Page 1

K

Service Source

LaserWriter Select

LaserWriter Select 300, LaserWriter Select 310,

LaserWriter Select 360

Page 2

K

Service Source

Basics

LaserWriter Select

Page 3

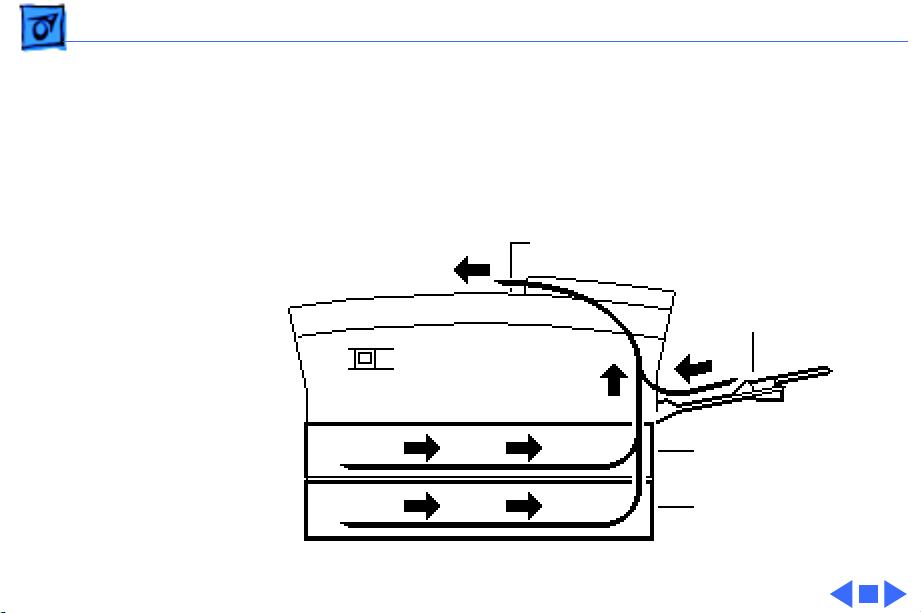

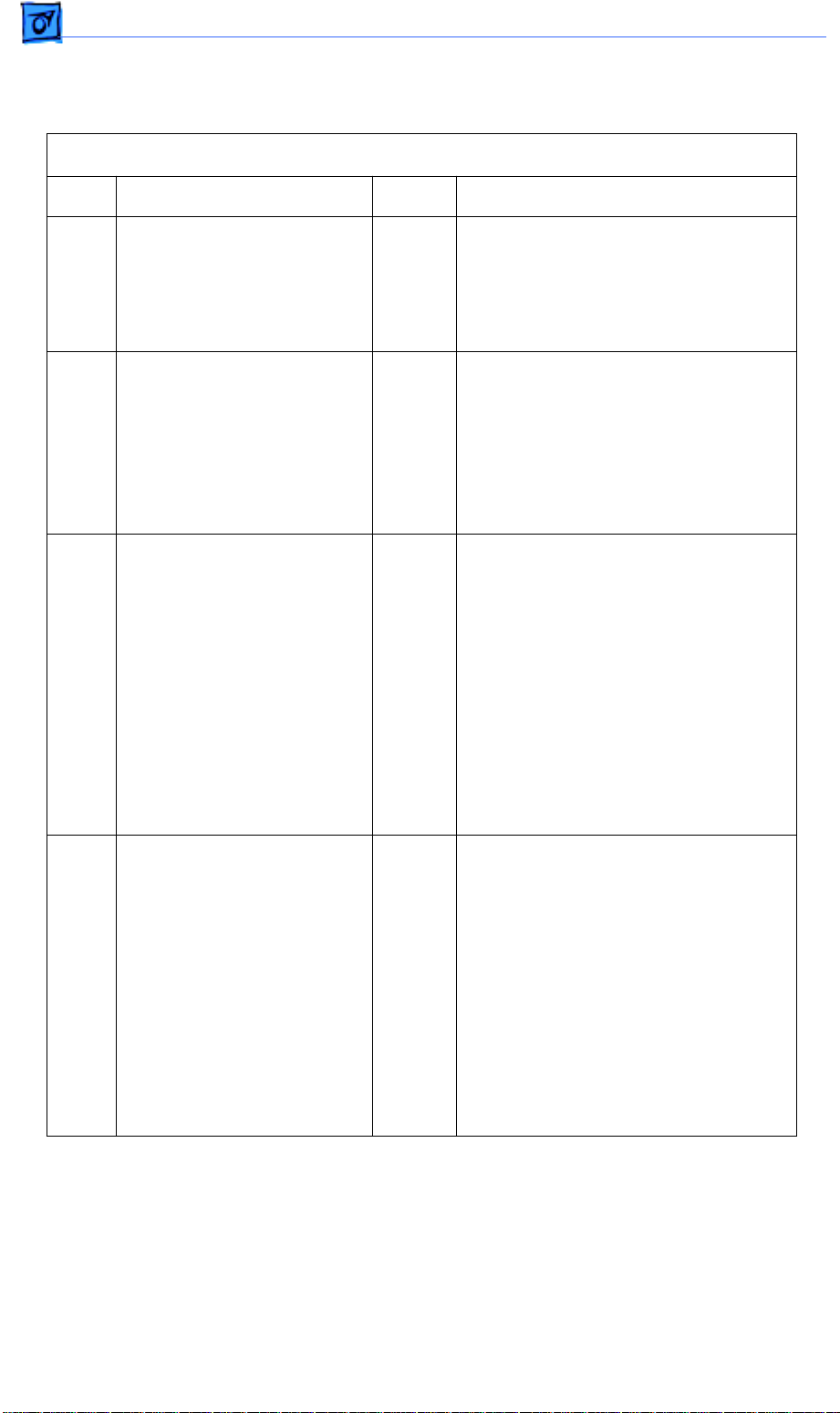

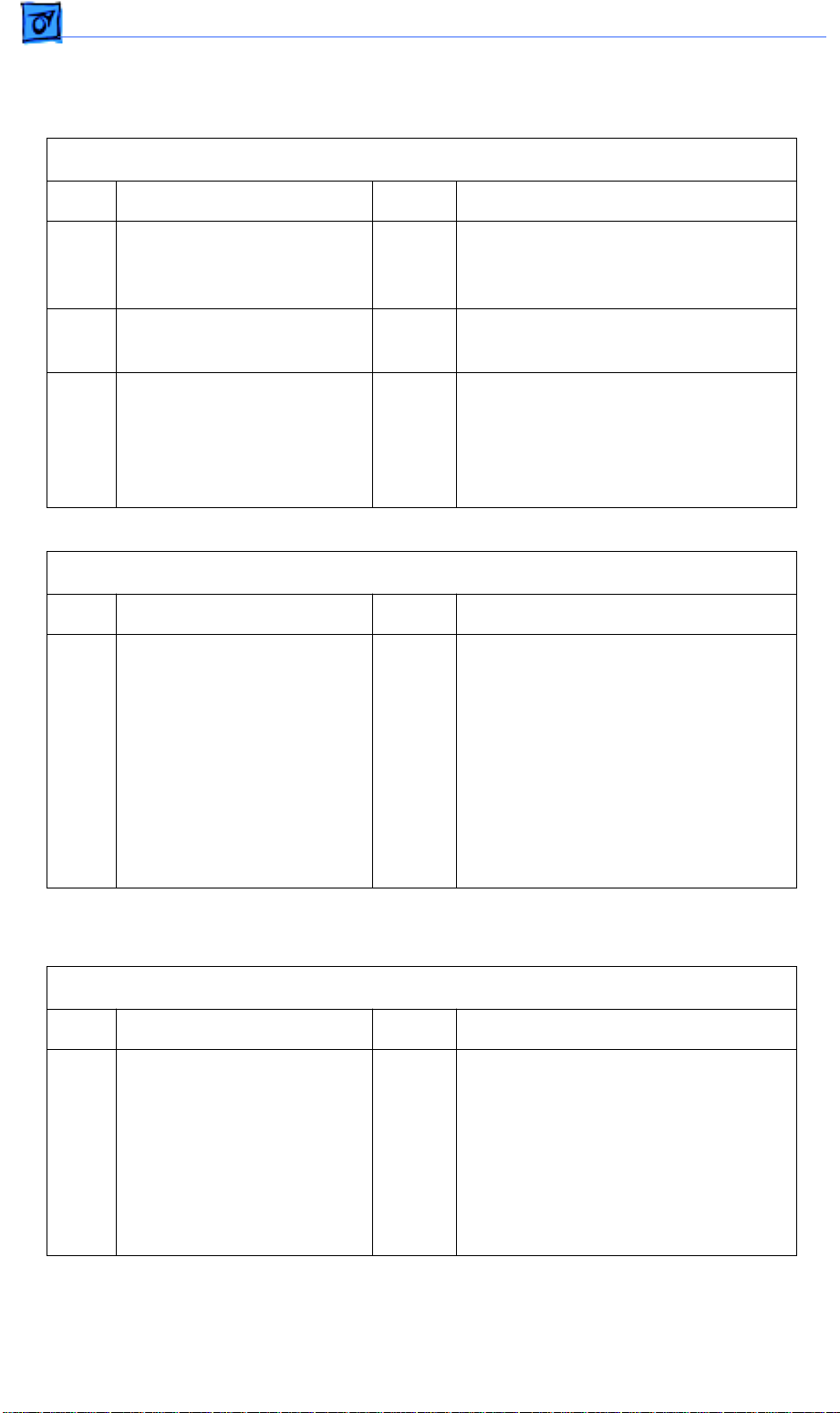

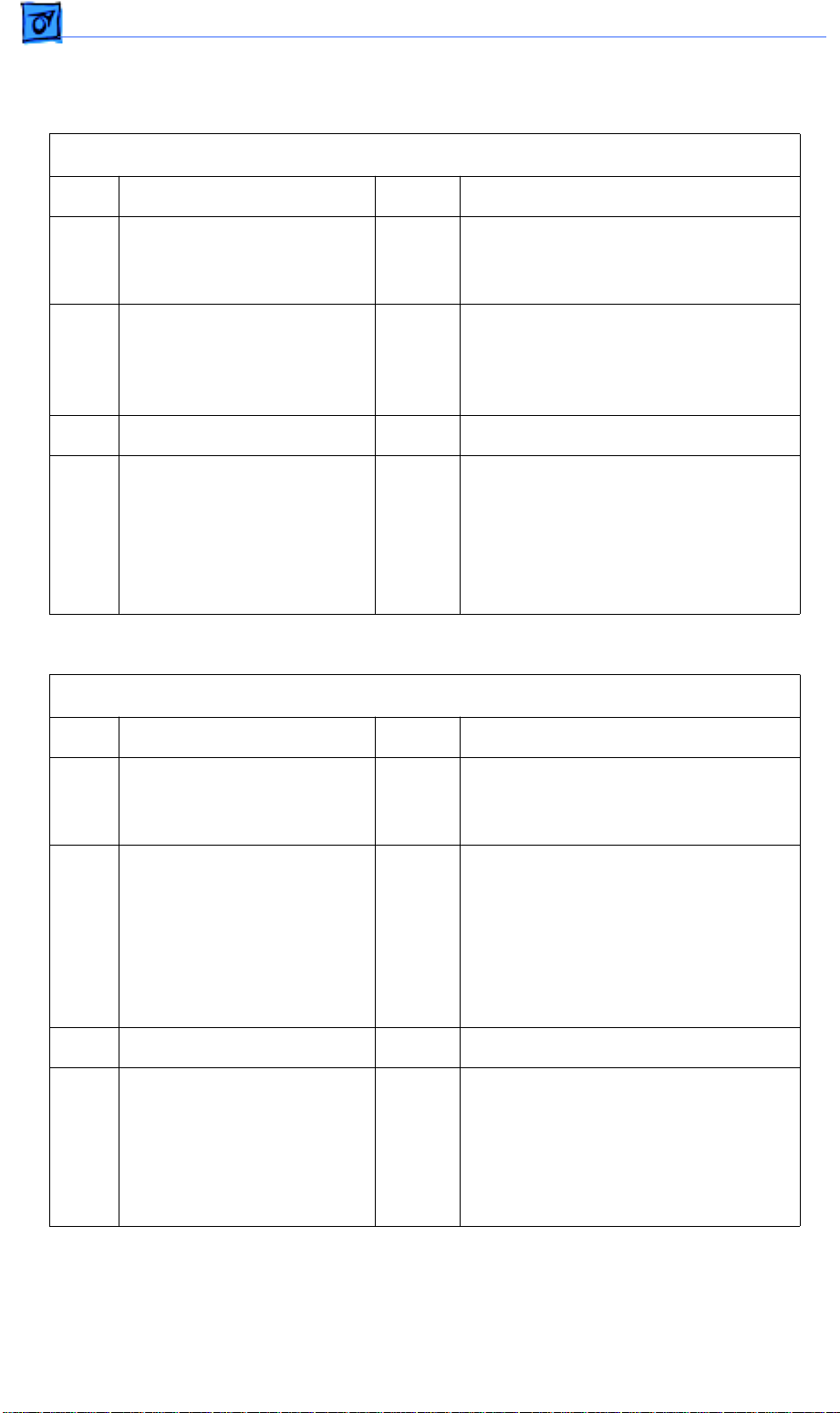

Basics Paper Path - 1

Paper Path

There are three paper sources and one output tray in a

complete system.

Output Tray

Manual Feed Tray

Standard Cassette

(250 Sheets)

Optional Sheet Feeder

(250 or 500 Sheets)

