Page 1

SERVICE STATION MANUAL

894159

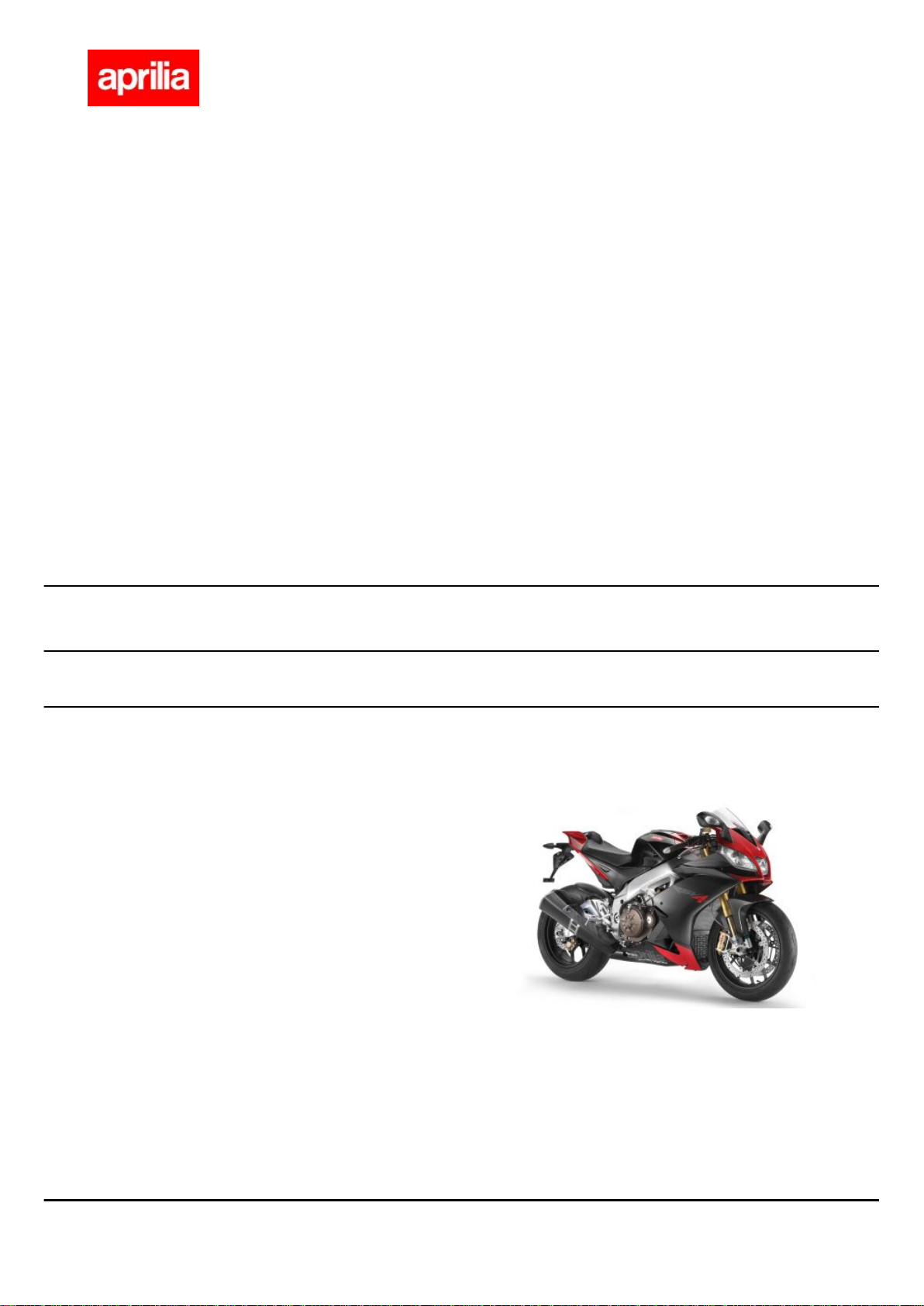

RSV4 Factory

Page 2

SERVICE STATION

MANUAL

RSV4 Factory

THE VALUE OF SERVICE

Due to the continuous technical updates and specific mechanic training programs for aprilia products,

only aprilia Official Network mechanics know this vehicle fully and have the special tools necessary to

carry out maintenance and repair operations correctly.

The reliability of the vehicle also depends on its mechanical state. Checking the vehicle before riding, its

regular maintenance and using only Original aprilia Spare Parts are essential!

For information about the nearest Official Dealer and/or Service Centre, consult the Yellow Pages or

search directly from the map on our Official Website:

www.aprilia.com

Only by requesting aprilia Original Spare Parts can you be sure of purchasing products that were

developed and tested together with the actual vehicle itself. All aprilia Original Spare Parts undergo

quality control procedures to guarantee reliability and durability.

The descriptions and illustrations given in this publication are not binding; While the basic characteristics

as described and illustrated in this booklet remain unchanged, aprilia reserves the right, at any time and

without being required to update this publication beforehand, to make any changes to components, parts

or accessories, which it considers necessary to improve the product or which are required for

manufacturing or construction reasons.

Not all versions/models shown in this publication are available in all Countries. The availability of

individual versions/models should be confirmed with the official aprilia sales network.

© Copyright 2009 aprilia. All rights reserved. Reproduction of this publication in whole or in part is

prohibited. aprilia - After-sales service.

Aprilia trademark is property of Piaggio & C. S.p.A.

Page 3

SERVICE STATION MANUAL

RSV4 Factory

- This manual provides the main information to carry out regular maintenance operations on your vehicle.

- This manual is intended to aprilia Dealers and their qualified mechanics; several concepts have been

deliberately omitted as they are considered unnecessary. As it is not possible to include complete

mechanical notions in this manual, users should have basic mechanical knowledge or minimum

knowledge about the procedures involved when repairing scooters. Without this knowledge, repairing or

checking the vehicle may be inefficient or even dangerous. As the vehicle repair and check procedures

are not described in detail, be extremely cautious so as not to damage components or injure individuals.

In order to optimise customer satisfaction when using our vehicles, aprilia s.p.a. commits itself to

continually improve its products and the relative documentation. The main technical modifications and

changes in repair procedures are communicated to all aprilia Sales Outlets and its International

Subsidiaries. These changes will be introduced in the subsequent editions of the manual. In case of need

or further queries on repair and check procedures, consult aprilia CUSTOMER DEPARTMENT, which

will be prepared to provide any information on the subject and any further communications on updates

and technical changes related to the vehicle.

NOTE Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

Page 4

Page 5

INDEX OF TOPICS

CHARACTERISTICS CHAR

SPECIAL TOOLS S-TOOLS

MAINTENANCE MAIN

TROUBLESHOOTING TROUBL

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

POWER SUPPLY P SUPP

SUSPENSIONS SUSP

CHASSIS CHAS

BRAKING SYSTEM BRAK SYS

COOLING SYSTEM COOL SYS

BODYWORK BODYW

PRE-DELIVERY PRE DE

Page 6

INDEX OF TOPICS

CHARACTERISTICS CHAR

Page 7

RSV4 Factory Characteristics

Rules

Safety rules

Carbon monoxide

If you need to keep the engine running while working on the vehicle, please ensure that you do so in

an open or very well ventilated area. Never run the engine in an enclosed area. If you do work in an

enclosed area, make sure to use a fume extraction system.

CAUTION

EXHAUST EMISSIONS CONTAIN CARBON MONOXIDE, A POISONOUS GAS WHICH CAN CAUSE

LOSS OF CONSCIOUSNESS AND EVEN DEATH.

Fuel

CAUTION

THE FUEL USED TO POWER INTERNAL COMBUSTION ENGINES IS HIGHLY FLAMMABLE AND

MAY BE EXPLOSIVE UNDER CERTAIN CONDITIONS. IT IS THEREFORE RECOMMENDED TO

CARRY OUT REFUELLING AND MAINTENANCE PROCEDURES IN A VENTILATED AREA WITH

THE ENGINE SWITCHED OFF. DO NOT SMOKE DURING REFUELLING OR NEAR FUEL VAPOUR.

AVOID ANY CONTACT WITH NAKED FLAME, SPARKS OR OTHER HEAT SOURCES WHICH MAY

CAUSE IGNITION OR EXPLOSION.

DO NOT ALLOW FUEL TO DISPERSE INTO THE ENVIRONMENT.

KEEP OUT OF REACH OF CHILDREN

Hot components

The engine and the exhaust system components become very hot and remain hot for some time after

the engine has been switched off. When handling these components, wear insulating gloves or wait

until the engine and the exhaust system have cooled down.

Coolant

The coolant contains ethylene glycol which, under certain conditions, can become flammable.

When it burns, ethylene glycol produces an invisible flame which however can cause burns.

CAUTION

TAKE CARE NOT TO SPILL COOLANT ONTO HOT ENGINE OR EXHAUST SYSTEM COMPONENTS; THE FLUID MAY IGNITE AND BURN WITH AN INVISIBLE FLAME. WHEN CARRYING

OUT MAINTENANCE, IT IS ADVISABLE TO WEAR LATEX GLOVES. EVEN THOUGH IT IS TOXIC,

COOLANT HAS A SWEET FLAVOUR WHICH MAKES IT VERY ATTRACTIVE TO ANIMALS. NEVER LEAVE THE COOLANT IN OPEN CONTAINERS IN AREAS ACCESSIBLE TO ANIMALS AS

THEY MAY DRINK IT.

CHAR - 7

Page 8

Characteristics RSV4 Factory

KEEP OUT OF REACH OF CHILDREN

DO NOT REMOVE THE RADIATOR CAP WHEN THE ENGINE IS STILL HOT. THE COOLANT IS

PRESSURISED AND MAY CAUSE SCALDING.

Used engine oil and transmission oil

CAUTION

IT IS ADVISABLE TO WEAR LATEX GLOVES WHEN SERVICING THE VEHICLE.

THE ENGINE OR GEARBOX OIL MAY CAUSE SERIOUS INJURIES TO THE SKIN IF HANDLED

FOR PROLONGED PERIODS OF TIME AND ON A REGULAR BASIS.

WASH YOUR HANDS CAREFULLY AFTER HANDLING OIL.

HAND THE OIL OVER TO OR HAVE IT COLLECTED BY THE NEAREST USED OIL RECYCLING

COMPANY OR THE SUPPLIER.

DO NOT DISPOSE OF OIL IN THE ENVIRONMENT

KEEP OUT OF REACH OF CHILDREN

THE BRAKE FLUID MAY DAMAGE PAINTED, PVC OR RUBBER SURFACES. WHEN SERVICING

THE BRAKING SYSTEM, PROTECT THESE COMPONENTS WITH A CLEAN CLOTH. ALWAYS

WEAR PROTECTIVE GOGGLES WHEN SERVICING THE BRAKING SYSTEM. THE BRAKE FLUID

IS EXTREMELY DANGEROUS TO THE EYES. IN THE EVENT OF ACCIDENTAL CONTACT WITH

THE EYES, RINSE THEM IMMEDIATELY WITH PLENTY OF COLD, CLEAN WATER AND SEEK

MEDICAL ADVICE.

KEEP OUT OF REACH OF CHILDREN

Battery electrolyte and hydrogen gas

CAUTION

THE BATTERY ELECTROLYTE IS TOXIC, CORROSIVE AND, AS IT CONTAINS SULPHURIC

ACID, MAY CAUSE BURNING IF IT COMES INTO CONTACT WITH THE SKIN. WHEN HANDLING

BATTERY ELECTROLYTE, WEAR TIGHT-FITTING GLOVES AND PROTECTIVE APPAREL. IN

THE EVENT OF SKIN CONTACT WITH THE ELECTROLYTIC FLUID, RINSE WELL WITH PLENTY

OF CLEAN WATER. IT IS PARTICULARLY IMPORTANT TO PROTECT YOUR EYES BECAUSE

EVEN TINY AMOUNTS OF BATTERY ACID MAY CAUSE BLINDNESS. IN THE EVENT OF CONTACT WITH THE EYES, RINSE WITH PLENTY OF WATER FOR FIFTEEN MINUTES AND CONSULT AN EYE SPECIALIST IMMEDIATELY. IF THE FLUID IS ACCIDENTALLY SWALLOWED,

DRINK LARGE QUANTITIES OF WATER OR MILK, FOLLOWED BY MILK OF MAGNESIA OR

VEGETABLE OIL AND SEEK MEDICAL ADVICE IMMEDIATELY. THE BATTERY RELEASES EXPLOSIVE GASES; KEEP IT AWAY FROM FLAMES, SPARKS, CIGARETTES OR ANY OTHER

HEAT SOURCES. ENSURE ADEQUATE VENTILATION WHEN SERVICING OR RECHARGING

THE BATTERY.

KEEP OUT OF REACH OF CHILDREN

BATTERY LIQUID IS CORROSIVE. DO NOT POUR OR SPILL ON PLASTIC COMPONENTS IN

PARTICULAR. ENSURE THAT THE ELECTROLYTIC ACID IS COMPATIBLE WITH THE BATTERY

BEING ACTIVATED.

Maintenance rules

GENERAL PRECAUTIONS AND INFORMATION

CHAR - 8

Page 9

RSV4 Factory Characteristics

When repairing, dismantling and reassembling the vehicle, follow the recommendations given below

carefully.

BEFORE REMOVING COMPONENTS

•

Before dismantling components, remove dirt, mud, dust and foreign bodies from the vehicle.

Use the special tools designed for this bike, as required.

COMPONENTS REMOVAL

•

Do not loosen and/or tighten screws and nuts using pliers or any other tools than the specific

wrench.

•

Mark positions on all connection joints (pipes, cables etc.) before separating them, and

identify them with distinctive symbols.

•

Each component needs to be clearly marked to enable identification during reassembly.

•

Clean and wash the dismantled components carefully using a low-flammability detergent.

•

Keep mated parts together since they have "adjusted" to each other due to normal wear.

•

Some components must be used together or replaced completely.

•

Keep away from heat sources.

REASSEMBLING COMPONENTS

CAUTION

BEARINGS MUST ROTATE FREELY, WITHOUT JAMMING AND/OR NOISE, OTHERWISE, THEY

NEED TO BE REPLACED.

•

Only use ORIGINAL aprilia SPARE PARTS.

•

Comply with lubricant and consumables use guidelines.

•

Lubricate parts (whenever possible) before reassembling them.

•

When tightening nuts and screws, start either from the components with the largest diameter

or from the innermost components, proceeding diagonally. Tighten nuts and screws in successive steps before applying the tightening torque.

•

Always replace self-locking nuts, washers, sealing rings, circlips, O-rings (OR), split pins

and screws with new parts if the thread is damaged.

•

When assembling the bearings, make sure to lubricate them well.

•

Check that each component is assembled correctly.

•

After a repair or routine maintenance, carry out pre-ride checks and test the vehicle on

private grounds or in an area with low traffic.

•

Clean all mating surfaces, oil seal rims and gaskets before refitting. Smear a thin layer of

lithium-based grease on the oil seal rims. Reassemble oil seals and bearings with the brand

or batch number facing outward (visible side).

ELECTRIC CONNECTORS

Electric connectors must be disconnected as described below; failure to comply with this procedure

causes irreparable damage to both the connector and the wiring harness:

Press the relative safety clips, if applicable.

CHAR - 9

Page 10

Characteristics RSV4 Factory

•

Grip the two connectors and disconnect them by pulling them in opposite directions.

•

If any signs of dirt, rust, moisture, etc. are noted, clean the inside of the connector carefully

with a jet of compressed air.

•

Ensure that the cables are correctly fastened to the internal connector terminals.

•

Then connect the two connectors, ensuring that they couple correctly (if fitted with clips, you

will hear them "click" into place).

CAUTION

DO NOT DISCONNECT CONNECTORS BY PULLING THE CABLES.

NOTE

THE TWO CONNECTORS CAN ONLY BE CONNECTED IN ONE DIRECTION: CONNECT THEM

THE RIGHT WAY ROUND.

TIGHTENING TORQUES

CAUTION

REMEMBER THAT THE TIGHTENING TORQUES FOR ALL FASTENING ELEMENTS ON WHEELS,

BRAKES, WHEEL BOLTS AND ANY OTHER SUSPENSION COMPONENTS PLAY A KEY ROLE

IN ENSURING VEHICLE SAFETY AND MUST COMPLY WITH SPECIFIED VALUES. CHECK THE

TIGHTENING TORQUES OF FASTENING ELEMENTS ON A REGULAR BASIS AND ALWAYS USE

A TORQUE WRENCH TO REASSEMBLE THESE COMPONENTS. FAILURE TO COMPLY WITH

THESE RECOMMENDATIONS MAY CAUSE ONE OF THESE COMPONENTS TO LOOSEN OR

EVEN DETACH, CAUSING A WHEEL TO LOCK OR COMPROMISING VEHICLE HANDLING. THIS

MAY LEAD TO FALLS, WITH THE RISK OF SERIOUS INJURY OR DEATH.

Running-in

Running the engine in correctly is essential for ensuring engine longevity and functionality. Twisty roads

and gradients are ideal for running in the engine, brakes and suspension effectively. Vary your riding

speed during the running in period. This ensures that components operate in "loaded" conditions and

then "unloaded" conditions, allowing the engine components to cool.

CAUTION

THE FULL PERFORMANCE OF THE VEHICLE IS ONLY AVAILABLE AFTER THE SERVICE AT

THE END OF THE RUNNING IN PERIOD.

Follow the guidelines detailed below:

•

Do not fully open the throttle grip abruptly at low engine speeds, either during or after the

running in period.

•

During the first 100 Km (62 miles) use the brakes gently, avoiding sudden or prolonged

braking. This allows the brake pad friction material to bed in correctly with the brake discs.

•

Preferably do not exceed 7500 rpm during the first 1000 km (621 mi) and 9500 rpm from

1000 to 2000 km (1243 mi).

AFTER THE SPECIFIED MILEAGE, TAKE YOUR VEHICLE TO AN Official aprilia Dealer FOR THE

CHECKS INDICATED IN THE "SCHEDULED MAINTENANCE" TABLE IN THE SCHEDULED MAINTENANCE SECTION TO AVOID INJURY TO YOURSELF OR OTHERS AND /OR DAMAGING THE

VEHICLE.

CHAR - 10

Page 11

RSV4 Factory Characteristics

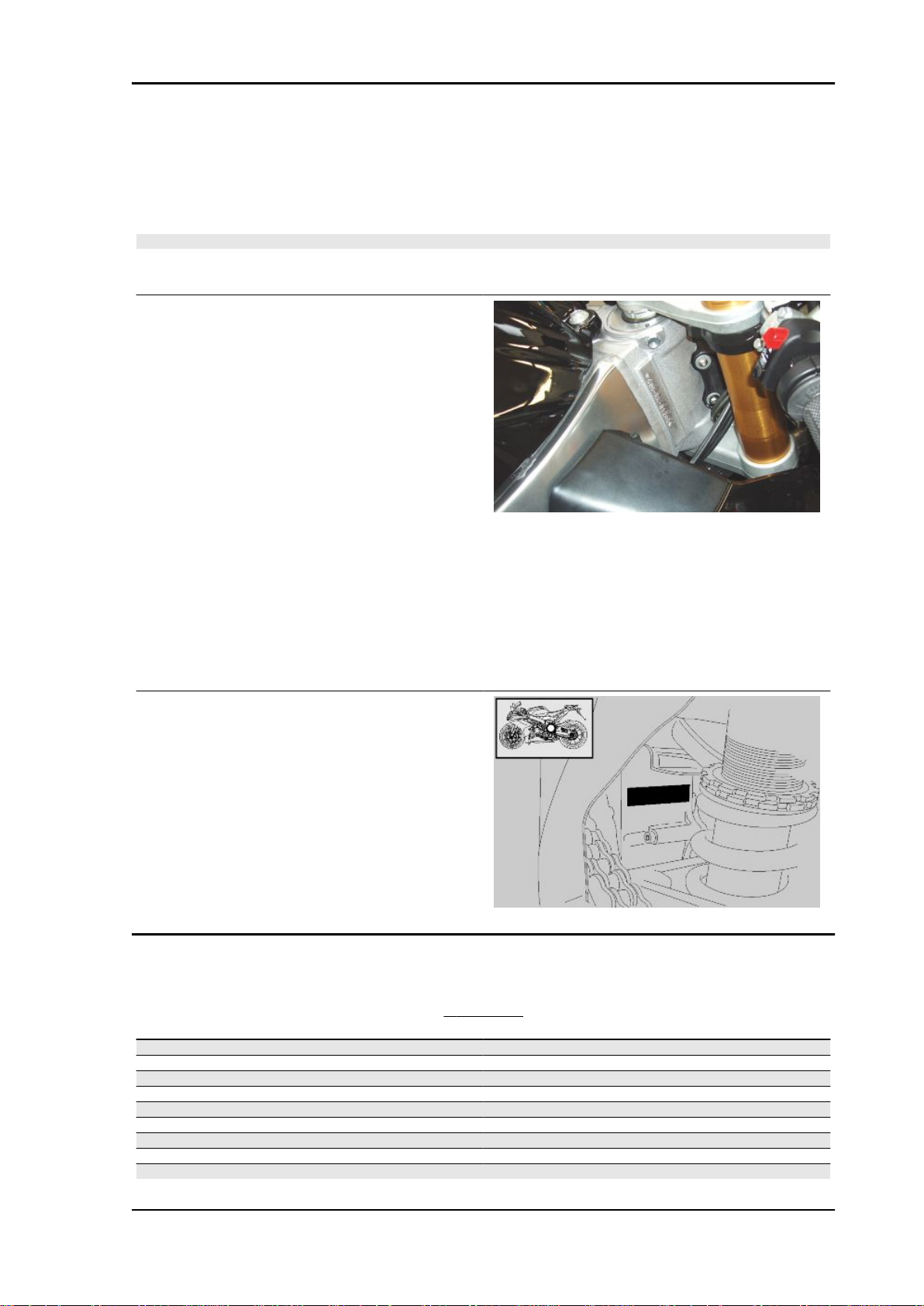

Vehicle identification

SERIAL NUMBER LOCATION

These numbers are necessary for vehicle registration.

