE:

Some parts of this section include

policies, equipment requirements, and

procedures that may apply only to U.S.

field use. For dealers, affiliates, or other

authorized service personnel who do not

use the domesticU.S. servicedocuments,

use your equivalent document, where

applicable.

NOTE:

CID should be presented to, and

reviewed with, the primary service contact and made accessible to both the

equipment user and the CSR.

In addition, system specifications

(

Ta b l e 2 A -- 1

) are included at the end of

this section to assist in evaluating the site.

2A--2 Required Materials

Tool Kit

x

DVM

x

Oscilloscope

x

ONEAC Line Viewer

x

Three-pronged Outlet Tester

x

Measuring Tape

x

ATL General Service Manual

x

(4720-0219-01)

ATL Power Primer (4760-0215-XX)

x

Power Line Data Sticker (4765-0247-XX)

x

Site Evaluation FSR (4765-0298-XX)

x

x

Installation Planning Manual

(4765-0001-XX)

Two documents are used exclusively with

the site evaluation program.

x

A comprehensive Site Evaluation FSR is

used to accurately record and document

all pertinent customer information as

well as the actual site findings. It accommodates evaluating two sites.

x

The Customer Information Directory

(CID) is a resource document that

enables the customer to more easily

communicate with ATL. It also serves as

a convenient file for keeping FSRs, MAs

and other pertinent documentation. The

Ultramark 4 Field Service Manual

2A--3 Initial Customer Contact

In notifying you of a pending new system

delivery, the Customer Support Center

(CSC) will give you as much lead-time as

possible. Although it is our goal to perform

an on-site inspection thirty days or more

prior to system installation, it is not always

possible. For those accounts in which

travel is excessive or costly, or in the event

that you are given less than three weeks

notice before system delivery, exercise

good judgement in determining if you will

do a site evaluation prior to installation. In

either case, conduct some of the site eval-

UM4--02A--1

Loading...

Loading...