Page 4

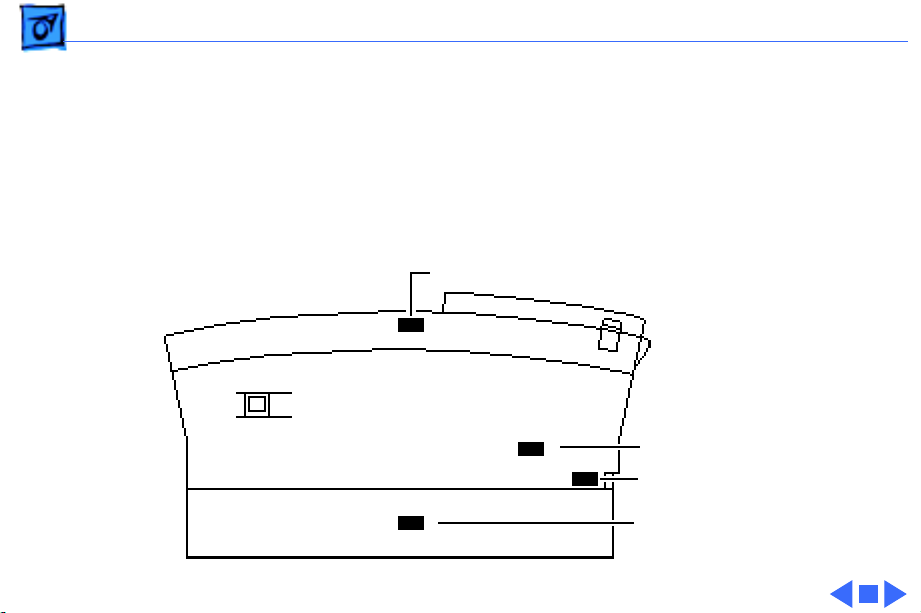

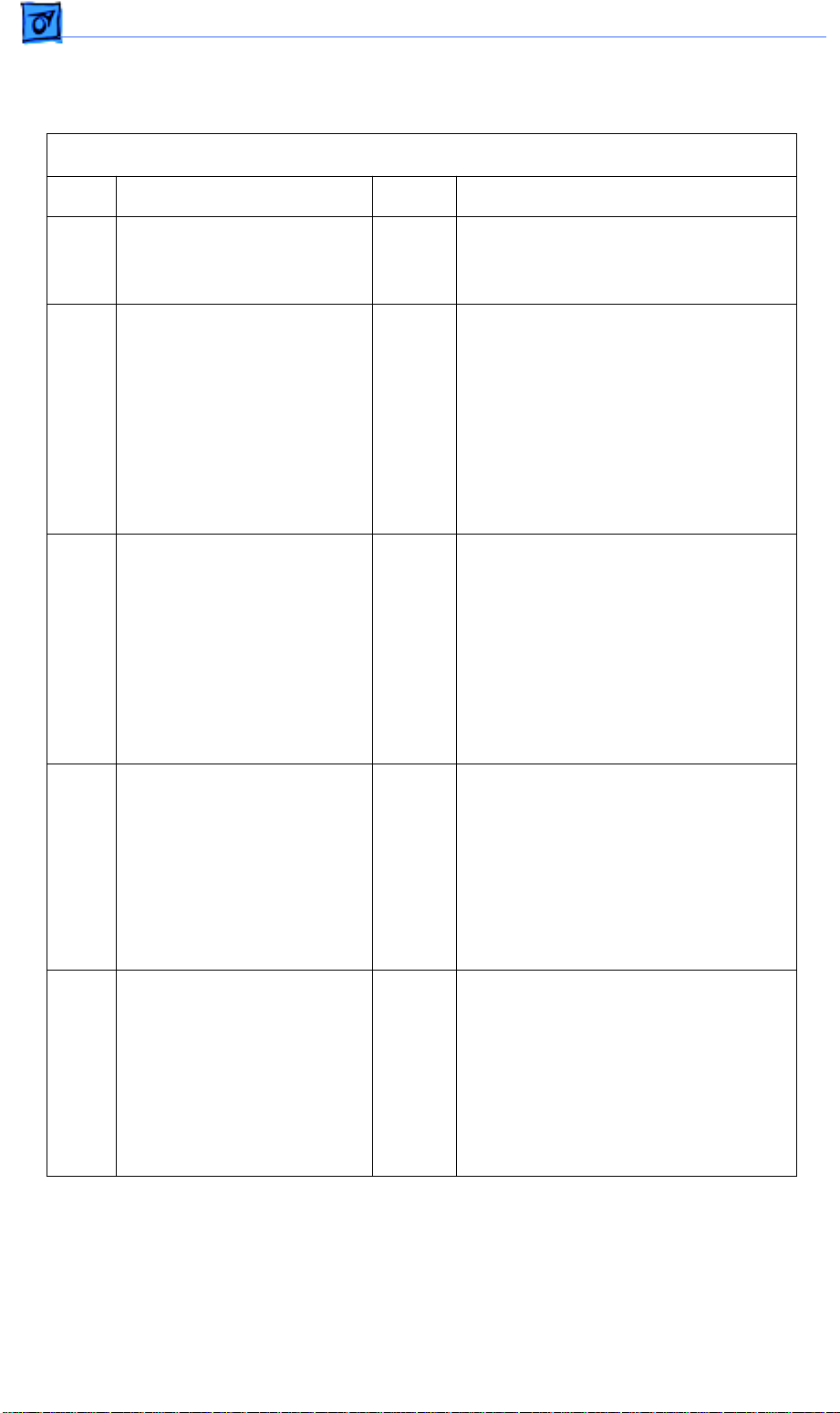

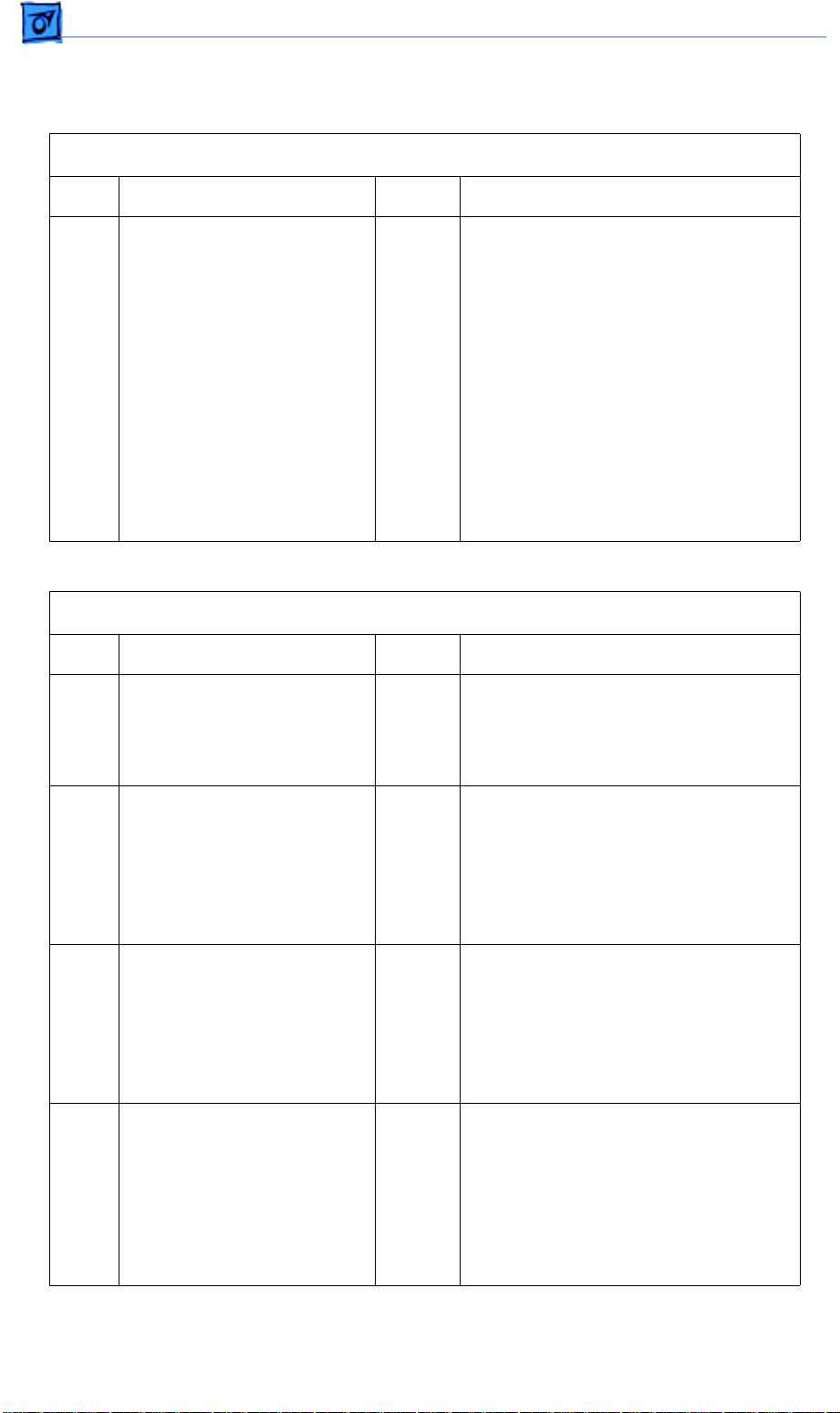

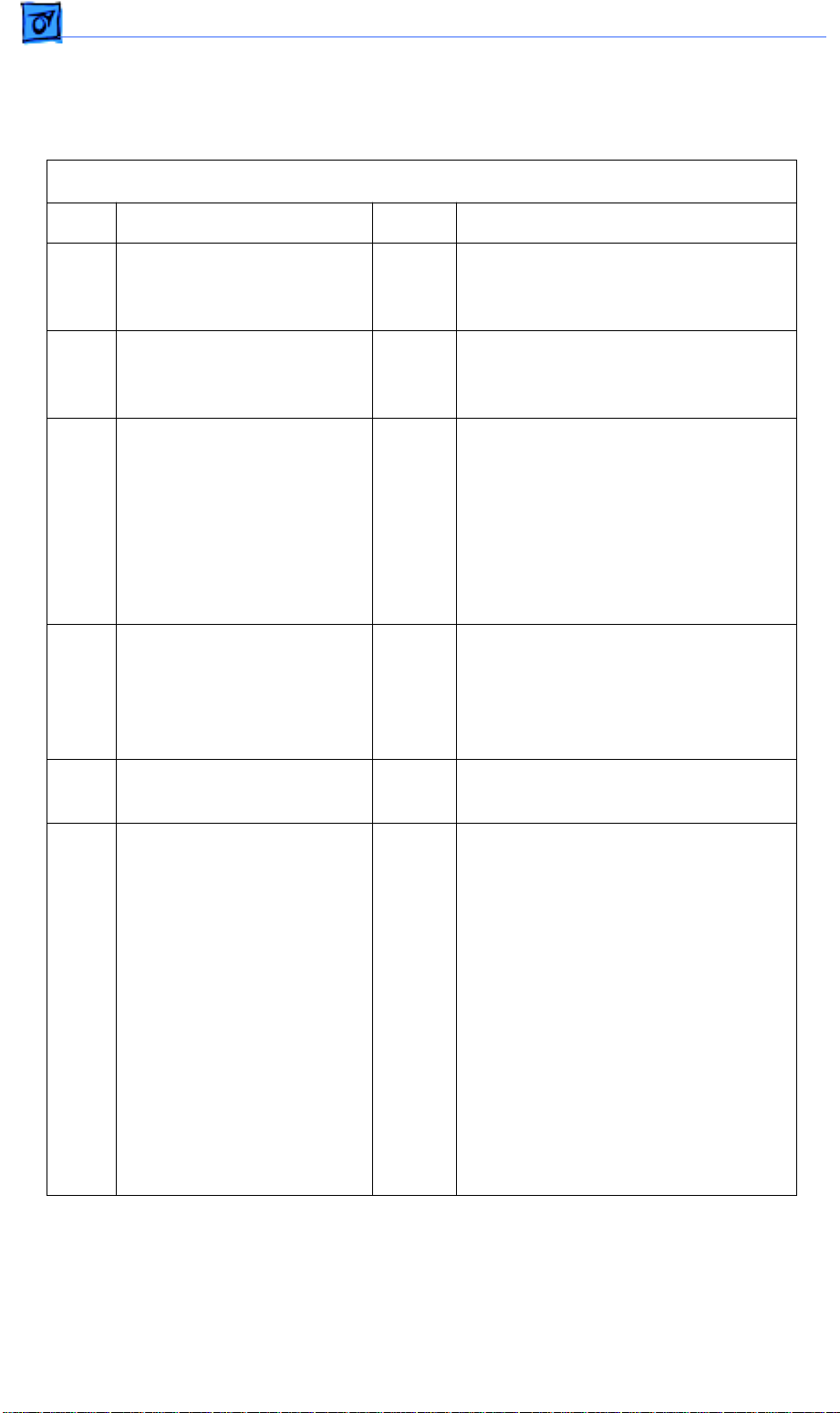

Basics Sensing System - 2

Sensing System

There are four paper sensors in the LaserWriter Select

printer. Each sensor consists of an actuator, a U-shaped

photo interrupter, and circuitry that communicates back to

the DC controller.

Paper Delivery Sensor PS201

Registration Sensor PS602

Manual Feed Sensor PS701

Paper-Out Sensor PS601

Page 5

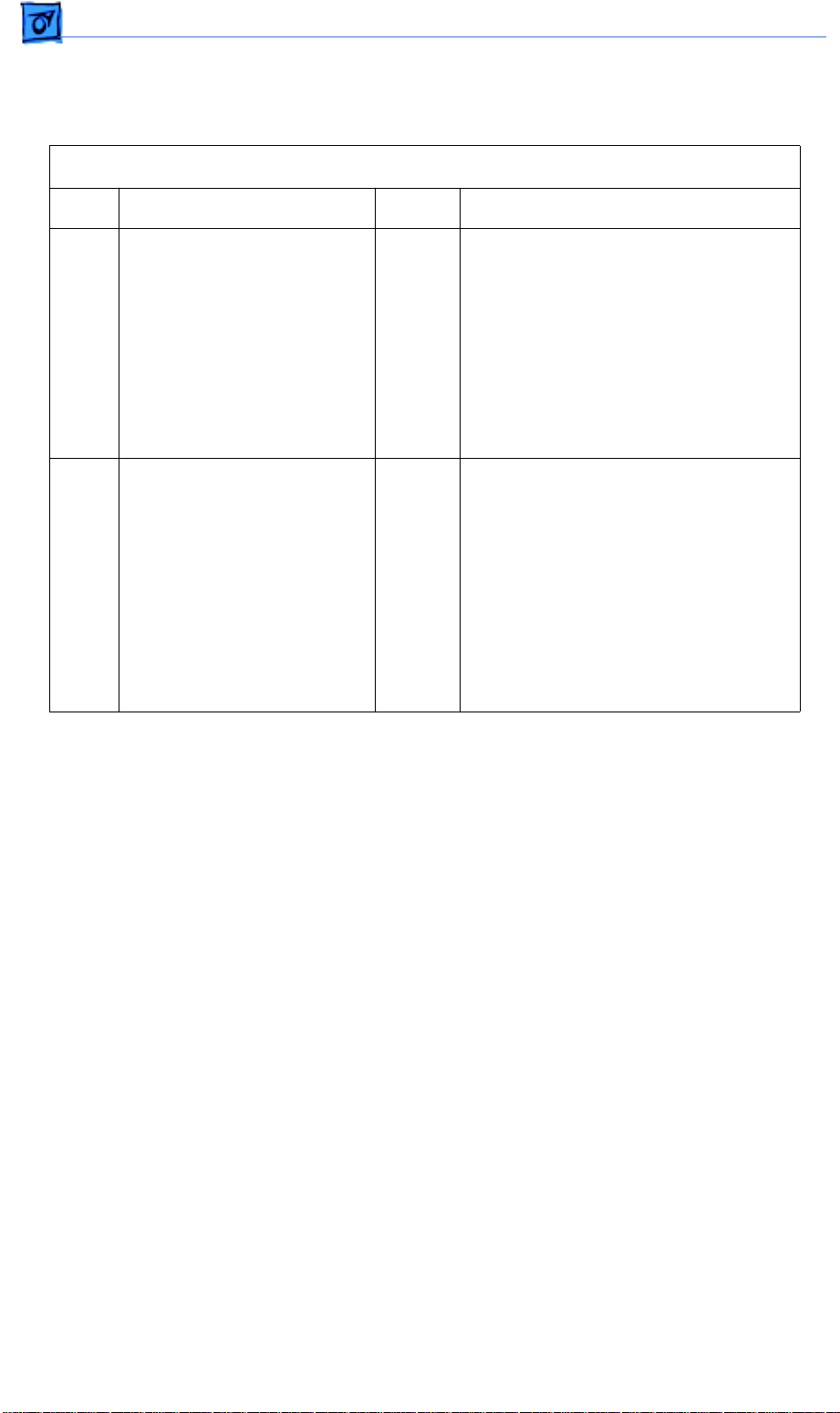

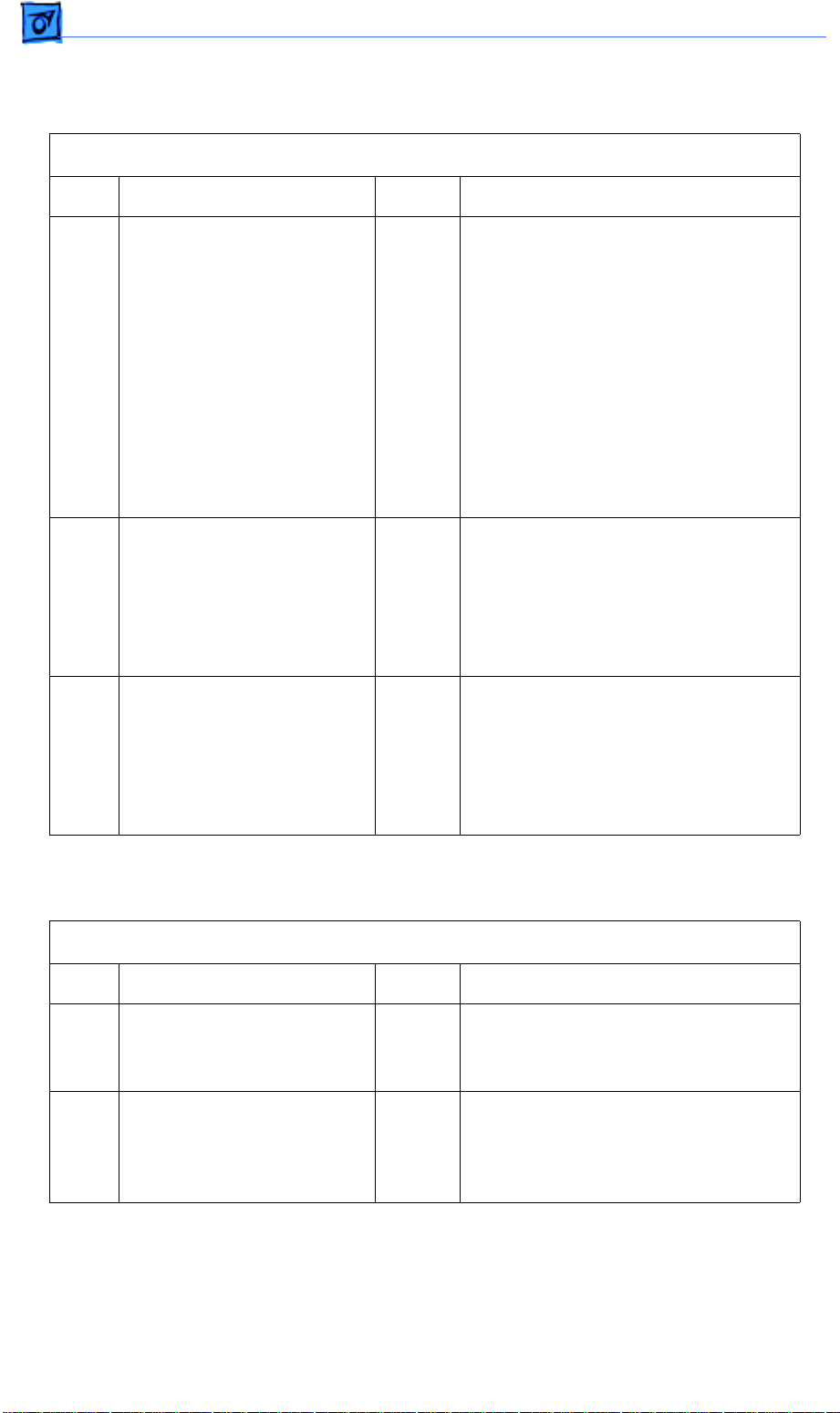

Basics Interface Connectors - 3

Interface Connectors

Interface connector diagrams for each of three LaserWriter

Select models are located on the following pages.