NOTE

ALTERING IDENTIFICATION NUMBERS MAY BE SERIOUSLY PUNISHABLE BY LAW. IN PARTICULAR, MODIFYING THE CHASSIS NUMBER IMMEDIATELY VOIDS THE WARRANTY.

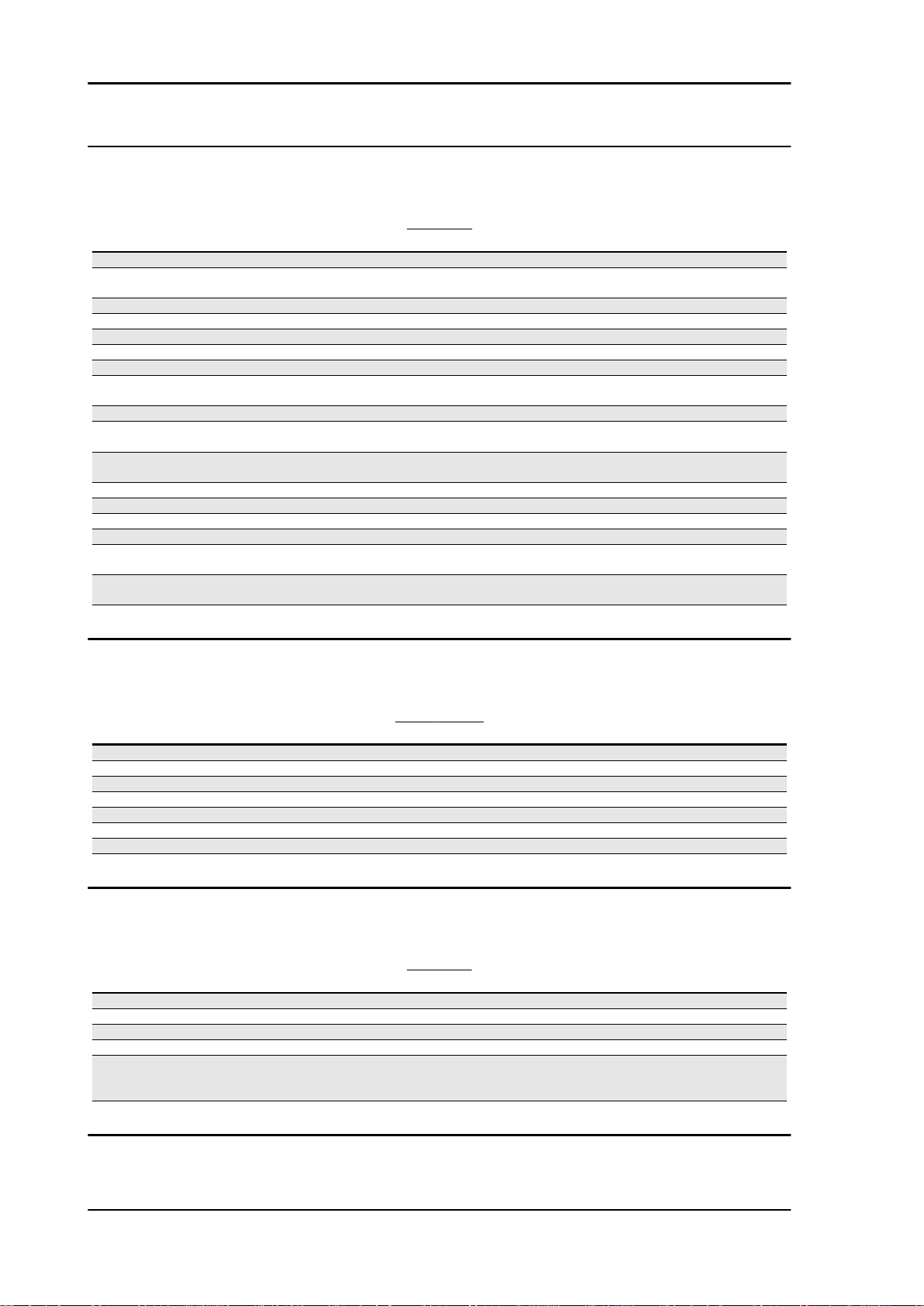

This number consists of numbers and letters, as in

the example shown below.

ZD4RK0000YSXXXXXX

KEY:

ZD4: WMI (World manufacturer identifier) code;

RK: model;

000: version variation;

0: free digit

Y year of manufacture

S: production plant (S= Scorzè);

XXXXXX: serial number (6 digits);

CHASSIS NUMBER

The chassis number is stamped on the right hand

side of the headstock.

ENGINE NUMBER

The engine number is printed on the base of the

engine crankcase, left hand side.

Engine No. ....................

Dimensions and mass

DIMENSIONS

Specification

Max. length 2040 mm (80.31 in)

Max width (at handlebar) 735 mm (28.94 in)

Max. height (to windshield) 1120 mm (44.09 in)

Saddle height 847 mm (33.35 in)

Wheelbase 1420 mm (55.90 in)

Minimum ground clearance 130 mm (5.12 in)

Kerb weight 189 kg (417 lb)

Kerb weight 200 kg (441 lb)

Full loaded weight (rider only) 275 kg (441 lb)

Desc./Quantity

CHAR - 11

Page 12

Characteristics RSV4 Factory

Engine

ENGINE

Specification Desc./Quantity

Model V4

Type 65° longitudinal V-4, 4-stroke, 4 valves per cylinder, double

Engine capacity 999 cm³ (60.96 cu.in)

Bore / stroke 78 mm / 52.26 mm (3.07 in / 2.06 in)

Compression ratio 13 : 1

Engine speed at idle 1400 ± 100 rpm

Engine revs at maximum speed 14000 ± 100 rpm

Clutch Multiplate wet clutch with mechanical control lever on left side

Ignition electronic

TIMING SYSTEM Morse chain on intake camshaft, cam to cam gear, bucket tap-

Acceptable values with control clearance between cam and

valve

Lubrication system Wet sump with oil radiator

Oil pump Dual trochoidal pump (lubrication + cooling)

Oil filter With external cartridge filter

Cooling Fluid

Cooling system 3-way thermostatic valve, cooling radiator with electric fan and

Coolant pump Centrifugal bearingless aspirating pump with integrated ce-

Air filter In cotton

of the handlebar Anti-juddering and slipper clutch systems

pets and valve clearance adjustments with calibrated pads

intake: 0.10 - 0.15 mm (0.0039 - 0.0059 in) exhaust: 0.20 - 0.25

overhead camshafts.

mm (0.0079 - 0.0098 in)

expansion tank

ramic gasket

Transmission

Capacities

Fuel capacity (reserve included) 17 l (3.74 UK gal)

Maximum weight capacity 201 kg (443 lb)

GEAR RATIOS

Specification

Primary drive ratio 44 / 73 (with gears)

1st gear ratio 15 / 39 (secondary)

2nd gear ratio 16 / 33 (secondary)

3rd gear ratio 20 / 34 (secondary)

4th gear ratio 22 / 32 (secondary)

5th gear ratio 26 / 34 (secondary)

6th gear ratio 27 / 33 (secondary)

Final drive gear ratio 16 / 40

Desc./Quantity

CAPACITY

Specification

Fuel tank reserve 3.6 l (0.79 UK gal)

Engine oil oil and filter change 4 l (0.88 UK gal)

Coolant 2.4 l (0.53 UK gal)

Seats 1 + 1

Two seat configuration: if vehicle is fitted with footrests and

Desc./Quantity

saddle for passenger

CHAR - 12

Page 13

RSV4 Factory Characteristics

Drive chain

DRIVE CHAIN

Specification Desc./Quantity

Type 525

Model Regina 108 links

Electrical system

ELECTRICAL SYSTEM

Specification Desc./Quantity

Spark plugs NGK-R CR9EB

Electrode gap 0.7 - 0.8 mm (0.027 - 0.031 in)

Battery YUASA YTZ10S, 12 V 8.6 Ah

alternatively YUASA YT12A-BS, 12 V 9.5 Ah

Coils Stick coil

Recharging system Flywheel with rare earth magnets

Alternator 420 W

Main fuses 30 A

Auxiliary fuses 5A - 7.5A - 15A

With sealed master link

NGK-R CR10E (for competition use)

Specification

Low-/ high-beam light 12V - 55W H11

Front daylight running light 12V - 5W

Turn indicators 12V - 10W (White light)

License plate light 12V - 5W

Specification

High-beam light LED

Right turn indicator LED

Left turn indicator LED

General warning LED

Gear in neutral LED

Side stand down LED

Fuel reserve LED

ABS NON ATTIVA

Frame and suspensions

Specification

Type Adjustable aluminium, dual beam chassis with pressed and

Steering inclination angle 26.5° (measurements with reference to bare chassis)

Trail 107 mm (4.21 in)

BULBS

Desc./Quantity

SPIE

Desc./Quantity

CHASSIS

Desc./Quantity

cast sheet elements.

(with adjustable inserts, headstock as a standard feature)

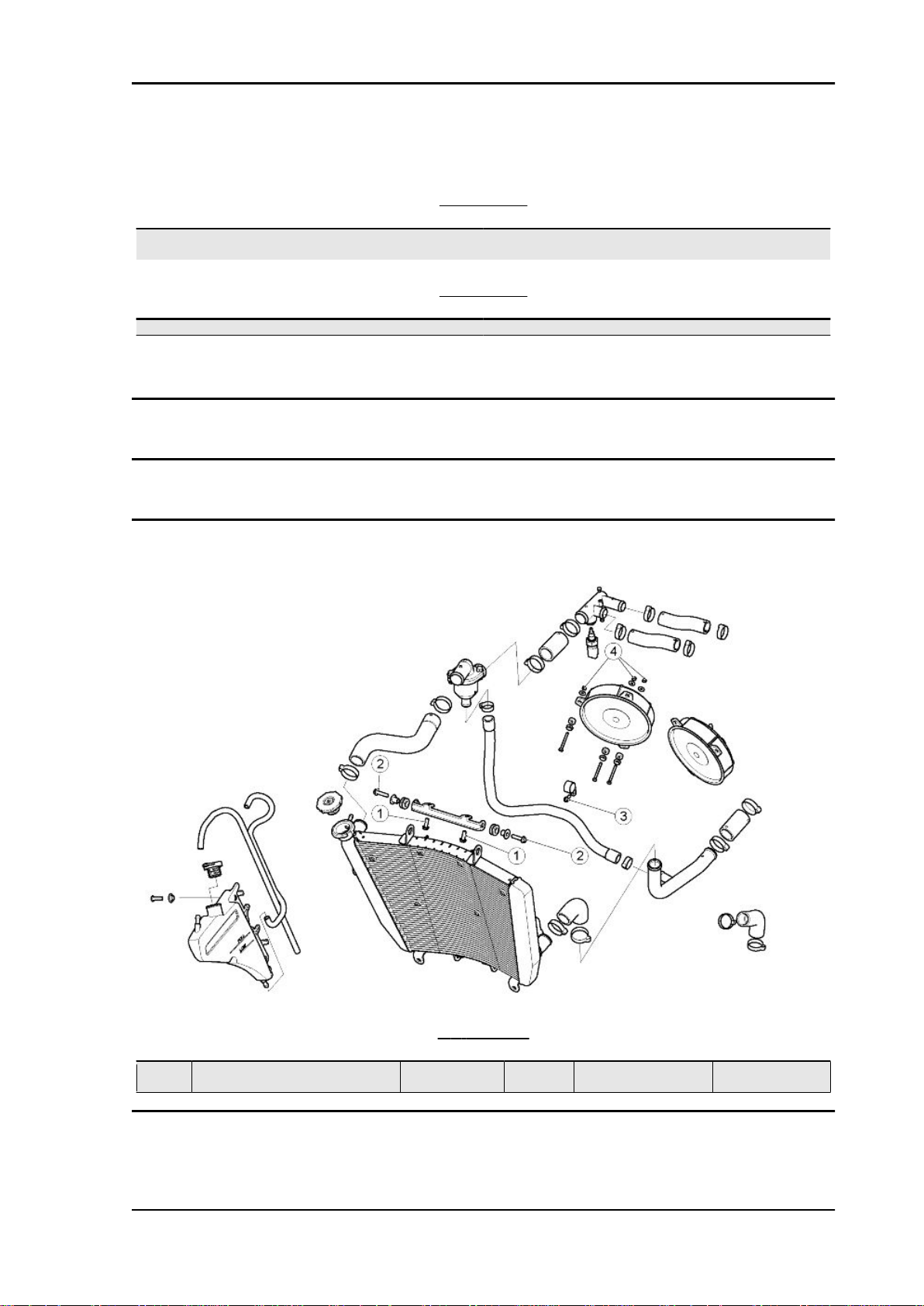

SUSPENSION

Specification

Front fork Ohlins upside down units with adjustable hydraulic damping

and 43 mm (1.69 in) diam. stanchions with Tin surface coating)

Front wheel travel 120 mm (4.72 in)

Rear shock absorber Lateral mounted hydraulic shock absorber with progressive

APS system. OHLINS shock absorbers with adjustable piggy-

Desc./Quantity

CHAR - 13

Page 14

Characteristics RSV4 Factory

Specification Desc./Quantity

back preload, centre to centre distance and hydraulic brake in

Rear wheel travel 130 mm (5.12 in)

compression and rebound damping

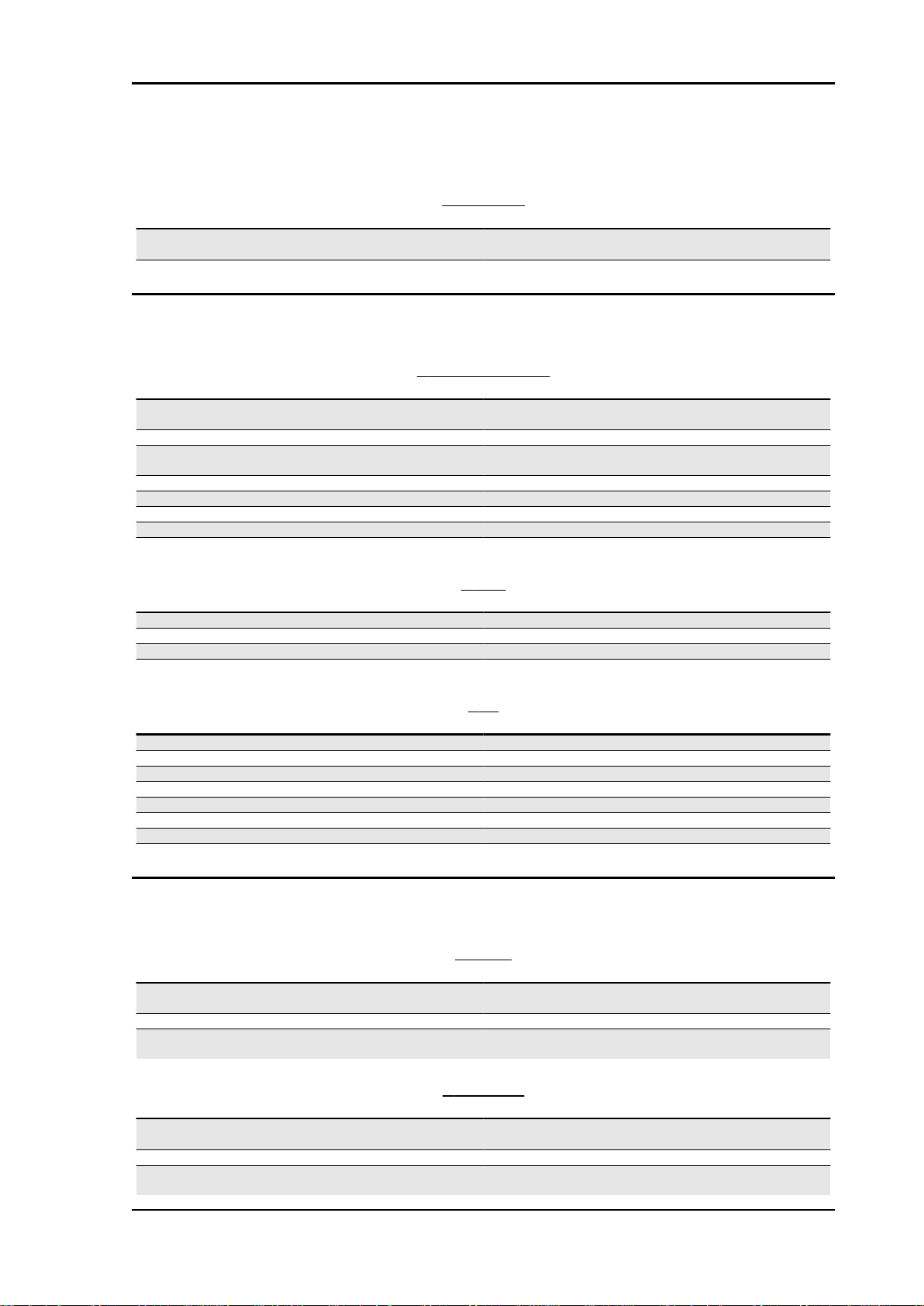

SIZES A AND B

Specification Desc./Quantity

Size "A" 639.5 mm (25.18 in) (measurements refer to the bare chassis)

Size "B" 329.5 mm (12.97 in) (measurements refer to the bare chassis)

Brakes

Specification

Wheels and tyres

Specification

Front wheel rim 3.50 x 17"

Rear wheel rim 6.00 x 17"

Specification

Tyre model Pirelli DIABLO Super Corsa SP

Front tyre 120/70 ZR17 (58W)

Inflation pressure 1 passenger: 2.3 bar (230 kPa) (33.36 PSI)

Rear tyre 190/55 ZR17 (75W)

Inflation pressure 1 passenger: 2.5 bar (250 kPa) (36.26 PSI)

BRAKES

Desc./Quantity

Front With dual floating disc 320 mm diam. (12.59 inches), enbloc

calipers with radial fixing and four pistons 34 mm diam. (1.34

inches) and 4 pads - radial pump and brake pipe in metal braid.

Rear disc type -220 mm diam. (8.66 inches), 2-piston calipers - 32

mm diam. (1.25 inches) - pump with built-in tank and metal

braid pipe.

WHEEL RIMS

Desc./Quantity

TYRES

Desc./Quantity

Metzeler RACETEC K3

Michelin Power One

Dunlop SPORTMAX GP Racer (Mixture "M" Front)

Dunlop SPORTMAX GP Racer (Mixture "E" Rear)

2 passengers: 2.5 bar (250 kPa) (36.26 PSI)

190/50 ZR17 (73W)

2 passengers: 2.8 bar (280 kPa) (40.61 PSI)

CHAR - 14

Page 15

RSV4 Factory Characteristics

Supply

FUEL SYSTEM

Specification Desc./Quantity

Fuel Premium unleaded petrol, minimum octane rating of 95

FUEL SYSTEM

Specification Desc./Quantity

Throttle body diameter 48 mm (1.89 in)

Type Electronic injection with 2 injectors per cylinder, 4 throttle bod-

ies motorised (Ride by wire). Intake cones at variable height. 2

Tightening Torques

Chassis

(NORM) and 85 (NOMM)

dynamic air intakes. Selectable multimap.

Front side

pos.

1 Screws fastening oil radiator to

Description Type Quantity Torque Notes

mounting bracket

OIL RADIATOR

M6 1 7 Nm (5.16 lbf ft) -

CHAR - 15

Page 16

Characteristics RSV4 Factory

pos.

1 Fastener screws for calliper mount-

Description Type Quantity Torque Notes

ing bracket (Öhlins)

FRONT FORK

M6 2 + 2 12 Nm (8.85 lbf ft) -

CHAR - 16

Page 17

RSV4 Factory Characteristics

STEERING

pos. Description Type Quantity Torque Notes

1 Screws fastening upper yoke to stan-

chions

2 Screws fastening lower yoke to stan-

chions

3 Headstock ring nut M35x1 1 60 Nm (44.25 lbf ft) 4 Headstock counter ring nut M35x1 1 Manual +35° or -10° 5 Upper yoke fixing cap - 1 100 Nm (73.76 lbf ft) 6 Screw fastening shock absorber to

frame

7 Screw fastening shock absorber to

lower yoke

M8 2 25 Nm (18.44 lbf ft) M8 4 25 Nm (18.44 lbf ft) -

M6 1 10 Nm (7.37 lbf ft) M6 1 10 Nm (7.37 lbf ft) -

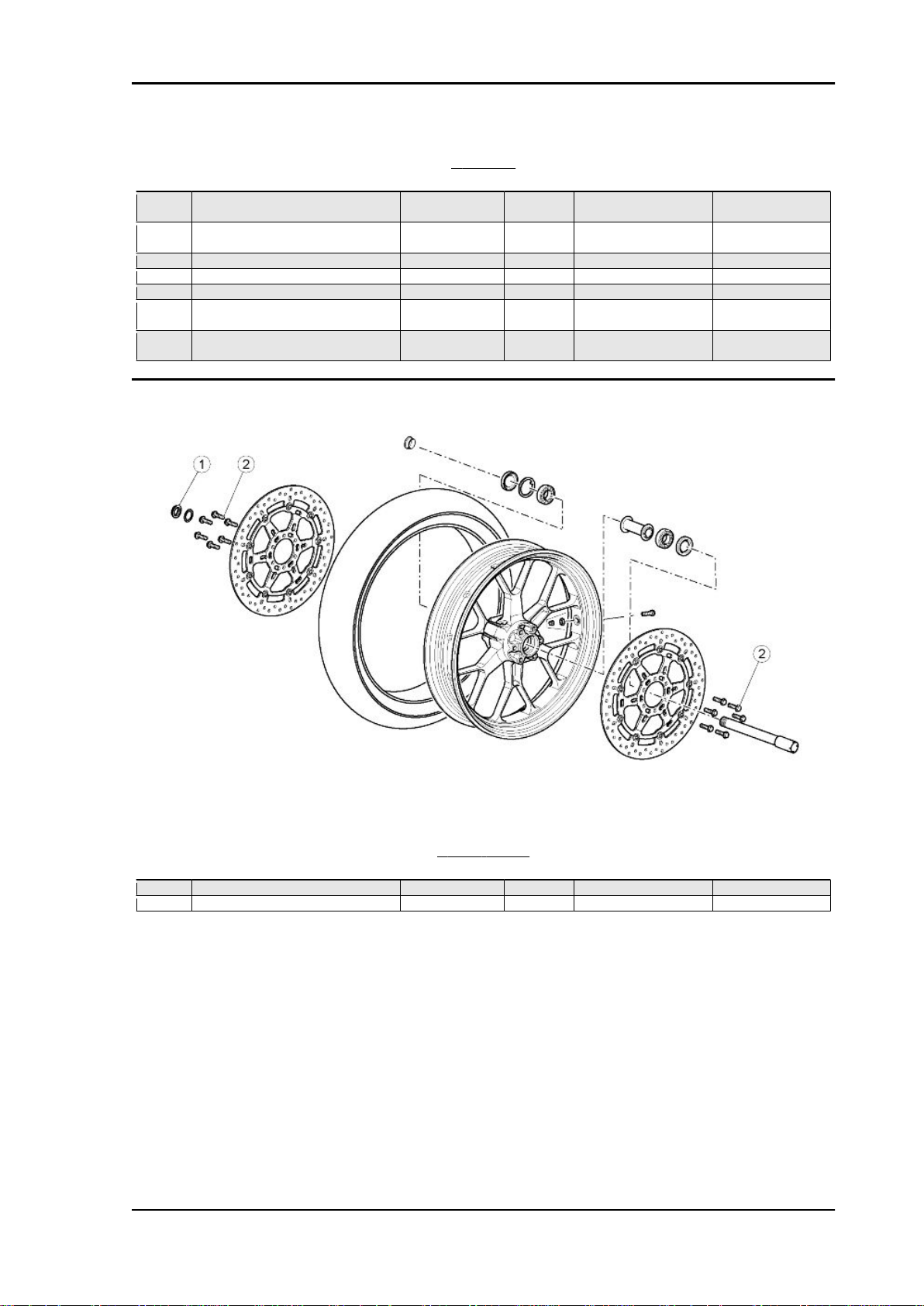

FRONT WHEEL

pos.