Page 6

Basics Interface Connectors - 4

LaserWriter Select 300

Mini DIN-8

Page 7

Basics Interface Connectors - 5

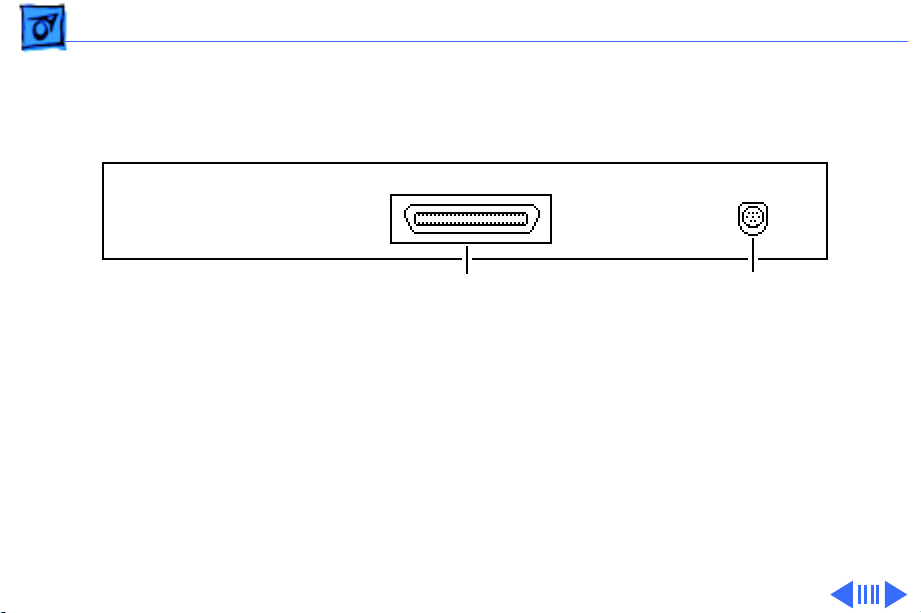

LaserWriter Select 310

Mini DIN-8Centronics Parallel

Page 8

Basics Interface Connectors - 6

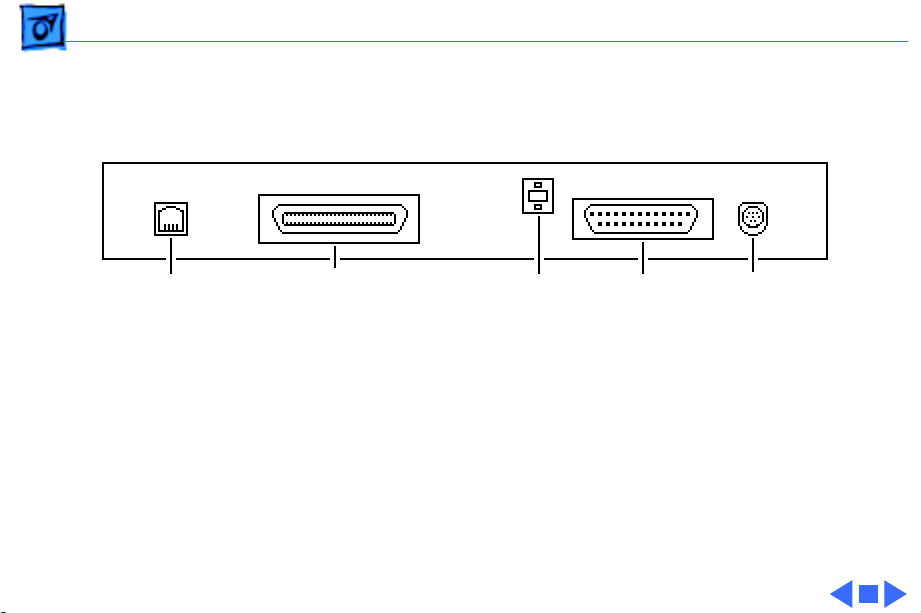

LaserWriter Select 360

RJ-11

(Optional

Fax Port)

Mini DIN-8RS-232Mode SwitchCentronics Parallel

Page 9

Basics LaserWriter Safety - 7

LaserWriter Safety

Unplug Printer

LaserWriter printers operate at high voltages. To prevent

serious injury, always switch off the printer and unplug the

AC power cord before servicing the printer.

Laser Beam Safety

Never remove the cover of the laser/optic assembly or

disconnect the beam-detect cabling when the printer is

switched on. Although the reflected laser beam is invisible,

direct exposure to it can permanently damage your eyes.

Never disassemble the laser/optical assembly, whether the

printer is powered on or not. The laser diode and focusing

lenses are factory-aligned.

Page 10

Basics LaserWriter Safety - 8

Fuser Heat

The fuser assembly rollers become very hot during printer

operation. Before servicing the fuser assembly, switch off

the printer for at least 5 minutes to allow the fuser

assembly rollers to cool.

Toner Safety

Toner is a nontoxic substance composed of plastic, iron, and

a small amount of pigment. Clean skin and clothing by

removing as much toner as possible with a dry tissue and

then washing with cold water. Hot water causes toner to jell

and permanently fuse into clothing. Toner attacks vinyl

materials, so don't allow toner to contact vinyl.

Motor Stops When Cassette is Removed

For safety purposes, the main motor on the LaserWriter

Page 11

Basics LaserWriter Safety - 9

Select 360 stops when the paper cassette is removed.

Weight

LaserWriter printers are heavy. When lifting or moving

the printer, be careful not to strain your back.

Page 12

K

Service Source

Specifications

LaserWriter Select

Page 13

Specifications General - 1

General

Engine

Printing Method

Optical System

Resolution

Imaging Languages Supported

Select 300/310: Fuji Xerox P0 engine

Select 360: Fuji Xerox P1 engine

Electrophotography using single-component dry toner

Semiconductor laser

Select 300/310: 300 dots per inch (dpi)

Select 360: 600 dpi (300 dpi in PCL mode)

Select 300: QuickDraw

Select 310: PostScript

Select 360: PostScript and HP PCL

Page 14

Specifications Intro Dates - 2

Intro Dates

Select 300/310

500-Sheet Feeder

Select 360

February 1993

August 1993

October 1993

Page 15

Specifications Logic Board - 3

Logic Board

CPU

DRAM

ROM

Select 300: N/A

Select 310: AMD Am29205; 16 MHz

Select 360: AMD Am29200; 15 MHz

Select 300: 512K, expandable to 1.5 MB or 4.5 MB

Select 310: 1.5 MB, expandable to 5.5 MB

Select 360: 7 MB (3 MB soldered on board), expandable to 16 MB

Note:

If you install a 16 MB RAM SIMM, the 3 MB of soldered

RAM is not used.

Select 300: 32K

Select 310: 1 MB, expandable to 2 MB

Select 360: 4 MB

Page 16

Specifications Logic Board - 4

I/O

Select 300: RS-422

Select 310: RS-232; Centronics parallel connector

Select 360: RS-232; Centronics parallel connector; AppleTalk

DIN-8

Page 17

Specifications Performance - 5

Performance

Print Delivery

Life Expectancy

Printing Speed

Face-down

Select 300/310: 150,000 pages

Select 360: 300,000 pages

Select 300/310: 5 pages-per-minute maximum; actual

performance depends on the application.

Select 360: 10 pages-per-minute maximum; actual performance

depends on the application.

Page 18

Specifications Built-In-Fonts - 6

Built-In-Fonts

LaserWriter Select 300

LaserWriter Select 310

LaserWriter Select 360

39 fonts from the following font families: Avant Garde, Bookman,

Chicago, Courier, Geneva, Helvetica, Helvetica Narrow, Monaco,

New Century Schoolbook, New York, Palatino, Symbol, Times,

Zapf Chancery, and Zapf Dingbats.

13 fonts from the following font families: Courier, Helvetica,

Times, and Symbol. Additional PostScript fonts can be

downloaded to printer memory.

Fonts from the following font families: Avant Garde, Bookman,

Courier, Helvetica, Helvetica Narrow, New Century

Schoolbook, Palatino, Symbol, Times, Zapf Chancery, and Zapf

Dingbats.

Page 19

Specifications Electrical - 7

Electrical

Line V oltage

Power Consumption

US/Japan:100-115 VAC, 50-60 Hz

Europe/Australia:220-240 VAC, 50 Hz

450 W maximum at115 V or 220V

Page 20

Specifications Physical - 8

Physical

Dimensions

Weight

Height: 8.0 in. (25.3 cm)

Width: 15 in. (38 cm)

Depth: 18.3 in. (45 cm)

26.4 lbs. (12 kg)

Page 21

Specifications Environmental - 9

Environmental

Temperature

Humidity

50° - 90.5°F (10° - 32.5°C)

20% - 80% relative humidity

Page 22

Specifications Paper - 10

Paper

Paper W eights

Cassette Size

Capacity In

Capacity Out

Cassette feed: 20 lb., single-sheet, photocopy bond

Manual feed: 20-28 lb., letterhead and colored stock, medium-

weight transparency material, envelopes, and labels

250-sheet universal cassette: US letter, A4, B5, executive

250-sheet legal cassette (optional)

500-sheet cassette (optional): US letter, A4, and B5

Envelope cassette (optional)

Cassette: 250 or 500 sheets

Manual: Single sheet

Envelope: 30 envelopes

Face-down tray: 150 sheets

Page 23

K

Service Source

Troubleshooting

LaserWriter Select

Page 24

Troubleshooting General - 1

General

Troubleshooting contains quick-reference troubleshooting

information for the LaserWriter Select. We encourage you to

review and print out this chapter before troubleshooting a

printer.

At the end of this chapter are troubleshooting flowcharts and

tables. If a table name clearly addresses your problem, you can go

directly to that table. If not, you should go to the flowchart

associated with the version of the printer you are working on.

Page 25

Troubleshooting Troubleshooting Tips - 2

Troubleshooting Tips

Multimeter Probes

When taking voltage and resistance readings, you will need to use

special multimeter probes. The connectors within the

LaserWriter Select are very small and require sharp needlepoint probes to make good contact. Do not use probes that do not

make proper contact.

Printer Overheating

To prevent possible overheating, do not run the LaserWriter

Select 360 printer for longer than 10 minutes with the covers

removed, and be sure to keep all vents clear.

Page 26

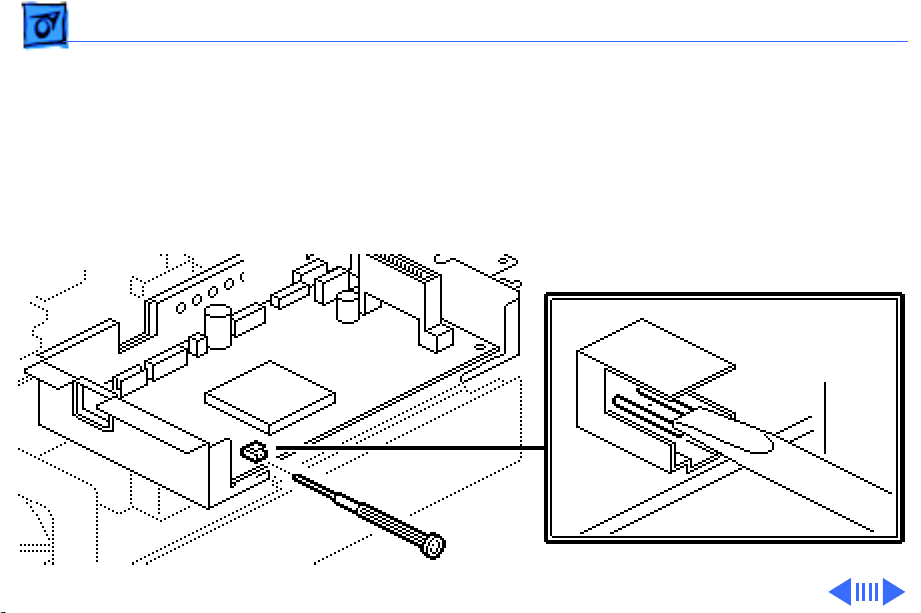

Troubleshooting Service Test Page - 3

Service Test Page

The LaserWriter Select service test page consists of a line matrix.

The LaserWriter Select printers produce a service test page when

you jumper the two pins at connector P32 on the DC controller

board. The test page confirms print engine operation.

DC Controller

Board

Screwdriver

or Paper Clip

P32

Page 27

Troubleshooting Service Test Page - 4

If the I/O controller mount is installed, you can access P32 by

inserting the straightened end of a paper clip through the small

access hole in the rear face of the I/O controller mount.

Caution:

is in an open test-ready state, you must manually actuate the

delivery sensor, otherwise a paper jam will occur. See "TestReady Configuration" in this chapter.

If you want to run a service test page while the printer

Page 28

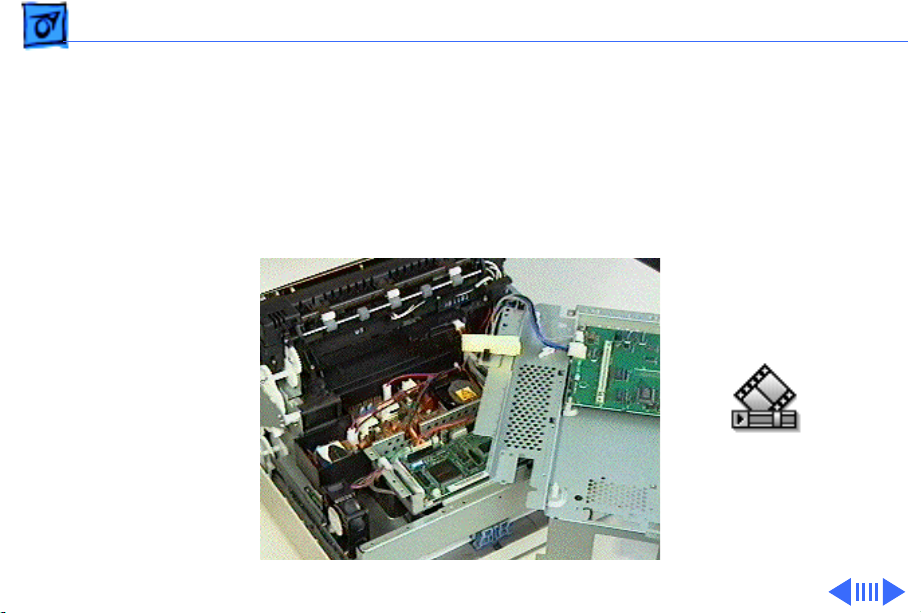

Troubleshooting Test-Ready Configuration - 5

Test-Ready Configuration

Paper delivery sensor PS201 is connected to the I/O controller

mount. When you remove the mount to troubleshoot inside the

printer or to run a service test page, you must reconfigure the

sensing system to simulate an operational printer.

Page 29

Troubleshooting Test-Ready Configuration - 6

To reconfigure the sensing system, remove the I/O controller

mount and set it at an angle on top of the power supply. Position

the mount so that connector P32 on the DC controller board is

accessible.

Insert a folded piece of paper into the U of sensor PS201, and

make sure that the two cables are securely attached to the I/O

board. If you need to communicate with a Macintosh, you can do so

by reconnecting the serial connector.

Caution:

If the printer is in a test-ready configuration, you must manually

actuate this sensor as paper hits the delivery sensor actuator

within the fuser assembly.

Jumpering connector P32 initiates a service test page.

Page 30

Troubleshooting 310/360 Power-On Self Test - 7

310/360 Power-On Self Test

The LaserWriter Select 310 and 360 go through a self diagnostic

each time that you switch the printer on. This diagnostic is called

the Power-On Self Test (POST). POST does not occur on the

LaserWriter Select 300 printer.

Note:

This test is not the same as the engine diagnostic (see next

topic). Unlike the engine diagnostic test, POST does not require

the placement of any loopback cable.

Observing how the LEDs extinguish from that point can help

isolate certain failure areas.

• The Ready LED extinguishes when no errors are found on the

I/O controller board.

• The Paper-Out LED then extinguishes when no errors are found

on the RAM card.

Page 31

Troubleshooting 310/360 Power-On Self Test - 8

• Finally the Jam LED extinguishes when no errors are found in

the engine.

In a functional printer, control will be passed on to the PostScript

interpreter at the end of this sequence.

Page 32

Troubleshooting 360 Printer Diagnostic - 9

360 Printer Diagnostic

Note:

Only the LaserWriter Select 360 offers diagnostic LEDs.

Switch off the LaserWriter Select 360 printer, and remove the

jumper from JMP1 on the I/O controller if a jumper is present.

Set the mode switch on the printer's back panel to 9.

The reporting sequence (which repeats continuously) is as

follows:

• All LEDs are on for 1 second.

• All LEDs are off for 1 second.

• The LED(s) that indicates the error is on for 1 second.

• All LEDs are off for 1 second.

Error configurations are shown on the next page.

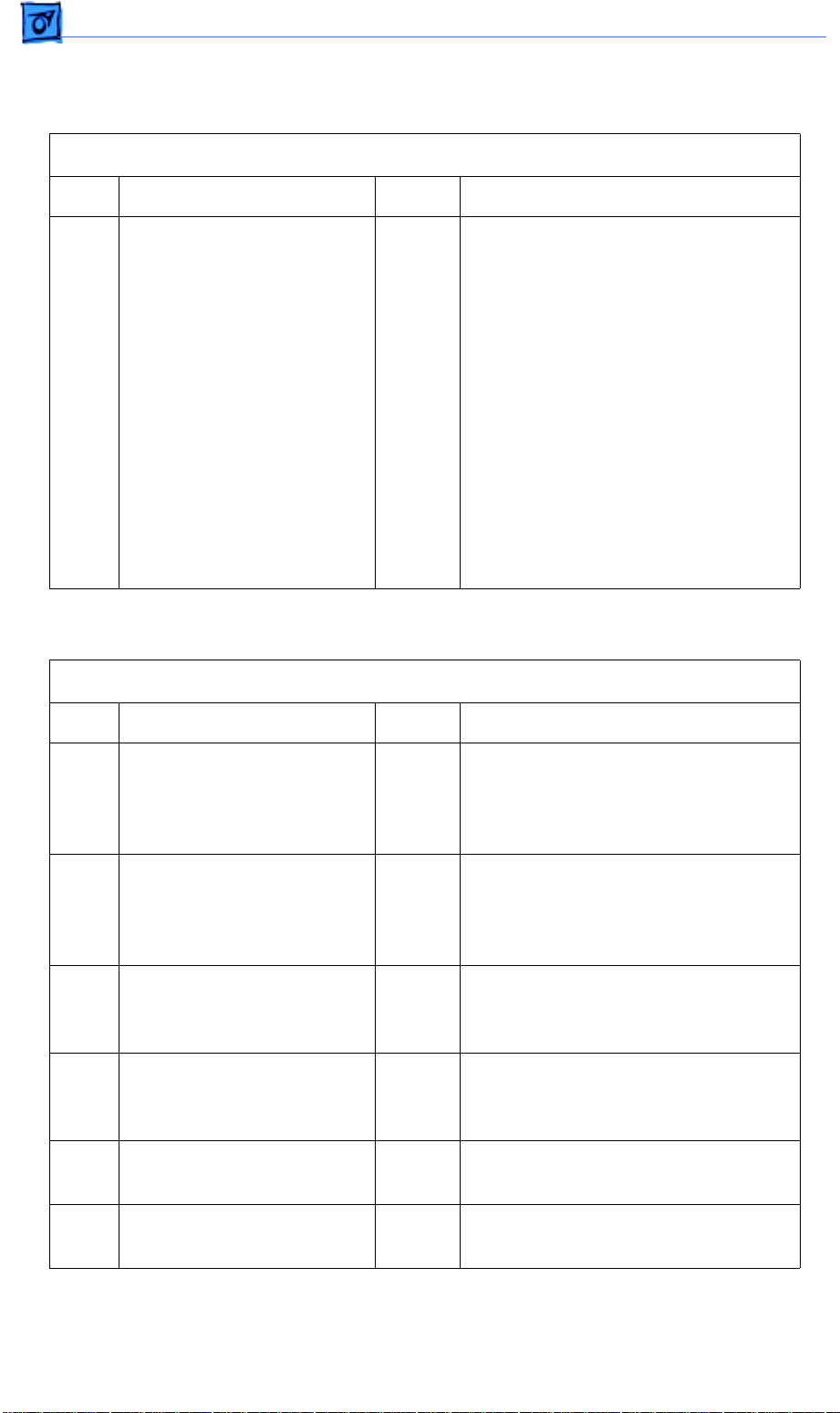

Page 33

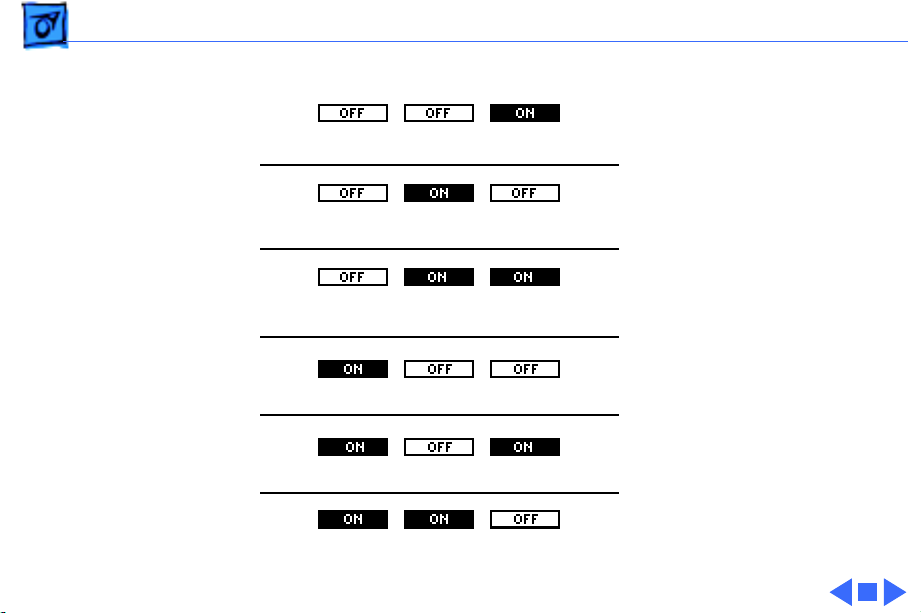

Troubleshooting 360 Printer Diagnostic - 10

I/O Controller Error

* A SIMM error can result

from insufficient memory.

SIMM Error*

Engine Controller Error

Fuser Error

Laser Error

Engine Error

You must have a minimum of

7 MB of RAM installed.

Page 34

Troubleshooting Circuit Board Diagrams - 11

Circuit Board Diagrams

Illustrations for the printed circuit boards below are located on

the following pages.

• LaserWriter Select 300 I/O Controller Board

• LaserWriter Select 310 I/O Controller Board

• LaserWriter Select 360 I/O Controller Board

• LaserWriter Select 300/310 DC Controller Board

• LaserWriter Select 360 DC Controller Board

• Cassette Feeder Board Diagram

• LaserWriter Select 300/310 High-Voltage Power Supply

• LaserWriter Select 360 High-Voltage Power Supply

• LaserWriter Select 360 Fax Card

Page 35

Troubleshooting Circuit Board Diagrams - 12

Select 300 I/O Controller Board

DRAM

P50 P51

SIMMs

Page 36

Troubleshooting Circuit Board Diagrams - 13

Select 310 I/O Controller Board

ROMs (1 or 2)

SIMMs

J3 JP2

DRAM

Page 37

Troubleshooting Circuit Board Diagrams - 14

Select 360 I/O Controller Board

P56

SIMMs

J3 JP2

J57

Page 38

Troubleshooting Circuit Board Diagrams - 15

Select 300/310 DC Controller Board

P14 P15 P16P17P18 P19

P11

P12

P31

P13

P32

Page 39

Troubleshooting Circuit Board Diagrams - 16

Select 360 DC Controller Board

P14 P15 P16P17P18 P19P20

P11

P12

P13

P32

P21

P31

Page 40

Troubleshooting Circuit Board Diagrams - 17

Cassette Feeder Board Diagram

P115

SW1

SW2

SW3

SW4

P116

P202

P201

Page 41

Troubleshooting Circuit Board Diagrams - 18

Select 300/310 High Voltage Power Supply

DB

RTN1

RTN2

P111

TR

CR

Page 42

Troubleshooting Circuit Board Diagrams - 19

Select 360 High Voltage Power Supply

CRTR

DB

RTN1 RTN2 P11

Page 43

Troubleshooting Circuit Board Diagrams - 20

Select 360 Fax Card

RJ-11

Battery

Volume Control

Speaker

J1

Page 44

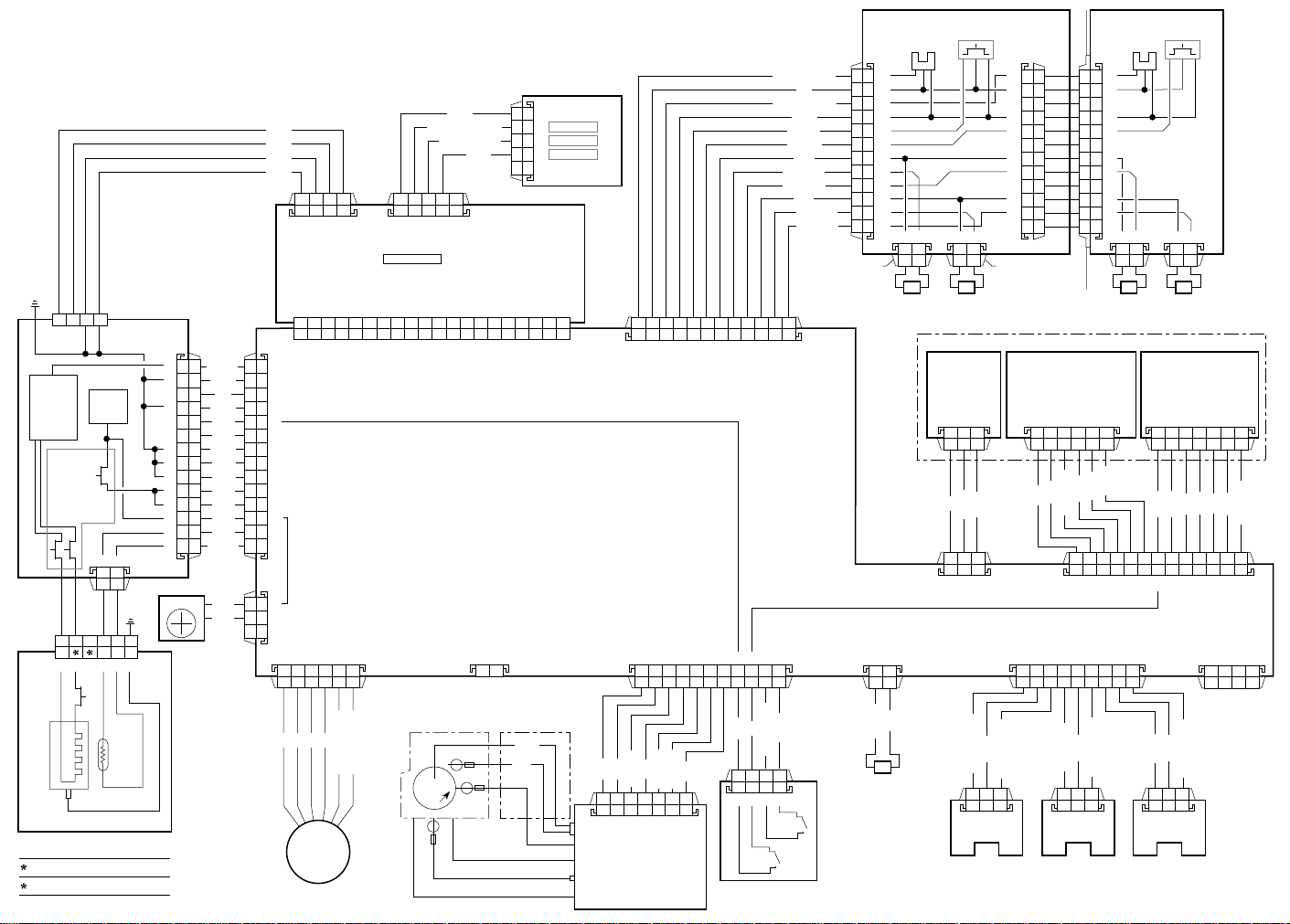

Troubleshooting Wiring Diagram - 21

Wiring Diagram

The LaserWriter Select wiring diagram can be found on the next

page. The detail in this document is too small to read easily at

100% view. You should either zoom into the diagram using the

zoom tool above, or print the diagram on a laser printer with a

resolution of 300 dpi (600 dpi preferred).

Page 45

FG

12

HEATER

CNT

INTERLOCK

P101

62314 5

J101

SW

3

24V

Supply

12

PS601

PAPER-OUT

1

2

3

4

5

6

7

8

9

10

11

12

FEED

CASSETTE FEEDER

P17

12

SENSOR

BEAM

DETECT

P113

5V

P19

J115 P115

LED STATUS PANEL

5VA

5VA

5VA

GND

GND

POWER

SUPPLY

P13

4

P11

14

4

1

5

2

3

6

7

8

9

10

11

12

13

FAN

/HEAT

GND

VS

GND

5VB

5VA

GND

RTN

RTN

24V

24V

24V

STS

(GND)

24V

RTN

J31

P31

1

2

3

4

5

6

7

P11

8

9

10

11

12

13

14

3

2

P18

1

J51

JP2

GND

GND

GND

/CMD

/CP RDY

/STARTNC/SBSY

B9B8B7B6B5B4B3B2B1

B10

P14

123456

READY/IN-USE

PAPER-OUT

JAM

123451234

J3

J57

/RDY

/BDNC/PRFD

/CCLK

A9A8A7A6A5A4A3A2A1

A10

DC CONTROLLER BOARD

P32

I/O BOARD

/VDONC/CBSY

/STA

12

5

4

3

2

1

/TOP

GREEN

RED

RED

/PPRDY

GND

1 2 3 4 5 6 7 8 9 10 11 12

1234567891011

P13

P15

NO PAPER 1

5V

NO PAPER 2

GND

SIZE 1

SIZE 2

24V

/TURN 1

/TURN 2

24V

/FEED 1

/FEED 2

SOLENOID

P116

SOLENOID

123

/SOS

GND

SIZING

SWITCHES

1

2

3

4

5

6

7

8

9

10

11

12

P201P202

PICKUP

LASER/OPTIC ASSEMBLY

SCANNER

MOTOR UNIT

P114

456

RTN

24V

/MOT ON

P16

1

2

3

4

5

6

Optional feeder

7

8

9

10

11

12

12 121212

OPTIONAL FEEDER

123

SPI2

SPI1

GND

10111213123

123456789

components

identical to

main feeder

LASER DRIVER

P112

1234567

VL1

VL2

5VB

GND

P12

12

MO

P21

5VA

123456789

34

/P DATA

Heater

Bulb

FUSER ASSEMBLY

100-120V

Pin 2

Heater NC

NC

Pin 3

STS

220-240V

Heater

/B

MOTOR

/A

MAIN

A

B

A-COM (24V)

B-COM (24V)