1 Front wheel spindle nut M25x1.5 1 80 Nm (59 lbf ft) 2 Front brake disc fixing screws M8 6 + 6 30 Nm (22.13 lbf ft) Loct. 243

Description Type Quantity Torque Notes

CHAR - 17

Page 18

Characteristics RSV4 Factory

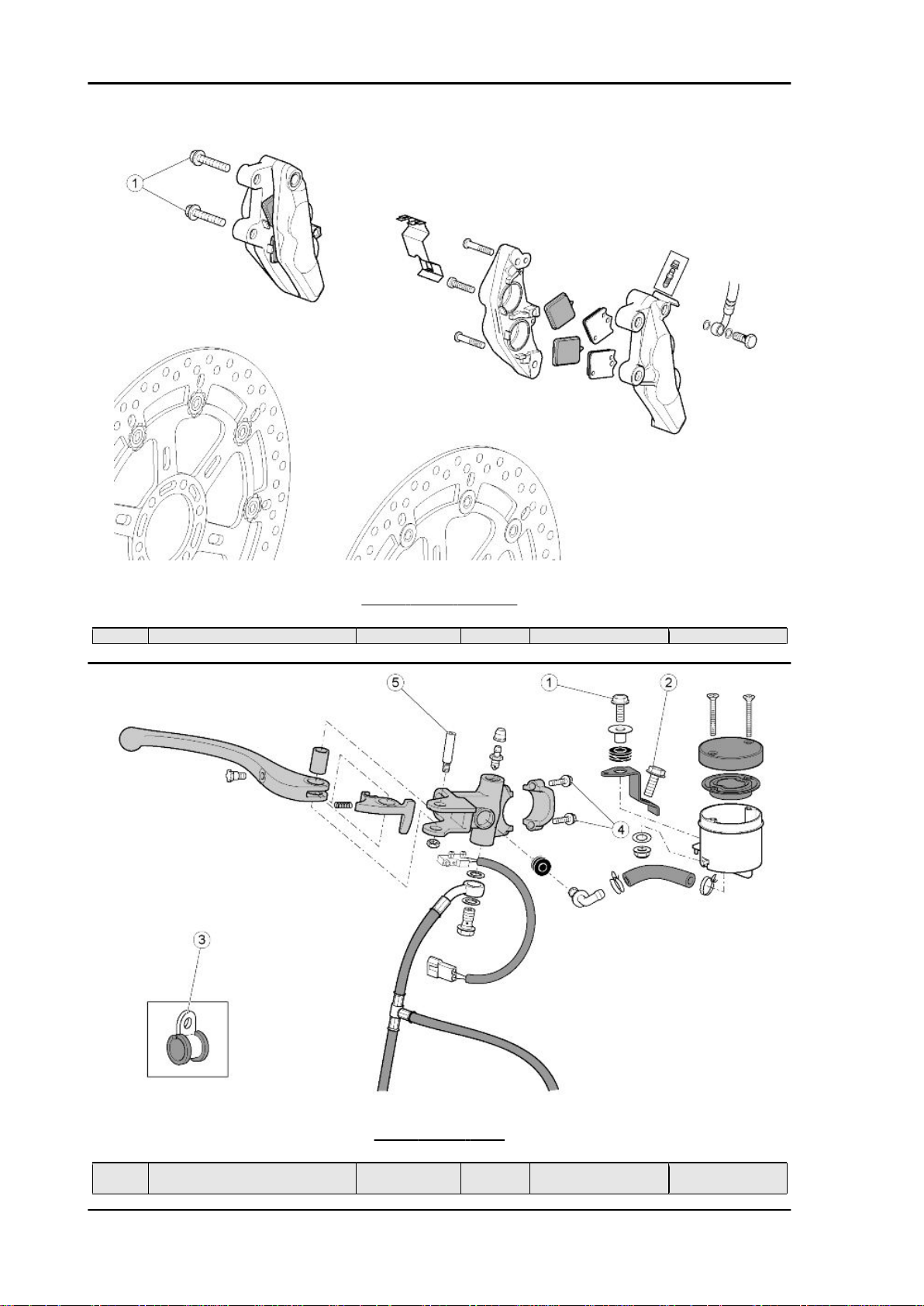

FRONT BRAKE CALLIPER

pos.

1 Front brake calliper fixing screws M10x1.25 2 + 2 50 Nm (36.88 lbf ft) -

Description Type Quantity Torque Notes

pos.

1 Screw fastening front brake fluid res-

Description Type Quantity Torque Notes

ervoir to bracket

CHAR - 18

FRONT BRAKE PUMP

M6 1 7 Nm (5.16 lbf ft) -

Page 19

RSV4 Factory Characteristics

pos. Description Type Quantity Torque Notes

2 Screw fastening brake fluid reservoir

mounting bracket to handlebar

3 Screw fastening brake pipe grommet

to the lower yoke

4 Front brake pump U bolt clamp M6 2 10 Nm (7.37 lbf ft) 5 Front brake lever pin fixing screw M6 1 10 Nm (7.37 lbf ft) -

M6 1 7 Nm (5.16 lbf ft) M5 1 8 Nm (5.9 lbf ft) -

HANDLEBAR AND CONTROLS

pos.

1 Screw fastening the semi-handlebar

2 Semi-handlebar safety screw M6 1+1 10 Nm (7.37 lbf ft) -

3 Anti-vibration counterweight fastener M18x1.5 1+1 20 Nm (14.75 lbf ft) 4 Right light switch M4 2 1.5 Nm (1.11 lbf ft) 5 Left light switch M5 2 1.5 Nm (1.11 lbf ft) 6 Throttle control fixing screws M5 2 2 Nm (1.47 lbf ft) -

Description Type Quantity Torque Notes

M8 1 + 1 25 Nm (18.44 lbf ft) -

collar to the fork sleeves

CHAR - 19

Page 20

Characteristics RSV4 Factory

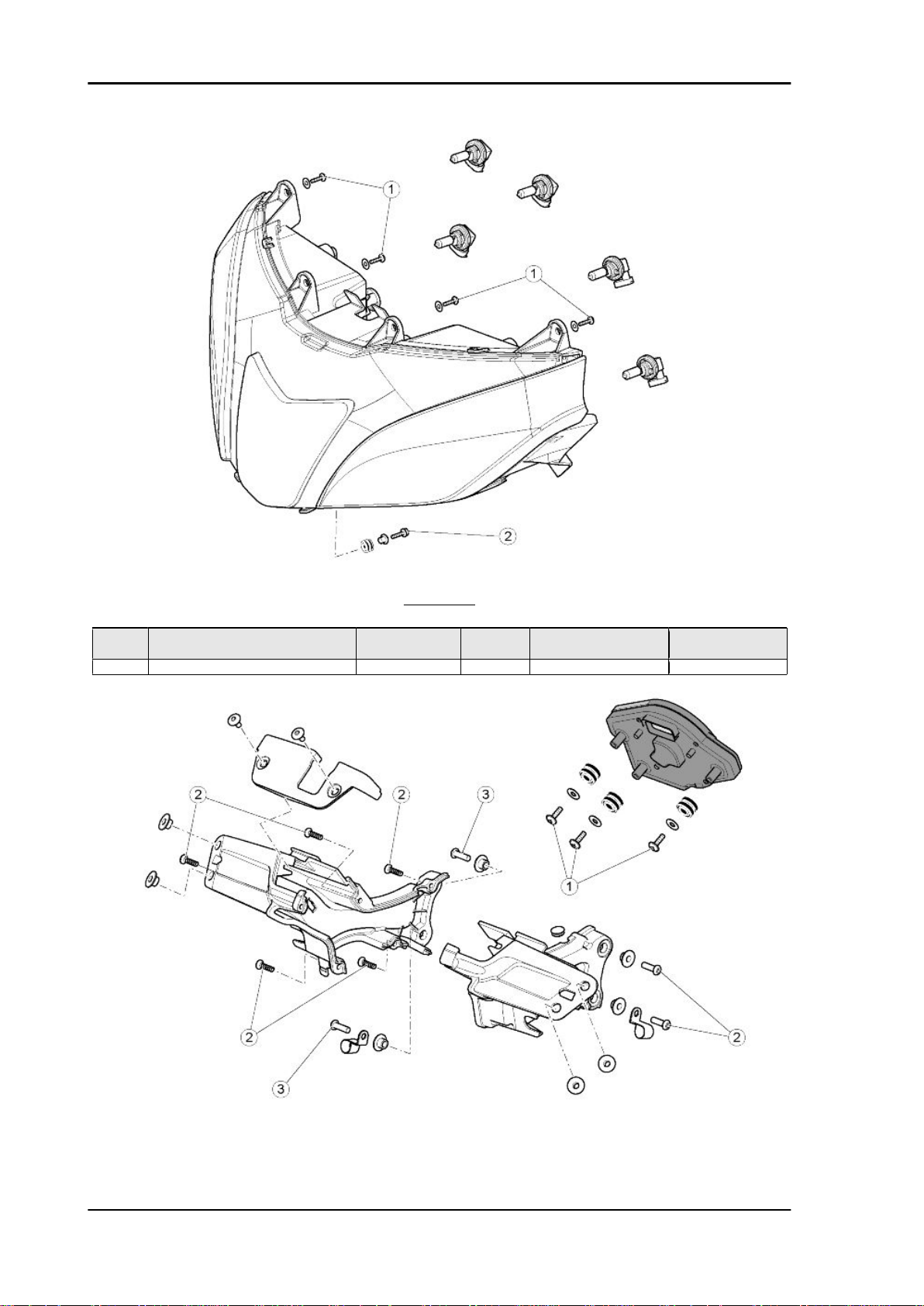

HEADLAMP

pos.

1 Screw fastening headlamp to front

2 Headlamp fixing screw M5 2 + 1 2 Nm (1.47 lbf ft) -

Description Type Quantity Torque Notes

SWP 4.9 4 2 Nm (1.47 lbf ft) -

fairing

CHAR - 20

Page 21

RSV4 Factory Characteristics

INSTRUMENT PANEL

pos. Description Type Quantity Torque Notes

1 Screws fastening the rubber rings to

the instrument panel

2 Instrument panel mounting shell fix-

ing screws

3 Screws fastening instrument panel

mounting to chassis

SWP 4.9 3 3 Nm (2.21 lbf ft) SWP 4.9 5 2 Nm (1.47 lbf ft) -

M6 4 8 Nm (5.9 lbf ft) -

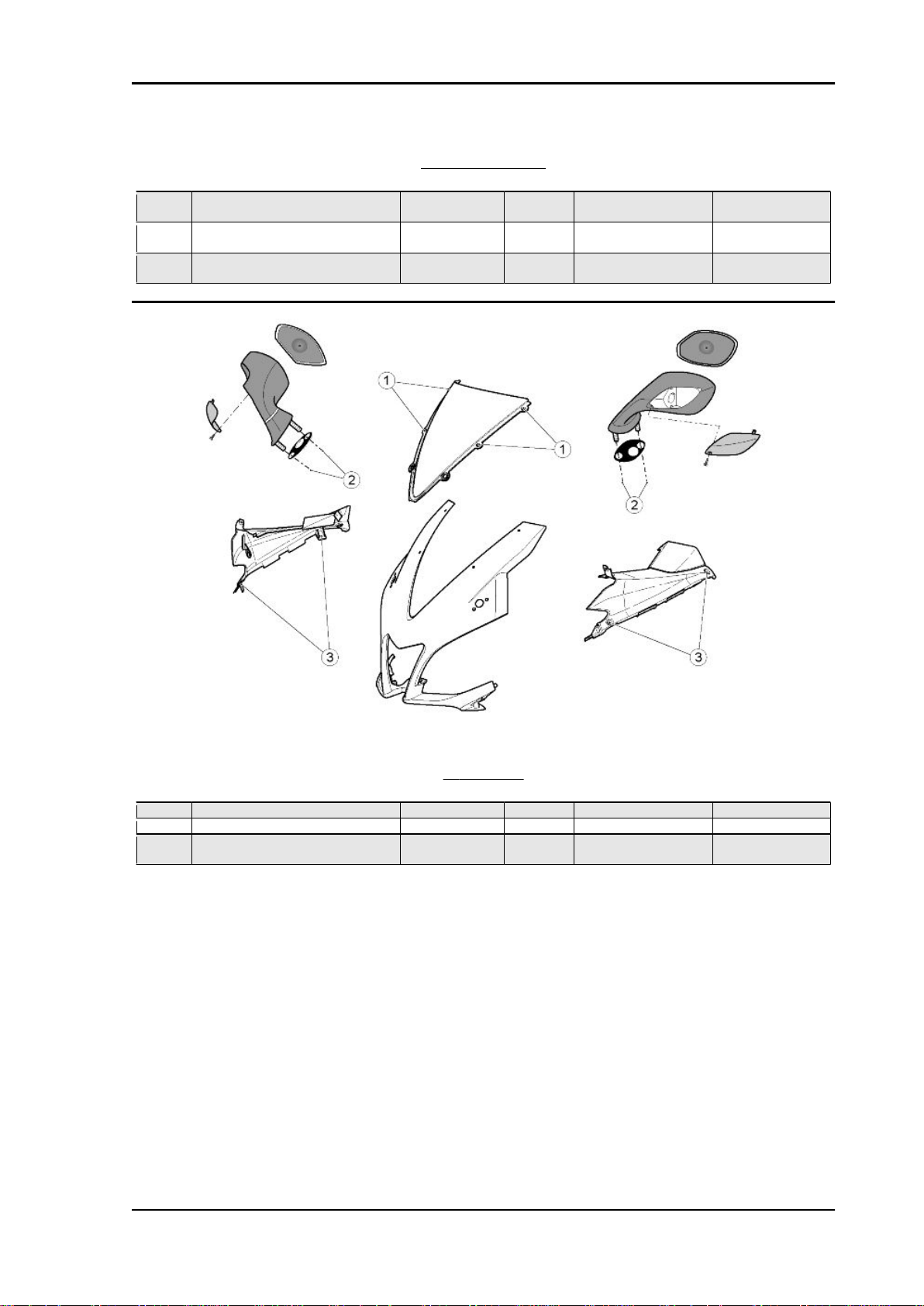

WINDSHIELD

pos.

1 Windshield fixing screws M4 4 0.5 Nm (0.37 lbf ft) 2 Rear-view mirror fixing nuts M6 2 + 2 10 Nm (7.37 lbf ft) 3 - Screws fastening the side fairings

Description Type Quantity Torque Notes

M5 4 1 Nm (0.74 lbf ft) -

to front fairing

CHAR - 21

Page 22

Characteristics RSV4 Factory

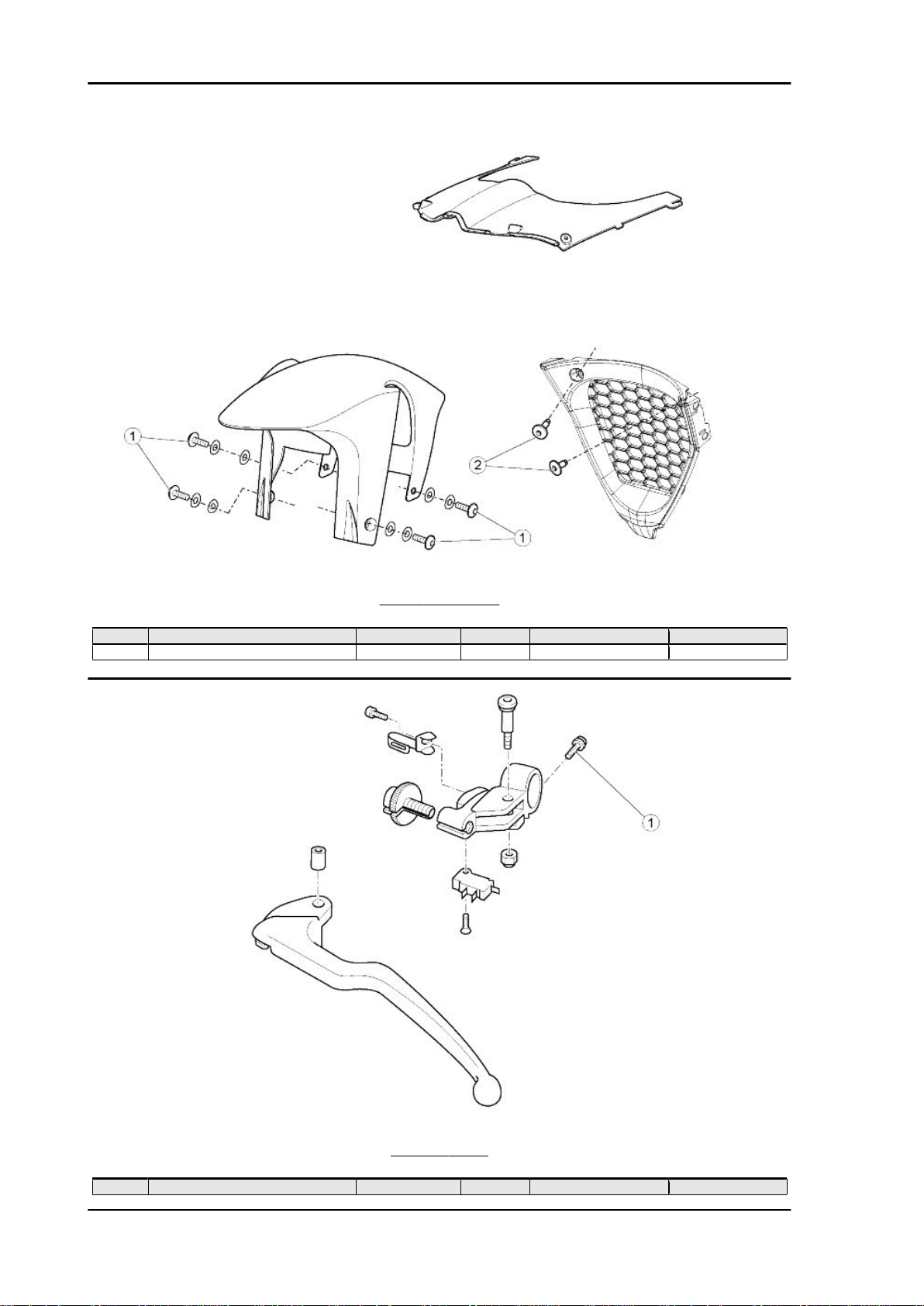

FRONT MUDGUARD

pos.

1 Front mudguard fixing screws M5 4 3 Nm (2.21 lbf ft) 2 Lug fixing screws M5 2 4 Nm (2.95 lbf ft) -

Description Type Quantity Torque Notes

CLUTCH LEVER

pos.