TONER

CARTRIDGE

Paper Charge Deflector

HIGH-VOLTAGE

CONTACT ASSEMBLY

RTN

DB

CRU

Paper Delivery Guide

Transfer Roller

Rtn

DB

CR

RTN

HIGH-VOLTAGE

TR

POWER SUPPLY

RTN

/DB

/TR +/-

P111

/TR

/CR-AC

/CR-DC

5VB

24V

TONER CARTRIDGE

SENSOR BOARD

S100

5V

EP Check

S101

1234

GND

P118

24V

/FEED

MANUAL FEED

PICKUP

SOLENOID

GND

/NO PAPER

PULLUP 5V

P121

PS701

MANUAL FEED

SENSOR

GND

/PREREG

PULLUP 5V

123

P120

PS602

REGISTRATION

SENSOR

GND

/EXIT

PULLUP 5V

123123

P119

PS201

PAPER DELIVERY

SENSOR

Page 46

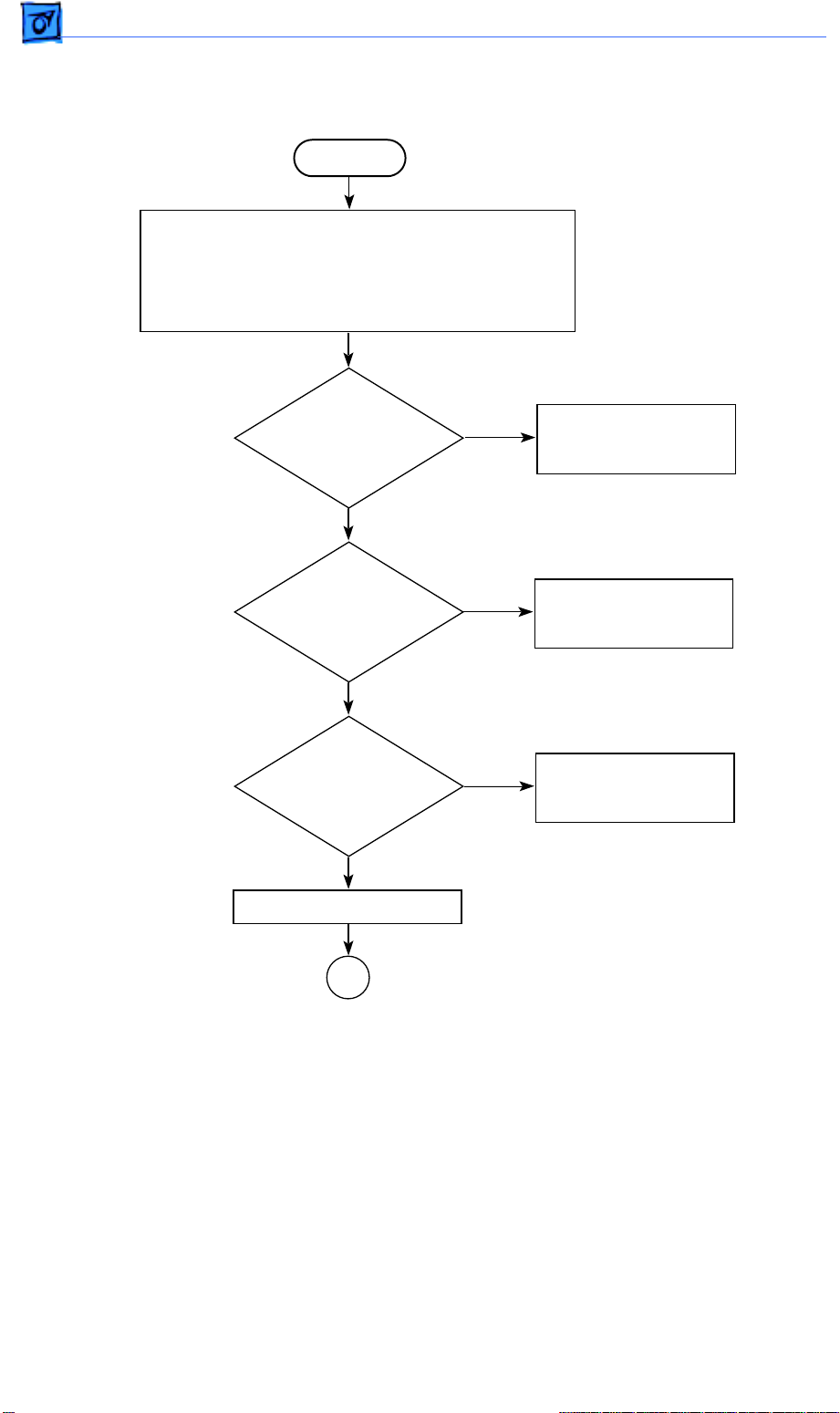

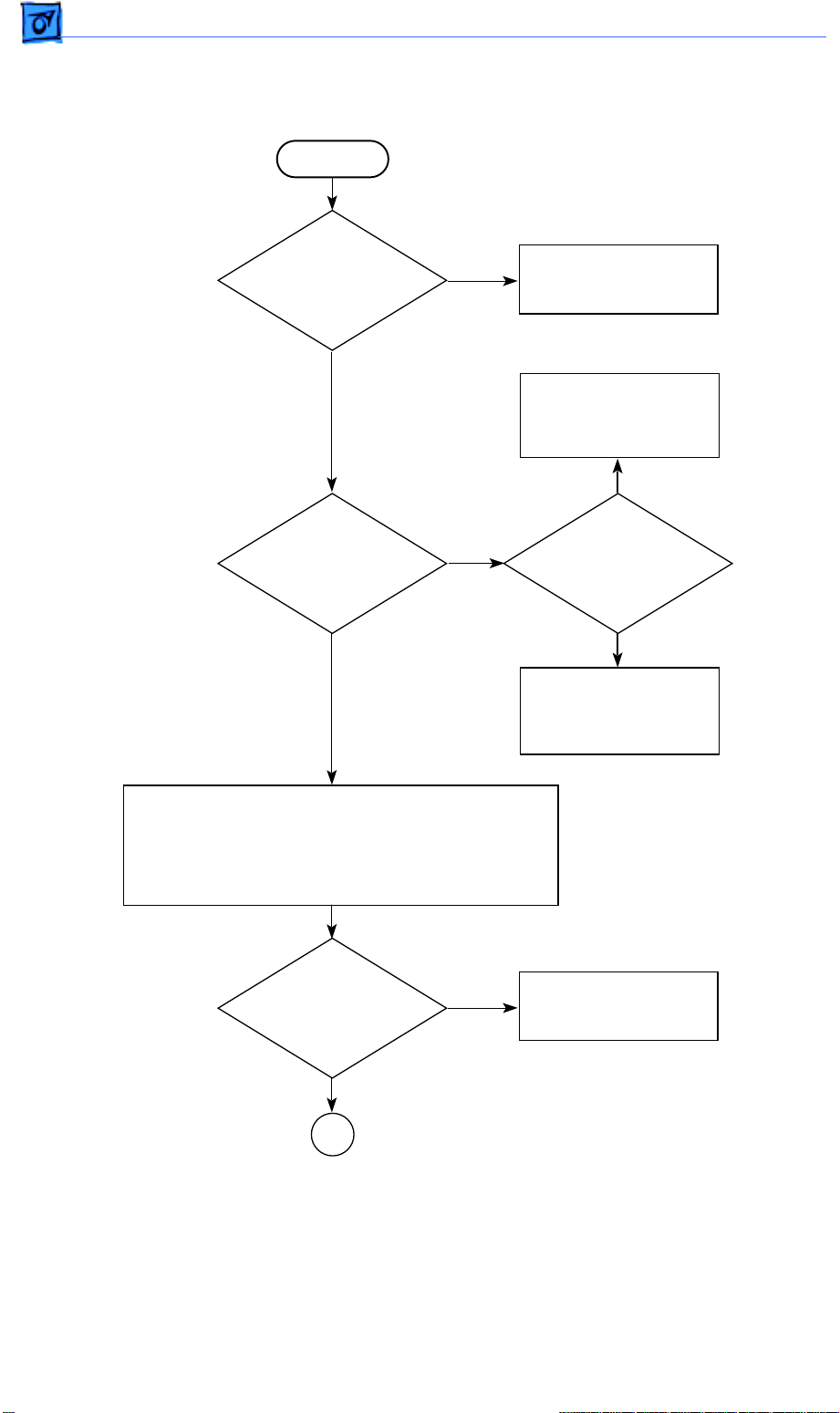

LaserWriter Select 300 Flowchart 1

START

1. Connect the printer to a Macintosh computer that is

using the LaserWriter Select 300 driver.

2. Open the printer and remove any paper jams.

3. Install the toner cartridge and fill the cassette tray.

4. Switch on the printer and the Macintosh computer

and wait 2 minutes.

5. Issue a Print Window or Print Directory command.

Flowcharts and TablesTroubleshooting

Does the

printer print

from a

Macintosh?

Yes

Is the

print quality

OK?

Yes

The printer is fully functional.

No

No

Go to LaserWriter

Select 300 Flowchart 2.

Go to "Print Quality

Problems."

Page 47

LaserWriter Select 300 Flowchart 2

START

1. Switch off the printer and disconnect it from the

Macintosh computer.

2. Remove the top cover, rear cover, and side covers.

3. Remove the I/O shield and I/O board.

4. Plug in and switch on the printer.

Flowcharts and TablesTroubleshooting

Does

the fan

come on?

Yes

Does the

fuser bulb glow every

few seconds during

startup?

Yes

Does the

main motor

rotate sometime

after startup?

Yes

Initiate a service test page.

No

No

No

Go to Table 2,

No Power to Fan.

Go to Table 3,

Fuser Assembly

Failure.

Go to Table 1,

Main Motor

Failure.

A

Page 48

Flowcharts and TablesTroubleshooting

LaserWriter Select 300 Flowchart 2 (Continued)

A

Did the

printer deliver

a service test

page?

Yes

Is the

print quality

OK?

No

No

Go to Table 27, 28, 29,

or 30, depending

on the specific paper

transport problem.

Yes

Did the

paper jam

inside the

printer?

No

Go to Table 4

or 5, depending

on the specific laser/

scanner malfunction.

Go to "Print Quality

Problems."

Yes

1. Make sure cable connections are correct, secure,

and undamaged.

2. Confirm that the proper print driver is installed.

3. If the printer is connected to the Macintosh printer

port, open the Chooser and make AppleTalk

inactive.

4. If the problem persists, replace the I/O board.

Page 49

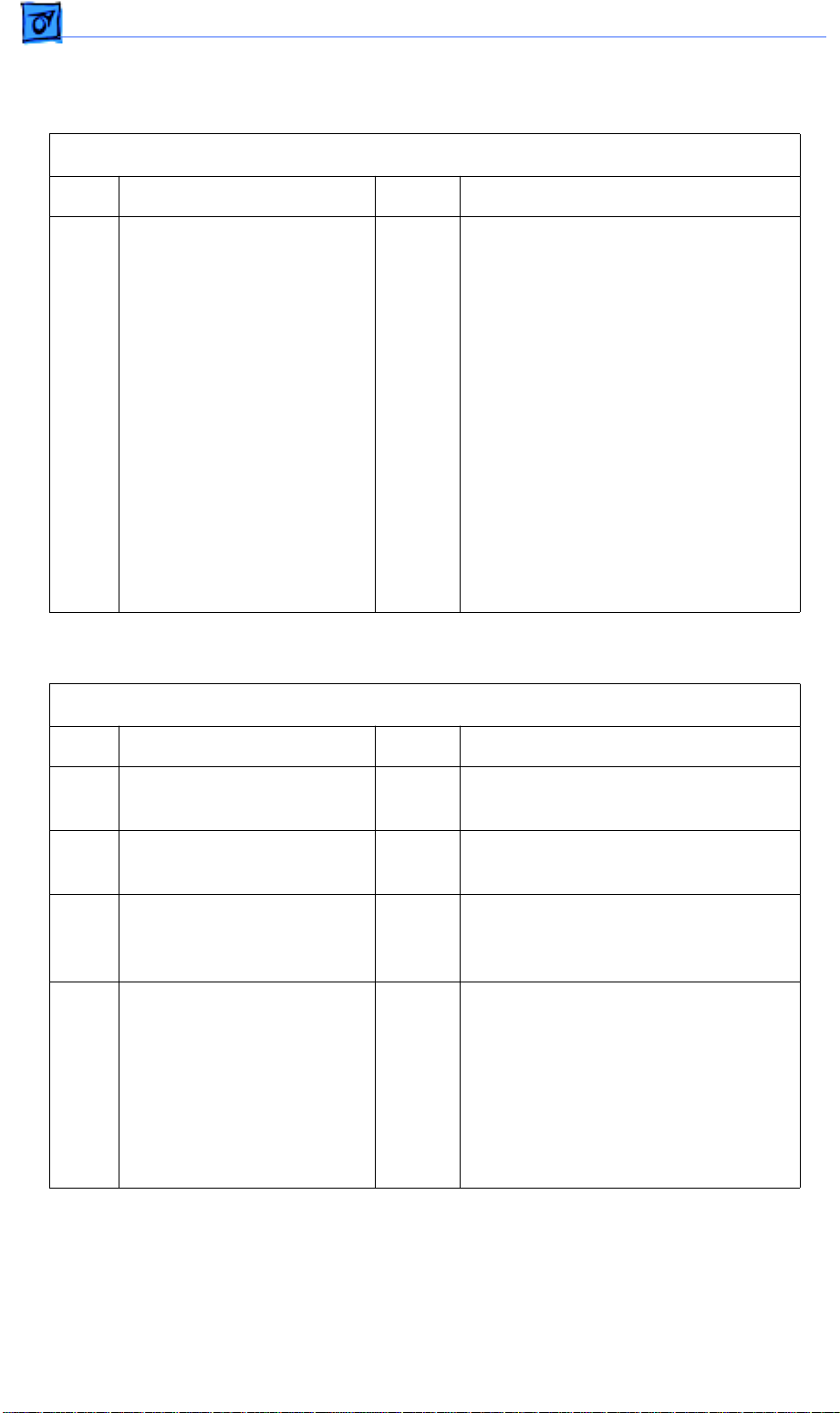

LaserWriter Select 310 Flowchart 1

START

1. Connect the printer to a Macintosh computer that

is using the LaserWriter Select 310 driver.

2. Open the printer and remove any paper jams.

3. Install the toner cartridge and fill the cassette tray.

4. Switch on the printer and the Macintosh computer

and wait 2 minutes.

Flowcharts and TablesTroubleshooting

Does the

Ready LED glow

steadily after

warmup?

Yes

Open the File menu and choose Print

Window or Print Directory.

Does the

printer print

from a

Macintosh?

Yes

Is the

print quality

OK?

Yes

1. Place paper on the manual feed tray.

2. Open the File menu and choose Print Window

or Print Directory.

3. Select Manual Feed as the paper source in the

Print dialog box.

No

No

No

Go to LaserWriter

Select 310 Flowchart 2.

Go to Table 7

or 8, depending

on the specific I/O

board error.

Go to "Print Quality

Problems."

Does the

printer deliver

a manually fed

page?

Yes

The printer is fully functional.

No

Go to Table 30,

No Paper Pickup From

Manual Feed or

Multipurpose Tray.

Page 50

Flowcharts and TablesTroubleshooting

LaserWriter Select 310 Flowchart 2

START

Is the

Paper-Out

LED on?

No

Is the

Paper-Jam

LED on?

No

Yes

Yes

Go to Table 13,

Paper-Out LED Lights

When There Is Paper.

Go to Table 27, 28, 29,

or 30, depending

on the specific paper

transport problem.

Yes

Is the

paper jammed

inside the

printer?

No

Go to Table 14,

Paper-Jam LED Lights

But No Jam

Has Occurred.

1. Switch off the printer and disconnect it from the

Macintosh computer.

2. Remove the top cover, rear cover, and side covers.

3. Remove the I/O shield and the I/O board.

4. Plug in and switch on the printer.

Does

the fan

come on?

Yes

A

No

Go to Table 2,

No Power to Fan.

Page 51

Flowcharts and TablesTroubleshooting

LaserWriter Select 310 Flowchart 2 (Continued)

A

Does the

fuser bulb glow every

few seconds during

startup?

Yes

Does the

main motor

rotate sometime

after startup?

Yes

Initiate a service test page.

Did the

printer deliver

a service

test page?

No

No

No

Go to Table 3,

Fuser Assembly

Failure.

Go to Table 1,

Main Motor

Failure.

Go to Table 27, 28, 29,

or 30, depending

on the specific paper

transport problem.

Yes

Did the

paper jam

inside the

printer?

Yes

Is the

print quality

OK?

Yes

B

No

No

Go to Table 4 or 5,

depending on the

specific laser or

scanner problem.

Go to "Print Quality

Problems."

Page 52

Flowcharts and TablesTroubleshooting

LaserWriter Select 310 Flowchart 2 (Continued)

B

1. Switch off the printer.

2. Replace the I/O board, I/O shield, and covers.

3. Reconnect the printer to a Macintosh computer.

4. Switch on the printer and the computer.

5. Open the File menu and choose Print Window

or Print Directory.

printout of the active

Is a

window produced?

Yes

1. Place paper on the manual feed tray.

2. Open the File menu and choose Print Window

or Print Directory.

3. Select Manual Feed as the paper source in the

Print dialog box.

Is a

printout of the active

window produced?

Yes

The printer is fully functional.

No

No

Go to Table 7 or 8,

depending on the

specific I/O

board problem.

Go to Table 30, No

Paper Pickup From

Manual Feed or

Multipurpose Tray.

Page 53

Flowcharts and TablesTroubleshooting

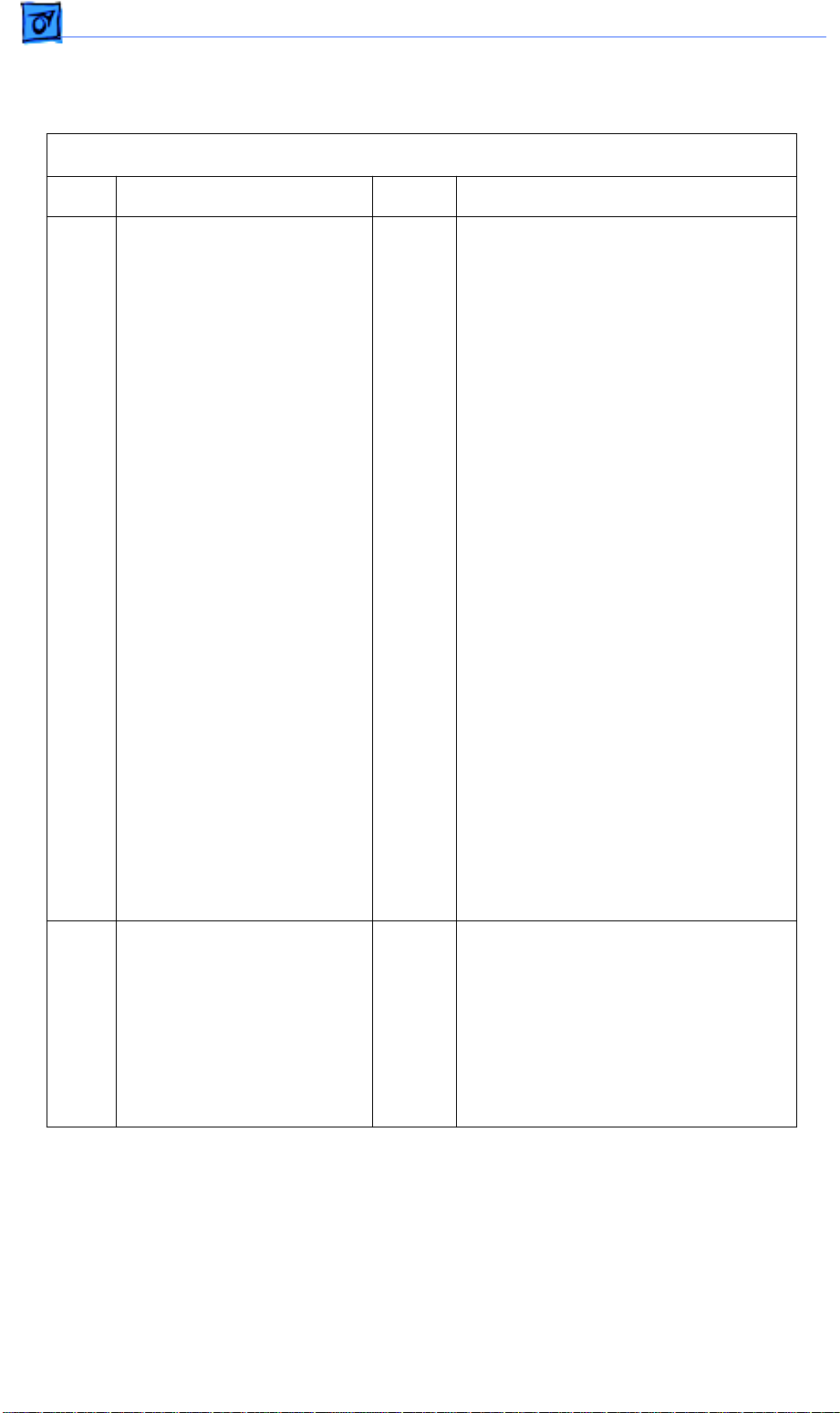

LaserWriter Select 360 Flowchart 1

START

Run the LaserWriter Select 360 printer diagnostic (see "Printer Diagnostics"

section). Replace modules as indicated in the "Printer Diagnostics" section.

If no specific error is indicated during the diagnostic, switch off the printer,

jumper the pins at JMP1 on the I/O controller, and return the mode switch

to its original setting.

Does the

Ready/In Use LED

glow steadily after

warmup?

Yes

Open the File menu and choose Print Window or Print Directory.

Does the

printer print

from a

Macintosh?

Yes

Is the

print quality

OK?

Yes

1. Place paper on the manual feed tray.

2. Open the File menu and choose Print Window or Print Directory.

3. Select Manual Feed as the paper source in the Print dialog box.

No

No

No

Go to Flowchart 2.

Go to Table 7 or 8,

depending on the specific

I/O board error.

Go to "Print Quality

Problems."

Does the

printer deliver

a manually fed

page?

Yes

The printer is fully functional.

No

Go to Table 30,

No Paper Pickup From

Manual Feed or

Multipurpose Tray.