1 Clutch lever collar fixing screws M6 1 10 Nm (7.37 lbf ft) -

CHAR - 22

Description Type Quantity Torque Notes

Page 23

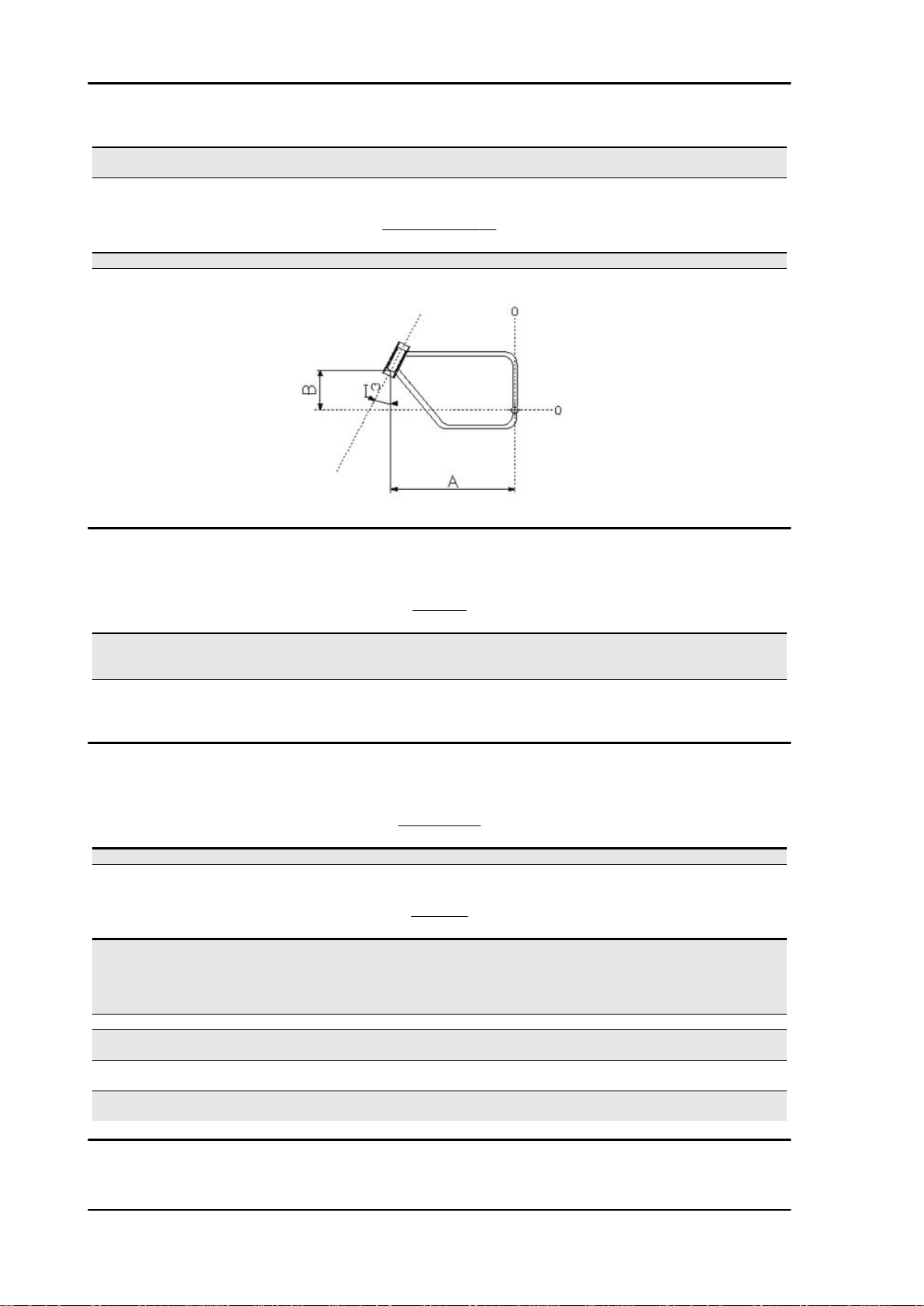

RSV4 Factory Characteristics

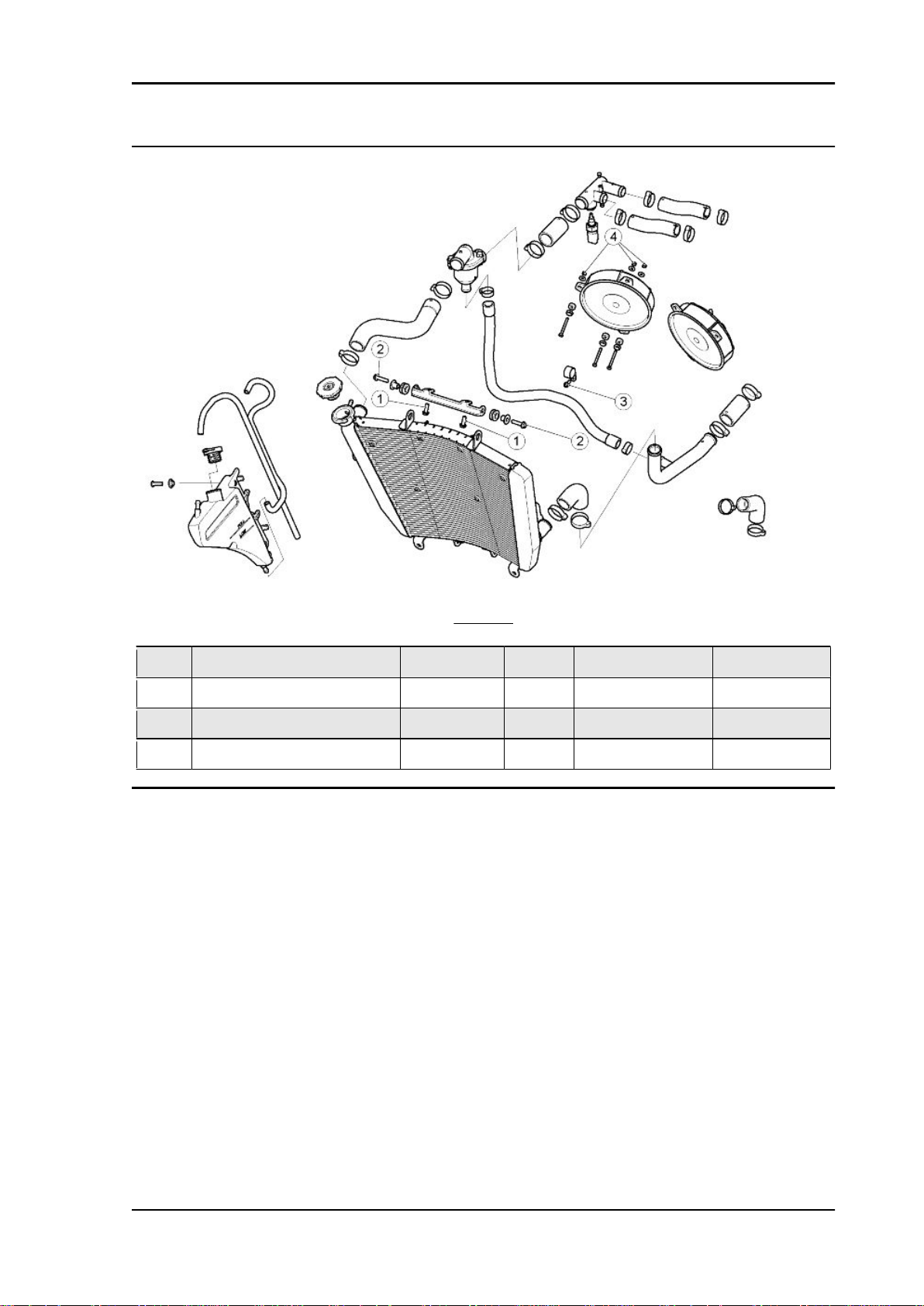

pos.

1 Screws fastening water radiator

2 Screws fastening water radiator to

3 Screw fastening pipe grommet for

4 Screws fastening electric fan to wa-

Description Type Quantity Torque Notes

mounting bracket to chassis

mounting bracket

By-pass water hose

ter radiator

COOLING

M6 2 10 Nm (7.37 lbf ft) M6 2 7 Nm (5.16 lbf ft) M5 1 6 Nm (4.42 lbf ft) M4 6 2 Nm (1.47 lbf ft) -

CHAR - 23

Page 24

Characteristics RSV4 Factory

Central part

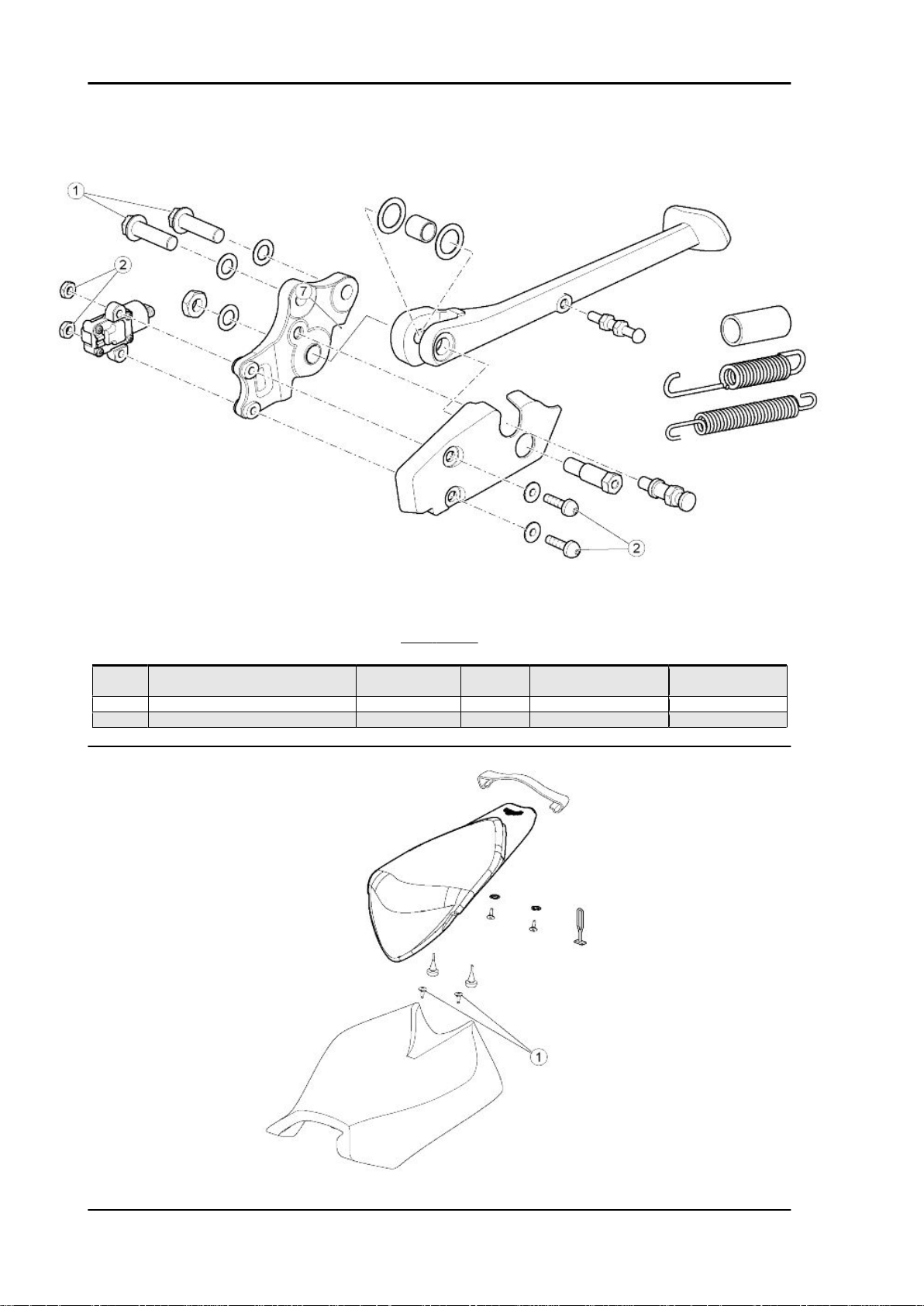

SIDE STAND

pos.

1 Screws fastening the stand to the

2 Linear switch retainer M5 2 4 Nm (2.95 lbf ft) -

- Rear stand bushing fastening screws M6 2 7 Nm (5.16 lbf ft) -

Description Type Quantity Torque Notes

M10 2 45 Nm (33.19 lbf ft) Loct. 243

chassis

CHAR - 24

Page 25

RSV4 Factory Characteristics

SADDLE

pos. Description Type Quantity Torque Notes

1 Rider saddle fixing screw M5 2 6 Nm (4.42 lbf ft) -

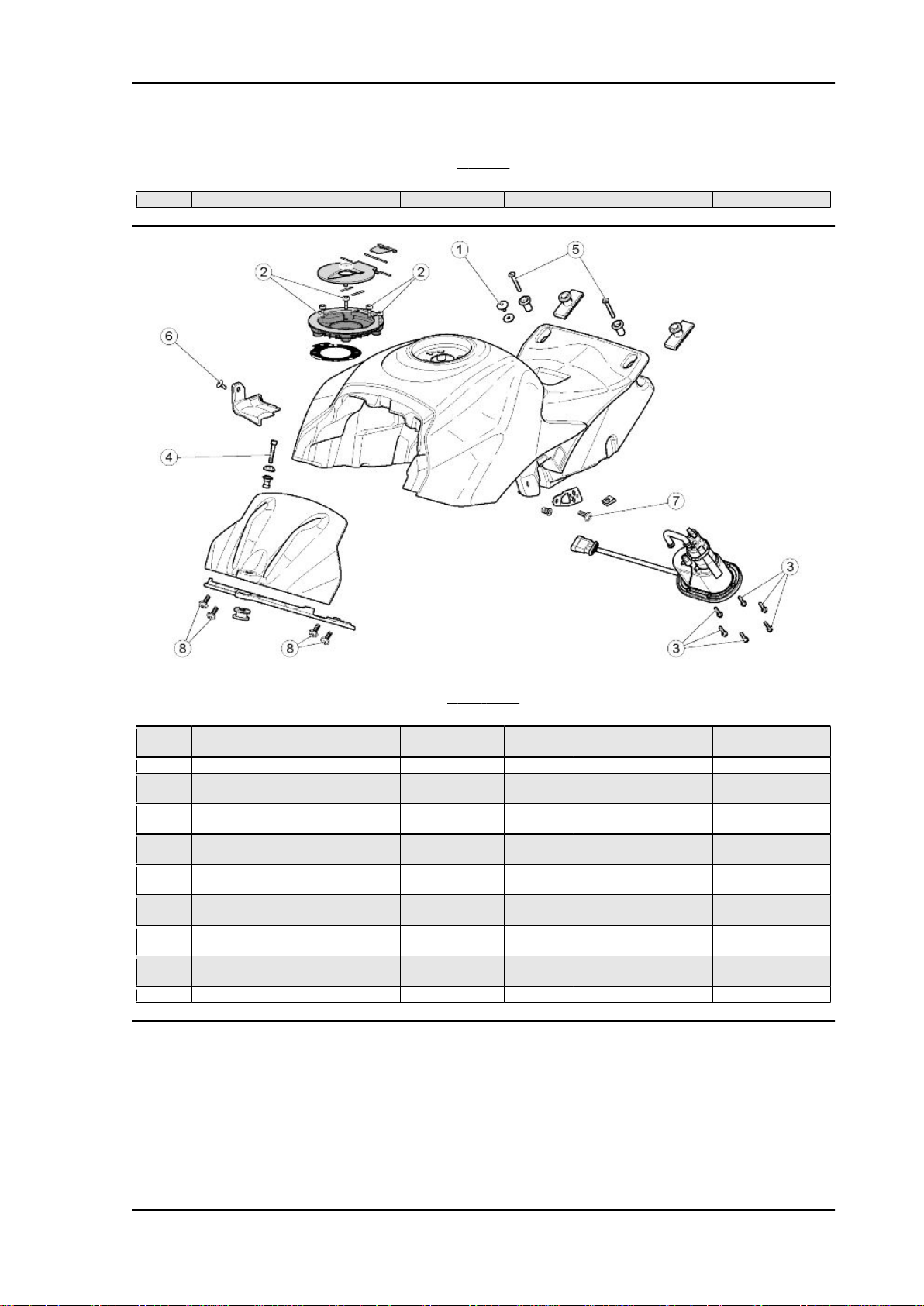

FUEL TANK

pos.

1 Special screw fastening rider saddle

2 Screws fixing the filler to the tank M5 4 4 Nm (2.95 lbf ft) -

3 Screws fixing the fuel pump flange to

4 Front screws fastening the tank to

5 Rear screws fastening the tank to the

6 Screws fastening plastic fuel pipe

7 Left fairing mounting bracket fixing

8 Screws fastening structural tank

- Central screw fastening the cover to

- Fuel tank breather pipe unions M7 2 3 Nm (2.21 lbf ft) -

Description Type Quantity Torque Notes

M6 1 4 Nm (2.95 lbf ft) -

to the tank

M5 8 3 Nm (2.21 lbf ft) -

the tank

M6 1 8 Nm (5.9 lbf ft) -

the chassis

M6 2 7 Nm (5.16 lbf ft) -

rear chassis

M5 1 2.5 Nm (1.84 lbf ft) -

mounting

M5 1 3 Nm (2.21 lbf ft) -

screws

M6 4 3 Nm (2.21 lbf ft) -

mounting to tank

M4 1 0.5 Nm (0.37 lbf ft) -

the tank

CHAR - 25

Page 26

Characteristics RSV4 Factory

FOOTPEGS

pos.

1 Screws fastening rider footpegs to

2 Screws fastening passenger foot-

3 Rider heelrest fixing screws M6 2 + 2 8 Nm (5.9 lbf ft) 4 Passenger heelrest fixing screws M6 2 + 2 8 Nm (5.9 lbf ft) -

- Anti-slip pin M6 1 8 Nm (5.9 lbf ft) -

Description Type Quantity Torques Notes

chassis

pegs to chassis

M8 2 + 2 25 Nm (18.44 lbf ft) M8 2 + 2 18 Nm (13.28 lbf ft) For countries in

which passenger

footpegs are man-

datory or for two

seat configuration

CHAR - 26

Page 27

RSV4 Factory Characteristics

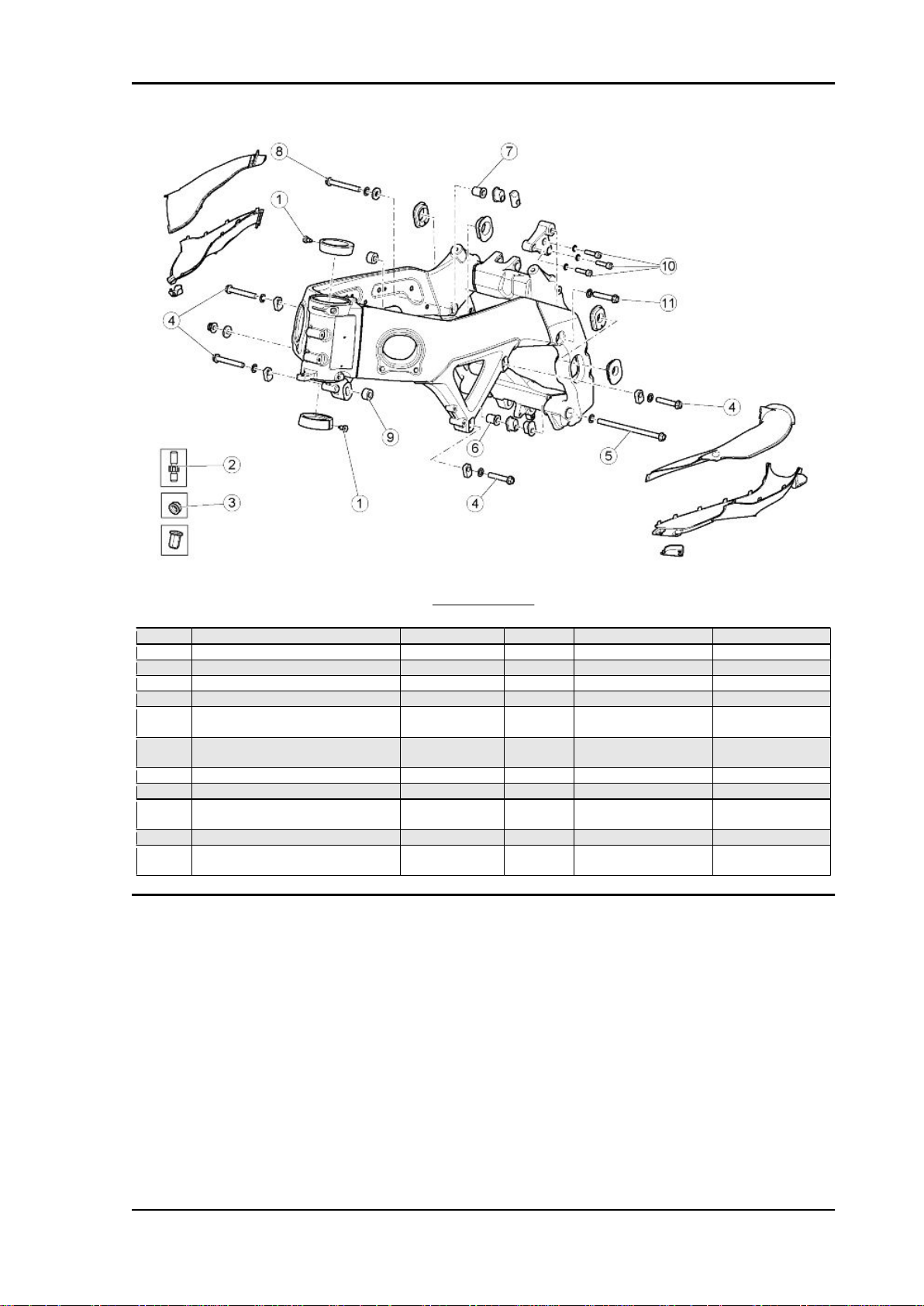

FRONT CHASSIS

pos.

1 Headstock locator dowel M8x1 2 10 Nm (7.37 lbf ft) 2 Threaded inlet duct fastener pins M6 2 + 2 4 Nm (2.95 lbf ft) Loct. 243

3 Inlet duct fixing nuts M6 2 + 2 Manual 4 Front mounts M10 2 + 2 50 Nm (36.88 lbf ft) 5 Lower rear mount M10 1 50 Nm (36.88 lbf ft) 6 Lower rear right hand adjuster screw

7 Upper rear right hand adjuster screw

8 Upper rear right hand mount M10 1 50 Nm (36.88 lbf ft) -

9 Right fairing spacer M6 1 10 Nm (7.37 lbf ft) Loct. 243

10 Upper rear left hand engine mount

11 Upper rear mount M10 1 50 Nm (36.88 lbf ft) -

- Screw fastening the ground cable to

Description Type Quantity Torque Notes

M18x1.5 1 12 Nm (8.85 lbf ft) -

bushing

M18x1.5 1 12 Nm (8.85 lbf ft) -

bushing

M8 3 25 Nm (18.44 lbf ft) -

fastener screws

M6 1 6 Nm (4.42 lbf ft) -

the left side chassis

CHAR - 27

Page 28

Characteristics RSV4 Factory

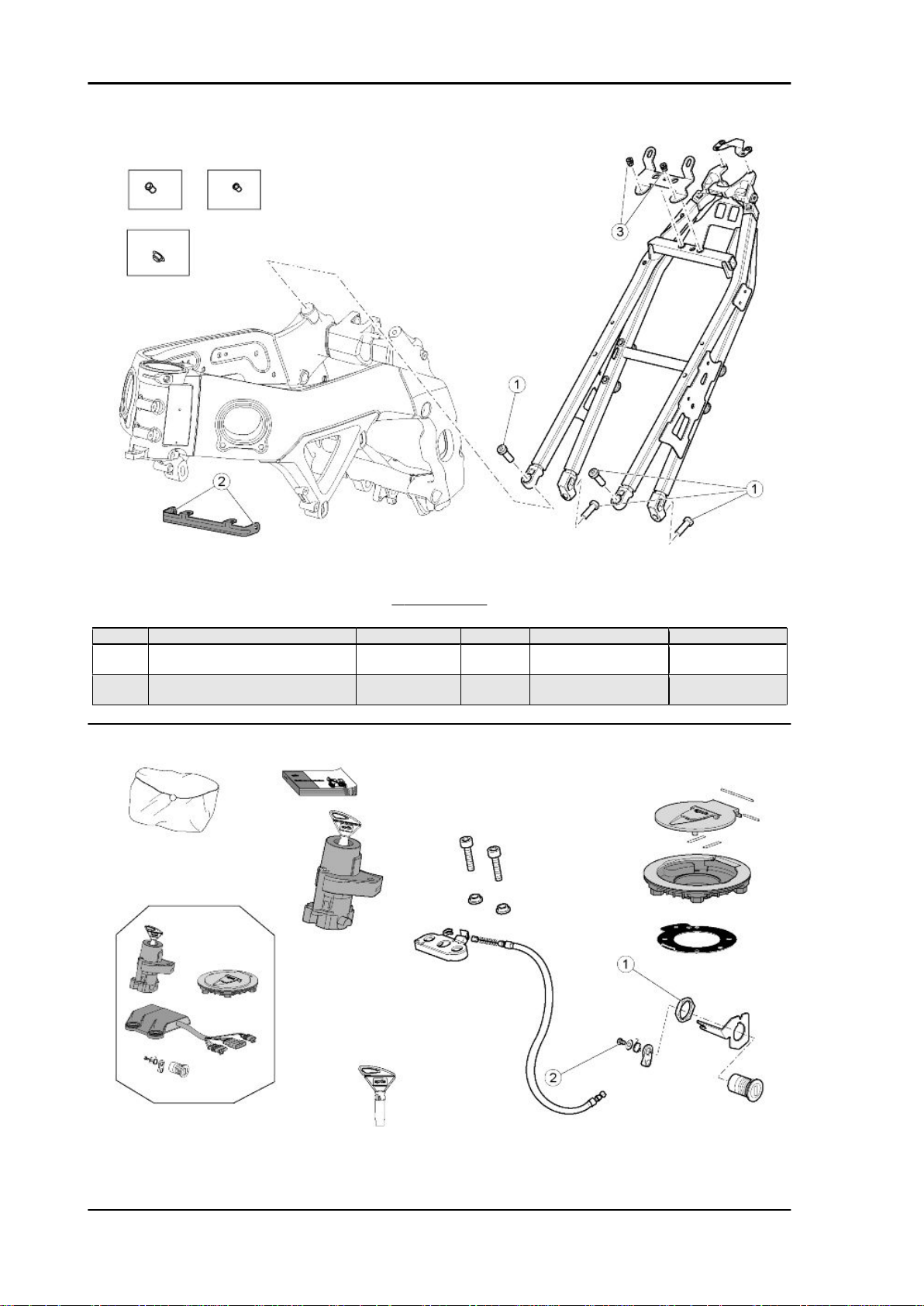

REAR CHASSIS

pos.

1 Saddle mounting fixing screws M10 4 50 Nm (36.88 lbf ft) 2 Screws fastening oil radiator mount-

3 Passenger saddle and saddle cover

Description Type Quantity Torque Notes

M6 2 8 Nm (5.9 lbf ft) -

ing bracket to engine

M6 2 8 Nm (5.9 lbf ft) -

catch plate fixing screws

CHAR - 28

Page 29

RSV4 Factory Characteristics

LOCKS

pos. Description Type Quantity Torque Notes

1 Nut fastening saddle lock to tail fair-

ing

2 Lock lever self-tapping screw M4 1 2 Nm (1.47 lbf ft) -

M22x1.5 1 5 Nm (3.69 lbf ft) -

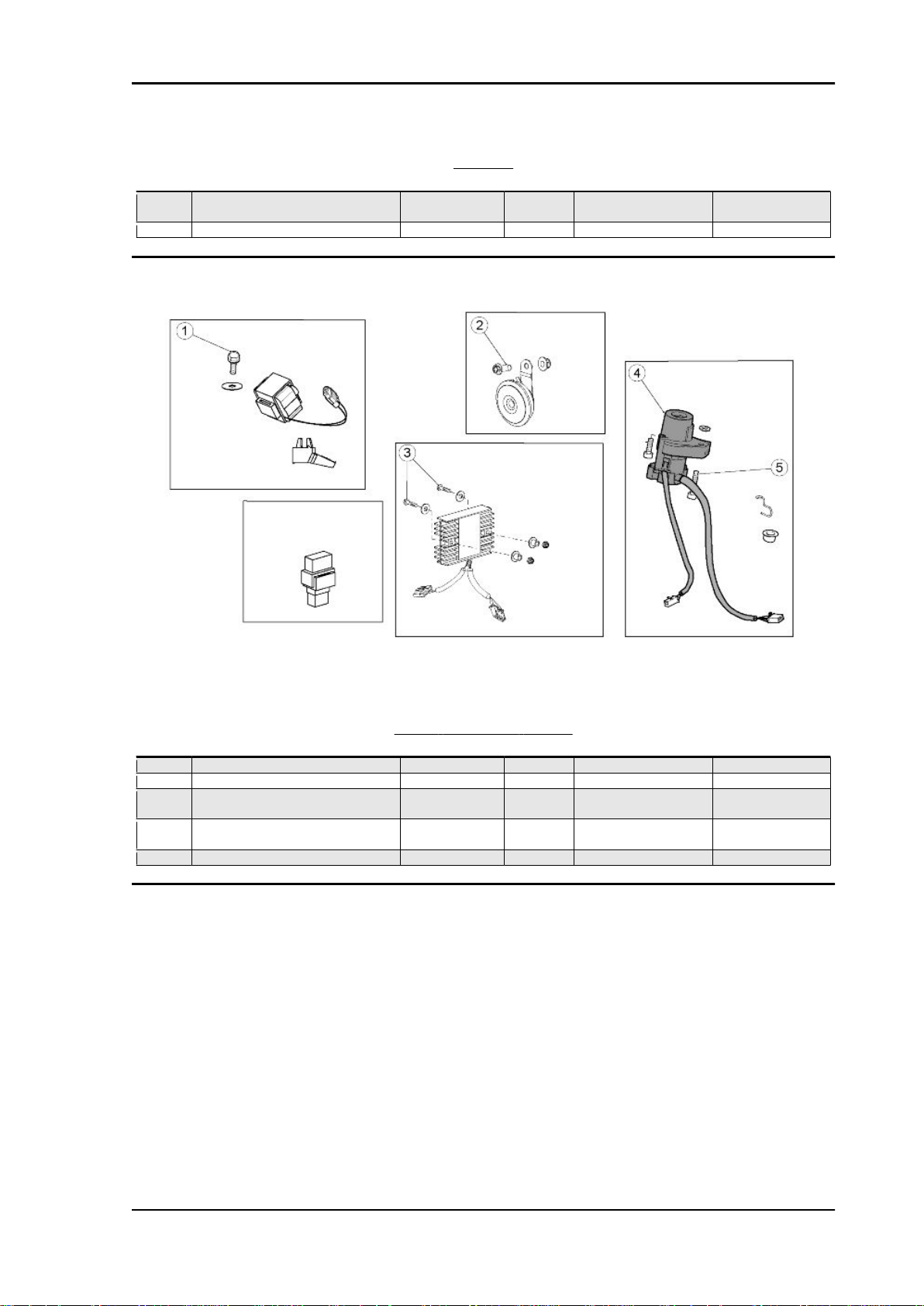

FRONT ELECTRICAL SYSTEM

pos.

1 Fall sensor mounting fixing screw M6 1 8 Nm (5.9 lbf ft) 2 Horn fixing screw M8 1 15 Nm (11.06 lbf ft) 3 Screw fastening the voltage regula-

4 Shear head screw (to the left of the

5 Right hand ignition lock screw M8 1 20 Nm (14.75 lbf ft) -

Description Type Quantity Torque Notes

M6 2 6 Nm (4.42 lbf ft) -

tor to the inner fairing

M8 1 Manual Tighten until the

ignition lock)

head shears off

CHAR - 29

Page 30

Characteristics RSV4 Factory

pos.

1 Upper Silentblock nut, demand sen2 Demand sensor fixing screw to

Description Type Quantity Torque Notes

sor mounting bracket

mounting plate

CENTRAL ELECTRICAL SYSTEM

M6 1 5 Nm (3.69 lbf ft) -

SWP 4.9 4 1.2 Nm (0.88 lbf ft) -

CHAR - 30

Page 31

RSV4 Factory Characteristics

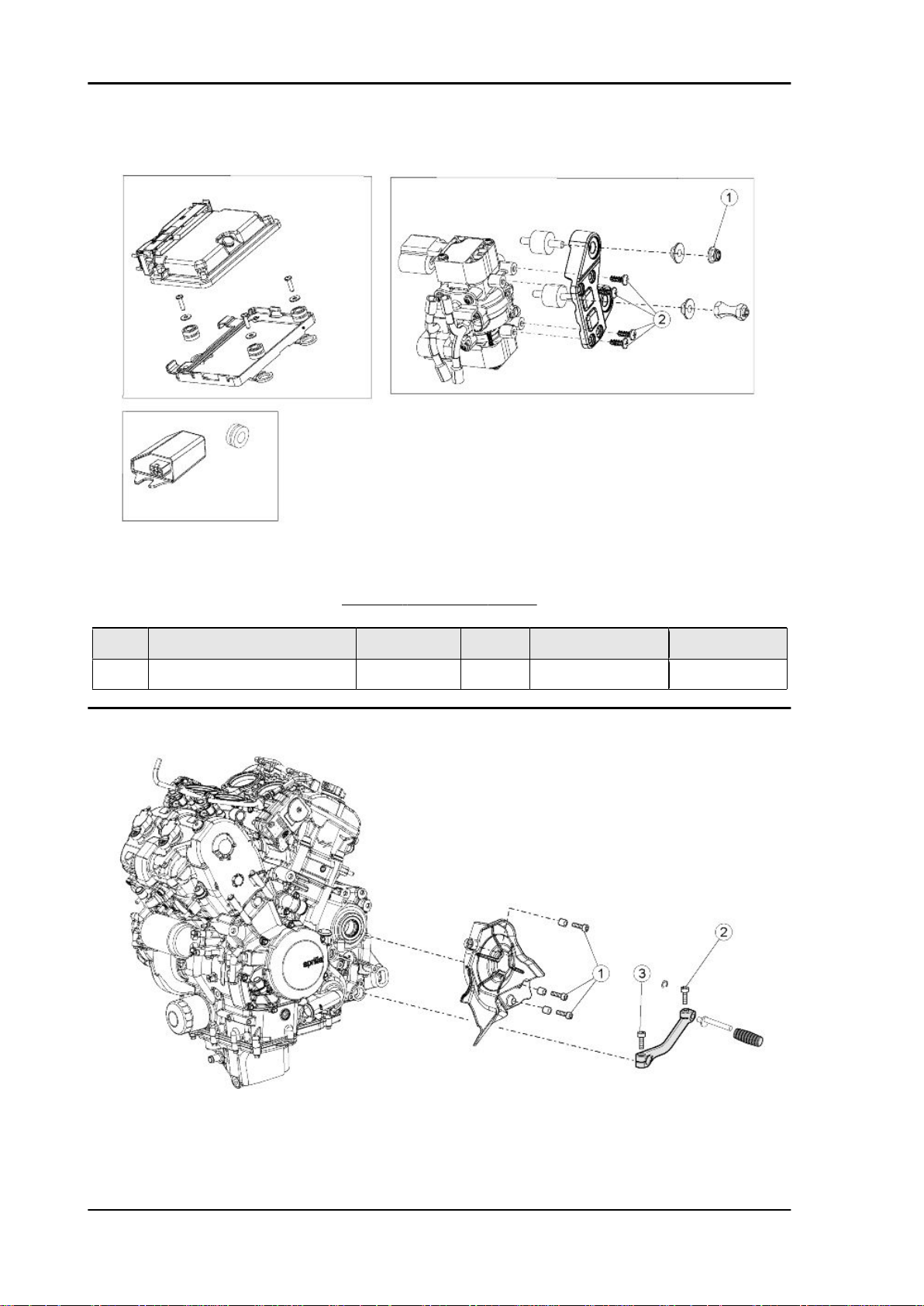

ENGINE

pos. Description Type Quantity Torques Notes

1 Pinion protector casing fixing screws M6 3 8 Nm (5.9 lbf ft) 2 Gearbox lever pin fixing screw M6 1 10 Nm (7.37 lbf ft) 3 Gearbox lever fixing screws M6 1 10 Nm (7.37 lbf ft) -

FAIRING

pos.

- Centre screws fastening lower fairing M6 2 10 Nm (7.37 lbf ft) -

- Right hand lower fairing mounting

- Left hand lower fairing mounting

- Screws fixing the side fairings to the

- Screws fixing upper fairing fastener

- Screws fixing upper fairing fastener

- Screws fixing upper fairing fastener

- Screws fixing upper fairing fastener

- Screws fastening the lower fairing to

- Screws fastening the lower fairing to

- Lower fairing lower fastening screws M5 2 2 Nm (1.47 lbf ft) -

- Lower fork fastener fixing screws M6 2 8 Nm (5.90 lbf ft) -

- Screws fixing lower front fairing fas-

- Inner screws fixing fairing to the low-

- Inner screws fastening the fairing to

Description Type Quantity Torque Notes

M6 2 10 Nm (7.37 lbf ft) -

bracket

M6 2 10 Nm (7.37 lbf ft) -

bracket

M5 2 1.5 Nm (1.11 lbf ft) -

side spacers

M5 2 1.5 Nm (1.11 lbf ft) -

to inlet duct

M5 2 1.5 Nm (1.11 lbf ft) -

to front fairing

self-tapping 2 1 Nm (0.74 lbf ft) -

to inlet duct

self-tapping 2 1 Nm (0.74 lbf ft) -

to headlamp

M5 2 + 2 1 Nm (0.74 lbf ft) -

the bracket

M5 2 2 Nm (1.47 lbf ft) -

the lug

SWP 3.9 2 1 Nm (0.74 lbf ft) -

tener to inlet ducts

M4 2 0.5 Nm (0.37 lbf ft) -

er front fairing fastener

M5 2 2 Nm (1.47 lbf ft) -

the lug

CHAR - 31

Page 32

Characteristics RSV4 Factory

Back side

EXHAUST

pos.

1 Exhaust manifold flange fixing nuts M7 8 13 Nm (9.59 lbf ft) 2 Silencer clamp fixing screw M6 1 10 Nm (7.37 lbf ft) 3 Screw fastening silencer to right

4 Screw fastening silencer to central

5 Cosmetic silencer shield fixing screw M5 2 5 Nm (3.69 lbf ft) -

6 Oxygen sensor fastener M18x1.5 1 38 Nm (28.03 lbf ft) 7 Fastener screw for cable grommet

for exhaust butterfly valve cables

8 Exhaust butterfly valve actuator fix-

Description Type Quantity Torque Notes

M8 1 25 Nm (18.44 lbf ft) -

hand footpeg mounting

M8 1 20 Nm (14.75 lbf ft) -

lower fairing bracket

M6 1 10 Nm (7.37 lbf ft) M6 2 10 Nm (7.37 lbf ft) -

ing screws

CHAR - 32

Page 33

RSV4 Factory Characteristics

REAR WHEEL

pos.

1 Rear wheel spindle nut M25x1.5 1 120 Nm (88.5 lbf ft) 2 Screws fastening sprocket on

Description Type Quantity Torque Notes

M10 5 50 Nm (36.88 lbf ft) -

sprocket mount

CHAR - 33

Page 34

Characteristics RSV4 Factory

REAR BRAKE PUMP

pos. Description Type Quantity Torque Notes

1 Rear brake rod lock nut M6 1 12 Nm (8.85 lbf ft) 2 Rear brake pump fixing screws M6 2 8 Nm (5.9 lbf ft) 3 Rear brake lever fixing screw M8 1 25 Nm (18.44 lbf ft) -

REAR BRAKE CALLIPER

pos.

1 Rear brake disc fixing screws M8 5 30 Nm (22.13 lbf ft) Loct. 243

2 Screw fastening odometer sensor

onto rear brake calliper mounting

3 Rear brake calliper mounting plate

4 Rear calliper fixing screw M5 2 25 Nm (18.44 lbf ft) -

5 Brake pipe clamp fixing screw M5 2 4 Nm (2.95 lbf ft) -

- Brake pipe bracket fixing screw M5 2 4 Nm (2.95 lbf ft) -

Description Type Quantity Torque Notes

M6 1 12 Nm (8.85 lbf ft) -

M12 1 50 Nm (36.88 lbf ft) Loct. 243

lock pin

CHAR - 34

Page 35

RSV4 Factory Characteristics

REAR FORK

pos.

1 Swingarm adjuster screw bushing M30x1.5 1 12 Nm (8.85 lbf ft) 2 Swingarm ring nut M30x1.5 1 60 Nm (44.25 lbf ft) 3 Swingarm pin nut M20x1.5 1 65 Nm (47.94 lbf ft) AGIP GREASE

4 Chain casing fixing screws M5 2 4 Nm (2.95 lbf ft) 5 Front chain guide fixing screw M5 1 4 Nm (2.95 lbf ft) 6 Rear chain guide fixing nut M6 1 7 Nm (5.16 lbf ft) 7 Chain skid fixing screws M5 2 2 Nm (1.47 lbf ft) -

- Lower chain skid fixing screws M6 2 10 Nm (7.37 lbf ft) -

- Chain guide fixing screw M6 1 8 Nm (5.90 lbf ft) -

Description Type Quantity Torque Notes

SM2

CHAR - 35

Page 36

Characteristics RSV4 Factory

REAR SHOCK ABSORBER

pos.

1 Upper shock absorber fixing screw M10 1 50 Nm (36.88 lbf ft) 2 Dual linkage fixing screw M10 3 50 Nm (36.88 lbf ft) 3 Screw fastening single linkage to

Description Type Quantity Torque Notes

M10 1 50 Nm (36.88 lbf ft) -

chassis

CHAR - 36

Page 37

RSV4 Factory Characteristics

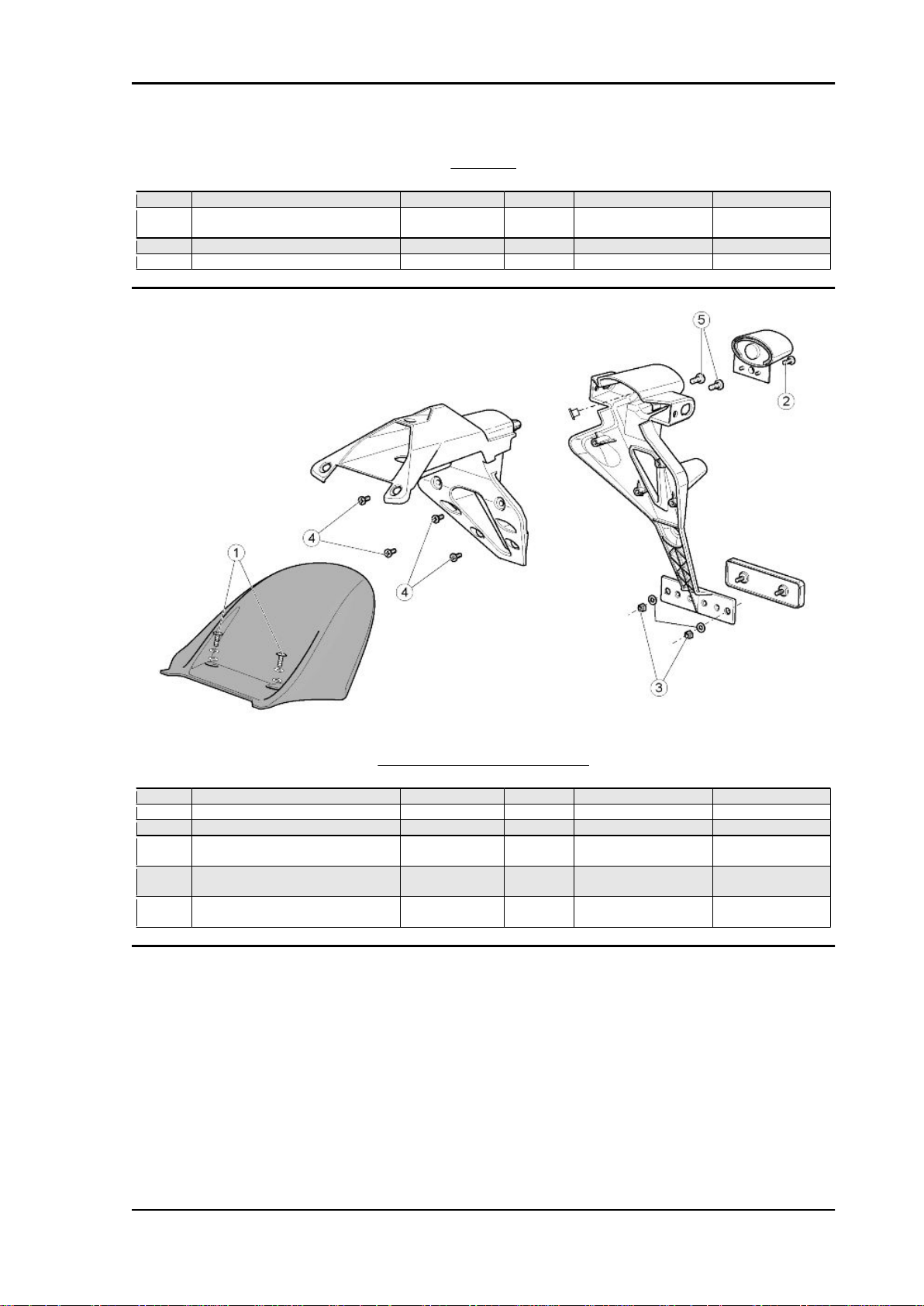

TAILLIGHT

pos. Description Type Quantity Torque Notes

1 Taillight fixing screws M5 2 3 Nm (2.21 lbf ft) 2 Taillight mounting bracket fixing

screws

3 Rear turn indicator fixing screws M6 2 2.5 Nm (1.84 lbf ft) 4 Taillight cover fixing screws SWP 2.9 1 0.5 Nm (0.37 lbf ft) -

M5 2 4 Nm (2.95 lbf ft) -

LICENSE PLATE HOLDER

pos.