Page 54

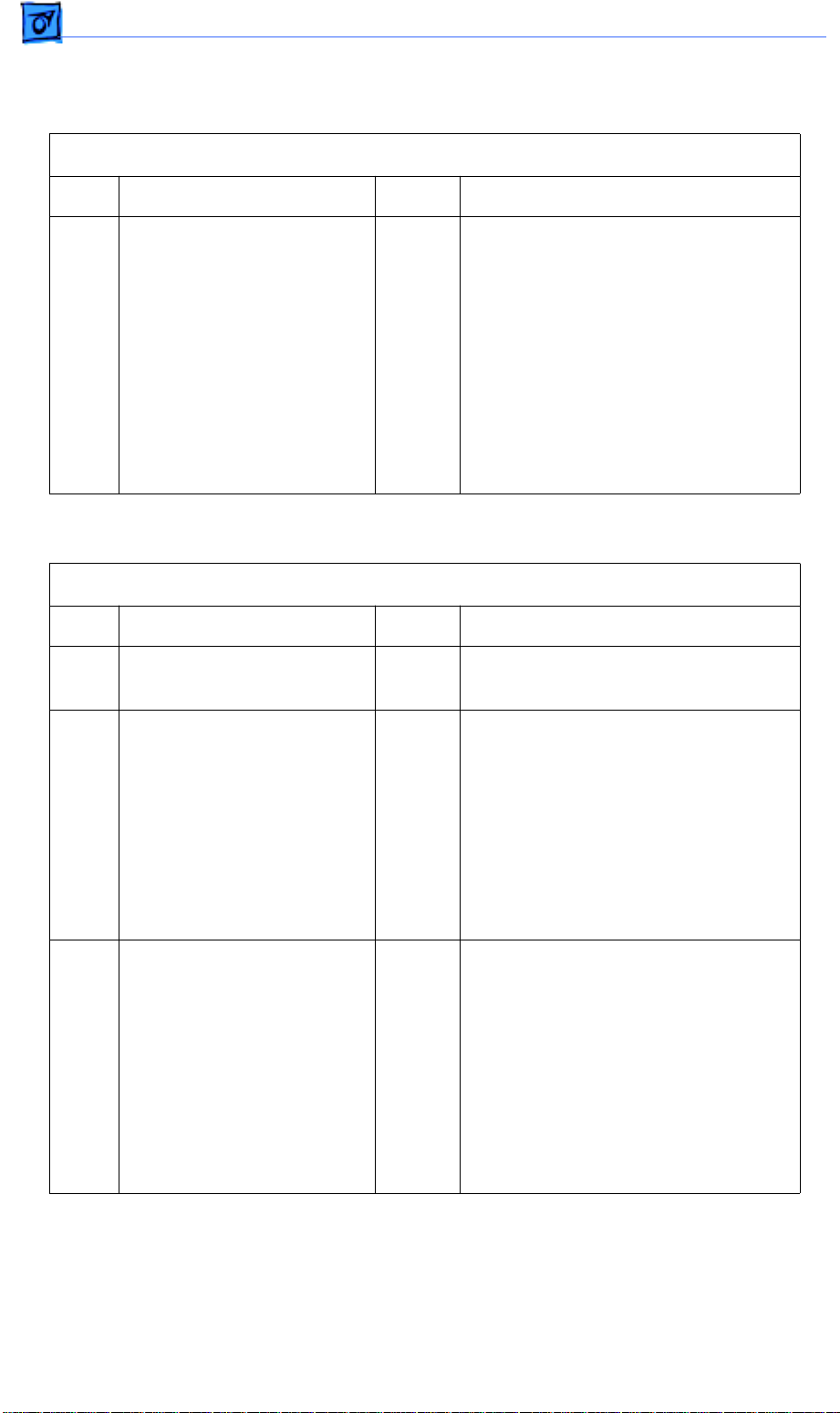

Flowcharts and TablesTroubleshooting

LaserWriter Select 360 Flowchart 2

START

Is the

Paper-Out

LED on?

No

Is the

Paper-Jam

LED on?

No

Yes

Yes

Go to Table 23,

Paper-Out LED Lights

When There Is Paper.

Go to Table 27, 28, 29,

or 30, depending

on the specific paper

transport problem.

Yes

Is the

paper jammed

inside the

printer?

No

Go to Table 24,

Paper-Jam LED Lights

But No Jam

Has Occurred.

1. Switch off the printer and disconnect it from the

Macintosh computer.

2. Remove the top cover, rear cover, and side covers.

3. Remove the I/O shield and the I/O board.

4. Close the front access door.

5. Plug in and switch on the printer.

Does

the fan

come on?

Yes

A

No

Go to Table 2,

No Power to Fan.

Page 55

Flowcharts and TablesTroubleshooting

LaserWriter Select 360 Flowchart 2 (Continued)

A

Does the

fuser bulb glow every

few seconds during

startup?

Yes

Does the

main motor

rotate sometime

after startup?

Yes

Initiate a service test page.

Did the

printer deliver

a service

test page?

No

No

No

Go to Table 3,

Fuser Assembly

Failure.

Go to Table 1,

Main Motor

Failure.

Go to Table 27, 28, 29,

or 30, depending

on the specific paper

transport problem.

Yes

Did the

paper jam

inside the

printer?

Yes

Is the

print quality

OK?

Yes

B

No

No

Go to Table 4 or 5,

depending on the

specific laser or

scanner problem.

Go to "Print

Quality Problems."

Page 56

Flowcharts and TablesTroubleshooting

LaserWriter Select 360 Flowchart 2 (Continued)

B

1. Switch off the printer.

2. Reinstall the I/O board, I/O shield, and covers.

3. Reconnect the printer to a Macintosh computer.

4. Switch on the printer and the computer.

5. Open the File menu and choose Print Window

or Print Directory.

printout of the active

Is a

window produced?

Yes

1. Place paper on the manual feed tray.

2. Open the File menu and choose Print Window

or Print Directory.

3. Select Manual Feed as the paper source in the

Print dialog box.

Is a

printout of the active

window produced?

Yes

The printer is fully functional.

No

No

Go to Table 6, 7, or 8,

depending on the

specific I/O

board problem.

Go to Table 30, No

Paper Pickup From

Manual Feed or

Multipurpose Tray.

Page 57

Flowcharts and TablesTroubleshooting

Important

As you proceed through the steps in a table, remember to retry the printer each

time you change its physical state–for example, when you replace a module. If

the problem remains, reinstall the original module before proceeding to the

next step in the table. Refer as necessary to the wiring diagram that follows the

tables.

Table 1. Main Motor Failure

Step Check Result Action

1 Is connector P14 on the DC

controller board making

good contact?

2 Are there any obstructions

in the drive assembly gear

train or paper path?

3 Inspect the drive assembly

gear train and replace any

damaged gears. (Check the

gears on the drive

assembly, the paper feed

roller, and the cassette

feeder assembly.) Does the

problem persist?

No Reconnect P14 to the DC controller

board.

Yes Remove the obstructions.

No Problem solved.

4 Switch off the printer and

connect a multimeter

between each of the

following pairs of pins:

• P14-1 (A-COM 24V)

and P11-2 (GND)

• P14-2 (B-COM 24V)

and P11-2 (GND)

Does the voltage measure

approximately +24 VDC

when you switch on the

printer?

No Go to Table 11, Power Supply Failure

(+24 VDC).

3

Page 58

Flowcharts and TablesTroubleshooting

Main Motor Failure (Continued)

Step Check Result Action

5 Switch off the printer and

connect a multimeter

between each of the

following pairs of pins:

• P14-1 (A-COM 24V) and

P14-3 (A)

• P14-1 (A-COM 24V) and

P14-5 (/A)

• P14-2 (B-COM 24V) and

P14-4 (B)

• P14-2 (B-COM 24V) and

P14-6 (/B)

Is the resistance

approximately 5 ohms?

No

Yes

Replace the main motor.

Replace the DC controller board. If

the problem persists, replace the

main motor.

Table 2. No Power to Fan

Step Check Result Action

1 Is a toner cartridge installed

in the printer?

2 Is the AC outlet providing

the correct voltage?

3 Is connector P119 making

good contact with the paper

delivery sensor?

4 Inspect the paper delivery

sensor. Does the lever on

the fuser assembly cover

the paper delivery sensor

when no paper is present

and uncover the sensor

when paper passes through

the fuser assembly?

No Install a toner cartridge.

No Try another AC outlet.

No Reconnect connector P119 to the

paper delivery sensor.

No Install the paper delivery sensor so

that it makes contact with the delivery

sensor lever. If the problem persists,

replace the delivery sensor lever.

Page 59

Flowcharts and TablesTroubleshooting

No Power to Fan (Continued)

Step Check Result Action

5 Connect a multimeter

between each of the

following sets of pins and

check for the following

voltages:

P11-10 (+24 V, brown wire)

and P11-2 (GND, black

wire) +24 VDC

P11-11 (+24 V, brown wire)

and P11-2 (GND, black

wire) +24 VDC

P11-12 (+24 V, orange wire)

and P11-2 (GND, black

wire) +24 VDC

P11-5 (+5 VB, yellow wire)

and P11-2 (GND, black

wire) +5 VDC

P11-6 (+5 VA, blue wire)

and P11-2 (GND, black

wire) +5 VDC

Are the voltages present

when you switch the printer

back on?

No Replace the power supply.

3

6 Switch off the printer,

connect a multimeter

between connectors P18-3

(+24V) and P18-2 (RTN) on

the DC controller, and

switch the printer back on.

Is the voltage approximately

+24 VDC?

Yes Replace the fan.

Page 60

Ω

Flowcharts and TablesTroubleshooting

No Power to Fan (Continued)

Step Check Result Action

7 Switch off the printer and

disconnect connector P119

from the paper delivery

sensor. Connect the

multimeter between P119-2

(GND) and P119-3

(+5 VDC) and switch on the

printer. Does the voltage

measure approximately +5

VDC when you switch on

the printer?

No

Yes

Check the cable connections between

P119 and P16 on the DC controller

board. If the connections are secure,

replace the DC controller board.

Replace the paper delivery sensor.

Table 3. Fuser Assembly Failure

Step Check Result Action

1 Is a toner cartridge installed

in the printer?

2 Switch off the printer,

connect a multimeter

between pins J101-2 and

J101-6 on the fuser

assembly , and s witch on the

printer. Does the voltage

measure between +90 and

+132 VAC when you switch

on the printer?

No Install a toner cartridge.

No Replace the power supply.

3 Switch off the printer,

disconnect connector P11

from the DC controller

board. Measure the

resistance between

connector pins P11-13

(STS) and P11-14 (GND). Is

the resistance between

200 k

temperature?

and 350 k Ω at room

No Replace the power supply.

Page 61

Flowcharts and TablesTroubleshooting

Fuser Assembly Failure (Continued)

Step Check Result Action

4 Measure the resistance

between pins J101-2 and

J101-6 on the fuser

assembly. Is the resistance

less than 10 Ω ?

5 Connect a multimeter

between pins P11-1 (HEAT,

red wire) and P11-2 (GND,

black wire). Does the

voltage measure about

+4.2 VDC when you switch

on the printer?

6 Connect a multimeter

between connector pins

P11-1 (HEAT, red wire) and

P11-2 (GND, black wire) on

the DC controller board.

When you open and close

the front access door, does

the voltage measure about

+3.7 VDC with the door

open and briefly drop to

0 VDC about five seconds

after you close the door?

7 Switch off the printer and

disconnect P111 from the

high-voltage power supply.

Connect a multimeter

between connector pins

P11-5 (5 VB, yellow wire)

and P11-2 (GND, black

wire) on the DC controller

board. Does the voltage

measure about +5 VDC

when you switch on the

printer?

No Replace the fuser heater bulb and the

thermoprotector.

No Replace the power supply.

No Go to Table 9, Temperature Sensor

Assembly Failure.

3

No Replace the power supply.

Page 62

Ω

Ω

Flowcharts and TablesTroubleshooting

Fuser Assembly Failure (Continued)

Step Check Result Action

8 Switch off the printer and

disconnect connector P12

from the DC controller

board. Does the fuser

heater bulb light when you

switch on the printer?

9 Switch off the printer and

disconnect connector P15

from the DC controller

board. Does the fuser

heater bulb light when you

switch on the printer?

10 Connect the multimeter

between pins P15-8 (5 VB,

yellow wire) and P15-9 (5 V,

orange wire) on the DC

controller board. When you

remove and insert the toner

cartridge does the

resistance change from 0

(cartridge inserted) to

infinity Ω (cartridge

removed)?

No Replace the laser/optic assembly.

Yes Replace the DC controller board.

No Replace the toner cartridge sensor

assembly.

11 Connect the multimeter

between pins P15-10 (EP

CHECK, red wire) and

P15-11 (GND, brown wire)

on the DC controller board.

When you remove and

insert the toner cartridge,

does the resistance

change from 0

inserted) to infinity Ω

(cartridge removed)?

(cartridge

No Replace the toner cartridge sensor

assembly.

Page 63

Ω

Flowcharts and TablesTroubleshooting

Table 4. Laser Scanner Failure

Step Check Result Action

1 Are connectors P12 and

P19 on the DC controller

board properly seated?

2 Switch on the printer, wait

until the main motor stops

rotating, and connect a

multimeter between

connector P12-11 (/MOT

ON) on the DC controller

board and chassis ground.

Can you hear the scanner

motor start to spin?

3 Switch off the printer,

connect a multimeter

between connectors P11-4

(GND, black wire) and

P11-5 (5 VB, yellow wire)

on the DC controller board,

and switch on the printer. Is

the voltage approximately

+5VDC?

No Reconnect connectors P12 and P19

to the DC controller board.

No Go to Table 5, Scanner Assembly

Failure.

No Replace the power supply.

4 Switch off the printer and

connect a multimeter

between connectors P11-5

(5 VB, yellow wire) and

P12-7 (5 VB, black wire) on

the DC controller board. Is

the resistance less than

?

5

5 Switch off the printer and

connect a multimeter

between connectors P12-7

(5 VB) and P12-6 (GND) on

the DC controller board.

Does the voltage measure

+5 VDC when you switch

on the printer?

No Go to Table 9, Toner Cartridge Sensor

Failure.

Yes

No

Replace the laser/optic assembly.

Replace the DC controller board.

3

Page 64

Flowcharts and TablesTroubleshooting

Table 5. Scanner Assembly Failure

Step Check Result Action

1 Switch off the printer and

connect a multimeter

between connectors

P12-13 (24 V) and P12-12

(RTN) on the DC controller

board. Does the voltage

measure about +24 VDC

when you switch on the

printer?

2 Connect a multimeter

between connectors P12-11

(/MOT ON) and P12-10

(GND) on the DC controller

board and initiate a service

test page. Does the voltage

drop to less than +1 VDC

during printing and rise to

about +4 VDC when the

printing stops?

No Go to Table 11, Power Supply Failure

(+24 VDC).

Yes

No

Replace the scanner assembly. If the

problem persists, replace the laser

and scanner motor cable.

Replace the DC controller board.

Page 65

Flowcharts and TablesTroubleshooting

Table 6. Select 360 I/O Board Error

Step Check Result Action

1 Are the serial and/or

parallel cables secure?

2 If you are using a

Macintosh, is the

LaserWriter Select 360

driver installed in the

System Folder?

3 If you are using an IBM PC

or compatible computer,

check that the correct

printer driver is installed.

Has it been installed?

No Tighten the cable connections.

No Use the installation disk to install the

appropriate driver in the System

folder.

No Install the correct Windows printer

driver. Refer to the user’s guide for

more information.

3

Page 66

Flowcharts and TablesTroubleshooting

Select 360 I/O Board Error (Continued)

Step Check Result Action

4 If you are using a

Macintosh, are the

LaserWriter 8.0 driver (icon)

and correct serial port

selected?

5 If you are using an IBM PC

or compatible computer, is

the Windows program

open and active?

6 If you are using a

Macintosh, is background

printing disabled?

No Use the Chooser to select the

LaserWriter 8.0 driver.

No Make sure the window is open and

the document window is active.

Choose Print from the File menu,

select the options you want, and click

Print.

No

Yes

Disable background printing (so that

error messages display on the

screen). Switch the printer off and on

again.

Install a different LaserWriter Select

360 I/O board.

Table 7. Select 310 or 360 I/O Board Error – Serial Connection

Step Check Result Action

1 Is the serial cable

connection secure?

2 Is the serial cable good? No Replace cable.

3 Is the LaserWriter Select

360 driver installed in the

System Folder?

4 Are the correct LaserWriter

Select driver and serial port

selected?

5 Is the printer connected to

the printer port on the

Macintosh?

6 Is background printing

disabled?

No Tighten cable connections.

No Use the Installer to install the

LaserWriter Select 360 driver in the

System Folder.

No Use the Chooser to select the

LaserWriter Select 310 or 360 driver

and the port (printer or modem) to

which the printer is connected.

Yes Make sure AppleTalk is inactive.

No Disable background printing. If the

problem persists, install a different

LaserWriter Select 360 I/O board.

Page 67

Flowcharts and TablesTroubleshooting

Table 8. Select 310 or 360 I/O Board Error – Parallel Connection

Step Check Result Action

1 Are the parallel cable

connections correct and

secure?

2 Are the parallel cables and

connectors good?

3 Are the software and

hardware properly

configured to communicate

with the parallel port on the

printer?

No Tighten cable connections.

No Replace the defective cables and

connectors.

No Refer to the printer’s owner’s guide

and the computer documentation for

proper configuration. Switch the

printer off and on again. If the problem

persists, install a different I/O board.

Table 9. Temperature Sensor Assembly Failure

Step Check Result Action

1 After allowing the fuser

assembly to cool to room

temperature, remove the

fuser assembly from the

printer. Measure the

resistance between J101-1

and J101-4 on the fuser

assembly. Is the resistance

between 200 k Ω and

350 k Ω ?

No Replace the sensor assembly.

3

Table 10. Toner Cartridge Sensor Failure

Step Check Result Action

1 Switch off the printer.

Connect a multimeter

between P15-8 (5 VB) and

P11-2 (GND) on the DC

controller board. Does the

voltage measure +5 VDC

when you switch on the

printer?

No Go to Table 12, Power Supply Failure

(+5 VDC).

Page 68

Flowcharts and TablesTroubleshooting

Ω

Toner Cartridge Sensor Failure (Continued)

Step Check Result Action

2 Connect a multimeter

between pins P15-8 (5 VB,

yellow wire) and P15-9 (5 V,

orange wire) on the DC

controller board. When you

remove and insert the toner

cartridge, does the

resistance change from 0 Ω

(cartridge inserted) to

infinity Ω (cartridge

removed)?

3 Connect a multimeter

between pins P15-10 (EP

CHECK, red wire) and

P15-11 (GND, brown wire)

on the DC controller board.

When you remove and

insert the toner cartridge,

does the resistance

change from 0

inserted) to infinity Ω

(cartridge removed)?

(cartridge

No Replace the toner cartridge sensor

assembly.