1 Rear mudguard fixing screws M6 2 3 Nm (2.21 lbf ft) 2 License plate light fixing screws M4 1 1 Nm (0.74 lbf ft) 3 Reflector fixing nuts M4 2 1 Nm (0.74 lbf ft) 4 Screws fastening rear license plate

holder to front license plate holder

5 Screws fastening rear license plate

holder to front license plate holder

- Screws fastening license plate

mounting to saddle mounting casting

Description Type Quantity Torque Notes

SWP 3.9 4 1 Nm (0.74 lbf ft) SWP 4.9 2 2 Nm (1.47 lbf ft) -

M6 3 4 Nm (2.95 lbf ft) -

CHAR - 37

Page 38

Characteristics RSV4 Factory

TAIL

pos.

1 Rear screws fastening tail fairing to

2 Screws fastening the saddle cover

3 Saddle cover pin fixing screws M4 1 1.5 Nm (1.11 lbf ft) -

4 Screws fastening grilles to tail fairing M5 2 0.5 Nm (0.37 lbf ft) 5 Screws fastening side fairings to tail

6 Screws fixing side fairings to tank M5 2 + 2 2 Nm (1.47 lbf ft) 7 Screws fastening tail fairing to saddle

8 Screws fastening tail fairing to saddle

9 Screws fixing tail fairing to lower sad-

Description Type Quantity Torque Notes

M5 2 3 Nm (2.21 lbf ft) -

taillight bracket

SWP 2.9 3 1 Nm (0.74 lbf ft) -

base to the saddle cover

M5 2 1 Nm (0.74 lbf ft) -

fairing

M5 2 3 Nm (2.21 lbf ft) -

mounting

M5 2 2 Nm (1.47 lbf ft) -

mounting bracket

M5 2 3 Nm (2.21 lbf ft) -

dle mounting fastener

CHAR - 38

Page 39

RSV4 Factory Characteristics

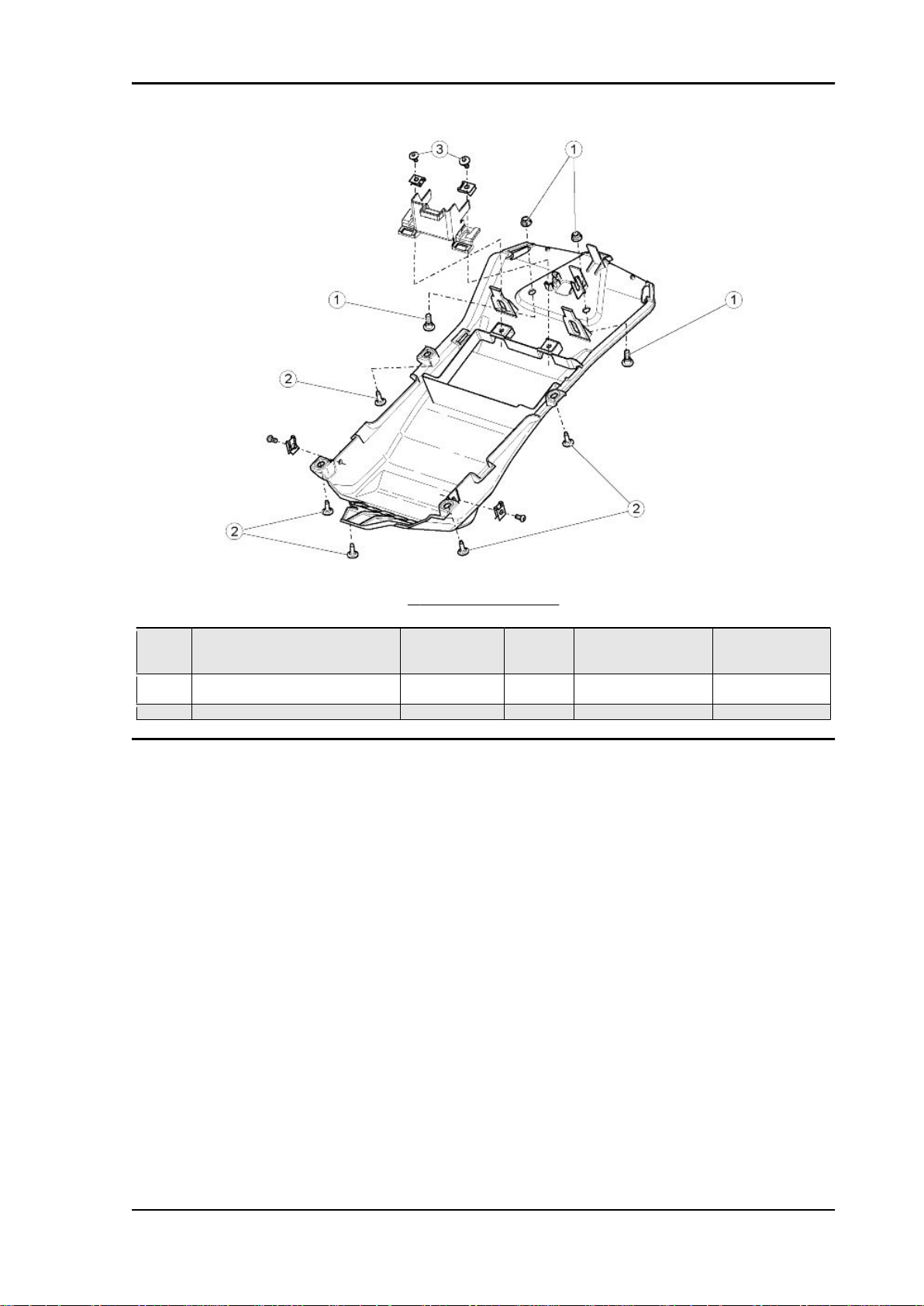

HELMET COMPARTMENT

pos.

1 Screws and nuts for fastening li-

cense plate holder to saddle mount2 Lower saddle mounting fastener fix3 Battery bracket fixing screws M5 2 2 Nm (1.47 lbf ft) -

Description Type Quantity Torque Notes

M6 2 4 Nm (2.95 lbf ft) -

ing plate

M5 5 3 Nm (2.21 lbf ft) -

ing screws

CHAR - 39

Page 40

Characteristics RSV4 Factory

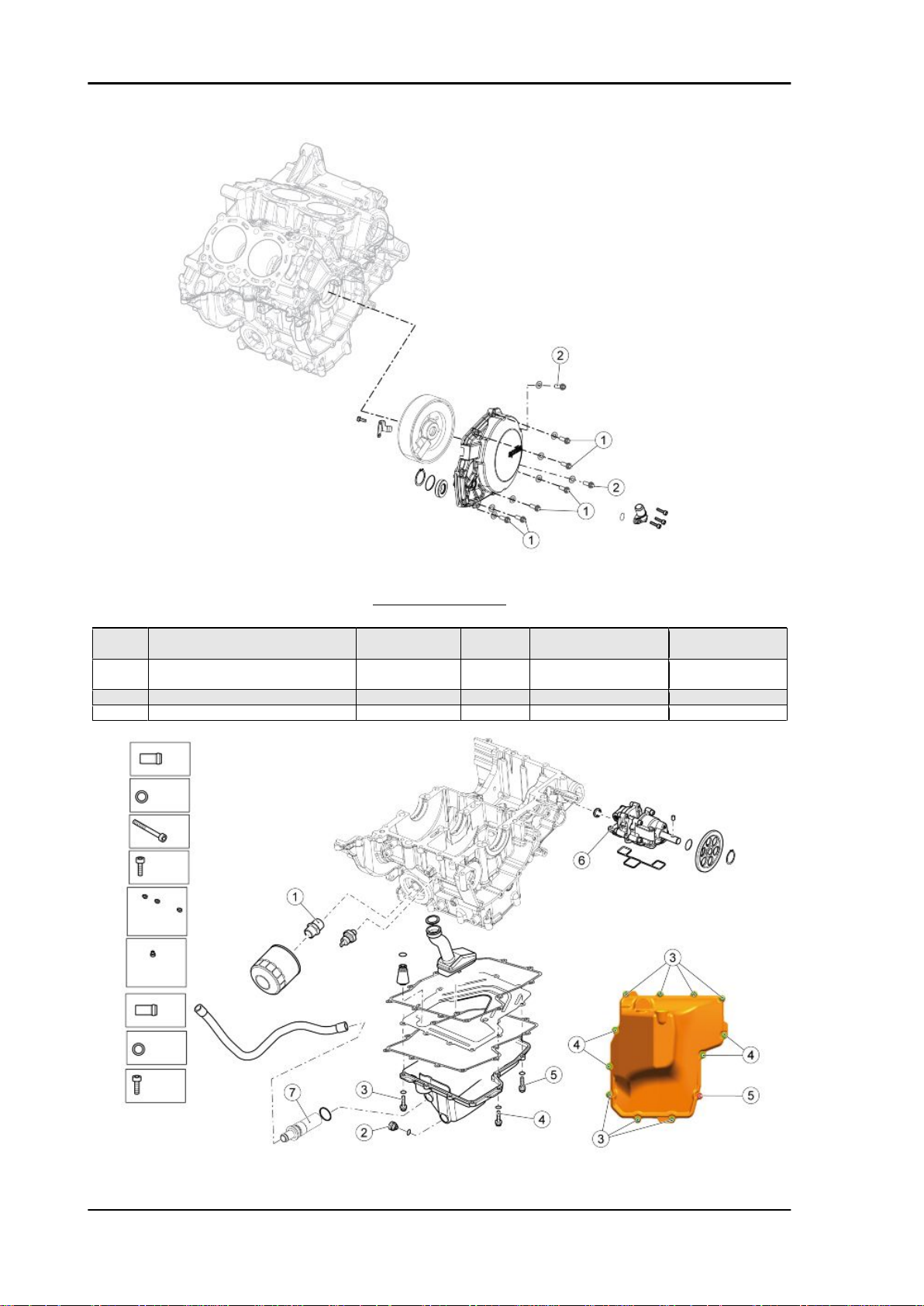

Engine

CLUTCH COVER

pos.

1 Rpm sensor fixing screw - 1 8 Nm (5.9 lbf ft) 2 TE flanged screw M6x20 1 12 Nm (8.85 lbf ft) 3 TE flanged screws M6x35 2 12 Nm (8.85 lbf ft) 4 TE flanged screws M6x22 16 12 Nm (8.85 lbf ft) 5 Engine timing inspection cap - 1 25 Nm (18.44 lbf ft) -

CHAR - 40

Description Type Quantity Torque Notes

Page 41

RSV4 Factory Characteristics

VALVE COVER

pos.

1 Head cover fixing screws - 6 10 Nm (7.37 lbf ft) 2 Coil fixing screws - 4 8 Nm (5.9 lbf ft) Loct. 243

3 Spark plugs - 4 12 Nm (8.85 lbf ft) -

Description Type Quantity Torque Notes

CHAR - 41

Page 42

Characteristics RSV4 Factory

CYLINDERS - PISTON

pos. Description Type Quantity Torque Notes

1 Screws fastening water union onto

crankcase

M6x40 2 10 Nm (7.37 lbf ft) -

HEADS

pos.

1 Exhaust stud bolts - 8 10 Nm (7.37 lbf ft) 2 Camshaft cam tower fixing screws M6x45 20 12 Nm (8.85 lbf ft) 3 Reed valve cover fixing screws - 6 6 Nm (4.42 lbf ft) 4 Water outlet union fixing screw - 2 12 Nm (8.85 lbf ft) Loct. 243

5 Flanged head nut - 12 30 + 55 Nm (22.13 +

6 Head fastener screw, chain side M6x55 4 12 Nm (8.85 lbf ft) -

Description Type Quantity Torque Notes

40.56 lbf ft)

Molykote spray on

thread and under

head

CHAR - 42

Page 43

RSV4 Factory Characteristics

TIMING SYSTEM

pos.

1 Screws fastening the timing system

2 Skid fastener screws M8 2 20 Nm (14.75 lbf ft) Loct. 243

3 Skid fastener screws M6x18 2 10 Nm (7.37 lbf ft) Loct. 243

Description Type Quantity Torque Notes

M8 4 30 Nm (22.13 lbf ft) Loct. 243

gear on the intake shaft

CHAR - 43

Page 44

Characteristics RSV4 Factory

CRANKSHAFT

pos.

1 Connecting rod screws - 8 15 Nm (11.06 lbf ft) +

2 Fastener ring nut for alternator side

3 Primary sprocket fixing ring nut - 1 200 Nm (147.51 lbf ft) Loct. 243

4 Alternator fixing screw M12x1.25 1 120 Nm (88.51 lbf ft) 5 Tone wheel fixing screw M8x1.25 1 30 Nm (22.13 lbf ft) Loct. 3M or 270

Description Type Quantity Torque Notes

40° + 60°

- 1 100 Nm (73.76 lbf ft) Loct. 243

timing sprocket

Lubricate the thread

and under the head

with Molykote

CHAR - 44

Page 45

RSV4 Factory Characteristics

CRANKCASES

pos.

1 Head stud bolts - 12 20 Nm (14.75 lbf ft) Loct. 648 or 270

2 Special screw for piston cooling oil jet - 4 6 Nm (4.42 lbf ft) Loct. 2045

3 Crankcase stud bolts - 6 20 Nm (14.75 lbf ft) Loct. 648 or 270

4 Main crank flanged nut - 6 30 + 55 Nm (22.13 +

5 Crankcase fixing screw M8x70 4 25 Nm (18.44 lbf ft) Lubricate the thread

6 Crankcase fixing screw M8x35 3 25 Nm (18.44 lbf ft) Lubricate the thread

7 Crankcase fixing screw M6x45 2 10 Nm (7.37 lbf ft) Lubricate the thread

8 Crankcase fixing screw M6x20 5 10 Nm (7.37 lbf ft) Lubricate the thread

9 Crankcase fixing screw M6x20 5 10 Nm (7.37 lbf ft) Lubricate the thread

Description Type Quantity Torque Notes

40.57 lbf ft)

Molykote - lubricate

the thread and un-

der the head

and under the head

and under the head

and under the head

and under the head

and under the head

CHAR - 45

Page 46

Characteristics RSV4 Factory

GEARBOX

pos.

1 Connector drum fastener screw M6x20 1 10 Nm (7.37 lbf ft) Loct. 243

2 Bearing retainer plate fixing screw M6x16 3 10 Nm (7.37 lbf ft) Loct. 243

3 Flange fixing screws M8x25 6 25 Nm (18.44 lbf ft) 4 Index lever fixing screw M6 1 10 Nm (7.37 lbf ft) Loct. 243

5 Pinion retainer - 1 50 Nm (36.88 lbf ft) Loct. 243

6 Screw retaining pre-selector on

- Gear indicator fixing screw M5x15 2 6 Nm (4.42 lbf ft) -

Description Type Quantity Torque Notes

- 1 25 Nm (18.44 lbf ft) Loct. 270

crankcase

CHAR - 46

Page 47

RSV4 Factory Characteristics

CLUTCH

pos. Description Type Quantity Torque Notes

1 Clutch nut - 1 150 Nm (110.63 lbf ft) Loct. 243

pos.

1 Hex headed nut, cl.10 type 2 ISO

Description Type Quantity Torque Notes

8674

IGNITION UNIT

M10x1 1 50 Nm (36.88 lbf ft) Loct. 243

CHAR - 47

Page 48

Characteristics RSV4 Factory

ALTERNATOR COVER

pos.

1 Screws fastening cover onto centre

2 Cover fastener screws, alternator

- Stator fixing screw UNI 5931 CL8.8 M6x25 3 10 Nm (7.37 lbf ft) Loct. 243

- Flanged screw M5x12 1 6 Nm (4.42 lbf ft) Loct. 243

Description Type Quantity Torque Notes

M6x25 6 12 Nm (8.85 lbf ft) -

pins

M6x40 2 12 Nm (8.85 lbf ft) -

side

CHAR - 48

Page 49

RSV4 Factory Characteristics

LUBRICATION

pos. Description Type Quantity Torque Notes

1 Oil filter union fixing screw - 1 30 Nm (22.13 lbf ft) 2 Oil drainage plug - 1 30 Nm (22.12 lbf ft) 3 Oil sump fixing screws M6x30 7 12 Nm (8.85 lbf ft) 4 Oil sump fixing screws M6x22 4 12 Nm (8.85 lbf ft) 5 Oil sump fixing screws M6x25 1 12 Nm (8.85 lbf ft) 6 Screws fastening the pump to the

crankcase

7 Oil pipe union fixing screw M6 1 8 Nm (5.90 lbf ft) Loct. 243

- Screw fastening the diffuser in the oil

sump

M6 5+1 10 Nm (7.37 lbf ft) -

- 1 10 Nm (7.37 lbf ft) -

pos.

1 Secondary air system solenoid

Description Type Quantity Torque Notes

screws

SECONDARY AIR SYSTEM

- 2 10 Nm (7.37 lbf ft) -

CHAR - 49

Page 50

Characteristics RSV4 Factory

WATER PUMP

pos.

1 Screws fastening the pump to the

Description Type Quantity Torque Notes

M6x25 2 10 Nm (7.37 lbf ft) -

crankcase

Recommended products chart

RECOMMENDED PRODUCTS

Product

AGIP TEC 4T, SAE 15W-50 Engine oil Use branded oils with performance

AGIP MP GREASE Grease for bearings, joints, couplings

AGIP PERMANENT SPEZIAL Coolant Ready for use mixed biodegradable cool-

AGIP BRAKE 4 Brake fluid As an alternative to the recommended

ÖHLINS 5W Fork oil -

Description Specifications

equivalent to or exceeding CCMC G-4

A.P.I. SG. SAE 15W-50 specifications

and linkages

As an alternative to the recommended

product, use top branded grease for roller

bearings with an operating temperature

range of -30°C to +140°C (-22°F to +284°

F), a drop point between 150°C and 230°

C (302°F and 446°F), high corrosion protection qualities and good water and rust

resistance.

ant with "long life" technology and characteristics (red). Freezing protection up to

-40°C. Compliant with CUNA 956-16

standard.

fluid, other fluids that meet or exceed the

required specifications may be used.

SAE J1703, NHTSA 116 DOT 4, ISO

4925 Synthetic fluid

CHAR - 50

Page 51

INDEX OF TOPICS

SPECIAL TOOLS S-TOOLS

Page 52

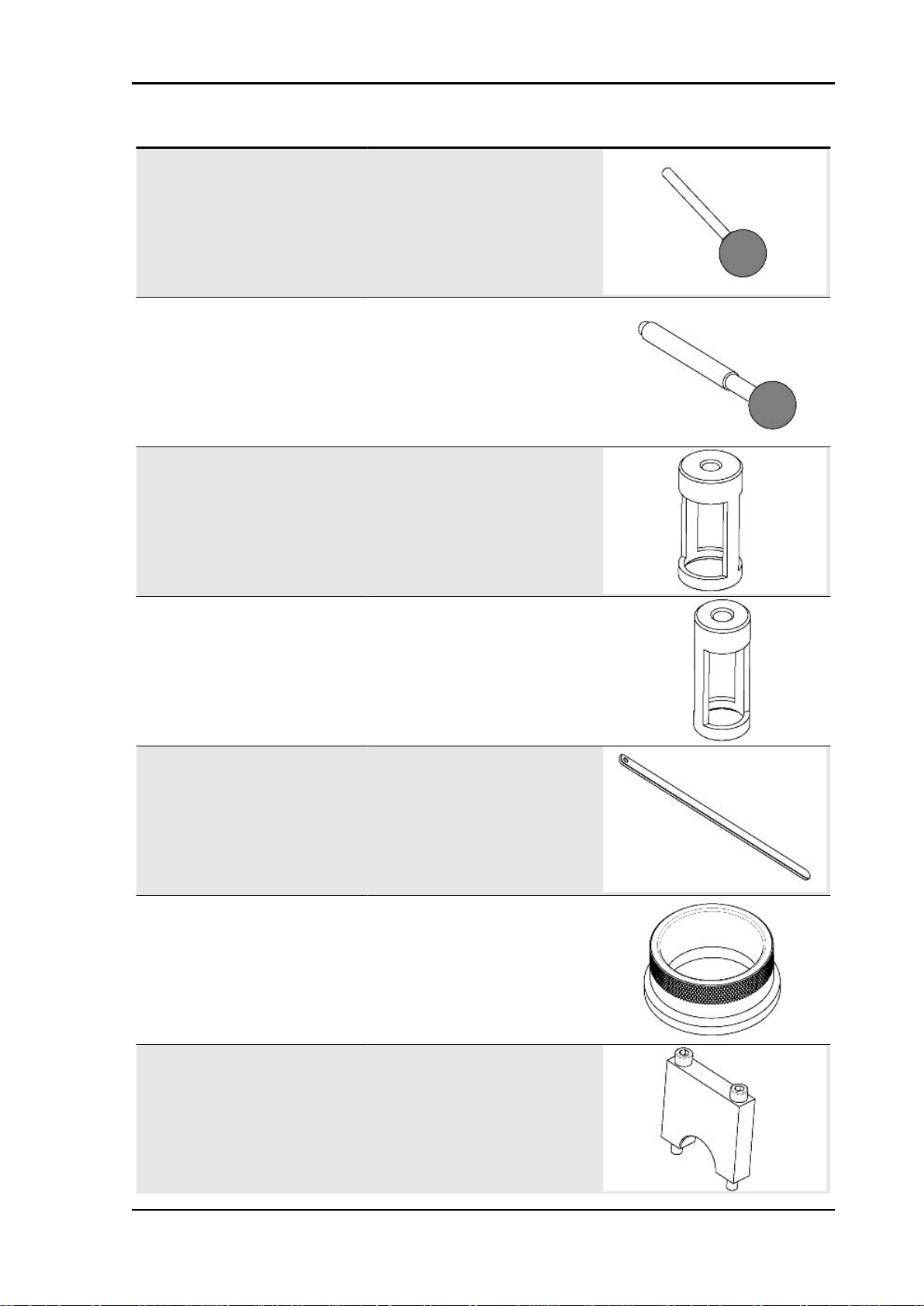

Special tools RSV4 Factory

SPECIAL TOOLS

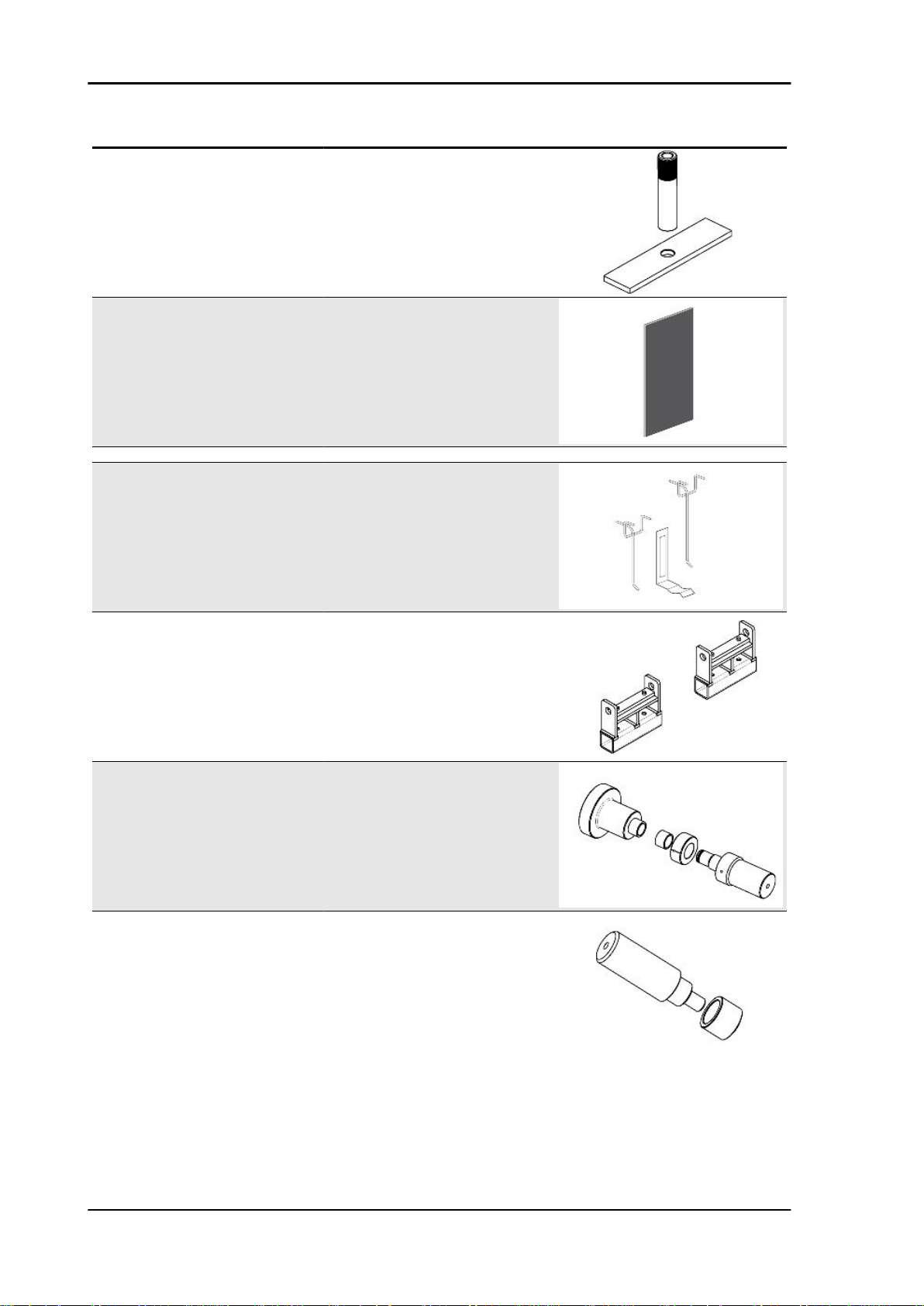

Stores code Description

020845Y Engine support

020846Y Retaining tray + plastic caps

020847Y Flywheel extractor

020848Y Flywheel retainer

020849Y Clutch retainer

020850Y Primary gear lock

S-TOOLS - 52

Page 53

RSV4 Factory Special tools

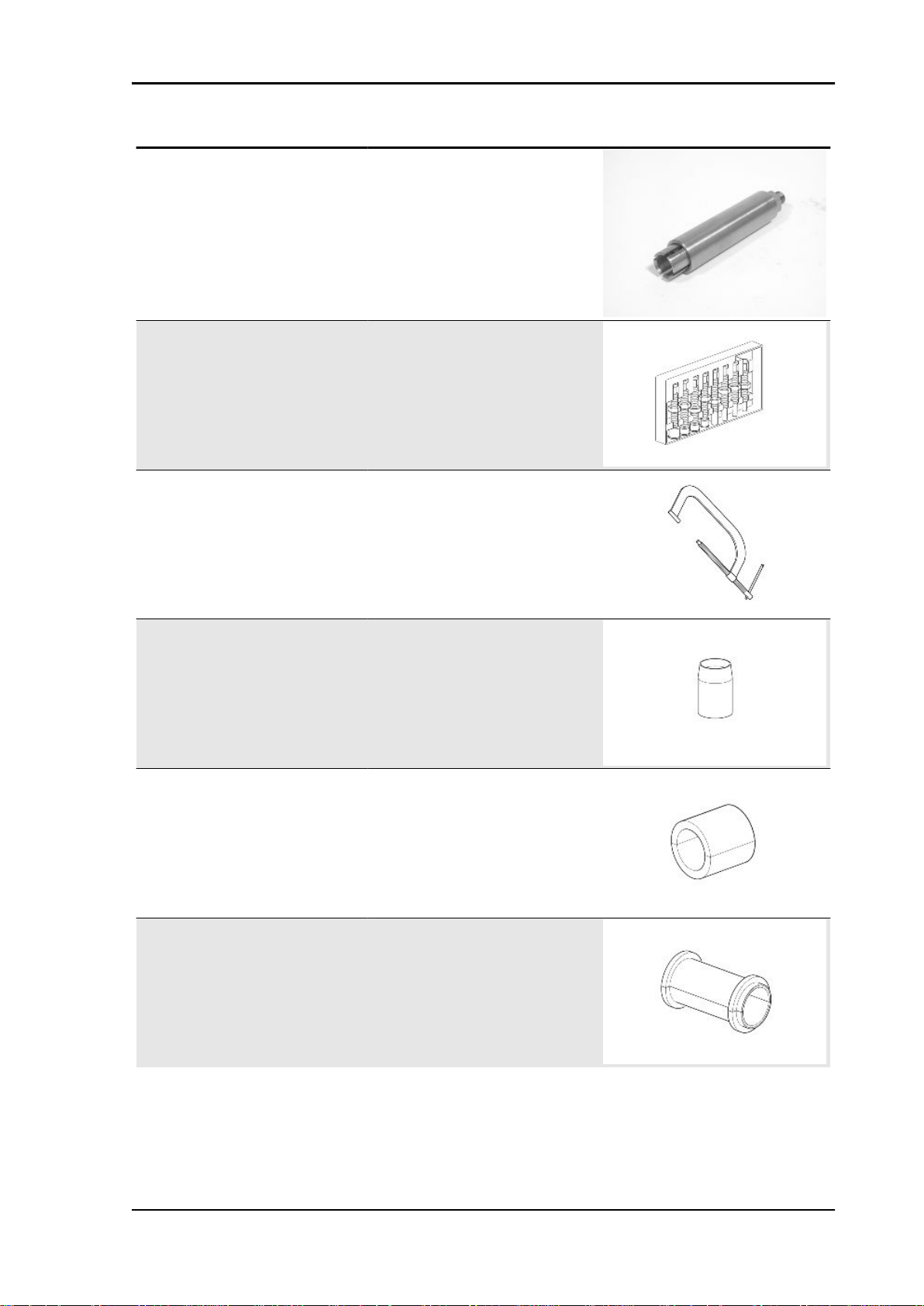

Stores code Description

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

020853Y Intake valve spring compressor

020854Y Outlet valve spring compressor

020855Y Lever for engaging the chain tensioner

020856Y Piston installation ring

020857Y Crankshaft bearing U bolt

S-TOOLS - 53

Page 54

Special tools RSV4 Factory

Stores code Description

020858Y Device for holding the pistons in the cyl-

AP8140199 Tool panel

020859Y Panel graphics

8140426 Hooks for panel

inders

020860Y Engine support extension

020861Y Countershaft bushing punch

020862Y Gearbox control rod roller cage fitting

punch

S-TOOLS - 54

Page 55

RSV4 Factory Special tools

Stores code Description

020863Y Desmodromic drum roller cage fitting

020864Y Engine mounting plate

020865Y Support for camshaft gear on head

punch

020709Y Engine support

AP8140187 Engine support stand

020376Y Adapter handle

020363Y 20-mm Oil seal guide

S-TOOLS - 55

Page 56

Special tools RSV4 Factory

Stores code Description

020364Y 25-mm Guide

020359Y 42 x 47 mm punch

020360Y 52x55 mm Adaptor

020655Y 62x68 mm Adaptor

020408Y 72x75-mm (2.83x2.95 in) adaptor

020306Y Punch for fitting the valve seal rings

S-TOOLS - 56

Page 57

RSV4 Factory Special tools

Stores code Description

020431Y Valve oil seal extractor

AP8140180 Extractor for bushings

AP8140179 Valve spring compressor

0277308 Guide bushing for secondary gearbox

AP8140146 Weight

AP8140189 Oil seal fitting tool for Ø 43 mm (1.69 in)

shaft

orifices

S-TOOLS - 57

Page 58

Special tools RSV4 Factory

Stores code Description

AP8140181 Fuel pressure checking tool

020481Y Control unit interface wiring

020680Y TXB Navigator

S-TOOLS - 58

Page 59

INDEX OF TOPICS

MAINTENANCE MAIN

Page 60

Maintenance RSV4 Factory

Maintenance chart

Correct maintenance is fundamental for ensuring the longevity of your vehicle and maintaining optimum

functionality and performance.

For this purpose, aprilia has formulated a series of checks and scheduled services (at the owner's

expense), are summarised in the table given in the following page. We recommend having any minor

faults resolved immediately by an Authorised aprilia Dealer, without waiting until the next scheduled

service interval.

All scheduled services must be carried out at the specified intervals and mileage, as soon as the predetermined mileage is reached. Carrying out scheduled services on time is essential for the validity of

your warranty. For further information regarding Warranty procedures and ''Scheduled Maintenance'',

please refer to the ''Warranty Booklet''.

NOTE

CARRY OUT MAINTENANCE OPERATIONS AT HALF THE INTERVALS SPECIFIED IF THE VEHICLE IS USED IN PARTICULAR RAINY OR DUSTY CONDITIONS, OFF ROAD OR FOR TRACK

USE.

I: INSPECT AND CLEAN, ADJUST, LUBRICATE OR REPLACE IF NECESSARY

C: CLEAN, R: REPLACE, A: ADJUST, L: LUBRICATE

(1) Check at each engine start

(2) Check and clean and adjust or replace, if necessary, before every journey.

(3) Check and clean and adjust or replace, if necessary, every 1000 Km (621 mi)

(4) Replace every 2 years

(5) Replace every 4 years

(6) Every 5000 Km (3107 mi) if the vehicle is used for racing

(7) Every 10000 Km (6213 mi) if the vehicle is used for racing

ROUTINE MAINTENANCE TABLE

Km x 1000

Rear shock absorber (6) I I

Set up (6) I I I I I

Cylinder equalisation I I I I

Spark plug (6) I R I R

Drive chain (3) I - L I - L I - L I - L I - L

Clutch cable L L L L L

Control cables and controls (6) I I I I I

Sprocket - pinion (6) I I I I

Rear suspension bearings - linkages I I

Steering bearings and steering free play (6) I I I I

Wheel bearings (6) I I I I

Control unit diagnosis I I I I

Brake discs (6) I I I I I

Air filter (6) I R I R

Engine oil filter (6) R R R R R

Engine oil filter (on pickup screen) (6) C

Fork I I

General vehicle operation (6) I I I I I

Valve clearance (7) A A

Cooling system (6) I I I I

1 10 20 30 40

MAIN - 60

Page 61

RSV4 Factory Maintenance

Km x 1000 1 10 20 30 40

Brake systems (6) I I I I I

Light circuit I I I I I

Stand switch I I I I

Safety switches I I I I I

Stop switches I I I I

Brake fluid (4) I I I I I

Coolant (4) I I I I I

Fork oil (7) R R

Engine oil (6) R R R R R

Light alignment I I I I

Fork oil baffles (6) I R I R

Flexible coupling I I

Tyres - pressure/wear (2) I I I I I

Wheels (6) I I I I I

Tightening torques (6) I I I I I

Clutch cover, flywheel and oil sump screws tightening

Fault warning light on instrument panel (1)

Fuel lines (5) I I I I

Clutch wear (7) I I

Brake pad wear (2) I I I I I

I I I I I

Spark plug

FRONT SPARK PLUGS

•

Remove the base of the air filter box.

•

Unscrew and remove the screw.

•

Slide off the front coil.

•

Unscrew and remove the front spark plug.

REAR SPARK PLUGS

MAIN - 61

Page 62

Maintenance RSV4 Factory

•

Remove the fuel tank.

•

Unscrew and remove the rear coil fixing screw.

•

Slide off the rear coil.

•

Unscrew and slide off the rear spark

plug.

Engine oil

Check

NOTE

HOT OIL IS LESS VISCOUS AND WILL DRAIN OUT MORE EASILY AND COMPLETELY.

•

Shut off the engine and wait for a few

seconds.

•

Keep the vehicle upright with both

wheels on the ground.

•

Ensure that the vehicle is on a level

surface.

•

Check, via the sight glass positioned

on the clutch casing, that the oil level

reaches at least three quarters of the

way up the sight glass itself.

•

If this is not the case, top-up the oil immediately through the filler plug.

CAUTION

THE OIL LEVEL MUST NEVER DROP BELOW THE MINI-

MUM (MIDDLE OF THE SIGHT GLASS), NOR EXCEED THE

MAXIMUM (SIGHT GLASS COMPLETELY FULL) LEVELS;

FAILURE TO OBSERVE THE MINIMUM AND MAXIMUM OIL

LEVELS MAY CAUSE SERIOUS DAMAGE TO THE ENGINE

Replacement

NOTE

HOT OIL IS LESS VISCOUS AND WILL DRAIN OUT MORE EASILY AND COMPLETELY.

MAIN - 62

Page 63

RSV4 Factory Maintenance

•

Place a container with a larger capacity

than the circuit under the drainage

plug.

•

Unscrew and remove the drainage

plug.

•

Unscrew and remove the filler cap.

•

Drain the oil into the container; allow

several minutes for oil to drain out completely.

•

Check and, if necessary, replace the

drainage plug sealing washers.

•

Screw and tighten the drainage plug.

•

Add 4 l (0.88 UK gal) of new engine oil

of the specified type.

•

Screw on the filler cap.

•

Warm up the engine up by running it for

a few minutes, then switch it off. After

thirty seconds, check the level in the

sight glass. Top up if necessary.

CAUTION

THE OIL LEVEL MUST NEVER DROP BELOW THE MINI-

MUM (MIDDLE OF THE SIGHT GLASS), NOR EXCEED THE

MAXIMUM (SIGHT GLASS COMPLETELY FULL) LEVELS;

FAILURE TO OBSERVE THE MINIMUM AND MAXIMUM OIL

LEVELS MAY CAUSE SERIOUS DAMAGE TO THE ENGINE

Engine oil filter

Replace the engine oil filter each time you

change the engine oil.

•

Drain the engine oil completely.

•

Unscrew and remove the engine oil filter from its seat.

NOTE

NEVER REUSE AN OLD FILTER.

MAIN - 63

Page 64

Maintenance RSV4 Factory

•

Spread a thin layer of oil on the sealing ring of the new engine oil filter.

•

Insert and screw the new engine oil filter in the seat, filling the filter to 1/3 of its capacity with

engine oil before fitting.

See also

Replacement

Air filter

•

Remove the fuel tank.

•

Unscrew and remove the eight air filter

box cover screws

•

See also

Fuel tank

•

Disconnect the upper injector fuel delivery union.

Disconnect the variable geometry intake system connector.

MAIN - 64

Page 65

RSV4 Factory Maintenance

•

Fit a suitably sized shim behind the filter box cover.

•

Lift the filter box cover on which the

control unit is installed.

•

Do not rotate the cover excessively to

avoid straining the pipes and cables.

•

Plug the inlet duct opening with clean

paper

•

Unscrew and remove the three air filter

screws.

•

Remove the filter and replace it with a

new component of the same type.

•

Remove the air filter.

Checking the valve clearance

FRONT HEAD

•

Remove both throttle bodies and the

coils.

•

Remove the front head cover and the

spark plugs.

•

Remove the cap on the clutch cover in

See also

order to turn the crankshaft, taking care

not to lose the O-ring.

MAIN - 65

Page 66

Maintenance RSV4 Factory

Removing the throttle body

Spark plug

Head cover removal

•

Use a feeler gauge to check the clearance between the cam of the shaft and

the relative tappet for both front head

shafts.

Characteristic

Acceptable values with control clearance between cam and valve

intake: 0.10 - 0.15 mm (0.0039 - 0.0059 in) exhaust: 0.20 - 0.25 mm (0.0079 - 0.0098 in)

REAR HEAD

•

Remove both throttle bodies and the spark plugs.

•

Remove the rear head cover.

See also

Removing the throttle body

Spark plug

Head cover removal

•

Use a feeler gauge to check the clearance between the cam on the shaft and

the relative tappet for both rear head

shafts.

Characteristic

Acceptable values with control clearance between cam and valve

intake: 0.10 - 0.15 mm (0.0039 - 0.0059 in) exhaust: 0.20 - 0.25 mm (0.0079 - 0.0098 in)

MAIN - 66

Page 67

RSV4 Factory Maintenance

Front cylinder head valves

•

Check the front valve head clearance and restore the correct clearance values if necessary,

proceeding as described below.

•

Remove both head covers, the alternator side cover and remove the cap

on the clutch cover in order to rotate

the crankshaft.

•

Remove the O ring.

See also

Head cover removal

Removing the flywheel cover

•

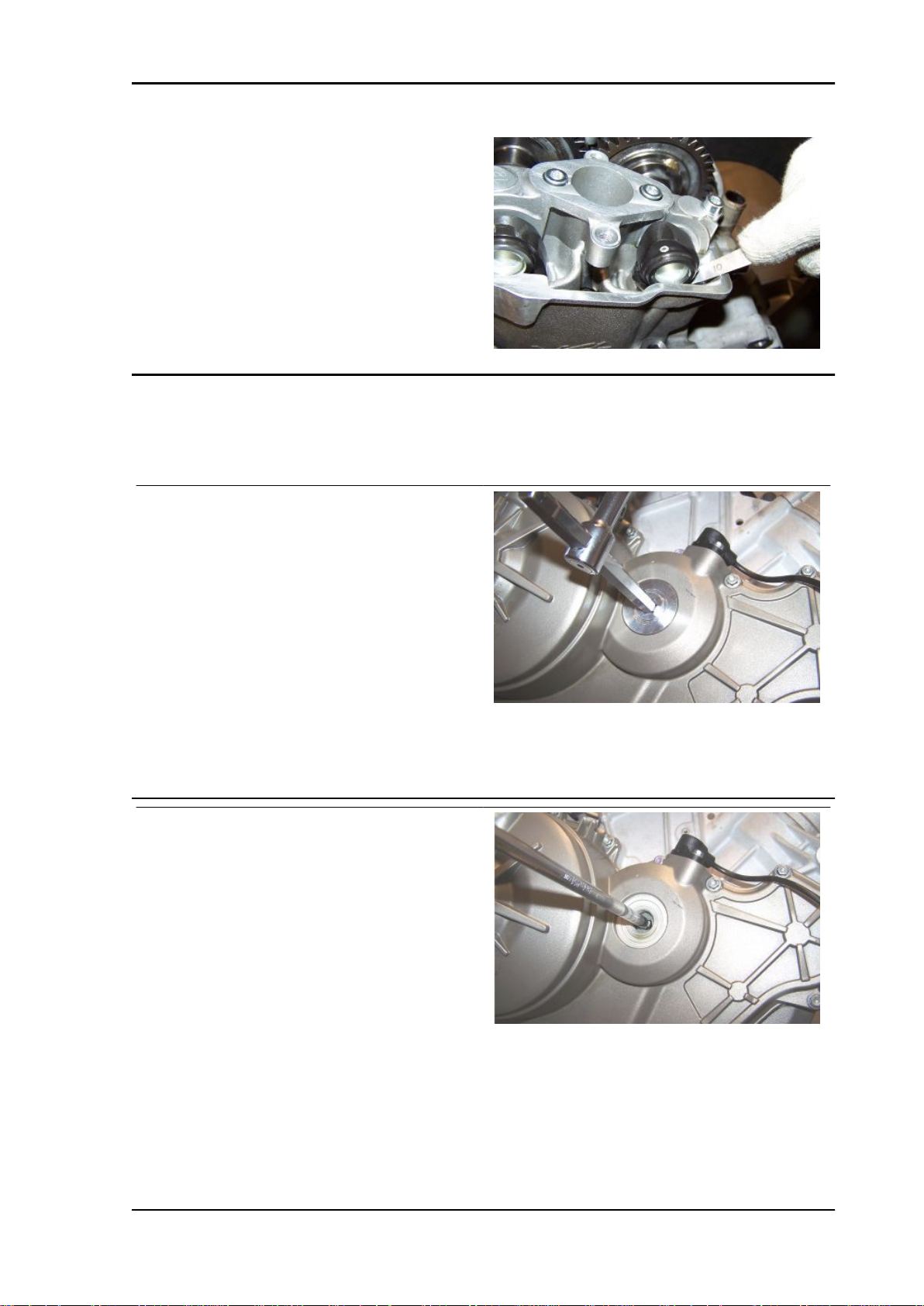

Turn the crankshaft from the hole on

the clutch cover.