No Replace the toner cartridge sensor

assembly.

4 Remove the toner cartridge

sensor cover and observe

the toner cartridge sensor

PCB and actuator.

Does the actuator turn on

switches S101 and S100

when you install a toner

cartridge and turn off the

switches when you remove

the toner cartridge?

5 Is there continuity between

connectors P15 on the DC

controller board and P118

on the toner cartridge

sensor board.

No Install a new toner cartridge. If

switches S101 and S100 still do not

turn on when you install the cartridge,

replace the toner cartridge sensor

assembly.

Yes

No

Replace the DC controller board.

Replace the high-voltage/toner

cartridge sensor cable.

Page 69

Flowcharts and TablesTroubleshooting

Table 11. Power Supply Failure (+24 VDC)

Step Check Result Action

1 Switch off the printer.

Connect a multimeter

between P11-12 (+24 VDC,

orange wire) and P11-2

(GND, black wire) on the

DC controller board. Switch

on the printer. Is the voltage

approximately +24 VDC?

2 Switch off the printer.

Connect a multimeter

between P11-10 (+24 VDC,

brown wire) and P11-2

(GND, black wire) on the

DC controller board. Switch

the printer back on. When

you open and close the

front access door, does the

voltage measure 0 VDC

with the door open and

+24 VDC with the door

closed?

No Replace the power supply.

Yes Replace the DC controller board.

3 Switch off the printer.

Connect a multimeter

between P11-11 (+24 VDC,

brown wire) and P11-2

(GND, black wire) on the

DC controller board. Switch

the printer back on. When

you open and close the

front access door, does the

voltage measure 0 VDC

with the door open and +24

VDC with the door closed?

Yes

No

Replace the DC controller board.

3

Replace the power supply.

Page 70

Flowcharts and TablesTroubleshooting

Table 12. Power Supply Failure (+5 VDC)

Step Check Result Action

1 Connect a multimeter

between the following pairs

of pins on the DC controller

board:

P11-5 (yellow wire) and

P11-2 (black wire)

P11-6 (blue wire) and

P11-2 (black wire)

Does the voltage measure

+5 VDC when you switch

on the printer?

No

Yes

Replace the power supply.

Replace the DC controller board.

Table 13. Paper-Out LED Lights When There Is Paper

Step Check Result Action

1 Is the paper cassette

installed and does it contain

paper?

No Remove the paper cassette tray and

fill it with paper. Reinstall the paper

cassette tray and make sure it is

seated properly.

2 Remove the paper

cassette tray and inspect

the paper sensing arm.

Does the paper sensing

arm appear to be

damaged?

3 While the paper cassette

tray is out, inspect the

paper cassette size

actuators. Do any of the

actuators appear to be bent

or damaged?

4 While the paper cassette

tray is out, switch on the

printer. Insert the paper

cassette tray. Does the

main motor rotate when you

insert the paper cassette

tray?

Yes Replace the paper sensing arm.

Yes Replace the cassette feeder board.

No Replace the cassette feeder board.

Page 71

Flowcharts and TablesTroubleshooting

Paper-Out LED Lights When There Is Paper (Continued)

Step Check Result Action

5 Prepare the printer for

troubleshooting as

described in the

“Troubleshooting

Preparation” section.

Disconnect P111 from the

high-voltage power supply.

Connect a multimeter

between connector pins

P13-1 (NOPAPER1) and

P13-4 (GND) on the DC

controller board. Remove

and insert the paper

cassette tray filled with

paper. Does the voltage

toggle from +5 VDC (tray

removed) to 0 VDC (tray

inserted)?

6 If an optional paper

cassette is installed,

connect a multimeter

between connector pins

p13-3 (NOPAPER2) and

P13-4 (GND) on the DC

controller board. Remove

and insert the paper

cassette tray filled with

paper. Does the voltage

toggle from +5 VDC (tray

removed) to 0 VDC (tray

inserted)?

No

Yes

No

Yes

Replace the cassette feeder board. If

the problem persists, replace the

cassette feeder tray cable.

Replace the DC controller board.

Replace the cassette feeder board. If

the problem persists, replace the

expansion feeder cable.

Replace the DC controller board.

3

Page 72

Flowcharts and TablesTroubleshooting

Table 14. Paper-Jam LED Lights But No Jam Has Occurred

Step Check Result Action

1 Is the paper cassette

installed and does it contain

paper?

2 Check the fuser/delivery

area or paper registration

area for paper fragments.

Are there any paper

fragments or other

obstructions?

3 Is the cable that runs to the

paper delivery sensor

securely connected?

4 Initiate a service test page

and observe the action of

the delivery lever on the

fuser assembly.

Does the delivery lever

swing freely when it passes

through the fuser

assembly?

No Remove the paper cassette tray and

fill it with paper. Reinstall the paper

cassette tray and make sure it is

seated properly.

Yes Remove the fragments or

obstructions.

No Reconnect the cable to the paper

delivery sensor.

No Replace the delivery sensor lever.

5 Open the front access door

and locate the paper

registration on the paper

charge deflector. Is the

paper sensing arm

damaged or broken.

Yes Replace the paper sensing arm.

Page 73

Flowcharts and TablesTroubleshooting

Paper-Jam LED Lights But No Jam Has Occurred (Continued)

Step Check Result Action

6 Prepare the printer for

troubleshooting as

described in

“Troubleshooting

Preparation.” Disconnect

connector P111 from the

high-voltage power supply

and connector P16 from the

DC controller board.

Connect a multimeter

between P16-4 (PULLUP 5

V) and P16-5 (GND) on the

DC controller board. Does

the voltage measure +5

VDC when you switch on

the power?

7 Switch off the printer and

reconnect connector P16

to the DC controller board.

Connect a multimeter

between connector P16-6

(PregReg) and P16-5

(GND) on the DC controller

board. Initiate a service test

page. Does the voltage

drop from +5 VDC to 0 VDC

when the paper passes the

paper registration sensor?

No Go to Step 9.

No Go to Step 9.

3

8 Switch off the printer.

Connect a multimeter

between connector P16-3

(EXIT) and P16-2 (GND).

Switch on the printer and

manually actuate the paper

delivery sensor by inserting

a sheet of paper between

the sensor arms.

Does the voltage drop from

+5 VDC to 0 VDC when you

remove the paper from the

sensor?

No Replace the paper delivery sensor. If

the problem persists, replace the

delivery sensor cable.

Page 74

Flowcharts and TablesTroubleshooting

Paper-Jam LED Lights But No Jam Has Occurred (Continued)

Step Check Result Action

9 Switch off the printer and

connect a multimeter

between the following pairs

of pins on the DC controller

board:

P11-5 (yellow wire) and

P11-2 (black wire)

P11-6 (blue wire) and

P11-2 (black wire)

Does the voltage measure

+5 VDC when you switch

on the printer?

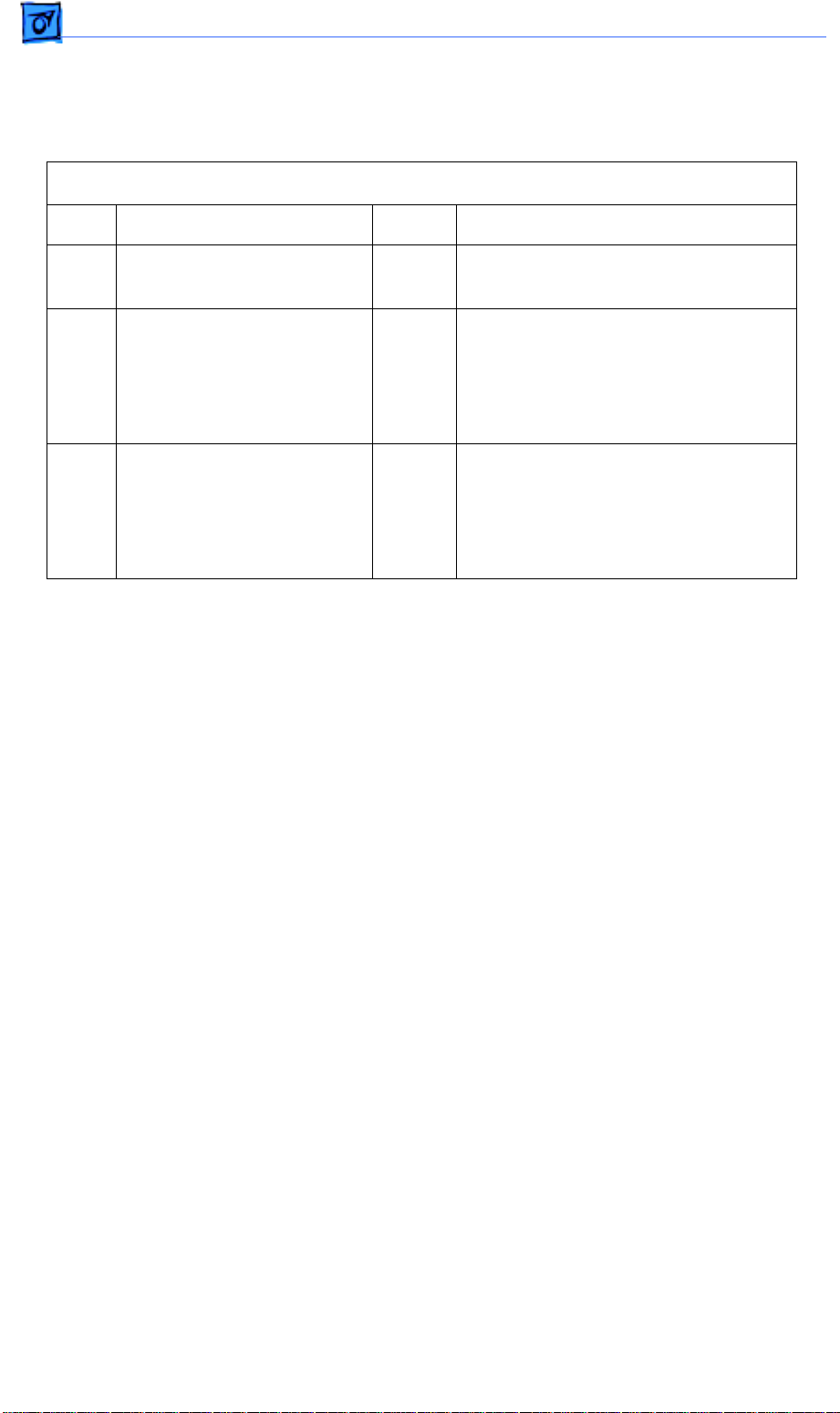

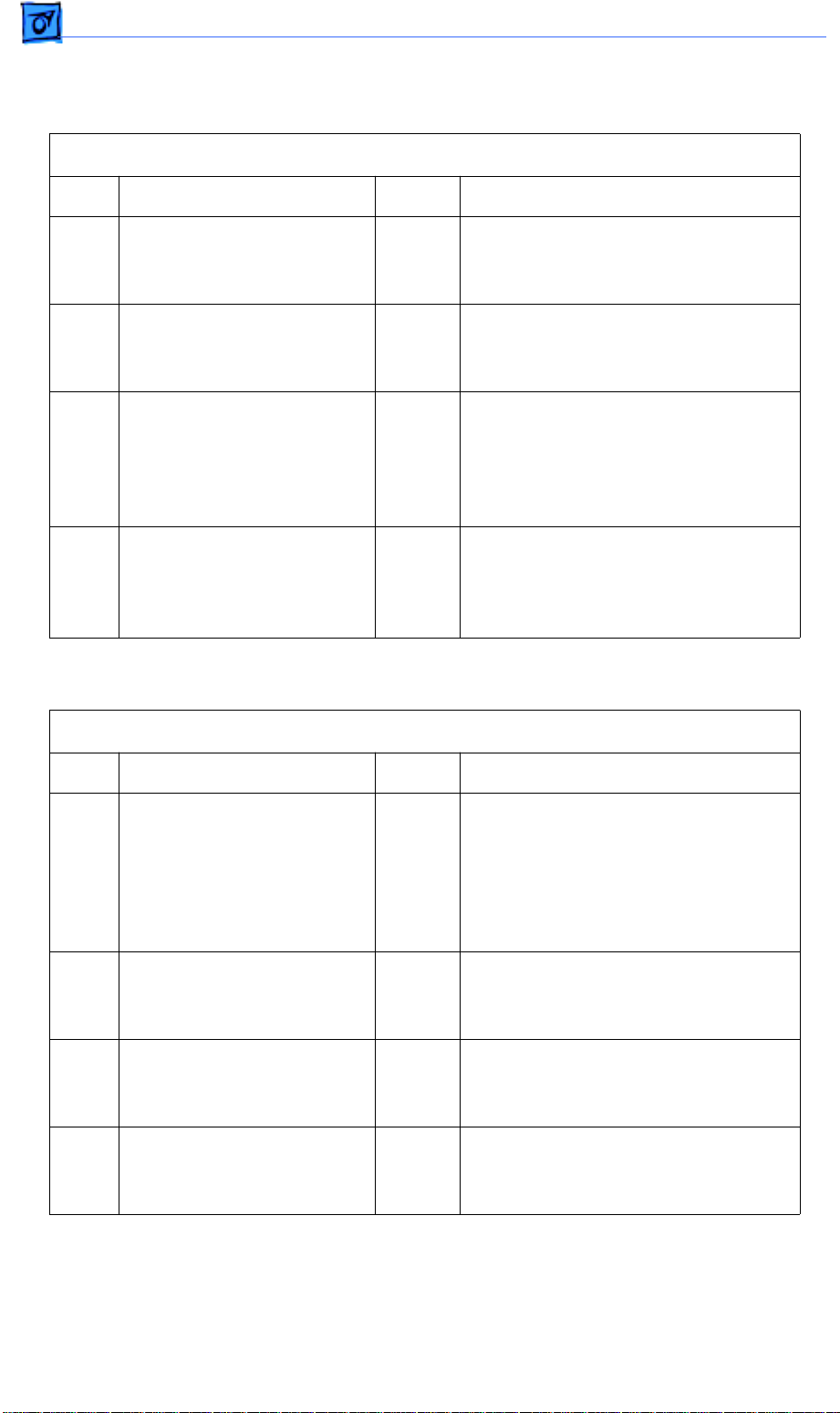

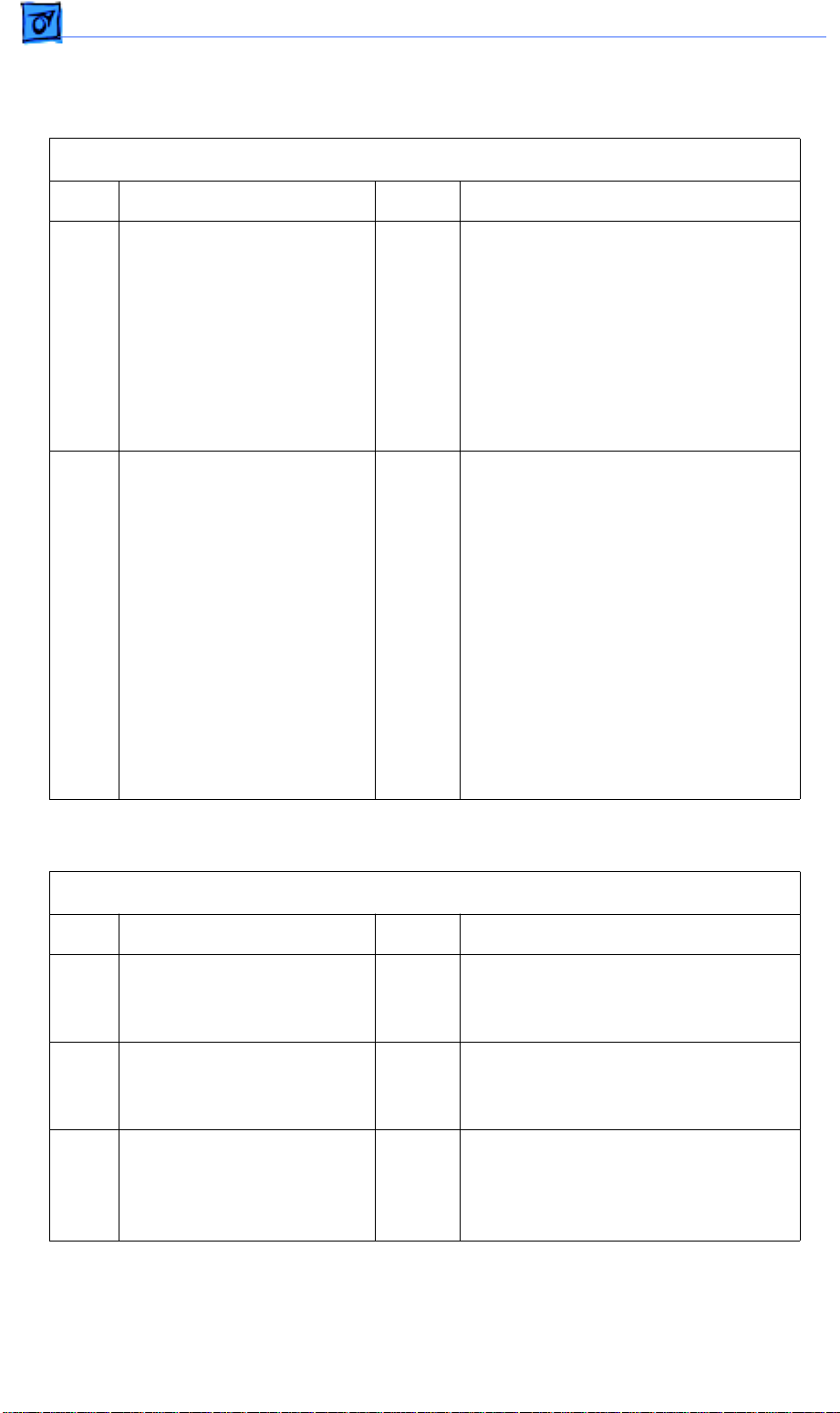

The following graphic shows examples of image quality defects. Refer to the

appropriate troubleshooting table to correct the quality of the image.