•

Move cylinder piston 1 (left rear piston)

to the overlap TDC;

•

Turn the crankshaft 150° in the direction of engine rotation (direction of travel).

MAIN - 67

Page 68

Maintenance RSV4 Factory

•

Insert the pin from the flywheel side, in

the hole in the crankshaft.

NOTE

THE SPECIAL TOOL IS ONLY USED FOR IDENTIFYING

THE CORRECT CRANKSHAFT POSITION.

DO NOT USE IT FOR TIGHTENING OPERATIONS.

Specific tooling

020852Y Crankshaft timing pin

•

Align the intake camshaft with the specific hole on the U bolt.

•

Insert the specified pin.

Specific tooling

020851Y Camshaft timing pin

•

Remove the two crankshaft and camshaft reference pins.

•

Turn the crankshaft until the gear

screw covered by the head when the

hole on the camshaft gear is aligned

with the hole on the U bolt, is visible.

•

Block crankshaft rotation using one of

the specific tools.

•

Unscrew and remove the camshaft

gear screw.

•

Remove the crankshaft locking tool.

Specific tooling

020850Y Primary gear lock

020848Y Flywheel retainer

MAIN - 68

Page 69

RSV4 Factory Maintenance

Repeat the following operations:

•

move cylinder piston 1 (left rear piston)

to TDC;

•

turn the crankshaft 150° in the direction

of engine rotation (direction of travel) in

order to align the hole on the intake

camshaft with the specific hole on the

U bolt; this ensures that all the front

cylinder bank valve springs are decompressed.

•

Refit the camshaft timing pin in the hole

of the front head U bolt and the crankshaft timing pin from the flywheel side.

•

Remove the camshaft timing pin.

•

Unscrew and remove the two U bolt

screws (1).

•

Remove the U bolt and the oil pipe.

Specific tooling

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

•

Block crankshaft rotation using one of

the specific tools.

•

Unscrew and remove the second intake camshaft gear screw.

•

Leave the gear on the camshaft.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

•

Install the specific camshaft gear support tool.

•

Fix it to the head using the two screws

(1).

•

Move the gear from the camshaft to the

tool.

Specific tooling

MAIN - 69

Page 70

Maintenance RSV4 Factory

020865Y Support for camshaft gear on head

•

Unscrew and remove the eight screws

(2), proceeding in stages and diagonally.

•

Retrieve the washers from the screws

near the spark plug holes.

•

Remove the U bolts with the O rings

and locator pins.

•

Remove the intake and exhaust camshafts.

If the two camshafts are timed correctly, the exhaust camshaft gear tooth (indicated with a dot) is

meshed with the trough of the intake camshaft

gear (indicated with two dots).

•

Use a magnet to remove the tappet.

CAUTION

REMOVE THE TAPPET CAREFULLY AS THE PAD MAY FALL INTO THE ENGINE.

•

Retrieve the pad and replace with a

suitable component to achieve the correct valve clearance.

Refer to the table: "Calibrated pad thicknesses" to identify the suitable thickness.

•

Fit the tappet.

See also

Calibrated pad thickness

MAIN - 70

Page 71

RSV4 Factory Maintenance

•

Install the intake and exhaust camshafts on the front head, bearing in

mind that:

the exhaust camshaft gear tooth (indicated with a

dot) is meshed with the trough of the intake camshaft gear (indicated with two dots).

CLEAN THOROUGHLY THE SEATS OF THE GEAR RETAINER SCREWS, ON THE INTAKE CAMSHAFT.

•

Fit the U bolts with the nine O rings and

locator pins.

•

Fit the new washers under the screws

(2) near the spark plug holes only.

•

Tighten the seven screws (2) operating

in stages and diagonally.

•

Do not fit the eighth screw (2 - fastening

the oil pipe) yet.

•

Move the gear from the mounting tool

to the camshaft.

•

Unscrew and remove the two screws

(1).

•

Remove the tool.

Specific tooling

020865Y Support for camshaft gear on head

•

Fit the U bolt and the oil pipe.

•

Tighten the two U bolt screws (1) and

the screw (2) that was not fitted previously.

MAIN - 71

Page 72

Maintenance RSV4 Factory

•

Align the intake camshaft with the specific hole on the U bolt.

•

Insert the specified pin.

Specific tooling

020851Y Camshaft timing pin

•

Apply Loctite 243 threadlock on the

timing gear screw.

•

Apply and loosely tighten the gear fixing screw on the camshaft.

•

Block crankshaft rotation using one of

the specific tools.

•

Tighten the gear fixing screw on the

camshaft to exactly the torque specified.

•

Remove the crankshaft locking tool.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

•

Remove the two crankshaft and camshaft reference pins.

•

Turn the crankshaft until the gear

screw covered by the head when the

hole on the camshaft gear is aligned

with the hole on the U bolt, is visible.

•

Block crankshaft rotation using one of

•

MAIN - 72

the specific tools.

Apply Loctite 243 threadlock on the

second gear screw.

Page 73

RSV4 Factory Maintenance

•

Tighten the second gear camshaft control gear screw rigourously to the torque value.

•

Remove the crankshaft locking tool.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

•

Turn the crankshaft back to the previous position in which the camshaft and U bolt holes

were aligned; insert the reference pin while checking with the crankshaft reference pin, that

the flywheel side hole and the hole on the crankshaft are perfectly aligned.

•

If this is not the case, repeat the timing operations.

Specific tooling

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

•

Check if the clearance between the cam on the shaft and the tappet is correct.

•

If not, repeat the valve clearance adjustment procedure.

Rear cylinder head valves

•

Check the rear valve head clearance and restore the correct clearance values if necessary,

proceeding as described below.

•

Remove the rear head cover and the clutch cover.

•

Move cylinder piston 1 (left rear piston) to the TDC;

•

Turn the crankshaft 450° (one complete turn + 90°) in the direction of motor rotation (direction

of travel).

•

Insert the pin from the clutch side into

the hole in the crankshaft.

NOTE

THE SPECIAL TOOL IS ONLY USED FOR IDENTIFYING

THE CORRECT CRANKSHAFT POSITION.

DO NOT USE IT FOR TIGHTENING OPERATIONS.

Specific tooling

020852Y Crankshaft timing pin

See also

Head cover removal

Removing the

MAIN - 73

Page 74

Maintenance RSV4 Factory

clutch cover

•

Align the intake camshaft with the specific hole on the U bolt.

•

Insert the specified pin.

Specific tooling

020851Y Camshaft timing pin

•

Remove the two crankshaft and camshaft reference pins.

•

Turn the crankshaft until the gear

screw covered by the head when the

hole on the camshaft gear is aligned

with the hole on the U bolt, is visible.

•

Block crankshaft rotation using one of

the specific tools.

•

Unscrew and remove the camshaft

gear screw.

•

Remove the crankshaft locking tool.

Specific tooling

020850Y Primary gear lock

020848Y Flywheel retainer

Repeat the following operations:

•

move cylinder piston 1 (left rear piston)

to TDC;

•

turn the crankshaft by 450° (one complete turn + 90°) in the direction of en-

MAIN - 74

gine rotation (direction of travel) to

align the hole on the intake camshaft

with the specific hole on the U bolt. This

ensures that all the rear cylinder bank

valve springs are decompressed.

Page 75

RSV4 Factory Maintenance

•

Refit the camshaft timing pin in the hole

in the rear head U-bolt and the crankshaft timing pin from the clutch side.

•

Remove the camshaft timing pin.

•

Unscrew and remove the two U bolt

screws (1).

•

Remove the U bolt and the oil pipe.

Specific tooling

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

•

Block crankshaft rotation using one of

the specific tools.

•

Unscrew and remove the second intake camshaft gear screw.

•

Leave the gear on the camshaft.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

•

Install the specific camshaft gear support tool.

•

Fix it to the head using the two screws

(1).

•

Move the gear from the camshaft to the

tool.

Specific tooling

020865Y Support for camshaft gear on head

•

Unscrew and remove the eight screws

(2), proceeding in stages and diagonally.

•

Retrieve the washers from the screws

near the spark plug holes.

•

Remove the U bolts with the O rings

and locator pins.

MAIN - 75

Page 76

Maintenance RSV4 Factory

•

Remove the intake and exhaust camshafts.

If the two camshafts are timed correctly, the intake

camshaft gear tooth (indicated with one dot) is

meshed with the trough of the exhaust camshaft

gear (indicated with two dots).

•

Use a magnet to remove the tappet.

CAUTION

REMOVE THE TAPPET CAREFULLY AS THE PAD MAY FALL INTO THE ENGINE.

•

Retrieve the pad and replace with a

suitable component to achieve the correct valve clearance.

Refer to the table: "Calibrated pad thicknesses" to identify the suitable thickness.

•

Fit the tappet.

See also

Calibrated pad thickness

•

Install the intake and exhaust camshafts on the rear head, remembering

that:

the intake camshaft gear tooth (indicated with a

dot) is inserted in the groove of the exhaust camshaft gear (indicated with two dots).

CLEAN THOROUGHLY THE SEATS OF THE GEAR RETAINER SCREWS, ON THE INTAKE CAMSHAFT.

MAIN - 76

Page 77

RSV4 Factory Maintenance

•

Fit the U bolts with the nine O rings and

locator pins.

•

Fit the new washers under the screws

(2) near the spark plug holes only.

•

Tighten the seven screws (2) operating

in stages and diagonally.

•

Do not fit the eighth screw (2 - fastening

the oil pipe) yet.

•

Move the gear from the mounting tool

to the camshaft.

•

Unscrew and remove the two screws

(1).

•

Remove the tool.

Specific tooling

020865Y Support for camshaft gear on head

•

Fit the U bolt and the oil pipe.

•

Tighten the two U bolt screws (1) and

the screw (2) that was not fitted previously.

•

Align the intake camshaft with the specific hole on the U bolt.

•

Insert the specified pin.

Specific tooling

020851Y Camshaft timing pin

MAIN - 77

Page 78

Maintenance RSV4 Factory

•

Apply Loctite 243 threadlock on the

timing gear screw.

•

Apply and loosely tighten the gear fixing screw on the camshaft.

•

Block crankshaft rotation using one of

the specific tools.

•

Tighten the gear fixing screw on the

camshaft to exactly the torque specified.

•

Remove the crankshaft locking tool.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

•

Remove the two crankshaft and camshaft reference pins.

•

Turn the crankshaft until the gear

screw covered by the head when the

hole on the camshaft gear is aligned

with the hole on the U bolt, is visible.

•

Block crankshaft rotation using one of

the specific tools.

•

Apply Loctite 243 threadlock on the

second gear screw.

•

Tighten the second gear camshaft control gear screw rigourously to the torque value.

•

Remove the crankshaft locking tool.

Specific tooling

020848Y Flywheel retainer

020850Y Primary gear lock

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

MAIN - 78

Page 79

RSV4 Factory Maintenance

•

Turn the crankshaft back to the previous position in which the camshaft and U bolt holes

were aligned; Refit the reference pin while checking, using the crankshaft reference pin, that

the clutch side hole and the hole in the crankshaft are perfectly aligned.

•

If this is not the case, repeat the timing operations.

Specific tooling

020851Y Camshaft timing pin

020852Y Crankshaft timing pin

•

Check if the clearance between the cam on the shaft and the tappet is correct.

•

If not, repeat the valve clearance adjustment procedure.

Calibrated pad thickness

Pad thicknesses for adjusting valve clearance correctly:

1.75 mm (0.0689 in)

1.80 mm (0.0709 in)

1.85 mm (0.0728 in)

1.90 mm (0.0748 in)

1.95 mm (0.0768 in)

2 mm (0.0787 in)

2.05 mm (0.0807 in)

2.1 mm (0.0827 in)

2.15 mm (0.0846 in)

2.2 mm (0.0866 in)

MAIN - 79

Page 80

Maintenance RSV4 Factory

2.25 mm (0.0886 in)

2.3 mm (0.0905 in)

2.35 mm (0.0925 in)

2.4 mm (0.0945 in)

2.45 mm (0.0964 in)

2.50 mm (0.0984 in)

2.55 mm (0.1004 in)

2.6 mm (0.1024 in)

2.65 mm (0.1043 in)

2.7 mm (0.1063 in)

2.75 mm (0.1083 in)

2.8 mm (0.1102 in)

2.85 mm (0.1122 in)

2.9 mm (0.1142 in)

2.95 mm (0.1161 in)

3 mm (0.1181 in)

3.05 mm (0.1201 in)

3.10 mm (0.1220 in)

3.15 mm (0.1240 in)

MAIN - 80

Page 81

INDEX OF TOPICS

TROUBLESHOOTING TROUBL

Page 82

Troubleshooting RSV4 Factory

TROUBLESHOOTING PROCEDURE IF THE EFI WARNING LIGHT ON THE INSTRUMENT PANEL

TURNS ON OR IF THERE IS ABNORMAL ENGINE PERFORMANCE

CAUTION

BEFORE CARRYING OUT ANY TROUBLESHOOTING, CAREFULLY READ THE GENERAL TROUBLESHOOTING CONCEPTS FOR ELECTRICAL DEVICES AT THE BEGINNING OF THE CHECK

AND CONTROL SECTION IN THE ELECTRICAL SYSTEM CHAPTER.

•

1 - THE "EFI" WARNING LIGHT IS ON AND THE WORD "SERVICE" IS SHOWN or THE

"EFI" WARNING LIGHT IS FLASHING AND THE WORDS "URGENT SERVICE" ARE

SHOWN or ONE OF THE TWO SITUATIONS TAKES PLACE AND IS SUDDENLY OUT or

THERE IS ABNORMAL ENGINE PERFORMANCE

•

2 - CONNECT TO THE DIAGNOSIS INSTRUMENT THROUGH CONTROL UNIT BY SELECTING "SELF-ACQUISITION, APRILIA, RSV4"

•

3 - ARE CURRENT- "ATT"- or STORED- "MEM"- ERRORS SHOWN IN THE "ERRORS

DISPLAY" SCREEN PAGE?

YES, go to 4; NO, go to 11.

•

4 - IF THE ERROR IN THE CENTRAL WINDOW IS SELECTED AND "?" IS DISPLAYED,

PRESS THE KEY "?" TO OBTAIN FURTHER INFORMATION ABOUT THE ERROR. THEN

GO TO THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS" CHAPTER AND READ

THE INFORMATION CONCERNING THE DEFECTIVE COMPONENT

•

5 - ACCORDING TO WHAT IS INDICATED ABOUT THE ERROR/S, PROCEED AS SUGGESTED AND SOLVE THE PROBLEM

•

6 - WAS THE PROBLEM SOLVED BY REPLACING THE MARELLI CONTROL UNIT?

YES, go to 7; NO, go to 8.

•

7 - READ THE ACTIVATION PROCEDURE FOR A NEW CONTROL UNIT ON THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS/ECU/MARELLI CONTROL UNIT" CHAPTER - END

•

8 - SELECT "ERROR CLEARING" FROM THE "DEVICES ACTIVATION (INJECTOR

ICON)" SCREEN PAGE

•

9 - WAS THE PROBLEM SOLVED BY REPLACING THE THROTTLE GRIP SENSOR

(DEMAND) OR THE THROTTLE BODY?

•

10 - READ THE RESET PROCEDURE ON THE "ELECTRICAL SYSTEM/CHECKS AND

CONTROLS/THROTTLE GRIP POSITION SENSOR OR THROTTLE BODY" CHAPTER END

•

11 - CHECK IF THERE ARE CURRENT OR STORED ERRORS DETECTED BY THE INSTRUMENT PANEL REFERRING TO THE "DIAGNOSIS" CHAPTER, "INSTRUMENT

TROUBL - 82

NO, END; YES, go to 10

Page 83

RSV4 Factory Troubleshooting

PANEL ERRORS" SECTION. IF THERE ARE ERRORS PRESENT, SOLVE THE FAULT

AND SELECT "CLEAR ERRORS"; IF THERE ARE NO ERRORS PRESENT, go to 12

•

12 - IN THE "ENGINE PARAMETER READING" SCREEN PAGE, DOES THE "AIR TEMPERATURE" PARAMETER INDICATE A VALUE EQUIVALENT TO ROOM TEMPERATURE?

YES, go to 13; NO, note A

•

13 - IN THE "ENGINE PARAMETER READING" SCREEN PAGE, DOES THE ENGINE

TEMPERATURE PARAMETER WITH COLD ENGINE INDICATE A VALUE SIMILAR TO

THAT OF THE AIR TEMPERATURE PARAMETER? AFTER STARTING THE ENGINE,

DOES THE PARAMETER INCREASE GRADUALLY INDICATING A CORRECT VALUE?

YES, go to 14; NO, note B

•

14 - IN THE "ENGINE PARAMETER READING" AND THE "LAMBDA SENSOR CORRECTION" SCREEN PAGES, WITH ENGINE AT IDLE AND ENGINE TEMPERATURE AT >

65°C, DOES THE VALUE VARY WITHIN THE 0.85 - 1.15 RANGE?

YES, go to 15; NO, note C

•

15 - IN THE "ENGINE PARAMETER READING" WITH ENGINE AT IDLE AND ENGINE

TEMPERATURE >65°c, "FRONT THROTTLE CORRECTION" OR "REAR THROTTLE

CORRECTION", WITH ENGINE AT IDLE, ARE THE PARAMETERS INCLUDED WITHIN

(-0.8° - +0.8°) INTERVAL? AND IN THE SAME SCREEN PAGE, ARE THE "FRONT

THROT., POT. 1 (DEGREES)" AND " "REAR THROT., POT. 1 (DEGREES)", WITH ENGINE AT IDLE, > OR = A 0.5°? CAUTION: THE DIFFERENCE OF THE THROTTLE

CORRECTION VALUES BETWEEN THE REAR AND FRONT CYLINDER MUST NOT BE

>1°

YES, go to 16; NO, note D

•

16 - CHECK: ENGINE SPEED SENSOR, FUEL PRESSURE, INJECTORS (MECHANICAL

OPERATION), COILS (SPARK), ENGINE MECHANICS - END

Note A: SEE THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS/AIR TEMPERATURE SENSOR" CHAPTER.

Note B: SEE THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS/ENGINE TEMPERATURE

SENSOR" CHAPTER.

Note C: SEE THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS/LAMBDA PROBE" CHAPTER.

Note D: SEE THE "ELECTRICAL SYSTEM/CHECKS AND CONTROLS/THROTTLE BODY" CHAPTER.

See also

Checks and inspections

TROUBL - 83

Page 84

Troubleshooting RSV4 Factory

The engine does not start

THE ENGINE DOES NOT START, THE INSTRUMENT PANEL TURNS ON.

CAUTION

AXONE SHOULD BE WORKING PROPERLY AND UPGRADED AT LEAST TO THE 7.0.0 VERSION

OR THE PGDS UPDATED AT LEAST TO THE 3.0.0 VERSION

CAUTION

BEFORE ANY TROUBLESHOOTING, MAKE SURE THAT:

1) BATTERY VOLTAGE IS ABOVE 12V;

2) THE MAIN 30A FUSE IS NOT DAMAGED AND IS ADEQUATELY FITTED;

3) AUXILIARY FUSES ARE NOT DAMAGED AND ARE ADEQUATELY FITTED.

NOTE

THE RELAY NUMBER SPECIFIED REFERS TO THE WIRING DIAGRAM. THE POSITION OF THE

RELAY ON THE VEHICLE IS INDICATED IN THE "ELECTRICAL SYSTEM/COMPONENT LAYOUT/

RELAY LAYOUT" CHAPTER.

•

1- WITH THE KEY TURNED TO "ON", THE INSTRUMENT PANEL LIGHTS UP BUT NO

FAULT INDICATION IS SHOWN WITH INDICATION "SERVICE" OR "URGENT SERVICE"

BUT THE WORD ECU IS READ BELOW and THE PLUG SOCKET DISCONNECTED?

YES, go to CONTROL UNIT SUPPLY CHECK; NO, go to 2

•

2. IS THE FUEL PUMP ACTIVATED?

YES, go to 3; NO, go to FUEL PUMP CHECK

•

3. THE DIAGNOSIS INSTRUMENT COMMUNICATES WITH THE CONTROL UNIT? THAT

IS, AFTER SELECTING FUEL INJECTION, AND FOLLOWING THE INSTRUCTION, WITH

KEY SET TO "ON", THE PARAMETERS, STATUSES, ETC ARE READ?

YES, go to 4; NO, go to DIAGNOSIS INSTRUMENT CONNECTION CHECK

•

4. WITH DIAGNOSIS INSTRUMENT ("DEVICES ACTIVATION" SCREEN PAGE, INJECTOR ICON) CARRY OUT ACTIVATION OF A LOWER INJECTOR (IT IS ADVISED TO

DISCONNECT THE BLACK FUEL PUMP CONNECTOR AT PIN 4, ON THE RIGHT): IS

THE INJECTOR ACTIVATED?

YES, go to 5, NO, go to INJECTION RELAY 33 CHECK

5. DOES THE MOTOR TURN WHEN THE STARTER SWITCH IS PRESSED?

YES, SEE CHAPTER "ELECTRICAL SYSTEM/CHECK AND CONTROLS/ENGINE SPEED SEN-

•

6. WHAT DOES THE "START-UP ENABLING SWITCH" STATUS IN THE DIAGNOSIS

INSTRUMENT, DEVICES STATUS SCREEN PAGE, ICON 0/1 MEAN?

•

7. WHAT DOES THE "FALL SENSOR" STATUS IN THE DIAGNOSIS INSTRUMENT, DEVICES STATUS SCREEN PAGE, ICON 0/1 MEAN?

TROUBL - 84