No

Yes

Replace the power supply

Replace the DC controller board.

All-Blank Page

See Table 15

Black Vertical

Line(s)

See Table 19

Ghosting

See Table 23

All-Black Page

See Table 16

White Vertical

Line(s)

See Table 20

Bad Fusing

See Table 24

Light/Faded Image

See Table 17

Black Horizontal

Lines

See Table 21

Blank Spots

See Table 25

Dark Image

See Table 18

White Horizontal

Lines

See Table 22

Toner on Back

See Table 26

Page 75

Flowcharts and TablesTroubleshooting

Figure 31. Print Quality Problems

Table 15. All-Blank Page

Step Check Result Action

1 Remove the toner cartridge

from the printer. Is the toner

cartridge sealing tape

removed?

2 Replace the toner cartridge.

Does the print quality

improve?

3 Are the high-voltage

contacts making good

contact with the toner

cartridge?

4 Remove the toner cartridge

from the printer. Is any

foreign material blocking

the laser beam outlet on the

inside of the printer

chassis? Is any

foreign material adhering to

the laser beam access slot

on the toner cartridge?

No Remove the sealing tape.

Yes Problem solved.

No Clean the contacts or replace the

high-voltage contact assembly.

Yes Remove the foreign material.

5 Inspect the drive assembly

gear train. Are any gears

damaged?

6 Replace the transfer roller.

Does the print quality

improve?

7 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

Yes Replace the drive assembly.

Yes Problem solved.

No Go to Table 11, Power Supply Failure

(+24 VDC).

3

Page 76

Flowcharts and TablesTroubleshooting

All-Blank Page (Continued)

Step Check Result Action

8 For Steps 8 and 9, remove

the top covers, side covers,

rear cover, I/O board

mount, and the power

switch lever.

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Do you find continuity on all

the high-voltage contacts?

9 Is there continuity between

connector RTN (red wire)

on the high-voltage power

supply and the red spade

connector on the paper

delivery guide?

10 Replace the DC controller

board. Does the print

quality improve?

No Replace the high-voltage contact

assembly.

No Replace the paper delivery guide.

Yes

No

Problem solved.

Replace the toner cartridge sensor

and high-voltage power supply cable.

If the problem persists, replace the

high-voltage power supply.

Table 16. All-Black Page

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Are the high-voltage

contacts making good

contact with the toner

cartridge?

Yes Problem solved.

No Clean the contacts or replace the

high-voltage contact assembly.

Page 77

Flowcharts and TablesTroubleshooting

All-Black Page (Continued)

Step Check Result Action

3 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

4 Is there continuity between

CRU (spring plate) on the

high-voltage contact

assembly and jack CR on

the high-voltage power

supply?

5 Is there continuity between

P15 on the DC controller

board and P111 on the

high-voltage power supply?

6 Replace the DC controller

board. Does the print

quality improve?

No Go to Table 11, Power Supply Failure

(+24 VDC).

No Replace the high-voltage contact

assembly.

Yes Replace the toner cartridge sensor

and high-voltage power supply cable.

Yes

No

Problem solved.

Replace the high-voltage power

supply.

Table 17. Light/Faded Image

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Reload the paper cassette

tray with known-good

paper. Does the print quality

improve?

Yes Problem solved.

Yes Problem solved.

3

Page 78

Flowcharts and TablesTroubleshooting

Light/Faded Image (Continued)

Step Check Result Action

3 Remove the toner cartridge

from the printer. Is any

foreign material blocking

the laser beam outlet on the

inside of the printer

chassis? Is any foreign

material adhering to the

laser beam access slot on

the toner cartridge?

4 Are the high-voltage

contacts making good

contact with the toner

cartridge?

5 Replace the transfer roller.

Does the print quality

improve?

6 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

Yes Remove the foreign material.

No Clean the contacts or replace the

high-voltage contact assembly.

No Problem solved.

No Go to Table 11, Power Supply Failure

(+24 VDC).

7 For Steps 7 and 8, remove

the top cover, side covers,

I/O board mount, and the

power switch lever.

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Did you find continuity on all

the high-voltage contacts?

8 Is there continuity between

connector RTN (red wire)

on the high-voltage power

supply and the red spade

connector on the paper

delivery guide?

No Replace the high-voltage contact

assembly.

No Replace the paper delivery guide.

Page 79

Flowcharts and TablesTroubleshooting

Light/Faded Image (Continued)

Step Check Result Action

9 Replace the DC controller

board. Does the print

quality improve?

Yes

No

Problem solved.

Replace the toner cartridge sensor

and high-voltage power supply cable.

If the problem persists, replace the

high-voltage power supply.

Table 18. Dark Image Over Entire Page

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Is the transfer roller dirty? Yes Replace the transfer roller.

3 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer.

4 Remove the top cover, side

covers, rear cover, I/O

board mount, and the

power switch lever.

Yes Problem solved.

No Go to Table 11, Power Supply Failure

(+24 VDC).

No Replace the high-voltage contact

assembly.

3

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Do you find continuity on all

the high-voltage contacts?

5 Replace the DC controller

board. Does the print

quality improve?

Yes

No

Problem solved.

Replace the toner cartridge sensor

and high-voltage power supply cable.

If the problem persists, replace the

high-voltage power supply.

Page 80

Flowcharts and TablesTroubleshooting

Table 19. Black Vertical Lines

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Replace the transfer roller.

Does the print quality

improve?

3 Remove the paper delivery

guide. Is the static

eliminator on the paper

delivery guide properly

grounded?

4 Remove the fuser assembly

and inspect the fuser heater

roller. Are there scratches

on the fuser heater roller?

Table 20. White Vertical Lines

Yes Problem solved.

No Connect the grounding contact to the

static eliminator.

No Connect the grounding contact to the

static eliminator.

Yes Replace the fuser heater roller or the

fuser assembly.

Step Check Result Action

1 Remove the toner cartridge

from the printer. Is any

foreign material blocking

the laser beam outlet on the

inside of the printer

chassis?

2 Inspect the paper path. Is

any foreign material

blocking the paper path?

3 Replace the toner cartridge.

Does the print quality

improve?

4 Replace the transfer roller.

Does the print quality

improve?

Yes Remove the foreign material.

Yes Remove the foreign material.

Yes Problem solved.

Yes Problem solved.

Page 81

Flowcharts and TablesTroubleshooting

White Vertical Lines (Continued)

Step Check Result Action

5 Remove the fuser assembly

and heater roller. Are there

scratches on the fuser

heater roller?

6 Replace the I/O board.

Does the print quality

improve?

Yes Replace the fuser heater roller or the

fuser assembly.

Yes Problem solved.

Table 21. Black Horizontal Lines

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Are the high-voltage

contacts making good

contact with the toner

cartridge?

Yes Problem solved.

No Clean the contacts or replace the

high-voltage contact assembly.

3 Replace the transfer roller.

Does the print quality

improve?

4 Remove the fuser assembly

and inspect the fuser heater

roller. Are there scratches

on the fuser heater roller?

5 Connect the multimeter

between connectors P15-7

and 15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

Yes Problem solved.

3

Yes Replace the fuser heater roller or the

fuser assembly.

No Go to Table 11, Power Supply Failure

(+24 VDC).

Page 82

Flowcharts and TablesTroubleshooting

Black Horizontal Lines (Continued)

Step Check Result Action

6 Remove the top cover, side

covers, rear cover, I/O

board mount, and the

power switch lever.

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Do you find continuity on all

the high-voltage contacts?

7 Replace the DC controller

board. Does the print

quality improve?

8 Replace the toner cartridge

sensor and high-voltage

power supply cable. Does

the print quality improve?

9 Replace the high-voltage

power supply. Does the

print quality improve?

No Replace the high-voltage contact

assembly.

Yes Problem solved.

Yes Problem solved.

Yes Problem solved.

10 Replace the I/O board.

Does the print quality

improve?

Yes Problem solved.

Table 22. White Horizontal Lines

Step Check Result Action

1 Check the paper in the

paper cassette tray for

dampness. Is the paper

damp?

2 Replace the toner cartridge.

Does the print quality

improve?

Yes Replace the paper.

Yes Problem solved.

Page 83

Flowcharts and TablesTroubleshooting

White Horizontal Lines (Continued)

Step Check Result Action

3 Are the high-voltage

contacts making good

contact with the toner

cartridge?

4 Remove the toner cartridge

from the printer. Is any

foreign material blocking

the laser beam outlet on the

inside of the printer

chassis? Is any foreign

material adhering to the

laser beam access slot on

the toner cartridge?

5 Replace the transfer roller.

Does the print quality

improve?

6 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

7 For Steps 7 and 8, remove

the top covers, rear cover,

I/O board mount, and power

supply switch lever.

No Clean the contacts or replace the

high-voltage contact assembly.

Yes Remove the foreign material.

Yes Problem solved.

No Go to Table 11, Power Supply Failure

(+24 VDC).

No Replace the high-voltage contact

assembly.

3

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Do you find continuity on all

the high-voltage contacts?

8 Is there continuity between

connector RTN (red wire)

on the high-voltage power

supply and the red spade

connector on the paper

delivery guide?

White Horizontal Lines (Continued)

No Replace the paper delivery guide.

Page 84

Flowcharts and TablesTroubleshooting

Step Check Result Action

9 Replace the DC controller

board. Does the print

quality improve?

10 Replace the toner cartridge

sensor and high-voltage

power supply. Does the

print quality improve?

11 Replace the high-voltage

power supply. Does the

print quality improve?

12 Replace the I/O board.

Does the print quality

improve?

Table 23. Ghosting

Yes

No

Yes Problem solved.

Yes Problem solved.

Yes Problem solved.

Problem solved.

Replace the toner cartridge sensor

and high-voltage power supply cable.

If the problem persists, replace the

high-voltage power supply.

Step Check Result Action

1 Replace the toner cartridge.

Does the print quality

improve?

2 Is the transfer roller dirty? Yes Replace the transfer roller.

3 Remove the fuser assembly

and inspect the fuser heater

roller and the fuser

pressure roller. Are there

scratches on either roller?

4 Connect the multimeter

between connectors P15-7

and P15-1 on the DC

controller board. Does the

voltage measure +24 VDC

when you switch on the

printer?

Yes Problem solved.

Yes Replace the fuser heater roller, the

fuser pressure roller, or the fuser

assembly.

No Go to Table 11, Power Supply Failure

(+24VDC).

Page 85

Flowcharts and TablesTroubleshooting

Ghosting (Continued)

Step Check Result Action

5 Remove the top cover, side

covers, rear cover, I/O

board mount, and power

supply switch lever.

Remove the high-voltage

contact assembly and

check the continuity on all

the high-voltage contacts.

Do you find continuity on all

the high-voltage contacts?

6 Replace the DC controller

board. Does the print

quality improve?

No Replace the high-voltage contact

assembly.

Yes

No

Problem solved.

Replace the toner cartridge sensor

and high-voltage power supply cable.

If the problem persists, replace the

high-voltage power supply.

Table 24. Bad Fusing

Step Check Result Action

1 Check the paper in the

paper cassette tray for

dampness. Is the paper

damp?

2 Is the fuser assembly

properly installed and

secure?

3 Install a known-good fuser

assembly. Does the print

quality improve?

4 Install a known-good power

supply. Does the print

quality improve?

5 Install a known-good DC

controller. Does the print

quality improve?

Yes Replace the paper.

No Reinstall the fuser assembly.

Yes Problem solved.

Yes Problem solved.

Yes Problem solved.

3

Page 86

Flowcharts and TablesTroubleshooting

Table 25. Blank Spots/Random Pattern or Location

Step Check Result Action

1 Replace the toner cartridge.

Yes Problem solved.

Does the print quality

improve?

2 Check the paper in the

Yes Replace the paper.

paper cassette tray for

dampness. Is the paper

damp?

3 Is the transfer roller dirty? Yes Replace the transfer roller.

4 Remove the fuser assembly

and inspect the fuser heater

roller and the fuser

Yes Replace the fuser heater roller, the

fuser pressure roller, or the fuser

assembly.

pressure roller. Are there

scratches on either of the

rollers?

v

Table 26. Toner on Back of Page

Step Check Result Action

1 Replace the toner cartridge.

Yes Problem solved.

Does the print quality

improve?

2 Does the printer operating

environment meet

recommended setup and

operating conditions?

No Make recommended changes to

printer operating environment or

setup. See the Pre-Power-On

Checklist section under

“Troubleshooting the LaserWriter

Select 360” for recommended setup

and operating instructions.

3 Is the transfer roller dirty? Yes Replace the transfer roller.

4 Remove the fuser assembly

and inspect the fuser heater

roller and the fuser

Yes Replace the fuser heater roller, the

fuser pressure roller, or the fuser

assembly.

pressure roller. Are there

scratches on either of the

rollers?

Page 87

Flowcharts and TablesTroubleshooting

Table 27. Paper Jams in Fuser/Delivery Area

Step Check Result Action

1 Initiate a service test page.

Does the test page jam as it

leaves the fuser assembly?

2 Is the cable that runs to the

paper delivery sensor

securely connected?

3 Initiate another test page

and observe the action of

the delivery lever on the

fuser assembly.

Does the lever swing freely

when paper passes through

the fuser assembly?

4 Allow the fuser rollers to

cool and then remove the

fuser assembly. Inspect the

fuser rollers. Are the fuser

rollers worn or damaged?

5 Do the fuser rollers rotate

without binding?

No Problem solved.

No Reconnect the cable to the paper

delivery sensor.

No Replace the delivery sensor lever.

Yes Replace the fuser assembly.

Yes Replace the fuser assembly.

6 Remove the I/O shield, the

I/O board, and the I/O board

mount. Replace the fuser

assembly and disconnect

P111 from the high-voltage

power supply.

Connect a multimeter

between connector pins

P16-1 (PULLUP +5 V) and

P16-2 (GND) on the DC

controller board. Does the

voltage measure +5 VDC

when you switch on the

printer?

No Go to Table 12, Power Supply Failure

(+5 V).

3

Page 88

Flowcharts and TablesTroubleshooting

Paper Jams in Fuser/Delivery Area (Continued)

Step Check Result Action

7 Verify that the cable that

runs to the paper delivery

sensor is still securely

connected. Connect a

multimeter across

connector pins P16-3

(EXIT) and P16-2 (GND) on

the DC controller board.

Manually actuate the paper

delivery sensor by inserting

a sheet of paper between

the sensor arms. Does the

voltage drop from +5 VDC

to 0 VDC when you remove

the paper from the sensor?

Yes

No

Replace the DC controller board.

Replace the paper delivery sensor. If

the problem persists, replace the

delivery sensor cable.

Table 28. Paper Jams in Paper Pickup Area

Step Check Result Action

1 Reload the paper cassette

tray with known-good

paper. Does the problem

still occur?

No Problem solved.

2 Does the jam occur when

the manual feed or optional

multipurpose tray is being

used?

3 Is the paper cassette

installed properly in the

printer?

4 Is the paper cassette

loaded with too much

paper?

5 Are the cassette feed rollers

damaged or worn?

6 Are the cassette feed rollers

damaged or worn?

Yes Go to Step 17.

No Reinstall the paper cassette properly.

Yes Remove the excess paper.

Yes Replace the cassette pickup rollers.

Yes Replace the cassette feed roller shaft.

Page 89

Flowcharts and TablesTroubleshooting

Paper Jams in Paper Pickup Area (Continued)

Step Check Result Action

7 Is connector P13 on the DC

controller board making

good contact?

8 Is connector P115 on the

cassette feeder board

making good contact?

9 Are the cassette pickup and

cassette feed solenoids

securely connected to the

cassette feeder board?

10 Switch off the printer.

Connect the multimeter

between P13-7 (+24 V)

and P13-8 (TURN1). Does

the resistance measure

between 220 and 240 Ω?

11 Connect the multimeter

between P13-10 (+24 V)

and P13-11 (FEED1). Does

the resistance measure

between 110 and 130 Ω?

No Reconnect P13 to the DC controller

board.

No Reconnect P115 to the cassette

feeder board.

No Reconnect P201 and P202 to the

cassette feeder board.

No Replace the cassette feed solenoid.

No Replace the cassette pickup solenoid.

12 Open the front access door

and locate the paper

registration arm on the

paper charge deflector. Is

the paper registration arm

damaged or broken?

13 Close the front access door

and disconnect connector

P16 from the DC controller

board. Connect a

multimeter between

connector pins P16-4

(PULLUP 5 V) and P16-5

(GND) on the DC controller

board. Does the voltage

measure +5 VDC when

you switch on the power?

Yes Replace the paper registration arm.

3

No Go to Table 12, Power Supply Failure

(+5 VDC).

Page 90

Paper Jams in Paper Pickup Area (Continued)

Step Check Result Action

14 Replace the DC controller

board. Does the problem

still occur?

15 Reconnect connector P16

to the DC controller board.

Connect a multimeter

between pins P16-6

(/PREREG) and P16-5

(GND) on the DC controller

board. Initiate a service test

page. Does the voltage

drop from +5 VDC to 0 VDC

when the paper passes the

paper registration sensor?

16 Does the manual feed or

multipurpose tray have too

much paper? (The manual

feed tra y holds one sheet of

paper at a time and the

multipurpose tray holds 50

sheets of paper.)

No Problem solved.

No Replace the paper registration

sensor located on the paper charge

deflector.

Yes Remove excess paper.

17 Is connector P17 on the DC

controller board making

good contact?

18 Open the front access door

and observe the rollers on

the pickup roller assembly.

Are the pickup rollers worn

or deformed?

19 Using a paper clip or screw-

driver, man ually activate the

manual feed solenoid.

Manually rotate the large

black gear on the pickup

roller assembly toward the

manual feed solenoid. Does